Page 1

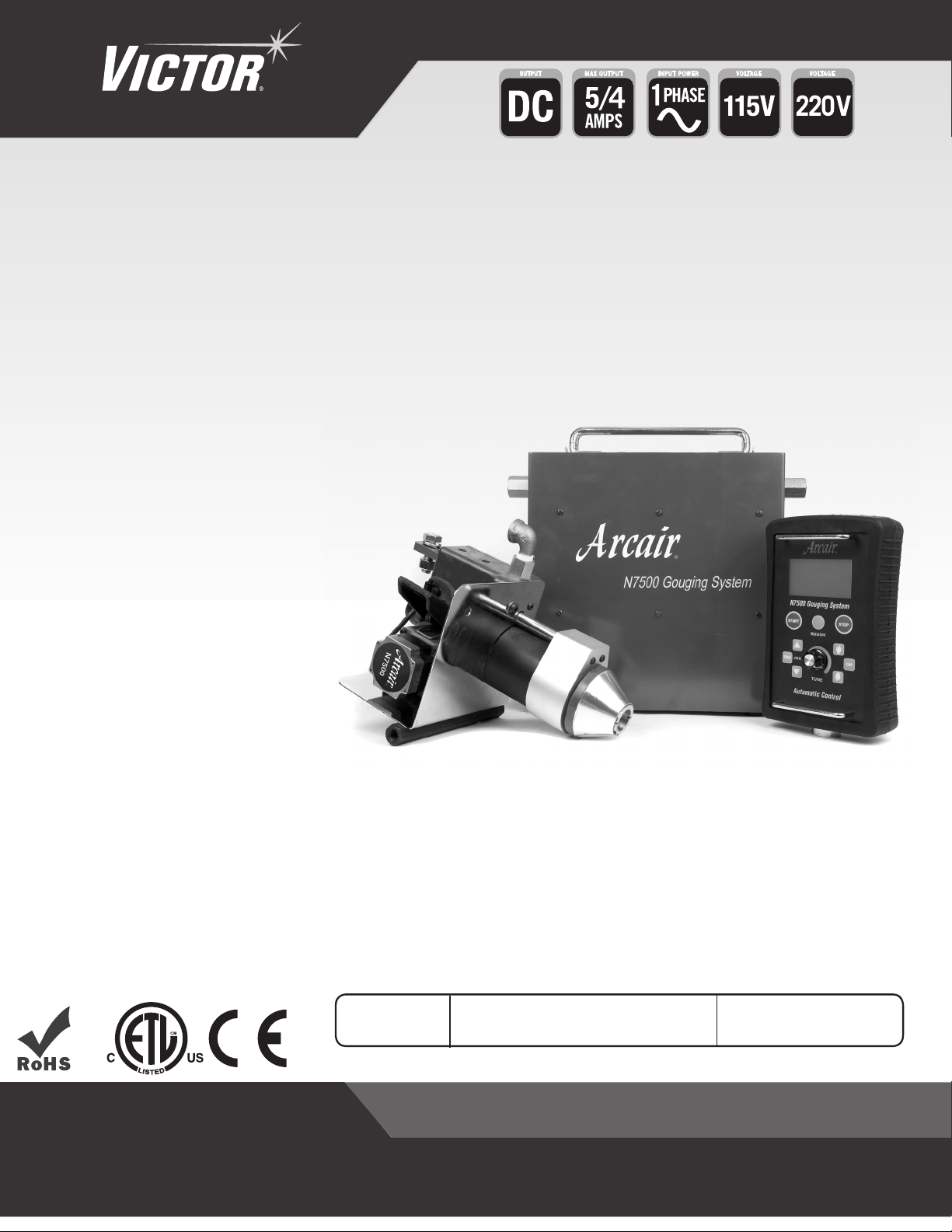

N7500

Arcair-Matic® Gouging System

Operating

Manual

English

Français Canadien

Revision: AF Issue Date: Feb. 19, 2014 Manual No.: 89250890

VictorTechnologies.com/Arcair

ART# A-10837_AB

ARCAIR

®

Cutting and Gouging Systems

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on receiving your new Victor® Arcair® product. We are proud to have you as our

customer and will strive to provide you with the best service and support in the industry. This product

is backed by our extensive warranty and world-wide service network.

We know you take pride in your work and we feel privileged to provide you with this high performance

product that will help you get the job done.

For more than 60 years Victor Arcair has provided quality products you can trust, when your reputation

is on the line.

YOU ARE IN GOOD COMPANY!

Victor Arcair is a global brand of cutting products for Victor Technologies™ Inc. We distinguish

ourselves from our competition through market-leading innovation and truly dependable products that

will stand the test of time.

We strive to enhance your productivity, efficiency and welding performance, enabling you to excel in

your craft. We design products with the welder in mind delivering- advanced features, durability, ease

of use and ergonomic comfort.

Above all, we are committed to a safer working environment within the welding industry. Your

satisfaction with this product and its safe operation is our ultimate concern. Please take the time to

read the entire manual, especially the Safety Precautions.

If you have any questions or concerns regarding your new Victor Arcair product, please contact our

friendly and knowledgeable Customer Service Team at:

1-800-462-2782 (USA) and 1-905-827-4515 (Canada),

or visit us on the web at www.victortechnologies.com/arcair

Page 3

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing,

operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer's best judgement,

the Manufacturer assumes no liability for its use.

Arcair-Matic® N7500 Gouging System

Operating Manual

Operating Manual Guide Number: 89250890

Published by:

Victor Technologies, Inc. 940-566-2000

2800 Airport Rd. www.victortechnologies.com/arcair

Denton, TX. 76208 U.S. Customer Care: 800-426-1888

International Customer Care: 905-827-9777

Copyright © 2012, 2013 Victor Technologies, Inc. All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the publisher

is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any loss

or damage caused by any error or omission in this Manual, whether such error results from

negligence, accident, or any other cause.

Publication Date: January, 2012

Revision Date: Feb. 19, 2014

Patent Pending

Record the following information for Warranty purposes:

Where Purchased:

Purchase Date:

Part Number Serial Number

Control Box: _____________________ ________________________

Pendant: _____________________ ________________________

Torch Head: _____________________ ________________________

Page 4

TABLE OF CONTENTS

SECTION 1: GENERAL INFORMATION ................................................................... 1-1

1.01 Notes, Cautions and Warnings ........................................................................ 1-1

1.02 Arc Welding Hazards ....................................................................................... 1-1

1.03 Principal Safety Standard Publications ........................................................... 1-4

1.04 Declaration of Conformity ............................................................................... 1-5

SECTION 2: SPECIFICATIONS ............................................................................. 2-1

2.01 Arcair-Matic N7500 Gouging System .............................................................. 2-1

2.02 N7500 Specifications ...................................................................................... 2-2

SECTION 3: SYSTEM COMPONENT DESCRIPTION .................................................... 3-1

3.01 Control Box ..................................................................................................... 3-1

3.02 Torch Head ...................................................................................................... 3-4

3.03 Remote Pendant ............................................................................................. 3-6

3.04 Electrodes ....................................................................................................... 3-7

3.05 Gouging Operation Settings ............................................................................ 3-8

3.06 Selecting the Proper Electrode Diameter ........................................................ 3-9

3.07 Keeping Electrodes Dry ................................................................................... 3-9

3.08 Secondary Power Cables (Welding Leads) ..................................................... 3-9

3.09 Compressed Air ............................................................................................ 3-10

3.10 Main Air Line ................................................................................................ 3-10

SECTION 4: ASSEMBLY AND INSTALLATION ........................................................... 4-1

4.01 Receiving and Handling .................................................................................. 4-1

4.02 Assembly ........................................................................................................ 4-3

4.03 Miscellaneous Cable/Plumbing Assemblies .................................................... 4-3

4.04 Control Box Installation .................................................................................. 4-4

4.05 Torch Head Installation ................................................................................... 4-7

4.06 Remote Pendant Installation ........................................................................... 4-8

4.07 Remote Pendant Storage ................................................................................ 4-9

SECTION 5: OPERATING THE N7500 SYSTEM .......................................................... 5-1

5.01 Remote Pendant Operation ............................................................................. 5-1

5.02 Position Torch Head ........................................................................................ 5-2

5.03 Insert the Electrode ......................................................................................... 5-2

5.04 Remote Pendant Programming ...................................................................... 5-3

SECTION 6: N7500 SYSTEM USES ....................................................................... 6-1

6.01 SYSTEM USES ................................................................................................ 6-1

6.02 Zero Force Rough Machining .......................................................................... 6-1

Page 5

TABLE OF CONTENTS

SECTION 7: MAINTENANCE ............................................................................... 7-1

7.01 Introduction .................................................................................................... 7-1

7.02 Remote Pendant ARCTIME ............................................................................. 7-2

SECTION 8: TROUBLESHOOTING GUIDE ................................................................ 8-1

8.01 Arcair-Matic N7500 Gouging System .............................................................. 8-1

8.02 N7500 General ................................................................................................ 8-1

8.03 Torch Head ...................................................................................................... 8-2

8.04 Remote Pendant ............................................................................................. 8-4

8.05 Control Box ..................................................................................................... 8-5

SECTION 9: REPLACEMENT PARTS ...................................................................... 9-1

9.01 Control Box Replacement Parts ...................................................................... 9-1

9.02 Torch Head Replacement Parts ....................................................................... 9-2

9.03 Remote Pendant Replacement Parts ............................................................... 9-3

9.04 110V Power Supply Cable Assembly .............................................................. 9-4

9.05 220V Power Supply Cable Assembly .............................................................. 9-4

9.06 Pendant Cable Assembly ................................................................................ 9-4

9.07 Motor Cable Assembly .................................................................................... 9-4

9.08 Power Supply Communication Cable Assembly .............................................. 9-4

9.09 Power Cables .................................................................................................. 9-4

9.10 Air Hose Assembly .......................................................................................... 9-4

SECTION 10: APPENDIX ................................................................................... A-1

10.01 Wiring Schematic ........................................................................................... A-2

PUBLICATION HISTORY ................................................................................... A-4

Statement of Warranty .................................................................. Inside Rear Cover

Page 6

Figures and Tables

SECTION 2: SPECIFICATIONS ............................................................................. 2-1

Table 2-1: N7500 Specifications .............................................................................. 2-2

SECTION 3: SYSTEM COMPONENT DESCRIPTION .................................................... 3-1

Figure 3-1: Control Box ........................................................................................... 3-1

Table 3-2: Control Box Features .............................................................................. 3-2

Figure 3-3: LEFT Side of Control Box ...................................................................... 3-3

Figure 3-4: RIGHT Side of Control Box ................................................................... 3-3

Figure 3-5: BACK of Control Box ............................................................................. 3-3

Figure 3-6: Torch Head ............................................................................................ 3-4

Figure 3-7: Torch Head Components ....................................................................... 3-4

Table 3-8: Torch Head Features ............................................................................... 3-5

