TVLOGIC LVM-173W-3G Schematic

MULTI FORMAT

BROADCAST MONITOR

SERVICE MANUAL

MODEL NAME:

LVM-173W-3G 17” MULTI FORMAT BROADCAST MONITOR

KEEP THIS SERVICE MANUAL FOR FUTURE REFERENCE.

PLEASE CALL 82-70-8668-6611 OR EMAIL TO support@tvlogic.co.kr FOR ASSISTANCES

IF YOU HAVE ANY QUESTION ABOUT LVM-173W-3G MODEL.

THIS INFORAMATION OF THIS MANUAL IS SUBJECT TO CHANGE WITHOUT ANY NOTICE.

ABOUT TVLOGIC SERVICE MANUAL:

TVLogic Service manual contains information and service procedures to

assist the service technician in understanding and correcting problem

about LVM-173W-3G model.

This information should be reviewed by a service personnel to provide a

basic understanding of how the components function in the working

system.

The troubleshooting section of this manual is intended to provide a

quick reference concerning issues that occur most frequently through

customer complaints.

We hope that technicians will repair LVM-173W-3G without any problem

through our service manual.

SERVICE PREPARATION:

A clean work area at the start of each job is essential for efficient service

work. Tools needed for the job should be ready for use before the work

is started.

2

1.SAFETY PRECAUTION

USE SET VOLTAGE.

USE SET VOLTAGE.

- AC 100 ~ 240V (1.2A / 50~60㎐)

- AC 100 ~ 240V (1.2A / 50~60Hz)

- DC 12 ~ 24V (MAX 6A)

- DC 12 ~ 24V (MAX 6A)

SAFETY PRECAUTION ABOUT PARTS

SAFETY PRECAUTION ABOUT PARTS

- Some parts of this product should be handled with

- Some parts of this product should be handled with

cauon. User can find these parts in a circuit diagram

cauon. User can find those parts in a circuit diagram

and part list.

and part list.

Do not use aachments not recommended by the

- Do not use aachments not recommended by the

manufacturer. Use of inadequate aachment can result

manufacturer. Use of inadequate aachment can

in accidents.

result in accidents.

- Drawing can’t be revised without TVLogic’s permission.

- Drawing can’t be revised without TVLogic’s permission.

SAFETY PRECAUTIONS ABOUT HANDING LCD MODULE

- Use the screw holes on the corner when installing the

- Use screw holes on the corner when installing the

LCD module.

LCD module.

- Do not push the panel or frame and do not cause an

- Do not push the panel or frame and do not cause an

electric shock to protect the product from damages.

electric shock to protect the product from damages.

- When handling the LCD module, put an wrist band

- When handling the LCD module, put a wrist band on to

to avoid the LCD module from stac electricity

avoid stac electricity with the LCD module which may

which may cause damages to the electric

cause damages to the electric components.

components.

- Do not leave the product in a hot or humid place for a

- Do not leave the product in a hot or humid place for

long me.

a long me.

- Keep the LCD module away from direct rays of sunlight.

- Keep the LCD module away from direct rays of the

Sun-light.

- Keep away the product from water because it’s the

reason for short circuit and reducing life span of electric

- Keep away the product from water because it’s the

components.

reason for short circuit and reducing lif

electric components.

- Use so cloths to wipe the surface of LCD module when

- Use so cloths to wipe the surface of LCD module

it gets dirty. Do not use coarse cloths which might cause

when it gets dirty. (Do not use coarse cloths which

damages to the LCD module.

might cause damages to the LCD module.)

- If the product is exposed to water, you must wipe the

-If the product is exposed to water, you must wipe

device with a dry cloth then dissemble the device to

the device with a dry cloth then dissemble the

dry.

device to dry.

e span of

SAFETY PRECAUTIONS ABOUT DISASSEMBLY

SAFETY PRECAUTIONS ABOUT DISASSEMBLY

- Please use soft cloths or cushioned sponge

- Please use so cloths or cushioned sponge when you

when you disassemble or assemble the

disassemble or assemble the products.

products.

- To separate the panel, release the screws on the four

- To separate the panel, release the screws

corners then slowly li up the panel while removing

on the four corners then slowly lift up the

the panel interface cable.

panel while removing the panel interface

- To separate the board, remove the cable from it first,

cable.

remove the bolt which is holding down the board then

- To separate the board, remove the cable

separate. Make sure the cable pin is firmly connected

from it first, remove the bolt which is

to the connector while doing it.

holding down the board then separate.

Make sure the cable pin is firmly connected

to the connector while doing it.

SAFETY PRECAUTIONS ABOUT ASSEMBLY

- Please set torque at 2K of electronic screw driver when

SAFETY PRECAUTIONS ABOUT ASSEMBLY

you assemble LCD panel and cases in order to avoid

damages of screw holes on the case. This might cause

- Please set torque at 2K of electronic screw

damage and require you to change the whole case if you

driver when you assemble LCD panel a

use over torque of electronic screw driver.

cases in order to avoid damages of screw

- The connector should be handled with cauon because

it is thin and weak. Wrong connecon causes malfuncon

holes of case. This might cause changing

of the board and the panel.

of whole case if you use over torque of

nd

electronic screw driver.

WARNING

- The connector should be handled with

BE CAREFUL OF THE ELECTRIC SHOCK!

caution because it is thin and weak. Wrong

connection causes malfunction of the

board and the panel.

- Make sure to disconnect the adapter from the AC power

when replacing CCFL or inverter circuit because high

WARNING

voltage of around 650 Vrms flows in the inverter circuit.

BE CAREFUL OF THE ELECTRIC SHOCK!

- Do not damage the cable covers in order to avoid

accidents such as a fire and an electric shock. All the

cables in inverter circuit must be handled with cauon.

- Make sure to disconnect the adapter from

the AC power when replacing CCFL or

inverter circuit because high voltage about

650Vrms flows in inverter circuit.

