True GDM Series, GDT Series Technical & Service Manual

Technical Service Manual

(All Models)

Index

Page

Cabinet Installation and Set-Up _____________________________________________________4

Electrical Requirements______________________________________________________________5

Conductors and Circuits _____________________________________________________________6

Cabinet Installation and Set-Up Checklist ______________________________________________7

Cabinet Installation and Set-Up (Swing & Slide Doors) ___________________________________8

GDM/T - Series Freezers_____________________________________________________________9

Remote Condensing Unit____________________________________________________________10

Temperature Control Altitude Adjustment_____________________________________________11

Temperature Control Altitude Adjustment(new temp. control) ____________________________12

Defrost Controls ________________________________________________________________13-14

Preventative Maintenance __________________________________________________________16

Cabinet Maintenance Schedule_______________________________________________________17

Condenser Cleaning________________________________________________________________18

Refrigeration Section _______________________________________________________________20

Polyol Ester Lubricant - The CFC Report _____________________________________________21

Service Contractors: Attention Please _________________________________________________22

Basic Refrigeration - The Capillary Tube System _______________________________________23

The Refrigeration Cycle ____________________________________________________________24

True’s Remote System - How it Works ________________________________________________25

Basic Refrigeration - Control of Liquid Refrigerant Floodback... __________________________26

General Maintenance & Repairs ___________________________________________________28

Top Removal for TBB and TDD Units_________________________________________________29

Top Removal forTD and T-GC Units _________________________________________________30

TPPCountertop Replacement Instructions_____________________________________________31

Top Removal for Various Coolers - TSSU, TWT,TUC ___________________________________32

Top Removal forTRCB 50 and 79 ____________________________________________________33

End Cap Replacement-T-Series Swing Door _________________________________________34-35

Side Panel Replacement - GDM Series ________________________________________________36

Side Panel Replacement - GDM-33C-PT_______________________________________________37

Floral Case Baffle Installation _______________________________________________________38

GDM-23FC Mirror Retrofit Kit______________________________________________________39

Undercounter Refrigerator/Freezer Perimeter Heater Wire Replacement ___________________40

GDM & T-Series Freezer Perimeter Heater Wire Replacement____________________________41

TD-Series and Glass Chillers ________________________________________________________42

Temperature Control Replacement for Cabinets Larger than 1/3 HPCompressors ________43-47

Temperature Control Change-Out - GDM _____________________________________________48

Temperature Control Change-Out - GDM & T-Series____________________________________49

Replacing Temperature Controls in GDM-7, GDM-10, & GDM-12 models__________________50

Surge Protector’s for the GDM-Series ______________________________________________51-52

Door and Lock Repair ______________________________________________________________54

Glass Insert - Slide Door ____________________________________________________________55

Slide Door Instruction - To improve slide door closing___________________________________56

Wiper Gasket Installation ___________________________________________________________57

Removal and Installation of GDM-Swing Door ______________________________________58-59

Torsion Spring Replacement - Swing Door __________________________________________60-61

IDLLamp Replacement ____________________________________________________________62

Index

Page

Glass Insert - Swing Door ________________________________________________________63-64

Glass Insert Gas Release (High Altitude Installation) ____________________________________65

GDM & T-Series IDLGlass Insert Replacement ________________________________________66

Replacement of Door Frame Heater on IDL Freezer Doors _______________________________67

IDL Door Wire Harness Replacement______________________________________________68-69

Shimming the Glass Insert________________________________________________________70-71

Lock Installations - GDM Single Swing Door (GDM-23/26)_______________________________72

Barrel Lock Installation (GDM Slide DoorModels) _____________________________________73

Slide Barrel Lock (Top View) ________________________________________________________74

Slide Barrel Lock (Front View)_______________________________________________________75

Lock Installation (GDM-5 & GDM-5PT Swing Door Models) _____________________________76

Ratchet Lock & Plastic Door Stop - Slide Door ______________________________________77-78

Lock Installation - TD Models _______________________________________________________79

General Instructions________________________________________________________________80

Overshelf Option - TSSU, TWT, TUC_________________________________________________81

Installing The Crumb Catcher _______________________________________________________82

Field Installing The TSSU Series 19” Cutting Board_____________________________________83

Anchoring the TSSU Hood Cover ____________________________________________________84

Installing the TTPSeries Service Shelf ________________________________________________85

Field Installing the TPPService Shelf _________________________________________________86

Sneezeguard Option - TSSU _________________________________________________________87

Castor and Leg Frame Installation ___________________________________________________88

GDM-33C-PT Castor Mounting Assembly _____________________________________________89

TDD-1 CO

TDD-2,3,4 (and Club Top models) CO2 Knock-out ______________________________________91

