Model 898X

Electronic Preset Counter

with two presets

hsilgne

Model 899X

www.GlobalTestSupply.com

Contador electrónico

de preselección

con dos preselecciones

Elektronischer

Vorwahlzähler

mit zwei Vorwahlen

Compteur à présélection

électronique

avec deux présélections

Contatore elettronico

a preselezione

con due preselezioni

022792-01 Issue 1.0 03/17

loñapse

hcstued

siaçnarf

onailati

Table of Contents

1 Preface

2

Safety instructions and Warnings

2.1 Use according to the intended purpose 4

2.2 Mounting in a control panel 4

2.3 Electrical Installation 5

2.4 Cleaning and maintenance 5

3 Description 5

4

Display/Operating elements 6

5

Inputs 6

5.1 INP A, INP B 6

5.2 RESET 6

5.3 GATE 6

5.4 LOC.INP 6

5.5 MPI 1 / MPI 2 6

6 Outputs 6

6.1 Output 1 / Output 2 6

6.2 Active Outputs 6

7 Programming 6

7.1 Entering the programming 6

7.2 Selecting the main menus 7

7.3 Entering a sub-menu 7

7.4 Selecting the parameters 7

7.5 Changing parameter values 7

7.6 Setting count values 7

7.7 Ending the programming 7

7.8 Programming menu 7

7.8.1 Select language 7

7.8.2 Setting the Basic Function 8

7.8.3 Pulse Counter 8

7.8.4 Tacho/Frequency meter 10

7.8.5 Timer 11

8 Operation 15

8.1 Switching the display during operation 15

8.2 Setting the presets 15

8.2.1 Setting via front keys 15

8.2.2 Teach Function 16

8.2.3 Teach-In with tracking presets 16

8.3 Set Function 16

8.4 Default Parameters 16

8.4.1 Entry into the default setting 16

8.4.2 Selecting the parameter sets 16

8.4.3 Accepting the setting 16

8.4.4 Parameter Set Table 17

9 Error Message 17

10

Connections 17

10.1 Signal and Control Inputs 17

10.2 Supply Voltage and Outputs 17

11 Technical Data 17

11.1 General Data 17

11.2 Pulse Counter 17

11.3 Tacho/Frequency Meter 18

(German is the original version)

4

4

Page 2 | ENG

www.GlobalTestSupply.com

11.4 Timer 18

11.5 Signal and Control Inputs 18

11.6 Outputs 18

11.7 Supply Voltage 18

11.8 Sensor Supply Voltage 18

11.9 Climatic Conditions 18

11.10 EMC 18

11.11 Device Safety 18

11.12 Mechanical Data 18

11.13 Connections 19

12 Scope of Delivery 19

13 Ordering Codes 19

14 Frequencies (typical) 19

14.1 Pulse Counter 19

14.2 Frequency Meter 19

15 Input modes: Pulse counting 20

16 Input modes: Timing 22

17 Input modes: Frequency meter 23

18 Output operations 24

19 Help Texts 26

20 Dimensional Drawings 28

english

Page 3 | ENG

www.GlobalTestSupply.com

entirely and carefully before installation

warnings and advice, both for your own

with this instruction manual, then the

Please bear in mind safety aspects and

device is integrated is the responsibility

work.

protected with approved external fuses.

that the terminals are out of the reach

1 Preface

Please read this instruction manual

and start-up. Please observe all

safety and for general plant safety. If

the device is not used in accordance

intended protection can be impaired.

2 Safety instructions and

Warnings

Please use the device only if its

technical condition is perfect. It should

be used only for its intended purpose.

potential dangers and adhere to the

operating instructions at all times.

Defective or damaged devices should

be disconnected from the mains

immediately and taken out of operation.

The device shall not be opened. Use

the repair service of the manufacturer.

Only connect the device to the

electricity networks provided to that

purpose.

The safety of the system in which the

of the installer.

Disconnect all electricity networks prior

to any installation or maintenance

Use exclusively cables approved in

your country and designed for your

temperature and power ranges.

Installation and service work shall be

carried out exclusively by qualified

personnel.

The device must compulsorily be

The value of these fuses can be found

in the technical information.

This symbol is used on the device to

remind of the existence of dangers,

which are referred to in this manual.

2.1 Use according to the intended

purpose

The preset counter detects and measures pulses,

times and frequencies up to max. 60 kHz and offers

a wide variety of different operating modes. At the

same time, the preset counter processes

programmed presets. Use for any purpose over

and beyond this will be deemed as not in

accordance with its intended purpose and thus not

complying with the requirements.

The application area for this device lies in industrial

processes and controls, in the fields of

manufacturing lines for the metal, wood, plastics,

paper, glass, textile and other like industries. Overvoltages at the terminals of the device must be kept

within the limits of over-voltage Category II.

The device must only be operated when mounted

in a panel in the correct way and in accordance

with the section “Technical Data”.

The device is not suitable for use in hazardous

areas and for areas excluded in EN 61010 Part 1. If

the device is used to monitor machines or

processes in which, in the event of a failure of the

device or an error made by the operator, there

might be the risk of damaging the machine or

causing an accident to the operators, it is your

responsibility to take the appropriate safety

measures.

The device has been designed for indoor operation.

It may nevertheless be used outdoors, provided the

technical data is adhered to. In this case, take care

to provide suitable UV protection.

2.2 Mounting in a control panel

Mount the device away from heat

sources and avoid direct contact with

corrosive liquids, hot steam or similar.

CAUTION

Provide a free space of 10mm all

around the device for its ventilation.

The device should be mounted so

of the operator and cannot be

touched by him. When mounting the

device, consider the fact that only the

front side is classified as accessible

Mounting instructions

1. Remove the mounting clip from the device.

2. Insert the device from the front into the panel

3. Slide the fixing clip from the rear onto the

Note: In case of proper installation, IP65 can be

reached on the front side.

for the operator.

cut-out, ensuring the front-panel gasket is

correctly seated.

housing, until the spring clamps are under

tension and the upper and lower latching lugs

have snapped into place.

Page 4 | ENG

www.GlobalTestSupply.com

2.3 Electrical Installation

via a switch or circuit breaker installed

Installation or maintenance work must

voltages entering or exiting the device

• During installation, make sure that the supply

• The cables and their insulation must be designed

• Before starting the device, check the cables for

The device must be disconnected

from any power supply prior to any

installation or maintenance work.

Make sure that no more voltages

DANGER

LIABLE TO CAUSE AN ELECTROCUTION

are present.

AC-powered devices must only be

connected to the low-voltage network

close to the device and marked as

their disconnecting device.

only be carried out by qualified

personnel and in compliance with the

applicable national and international

standards.

Take care to separate all extra-low

from hazardous electrical conductors

by means of a double or reinforced

insulation (SELV circuits).

The device must be protected

externally for its proper operation.

Information about the prescribed

fuses can be found in the technical

DANGER

information.

The relay outputs are not protected

internally in the device. Without

suitable protection of the relay

outputs, undesired heat development

or even fire may occur. The relay

outputs must be protected externally

by the manufacturer of the plant. It

must also be made sure that, even in

case of a malfunction, the values

stated in the technical data are under

no circumstances exceeded.

voltage and the wiring of the output contacts are

both fed from the same mains phase, in order not

to exceed the maximum permitted voltage of

250V.

for the planned temperature and voltage ranges.

Regarding the type of the cables, adhere to the

applicable standards of the country and of the

plant. The cross sections allowed for the screw

terminals can be found in the technical data.

proper wiring and tightening. The screws of

unused screw terminals must be screwed to the

stop, so that they cannot loosen and get lost.

• The device has been designed for overvoltage

category II. If higher transient voltages cannot be

excluded, additional protection measures must be

taken in order to limit the overvoltage to the

values of CAT II.