Figure 3-9: Remote Pendant ................................................................................... 3-6

Table 3-10: Remote Pendant Controls ..................................................................... 3-6

Chart 3-11: Electrode Selection ............................................................................... 3-7

Table 3-12: Operating Parameters ........................................................................... 3-8

Table 3-13: Power Cable Requirements ................................................................ 3-10

Table 3-14: Compressed Air Input Requirements .................................................. 3-10

SECTION 4: ASSEMBLY AND INSTALLATION ........................................................... 4-1

Figure 4-1: Control Box .......................................................................................... 4-1

Figure 4-2: Torch Head ............................................................................................ 4-1

Figure 4-3: Remote Pendant ................................................................................... 4-1

Figure 4-4: Control Box Nameplate ......................................................................... 4-2

Figure 4-5: Remote Pendant and Torch Head Nameplates ...................................... 4-2

Figure 4-6: Nameplate Locations ............................................................................ 4-2

Table 4-7: Cable Identification ................................................................................. 4-3

Figure 4-8: Assembly Stage 1 ................................................................................. 4-4

Figure 4-9: Power Supply Comm. Cable Pin Configuration ..................................... 4-5

Table 4-10: Standard Wiring Connections ............................................................... 4-6

Figure 4-11: Assembly Stage 2 ............................................................................... 4-7

Figure 4-12: Assembly Stage 3 ............................................................................... 4-8

Figure 4-13: Pendant Mounting .............................................................................. 4-9

Figure 4-14: Pendant Mounted ................................................................................ 4-9

Page 7

SECTION 5: OPERATING THE N7500 SYSTEM .......................................................... 5-1

Figure 5-1: Remote Pendant ................................................................................... 5-1

Table 5-2: Remote Pendant Controls ....................................................................... 5-1

Figure 5-3: Torch Head Parts .................................................................................. 5-2

Figure 5-4: Default Pendant Screen CC or CV mode ............................................... 5-3

Table 5-5: Parameter Table ...................................................................................... 5-4

Figure 5-6: Parameter Guide Screen ....................................................................... 5-5

Figure 5-7: Parameter Guide Setting Examples ....................................................... 5-5

Figure 5-8: Current Setting Example ....................................................................... 5-5

Figure 5-9: Travel Delay Screen ............................................................................... 5-6

Table 5-10: Travel Delay Setting .............................................................................. 5-6

Figure 5-11: No Current Detect screens .................................................................. 5-7

SECTION 6: N7500 SYSTEM USES ....................................................................... 6-1

Figure 6-1: N7500 DC Straight Polarity (DCEN) ...................................................... 6-1

SECTION 7: MAINTENANCE ............................................................................... 7-1

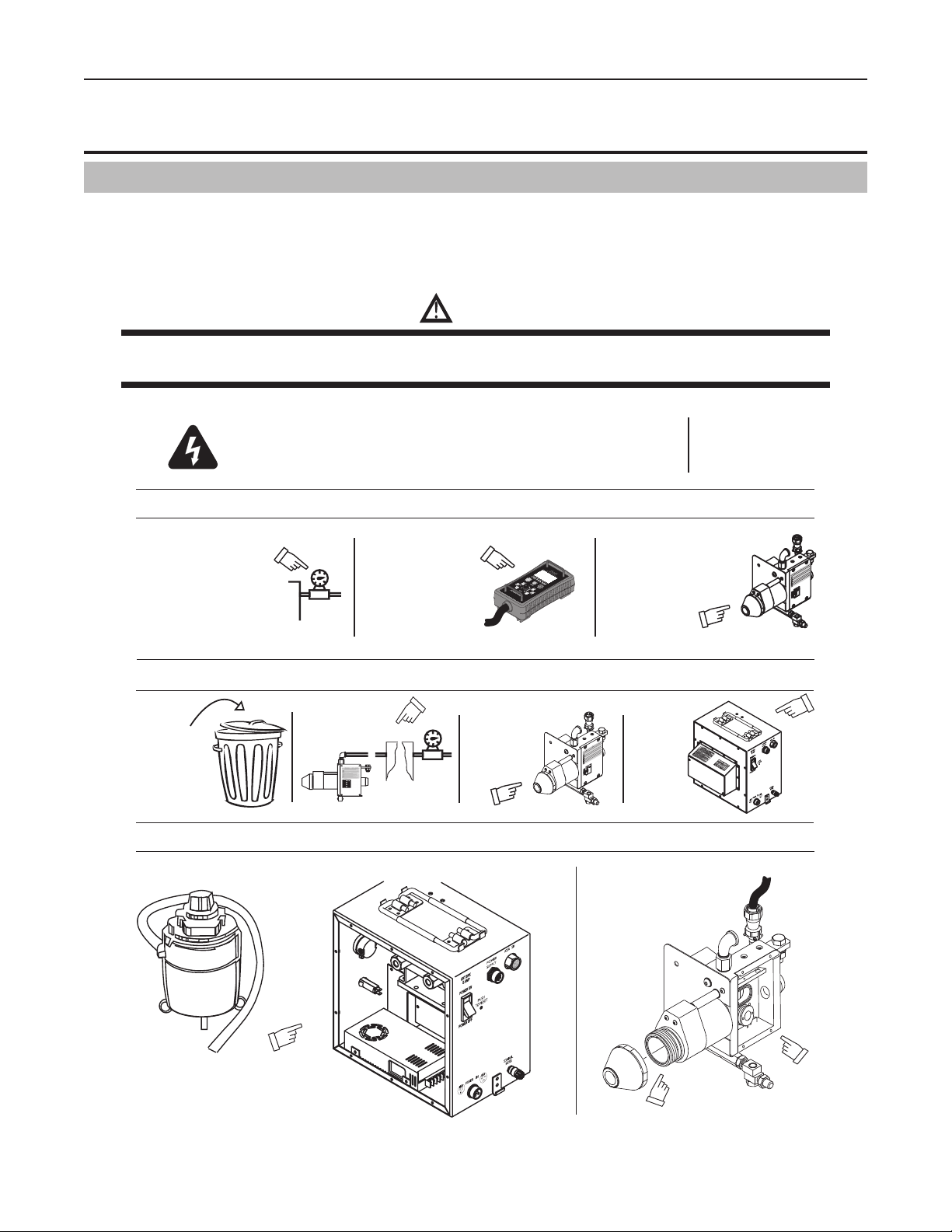

Figure 7-1: Maintenance ......................................................................................... 7-1

Figure 7-2: Arctime Screen ..................................................................................... 7-2

SECTION 8: TROUBLESHOOTING GUIDE ................................................................ 8-1

Table 8-1: General Troubleshooting ......................................................................... 8-2

Table 8-2: Torch Head Motor 6 PIN Wire Schedule ................................................. 8-2

Table 8-3: Torch Head Troubleshooting ................................................................... 8-2

Table 8-4: Pendant Cable Pin Identification ............................................................. 8-4

Table 8-5: Remote Pendant Troubleshooting .......................................................... 8-4

Table 8-6: Control Box Troubleshooting .................................................................. 8-5

Table 8-7: Power Supply Cable Pin Identification .................................................... 8-5

SECTION 9: REPLACEMENT PARTS ...................................................................... 9-1

Figure 9-1: Control Box PARTS ............................................................................... 9-1

Table 9-2: Control Box PARTS ................................................................................. 9-1

Figure 9-3: Torch Head PARTS ................................................................................ 9-2

Table 9-4: Torch Head PARTS ................................................................................. 9-2

Figure 9-5: Remote Pendant PARTS ....................................................................... 9-3

Table 9-6: Remote Pendant PARTS ......................................................................... 9-3

SECTION 10: APPENDIX ................................................................................... A-1

Figure 10-1: N7500 Wiring Schematic .................................................................... A-3

Page 8

This Page Intentionally Blank

Page 9

GENERAL INFORMATION N7500

SECTION 1:

GENERAL INFORMATION

1.01 Notes, Cautions and Warnings

WARNING

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS KEEP AWAY UNTIL CONSULTING YOUR DOCTOR. DO NOT LOSE THESE INSTRUCTIONS. READ

OPERATING/INSTRUCTION MANUAL BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or property,

if the operator does not strictly observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be learned

through study and training before using this equipment. Some of these practices apply to equipment connected to

power lines; other practices apply to engine driven equipment. Anyone not having extensive training in welding and

cutting practices should not attempt to weld.

Safe practices are outlined in the American National Standard Z49.1 entitled: SAFETY IN WELDING AND CUTTING.

This publication and other guides to what you should learn before operating this equipment are listed at the end of

these safety precautions. HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED

ONLY BY QUALIFIED PEOPLE.

WARNING

SERIOUS INJURY OR DEATH may result if welding and cutting equipment is not properly installed, used, and

maintained. Misuse of this equipment and other unsafe practices can be hazardous. The operator, supervisor, and helper must read and understand the following safety warnings and instructions before installing

or using any welding or cutting equipment, and be aware of the dangers of the welding or cutting process.

Training and proper supervision are important for a safe work place. Keep these instructions for future

use. Additional recommended safety and operating information is referenced in each section.

1.02 Arc Welding Hazards

WARNING

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal

shocks or severe burns. The electrode and

work circuit is electrically live whenever the

output is on. The input power circuit and

machine internal circuits are also live when

power is on. In semi-automatic or automatic

wire welding, the wire, wire reel, drive roll

housing, and all metal parts touching the

welding wire are electrically live. Incorrectly

installed or improperly grounded equipment

is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry

insulating mats or covers.

4. Disconnect input power or stop engine before installing or servicing this equipment. Lock input power

disconnect switch open, or remove line fuses so power

cannot be turned on accidentally.

5. Properly install and ground this equipment according

to its Owner’s Manual and national, state, and local

codes.

6. Turn off all equipment when not in use. Disconnect

power to equipment if it will be left unattended or out

of service.

7. Use fully insulated electrode holders. Never dip holder

in water to cool it or lay it down on the ground or the

work surface. Do not touch holders connected to two

welding machines at the same time or touch other

people with the holder or electrode.

Manual 89250890 1-1 GENERAL INFORMATION

Page 10

N7500 GENERAL INFORMATION

8. Do not use worn, damaged, undersized, or poorly

spliced cables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth)

ground.

11. Do not touch electrode while in contact with the work

(ground) circuit.

12. Use only well-maintained equipment. Repair or replace

damaged parts at once.

13. In confined spaces or damp locations, do not use a

welder with AC output unless it is equipped with a

voltage reducer. Use equipment with DC output.

14. Wear a safety harness to prevent falling if working

above floor level.

15. Keep all panels and covers securely in place.

WARNING

ARC RAYS can burn eyes and skin; NOISE can

damage hearing. Arc rays from the welding

process produce intense heat and strong

ultraviolet rays that can burn eyes and skin.

Noise from some processes can damage

hearing.

1. Wear a welding helmet fitted with a proper shade of

filter (see ANSI Z49.1 listed in Safety Standards) to

protect your face and eyes when welding or watching.

