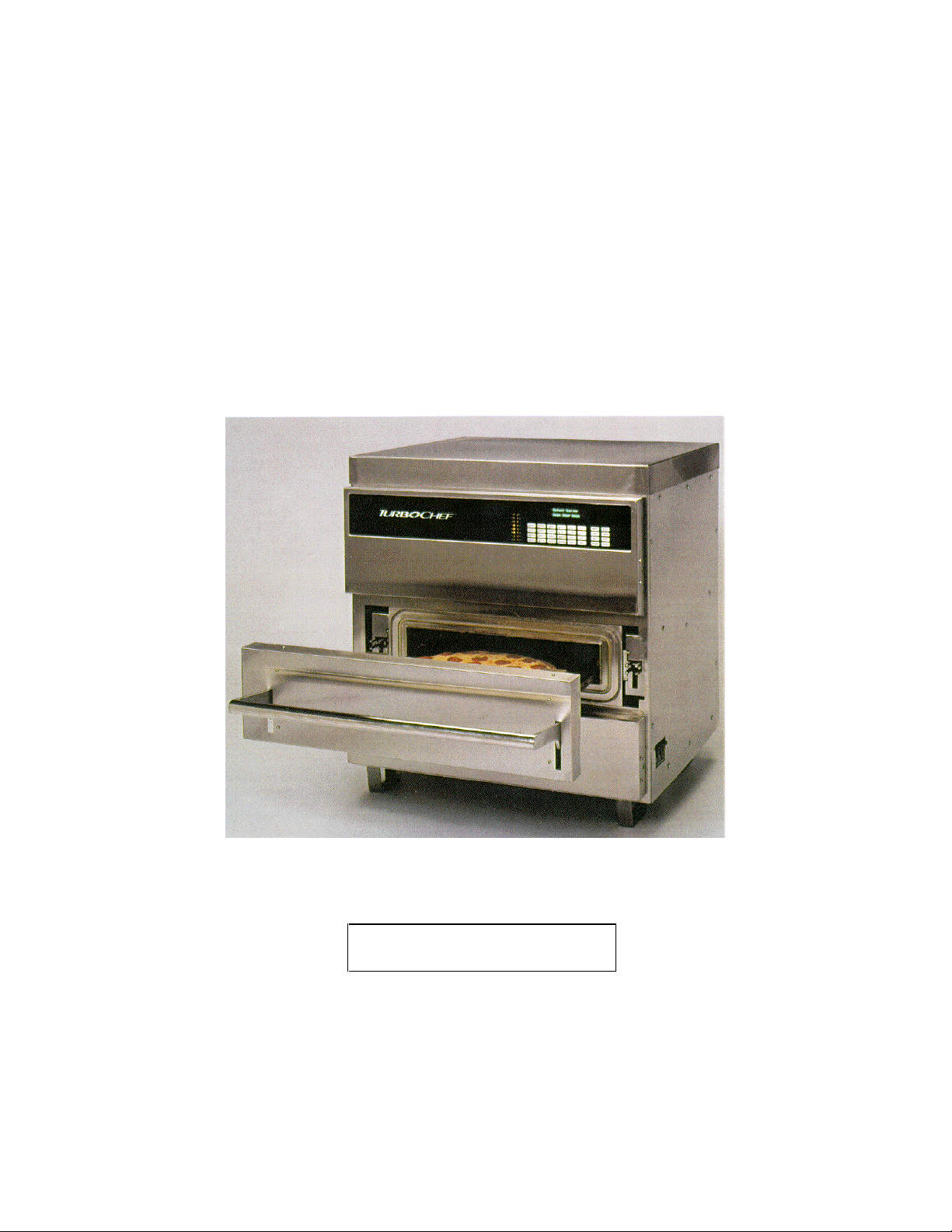

Page 1

Service Manual

for

TurboChef Model D3 Ovens

See Inside for Important

Steps before Operating Oven.

Customer Service Toll Free Number (888) 992-6624

Copyright July 1, 1999

Blodgett Advanced Cooking Technologies® Inc., All Rights Reserved

P/N T0032 Rev A (2/00)

Page 2

TABLE OF CONTENTS

Contents Page

IMPORTANT SAFETY INSTRUCTIONS - READ FIRST.......................................... 4, 5

RF INTERFERENCE CONSIDERATIONS .................................................................... 6

GROUNDING INSTRUCTIONS.....................................................................................6

POWER CORD REPLACEMENT..................................................................................6

SECTION 1 - INSTALLATION

1.1 Model Identification and Rating........................................................................7

1.2 Installation Instructions..................................................................................... 7

1.3 Specifications................................................................................................... 8

1.4 Oven Assembly................................................................................................ 9

SECTION 2 - OPERATING INSTRUCTIONS

2.1 Glossary of Common Terms.......................................................................... 11

2.2 Basic Operating Instructions.......................................................................... 12

2.3 Other Oven Operations.................................................................................. 13

2.4 Developing Cook Settings and Programming ................................................ 15

2.5 Control Panel Layout......................................................................................20

SECTION 3 – CLEANING AND SELF TEST

3.1 Basic Cleaning Procedures - Care and Cleaning...........................................21

3.2 Maintenance Mode Troubleshooting..............................................................33

3.3 Self Test and On-Line Error Messages.......................................................... 35

3.4 Self Test Flow Chart....................................................................................... 37

3.5 On-Line Flow Chart........................................................................................39

SECTION 4 – CONVECTION SYSTEM

4.1 Blower Motor Assembly..................................................................................40

4.2 Blower Motor Controller Tests........................................................................41

4.3 Blower Defective Messages........................................................................... 41

4.4 Blower Motor Controller Defective Messages ................................................ 42

4.5 Blower Operation ...........................................................................................45

4.6 Blower Wheel Replacement...........................................................................46

4.7 Heat Exchanger .............................................................................................47

4.8 Ceramic Insulator Replacement.....................................................................49

4.9 Heat Exchanger Defective Messages............................................................50

SECTION 5 - MICROWAVE SYSTEM

5.1 Measuring Microwave Radiation Leakage......................................................51

5.2 How to Turn Magnetrons On/Off for Testing..................................................52

5.3 Microwave Component Locations..................................................................53

5.4 Microwave Error Messages............................................................................55

5.5 Magnetron...................................................................................................... 56

5.6 High Voltage (HV) Magnetron Transformers..................................................57

5.7 High Voltage Diode........................................................................................ 58

5.8 High Voltage Capacitor.................................................................................. 60

Page 3

5.9 Microwave Mode Stirrer................................................................................. 61

5.10 Magnetron Over-Temperature Switch............................................................ 61

5.11 RF Output Monitor Circuit...............................................................................62

5.12 Magnetron Power Verification........................................................................62

5.13 Waveguide Seal Installation...........................................................................64

SECTION 6 - COOK DOOR ASSEMBLY

6.1 Cook Door and Related Assemblies.............................................................. 66

6.2 Cook Door and Interlock Switch Adjustments................................................68

SECTION 7 - FILTER DOOR SWITCH LOCATION / ASSEMBLY..............................69

SECTION 8 - CONTROL

8.1 Electrical Enclosure Assembly.......................................................................70

8.2 Electrical Enclosure Diagnostic Message ...................................................... 71

8.3 Display and Keypad Assembly....................................................................... 71

SECTION 9 - MAG. FAN/COOLING FAN/TRANSFORMERS/DIODES/CAPS............ 72

SECTION 10 - TROUBLESHOOTING

10.1 Common Door Related Problems.................................................................. 74

10.2 Miscellaneous Problems................................................................................ 75

SECTION 11 - DIAGNOSTIC INFORMATION (INCLUDING SCHEMATICS)............. 77

SECTION 12 - LIMITED WARRANTY FOR “D” SERIES OVENS............................... 83

SECTION 13 – TECHNICAL APPENDIX

13.1 Appendix A – Oven Connection to Computer................................................ 84

13.2 Appendix B – Japanese Input Power Frequency Conversion........................85

13.3 Appendix C – Japanese Additional EMI Filter................................................ 86

13.4 Appendix D – T3 & T4 Filament Transformer 200-208 Voltage Selection...... 87

Page 4

IMPORTANT SAFETY INSTRUCTIONS

WHEN USING ELECTRICAL APPLIANCES, BASIC SAFETY PRECAUTIONS

SHOULD BE FOLLOWED, INCL UDING THE FOLLOWING:

WARNING - To reduce the risk of burns, electric shock, fire, injury to persons or

exposure to excessive microwave energy:

1. Read all instructions before using the appliance.

2. Read and follow the specific “PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE TO EXCESSIVE MICROWAVE ENERGY” found on

page 5.

3. This appliance must be grounded. Connect only to properly grounded outlet. See “GROUNDING

INSTRUCTIONS” found on page 6.

4. Install or locate this appliance only in accordance with the provided installation instructions.

5. Some products such as whole eggs and sealed containers - for example, closed glass jars - may

explode and SHOULD NOT be heated in this oven.

6. Use this appliance only for its intended use as described in the owner’s manual. DO NOT use

corrosive chemicals or vapors in this appliance. This type of oven is specifically designed to heat,

cook, or dry food. It is NOT designed for industrial or laboratory use.

7. Children SHOULD NOT use this appliance.

8. DO NOT operate this appliance if it has a dam aged cord or plug, if it is not working proper ly, or if it

has been damaged or dropped. See “POWER SUPPLY CORD REPLACEMENT” found on page 6.

9. This appliance should be serviced only by qualified service personnel

10. DO NOT cover or block any openings on the appliance.

11. DO NOT store this appliance outdoors. DO NOT use this product near water - for exam ple, near a

kitchen sink, in a wet basement, or near a swimming pool, and the like.

12. DO NOT immerse cord or plug in water.

13. Keep cord away; from heated surfaces.

14. DO NOT let cord hang over edge of table or counter.

15. DO NOT use a water jet for cleaning.

16. See “Basic Maintenance Procedures - Care and Cleaning” provided in this manual.

17. To reduce the risk of fire in the oven cavity:

a) DO NOT overcook food. Carefully attend appliance if paper, plastic, or other combustible

materials are placed inside the oven to facilitate cooking.

b) Remove wire twist-ties from paper or plastic bag in oven.

c) If materials inside the oven should ignite, keep oven door c losed, turn oven off, and disconnect

the power cord, or shut off power at the fuse or circuit breaker panel.

d) DO NOT use the cavity for storage purposes. DO NOT leave paper products, c ooking utensils , or

food in the cavity when not in use.

SAVE THESE INSTRUCTIONS

Page 4 of 87

Page 5

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING

SERVICING TO AVOID POSSIBLE EXPOSURE TO

EXCESSIVE MICROWAVE ENERGY

1. DO NOT attempt to operate this oven with the door open since open-door operation

can result in harmful exposure to microwave energy. It is important not to defeat or

tamper with the safety interlocks.

2. DO NOT place any object between the oven front face and the door or allow soil or

cleaner residue to accumulate on the sealing surfaces.

3. Make the following safety checks on all ovens to be serviced before activating the

magnetron or other microwave source, and make repairs as necessary:

a) Interlock operation.

b) Proper door closing.

c) Door (bent).

d) Hinges and latches (broken or loosened).

e) Door seals and sealing surfaces (arcing, wear, and other damage).

f) Evidence of dropping or abuse.

4. Before turning on microwave power for any service test or inspection within the

microwave generating compartments, check the magnetron, wave guide, or

transmission line, and cavity for proper alignment, integrity, and connection.

5. Any defective or mis-aligned components in the interlock, monitor, door seal, and

microwave generation and transmission systems must be repaired, replaced, or

adjusted by procedures described in this manual before the oven is released to the

owner.

6. The oven SHOULD NOT be adjusted or repaired by anyone except properly

qualified service personnel.

7. A microwave leakage check to verify compliance with the Federal Performance

Standard MUST BE performed on each oven prior to release to the owner.

SAVE THESE INSTRUCTIONS

Page 5 of 87

Page 6

RF INTERFERENCE CONSIDERATIONS

This oven generates radio frequency signals. This device has been tested and

determined to be in compliance with applicable part of FCC part 18 requirements and to

the protection requirements of Council Directive 89/336/EEC on the approximation of

the laws of the Member States relating to electromagnetic co mpatibility at the time of

manufacture. However, some other equipment may exhibit sensitivity to signals below

these limits resulting in interference with that equipment.

If your equipment experiences interference, the following steps should be considered:

1. Increase the physical separation between this oven and the sensitive equipment.

2. If the sensitive device can be grounded, do so following accepted grounding

practices.

3. If battery powered microphones are being affected, insure that the batteries are fully

charged.

