Page 1

1

------------------------------------------------------------------------------------------------------------------------

Document Type: Instruction Manual

Product Name: E-Boost Street 40PSI

Product Description: Electronic boost controller

Product Number: TS-0302-1002

BEFORE YOU START – IMPORTANT NOTES

Turbosmart recommends that your E-Boost Street is fitted by an appropriately qualified technician.

Consult your local tuning specialist before setting your boost pressure as setting boost beyond your engines capability can result in

severe engine damage or failure

Turbosmart recommends that the engines Air/Fuel ratio is checked once the desired boost pressure is set. Any increase in boost

pressure can cause the engine to run lean resulting in severe engine damage or failure

Turbosmart recommends that the E-Boost Street is not used in conjunction with any type of “Draw Through” induction System.

Turbosmart recommends that boost pressure is set using a Dynamometer and not on public roads.

The E-Boost Street may not be able to completely compensate for a drop in boost pressure at high RPM due to the turbocharger

operating beyond its maximum efficiency range i.e. incorrect turbocharger sizing or excessive exhaust backpressure.

The E-Boost Street cannot compensate for increases in boost pressure at high RPM due to inadequate waste gate flow capacity;

the turbo system must maintain a steady base boost curve before you start using a boost controller.

The E-Boost Street cannot be used with external waste gates that are in a poor, worn or non-serviceable condition.

For best results your turbocharger should be correctly sized for your application.

Erratic operation of electronic parts can be caused by Electro Magnetic Interference (EMI). EMI can be generated by aftermarket

ignition systems such as CDI which, if wired incorrectly, generate large amounts of EMI through the vehicles electrical system. This

can cause items such as ECU’s and boost controllers to be effected. Please follow ignition system installation instructions VERY

carefully to avoid EMI affecting the E-Boost Street. Sometimes, using resistor type spark plugs can reduce this problem.

The E-Boost Street is not waterproof and must be mounted inside the cabin. The unit has an operating temperature range of -5OC

to 70OC.

Page 2

2

CONTENTS

INSTALLATION .................................................................................................................. 3

Wiring .............................................................................................................................................. 3

RPM Signal Connection (OPTIONAL) ........................................................................................... 3

Vacuum/pressure signal ................................................................................................................... 4

Installing the E-Boost Street Solenoid ............................................................................................. 4

SOLENOID HOOK UP METHODS ..................................................................................... 4

INTERNAL WASTEGATE CONNECTION ................................................................................. 5

Single solenoid, single turbocharger hook up .................................................................................. 5

Single solenoid, twin parallel turbocharger hook up ....................................................................... 6

Twin solenoid, twin parallel turbocharger hook up ......................................................................... 6

EXTERNAL WASTEGATE CONNECTION ................................................................................ 7

Single port, single solenoid, single turbo connection Method ......................................................... 7

Single port, single solenoid, twin turbo connection Method ........................................................... 7

Single port, twin solenoid, twin turbo connection Method .............................................................. 8

Two port, single solenoid, single turbo connection Method (1) ...................................................... 8

Two port, single solenoid, twin turbo connection Method (1)......................................................... 9

Two port, twin solenoid, twin turbo connection Method (1) ........................................................... 9

Two port, single solenoid, single turbo connection Method (2) .................................................... 10

Two port, single solenoid, Twin turbo connection Method (2) ..................................................... 10

Two port, twin solenoid, Twin turbo connection Method (2) ........................................................ 11

Two port, single 4 port solenoid, single turbo connection Method (3) .......................................... 11

Two port, single 4 port solenoid, twin turbo connection Method (3) ............................................ 11

Two port, twin 4 port solenoid, twin turbo connection Method (3)............................................... 12

BASIC FUNCTIONALITY .................................................................................................. 13

Unit Layout .................................................................................................................................... 13

OFF mode ...................................................................................................................................... 13

Live mode menu............................................................................................................................. 13

Changing between 2 boost groups ................................................................................................. 13

SETUP ............................................................................................................................... 14

OVER BOOST SHUTDOWN (OBS) ........................................................................................... 15

SCALE (SCL) ................................................................................................................................ 15

BOOST SETUP (bG1 and bG2) .................................................................................................... 15

Setting SP1 (Set point): .......................................................................................................... 16

Setting GP1 (Gate pressure): ................................................................................................ 16

Setting SN1 (Sensitivity): ....................................................................................................... 16

RPM DISPLAY CONFIGURATION (CYL) ................................................................................ 17

LIGHT DIM (DM) ......................................................................................................................... 17

SWITCH LOGIC (sL) ................................................................................................................... 17

AUXILIARY OUTPUT (AU) ....................................................................................................... 17

BOOST CORRECTION (COR) .................................................................................................... 17

SECURITY PIN (PIN)................................................................................................................... 18

RPM SHIFT LIGHT (RL) ............................................................................................................. 18

ZERO DISPLAY (ZER) ................................................................................................................ 18

SOLENOID CYCLE(SOL) ........................................................................................................... 19

FACTORY RESET (RES) ............................................................................................................. 19

TROUBLESHOOTING ...................................................................................................... 19

