Page 1

TBV BERLIN SERIES

TBV118L

18" Front Loaded Subwoofer for Touring, Portable and Installation Applications

TBV123

Arrayable 2 Way 12" Constant Curvature Loudspeaker with

Dendritic Waveguide for Touring, Portable and Installation Applications

TBV118L-AN

18" Powered Subwoofer with KLARK TEKNIK DSP Technology and ULTRANET Networking

TBV123-AN

Arrayable 2 Way 12" Constant Curvature Loudspeaker with

Dendritic Waveguide, KLARK TEKNIK DSP Technology and ULTRANET Networking

TBV123-FB

Fly Bar for TBV BERLIN Series speakers for Flown or Ground Stacked Arrays

WARNING!

This rigging manual contains important safety information, and it must be kept in a safe place for future reference. It must be supplied with the equipment

during the original sale, rental, or re-sale, and all operators and users of the equipment must be made aware that this manual is available. Please visit our website

turbosound.com regularly and check for any updates to this manual.

Page 2

2 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Table of Contents

Important Safety Instructions ..............................................................................................................3

Legal Disclaimer .....................................................................................................................................3

Limited warranty ....................................................................................................................................3

Chapter 1: Safety Information ..............................................................................................................4

Chapter 2: Introduction .........................................................................................................................6

Chapter 3: Assembling a TBV123 Array on a TBV123-FB Flybar .......................................................19

Chapter 4: Assembling a TBV118L Array on a TBV123-FB Flybar .....................................................22

Chapter 5: Assembling a Mixed Array on a TBV123-FB Flybar .........................................................25

Chapter 6: Assembling a TBV118L Ground Stack ..............................................................................28

Chapter 7: Assembling a TBV118L Subwoofer and TBV123 Ground Stack .....................................31

Chapter 8: Assembling a TBV123 Array Ground Stack ..................................................................... 34

Chapter 9: Pole Mounting a TBV123 Cabinet on a TBV118L Subwoofer .........................................37

Chapter 10: Assembling an Inverted TBV123 Array ..........................................................................39

Chapter 11: Using Eyebolts ..................................................................................................................45

Chapter 12: Safety Inspection .............................................................................................................47

Chapter 13: TBV Enclosure Quantities and Combinations for

TBV123-FB Flybar Suspension at 10:1, 7:1, 5:1 Design Factors ................................... 48

Manufacturer’s Declaration ................................................................................................................49

Page 3

Rigging Manual 3

Terminals marked with this symbol carry

electrical current of su cient magnitude

to constitute risk of electric shock.

Use only high-quality professional speaker cables with

¼" TS or twist-locking plugs pre-installed. Allother

installation or modi cation should be performed only

by quali edpersonnel.

This symbol, wherever it appears,

alertsyou to the presence of uninsulated

dangerous voltage inside the

enclosure-voltage that may be su cient to constitute a

risk ofshock.

This symbol, wherever it appears,

alertsyou to important operating and

maintenance instructions in the

accompanying literature. Please read the manual.

Caution

To reduce the risk of electric shock, donot

remove the top cover (or the rear section).

No user serviceable parts inside. Refer servicing to

quali ed personnel.

Caution

To reduce the risk of re or electric shock,

do not expose this appliance to rain and

moisture. The apparatus shall not be exposed to dripping

or splashing liquids and no objects lled with liquids,

suchas vases, shall be placed on the apparatus.

Caution

These service instructions are for use

by quali ed service personnel only.

Toreduce the risk of electric shock do not perform any

servicing other than that contained in the operation

instructions. Repairs have to be performed by quali ed

servicepersonnel.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in

accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as

radiators, heat registers, stoves, or other apparatus

(including ampli ers) that produce heat.

9. Do not defeat the safety purpose of the polarized

or grounding-type plug. A polarized plug has two blades

with one wider than the other. A grounding-type plug

has two blades and a third grounding prong. The wide

blade or the third prong are provided for your safety. Ifthe

provided plug does not t into your outlet, consult an

electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or

pinched particularly at plugs, convenience receptacles,

and the point where they exit from the apparatus.

11. Use only attachments/accessories speci ed by

themanufacturer.

12. Use only with the

cart, stand, tripod, bracket,

or table speci ed by the

manufacturer, orsold with

the apparatus. When a cart

is used, use caution when

moving the cart/apparatus

combination to avoid

injury from tip-over.

13. Unplug this apparatus during lightning storms or

when unused for long periods of time.

14. Refer all servicing to quali ed service personnel.

Servicing is required when the apparatus has been

damaged in any way, such as power supply cord or plug

is damaged, liquid has been spilled or objects have fallen

into the apparatus, the apparatus has been exposed

to rain or moisture, does not operate normally, or has

beendropped.

15. The apparatus shall be connected to a MAINS socket

outlet with a protective earthing connection.

16. Where the MAINS plug or an appliance coupler is

used as the disconnect device, the disconnect device shall

remain readily operable.

17. Correct disposal of this

product: This symbol indicates that

this product must not be disposed

of with household waste,

according to the WEEE Directive

(2012/19/EU) and your national

law. This product should be taken

to a collection center licensed for the recycling of waste

electrical and electronic equipment (EEE). The

mishandling of this type of waste could have a possible

negative impact on the environment and human health

due to potentially hazardous substances that are generally

associated with EEE. At the same time, your cooperation

in the correct disposal of this product will contribute to

the e cient use of natural resources. For more

information about where you can take your waste

equipment for recycling, please contact your local city

o ce, or your household waste collection service.

18. Do not install in a con ned space, such as a book

case or similar unit.

19. Do not place naked ame sources, such as lighted

candles, on the apparatus.

20. Please keep the environmental aspects of battery

disposal in mind. Batteries must be disposed-of at a

battery collection point.

21. Use this apparatus in tropical and/or

moderate climates.

MUSIC Group accepts no liability for any loss which

may be su ered by any person who relies either

wholly or in part upon any description, photograph,

or statement contained herein. Technical speci cations,

appearances and other information are subject to

change without notice. All trademarks are the property

of their respective owners. MIDAS, KLARK TEKNIK,

LAB GRUPPEN, LAKE, TANNOY, TURBOSOUND,

TC ELECTRONIC, TC HELICON, BEHRINGER, BUGERA

and DDA are trademarks or registered trademarks

of MUSIC Group IP Ltd. © MUSIC Group IP Ltd.

2017 All rights reserved.

For the applicable warranty terms and conditions

and additional information regarding MUSIC Group’s

Limited Warranty, please see complete details online at

music-group.com/warranty.

Important Safety

Instructions

LEGAL DISCLAIMER

LIMITED WARRANTY

Page 4

4 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Chapter 1: Safety Information

1.1 Intended Use

The rigging components (TBV123-FB ybar, rigging pins, mounting links) shall only be used in conjunction with TURBOSOUND TBV123, TBV123-AN loudspeakers and

TBV118L and TBV118L-AN subwoofers as described in this manual.

NOTE: Throughout this manual, and unless otherwise noted, the term "TBV123" refers to the TBV123 passive loudspeaker or the TBV123-AN powered loudspeaker.

These speakers share identical cabinet dimensions and rigging points. The term "TBV118L" refers to the TB118L passive subwoofer, or the TBV118L-AN powered

subwoofer. These subwoofers share identical cabinet dimensions and rigging points.

1.2 Intended Use of this Manual

The instructions in this manual describe how to assemble various congurations of TBV123 loudspeaker cabinets, TBV118L subwoofers, and the TBV123-FB ybar,

in readiness for suspending or ground stacking.

These instruc tions shall only be used with the TURBOSOUND TBV123, TBV123-AN, TBV118L, TBV118L-AN, and TBV123-FB components.

The instructions do not show details of external lifting equipment, and do not contain details of safe lifting procedures or installation.

Possession of these instructions and procedures does not imply authorisation for their use.

1.3 General Safety

The operation of your product as part of a suspended system, if installed incorrectly and improperly, can potentially expose persons to

serious health risks and even death.

In addition, please ensure that electrical, mechanical and acoustic considerations are discussed with qualied and certied (by local, state or national authorities)

personnel prior to any installation.

Installation and setup should only be carried out by qualied and authorised personnel observing the valid local, state and other safety regulations applicable in your

country. If any parts or components are missing please contac t your dealer before attempting to set up the system.

It is the responsibility of the person installing the assembly to ensure that the suspension/xing points are suitable for the intended use.

We also recommend you schedule TURBOSOUND line array training with our sales par tners and applications team.

Equipment used to connect to the TURBOSOUND rigging system must be properly rated and must conform to the local, state and other safety regulations. Do not use

TURBOSOUND rigging with other types or brands of loudspeakers. This practice may compromise safety standards and MUSIC Group will not be responsible for damage

or injury so caused. Do not modify the rigging accessories, or use them in a way other than that described in this rigging manual. Rigging components supplied as part

of a complete assembly are non-interchangeable and must not be exchanged with the component parts of any other assembly.

Welding, or any other means of permanently xing rigging components to each other or to cabinet xing points is not allowed. Rigging components or assemblies

must only be xed to TURBOSOUND loudspeaker cabinets using the cabinet xing points.

MUSIC Group assumes no liability for any damage or personal injury resulting from improper use, installation or operation of the product. Regular checks must be

conducted by qualied personnel to ensure that the system remains in a secure and stable condition. Make sure that, where the product is suspended, the area

underneath the produc t is free of human trac. Do not suspend the product in areas which can be entered or used by members of the public.

1.4 Loudspeaker Cabling

Attach and suppor t the speaker cables from your ampliers to the loudspeaker cabinets, so that no signicant additional weight or lateral force is applied to the array

by the input wiring.

Input cables or link cables should never be used to angle the array or used as rigging in any way.

1.5 Load Capacity and System Safety

The TBV123-FB ybar is designed to suspend a maximum of 4 TBV123 loudspeaker cabinets, or 2 TBV118L subwoofers, or a mixed array of 1 TBV118L subwoofer with

2 TBV123 loudspeaker cabinets. The speakers may be own with any vertical splay angle conguration and from any of the pick points. This corresponds to a Working

Load Limit (WLL) of 100 kg with a design factor of 10:1.

TBV installation procedures and recommendations described in Chapters 3-5 are based on 10:1 design factor. TBV enclosure counts and combinations are also given for

5:1 and 7:1 design factors in Chapter 13. Check local regulations in order to comply with regional design factor requirements. Always refer to EASE FOCUS II modeling

software error and warning indications prior to installation.

Page 5

Rigging Manual 5

1.6 Safety Inspections

Carefully inspec t rigging system components and cabinets for defects or signs of damage before proceeding to assemble the array to be own. If any parts are

damaged or suspect, or if there is any doubt as to the proper functioning and safety of the items DO NOT USE THEM and withdraw them from use immediately.

Refer to Chapter 12 for information about care maintenance and disposal.

1.7 Secondary Safeties

All loudspeakers own in theatres, studios or other places of work and enter tainment, in addition to the principle load bearing means of suspension, shall be provided

with an independent, properly rated, and securely attached secondary safety. Only steel wire ropes or steel chains of an approved construction and load rating shall be

used as secondary safeties. Plastic-covered steel wire ropes are not permitted for use as secondary safeties.

The secondary safety suspension must be independent of the primary suspension points and capable of carr ying the total system weight. The additional safety device

must be mounted in a way that the array is caught by the safety device without any drop and swing in the event that the primary suspension fails.

1.8 Wind Loads

The loudspeakers must not be suspended or ground stacked in winds greater than:

Beaufort Scale 6 bft (39-49 km/h, 25-31 mph, 22-27 knots)

If the forecast or actual winds reach:

Beaufort Scale 8 bft (62-74 km/h, 39-46 mph, 34-40 knots)

1) Clear the area of personnel

2) Lower and secure the array

1.9 Operational Safety

The procedures require the use of two or more authorised persons.

Produce a lift plan: before any lift takes place, you must formulate a lift plan that describes the exact steps and procedures that will be carried out. The plan must be

shared with all assistants and stake-holders in the lift so that each person will understand their responsibilities.