2. Wear approved safety glasses. Side shields recommended.

3. Use protective screens or barriers to protect others

from flash and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flameresistant material (wool and leather) and foot protection.

5. Use approved ear plugs or ear muffs if noise level is

high.

FUMES AND GASES can be hazardous to your

health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to

your health.

1. Keep your head out of the fumes. Do not breath the

fumes.

2. If inside, ventilate the area and/or use exhaust at the

arc to remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied

respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction for metals, consumables,

coatings, and cleaners.

5. Work in a confined space only if it is well ventilated,

or while wearing an air-supplied respirator. Shielding

gases used for welding can displace air causing injury

or death. Be sure the breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or

spraying operations. The heat and rays of the arc can

react with vapors to form highly toxic and irritating

gases.

7. Do not weld on coated metals, such as galvanized,

lead, or cadmium plated steel, unless the coating is

removed from the weld area, the area is well ventilated,

and if necessary, while wearing an air-supplied respirator. The coatings and any metals containing these

elements can give off toxic fumes if welded.

WELDING can cause fire or explosion.

WARNING

WARNING

Sparks and spatter fly off from the welding arc.

The flying sparks and hot metal, weld spatter,

hot workpiece, and hot equipment can cause

fires and burns. Accidental contact of electrode

or welding wire to metal objects can cause

sparks, overheating, or fire.

1. Protect yourself and others from flying sparks and hot

metal.

2. Do not weld where flying sparks can strike flammable

material.

GENERAL INFORMATION 1-2 Manual 89250890

Page 11

GENERAL INFORMATION N7500

3. Remove all flammables within 35 ft. (10.7 m) of the

welding arc. If this is not possible, tightly cover them

with approved covers.

4. Be alert that welding sparks and hot materials from

welding can easily go through small cracks and openings to adjacent areas.

5. Watch for fire, and keep a fire extinguisher nearby.

6. Be aware that welding on a ceiling, floor, bulkhead, or

partition can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks or

drums.

8. Connect work cable to the work as close to the welding

area as practical to prevent welding current from

traveling long, possibly unknown paths and causing

electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding

wire at contact tip when not in use.

WARNING

FLYING SPARKS AND HOT METAL can cause

injury.

Chipping and grinding cause flying metal. As

welds cool, they can throw off slag.

1. Wear approved face shield or safety goggles. Side

shields recommended.

2. Wear proper body protection to protect skin.

WARNING

MOVING PARTS can cause injury.

NOTE

The following is a quotation from the General Conclusions

Section of the U.S. Congress, Office of Technology

Assessment, Biological Effects of Power Frequency Electric

& Magnetic Fields - Background Paper, OTA-BP-E-63

(Washington, DC: U.S. Government Printing Office, May

1989): “...there is now a very large volume of scientific

findings based on experiments at the cellular level and from

studies with animals and people which clearly establish

that low frequency magnetic fields interact with, and

produce changes in, biological systems. While most of

this work is of very high quality, the results are complex.

Current scientific understanding does not yet allow us to

interpret the evidence in a single coherent framework.

Even more frustrating, it does not yet allow us to draw

definite conclusions about questions of possible risk or to

offer clear science-based advice on strategies to minimize

or avoid potential risks.”

To reduce magnetic fields in the workplace, use the

following procedures.

1. Keep cables close together by twisting or taping

them.

2. Arrange cables to one side and away from the

operator.

3. Do not coil or drape cable around the body.

4. Keep welding power source and cables as far away

from body as practical.

ABOUT PACEMAKERS:

The above procedures are among those

also normally recommended for pacemaker

wearers. Consult your doctor for complete

information.

Moving parts, such as fans, rotors, and belts can cut

fingers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed and

securely in place.

2. Stop engine before installing or connecting unit.

3. Have only qualified people remove guards or covers

for maintenance and troubleshooting as necessary.

4. To prevent accidental starting during servicing, disconnect negative (-) battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away from

moving parts.

6. Reinstall panels or guards and close doors when servicing is finished and before starting engine.

Manual 89250890 1-3 GENERAL INFORMATION

Page 12

N7500 GENERAL INFORMATION

1.03 Principal Safety Standard Publications

1. Code of Federal Regulations (OSHA) Section 29, Part 1910.95, 132, 133, 134, 139,

251, 252, 253, 254, and 1000. U.S. Government Printing Office, Washington, DC 20402

http://www.osha.gov/pls/oshaweb/owasrch.

search_form?p_doc_type=STANDARDS&p_toc_

level=1&p_keyvalue=1910

2. ANSI Z49.1 “Safety in Welding and Cutting”

http://www.nssn.org/

3. ANSI Z87.1 “Practice for Occupational

and Educational Eye and Face Protection”

http://www.nssn.org/

4. ANSI Z88.2. “Standard Practice for Respiratory Protection.” American National Standards

Institute, 1430 Broadway, New York, NY 10018

http://www.nssn.org/

5. AWS F4.1. “Recommended Safe Practices for Welding and Cutting Containers”

http://www.aws.org/w/a/technical/index.html

6. AWS C5.3. “Recommended Practices for

Air Carbon-Arc Gouging and Cutting.” The

American Welding Society, 550 NW Lejeune

Rd., P.O. Box 351040, Miami, FL 33135

http://www.aws.org/w/a/technical/index.html

7. NFPA 51B. “Fire Prevention in Cutting and Welding Processes.”

http://www.nfpa.org/aboutthecodes/list_of_

codes_and_standards.asp

8. NFPA-7. “National Electrical Code” National Fire Protection Association, Battery Park, Quincy, MA 02269

http://www.nfpa.org/aboutthecodes/list_of_

codes_and_standards.asp

9. CSA W117.2. “Safety in Welding, Cutting and Allied

Processes”. Canadian Standards Association, 178

Rexdale Blvd., Rexdale, Ontario, Canada M9W 1R3

http://ccinfoweb.ccohs.ca/

10. ANSI Z535 Safety Alerting Standards

http://www.nssn.org/

11. Refer to your local codes.

GENERAL INFORMATION 1-4 Manual 89250890

Page 13

GENERAL INFORMATION N7500

1.04 Declaration of Conformity

Manufacturer: Victor Technologies

Address: 2800 Airport Rd.

Denton, TX 76208

USA

Description of equipment: Gouging Equipment (GMAW, MMAW, GTAW, CAG and wirefeeders). Including, but not

limited to Arcair-Matic N7500 Gouging System and associated accessories.

Serial numbers are unique with each individual piece of equipment and details the description and parts that are used

to manufacture a unit and date of manufacture.

The equipment conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’ (Directive 73/23/EU,

as recently changed in Directive 93/68/EU and to the National legislation for the enforcement of the Directive.

National Standard and Technical Specifications

The product is designed and manufactured to a number of standards and technical requirements among them are:

• AS1966-1 applicable to welding equipment and associated accessories.

• AS/NZS 3652-(EMC Directive EN50199) applicable to arc welding equipment - generic emissions and regulations.

• EN60974-1 applicable to welding equipment and associated accessories.

• AS60974.1 applicable to welding equipment and associated accessories.

• IEC 60974-1 applicable to welding equipment and associated accessories

• 2002/95/EC RoHS directive

Extensive product design verification is conducted at the manufacturing facility as part of the routine design and

manufacturing process, to ensure the product is safe and performs as specified. Rigorous testing is incorporated into

the manufacturing process to ensure the manufactured product meets or exceeds all design specifications.

Victor Arcair has been manufacturing and merchandising an extensive equipment range with superior performance,

ultra safe operation and world class quality for years and will continue to achieve excellence.

Manual 89250890 1-5 GENERAL INFORMATION

Page 14

N7500 GENERAL INFORMATION

This Page Intentionally Blank

GENERAL INFORMATION 1-6 Manual 89250890

Page 15

SPECIFICATIONS N7500

SECTION 2:

SPECIFICATIONS

2.01 Arcair-Matic N7500 Gouging System

The Arcair-Matic N7500 Gouging System adds new dimensions of flexibility and control in modern weld preparation. It’s the most advanced air carbon-arc gouging/grooving system in the world. The N7500 System assures

improved productivity in the following ways:

• Higheryieldsofoptimumqualityendproduct

• Dramaticreductionsofman-hoursandprocesscost

• Expandedareasofapplicability

FEATURES

Remote Pendant providing complete control of the gouging operation where it needs to be .... in the welder/

operator hands.

All functions from determining gouge parameters, start/stop function, travel delay, and the capability to manually

feed or retract the electrode in the Torch Head. The welder/operator can view the amperage and voltage during

gouging sequence easily while maintaining the electrode on the weld seam that’s being back gouged.

A single electrode contact shoe assembly accepts the entire range of Victor Arcair gouging electrodes from

5/16” (7.9 mm) through 3/4” (19.1 mm).

The N7500 Torch Head eliminates the necessity of stocking or changing contact shoe assemblies when changing electrode sizes.

The gouging system uses the Power Supply “contactor” to ensure that the gouging current is only present

when the welder/operator presses the “start” button on the Remote Pendant.

System is easily connected to the various power supplies available in the industry.

Ensures conformity to pre-determined, pre-selected groove depth and width specifications.

Welder/Operator can use the “Parameter Guide” option on the Remote Pendant to view the recommended

amperage and travel speed once the electrode and gouge depth is chosen.

A unique “travel delay” function assures excellent groove geometry at the very beginning of the groove.

This function eliminates a sloped groove at the beginning of the gouge, eliminating the need for a starting pad.

No current detect and low voltage functions shut down the system when these conditions are sensed.

These functions ensure optimum groove quality and prevent damage to the equipment and work.

Redesigned Torch Head

Redesigned Torch Head with extended front end to give the welder/operator better range of viewing during the

gouging operation ensuring the electrode is maintained in the correct position to the weld seam.

Manual 89250890 2-1 SPECIFICATIONS

Page 16

N7500 SPECIFICATIONS

2.02 N7500 Specifications

Rated Output

Output Current

Duty Cycle

Open Circuit Voltage Minimum of 60VDC

Rated Input

Rated Input Voltage 110V - 220V

Rated Input Amperage

Input Frequency 50/60 Hz

Control Box Controls

5A Circuit Breaker ON/OFF Switch w/reset ON/OFF Switch w/reset

110V/220V Control Box Power Input 3-Pin Socket

110V Auxiliary Outlet 4A, 110V

220V Auxiliary Outlet 4A, 220V

(2) 5A Circuit Breaker

Circuit Interface to Remote Pendant 7-Pin Socket

1 off push-button circuit breaker for the 110V outlet

1 off push-button circuit breaker for the 220V outlet

MAX. 1600A/42V @ 100%

400-1600

5A

Circuit Interface to Torch Head 6-Pin Socket

Circuit Interface to Power Supply 6-Pin Socket

Signal Interface to Work Piece 1-Pin Socket

Table 2-1: N7500 Specifications

N7500 SYSTEM

The N7500 System produces in a single pass uniform “U” or “J” grooves of various depths up to 1-1/8” (28.6

mm). Two or more passes produce grooves of greater depth. Through continuous control of arc voltage or amperage and a constant travel speed, the groove is held within 0.025” (0.635 mm) target depth. Victor Arcair Jointed

Jetrods® Electrodes, with tapered male and female ends, make it possible to produce grooves of unlimited length.

