Page 1

External

Original Publication Date: 2006 Manual no.: 0-4737

Revision Date: 2014 Revision: AD

Command & Control Module,

No. 9-9417 / 9-9418

for Automated Plasma Cutting

Power Supplies

Installation Instructions

General Information

These instructions cover the CCM (Command & Control

Module) for Thermal Dynamics Automated Plasma Cutting Power Supplies. Do not install this module on any

other equipment.

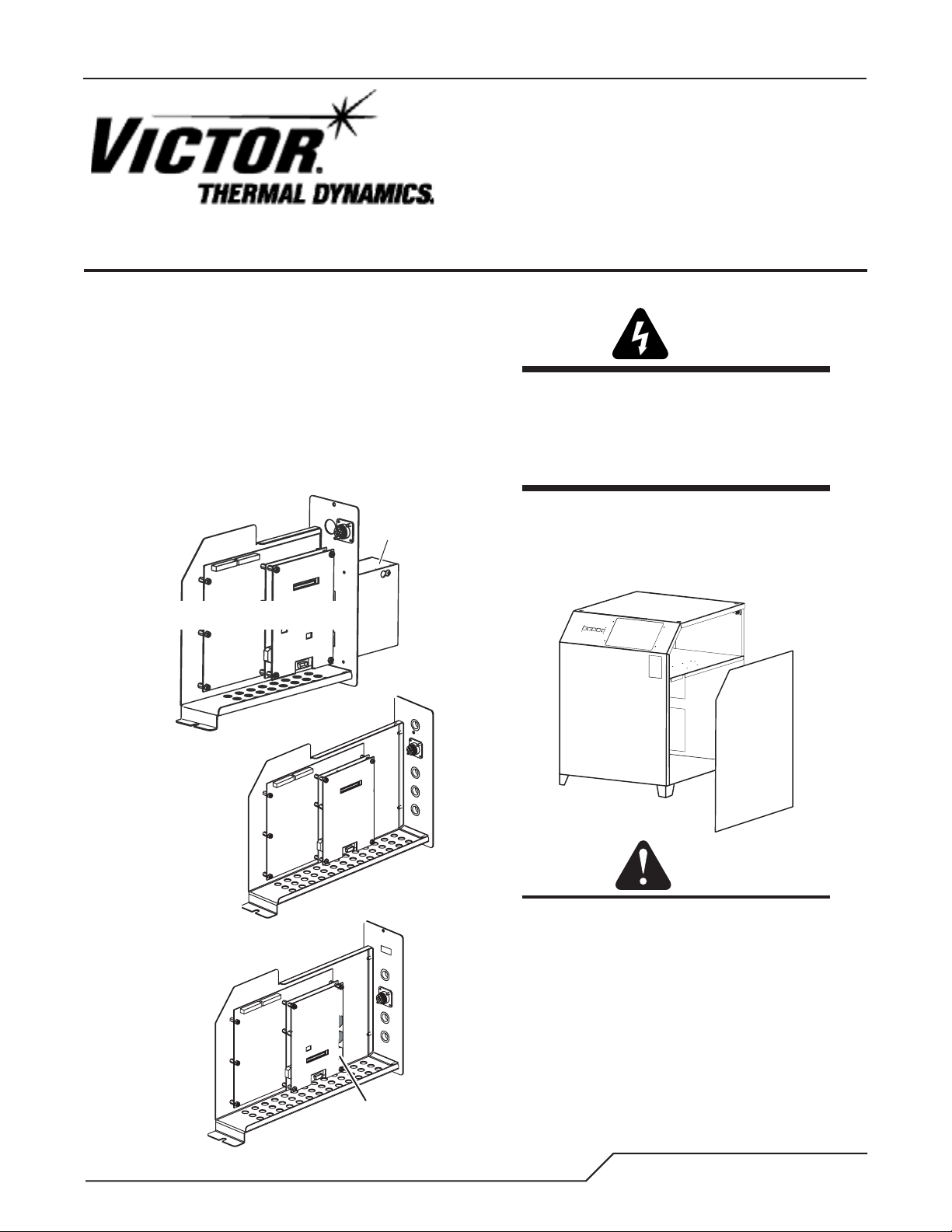

There are two types of module. One includes an external

strain relief cover assembly protruding from the back

panel. The other has a flat back panel. Refer to the illustration to confirm that the module is correct for the power

supply being serviced.

CCM Type 1

NO LONGER AVAILABLE

Connection

Cover

Procedure

WARNING

Disconnect primary power at the source and

bleed down the system before installing, inspecting, or repairing this equipment.

Only a qualified technician should install or

service this equipment.

1. Remove the power supply right side panel. Set the

panel aside carefully. A ground wire connects to the

inside of the side panel. Disconnect this wire if necessary to provide more room to work.

