1

Product Name:

Ultra

-

Gate38

Product Description: 38mm External Wastegate

Product Number: TS-0501-1XXX

------------------------------------------------------------------------------------------------------------------------

IMPORTANT NOTES ON YOUR EXTERNAL WASTEGATE

- Fitting your Ultra-Gate38 may require fabrication or modification to your exhaust manifold. Turbosmart recommends that your

Ultra-Gate38 is fitted by an appropriately qualified technician.

- The Ultra-Gate38 is designed for use with a turbocharger that does not have an internal wastegate.

- Consult your local specialist before setting your desired boost pressure, setting boost beyond your engines capability may result in

engine damage.

- DO NOT wrap the body of the wastegate with exhaust wrap

- DO NOT Mount the wastegate so that the top diaphragm housing is less than 100mm from a heat source

- Allow for adequate cool airflow around the top diaphragm housing

RECOMMENDATIONS

- Turbosmart recommends that boost pressure is set using a Dynamometer and not on public roads.

- Turbosmart recommends that a boost gauge be permanently fitted to the vehicle.

- Turbosmart recommends that the engines Air/Fuel ratio is checked while setting the desired boost pressure, as any increase in

boost pressure can cause the engine to run “LEAN”, resulting in possible engine damage.

------------------------------------------------------------------------------------------------------------------------