Control elements and circuitry for the N7500 System are housed in a Control Box and a splash-proof Pendant.

Gouging operations are managed remotely using the Remote Pendant with a multi-function LCD display and touch

pad controls.

Groove depth and width are controlled in two ways:

• By changing the travel carriage’s forward speed or by changing the work piece rotational speed.

• By changing the electrode’s diameter and increasing or decreasing amperage.

NOTE

Remote Pendant is NOT submersible.

This manual has been structured to provide the user with all the information required for assembly, operation and

troubleshooting of the N7500 System. Illustrations, charts and other supporting data are provided to bridge the

gap between theory and practice.

In addition, the N7500 System can be integrated with any mechanized travel system that provides forward travel

over a steel plate while in the flat, vertical, or over-head positions. The N7500 Torch Head can also be mounted

in a stationary position for work on rotating shafts, round steel, or a vessel. In a stationary set up the work-piece

rotates in a

For additional information, contact your local Victor Arcair Distributor or Victor Technologies.

SPECIFICATIONS 2-2 Manual 89250890

counter-clockwise direction

and the Torch Head is generally located at the work-piece’s 4 o’clock position.

Page 17

SYSTEM COMPONENT DESCRIPTION N7500

ART# A-10928_AC

SECTION 3:

SYSTEM COMPONENT DESCRIPTION

There are three (3) main components making up the Arcair-Matic N7500 Gouging System; Torch Head, Control

Box, and Remote Pendant.

3.01 Control Box

ART# A-10855_AC

Figure 3-1: Control Box

The Control Box controls the system’s operation before, during and after gouging. Under command of the Remote

Pendant, the Control Box supplies DC power and compressed air to the Torch Head. The unit has a power cord

for required AC voltage, clamping fixtures, and handles for secure lifting. See “Table 3-2: Control Box Features”

for each of the Control Box’s connectors/fittings and the function of each component.

Manual 89250890 3-1 SYSTEM COMPONENT DESCRIPTION

Page 18

N7500 SYSTEM COMPONENT DESCRIPTION

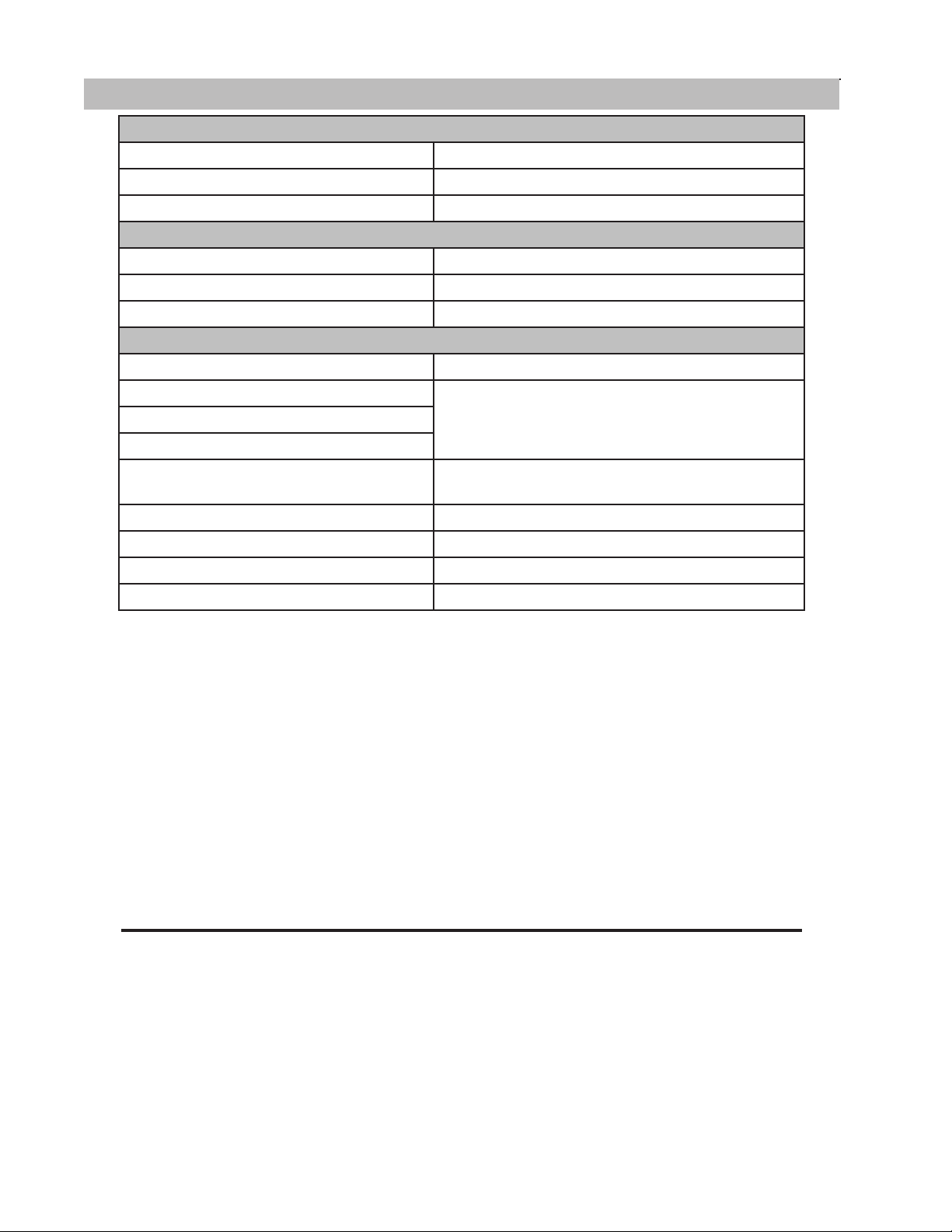

Item Fitting Function

Two (2) 4 amp AC power receptacles provide AC power for a travel system

1

Travel System

Power Connector

if needed, 110 VAC or 220 VAC. The Remote Pendant controls when these

receptacles receive AC power through the Remote Pendant travel delay

circuitry. Only the AC power voltage (110V or 220V from the Input Power

AC) that the Control Box is connected to will be delivered.

2 Air Out Conn.

Delivers compressed shop air to the Torch Head when the

START

“Start”

button is pressed on the Remote Pendant.

Connector to

3

Torch Head Elec-

trode Motor

Remote Pendant

4

5

Connector

Circuit Breaker

w/reset

6 ON/OFF switch

Input and Output

7

DC Power Conn.

Delivers the signal from the Control Box to the Torch Head to either

feed or retract the electrode to maintain the preset arc voltage.

Links the Remote Pendant to the Control Box to initiate start/stop of

the gouging operation.

Circuit breaker reset push button for 110 VAC and 220 VAC AC Travel

System Power Connector receptacles.

Control Box ON/OFF control switch with built in 5 amp circuit breaker

and reset.

Output and Input DC (+) positive power buss connections.

8 Air In Conn. This port accepts compressed shop air to the Control Box.

9

Power Supply

Connector

Links the Control Box to the Power Supply. On demand from the Remote Pendant the internal contactor of the Power Supply can be closed

and opened to deliver the current to the Torch Head.

10 Input Power (AC) Delivers AC voltage to the Control Box from a standard wall receptacle.

11 Signal Wire Conn.

Control Box Hold

12

13

Down Fixture

Remote Pendant

Cradle

Allows the Control Box to detect open circuit voltage when the Power

Supply contactor is closed.

Hold down fixtures located on both sides of the Control Box to allow

fastening to a base.

Secure holding fixture for Remote Pendant.

Table 3-2: Control Box Features

NOTE

The 110V and 220V power supply receptacles may be used to run any device that has the same linevoltage requirements and that require “ON-OFF” or “Start-Stop” control. However, any such device

must be rated with a maximum current draw of 4 amperes.

SYSTEM COMPONENT DESCRIPTION 3-2 Manual 89250890

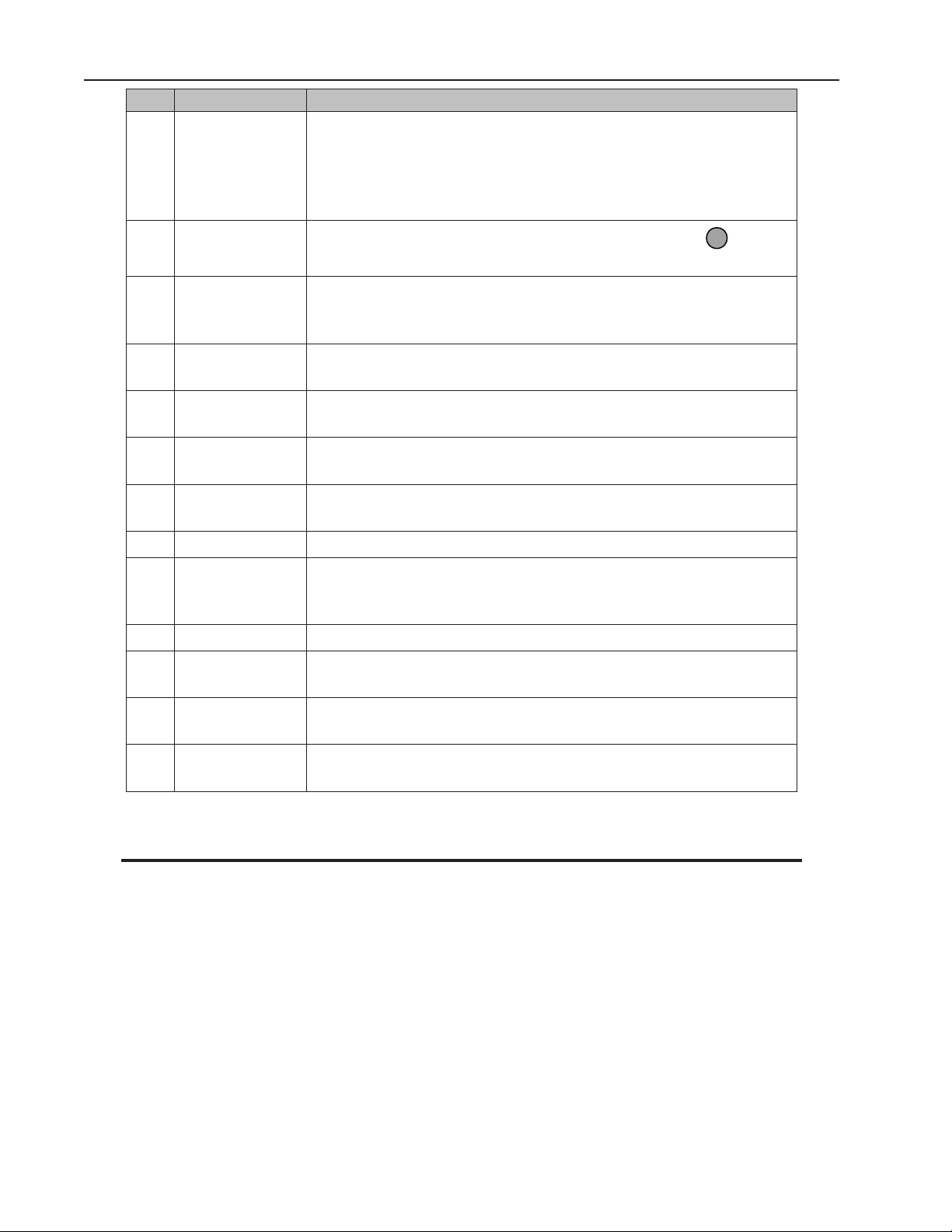

Page 19

SYSTEM COMPONENT DESCRIPTION N7500

13

7

6

(Rear panel assembly

not shown for clarity)

7

10

12

Figure 3-3: LEFT Side of Control Box

MAX 100 psi

8

9

11

ART# A-10851_AC

2

1

(Rear panel assembly

not shown for clarity)

3

4

7

5 AMP

5

12

Figure 3-4: RIGHT Side of Control Box

5 AMP

5

ART# A-10844_AB

13

8

2

WARNING! AVERTISSEMENT!

