Page 1

Manual 0-4952

82 Benning Street, West Lebanon, NH 03784 USA

(603) 298-5711 • www.thermal-dynamics.com

Main PCB / Transducer Kit

Catalog# 9-9515

Gas Control Module

Installation Instructions

Unpacking

The product is packaged and protected to prevent damage during shipping. Inspect for possible shipping damage. If

damage is evident, contact your distributor and/or shipping company before proceeding with installation.

Contents

• Main PC Board for Gas Control Module

• Static handling items and instructions

• (2) Pressure Transducers/ Harness assemblies

• (2) 1/8" NPT 2 position fittings

• Installation Instructions

Applications

This product is for use only with for Thermal Dynamics Gas Control Modules 2000 and 2010. Do not use this product

with any other equipment.

© 2006 by Thermal Dynamics Corp., Printed in USA

December 7, 2006 1 Manual 0-4952 Rev. AA.01

Page 2

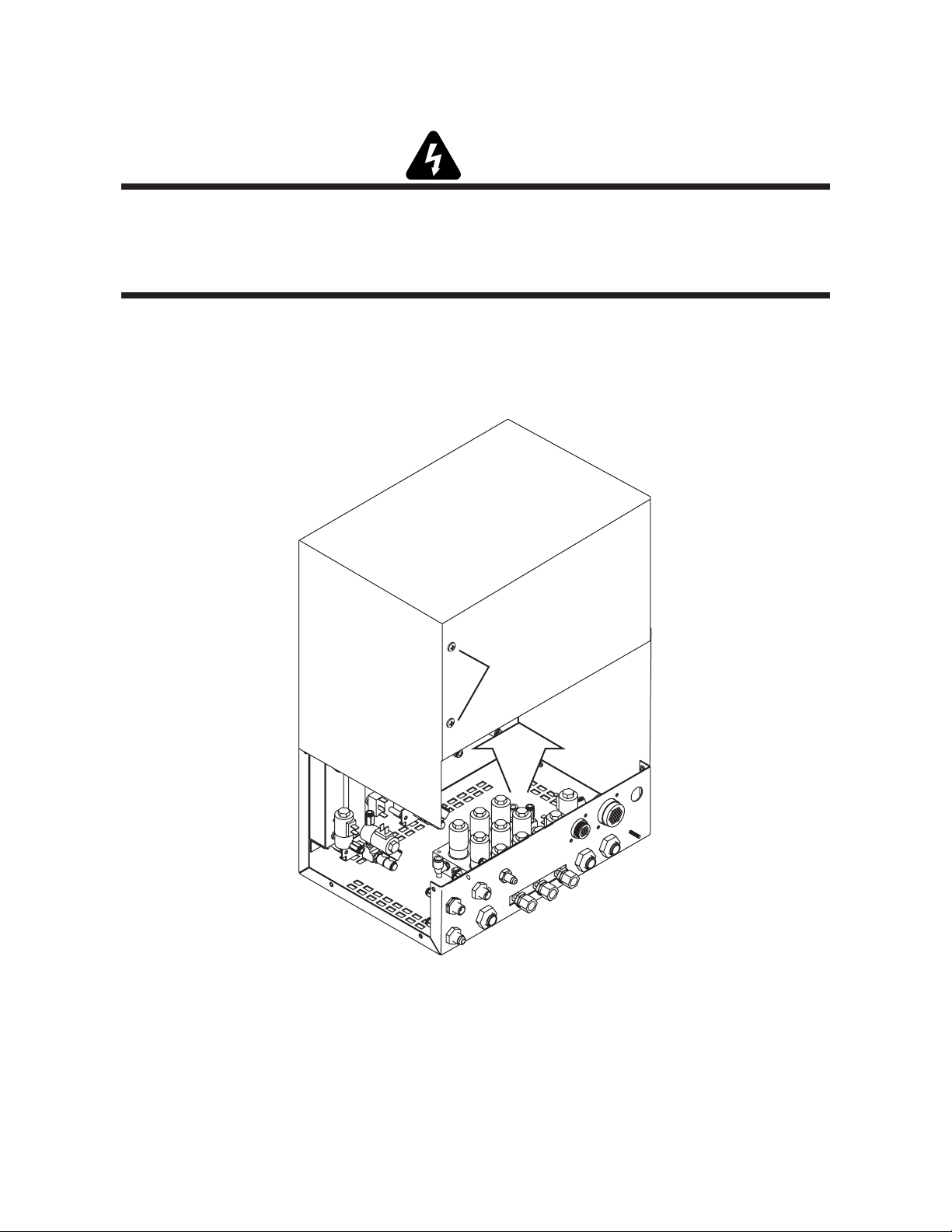

PC Board Removal

WARNINGS

Disconnect primary power at the source before starting the procedure.

Use caution when handling the printed circuit board as damage can result from improper handling or from electrostatic discharge. Wear appropriate static-handling equipment and grounding strap while performing this replacement procedure.