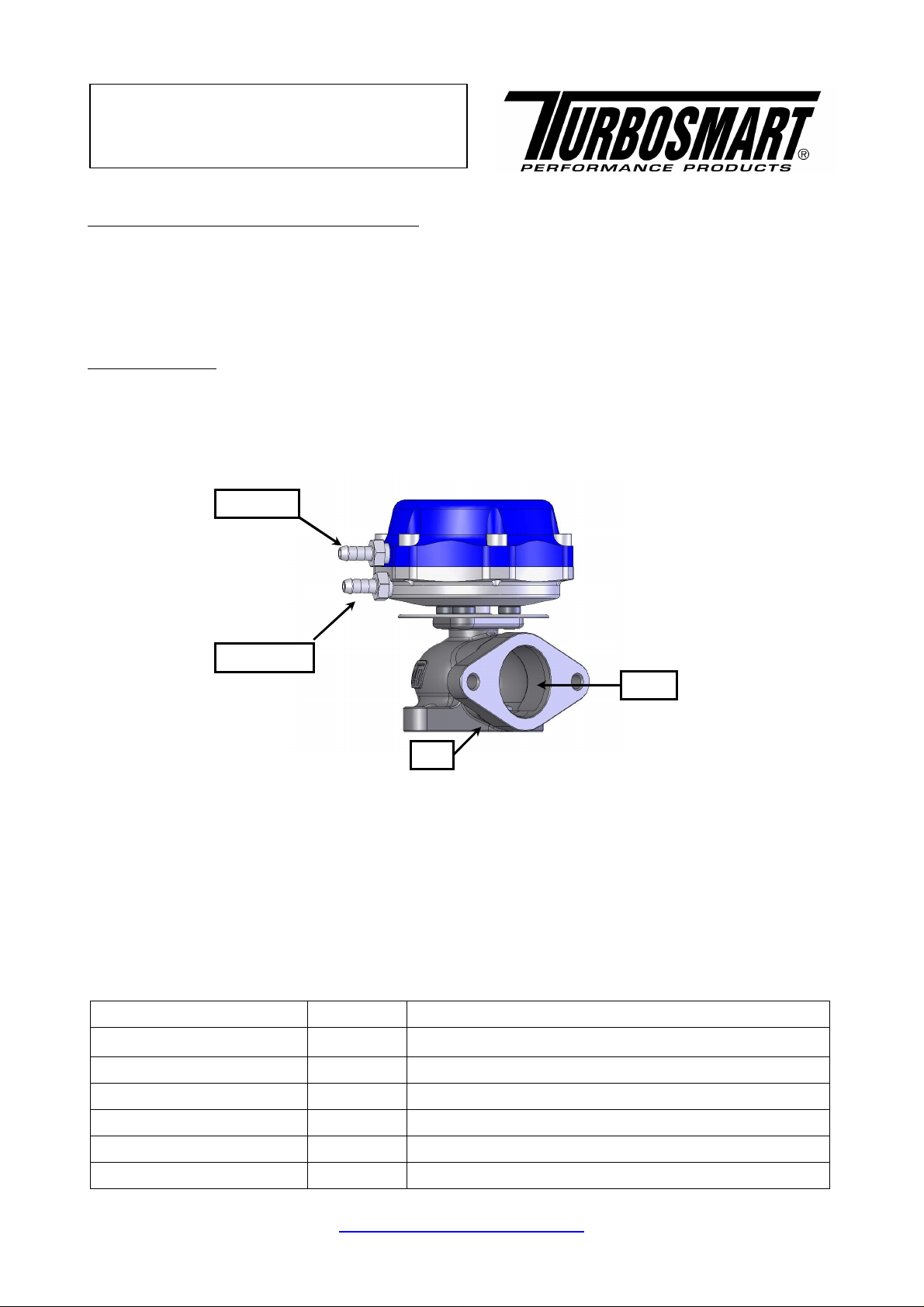

BASIC COMPONENTS OF YOUR ULTRA-GATE38 38MM EXTERNAL WASTEGATE

Use the diagram to help identify the “top” and “bottom” ports, and inlet/outlet ports of your wastegate.

- When pressure is applied to the “bottom” port of a wastegate, i.e. underneath the wastegate diaphragm, it acts against the

wastegate spring and the wastegate valve opens.

- When pressure is applied to the “top” port of a wastegate, i.e. above the wastegate diaphragm, its acts with the wastegate

spring and helps to close the wastegate valve.

- The Inlet is connected to the exhaust manifold before the turbine housing of your turbocharger. See recommendations

following for Ultra-Gate38 mounting position.

- Outlet returns exhaust gas back into the exhaust system after the turbocharger. (NOTE if mounted on a dedicated race car

the outlet can be vented directly to atmosphere towards the ground)

CONTENTS

Please make sure that the following parts have been included in the box

Part Quantity Description

“Top” Port

“Bottom” Port

Outlet

Inlet

Ultragate 38 mm wastegate 1 38mm external wastegate with pre-fitted spring (check the label on the

box for rating)

Stainless steel gasket 2 Stainless steel gaskets for sealing external wastegate to flanges