Page 3

3

INSTALLATION

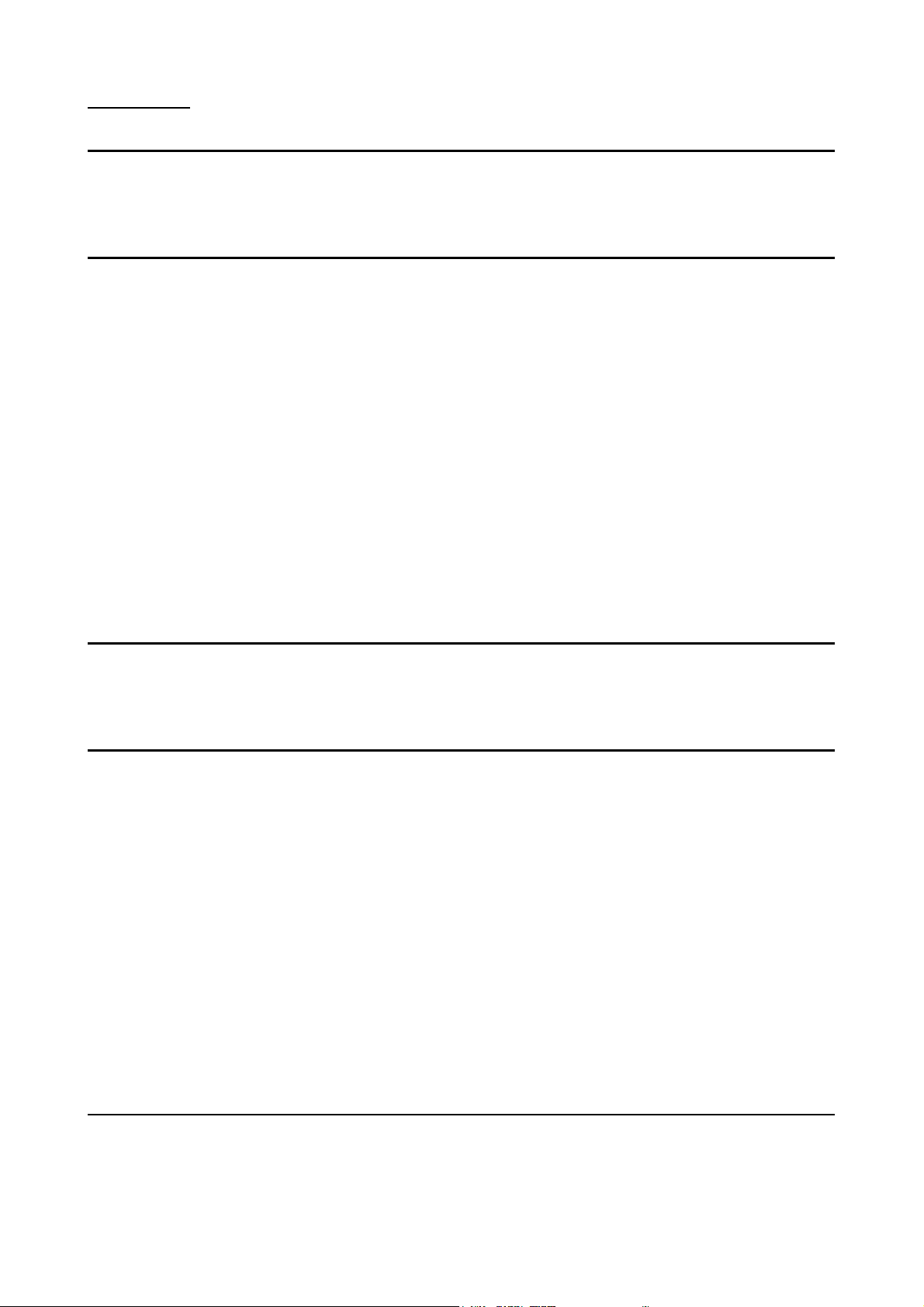

Wiring

(Solder all wires together and insulate the joints with the supplied heat shrink)

Note: Unused wires must be insulated with electrical tape so that they do not touch other wires or the chassis

Red Wire – +12 Volts switched through ignition – connect via 5 Amp fuse supplied

Black Wire – Chassis, earth or ground

Yellow Wire – To 3.5V – 12V Square wave (RPM) Signal OPTIONAL

Green Wire – External set point switching (Ground to activate) OPTIONAL

Orange Wire – Dimming trigger (Ground to activate) OPTIONAL

White Wire – Auxiliary Output (Negative switched) OPTIONAL

Brown and grey wire – to boost control solenoid (Polarity not important)

RPM Signal Connection (OPTIONAL)

RPM signal connection is ONLY for Tacho mode, RPM set point mapping, Boost correction, shift light function and other advanced

features. Turbosmart recommends your RPM signal be connected by an appropriately qualified technician or automotive electrician. For

further information consult your vehicle’s manuals or your local automotive electrician. The E-Boost Street is ONLY able to accept an

RPM signal in the form of a square wave that is switching between 0V and 3.5-12 volts.

The following points should be followed to connect your RPM signal to an ECU pin.

- Locate your ECU RPM signal wire and splice into the signal wire coming from your ECU.

- Check the output you are splicing into is a square wave that is switching between switching between 0V and 3.5-12 volts with an

appropriate meter.

- Connect the yellow RPM wire from the E-Boost Street to the spliced section of the ECU RPM out.

- Turn on the E-Boost Street and configure your signal to the number of cylinders or rotors your engine has using the CYL (cylinder)

parameter located in the setup menu.

- In live mode with your engine running press mode once to show live RPM. The display should be reading RPMx100 e.g. 015 on

the display indicates 1500 RPM. If the display is not reading correctly re-check the cylinder configuration in the setup menu.

- Note: If the OEM tachometer does not display RPM after installing the E-Boost Street, a 2 ohm or higher resistor needs to

be installed in line between the ECU RPM output pin and the E-Boost Street.

The following points should be followed to connect your RPM signal to the negative terminal of an ignition coil. NOTE: Caution should

be exercised when connecting to the negative terminal of an ignition coil and Turbosmart recommends an ECU connection where

possible. IMPORTANT! The RPM signal should not be connected to a coil of a capacitive discharge ignition (CDI) system.

Page 4

4

- Check the signal from the negative terminal is a square wave that is switching between switching between 0V and 3.5-12 volts with

an appropriate meter. If the voltage is below 3.5V (coil trigger signals tend to have a very low voltage) the e-Boost will not read a

signal. In this case, a signal amplifier (also known as a tach adapter) must be used to boost the signal.

- Connect the RPM signal wire from the E-Boost Street to the negative terminal of an ignition coil or tach adapter (which ever

method is used).

- Turn on the E-Boost Street and configure your signal to the number of cylinders or rotors your engine has using the CYL (cylinder)

parameter located in the setup menu

- In live mode with your engine running press mode once to show live RPM. The display should be reading RPMx100 e.g. 015 on

the display indicates 1500 RPM. If the display is not reading correctly re-check the cylinder configuration in the setup menu.

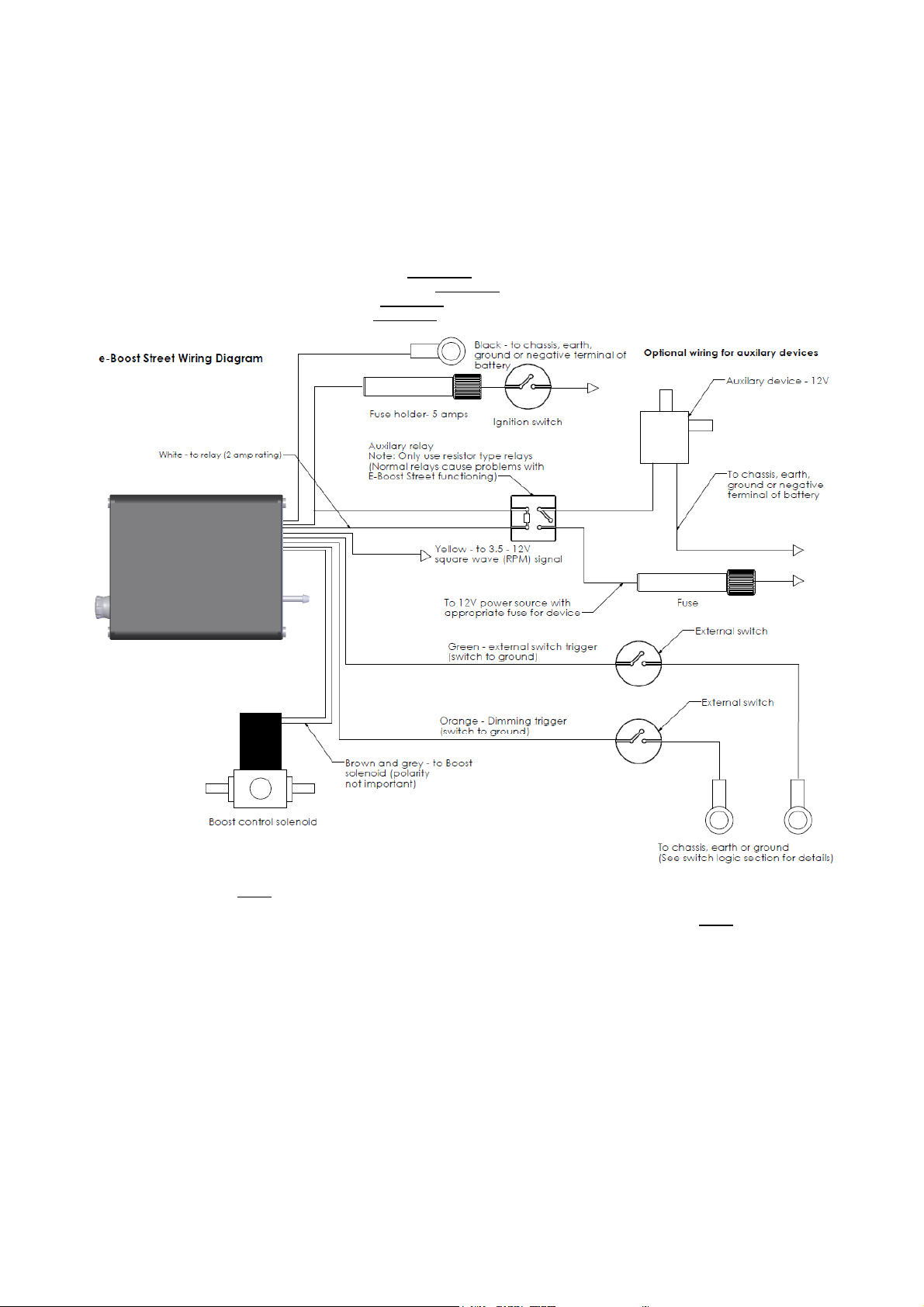

Vacuum/pressure signal

The E-Boost Street requires a vacuum/pressure signal from the intake manifold to function. A combination of poly tube and silicone