4. Keep sensitive equipment on electrically separate circuits, if possible.

5. DO NOT route intercom wires, microphone wires, or speaker cables near oven.

GROUNDING INSTRUCTIONS

This appliance MUST BE grounded. In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an escape wire for the electric current.

This appliance is equipped with a cord having a grounding wire with a grounding plug.

The plug must be plugged into an outlet that is properly installed and grounded.

WARNING - Improper use of the grounding can result in a risk of electric shock.

Consult a qualified electrician or serviceman if the grounding instructions are not

completely understood, or if doubt exists as to whether the appliance is properly

grounded.

DO NOT use an extension cord. If the power supply cord is too short, have a qualified

electrician or serviceman install an outlet near the appliance.

POWER SUPPLY CORD REPLACEMENT

If the power supply cord is damaged, it MUST BE replaced by the manufacturer or its

service agent or a similarly qualified person in order to avoid a hazard.

SAVE THESE INSTRUCTIONS

Page 6 of 87

Page 7

SECTION 1 - INSTALLATION

1.1 MODEL IDENTIFICATION AND RATING

MODEL NUMBER, NAMEPLATE INFORMATION AND SERIAL NUMBER is

located on the nameplate label on the rear cover of the oven.

NOTE: An electrical schematic is supplied with the oven. It is located in the

back of the Display Panel in an envelope. Please return the schematic to

the storage envelope for future use.

SERIAL NUMBER IDENTIFICATION is located on a serial number label

attached underneath the lower right corner of the oven frame and on the rear

cover.

CAUTION: It is extremely important that the model number be correctly

identified. Electrical wiring and program changes have been made to the

D3 oven. Information from earlier D models must not be applied to the D3

model. Use information from this manual only.

Wiring Information:

• European D3 models require a three phase WYE 5 wire power cord. This

oven must not be operated on three phase DELTA or single phase

power.

• North American and Japanese three phase D3 ovens require a three phase

DELTA 4 wire power cord. This oven must not be operated on three phase

WYE or single phase power.

• North American single phase D3 ovens require a 3 wire power cord. This

oven must not be operated on three phase power.

1.2 INSTALLATION INSTRUCTIONS

1.2.1 Installation Requirements

The installation must be made in conjunction with an understanding of applicable

CE, UL, cUL, NSF, and FDA requirements and appropriate local codes.

Before starting installation, the owner/installer should understand and agree

upon:

a) The installation policies of TurboChef Technologies Inc.

b) The installation plan based on overview and preparation.

c) The responsibility for testing, instruction of proper operation, use & care, and

preventative maintenance.

WARNING

a) DEATH, INJURY, AND EQUIPMENT DAMAGE could result from improper

installation of the TurboChef oven or installation of a unit which has been

damaged during shipment or storage. Either of these conditions could void the

equipment warranty.

b) DO NOT INSTALL a TurboChef oven suspected of damage.

c) INSTALL the TurboChef oven according to the policies and procedures outlined

in this manual.

Page 7 of 87

Page 8

1.2.2 Installation Precautions

(FRONT)

This equipment is designed and manufactured to comply with applicable CE, UL,

cUL FDA, and FCC requirements. In addition, the unit is UL classified to NSF 4.

All equipment is designed and certified for safe operation when installed in

accordance with local and or national codes. Many local codes exist, and it is the

responsibility of the owner and installer to comply with these codes.

In no event shall the manufacturer assume any liability for damages or injury

resulting from installations which are not in compliance with the instructions and

codes listed above. The manufacturer shall not assume liability for damage or

injury resulting from improper installation of equipment including temporary or

unstable work stations or counter tops.

The counter top or work surface must be able to support the weight of 650

pounds and should not exceed 30 inches in height.

There must be 1.75” (4.4cm) between the top of the unit and any shelf or

surface.

The oven must be level front to back and side to side. The oven legs may be

bolted to the counter top and must be bolted if it is placed on a rolling cart.

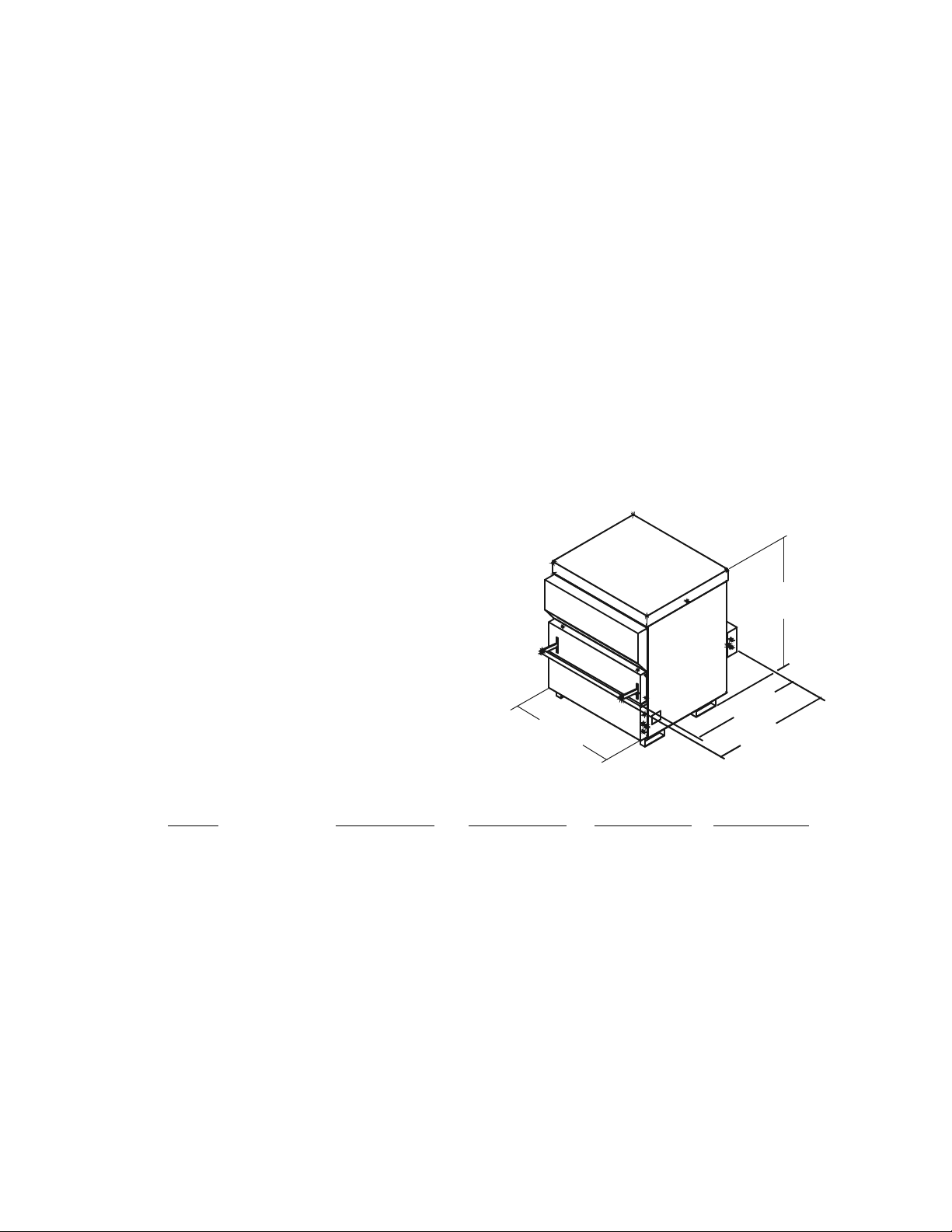

1.3 SPECIFICATIONS

Physical characteristics:

Width: 31.5” (80cm)

Height: 40.0” (101.6cm)

Depth: 35.3” (89.6cm)

(Door handle closed)

37.0” (94.0 cm)

(Door handle up)

Weight: 540 lb. (1190.7kg)

31.5”

(80cm)

(101.6cm)

35.3”

(89.6cm)

37”

(94cm)

40”

Electrical Characteristics:

North American European Japanese

Model D3-A-5/6D4 D3-S-5/6S3 D3-E-5/6Y5 D3-J-5/6D4

Voltage: 208/240 V 208/240 V 400-415 V 200 V

Frequency: 50/60 Hz 50/60 Hz 50/60 Hz 50/60 Hz

Connections*: 3Φ, 4 wire 1Φ, 3 wire 3NΦ, 5 wire 3Φ, 4 wire

Current: 30/33 Amps 50 Amps 18 Amps 32 Amps

Max Power Usage:

Convection Oven: 7.0/9.0 kW 7.0/9.0 kW 9.0 kW 6.5 kW

Microwave Oven: 4.0 kW 4.0 kW 4.0 kW 4.0 kW

Microwave Freq.: 2450 MHz 2450 MHz 2450 MHz 2450 MHz

Connector Type: NEMA 15-50P NEMA 6-50P IEC 309-32A NEMA 15-50P

* connections including ground

The oven is supplied with a 6’ power cord that includes a male connector. The

outlet box, receptacle and wall plate are to be furnished by the installing

contractor.