Observe all instructions given on the respective instruction labels of the rigging components and loudspeakers.

When using chain hoists make sure nobody is directly underneath or in the vicinity of the array.

During assembly pay attention to the possible risk of crushing.

Wear suitable protective clothing.

Safety Logo Description Safety Logo Description Safety Logo Description

Protective Headwear

shall be worn

Protective Eyewear

shall be worn

Protective Gloves

shall be worn

Protective Footwear

shall be worn

Practice Safe Lifting

1.10 Safety Notices in this manual

WARNING

THIS INDICATES ADVICE THAT IF NOT FOLLOWED, MAY LEAD TO PERMANENT INJURY OR DEATH.

CAUTION

THIS INDICATES ADVICE THAT IF NOT FOLLOWED, MAY LEAD TO DAMAGE TO THE EQUIPMENT.

NOTE

This indicates extra advice that may be useful when performing the procedures.

Page 6

6 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Chapter 2: Introduction

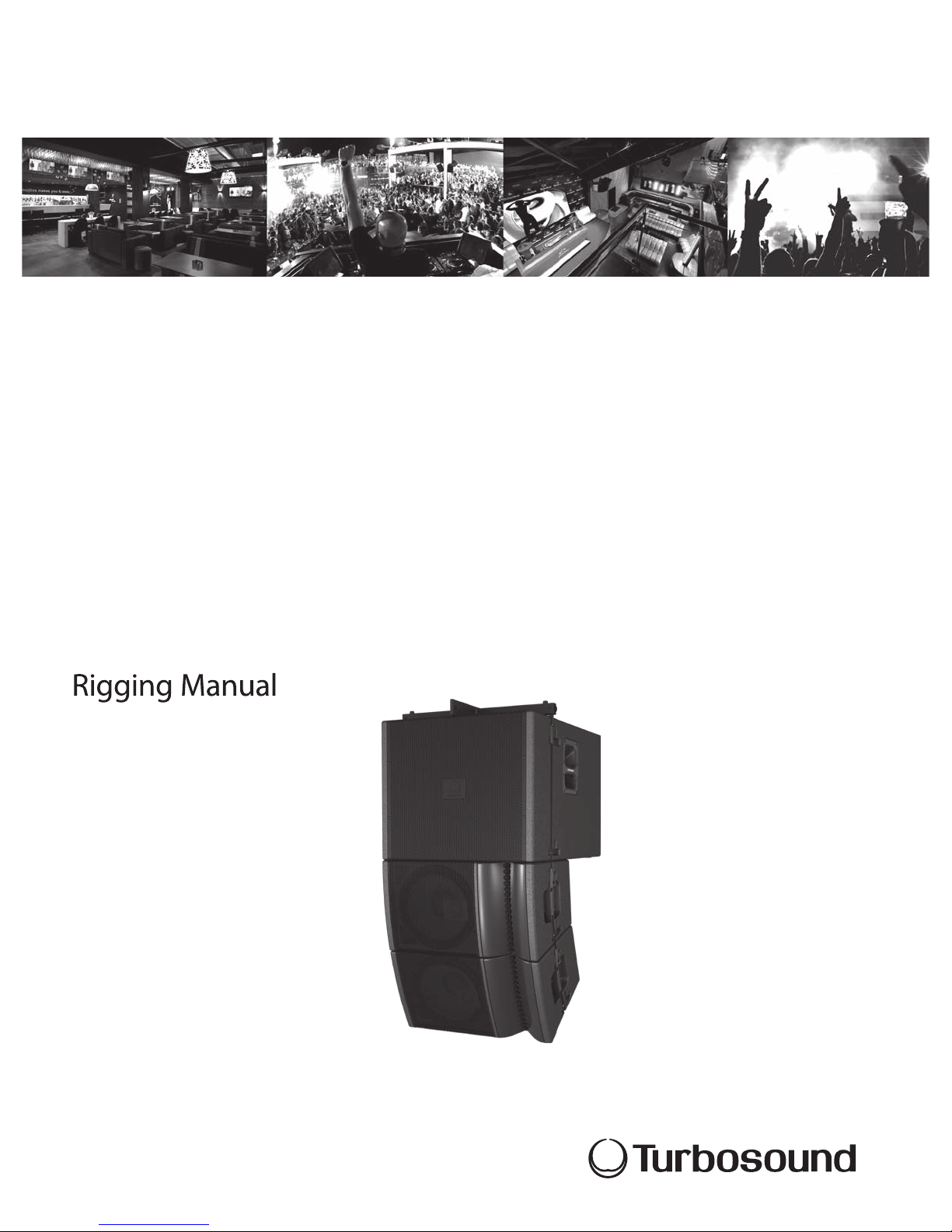

2.1 Typical Congurations

TBV123 Array (See Chapter 3)

TBV118L Array (See Chapter 4)

TBV118L and TBV123 Array (See Chapter 5)

Page 7

Rigging Manual 7

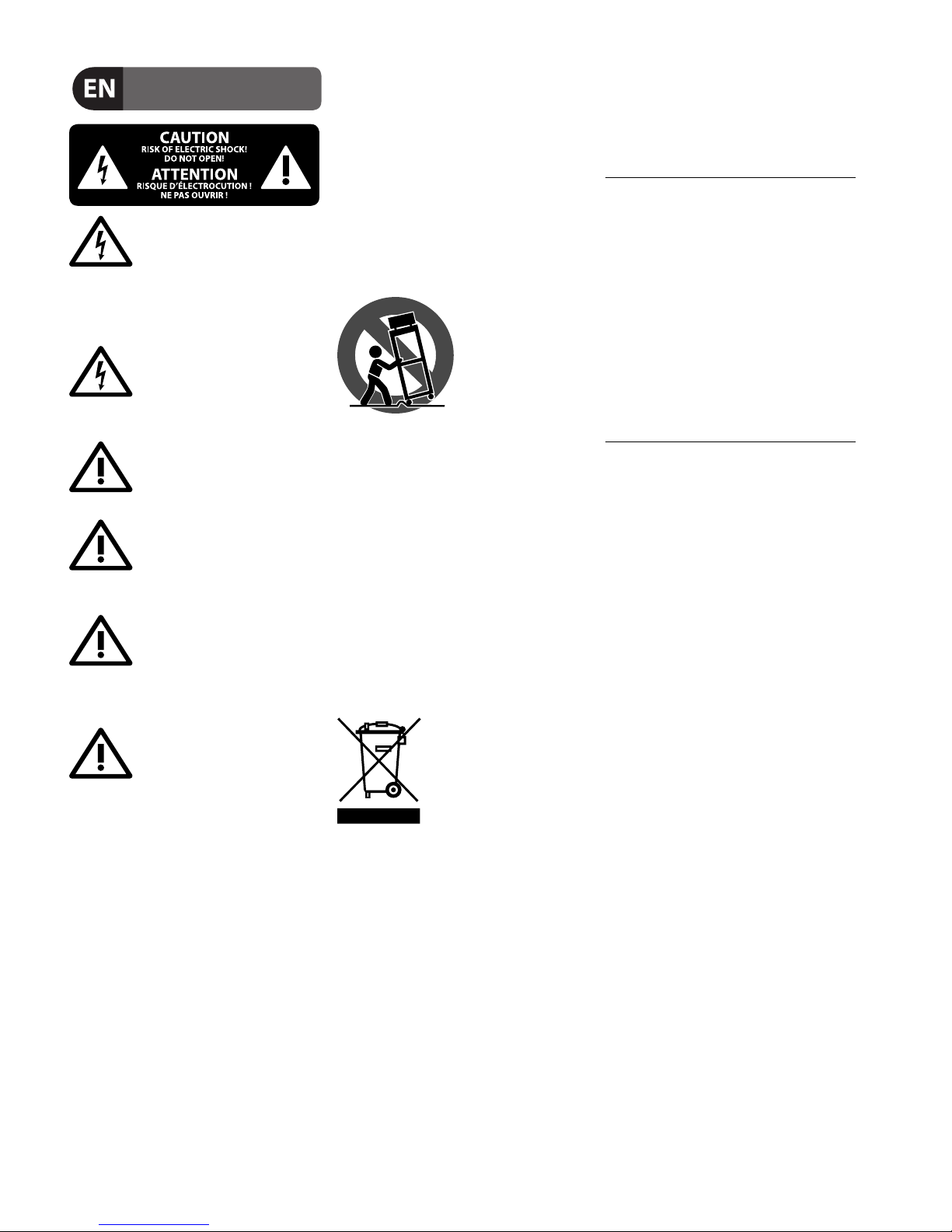

TBV118L Subwoofer Ground Stack (See Chapter 6)

TBV123 Array Ground Stack (See Chapter 8)

TBV118L and TBV123 Array Ground Stack (See Chapter 7

)

TBV118L and TBV123 Array Pole Mount (See Chapter 9)

Page 8

8 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

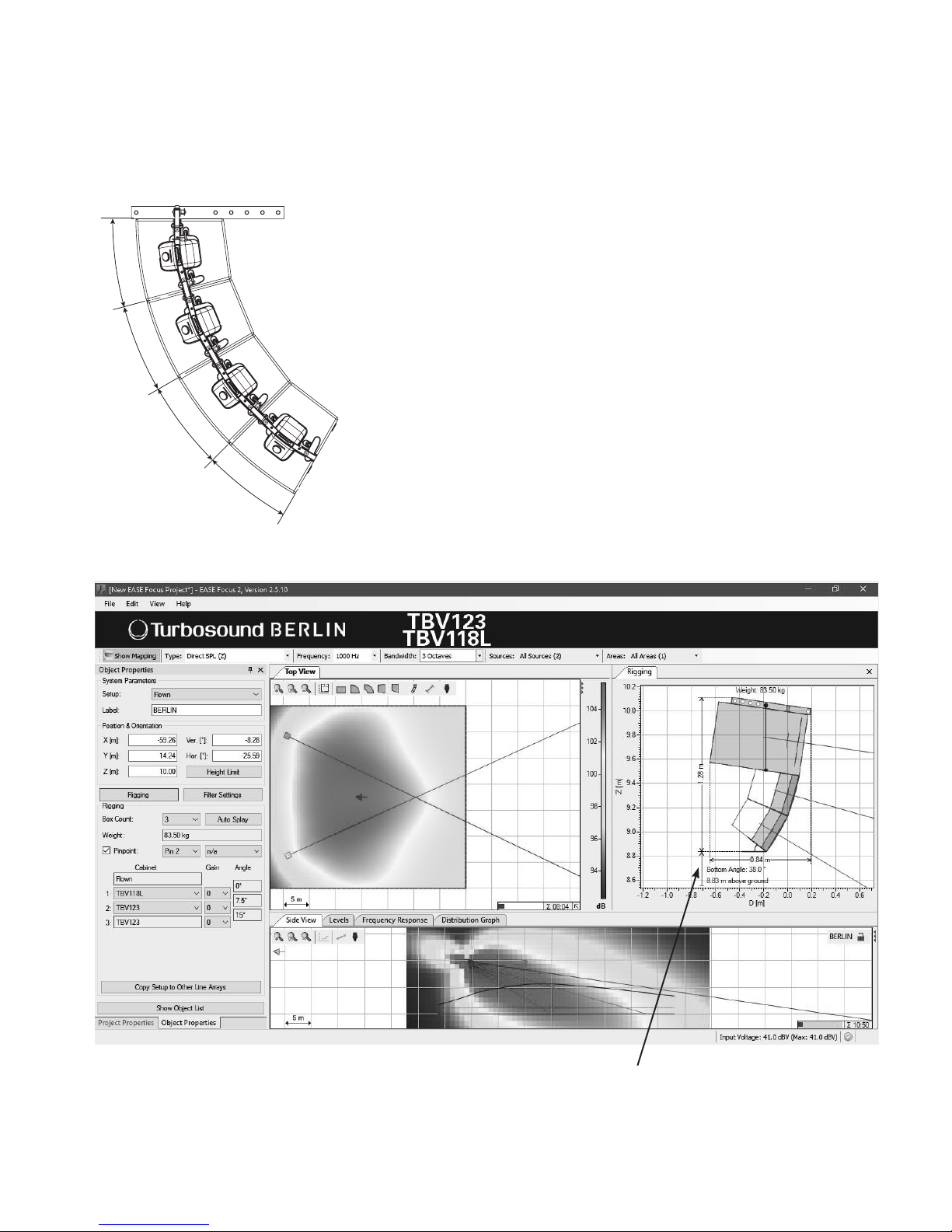

2.2 Rigging and Acoustic Simulation Software

The EASE FOCUS II software allows you to congure the system for optimal performance and coverage

in the venue.