- Do not make the cover of cables damaged

in order to avoid accidents such as a fire

3

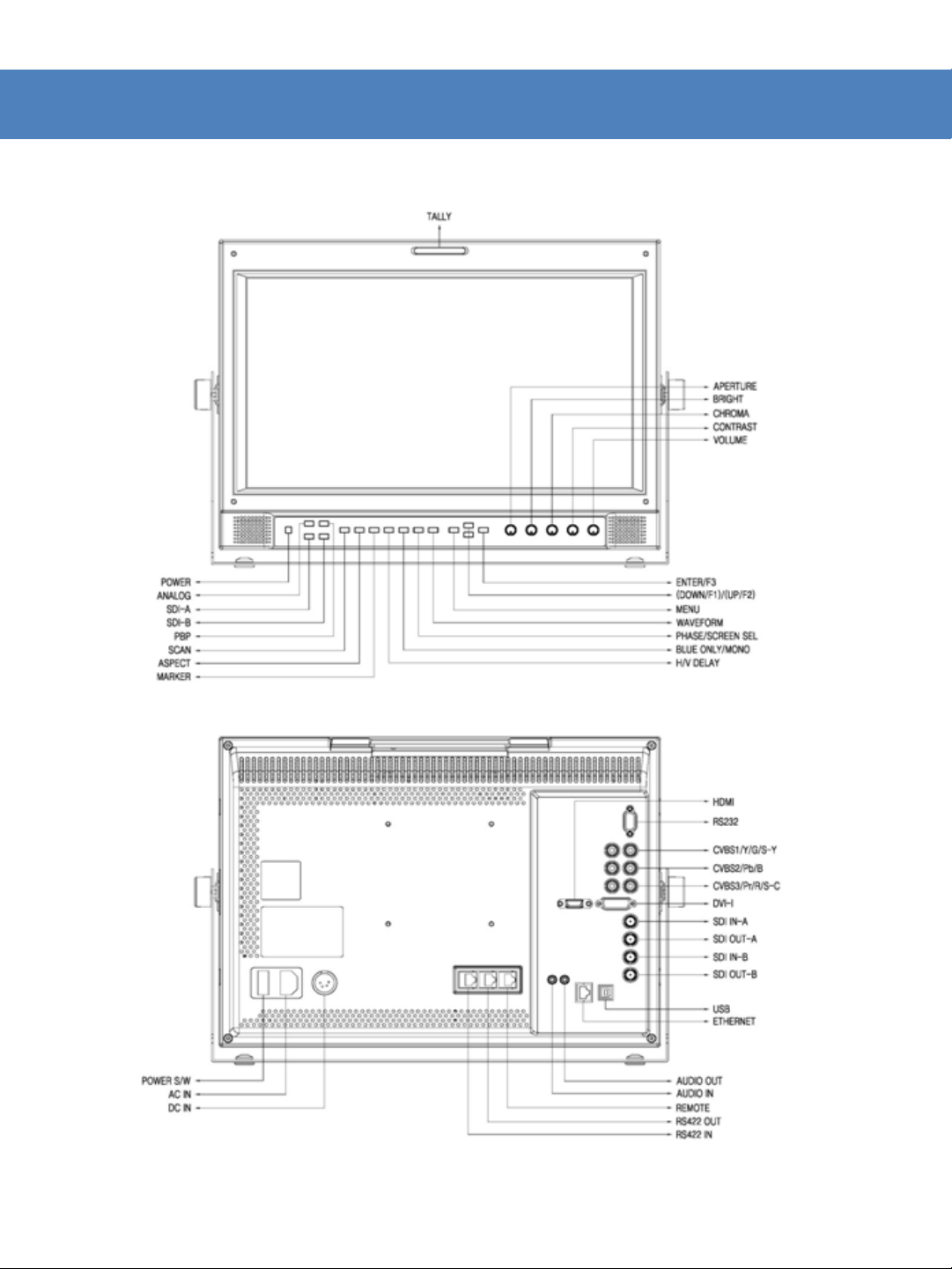

2.CONTROLS & FUNCTIONS

4

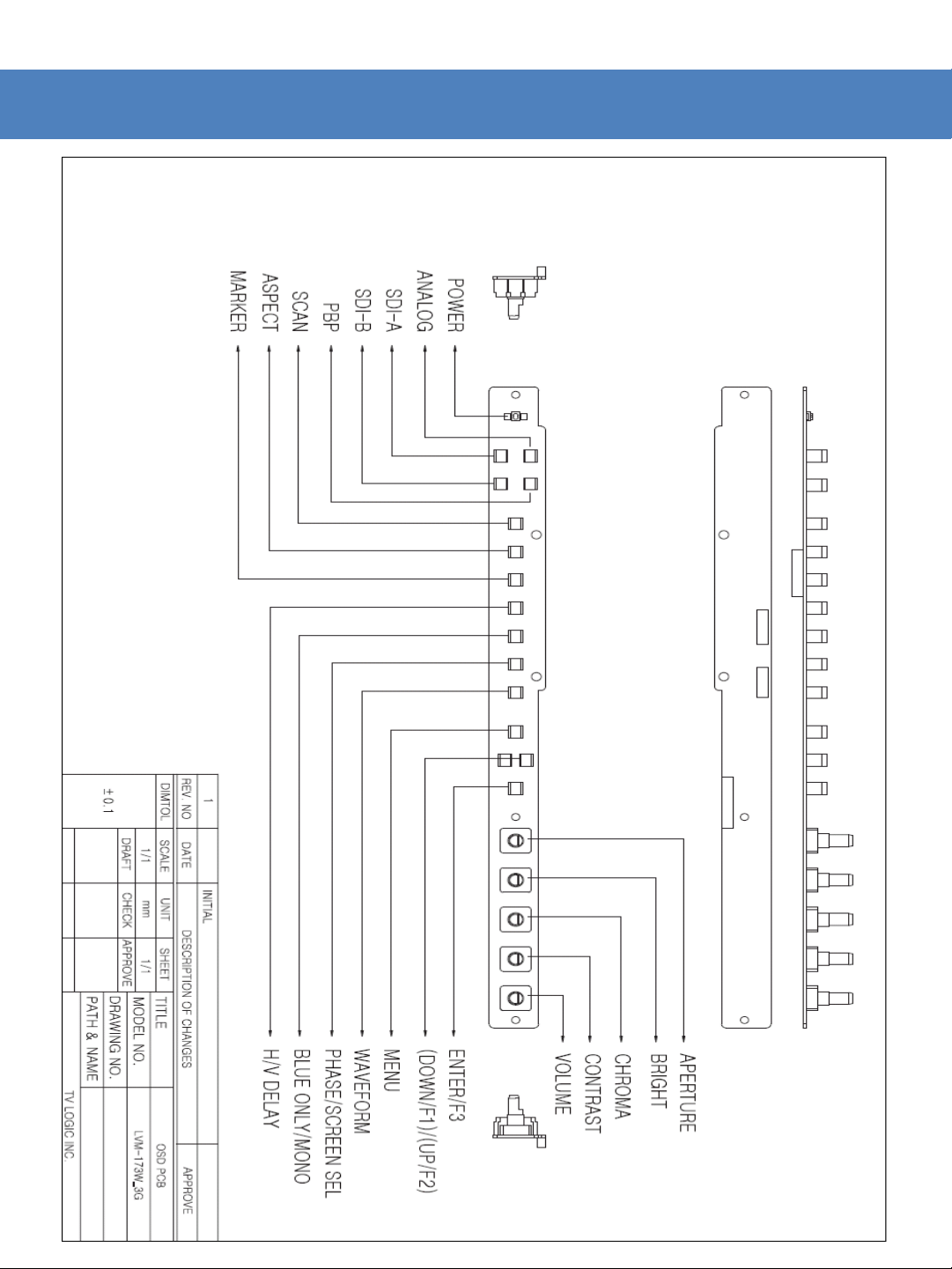

3.FRONT KEY BUTTON

5

5