hose is used to connect the E-boost Street to a adequate vacuum/pressure signal. Route the poly tube from the E-boost Street

head unit through the fire wall approximately 100mm (4”) only as the poly tube is not rated to the high temperatures of the engine

bay.

Use the connecting barb to join the poly tube to the 3mm ID silicon hose at the firewall/bulkhead. Ensure the poly tube is pressed

all the way onto the connecting barb

Route the silicon hose through the engine bay and connect it to a pressure/vacuum signal from the inlet manifold. Use the supplied

tee piece if necessary.

Secure all connections with the supplied hose clamps

Installing the E-Boost Street Solenoid

- The E-Boost Street solenoid is rated to a maximum temperature of 100

degrees Celsius (212 degrees Fahrenheit), ensure that it is mounted a

minimum of 250mm (10 Inches) away from the heat of the turbo or

exhaust manifold, otherwise heat shielding maybe required.

- Mount the E-Boost Street solenoid in an appropriate position in the

engine bay with the mounting kit supplied.

- Fit the rubber grommet inside the mounting plate. Slide the sleeve

inside the grommet. Use the M3 screws to bolt the solenoid to the

mounting bracket – Note use loctite on the threads to secure. Use the

M6 screw, washer and Nyloc nut to mount in a suitable location in the

engine bay.

- The E-Boost Street head unit is capable of controlling two solenoids. The use of twin solenoids is not necessary but is

recommended in twin turbo setups on V configuration engines as this reduces the length of hose required for plumbing which aids

in response and control of the wastegates.

- The solenoid must be connected to a pressure only source which must be located before the intercooler, ideally off the compressor

cover of the turbocharger. The air temperature before the intercooler is less affected by ambient conditions which will give you

more consistent boost control.

SOLENOID HOOK UP METHODS

WARNING! Changing to different connection method can cause a higher than expected increase in boost pressure. Turbosmart

recommends adjusting your boost controller back to its minimum setting and measuring the new minimum boost pressure achieved by

the new setup before increasing your boost again.

Page 5

5

Note: If your vehicle is fitted with a factory boost control solenoid, the hoses that run from the pressure source and to the

Turbocharger

Solenoid

Port 1 of solenoid vent

to atmosphere

Pressure only source to

Port 3 of solenoid

Port 2 of solenoid

to actuator

Actuator

Pressure only

source to port 3

of solenoid

Port 1 of solenoid vent

to atmosphere

Port 2 of solenoid

to actuator

Block off unused

port

wastegate actuator must be disconnected. Leave the solenoid plugged into the wiring loom so that the ECU is not affected.

Failure to disable the factory boost control solenoid and hoses will result in erratic or fluctuating boost pressures which could

damage your engine.

INTERNAL WASTEGATE CONNECTION

WARNING! Changing to different connection methods can cause a higher than expected increase in boost pressure. Turbosmart

recommends adjusting your boost controller back to its minimum setting and measuring the new minimum boost pressure achieved by

the new setup before increasing your boost again.

Note: If your vehicle is fitted with a factory boost control solenoid, the hoses that run from the solenoid to the pressure source

and to the wastegate actuator must be disconnected from the solenoid. Leave the solenoid plugged into the wiring loom so

that the ECU is not affected.

Most factory turbocharged vehicles use an internal waste gate system to control boost pressure. The E-Boost Street controls boost

pressure by controlling the pressure signal that the waste gate actuator receives from the turbocharger. Please note that the E-Boost

Street cannot be used to obtain a boost pressure lower than the standard waste gate actuator’s pressure setting.

Some factory hoses have a small restrictor fitted inside them, if the factory hoses are reused over boosting or boost spiking may

occur.

Secure all connections with hose clamps.

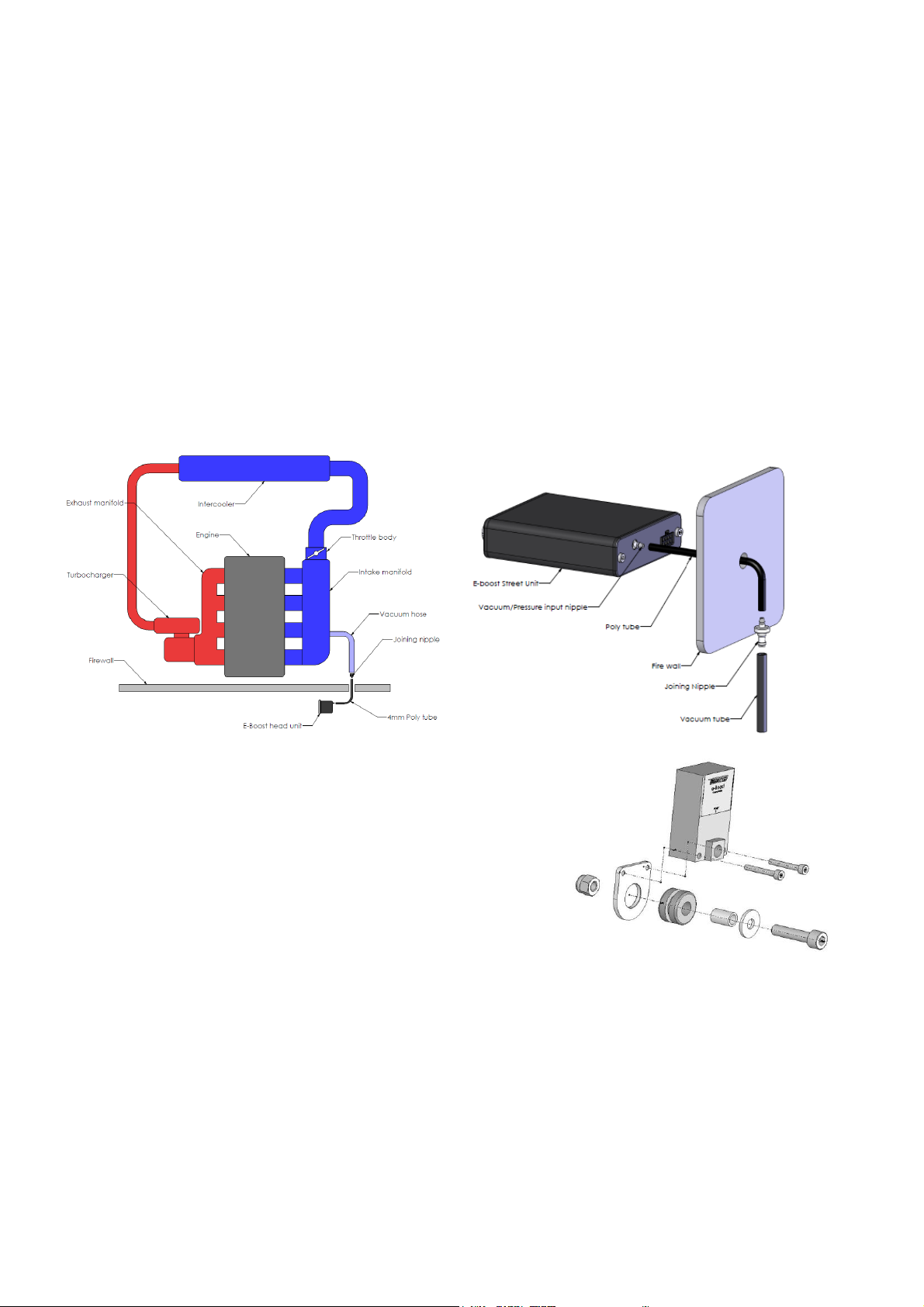

Single solenoid, single turbocharger hook up (Basic single internal wastegate setups)