CCM Type 2

(Cat. No. 9-9418)

There is one section in these instructions for

each type of module. Be sure to follow the

CCM Type 3

(Cat. No. 9-9417)

Art # A-06871_AB

Manual 0-4737 1

USB

correct section for the type of module being

replaced.

Art # A-07333

CAUTION

Page 2

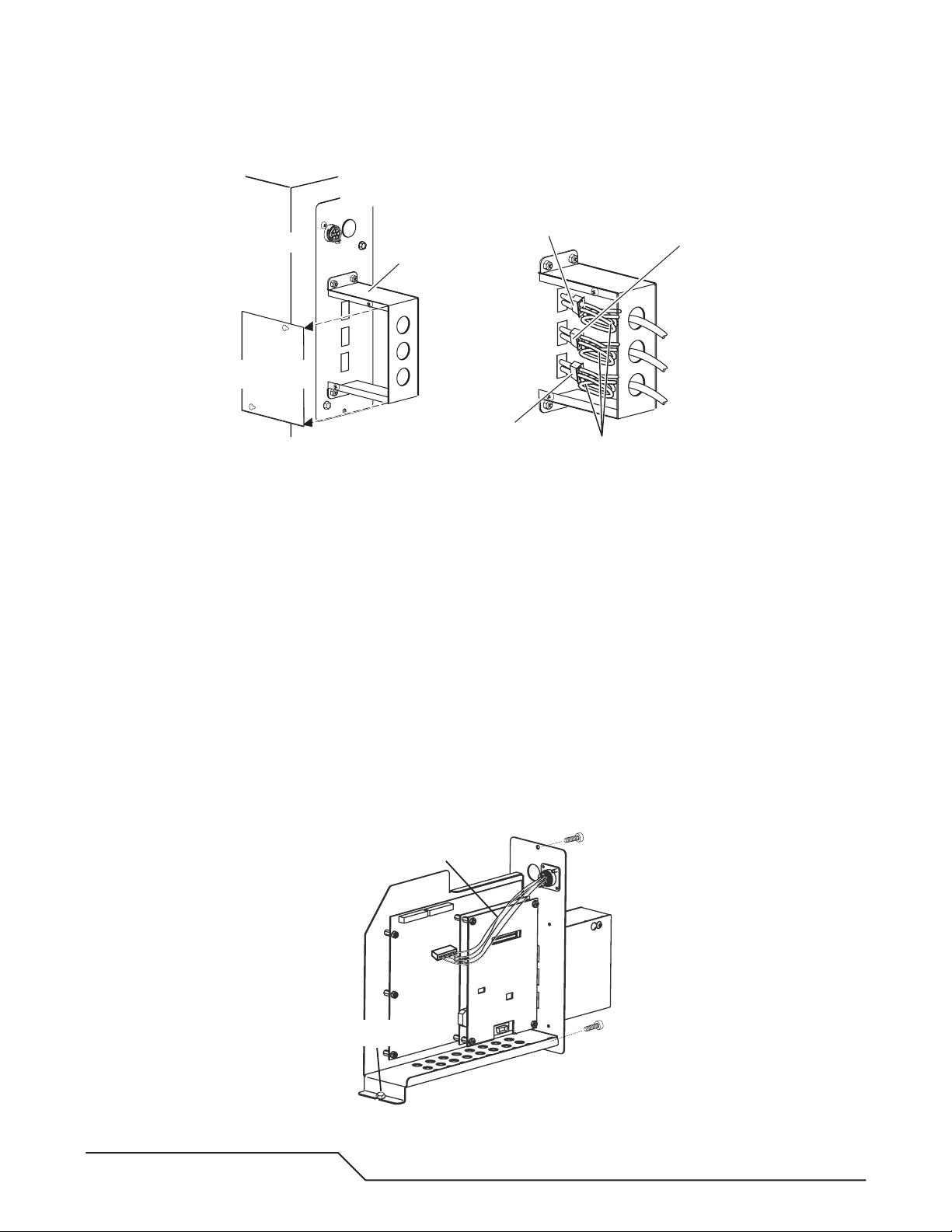

Removal and Replacement, Type 1 Module

A. Disconnect External Connections (Type 1 Module)

Power Supply

Right Side Panel

Connection Cover

Side Panel

1

Power Supply

Rear Panel

Connection Cover

To Gas Control Module

To Slave Power Supply

(if installed)

2

Cable Loops

To Remote HMI

(if installed)

Art # A-06873

1. Remove the side panel from the connection cover.

2. Carefully label and disconnect all external cables connected to the module.

3. Remove and keep the strain relief nut(s) holding the strain relief(s) to the connection cover. Carefully pull the

cable(s) and strain relief(s) out of the connection cover. Leave the strain relief(s) on the cable(s).

