TVLOGIC XVM-175W Schematic

Multi Format

LCD MONITOR

Service Manual

17” Multi Format LCD Monitor

XVM-175W

1

Caution

• Always use set voltage.

- AC 100 ~ 240V (1.6A/50~60Hz)

- DC 12V(MAX 3.5A)

• All operating instructions must be read and understood before the products is operated.

• These safety and operating instruction must be kept in safe place for future reference.

• All warning in this instruction must be observed closely and be followed.

• Do not use attachments not recommended by the manufacturer. Use of inadequate attachments

can result in accidents.

• If you are not sure of the type of power supply used in your home, consult your dealer or local

power company. For units designed to operate on batteries or another power source, refer to the

operating instruction.

• The power cord must be routed properly to prevent people from stepping on them or objects

from resting on them. Check the cords at the plugs and products.

• Do not overload DC outlets or extension cords. Overloading can cause fire or electric shock.

• Do not attempt to service the products yourself. Removing covers can expose you to high voltage

and other dangerous conditions. Request a qualified person to perform servicing.

• If any of the following conditions occurs, unplug the power cord from the DC outlet, and request a

qualified service person to perform repairs.

a. When the power cord or plug in damaged.

b. When a liquid was spilled on the products or when objects have fallen into the products.

c. When the products have been exposed to rain or water.

d. When the products have been dropped or damaged.

e. When the products display an abnormal condition. Any noticeable abnormality in the products

indicate that the products need servicing.

• Upon completion of service of repair work, request the service technician to perform safety checks

to ensure that the products is in proper operating condition.

• Keep the products away from direct rays of the Sun-light.

• Do not place the products on an unstable cart, stand, tripod or table. Placing the products on an

unstable base can cause the products to fall.

• When you disassemble the products, you lay smooth fabric so that the products keep away from

scratch.

• When you assemble the products, you set the electronic screwdriver’s torque as less than 2k and

screw each bolt and check if the cables connect properly. Setting the torque as more than 2k can

cause the case broken.

