Page 1

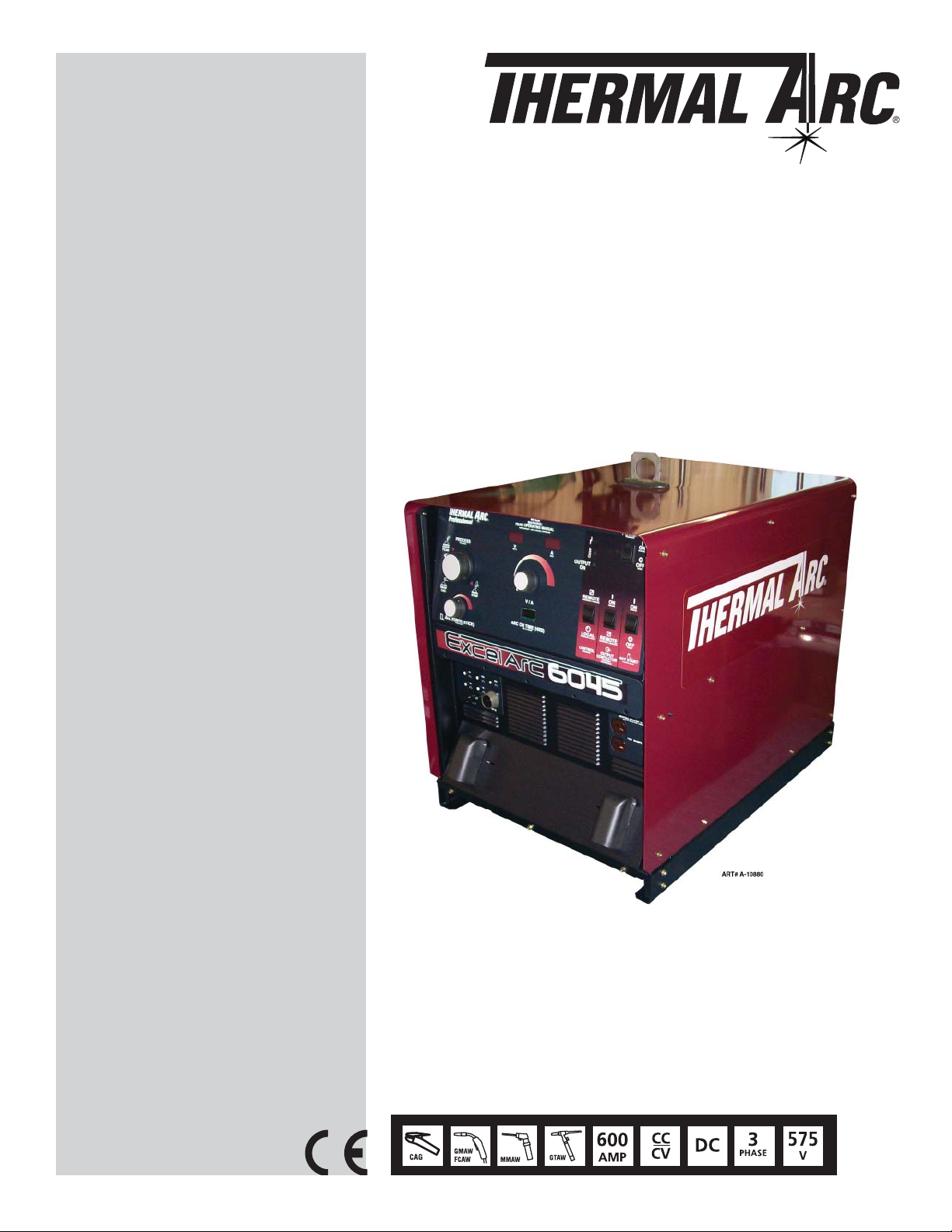

6045

®

EXCEL ARC

CC/CV POWER SOURCE

Operating Manual

Revision: AA Issue Date: August 26, 2011 Manual No.: 0-5213

Operating Features:

Page 2

WE APPRECIATE YOUR BUSINESS!

Congratulations on your new Thermal Arc product. We are proud to

have you as our customer and will strive to provide you with the best

service and reliability in the industry. This product is backed by our

extensive warranty and world-wide service network. To locate your

nearest distributor or service agency call 1-800-752-7621, or visit

us on the web at www.thermadyne.com/thermalarc.

This Operating Manual has been designed to instruct you on the

correct use and operation of your Thermal Arc product. Your

satisfaction with this product and its safe operation is our ultimate

concern. Therefore please take the time to read the entire manual,

especially the Safety Precautions. They will help you to avoid potential

hazards that may exist when working with this product.

YOU ARE IN GOOD COMPANY!

The Brand of Choice for Contractors and Fabricators Worldwide.

Thermal Arc is a Global Brand of Arc Welding Products for

Thermadyne Industries Inc. We manufacture and supply to major

welding industry sectors worldwide including; Manufacturing,

Construction, Mining, Automotive, Aerospace, Engineering, Rural

and DIY/Hobbyist.

We distinguish ourselves from our competition through market

leading, dependable products that have stood the test of time. We

pride ourselves on technical innovation, competitive prices, excellent

delivery, superior customer service and technical support, together

with excellence in sales and marketing expertise.

Above all, we are committed to developing technologically advanced

products to achieve a safer working environment within the welding

industry.

Page 3

!

WARNINGS

Read and understand this entire Manual and your employer’s safety practices before installing,

operating, or servicing the equipment.

While the information contained in this Manual represents the Manufacturer’s best

judgement, the Manufacturer assumes no liability for its use.

Operating Manual Number 0-5213 for:

Excel Arc® 6045 Welding Power Supply

Catalog Number W1001703

Published by:

Thermadyne Industries Inc.

82 Benning Street

West Lebanon, New Hampshire, 03784

www.thermadyne.com/thermalarc

Copyright 2011 by

Thermadyne Industries Inc.

All rights reserved.

Reproduction of this work, in whole or in part, without written permission of the

publisher is prohibited.

The publisher does not assume and hereby disclaims any liability to any party for any

loss or damage caused by any error or omission in this Manual, whether such error

results from negligence, accident, or any other cause.

Publication Date: August 26, 2011

Record the following information for Warranty purposes:

Where Purchased: ____________________________________

Purchase Date: ____________________________________

Equipment Serial #: ____________________________________

i

Page 4

TABLE OF CONTENTS

SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS ............................. 1-1

1.01 Arc Welding Hazards ....................................................................................... 1-1

1.02 Principal Safety Standards .............................................................................. 1-5

1.03 Product Lifting Safety ..................................................................................... 1-6

1.04 Welding Symbol Chart .................................................................................... 1-7

1.05 Declaration Of Conformity .............................................................................. 1-8

SECTION 2: INTRODUCTION ............................................................................. 2-1

2.01 How To Use This Manual ................................................................................ 2-1

2.02 Equipment Identifi cation ................................................................................. 2-1

2.03 Receipt Of Equipment ..................................................................................... 2-1

2.04 Description ..................................................................................................... 2-2

2.05 Features .......................................................................................................... 2-3

2.06 Functional Block Diagram ............................................................................... 2-4

2.07 Duty Cycle ....................................................................................................... 2-4

2.08 Specifi cations ................................................................................................. 2-5

2.09 Dimensions and Weight .................................................................................. 2-6

2.10 Excel Arc

®

6045 Data Tag ............................................................................... 2-6

SECTION 3: INSTALLATION ............................................................................... 3-1

3.01 Location .......................................................................................................... 3-1

3.02 Electrical Input Connections ........................................................................... 3-1

3.03 Electrical Input Requirements ......................................................................... 3-2

3.04 Grounding ....................................................................................................... 3-3

3.05 Replacing the Input Power Cable .................................................................... 3-4

3.06 Welding Leads ................................................................................................ 3-5

3.07 Installation Diagram ........................................................................................ 3-6

SECTION 4: OPERATION ................................................................................... 4-1

4.01 Front Panel ..................................................................................................... 4-1

4.02 Machine Set-Up and Operation ....................................................................... 4-3

4.03 Adjustments Behind the Control Panel ............................................................ 4-3

4.04 Hot Start Switch Enable/Disable ..................................................................... 4-4

4.05 SMAW (Stick) Welding & Carbon Arc Gouging ............................................... 4-5

4.06 GTAW (TIG) Welding ....................................................................................... 4-6

4.07 GMAW / FCAW with Constant Speed Wire Feeder ........................................... 4-6

4.08 GMAW / FCAW with Voltage Sensing Wire Feeder with Contactor .................. 4-6

Page 5

TABLE OF CONTENTS

SECTION 5: SERVICE....................................................................................... 5-1

5.01 General ........................................................................................................... 5-1

5.02 Maintenance ................................................................................................... 5-1

5.03 Maintenance Diagram ..................................................................................... 5-2

5.04 Basic Troubleshooting Guide .......................................................................... 5-3

5.05 General Thermal Conditions ............................................................................ 5-3

5.06 Operator Troubleshooting ............................................................................... 5-4

5.07 Troubleshooting All Modes of Operation ......................................................... 5-4

5.08 Troubleshooting STICK (SMAW / CAG) Mode Problems ................................. 5-5

5.09 Troubleshooting TIG (GTAW) Mode Problems ................................................ 5-5

5.10 Troubleshooting MIG (GMAW / FCAW) Mode Problems ................................. 5-5

APPENDIX 1: WIRING SCHEMATICS ..................................................................... A-1

Wiring Schematics .................................................................................................. A-2

LIMITED WARRANTY ................................................................. INSIDE BACK COVER

WARRANTY SCHEDULE .............................................................. INSIDE BACK COVER

GLOBAL CUSTOMER SERVICE CONTACT INFORMATION ........................ INSIDE BACK COVER

TABLE OF CONTENTS (continued)

Page 6

Figures and Tables

SECTION 1: ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS ............................. 1-1