Page 8 of 87

Page 9

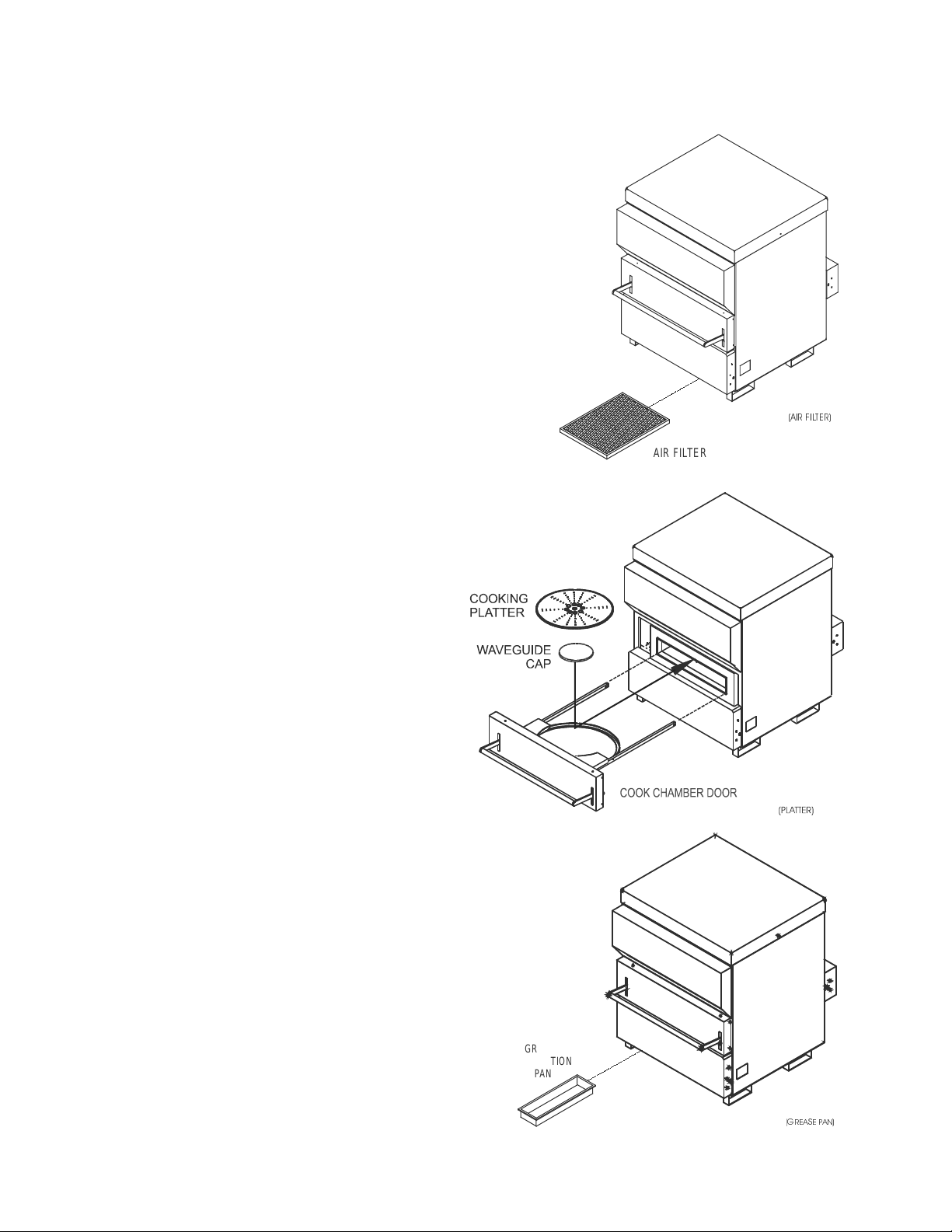

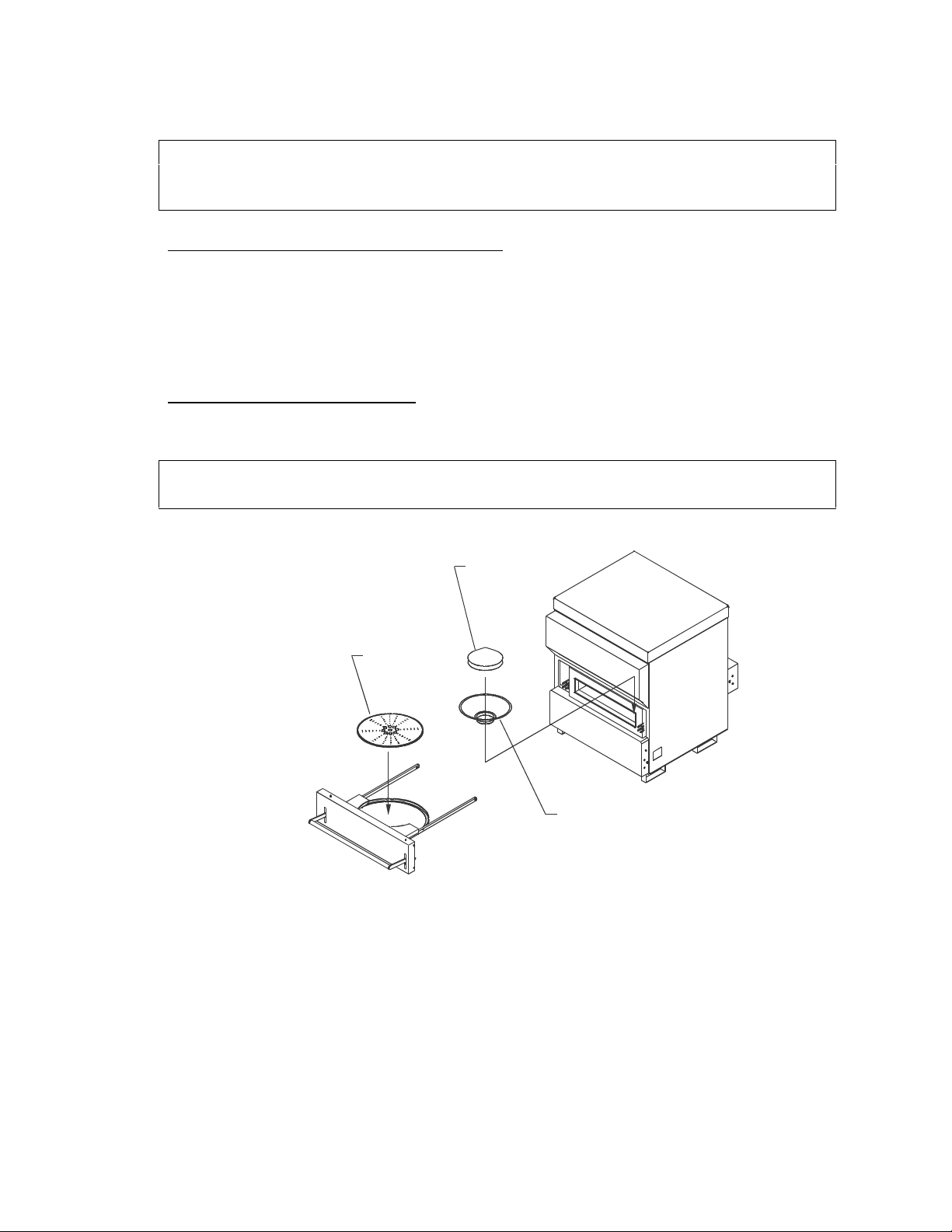

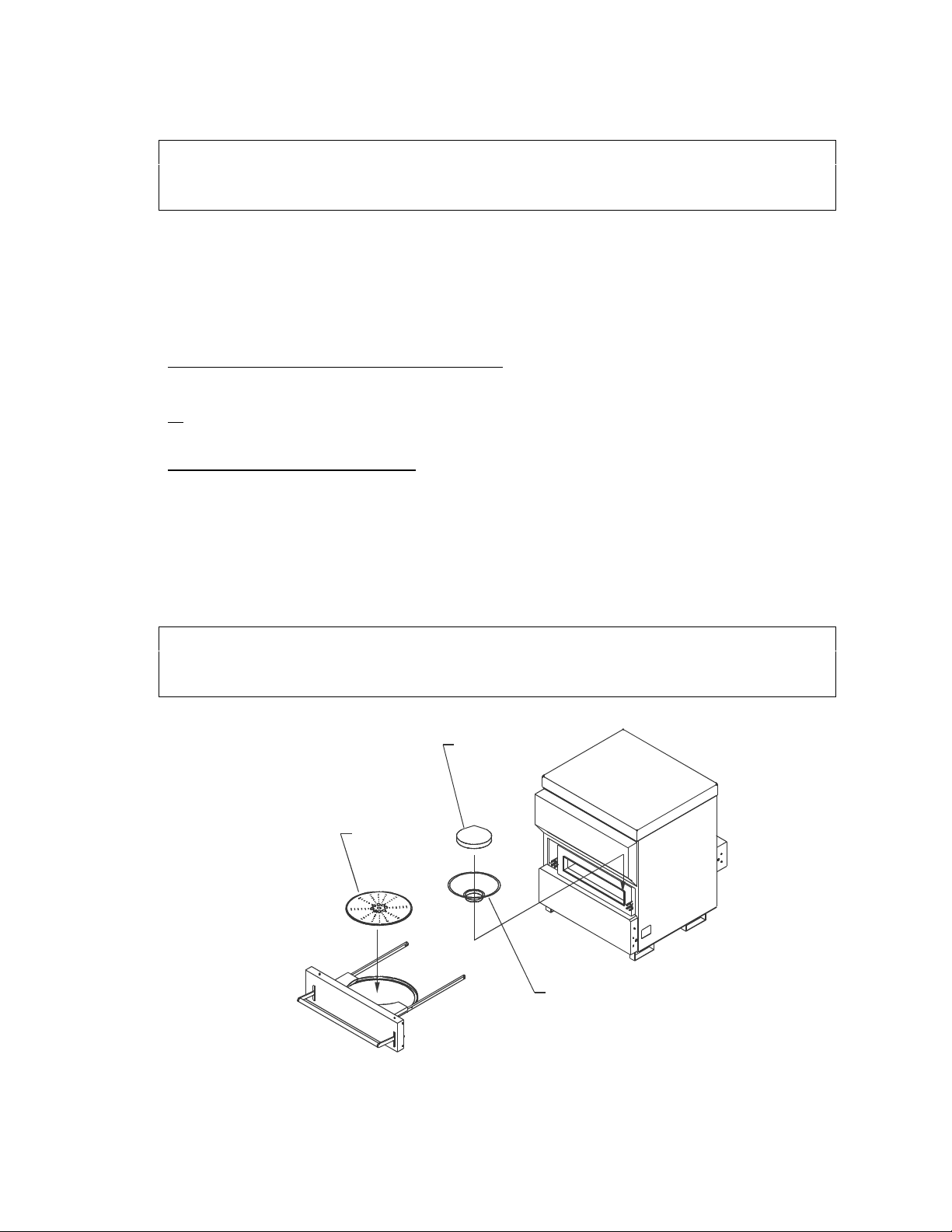

1.4 OVEN ASSEMBLY

AIR FILTER

Air Filter and Frame

1. Remove the air filter and frame from their

shipping location on the back of the unit.

2. Slide the air filter frame into the brackets

on the bottom of oven below the cooking

chamber. Secure the frame to the bottom

front of the unit with a thumbscrew.

3. Slide the air filter into the frame.

Ceramic Cooking Platter

1. Carefully remove the packing

material from the ceramic

Cooking Platter.

$,5),/7(5

2. Open the cooking chamber

door.

3. Place the cooking platter onto

the ring in the cook chamber

door.

Waveguide Cap

1. Place the waveguide cap

centered on top of the screen

basket.

Grease Pan

1. Slide the grease pan into the frame

on the bottom left side of the oven.

Position the grease pan with the

weep hole to the front of the oven.

GREASE

COLLECTION

PAN

*5($6(3$1

Page 9 of 87

Page 10

Cart (if applicable)

1. Lift the oven onto the cart. The holes in the top frame of the cart should line

up with the holes in the base supports of the oven.

2. Secure the oven to the cart as follows:

a) Place a washer, lock washer and nut on the bolt and tighten. DO NOT

over tighten or the cart’s tubing will become deformed.

b) Repeat for each leg

Additional Consumable Parts

These additional parts are to be used as spares. They should not be installed in

the oven at this time.

Part Number Description Quantity of Spares (US only)

T100532 Grease Filter 3

T7000301 Ceramic Cooking Platter 2 + 1 (included with oven)

T7000302 Waveguide Cap 2 + 1 (included with oven)

T7001189 Chamber Basket 1

Page 10 of 87

Page 11

SECTION 2 - OPERATING INSTRUCTIONS

2.1 GLOSSARY OF COMMON TERMS

Air - Percent of convection air flow during a cook event.

Cook Temperature Set Point - The constant parameter, Cook Temperature Set

Point, is used by all Cook Settings.

Cook Chamber - Cavity in which the food products are cooked.

Cook Cycle - Time of operation for a Cook Setting.

Cook Setting Recipe - The food product cooking process. It consists of

duration, percentage of the hot air flow (AIR) required and microwave (TW)

required.

Cook Mode - Execute the Cook setting instructions for selected food product.

Cooking Product - The food product to be cooked in the oven.

Cook Event - Segment of a cook cycle, up to 4 events can be used for each

cycle.

COOL-DOWN Mode - Turns OFF all oven components except the cooling fan.

Display - Primary interface to relay messages to the operator.

Duration - Time, in seconds, of a single cook event.

EDIT Mode - Mode used to adjust the Cook Setting parameters.

Keypad - Primary interface for the operator to control the oven.

HEAT - Selects the cook temperature set point in EDIT mode.

LED - Individual light indicators numbered 1 through 16 to show component

status.

MAINTenance Mode - Mode used by authorized service personnel to check the

operation of oven components.

Mode - The software environment which allows certain operations to occur.

There are several modes, NORMAL, COOK, SELF-TEST, EDIT, WARM UP,

COOL DOWN and MAINTenance, in which the oven can operate.

NORMAL Operation Mode - Mode used to perform the "NORMAL" oven

operations, such as, monitor the key pad for requests to cook or change mode,

and maintain the oven at the Cook Temperature Set Point.

Parameter - A Cook Setting consists of two different kinds of parameters. Those

which stay constant during a Cook Setting execution and those which can vary

during different events of a Cook Setting.

Radio Frequency (RF) - The term used to describe the microwave emissions.

Recipe - Cook Setting. The food product cooking plan. It will consist of up to four

Cook Events, each of which consists of duration, percentage usage of the hot air

flow (AIR) required and microwave (TW) required.

RESUME - Continues Cook Cycle if interrupted such as by opening oven door.

TW - Percent of Microwave used during a Cook Event.

WARM-UP Mode - Brings the oven up to the Cook Temperature Set Point.

SELF-TEST Mode - Self checks all critical components (magnetrons, heat

exchanger and blower are operational.

Page 11 of 87

Page 12

2.2 BASIC OPERATING INSTRUCTIONS

2.2.1 Power On

The power switch is on the right side, lower front when your are facing the oven.

Pull the power switch toward the top of the oven to energize.

2.2.2 Self Test/Warm Up

1. The machine will go through a self-check to verify that the critical components

(magnetrons, heat exchanger and blower) are operational. (If the oven

displays the message “Cooling Down”, Depress the “Warm Up” key to start.)

CAUTION: Self Test results are unpredictable if the oven door or filter

door are not closed prior to or opened during the self test.

2. If any of the critical components are malfunctioning, the machine will stop at

the end of the test displaying a message identifying the faulty component.

Refer to Troubleshooting Section for message definition. To continue press

Stop.

3. When the self-check is complete and satisfactory, the machine will start

warming up and display "WARMING UP, HX Temp …". The HX Temp is the

temperature of the heat exchanger. When the HX temperature exceeds a

value determined by the cook temperature set point, the blower begins

circulating air and the display indicates “CC Temp/HX Temp” on the lower

line. The CC Temp is the temperature in the oven cook chamber. When the

CC temperature reaches the cook temperature set point, warm-up is

complete. The Warm Up should take approximately 30 minutes (shorter if the

machine has not cooled down completely).