The software can be downloaded from http://www.afmg.eu/index.php/products.html

Further information about the TBV models is available from www.turbosound.com

The TBV123 is a constant curvature line array, and the inter-cabinet angle is xed at 15 degrees.

The quantity of cabinets can be varied, and the SPL coverage calculated for any conguration.

Once an optimum system has been designed using the EASE FOCUS II sof tware, the correct suspension hole on

the TBV123-FB ybar should be noted, where your bow shackle would be tted for single-point suspension.

For two-point suspension, pick point holes #1 and #6 can be utilized in conjunction with front and rear chain

motors to obtain the desired array site angle.

The EASE FOCUS II screenshot below is for a typical TBV123 conguration. Check the “RIGGING” Tab and note

installation parameters such as: array weight, bottom element elevation above ground level,

bottom enclosure angle.

WARNING

ERROR AND WARNING INDICATIONS ARE GIVEN IN THE OBJECT PROPERTIES WINDOW IF WORKING LOAD

LIMITS ARE EXCEEDED AT 10:1, 7:1 OR 5:1 DESIGN FACTORS. HEED THESE WARNINGS AT ALL TIMES IN

ACCORDANCE WITH LOCAL REGULATIONS.

EASE FOCUS II Typical Screenshot for a TBV123/TBV118 Mixed Array

Rigging Tab Shows the layout graphically,

and indicates the correct suspension pick

point to choose on the ybar.

15°

15°

15°

15°

Page 9

Rigging Manual 9

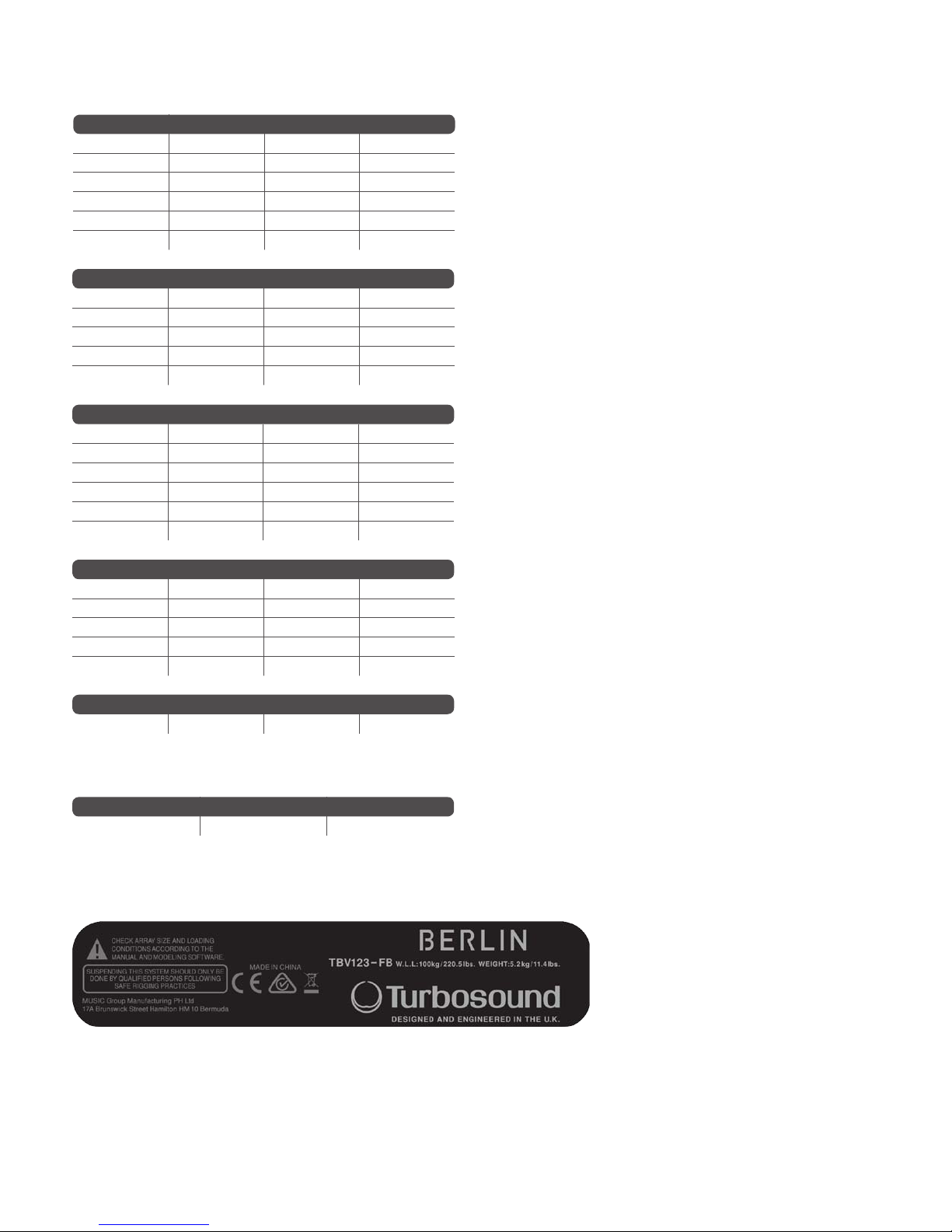

2.3 Weights

Item Quantity Weigh t (kg) Weight (lbs)

TBV123-AN 1 23.0 50.7

2 46.0 101.4

3 69.0 15 2.1

4 92.0 202.8

5 115. 0 253.5

6 138.0 304.2

Item Quantity Weigh t (kg) Weight (lbs)

TBV 123 1 22.0 48.5

2 44.0 97. 0

3 66.0 145.5

4 88.0 194.0

5 110. 0 242. 5

6 132.0 291.0

Item Quantity Weig ht (kg) Weight (lbs)

TB V118L 1 3 7.0 81.6

2 74. 0 16 3.1

3 111. 0 244.7

4 148.0 326.3

5 185.0 4 07. 9

Item Quantity Weig ht (kg) Weight (lbs)

TB V118 L-A N 1 38.5 8 4.9

2 7 7.0 169.8

3 115. 5 254.6

4 154.0 339. 5

5 192.5 424 .4

Item Quantity Weig ht (kg) Weight (lbs)

TBV 123-F B 1 5.2 11.4

2.4 TBV123-FB Flybar Working Load Limit (WLL)

Item WLL (kg) WLL ( lbs)

TBV 123-F B 100 220.5

2.5 TBV123-FB Flybar Safety Warning Label

Page 10

10 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

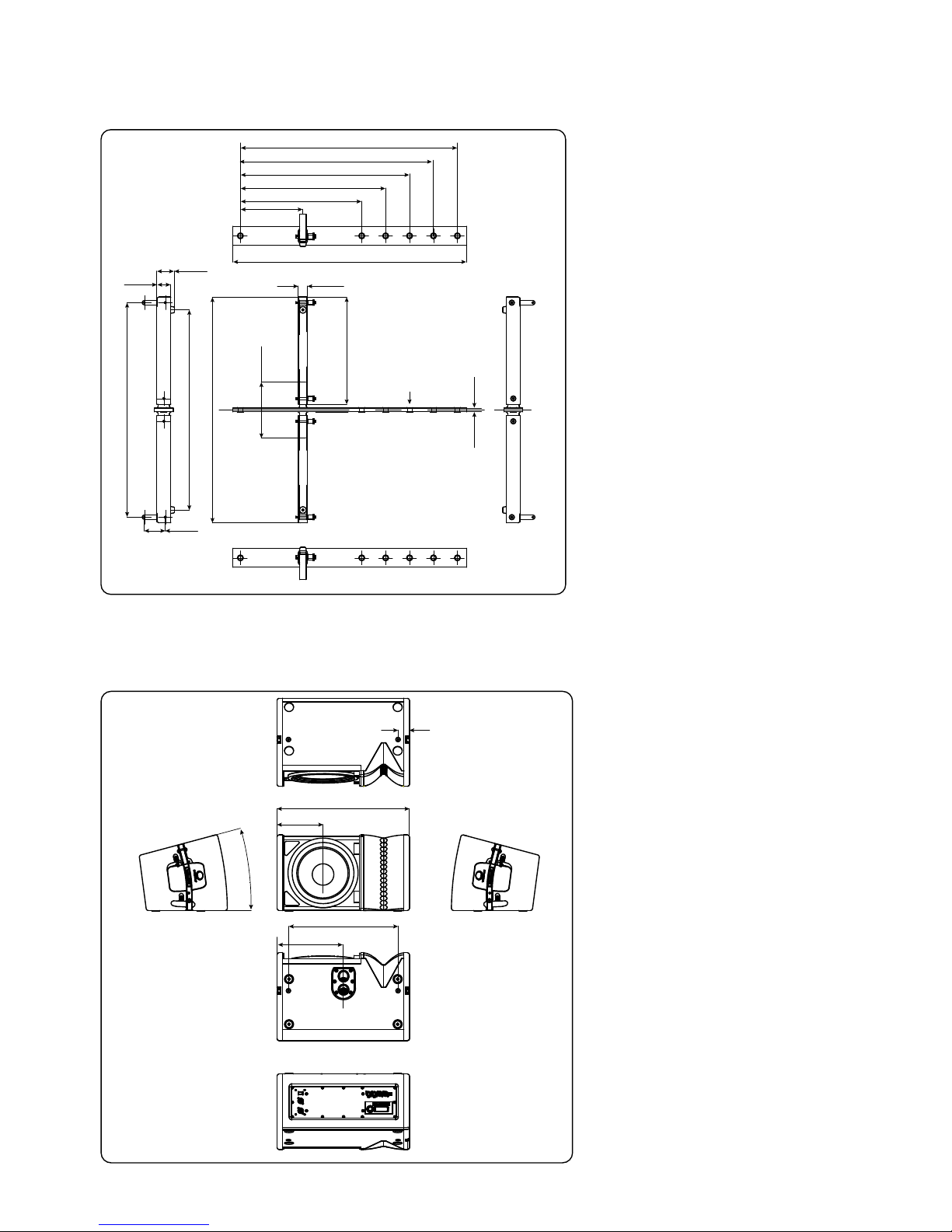

2.6 TBV123-FB Flybar Dimensions

See Chapter 12 for information regarding inspection, care, and maintenance.

2.7 TBV123 Cabinet Dimensions

See Chapter 12 for information regarding inspection, care, and maintenance.