Port (1): vents pressure from the solenoid. Connect this hose to the intake side of the turbo, between the air cleaner and the inlet

of the turbocharger. Otherwise connect a short piece of the silicon hose and face the vent downwards to stop water or debris

entering the solenoid.

Port (2): to the internal wastegate actuator

Port (3): to pressure only source

If you are unable to achieve your desired boost pressure, it is normally due to exhaust manifold backpressure forcing the internal waste

gate to open. To increase your boost pressure further, fit a higher pressure waste gate actuator to increase your minimum boost

pressure.

WARNING! Fitting a higher pressure waste gate actuator may cause a higher than expected increase in boost pressure.

Turbosmart recommends resetting the boost set point values to Zero and measure the new minimum boost pressure before increasing

your boost set point values.

Internal wastegates with 2 ports

Port (1): vents pressure from the solenoid.

Port (2): connect to one of the ports of the actuator

Port (3): to pressure only source

Block off unused port on the actuator with suitable blank

Page 6

6

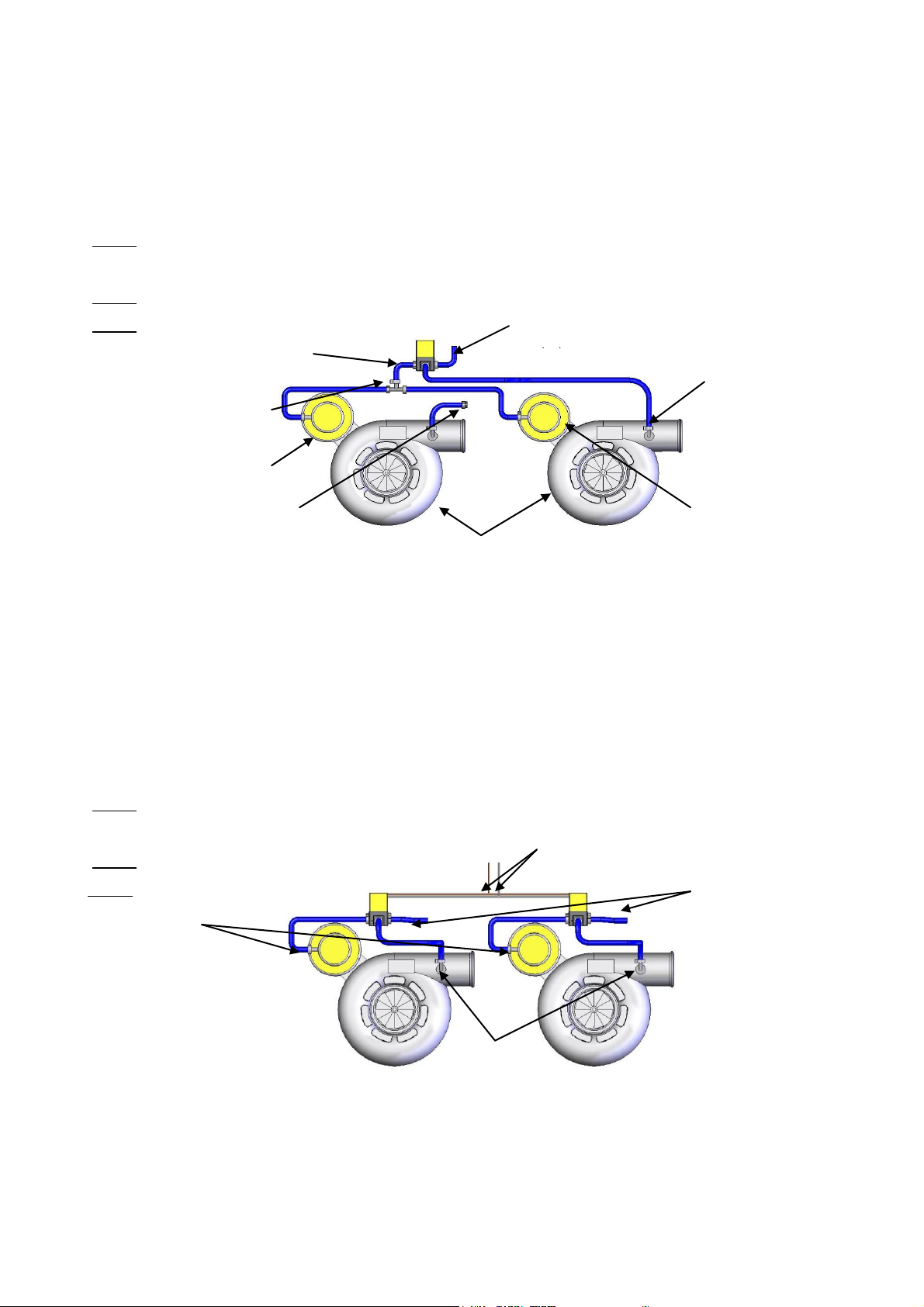

Single solenoid, twin parallel turbocharger hook up

Pressure only source

to port 3 of solenoid

Port 1 of solenoid

vent to atmosphere

Port 2 of solenoid to

actuator

Wires to E-Boost

Block off with

suitable blank

Turbochargers

Port 1 of solenoid

Vent to atmosphere

Port 3 of solenoid to

pressure only source

Tee Piece

Actuator

Actuator

Port 2 of solenoid to

tee piece

(For straight configuration twin parallel turbocharger engines E.g. RB26DETT)

The E-Boost Street is capable of controlling twin internal wastegate turbochargers with a single solenoid.

This method is used when the turbochargers are mounted close to each other allowing the solenoid to be mounted close to both

actuators

Each solenoid port is connected as follows:

-Port (1): vents pressure from the solenoid. Connect this hose to the intake side of the turbo, between the air cleaner and the inlet of

the turbocharger. Otherwise connect a short piece of the silicon hose and face the vent downwards to stop water or debris entering the

solenoid.

-Port (2): to tee piece that feeds both actuators

-Port (3): to pressure only source

Twin solenoid, twin parallel turbocharger hook up

(For V configuration twin parallel turbocharger engines E.g. V6, V8 etc)

The E-Boost Street is capable of controlling two solenoids for twin parallel turbocharger setups.

This method is used when there is a great distance between the wastegates. This allows the solenoids to be mounted close to the

wastegates to minimise the length of hose used and to maximise response

You will need a second solenoid for this method (TS-0301-3003)

Connect the grey wire from the e-Boost wiring loom to one of the wire from each solenoid.

Connect the brown wire from the e-Boost wiring loom to the remaining wire from each solenoid.

Each solenoid port is connected as follows:

-Port (1): vents pressure from the solenoid. Connect this hose to the intake side of the turbo, between the air cleaner and the inlet of

the turbocharger. Otherwise connect a short piece of the silicon hose and face the vent downwards to stop water or debris entering the

solenoid.