B. Disconnect Internal Wire Harnesses

1. A wire harness connects the module rear panel to the larger PC Board in the module. Leave this harness in

place. Carefully label and disconnect all other internal wire harnesses connected to the module. Take care to

label the harnesses connected to terminals J1 and J7 properly to ensure connections to the correct terminals

on the replacement assembly. The harness connectors include latches that must be compressed to release

them from the PC Board receptacles.

2. Loosen, but do not remove, the internal bolt fastening the module to the power supply inner horizontal panel.

3. Remove the hardware holding the module rear panel to the power supply rear panel. Save the hardware for

re-use.

4. Carefully slide the module out of the power supply. Keep the module nearby to serve as a reference for setting

the switches on the replacement module.

Leave this harness in place

Internal Bolt

Art # A-06874

2 Manual 0-4737

Page 3

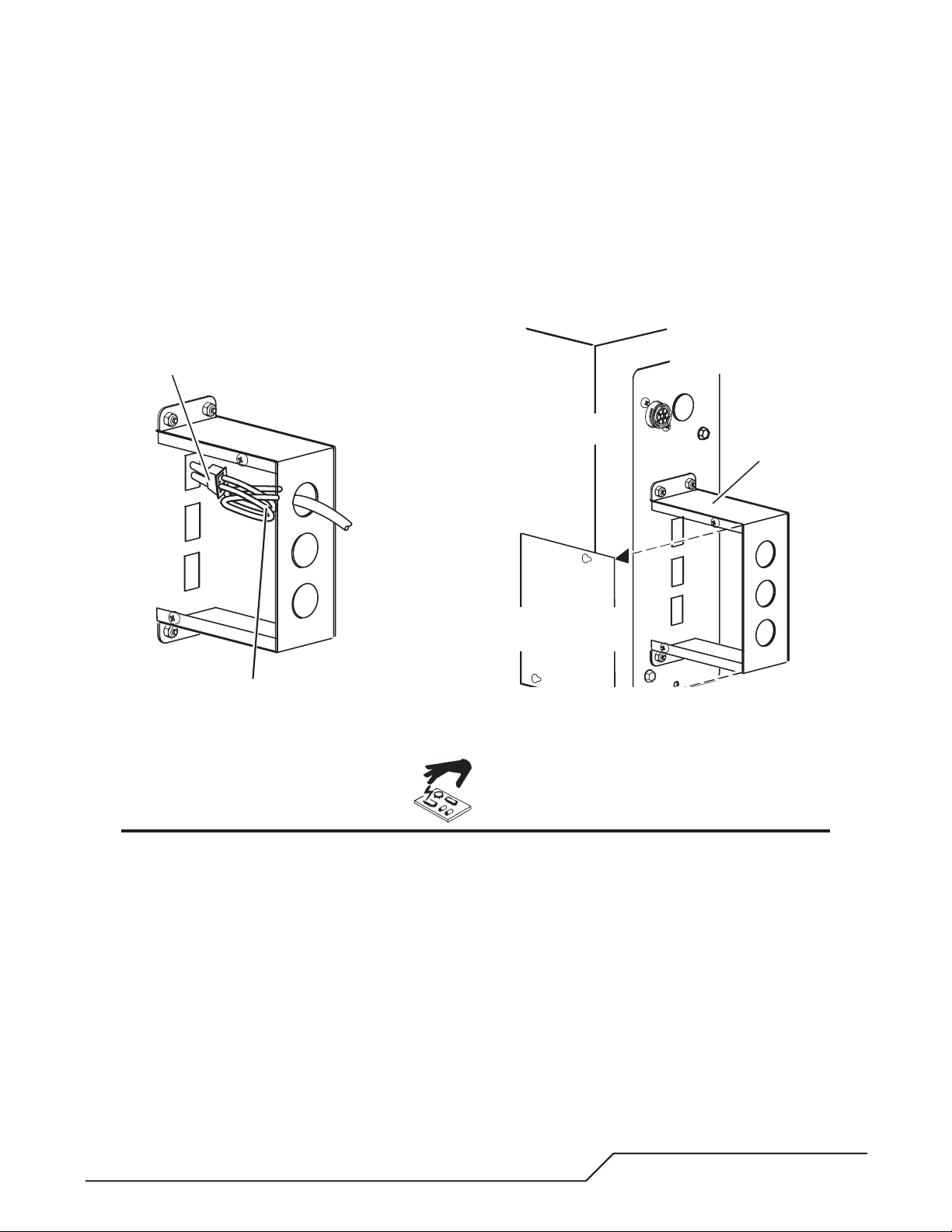

C. Install Replacement Module

1

2

1. Lift the internal wire harnesses to let the module slide under them. Carefully slide the replacement module

into the power supply. Ensure that the internal bolt engages the slot in the inner end of the module’s bottom

plate. Fasten the module back panel in place with the hardware removed previously. Tighten all hardware

securely. Do not overtighten.