614.00 [24.2]

583.00 [23.0]

330.00 [13.0]

395.00 [15.6]

460.00 [18.1]

525.00 [20.7]

590.00 [23.2]

170.00 [6.7]

47.84 [1.9]

635.00 [25.0]

292.00 [11.5]

153.00 [6.0]

10.00 [0.4]

544.00 [21.4]

25.00 [1.0]

38.00 [1.5]

57.00 [2.2]

Ø13 [0.5"]

598 [23.5 "]

15°

208 [8.2 "]

300 [11.8 " ]

493 [19.4 "]

51.3 [2.02 "]

TBV123-AN shown

TBV123 shares all the same dimensions

Page 11

Rigging Manual 11

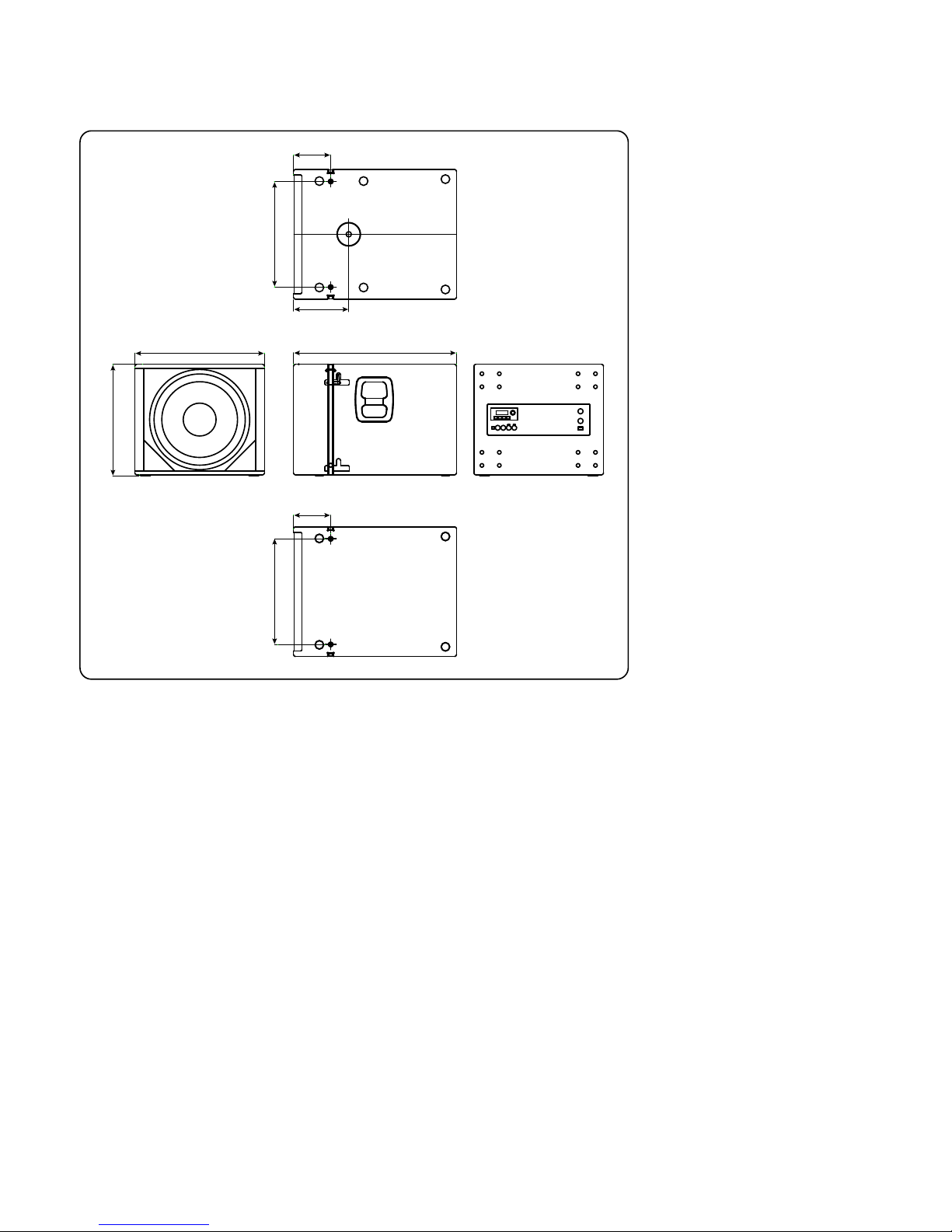

2.8 TBV118L Subwoofer Dimensions

See Chapter 12 for information regarding inspection, care, and maintenance.

172 [6.8"]

255 [10.0"]

172 [6.8"]

485 [19.1"] Eyebolt485 [19.1"] Eyebolt

598 [23.5"]

513 [20.2"]

751 [29.6"]

TBV118L-AN shown

TBV118L shares all the

same dimensions

Page 12

12 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

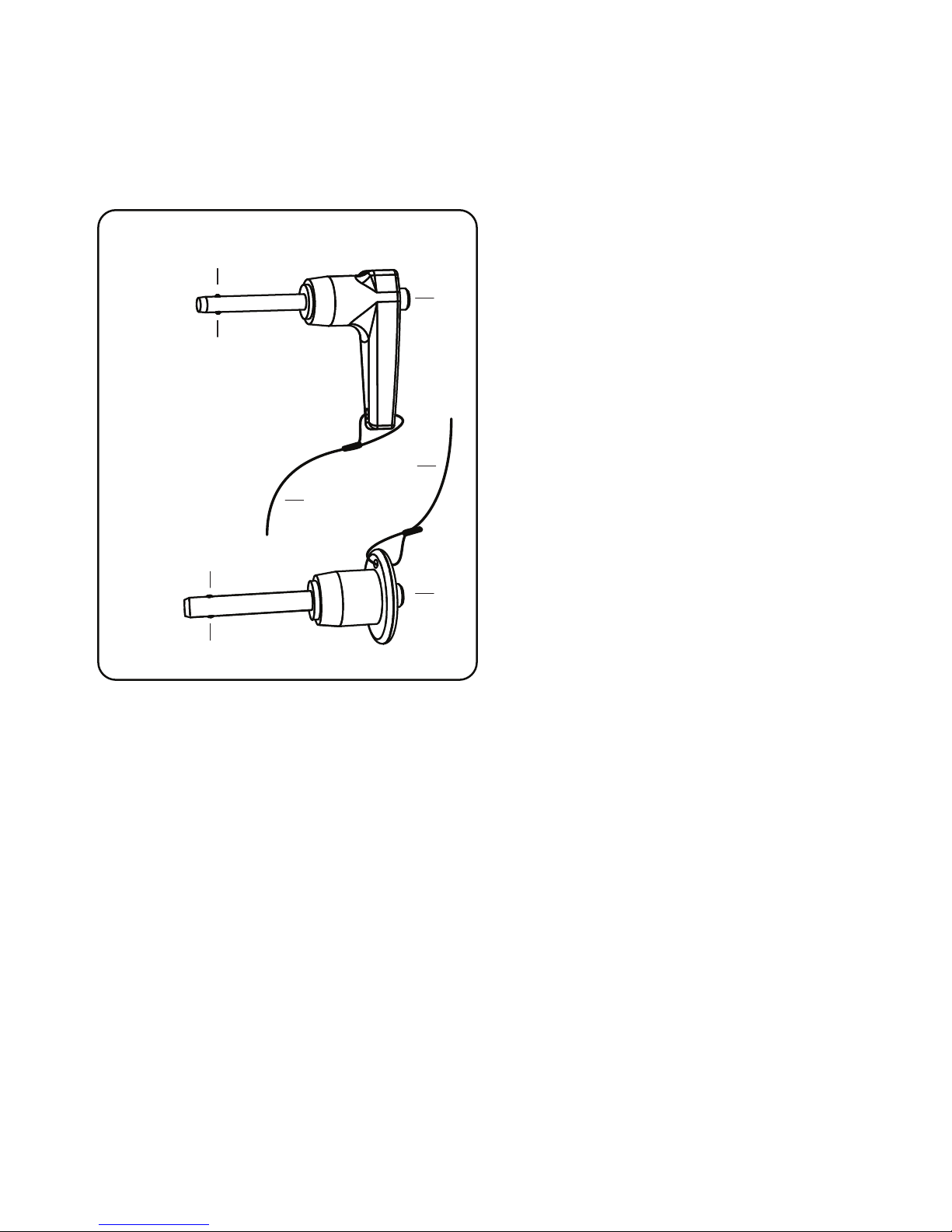

2.9 Rigging Pins

See Chapter 12 for information regarding inspection, care, and maintenance.

These pins are the fundamental mechanical fastener for the assembly of the TBV123-FB ybar, TBV123 cabinet, and the TBV118L subwoofer.

The rigging pins for the cabinets and subwoofer have an "L" shape. The pins used for assembling the TBV123-FB ybar are straight, and should only be used for the

ybar connections.

1. Spring Balls – These are locking devices that prevent the pin from

pulling out once it has been inserted.

2. Spring Release – Press this button in and the spring balls (1) will

unlock and allow the pin to be inser ted into the mounting holes and

links. Release this button and the spring balls will lock and prevent the

pin from pulling back out.

3. Lanyard – These prevent the pins from being easily lost.

WAR N ING

BEFORE EVERY USE, INSPECT ALL PINS FOR DAMAGE, AND VERIFY THE CORRECT

OPERATION OF THE SPRING LOCKING MECHANISM. DO NOT USE ANY PINS THAT

SHOW SIGNS OF DAMAGE. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

WARNING

BEFORE EVERY USE, MAKE SURE THAT ALL PINS ARE CLEAN AND FREE FROM

DIRT AND DEBRIS THAT MAY INTERFERE WITH THE CORRECT OPERATION OF THE

SPRING LOCKING MECHANISM. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

2

1

1

1

1

2

3

3

Page 13

Rigging Manual 13

2.9.1 Rigging Pin Installation

Pin Installation

The following example shows how to use the rigging pins to join two TBV123

cabinets together. Exact details are given in later chapters of this manual.

1. Suppor t the weight of the cabinets to be joined.

2. Align the top mounting link (1) of the lower TBV123 cabinet with the

corresponding mounting holes in the upper TBV123 cabinet.

Align the link with the mounting holes so the pin can pass through

and join them together.

3. Press the button (2) at the end of the pin, and insert the pin in as far as

it will go. The spring balls (3) will retract while the button is being held,

allowing the pin to pass through the holes.

4. Release the button (2) when the pin is fully inserted.

5. Check the pin is correctly inserted as far as it will go, and that both spring

balls (3) are visible. Check that the components being connected have been

correctly captured together by the pin.

6. With the weight of the components still supported, and without pressing

the button (2), try to pull on the pin sharply, to check it is secured in position

by the spring ball locking mechanism.

7. Rotate the arm of the pin until it is captured by the spring clip (4).

This makes the pin extra secure, and will also prevent the pins from

vibrating and rattling when the speaker is in use.