-Port (2): to the internal wastegate actuator

Port (3): to pressure only source

Page 7

7

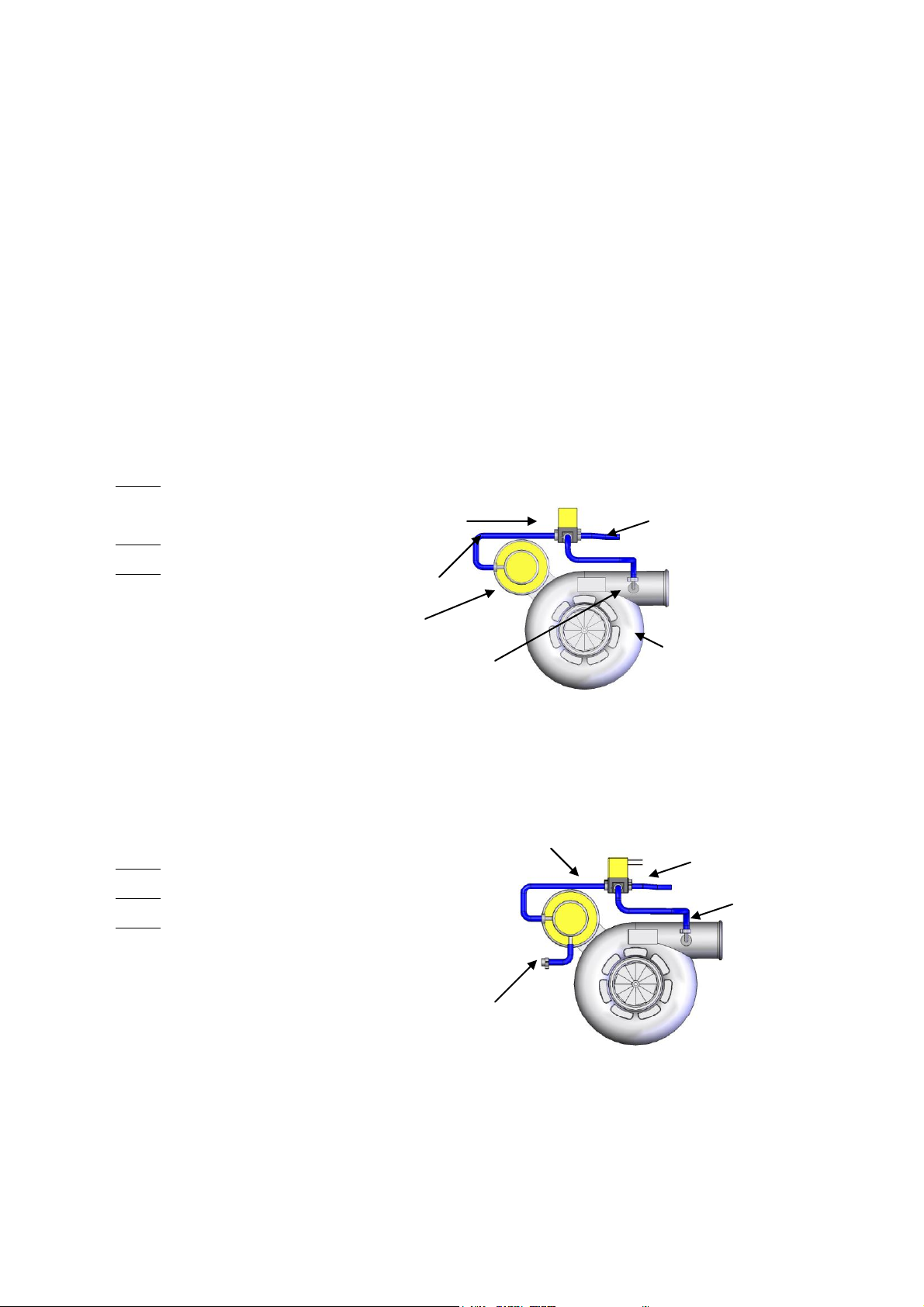

EXTERNAL WASTEGATE CONNECTION

External wastegate

Bottom port of

wastegate to port 2

of solenoid

Top port vent to

atmosphere

Turbocharger

Port 1 of solenoid

vent to atmosphere

Pressure only to Port

3 of solenoid

Tee Piece

Port 2 to bottom port

of both wastegates

Solenoid

Pressure only to Port

3 of solenoid

Plug pressure port on

one turbo only

Port 1 of solenoid

vent to atmosphere

Vent top port of both

wastegates

The first method of installation is a one port connection. If the desired boost level is not achieved i.e. boost level is too low, or not

controllable, it is recommended that the wastegate spring be changed to a spring which is closer to the desired boost pressure or to trial

a 2 port connection method.

There are 3 different 2 port connection methods that can be trialled to achieve different results. The 2 port method (1) can be used if

there is high exhaust manifold back pressure forcing the valve open. The 2 port method (2) allows the user to achieve the maximum

boost pressure their turbo system is capable of. If a wide range of boost pressures is desired i.e. 5 – 40 PSI, the 2 port method (3) with

a 4 port solenoid (sold separately – TS-0301-2003) might be needed.

A single solenoid can be used to control twin wastegates in a twin turbo setup but it is recommended that twin solenoids are used in

twin turbo setups to reduce the length of the pressure hoses to aid in control and response of the wastegates.

Single port, single solenoid, single turbo connection Method

(Basic single wastegate setup)

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

Single port, single solenoid, twin turbo connection Method

(For straight configuration twin parallel turbocharger engines E.g. RB26DETT)

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

Block off other turbocharger pressure port (if needed)

Page 8

8

Single port, twin solenoid, twin turbo connection Method

Wastegate

Port 2 of solenoid to top

port of wastegate

Solenoid

Port 1 of solenoid to pressure

only source

Tee Piece

Port 3 of solenoid vent

To atmosphere

Bottom port of wastegate

To pressure only source

Pressure only source

Turbocharger

Top port vent to

atmosphere

Port 1 of solenoid

vent to atmosphere

Pressure only to Port

3 of solenoid

Port 2 of solenoid to

bottom port of wastegate

Join wires

(For V configuration twin parallel turbocharger engines E.g. V6, V8 etc)

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the

wiring loom

Two port, single solenoid, single turbo connection Method (1)

(For controlling boost on a single turbo, single wastegate, single solenoid turbo system with high back pressure)

*NOTE: An increase in your minimum boost pressure is expected when using any of the 2 port connection methods. Ensure all boost

set point values and gate pressure values are set to Zero and measure the new minimum boost pressure achieved by this method

before increasing your Boost Set Point values.