4. When the oven is ready to cook, it will display:

Select Recipe Or Select Recipe

CC 480° HX 571° If in Diagnostic Mode Heat 480/571°

2.2.3 Running A Recipe/Cook Setting

CAUTION: DO NOT operate the oven without food or a suitable microwave

load in the cook chamber. This may damage the oven.

CAUTION: DO NOT operate the oven with metal in the cook chamber. This

will damage the oven.

1. Open cooking chamber door by pulling the handle up, then pull the handle

outward until the door opens.

2. Place the food product in the appropriate position on the cooking platter.

3. Close cooking chamber door by pushing forward on the handle until the door

shuts, then push the handle down to latch into place.

4. Press the desired food (group) Cook Setting button.

Page 12 of 87

Page 13

5. Press a button numbered 1 to 6 (subgroup) for food quantity or special food

definition. The display indicates the food group/subgroup name and cook

time seconds (counting down).

6. W hen the cooking cycle is complete, the oven will beep and the display will

indicate "PLEASE REMOVE FOOD FROM OVEN". Remove the food product

from the oven.

Note: Food will continue to cook with radiant and convection

energy when left in the oven due to the high cook chamber temperature.

7. The cook cycle is now ready to begin again.

Notes:

• If for any reason you want to stop the cooking cycle, press the “STOP” button

at any time. The user may close the door and press "RESUME" for the Cook

Setting to continue.

• If the oven door or filter door is opened during a cook cycle, the oven will

automatically stop the current Cook Setting. The user may close the door and

press “RESUME” for the Cook Setting to continue.

• If the “DARKER” key is depressed, 25% of the last cooking event is added as

additional cook time.

• Protection against exposure to microwave energy: Safety interlocks in the

oven doors prevent or terminate microwave operation when either the oven

door or filter door is open.

2.2.4 Power Off

The power switch is on the lower right side, near the front when facing the oven.

Push the power switch toward the bottom of the machine to de-energize.

2.3 OTHER OVEN OPERATIONS

2.3.1 Cool Down

An alternative to turning the power switch OFF when cooking is finished for the

day is the "COOL DOWN" mode. This mode turns off all the major components

but still allows the cooling fan to operate to keep the internal temperatures of the

oven electrical parts down while the oven is cooling. To select "COOL DOWN"

press the "COOL DOWN" button followed by the "ENTER" button. Opening the

oven door will shorten the cool down time.

2.3.2 Warm Up

To remove the oven from "COOL DOWN" and return to the ready to cook state,

press the "WARM UP" button. Make sure the oven and filter doors are securely

closed. Remember, the oven may take up to 30 minutes to warm up.

2.3.3 Stop Key

The "STOP" key can be utilized to stop the Cook Setting at any point in the

cook cycle. The Cook Setting may be continued by pressing the "RESUME"

key. The "STOP" key is also used to exit other modes such as "EDIT" or

"MAINTENANCE".

Page 13 of 87

Page 14

2.3.4 Darker Key

The "DARKER" key may be used to cook the food an additional 25% of the last

cooking event. This may be useful to brown the food product or make the

product well done.

2.3.5 Resume Key

The "RESUME" key allows a Cook Setting which was interrupted by the "STOP"

key or opening the oven door to continue.

2.3.6 MAINTenance, Edit, and Heat Keys

Described in the section on Developing Cook Settings and Programming.

2.3.7 Catalytic Converter

The catalytic converter, T7001197, is installed in the return air duct downstream

of the grease filter assembly. The installation of the catalytic converter requires a

catalytic converter support frame, part # T7001195, to properly position it in the

air path. The above parts may be ordered in kit form, # T7001200.

Operation and Indication of Problems

Due to the nature of most foods and the physics governing the operation of the

TurboChef Oven, grease buildup downstream of the cooking chamber is

inevitable. Strict cleaning regiments can solve a majority of the problems,

however, recirculation of undiluted grease saturated air that is the main cause of

downstream grease accumulation and any associated residual flavors.

The airborne grease will tend to collect and bake onto the oven surface

downstream of the cooking chamber. This grease, due to the high operating

temperatures of the oven, will start to rapidly decompose into derivative organic

compounds.

These decompositional derivatives generally have positive and negative effects

on cooking; the shorter chain derivatives add favorable flavor characteristics to

the food, while the higher order carbon chains lend unpleasant flavor

characteristics, such as bitter tarry tastes.

The installation of the catalytic converter greatly effects the grease handling and

any residual flavors which might build up over time. A properly operating catalytic

converter causes the conversion of airborne grease into water, carbon dioxide

and small amounts of nitrogen and oxygen. The catalytic converter acts as a

combustion chamber for the airborne grease. The catalysts present on the filter

lowers the ignition temperature of the airborne grease from approximately 7000F

to 450-5500F, allowing combustion to occur. The operating temperature of the

oven directly determines the percentage of airborne grease conversion. A single

pass of the air stream yields a 20-30% improvement in air quality.

A problem with the catalytic converter is indicated by a decrease in the

effectiveness of browning (caused by a reduction in airflow) or by flavor transfer

from one food group to another. Your operating parameters (daily use and oven

run time) determines inspection/cleaning frequency. See cleaning instructions for

procedure.

Page 14 of 87

Page 15

2.4 DEVELOPING COOK SETTINGS AND PROGRAMMING

2.4.1 How to Develop your Cook Settings

Cooking with a TurboChef oven is different and exciting! It delivers hot food

faster, at a higher quality than other ovens available today.

TurboChef uses both hot air and microwave energy to cook food. If you have

experience with either a convection oven or microwave oven you will see

similarities and significant differences. The key to creating good cook settings for

your food is to understand the following rules:

1. TurboChef uses a moving shroud of hot air to surround the food. This locks in

the food’s moisture.

2. The hot air provides most of the heating and browning of foods. The higher

the air velocity, the faster heat energy is transferred to food.

3. The microwave provides heat to the center of the food. Don’t try to do all the

cooking with microwave!

4. The weight of food determines the total time required to cook. The more

weight, the longer the time required. (Most medium thick crust pizzas cook in

about 100 seconds.)

5. Thick and dense foods may need to be flipped half way through the cooking

cycle.

6. Microwave works best in the early stages of cooking, then use hot air to finish

the cooking.

7. Color develops mostly at the end of the cooking cycle. Higher velocity air in

the later stages of cooking will strongly control the food’s color.

Don’t be afraid to experiment! Write down your current cook settings and then

start testing. You can always go back to the old cook settings in a few seconds.

Enjoy the power and flexibility of your TurboChef System.

2.4.2 Reviewing Existing Cook Settings

1. Press the EDIT key, key in the Access Number (PIN) and press ENTER.

2. Press the Recipe GROUP key you wish to review and observe the group

name.

3. Press ENTER.

4. Press a SUBGROUP key, key 1 through key 6, and the subgroup name

appears to the right of the GROUP name.

5. Press ENTER and observe the Duration in seconds, the percentage of hot air

flow (Air), and the percentage of microwave (TW) for the first event of the

cook cycle.

Page 15 of 87

Page 16

6. Press ENTER and the second event parameters are displayed. The Cook

Setting ends when an event with zero time duration is encountered or all four

events are used. If the first event of a Cook Setting has a duration of zero

time, no Cook Setting is defined.

7. Press EDIT to return to step 2.

8. Press HEAT and observe the cook temperature set point. The cook

temperature set point applies to all GROUP/SUBGROUP cook settings.

9. Press STOP to return to normal operation.

2.4.3 E diting Cook Settings

1. Press the EDIT key, enter Access Number (PIN) and Press ENTER.

2. Press the Recipe GROUP name key of the Cook Setting you wish to edit.

3. Edit the food group name using the left/right arrow keys to position the

blinking cursor. Nine characters are available for the food group name.

Repeat pressing an alpha/numeric key until the needed letter or number

appears. The up/down arrow keys select upper case or lower case letters.

Use the right arrow key to advance to the next character position. The SP key

replaces a character with a space and advances to the next character

position. Press ENTER when the new name is complete. Note: When the

existing information is correct, simply press ENTER to store the information

and move to the next display.

4. Press a SUBGROUP key number, 1 through 6, to indicate quantity or special

food definition.

5. As described in Step 3, likewise edit the subgroup name. Press ENTER.

6. Observe the three parameters for cook event 1. The blinking cursor indicates

the Event Duration is selected for editing. Use the left/right arrow keys to

select the other parameters, blower power (AIR) or microwave power (TW).

7. Using the numeric section of the keypad, key in the correct time or

percentage and press ENTER. The blinking cursor will advance to the next

parameter. Note: You must press ENTER to replace previous settings with

new settings. Be careful not to change a setting and move the blinking cursor

without pressing ENTER to save the setting.

8. If a setting is not changed and ENTER is pressed, the display will advance to

the next event. Use the up/down arrow keys to select any of the 4 events to

edit or review.

9. W hen 4 events are not required for the cook setting, set the duration of the

first unused event to 0. Note: If the duration of event #1 is set to 0, the

GROUP/SUBGROUP selection has no cook setting and displays “NO

RECIPE ENTERED” when selected.

Page 16 of 87

Page 17

10. Valid event duration time is 1 to 255 seconds. However, the combined

duration of all events, i.e., the total Cook Setting cook time, should not

exceed 999 seconds. Valid blower power (AIR) is 20% to 100% in 5%

increments. Valid microwave power (TW) is 0%, 50%, or 100%.

11. Anytime you wish to select a different Cook Setting to edit, press EDIT and

return to step 2.

12. To review or edit the Cook Temperature Set Point, press HEAT. Enter a new

temperature from the numeric keys and press ENTER. Note: The same Cook

Temperature Set Point applies to all GROUP/SUBGROUP Cook Settings.

13. When editing is complete, press STOP to return to normal cook mode.

2.3.4 Maintenance Operations

The MAINTenance mode allows you to manually control the various hardware

components of the oven and display operational information

Press the MAINTenance key, enter access number (PIN) and press ENTER.

1. VER key alternately displays the version of the oven operating system

(hardware and software) and the oven recipe version if loaded by the

ChefComm utility.

2. HTR key turns the Heat Exchanger On and Off. If the heat exchanger is over

the maximum allowed temperature (Approximately 700 degrees F), the

heaters can not be turned on. An over temperature thermostat also prevents

heater runaway. LED 11 indicates heaters are selected and LED 16 indicates

current is flowing to the heaters. This key also resets the COOK TEMP TOO

LOW message.

CAUTION: DO NOT leave the heaters on for long periods, as the oven will

rapidly heat to maximum allowed temperature (Approximately

720qF(382qC).

3. %BLO key increases the convection airflow in 10% increments. Repeat

pressing key to select new air speeds. When the airflow is 100%, the next

key press resets airflow to 0%. If the blower is Off (LED 7 is no t illuminated)

the %BLO key is ignored.

4. BLR key turns the convection air blower On or Off. LED 7 indicates the status

of the blower motor speed controller. The blower will return to controlled

operation when MAINTenance is exited. This key also resets the BMSC

DEFECTIVE message.

Page 17 of 87

Page 18

5. M12 key energizes both magnetron 1 and 2 when the key is held depressed.

There will be a 3 second delay while magnetron filaments heat up initially.

The filaments will stay on for 3 minutes after the end of the last time the

magnetrons were energized. To conserve power, the Heat Exchanger is

turned OFF when the key is pressed. The display provides an un-calibrated

indication of the power level in the microwave waveguide cavity. The power

reading varies with the motion of the microwave stirrer blade. The magnetron

turns OFF when the key is released. This key also resets the Mag RF FLUC

LO, Mag CURRENT LOW and Mag THERMO SW messages.

CAUTION: DO NOT hold the key more than 5 seconds without a cooking

product or suitable microwave load in the oven.

6. PIN key allows for entry of an alternate personal identification number for

accessing EDIT and MAINTenance modes. If ChefComm is implemented, the

PIN will also reset the “New Settings” message. Enter from 1 to 4 n umbers or

letters and press ENTER. Be sure to keep a record of the PIN you choose.

7. CCC key displays the Cook Cycle Count. Press key a second time and a

message prompts to press SP/CLR to reset the count to zero.

8. EC key displays the temperature of the electronics compartment. If the EC

thermocouple is open or missing, “EC THERMO OPEN” is displayed. The EC

temperature should not exceed 140°F(60°C) under normal conditions.

9. WARM key causes the MAINTenance mode to be exited and the WARM-UP

mode to be selected without executing SELF-TEST.