8. Repeat the pin installation for the other side of the cabinets.

Pin Removal

1. Suppor t the weight of the components to be disconnected.

2. Rotate the arm of the pin until it is released by the spring clip (4).

3. Press the button (2) and pull out the pin joining the components together.

4. Do this for both sides of the cabinet.

5. Carefully separate the cabinets.

1

2

3

3

4

3

3

Page 14

14 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

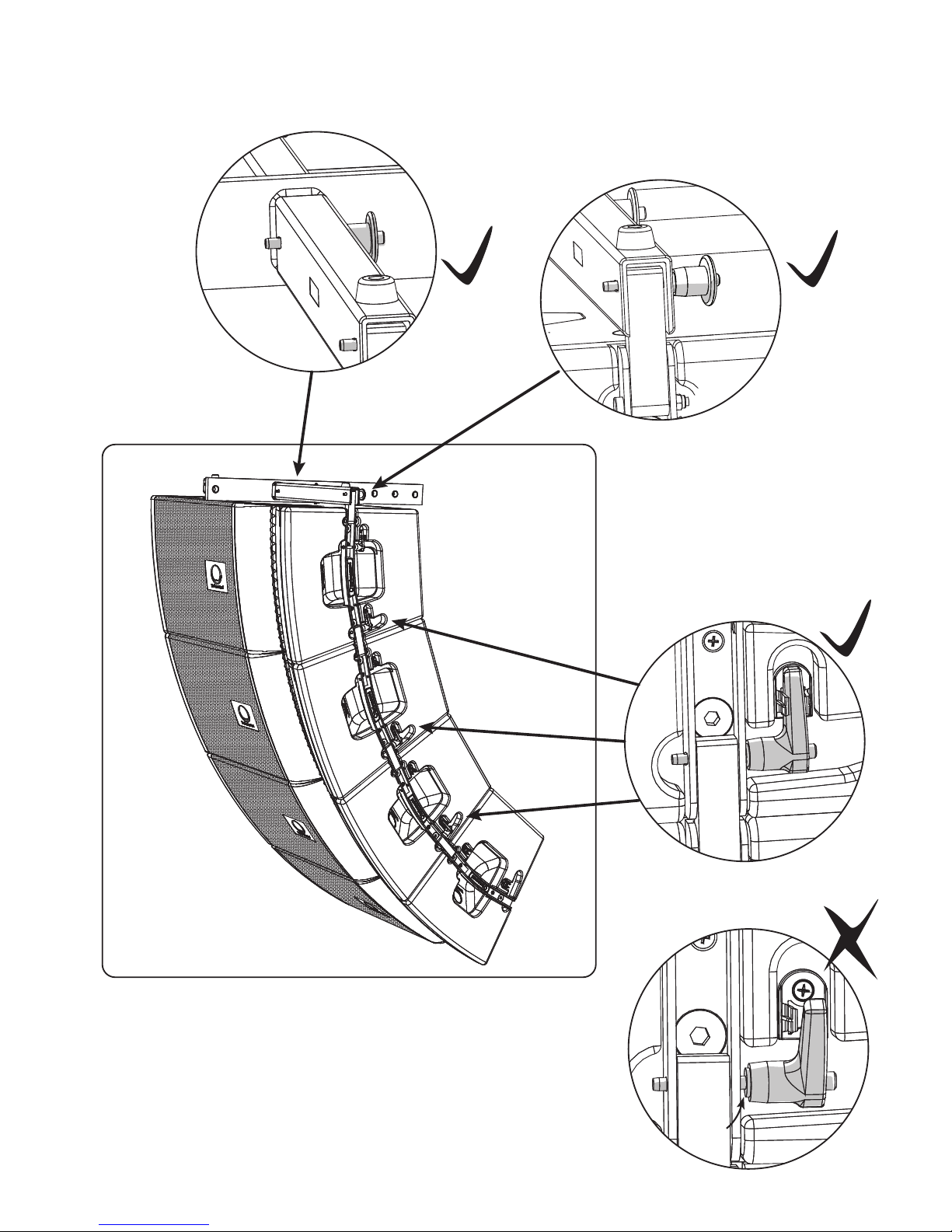

2.9.2 Typical Locations where Rigging Pins are used

GAP !

Pins correctly inserted, all the way in

Pins correctly inserted, all the way in,

and arm clipped in place

WARNING

VERIFY THAT EACH PIN IS CORRECTLY INSERTED, AND THAT EACH PIN CANNOT BE PULLED OUT WITHOUT

PRESSING THE RELEASE BUTTON FIRST. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE PERMANENT

INJURY OR DEATH.

Pins incorrectly inserted (Not inserted fully, spring

balls are not visible, and arm not clipped in place)

Page 15

Rigging Manual 15

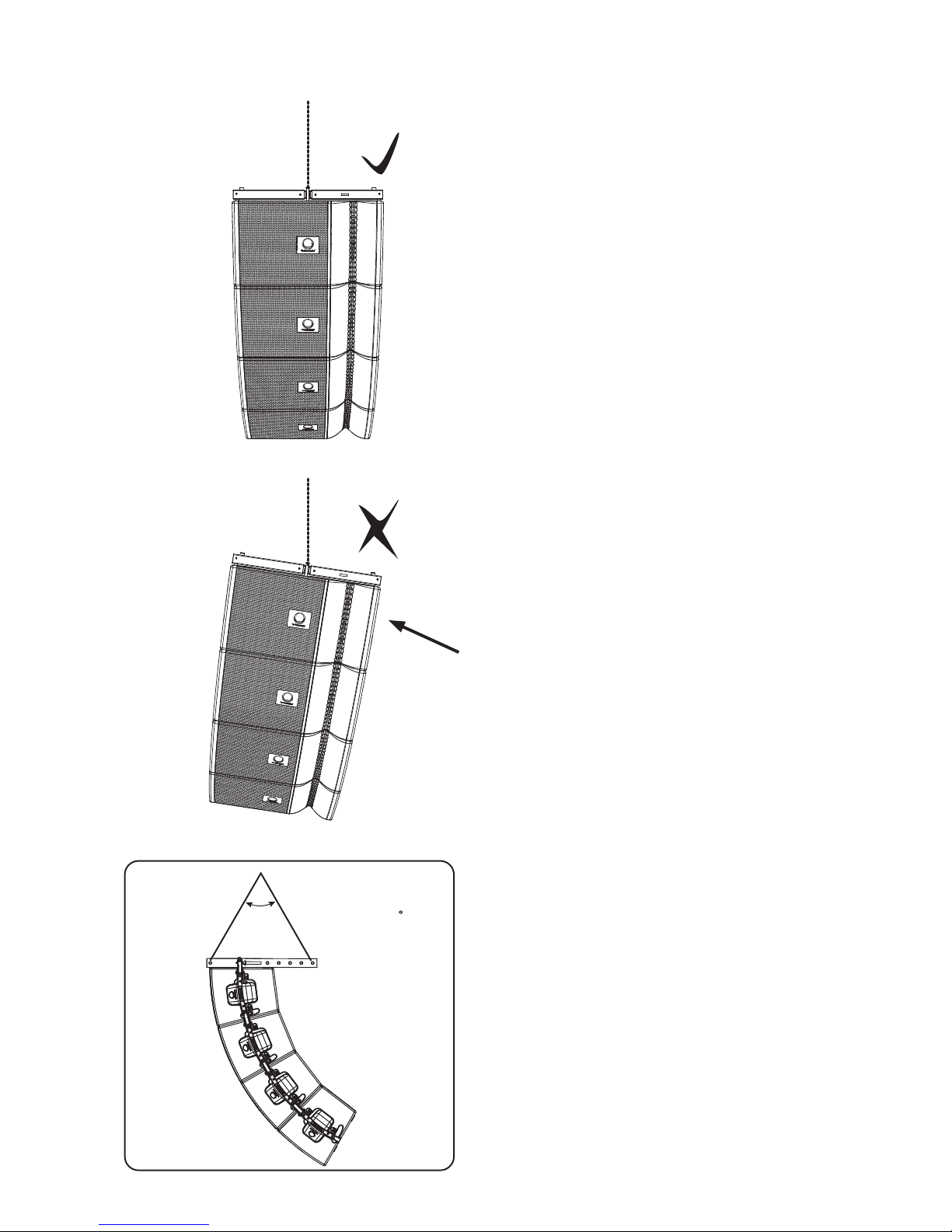

2.10 Vertical Orientation

Vertical Orientation Only!

The mechanical design of the TBV123 cabinet, TBV118L subwoofer, and the

TBV123-FB ybar uses mounting links and rigging pins to assemble the various

components. The mechanical strength comes from the cabinet's metal side

pieces and the pins, and not through the wooden cabinets. The cabinets are

supported vertically below each other, and vertically below the ybar.

WARNING

THE ASSEMBLY MUST BE ORIENTED SO THAT THE SIDES OF THE CABINETS AND

SUBWOOFER ARE ALWAYS KEPT IN THE VERTICAL PLANE. FAILURE TO DO THIS

MAY CAUSE STRAIN AND FAILURE OF THE MECHANICAL STRUCTURE, LEADING TO

POSSIBLE PERMANENT INJURY OR DEATH.

WARNING

THE TBV123 CABINETS, TBV118L SUBWOOFERS, AND TBV123-FB FLYBAR

SHALL NOT BE CLIMBED UPON. THIS MAY CAUSE STRAIN AND FAILURE OF THE

MECHANICAL STRUCTURE, LEADING TO POSSIBLE PERMANENT INJURY OR DEATH.

WARNING

THIS ILLUSTRATION SHOWS AN INCORRECT INSTALLATION, WHERE THE SIDES OF

THE CABINETS ARE NOT IN THE VERTICAL PLANE. THIS MAY CAUSE STRAIN AND

FAILURE OF THE MECHANICAL STRUCTURE, LEADING TO POSSIBLE PERMANENT

INJURY OR DEATH

WARNING

DO NOT EXCEED A MAXIMUM 2-LEG BRIDLE HITCH ANGLE OF 60 DEGREES.

FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

MAXIMUM

ANGLE 60

INCORRECT INSTALLATION

CORRECT INSTALLATION

Page 16

16 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

2.11 TBV118L Subwoofer Mounting Components

The TBV118L subwoofer has two retractable mounting links at the top

(4), that allow it to be attached to a TBV123-FB ybar, or to another

TBV118L subwoofer, or to a TBV123 cabinet. Eyebolt holes and a pole

mount hole are also present.

1. Eyebolt locations – 4 threaded holes (2 top, 2 bottom)

allow eyebolts to be tted for ying the subwoofer without the

TBV123-FB ybar.

2. Pole Mount – This M20 threaded hole is for the optional

pole mounts, and allows up to 2 TBV123 cabinets to be pole

mounted above the subwoofer.

3. Recesses – These shallow recesses are designed to t the

feet of another TBV118L subwoofer above, or another TLX123

cabinet.

4. Mounting Links – These mounting links are used to

secure the TBV118L subwoofer to a TBV123-FB ybar, or to

another TBV118L, or a TBV123 cabinet in ground stacked mode

only (do not suspend TBV118L enclosures underneath TBV123).

They rotate about a captive pivot bolt.

5. Pins – If the mounting links (4) are in the down position,

then the rigging pins are used to secure them. If the mounting

links are used in the up position, the pins can be used to secure

another TBV118L subwoofer or TBV123 cabinet above. A lanyard

is connected to prevent the loss of the pins.

6. Feet – The TBV118L subwoofer has 4 feet for resting on the

ground, stage, or on top of another TBV118L subwoofer.

Bottom View

6

1

1

Mounting Links Down

4

5

3

1

2

Mounting Links Up

4

4

5

4

5

Page 17

Rigging Manual 17

The TBV123 cabinet has two retractable mounting links at the top (3),

that allow it to be attached to a TBV123-FB ybar, to another TBV123

cabinet, or to a TBV118L subwoofer. Eyebolt holes and pole mount

holes are also present.

1. Eyebolt locations – 4 threaded holes (2 top, 2 bottom)

allow eyebolts to be tted for ying the TBV123 cabinet without

the TBV123-FB ybar.

2. Recesses – These shallow recesses are designed to t the

feet of another TBV123 cabinet above it.

3. Mounting Links – These mounting links are used to

secure the TBV123 cabinet to a TBV123-FB ybar, or another

TBV123 cabinet or a TBV118L subwoofer. They rotate about a

captive pivot bolt.

4. Pins – If the mounting links (3) are in the down position,

then the rigging pins are used to secure them. If the mounting

links are used in the up position, the pins can be used to secure

another TBV123 cabinet or TBV118L subwoofer above.

A lanyard is connected to prevent the loss of the pins.

5. Feet – The TBV123 cabinet has 4 feet for resting on top of

another TBV123 cabinet or TBV118L subwoofer.

6. Pole Mount Holes – These 35 mm holes underneath are

for the optional pole mounts, and allow the cabinet to be pole

mounted above a TBV118L subwoofer. The front hole allows the

TBV123 cabinet to tilt down compared to the second hole.

2.12 TBV123 Cabinet Mounting Components

Bottom View

5 6

1

1

3

4

Mounting Links Down

3

4

1

2

Mounting Links Up

3

3

4

Page 18

18 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

2.13 TBV123-FB Flybar Mounting Components

The TBV123-FB ybar shall only be used with TBV123 cabinets and

TBV118L subwoofers. Before use, it must be assembled by securing

the arms to the main bar using the supplied rigging pins.

1. Main Bar – The main bar has six suspension pick points

including one at the front. These 13 mm diameter holes are used

to attach a bow shackle or similar lifting equipment for ying the

assembly.

Use the EASE FOCUS II software to determine the correct y point

for each conguration. The main bar is only used with the arms

(2) attached.

2. Arms – These connec t to the main bar (1) using two supplied

rigging pins (3). Note: The main bar is supplied with a rubber

U-gasket to protect loudspeaker enclosures suspended below the

TBV123-FB. Always attach arms so that the rubber U-gasket is

oriented downwards.

3. Rigging Pins – These rigging pins are used to secure arms

(2) to the main bar (1) and TBV123 or TBV118L mount links to the

arm s (2).

4. Mounting Links and Pins– These extra components

are supplied so that the TBV123 cabinets can be suspended

under TBV123-FB or TBV118L subwoofers in inverted orientation

for mirror image LR congurations. Keep these components in a

safe and dry place if not used.