Connect the bottom port of the wastegate and Port 1 of the solenoid to a Pressure only source via a tee piece

Port 2 of the solenoid to the top port of the wastegate

Port 3 of solenoid vent to atmosphere

Page 9

9

Two port, single solenoid, twin turbo connection Method (1)

Solenoid

Port 1 of solenoid to

pressure only source

Join wires

Port 2 of solenoid to top

port

Tee Piece

Vent to

atmosphere

Solenoid

Pressure source only to port 1

of solenoid and bottom port of

both wastegates

Port 3 of solenoid vent

to atmosphere

Port 2 of solenoid to top port

Of both wastegates

Tee Piece

Plug pressure port on

one turbo only

(For controlling boost on a twin turbo, twin wastegate, single solenoid turbo system, on a straight configuration engine with high back

pressure)

Connect the bottom port of the wastegates and Port 1 of the solenoid to a Pressure only source via tee pieces

Port 2 of the solenoid to the top port of the wastegates via tee pieces

Port 3 of solenoid vent to atmosphere

Block off other turbocharger pressure port (if needed)

Two port, twin solenoid, twin turbo connection Method (1) (For controlling boost on a

twin turbo, twin wastegate, twin solenoid turbo system, on a V configuration engine with high back pressure)

Connect the bottom port of the wastegate and Port 1 of the solenoid to a Pressure only source via a tee piece

Port 2 of the solenoid to the top port of the wastegate

Port 3 of solenoid vent to atmosphere

Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the

wiring loom

Page 10

10

Two port, single solenoid, single turbo connection Method (2)

Turbocharger

Port 2 of solenoid to

pressure only source

Solenoid

Port 1 of solenoid to

Top port of wastegate

Port 3 of solenoid to

bottom port of wastegate

Wastegate

Solenoid

Port 2 of solenoid to

pressure only source

Port 1 of solenoid to top port

of wastegates via tee piece

Port 3 of solenoid to bottom

port of wastegates via tee

Tee Piece

Plug pressure port on

one turbo only

(For obtaining maximum boost pressure on your single turbo system)

Port 1 of solenoid to Top port of wastegate

Port 2 of solenoid to Pressure only source

Port 3 of solenoid to Bottom port of wastegate

Two port, single solenoid, Twin turbo connection Method (2)

(For obtaining maximum boost pressure on your twin turbo straight engine)

Port 1 of solenoid to Top port of wastegates

Port 2 of solenoid to Pressure only source

Port 3 of solenoid to Bottom port of wastegates

Block off other turbocharger pressure port (if needed)

Page 11

11

Two port, twin solenoid, Twin turbo connection Method (2)

4 Port solenoid

EX Port of solenoid vent

to atmosphere

IN Port of solenoid to

pressure only source

Turbocharger

Port A of solenoid to top port of

wastegate

Wastegate

Port B of solenoid to

bottom port of wastegate

Port 3 of solenoid to bottom

port of wastegates via tee

Port 1 of solenoid to top port

of wastegates via tee piece

Port 2 of solenoid to

pressure only source

Join wires

4 Port solenoid

Port A of solenoid to top port of

wastegates via tee piece

Port B of solenoid to

bottom port of wastegates

via tee piece

EX Port of solenoid vent

to atmosphere

IN Port of solenoid to

pressure only source

Plug pressure port on

one turbo only

(For obtaining maximum boost pressure on your twin turbo V configuration engine)

Port 1 of solenoid to Top port of wastegates

Port 2 of solenoid to Pressure only source

Port 3 of solenoid to Bottom port of wastegates

Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the

wiring loom

Two port, single 4 port solenoid, single turbo connection Method (3)

(For obtaining a wide range of boost pressures e.g. 5 – 40 PSI. This connection method has varying degrees of success depending on

turbo system)

Port A of solenoid to Top port of wastegate

Port B of solenoid to Bottom port of wastegate

EX port of solenoid vent to atmosphere

IN port of solenoid to Pressure only source

Two port, single 4 port solenoid, twin turbo connection Method (3)

(For obtaining a wide range of boost pressures e.g. 5 – 40 PSI on a straight configuration engine. This connection method has varying

degrees of success depending on turbo system)

Port A of solenoid to Top port of wastegates

Port B of solenoid to Bottom port of wastegates

EX port of solenoid vent to atmosphere

IN port of solenoid to Pressure only source

Page 12

12

Two port, twin 4 port solenoid, twin turbo connection Method (3)

Port B of solenoid to

bottom port of wastegate

Port A of solenoid to top port of

wastegates via tee piece

EX Port of solenoid

vent to atmosphere

IN Port of solenoid to

pressure only source

Join wires

(For obtaining a wide range of boost pressures e.g. 5 – 40 PSI on a V configuration engine. This connection method has varying

degrees of success depending on turbo system)

Port A of solenoid to Top port of wastegates

Port B of solenoid to Bottom port of wastegates

EX port of solenoid vent to atmosphere

IN port of solenoid to Pressure only source

Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the

wiring loom

Page 13

13

BASIC FUNCTIONALITY

Press knob to change between

boost groups

Display

Knob

Vacuum/pressure

poly tube connector

8 Pin Connector

Unit Layout

OFF mode

The E-Boost Street can be switched off by holding the knob down for 10 seconds. This will disable the functionality of the E-Boost Street

and result in wastegate spring tension boost levels. To turn the unit back on, press the knob.

Live mode menu

LIVE BOOST: Displays the amount of vacuum/boost being read by the unit.

LIVE RPM: Displays the RPM X100 (020 = 2000 RPM) of the engine if the RPM wire is connected to a Square wave signal from the

ECU.

CURRENT SP VALUE: Displays the SP value the unit is currently set to.

PEAK HOLD BOOST: Displays the peak boost level the unit has measured.

PEAK HOLD RPM: Displays the peak RPM the unit has measured.

Changing between 2 boost groups

Page 14

14

SETUP

To enter the setup menu, press and hold the knob for 3 seconds. To navigate through the setup menu, rotate the knob to the left or right

for the various options as shown below. To enter any of the menus, press the knob. Once your settings are entered via turning the knob

left or right, you can save the setting by pressing the knob once. To exit any menu, press the knob for 3 seconds or alternatively, go to

END in the menu. This will take you back to the previous menu.

Page 15

15

OVER BOOST SHUTDOWN

Turbosmart recommends that this function is used in conjunction with another form of Over-boost protection such as

fuel/ignition cut or over-boost valve. The OBS will not stop an over-boost scenario if there is a mechanical failure on the car

that inhibits the E-Boost Street from controlling the wastegate or if electromagnetic interference due to incorrect wiring

If the OBS is triggered the E-Boost Street will reduce the boost pressure to half of that set in the OBS parameter. Once this safe

pressure is achieved the E-Boost Street will return to normal operation. OBS must be set to the maximum safe level your engine can

handle and your set points must be below the OBS setting. When the OBS is triggered OBS will flash on the display to indicate that your

boost pressure has reached the over boost shut down value. OBS will flash on the screen when triggered in live mode and when a set

point is being edited. Please note, OBS will not work in setup mode.

The OBS is factory set to 7 PSI (0.48 Bar or 48 KPa), so you must enter a figure in order for the E-Boost Street to produce more than

the standard boost pressure. The purpose of this feature is to protect your engine against accidentally entering a boost set point value

that is too high, preventing a dangerously high boost pressure. Extreme care should be taken when setting this parameter. Turbosmart

recommends that you seek advice from an appropriately qualified technician with regard to the OBS setting.

In order to successfully program your E-Boost Street you MUST carefully follow this section.

causes electrical interference to the E-Boost Street.

SCALE

The E-Boost Street readout can be configured in either Bar, PSI or KPa, the default setting is in psi. This allows you to tailor the readout

to suit your own preference. Note that when the PSI scale is selected and the E-Boost Street is under vacuum conditions the display will

read in inches of Mercury (inHg), not negative PSI.

BOOST SETUP (bG1 and bG2)

The E-Boost Street has the ability to control two levels of boost (BG1/BG2). The parameters that can be adjusted in each boost group

are set point (SP1/SP2), gate pressure (GP1/GP2) and sensitivity (SN1/SN2). Set up the boost groups in the following order:

Page 16

16

Setting SP1 (Set point): The SP value determines the DUTY CYCLE the solenoid will operate at when the gate pressure is reached.