Table 1-1: Eye Protection Shade Chart .................................................................... 1-2

SECTION 2: INTRODUCTION ............................................................................. 2-1

®

Figure 2-1: Excel Arc

Figure 2-2: Functional Block Diagram for Excel Arc

Figure 2-3: Duty Cycle Chart ................................................................................... 2-4

Table 2-4: Specifi cations ......................................................................................... 2-5

Figure 2-5: Dimensions and Weight ........................................................................ 2-6

Figure 2-6: Data Tag ................................................................................................ 2-6

SECTION 3: INSTALLATION ............................................................................... 3-1

Figure 3-1: Electrical Input Connections ................................................................. 3-2

Figure 3-2: Grounding Diagram .............................................................................. 3-3

Table 3-3: Recommended Wire and Fuse Size ........................................................ 3-3

Table 3-4: Mains Current Circuit Sizes .................................................................... 3-4

Figure 3-5: Power Cable Compression Nut ............................................................. 3-4

Figure 3-6: Input Power Cable Connection .............................................................. 3-5

Table 3-7: Electrode Lead and Work Lead Size ........................................................ 3-5

Figure 3-8: Installation Diagram .............................................................................. 3-6

6045 Volt-Ampere Curves ................................................... 2-2

®

6045 ..................................... 2-4

SECTION 4: OPERATION ................................................................................... 4-1

Figure 4-1: Excel Arc

®

6045 Front Panel ................................................................ 4-1

Figure 4-2: Fuse Location ....................................................................................... 4-2

Figure 4-3: Front Panel Access ............................................................................... 4-4

Figure 4-4: Hot Start Level and Duration Adjustments ............................................ 4-5

SECTION 5: SERVICE....................................................................................... 5-1

Figure 5-1: Maintenance Diagram ........................................................................... 5-2

APPENDIX 1: WIRING SCHEMATICS ..................................................................... A-1

Figure A-1: System Schematic ................................................................................ A-2

Page 7

SAFETY INSTRUCTIONS EXCEL ARC 6045

!

SECTION 1:

ARC WELDING SAFETY INSTRUCTIONS AND WARNINGS

WARNING

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY.

PACEMAKER WEARERS KEEP AWAY UNTIL CONSULTING YOUR DOCTOR. DO NOT LOSE THESE INSTRUCTIONS.

READ OPERATING/INSTRUCTION MANUAL BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage to other equipment or property,

if the operator does not strictly observe all safety rules and take precautionary actions.

Safe practices have developed from past experience in the use of welding and cutting. These practices must be learned

through study and training before using this equipment. Some of these practices apply to equipment connected to

power lines; other practices apply to engine driven equipment. Anyone not having extensive training in welding and

cutting practices should not attempt to weld.

Safe practices are outlined in the Australian Standard AS1674.2-2003 entitled: Safety in welding and allied processes

Part 2: Electrical. This publication and other guides to what you should learn before operating this equipment are listed

at the end of these safety precautions. HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK

PERFORMED ONLY BY QUALIFIED PEOPLE.

1.01 Arc Welding Hazards

WARNING

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal

shocks or severe burns. The electrode and

work circuit is electrically live whenever the

output is on. The input power circuit and

machine internal circuits are also live when

power is on. In semiautomatic or automatic

wire welding, the wire, wire reel, drive roll

housing, and all metal parts touching the

welding wire are electrically live. Incorrectly

installed or improperly grounded equipment

is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body

protection.

5. Properly install and ground this equipment according

to its Owner’s Manual and national, state, and local

codes.

6. Turn OFF all equipment when not in use. Disconnect

power to equipment if it will be left unattended or out

of service.

7. Use fully insulated electrode holders. Never dip holder

in water to cool it or lay it down on the ground or the

work surface. Do not touch holders connected to two

welding machines at the same time or touch other

people with the holder or electrode.

8. Do not use worn, damaged, undersized, or poorly

spliced cables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical (earth)

ground.

11. Do not touch electrode while in contact with the work

(ground) circuit.

12. Use only well-maintained equipment. Repair or replace

damaged parts at once.

3. Insulate yourself from work and ground using dry

insulating mats or covers.

4. Disconnect input power or stop engine before installing

or servicing this equipment. Lock input power

disconnect switch open, or remove line fuses so power

cannot be turned ON accidentally.

August 26, 2011 1-1 Manual 0-5213

13. In confi ned spaces or damp locations, do not use a

welder with AC output unless it is equipped with a

voltage reducer. Use equipment with DC output.

14. Wear a safety harness to prevent falling if working

above fl oor level.

15. Keep all panels and covers securely in place.

Page 8

EXCEL ARC 6045 SAFETY INSTRUCTIONS

WARNING

ARC RAYS can burn eyes and skin; NOISE can

damage hearing.

Arc rays from the welding process produce

intense heat and strong ultraviolet rays that

can burn eyes and skin. Noise from some

processes can damage hearing.

1. Wear a welding helmet fi tted with a proper shade of

fi lter (See ANSI Z49.1 in “1.02 Principal Safety

Standards” on page 1-5) to protect your face and

eyes when welding or watching.

2. Wear approved safety glasses. Side shields

recommended.

3. Use protective screens or barriers to protect others

from fl ash and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable,

fl ame-resistant material (wool and leather) and foot

protection.

5. Use approved ear plugs or ear muffs if noise level is

high.

WARNING

FUMES AND GASES can be hazardous to your

health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to

your health.

1. Keep your head out of the fumes. Do not breath the

fumes.

2. If inside, ventilate the area and/or use exhaust at the

arc to remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied

respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction for metals, consumables,

coatings, and cleaners.

5. Work in a confi ned space only if it is well ventilated,

or while wearing an air-supplied respirator. Shielding

gases used for welding can displace air causing injury

or death. Be sure the breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or

spraying operations. The heat and rays of the arc can

react with vapors to form highly toxic and irritating

gases.

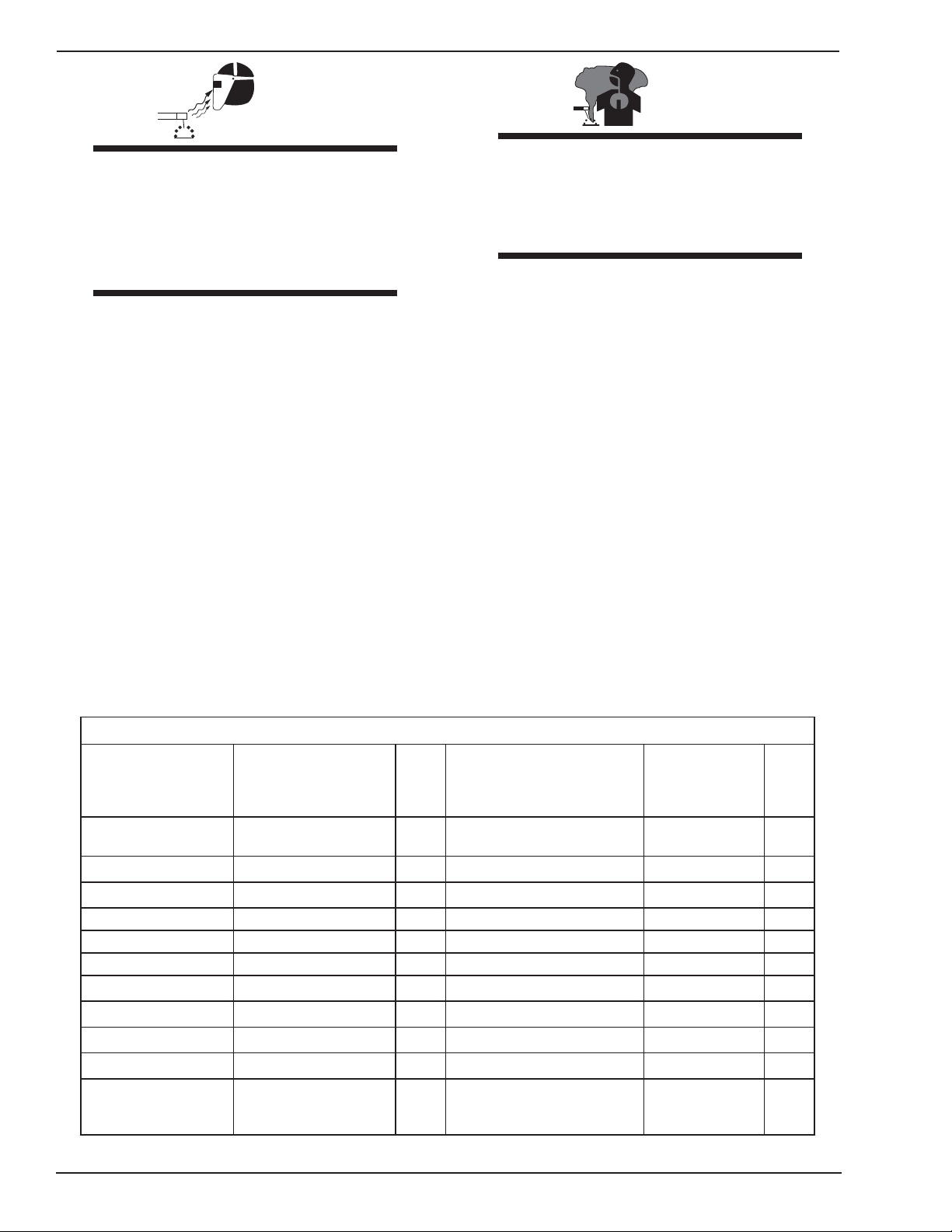

Eye protection fi lter shade selector for welding or cutting (goggles or helmet), from AWS A6.2-73.

