TS1909

MicroPower VFM Boost DC to Dc Converter

1/1 Version: A10

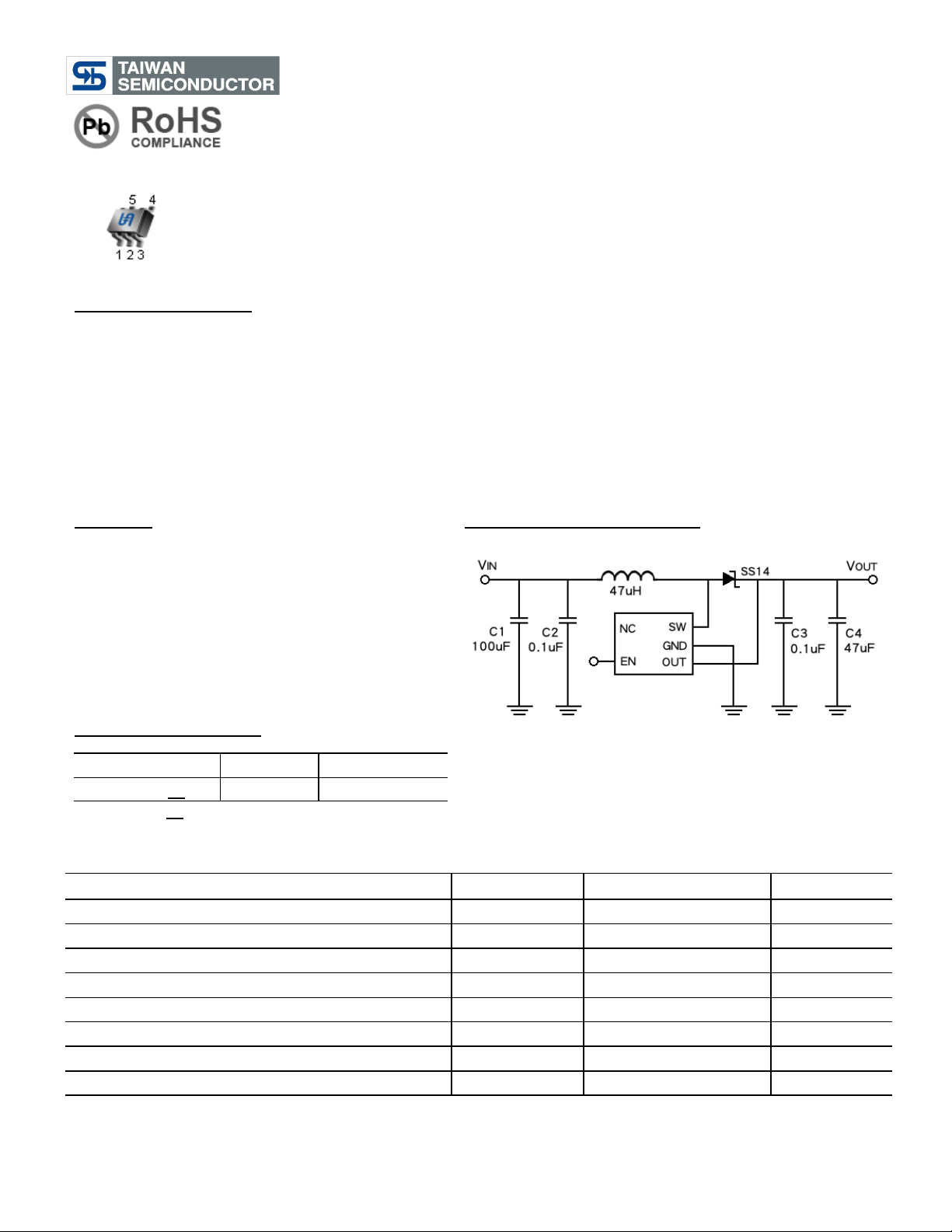

SOT-25

General Description

The TS1909 is a high efficiency VFM Step-up DC/DC converter for small, low input voltage or battery powered

systems with ultra low quiescent supply current. The TS1909 accept a positive input voltage from start-up voltage to

V

OUT

and convert it to a higher output voltage in the 2.5 to 5V range.

The TS1909 combine ultra low quiescent supply current and high efficiency to give maximum battery life. The high

switching frequency and the internally limited peak inductor current permits the use of small, low cost inductors. Only

three external components are needed an inductor a diode and an output capacitor. The TS1909 is suitable to be

used in battery powered equipment where low noise, low ripple and ultra low supply current are required.

Typical applications are pagers, cameras & video camera, cellular telephones, wireless telephones, palmtop

computer, battery backup supplies, battery powered equipment.

Features

● Very Low Supply Current 22µA (Typ.)