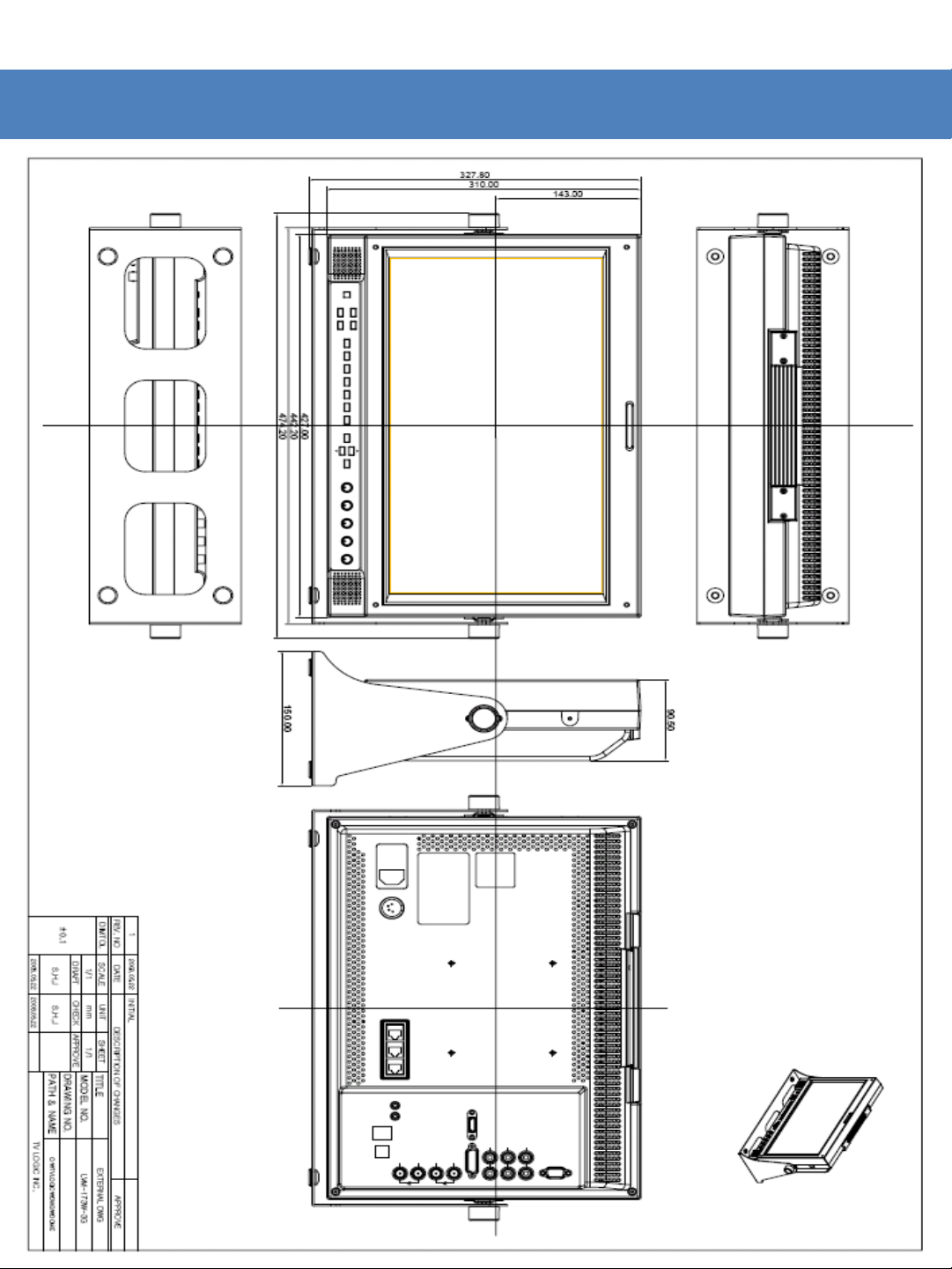

4.MONITOR DRAWING

6

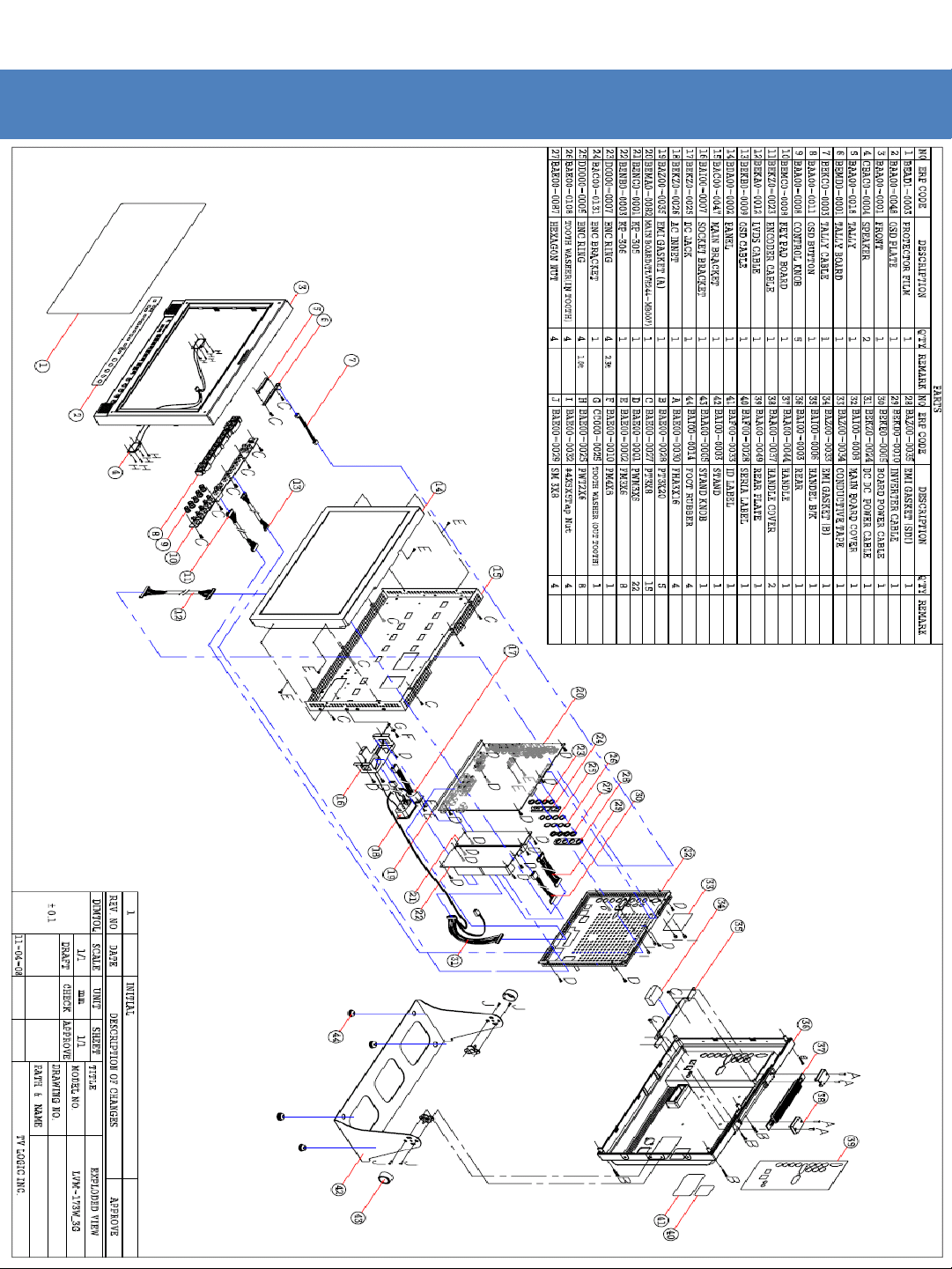

5.EXPLODED DIAGRAM

7

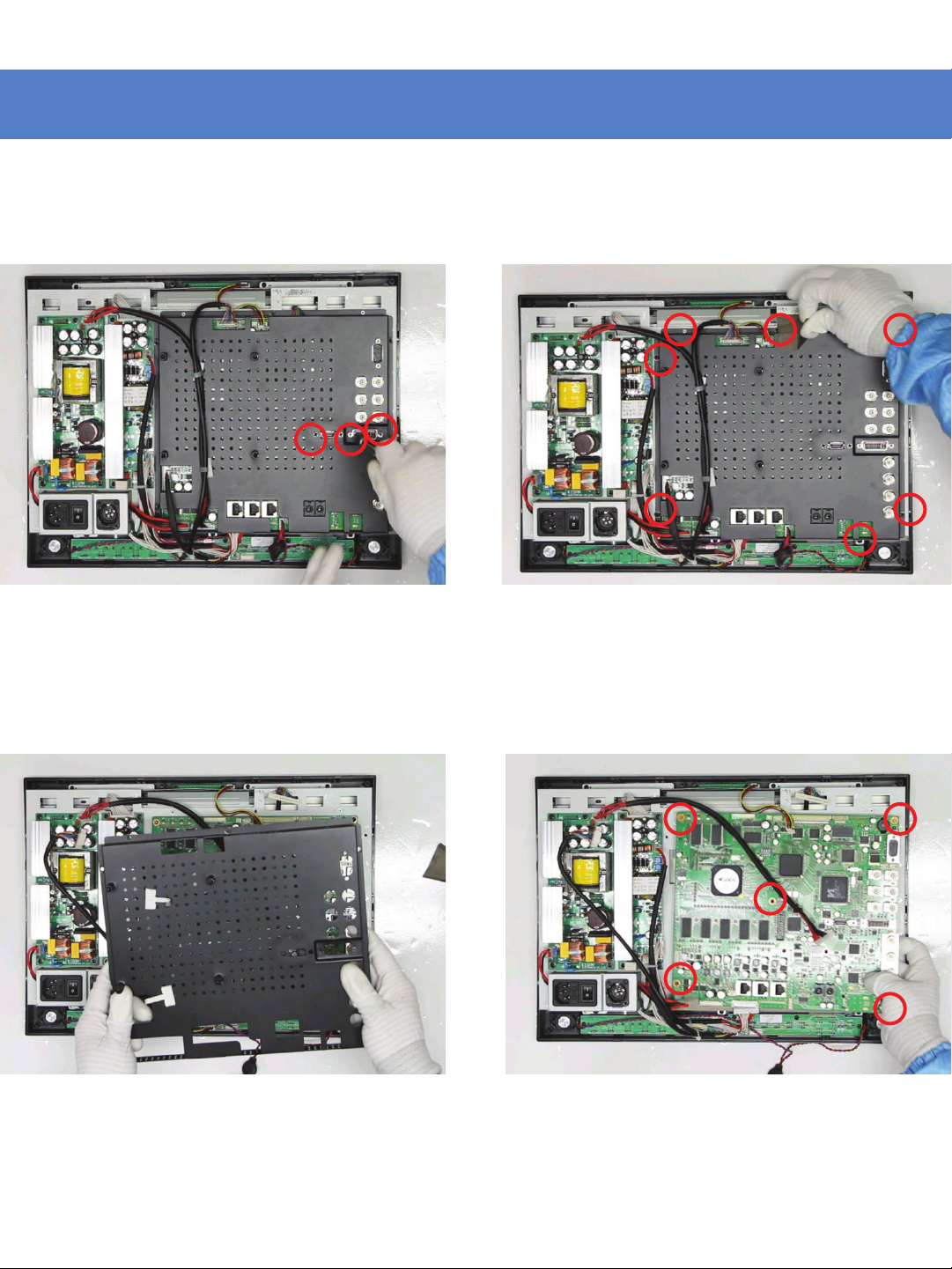

6.1 DISASSEMBLY PROCEDURE

1) Loosen and remove 2 stand knobs on

both sides of LVM-173W-3G.

3) Loosen and remove all the screws

around the rear and take the Rear panel

away from the product.

2) Release the screws. Then separate the

stand from the product.

4) Disconnect all the cables around

the main board cover.