Welding or Cutting

Operation

Torch soldering 2

Torch brazing 3 or 4 Non-ferrous base metal All 11

Oxygen Cutting Non-ferrous base metal All 12

Light Under 1 in., 25 mm 3 or 4 Gas tungsten arc welding All 12

Medium 1 to 6 in., 25-150 mm 4 or 5 (TIG) All 12

Heavy Over 6 in., 150 mm 5 or 6 Atomic hydrogen welding All 12

Gas welding Carbon arc welding All 12

Light Under 1/8 in., 3 mm 4 or 5 Plasma arc welding

Medium 1/8 to 1/2 in., 3-12 mm 5 or 6 Carbon arc air gouging

Heavy Over 1/2 in., 12 mm 6 or 8 Light 12

Shielded metal-arc

welding

(stick) electrodes

Electrode Size

Metal Thickness

or Welding Current

Under 5/32 in., 4 mm 10 Heavy 14

Filter

Shade

No.

Welding or Cutting

Operation

Gas metal-arc

welding (MIG)

Electrode Size

Metal Thickness

or Welding Current

Table 1-1: Eye Protection Shade Chart

Filter

Shade

No.

Manual 0-5213 1-2 August 26, 2011

Page 9

SAFETY INSTRUCTIONS EXCEL ARC 6045

!

7. Do not weld on coated metals, such as galvanized, lead,

or cadmium plated steel, unless the coating is removed

from the weld area, the area is well ventilated, and if

necessary, while wearing an air-supplied respirator.

The coatings and any metals containing these elements

can give off toxic fumes if welded.

FLYING SPARKS AND HOT METAL can cause

injury.

Chipping and grinding cause fl ying metal. As

welds cool, they can throw off slag.

WARNING

WARNING

WELDING can cause fi re or explosion.

Sparks and spatter fl y off from the welding arc.

The fl ying sparks and hot metal, weld spatter,

hot workpiece, and hot equipment can cause

fi res and burns. Accidental contact of electrode

or welding wire to metal objects can cause

sparks, overheating, or fi re.

1. Protect yourself and others from fl ying sparks and hot

metal.

2. Do not weld where fl ying sparks can strike fl ammable

material.

3. Remove all fl ammables within 35 ft. (10.7M) of the

welding arc. If this is not possible, tightly cover them

with approved covers.

4. Be alert that welding sparks and hot materials from

welding can easily go through small cracks and

openings to adjacent areas.

5. Watch for fi re, and keep a fi re extinguisher nearby.

6. Be aware that welding on a ceiling, fl oor, bulkhead, or

partition can cause fi re on the hidden side.

7. Do not weld on closed containers such as tanks or

drums.

8. Connect work cable to the work as close to the welding

area as practical to prevent welding current from

traveling long, possibly unknown paths and causing

electric shock and fi re hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding

wire at contact tip when not in use.

1. Wear approved face shield or safety goggles. Side

shields recommended.

2. Wear proper body protection to protect skin.

WARNING

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under

high pressure. If damaged, a cylinder can

explode. Since gas cylinders are normally part

of the welding process, be sure to treat them

carefully.

1. Protect compressed gas cylinders from excessive heat,

mechanical shocks, and arcs.

2. Install and secure cylinders in an upright position by

chaining them to a stationary support or equipment

cylinder rack to prevent falling or tipping.

3. Keep cylinders away from any welding or other

electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators,

hoses, and fi ttings designed for the specifi c application;

maintain them and associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder

valve.

7. Keep protective cap in place over valve except when

cylinder is in use or connected for use.

8. Read and follow instructions on compressed gas

cylinders, associated equipment, and CGA publication

P-1 listed in Safety Standards.

WARNING

Engines can be dangerous.

August 26, 2011 1-3 Manual 0-5213

Page 10

EXCEL ARC 6045 SAFETY INSTRUCTIONS

WARNING

ENGINE EXHAUST GASES can kill.

Engines produce harmful exhaust gases.

1. Use equipment outside in open, well-ventilated areas.

2. If used in a closed area, vent engine exhaust outside

and away from any building air intakes.

WARNING

ENGINE FUEL can cause fi re or explosion.

Engine fuel is highly fl ammable.

1. Stop engine before checking or adding fuel.

2. Do not add fuel while smoking or if unit is near any

sparks or open fl ames.

3. Allow engine to cool before fueling. If possible, check

and add fuel to cold engine before beginning job.

4. Do not overfi ll tank — allow room for fuel to expand.

5. Do not spill fuel. If fuel is spilled, clean up before

starting engine.

WARNING

SPARKS can cause BATTERY GASES TO

EXPLODE; BATTERY ACID can burn eyes and

skin.

Batteries contain acid and generate explosive gases.

1. Always wear a face shield when working on a battery.

2. Stop engine before disconnecting or connecting

battery cables.

3. Do not allow tools to cause sparks when working on

a battery.

4. Do not use welder to charge batteries or jump start

vehicles.

5. Observe correct polarity (+ and –) on batteries.

WARNING

STEAM AND PRESSURIZED HOT COOLANT

can burn face, eyes, and skin.

The coolant in the radiator can be very hot and

under pressure.

WARNING

MOVING PARTS can cause injury.

Moving parts, such as fans, rotors, and belts can cut

fi ngers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed

and securely in place.

2. Stop engine before installing or connecting unit.

3. Have only qualified people remove guards or

covers for maintenance and troubleshooting as

necessary.

4. To prevent accidental starting during servicing,

disconnect negative (-) battery cable from battery.

5. Keep hands, hair, loose clothing, and tools away

from moving parts.

6. Reinstall panels or guards and close doors when

servicing is fi nished and before starting engine.

1. Do not remove radiator cap when engine is hot. Allow

engine to cool.

2. Wear gloves and put a rag over cap area when

removing cap.

3. Allow pressure to escape before completely removing

cap.

Manual 0-5213 1-4 August 26, 2011

Page 11

SAFETY INSTRUCTIONS EXCEL ARC 6045

1.02 Principal Safety Standards

LEAD WARNING

This product contains chemicals, including

lead, or otherwise produces chemicals known

to the State of California to cause cancer, birth

defects and other reproductive harm. Wash

hands after handling. (California Health &

Safety Code § 25249.5 et seq.)

NOTE

Considerations About Welding And The Effects

of Low Frequency Electric and Magnetic Fields

The following is a quotation from the General

Conclusions Section of the U.S. Congress, Office of

Technology Assessment, Biological Effects of Power

Frequency Electric & Magnetic Fields - Background Paper,

OTA-BP-E-63 (Washington, DC: U.S. Government Printing

Offi ce, May 1989): “...there is now a very large volume

of scientifi c fi ndings based on experiments at the cellular

level and from studies with animals and people which

clearly establish that low frequency magnetic fi elds and

interact with, and produce changes in, biological systems.

While most of this work is of very high quality, the results

are complex. Current scientifi c understanding does not

yet allow us to interpret the evidence in a single coherent

framework. Even more frustrating, it does not yet allow us

to draw defi nite conclusions about questions of possible

risk or to offer clear science-based advice on strategies

to minimize or avoid potential risks.”

To reduce magnetic fields in the workplace, use the

following procedures.

1. Keep cables close together by twisting or taping

them.

2. Arrange cables to one side and away from the

operator.

Safety in Welding and Cutting, ANSI Standard Z49.1,

from American Welding Society, 550 N.W. LeJeune Rd.,

Miami, FL 33126.

Safety and Health Standards, OSHA 29 CFR 1910, from

Superintendent of Documents, U.S. Government Printing

Offi ce, Washington, D.C. 20402.

Recommended Safe Practices for the Preparation for

Welding and Cutting of Containers That Have Held

Hazardous Substances, American Welding Society

Standard AWS F4.1, from American Welding Society, 550

N.W. LeJeune Rd., Miami, FL 33126.

National Electrical Code, NFPA Standard 70, from National

Fire Protection Association, Batterymarch Park, Quincy,

MA 02269.

Safe Handling of Compressed Gases in Cylinders, CGA

Pamphlet P-1, from Compressed Gas Association, 1235

Jefferson Davis Highway, Suite 501, Arlington, VA 22202.

Code for Safety in Welding and Cutting, CSA Standard

W117.2, from Canadian Standards Association, Standards

Sales, 178 Rexdale Boulevard, Rexdale, Ontario, Canada

M9W 1R3.

Safe Practices for Occupation and Educational Eye and

Face Protection, ANSI Standard Z87.1, from American

National Standards Institute, 1430 Broadway, New York,

NY 10018.

Cutting and Welding Processes, NFPA Standard 51B, from

National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269.

Safety in welding and allied processes Part 2: Electrical,

AS1674.2-2003 from SAI Global Limited, www.saiglobal.

com

3. Do not coil or drape cable around the body.

4. Keep welding power source and cables as far away

from body as practical.

ABOUT PACEMAKERS:

The above procedures are among those

also normally recommended for pacemaker

wearers. Consult your doctor for complete

information.

August 26, 2011 1-5 Manual 0-5213

Page 12

EXCEL ARC 6045 SAFETY INSTRUCTIONS

!

1.03 Product Lifting Safety

The Excel Arc® 6045 is equipped with a lifting eye that is located in the middle of the top panel. The lifting eye is positioned to allow for balanced weight distribution when hoisting the unit.

WARNING

Do not attempt to lift the Excel Arc

®

6045 with other components attached to it.

Manual 0-5213 1-6 August 26, 2011

Page 13

SAFETY INSTRUCTIONS EXCEL ARC 6045

Gas Tungsten Arc

Welding (GTAW)

Air Carbon Arc

Cutting (CAC-A)

Constant Current

Constant Voltage

Or Constant Potential

High Temperature

Fault Indication

Arc Force

Touch Start (GTAW)

Variable Inductance

Voltage Input

Single Phase

Three Phase

Three Phase Static

Frequency ConverterTransformer-Rectifier

Dangerous Voltage

Off

On

Panel/Local

Shielded Metal

Arc Welding (SMAW)

Gas Metal Arc

Welding (GMAW)

Increase/Decrease

Circuit Breaker

AC Auxiliary Power

Remote

Duty Cycle

Percentage

Amperage

Voltage

Hertz (cycles/sec)

Frequency

Negative

Positive

Direct Current (DC)

Protective Earth

(Ground)

Line

Line Connection

Auxiliary Power

Receptacle RatingAuxiliary Power

Art # A-04130_AB

115V 15A

t

t1

t2

%

X

IPM

MPM

t

V

Fuse

Wire Feed Function

Wire Feed Towards

Workpiece With

Output Voltage Off.