● Maximum shutdown current <1µA

● Output Voltage Accuracy ±2.5%

● Output Current up to 100mA

● Low Ripple and Low Noise

● Very Low Start-up Voltage

● High Efficiency Typ. 87% @ V

OUT

=5V

● Few External Components

Ordering Information

Part No.

Package

Packing

TS1909CX5xx RF

SOT-25

3Kpcs / 7” Reel

Note: Where xx denotes voltage option.

Available output: 27=2.7V, 30=3V, 33=3.3V, 50=5V

Typical Application Circuit

Absolute Maximum Rating

Parameter

Symbol

Limit

Unit

VIN Pin Voltage

V

IN

5.5

V

SW Voltage

V

SW

5.5

V

OUT Pin Voltage

V

OUT

5.5

V

Storage Temperature Range

T

STG

-40 to +150

o

C

Operating Junction Temperature Range

TJ

-20 to +100

o

C

Power Dissipation

PD

( TJ-TA ) / θ

JA

mW

Thermal Resistance from Junction to case

θ

JC

110

o

C/W

Thermal Resistance from Junction to ambient

θ

JA

250

o

C/W

Note: θ

JA

is measured with the PCB copper area of approximately 1 inch (Multi-layer) that need connect to GND pin.

Pin Definition:

1. Enable

2. Output

3. N.C

4. Ground

5. SW

TS1909

MicroPower VFM Boost DC to Dc Converter

2/2 Version: A10

Electrical Specifications (Ta = 25

o

C, VIN=5V, EN=VIN, IL=0A unless otherwise noted)

Characteristics

Symbol

Conditions

Min

Typ

Max

Units

Output Voltage Accuracy

∆V

OUT

-2.5

--

+2.5

%

Start-up Voltage (VIN-VF)

(Note 1)

V

START-UP

I

OUT

=1mA, VIN=rising from 0 to 2V

--

0.8

1.2

V

Hold-on Voltage

V

HOLD

I

OUT

=1mA, VIN=falling from 2 to 0V

0.6

--

--

V

Supply Current

I

SUPPLY

No Load

--

22

--

uA

Internal Switch RDSON

RLX

(DSON)

ILX=150mA

--

850

--

mΩ

Internal Leakage Current

ILX

(Leak)