8

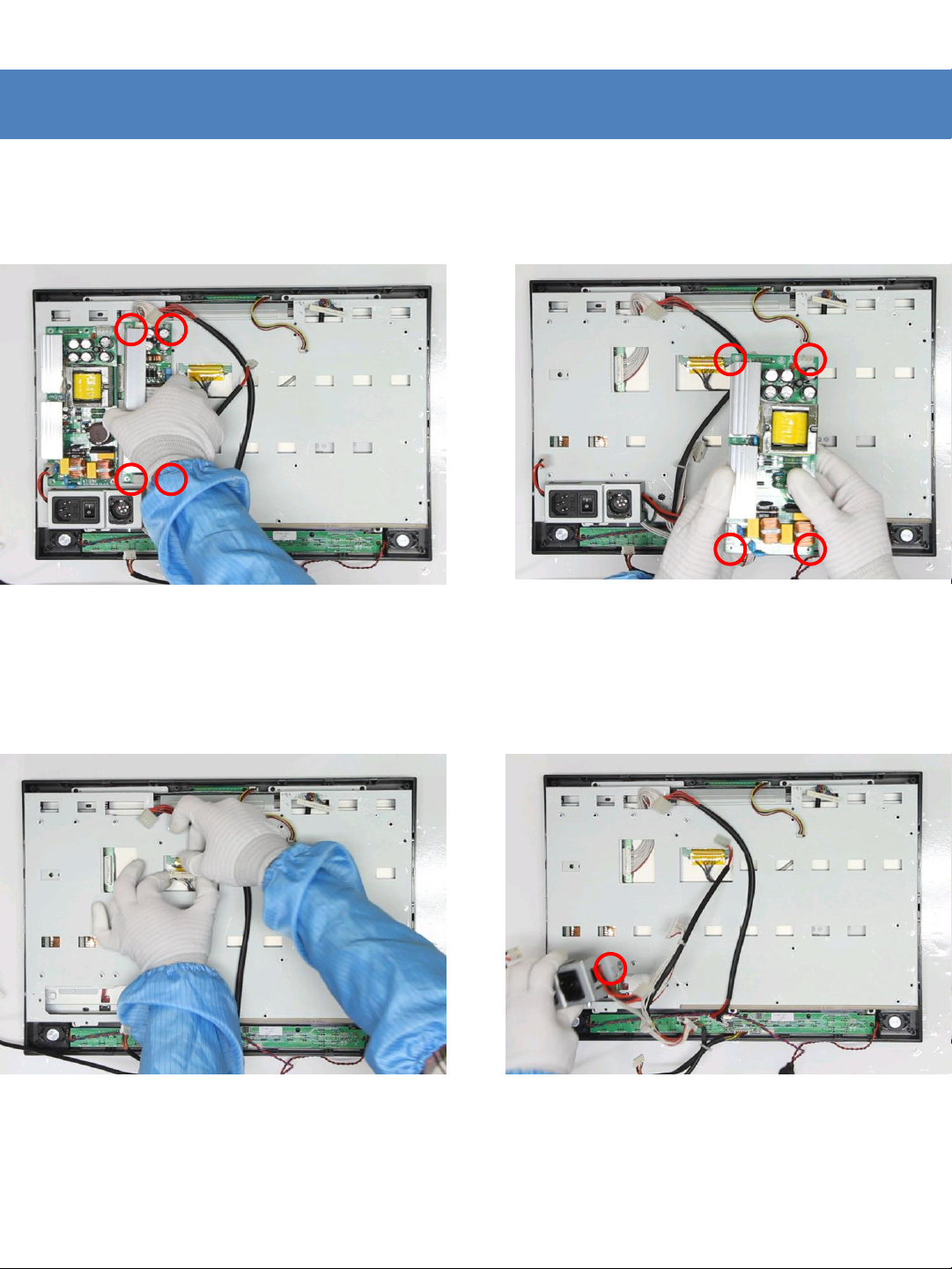

6.2 DISASSEMBLY PROCEDURE

5) Release all the screws on the main board

Cover DVI and HDMI.

7) Take the main board cover away from

the product.

6) Remove all the screws on the main

board cover.

8) Loosen and remove all the screws

attached to the main board and

dismount it.

9

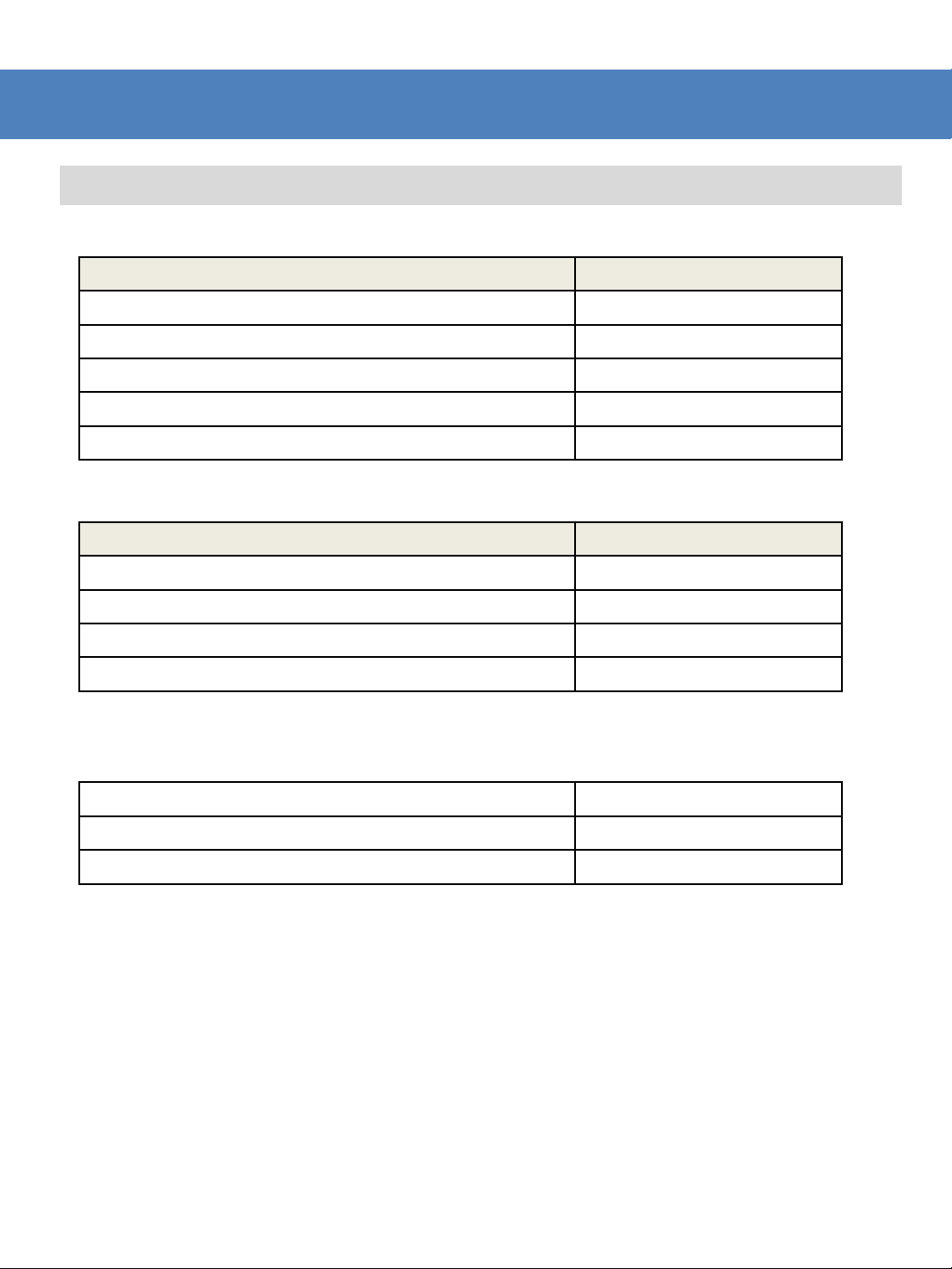

6.3 DISASSEMBLY PROCEDURE

9) Remove all the screws attached to the

KP-305 and pull up the KP-305.