5. Feet– These are used when the TBV123-FB Flybar is inverted

and used to support a ground stack conguration.

Suspend the array by attaching one or more bow shackles or similar

lifting devices with a pin diameter (D) to t the 13 mm diameter

suspension pick point. Typically, manufacturers of bow shackles

provide suitable devices with pin diameters between 11 mm and

19 mm, and with work loads between 1 tonnes and 3.25 tonnes.

If third-party shackles are used, they must be of the correct size and

correct WLL, and must be supplied and specied by an

authorised person.

WARNING

INSTALLATION AND SETUP SHOULD ONLY BE CARRIED OUT BY

QUALIFIED AND AUTHORIZED PERSONNEL OBSERVING THE VALID

NATIONAL RULES FOR THE PREVENTION OF ACCIDENTS RPA.

REFER TO CHAPTER 1 FOR MORE DETAILS.

Typical Bow Shackle

Flybar Unassembled

3

3

5

1

2

5

4

Flybar Assembled

Page 19

Rigging Manual 19

Chapter 3: Assembling a TBV123 Array on a TBV123-FB Flybar

3.0.1 Required Components

Item Quantity

TBV123-FB Flybar 1

TBV123 Cabinet 4 (maximum)

3.0.2 Preparation

Use the EASE FOCUS II software application to design your system to suit

the venue. This will calculate which ybar mounting hole to attach your

bow shackle.

3.0.3 Location

Move the rst TBV123 cabinet so it is sitting upright on a safe at surface, directly

below the suspension point.

3.0.4 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

TBV123-FB Flybar Working Load Limit (WLL)

Item Working Load Limit (WLL)

TBV 123-F B 100 kg 220.5 lbs

The following procedure shows how to build an array of TBV123 cabinets by

adding them one at a time, up to a maximum of 4.

Alternatively, the cabinets can be pre-assembled into a group of 4,

and then connected to the ybar at a later time.

The system is own using a TBV123-FB ybar that attaches to your

lifting system.

The top TBV123 cabinet connects to two mounting points on the ybar.

Each TBV123 cabinet connects to the cabinet above using the integral

mounting points and rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 4 TBV123 CABINETS FOR 1 TBV123-FB

FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE PERMANENT INJURY

OR DEATH.

3.0.5 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 20

20 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

4. Remove the captive rigging pins (3) on the TBV123-FB.

5. Align the holes in the ends of the ybar arms with the corresponding holes

in the TBV123 cabinet’s mounting links (1). Insert the ybar’s 2 rigging pins

(3) to secure the mounting links and the ybar together.

Double check that both pins are correctly inserted,

before proceeding further.

3

1

3

1

1. Assemble the ybar as shown on page 18.

2. Remove the rigging pins (2) from the TBV123 cabinet and lift up the 2

mounting links (1). Place the rigging pins back into their storage positions.

3. Lift the assembled TBV123-FB ybar into position above the prepared

TBV123 cabinet.

Take care not to trap your ngers between components.

2

1

1

3

3

3

3

Procedure 3.1 Attaching a TBV123 Cabinet to the TBV123-FB Flybar

Page 21

Rigging Manual 21

4. Adjust the position of the mounting links (1) of the lower cabinet to align

with the mounting holes of the top cabinet. Fully insert the rigging pins (2)

and rotate their arms until they are held in place by the clips. This will secure

the rigging pins and also prevent them from rattling from audio vibrations

during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

1. Prepare the next TBV123 cabinet, by lifting the mounting links (1) to the

upwards position. The rigging pins (2) will be used to secure this cabinet to

the TBV123 cabinet above.

2. Attach the bow shackle or other lifting equipment securely to the ybar

mounting hole recommended by the EASE FOCUS II software, then attach

the hook and chain.

3. Carefully position the ybar and cabinet assembly until it is on top of the

lower cabinet. The feet of the top cabinet should t into the recesses on the

top surface of the lower cabinet.

Take care not to trap your ngers between components.

Procedure 3.2 Attaching further TBV123 Cabinets

2

2

1

5. The addition of other TBV123 cabinets is performed by repeating steps 3 and

4 for each additional cabinet.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 4 TBV123 CABINETS FOR 1 TBV123-FB

FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE PERMANENT INJURY

OR DEATH.

NOTE

Disassembly is the reverse of assembly.

Page 22

22 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

The following procedure shows how to build an array of TBV118L subwoofers by

adding them one at a time, up to a maximum of 2.

The system is own using a TBV123-FB ybar that attaches to your lifting system.

The top TBV118L subwoofer connects to two mounting points on the ybar.

Each TBV118L subwoofer connects to the subwoofer above using the integral

mounting points and rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 2 TBV118L SUBWOOFERS FOR

1 TBV123-FB FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

4.0.5 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Chapter 4: Assembling a TBV118L Array on a TBV123-FB Flybar

4.0.1 Required Components

Item Quantity

TBV123-FB Flybar 1

TBV118L Subwoofer 2 (maximum)

4.0.2 Preparation

Use the EASE FOCUS II software application to design your system to suit the

venue. This will calculate which ybar mounting hole to attach your bow shackle.

4.0.3 Location

Move the rst TBV118L subwoofer cabinet so it is sitting upright on a safe at

surface, directly below the suspension point.

4.0.4 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

TBV123-FB Flybar Working Load Limit (WLL)

Item Working Load Limit (WLL)

TBV 123-F B 100 kg 2 20.5 lbs

Page 23

Rigging Manual 23

Procedure 4.1 Assembling a TBV118L Array on a TBV123-FB Flybar

1. Prepare the TBV118L subwoofer, by removing the rigging pins (2) and lifting

the mounting links (1) to the upwards position.

2. Lif t the assembled TBV123-FB ybar into position above the prepared

TBV118L subwoofer.

Take care not to trap your ngers between components.

3. Remove the captive rigging pins (3) on the TBV123-FB and place the TBV118L

rigging pins (2) back in their storage position on the top enclosure.

4. Align the holes in the ends of the ybar arms with the corresponding holes

in the TBV118L subwoofer's mounting links (1). Insert the two, captive ybar

rigging pins (3) to secure the mounting links and the ybar together.

Double check that both pins are correctly inserted,

before proceeding further.

3

1

3

1

1

2

3

3

Page 24

24 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

5. If you are ying just one TBV118L subwoofer, then this completes the

assembly procedure. To add another TBV118L subwoofer, continue with the

procedure steps below.

6. Attach the bow shackle or other lifting equipment securely to the ybar

mounting hole recommended by the EASE FOCUS II software, then attach

the hook and chain.

7. Prepare the next TBV118L subwoofer, by removing the rigging pins (2) and

lifting the mounting links (1) to the upwards position.

8. Carefully position the ybar/rst subwoofer assembly until it is on top of the

prepared lower subwoofer (with its mounting links (1) up). The feet of the

top subwoofer should t into the recesses on top of the lower subwoofer.

Take care not to trap your ngers between components.

9. Adjust the position of the mounting links (1) of the lower subwoofer to align

with the lower mounting holes of the upper subwoofer. Fully insert the

rigging pins (2) and rotate the arms until they are held in place by the clips.

This will further secure the rigging pins and also prevent them from rattling

from audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 2 TBV118L SUBWOOFERS FOR

1 TBV123-FB FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

NOTE

Disassembly is the reverse of assembly.

Procedure 4.1 continued

2

1

2

1

Page 25

Rigging Manual 25

Chapter 5: Assembling a Mixed Array on a TBV123-FB Flybar

5.0.1 Required Components

Item Quantity

TBV123-FB Flybar 1

TBV118L Subwoofer 1 (maximum)

TBV123 Cabinet 2 (maximum)

5.0.2 Preparation

Use the EASE FOCUS II software application to design your system to suit the

venue. This will calculate which ybar mounting hole to attach your bow shackle.

5.0.3 Location

Move the TBV118L subwoofer cabinet so it is sitting upright on a safe at surface,

directly below the suspension point.

5.0.4 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

TBV123-FB Flybar Working Load Limit (WLL)

Item Working Load Limit (WLL)

TBV 123-F B 100 kg 220.5 lbs

The following procedure shows how to build a mixed array of one TBV118L

subwoofer and 2 TBV123 cabinets.

The system is own using a TBV123-FB ybar that attaches to your

lifting system.

The TBV118L subwoofer connects to the mounting points on the ybar. The top

TBV123 cabinet connects to the subwoofer above using the integral mounting

points and rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 1 TBV118L SUBWOOFER AND 2 TBV123

CABINETS FOR 1 TBV123-FB FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY

CAUSE PERMANENT INJURY OR DEATH.

WARNING

THIS ARRAY SHALL ONLY BE MADE WITH THE TBV118L SUBWOOFER ON TOP, AND

THE TBV123 CABINETS BELOW. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

5.0.5 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 26

26 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

1. Assemble the TBV123-FB ybar and a TBV118L subwoofer as shown in

procedure 4.1.

2. Attach the bow shackle or other lifting equipment securely to the ybar

mounting hole recommended by the EASE FOCUS II software, then attach

the hook and chain.

3. Carefully position the ybar/rst subwoofer assembly until it is on top of the

prepared TBV123 cabinet (with its mounting links (1) up). The front feet of

the subwoofer should t into the recesses on the top surface of the

TBV123 cabinet.

Take care not to trap your ngers between components.

Procedure 5.1 Assembling a Mixed Array on a TBV123-FB Flybar

4. Adjust the position of the mounting links (1) of the TBV123 cabinet to align

with the lower mounting holes of the subwoofer. Fully insert the rigging

pins (2) and rotate the arms until they are held in place by the clips. This will

further secure the rigging pins and also prevent them from rattling from

audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

2

1

2

1

2

5. If you are only adding one TBV123 cabinet, then this completes

the procedure.

6. Carefully hoist and position the ybar/subwoofer/cabinet assembly until it

is on top of the prepared lower TBV123 cabinet (mounting links (1) up). The

feet of the upper TBV123 cabinet should t into the recesses on top of the

lower cabinet.

Take care not to trap your ngers between components.

Page 27

Rigging Manual 27

7. Adjust the position of the mounting links (1) of the TBV123 cabinet to align

with the lower mounting holes of the upper TBV123 cabinet. Fully insert the

rigging pins (2) and rotate the arms until they are held in place by the clips.

This will further secure the rigging pins and also prevent them from rattling

from audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

8. This completes the mixed array assembly procedure.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 1 TBV118L SUBWOOFER AND 2 TBV123

CABINETS FOR 1 TBV123-FB FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY

CAUSE PERMANENT INJURY OR DEATH.

WARNING

THIS ARRAY SHALL ONLY BE MADE WITH THE TBV118L SUBWOOFER ON TOP, AND

THE TBV123 CABINETS BELOW. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

NOTE

Disassembly is the reverse of assembly.

2

1

Page 28

28 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Chapter 6: Assembling a TBV118L Ground Stack

The following procedure shows how to build a ground stack of TBV118L

subwoofers by adding them one at a time, up to a maximum of 3.

Each TBV118L subwoofer connects to the subwoofer above using the integral

mounting points and rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 3 TBV118L SUBWOOFERS FOR THIS

GROUND STACK CONFIGURATION. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

6.0.5 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

6.0.1 Required Components

Item Quantity

TBV118L Subwoofer 3 (maximum)

6.0.2 Preparation

Use the EASE FOCUS II software application to design your system to suit the

venue. This will calculate the coverage of the ground stack.

6.0.3 Location

The TBV118L subwoofers should be located on a at, horizontal, and dry surface,

capable of supporting the weight of the complete assembly.

6.0.4 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

Page 29

Rigging Manual 29

Procedure 6.1 Assembling a TBV118L Ground Stack

1. Prepare the rst TBV118L subwoofer, by lifting the mounting link s (1) to the

upwards position. The rigging pins (2) will be used to secure this subwoofer

to the subwoofer to be added on top.

2. Carefully position the next TBV118L subwoofer until it is on top of the

prepared lower subwoofer. The feet of the top subwoofer should t into the

recesses on the top sur face of the lower subwoofer.