Advice on noise immunity

All connections are protected against external

sources of interference. The installation location

should be chosen so that inductive or capacitive

interference does not affect the device or its

connecting lines! Interference (e.g. from switchmode power supplies, motors, clocked controllers

or contactors) can be reduced by means of

appropriate cable routing and wiring.

Measures to be taken:

Use only shielded cable and control lines. Connect

shield at both ends. The conductor cross-section of

the cables should be a minimum of 0.14 mm².

The shield connection to the equipotential bonding

should be as short as possible and with a contact

area as large as possible (low-impedance).

Only connect the shields to the control panel, if the

latter is also earthed.

Install the device as far away as possible from

noise-containing cables.

Avoid routing signal or control cables parallel to

power lines.

2.4 Cleaning and maintenance

The front side of the unit should only be cleaned

using a soft damp (water!) cloth. Cleaning of the

embedded rear side is not planned and is the

responsibility of the service personnel or of the

installer.

In normal operation, this device is maintenancefree. Should the device nevertheless not operate

properly, it must be sent back to the manufacturer

or to the supplier. Opening and repairing the device

by the user is not allowed and can adversely affect

the original protection level.

3 Description

6-digit 14-segment LED display, 14 mm

Help Text display

Preset counter with two relay outputs

Preset entry via the front keys or via the Teach-In

function

Step or tracking preset

Pulse counter, Frequency meter, Timer or Hour

meter

Preset-, Batch- or Total counter

Set function for pulse counter and timer

www.GlobalTestSupply.com

english

Page 5 | ENG

Multiplication and division factor

Averaging and Start Delay for frequency meter

Input modes:

Pulse counter: cnt.dir, up.dn, up.up, quad, quad2,

quad4, A/B, (A-B)/Ax100%

Frequency meter: A, A – B, A + B, quad, A/B,

(A-B)/Ax100%

Timer: FrErun, Auto, InpA.InpB, InpB.InpB

Output operations:

Add, Sub, AddAr, SubAr, AddBat, SubBat, AddTot,

SubTot, Trail, TrailAr

4-stage RESET mode

3-stage keypad locking (Lock)

MPI input for Display Latch, Teach-In or Set

function

Supply voltage 100 … 240 V AC ±10% or

10 ... 30 VDC

4 Display/Operating elements

6-digit LED display

1

Status display LED1 / LED2

2

RESET key / ENTER key

3

4 Key LEFT

5 Key UP

6 Key DOWN

7 Key RIGHT

5 Inputs

5.1 INP A, INP B

Signal inputs: function acc. to operating mode.

Max. frequency 60 kHz, can be damped in the

programming menu to 30 Hz.

Pulse counter: Count inputs

Frequency meter: Frequency inputs

Timer: Start input or

Start/Stop inputs

5.2 RESET

Dynamic reset input: resets the pulse counter or

timer to zero (‘Add’ output operations) or to preset

value 2 (‘Sub’ output operations). The reset input

can be inhibited in the programming menu.

Pulse counter: RESET input

Frequency meter: no function

Timer: RESET input

5.3 GATE

Static gate input: function dependent on operating

mode.

Pulse counter: no counting while active

Frequency meter: no counting while active

Timer: no time measurement while

active

5.4 LOC.INP

Static keypad lock input for preset or programming.

Lock-out level can be set in the programming

menu.

5.5 MPI 1 / MPI 2

User Input. Programmable as Display Latch, Set or

Teach-In input.

6 Outputs

6.1 Output 1 / Output 2

Relays with potential-free changeover contacts.

6.2 Active Outputs

LED1 and LED2 indicate an active output.

For safety switching the relays can be inverted, i.e.

the relays will be de-energized when the presets

are reached. To do this, the parameters Pr.OUT1

and Pr. OUT2 must be set to

signal) and to

or (for timed signal).

7 Programming

7.1 Entering the programming

Simultaneously press the UP key

and the DOWN key for 3 sec.

The security prompt appears

alternately in the display

Programming can be exited

again using the ENTER key.

Press the UP key or DOWN key

to continue with the

programming.

(for permanent

Page 6 | ENG

www.GlobalTestSupply.com

PROG.

The security prompt YES

appears in the display

Enter the main menu by pressing

the ENTER key

The first menu item in the main

menu appears in the display

When ending the programming via

NO the counter contents are not reset.

7.2 Selecting the main menus

The main menus are selected

using the UP and DOWN keys

Indicated by LED1

7.3 Entering a sub-menu

Press the ENTER key.

The first parameter is displayed

with the current setting flashing.

Indicated by LED1 and

LED2

7.4 Selecting the parameters

The parameters are selected

using either the RIGHT key or

the LEFT key.

7.5 Changing parameter values

Press the ENTER key.

Change the parameter value

using the UP or DOWN keys.

Press the ENTER key.

The new setting is again

displayed flashing.

7.6 Setting count values

Press the ENTER key.

Select the decade using the

RIGHT key or the LEFT key.

the corresponding

decade flashes

Change the count value using

the UP key or the DOWN key.

Press the ENTER key.

The new setting is again

displayed flashing.

7.7 Ending the programming

Select the menu item

Pressing the ENTER key

acknowledges this prompt and

allows the programming to be

repeated. The previouslyprogrammed values are

preserved. These can now be

checked or changed once again.

Pressing the UP key or the

DOWN key selects the

termination of the programming.

The security prompt YES

appears in the display

Pressing the ENTER key

acknowledges this prompt and

terminates the programming; the

modified settings are saved in

the EEPROM.

The text SAVE is shown in the

display for 2 sec.

When ending the programme via

END.PRG. YES the counter contents are

reset.

No count pulses, frequencies or times are

detected or measured whilst programming

is taking place.

7.8 Programming menu

Factory settings are highlighted in grey

7.8.1 Select language

Submenu: Select language

Help Text

Help Text ON

Help Text OFF

english

Page 7 | ENG

www.GlobalTestSupply.com

Select language for Help Text

English

German (Deutsch)

When ‘Help Text ON’ is selected, a

running text in English or German

automatically appears after 3 sec. in the

display. This provides an explanation of

the menu item. Once a running text has

started, it can be cancelled by pressing

any key.

7.8.2 Setting the Basic Function

Submenu: Basic function

Basic Function

Pulse counter (7.8.3)

Timer/Hour meter

(7.8.5)

Tacho/Frequency meter (7.8.4)

Changing the basic function causes all

parameters to be reset to factory settings.

7.8.3 Pulse Counter

7.8.3.1 Submenu for the Signal and Control

inputs

Submenu for programming the

signal and control inputs

Input polarity

PNP: switching to Plus

for all inputs in common

NPN: switching to 0 V

for all inputs in common

Filter for signal inputs INP A

and INP B

Maximum count frequency

Damped to approx. 30 Hz

(for control with mechanical

contacts)

Count Input mode

(See also under 15.)

Count/Direction control

INP A: count input

INP B: count direction input

Differential counting [A – B]

INP A: count input add

INP B: count input sub

Totalising [A + B]

INP A: count input add

INP B: count input add

Quadrature input

INP A: count input 0°

INP B: count input 90°

Quadrature with pulse

doubling (x2)

INP A: count input 0°

INP B: count input 90°

Each pulse edge of INP A will be

counted

Quadrature x4

INP A: count input 0°

INP B: count input 90°

Each pulse edge of INP A and

INP B will be counted.

Ratio measurement [A / B]

INP A: count input A

INP B: count input B

Percentage differential

counting

[(A – B) / A in %]

INP A: count input A

INP B: count input B

User input 1

User input 2

When the MPI input is activated

the display is “frozen” and

remains “frozen” until the MPI

input is deactivated.

Internally the preset counter

continues counting.

When the MPI input is activated

the current count value for the

preset that has just been

selected will be adopted as the

new preset value.