11) Disconnect the LVDS Cable.

10) Remove all the screws attached to the

KP-306 and pull up the KP-306.

12) Release screws on the socket bracket

and dismount it.

10

6.4 DISASSEMBLY PROCEDURE

13) Loosen and remove all the screws on

the Front and dismount the key Pad

board.

15) Separate the Front from the main

bracket.

14) Loosen and remove screws on the speaker

and dismount the speaker.

16) Remove all the screws on the side

of the panel and main bracket, then

separate them.

11

6.5 DIASSEMBLY PROCEDURE

17) Separate the tally board from the

front.

19) Front

18) Separate the tally from the front.

20) Rear

12

Other Functions

7. DVI ANALOG/ DVI DIGITAL / HDMI RESOLUTION

DVI ANALOG/DVI DIGITAL/HDMI Support Resolution(LVM-173W-3G)

• DVI-ANALOG mode supports the following modes :

Resolution Frequency

640 × 480 60Hz, 75Hz

720 x 400 70Hz

800 × 600 60Hz, 72Hz, 75Hz

1024 × 768 60Hz, 70Hz, 75Hz

1366 x 768 60Hz/75Hz

• DVI DIGITAL/HDMI Graphic mode supports the following modes

• DVI DIGITAL/HDMI Video mode support the following input signals :

• DVI DIGITAL mode is separated into Graphic mode and Video mode.

• In DVI ANALOG/DIGITAL mode, ZERO scan must be selected for normal function.

• If the input image is in non-wide mode, press ASPECT button to change to wide display.

Resolution Frequency

640 × 480 60Hz, 75Hz

800 × 600 60Hz, 72Hz, 75Hz

1024 × 768 60Hz, 70Hz, 75Hz

1366 x 768 60Hz/75Hz

SMPTE-274M 1080i (60 / 59.94)

SMPTE-296M 720p (60 / 59.94)

SMPTE-125M 480i (59.94), 480p(59.94)

13

8.PRODUCT SPECIFICATIONS

LVM-173W-3G

1 x DVI-I DVI-I(RGB) IN

Input

Output

Input Signal

Analog Input Spec

SDI Input Signal Formats

Audio In Embedded Audio / Analog Stereo (Phone Jack)

Audio Out Analog Stereo (Phone Jack). Internal Speaker(Stereo)

LCD

Power DC 12V/24V/AC100~240V(1.8A/50~60Hz)

Power Consumption (Approx.) 60 Watts(Max)

Operating Temperature 0°C to 40°C (32°F to 104°F)

Storage Temperature -20°C to 60°C (- 4°F to 140°F)

Main Body Dimensions (mm/inch) 427 x 310 x 90.5 (16.8 x 12.2 x 3.5)

Main Body Dimensions (With Stand) 474 x 327 x 150 (18.6 x 12.8 x 5.9)

Weight 7.1Kg / 15.65 lb

Accessory AC Power cord, Manual

Option Carrying case, V-Mount, Hood, 19” Rack Mountable Kit(7U), ND Filter, Sun-Hood

3 x BNC Analog Input

2 x BNC SDI A/B Channel Input

1 x HDMI HDMI Input

3 x BNC Analog Output

2 x BNC SDI A/B Channel (Loop Through Out)

Analog Composite / S-Video / Component / RGB

HD-SDI 1.485Gbps

SD-SDI 270Mbps

DVI VESA/IBM Modes

HDMI 480i/480p/720p/1080i & VESA/IBM Modes

Composite 1.0Vpp (With Sync)

S-Video 1.0Vpp (Y With Sync), 0.286Vpp(C)

Component 1.0Vpp (Y With Sync), 0.7Vpp (Pb,Pr)

RGB 1.0Vpp (G With Sync), 0.7Vpp (B,R)

SMPTE-425M-A/B

SMPTE-372M

SMPTE-274M

SMPTE-296M 720p (60/59.94/50)

SMPTE-260M 1035i (60/59.94)

SMPTE-125M 480i (59.94)

ITU-R BT.656 576i (50)

2K Format 2048 x 1080(23.98p/psf, 24p/psf)

Size 16.84”

Resolution 1366 x 768 (16:9)

Pixel Pitch 0.273(H) x 0.273(W) mm

Color 16.7M(true 8bit)

Viewing Angle H : 178 degrees / V : 178 degrees

Luminance of white 350 cd/㎡(Center)

Contrast 900:1

Display Area 372.9(H) x 209.6(V) mm

1080p (60/59.94/50/30/29.97/25/24/23.98/30sF/29.97sF/25sF/24sF/23.98sF)

1080i (60/59.94/50)

Dual HD-SDI YPbPr (4:2:2) 1080p (50 / 59.94 / 60)

Dual HD-SDI YPbPr/RGB (4:4:4)

1080i (60/59.94/50)

1080p (30/29.97/25/24/24sF/23.98/23.98sF)

1080i (50 / 59.94 / 60)

1080p/psf (30 / 29.97 / 25 / 24 / 23.98)

