Page 1

Arraying and Rigging

TCS series

TCS Arraying and Rigging

This document explains how TCS loudspeakers can be arrayed and the reasons for the rotatable

horns in some models. The TCS-122 and TCS-152 both feature Turbosound’s unique Dendritic high

frequency waveguide. This can be rotated for two reasons:

1. To allow a single speaker to be mounted horizontally but still retain the wider horizontal

pattern, or

2. To allow two or more speakers of the same to be arrayed with minimal interference

The second application is explained here in detail.

One of the benefits of the Dendritic waveguide is its exceptional coverage pattern and sharp edge-ofpattern cut-off as demonstrated in Flex Array. The sharp cut-off works either vertically or horizontally,

depending on which way the horn is rotated.

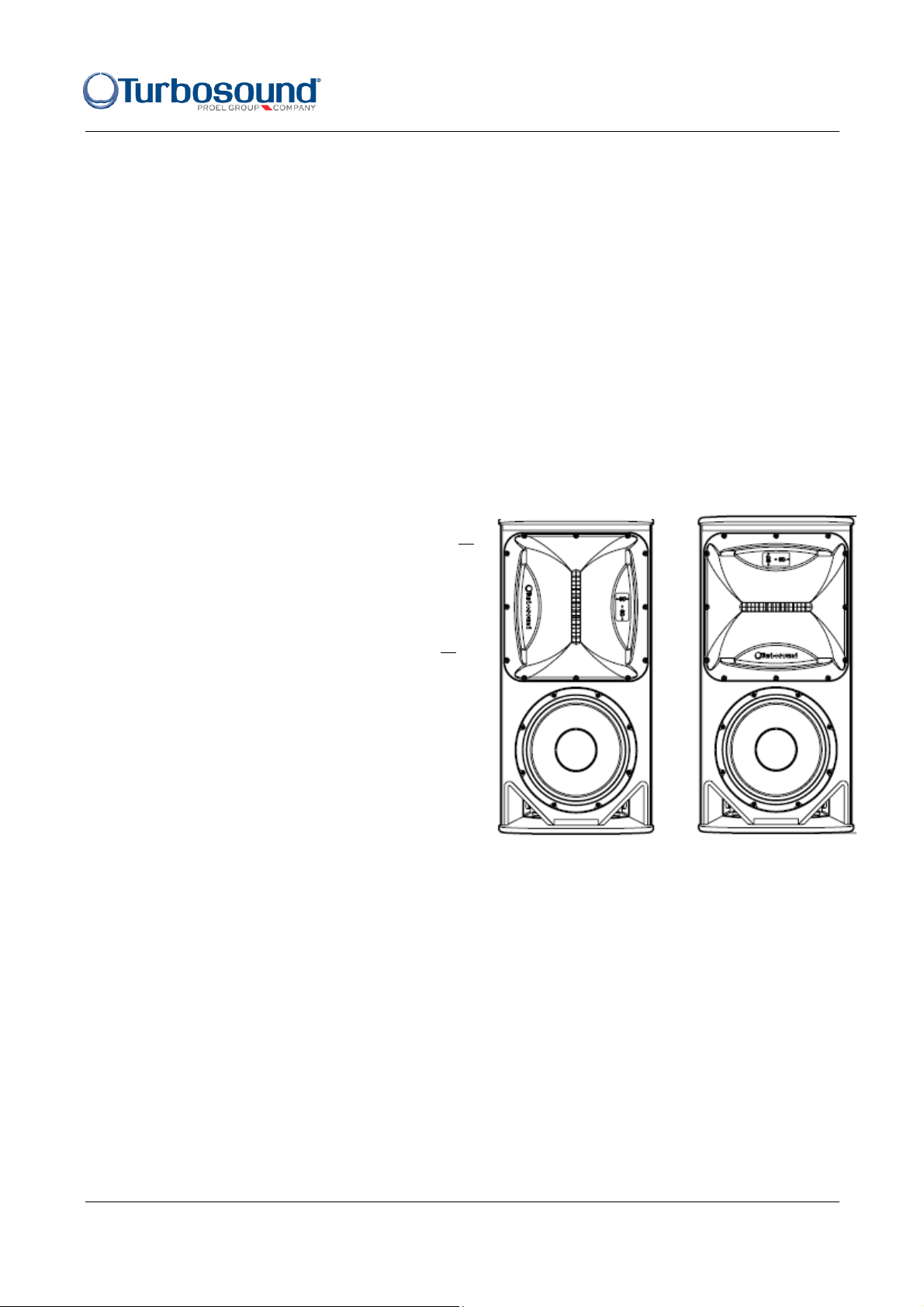

To explain this further, the TCS-122 and TCS-152

feature exceptional pattern control either left/right or

up/down depending on how the horn is rotated. This

allows them to be arrayed with adjacent speakers

without lobes or destructive interference. So the true

arrayable benefit of the Dendritic is

plane of the Dendritic device

up/down depending on orientation. The other plane

of the Dendritic device functions in a similar way to a

standard horn.

i.e. either left/right or

in the physical

The diagram here shows a TCS-122 with the horn in

two possible orientations. The one on the left is the

typical orientation, so for example the TCS-122/94

model has a dispersion pattern of 90 degrees wide

by 40 degrees in the vertical. The box on the right

shows the box with the horn rotated to give 40

degrees in the horizontal and 90 degrees in the vertical.

So the speaker on the left has a very controlled vertical pattern, whereas the one on the right (the

same speaker with the HF horn rotated) has a very controlled horizontal pattern.

The TCS-122 and TCS-152 are both available with three dispersion options: 60° x 40°, 90° x 60° and

60° x 40°. However note that only the 40 degree boxes benefit from being tightly arrayed, i.e with the

sides touching. So in a cluster of two or three tight packed boxes, you should use either the 60° x 40°

or 90° x 40° models and the horns should be orientated to give 40° dispersion in the horizontal plane.

The TCS-122 and TCS-152 are double trapezoidal boxes and it is this feature, in combination with the

rotatable horns that gives you the flexibility to build so many cluster options. The simple rule is that

the side that is touching the adjacent speaker needs to be orientated to 40 degrees.

The following options only apply to TCS-122 and TCS-152 models with Dendritic horns. The TCS-1561

and TCS-61 use conventional horns.