Protect yourself and others. Wear ear, eye, and body protection.

Protégez-vous et d'autres. Portez l'oreille, l'oeil, et la protection de corps.

Insure good ground from power supply to workpiece. Poor ground may cause

damage to any or all components. Use only with compressed air. See manual.

Assurez la bonne terre de l'alimentation d'énergie à l'objet. La terre pauvre peut endommager

quelques des ou tous composants. Employez seulement avec l'air comprimé. Voir le manuel.

Noise can damage hearing.

Le bruit peut endommager l’ouïe.

Smoke, fumes, and gases can be dangerous to your health. Use adequate

ventilation. Keep your head out of the smoke.

La fumée, les émanations et les gaz peuvent être dangereux pour votre santé.

Employez à ventilation proportionnée. Gardez votre tête hors de la fumée.

Arc rays, hot slag, and sparks can injure eyes and burn skin.

L les rayons de l’arc,

es scories et les étincelles chauds peuvent blesser les yeux et brûler la peau.

Welding sparks can cause res and explosions.

Les étincelles de soudage peuvent causer des incendies et des explosions.

Electric shock can cause injury or death. Disconnect power before servicing.

Un choc électrique peut causer des blessures ou la mort. Déconnectez la puissance

avant l'entretien.

POWER

SUPPLY OUT

POWER

SUPPLY IN

6

ART# A-10853_AB

(rear cover plate not shown for clarity)

Figure 3-5: BACK of Control Box

Manual 89250890 3-3 SYSTEM COMPONENT DESCRIPTION

Page 20

N7500 SYSTEM COMPONENT DESCRIPTION

4

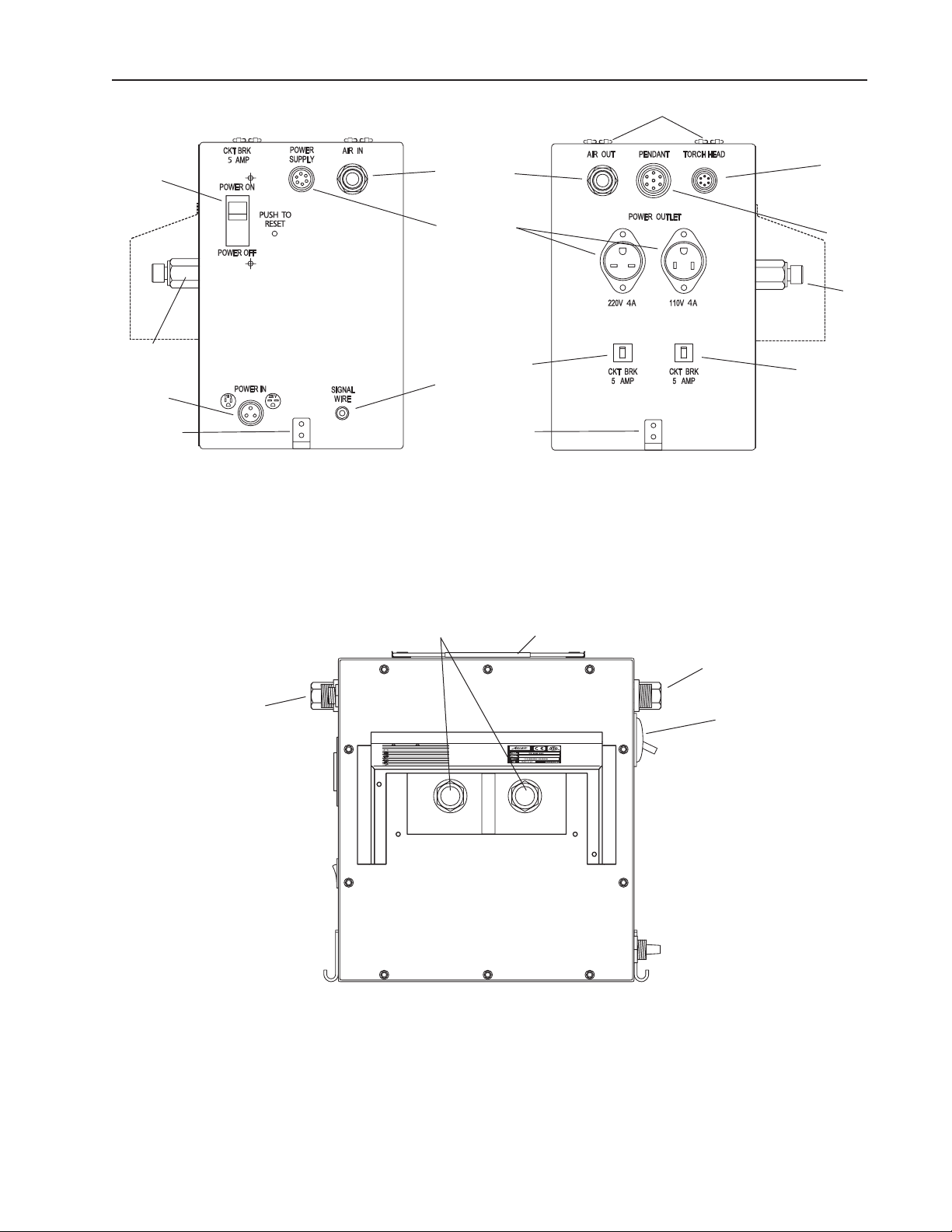

3.02 Torch Head

ART# A-10838_AB

Figure 3-6: Torch Head

The N7500 Torch Head feeds the jointed electrodes down to the work surface. The Control Box controls and signals the motor on the Torch Head to feed or retract the electrode. This action maintains arc voltage or current, set

on the Remote Pendant. The Control Box (See “Figure 3-1: Control Box” on page 3-1) channels the DC current

from the DC Welding Power Supply to the Torch Head using standard welding cables. Compressed air coming

from the Control Box connects at the Torch Head with a 3/8” NPT female pipe elbow.

9

ART# A-10833_AB

2

6

10

3

- 5/16 3/8

- 1/2

- 5/8

- 3/4

N7500

5

7

1

Figure 3-7: Torch Head Components

8

SYSTEM COMPONENT DESCRIPTION 3-4 Manual 89250890

Page 21

SYSTEM COMPONENT DESCRIPTION N7500

Item Fitting Function

1 Motor

2 Motor Cable

DC Power Cable

3

4 Air Inlet

5 Air Plenum

6

7 Electrode Size

8

9 Air Plenum Shield

10 Torch Head Shield

Busbar

Electrode Release

Lever

Carriage Mounting

Fixture

This motor feeds the electrode away from and towards the work. The

Motor’s action is controlled by the Pendant settings.

This Motor Cable end is connected to the Control Box via a cable assembly that comes in 3, 15, 25, or 50 foot lengths. See “9.07 Motor

Cable Assembly” on page 9-4 for part numbers.

This is the connection point on the Torch Head for the DC power cables

from the Control Box.

Air is fed into a 3/8” NPT fitting on the Torch Head using an air supply

line from the Control Box.

This housing circulates air around electrode housing before releasing

in a directed spray to remove gouging slag.

This lever is used to open the Motor Feed assembly allowing the operator to manually remove or replace an Electrode.

The guide inside helps the insertion of the electrode through the Torch

Head.

The mounting bracket that comes with the Torch Head allows it to

fasten to a vertical adjustment assembly which is either mounted on a

travel system or stationary fixture.

This metal shield protects the Air Plenum housing from slag splash

back.

This metal shield protects the motor and housing from slag splash

back.

Table 3-8: Torch Head Features

Manual 89250890 3-5 SYSTEM COMPONENT DESCRIPTION

Page 22

N7500 SYSTEM COMPONENT DESCRIPTION

4

3.03 Remote Pendant

Remote Pendant provides the welder/operator the ability to:

• Start/stop the gouging operation,

• Manually jog of the air carbon-arc electrode in the Torch Head prior to gouging,

• Pre-set options to ensure proper operation of the system.

2

11

7

6

1

5

3

10

9

12

8

ART# A-10856_AB

Figure 3-9: Remote Pendant

Item Feature Item Feature

1 Mode-indicator Display 7

Jog Up/Down Travel

START

2

8

Start Button

STOP

3

9

Stop Button

4

10 Connector

Mode Selector

OK

OK Button

Rough (Machining)

5

11 Bumper

Rotary Dial

TRV

6

12 Grip Feet

Travel Button

Table 3-10: Remote Pendant Controls

For additional details on the operation of the Remote Pendant see “5.04 Remote Pendant Programming” on page

5-3. For storage information see “4.07 Remote Pendant Storage” on page 4-9.

SYSTEM COMPONENT DESCRIPTION 3-6 Manual 89250890

Page 23

SYSTEM COMPONENT DESCRIPTION N7500

3.04 Electrodes

The most important part of the N7500 System is the electrode. Since the N7500 system uses only DC power, the

electrodes must be formulated and manufactured for use exclusively with Direct Current.

The use of Victor Arcair Jointed Jetrods Copperclad DC Electrodes is highly recommended. These electrodes are

manufactured to Victor Arcair specifications to provide the best electrical conductivity, to maintain proper electrode

diameter at the point of the arc, and to minimize carbon sublimation. A male/female joint enables electrodes to

be joined together while the gouging operation is taking place.