Preflow Time

Postflow Time

Spot Time

Spot Weld Mode

Continuous Weld

Mode

Press to initiate wirefeed and

welding, release to stop.

Purging Of Gas

Inches Per Minute

Meters Per Minute

Welding Gun

Burnback Time

Press and hold for preflow, release

to start arc. Press to stop arc, and

hold for preflow.

4 Step Trigger

Operation

2 Step Trigger

Operation

See Note

See Note

Note: For environments with increased hazard of electrical shock, Power Supplier bearing the mark conform to EN50192

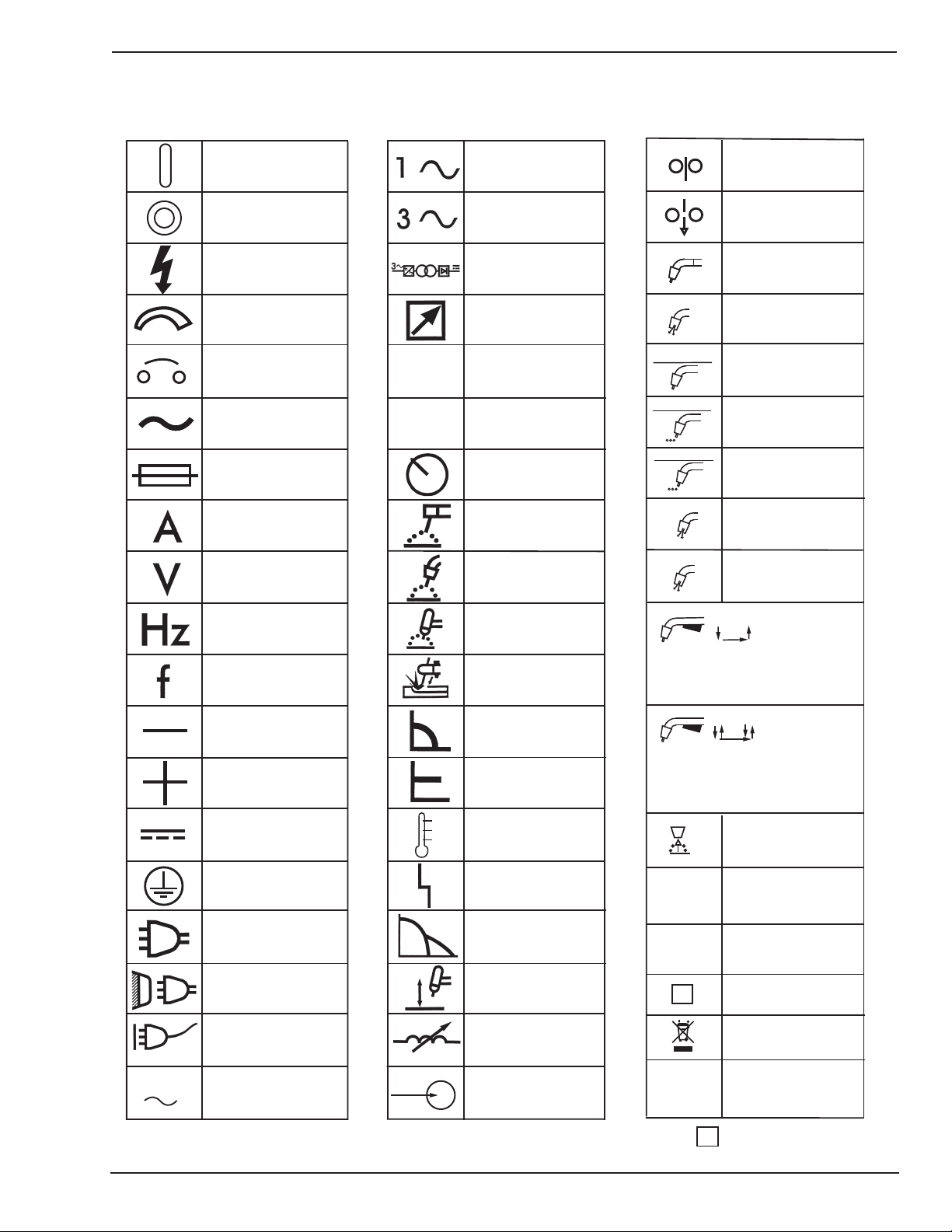

1.04 Welding Symbol Chart

Note that only some of these symbols will appear on your model.

S

S

August 26, 2011 1-7 Manual 0-5213

Page 14

EXCEL ARC 6045 SAFETY INSTRUCTIONS

1.05 Declaration Of Conformity

Manufacturer: Thermal Arc for CIGWELD

Address: 82 Benning Street

West Lebanon, NH 03784

USA

Description of equipment: Welding Equipment (GMAW, SMAW, GTAW, CAG and wirefeeders). Including, but not limited

to Thermal Arc Excel Arc

400i , VS212 Stealth, TRANSARC 130, 160 and associated accessories.

Serial numbers are unique with each individual piece of equipment and details the description and parts that are used

to manufacture a unit and date of manufacture.

The equipment conforms to all applicable aspects and regulations of the ‘Low Voltage Directive’ (Directive 73/23/EU,

as recently changed in Directive 93/68/EU and to the National legislation for the enforcement of the Directive.

National Standard and Technical Specifi cations

The product is designed and manufactured to a number of standards and technical requirements among them are:

• AS1966-1 applicable to welding equipment and associated accessories.

• AS/NZS 3652-(EMC Directive EN50199) applicable to arc welding equipment - generic emissions and

regulations.

• EN60974-1 applicable to welding equipment and associated accessories.

• AS60974.1 applicable to welding equipment and associated accessories.

Extensive product design verifi cation is conducted at the manufacturing facility as part of the routine design and

manufacturing process, to ensure the product is safe and performs as specifi ed. Rigorous testing is incorporated into

the manufacturing process to ensure the manufactured product meets or exceeds all design specifi cations.

Thermal Arc has been manufacturing and merchandising an extensive equipment range with superior performance,

ultra safe operation and world class quality for more than 30 years and will continue to achieve excellence.

®

6045 Powermaster 500SP, 400SP, 320SP, TRANSTIG 200Pi, 300Si, 200AC/DC, 300AC/DC,

Manual 0-5213 1-8 August 26, 2011

Page 15

INTRODUCTION EXCEL ARC 6045

!

SECTION 2:

INTRODUCTION

2.01 How To Use This Manual

This manual applies to just specifi cation or part numbers

listed on page i.

To ensure safe operation, read the entire manual, including

the chapter on safety instructions and warnings.

Throughout this manual, the words WARNING,

CAUTION, and NOTE may appear. Pay particular attention

to the information provided under these headings. These

special annotations are easily recognized as follows:

WARNING

A WARNING gives information regarding

possible personal injury.

CAUTION

A CAUTION refers to possible equipment

damage.

NOTE

A NOTE offers helpful information concerning

certain operating procedures.

2.02 Equipment Identifi cation

The unit’s identifi cation number (specifi cation or part

number), model, and serial number usually appear on a

nameplate attached to the control panel. In some cases, the

nameplate may be attached to the rear panel. Equipment

which does not have a control panel such as gun and cable

assemblies is identifi ed only by the specifi cation or part

number printed on the shipping container. Record these

numbers on the bottom of page i for future reference.

2.03 Receipt Of Equipment

When you receive the equipment, check it against the

invoice to make sure it is complete and inspect the

equipment for possible damage due to shipping. If there is

any damage, notify the carrier immediately to fi le a claim.

Furnish complete information concerning damage claims

or shipping errors to the location in your area listed in the

inside back cover of this manual.

Include all equipment identifi cation numbers as described

above along with a full description of the parts in error.

Move the equipment to the installation site before

un-crating the unit. Use care to avoid damaging the

equipment when using bars, hammers, etc., to un-crate

the unit.

Additional copies of this manual may be purchased

by contacting Thermal Arc at the address and phone

number for your location listed in the inside back cover

of this manual. Include the Owner’s Manual number and

equipment identifi cation numbers.

Electronic copies of this manual can also be downloaded at

no charge in Acrobat PDF format by going to the Thermal

Arc web site listed below and clicking on the Literature

Library link:

www.thermadyne.com/thermalarc

August 26, 2011 2-1 Manual 0-5213

Page 16

EXCEL ARC 6045 INTRODUCTION

0

5

10

15

20

25

30

35

40

45

50

VOLT-AMP CURVES FOR CV MODE

50%

MIN.

MAX.

DC VOLTS

DC AMPS

0 100 200 300 400 500 600 700 800 900

Art# A-10914

0

10

20

30

40

50

60

70

0 100 200 300 400 500 600 700

50%

VOLT-AMP CURVES FOR CC STICK MODE

DC VOLTS

DC AMPS

MIN. ARC

FORCE

MAX.

2.04 Description

The Excel Arc® 6045 (CC/CV) is a combination constant-current and constant-voltage transformer-rectifi er type

conventional DC welding machine that provides excellent welding characteristic for STICK (SMAW), LIFT TIG (GTAW),

submerged arc & GMAW/FCAW welding as well as carbon arc gouging (CAG).

Applications include Shipbuilding, Fabrication & Construction, Heavy Manufacturing, Rental Fleets, Pipe Welding,

Refi neries & Foundries, Railcar Manufacturing, Earth-Moving Equipment Manufacturing, Pressure Tank/Vessel

Fabrication.