10. DIAG key performs two functions. The first press displays the heat exchanger

rate of temperature rise, degrees per minute. This number is used by the

oven operating system to replace heat lost during cooking and maintain cook

temperature when the oven is idle. If MAINTenance mode is exited after the

first press, a diagnostic display is presented during cook and heat

maintenance cycles. The display shows all parameters, RF power, percent

airflow, CC and HX temperature, and the accumulated and target BTU during

cooking for each event.

The second press indicates if the temperature rise was measured or

defaulted to the last known measurement. The measurement is taken during

oven warm up when the initial cook chamber temperature is less than one

half the cook temperature set point. To keep the normal display, exit

MAINTenance after the key press showing the measured or default message.

11. IAF key selects the amount of air flow when the oven is idle (not Cooking).

When IAF is first pressed, the current Idle Air Flow is displayed. The IAF

range is 0% to 50% in 5% increments. Repeat pressing the IAF key to select

a new air flow. Then press ENTER to set the new IAF.

Page 18 of 87

Page 19

12. SN key is used to enter the oven serial number. The first time SN is pressed

the current serial number is displayed. A second press clears the serial

number field and awaits entry of a new number. Up to 14 alpha/numeric

characters may be entered. Repeat pressing an alpha/numeric key until the

needed letter or number appears. Use the right arrow key to advance to the

next character position. The left arrow key moves the cursor to the left to

permit changing a previously entered character. The SP key replaces a

character with a space and advances to the next character position. The

serial number is updated when ENTER is pressed.

13. FF key is used to display and reset oven fault flag counters. Repeat pressing

the FF key to display the 6 faults, BMSC Status, Low Cook Temperature, Low

Mag Current, Low RF Fluctuation, Mag Thermo Switch, and EC Over

Temperature. The counters increment from 0 to 255 and roll over to 0. To

reset a counter, repeat pressing FF to select the fault and press SP/CLR.

14. F/C key is used to select Fahrenheit (ºF) or Celsius (ºC) temperature scale for

the display. If Fahrenheit temperature is currently displayed, pressing F/C will

change the display to Celsius and visa versa.

15. MS key is used for modem selection when the oven is connected via

telephone to a remote ChefComm facility. Refer to document T700155 for

ChefComm operation.

Press the MAINTenance or STOP key to return to normal cooking operation. The

magnetrons and heaters are turned OFF, the blower controller is returned to the

ON or operational state and the air flow is set to the IAF setting bef ore returning

to normal cooking operation.

2.4.5 Replacing Keypad Menu Label Strips

1. Remove menu label strips by inserting a small pointed object, such as a

wooden toothpick, under the keypad film and pull out until the strip appears

and can be removed by hand. Use caution in order to avoid damaging keys,

cutting the keypad film or scratching the stainless steel panel.

2. Install a new menu strip by holding the keypad slot open with a small pointed

object and sliding the new menu strip into place. Again, use caution to avoid

cutting the keypad film or scratching the stainless steel panel.

Page 19 of 87

Page 20

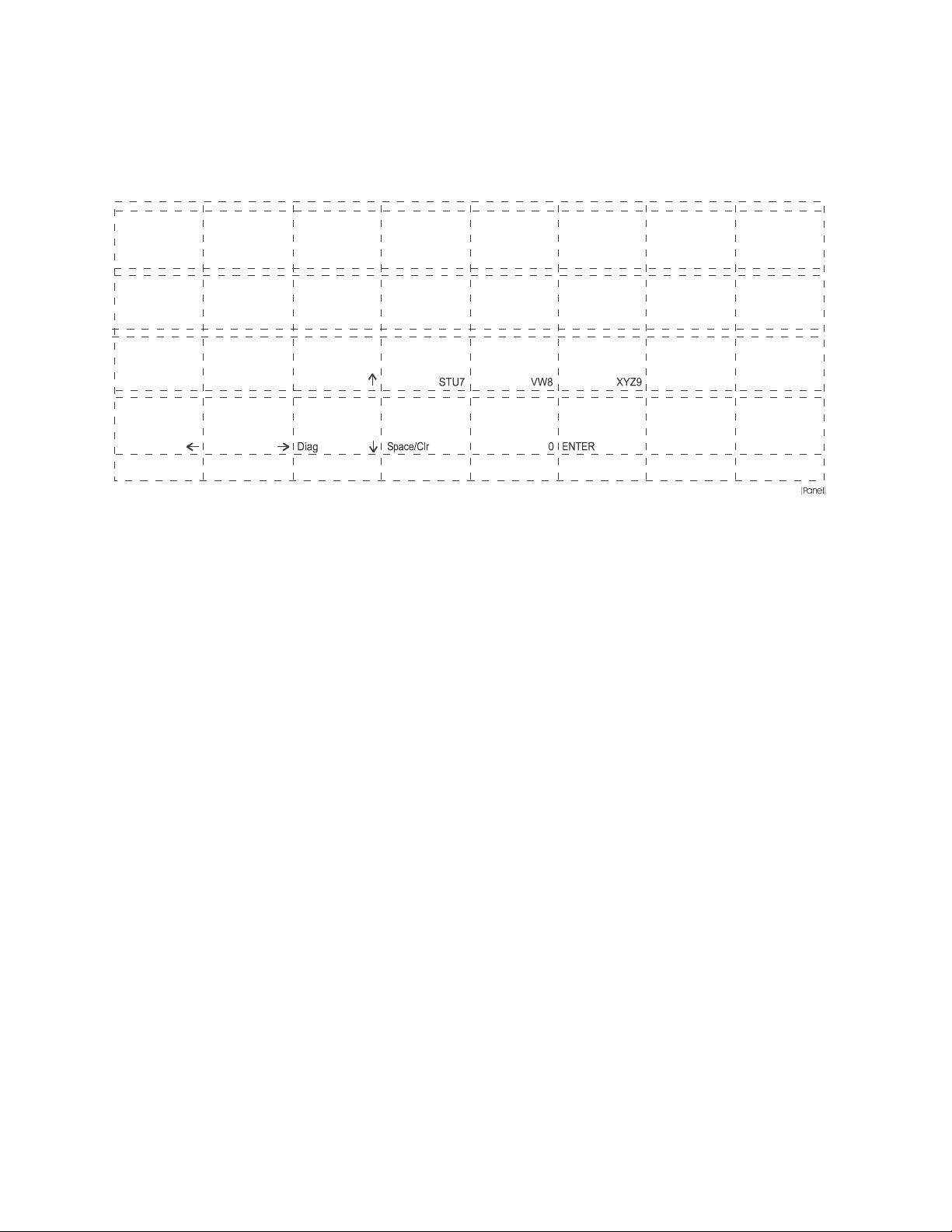

2.5 CONTROL PANEL LAYOUT

/#+06

2.5.1 Keypad Layout

NOTE: Subscripts used in MAINTenance and EDIT modes only.

#

Ver

$

Htr

%

%Blr

&

Blr

2.5.2 Status LED Indicator Layout

Cook Door Primary 1

Cook Door Secondary 2

Cook Door Monitor 3

Filter Door Primary 4

Filter Door Secondary 5

M12

Pin

'

(

)

*

CCC

EC

,

.

/

IAF ABC1

JKL4

0

/+%41

••

••

••

••

••

SN DEF2

FF MNO5

2

/+%41

#+4

°C/°F

9

10

11 Heat Exchanger

12 Magnetron 1 Temperature OK

13 Magnetron 2 Temperature OK

MS GH13

PQR6

4

#+4

'&+6

*'#6

%11.

&190

5612

9#4/

72

-'4

4'57/'

3DQHO

Filter Door Monitor 6

Blower Running 7

When light is on, item is active.

••

••

8

••

14 Magnetron 1 On

15 Magnetron 2 On

16 Heat On

Page 20 of 87

Page 21

SECTION 3 – CLEANING AND SELF TEST

3.1 BASIC CLEANING PROCEDURES - CARE AND CLEANING

Carbon and grease build-up will adversely affect the cooking performance

and life expectancy of certain components of the TurboChef oven. It is the

operator’s responsibility to properly maintain this unit. Failure to maintain

this unit in a clean condition will void the warranty.

WARNING: Never use a NaOH (Lye) based chemical to clean the

Turbochef oven. Use of NaOH (Lye) based chemicals can damage critical

components and will void the warranty.

3.1.1 SUPPLIES NEEDED

•

Non-Lye Non-Caustic Oven Cleaner

•

Non-Lye Non-Caustic Degreaser

•

All Purpose Cleaner

•

Oven Coating (optional) To more easily maintain a clean oven (especially

back wall of cooking chamber), grease shield oven coatings may be applied,

after oven has been cleaned

NOTE: For a specific listing of non-caustic, non-lye cleaning products,

call your local Authorized Service Provider.

3.1.2 CLEANING EQUIPMENT

•

Nylon 3x5 green scrub pads

•

Dry, clean towels

•

Sheet pan

•

Firm bristle brush (6-8 inch handle with 2x2x1 bristles)

•

Bottle brush – small (3 inch test tube diameter),

•

Protective rubber gloves,

optional

optional

Page 21 of 87

Page 22

3.1.3 DO’S AND DON’TS OF CLEANING

DO – Keep the oven clean. Daily cleaning is recommended.

DO – Be careful when cleaning the oven. Surfaces stay hot for a long time.

DO – Switch the oven off at the circuit breaker before cleaning.

DO – Thoroughly wipe all surfaces that come in contact with oven cleaner with a

damp sponge or cloth.

DO – Remember oven door is heavy. Use two people to remove and replace.

DO – Change the grease filter if it is holed or clogged.

DO – Put grease filter back in the correct way.

DO – Clean bottom air filter weekly.

DO – Clean ceramic platter with a non Lye based cleaner then rinse off and dry.

DO – Clean ceramic wave guide cap with a non Lye based cleaner then rinse off

and dry.

DO NOT – Place hot ceramics on cold surfaces.

DO NOT – Allow ceramics to soak in any liquid for any period of time.

DO NOT – Remove any panels from the oven (except lower access panel).

DO NOT – Allow water to be forced up into the air holes in the roof of oven.

DO NOT – Allow build up of grease or carbon on any surface in the oven.

DO NOT – Spray LYE BASED oven cleaners into the oven.

DO NOT – Use metal objects to clean the oven. (Other than scraper used for

hard to remove carbon and debris in weekly / monthly cleaning).

DO NOT – Spray non-caustic oven cleaners, degreasers, and grease shield

products or any other liquid onto the wave guide seal.

DO NOT – Scrub the wave guide seal.

DO NOT – Throw the grease filter frame assembly away.

DO NOT – Spray grease shield products on the catalytic converter

DO NOT – Bang catalytic converter on a hard surface to clean

Page 22 of 87

Page 23

3.1.4 MINIMUM DAILY CLEANING PROCEDURE

CAUTION: Before cleaning turn the unit off at the unit’s power switch,

then turn off main power supply breakers! (Power switch is located on the

right side panel at lower front corner)

STEP 1: Preparing the oven for cleaning

1. Turn off power at the switch. Disconnect the power supply.

2. Open the oven door.

3. Allow the oven to cool for a minimum of 45-60 minutes to ensure safe

handling.

STEP 2: Cook Chamber parts

Carefully remove the cooking platter, chamber basket and ceramic

waveguide cap. Set aside.

CAUTION: Handle the Ceramic Cook Platter and Wave-guide Cap carefully

to avoid breakage.

CERAMIC

WAVEGUIDE

CAP

COOK CHAMBER

DOOR ASSEMBLY

COOKING

PLATTER

CHAMBER BASKET

(COOK CHAMBER)

Page 23 of 87

Page 24

STEP 3: Cleaning

1. Take the dirty parts to a well ventilated area for cleaning.

2. Spray all three pieces generously with non-lye non-caustic oven cleaner or

non-lye non-caustic degreaser and set aside (Allow the cleaner to

penetrate).

CAUTION: DO NOT soak Ceramic Cook Platter or Waveguide Cap in

water.

NOTE: Use a second ceramic cooking platter, wave-guide cap, and chamber basket in

daily rotation (ovens are shipped with spare parts) to eliminate the wait time for the

oven cleaner to work. Spray the pieces coming out of the oven and set aside until the

next day. Clean, rinse, and dry the set from the previous day, (or use new), install into

the oven, and proceed to warm up.

3. Thoroughly scrub inside of oven door, front ledge, top, side and back walls of

cook chamber using non-caustic degreaser (non-lye based), and a scrub pad

(green mesh).

4. Clean ceramic cooking platter, wave guide cap, and chamber basket using

recommended brushes and scrub pads. Rinse to remove all cleaner and

debris. Only the chamber basket may be placed in a dishwasher.