Valve seat 1 Stainless steel valve seat

M8X25 Socket head cap screw 2 For securing the outlet flange to the wastegate

M8 Nuts 2 For securing the Wastegate to the inlet flange

M8X35 Socket head cap screw 2 For securing the inlet flange to the wastegate

www.TURBOSMARTONLINE.com

2

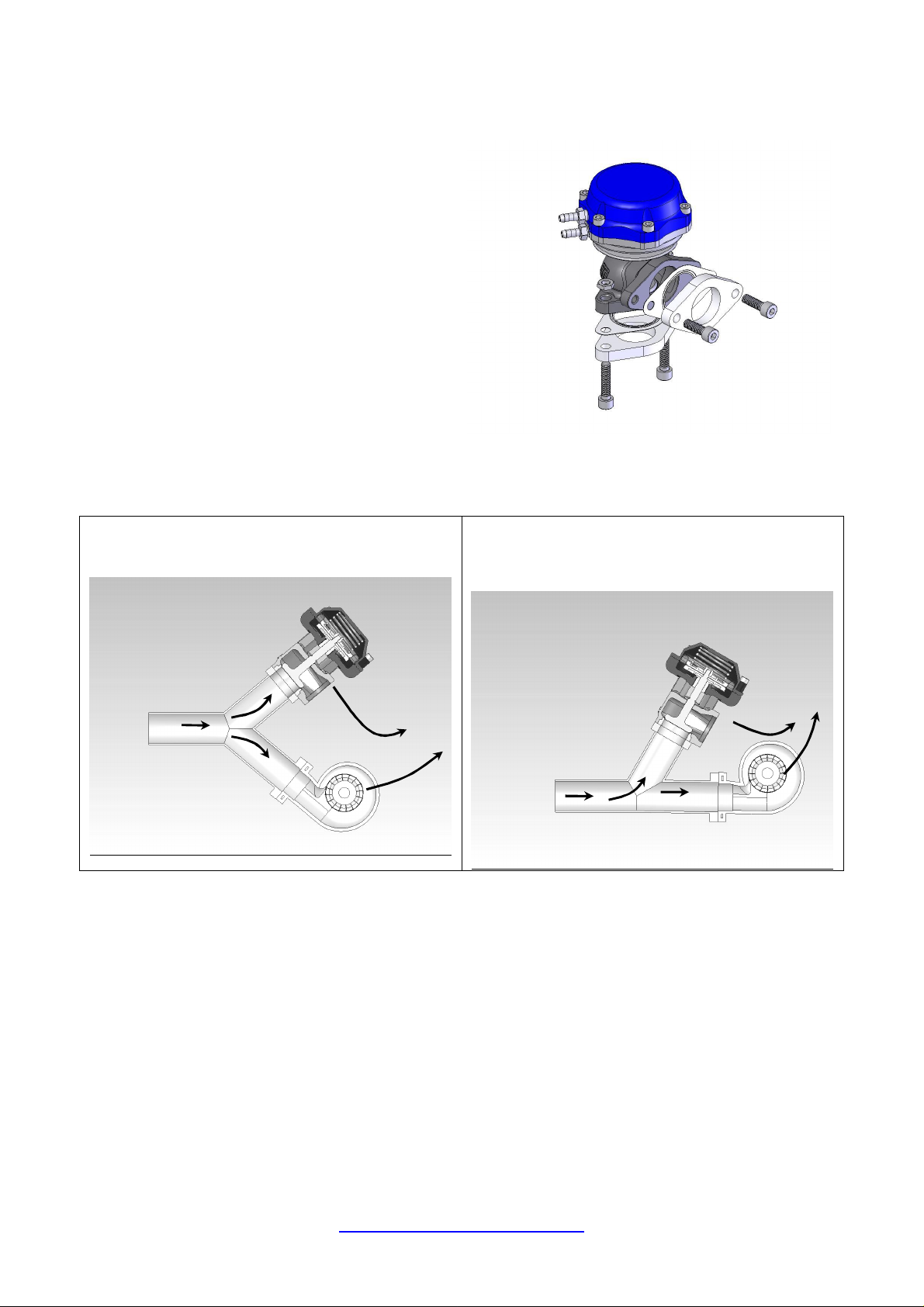

RECOMMENDATIONS FOR MOUNTING YOUR ULTRA-GATE38

The mounting position of your Ultra-Gate38 will be largely

determined by your turbo and manifold setup and may be

constrained by space restrictions in your engine bay. The following

points should be considered when mounting your Ultra-Gate38.

- The optional exhaust weld flanges should be welded to

your exhaust system. The weld flanges are compatible

with Stainless Steel and Mild steel welding rod material.

- When securing your Ultra-Gate38 use the supplied

gaskets between the weld flanges and the inlet/outlet

flanges. Use the M8X25 screws to secure the outlet

flange (Note: The bolts screw into the threaded holes on

the outlet flange). Use the M8 nuts and M8X35 screws if

needed to secure inlet flange to your manifold (Note:

Your manifold may have studs to suit so the screws may

not be necessary). Tighten the screws and nuts to a

torque of 8 Nm & lubricate with Never Seize every time

you re-fit the wastegate.

- For best results an attempt should be made if space

allows to mount the Ultra-Gate38 at an angle to the

exhaust flow to allow for better flow than a 90 degree

mounting. See the schematic diagrams below for

examples of mounting positions.

Best Flow – Symmetric Mounting

Symmetric mounting allows an excellent flow of exhaust to the

Ultra-Gate38.

Good Flow – Angled Mounting

Angled mounting allows a good flow of exhaust to the UltraGate38.