* Above specifications may be changed without notice

14

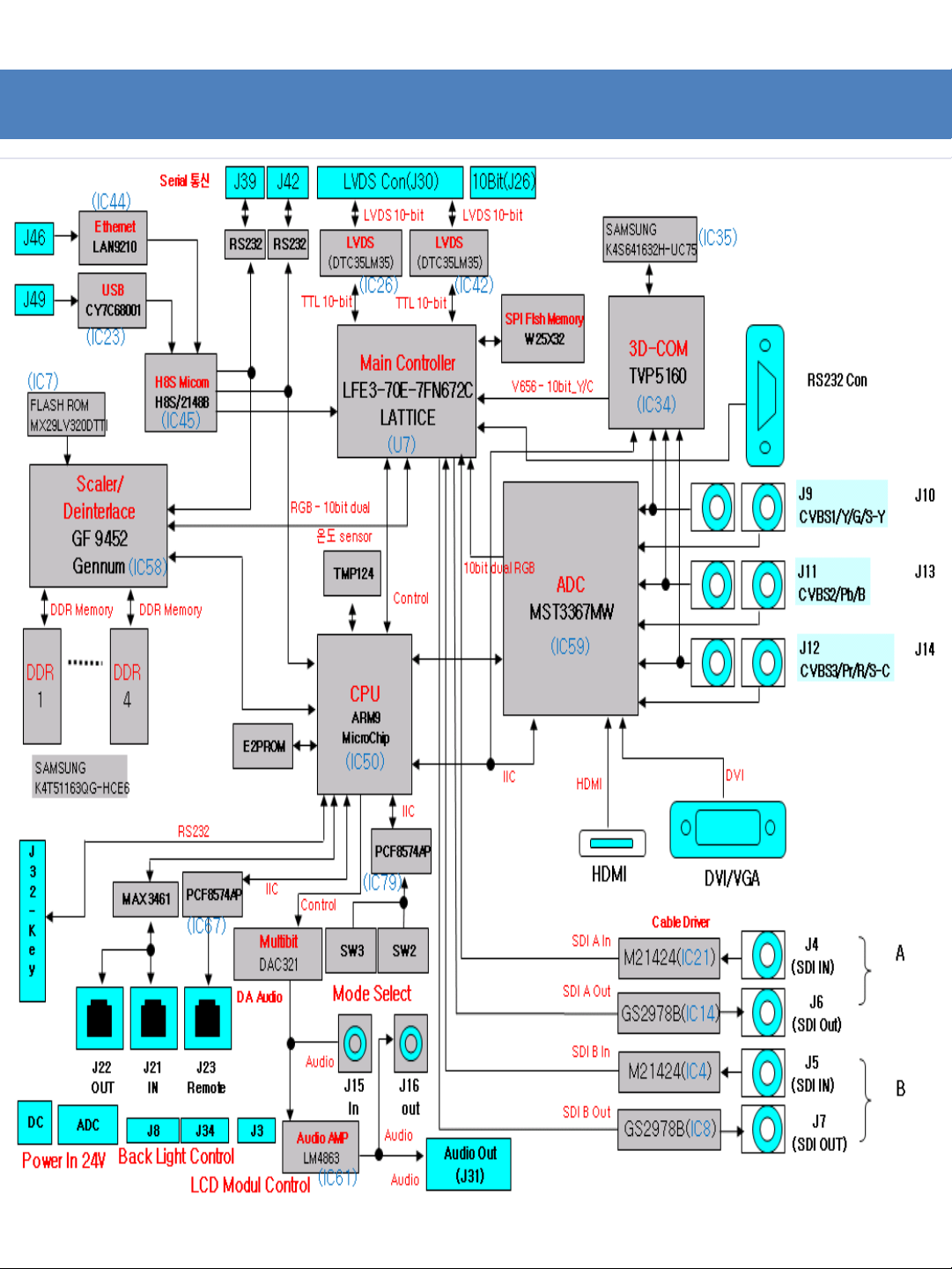

9. PCB BLOCK DIAGRAM

15

10. CIRCUIT OPERATION

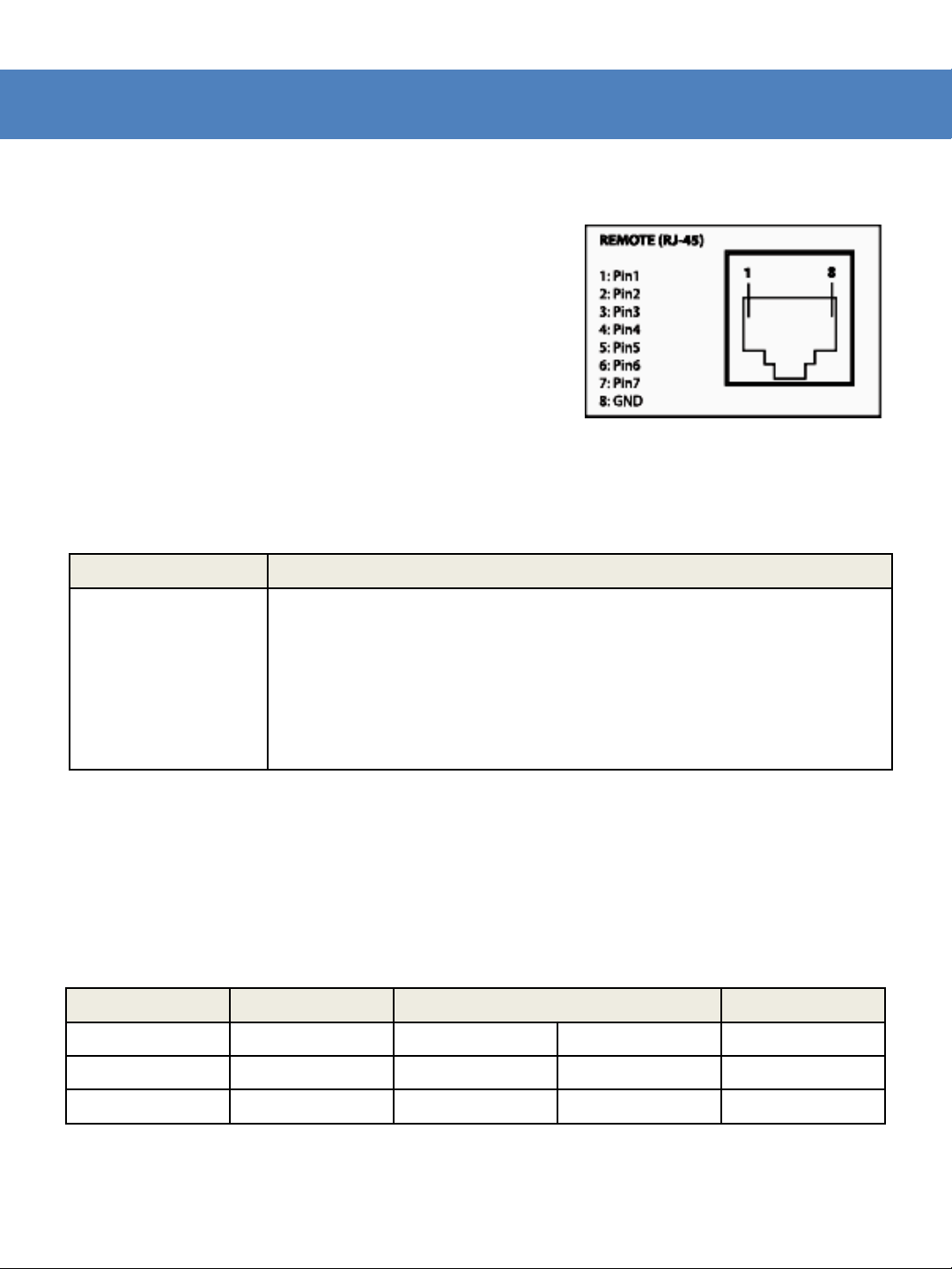

<GPI Remote>

- The location of each pin is shown on the right picture.