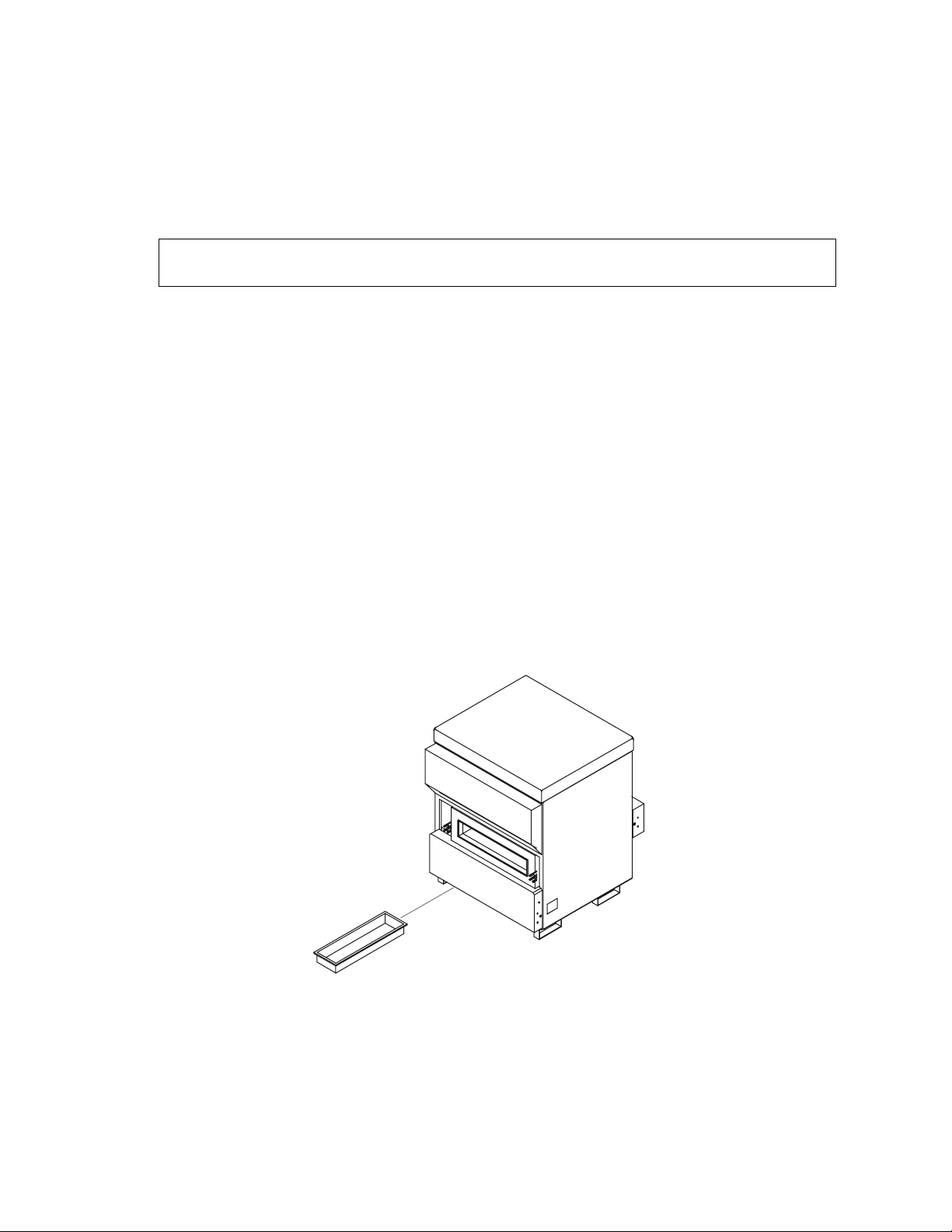

5. Check grease collection pan (located on bottom of oven) for grease and

debris. Empty, clean and reinstall.

6. Rinse parts thoroughly; and reinstall clean parts into the oven.

7. Turn on oven and observe the oven’s self-test.

GREASE

COLLECTION PAN

(GREASE CLEANING)

Page 24 of 87

Page 25

3.1.5 WEEKLY/MONTHLY CLEANING PROCEDURE

CAUTION: Before cleaning turn the unit off at the unit’s power switch,

then turn off main power supply breakers! (Power switch is located on the

right side panel at lower front corner)

We recommend completing the following procedure once a week. Certain oven

applications will require more or less frequent cleaning.

Oven cleaners require up to four hours to effectively clean the cook and filter

cavities. We recommend completing steps 1-4 after closing and finishing the

cleaning procedure the following morning.

STEP 1: Preparing the oven for cleaning

1. Turn off power at the switch. Disconnect the power supply.

2. Open the oven door. Allow the oven to cool for a minimum of 45-60 minutes

to ensure safe handling.

STEP 2: Cook Chamber parts

1. Carefully remove the cooking platter, chamber basket and ceramic wave-

guide cap.

Spray all three pieces generously with non-lye non-caustic oven cleaner or

non-lye non-caustic degreaser. (Allow the cleaner to penetrate)

Place the clean wave-guide cap into the oven. This will protect the wave-

guide seal while the cook chamber is cleaned.

CAUTION: Handle the Ceramic Cook Platter and Wave-guide Cap carefully

to avoid breakage. DO NOT soak Ceramic Cook Platter or Waveguide Cap

in water.

CERAMIC

WAVEGUIDE

CAP

COOKING

PLATTER

CHAMBER BASKET

COOK CHAMBER

DOOR ASSEMBLY

(COOK CHAMBER)

Page 25 of 87

Page 26

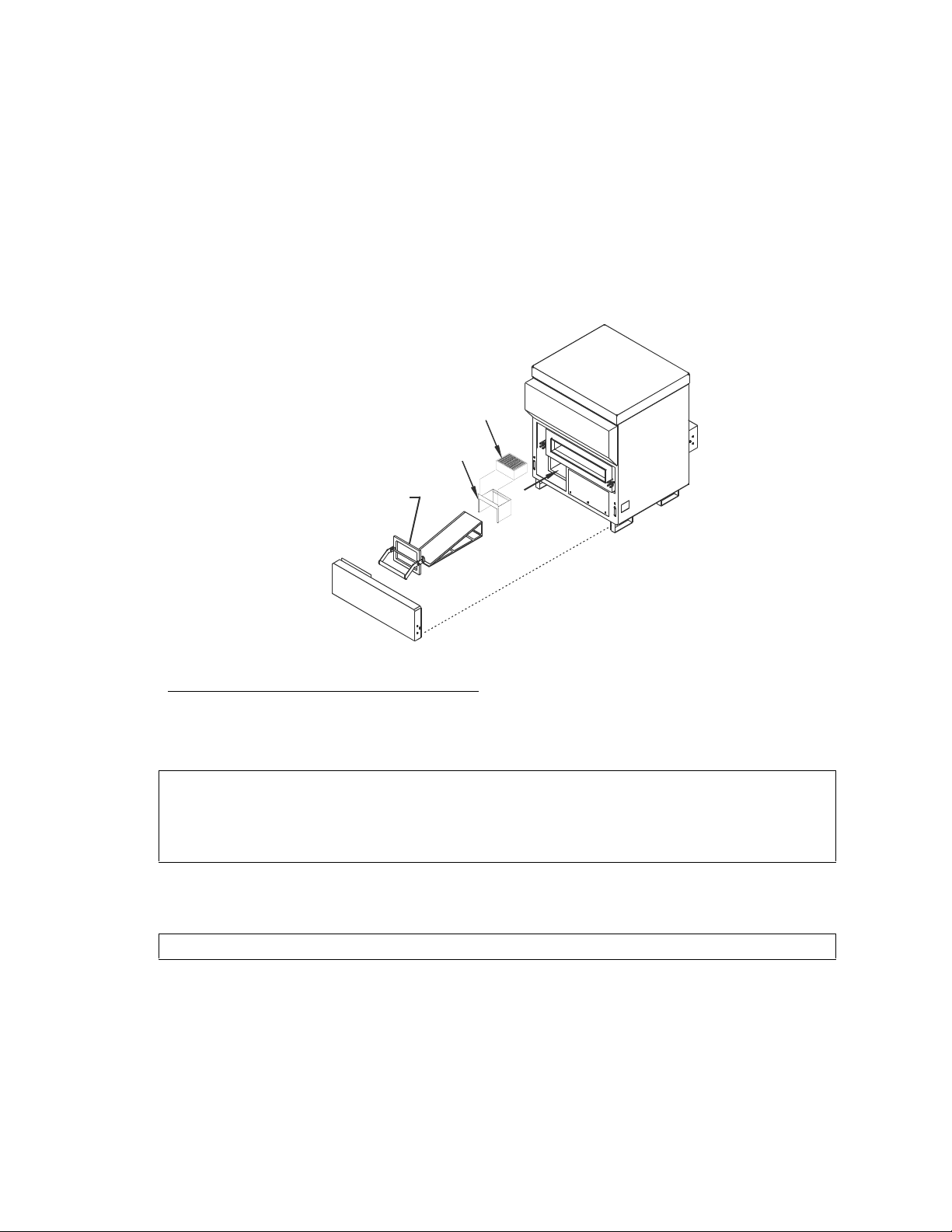

STEP 3: Grease Filter

PANEL

(GREASE FILTER)

1. Remove the lower access panel.

2. Remove the filter door. Spray the filter door with a non-caustic non-lye oven

cleaner.

3. Remove the filter assembly from the housing.

4. Tap the filter assembly gently, on the side of the trash can to remove loose

carbon particles. You may run the filter assembly through the dishwasher if

necessary. Set all of the filter parts aside.

CATALYTIC

CONVERTER

SUPPORT

FRAME

FILTER DOOR/GREASE FILTER

BOTTOM ACCE SS

ASSEMBLY

STEP 4: Cleaning the Cook Chamber

1. Spray non-caustic non-lye oven cleaner evenly and thoroughly into cooking

chamber and filter chamber. Be sure to cover inside walls, top, sides, etc. of

cooking chamber.

CAUTION: The wave-guide seal (located under ceramic wave-guide cap)

should be protected by the wave-guide cap during oven cleaning. Make

sure cap is in place while spraying cleaners into cooking chamber and

during the cleaning process.

2. Remove cook chamber door by releasing the latches at the rear of each side.

The door should be thoroughly cleaned with a non-lye oven cleaner.

CAUTION: Oven door is extremely heavy, use two people.

Page 26 of 87

Page 27

In the Morning

STEP 5: Cleaning the oven

1. Using damp cloth or green scrubby, thoroughly scrub the side and back walls,

as well as the top of the oven chamber. Use stiff blade scraper if needed (do

not use scraper on the wave-guide plug seal).

2. Once oven chamber has been cleaned, push debris through the opening

down into the filter chamber.

3. Wipe down interior of oven with damp cloth.

CAUTION: Remove all chemical residue to ensure food safety.

4. Remove ceramic wave-guide cap and wipe clean.

5. Clean filter chamber and pull debris into crumb tray. Empty crumb tray and

rinse with a damp cloth and wipe dry.

6. Use brush to loosen debris, or run through dish machine (do not soak). Allow

parts adequate time to dry.

7. Check grease collection pan (located on bottom of oven, below filter door)

and empty. Clean and replace.