Take care not to trap your ngers between components.

3. Adjust the position of the mounting links (1) of the lower subwoofer to align

with the lower mounting holes of the upper subwoofer. Fully insert the

rigging pins (2) and rotate the arms until they are held in place by the clips.

This will further secure the rigging pins and also prevent them from rattling

from audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

1

1

2

2

1

Page 30

30 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Procedure 6.1 continued

4. The addition of other TBV118L subwoofers is performed by repeating steps

1, 2 and 3 for each additional subwoofer.

5. Make sure that the assembly is securely tied down

with guy wires to prevent tipping.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 3 TBV118L SUBWOOFERS FOR THIS

GROUND STACK CONFIGURATION. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

NOTE

Disassembly is the reverse of assembly.

Page 31

Rigging Manual 31

7.0.1 Required Components

Item Quantity

TBV118L Cabinet 2 (maximum)

TBV123 Cabinet 3 (maximum)

7.0. 2 Preparation

Use the EASE FOCUS II software application to design your system to suit the

venue. This will calculate the coverage of the ground stack.

7.0. 3 Location

The TBV118L subwoofer should be located on a at, horizontal, and dry surface,

capable of supporting the weight of the complete assembly.

7.0. 4 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

Chapter 7: Assembling a TBV118L Subwoofer and TBV123 Ground Stack

The following procedure describes how to assemble a ground stack with a

TBV118L subwoofer as a base and and one or two TBV123 cabinets on top.

The TBV123 cabinet connects to the TBV118L subwoofer using the integral

mounting points and rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 2 TBV118L SUBWOOFER AND 3 TBV123

CABINETS FOR THIS GROUND STACK CONFIGURATION. FAILURE TO FOLLOW

INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

7.0. 5 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 32

32 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Procedure 7.1 - Assembling a TBV118L Subwoofer and TBV123 Ground Stack

1. Prepare the TBV118L subwoofer, by lifting the mounting links (1) to the

upwards position. The rigging pins (2) will be used to secure this subwoofer

to the TBV123 cabinet on top.

2. Carefully position the TBV123 cabinet until it is on top of the prepared lower

subwoofer. The feet of the TBV123 cabinet should t into the recesses on the

top surface of the TBV118L subwoofer.

Take care not to trap your ngers between components.

3. Adjust the position of the mounting links (1) of the TBV118L subwoofer to

align with the lower mounting holes of the TBV123 cabinet. Fully insert the

rigging pins (2) and rotate the arms until they are held in place by the clips.

This will further secure the rigging pins and also prevent them from rattling

from audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

1

1

2

2

1

Page 33

Rigging Manual 33

4. A second TBV123 cabinet can be added to the ground stack. Lower it onto

the rst TBV123 cabinet and make sure its feet t into the recesses on the

top surface of the rst TBV123 cabinet. Attach it to the mounting links of the

rst TBV123 cabinet, and secure with the rigging pins in the same way as

shown in step 3.

Take care not to trap your ngers between components.

Double check that all pins are correctly inserted.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 2 TBV118L SUBWOOFER AND 3 TBV123

CABINETS FOR THIS GROUND STACK CONFIGURATION. FAILURE TO FOLLOW

INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

NOTE

Disassembly is the reverse of assembly.

Page 34

34 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

8.0.1 Required Components

Item Quantity

TBV123-FB Flybar 1

TBV123 Cabinet 3 (maximum)

8.0.2 Preparation

Use the EASE FOCUS II software application to design your system to suit the

venue. This will calculate the coverage of the ground stack.

8.0.3 Location

The TBV123 array ground stack should be located on a at, horizontal, and dry

surface, capable of supporting the weight of the complete assembly.

8.0.4 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

Chapter 8: Assembling a TBV123 Array Ground Stack

The following procedure describes how to assemble a ground stack with TBV123

cabinets mounted on a TBV123-FB ybar as a base.

The TBV123 cabinets connect to each other and the TBV123-FB ybar using the

integral mounting points and rigging pins. No tools are required.

The purpose of the TBV123-FB ybar is to add stability and prevent the ground

stack from tipping backwards. Its main bar extends out behind the ground stack.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 3 TBV123 CABINETS FOR THIS GROUND

STACK CONFIGURATION. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

WARNING

ALWAYS GROUND STACK THE TBV123 CABINETS WITH THE TBV123-FB FLYBAR TO

PREVENT TIPPING.

8.0.5 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 35

Rigging Manual 35

Procedure 8.1 - Assembling a TBV123 Array Ground Stack

1. Prepare the TBV123-FB ybar by adding the ex tra mounting links

(supplied with the ybar) to the end of each arm. Lift the mounting links to

the upwards position.

Double check that all pins are correc tly inserted,

before proceeding further.

2. Carefully position the TBV123 cabinet until it is on top of the prepared

TBV123-FB ybar. Remove the rigging pins from the top of the

TBV123 cabinet; these will be used to join the cabinet to the ybar.

Take care not to trap your ngers between components.

3. Adjust the position of the mounting links (1) of the TBV123-FB ybar to

align with the lower mounting holes of the TBV123 cabinet. Fully insert the

rigging pins (2) and rotate the arms until they are held in place by the clips.

This will further secure the rigging pins and also prevent them from rattling

from audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

2

1

Page 36

36 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

4. Lower the second TBV123 cabinet onto the rst TBV123 cabinet and make

sure its feet t into the recesses on the top surface of the rst TBV123

cabinet. Attach it to the mounting links of the rst TBV123 cabinet, and

secure with the rigging pins in the same way as shown in step 3.

Take care not to trap your ngers between components.

Double check that all pins are correc tly inserted,

before proceeding further.

5. A third cabinet can be added in the same way.

Make sure that the nal assembly is securely tied down with

guy wires to prevent tipping. (The top cabinet’s unused

mounting links can be used to attach the guy wires.)

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 3 TBV123 CABINETS FOR THIS GROUND

STACK CONFIGURATION. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

WARNING

ALWAYS GROUND STACK THE TBV123 CABINETS WITH THE TBV123-FB FLYBAR TO

PREVENT TIPPING.

NOTE

Disassembly is the reverse of assembly.

NOTE

The TBV123 cabinet ground stack can also be assembled inverted on the ybar.

In this case, the lowest TBV123 cabinet uses its own mounting links and rigging

pins to attach to the ybar. This will create a mirror-image groundstack to

complement the ground stack described above.

Procedure 8.1 continued

Page 37

Rigging Manual 37

9.0.1 Required Components

Item Quantity

TBV118L Subwoofer 2 (maximum)

TBV123 Cabinet 2 (maximum)

Item Length

TPole 60 60 cm

TPole 90 90 cm

TPo le 120 120 c m

9.0.2 Location

The TBV118L subwoofer should be located on a at, horizontal, and dry surface,

capable of supporting the weight of the complete assembly.

9.0.3 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

Chapter 9: Pole Mounting a TBV123 Cabinet on a TBV118L Subwoofer

The following procedure describes how to pole mount a TBV123 cabinet onto a

TBV118L Subwoofer.

The subwoofer has a top panel M20 thread mount receptacle that can accept an

optional distance rod accessory and the TBV123 has two pole mount receptacles

underneath that allow it to be mounted at two dierent angles for

best coverage.

The M20 distance rods are available in three dierent lengths:

60, 90, and 120 cm.

A second TBV123 cabinet may be added on top of the rst cabinet and secured

using the integral mounting link s and rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 2 TVB123 AND 2 TBV118L CABINETS FOR

THIS GROUND STACK CONFIGURATION. FAILURE TO FOLLOW INSTRUCTIONS MAY

CAUSE PERMANENT INJURY OR DEATH.

WARNING

FOR GROUND STACKED CONFIGURATIONS OF 2 TBV123 CABINETS PLUS 1 OR

2 TBV118L SUBWOOFERS, THE STACKED SYSTEM MUST BE SECURED TO THE

STACKING PLATFORM USING RATCHET STRAPS OR GUY WIRES. FAILURE TO FOLLOW

INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

9.0.4 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of

three or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 38

38 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

Procedure 9.1 - Pole mounting a TBV123 cabinet on a TBV118L subwoofer

1. Screw the pole into the top of the TBV118L subwoofer using the M20

threaded attachment, and make sure it is tight and secure.

2. Carefully position the TBV123 cabinet until one of its mounting holes ts

over the top of the pole, then lower it fully down onto the pole.

3. There are two holes to choose from; the front hole allows the TBV123

cabinet to tilt down.

Double check that the assembly is secure on the

TBV118L subwoofer, and that the TBV123 cabinet is

fully mounted all the way onto the pole.

4. A maximum of 2 TBV123 cabinets can be pole mounted.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 2 TBV123 and 1 or 2 TBV118L CABINETS FOR

THIS GROUND STACK CONFIGURATION. FAILURE TO FOLLOW INSTRUCTIONS MAY

CAUSE PERMANENT INJURY OR DEATH.

5. If a second TBV123 cabinet is used, double check that all pins are correctly

inserted, and that the 2 TBV123 cabinets are securely connected together

before tting them onto the pole.

For most applications, the forward socket of the dual angle TBV123 pole

socket should be used. This will tilt the lower of the two speakers 15° down

to provide coverage for the near listeners while the upper speaker will face

straight out to cover more distant audience members. As a visual coverage

check, listeners should not be able to see the bottom or top surfaces of the

two-speaker array.

WARNING

FOR GROUND STACKED CONFIGURATIONS OF 2 TBV123 CABINETS PLUS 1 OR

2 TBV118L SUBWOOFERS, THE STACKED SYSTEM MUST BE SECURED TO THE

STACKING PLATFORM USING RATCHET STRAPS OR GUY WIRES. FAILURE TO FOLLOW

INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

6. Disassembly is the reverse of assembly.

Page 39

Rigging Manual 39

Inverted array

10.0.1 Required Components

Item Quantity

TBV123-FB Flybar 1 (maximum)

TBV123 Cabinet 4 (maximum)

10.0.2 Location

Move the rst TBV123 cabinet so it is sitting upright on a safe at surface,

directly below the suspension point.

10.0.3 Measured Weights

Please see Section 2.3 Weights on Page 9, and refer to EASE Focus Rigging

Parameters when designing your system.

TBV123-FB Flybar Working Load Limit (WLL)

Item Working Load Limit (WLL)

TBV123-FB 100 kg 220.5 lbs

Chapter 10: Assembling an Inverted TBV123 Array

The TBV123 cabinets may be mounted inverted on the TBV123-FB ybar to create

a mirror-image to complement TBV123 cabinets in their normal orientation. For

example, a normal array on the right would have its high-frequency drivers away

from the stage; an inverted array on the left would also have its high-frequency

drivers away from the stage

The following procedure shows how to build an array of inverted TBV123 cabinets

by adding them one at a time, up to a maximum of 4.

The system is own using a TBV123-FB ybar that attaches to your lifting system.

The top TBV123 cabinet connects to 2 mounting points on the ybar, using the

2 extra mounting links and rigging pins supplied with the ybar. Each TBV123

cabinet connects to the cabinet above using the integral mounting points and

rigging pins. No tools are required.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 4 TBV123 CABINETS FOR 1 TBV123-FB

FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE PERMANENT INJURY

OR DEATH.

10.0.4 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 40

40 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

3. Adjust the position of the mounting links (1) of the TBV123-FB ybar to align

with the top mounting holes of the TBV123 cabinet. Fully insert the rigging

pins (2) and rotate the arms until they are held in place by the clips. This will

further secure the rigging pins and also prevent them from rattling from

audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

2. Invert the rst TBV123 cabinet and remove its rigging pins so the mounting

links drop down. Carefully position the TBV123-FB ybar until it is on top of

the inverted TBV123 cabinet.

Take care not to trap your ngers between components.

Procedure 10.1 - Assembling an Inverted TBV123 Array

1. Prepare the TBV123-FB ybar by adding the ex tra mounting links

(supplied with the ybar) to the end of each arm.