Electrode Diameter Gouge Width Amperage

Inch mm Inch mm Min Max

⁄

⅜

½

⅝

¾

The formulation and design of the Jetrods Electrodes embody numerous laboratory-proven advantages under the

user’s production conditions. Among these advantages are:

7.9

9.5

12.7

15.9

19.1

Chart 3-11: Electrode Selection

⁄

½

⁄

⁄

1⁄

11.1 400 450

12.7 450 600

20.7 800 1000

24.9 1000 1250

27.0 1250 1600

• Cooler operation due to a small incandescent area at the tip and joint

• Excellent arc stability

• High metal-removal rates

• Uniformity of diameter

• Clean grooves or cuts

Manual 89250890 3-7 SYSTEM COMPONENT DESCRIPTION

Page 24

N7500 SYSTEM COMPONENT DESCRIPTION

3.05 Gouging Operation Settings

“Table 3-12: Operating Parameters”” shows recommended operating amperage by electrode sizes. The travel

speeds listed for each size carbon and gouge depth were derived in the laboratory using a 1500 amp Power Supply.

Your results may vary depending on the arc current, voltage and other parameters you use.

Automatic Gouging Operating Data

Electrode Diameter Desired Depth DC Current Travel Speed Per Min.

Inch mm Inch mm Amps Inch mm

⁄

⁄

⁄

⁄

⁄

⅜

⅜

⅜

⅜

⅜

½

½

½

½

½

⅝

⅝

⅝

⅝

⅝

¾

¾

¾

¾

¾

¾

7.9

7.9

7.9

7.9

7.9

9.5

9.5

9.5

9.5

9.5

12.7

12.7

12.7

12.7

12.7

15.9

15.9

15.9

15.9

15.9

19.1

19.1

19.1

19.1

19.1

19.1

⅛

⁄

¼

⁄

⁄

⅛

⁄

¼

⅜

⁄

⅛

¼

⅜

½

¾

¼

⅜

½

⅝

⁄

¼

⅜

½

⅝

¾

1⅛

Table 3-12: Operating Parameters

3.2 400 65 1651

4.8 400 45 1143

6.4 450 36 914

7.9 450 33 838

11.1 500 22.5 572

3.2 500 70 1778

4.8 500 44 1118

6.4 500 35 889

9.5 500 20 508

14.3 500 17.5 445

3.2 850 96 2438

6.4 850 57 1448

9.5 850 35 889

12.7 850 24 610

19.1 850 17.5 445

6.4 1250 72 1829

9.5 1250 48 1219

12.7 1250 37 940

15.9 1250 30 762

23.8 1250 19.5 495

6.4 1400 72 1829

9.5 1400 42 1068

12.7 1400 34 865

15.9 1400 27 687

19.1 1400 22 560

28.6 1400 13 330

NOTE

If you want a groove depth that is greater than 1-1/2 times the diameter of the electrode being used,

make the groove in two or more passes.

SYSTEM COMPONENT DESCRIPTION 3-8 Manual 89250890

Page 25

SYSTEM COMPONENT DESCRIPTION N7500

3.06 Selecting the Proper Electrode Diameter

Your choice should be based on the depth and width of

the gouge you need. If you want a gouge 1-1/2 times

greater than the diameter of the electrode being used,

make the groove in two or more passes or oscillate

the Torch Head.

3.07 Keeping Electrodes Dry

Keep electrodes dry. Damp electrodes should be dried

before using. (Ten hours at 300°F [176.7°C]) Wet

electrodes may shatter from internal steam pressure

when an arc is struck.

POWER SUPPLY (SUPPLIED BY USER) FOR THE

N7500 SYSTEM

WARNING

Direct current/electrode positive (reverse

polarity) is required for the N7500 System. Use direct current/electrode negative

(straight polarity) for special applications.

DO NOT use alternating current with the

system.

CAUTION

Power Supplies must be rated for 100%

duty cycle at the amperage required for the

size (diameter) electrode used. Contact the

manufacturer of the Power Supply for paralleling procedures or with questions concerning

amperage ratings and duty cycles.

NOTE

Recommendations are based on a 4 volt DC

drop per 100 ft. (30.48 m) length given is onehalf the sum of lengths of electrode and ground

leads. Inadequate grounding may cause cable

overheating. There should be at least 1 square

inch (6.45 cm2) of contact per 1000 amps.

DC Welding Power Supply with a minimum Open-Circuit

Voltage (OCV) of 60 volts and 45 volts at rated load supply

the DC current for the N7500 System. Use single Power

Supplies rated at 1,000 or 1,500 amperes to get enough

amperage for larger diameter electrodes. Power Supplies

may be paralleled in combinations of two or more similar

units.

3.08 Secondary Power Cables (Welding Leads)

Recommended Number and Size of Secondary Cables

Amps

100 4 4 1 1 1/0 1 2/0 1 4/0

200 3 2 1 1/0 1 3/0 1 3/0 3 3/0

300 2 1 1 3/0 2 2/0 2 4/0 4 4/0

400 2 1 1/0 1 4/0 3 3/0 3 4/0

500 1 1 2/0 2 2/0 3 4/0 4 4/0

600 1 1 3/0 2 3/0 3 4/0

800 1 3/0 1 4/0 2 4/0 5 4/0

1000 1 4/0 2 2/0 3 3/0

1200 2 2/0 2 3/0 3 4/0

1400 2 4/0 2 4/0 4 3/0

1600 3 3/0 2 4/0 4 4/0

1800 2 4/0 3 3/0

2000 3 4/0 3 4/0

25 ft. (7.5 m) 50 ft. (15 m) 100 ft. (30 m) 150 ft. (46 m) 200 ft. (61 m) 250 ft. (76 m)

No. Size No. Size No. Size No. Size No. Size No. Size

Table 3-13: Power Cable Requirements

Choose the number and size of secondary power cables on the basis of the combined length of both the positive

(Electrode) and negative (work piece/ground) cables to ensure greatest efficiency and safe operation in terms of

100% duty cycle.

Manual 89250890 3-9 SYSTEM COMPONENT DESCRIPTION

Page 26

N7500 SYSTEM COMPONENT DESCRIPTION

3.09 Compressed Air

Compressed air flows from an air nozzle in the N7500 Torch Head, travels parallel along the axis of the electrode,

and is directed into the molten puddle. The air solenoid included in the N7500 Control Box accepts ordinary shop

compressed air. An air regulator (supplied by user) should be mounted on the air line and adjacent to the Control

Box. Use at least 60 psi, but not greater than 100 psi input of compressed air to the regulator. “Table 3-14: Compressed Air Input Requirements” shows recommended pressure and volume inputs:

Compressed Air Requirements

Air Pressure Air Volume

psi* kg/cm

60 4.2 46 1.3

80 5.6 63 1.8

100 7.0 81 2.3

Table 3-14: Compressed Air Input Requirements

*To convert psi to kpa (kilopascals), multiply by 6.895

3.10 Main Air Line

Up to the air regulator mounted (see “Figure 4-9: Assembly Stage 1” on page 4-4) on the N7500 system, the

Primary Air Line may be either rigid or flexible. The inside diameter of the Primary Air Line varies with the length

of the line between compressor and regulator.

2

CFM m3/min.

Recommended Air Line Requirements

Line length up to 25’ (7.6 m): 1/2” (12.7 mm) inside diameter

Line length above 26’ (7.9 m): 5/8” (15.9 mm) inside diameter

SYSTEM COMPONENT DESCRIPTION 3-10 Manual 89250890

Page 27

ASSEMBLY AND INSTALLATION N7500

SECTION 4:

ASSEMBLY AND INSTALLATION

CAUTION

Be sure to read this manual completely before trying to install or use this equipment. Call your Victor

Arcair Representative or Distributor if you have any questions.

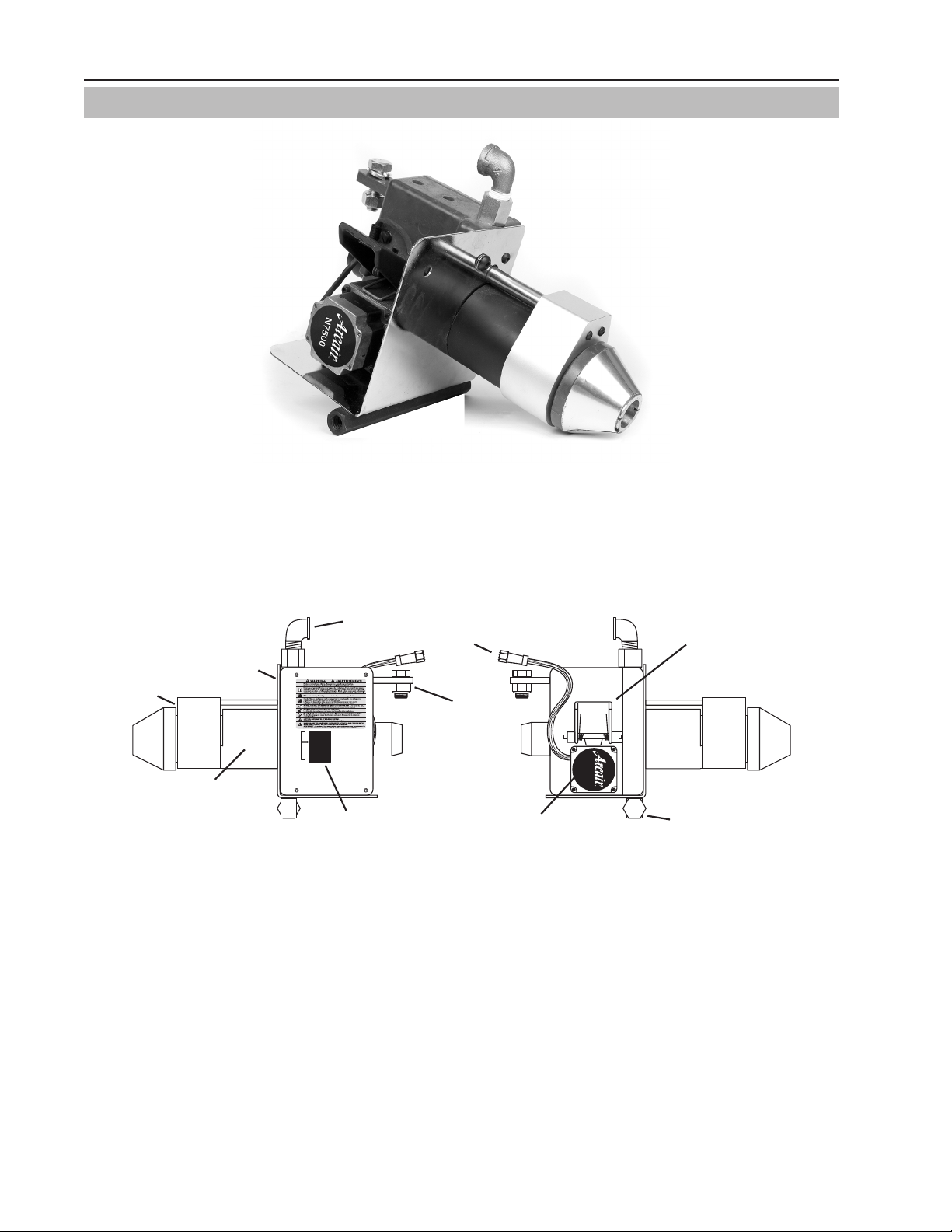

4.01 Receiving and Handling

Remove all components from the boxes. Using the packing lists, check to be sure you have all parts. Inspect each

part for damage. Buyers may file claims for loss or damage with the carrier.