2

Part Name & Function

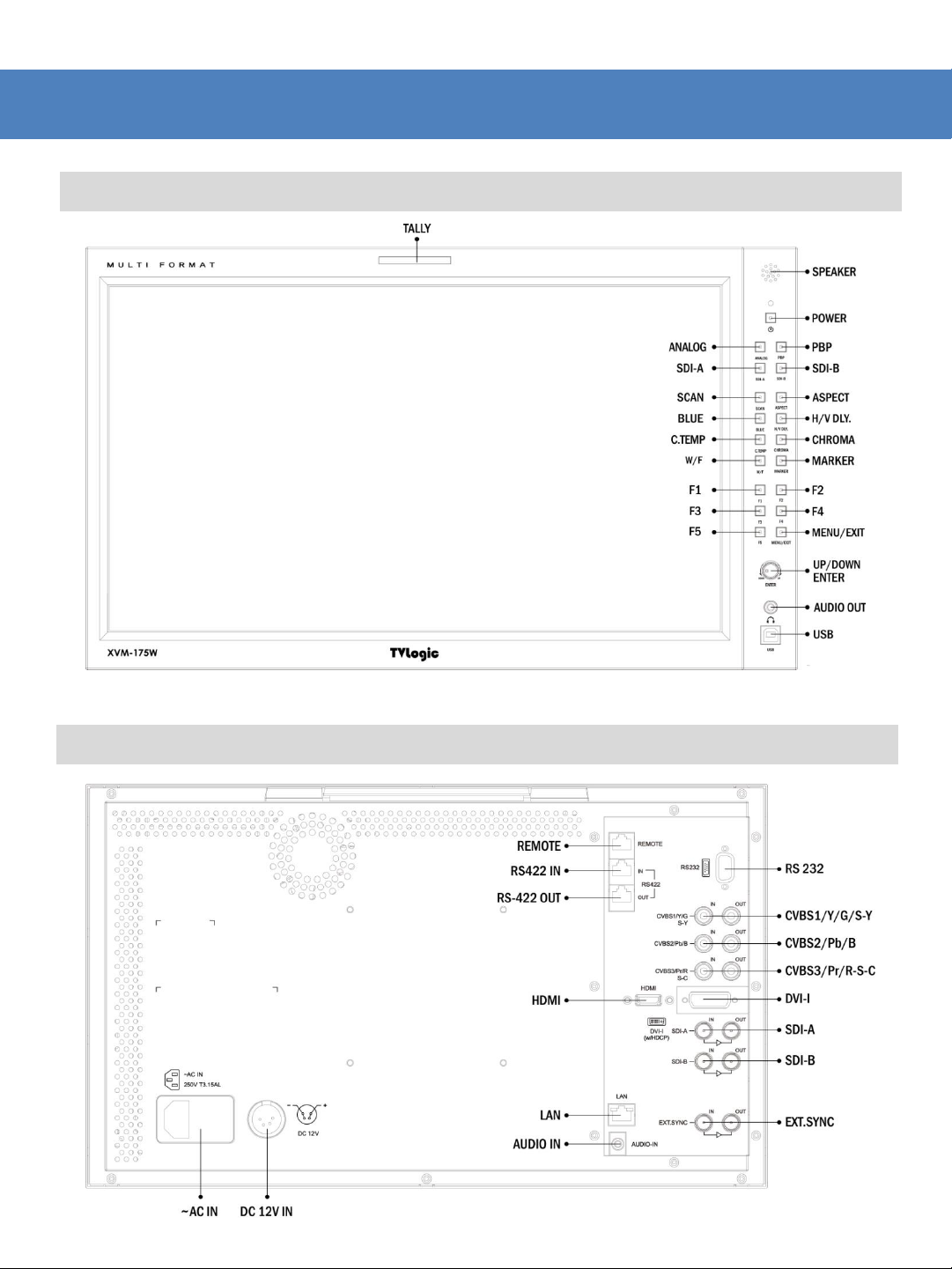

XVM-175W : Front

XVM-175W : Rear

3

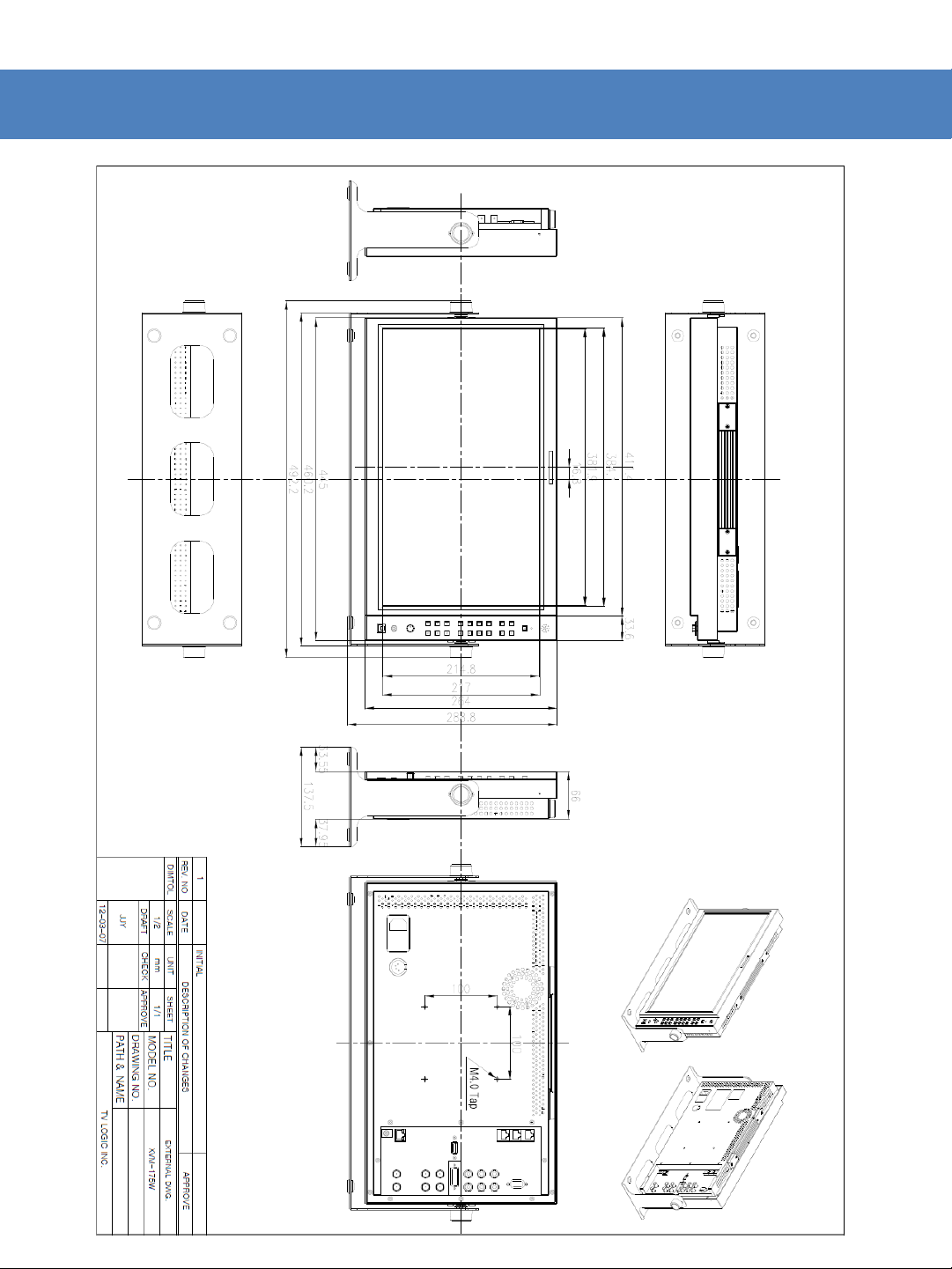

Drawing

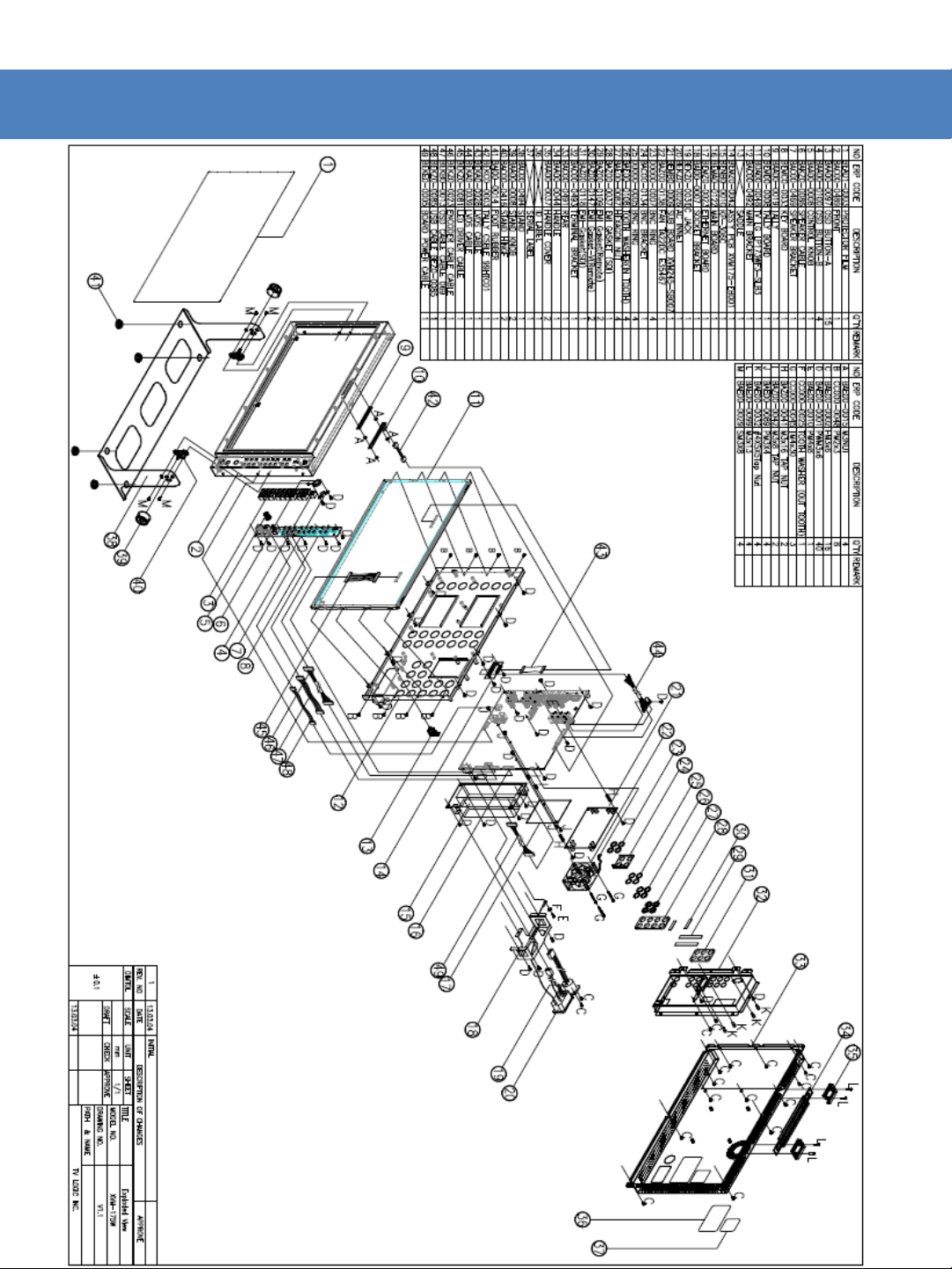

Exploded View

DVI ANALOG/DIGITAL Support Resolution

DVI ANALOG/DVI DIGITAL/HDMI support resolution

• DVI-ANALOG mode support resolution :

Resolution Frequency

640 × 480 60Hz, 75Hz

720 x 400 70Hz

800 × 600 60Hz, 72Hz, 75Hz

1024 × 768 60Hz, 70Hz, 75Hz

1366 x 768 60Hz/75Hz

1280 x 1024 60Hz/75Hz

1600 x 1200 60Hz

1920 x 1080 60 Hz

• DVI DIGITAL Video mode support resolution :

• DVI DIGITAL Video mode support resolution :

• DVI DIGITAL/HDMI is divided into graphic and video mode.

• DVI ANALOG/DIGITAL/HDMI mode, when scan is not zero scan, the picture may not be output

properly.

• When output image is not wide mode but aspect mode, the image is output by pressing ASPECT

button.