- The selectable functions are as follows

Menu Classification Settable Values

NONE, ANALOG CHANNEL, DIGITAL A CHANNEL, DIGITAL B CHANNEL,

PBP CHANNEL, TALLY R, TALLY G, TALLY Y, UNDER SCAN, 1:1 SCAN,

ASPECT, H/V DELAY, BLUE ONLY, MONO, 16:9 MARKER, 4:3 MARKER,

PIN 1~6

4:3 ON AIR MARKER, 15:9 MARKER, 14:9 MARKER, 13:9 MARKER,

1.85:1 MARKER, 2.35:1 MARKER, 1.85:1&4:3 MARKER, CENTER MARKER,

SAFETY AREA 80%, SAFETY AREA 85%, SAFETY AREA 88%,

SAFETY AREA 90%, SAFETY AREA 93%, SAFETY AREA 100%, 708,

608(LINE 21), 608(ANC), DYNAMIC-UMD

<LVM-173W-3G>

- PIN 7 is POWER ON/OFF use only, PIN 8 is GND.

< Video Input >

- Video input connection method

Connector Composite Component S-Video

1 CVBS 1 Y G Y

2 CVBS 2 Pb B No Con.

3 CVBS 3 Pr R C

16

11. PROGRAM UPDATE – WEBHARD

TVLOGIC WEBHARD INFORMATION

If you need to upgrade to a new firmware with TVLogic monitors,

please visit the TVLogic webhard at h

p://tvlogic.webhard.co.kr/english

ID: dealer

Password: XXXXXXXXX

Please request the password from TVLogic overseas sales team.

the password may be changed without any n

e.

17

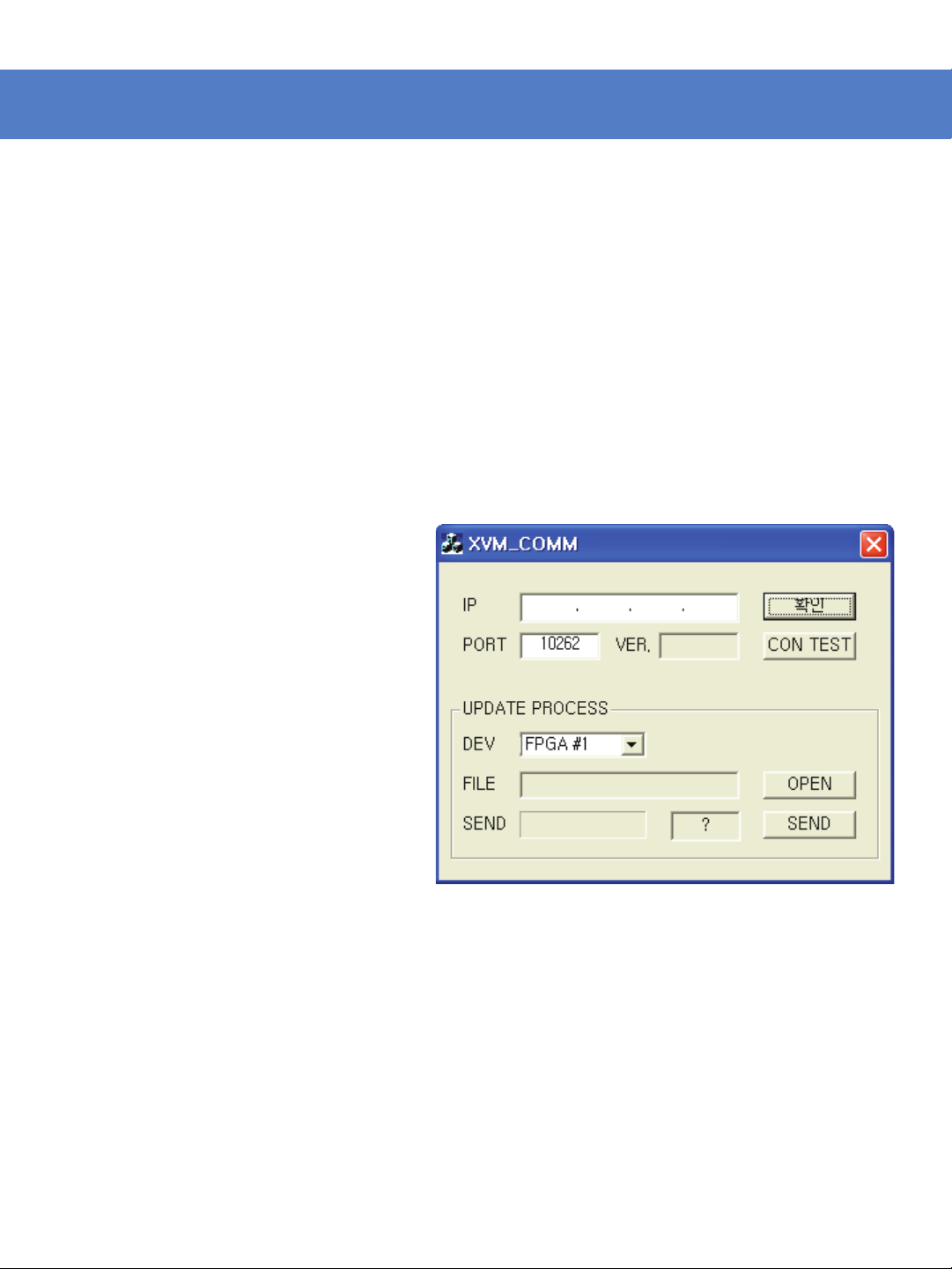

12.1 PROGRAM UPDATE WITH ETHERNET

1) Monitor Sengs

- In the OSD Menu -> REMOTE -> Enter IP Address, Subnet Mask, Gateway value.

* Changing the PORT NO. is not recommended.

* Enter the IP Address of the connected internet with monitor.

* PASSWORD feature is available with Ver. 1.0 and above.

- Leave the monitor on.

2) Upgrade program sengs

- Run XVM_COMM.exe

Picture 1 : Monitor upgrade SW=>

- Enter the same IP address as entered for the monitor. (See Picture 2)

* Changing the PORT NO. is not recommended.

- When the “CON TEST“ buon is pressed, Version number will appear in the

Ver. Box if connected properly. If not, “??” will appear in the box.

- If “??” appears, check the IP address for the monitor and program, then

try again.

18

Loading...

Loading...