TCS series Arraying and Rigging - Page 1

Page 2

Arraying and Rigging

TCS series

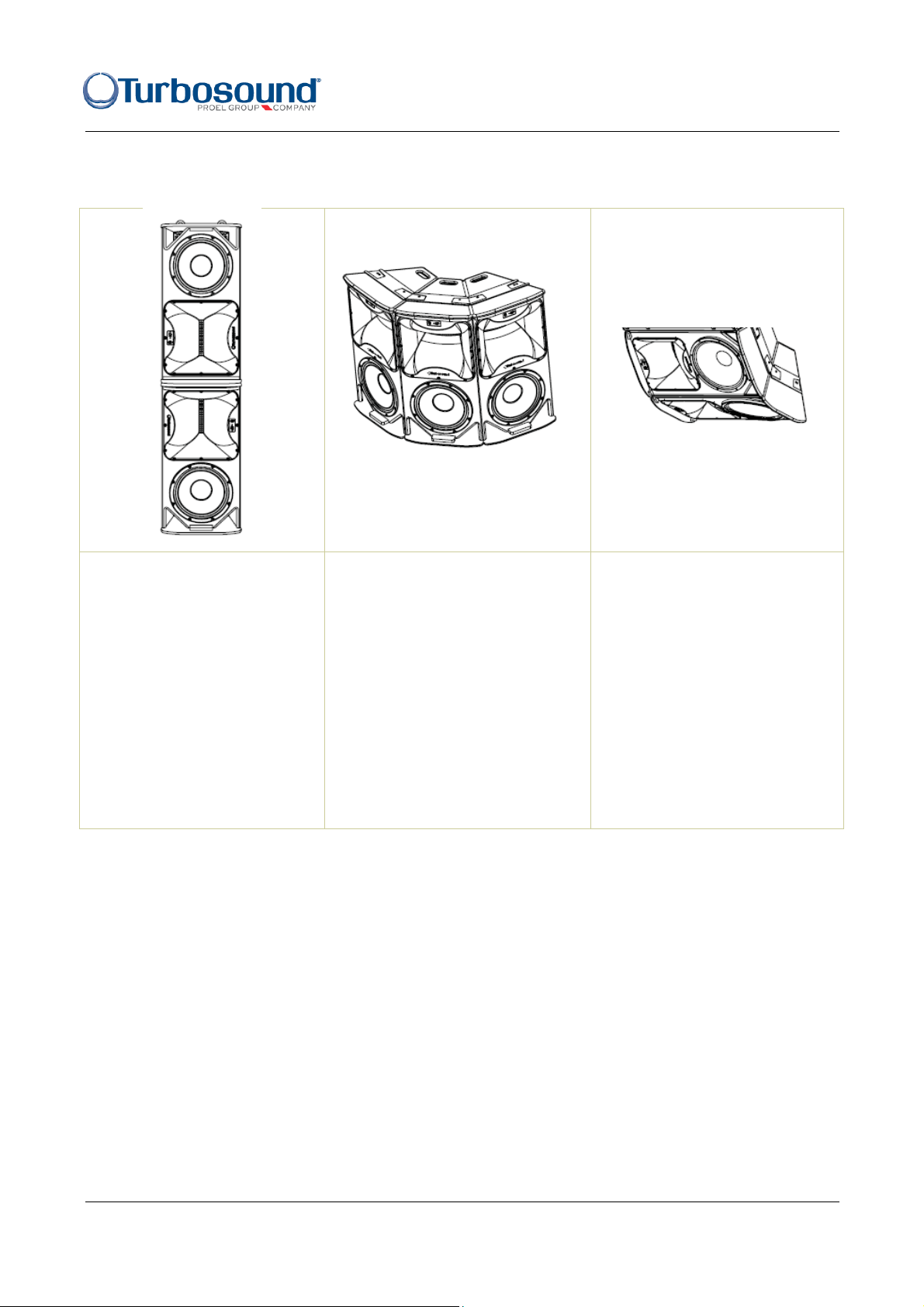

In this example the TCS-122/94

loudspeakers with horns in the

standard 90° x 40° orientation

are tight packed vertically

horn-to-horn, providing a

combined coverage of 90°

horizontal by approximately

80° vertical, with a useful

vertical beam and a mid-range

lobe that projects well down a

longer, thinner room.

These examples are based on the 90° x40° model. If using the 60° x40° models, a further three

coverage pattern options of 60° x 80°, 120° x 60°, and 60° x 80° would be available to you, depending

on the shape of the room.

The HF horns in this horizontal

array of TCS-122/94 boxes have

been rotated to give individually

40° horizontal by 90° vertical. The

horizontal coverage patterns add

up to give combined dispersion

of 120° horizontal by 90° vertical.

This example shows how the

same coverage pattern as the

vertical array on the far left can

result from a completely

different physical array. The HF

horns are rotated to give 40°h x

90°v and then the whole array

is assembled horizontally to

give combined coverage of 90°

horizontal by 80° vertical.

Rigging options

All of the TCS boxes have rigging points on the top, bottom and both sides, so they can be mounted

practically any way you like. For example, one option is to mount a single TCS-122 upside down to

get the HF waveguide closer to the audience.

Flying single boxes

This can be simply achieved with M10 eyebolts, WB-20 and WB-55 wall brackets, CB-55 ceiling

brackets, and OmniMount™ speaker brackets, for which bolt patterns are provided on the back of the

TCS series Arraying and Rigging - Page 2

Page 3

Arraying and Rigging

TCS series

cabinets where appropriate.

Flying multiple cabinets

When creating loudspeaker arrays the essential components are a pair of steel flyplates fitted to the

sides of each flown cabinet, ensuring that all the rigging is steel-to-steel without any load being taken

through the cabinets’ woodwork. Sets of joiners mate with the flyplates to connect one cabinet to the

next adjacent cabinet.

Following is a summary of the kits required and their component parts.