2. Carefully connect all internal wire harnesses to the module according to the labels applied to the harnesses

previously.

3. Reconnect the external harness connections to the module. Re-install the connections cover side panel.

To Gas Control Module

Power Supply

Right Side Panel

Connection Cover

Side Panel

Power Supply

Rear Panel

Connection Cover

D. Set Command-Control Module Switches

Set switches on the module per the illustrations, or match the switch settings to those on the original module.

CAUTION

Printed circuit boards in the Command - Control Module are static - sensitive. Discharge any built-up

static charges in your body or surroundings before touching the printed circuit boards.

Manual 0-4737 3

Page 4

Future Use

2

SW1

3

O

N

1

SW-1-1: Auto Pilot Restart. 1 = ON = Auto Pilot Function enabled.

1 = OFF = Auto Pilot Function disabled (Factory default setting).

SW-1-2: Pilot Delay 2 = OFF, 3 = OFF, 4 = OFF: 0 Seconds (Factory default setting).

SW-1-3: Pilot Delay 2 = ON, 3 = OFF, 4 = OFF: 0.1 Seconds

SW-1-4: Pilot Delay 2 = OFF, 3 = ON, 4 = OFF: 0.2 Seconds

2 = ON, 3 = ON, 4 = OFF: 0.4 Seconds

2 = OFF, 3 = OFF, 4 = ON: 0.8 Seconds

2 = ON, 3 = OFF, 4 = ON: 1.0 Seconds

2 = OFF, 3 = ON, 4 = ON: 1.5 Seconds

2 = ON, 3 = ON, 4 = ON: 2.0 Seconds

SW-3: Gas Preflow Time 1 = OFF, 2 = OFF: 2 Seconds (Factory default setting).

1 = ON, 2 = OFF: 4 Seconds

1 = OFF, 2 = ON: 6 Seconds

1 = ON, 2 = ON: 8 Seconds

SW-4: Postflow Time 1 = OFF, 2 = OFF: 10 Seconds (Factory default setting).

1 = ON, 2 = OFF: 20 Seconds

1 = OFF, 2 = ON: 5 Seconds

1 = ON, 2 = ON: 0 Seconds (Disabled)

SW-5-1: Tip Saver 1 = OFF = Disabled (Factory default setting).

1 = ON = Enabled

SW-5-2: Off Plate 2 = OFF = Disabled (Factory default setting).

2 = ON = Enabled

SW 8-1: Pilot Time 1 = OFF = Short (85 ms.) (Factory default setting).

1 = ON = Long (3 s.)

SW 8-2: Remote Current 1 = ON (Remote Analog Current Control)

SW8-3, SW 8-4: Reserved for Factory use.

SW3 SW4

1

4

SW5 SW8

2

1

1

2

2

1

2

4

3

O

N

1

2

Active only when

SW-1-1 is set to ON.

Art # A-04825

CAUTION

Printed circuit boards in the Command - Control Module are static - sensitive. Discharge any built-up

static charges in your body or surroundings before touching the printed circuit boards.

4 Manual 0-4737

Page 5

SW6: OK-to-Move: Contact closure, 120VAC @ 1A (Factory default setting) or

DC Volts (16-18vdc@ up to 100 ma.)

SW11: Analog Current Control. B = from Gas Control (Factory default setting) or A = from CNC.

Position A requires that SW-8-2 be ON.

SW12-1/2/3/4: Divided Arc signal

All = OFF = 50:1 (Factory default setting)

1 = ON = 16.6:1

2 = ON = 30:1

3 = ON = 40:1

4 = Not used.

Art # A-07673

Only 1 on at a time.

SW11

SW13

SW6

SW12

SW13: TVA and XTL Switch positions

SW13

1

2

1

2

TVA XTL TVA

NOTE

Standoff Control SC-11 requires Switch 12-1 set to ON.

Reinstall the power supply side panel. Reconnect input power. Test the system for proper operation.