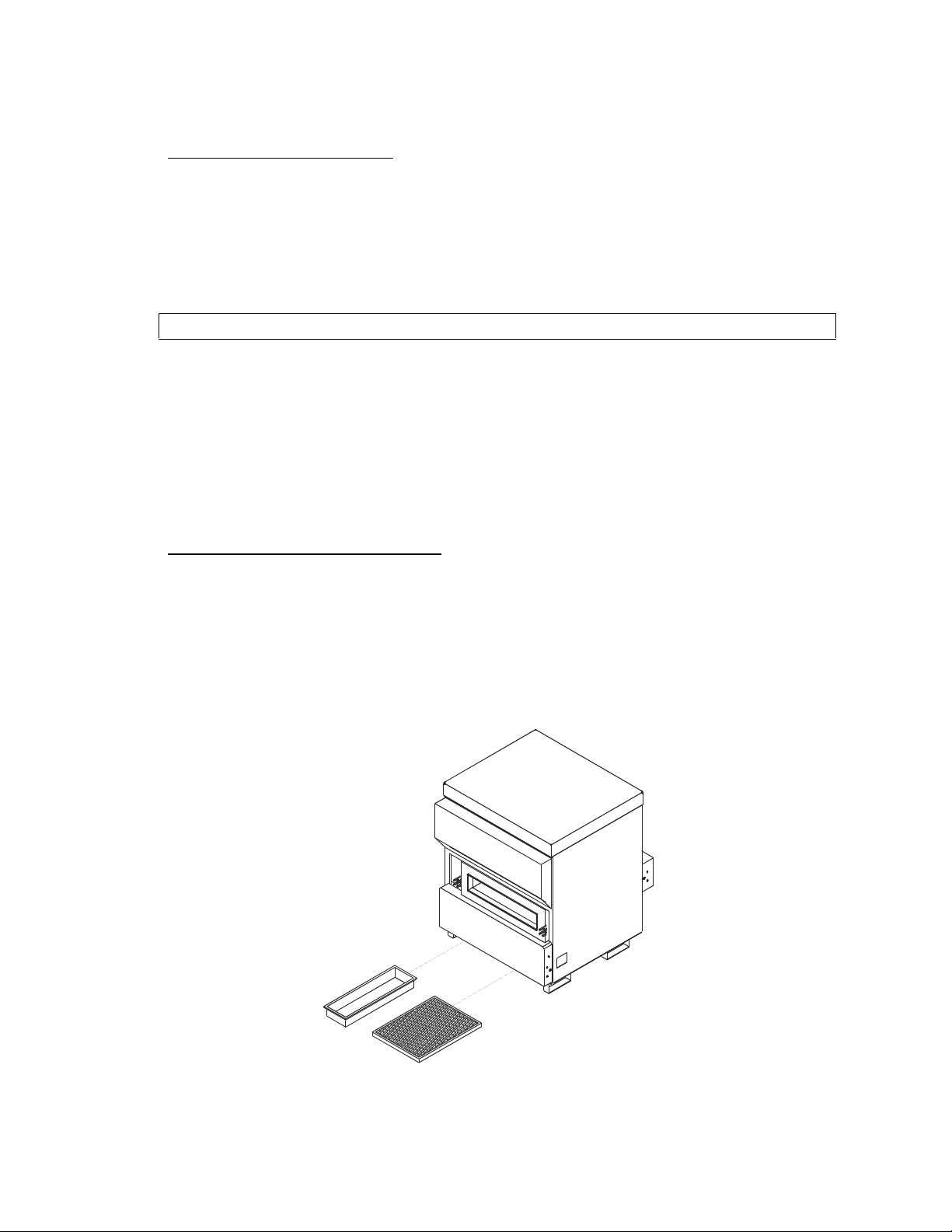

STEP 6: Air Filter and Ventilation

1. Check bottom air filter (located next to grease collection pan on bottom of

oven). If dirty, soak in water with mild detergent.

2. Check circular vent located above bottom screen and clean vent screen as

needed.

3. Replace bottom air filter.

GREASE

COLLECTION

PAN

AIR FILTER

(FILTER CLEANING)

Page 27 of 87

Page 28

STEP 7: Reassemble oven

1. Replace door back into oven.

2. Caref ully replace filter door and lower access panel (oven will not start up if

filter door is not properly in place).

3. Replace cleaned ceramic cooking platter, chamber basket, wave-guide cap

and bottom air filter into oven.

4. Wipe down exterior of oven with a damp cloth and all-purpose cleaner.

Stainless steel polish may be used on the exterior only.

5. Reconnect oven at power supply.

6. Turn on oven at breaker switch.

7. Power on oven and observe Self-Test.

3.1.7 PERIODIC SIX-MONTH SCHEDULED CLEANING PROCEDURES

This procedure is recommended to lengthen the life of your TurboChef oven.

STEP 1: Cook Chamber Door

1. Release the latches on the rear slide rails of the cook chamber door

assembly.

2. Remove the cook chamber door.

CAUTION: Door assembly is extremely heavy (approximately 39.5 lbs.)

and awkwardly balanced. It is recommended that two people remove and

re-install the door assembly.

LATCH

RELEASE

(LTCHREL)

Page 28 of 87

Page 29

STEP 2: Slide Bearing Assemblies

1. Remove the socket head screws holding the four slide roller bearing

assemblies to the cook chamber side walls.

2. Clean the assemblies with hot water mild detergent.

3. Water rinse and dry.

4. Clean the oven side walls with hot water mild detergent. Take caution to

avoid excessive wetting or damage to the waveguide plug.

5. Water rinse and dry.

6. Reinstall four bearing assemblies.

WARNING: Be sure to reinstall the door stop brackets on the rear

assemblies for proper operation.

DOOR STOP

BRACKETS

(SLIDE)

Page 29 of 87

Page 30

STEP 3: Rear Access Panel

L

1. REMOVE the rear access panel from the oven to expose the rear slide

channel end caps.

REAR

ACCESS PANE

(BACKPNL)

STEP 4: Rear Slide Channel End Caps

1. REMOVE four screws holding each rear slide channel end cap

2. CLEAN inside the rails with hot water and mild detergent using a wire brush.

3. WATER rinse and dry.

4. REINSTALL the end caps.

REAR SLIDE CHANNEL

END CAPS

WITH HARDWARE

(CHCAPS)

Page 30 of 87

Page 31

CAUTION: DO NOT operate without end caps in place.

5. REINSTALL rear access panel.

Page 31 of 87

Page 32

STEP 5: Catalytic Converter

CAUTION: To prevent burns, only service the catalytic converter when the

oven is cool.

1. Remove the lower access panel by rotating installed handles up to expose

the grease filter area.

2. REMOVE the filter door and grease filter assembly by lifting up on the filter

door handle and removing the grease filter assembly.

3. REACH into the rear of the grease filter area and push the catalytic converter

up into the return airduct. Pull the support frame out while the catalytic

converter is raised. Remove the catalytic converter from the rear of the

grease filter area. CLEAN the catalytic converter support frame if necessary.

4. Inspect the catalytic converter for cleanliness. Look mainly for any blockages

caused by gummy organic particles. If there are no blockages, a simple rinse

with distilled water is sufficient and the catalytic converter can be reinstalled.

CAUTION: At no time should the catalytic converter be exposed to any

oven cleaners or degreasers, unless otherwise specified.

If there are blockages use the following procedure to dislodge them:

a) Shake catalytic converter to dislodge any large particles trapped in the

filter cells.

b) Mix a 6.5:1 solution of grease-off oven cleaner concentrate (6.5 parts) and

distilled water (1 part). Soak the catalytic converter in the solution for 30

minutes to 1 hour.

c) Soak/rinse the catalytic converter using distilled water for 10 minutes. This

process may be repeated if necessary.

CAUTION: Do not pound filter on counter tops or tap with any objects.

DO NOT use any type of abrasive materials to clean Catalytic converter.

CAUTION: Solutions containing phosphates, sodium, or other surfactants

must be avoided. Also it is very important, due to varying water qualities,

that the user only use distilled water during cleaning of this unit.

5. Reinstall the catalytic converter. Be certain that the catalytic converter and

support frame are properly positioned in the return air duct. Reinstall the

grease filter, filter door and lower access panel. Allow the oven to undergo a

warm-up cycle to dry the catalytic converter.

Page 32 of 87

Page 33

Catalytic Converter

Support Frame

Grease Filter Assembly

Filter Door

Grease Filter Area

STEP 6: Reinstall Door

1. REINSTALL the cook chamber door assembly.

CAUTION: Be sure the door rail catches are caught and door stops

operate correctly

(Cat Conv)

3.2 MAINTENANCE MODE TROUBLESHOOTING

Only authorized service personnel familiar with electrical repair and related

personal service considerations should attempt the following diagnostics and

repair.

Maintenance Mode Diagnostic Tests

Place the oven in MAINTenance mode for the following tests. (Press the MAINT

key, enter the appropriate Access Code and press ENTER). Take the following

readings and record the data:

1. Cooking chamber temperature recorded after oven is warmed up and

stabilized in Heat Maintenance Cycle. (CC °F) ___________

The cooking chamber temperature, after the oven has completed its warm up

cycle, should be within 20°F of Cook Point Setting (typically 540°F).

2. Heat exchanger temperature recorded after oven is warmed up and

stabilized. (HX °F) ___________

Page 33 of 87

Page 34

If the IAF setting is 0%, the HX temperature should be approximately 60°F

above the Cook Set Point temperature after the oven is properly warmed up.

If the IAF is greater than 0%, the HX temperature will be much closer to the

Cook Set Point temperature.

If the temperature is LOW, go to 5 (Heat Exchanger).

If the temperature is HIGH, go to 3 (Blower).

3. Blower (press BLR). The blower condition changes when the BLR key is

pressed. LED 7 will turn on to indicate the blower is on. ______ON

______OFF

If the blower does not come on proceed with the following steps. After each

step, press the BLR key and then STOP once the blower comes on.

a) Reset the blower motor drive by turning the oven off, wait 30 seconds

minimum, then turn the oven on.

b) Check AUX1 (AUX2) fuse(s). If a fuse is found to be open, replace with a

fuse identical in type and rating. For additional reference see the

appropriate schematic for the oven mode.

c) Check the connectors to the printed circuit boards located in the electrical

control box behind the keypad panel to ensure proper mating.

4. Blower Speed (press %BLR key). With the blower in the On condition the

blower speed should increase in 10% increments up to 100%. ______YES

______NO

5. Heat Exchanger (press HTR key). LED’s 11 and 16 should come on when the

key is pressed. _____YES ______NO

a) IF neither LED comes on, the heat exchanger may be over the maximum

temperature (700°F).

b) IF LED 16 does not come on, check HTR1 and HTR2 fuses and replace if

necessary with the same type and rating.

c) If the fuses are good, the over temperature thermostat, OT1, may by

tripped.

6. Mag1 and 2 (press M12 key). LEDs 14 and 15 should come on when the key

is pressed and held. ______ON ______OFF

If LED 14 or 15 do not come on, verify status LEDs 1, 2, 3, 4, 5 and 6 are on

with the cook door and filter door closed.

a) If status LEDs are all on, check and replace magnetron fuses as

required.

b) If status LED’s are not all on, determine which LED’s are not on and

check the appropriate interlock and monitor switches for proper contact

and alignment.

Page 34 of 87

Page 35

7. Magnetron Power Verification:

CAUTION: Use care in disposing of hot water.

Check the combined magnetron power by placing a shallow microwave safe

dish with 1000ml or 33.8 oz of cold water (approximately 40°F) in the oven.

Measure the initial water temperature. Using MAINTenance mode and M12

key, turn both magnetrons on for 60 seconds. Measure the final water

temperature. The water temperature rise should be a minimum of 45°F

(25°C).

3.3 SELF TEST AND ON-LINE ERROR MESSAGES

3.3.1 SELF TEST - Defective Messages

Refer to 3.3 Self Test Flow Chart to determine logic tests performed.

Note: When a “… Defective” Message is encountered, the operator may press

any key to continue the self-test. The software will track this fault for future

verification.

Displayed Message Go To

1. “BMSC DEFECTIVE” 4.3

2. “HX Heat Thermo OPEN” 4.7

3. “HX Heat °F RISE LOW” 4.7

4. “CC Heat Thermo OPEN” 4.7

5. “CC Heat °F RISE LOW” 4.7

6. “Mag 1/ (2) CURRENT LOW” 5.4

7. “Mag 1/(2) RF FLUC LOW” 5.4

8. “Mag 1/ (2) THERMO SW” 5.4

9. “Oven Door Open” 6.2

10. “Filter Door Open” 7.0

11. “Keypad DEFECTIVE” 8.3

Page 35 of 87

Page 36

3.3.2 ON LINE (while cooking) - Diagnostic Messages

Refer to 3.4 On-Line Flow Chart to determine logic tests performed.

Note: Only “Cook Temp Too Low” and “BMSC DEFECTIVE” cause a cook cycle

to terminate. Magnetron failures as well as cook temperature variances cause

cook cycle time extensions (shortening) to compensate for lost (increased)

available cooking energy. Each time another cook cycle is started, the faults are

reset and retested.

Displayed Message Go To

1. “BMSC DEFECTlVE” 4.3

2. “COOK TEMP TOO LOW” 4.7

3. “EC Temp ___ °F” 8.2

4. “Mag CURRENT LOW” 5.4

5. “Mag RF FLUC LOW” 5.4

6. “Mag THERMO SW” 5.4

Page 36 of 87

Page 37

3.4 SELF TEST FLOW CHART

Turn

on oven

power

1 sec later

In

Cool Down

state?

No

Is

Filter Door

secure?

Yes

Is

Oven Door

secure?

Yes

Energize MAG

Filaments

Is

MAG 1

Over Temp

OK?

Yes

Energize

MAG 1 and 2

Yes

COOLING DOWN

No

Alarm and Display

FILTER DOOR OPEN

No

Alarm and Display

OVEN DOOR OPEN

No

MAG 1 THERMOSW

Display

Cool

Down

Display

After 3

sec is MAG 1

current

?