Exhaust Gas

from manifold

Wastegate

Exhaust gas

to exhaust

pipe

Turbocharger Turbine

Wastegate

Exhaust gas

to exhaust

pipe

Exhaust Gas

from manifold

Turbocharger Turbine

www.TURBOSMARTONLINE.com

3

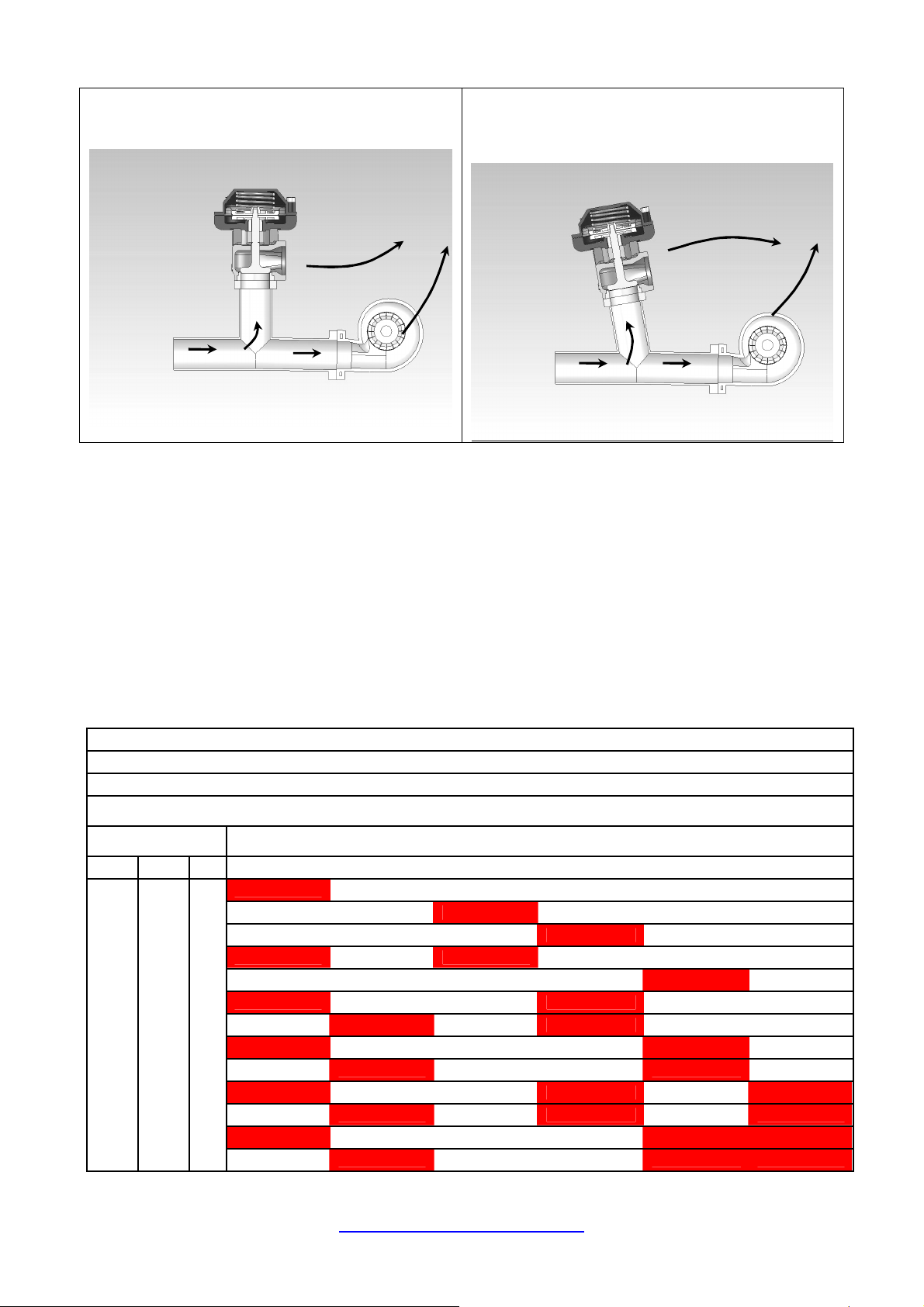

Poor Flow – 90 Degree Mounting

90 degree mounting gives poor exhaust flow to the Ultra-Gate38

and in some circumstances may contribute to over boosting.