Manual 0-4737 5

Page 6

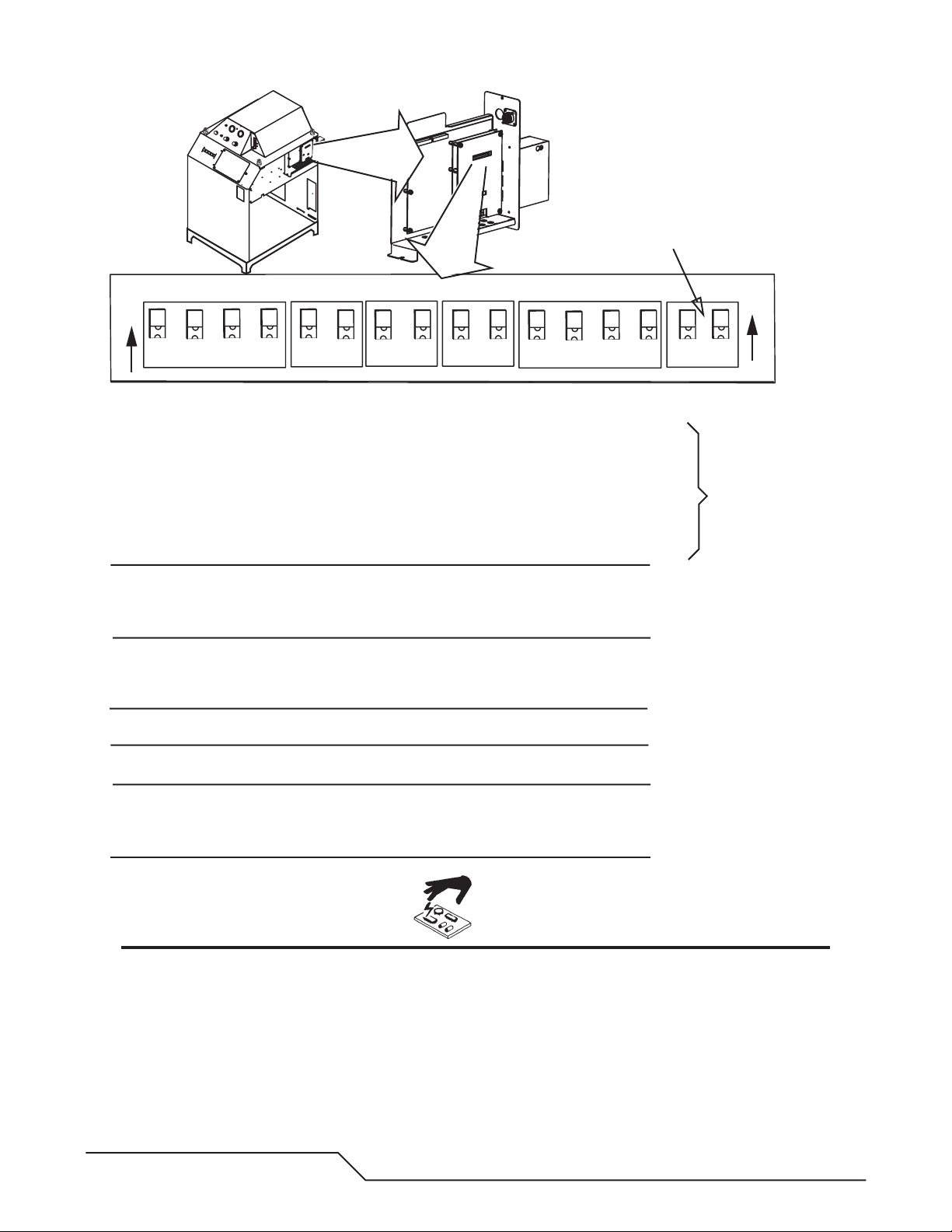

Removal and Replacement, Type 2 Module

A. Disconnect and Remove Type 2 Module

1. A wire harness connects the module rear panel to the larger PC Board in the module. Leave this harness in

place. Carefully label and disconnect all other internal wire harnesses connected to the module. Take care to

label the harnesses connected to terminals J1 and J7 properly.

2. Carefully label and disconnect all external wire harnesses connected to the module.

Cable Receptacles

Use top ONLY

Profile Detail, Fiber Optic Cable Installation

To Gas Control Module

Art # A-06793_AB

3. Loosen, but do not remove, the internal bolt fastening the module to the power supply inner horizontal panel.

4. Remove the hardware holding the module rear panel to the power supply rear panel. Save the hardware for

re-use.

5. Carefully slide the module out of the power supply. Keep the module nearby to serve as a reference for setting

the switches on the replacement module.

B. Install and Connect Type 2 Module

1. Lift the internal wire harnesses to let the module slide under them. Carefully slide the replacement module

into the power supply. Ensure that the internal bolt engages the slot in the inner end of the module’s bottom

plate. Fasten the module back panel in place with the hardware removed previously. Tighten all hardware

securely. Do not overtighten.

2. Carefully connect all internal wire harnesses to the module according to the labels applied to the harnesses

previously.

3. Reconnect the external harness connections to the module.

6 Manual 0-4737

Page 7

Cable Receptacles

Use top ONLY

To Gas Control Module

Profile Detail, Fiber Optic Cable Installation

Art # A-06793_AB

C. Set Switches for Type 2 Command-Control Module

Set switches on the module per the illustrations, or match the switch settings to those on the original module.

CAUTION

Printed circuit boards in the Command - Control Module are static - sensitive. Discharge any built-up

static charges in your body or surroundings before touching the printed circuit boards.