NOTE

Volt-Ampere curves show the maximum Voltage and Amperage output capabilities of the welding power

source. Curves of other settings will fall between the curves shown.

Manual 0-5213 2-2 August 26, 2011

Figure 2-1: Excel Arc® 6045 Volt-Ampere Curves

Page 17

INTRODUCTION EXCEL ARC 6045

2.05 Features

1. Auxiliary power receptacles.

a. 1 x 19 pin (MS Compatible) with 115V 8-amp/42V 8-amp/24V 8-amp auxiliary power for wirefeeders, tractor

and SAW accessories.

b. 2 x 115V @ 20A.

2. Circuit breaker protection for 115V, 42V, 24V.

3. Simple, easy to operate front control panel.

4. Access to control PCB via the front panel control cover.

5. Front panel ON/OFF switch and pilot light.

6. Contactor ON switch for voltage sensing wire feeders.

7. Multi-process switch for GTAW, SMAW/CAG, GMAW/FCAW.

8. Large meter amps / volts + Memory holds for 20 seconds.

9. All user interfaces accessed from front of unit.

10. Line voltage compensation.

11. Fan turns ON when the arc is established and stays on for 10-15 minutes after it is extinguished.

12. Windings and rectifi ers protected against moisture and corrosive environments.

13. Thermal overload protection / Temperature shutdown light.

14. Circuit protection - In the event of a mains power failure machine defaults to OFF.

15. Accessories:

a. Remote output control

b. Control cable adapters

c. Hour meter

August 26, 2011 2-3 Manual 0-5213

Page 18

EXCEL ARC 6045 INTRODUCTION

750

650

550

450

40

50

60

80

100

% Duty Cycle

Weld Amperes

Art# A-10881

2.06 Functional Block Diagram

Input

Main

Contactor

Aux. Power

Accessories /

Features

2.07 Duty Cycle

Main Power

Amplifier

(XFMR)

Cooling

.

Rectifier

System Controls

Measuring

User Controls

Figure 2-2: Functional Block Diagram for Excel Arc® 6045

Current

Device

Welding Output

Power

CC/CV

Welding

Performance

Control

Output

CC/CV/Neg

Connections

Output

Art# A-10882

Duty cycle is the percentage of each ten-minute period of time that the welding machine may be operated under rated

load conditions. For example, a duty cycle of 60% means that the machine can be operated at rated load for an average

of 6 minutes of each 10 minute period of operation. During the remaining 4 minutes, the machine must idle to permit

proper cooling. Figure 2-3 enables the operator to determine the duty cycle at various welding amperages.

Figure 2-3: Duty Cycle Chart

Manual 0-5213 2-4 August 26, 2011

Page 19

INTRODUCTION EXCEL ARC 6045

2.08 Specifi cations

Rated Output

Output Current

Duty Cycle

Open Circuit Voltage 68VAC maximum for all input voltages

Arc Voltage in CV Mode 10-44V

Output Current Range STICK (MMAW) 20-650A

GMAW/FCAW 50-700A

Operating Temperature Range 0 to 40° C (32 to 104° F)

Maximum Temperature 50° C (120° F)

Minimum Temperature -4° C (-40° F)

Storage Temperature Range -4 to +80° C (-40 to +176° F)

Rated Input

Rated Input Voltage 400VAC - three phase - 50Hz

Rated Input Amperage

Input Frequency 50 Hz

Input Phase 3 Phase

Auxiliary Power 1 kVA –115V, 9A

No Load Input Voltage 400VAC

Auxiliary Power Supplies

Remote Receptacle for Wire Feeder or Remote

Control Device(s)

Auxiliary Power for tractor or SAW accessories 1 -15 A 115V Duplex

Front Panel Controls

115V auxiliary outlet 1 -10 A 115V

450 Amps at 38 Volts DC for all input voltages

600 Amps at 42 Volts DC for all input voltages

450A @ 100%

600A @ 60%

43A @ 100%

39A @ 60%

19 Pin MS socket

(2) 10A circuit breaker for 115V

1 off push-button circuit breaker for the 115V outlet8A circuit breaker for 115V wirefeeder circuit

8A circuit breaker for 42V

Multi-Pin Sockets 19 Pin MS socket

Thermal Arc/Cigweld: A2000, VA2000, VA4000, VS212, VA48,

VS48, VA412

Circuit Interface to Wire feeders

Sub arc automatic and semi automatic wirefeeder

Lincoln: NA3, NA5, LN7, & LN9 (adapter required - see section

4.07 and Appendix 1)

Table 2-4: Specifi cations

August 26, 2011 2-5 Manual 0-5213

Page 20

EXCEL ARC 6045 INTRODUCTION

a

3~

2.09 Dimensions and Weight

[837]

32.9"

[402]

15.8"

[701]

27.6"

[301]

11.9”

[75]

3.0”

[602]

23.7"

[92]

3.6”

Art# A-10916

2.10 Excel Arc® 6045 Data Tag

ExcelArc 6045

3~

Serial No:

U

U

U

U1=460V I

Figure 2-5: Dimensions and Weight

IDENTIFICATION

Part No: W1001703

IEC 60974-1

WELDING OUTPUT

MIG Output 50A/16.5V - 600A/44V

X 60% 100%

I

=61.7V

o

2

U

2

44V 36.5V

MMAW Output 25A/21V - 600A/44V

X 60% 100%

I

=61.7V

o

2

U

2

44V 38V

TIG Output 25A/11V - 600A/34V

X 60% 100%

I

=61.7V

o

2

U

2

34V 28V

ENERGY INPUT

=45.4A I

1max

[510]

20.1"

Thermal Arc

82 Benning Street,

West Lebanon, NH 03784

MADE IN USA

450A600A

450A600A

450A600A

=37.2A

1e

3

60Hz

IP23S

N1890

Art# A-10896

Figure 2-6: Data Tag

Manual 0-5213 2-6 August 26, 2011

Page 21

INSTALLATION EXCEL ARC 6045

!

!

SECTION 3:

INSTALLATION

3.01 Location

Be sure to locate the welder according to the following guidelines:

• Ambient temperature between 0 degrees C to 40 degrees C.

• In areas, free from oil, steam and corrosive gases.

• In areas, not subjected to abnormal vibration or shock.

• In areas, not exposed to direct sunlight or rain.

• Place at a distance of 12" (304.79 mm) or more from walls or similar boundaries that could restrict natural

airfl ow for cooling.

WARNING

Thermal Arc advises that this equipment be electrically connected by a qualifi ed electrician.

3.02 Electrical Input Connections

WARNING

ELECTRIC SHOCK can kill; SIGNIFICANT DC VOLTAGE is present after removal of input power.

DO NOT TOUCH live electrical parts.

SHUT DOWN welding power source, disconnect input power employing lockout/tagging procedures. Lockout/tagging

procedures consist of padlocking line disconnect switch in open position, removing fuses from fuse box, or shutting

OFF and red-tagging circuit breaker or other disconnecting device.

August 26, 2011 3-1 Manual 0-5213

Page 22

EXCEL ARC 6045 INSTALLATION

3.03 Electrical Input Requirements

NOTE

®

The Excel Arc

ground power cable that is connected at the welding power source for three phase electrical input power.

For direct wiring installation have a qualifi ed person install according to all applicable codes and instructions.

Operate the welding power source from a three-phase 60 Hz, AC power supply. The input voltage must match one of

the electrical input voltages shown on the input data label on the unit nameplate. Contact the local electric utility for

information about the type of electrical service available, how proper connections should be made, and any inspection

required.

The line disconnect switch provides a safe and convenient means to completely remove all electrical power from the

welding power supply whenever necessary to inspect or service the unit.

Do not connect an input conductor to the ground terminal.

Do not connect the ground conductor to an input line terminal.

Refer to "Figure 3-1: Electrical Input Connections" and:

1. Connect end of ground conductor to a suitable ground. Use a grounding method that complies with all applicable

electrical codes.

6045 comes equipped from the factory with a pre-connected three-conductor with earth

2. Connect ends of line 1 and line 2 and line 3 input conductors to a de-energized line disconnect switch.

3. Use "Figure 3-1: Electrical Input Connections" and "Table 3-3: Recommended Wire and Fuse Size" on page 3-3

as a guide to select line fuses for the disconnect switch. "Table 3-3: Recommended Wire and Fuse Size" provides

minimal information for selection of line conductors, fuses, and the equipment grounding conductor. This information is from AS1966-1, AS/NZS 3652-(EMC Directive EN50199), EN60974-1 and AS60974.1.

Ground

Conductor

Ground

Excel Arc 6045 Power Supply

Terminal

Art # A-10419

Primary Power Cable

Line Fuse

Line

Disconnect

Switch

Line Fuse

Figure 3-1: Electrical Input Connections

Manual 0-5213 3-2 August 26, 2011

Page 23

INSTALLATION EXCEL ARC 6045

3.04 Grounding

The frame of this welding machine should be grounded for

personnel safety, and to assure operation of the overcurrent

protection. The grounding method, and the equipment

grounding conductor size and type shall conform to local

and national codes. For the National Electrical Code, the

equipment grounding conductor shall be green, green with

a yellow stripe, or bare. If fl exible power cable is used, use

a cable assembly which includes the equipment grounding

conductor. If metallic armored cable or conduit is used, the

metal sheathing or conduit must be effectively grounded

per local and national codes.

9.1-13.6 kg (20-30 lbs.) Soil Treating Material

(copper sulphate, magnesium sulphate or rock salt)

placed in circular trench and covered

with earth.

Grounding Conductor

Fasten Grounding

Conductor to the

rod with an

approved

ground clamp.