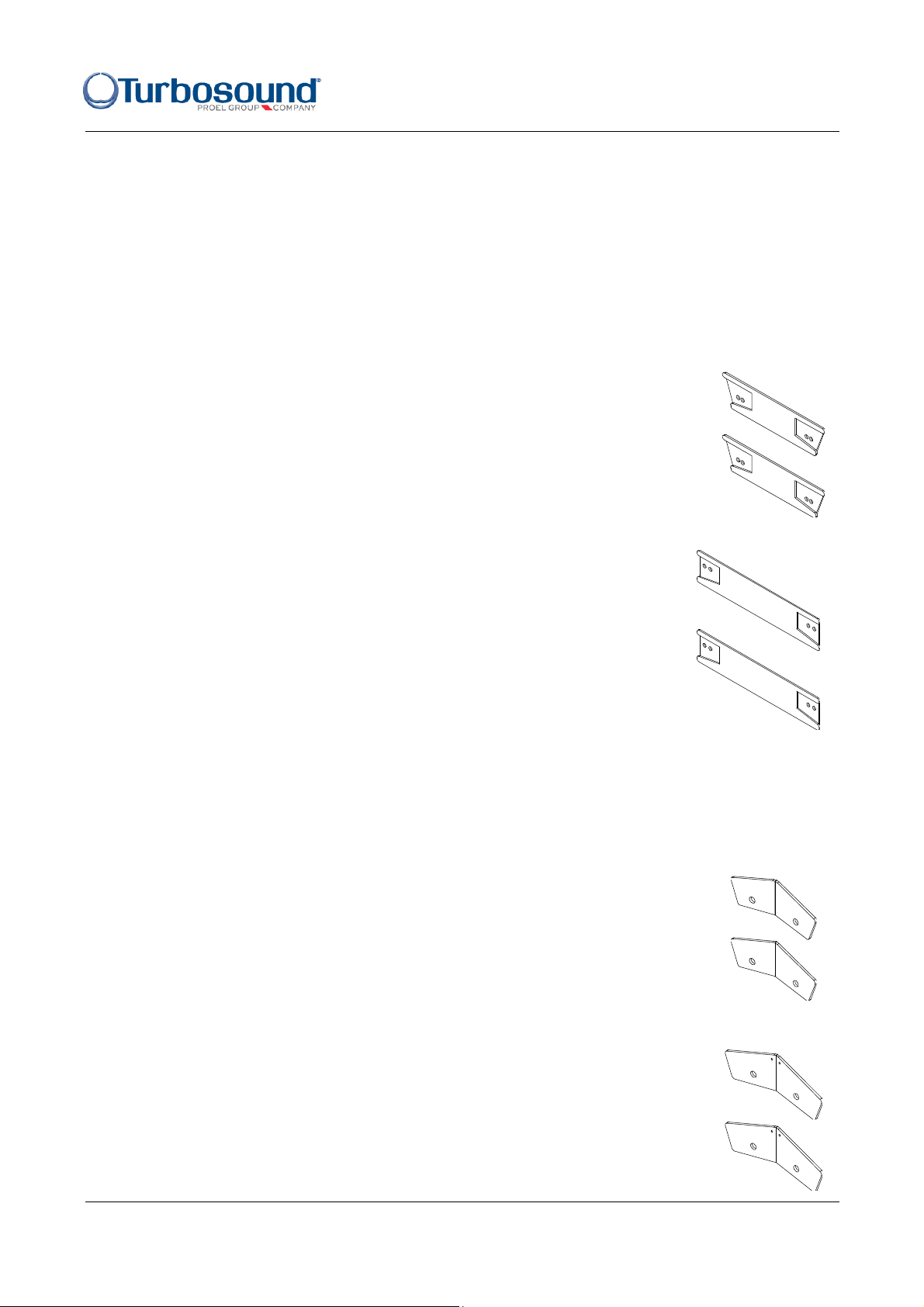

FP-1 KIT 07G0335

Consists of a pair or steel flyplates that fit both the TCS-122 and TCS-152 cabinets.

1 x FP-1 kit is required for each cabinet that is to be arrayed.

The FP-1 kit includes two flyplates, four M10 x 40mm bolts and four M10 spring

washers.

FP-2 KIT 07G0340

Consists of a pair of steel flyplates for the flyable TCS-B15A and TCS-B15B

subs. 1 x FP-2 kit is required for each sub cabinet. The TCS-B15A is

dimensioned to fly with the TCS-122, while the TCS-B15B is dimensioned to fly

with the TCS-152.