The SP value is not the amount of boost pressure your turbo will produce. This is a value between 0 – 99. The larger the value, the

more boost the turbocharger will produce. Start the setup by increasing the SP value to 20. Bring the car onto boost and see what the

maximum boost pressure is. Increase the value in small increments until you achieve your desired boost pressure. The SP value can

also be adjusted while the car is on boost however, instead of the SP value being displayed, the boost pressure will be displayed so you

know what pressure you are achieving. This is the easiest way to set your set points. Press the KNOB to enter the menu and adjust the

values rotating the knob LEFT or RIGHT. Press the KNOB again to save the desired setting.

Setting GP1 (Gate pressure): This feature helps bring boost on faster at lower rpm and will give an increase in torque. Start by setting

the gate pressure 5 PSI below the desired boost pressure with the corresponding SP value e.g. if the desired boost pressure is 15 PSI,

set the gate pressure to 10 PSI first and adjust from there. Adjust the value higher to increase the response of the turbocharger or

decrease the value to reduce the response. If this setting is too close to target boost, you will get a boost spike. Press the KNOB to

enter the menu and adjust the values by rotating the knob LEFT or RIGHT. Press the KNOB again to save the desired setting.

Setting SN1 (Sensitivity): The sensitivity is how sensitive the E-Boost Street is to changes in the boost curve. Under normal

circumstances the sensitivity is left at the factory set level of 20. If your boost curve is wavy through the rev range, reduce the sensitivity,

if your boost curve drops off at the end of the rev range, increase the sensitivity. Note: do not increase this value higher than 30. Press

the KNOB to enter the menu and adjust the values by rotating the knob LEFT or RIGHT. Press the KNOB again to save the desired

setting.

Page 17

17

RPM DISPLAY CONFIGURATION

Bof

Bon

Ron

Rof

AU on in

window

If you have connected the yellow RPM wire to an RPM signal from your ECU or negative terminal of an ignition coil you will need to

input the number of cylinders / rotors in order to configure the RPM signal correctly i.e. the number of pulses per revolution being picked

up from the RPM output of the ECU. The number of cylinders available is between 1 and 16. The RPM input can accept a square wave

signal between 3.5 and 12V. For Mazda Rotary engines, 13B and 20B engines can be configured as 4 and 6 cylinders respectively.

LIGHT DIM

The brightness of the display can be adjusted on a scale of 0 – 6. The display can also be dimmed automatically by earthing the orange

wire when the vehicle’s light system is switched on and setting the scale to 0.

SWITCH LOGIC

The switch logic determines how the E-Boost Street switches between boost groups BG1 and BG2. It is factory set to internal switching

(ISP) where boost groups are changed by pushing the knob. Alternatively, boost groups can be switched remotely when the switch logic

is set to external switching (ESP). By earthing the green wire using a switch, you can toggle change from SP1 to SP2. Un-earthing this

wire will return the set point back to SP1.

AUXILIARY OUTPUT

The e-Boost Street has an auxiliary output function designed to control an auxiliary device once a certain boost pressure or RPM value

is reached i.e. water spray, water injection, warning light or nitrous controller. This circuit can be used to control a resistor type

automotive relay with a maximum current draw of 2 amps.

There are four options bOn, bOF, rOn and rOF. The boost setting on (bOn) and off (bOF) value will be entered in the units that are

currently selected for display. Between the bOn and bOF values the auxiliary output circuit will be closed and therefore will switch the

relay on.

The RPM setting on (rOn), and off (rOF) are entered as RPM x 100 e.g. if 5000 RPM is the desired setting the user will input 050.

Between the rOn and rOF values the auxiliary output circuit will be closed.

If the bOF or rOF is set to zero there will be no off and the circuit will remain closed until boost or RPM drops below the rOn or bOn

value. If using a boost setting only to switch the relay the RPM parameter values should be set to zero to turn off or vice versa.

If using the auxiliary circuit as a nitrous controller, you can enter all four user definable parameters bOn, bOF, rOn, and rOF. The

auxiliary circuit will be closed when boost and RPM fall with the window created by these four parameters. That is when boost pressure

is between bOn and bOF AND when RPM is between rOn and rOF.

BOOST CORRECTION

This function is use to reduce or eliminate boost drop off at high RPM. Switching this function on will display the boost correction menu

in the boost group menu. This function is best performed on a chassis dyno where the graph of the boost curve can be displayed and

accurately interpreted.

The boost correction function requires 3 parameters to work; the START RPM, the END RPM and the correction factor.

START RPM (RP1): This is the engine RPM at which boost begins to drop off.

END RPM (RP2): This is the engine RPM at which you want to turn off the boost correction function, normally set at redline.

Correction factor (FAC): The percentage at which boost is dropping off between the START and END RPM.

Page 18

18

Boost curve after COR is setup

Boost curve before COR is setup

Example:

The following boost curve shows that between 5000 and 7000 RPM, the boost drops off from 15 PSI to 10 PSI.

To reduce or eliminate this boost drop off, you need to input the following values:

RP1 = 050 (5000 RPM)

RP2 = 070 (7000 RPM)

FAC = 100 - [(10 ÷ 15) X 100] = 33

SECURITY PIN

The user or workshop can set a 3 digit password that will lock the boost menu, obS, SL, rSP, COR, dS, nSP, and CYL parameters for

editing. The default code is 000 set from the factory. If the code has not been changed then the unit will be fully accessible and

everything will be available for editing. As soon a different value is entered under the PIn parameter in the setup menu this will be the

new password.

Once a password has been set under PIN in the setup menu pressing mode and down to access the boost menu will bring up a 3 digit

prompt (triple zeros) where a PIN must be entered correctly to enter the boost group and unlock the unit.

Once a password has been configured the obS, CYL, SL, rSP, COR, dS, nSP, in the setup menu will be masked and not available for

editing. To unmask these parameters go to the PIn parameter and enter the current password to unlock the setup parameters for

editing. Alternatively enter the correct PIN in the boost group prompt and the entire unit will be unlocked until the PIN is re-entered in the

PIN parameter to re-lock the unit.

Applying the factory reset will reset the code and reset all stored values to the factory defaults. This function enables workshops or

tuners to lock their setup against tampering. Returning the PIN to 000 will de-activate the password protection.

RPM SHIFT LIGHT

This function allows the user to preset a RPM value at which the display will begin to flash. The RPM will continue to flash until the

engine RPM drops below the preset value. RPM values are entered in multiples of 100, e.g. 5000 RPM = 050. The yellow wire needs to

be connected as per the wiring diagram.

ZERO DISPLAY

The E-Boost Street is factory calibrated to read zero at standard atmospheric pressure and temperature. The E-Boost Street is altitude

compensated however a large change in temperature can cause the display to read slightly above or below zero even when there is

zero pressure applied to the E-Boost Street. This function allows you to zero the E-Boost Street display. IMPORTANT! Before using

the zero function ensure the vacuum/pressure line is removed from the back of the unit.

Page 19

19

SOLENOID CYCLE

This function is used to check whether the solenoid is properly connected to the head unit. Selecting this function will cause the solenoid

to cycle (click) 4 times.

FACTORY RESET

This function performs a factory reset and returns all the settings back to factory default. Be sure that you have written down the settings

that you wish to keep before performing this function.

TROUBLESHOOTING

The following points should be checked if you find that your engine is over-boosting, under-boosting or the boost pressure is fluctuating

erratically. Please note the following checks will cure 99% of problems experienced when fitting a Turbosmart E-Boost Street.

- Check that the E-Boost Street solenoid is installed correctly.