Rubber-tire mounted equipment shall be grounded to

conform to local and national codes. The grounding

assists in providing protection against line voltage

electrical shock and static shock. The grounding serves

to discharge the static electric charge which tends to

build up on rubber-tire mounted equipment. This static

charge can cause painful shock and lead to the erroneous

conclusion that an electrical fault exists in the equipment.

If a system ground is not available, consult the electrical

code enforcement body for instructions. The welding

machine should be connected to an adequate driven

ground rod, or to a water pipe that enters the ground not

more than 30 meters (10 feet) from the machine.

Art # A-05234_AB

Removable Cover

Floor

457 mm

Approx. 305 mm (1 Ft.)

Not less than

24.4 cm (8 Ft.)

Ground

Rod

(18 inches)

Approx.

Soil

Treating

Ground Rod

Not less than 24.4 cm (8 Ft.)

Material

152 mm (6 Inches) Approx.

Figure 3-2: Grounding Diagram

The equipment grounding conductor size is listed in "Table 3-3: Recommended Wire and Fuse Size" as a guide, if

no local or national code is applicable. Attach the equipment grounding conductor to the stud provided on the yoke.

Determine that the ground wire size is adequate before the machine is operated.

CAUTION

Be sure to replace all covers to assure adequate internal ventilation and prevent component failure.

COPPER LINE WIRE SIZE* COPPER

LINE VOLTS

RATED LOAD

AMPS

APPROX. LINE

FUSE SIZE

IN CONDUIT FLEXIBLE CABLE

GROUNDING

CONDUCTOR

MIN. SIZE

460 38 60 No. 8 No. 8 No. 8

*Conductor size shall be modifi ed as required for line voltage drop and ambient temperature. Sizes listed for conduit installation are based on 90° C conductor

insulation, designated as FEP, FEPB, RHH, and THHN.

Table 3-3: Recommended Wire and Fuse Size

August 26, 2011 3-3 Manual 0-5213

Page 24

EXCEL ARC 6045 INSTALLATION

!

3.05 Replacing the Input Power Cable

The input power should be connected to the unit through a fused disconnect switch, or other suitable disconnecting

means furnished by the user. A hole is provided in the rear panel of the machine, near to the input connections, for the

entry of the input conductors. Refer to "Figure 3-1: Electrical Input Connections".

WARNING

ELECTRIC SHOCK CAN KILL. Open the disconnect switch, or breaker, and determine that no voltage is

present, before connecting wires between welding machine and power supply.

CAUTION

The method of installation, conductor size, and overcurrent protection shall conform to the requirements of

the local electrical code, the National Electrical Code, or other national codes, as applicable. All installation

wiring and machine re-connections shall be done by qualifi ed persons.

Mains Supply Lead Size

Minimum Mains Current

Circuit size

Mains Supply Voltage

Weld Current & Duty

Cycle

8 AWG 40A 460V 3 phase 600A@60%

Table 3-4: Mains Current Circuit Sizes

1. Open the disconnect switch, or breaker, and determine that no voltage is present, before disconnecting wires be-

®

tween the Excel Arc

2. Remove the left-side cover of the Excel Arc

6045 and the power supply.

®

6045.

3. Loosen the compression clamp nut on the rear panel where the existing power cable enters the unit. Refer to "Figure

3-5: Power Cable Compression Nut".

4. Disconnect the three-phase line leads from terminals L1, L2, and L3 on the line contactor inside the welding machine

cabinet. Disconnect the ground wire from the ground terminal. Refer to "Figure 3-6: Input Power Cable Connection".

5. Remove the old power cable from the Excel Arc

®

6045 and route the new cable in through the same access hole.

6. Connect the three-phase line leads to terminals L1, L2, and L3 on the line contactor inside the welding machine

cabinet. Connect the ground wire to the ground terminal. Refer to "Figure 3-6: Input Power Cable Connection".

7. Tighten the compression nut on the rear panel where the new power cable enters the unit. Refer to "Figure 3-5:

Power Cable Compression Nut".

8. Replace the left-side cover of the Excel Arc

9. Close the disconnect switch, or breaker, and reapply power to the Excel Arc

®

6045.

®

6045 and the power supply.

Compression

Nut

Art# A-10902

Figure 3-5: Power Cable Compression Nut

Manual 0-5213 3-4 August 26, 2011

Page 25

INSTALLATION EXCEL ARC 6045

L1

L2

L3

Ground

Terminal

Green/Yellow Wire

CAUTION

Power is present if

this is illuminated.

Art# A-10897

Figure 3-6: Input Power Cable Connection

(Unrelated wiring not shown for clarity purposes)

3.06 Welding Leads

Use "Table 3-7: Electrode Lead and Work Lead Size" for selection of the proper size copper welding leads.

TOTAL LENGTH OF LEAD CIRCUIT IN (AND METERS)

Welding Current

Amperes

50 Feet

(15.2M)

100 #4 #4 #4 #3 #2

150 #3 #3 #2 #1 #1/0

200 #2 #2 #1 #1/0 #2/0

250 #1 #1 #1/0 #2/0 #3/0

300 #1/0 #1/0 #2/0 #3/0 #4/0

350 #1/0 #1/0 #3/0 #4/0 #4/0

400 #2/0 #2/0 #3/0 #4/0 2 — #2/0

450 #2/0 #2/0 #4/0 2 — #2/0 2 — #3/0

500 #3/0 #3/0 #4/0 2 — #2/0 2 — #3/0

Table 3-7: Electrode Lead and Work Lead Size

(ELECTRODE LEAD PLUS WORK LEAD)

100 Feet

(30.5M)

150 Feet

(45.7M)

(For 60% duty cycle)

200 Feet

(61.0M)

250 Feet

(76.2M)

NOTE

Lead size shown is for 90°C cable insulation, 30°C (86°F) ambient, and not over 4.5 volts lead drop.

August 26, 2011 3-5 Manual 0-5213

Page 26

EXCEL ARC 6045 INSTALLATION

3.07 Installation Diagram

Terminal

Bolt

Professional

PROCESS

FCAW

CAG

ARC FORCE (STICK)

Negative

Terminal

FORCE D'ARC

PROCESSUS

WARNING:

READ OPERATING MANUAL

AVERTISSEMENT : LIRE LE MANUEL D’OPERATING

V

VOLTS

V / A

ARC ON TIME (HRS)

ARC À L'HEURE

POWER

ON

MARCHE

REMOTE

COMMANDE À DISTANCE

OUTPUT

CONTACTOR

RENDEMENT

CONJONCTEUR

PUISSANCE

ON

MARCHE

OFF

ARRÊT

HOT START

DE DÉPART CHAUD

ON

MARCHE

OFF

ARRÊT

A

AMPS

OUTPUT

ON

REMOTE

COMMANDE À DISTANCE

LOCAL

COMMANDE LOCALE

CONTROL

COMMANDE

Positive Terminal

to Wire Feeder—shown

for reverse polarity—DCEP

Stick

NOTE

Base Metal

To change polarity, reverse

connections on power output

terminals on power source.

Art# A-10898

Work Piece—should be grounded

Figure 3-8: Installation Diagram

Manual 0-5213 3-6 August 26, 2011

Page 27

OPERATION EXCEL ARC 6045

ARC FORCE (STICK)

V

VOLTS

V / A

A

AMPS

Professional

ON

MARCHEONMARCHE

OUTPUT

ON

POWER

PUISSANCE

ON

MARCHE

WARNING:

READ OPERATING MANUAL

AVERTISSEMENT : LIRE LE MANUEL D’OPERATING

PROCESS

PROCESSUS

FCAW

CAG

ARC ON TIME (HRS)

ARC À L'HEURE

REMOTE

COMMANDE À DISTANCE

REMOTE

COMMANDE À DISTANCE

LOCAL

COMMANDE LOCALE

CONTROL

COMMANDE

HOT START

DE DÉPART CHAUD

OUTPUT

CONTACTOR

RENDEMENT

CONJONCTEUR

OFF

ARRÊT

OFF

ARRÊT

(

)

CONJONCTEUR

115V 20AMPS

NEUTRAL BONDED TO FRAME

NUETRE COLLÉ SUR L'ARMATURE

8A 20A 20A

8A 8A

19P

1

2

6

5

7

4

8

9

13 10 11 12 18 15

14 1716

19

20

3

21

23 22

Art# A-10891

SECTION 4:

OPERATION

4.01 Front Panel

Figure 4-1: Excel Arc® 6045 Front Panel

1. MODE SELECTOR SWITCH (SW2)

Selects between the three (3) following operational modes:

a. MIG (GMAW / FCAW) - Constant Voltage (CV) mode for MIG welding with constant speed wire feeder.

b. STICK (SMAW / CAG) - Constant Current (CC) mode for Stick Electrode Welding and Carbon Arc Gouging.

c. TIG (GTAW) - Constant Current (CC) mode for TIG welding.

August 26, 2011 4-1 Manual 0-5213

Page 28

EXCEL ARC 6045 OPERATION

Art# A-10894

2. ARC FORCE CONTROL POTENTIOMETER (R2)

(SMAW/CAG)

To prevent electrode "sticking" this potentiometer

controls the short circuit welding current to produce

an increase in current as the arc length is shortened.

Arc Force Current is continuously adjustable from 0 350 amps.

3. REMOTE OUTPUT CONTACTOR

Remote output control. NOTE: Welding will not

start in GTAW mode without a Remote OUTPUT ON

(CONTACTOR ON) signal.

4. FUSE (F1)

1/4A 250V fuse protecting the 24 volt auxiliary

transformer.

8A 20A 20A

11. VOLTAGE / CURRENT CONTROL POTENTIOMETER

(R1)

Adjusts the output voltage (CV modes) or output

current (CC modes). This potentiometer will set the

maximum limit when REMOTE control is selected.

12. CURRENT LED DISPLAY

Three digit display for preview current prior to enabling

the output and actual output current when it is enabled.