Double check that all pins are correc tly inserted,

before proceeding further.

2

1

Page 41

Rigging Manual 41

4. Attach the bow shackle or other lifting equipment securely to the ybar

mounting hole recommended by the EASE FOCUS II software, then attach

the hook and chain.

5. Prepare the next TBV123 cabinet, by removing the rigging pins (2) so the

mounting links drop down.

6. Carefully hoist and position the ybar and cabinet assembly until it is on

top of the lower cabinet. The feet of the lower cabinet should t into the

recesses on the bot tom of the top cabinet.

Take care not to trap your ngers between components.

7. Adjust the position of the mounting links (1) of the upper cabinet to align

with the mounting holes of the lower cabinet. Fully insert the rigging pins

(2) and rotate their arms until they are held in place by the clips. This will

secure the rigging pins and also prevent them from rattling from audio

vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

2

1

8. The addition of other TBV123 cabinets is performed by repeating steps 5, 6,

and 7 for each additional cabinet (upto a maximum total of 4). Mount links

for the bottom TBV123 cabinet can be secured using the spare L-rigging pins

that are supplied with the TBV123-FB.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 4 TBV123 CABINETS FOR 1 TBV123-FB

FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE PERMANENT INJURY

OR DEATH.

WARNING

ALWAYS USE A TBV123-FB FLYBAR WHEN FLYING AN ARRAY. FAILURE TO FOLLOW

INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

NOTE

Disassembly is the reverse of assembly.

Page 42

42 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

An inverted mixed array can be assembled by attaching an inverted TBV118L

cabinet to the TBV123-FB ybar, using the extra mounting links (1) supplied with

the ybar. Inverted TBV123 cabinets can then be attached to the lower side of the

inverted TBV118L cabinet.

1. Prepare the TBV123-FB ybar by adding the ex tra mounting links (1)

(supplied with the ybar) to the end of each arm, and secure with the

rigging pins (3).

Double check that all pins are correc tly inserted,

before proceeding further.

2. Invert the rst TBV118L cabinet and carefully position the TBV123-FB ybar

until it is on top of the inverted TBV118L cabinet.

Take care not to trap your ngers between components.

3. Adjust the position of the mounting links (1) of the TBV123-FB ybar to align

with the top mounting holes of the TBV118L cabinet. Fully insert the rigging

pins (2) and rotate the arms until they are held in place by the clips. This will

further secure the rigging pins and also prevent them from rattling from

audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

1

2

10.2 Assembling an Inverted Mixed Array

21

3

3

1

2

3

4

Page 43

Rigging Manual 43

4. Attach the bow shackle or other lifting equipment securely to the ybar

mounting hole recommended by the EASE FOCUS II software, then attach

the hook and chain.

5. Prepare the inverted TBV123 cabinet. Carefully hoist and position the

ybar and cabinet assembly until it is on top of the TBV123 cabinet.

The feet of the TBV123 cabinet should t into the recesses on the bottom of

the TBV118L cabinet.

Take care not to trap your ngers between components.

6. Remove TBV118L rigging pins(3) so the mounting links (4)drop down.

Adjust the position of the mounting links (4) of the TBV118L cabinet to align

with the mounting holes of the TBV123 cabinet. Fully insert the rigging

pins (3) and rotate their arms until they are held in place by the clips.

This will secure the rigging pins and also prevent them from rattling from

audio vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

3

4

3

5

6

4

Page 44

44 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

7. If you are only adding one inverted TBV123 cabinet, then this completes

the procedure.

8. Carefully hoist and position the ybar/subwoofer/cabinet assembly until it is

on top of the prepared lower TBV123 cabinet. The feet of the upper TBV123

cabinet should t into the recesses on top of the lower cabinet.

Take care not to trap your ngers between components.

9. Remove upper TBV123 rigging pins(5) so the mounting links (6)drop down.

Adjust the position of the mounting links (6) of the TBV123 cabinet to align

with the mounting holes of the lower cabinet. Fully insert the rigging pins

(5) and rotate their arms until they are held in place by the clips. This will

secure the rigging pins and also prevent them from rattling from audio

vibrations during operation.

Double check that all pins are correc tly inserted,

before proceeding further.

10. This completes the mixed array assembly procedure.

WARNING

DO NOT EXCEED A TOTAL QUANTITY OF 1 TBV118L SUBWOOFER FOR 2 TBV123

CABINETS FOR 1 TBV123-FB FLYBAR. FAILURE TO FOLLOW INSTRUCTIONS MAY

CAUSE PERMANENT INJURY OR DEATH.

WARNING

THIS ARRAY SHALL ONLY BE MADE WITH THE TBV118L SUBWOOFER ON TOP, AND

THE TBV123 CABINETS BELOW. FAILURE TO FOLLOW INSTRUCTIONS MAY CAUSE

PERMANENT INJURY OR DEATH.

NOTE

Disassembly is the reverse of assembly.

5

6

5

6

Page 45

Rigging Manual 45

11. 0 .1 Required Components

Item Quantity

M10 x 40 mm 2 (minimum)

TBV 123 As required

TB V118L As required

11. 0 . 2 Measured Weights

Item Quantity Weigh t

TB V118L 1 37.0 kg 81. 6 lbs

TBV 123 1 22.0 kg 48.5 lbs

TB V118 L-A N 1 38.5 kg 8 4.9 lbs

TBV123-AN 1 23.0 kg 50.7 lbs

11. 0 . 3 Maximum Quantities

Maximum allowed quantities and system weights for 10:1, 7:1 and 5:1 design

factors. Ensure that eyebolts are specied with sucient WLL to support the

system weight at the desired design factor. It is recommended to check local

regulations regarding design factor requirements in order to comply with

regional codes.

10:1 Design Factor Eyebolt Suspension - Passive Or Powered

TB V118 L-A N 3 2 1 0

TBV123-AN 0 2 3 4

System 115 .5 k g 123.0 kg 10 7.5 kg 92.0 kg

Weight 254.6 lbs 271.2 lbs 237.0 lbs 202.8 lbs

7:1 Design Factor Eyebo lt Suspension - Passive Or Powered

TB V118 L-A N 5 4 3 2 1 0

TBV123-AN 0 2 3 5 6 6

System 192.5 kg 200.0 kg 184. 5 kg 192.0 kg 176. 5 kg 138.0 kg

Weight 424.4 lbs 4 40.9 lbs 4 06.7 lbs 423.3 lbs 3 89.1 lb s 30 4.2 lbs

5:1 Design Factor Eyebo lt Suspension - Passive Or Powered

TB V118 L-A N 6 5 4 3 2 1 0

TBV123-AN 0 1 3 4 5 6 7

System 231.0 kg 215. 5 kg 2 23.0 kg 2 07. 5 k g 192.0 kg 176 .5 kg 161.0 kg

Weight 50 9.3 lb s 47 5.1 l bs 491. 6 lbs 457.5 lbs 423.3 lbs 38 9.1 l bs 354.9 l bs

Chapter 11: Using Eyebolts

The various arrays shown in this manual may be own using 2 eyebolts instead of

the TBV123-FB ybar.

The recommended eyebolt is M10, with a thread greater than 18 mm, and a

working load limit adequate for the size of the specic array to be suspended.

Third party eyebolts must be specied and supplied by authorised,

qualied personnel.

The system is own with 2 two eyebolts securely attached to the threaded holes

in the top surface of the uppermost TBV123 cabinet or TBV118L subwoofer.

Two threaded holes are also provided on the bottom surface. These can be used

with eyebolts for tether points, or for ying the systems inverted.

WARNING

DO NOT EXCEED THE QUANTITY OF TBV118L SUBWOOFERS OR TBV123 CABINETS

SHOWN IN 11.0.3 THE TABLE OF MAXIMUM QUANTITIES. FAILURE TO FOLLOW

INSTRUCTIONS MAY CAUSE PERMANENT INJURY OR DEATH.

DO NOT EXCEED A MAXIMUM 2LEG BRIDLE HITCH ANGLE OF 60 DEGREES FOR

SINGLE POINT SUSPENSION CONFIGURATIONS. FAILURE TO FOLLOW INSTRUCTIONS

MAY CAUSE PERMANENT INJURY OR DEATH.

11. 0 . 4 Personnel

The following procedures shall be undertaken by experienced, certied,

qualied, and authorised personnel only. The procedures require the use of three

or more authorised persons.

Protective Headwear shall be worn

Protective Foot wear shall be worn

Protective Gloves shall be worn

Protective Eyewear shall be worn

Practice Safe Lifting

Page 46

46 TBV123 / TBV123-AN and TBV118L / TBV118L-AN Rigging Manual

The TBV123 cabinets and TBV118L cabinets may be own individually,

or assembled into the arrays shown in this manual.

1. If ying individually, the top 2 eyebolts are used for suspension, and the

lower 2 eyebolts can be used for positioning or ying inverted.

2. If ying in an array, follow all the instructions and safety warnings in the

preceeding chapters to assemble the TBV123 cabinets and/or TBV118L

subwoofer cabinets together using the integral mounting links and

rigging pins.

3. In a mixed array, the TBV123 cabinets shall always be

own below the TBV118L subwoofer.

4. Double check that all rigging pins are correctly inserted,

and that the arrays are correctly and securely assembled

before proceeding further.

5. Apply thread lock (Loctite Blue 242 or equivalent) to eyebolts then securely

screw into the top threaded eyebolt holes of the uppermost TBV123 cabinet

or TBV118L subwoofer.

6. 2 threaded holes are also provided on the bottom surface. Eyebolts can be

tted in these locations, and can be used for tether points, or for ying the

systems inverted.

7. Secondary safet y connections shall always be used.

8. Do not exceed a maximum angle of 60 degrees for 2-leg

bridle hitch suspension. Failure to follow instructions may

cause permanent injur y or death.

MAXIMUM

ANGLE 60

60

Top eyebolts x2

for suspension

Bottom eyebolts

for guy wires

Threaded Eyebolt

Holes

Threaded Eyebolt

Holes

Page 47

Rigging Manual 47

Chapter 12: Safety Inspection

The following notes must be read and followed before suspending the systems or ground stacking:

Cabinets

Inspect all cabinets carefully and make sure that all sur faces are clean, in good condition, and free from cracks, corrosion, or any other defects that may

weaken the assembly. Check for any missing screws, rigging pins, mounting links, pivot pins, or their nuts.

All cabinets must be clean and dry, and free from any debris that might cause incorrect or faulty operation.

Check that all mounting holes are clean and in good condition, and will accept the rigging pins correctly.

Flybar

Inspect the ybar carefully and make sure it is in good condition and free from cracks, corrosion, or any other defects that may weaken the assembly.

Check for any missing rigging pins, or mounting links.

Check that all mounting holes are clean and in good condition, and will accept the rigging pins correctly.

Rigging Pins

Inspect all rigging pins carefully and make sure they are in good condition and free from cracks, corrosion, or any other defects that may weaken them.

Check that the retaining ball bearings are present and operate correctly.

Check that all rigging pins and connecting mounting links are correctly and fully inserted.

Mounting Links

Inspect all mounting links and their pivot pins and nuts carefully and make sure they are in good condition and free from cracks, corrosion,

or any other defects that may weaken them.

Check that the retaining pivot pins are present and operate correctly to retain the mounting link s.

Check that all nuts are present, installed correctly, and retain the pivot pins of the mounting links correctly.

Care and Maintenance

In addition to regular inspec tions, make sure that all equipment is kept clean and dry by careful brushing and wiping down with a cloth.

Light use of lubrication such as WD40® may be applied to the rigging pins and mounting holes.

All equipment must be stored in a clean and dry state to prevent corrosion.

Transportation

Use only recommended road cases to transport the loudspeakers and components.

Regularly Scheduled Inspections

In addition to the visual inspection of all rigging components, regular, more rigorous test and inspection of rigging components must also be carried out.

Safety legislation and test and inspection requirements will vary from country to country. In most cases, semi-annual or annual independent test and inspection by a

suitably approved and qualied inspector will be required. Users must ensure compliance with all applicable safety requirements. TURBOSOUND recommends regular