Resolution Frequency

640 × 480 60Hz, 75Hz

800 × 600 60Hz, 72Hz, 75Hz

1024 × 768 60Hz, 70Hz, 75Hz

1366 x 768 60Hz/75Hz

1280 x 1024 60Hz/75Hz

1600 x 1200 60Hz

1920 X 1080 60hZ

1920 x 1200 60 Hz

SMPTE-274M 1080i (60 / 59.94)

SMPTE-296M 720p (60 / 59.94)

SMPTE-125M 480i (59.94), 480p(59.94)

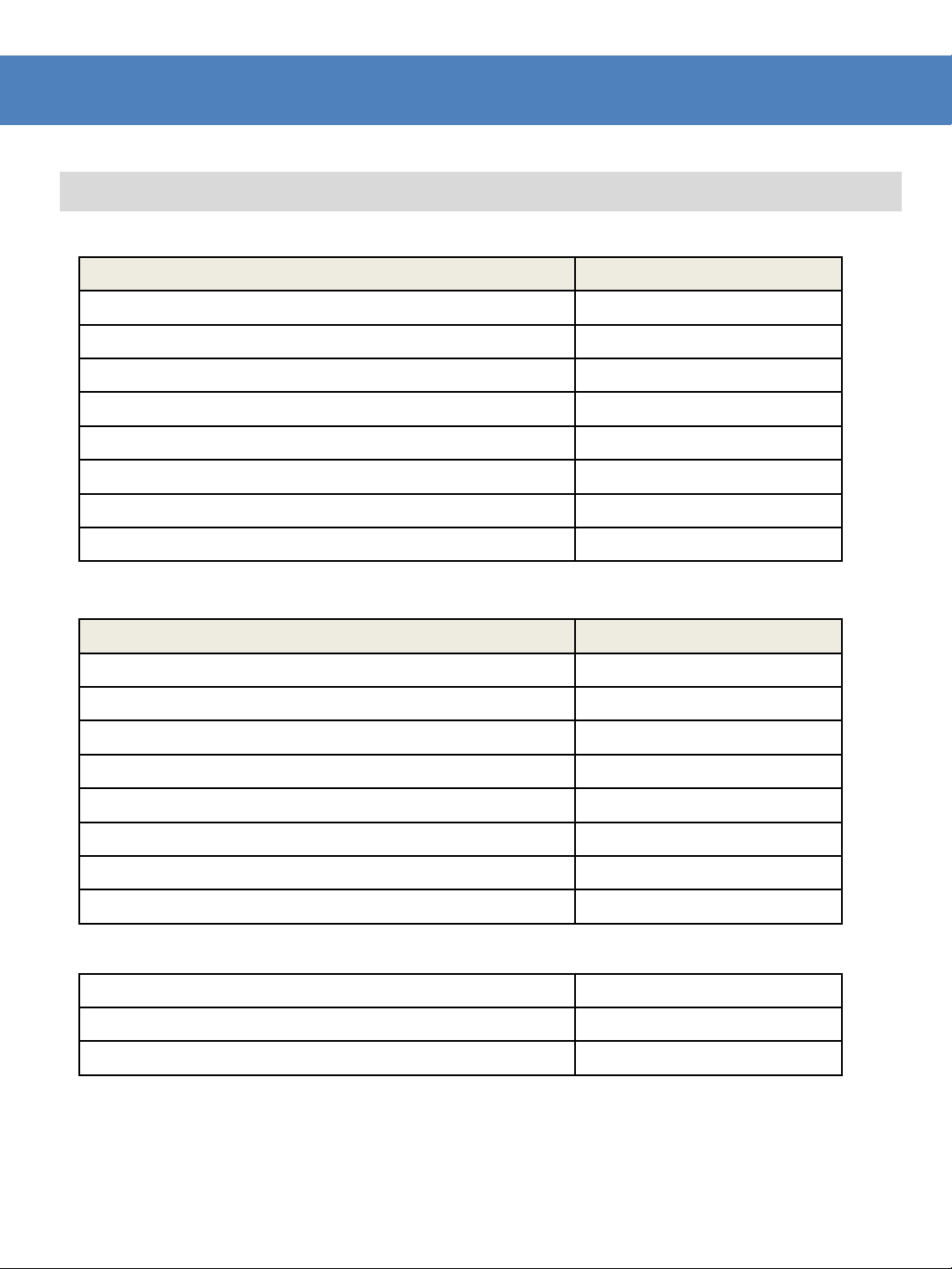

Product Specification

1 x DVI-I DVI IN

3 x BNC Analog Input

Input

Output

Input Signal

Analog Input Spec

SDI Input Signal Formats

Audio In Embedded Audio / Analog Stereo (Phone Jack)

Audio Out Analog Stereo (Phone Jack)

LCD SPEC

Power AC100~240V

Power Consumption (Approx.) 77 Watts(AC / Typ.)

Operating Temperature 0°C to 40 °C (32°F to 104 °F )

Storage Temperature -20 °C to 60 °C (-4 °F to 140 °F )

Main Body Dimensions (mm/inch) 445x264x66 (17.52x10.39x2.6)

Main Body Dimensions (With Stand) 492.2x288.8x137.5 (19.38x11.37x5.41)

Weight 6.4kg(14.08lbs)

Accessory AC Power Cord / Stand

Option

* Above specifications may be changed without notice

2 x BNC SDI A/B Channel Input

1 x HDMI HDMI Input

1 x BNC EXT SYNC INPUT

3 x BNC Analog Output

2 x BNC SDI A/B Channel (Active Through Out)

1 x BNC EXT SYNC OUT(Active Through Out)

Analog Composite / S-Video / Component / RGB

3G-SDI 2.970Gb/s

HD-SDI 1.485Gbps

SD-SDI 270Mbps

DVI VESA/IBM Modes

HDMI 480i/480p/720p/1080i /1080p

Composite 1.0Vpp (With Sync)

S-Video 1.0Vpp (Y With Sync), 0.286Vpp(C)

Component 1.0Vpp (Y With Sync), 0.7Vpp (Pb,Pr)

RGB 1.0Vpp (G With Sync), 0.7Vpp (B,R)

SMPTE-425M-A/B 1080p (50/59.94/600)

Dual HD-SDI YPbPr (4:2:2) 1080p (50 / 59.94 / 60)

SMPTE-372M

SMPTE-274M

SMPTE-296M 720p (60/59.94/50)

SMPTE-260M 1035i (60/59.94)

SMPTE-125M 480i (59.94)

ITU-R BT.656 576i (50)

Size 17”

Resolution 1920*1080

Dot Pitch 0.199mm * 0.199mm

Color 10-bit 1.07B color

Viewing Angle (Typical) R/L, U/D 178°

Luminance of white 300 cd/m

Contrast 800:1

Display Area (H)381.9mm (V)214.8mm

Dual HD-SDI YPbPr/RGB (4:4:4)

1080i (60/59.94/50)

1080p (30/29.97/25/24/24sF/23.98/23.98sF)

Carrying Case, Rack Mountable Kit(With OSD Cover), V-mount, Gold mount,

Sun hood

1080i (50 / 59.94 / 60)

1080p/psf (30 / 29.97 / 25 / 24 / 23.98)