- Ensure the factory boost control solenoid is not connected in the hose between the pressure source and the wastegate actuator

- Ensure the length of the waste gate actuator rod has not been modified, refer to the manufactures specifications

- Check to see if the E-Boost Street solenoid is not blocked or contaminated with dirt, oil build up or debris

- Check the joining hoses for splits, cracks or loose connections and ensure they are not blocked, kinked or restricted, particularly if

the existing hose was reused

- Pressure test the waste gate actuator for leakage, the diaphragm or housing may be cracked or split

- Ensure the smooth and free operation of the wastegate arm in the turbo exhaust housing.

- Check that the hose between the E-Boost Street and the inlet manifold is not obstructed, broken or kinked.

- Check that the OBS is set higher than the boost pressure you are aiming for.

- Check the Blow-off Valve for leakage, some are used as over-boost valves

- Gate pressure maybe set too close to your desired boost pressure

- Ensure correct sensitivity setting.

- Check to see you can achieve constant steady boost with only the wastegate actuator connected directly to the pressure only

source on the turbocharger.

- Use the Solenoid check function to determine whether the solenoid is electrically connected to the head unit.

Page 20

20

ONE YEAR LIMITED WARRANTY

Turbosmart is a company built on Customer Satisfaction and Service. That is why all of our products go through regimented test procedures before they are

packaged and shipped. Turbosmart stands behind its products for one full year after purchase. Terms of Warranty, Service and Returns are as follows:

Limited Warranty: Turbosmart warrants its products to be free from defects in material and workmanship under normal use and if properly installed for a period

of one year from date of purchase. If found to be defective, it will be replaced or repaired if returned prepaid along with proof of date of purchase. This shall

constitute the sole remedy of the purchaser and the sole liability of Turbosmart to the extent permitted by law, the foregoing is exclusive and in lieu of all other

warranties or representations whether expressed or implied, including any implied warranty of merchantability or fitness. In no event shall Turbosmart be liable

for special or consequential damages. This warranty is only valid on products purchased from Turbosmart Authorized Dealers.

Service: After the warranty period has expired, repair service is charged based on a minimum and maximum charge rate. (Contact Customer Service for current

rate).

Returns: When returning a Turbosmart product for repair, it must be accompanied by a completed Customer Warranty Form and RMA number. To access this

form please go to our website www.turbosmartonline.com and you will find it on the Downloads page.

THE TURBOSMART PLEDGE

DO NOT USE ANY TURBOSMART PRODUCT UNTIL YOU HAVE CAREFULLY READ AND UNDERSTOOD THE FOLLOWING AGREEMENT. Please call if

you have any questions or do not understand this agreement. Refer to our brochure, website or catalogue for terms and conditions and further information

regarding your product. Turbosmart appreciates your business and pride ourselves on our customer service. We are always happy to offer you advice and will

provide you with help in any way we can. The purpose of this agreement is to avoid any problems or hard feelings.

We sometimes make mistakes, as do our dealers, distributors and suppliers. Even customers can sometimes order the wrong parts. Do not use, modify, install,

trial assemble, nick, drop, scratch or adjust any part until you first check for any damage. Damage must be reported immediately. NO EXCEPTIONS. If there are

any components missing please contact your authorized reseller immediately upon receipt of your shipment. Missing components must be reported within five

(5) business days of receipt. Parts returned for any reason MUST BE IN RESALABLE CONDITION. It is YOUR responsibility, “THE C USTOMER” to carefully

package any returns to avoid shipping damage. Insurance is highly recommended. Credit cannot be issued for damaged goods.

Warranty as to Defects – Australian Consumer Law

1.1 We warrant for a period of twelve (12) months from the date of supply of the Goods and/or Services that if due to the fault of Turbosmart the Goods

and/or Services (as the case may be) provided by Us are defective then We will, as determined by Us do one or more of the following:

(a) In the case of Goods; the replacement of the Goods, the supply of equivalent Goods, the repair of the Goods, the payment of the cost of

replacing the Goods or of acquiring equivalent Goods, or the payment of having the Goods repaired; or

(b) In the case of Services; the supplying of the Services again, or the payment of the cost of having the Services supplied again.

1.2 You will only be entitled to the benefit of the warranty set out in this pledge, if You have not wholly or partially caused or contributed to the defect

to the Goods by the misuse of the Goods or the failure to use the Goods in accordance with any specifications or instructions applicable to the Goods.

1.3 The warranty contained in this pledge is provided by Turbosmart Pty Limited of 32 Milton Street North, Ashfield NSW 2131, Australia, Telephone:

+(61) 1300 735 506, Email: sales@turbosmart.com.au.

1.4 In order for a You to make a claim on the warranty You must within twelve (12) months of delivery of the Goods or Services give written notice to Us

at the address specified in clause 1.3 above of the details of any defects in respect thereof. Any Goods referred to in a notice given pursuant to this

clause should be left in the state and condition in which they were delivered until such time as We or Our duly authorised agent have inspected the

Goods with such inspection to be carried out within a reasonable time after service of such notice. If the Goods are not so left in the state and

condition

in which they were delivered then the You shall be deemed to have accepted the Goods and the warranty contained in this pledge shall not apply.

1.5 You shall be responsible for all expenses associated with making a warranty claim under this pledge however if the Goods and/or Services are found to

be defective due to Our fault then We shall reimburse You for any expenses incurred by You in making a warranty claim upon receiving evidence

satisfactory to Turbosmart to support such expenditure.

1.6 The benefits to You given by the warranty contained in this pledge are in addition to other rights and remedies of You have under a law in relation to

the Goods or Services to which the warranty relates.

1.7 In accordance with the Australian Consumer Law We makes the following statement:

“Our goods come with guarantees that cannot be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a

major

failure and compensation for any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the

goods

fail to be of acceptable quality and the failure does not amount to a major failure.”

EXCEPT AS PROVIDED BY LAW, THIS LIMITED WARRANTY IS THE ONLY EXPRESS WARRANTY, WHICH APPLIES TO TURBOSMART PRODUCT AS

EXPRESSLY GIVEN IN LIEU OF ANY OTHER WARRANTY EXPRESSED OR IMPLIED, INCLUDING THAT OF MERCHANTABILITY. ANY IMPLIED

WARRANTY INCLUDING THAT OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICCULAR PURPOSE IS HEREBY LIMITED BY THE SAME TERMS

AND TIME LIMITATIONS SET FORTH IN THIS LIMITED EXPRESS WARRANTY AND OTHERWISE EXCLUDED.

EXCEPT FOR THOSE OBLIGATIONS ASSUMED HEREIN, TURBOSMART ASSUMES NO OTHER OBLIGATIONS IN CONNECTION WITH THE SALE OF

ITS PRODUCTS.

IN THE EVENT THAT THE INDIVIUDAL PURCHASER DOES NOT AGREE WITH THIS AGREEMENT THE BUYER MAY PROMPTLY RETURN THIS

PRODUCT, IN A NEW AND UN-USED CONDITION, WITH A DATED PROOF OF PURCHASE, TO THE PLACE OF PURCHASE WITHIN SEVEN (7) DAYS

FROM THE DATE OF PURCHASE FOR A FULL REFUND.

THE INSTALLATION OF THIS PRODUCT INDICATES THAT THE INDIVIDUAL PURCHASER HAS READ AND UNDERSTOOD THIS AGREEMENT AND

ACCEPTS ITS TERMS AND CONDITIONS.

Happy motoring!

The Turbosmart Team

Turbosmart Pty Limited P.O. Box 264 Croydon, NSW 2132 Australia ABN: 69 081 069 794

Ph: +61 1300 735 506 Fax: +61 1300 735 509 Email: instructions@turbosmart.com.au

www.turbosmartonline.com

Loading...

Loading...