The FP-2 kit includes two plates, four M10 x 40mm bolts and four M10 spring

washers.

With the flyplates installed on each box to be flown, now select the appropriate inter-cabinet couplers

to connect the flyplates from one box to the flyplates of another.

ICC-2H KIT 07G0345

A pair of steel inter-cabinet couplers for linking two TCS-122 cabinets together.

The couplers fit into the recesses provided in the flyplates and are secured using

the M10 bolts and washers that are supplied with the FP-1 flyplate kits.

ICC-3H KIT 07G0350

A pair of steel inter-cabinet couplers for linking two TCS-152 cabinets together.

The couplers fit into the recesses provided in the flyplates and are secured using

the M10 bolts and washers that are supplied with the FP-1 flyplate kits.

TCS series Arraying and Rigging - Page 3

Page 4

Arraying and Rigging

ICC-4H KIT 07G0355

A pair of steel inter-cabinet couplers for linking two TCS-B15 subs together.

These can be either TCS-B15A or TCS-B15B versions, but in a cluster both subs

should the same type. The couplers fit into the recesses in the flyplates and are

secured using the M10 bolts and washers that are supplied with the FP-2

flyplate kits.

TCS series

ICC-5H 07G0360

A pair of steel inter-cabinet couplers for linking a TCS-152 cabinet to a TCSB15B sub. Each box needs their respective FP-1 and FP-2 flyplate kits of course.

The couplers are handed i.e. there are left and right versions. The couplers fit

into the recesses in the flyplates and are secured with the M10 bolts and

washers that are supplied with the FP flyplate kits.

ICC-6H 07G0365

A pair of steel inter-cabinet couplers for linking a TCS-122 cabinet to a TCS-B15A

sub. Each box needs their respective FP-1 and FP-2 flyplate kits of course. As with

the ICC-5H kit, the couplers are handed left and right. The couplers fit into the

recesses in the flyplates and are secured with the M10 bolts and washers that are

supplied with the flyplate kits.

ICC-2V 07G0330

A pair of steel inter-cabinet couplers for flying two TCS-122 or TCS-152 cabinets in

a vertical column with one cabinet inverted to position the horns adjacent to each

other. FP-1 kits are not needed to assemble this configuration; all that is required is

one ICC-2V kit per hang.

The kit includes two plates, four M10 x 40mm bolts and four M10 spring washers.

TCS series Arraying and Rigging - Page 4

Page 5

SB-61 07G0375

The SB-61 is a swivel bracket used to hang the TCS-61 in standalone

applications such as ceiling mounting in bars or clubs, or as an underbalcony fill. It consists of two parts: a ceiling plate and a speaker plate,

allowing each part to be fixed individually and then assembled and

angled to achieve the desired coverage.

Arraying and Rigging

TCS series

The SB-61 can also be used to hang the TCS-61 underneath the wider

TCS-152 cabinet, with the facility to alter the downward angle.

ICC-61 07G0370

To hang the TCS-61 as a downfill speaker underneath the TCS-122, you

will need a pair of ICC-61 inter-cabinet links fitted between the cabinets

which positions the TCS-61 at an optimum angle to the TCS122.

Following are some diagrams that illustrate these components and kits in action.

In this example cluster three TCS-122

cabinets are tight packed together using

FP-1 flyplates on top and bottom and

tied together with ICC-2H couplers. The

horns are rotated to 40°h by 90°v and

the cluster produces combined

coverage of 120°h by 90°v. Pick up the

array using M10 eyebolts attached to

the inside flypoints on the two outer

boxes. Parts required:

3 x FP-1 kits (6 pcs)

2 x ICC-2H kits (4 pcs)

2 x M10 eyebolts

TCS series Arraying and Rigging - Page 5

Page 6

Arraying and Rigging

TCS series

This cluster of three TCS-152

cabinets is assembled with FP-1

flyplates and ICC-3H couplers.

Again the horns are rotated to

40°h x 90°v, giving combined

cluster coverage of 120°h x 90°v.