7

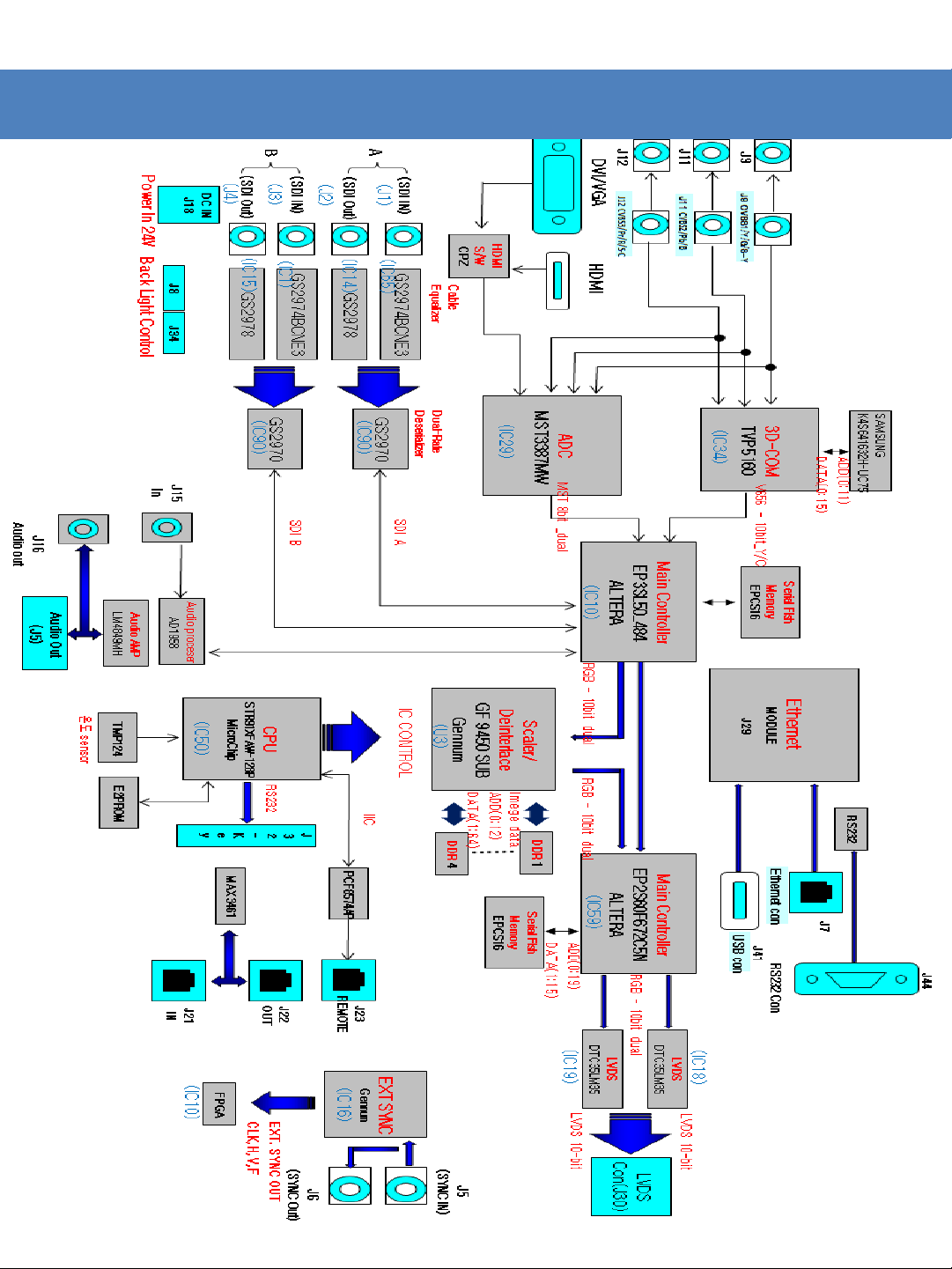

PCB Block Diagram

8

Circuit Operation Progress

•

SDI Equalizer + Deserializer sends out YUV(4:2:2) 20bit digital Signal fed SD/HD-SDI. 20bit Signal as

in output sends out audio Signal.

•

HDMI S/W, ADC(HDMI+ADC -Input) sends out 8bit 2ch R,G,B data selected DVI or HDMI signal.

YPbPr(480p,720p,1080i-Input) sends out 30bit 2ch R,G,B data via A/D CONVERTER.

•

Analog R,G,B(IBM,VESA -Input) is sent out 30bit 2ch R,G,B data via A/D CONVERTER.

•

ALTERA FPGA A makes DIGITAL Signal switching then send out ALTERA FPGA B.

In Fast Mode, it sends out ALTERA FPGA B by deinterlacing without using Scaler.

It sends out I2S Signal in H part by extracting Audio signal on SD/HD-SDI..

•

3D-ROM handles with CVBS1~3.

• HDMI, DVI, RGB, and YPbPr don’t get a signal at the same time.

• After changing Digital signal into Analog one, Audio AMP(LM4849) amplifies audio then puts out

Audio Out(J16).

• SAMSUNG K4S641632H-UC75 memory is used for 3D-COM.

• Serial Flash Memory is a device that saves images and loads them when they are needed.

• CPU controls whole circuit.

• Temperature sensor and keys are under CPU control.

• Scaler/Deinterlace have 4 of DDR, save images, and load them whenever needed.

• PCF8574 ‘s role is to extend I/O port.

• GPI Remote(J23) consis of parallel switch then control monitors the outside.

• GPI IN/OUT(J21, J22) controls protocol monitors or supports TSL protocol.

•

EXT. SYNC Generater takes out SYNC on Analog signal, makes CLK,H,V F, and puts out FPGA.

•

Ethernet Module is for Program Download and Calibration by connecting an Ethernet Cable with

I2C signal.

• [Ethernet & USB]

- Updates new firmware such as features, debugging.

• ~ AC IN

- AC 100 ~ 240V (1.6A/50~60㎐)

- DC 12V(MAX 3.5A)