Unpacking Components

Write down the Part Number and Serial Number for the Control Box, Remote Pendant, and Torch Head on the

Warranty page in the back of this book.

ART# A-10855_AC

ART# A-10838_AB

Figure 4-1: Control Box

ART# A-10865_AC

Figure 4-3: Remote Pendant

Manual 89250890 4-1 ASSEMBLY AND INSTALLATION

Figure 4-2: Torch Head

Page 28

N7500 ASSEMBLY AND INSTALLATION

MAX 100 p

!

When asking about your equipment, be sure to give its full serial and model number(s) that appear on the nameplate of each component. The N7500 has name plates on each major component; Control Box, Torch Head, and

Remote Pendant. The Torch Head and the Pendant have smaller nameplates than the Control Box. The Control

Box nameplate is located on the rear plate. The nameplate for the Torch Head is located on the inside shield and

the nameplate for the Pendant is on it’s back surface.

Art# A-10857_AB

Art# A-10845_AC

Figure 4-4: Control Box Nameplate

Art# A-10849_AB

Figure 4-5: Remote Pendant and Torch Head

Nameplates

Remote Pendant

Control Box

Torch Head

ART# A-10924_AC

Figure 4-6: Nameplate Locations

NOTE

When using the Arcair-Matic N7500 Gouging System with a travel system, the Control Box should be

centrally placed.

Prior to installing the N7500 components please have the following components or items in place:

WARNING

Connections to ‘live’ or “hot” are inherently dangerous. DO NOT service or repair equipment with power

ON. DO NOT operate equipment with protective insulators or covers removed.

• Confirm that your Power Supply cable size is rated for the work and the cable ends have fittings that will

mount on the Control Box Power Supply buss poles (See Step 6). See "Table 3-13: Power Cable Requirements" on page 3-10.

• Confirm that your air supply is rated for the work (See Step 6). See "Table 3-14: Compressed Air Input

Requirements" on page 3-10.

ASSEMBLY AND INSTALLATION 4-2 Manual 89250890

Page 29

ASSEMBLY AND INSTALLATION N7500

4.02 Assembly

The assembly instruction steps are divided into five groups; Miscellaneous Cable/Plumbing Assemblies, Control Box,

Torch Head, Remote Pendant, and Final Connections. Remote Pendant Storage is located at the end of this section.

4.03 Miscellaneous Cable/Plumbing Assemblies

Cable assemblies required to operate the N7500 system come in various lengths and must be specified by the end

user to meet their specific needs.

Cable

Description

Routing

AC Power Cable Assembly

Plug rated for 110VAC 60Hz or 220VAC 50Hz with

3 pin connector at opposite end.

Outside power to Control Box

ART# A-10858_AB

ART# A-10863_AB

ART# A-10854_AB

Remote Pendant Cable Assembly

Large 7 pin connector with male/female ends.

Pendant to Control Box

Motor Cable (on Torch Head) Assembly

6 pin connector with male/female connectors.

Control Box to Torch Head

Power Supply Communication Assembly

6 pin connector with female connector and a cut

end.

Control Box to Power Supply

DC Power Cable Assembly

Based on customer requirements.

Control Box to Torch Head

Air Hose Assembly

ART# A-10862_AC

ART# A-10859_AB

ART# A-10839_AC

ART# A-10860_AC

Based on customer requirements.

Control Box to Torch Head

Table 4-7: Cable Identification

Manual 89250890 4-3 ASSEMBLY AND INSTALLATION

Page 30

N7500 ASSEMBLY AND INSTALLATION

4.04 Control Box Installation

Determine where the Control Box should be located in relationship to where the gouging will take place. It is not

recommended to carry the Control Box on any travel system other than the Victor Arcair Titan® Machine Carriage

due to the added weight of the Control Box and the weight of the power cables coming from the DC Power Supply.

The Control Box can be secured to a stationary surface with the mounting brackets on both sides. Refer to "Table

3-2: Control Box Features" on page 3-2 for the mounting brackets and "Figure 3-4: RIGHT Side of Control Box"

and "Figure 3-5: BACK of Control Box" on page 3-3 for bracket locations.

NOTE

DO NOT force connections. All connectors should be fastened easily. Be sure to tighten connections

as you go through each step. Avoid crimping hoses or wires.

WARNING

Select the receptacle voltage that correctly matches the plug and power requirements of the Carriage

System.

WARNING

Confirm that the Power Supply and Control Box Power In switches are OFF.

Make the following connections from Power Supply to Control Box and work piece. See "Figure 4-8: Assembly

Stage 1".

POWER SUPPLY

POWER

SUPPLY

DC POWER CABLE (+) IN

GROUND CABLE (–)

CONTROL BOX INPUT

AC POWER CABLE

120V

OR

220V

COMMUNICATION CABLE

(Rear panel assembly

not shown for clarity)

MAX 100 psi

CONTROL BOX

AIR REGULATOR

SIGNAL WIRE

INCOMING

AIR LINE

(VIEWED FROM CABINET LEFT SIDE)

ART# A-10850_AC

GROUND CABLE (–)

WORK PIECE

Figure 4-8: Assembly Stage 1

1. Connect the air regulator to the side of the Control Box labeled “AIR IN”. Preset the regulator to the recommended operating pressure based on "Table 3-14: Compressed Air Input Requirements" on page 3-10.

(The compressed air inlet and outlet fittings on the Control Box are 1/2-14 NPT.)

2. Connect the incoming shop compressed air line to the air regulator. Charge the shop compressed air supply to the air regulator on the Control Box’s AIR IN side to confirm air pressure is within recommended

specifications. Refer to the specifications listed on the Control Box nameplate.

3. Attach the AC Power Cable to the connector labeled “POWER IN”.

4. Loosen the screws holding the Control Box rear cover plate. Re-position and tighten one screw.

ASSEMBLY AND INSTALLATION 4-4 Manual 89250890

Page 31

ASSEMBLY AND INSTALLATION N7500

WARNING

Confirm the DC Power Supply is OFF before beginning the next step.

5. Connect the positive (+) Power Supply cable(s) of the DC Power Supply to the busbar terminal on the back

side of the Control Box labeled “POWER SUPPLY IN”. This connection must be wrench tight to avoid over

heating of the connection. Refer to "Table 3-13: Power Cable Requirements" on page 3-10 in this manual

for proper amount and size Power Supply cabling that you plan to use.

NOTE

It is recommended to use a minimum of two Power Cable assemblies with the N7500. The cables should

be connected at the same points on the Control Box. Refer to "Table 3-13: Power Cable Requirements"

on page 3-10.

6. Connect the negative (-) cable(s) of the DC Power Supply to the work piece.

7. A signal wire (not supplied) must be attached to the work piece and the other end to the ground post on

the left side of the Control Box labeled “SIGNAL WIRE”.

NOTE

Use standard #12 insulated copper wire as your signal wire. It must be long enough to prevent stress

on the Control Box connection.

8. Connect the Power Supply Communication Cable Assembly (6 pin female connector) to the side of the

Control Box labeled “POWER SUPPLY” and run it back to the Power Supply. Refer to "Table 4-7: Cable

Identification" on page 4-3 for cable identification. "Figure 4-9: Power Supply Comm. Cable Pin Configuration" below illustrates the pin arrangement for the Power Supply Communication Cable and "Table 4-10:

Standard Wiring Connections" has the wire connection schedule for several common power supplies. If

your Power Supply is not listed here please refer to the Owner’s manual of your Power Supply for correct

wiring instructions.

DE

F

C

BA

PIN F BLACK #2

PIN A BLACK #1

CONTROL BOX POWER SUPPLY

COMMUNICATION CABLE PIN LAYOUT

ART# A-10832_AD

Figure 4-9: Power Supply Comm. Cable Pin Configuration

Manual 89250890 4-5 ASSEMBLY AND INSTALLATION

Page 32

N7500 ASSEMBLY AND INSTALLATION

Power Supply Control Connection Chart

N7500 Control Box Power Supply

Brand Model

Lincoln Idealarc® DC 600 2 4

Lincoln Idealarc DC 600 PRO 2 4

Lincoln Idealarc DC 650 PRO 2 4

Lincoln Idealarc DC 655 - EUROPE 2 4

Lincoln Idealarc DC 655 2 4

Lincoln Idealarc DC 750 2 4

Lincoln

Lincoln Idealarc DC 1000 (Prior to Nov 1991) 2 4

Lincoln Idealarc DC 1000 (for code numbers 9919 - 9925,

10293, 11305, 11330, 11331, 11332, 11333, 11334, 11681

thru 11684)

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5

2 4

Comm. Cable

Miller

ESAB

Lincoln Idealarc DC 1500 (Prior to May 1979) 2 4

Lincoln Idealarc 1500 (for Code Numbers 8294 and above) 2 4

Lincoln RED-D-ARC DC 600 2 4

Miller BIG BLUE 500D - 600X A or I B or J

Miller Deltaweld® 450-650 A or I B or J

Miller Deltaweld SERIES A or I B or J

Miller Dimension™ 650 A or I B or J

Miller Dimension 1000 A or I B or J

Miller Dimension SUBARC A or I B or J

Miller Dynasty® 700 - MAXSTAR 700 A B

Miller Gold Star® 300SS - 400SS - 600SS A B

ESAB 653 CVCC U V

ESAB MULTIPOWER 460 PULSE U V

Table 4-10: Standard Wiring Connections

ASSEMBLY AND INSTALLATION 4-6 Manual 89250890

Page 33

ASSEMBLY AND INSTALLATION N7500

G

)

G

AIR LINE

POWER

S

Y

A

C

P

C

E

WO

CE

SIGNAL

G

CO

AC PO

E

O

V

4.05 Torch Head Installation

Make connections from Control Box to the Torch Head. See "Figure 4-11: Assembly Stage 2".

OWER SUPPLY

OMMUNICATION CABL

UPPL

AIR HOSE

MOTOR CABLE -

CONTROL BOX TO

TORCH HEAD

INCOMIN

AIR REGULATOR

DC POWER CABLE (+) IN

NTROL BOX INPUT

WER CABL

120V

R

220

ROUND CABLE (–

RT# A-10848_A

TORCH HEADPENDANTAIR OUT

5 AMP

5 AMP

ON OTHER SIDES

THESE CONNECTIONS

WIR

CONTROL BOX

(VIEWED FROM CABINET RIGHT SIDE)

ROUND CABLE (–)

DC POWER

CABLE (+) OUT

(Rear panel assembly

not shown for clarity)

N7500

MOUNTING

FIXTURE

AIR INLET

TORCH HEAD

RK PIE

Figure 4-11: Assembly Stage 2

9. Mount the Torch Head to the vertical adjustment assembly located on the travel system or fixed stationary

fixture using the mounting hardware supplied with the Torch Head. Further adjustments will be discussed

in the operating section of this manual. See "5.02 Position Torch Head" and "5.03 Insert the Electrode"

on page 5-2.