(See also 8.2.2)

When the MPI input is activated

the preset counter will be set to

the value specified in the

parameter SETPT. (See also 8.3)

Lock input

When the Lock input is activated,

the programming is inhibited.

When the Lock input is activated,

the setting of the preset values is

inhibited.

Page 8 | ENG

www.GlobalTestSupply.com

When the Lock input is activated,

the setting of the preset values

and the programming are both

inhibited.

7.8.3.2 Submenu for Output operations

Submenu for determining the

operation of the outputs

Output operation

(See also under 18.)

Count mode ADDING

Outputs active when count status

> preset value

Reset to zero

Count mode SUBTRACTING

Output 1 active when

count status < preset value 1

Output 2 active when

count status < 0

Reset to preset 2

Count mode ADDING with

automatic reset

Output 1 active when count

status > preset value 1

Output 2 (timed signal) active

when count status = preset value

2

Automatic reset to zero when

count status = preset value 2

Reset to zero

Count mode SUBTRACTING

with automatic reset

Output 1 active when count

status < preset value 1

Output 2 (timed signal) active

when count status = 0

Automatic reset to preset 2 when

count status = 0

Reset to preset 2

Count mode ADDING with

automatic reset and Batch

counter

Output 2 (timed signal) active

when main counter = preset

value 2

Automatic reset to zero when

main counter = preset 2

Batch counter counts the number

of automatic repetitions of preset

2

Output 1 active when Batch

counter > preset 1

Manual reset sets both counters

to zero.

Electrical reset sets only the

main counter to zero.

Count mode SUBTRACTING

with automatic reset and Batch

counter

Output 2 (timed signal) active

when main counter = zero

Automatic reset to preset 2 when

main counter = zero

Batch counter counts the number

of automatic repetitions of preset

2

Output 1 active when Batch

counter > preset 1

Manual reset sets main counter

to preset value 2 batch counter to

zero

Electrical reset only sets the

main counter to preset value 2

Count mode ADDING with

automatic reset and Total

counter

Output 2 (timed signal) active

when main counter = preset

value 2

Automatic reset to zero when

main counter = preset value 2

Total counter counts all the count

pulses from the main counter

Output 1 active when total

counter > preset value 1

Manual Reset sets both counters

to zero

Electrical reset sets only the

main counter to zero

Count mode SUBTRACTING

with automatic reset and Total

counter

Output 2 (timed signal) active

when main counter = zero

Automatic reset to preset value 2

when main counter = zero

Total counter counts (sub from

preset value 1) all count pulses

from main counter

Output 1 active when Total

counter < zero

Manual reset sets both counters

to the preset values

Electrical reset sets only main

counter to preset value 2

Tracking Preset mode

When preset 2 is changed then

preset 1 automatically tracks it.

Reset to zero

Preset 1 relative to Preset 2

Tracking Preset mode with

automatic reset

english

www.GlobalTestSupply.com

Page 9 | ENG

Ele

ctrical Reset

:

if the

7.8.3.3 Submenu for configuration

7.8.3.4 Submenu for reset mode

Page 10 | ENG

When preset 2 is changed then

preset 1 automatically tracks it.

Reset to zero.

Automatic reset to zero when

main counter = preset value 2.

Preset 1 relative to Preset 2

Submenu for matching the input

pulses to the display.

Multiplication factor

can be programmed from

00.0001 to 99.9999 The setting

00.0000 will not be accepted.

Division factor

can be programmed from

01.0000 to 99.9999

A setting < 01.0000 will not be

accepted.

Decimal point setting

(only optical function)

0 no decimal place

0.0 1 decimal place

0.00 2 decimal places

0.000 3 decimal places

0.0000 4 decimal places

0.00000 5 decimal places

Set value

Set value can be programmed

from -999999 to 999999

A previously programmed

decimal point will be displayed

Submenu for setting the reset

mode

Reset mode

Manual reset (reset key) and

electrical reset (reset input)

No reset possible

(reset key and reset input

inhibited)

Only electrical reset possible

(reset input)

Only manual reset possible

(reset key)

www.GlobalTestSupply.com

Always resets only the main counter.

Manual Reset:

Resets the main counter (ACTUAL) and

auxiliary counters (BATCH or TOTAL),

value of the main counter or the value of an

auxiliary counters is shown on the display.

7.8.3.5 Preset 1

see below 7.9.5.5

7.8.3.6 Preset 2

see below 7.9.5.6

7.8.4 Tacho/Frequency meter

7.8.4.1 Submenu for the Signal and

Control inputs

Submenu for programming the

signal and control inputs

Input polarity

PNP: switching to Plus

for all inputs in common

NPN: switching to 0 V

for all inputs in common

Filter for signal inputs INP A

and INP B

maximum count frequency

Damped to approx. 30 Hz

(for control with mechanical

contacts)

Input mode Frequency

measurement

(see also under 17.)

Simple frequency

measurement

INP A: Frequency input

INP B: no function

Differential measurement

[A – B]

INP A: Frequency input A

INP B: Frequency input B

Total measurement [A + B]

INP A: Frequency input A

INP B: Frequency input B

Frequency measurement with

direction detection [Quad]

INP A: Frequency input 0°

INP B: Frequency input 90°

Ratio measurement [A / B]

INP A: Frequency input A

INP B: Frequency input B

Percentage differential

measurement [(A-B) / A in %]

INP A: Frequency input A

INP B: Frequency input B

User input 1

User input 2

When the MPI input is activated

the display is “frozen” and

remains “frozen” until the MPI

input is deactivated.

Internally the frequency meter

continues running

(Display store).

When the MPI input is activated

the current frequency for the

preset that has just been

selected will be adopted as the

new preset value.

(See also 8.2.2)

Lock input

When the Lock input is activated

the programming is inhibited

When the Lock input is activated

the setting of the preset values is

inhibited.

When the Lock input is activated

the setting of the preset values

and the programming are both

inhibited

7.8.4.2 Submenu for configuration

Submenu for matching the input

pulses to the display.

Multiplication factor

can be programmed from

00.0001 to 99.9999 .The setting

00.0000 will not be accepted

Division factor

can be programmed from

01.0000 to 99.9999

A setting < 01.0000 will not be

accepted.

Display mode

Calculation and display of the

frequency / speed in 1/sec

Calculation and display of the

frequency / speed in 1/min

Decimal point setting

(determines the resolution)

0 no decimal place

0.0 1 decimal place

0.00 2 decimal places

0.000 3 decimal places

Moving average

Moving average calculated

AVG 2 over 2 measurements

AVG 5 over 5 measurements

AVG 10 over 10 measurements

AVG 20 over 20 measurements

Start delay

Programmable from 00.0 up to

99.9 sec.

At the start of a measurement the

measurement results within this

time-period are ignored.

Waiting time

Programmable from 00.1 up to

99.9 sec.

This value specifies how much

time should elapse, after the last

valid edge, before zero is to be

displayed.

7.8.4.3 Preset 1

See below 7.9.5.5

7.8.4.4 Preset 2

See below 7.9.5.6

7.8.5 Timer

7.8.5.1 Submenu for the Signal and

Control inputs

Submenu for programming the

signal and control inputs

Input polarity

PNP: switching to Plus

for all inputs in common

NPN: switching to 0 V

for all inputs in common

Filter for signal inputs INP A

and INP B

for electronic control of the

signal inputs

for mechanical control of the

signal inputs (for control with

mechanical contacts)

english

www.GlobalTestSupply.com

Page 11 | ENG

Page 12 | ENG

Input mode Time measurement

(see also under 16.)

Start: Edge to INP A

Stop: Edge to INP B

Start: 1. Edge to INP B

Stop: 2. Edge to INP B

Timing can only be controlled via

the Gate input. INP A and INP B

have no function.