9

Circuit Operation Progress

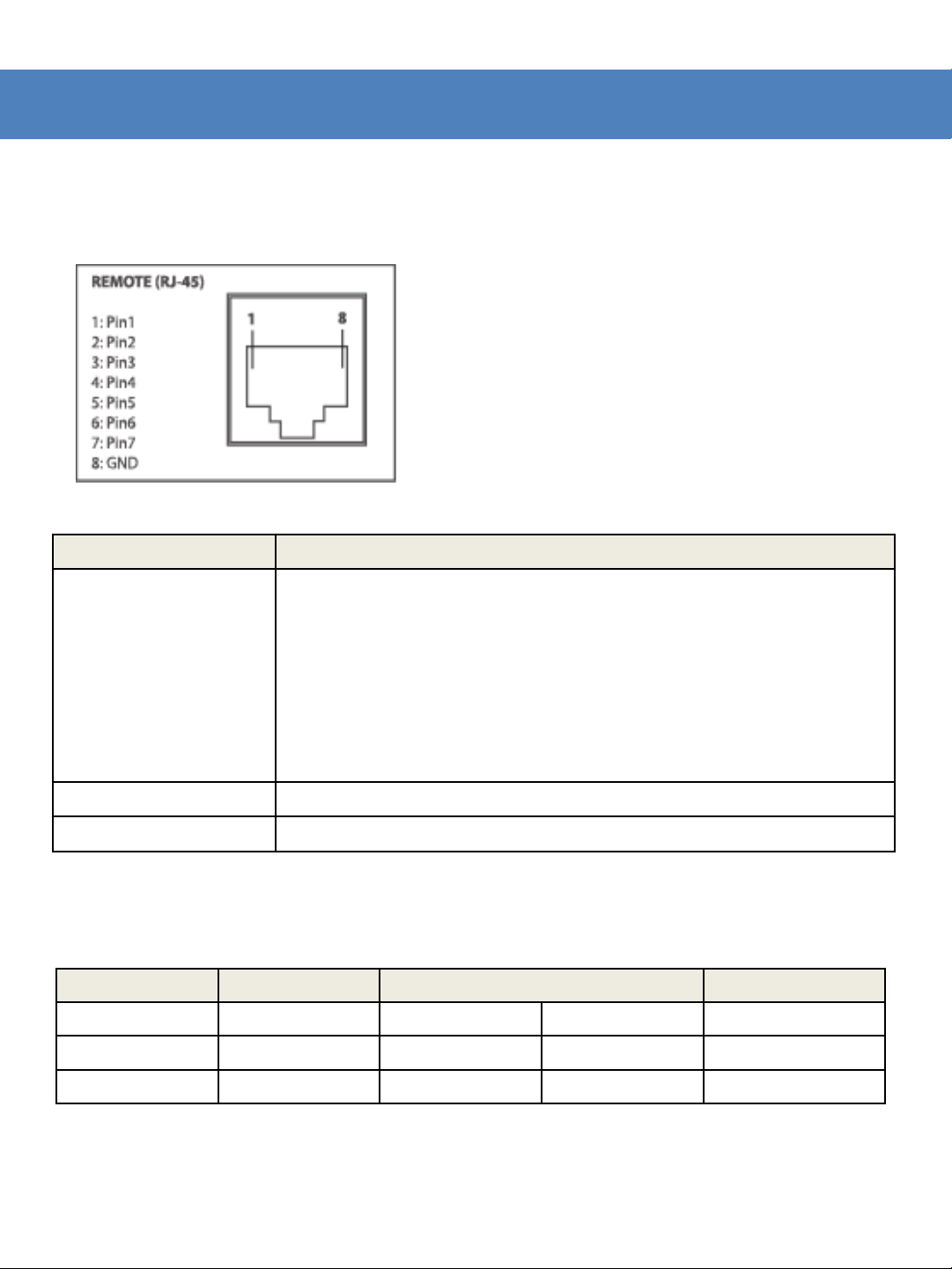

<GPI Remote>

- Each pins is located as below.

- You can set the functions of pins 1~6 as the following:

Menu Classification Settable Values

PIN 1~6

NONE, ANALOG CHANNEL, SDI-A CHANNEL, SDI-B CHANNEL, PBP

CHANNEL, TALLY R, TALLY G, UNDER SCAN, 1:1 SCAN, ASPECT, H/V

DELAY, BLUE ONLY, MONO, 16:9 MARKER, 4:3 MARKER, 4:3 ON AIR

MARKER, 15:9 MARKER, 14:9 MARKER, 13:9 MARKER, 1.85:1 MARKER,

2.35:1 MARKER, 1.85:1&4:3 MARKER, CENTER MARKER, SAFETY AREA

80%, SAFETY AREA 85%, SAFETY AREA 88%, SAFETY AREA 90%,

SAFETY AREA 93%, SAFETY AREA 100%, 708, 608(LINE21), 608(ANC),

OP47

PIN 7 POWER ON/OFF CONTROL

PIN 8 GND

<Video Input>

- How to connect analog video signal

Connector Composite Component S-Video

1 CVBS 1 Y G Y

2 CVBS 2 Pb B No Con.

3 CVBS 3 Pr R C

10

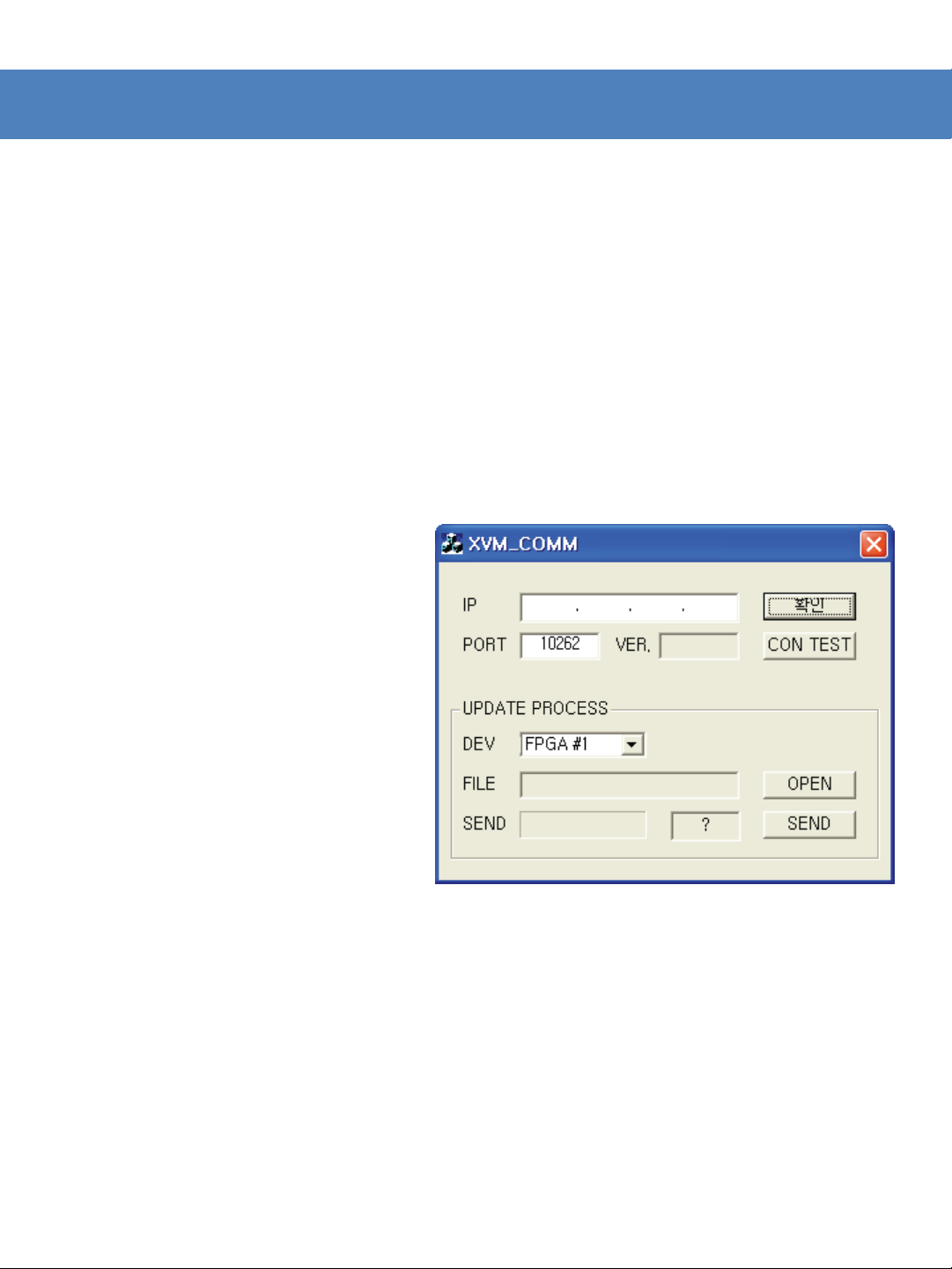

PROGRAM UPDATE – ETHERNET

1) Monitor Settings

- In OSD Menu -> REMOTE -> IP Address, Subnet Mask, Gateway value.

* Changing the PORT NO. is not recommended.

* Enter the IP Address of the connected internet with monitor.

* PASSWORD feature is available with V1.0 and above.

- Leave the monitor on.