Wastegate

Not recommended – Less than 90 Degree Mounting

An angled mounting as shown is not recommended and gives

extremely poor exhaust flow to the Ultra-Gate38.

Exhaust Gas

from manifold

Exhaust gas

to exhaust

pipe

Turbocharger Turbine

Wastegate

Exhaust Gas

from manifold

Turbocharger Turbine

Exhaust gas

to exhaust

pipe

ACHIEVING YOUR TARGET BOOST PRESSURE

There are various factors involved in achieving your target boost pressure including.

- The size of the spring fitted in your wastegate i.e. the boost pressure achieved by the wastegate spring only.

- The desired level of boost pressure and the difference between this and your wastegate spring pressure.

- The size of your turbocharger and wastegate and the resulting exhaust manifold backpressure in your system.

Turbosmart recommends the ideal setup for achieving your target boost pressure is to use the Ultra-Gate38 in conjunction

with a Turbosmart eBoost controller.

IMPORTANT NOTES ON SETTING THE WASTEGATE SPRING PRESSURE

A stiffer spring should only be used when necessary. The Ultra-Gate38 allows for different combinations of spring pressures. All springs

that are adaptable with the Ultra-Gate38 are shown in the table below. The tuner can use combinations of the 3 springs to achieve the

following base boost pressures. To aid in the identification of these springs they are supplied colour coded. If this colour coding is not

clear please use the dimensions in the following table to identity the wastegate spring. Please see the following detailed instructions on

setting your Ultra-Gate38’s spring pressure. The springs chosen should be rated to the lowest boost level desired.

Pressure rating 5 PSI Inner 7 PSI Inner 7 PSI Middle 10 PSI Middle 14 PSI Middle 7 PSI Outer

Part number TS-0501-2003 TS-0501-2004 TS-0501-2005 TS-0501-2006 TS-0501-2007 TS-0501-2008

Colour GRN/GRY GRN/WHT GRN/PUR GRN/BLU GRN/RED GRN/PNK

Dimensions

Desired Boost

Pressure

KPa BAR PSI

34.47 0.345 5 ▲

48.26 0.483 7

68.95 0.69 10

82.74 0.827 12 ▲

96.53 0.965 14

103.4 1.03 15 ▲

117.2 1.172 17

131 1.31 19 ▲

144.8 1.448 21

151.7 1.517 22 ▲

165.5 1.655 24

179.3 1.793 26 ▲

193.1 1.931 28

36.5mm OD,

55mm length

Changing the springs

36.5mm OD,

93mm length

▲

▲

▲

▲

49mm OD,

118mm length

▲

▲

49mm OD,

71mm length

▲

▲

▲

▲

▲

49mm OD,

86mm length

▲

▲

▲

▲ ▲

▲ ▲

www.TURBOSMARTONLINE.com

59mm OD,

63mm length

▲

▲

4

WARNING! Fitting a heavier wastegate spring may cause a higher than expected increase in boost pressure.

Turbosmart recommends adjusting your boost controller back to its minimum setting and measuring the new minimum boost pressure

achieved by the new spring, before increasing your boost pressure again.

1) Remove the wastegate from the exhaust manifold. Use CAUTION! The wastegate may still be HOT!

2) Hold the cap down in a press or vice. Using a 5mm Allen Key, remove the M6 Socket head cap screws that secure the upper

wastegate cap. WARNING! The cap is under spring tension, wear safety glasses and remove with care! Slowly back off the

vice or press and remove the cap.

3) Select and locate the required wastegate spring or combination of inner and outer springs on the upper diaphragm spring

support. See spring information above for detail on wastegate spring identification and selection.

4) Ensure that the diaphragm is inside the diaphragm groove. The six holes on the outer ring of the wastegate diaphragm should

be in line with the 6 holes in the lower wastegate cap.