The timer is reset by means of a

RESET (to zero when adding, to

preset 2 when subtracting) and

then starts timing again. Timing

is stopped with adding

operations when preset 2 is

reached. Timing is stopped with

subtracting operations when zero

is reached. A RESET during the

timing process also causes this

to stop. .

INP A and INP B: no function.

With AUTO: no output operations with

automatic repeat.

User input 1

User input 2

When the MPI input is activated

the display is “frozen” and

remains “frozen” until the MPI

input is deactivated.

Internally the preset timer

continues counting.

When the MPI input is activated

the current count value for the

preset that has just been

selected will be adopted as the

new preset value.

(See also under 8.2.2)

When the MPI input is activated

the preset counter will be set to

the value specified in the

parameter SETPT. (See also

under 8.3)

Lock input

When the Lock input is activated

the programming is inhibited

When the Lock input is activated

the setting of the preset values is

inhibited.

When the Lock input is activated

the setting of the preset values

and the programming is both

inhibited.

www.GlobalTestSupply.com

7.8.5.2 Submenu for output operations

Submenu for determining the

operation of the outputs

Output operation

(See also under 18.)

Count mode ADDING

Outputs active when count status

> preset value

Reset to zero

Count mode SUBTRACTING

Output 1 active when

count status < preset value 1

Output 2 active when

count status < 0

Reset to preset 2

Count mode ADDING with

automatic reset

Output 1 active when count

status > preset value 1

Output 2 (timed signal) active

when count status = preset value

2

Automatic reset to zero when

count status = preset value 2

Reset to zero

Count mode SUBTRACTING

with automatic reset

Output 1 active when count

status < preset value 1

Output 2 (timed signal) active

when count status = 0

Automatic reset to preset 2 when

count status = 0

Reset to preset 2

Count mode ADDING with

automatic reset and Batch

counter

Output 2 (timed signal) active

when main counter = preset

value 2

Automatic reset to zero when

main counter = preset 2

Batch counter counts the number

of automatic repetitions of preset

2

Output 1 active when Batch

counter > preset 1

Manual reset sets both counters

to zero.

Electrical reset sets only the

main counter to zero.

Count mode SUBTRACTING

with automatic reset and Batch

counter

Output 2 (timed signal) active

when main counter = zero

Automatic reset to preset 2 when

Ele

ctrical Reset

:

auxiliary counters (BATCH or TOTAL), if the

main counter = zero

Batch counter counts the number

of automatic repetitions of preset

2

Output 1 active when batch

counter > Preset 1

Manual reset sets main counter

to preset value 2 and batch

counter to zero

Electronic reset only sets the

main counter to preset value 2

Count mode ADDING with

automatic reset and Total

counter

Output 2 (timed signal) active

when main counter = preset

value 2

Automatic reset to zero when

main counter = preset value 2

Total counter counts all the count

pulses from the main counter

Output 1 active when total

counter > preset value 1

Manual Reset sets both counters

to zero

Electrical reset sets only the

main counter to zero

Count mode SUBTRACTING

with automatic reset and Total

counter

Output 2 (timed signal) active

when main counter = zero

Automatic reset to preset value 2

when main counter = zero

Total counter counts (sub from

preset value 1) all count pulses

from main counter

Output 1 active when Total

counter < zero

Manual reset sets both counters

to the preset values

Electrical reset sets only main

counter to preset value 2

Tracking Preset mode

When preset 2 is changed then

preset 1 automatically tracks it.

Reset to zero

Preset 1 relative to Preset 2

Tracking Preset mode with

automatic reset

When preset 2 is changed then

preset 1 automatically tracks it.

Reset to zero.

Automatic reset to zero when

main counter = preset value 2.

Preset 1 relative to Preset 2

7.8.5.3 Submenu for configuration

Submenu for matching the input

pulses to the display.

Unit of time

Seconds

Decimal point setting determines

the resolution

Minutes

Decimal point setting determines

the resolution

Hours

Decimal point setting determines

the resolution

Hrs. Min. Sec.

Decimal point setting

(determines the resolution)

0 no decimal place

0.0 1 decimal place

0.00 2 decimal places

0.000 3 decimal places

Set value

Set value can be programmed

from 000000 to 999999

A previously programmed

decimal point will be displayed

7.8.5.4 Submenu for reset mode

Submenu for setting the reset

mode

Reset mode

Manual reset (reset key) and

electrical reset (reset input)

No reset possible

(reset key and reset input

inhibited)

Only manual reset possible

(reset key)

Only manual reset possible

(reset key)

Always resets only the main counter.

Manual Reset:

Resets the main counter (ACTUAL) and

value of the main counter or the value of an

auxiliary counters is shown on the display.

english

www.GlobalTestSupply.com

Page 13 | ENG

7.8.5.5 Submenu for Preset 1

Submenu Preset 1

Preset 1 ON/OFF

Preset 1 ON

Preset 1 OFF and no function

Output signal

ADD mode output operations:

permanent signal at Output 1,

becomes active when count >

Preset 1

SUB mode output operations:

permanent signal at Output 1,

becomes active when count <

Preset 1

ADD mode output operations:

permanent signal at Output 1,

becomes passive when count >

Preset 1

SUB mode output operations:

permanent signal at Output 1,

becomes passive when count <

Preset 1

ADD mode output operations:

timed signal at Output 1,

becomes active when count >

Preset 1. (Activation only in

positive direction)

SUB mode output operations:

timed output at Output 1,

becomes active when count <

Preset 1 (Activation only in

negative direction)

ADD mode output operations:

timed signal at Output 1,

becomes passive when count >

Preset 1. (Deactivation only in

positive direction)

SUB mode output operations:

timed output at Output 1,

becomes passive when count <

Preset 1. (Deactivation only in

negative direction)

ADD mode output operations:

timed signal at Output1,

becomes active with positive

direction and when count >

Preset 1 and subsequently active

with negative direction and when

count < Preset 1

SUB mode output operations:

timed signal at Output 1,

becomes active with negative

direction and when count <

Preset 1 and subsequently active

with positive direction and when

count > Preset 1

ADD mode output operations:

timed signal at Output1,

becomes passive with positive

direction and when count >

Preset 1 and subsequently

passive with negative direction

and when count < Preset 1

SUB mode output operations:

timed output at Output 1,

becomes passive with negative

direction and when count <

Preset 1 and subsequently

passive with positive direction

and when count > Preset 1

Duration of timed signal of

Output 1

programmable from 00.01 to

99.99 sec.

Timed signal is post-triggered

7.8.5.6 Submenu for Preset 2

Output signal

ADD mode output operations:

permanent signal at Output 2,

becomes active when count >

Preset 2

SUB mode output operations:

permanent signal at Output 2,

becomes active when count <

zero

ADD mode output operations:

permanent signal at Output 2,

becomes passive when count >

Preset 2

SUB mode output operations:

permanent signal at Output 2,

becomes passive when count <

zero

ADD mode output operations:

timed signal at Output 2,

becomes active when count >

Preset 2 (Activation only in

positive direction).

SUB mode output operations:

timed signal at Output 2,

becomes active when count <

zero (Activation only in negative

direction)

ADD mode output operations:

timed signal at Output 2,

becomes passive when count >

Preset 2 (Deactivation only in

positive direction)

SUB mode output operations:

timed signal at Output 2,

Page 14 | ENG

www.GlobalTestSupply.com

becomes passive when count <

zero (Deactivation only in

negative direction).