2) Upgrade program settings

- Run XVM_COMM.exe

Picture 1 : Monitor upgrade SW =>

- Enter the same IP address as entered for the monitor. (See picture 2)

* Changing the PORT No. is not recommended.

- When the “CON TEST” button is pressed, Version number will appear in

the Ver. Box if connected properly. If not, “??” will appear in the box.

- If “??” appears, check the IP address for the monitor and program, then

try again.

11

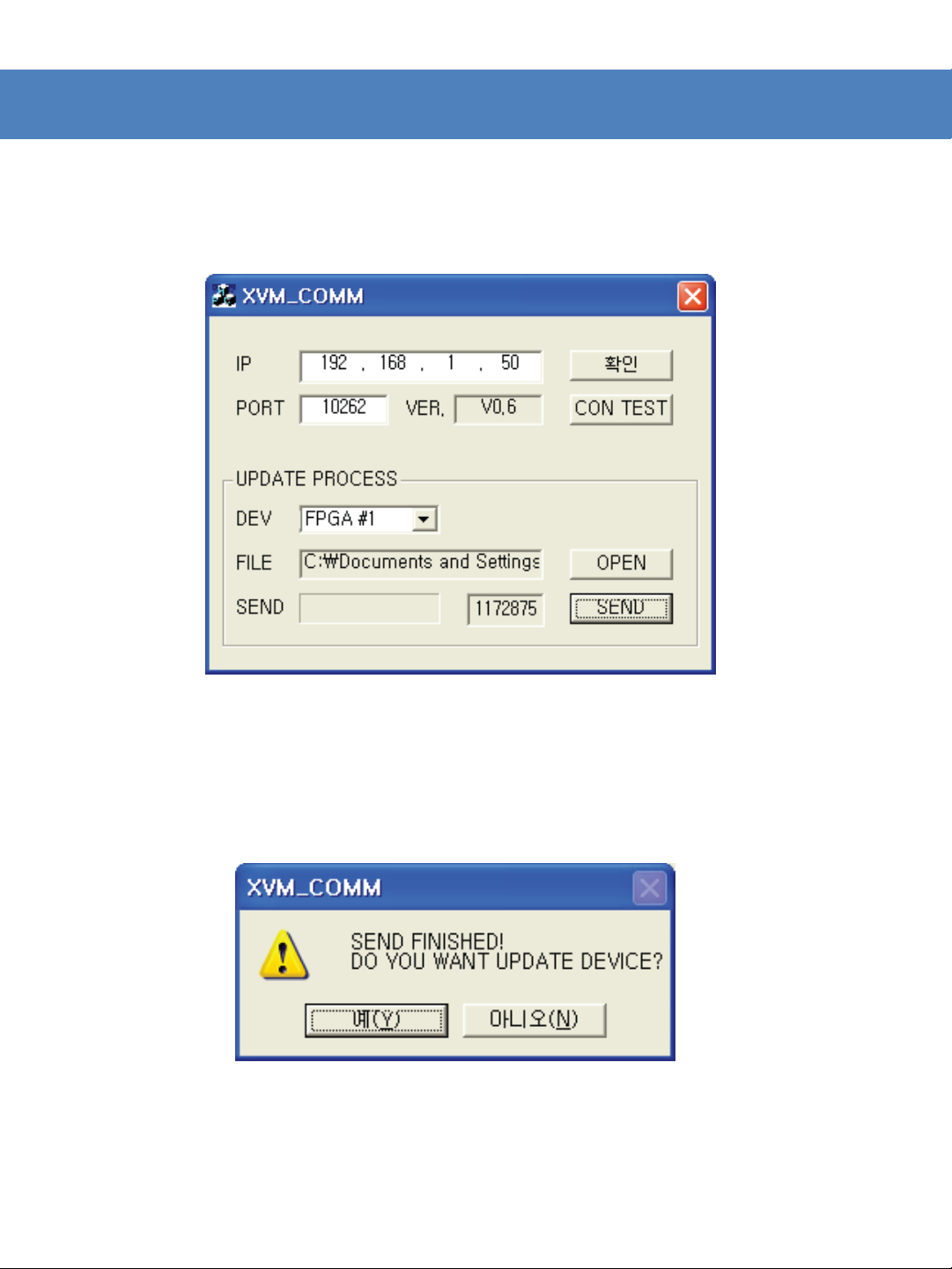

PROGRAM UPDATE – ETHERNET

3) Firmware update

- FPGA

Picture 2 : Update setting

* Select FPGA #1 for DEV in UPDATE PROCESS. Then, press OPEN and

select the FPGA firmware file.

* Press the SEND button to start transferring the firmware file to the

Ethernet Board.

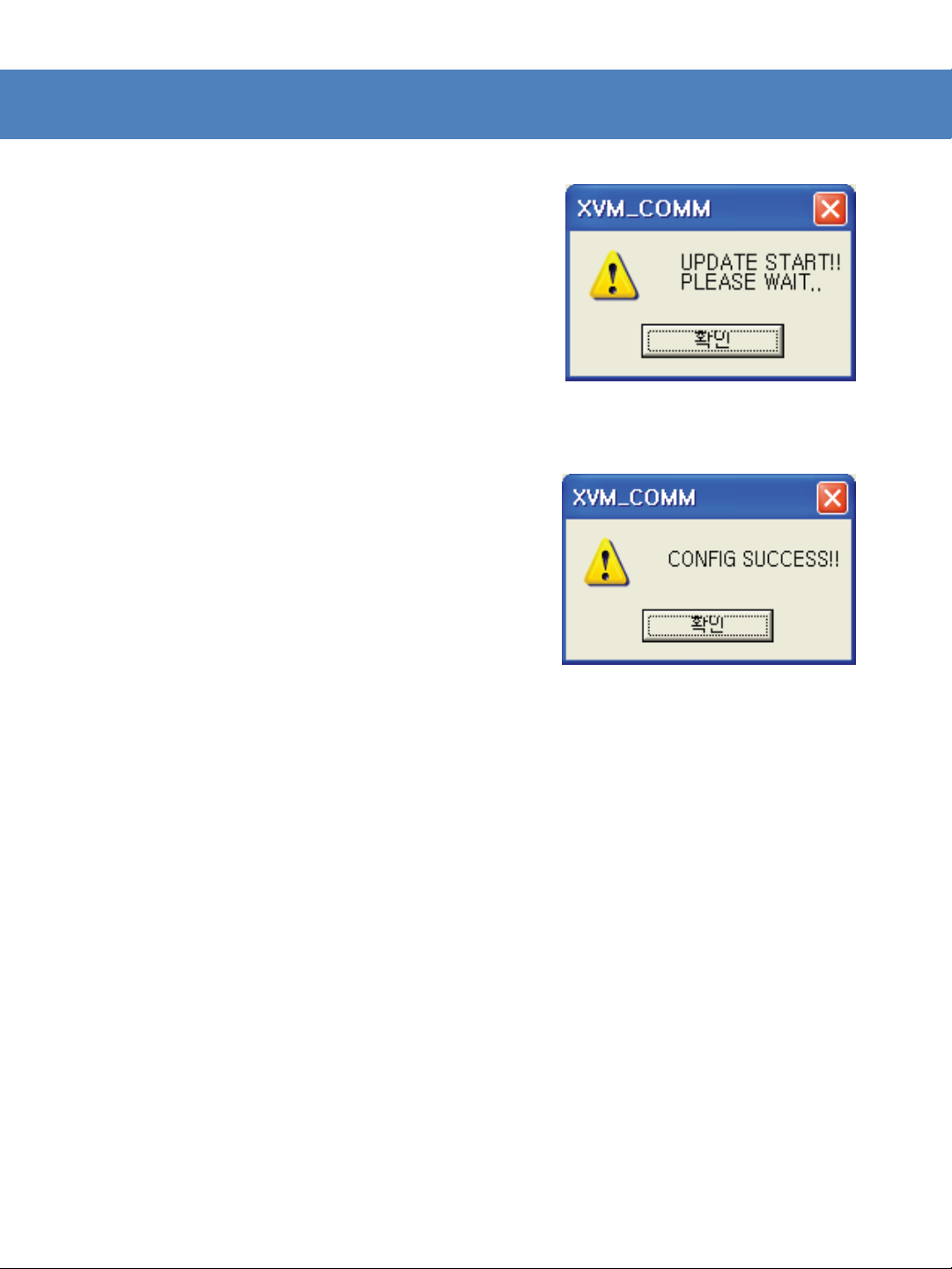

Picture 3 : Transfer finished message window

* Once the transfer finishes, message window appears to confirm the

start of update.