5) Slowly push the top cap down on the lower diaphragm housing in a vice or press. As the cap reaches the diaphragm, slowly

turn the cap left and right as you lower the cap to the lower diaphragm housing. Make sure that the convolution of the

diaphragm is not pinched between the top cap and the lower diaphragm housing. Refit the upper wastegate cap re-using the

M6 Socket head cap screws. Again you may find it helpful to use a press to hold down the cap with a press or a clamp while

tightening these screws. Tighten the M6 Socket head cap screws using a 5mm Allen Key and torque to 8 N-m (5.9 lb-ft)

Diaphragm removal and lower diaphragm housing rotation

1) Follow steps 1 and 2 of the spring change instructions.

2) Using a pair of circlip pliers, remove the retaining circlip on the diaphragm support.

3) Carefully back off the 3 securing grub screws in the top of the diaphragm support, DO NOT REMOVE COMPLETELY FROM

DIAPHAGM SUPPORT.

4) Remove diaphragm assembly and valve.

5) Remove the 3 M6 counter sunk cap screws and remove lower diaphragm housing. Check that the sealing O-Ring is in good

condition. Replace if necessary (TS-0501-3004).

6) Refit the lower diaphragm housing in the desire orientation and replace M6 Countersunk screws.

7) Slide the valve back through the guide and place the diaphragm assembly on top of the valve. Apply a small drop of Loctite

onto the threads of the grub screw and tighten. Make sure that the valve is hard up against the diaphragm assembly.

8) Select and locate the required wastegate spring or combination of inner and outer springs on the upper diaphragm spring

support. See spring information above for detail on wastegate spring identification and selection.

9) Ensure that the diaphragm is inside the diaphragm groove. The six holes on the outer ring of the wastegate diaphragm should

be in line with the 6 holes in the lower wastegate cap.

www.TURBOSMARTONLINE.com

5

10) Slowly push the top cap down on the lower diaphragm housing in a vice or press. As the cap reaches the diaphragm, slowly

turn the cap left and right as you lower the cap to the lower diaphragm housing. Make sure that the convolution of the

diaphragm is not pinched between the top cap and the lower diaphragm housing. Refit the upper wastegate cap reusing the M6 Socket head cap screws. Again you may find it helpful to use a press to hold down the cap with a press or a

clamp while tightening these screws. Tighten the M6 Socket head cap screws using a 5mm Allen Key and torque to 8 N-m

(5.9 lb-ft)

www.TURBOSMARTONLINE.com

6

NOTES ON BOOST CONTROL HOOKUP

WARNING! Changing your connection method can cause a higher than expected increase in boost pressure. Turbosmart recommends

adjusting your boost controller back to its minimum setting and measuring the new minimum boost pressure achieved by the new setup

before increasing your boost again.

IMPORTANT! Refer to your boost controller instructions for most suitable connection method to an external wastegate.

Basic setup

If no boost controller is being used connect the boost pressure source to the “bottom” port as shown. Connect the wastegate “top” port

to the intake side of the turbo, between the air cleaner and the inlet on the front of the turbocharger. Otherwise connect a short piece of

the silicon hose and face the vent downwards to stop water or debris entering the top port.

Boost Tee setup

When using your Ultra-Gate38 in conjunction with a Turbosmart Boost Tee, fit the controller between the boost pressure source and

“bottom” port as shown. Ensure the arrow on the Boost Tee is pointing in the direction illustrated. Connect the Ultra-Gate38 “top” port to

the intake side of the turbo, between the air cleaner and the inlet on the front of the turbocharger. Otherwise connect a short piece of the

silicon hose and face the vent downwards to stop water or debris entering the top port.

Refer to the instructions supplied with your Boost Tee for further detail if necessary.

Wastegate

Bottom port of wastegate

vent to pressure only

source

Wastegate

Bottom port of wastegate

to Boost Tee

Top port of wastegate

vent to atmosphere

Turbocharger

Top port of wastegate

vent to atmosphere

Pressure only source to

Boost Tee

Turbocharger

www.TURBOSMARTONLINE.com

7

e-Boost 2 connection methods

Turbosmart recommends using the wastegate in conjunction with the Turbosmart e-Boost.

The first method of installation is a one port connection. If the desired boost level is not achieved i.e. boost level is too low, or not

controllable, it is recommended that the wastegate spring be changed to a spring which is closer to the desired boost pressure or to trial

a 2 port connection method.