ADD mode output operations:

timed signal at Output 2,

becomes active with positive

direction and when count >

Preset 2 and subsequently with

negative direction and when

count < Preset 2

SUB mode output operations:

timed signal at Output 2,

becomes active with negative

direction and when count < zero

and subsequently with positive

direction and when count > zero

ADD mode output operations:

timed signal at Output 2,

becomes passive with positive

direction and when count >

Preset 2 and subsequently with

negative direction and when

count < Preset 2

SUB mode output operations:

timed signal at Output 2,

becomes passive with negative

direction and when count < zero

and subsequently with positive

direction and when count > zero

Duration of timed signal of

Output 2

programmable from 00.01 to

99.99 sec.

Timed signal is post-triggered

Active:

Relays are activated when the preset

value is reached.

Passive:

Relays becomes de-energized when the

preset value is reached.

Timed outputs that have started are not

aborted by a RESET.

8 Operation

8.1 Switching the display during

operation

Pressing the DOWN key or the

UP key once causes the name of

the currently selected display

t = 2 sec

function to be displayed for 2

sec. If within this time the DOWN

key or the UP key is pressed a

second time, then the display

switches to the next or previous

display function. This is

confirmed by displaying the new

name for a period of 2 sec. After

2 sec the count value that

corresponds to the selected

display function is displayed.

Main counter

Batch counter

Total counter

Preset 1

Preset 2

8.2 Setting the presets

8.2.1 Setting via front keys

Using the UP key or the DOWN key, select the

preset to be changed, either PRES1 or PRES2

(see 8.1).

Select the decade using the

RIGHT key or the LEFT key.

the corresponding

decade flashes

Set the count value using the UP

key or the DOWN key.

The new setting is accepted

either by pressing the ENTER

key or after a period of 2 sec.

Preset setting is inhibited if the lock

function for the presets is active

(Parameter LOC.INP set to PRESET or

PRG.PRE and keypad lock input LOCK

active).

english

www.GlobalTestSupply.com

Page 15 | ENG

8.2.2 Teach Function

acknowledgment of the parameter sets, all

1. In the programming menu, programme MPI

input 1 or MPI input 2 (MP.INP.1 / MP.INP.2)

to TEACH

2. In operating mode, select the preset to be

changed: PRES1 or PRES2

3. In operating mode, briefly activate MPI input 1

or MPI input 2 (NPN or PNP input logic)

the current count value will be adopted as

the new preset value

See also 9. Error messages.

The preset value can subsequently be

further modified via the keypad. If preset

entry is inhibited (see note 8.2.1), then the

Teach Function is also locked out.

8.2.3 Teach-In with tracking presets

If a tracking (trailing) preset (TRAIL or TR.AR) has

been programmed, the value for Preset 2 can be

set either via the keypad or via the Teach-In

function.

However the value for Preset 1 must be entered via

the keypad. In this instance, it is not possible to use

the Teach-In function.

.

With output operations ADD.BAT,

SUB.BAT, ADD.TOT, SUB.TOT, TRAIL

and TR.AR, the Teach-In function is not

available for Preset 1.

8.3 Set Function

The pulse counter and the timer can be set to a

value by means of the Set function.

1. In the programming menu, programme MPI

Input 1 or MPI Input 2 (MP.INP1 / MP.INP2)

to SET

2. In the programming menu, set the parameter

SETPT to the desired value

3. In operating mode, briefly activate MPI input 1

or MPI input 2 (NPN or PNP input logic)

For add. output operations the pulse

counter or timer will be set to the SETPT

value

For sub. output operations the pulse

counter or timer will be set to the

difference between the value of Preset 2

and the value of SETPT

See also 9. Error messages

Page 16 | ENG

8.4 Default Parameters

Note: Three default parameter sets have

been permanently stored; these can be

adapted as required. With each

parameters will be reset to the values

listed in the table.

8.4.1 Entry into the default setting

8.4.2 Selecting the parameter sets

8.4.3 Accepting the setting

www.GlobalTestSupply.com

Simultaneously press the UP key

and the DOWN key for 3 sec.

The security prompt appears in

the display

Programming can be exited

again using the ENTER key.

Press the UP key or the DOWN

key to continue with the

programming.

The security prompt YES

appears in the display

Enter the default menu by

pressing the ENTER key

The parameter set last

programmed appears in the

display

The parameter sets are selected

using the UP key and the DOWN

key.

Default parameter set 1

Default parameter set 2

Default parameter set 3

Pressing the ENTER key accepts

the current setting and returns to

the operating mode.

The text SAVE is shown in the

display for 2 sec.

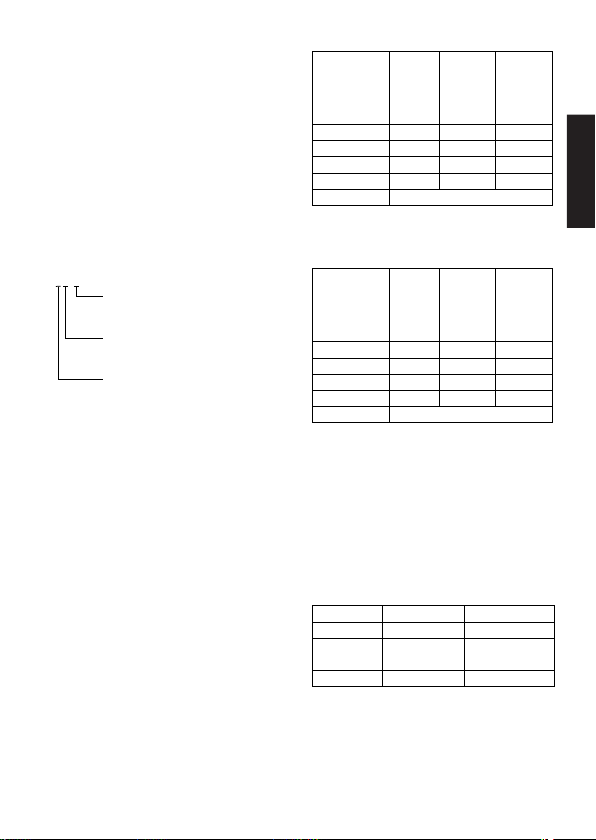

8.4.4 Parameter Set Table

P.SET1 P.SET2 P.SET3

HLP.TXT. ON ON ON

SL.LANG. EN EN EN

FUNCT COUNT COUNT COUNT

INP.POL. PNP PNP PNP

FILTER ON OFF OFF

COUNT CNT.DIR UP.DN QUAD

MP.INP.1 LATCH LATCH SET

MP.INP.2 TEACH SET TEACH

LOC.INP. PROG PROG PROG

MODE ADD SUB TRAIL

FACTOR 01.0000 01.0000 01.0000

DIVISO. 01.0000 01.0000 01.0000

DP 0 0 0.00

SETPT. 000000 000000 0000.00

RES.MOD. MAN.EL MAN.EL MAN.EL

PRES.1 ON ON ON

PR.OUT1

T.OUT1 00.10

PR.OUT2

T.OUT2 00.10 00.10

9 Error Message

Err 1 Set value ≤ 0 not allowed

Err 2 Set value ≥ Preset 2 not allowed

Err 3 negative Teach-In value for Preset 1 not

permitted

Err 4 Zero or negative Teach-In value for

Preset 2 not permitted

Err 45 EEPROM error

10 Connections

10.1 Signal and Control Inputs

N° Designation Function

1 INP A Signal input A

2 INP B Signal input B

3 RESET Reset input

4 LOCK Keypad lock

5 GATE Gate input

6 MPI 1 User input 1

7 MPI 2 User input 2

8 AC: 24 VDC/80 mA

DC: U

connected

B

through

9 GND (0 VDC) Common connection

Sensor supply

voltage

Signal and Control

inputs

10.2 Supply Voltage and Outputs

N° Designation Function

10 Relay contact C.2

11 Relay contact N.O.2

12 Relay contact N.C.2

13 Relay contact C.1

14 Relay contact N.O.1

15 Relay contact N.C.1

16 AC: 100…240 V AC ±10% N~

DC: 10..30 VDC

17 AC: 100…240 V AC ±10% L~

DC: GND (0 VDC)

Output 2

Output 1

Supply

voltage

Supply

voltage

11 Technical Data

11.1 General Data

Display 6-digit, 14-segment LED

Digit height 14 mm

Overload/ Blinking, 1 sec., counter loses

Underload no pulses up to 1 decade

Data retention > 10 years, EEPROM

Operation 5 keys

11.2 Pulse Counter

Count frequency max. 55 kHz (see under 14.