12

PROGRAM UPDATE – ETHERNET

Picture 4 : Update start message window=>

* Press the “OK” button to start updating.

Picture 5 : CONFIG SUCCESS message window=>

* Select FPGA #2 for DEV in UPDATE PROCESS. Then, OPEN and

select the FPGA firmware file.

* Press the SEND button to start transferring the firmware file to

the Ethernet Board.

- CPU

* Se lect ARM/GEN for DEV in UPDATE PROCESS. Then, press OPEN and

select the ARM/GEN firmware file.

* Press the SEND button to start transfer.

* Follow the above FPGA updating steps to finish the update.

- VXP

* Select VXP #1 for DEV in UPDATE PROCESS. Then, press OPEN and

select the VXP firmware file.

* Press the SEND button to start transfer.

* Follow the above FPGA updating steps to finish the update.

13

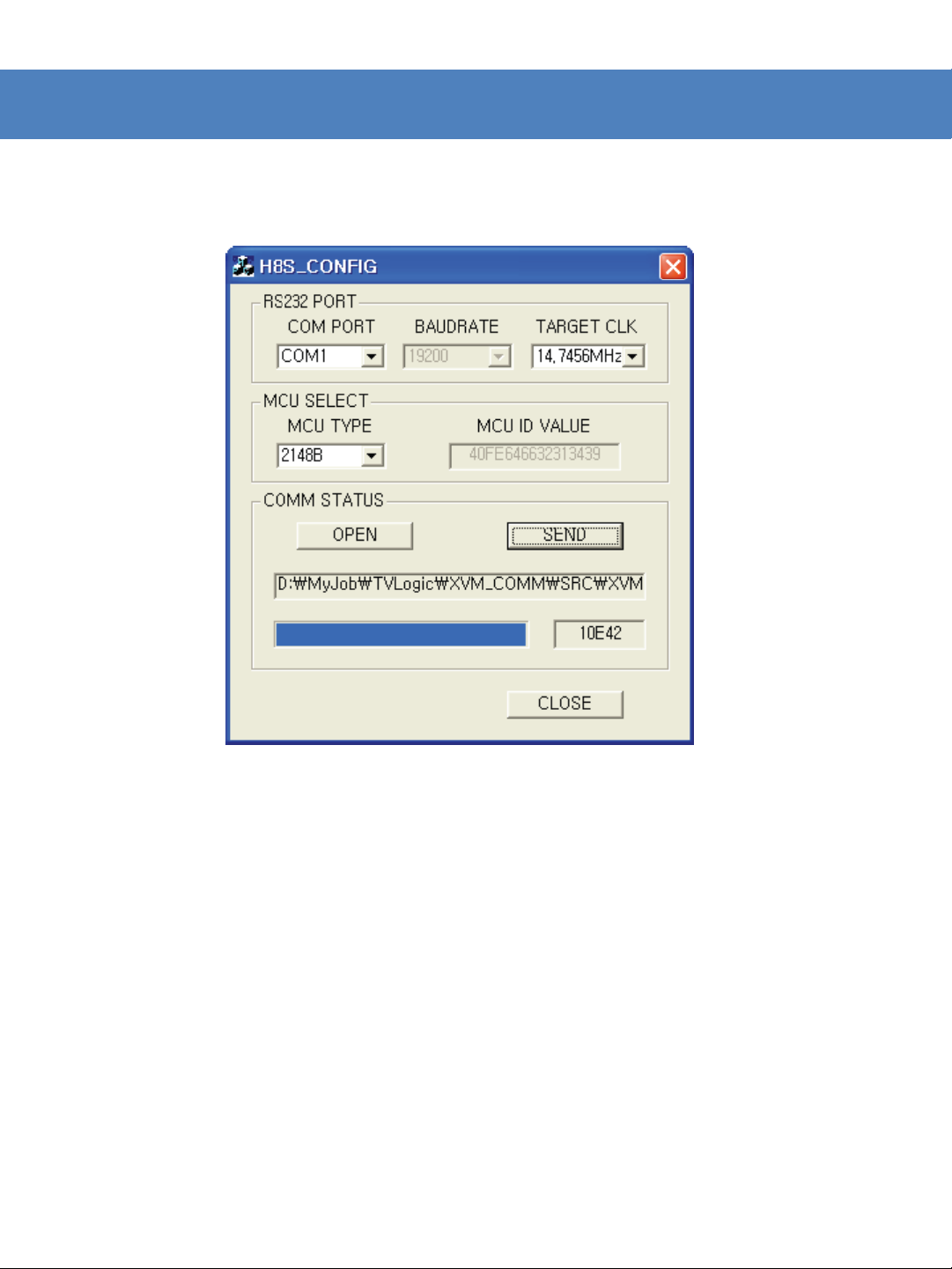

UPGRADE – ETHERNET BOARD

3) How to Upgrade ETHERNET BOARD

Picture 6 : ETHERNET BOARD Upgrade SW

- Connect the cable with serial port of PC and RS232 port of monitor. The

PC must have RS232 port and can not use the USB to RS232 converter. See

Picture 7 for the cable connection.

- Select COM PORT.

- Select “14.7456MHz” for TARGET CLK.

- Select “2148B” for MCU TYPE.

- OPEN and select the “*.mot” file. - Press the SEND button.