There are 3 different 2 port connection methods that can be trialled to achieve different results. The 2 port method (1) can be used if

there is high exhaust manifold back pressure forcing the valve open. The 2 port method (2) allows the user to achieve the maximum

boost pressure their turbo system is capable of. If a wide range of boost pressures is desired i.e. 5 – 40 PSI, a 2 port connection with a

4 port solenoid (sold separately – TS-0301-2003) might be needed.

Single port connection Method

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

*NOTE: An increase in your minimum boost pressure is expected when using any of the 2 port connection methods. Ensure all boost

set point values and gate pressure values are set to Zero and measure the new minimum boost pressure achieved by this method

before increasing your Boost Set Point values.

Two port connection Method (1) (For controlling boost on a turbo system with high back pressure)

External wastegate

Bottom port of

wastegate to port 2

of solenoid

Connect the bottom port of the wastegate and Port 1 of the solenoid to a Pressure only source

Port 2 of the solenoid to the top port of the wastegate

Port 3 of solenoid vent to atmosphere

Port 2 of solenoid to top

port of wastegate

Wastegate

Bottom port of wastegate

To pressure only source

Port 3 of solenoid vent

To atmosphere

Top port vent to

atmosphere

Port 1 of solenoid

vent to atmosphere

Pressure only to Port

3 of solenoid

Turbocharger

Solenoid Port 1 of solenoid to pressure

only source

Tee Piece

Pressure only source

Turbocharger

www.TURBOSMARTONLINE.com

8

Two port connection Method (2) (For obtaining maximum boost pressure on your turbo system)

Port 1 of solenoid to Top port of wastegate

Port 2 of solenoid to Pressure only source

Port 3 of solenoid to Bottom port of wastegate

Two port connection Method (3) (For obtaining a wide range of boost pressures e.g. 5 – 40 PSI, note that this method of boost control

may not provide a smooth boost curve)

Turbocharger

Port 2 of solenoid to

pressure only source

Solenoid Port 1 of solenoid to

Top port of wastegate

Wastegate

Port 3 of solenoid to

bottom port of wastegate

Port A of solenoid to Top port of wastegate

Port B of solenoid to Bottom port of wastegate

EX port of solenoid vent to atmosphere

IN port of solenoid to Pressure only source

Port A of solenoid to top port of

wastegate

4 Port solenoid

EX Port of solenoid vent

to atmosphere

IN Port of solenoid to

pressure only source

Wastegate

Turbocharger

Port B of solenoid to

bottom port of wastegate

www.TURBOSMARTONLINE.com

9

TURBOSMART

ONE YEAR LIMITED WARRANTY

Turbosmart is a company built on Customer Satisfaction and Service. That is why all of our products go through regimented test procedures before they are packaged and

shipped. Turbosmart stands behind its products for one full year after purchase. Terms of Warranty, Service and Returns are as follows:

Limited Warranty: Turbosmart warrants its products to be free from defects in material and workmanship under normal use and if properly installed for a period of one

year from date of purchase. If found to be defective, it will be replaced or repaired if returned prepaid along with proof of date of purchase. This shall constitute the sole

remedy of the purchaser and the sole liability of Turbosmart to the extent permitted by law, the foregoing is exclusive and in lieu of all other warranties or representations

whether expressed or implied, including any implied warranty of merchantability or fitness. In no event shall Turbosmart be liable for special or consequential damages.

This warranty is only valid on products purchased from Turbosmart Authorized Dealers.

Service: After the warranty period has expired, repair service is charged based on a minimum and maximum charge rate. (Contact Customer Service for current rate).

Returns: When returning a Turbosmart product for repair, it must be accompanied by a completed Customer Warranty Form and RMA number. To access this form

please go to our website www.turbosmartonline.com and you will find it on the Downloads page.

THE TURBOSMART PLEDGE

DO NOT USE ANY TURBOSMART PRODUCT UNTIL YOU HAVE CAREFULLY READ AND UNDERSTOOD THE FOLLOWING AGREEMENT.