Manual 0-4737 7

Page 8

.

Future Use

O

N

SW1

1

3

2

SW3 SW4

1

4

Switches shown in OFF position

2

1

SW5 SW8

1

2

2

4

1

3

2

1

SW-1-1: Auto Pilot Restart. 1 = ON = Auto Pilot Function enabled.

1 = OFF = Auto Pilot Function disabled (Factory default setting).

SW-1-2: Pilot Delay 2 = OFF, 3 = OFF, 4 = OFF: 0 Seconds (Factory default setting).

SW-1-3: Pilot Delay 2 = ON, 3 = OFF, 4 = OFF: 0.1 Seconds

SW-1-4: Pilot Delay 2 = OFF, 3 = ON, 4 = OFF: 0.2 Seconds

2 = ON, 3 = ON, 4 = OFF: 0.4 Seconds

2 = OFF, 3 = OFF, 4 = ON: 0.8 Seconds

2 = ON, 3 = OFF, 4 = ON: 1.0 Seconds

2 = OFF, 3 = ON, 4 = ON: 1.5 Seconds

2 = ON, 3 = ON, 4 = ON: 2.0 Seconds

SW-3: Gas Preflow Time 1 = Off, 2 = OFF: 2 seconds

1 = ON, 2 = OFF: 4 seconds

1 = OFF, 2 = ON: 6 seconds

1 = ON, 2 = ON: 8 seconds

SW-4: Postflow Time 1 = OFF, 2 = OFF: 10 Seconds (Factory default setting).

1 = ON, 2 = OFF: 20 Seconds

1 = OFF, 2 = ON: 5 Seconds

1 = ON, 2 = ON: 0 Seconds

SW-5-1: Tip Saver Reserved for Factory use.

SW-5-2: Off Plate Reserved for Factory use.

SW 8-1: Pilot Time 1 = OFF = Short (85 ms.) (Factory default setting).

1 = ON = Long (3 s.)

SW 8-2: Remote Current 1 = OFF = Disabled (Factory default setting).

1 = ON = (Remote Analog Current Control)

*SW 8-3: Auto Tr ansfer Retry1 = OFF = Enabled Up to 3 tries (Factory default setting).

1 = ON = Disabled

SW 8-4: Reserved for Factory use.

O

N

2

Active only when

SW-1-1 is set to ON

* SW 8-3 is reserved for

Factory use prior to

Art # A-06869_AB

Firmware V3.5

CAUTION

Printed circuit boards in the Command - Control Module are static - sensitive. Discharge any built-up

static charges in your body or surroundings before touching the printed circuit boards.

NOTE

Standoff Control SC-11 requires Switch 12-1 set to ON.

8 Manual 0-4737

Page 9

SW-6: OK-to-Move: Contact closure, 120VAC @ 1A (Factory default setting) or

DC Volts (16-18vdc@ up to 100 ma.)

SW-11: Analog Current Control. B = from Gas Control (Factory default setting) or A = from CNC.

Position A requires that SW-8-2 be ON.

SW-12-1/2/3/4: Divided Arc signal

All = OFF = 50:1 (Factory default setting)

1 = ON = 16.6:1

2 = ON = 30:1

3 = ON = 40:1

4 = Not used.

Art # A-07674

Only 1 on at a time.

SW11

SW13

SW6

SW12

No external

connection cover

SW13: TVA and XTL Switch positions

SW13

1

2

1

2

TVA XTL TVA

Manual 0-4737 9

Page 10

D. CCM CPU PC Board Layout

Note: Switch Settings May Vary.