Parts required:

3 x FP-1 kits (6 pcs)

2 x ICC-3H kits (4 pcs)

2 x M10 eyebolts

This diagram shows how bass

cabinets are combined in an array

of TCS-152 cabinets. The

mid/highs are fitted with FP-1

flyplates and the TCS-B15B bass

cabinets with FP-2 flyplates. Three

types of inter-cabinet couplers

complete the cluster as shown.

Parts required:

2 x FP-2 kits (4 pcs)

2 x FP-1 kits (4 pcs)

1 x ICC-4H kit (2 pcs)

1 x ICC-5H kit (2 pcs)

1 x ICC-3H kit (2 pcs)

TCS series Arraying and Rigging - Page 6

Page 7

Arraying and Rigging

TCS series

A simple vertical hang of

TCS-122 or TCS-152

cabinets with vertical

couplers. The cluster is

suspended on M10

eyebolts with a third

eyebolt for a pull-back

attached in the centre of

the lower cabinet. Parts

required:

1 x ICC-2V kit (2 pcs)

3 x M10 eyebolts

The TCS-61 shares the

same width dimension as

the TCS-122, providing an

ideal visually discreet

downfill application. The

cluster is suspened with

M10 eyebolts, with a

further eyebolt in the centre

of the TCS-122 as a pullback. Parts required:

1 x ICC-61 kit (2 pcs)

3 x M10 eyebolts

TCS series Arraying and Rigging - Page 7

Page 8

Arraying and Rigging

TCS series

Important notes on rigging

As with all rigging, the flying of these arrays should only be carried out by a professional rigger.

The Turbosound rigging system has been designed and constructed to a high standard of safety, and

tested to the most demanding of specifications. In order to ensure the highest safety standards, this

information on the assembly and safe use of rigging accessories must be understood and followed.

Only use Turbosound recommended rigging accessories, which are specifically designed for their

intended purpose. Do not use Turbosound rigging with other types or brands of loudspeakers. This

practice may compromise safety standards and Turbosound will not be responsible for damage or

injury so caused. Do not modify the rigging accessories, or use them in a way other than that

described in this user manual. Rigging components supplied as part of a complete assembly are noninterchangeable and must not be exchanged with the component parts of any other assembly. The

component parts of a Turbosound rigging accessory must only be assembled using the fasteners and

methods of assembly recommended in this guide. The use of fasteners and methods of assembly not

specified or approved by Turbosound may result in an unsafe rigging assembly. Welding, or any

other means of permanently fixing rigging components to each other or to cabinet fixing points is not

allowed. Rigging assemblies must only be assembled using the appropriate parts and fixings as

specified in this manual using the specific mounting instructions. Rigging components or assemblies

must only be fixed to Turbosound loudspeaker cabinets using the cabinet fixing points, assembly

methods and fasteners specified in this guide and the specific mounting instructions. When

assembling the loudspeaker array ensure that all fixings are securely tightened before lifting the

array.

Secondary Safeties

All loudspeaker clusters flown in theatres, studios or other places of work and entertainment must, in

addition to the principle load bearing means of suspension, be provided with an independent, and

properly rated and securely attached secondary safety. Only steel wire ropes or steel chains of an

approved construction and load rating may be used as secondary safeties.

Safety Inspections

Carefully inspect rigging systems components and cabinets for defects or signs of damage before

proceeding to assemble a flown array. If any parts are damaged or suspect, DO NOT USE THEM.

Regular, more rigorous test and inspection of rigging components must also be carried out. Safety

legislation and test and inspection requirements will vary from country to country. In most cases,

annual independent test and inspection by a suitably approved and qualified inspector will be

required. Users must ensure compliance with all applicable safety requirements. Turbosound

recommends regular safety inspections and further recommends that a logbook be kept detailing the

test and inspection history of each Turbosound rigging accessory. Always wear protective headwear,

footwear and eye protection in accordance with local regulations. Anyone involved in flying ANY

sound system should take note of the following advice:

The rigging of a flown sound system may be dangerous unless undertaken by qualified personnel

with the required experience and certification to perform the necessary tasks. Fixing of hanging

points in a roof should always be carried out by a professional rigger and in accordance with the local

rules of the venue. The house rigger and/or building manager must always be consulted.

TCS series Arraying and Rigging - Page 8

Loading...

Loading...