Yes

After 6

sec RF pwrd

stirrer

?

No

After

12 sec into

test

No

Was Test

MAG 1

?

Yes

Replace MAG 1

with MAG 2

No

Display

MAG 1 CURRENT LOW

Yes

Display

MAG 1 TEST OK

Yes

Display

MAG 1 RF FLUC LOW

No

Press any key

to continue

Go to

A

(Flow 1)

Page 37 of 87

Page 38

(Flow 2)

Equals

240

Page 38 of 87

Page 39

3.5 ON-LINE FLOW CHART

No

Is

Blower ON

No

For Current

Event

?

Is

No

TW ON

For Current

Event

?

Yes

No

Yes

Is

Is

TW = 50%

TW = 50%

?

?

No

No

Yes

Are

Both MAGS

Drawing

Current

?

Either

Magnetron

Drawing

Current

?

Yes

Yes

P/O

COOK

After

5 sec Cook

With Blr On Is

Temp 85 Deg

Below Set

Point

?

Yes

Blower

Running

No

Is

RF Delta

OK and NO

Prior Low

Fluc

Yes

Yes

Is

?

No

Is

13 Seconds

Into Event

?

Yes

Queue Message

"MAG RF FLUC LOW"

Keep MAGs on

(Do not pulse)

Stop Cook, Display

COOK TEMP TOO LOW

Stop Cook, Display

BMSC DEFECTIVE

NoYes

Reset Fault

MAG CURRENT LOW

Increment Fault Counter

COOK TEMP TOO LOW

Increment Fault Counter

BMSC DEFECTIVE

Increment Fault Counter

"MAG RF FLUC LOW"

Go to

SELECT

RECIPE

Yes

No

Already

Mag Current Lo

or

Thermo Sw Fault

?

Is

Mag Thermo Sw

and NO Previous

Mag Thermo

Sw?

No

Is

TW = 50%

Yes

Yes

?

No

Queue Message

MAG THERMO SW

Queue Message

MAG CURRENT LOW

Have

5 seconds

Yes

past?

No

Increment Fault Counter

MAG THERMO SW

Increment Fault Counter

MAG CURRENT LOW

Are

Yes

MAGS

on?

No

Turn off

Turn on

MAGS

MAGS

CONTINUE

COOK

(Flow 3)

Page 39 of 87

Page 40

SECTION 4 - CONVECTION SYSTEM

4.1 BLOWER MOTOR ASSEMBLY

1. BLOWER WHEEL TIPS FACE AWAY FROM MOTOR (AS SHOWN)

2. LABEL ORIENTATION IS TO BE LEFT TO RIGHT AS FACING MOTOR. LOCATE IN AREA SHOWN,

KEEPING LEFT EDGE PARALLEL TO MOTOR FLANGE.

4 PL

(0.150 .020)+

3

4

2

134 PL

14

21

222 PL

23

DETA IL A

SCALE: 2/1

26 2 PL

27

2 PL

2 PL

28

24

8

25

(4.00)

10 4 PL

4

SEE DETAIL A

7 4 PL

1

6

BLOWER MOTOR ASSEMBLY - DWG 700-0310

ITEM PART NO. DESCRIPTION

1 T7000304 MOTOR MOUNTING PLATE

2 T7000306-2 HUB, FAN, SMALL

- T0048 BLADE RING

3 T7000307-1 BLADE, FAN

4 T7000308 BLOWER RING

5 T7000311 BLOWER CAP

6 T102708 HEAT SLINGER

7 T7000314 STANDOFF, MOTOR

8 T7000284 SHIM, SHAFT SEAL

- T0052 MOTOR MOUNT FANGE, NUTS AND BOLTS

9 T102732 MOTOR, FLANGE MOUNT, 1 HP, 7050 RPM

10 T101391 1/4-20 X .75 LG. SCREW, PFH, SS

11 T101830 3/8-16 X .75 LG. SCREW, SOCKET HD. CAP, SS

12 T101751 1/4-20 X .75 LG. SCREW, SOCKET HD. CAP, SS

13 T101746 8-32 X .38 LG. SCREW, SOCKET HD BUTTON, SS

14 T102320 # 8 WASHER, LOCK, INTERNAL TOOTH, SS

15 T100791 #242 LOCTITE THREADLOCKER

16 T7001154 LABEL, EXPOSED FAN DANGER

17 T102410 # 3/8 WASHER, LOCK, SPLIT, SS

19 T102400 # 1/4 WASHER, LOCK, SPLIT, SS

21 T100730 KEY, WOODRUFF, SS

22 T101715 8-32 X .25 LG. SET SCREW, SOCKET HD, SS

23 T7001177 GRAPHITE BLOCK, BEARING SEAL

24 T101733 SPRING, COMPRESSION, SS

25 T7001179 CLAMP, BEARING SPRING

26 T101005 10-32 NUT, LOCK, CRES

27 T102140 # 10 FLAT WASHER

28 T102350 #10 SPLIT LOCK

17 4 PL

11

9

1

12 4 PL

19

4 PL

4 PL

16

2

(Blower Motor)

Page 40 of 87

Page 41

4.2 BLOWER MOTOR CONTROLLER TESTS

The blower motor operates during the normal idle operation (the speed is set by

IAF in Maintenance mode for stabilization of the oven temperatures), while in the

cooking mode at the desired speed, and during the MAINTenance mode. The

MAINTenance mode allows the service technician to manually operate the

blower on and off and to change the speed.

Note: The Blower Shaft rotates in the clockwise direction when viewed

from front of oven.

4.3 BLOWER DEFECTIVE MESSAGES

The TurboChef oven will display a defective (fail) message, “BMSC

DEFECTIVE”, if the RUN status from the Blower Motor Speed Controller is

absent during self-test or while cooking.

In either case, they can be caused by the following problems:

SELF TEST WHILE

COOKING

BMSC

DEFECTIVE

BMSC

DEFECTIVE

CAUSE CORRECTIVE ACTION

Blower Motor Speed

Controller not returning the

“Running” status. (See

indicator LED 7)

1. Check BMSC Temperature. If

below 0°C, let controller warm

up and try again

2. Check Blower Fuses (See 8.0)

3. Check Air Filter for cleanliness.

4. Check Cooling Fan operation.

5. Check for proper operation of

interlock/monitor switches.

6. Check fault message on BMSC.

(See 4.4.2 or Reliance Electric

Manual.)

7. Check BMSC Settings. (See

4.5.2.)

8. Check all connections in the

blower circuit (Ribbon cables,

all blue wire signal circuits).

9. Replace BMSC. (See 8.0)

10. Replace I/O CCA. (See 8.0.)

11. Replace Blower Motor

Assembly. (See 4.1.)

12. Replace Controller CCA. (See

8.3.)

Page 41 of 87

Page 42

4.4 BLOWER MOTOR CONTROLLER DEFECTIVE MESSAGES

4.4.1 Fault Codes

The SP500 controller requires only minor troubleshooting. If a fault occurs, the

controller displays fault (ERR) codes to assist in troubleshooting. If a fault

condition occurs while the drive is running, (LED 7 on), the drive coasts to rest

and a 2-digit fault code is flashed on the display.

The fault code is also entered into the error log. The error log is designated as

“ERR” on the display.

4.4.2 How to Access and Read the Error Log

Multiple fault codes are entered into the error log in sequential order. The first

error to occur flashes on the display and two more errors may be logged into the

error log. (The error log must be accessed to see them). After three faults have

occurred, no more subsequent faults will be entered into the error log.

The faults entered into the error log are numbered sequentially. If first an

overcurrent fault were to occur, it would be in the error log as "1=OC". If next a

thermal overload fault were to occur (and the first error was not yet cleared), it

would be in the error log as "2-OL", and so on.

The last fault to occur will appear first when accessing the error log. For

example, if the last fault was a low bus fault, and the error log has 3 entries, then

the error log would display "3-LU" when the error log is first accessed.

Faults are retentive to the error log if a power loss occurs. The entire error log

can be cleared by pressing the STOP/RESET button.

To access the error log:

1. Press the MODE/ENTER

key until the Program LED

lights.

2. Press the down arrow key

until “ERR” is displayed.

The error log precedes

parameter F-00 and follows

F-49.

RPM RUN

% Load Program

Volts Forward

Remote Reverse

RPM RUN

% Load Program

Volts Forward

Remote Reverse

Mode

Enter

START

Mode

Enter

START

Forward

Reverse

STOP

RESET

(Error 1)

Forward

Reverse

STOP

RESET

(Error 2)

Page 42 of 87

Page 43

3. Press the MODE/ENTER

key to access the error log.

4. Press the up arrow key to

move through the error

codes.

5. Press the STOP/RESET

key to clear the error log.

Refer to 4.4.3.

6. The display returns to the

active monitor display.

RPM RUN

% Load Program

Volts Forward

Remote Reverse

RPM RUN

% Load Program

Volts Forward

Remote Reverse

RPM RUN

% Load Program

Volts Forward

Remote Reverse

Mode

Enter

START

Mode

Enter

START

Mode

Enter

START

Forward

Reverse

STOP

RESET

(Error 3)

Forward

Reverse

STOP

RESET

(Error 4)

Forward

Reverse

STOP

RESET

4.4.3 Messages in Error Log

OH: Thermostat / Drive Overload

Cause Action

The internal thermostat has caused a trip that indicates

excessive temperatures in the controller.

1. The ambient temperature of the controller is

exceeded.

Press the STOP/RESET button (or cycle oven power off for 30

seconds, then on.) The error will not clear until the internal drive

temperature is back withi n range. This may take a few seconds.

1. Check Blower shaft to see if it freely turns.

2. Check t he Oven Air Fi lter and veri fy the Floor Fan is operat ing (If

(Error 5)

the oven is hot). Refer to the bl ower motor/controller test.

Page 43 of 87

Page 44

OC: Overcurrent

Cause Action

The current rating of the controller (>200% rated drive

current) had been exceeded.

This fault can be caused by any of the following conditions:

1. S hort i n drive outputs 1. V erify that the input and output wiring to the drive are properly

2. Ground fault condition 2. Verify that the output wiring to the motor is not connected to

3. Instantaneous overcurrent resulti ng in greater than

200% rated drive current.

FL: Function Loss

Cause Action

The remote (external) function loss signal has been

asserted. (Terminals 10 and 11.)

1. The external equipm ent connected to the function

loss terminals has failed, or is giving repeated stop

requests.

HU: High bus voltage conditi ons

Cause Action

The D-C bus charged above the IET threshold level of

430 volts.

1. Power Line voltage transient has caused the overvoltage condition to occur.

2. Deceleration rate to fast (Function 2). 3. Check the decel rate (Function 2), and compare with chart on

LU: Low bus voltage conditions

Cause Action

The D-C bus has fallen below the IET low threshold

level of 180 volts.

1. Momentary loss of input power.

2. Low line voltage on i ncoming power.

Note: If a line dip or mom entary power loss occurs and t he bus level is able to rise back t o the proper range withi n 500 ms., the

drive will automatically restart (if the drive was already running when the fault occurred.) If t he drive does not res tart , perform above

steps, or cycle oven power off for 30 seconds, then on.

OL: Electronic thermal overload

Cause Action

The electronic thermal overload trip level has been

exceeded. This fault protects the drive and motor from

overheating due to excessive current within a specified

period.

1. The Current Limit Setting (Function 5) is not set

correctly.

2. Function 14, Elec tronic Thermal Overl oad is not s et

correctly to match the motor and controller

combination.

3. Motor Shaf t is bound up or hard to turn.

Any of the following codes indic ate a SP500 motor controller failure.

Codes Action

AdPF, CH, diSc, E Erd, EEOU, EPCH, FSF, In00, In02,

In04, In06, In08, In10, In15, noAd, OLP2, rSF, rEF1,

rEF2, SELU, UnOP, 7rAP, r1, r2

Press the STOP/RESET button (or cycle oven power off for 30

seconds, then on).

connected

Ground or any other voltage source.

3. Check motor to insure shaft is free to turn.

Press the STOP/RESET button (or cycle oven power off for 30

seconds, then on.) This fault will not clear until t he func tion los s si gnal

is unasserted.

1. Check the external equipment wired to the remote function l oss

terminals (10 and 11.)

2. Check function loss connections.

Press the STOP/RESET button (or cycle oven power off for 30

seconds, then on.) The error will not clear until the bus falls below the

high bus level.

1. If occurrence seldom, possible no problem.

2. If occurrence is high, suspect incoming power problem or

incorrect setting of the SP500 controller (Replace).

4.5.2.

Press the STOP/RESET button (or cycle oven power off for 30

seconds, then on.) The error will not clear until the input line voltage is