O

N

1

TP1

TP3

TP6

PRE

FLOW

SW1

SW3

1

1

J2

J3

Art # A-06906

3

2

+

H5

1

29

+

U22

U26

4

R1

C1

R7

H2

R10

C2

21

R17

C4

J2

3029

C7

C8

R33

R34

R38

R41

GP1

2

J3

30

C31

C34

U18

GP2

R74

R91

H1

TP8

D11

1

1

TEMP

SENSE

R51

R61

R78

R88

C47

C26

R2

R18

C5

TP3

+5.0V

R32

U10

R52

U6

TP6

R62

C48

R30

R53

D12

R79

C53

TP1

GND

1

C58

1

R3

R19

R31

R35

J4

C21

TPAD1

R63

R80

R25

C9

1

POST

FLOW FUNC

SW4

1

R20

R26

R27

R29

D3

D7

C22

R55

C28

R64

R82

R85

R89

RC

J5

1

R5

R6

R8

1

C3

R11

AUTO PILOT

1

1

2

D2

D4

D5

D8

D10

C12

C19

C18

R58

160

1

U20

R83

R86

R90

C57

SW1

3

120

C54

R12

C35

R76

1

U23

R94

1

4

1

U14

TP8

CLKO

U27

R54

U31

2

R4

U7

R28

C6

D1

D6

D9

C25

NC

R60

C32

R75

R81

1

2

Switches

R13

R14

R21

R22

POST

PRE

FLOW

FLOW FUNC

SW3

SW4

1

1

2

44

1

R44

C14

C13

C37

L2

C42

+

C43

L5

C49

+

C55

J1

1

6

J1

SW5

1

U5

R15

R16

R24

R23

SW5

1

1

2

U4

C16

C15

D13

U21

L3

+

5

9

SYS

CONTAUTO PILOT

SW8

1

2

R9

1

1

2

23

R39

22

R45

L1

80

40

R70

1

R84

C44

C50

1

2

CPU/COMMUNICATIONS

SYS

OK TO

CONT

MOVE/D

SW8

SW9

C 2004 TDC

19X2169 REV

1

1

R42

C20

D14

R36

R49

2

R71

R59

R67

+

3

C23

C36

R40

C45

C51

4

TP4

/WR

TP7

/RD

Y1

R65

+3.3VA

L4

TP2

AGND

C46

C56

C59

1

2

1

C10

R46

+

C17

R47

R48

R57

R56

C30

C29

R66

R68

R69

TP5

R72

C38

C41

R87

U28

C52

U32

+

OK TO

MOVE/D

SW9

1

C40

R93

-15V

AC

R37

H4

H3

U9

U12

C24

U15

U17

U25

U29

+3.3V

TP11TP10TP9

1

H6

3

4

U8

C11

R43

U11

1

U13

1

R50

C27

U16

1

C33

U19

1

R73

C39

R77

1

U24

1

R92

+15V

DACDAC

U30

1

L6

D15

TP9 TP10 TP11

O

N

2

TP4

TP7

TP5

TP2

10 Manual 0-4737

Page 11

E. CCM PC Board Layout

SW11

SW6

J36

SW12

J1

H2

1

DC VOLTS

SW6

R227

R228

OK TO MOVE SELECT

CONTACTS

Q2

D14

R226

R55

R73

H9

R79

R82

R88

R93

R100

R109

R114

C64

R129

R128

R131

ALL SW OFF FOR 50:1 (DEFAULT)

SW12-1 ON FOR 16.7:1 (SC-11)