1. Remove the screws securing the cover panel to the gas control module. Save the hardware for re-use.

2. Remove the cover from the module.

Gas Control Module Cover

Do not remove

Art # A-06882

December 7, 2006 2 Manual 0-4952 Rev. AA.01

Page 3

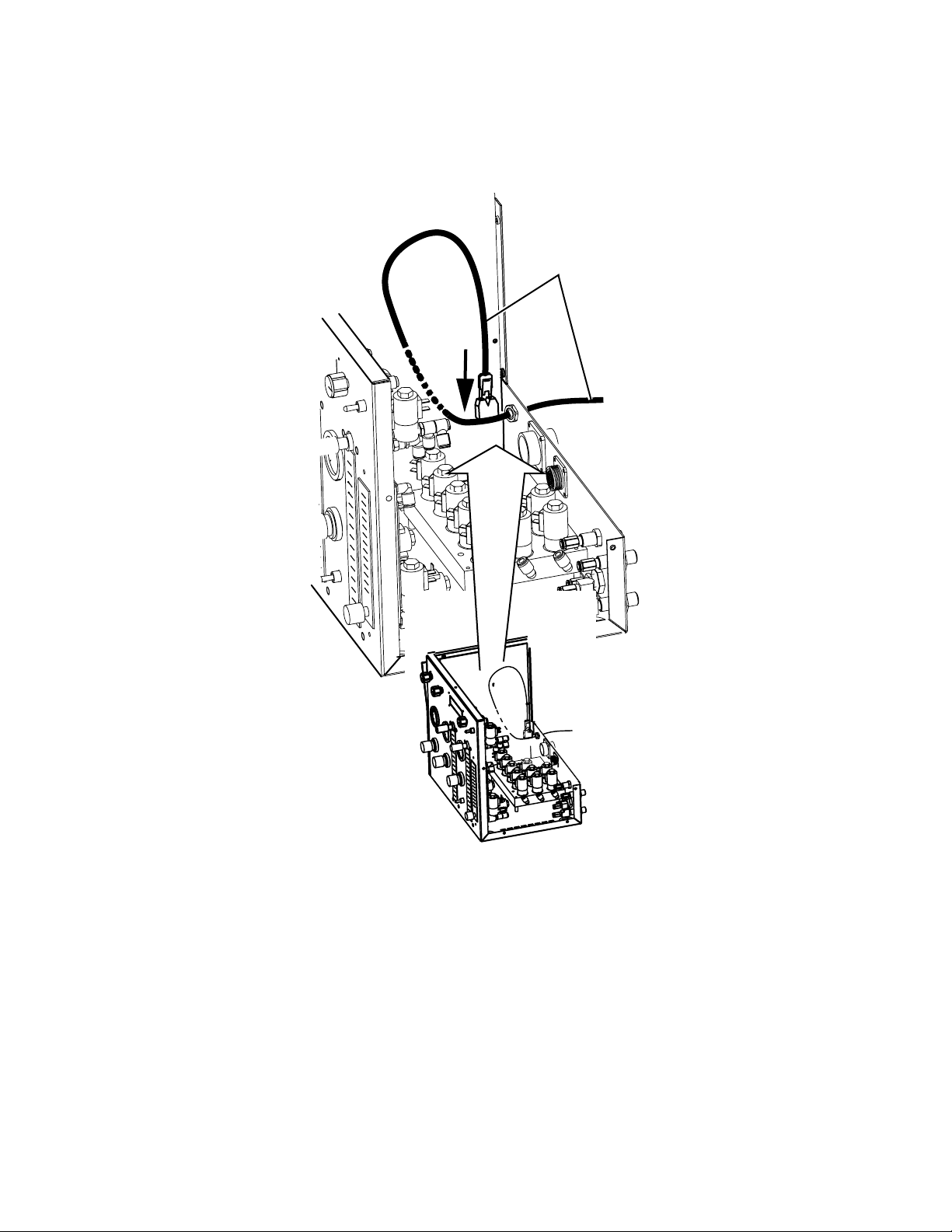

3. Disconnect the fiber-optic cable connector from the receptacle on the printed circuit board. Set the connector

aside carefully in a secure location.

Circuit Board

Fiber Optic Cable

Art # A-04773

4. Use the anti-static equipment as detailed on the instructions provided separately.

5. Wire harness connection points on the PCB are marked with a 'J' number such as "J5" or "J8". Label each wire

harness connector with this number to ensure reconnection to the correct point when installing the replacement PCB. Connection points are illustrated on the last page of these instructions. The application may not use

all connection points shown in the illustration.

6. Unplug the harnesses from the Main PCB that are easy for you to access. Leave the ones along the bottom for a

little later.

December 7, 2006 3 Manual 0-4952 Rev. AA.01

Page 4

7. Disconnect the hardware fastening the side panel to the control module. Carefully pull the panel away from the

module. Any remaining harnesses connected to the PCB on the inside of the panel will restrict motion. Do not

cause any tension on these wire harnesses.

Hardware Locations

Art # A-07025

8. Carefully disconnect any remaining wire harnesses connected to the PCB. The J8 connector for the ribbon cable

includes levers at each end. Move these levers away from the ribbon cable to release the cable from the connector.

9. When all harnesses are disconnected, let the side panel and PCB assembly lie on a flat surface.