NOTE

Tuning the mounting position of the Torch Head or adjusting the traveler fixture or carriage system may

be required to achieve best gouging results.

10. Connect the DC power cable(s) to the Torch Head busbar and to the busbar terminal on the back side of the

Control Box labeled “POWER SUPPLY OUT”. These connections must be wrench tight to avoid overheating

the connection. Slide the cable boot over the busbar on the Torch Head. Use the 1/2”-13 hex head bolt

and nut supplied for the cable connection on the Torch Head busbar.

11. Return the Control Box Power Supply cover plate to its original position and tighten both screws.

12. Connect the Air Hose Assembly to the Torch Head and to the side of the Control Box labeled “AIR OUT”.

Slide the rubber boot over the connection on the Torch Head.

13. Connect the Torch Head Motor Cable Assembly to the connector on the side of the Control Box labeled

“TORCH HEAD” and the other end to the motor cable connection on the Torch Head. This cable has a 6

pin connector at each end. Refer to "Table 4-7: Cable Identification" on page 4-3.

Manual 89250890 4-7 ASSEMBLY AND INSTALLATION

Page 34

N7500 ASSEMBLY AND INSTALLATION

n for clarity

CO

O

A

OSE

R

C

TORC

G

)

G

AIR LINE

POWER

S

Y

G

A

B

P

C

E

OU

WO

CE

SIGNAL

E

G

CO

AC PO

E

O

V

4.06 Remote Pendant Installation

Make the following connections from the Pendant to the Control Box. See "Figure 4-12: Assembly Stage 3".

REMOTE PENDANT

N7500 Gouging System

TRV

JOG

START

Automatic Control

TUNE

ROUGH

STOP

OK

UPPL

OWER SUPPLY

OMMUNICATION CABL

REMOTE PENDANT CABLE

IR H

TORCH HEADPENDANTAIR OUT

DC POWE

ABLE (+) OUT

MOTOR CABLE -

NTROL BOX T

TORCH HEAD

AIR INLET

INCOMIN

AIR REGULATOR

DC POWER CABLE (+) IN

NTROL BOX INPUT

WER CABL

120V

R

220

ROUND CABLE (–

RT# A-10854_A

ON OTHER SIDES

THESE CONNECTIONS

WIR

(VIEWED FROM CABINET RIGHT SIDE)

5 AMP

5 AMP

CONTROL BOX

(Rear panel assembly

not shown for clarity)

ROUND CABLE (–)

MOUNTIN

FIXTURE

H HEAD

RK PIE

Figure 4-12: Assembly Stage 3

14. Connect the Remote Pendant Cable Assembly to the Remote Pendant and the Control Box. Cable has a

large 7 pin connector at each end. Refer to "Table 4-7: Cable Identification" on page 4-3.

15. Plug the travel system grounded power cord into the receptacle labeled “POWER OUTLET”.

WARNING

Select the receptacle voltage that correctly matches the plug and power requirements of the Carriage

System.

ASSEMBLY AND INSTALLATION 4-8 Manual 89250890

Page 35

ASSEMBLY AND INSTALLATION N7500

4.07 Remote Pendant Storage

Use safe storage practices when storing the Remote Pendant and cable. When not in use, mount the Remote

Pendant to the top of the Control Box as shown below.

Automatic Control

TUNE

STOP

N7500 Gouging System

ROUGH

START

MAX 100 psi

ART# A-10831_AC

Figure 4-13: Pendant Mounting

Automatic Control

TUNE

STOP

ROUGH

START

ART# A-10830_AC

Figure 4-14: Pendant Mounted

N7500 Gouging System

MAX 100 psi

Manual 89250890 4-9 ASSEMBLY AND INSTALLATION

Page 36

N7500 ASSEMBLY AND INSTALLATION

This Page Intentionally Blank

ASSEMBLY AND INSTALLATION 4-10 Manual 89250890

Page 37

SYSTEM OPERATION N7500

4

SECTION 5: OPERATING THE N7500 SYSTEM

5.01 Remote Pendant Operation

2

7

6

5

10

12

8

11

9

ART# A-10856_AB

Figure 5-1: Remote Pendant

Item No. Feature Function

1

2

3

4

Mode-indicator

Display

START

Start Button

STOP

Stop Button

Rough

Digital display of current mode setting/adjustment value/rate.

Signals the Power Supply to close it’s internal contactor to supply current to the

Torch Head and the electrode in the Torch Head feeds down to begin the gouging

operation.

Signals the Power Supply to open it’s internal contactor shutting OFF the current to

the Torch Head and the electrode in the Torch Head will retract away from the work

surface.

Stalls the Torch Head feed motor while maintaining current to the electrode to avoid

gouging to irregular surface defects.

(Machining)

1

3

5

Potentiometer to adjust settings based on operation mode.

Rotary Dial

TRV

6

Travel Button

7

Jog Up/Down

When pressed, supplies AC voltage to the travel system that is plugged into the

Control Box. Used when adjustments are required to locate the electrode to the

start point of gouging.

Feeds or retracts the electrode in the Torch Head

Travel

8

Mode Selector

OK

9

10 Connector Cable connection running from the Remote Pendant to Control Box

OK Button

Shifts mode (program display) selection in digital display to access a setting or

adjustment.

Enters and Accepts data adjustments for the mode of operation.

11 Bumper Protective housing.

12 Grip Feet Plastic snap on feet to fasten Remote Pendant to Control Box.

Table 5-2: Remote Pendant Controls

Determine whether you will use a Constant Current (CC) or Constant Voltage (CV) Power Supply. A menu option

on the Remote Pendant LED will prompt you to choose CC or CV to match your Power Supply.

Manual 89250890 5-1 SYSTEM OPERATION

Page 38

N7500 SYSTEM OPERATION

3/8” NPT AIR INLET

WARNING! AVERTISSEMENT!

Insure good ground from power supply to workpiece. Poor ground may cause

damage to any or all components.

gg p

gg

U

ppyp g

ppyp g

See manual.

y

y

Smoke, fumes, and gases can be dangerous to your health.

ventilation. Keep your head out of the smoke.

gg

,,gg

l.

L les rayons de l’arc,

.

5.02 Position Torch Head

1. Position the Torch Head above the work piece you want to start gouging.

2. Using the Angle Gauge supplied with the N7500, adjust the Torch Head to the work piece. The angle gauge

sets the torch angle, electrode stick-out and aligns the air nozzle.

3. The air should flow between the electrode and the work piece.

Charts, graphs and other data in this manual are based on a 45° electrode angle, but you can use electrode angles

from 45° to 60°. Users should develop their own standards based on shop conditions and application.

5.03 Insert the Electrode

1. Adjust the Electrode Guide Block for the electrode diameter being used. Loosen thumbscrew, adjust, and

then tighten the thumbscrew again (See “Figure 5-3: Torch Head Parts”).

2. Push the Electrode Release (clamping) Lever down and insert the electrode FEMALE END FIRST into the

rear of the Torch Head until it protrudes through the nozzle. The two-legged spring and protective shield

should rest squarely on top of the electrode. To check their positions, look down the rear of the torch. If

the spring and shield are pushed to either side, withdraw the electrode and insert it again. Release the

clamping lever.

ELECTRODE

TORCH HEAD

Protect yourself and others. Wear ear, eye, and body protection.

Protégez-vous et d'autres. Portez l'oreille, l'oeil, et la protection de corps.

se only with compressed air.

Assurez la bonne terre de l'alimentation d'énergie à l'objet. La terre pauvre peut endommager

quelques des ou tous composants. Employez seulement avec l'air comprimé. Voir le manue

Noise can damage hearing.

Le bruit peut endommager l’ouïe.

Use adequate

La fumée, les émanations et les gaz peuvent être dangereux pour votre santé.

Employez à ventilation proportionnée. Gardez votre tête hors de la fumée.

Arc rays, hot slag, and sparks can injure eyes and burn skin.

es scories et les étincelles chauds peuvent blesser les yeux et brûler la peau.

Welding sparks can cause res and explosions.

Les étincelles de soudage peuvent causer des incendies et des explosions

Electric shock can cause injury or death. Disconnect power before servicing.

Un choc électrique peut causer des blessures ou la mort. Déconnectez la puissance

- 5/16 3/8

- 1/2

- 5/8

- 3/4

MOTOR CABLE

DC POWER

CABLE

BUSBAR

N7500

RELEASE

LEVER

AIR PLENUM HOUSING

MOUNTING

FIXTURE

ART# A-10834_AB

ELECTRODE

GUIDE BLOCK

MOTOR

Figure 5-3: Torch Head Parts

3. Flip the power switch located on the side of the Control Box labeled “POWER OFF” & “POWER ON” to the

“ON” position.

4. The electrode will retract for several seconds and stop.

5. The Mode Indicator Display on the Remote Pendant will light up showing the various menu options preprogrammed in the unit.

“Menu Setting” is the default display whenever the unit is powered up.

SYSTEM OPERATION 5-2 Manual 89250890

Page 39

SYSTEM OPERATION N7500

e4

5.04 Remote Pendant Programming

The first (default) menu setting option is “Power Mode”, see “Figure 5-4: Default Pendant Screen CC or CV mode”.

This setting must match the DC Power Supply being used.

1. Select the CC or CV mode setting. To set the CC or CV mode;

a. Press the “OK” OK button on the Pendant. Once pressed, the CC or CV letters will begin blinking.

b. Rotate the Rotary Dial to switch between CC or CV modes. The screen displays as follows:

Menu Setting

Power Mode CV

Parameter Guide

Current1400A

ART# A-10825_AC

Figure 5-4: Default Pendant Screen CC or CV mode

c. Press the “OK” OK button on the Pendant. The CC or CV choice displayed on the screen is entered.

If the “OK” button is not pressed within one minute, the blinking will stop and the mode will be whatever

is shown.

2. Using the down “Mode Selector” button move the cursor to highlight “Parameter Guide” and press

the “OK” OK button. See “Figure 5-6: Parameter Guide Screen”.

3. There are 2 Parameter Guide settings based on the work performed. Use the “Mode Selector” or

buttons to scroll up or down the choices. Press the “OK” OK button and use the dial to select a value

for any of these settings. Use the “Mode Selector” button again to exit a setting choice. The displayed

setting value is accepted when you move to another setting.

NOTE

Menu Setting

Power Mode CC

Parameter Guide

Voltag

ART# A-10826_AC

2.0V

Unit - (of measurement) Inches or Millimeters

Diameter - Electrode diameter. Available settings are listed in the Parameter Table.