VLX=4V, Forced V

OUT

=3.8V

--

--

0.5

uA

Maximum Oscillator Frequency

F

OSC

--

150

--

KHz

Oscillator Duty On

DON

To be measure on SW pin

--

77

--

%

V

ENH

Driver ON

0.75

--

--

V

Enable Input Threshold

V

ENL

Driver OFF

--

--

0.2

I

ENH

VEN=VIN

--

--

0.1

µA

Enable Input Current

I

ENL

VEN=0V

--

--

-0.1

V

OUT

=2.5V~3.0V, I

OUT

=50mA

--

82

--

%

V

OUT

=3.1V~4.0V, I

OUT

=50mA

--

83

--

%

Efficiency

η

V

OUT

=4.1V~5.0V, I

OUT

=50mA

--

87

--

%

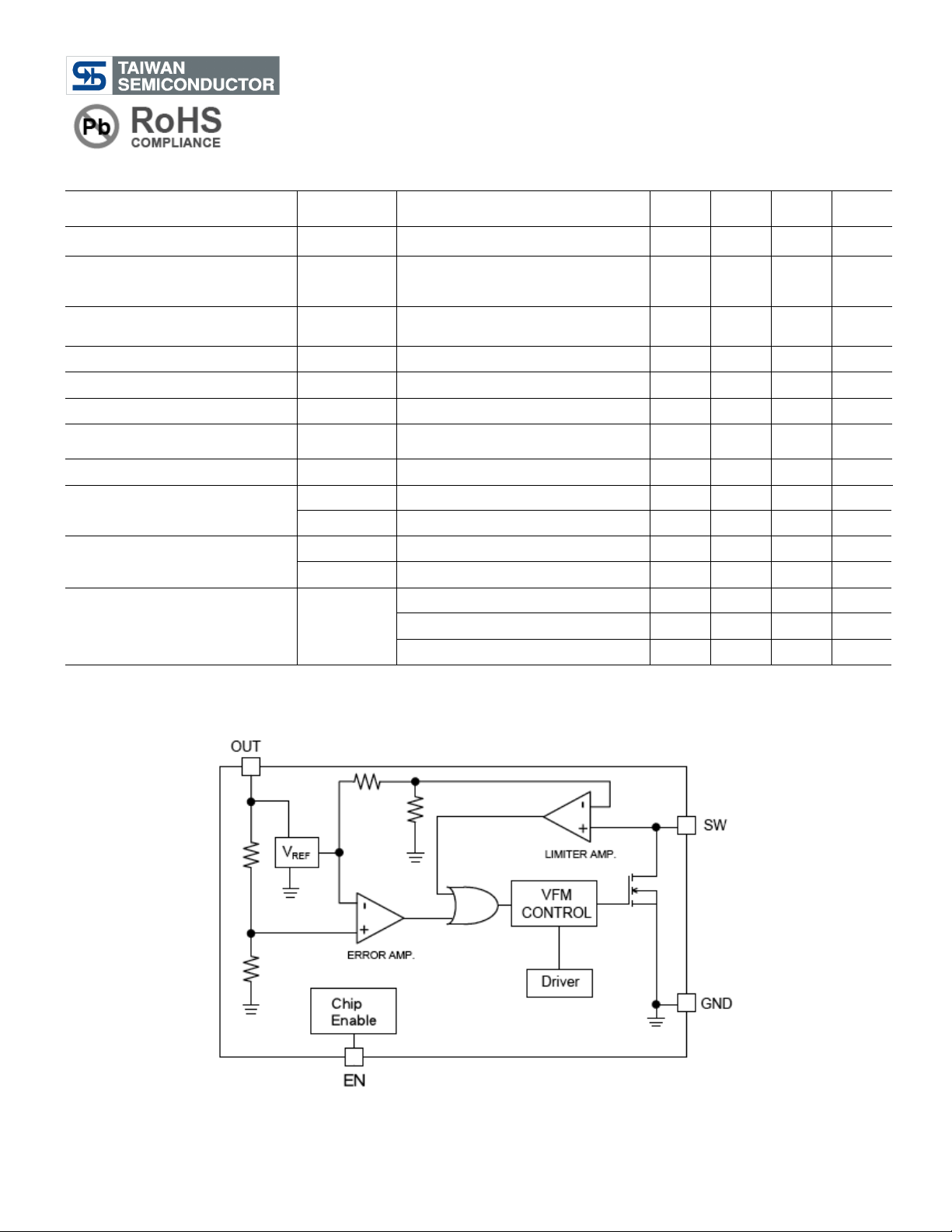

Block Diagram

TS1909

MicroPower VFM Boost DC to Dc Converter

3/3 Version: A10

Detailed Description

The TS1909 architecture is built around a VFM CONTROL logic core, switching frequency is set through a built in

oscillator. TON time is fixed (Typ. 5uS) while T

OFF

time is determined by the error amplifier output, a logic signal coming

from the comparison made by the Error Amplifier Stage between the signal coming from the output voltage divider

network and the internal Band-Gap voltage reference (V

REF

). T

OFF

reaches a minimum (Typ. 1.7uS) when heavy load

conditions are met (Clock frequency 150KHz). An over current conditions, through the internal power switch, causes a

voltage drop VLX=R

DSON

x ISW and the VLX limiter block forces the internal switch to be off, so narrowing TON time

and limiting internal power dissipation. In this case the switching frequency may be higher than the 150KHz set by the

internal clock generator.

VFM control ensures very low quiescent current and high conversion efficiency even with very light loads. Since the

Output Voltage pin is also used as the device Supply Voltage, the versions with higher output voltage present an

higher internal supply voltage that results in lower power switch R

DSON

, slightly greater output power and higher

efficiency. Moreover, bootstrapping allows the input voltage to sag to 0.6V (at IOUT=1mA) once the system is started.

If the input voltage exceeds the output voltage, the output will follow the input, however, the input or output voltage

must not be forced above 5.5V.

Application Information

Input/Output Capacitor Selection

The Output Ripple Voltage, as well as the Efficiency, is strictly related to the behavior of these elements. The output

ripple voltage is the product of the peak inductor current and the output capacitor Equivalent Series Resistance (ESR).

Best performances are obtained with good high frequency characteristics capacitors and low ESR. The best

compromise for the value of the Output Capacitance is 47µF Tantalum Capacitor; Lower values may cause higher

Output Ripple Voltage and lower Efficiency without compromising the functionality of the device. An Input Capacitor is

required to compensate, if present, the series impedance between the Supply Voltage Source and the Input Voltage of

the Application.

Inductor Selection

A 47µH inductor is recommended for most TS1909 applications. However, the inductance value is not critical, and the

TS1909 will work with inductors in the 33µH to 120µH.

Diode Selection

Schottky diodes with higher current ratings usually have lower forward voltage drop, larger diode capacitance and fast

reverse recovery, it is the ideal choices for TS1909 applications. The forward voltage drop of a Schottky diode

represents the conduction losses in the system, while the diode capacitance (CT or CD) represents the switching

losses. For diode selection, both forward voltage drop and diode capacitance need to be considered.

PCB layout guide

When laying out the PC board, the following suggestions should be taken to ensure proper operation of the TS1909.

These items are also illustrated graphically in below. The power traces, including the GND trace, the SW trace and the

VCC trace should be kept short, direct and wide to allow large current flow. Put enough multiply-layer pads when they

need to change the trace layer. Do not trace signal line under inductor.

Loading...

Loading...