December 7, 2006 4 Manual 0-4952 Rev. AA.01

Page 5

10. Remove the hardware securing the PCB to the side panel.

Mounting Hardware Locations

Art # A-07347

11. Gently lift the PCB off the side panel and carefully set it aside.

December 7, 2006 5 Manual 0-4952 Rev. AA.01

Page 6

One Touch Fitting Replacement

1. Locate the two 90° One Touch elbow connections shown in the illustration below. Disconnect the black air

tubes from the fittings. Using an open end wrench or your fingers, depress the locking ring on the fitting and

pull the tube to release it from the fitting.

2. Remove the elbows. For the one on the right in this illustration, you will need to place an open end wrench on

the brass "T" fitting to keep it from turning while removing the elbow.

Remove 90°

fitting here

Place wrench here

Remove 90°

fitting here

to avoid movement

from this fitting while

removing 90° fitting.

One Touch Elbow removal. Some items removed for clarity.

Art # A-07616

December 7, 2006 6 Manual 0-4952 Rev. AA.01

Page 7

3. Install the two new One Touch fittings in the two locations where the last fittings were just removed. See

illustration. You will need to place an open end wrench on the brass "T" fitting to keep it from moving while

installing the new fitting on the right. Do not over tighten these fittings.

Install new

fitting here

Place wrench here

Install new

fitting here

to avoid movement

from this fitting while

installing new fitting.

Art # A-07617

New Fittings in place. Some items removed for clarity

4. Reinstall the two black tubing pieces removed in step 1, making sure they seat all the way. You should feel this

when done properly.