Frequencies - typical)

Response time of the outputs:

Add;Sub;Trail < 13 ms

With automatic repeat < 13 ms

A/B; (A-B)/A < 34 ms

english

www.GlobalTestSupply.com

Page 17 | ENG

11.3 Tacho/Frequency Meter

Frequency range 0.01 Hz to 65 kHz (see

under 14. Frequencies typ.

Measuring principle ≤ 76.3 Hz Time interval

(Period measurement)

> 76.3 Hz Gate time

Gate time approx. 13.1 ms

Measuring error < 0.1% per channel

Response time of the outputs:

1-channel operation < 100 ms @ 40 kHz

< 350 ms @ 65 kHz

2-channel operation < 150 ms @ 40 kHz

< 600 ms @ 65 kHz

11.4 Timer

Seconds 0.001 sec ... 999 999 sec

Minutes 0.001 min ... 999 999 min

Hours 0.001 hrs … 999 999 hrs

Hrs.Min.Sec 00hrs.00min.01sec ...

99hrs.59min.59sec

Min. time measurable 500µs

Measuring error < 100 ppm

Output response time: < 13 ms

11.5 Signal and Control Inputs

SELV circuits, reinforced / double insulation

Polarity: programmable NPN/PNP

for all inputs in common

Input resistance 5 kΩ

Pulse shape any

Switching level with AC supply:

HTL level Low: 0 ... 4 VDC

High: 12 ... 30 VDC

4…30 V DC level Low: 0 ... 2VDC

High: 3.5 … 30 VDC

Switching level with DC supply:

HTL level Low: 0 ... 0,2 x U

High: 0.6 x U

4…30 V DC level Low: 0 ... 2 VDC

High: 3.5 ... 30 VDC

Minimum pulse length of the Reset input: 1 ms

Minimum pulse length of the Control inputs:10 ms

11.6 Outputs

Output 1 / Output 2

Relays with changeover contacts

Prescribed fuse: 3A

Switching voltage max. 250 V AC/ 150 V DC

Switching current max. 3 A AC/ DC

min. 30 mA DC

Switching capacity max. 750 VA/ 90 W

The maximum values shall in no case be

exceeded!

Mechanical service life (switching cycles) 20x10

N° of switching cycles at 3 A/ 250 V AC 5x10

N° of switching cycles at 3 A/ 30 V DC 5x10

B

... 30 VDC

B

11.7 Supply Voltage

AC supply: 100 ... 240 V AC / max. 11 VA

50/60 Hz, Tolerance ± 10%

ext. fuse protection: T 0.1 A

DC supply: 10 ... 30 V DC/ max. 5.5 W

ext. fuse protection T 0.25 A

reverse polarity protection,

SELV, CLASS II (Limited

Power Source)

11.8 Sensor Supply Voltage

(Voltage output for external sensors)

SELV circuits, reinforced / double insulation

for AC supply: 24 V DC ±15%, 80 mA

for DC supply: max. 80 mA, ext. voltage

supply is connected through

11.9 Climatic Conditions

Operating temperature: -20°C … +65°C

Storage temperature: -25°C … +75°C

Relative humidity: R.H. 93% at +40°C,

Non-condensing

Altitude: up to 2000 m

11.10 EMC

Noise immunity: EN 61000-6-2

Noise emission: EN 55011 Class B

with shielded signal and

control cables

11.11 Device Safety

Design to: EN 61010 Part 1

Protection Class: Protection Class 2 (front side)

Only the front side is classified as accessible

for the operator.

Application area: Pollution level 2

over-voltage Category II

Insulation: Front: double insulation,

Rear side: basic insulation,

Signal inputs and und sensor power supply: SELV

11.12 Mechanical Data

Housing: Panel-mount housing

to DIN 43 700, RAL 7021

Dimensions: 96 x 48 x 102 mm

Panel cut-out: 92

Installation depth: ca. 92 mm incl. terminals

Weight: ca. 180 g

Protection: IP65 (front, device only)

Housing material: Polycarbonate UL94 V-2

Vibration resistance: 10 - 55 Hz / 1 mm / XYZ

EN 60068-2-6 30 min. in each direction

Shock resistance:

EN 60068-2-27 100G / 2 ms / XYZ

6

3 times in each direction

4

EN 60068-2-29 10G / 6 ms / XYZ

4

2000 times in each direction

+0,8

+0,6

x 45

mm

Page 18 | ENG

www.GlobalTestSupply.com

11.13 Connections

Supply voltage and outputs:

Plug-in screw terminal, 8-pin, RM 5.00

Core cross - section, max. 2.5 mm²

Signal and control inputs:

Plug-in screw terminal, 9-pin, RM 3.50

Core cross - section, max. 1.5 mm²

12 Scope of Delivery

Preset counter

Mounting clip

Instruction manual

13 Ordering Codes

89XX-X

Interface

1 = None

5 = RS485

Supply voltage

0 = 10 … 30 V DC

1 = 100 … 240 V AC ± 10%

Input trigger levels

8 = 4 … 30 V DC level

9 = HTL level

14 Frequencies (typical)

NOTE: Switching levels of the inputs

Switching levels with AC supply:

HTL level Low: 0 …4 V DC

High: 12 … 30 V DC

4 … 30 V DC level Low: 0 … 2 V DC

High: 3.5 … 30 V DC

Switching levels with DC supply:

HTL level Low: 0 … 0.2 x U

High: 0.6 x U

4 … 30 V DC level Low: 0 … 2 V DC

High: 3.5 … 30 V DC

14.1 Pulse Counter

HTL level, signal shape square wave 1:1

AC supply typ. Low 2.5 V

typ. High 22 V

DC supply 12V typ. Low 2 V

typ. High 10 V

DC supply 24V typ. Low 2.5 V

typ. High 22 V

B

… 30 V DC

B

Cnt.Dir 55 kHz 2.6 kHz 2.5 k Hz

Up.Dn ; Up.Up 29 kHz 2.6 kHz 2.5 kHz

Quad ; Quad 2 28 kHz 1.2 kHz 1.1 kHz

Quad 4 18 kHz 1.1 kHz 0.8 kHz

A/B ; (A-B)/A 29 kHz

4…30 V DC level, signal shape square wave 1:1

typ. Low 1.0 V

typ. High 4.0 V

Cnt.Dir

Up.Dn ; Up.Up

Quad ; Quad 2

Quad 4

A/B ; (A-B)/A

Add

AddAr

SubAr

AddBat

SubBat

TrailAr

AddTot

SubTot

Sub

Trail

Add

AddAr

SubAr

AddBat

SubBat

TrailAr

AddTot

SubTot

Sub

Trail

9 kHz 2.5 kHz 2.2 kHz

9 kHz 2.5 kHz 2.2 kHz

9 kHz 1.1 kHz 1.1 kHz

9 kHz 1.1 kHz 0.9 kHz

9 kHz

14.2 Frequency Meter

HTL level, signal shape square wave 1:1

AC supply typ. Low 2.5 V

typ. High 22 V

DC supply 12V typ. Low 2 V

typ. High 10 V

DC supply 24V typ. Low 2.5 V

typ. High 22 V

4…30 V DC level, signal shape square wave 1:1

typ. Low 1.0 V

HTL 5V

A

A – B ; A + B

A / B ; (A-B)/A

Quad

typ. High 4.0 V

65 kHz 9 kHz

65 kHz 9 kHz

30 kHz 9 kHz

english

www.GlobalTestSupply.com

Page 19 | ENG

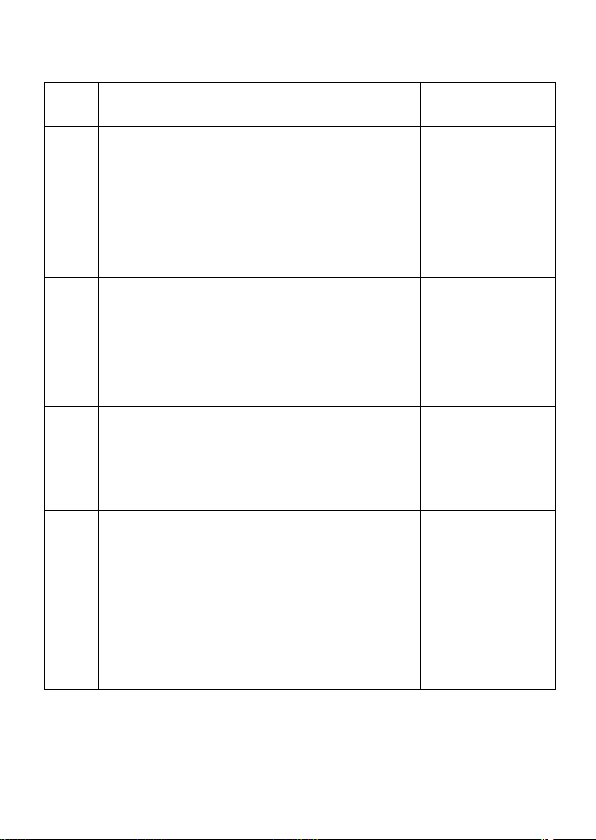

15 Input modes: Pulse counting

Function Diagram

Note: No counting when GATE input is active

P = Preset

CNT.DIR

PNP: Count on rising edge

NPN: Count on falling edge

Inp A: Count input

Inp B: Count direction

Add: Display 0 --> Preset

Sub: Display Preset -> 0

UP.DN

UP.UP

QUAD

QUAD2

Page 20 | ENG

www.GlobalTestSupply.com

Inp A: Count input add

Inp B: Count input sub

Add: Display 0 --> Preset

Sub: Display Preset -> 0

Inp A: Count input 1 add

Inp B: Count input 2 add

Add: Display 0 --> Preset

A 90° B

Inp A: Count input

Count on one edge

Inp B: Reverse direction

Add: Display 0 --> Preset

Sub: Display Preset -> 0

A 90° B

Inp A: Count input

Count on rising and on falling

edges

Inp B: Reverse direction

Add: Display 0 --> Preset

Sub: Display Preset -> 0

Function Diagram

QUAD4

A / B

Note: No counting when GATE input is active

PNP: Count on rising edge

NPN: Count on falling edge

A 90° B

Inp A: Count input

Count on rising and on

falling edges

Inp B: Count input

Count on rising and on

falling edges, Reverse

direction

Add: Display 0 --> Preset

Sub: Display Preset -> 0

Inp A: Count input 1

Inp B: Count input 2

Formula:

A / B

english

A % B

www.GlobalTestSupply.com

Inp A: Count input 1

Inp B: Count input 2

Formula:

(A – B)/A x100

Page 21 | ENG

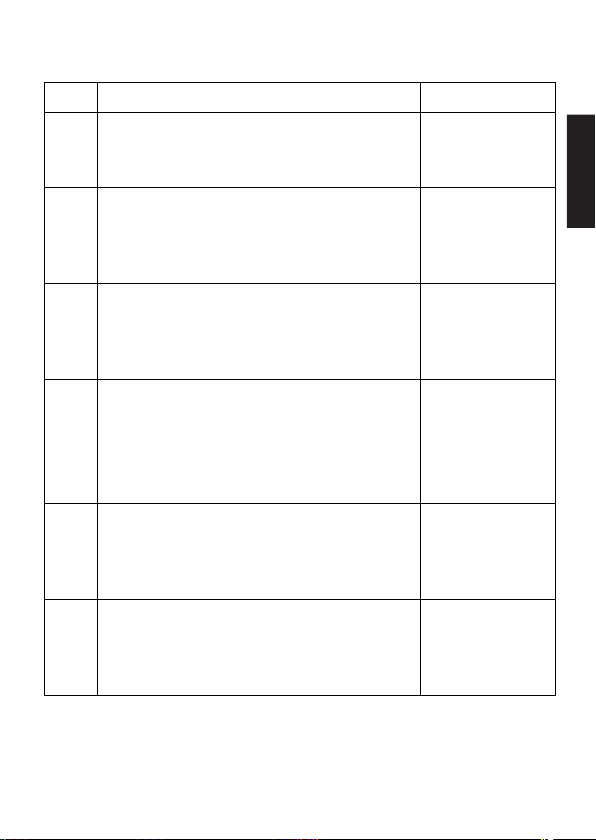

16 Input modes: Timing

Function Diagram PNP: Count on rising edge

INA.INB

NPN: Count on falling

edge

Inp A: Start

Inp B: Stop

Add: Display 0 --> Preset

Sub: Display Preset -> 0

INB.INB

FREE.RN

AUTO

Page 22 | ENG

www.GlobalTestSupply.com

Inp A: no function

Inp B: Start/Stop

Add: Display 0 --> Preset

Sub: Display Preset -> 0

Inp A: no function

Inp B: no function

Control of the timing only

via the GATE input

Add: Display 0 --> Preset

Sub: Display Preset -> 0

Inp A: no function

Inp B: no function

Control of the timing via

RESET (manual or

electrical)

Add: Display 0 --> Preset

Sub: Display Preset -> 0

17 Input modes: Frequency meter

Function Diagram PNP: Count on rising edge

A

A - B

A + B

QUAD

NPN: Count on falling edge

Inp A: Frequency input

Inp B: no function

Inp A: Frequency input 1

Inp B: Frequency input 2

Formula:

A - B

Inp A: Frequency input 1

Inp B: Frequency input 2

Formula:

A + B

A 90° B

Inp A: Frequency input 1

Inp B: Reverse direction

english

A / B

A % B

www.GlobalTestSupply.com

Inp A: Frequency input 1

Inp B: Frequency input 2

Formula:

A / B

Inp A: Frequency input 1

Inp B: Frequency input 2

Formula:

(A – B)/A x100

Page 23 | ENG

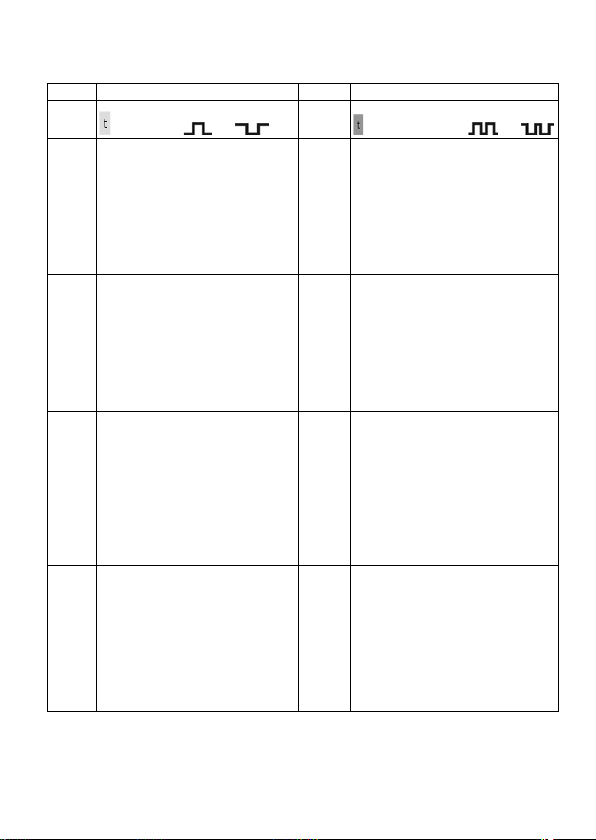

18 Output operations

Mode Diagram Mode Diagram

Only in mode and

ADD

SUB

Additionally in mode and

ADD.AR

ADD.BAT

ADD.TOT

Page 24 | ENG

SUB.AR

SUB.BAT

SUB.TOT

www.GlobalTestSupply.com

Mode Diagram

TRAIL

english

TR.AR

Page 25 | ENG

www.GlobalTestSupply.com

19 Help Texts

PROG. NO NO PROGRAMMING

PROG. YES ST ART PROGRAMMING

LANGU. MAIN MENU SELECT LANGUAGE

HLP.TXT. YES HELPTEXT ON

SL.LANG. DE DEUTSCH

SL.LANG. EN EN GLISH

FUNCT. MAIN MENU BASIC FUNCTION

FUNCT. COUNT BASIC FUNCTION COUNTER

FUNCT. TIMER BASIC FU NCTION TIMER

FUNCT. TACHO BASIC FUNCTION TACHOMETER/FREQUENCY METER

INPUT MAIN M ENU INPUTS

INP.POL. PNP INPUT POLARITY PN P

INP.POL. NPN INPUT POLARITY NPN

FILTER OFF INPUT 30HZ FILTER OFF

FILTER ON INPUT 30HZ FILT ER ON

CNT.INP. CNT.DIR INPUT MODE COUNT DIRECTION

CNT.INP. UP.DN INPUT MODE UP-DOWN

CNT.INP. UP.UP INPUT MODE UP-UP

CNT.INP. QUAD INPUT MODE QUADRATURE

CNT.INP. QUAD2 INPUT MODE QUADRATURE x 2

CNT.INP. QUAD4 INPUT MODE QUADRATURE x 4

CNT.INP. A/B INPUT MODE A/B

CNT.INP. A%B INPUT MODE ( A-B)/A IN %

START INA.INB START INPUT A / STOP INPUT B

START INB.INB START INPUT B / STOP INPUT B

START FRE.RUN TIMER IN FREE RUN MODE

START AUTO TIMER IN AUTO ST OP MODE

TAC.INP. A ONLY INPUT A

TAC.INP. A-B INPUT MODE A-B

TAC.INP. A+B INPUT MODE A+B

TAC.INP. QUAD INPUT MODE QUADRATURE

TAC.INP. A/B INPUT MODE A/B

TAC.INP. A%B INPUT MODE (A- B)/A IN %

MP.INP._ LATCH FUNCTION MP-INPUT _ LATCH

MP.INP._ TEACH FUNCTION MP-INPUT_ TEACH

MP.INP._ SET FUNCT ION MP-INPUT_ SET

LOC.INP. PROG. LOCK PROGRAMMING

LOC.INP. PRES ET LOCK EDITIN G OF PRESETS

LOC.INP. PRG.PRE. LOCK PROGRAMMING A ND EDITING OF PRESETS

MODE MAIN MENU OPERATION MODE

MODE ADD MODE ADDING

MODE ADD.AR MODE ADDING WITH AUTOMATIC RESET

MODE ADD.BAT MODE ADDING WITH AUTOMATIC RESET + BATCH COUNTER

MODE ADD.TOT MODE ADDING WITH AUTOMATIC RESET + TOTAL COUNT ER

MODE TRAIL MODE ADDING OUTPUT 1 TRACKING PRESET OF OUTPUT 2

MODE TR.AR MODE ADDING OUTPUT 1 TRACKING PRESET OF OUTPUT 2 WITH AUTOMATIC

MODE SUB MODE SUBTRACTING

RESET

Page 26 | ENG

www.GlobalTestSupply.com

MODE SUB.AR MODE SUBTRACTING WITH AUTOMATIC RESET

MODE SUB.BAT MODE SUBTRACTING W ITH AUTOMATIC RESET + BATCH COUNTER

MODE SUB.TOT MODE SUBTRACTING WITH AUTOMATC RESET + TOTAL COUNTER

CONFIG. MAIN MENU CONFIGURATION

FACTOR MULTIPLICATION FACTOR

DIVISO. DIVISION FACTOR

T.MODE SEC TIME RANGE SECONDS

T.MODE MIN TIME RANGE MINUTES

T.MODE HOUR TIME RANGE HOUR S

T.MODE HH.MM.SS TIME RANGE HH.MM.SS

T.MODE SEC-1 TACHO RANGE SEC-1

T.MODE MIN-1 TACHO RANGE MIN-1

DP DECI MAL POINT

SETPT. SET VALUE

AVG OFF NO AVERAGE

AVG AVG 2 AVERAGE OF 2 ME ASUREMENTS

AVG AVG 5 AVERAGE OF 5 ME ASUREMENTS

AVG AVG10 AVERAGE OF 10 MEASUREMENTS

AVG AVG20 AVERAGE OF 20 MEASUREMENTS

START START D ELAY TIME [SEC]

WAIT 0 W AIT TIME UNTIL DISPLAY ZERO [SEC]

RES.MOD MAIN MENU RESET MODE

RES.MOD. NO.RES. NO RESET FUNCTION

RES.MOD. MAN.RES. RESET VIA FRONT BUTTON

RES.MOD. EL.RES. RESET VIA RE SET INPUT

RES.MOD. MAN.EL. RESET VIA FRONT BUTTON OR RESET INPUT

PRES. 1 MAIN MENU PR ESET 1

PRES. 1 ON PRESET 1 ON

PRES. 1 OFF PRESET 1 OF F

PR.OUT1 ____------ PERMANENT SIGNAL FORM AT OUTPUT 1

PR.OUT1 ------____ PERMANENT SIGNAL FORM AT OUTPUT 1

PR.OUT1 __---__ TIMED SIGNAL FORM IN MAIN DIRECTION AT OUTPUT 1

PR.OUT1 ---__--- TIMED SIGNAL FORM IN MAIN DIRECTIO N AT OUTPUT 1

PR.OUT1 __--__--__ TIMED SIGNAL FORM IN BOTH DIRECTION AT OUT PUT 1

PR.OUT1 --_----_-- TIMED SIGNAL FORM IN BOTH DIRECTION AT OUTPUT 1

T.OUT 1 ACTIVE TIME FOR OUTPUT 1

PRES. 2 MAIN MENU PR ESET 2

PR.OUT2 ____------ PERMANENT SIGNAL FORM AT OUTPUT 2

PR.OUT2 ------____ PERMANENT SIGNAL FORM AT OUTPUT 2

PR.OUT2 __---__ TIMED SIGNAL FORM IN MAIN DIRECTION AT OUTPUT 2

PR.OUT2 ---__--- TIMED SIGNAL FORM IN MAIN DIRECTIO N AT OUTPUT 2

PR.OUT2 __--__--__ TIMED SIGNAL FORM IN BOTH DIRECTION AT OUT PUT 2

PR.OUT2 --_----_-- TIMED SIGNAL FORM IN BOTH DIRECTION AT OUTPUT 2

T.OUT 2 ACTIVE TIME FOR OUTPUT 2

END.PRG. NO REPEAT PROGRAM MING

END.PRG. YES EXIT PROGRAMMING AN D STORE DATAS

english

Page 27 | ENG

www.GlobalTestSupply.com

20 Dimensional Drawings

Dimensions in mm [inch]

Rear view:

Panel cut-out:

Page 28 | ENG

www.GlobalTestSupply.com

Loading...

Loading...