Please call if you have any questions or do not understand this agreement. Refer to our brochure, website or catalogue for terms and conditions and further information

regarding your product. Turbosmart appreciates your business and pride ourselves on our customer service. We are always happy to offer you advice and will provide you

with help in any way we can. The purpose of this agreement is to avoid any problems or hard feelings.

We sometimes make mistakes, as do our dealers, distributors and suppliers. Even customers can sometimes order the wrong parts. Do not use, modify, install, trial

assemble, nick, drop, scratch or adjust any part until you first check for any damage. Damage must be reported immediately. NO EXCEPTIONS. If there are any

components missing please contact your authorized reseller immediately upon receipt of your shipment. Missing components must be reported within five (5) business

days of receipt. Parts returned for any reason MUST BE IN RESALABLE CONDITION. It is YOUR responsibility, “THE CUSTOMER” to carefully package any returns to

avoid shipping damage. Insurance is highly recommended. Credit cannot be issued for damaged goods.

Turbosmart warranties the quality of the products it designs and manufactures to be free of defects in material and workmanship. This limited warranty is extended only to

the original purchaser and may not be transferred or assigned. This limited warranty applies to any product, which after careful inspection by Turbosmart, after receipt of

the product from our authorized reseller, is found to have a defect in either material or workmanship. Any modifications to the product will void any and all warranties and

will not be exchanged. Before installation, check new car warranty. Turbosmart is not responsible for voiding any original manufactures warranty.

All warranty claims must be returned to the nearest Turbosmart Office, you must return the product and sales receipt, at your own expense, accompanied by the Customer

Warranty Form stating the reason for the claim. Proof of purchase must be provided with any warranty claim and will be verified with the authorized reseller from which the

product was purchased.

If all the above procedures are followed, and the product is found to be defective in either workmanship or material, Turbosmart shall either repair or replace the product, at

its sole discretion, and sole cost. This limited warranty does not cover or apply to any personal injury, labor charges or any other incidental costs or damages caused by

the defective product. The individual purchaser acknowledges and agrees that the disclaimer of any liability for personal injury is a material term for this agreement and the

individual purchaser agrees to indemnify Turbosmart and to hold Turbosmart harmless for any claim related to the item of the equipment purchased. Under no

circumstances will Turbosmart be liable for any damages or expenses by reason of use or sale of any such equipment.

THIS LIMITED WARRANTY IS THE ONLY EXPRESS WARRANTY, WHICH APPLIES TO TURBOSMART PRODUCT AS EXPRESSLY GIVEN IN LIEU OF ANY OTHER

WARRANTY EXPRESSED OR IMPLIED, INCLUDING THAT OF MERCHANTABILITY. ANY IMPLIED WARRANTY INCLUDING THAT OF MERCHANTABILITY AND/OR

FITNESS FOR A PARTICCULAR PURPOSE IS HEREBY LIMITED BY THE SAME TERMS AND TIME LIMITATIONS SET FORTH IN THIS LIMITED EXPRESS

WARRANTY AND OTHERWISE EXCLUDED. EXCEPT FOR THOSE OBLIGATIONS ASSUMED HEREIN, TURBOSMART ASSUMES NO OTHER OBLIGATIONS IN

CONNECTION WITH THE SALE OF ITS PRODUCTS.

IN THE EVENT THAT THE INDIVIUDAL PURCHASER DOES NOT AGREE WITH THIS AGREEMENT THE BUYER MAY PROMPTLY RETURN THIS PRODUCT, IN A

NEW AND UN-USED CONDITION, WITH A DATED PROOF OF PURCHASE, TO THE PLACE OF PURCHASE WITHIN SEVEN (7) DAYS FROM THE DATE OF

PURCHASE FOR A FULL REFUND. THE INSTALLATION OF THIS PRODUCT INDICATES THAT THE INDIVIDUAL PURCHASER HAS READ AND UNDERSTOOD

THIS AGREEMENT AND ACCEPTS ITS TERMS AND CONDITIONS.

Happy motoring!

The Turbosmart Team.

www.TURBOSMARTONLINE.com

Loading...

Loading...