December 7, 2006 7 Manual 0-4952 Rev. AA.01

Page 8

Transducer Installation

1. Find the two TransducerAssemblies supplied with this kit. There will be a small black tube and a harness

attached to them. Insert the free end of the tubing into each of the other new One Touch fittings just installed. Be

careful not to press on the transducer but firmly grasp the tubing below the white clamp, pressing it into the

fitting until you feel it lock in place.

Transducers, harness and tubing

New One Touch Fittings

Art # A-07619

December 7, 2006 8 Manual 0-4952 Rev. AA.01

Page 9

PC Board Installation

CAUTION

Use the antistatic equipment according to the instructions supplied separately.

1. Carefully place the replacement PCB in position on the module side panel.

2. Use the same hardware that held the previous PCB in place and fasten the PCB to the side panel. Tighten

snugly. Do not overtighten.

Mounting Hardware Locations

Art # A-07347

Illustration is for Reference Only

December 7, 2006 9 Manual 0-4952 Rev. AA.01

Page 10

3. Refer to Illustration at the end of these instructions. Carefully reconnect all wire harnesses to the 'J' connectors

on the PCB. Refer to Step 4 for details on the harness connector for receiver J6. Close the levers on the ends of

the J8 receptacle to secure the ribbon cable in place. Check all connections for a secure fit. Some connectors

include a locking feature; align the parts as shown, press them firmly together, then check for a secure fit.

Art # A-07348

Locking Notch

Harness Connector

Receiver

Locking Rib

Harness Receiver

Align Harness Connector

and Harness Receiver

Assembled Connector

and Receiver

4. If the cable connector has fewer pins than a board receptacle, it may be necessary to trim an alignment pin off

the cable connector as shown. When joining a connector to a receptacle, align the end of the connector with the

number 1 pin on the receptacle.

Trim Alignment Tab Off

Cable Connector

Trimmed Tab

Pin numbers

appearing

on PC Board

Art # A-07359

Even number of sockets on connector, odd number of pins on board receptacle

Pin numbers

appearing

on PC Board

9

Align this end of connector

with receptacle pin # 1

1

Align this end

of connector

with receptacle

pin # 1

1

Pin numbers

appearing

on PC Board

9

Align this end of connector

Art # A-07361

with receptacle pin # 1

1

Odd number of sockets on connector, even number of pins on board receptacle

Pin numbers

appearing

on PC Board

8

Align this end of connector

with receptacle pin # 1

Align this end

of connector

with receptacle

pin # 1

1

Pin numbers

appearing

1

on PC Board

8

December 7, 2006 10 Manual 0-4952 Rev. AA.01

Page 11

5. In GCM-2000 applications, the harness connector for harness receiver J6 must be aligned as shown.

Harness Receiver J6

Align connector edges

on this side.

Art # A-07349

6. Position the side panel and PCB assembly against the module. Fasten the assembly in place with hardware

removed previously.

7. Attach the two new Transducer harnesses to the PCB. The one from the manifold will go to JP4 and the one from

the H-35 input will go to JP3. See illstration below.

Transducer harness from the “Right side” H-35 input connection to JP3

Transducer harness from the manifold (left) to JP4

Art # A-07622

Illustration is for showing new Transducer connections only. Other connections may not apply.

December 7, 2006 11 Manual 0-4952 Rev. AA.01

Page 12

8. Connect the fiber-optic cable to the receptacle on the PCB.

9. Put the module cover in place and fasten it with hardware removed previously.

10. This completes the installation.

NOTE

Every effort has been made to provide complete and accurate information in this manual. However, the

publisher does not assume and hereby disclaims any liability to any party for any loss or damage caused by

errors or omissions in this manual, whether such errors result from negligence, accident or any other cause.

December 7, 2006 12 Manual 0-4952 Rev. AA.01

Page 13

Board Connection Points

The installation may not include connection to all points shown.

NOTE

J3

J1

J13

J12

J5

JP1

J801

J802

Art # A-07615

J6

J7

J11

JP3 JP4

J8 J10

December 7, 2006 13 Manual 0-4952 Rev. AA.01

Loading...

Loading...