Display will "HOLD" actual output current when the arc

was stopped for approximately. 20 seconds and then

will revert to preview setting.

13. HOUR METER (OPTIONAL)

Displays the unit arc hours.

14. OVER-TEMPERATURE LED INDICATOR (YELLOW)

Yellow Over-temperature LED indicates that the

unit is overheated and that the unit output has

been disabled. If the transformer is overheated, the

power is disconnected.

8A 8A

19P

Figure 4-2: Fuse Location

5. CIRCUIT BREAKER (CB4) 8A - For 42VAC to J1.

6. 2 CIRCUIT BREAKERS (CB3) 20A - For 115VAC to J1.

7. CIRCUIT BREAKER (CB4) 8A - For 42VAC to J1.

8. CIRCUIT BREAKER (CB5) 8A - For 24VAC to J1.

9. FEEDER / REMOTE INTERFACE CONNECTOR (J1).

19 Pin amphenol connector - for interface with Wire

Feeder, remote control devices and controllers.

10. VOLTAGE LED DISPLAY

Three digit display for preview voltage prior to enabling

the output and actual output voltage when it is enabled.

Display will "HOLD" actual output voltage when the arc

was stopped for approximately. 20 seconds and then

will revert to preview setting.

15. FAULT LED INDICATOR (RED)

Red Fault LED indicates a fault from the J1 Connector.

If any of the supply voltages (24VAC, 42VAC, 115VAC)

are shorted to any of the signal wires connected to the

J1 connector, this indicator will turn ON.

16. ON/OFF INDICATOR LED (GREEN)

Green ON/OFF LED indicates when the ON/OFF SWITCH

(SW1) is set in the ON position; Control circuits are

active.

17. ON/OFF SWITCH (SW1)

Turns the control circuitry ON/OFF. In the OFF position,

the high power circuits and output terminals are

disabled.

18. OUTPUT ON LED

Green LED indicates that an OUTPUT ENABLE (START)

signal is present.

NOTE

This will come ON immediately when either

STICK (CC) or VS MIG (GMAW or FCAW)

modes are selected.

19. LOCAL / REMOTE SWITCH (SW4)

Switches between front panel or remote voltage/

amperage control.

Manual 0-5213 4-2 August 26, 2011

Page 29

OPERATION EXCEL ARC 6045

!

to welding machine, and remove its fuse.

LOCAL position is used when the output

voltage/amperage is controlled by the OUTPUT

VOLTAGE / AMPERAGE CONTROL POTENTIOMETER

on the front panel.

20. HOT START SWITCH (SW3) – For STICK mode only

REMOTE position is selected when the output

voltage/amperage is controlled through the 19 Pin

Amphenol Receptacle. The maximum limit is set by

the LOCAL (front panel) Voltage/Amperage Control

Potentiometer.

(SMAW/CAG)

ELECTRIC SHOCK can kill! Do not touch live

electrical parts, including the output terminals

and electrode.

2. Plug remote control into 19-pin amphenol receptacle

(J1).

3. Set Output Control to desired value.

4. Set the Local/Remote control switch in the desired

mode.

5. Make any DIP switch and/or trim pot adjustments on

or next to the control panel PCB (located behind the

front panel) as defi ned in the next fi ve sections.

Allows a short duration pulse of higher current for ease

of starting an arc in SMAW mode only. The current

level and duration are adjustable by trim pots on the

Main PCB.

21. AC RECEPTACLE

Four (4) Circuit breakers protected auxiliary 115VAC

20 amp outlet.

22. POSITIVE OUTPUT RECEPTACLE CC/CV

Main positive output supply terminal for CC and CV

modes.

23. NEGATIVE OUTPUT TERMINAL

Main negative output supply terminal.

4.02 Machine Set-Up and Operation

General

Before operating this system, be sure that all installation

instructions have been accomplished. When operating this

system, observe all applicable Safety Warnings listed in

this and related system manuals.

The operating instructions in this manual pertain only to

the Excel Arc

instructions for components used with this system before

operating.

®

6045 welding machine. Consult operating

4.03 Adjustments Behind the Control

Panel

The Excel Arc® 6045 provides four different user adjustable

settings behind the Control Panel to accommodate fi xed

installations and operator preferences. These user-defi ned

settings do not require continuous access and are normally

for one-time, "set and forget" functions. Therefore, they

are located on and next to the Control Panel PCB behind

the front panel.

The adjustments behind the Control Panel are:

1. Hot Start Switch Enable/Disable.

2. Hot Start - Duration and amplitude adjustment on

PCB. Refer to “Figure 4-3: Front Panel Access”.

In order to make any of these adjustments, the upper front

panel section needs to be pulled down as follows:

A. Turn the two slotted screws 1/4 turn to release panel.

See “Figure 4-3: Front Panel Access”.

B. Pull down the front panel and locate the Control Panel

PCB behind it.

Preweld Operation

1. Connect welding leads to terminals on front panel.

WARNING

Disconnect line voltage from the unit before

making any connections inside unit. Turn OFF

fused disconnect switch that supplies power

August 26, 2011 4-3 Manual 0-5213

Page 30

EXCEL ARC 6045 OPERATION

ARC FORCE (STICK)

FORCE D'ARC

V

VOLTS

V / A

A

AMPS

Professional

ON

MARCHE

ON

M

ARC

HE

OUTPUT

ON

POWER

PUISSANCE

ON

MARCHE

WARNING:

READ OPERATING MANUAL

AVERTISSEMENT : LIRE LE MANUEL D’OPERATING

PROCESS

PROCESSUS

FCAW

CAG

ARC ON TIME (HRS)

ARC À L'HEURE

REMOTE

COMMANDE À DISTANCE

REMOTE

COMMANDE À DISTANCE

LOCAL

COMMANDE LOCALE

CONTROL

COMMANDE

HOT START

DE

D

ÉPA

R

T C

H

AUD

OUTPUT

CONTACTOR

RENDEMENT

CONJONCTEUR

OFF

ARRÊT

OFF

ARRÊT

Art# A-10892

1/4 turn both Front Cover Screws to release

Pull Down Front Panel

Control Panel PCB

Hinge Pin

A

B

4.04 Hot Start Switch Enable/Disable

When activated, the HOT START SWITCH (Item “20.

HOT START SWITCH (SW3) – For STICK mode only

(SMAW/CAG)” on page 4-3) allows a short duration

pulse of higher current for ease of starting an arc in SMAW/

CAG mode only. The level and duration of the hot start

current are adjustable using two trim pots on the Control

Panel PCB.

1. Pull down the front panel. Refer to Section “4.03

Adjustments Behind the Control Panel” and “Figure

4-3: Front Panel Access”.

2. Locate the HOT START two trim pots on the Control

Panel PCB. R295 adjusts the hot start duration and

R275 adjusts the hot start current level. Refer to “Figure

4-4: Hot Start Level and Duration Adjustments”.

3. Using a small fl at-blade screwdriver, adjust the trim

pots in accordance with the parameters defi ned in

“Figure 4-4: Hot Start Level and Duration Adjustments”.

Figure 4-3: Front Panel Access

Manual 0-5213 4-4 August 26, 2011

Page 31

OPERATION EXCEL ARC 6045

SW1

SW2 SW3

Art# A-10895

R295 HOT START DURATION- Continuously adjustable from 0.5 to 2 seconds.

R275 HOT START VALUE - Continuously adjustable between 0 - 100% of the LOCAL

or REMOTE demand level up to 700 amps total.

Figure 4-4: Hot Start Level and Duration Adjustments

4.05 SMAW (Stick) Welding & Carbon Arc Gouging

1. Connect the work cable and electrode holder lead. The

positive lead should be connected to the POSITIVE

OUTPUT RECEPTACLE.

2. Connect the work clamp to the work piece or work

table.

R295

R275

5. If HOT START feature is desired, turn HOT START

SELECTOR SWITCH (SW3) to ON position.

5a. If required, to adjust HOT START current level and

duration.

6. Set ARC FORCE CONTROL POTENTIOMETER (R2) to

the maximum level.

7. Set LOCAL / REMOTE SWITCH (SW4) to LOCAL.

3. Turn ON/OFF SWITCH (SW1) to ON position.

NOTE

The output enable LED (green) will be ON at

this time.

4. Set MODE SELECTOR SWITCH (SW2) to STICK

position (SMAW / CAG - CC).

8. Set VOLTAGE CURRENT CONTROL POTENTIOMETER

(R1) to select desired current level.

9. If VRD protection is desired, set SW1-A located on the

Main PCB to ON (DN) position. Factory setting is ON

(Down) position.

10. Hold electrode clear of work.

11. Strike the arc.

12. When welding / gouging is fi nished, turn the ON/OFF

SWITCH (SW1) to OFF position.

August 26, 2011 4-5 Manual 0-5213

Page 32

EXCEL ARC 6045 OPERATION

4.06 GTAW (TIG) Welding

1. Connect the work lead to the POSITIVE OUTPUT

RECEPTACLE.

2. Connect the TIG torch lead to the NEGATIVE OUTPUT

RECEPTACLE.

3. Set MODE SELECTOR SWITCH (SW2) to TIG position

(GTAW - CC).

4. Turn the ON/OFF SWITCH (SW1) to ON position.

a. Connect remote to J1 Connector.

5. When using a Remote Potentiometer to control the

output current:

a. Set the VOLTAGE / CURRENT CONTROL

POTENTIOMETER (R1) to select the maximum

current level for the remote.

b. Set LOCAL / REMOTE SWITCH (SW4) to REMOTE

position.

If no remote current control is to be used:

a. Set LOCAL / REMOTE SWITCH (SW4) to LOCAL

position.

4.07 GMAW / FCAW with Constant Speed Wire Feeder

1. Complete all Wire Feeder and MIG Gun connections.

2. Turn ON/OFF SWITCH to ON position.

3. Set MODE SELECTOR SWITCH (SW2) to MIG position

(CV GMAW / FCAW).