SW12-2 ON FOR 30:1

SW12-3 ON FOR 40:1

SW12-4 SPARE

D31

4

3

2

SW12

1

C76

1

ISOLATED

TP6

-15V

+15V

H1

+18VGND

TP10

R5

R9

1

C6

C8

R25

AUTO PILOT

U6

R49

U10

D10

C19

U12

C18

R119

R83

R86

C87

R145

J7

J7

1

L2

1

R225

C1

R6

R8

C3

C3

R12

R11

R12

R27

R26

SW1

1

1

C24

C23

C25

1

3

2

4

D2

D4

R51

R50

R68

D5

D8

R44

1

R67

R66

C14

C13

C12

1

120

R107

C54

R58

C53

R112

160

1

U14

C35

R123

1

R124

U20

TP8

CLKO

R76

+

1

U23

D33

D34

D35

R90

U22

+

C88

U27

1

R94

C54

C57

R13

R28

PRE

FLOW

SW3

44

R21

1

1

1

C4

R13

R14

R29

C12

2

R52

R69

C37

C42

R98

C37

D61

L2

C42

C43

+

L5

6

U1

R5

R10

C7

R15

R16

C9

R22

R23

POST

FLOW FUNC

SW4

R32

1

C26

1

C27

R54

R53

R71

R70

R78

C15

C43

+

U14

C60

C62

C79

+

C49

C89

C55

R142

J1

R150

1

R33

2

U4

U17

C91

R146

U5

1

L3

1

U4

R87

R120

C2

R223

R9

R16

R24

SW5

C13

1

1

2

U7

23

C16

L1

1

40

D13

R127

D60

U21

1

C80

C83

+

R143

5

R147

9

TP9

CC POT

CPU/COMMUNICATIONS

R6

U2

U3

C5

D5

C10

R17

SYS

OK TO

CONT

MOVE/D

SW8

SW9

K5-E-STOP

1

R34

R35

C14

R36

1

1

3

2

4

R42

R37

TP4

/WR

R36

C30

D18

R40

TP7

R39

/RD

R42

22

Y1

+

R45

C39

C20

C23

80

C44

R49

R99

R56

R108

C55

R59

C29

R113

C63

R65

R121

R67

+

1

R125

C36

C67

R70

+3.3VA

+

R71

D14

L4

C75

TP2

AGND

R84

+

C45

+

C46

C44

C90

+

C51

C50

D36

R144

C56

U24

1

R151

C59

B

D1

SW11

A

GAS ON

1

C 2004 TDC

19X2169 REV

D13

1

2

U8

1

R38

R57

C11

C10

R46

C TDC 2005

19X2174

C17

REV

R47

R48

R57

C30

R66

R68

R69

TP5

R72

C38

R77

C41

U24

R87

U28

C52

U32

D37

+

D2

E-STOP_PS

R39

AD+

C27

C33

C39

R92

L6

1

K7-GAS ON

R43

U11

1

U13

1

R50

U16

1

U19

1

R73

1

1

+15V

DACDAC

U30

1

D15

J8

J8

H3

H3

AC

H8

H6

R37

U9

U12

C24

U15

U17

C40

U25

U29

R93

-15V

+3.3V

TP11TP10TP9

H4

H4

Art # A-07395

TB1

TB1

J1

K4-OK

D7

K3-E-STOP CNC

R30

1

Q3

K1-PSR

K2-START

D17

R56

C33

D20

D21

C40

CNC_E-STOP

D22

D23

C45

CNC_START

D25

D26

C56

HOLD_START

D28

D27

CNC PREFLOW

C66

R126

C65

U18

1

C72

+

R134

R157

R136

R156

+

R138

R155

C85

R158

C84

C93

TP7

+

C92

TP8

R149

C95

TB2

11

TB2

R1

OK CNC

R31

D9

R40

D15

U11

1

D24

C46

U15

1

TP4

+5V

J35

2

1

C68

1

U19

C73

U20

U23

1

+

C94

D38

+

R148

1

R7

R14

D3

R15

D4

D6

C15

C28

D16

R43

C31

PSR

R59

R58

R74

R72

C34

R80

C35

R83

R95

U13

R94

R101

R110

C57

C61

C69

R132

R135

C74

C78

C77

1

U21

T1

D39

J35

J9 J5

J4

J4

J9

K6

D10

+

D11

+

C29

L1

1

D19

U8

C32

1

R75

C41

U9

R84

+

R89

R96

R102

R103

1

D29

C58

1

D30

+

R130

TP1

GND

C70

TP5

-15V

TP3

+15V

R8

D8

D12

C36

33

R105

R104

R111

U16

TP2

+29-41 VDC

SW13

TP11

ARC V-

1

34

CUT

DEMAND

+

26

25

SW13

1

1

2

2

J2

J5

1 1

H6

C2

+

J2

R154

R152

29

C7

H7

J36

H5

H10

1

PILOT

DEMAND

TP14

J3

TP13

R106

29

C59

29

C31

+

H11

U22

R133

U26

H5

J6

J6

PILOT V

R224

R2

R1

R3

C1

R7

H2

R11

R10

2

1

21

R17

C4

J2

3029

30

C8

R33

R34

R38

R41

GP1

2

1

R77

2

R81

R85

J3

R90

C47

D11

30

30

R115

C34

U18

GP2

1

R74

C71

Q1

1

R91

H1

TP12

R2

1

R19

C5

R18

TP3

+5.0V

C11

C16

R32

R41

R60

TEMP

SENSE

U10

R76

R91

R52

R97

R51

C48

R61

R116

R78

R88

C86

C47

R141

D40

C26

R4

R4

R3

U6

U7

R18

R20

R19

R21

R20

R23

R24

R22

R26

R25

TP1

R27

GND

R28

1

R29

U5

1

C17

C18

R30

C22

C6

C20

R31

C21

D1

R47

D3

R35

R45

C19

R44

R64

R48

R46

D6

TP6

R62

C9

D7

R65

R63

R61

1

D9

R86

J4

C38

R53

C21

C22

R92

R55

R54

C25

C50

TPAD1

C49

D12

C51

NC

C52

C28

R62

R63

R60

R64

C32

R117

R118

R122

R75

R82

R81

R80

R79

C82

+

D32

R85

C81

R89

RC

R139

C48

R140

J5

C53

U31

C58

1

NOTE

Wire harnesses connected to Terminals J1 and J7 must not be reversed.

Manual 0-4737 11

Page 12

NOTE

Every effort has been made to provide complete and accurate information in this manual. However,

the publisher does not assume and hereby disclaims any liability to any party for any loss or damage

caused by errors or omissions in this Manual, whether such errors result from negligence, accident, or

any other cause.

INNOVATION TO SHAPE THE WORLD™

INNOVATION TO SHAPE THE WORLD™

U.S. Customer Care: 800-426-1888 Canada Customer Care: 905-827-4515 International Customer Care: 940-381-1212

U.S. Customer Care: 800-426-1888 Canada Customer Care: 905-827-4515 International Customer Care: 940-381-1212

© 2001 Victor Technologies International, Inc. www.victortechnologies.com Printed in USA

© 2001 Victor Technologies International, Inc. www.victortechnologies.com Printed in USA

Loading...

Loading...