14

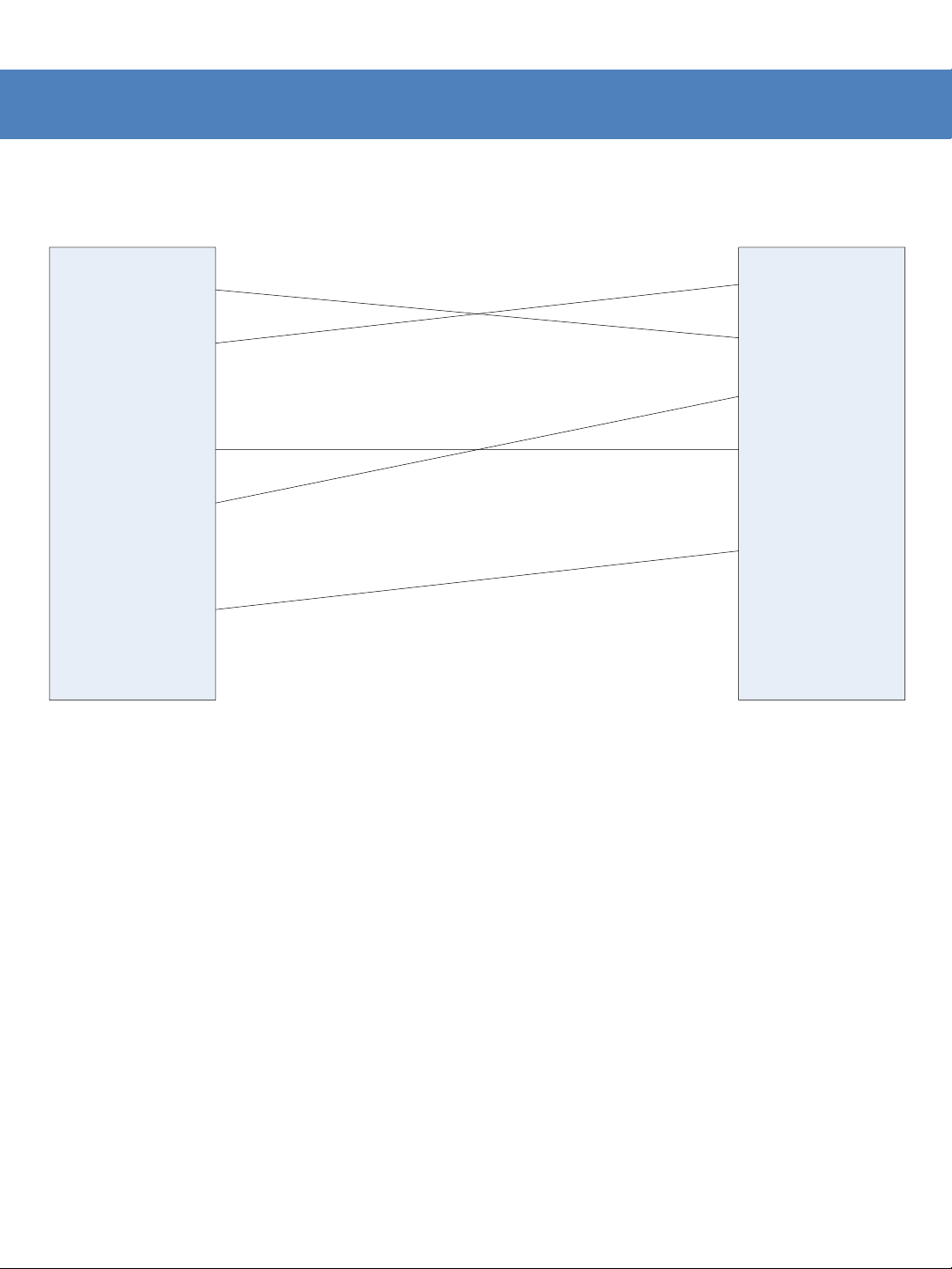

UPGRADE – ETHERNET BOARD

2 : RX

3 : TX

4 : DTR

5 : GND

6 : DSR

7 : RTS

8 : CTS

2 : RX

3 : TX

4 : DTR

5 : GND

6 : DSR

7 : RTS

8 : CTS

MONITOR

RS232

MALE

PC

RS232

MALE

9 : RI 9 : RI

Picture 7: Cable connection for ETHERNET BOARD upgrade

15

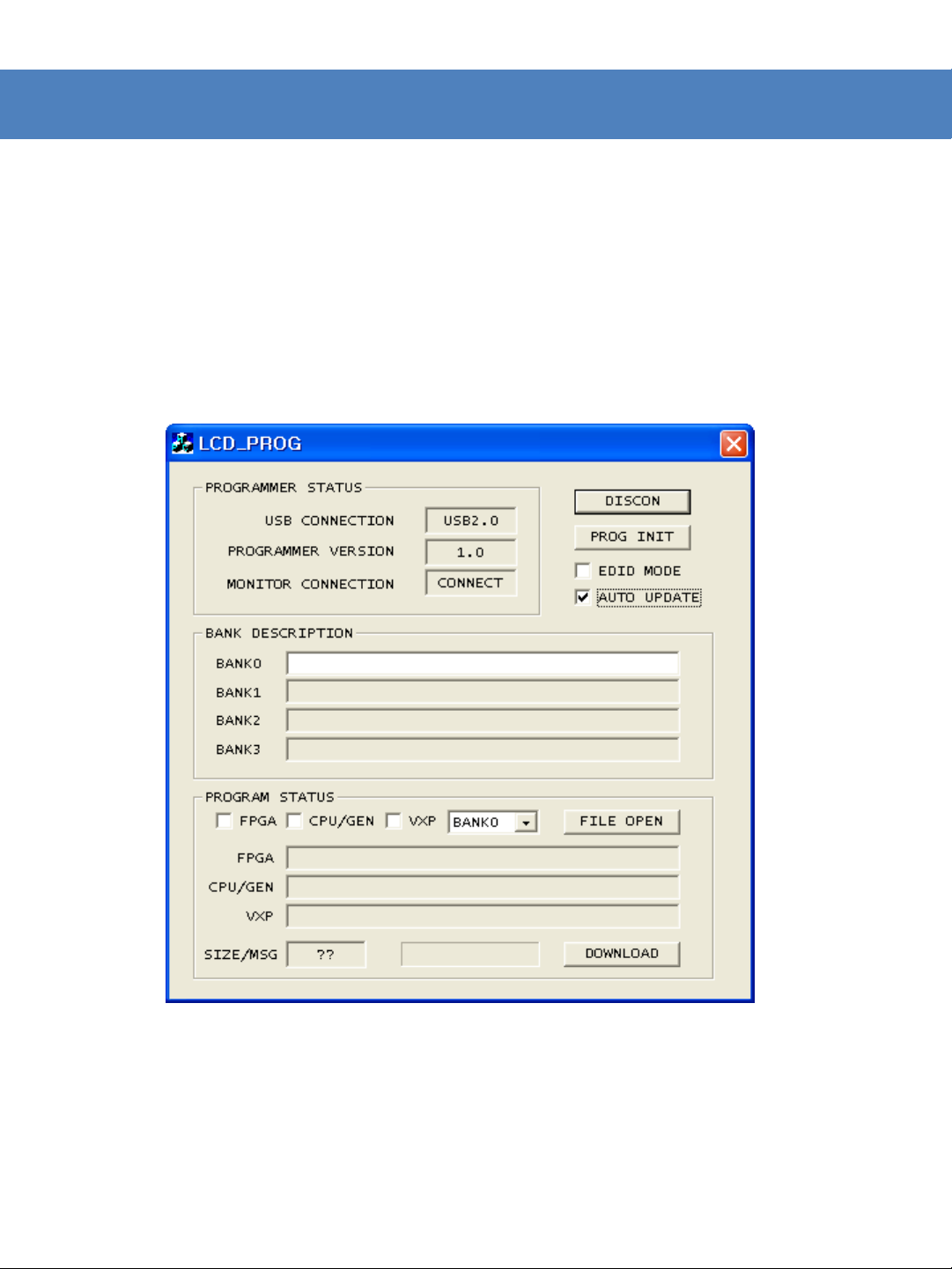

PROGRAM UPDATE - USB

1) Install the CyUSB driver on your PC.

2) Turn on the monitor after connecting the PC with monitor by USB Cable.

3) Upgrade program settings

- Run LCD_PROG.exe

- LCD_PROG.exe 실행

- Check the connection in PROGRAMMER STAUS.

- Select AUTO UPDATE from check box.

16

Loading...

Loading...