4. VOLTAGE CONTROL.

If using a wire feeder with remote voltage control:

a. Set the VOLTAGE / CURRENT CONTROL

POTENTIOMETER (R1) to set the maximum

voltage level for the remote.

b. Set the LOCAL / REMOTE SWITCH (SW4) to

REMOTE position.

If using a wire feeder without remote voltage control:

a. Set LOCAL / REMOTE SWITCH (SW4) to LOCAL

position.

b. Set the VOLTAGE / CURRENT CONTROL

POTENTIOMETER (R1) to desired voltage level.

5. Position the MIG Gun for welding and close gun switch

and start welding.

b. Set the VOLTAGE / CURRENT CONTROL

POTENTIOMETER (R1) to select the desired

welding current.

6. Position the torch for welding.

7. Touch the electrode to the work piece, activate the

Remote OUTPUT ON (CONTACTOR ON) signal, then

lift the electrode off from the plate and the welding arc

will initiate.

8. When finished welding, deactivate OUTPUT ON

(CONTACTOR ON) signal.

NOTE

Welding will not start in GTAW mode without a

Remote OUTPUT ON (CONTACTOR ON) signal.

4.08 GMAW / FCAW with Voltage Sensing Wire Feeder with Contactor

1. Complete all Wire Feeder and MIG Gun connections.

2. Turn ON/OFF SWITCH (SW1) to ON position.

NOTE

The output enable LED (green) will be on at

this time and there should be output at the (+)

and (-) terminals.

3. VOLTAGE CONTROL.

If using a wire feeder

a. Set the LOCAL / REMOTE SWITCH (SW4) to

REMOTE position.

b. Set the VOLTAGE / CURRENT CONTROL

POTENTIOMETER (R1) to set the maximum

voltage level for the remote.

If using a wire feeder

a. Set LOCAL / REMOTE SWITCH (SW4) to LOCAL

position.

with

remote voltage control:

without

remote voltage control:

b. Set the VOLTAGE / CURRENT CONTROL

POTENTIOMETER (R1) to desired voltage level.

4. Position the MIG Gun for welding and close gun switch

and start welding.

Manual 0-5213 4-6 August 26, 2011

Page 33

SERVICE EXCEL ARC 6045

!

!

SECTION 5:

SERVICE

5.01 General

(Also refer to Troubleshooting Sections in wire feeder and

MIG gun manuals.)

If this equipment does not operate properly, stop

work immediately and investigate the cause of the

malfunction. Maintenance work must be performed by

an experienced, qualifi ed person only. Any electrical work

must be performed by an electrician or other person

properly trained in servicing electrical equipment. Do not

permit untrained persons to inspect, clean or repair this

equipment. Use only recommended replacement parts

when servicing this machine.

WARNING

HIGH VOLTAGE is present internally even with

the control power switch in the OFF position.

Before inspecting, cleaning, or servicing

disconnect and lock out input power to the

power source.

5.02 Maintenance

Periodically clean the inside of the welding power source

by using a shop vacuum cleaner as normal preventive

maintenance. At the time of cleaning, a full inspection

of the welding machine and setup should be performed.

Check warning labels on the machine for readability and

replace if necessary. Check input and output connections

as well as frame ground connections to the machine to

insure that they are tight and that the wires are not frayed

or overheated. Inspect the internal wiring of the machine

for loose or frayed connections and tighten or repair as

necessary. It would also be advisable to check connections

to wire feeders, fi xtures, etc., at this time. Any damaged

cables or hoses should be replaced.

WARNING

ALL SERVICE SHOULD BE PERFORMED BY

TRAINED PERSONNEL ONLY.

August 26, 2011 5-1 Manual 0-5213

Page 34

EXCEL ARC 6045 SERVICE

Warning!

Disconnect input power before maintaining.

Each Use

Visual check of

regulator and pressure

Visual check of torch

Consumable parts

Weekly

Visually inspect the torch

body and consumables

Visually inspect the

cables and leads.

Replace as needed

3 Months

Clean

exterior

of power

supply

6 Months

Replace all

broken parts

Visually check and

use a vacuum to carefully

clean the interior

Maintain more

often if used

under severe

conditions

Gas and

air lines

Art # A-10883

!

ARC FORCE (STICK)

FORCE D'ARC

V

VOLTS

V / A

A

AMPS

Professional

ON

MARCHE

ON

MARCHE

OUTPUT

ON

POWER

PUISSANCE

ON

MARCHE

WARNING:

READ OPERATING MANUAL

AVERTISSEM

ENT : LIRE LE MANUEL D’OPERATING

PROCESS

PROCESSUS

FCAW

CAG

ARC ON TIME (HRS)

ARC À L'HEURE

REMOTE

COMMANDE À DISTANCE

REMOTE

COMMANDE À DISTANCE

LOCAL

COMMANDE LOCALE

CONTROL

COMMANDE

HOT START

DE DÉPART CHAUD

OUTPUT

CONTACTOR

RENDEMENT

CONJONCT

EUR

OFF

ARRÊT

OFF

ARRÊT

ARC FORCE (STICK)

FORCE D'ARC

V

VOLTS

V / A

A

AMPS

Professional

ON

MARCHE

ON

MARCHE

OUTPUT

ON

POWER

PUISSANCE

ON

MARCHE

WARNING:

READ OPERATING MANUAL

AV

ERTISSEMENT : LIRE LE MANUEL D’OPERATING

PROCESS

PROCESSUS

FCAW

CAG

ARC ON TIME (HRS)

ARC À L'H

E

URE

REMOTE

COMMANDE À DISTANCE

REMOTE

COMMANDE À DISTANCE

LOCAL

C

O

MMANDE LOCALE

CONTROL

COMMANDE

HOT START

DE DÉPART CHAUD

OUTPUT

CONTACTOR

RENDEMENT

CONJONCTEUR

OFF

A

RRÊT

OFF

ARRÊT

5.03 Maintenance Diagram

Manual 0-5213 5-2 August 26, 2011

Figure 5-1: Maintenance Diagram

Page 35

SERVICE EXCEL ARC 6045

!

5.04 Basic Troubleshooting Guide

A. Scope:

This Operator Troubleshooting guide is intended to correct

unsatisfactory operation of the Excel Arc

intended to be an electrical service troubleshooting or

repair guide. Refer to “Figure A-1: System Schematic”

on page A-2 to gain an overview of the interconnections

of the electrical components that are cited in this guide.

B. Safety:

To ensure safe operation and service, read this entire

manual before attempting to service this machine.

WARNING

Disconnect the power source from the input

power source before carrying out any service

or repair work. Hazardous voltages can be

present in the machine whenever input power

is connected.

C. Troubleshooting Hints:

®

6045. It is not

5.05 General Thermal Conditions

The fan on the unit will turn ON whenever a welding arc

is active and will remain on for approximately 10 minutes

after welding is stopped. This will help to minimize the

entry of dust and foreign material into the unit while at idle.

There are two types of thermal overload conditions. The

thermal switch on the SCR heatsink protects the SCRs by

shutting the gating signals OFF when the switch opens

due to excessive heat. The output voltage / current will

be disabled until the heatsink has cooled suffi ciently. At

that time in STICK (CC) or VS MIG (GMAW or FCAW)

modes the output will come back on. In MIG (GMAW) or

TIG (GTAW) mode, the operator will have to reapply the

remote trigger switch.

The thermal switches in the Main Transformer will cause

the system to shut down when excessive heat causes any

of them to open. The contactors will turn OFF, disabling the

output. The fan and all lights will turn OFF. This condition

should alert the operator that a serious overheating

condition has occurred and that the unit and primary

power should be checked by a qualifi ed technician before

attempting to use the unit further.

Examine connections for proper assembly and contact

before replacing a component. Wire lugs should be in

tight contact with the lead's conductor and should be

crimped to the lead's insulation. The mating surfaces of

the connection should be clean and free of oxidation. Faulty

connections or wiring problems are often the cause of an

equipment malfunction.

Do not pull on wires to disassemble connections. Firmly

grasp each lug or connector when disconnecting. Pulling

on wires for disassembly can damage the integrity of the

connection and cause future malfunctions.

Prior to disassembly or servicing of the machine, note

the wiring and connections in the machine. Reassembling

should place wires in the same location and routing as

received from the factory. Keep wires and leads away from

hot parts and sharp objects.

LIVE POWER WARNING

CC Mode Only

When the (SW1) ON/OFF is turned to the ON

position, there will be output power. Therefore,

when the unit is in STICK or VS MIG modes

turn the ON/OFF switch to OFF when not in use.

VS MIG (VS GMAW) will also have output

power when switched to that mode.

August 26, 2011 5-3 Manual 0-5213

Page 36

EXCEL ARC 6045 SERVICE

5.06 Operator Troubleshooting

The Excel Arc® 6045 is the power supply, one component in

a welding system. Other system components may include

a Wire Feeder, Remote Current Control Potentiometer,

Remote Output Enable (START) switch, MIG Gun, TIG

Torch, Electrode Holder and cables, Gas Control Valve

and Gas Regulators. These components may each have a

manual and may be required to solve the problem.

Before proceeding with this manual section, it is

recommended to review the Machine Set-Up and

Operation section and also verify that the correct polarity

is observed for the particular welding operation being

performed.

How to Use This Guide

The following information will help the Operator determine

the most likely causes for various symptoms. Follow all

instructions as listed and complete each section in the

order presented.

This guide is set up in the following manner:

5.07 Troubleshooting All Modes of Operation

A. All indicator lights on the machine are OFF. Fan

does not turn.

1. ON / OFF SWITCH (SW1) is in the OFF position.

a. Turn SW1 to ON position.

2. Fuse F1 blown.

a. Check and replace if open.

3. Primary Power Problem.

a. Measure for correct voltage at the Primary

Power Receptacle.