Vandal Panel Installation for a GDM-33CPT-54 ________________________________________92

Vandal Panel - GDM-69 __________________________________________________________93-94

Troubleshooting ____________________________________________________________________96

Calibrate Temperature Control____________________________________________________97-98

Troubleshooting and Service Chart _______________________________________________99-100

Capillary Tube Replacement Instructions - Upright GDM/T-Series Equipment__________101-102

Refrigeration Trouble Shooting Chart - Refrigerator________________________________103-104

Refrigeration Trouble Shooting Chart - Freezer ____________________________________105-106

Capillary Tube Replacement Instructions - Refrigerators and Freezers ____________________107

Field Troubleshooting__________________________________________________________108-110

Troubleshooting Fluorescent Lighting Circuits

GDM & T Series Coolers IDLConnector _____________________________________________112

Equipment Care and Cleaning ____________________________________________________114

Cleaning Your Cabinet_____________________________________________________________115

Stainless Steel Equipment Care and Cleaning (NAFEM)_____________________________116-120

Knock-out______________________________________________________________90

2

Rapid Start, Electric, and Preheat Fluorescent Light Circuits ____________________________111

4

Please read these instructions. Failure to follow maintenance guidelines

may result in a n o n - w a r r a n t e d service call.

CABINET

INSTALLATION

AND SET-UP

5

ELECTRICAL REQUIREMENTS

There are several factors that will affect the proper operation of your True unit. A m o n g

these factors, the electrical installation is the most important and should always be

checked before connecting your True cabinet as follows:

1. Make sure the circuit is dedicated exclusively to your True unit.

2. Make sure the electrical installation complies with national, state, and local codes.

3. Make sure the circuit is properly ground.

4. Check circuit for proper voltage at receptacle (+/-10% 115 Volt)

(- 5% + 10% 208/230 Volt)

5. Make sure that the wire gauge and breaker sizes are correct and comply with the min-

imum allowance for voltage drops

WARNING: FAILURE TO COMPLY WITH THESE REQUIREMENTS MIGHT

R E S U LT IN PERSONAL I N J U RY AND (OR) PROPERTY DAMAGE, AND W I L L V O I D

WA R R A N T Y.

6

CONDUCTORS AND CIRCUITS

Wi re Gauge for 2% Voltage Drop in Supply Circ u i t s

115 Vo l t Distance In Feet To Center of Load

A m p s 2 0 3 0 4 0 5 0 6 0 7 0 8 0 9 0 1 0 0 1 2 0 1 4 0 1 6 0

2 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4

3 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4

4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2

5 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0

6 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0

7 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0 8

8 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0 8 8

9 1 4 1 4 1 4 1 2 1 2 1 2 1 2 1 0 1 0 8 8 8

1 0 1 4 1 4 1 4 1 2 1 2 1 0 1 0 1 0 1 0 8 8 8

1 2 1 4 1 4 1 2 1 2 1 0 1 0 1 0 8 8 8 8 6

1 4 1 4 1 4 1 2 1 0 1 0 1 0 8 8 8 6 6 6

1 6 1 4 1 2 1 2 1 0 1 0 8 8 8 8 6 6 6

1 8 1 4 1 2 1 0 1 0 1 0 8 8 8 8 8 8 5

2 0 1 4 1 2 1 0 1 0 8 8 8 6 6 6 5 5

2 5 1 2 1 0 1 0 8 8 6 6 6 6 5 4 4

3 0 1 2 1 0 8 8 6 6 6 6 5 4 4 3

3 5 1 0 1 0 8 6 6 6 5 5 4 4 3 2

4 0 1 0 8 8 6 6 5 5 4 4 3 2 2

4 5 1 0 8 6 6 6 5 4 4 3 3 2 1

5 0 1 0 8 6 6 5 4 4 3 3 2 1 1

230 Vo l t s Distance In Feet To Center of Load

A m p s 2 0 3 0 4 0 5 0 6 0 7 0 8 0 9 0 1 0 0 1 2 0 1 4 0 1 6 0

5 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4

6 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2

7 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2

8 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2

9 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0

1 0 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0

1 2 1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0

1 4 1 4 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0 8

1 6 1 4 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0 8 8

1 8 1 4 1 4 1 4 1 2 1 2 1 2 1 0 1 0 1 0 8 8 8

2 0 1 4 1 4 1 4 1 2 1 2 1 0 1 0 1 0 1 0 8 8 8

2 5 1 4 1 4 1 2 1 2 1 0 1 0 1 0 1 0 8 8 6 6

3 0 1 4 1 2 1 2 1 0 1 0 1 0 8 8 8 6 6 6

3 5 1 4 1 2 1 2 1 0 1 0 1 0 8 8 8 6 6 6

4 0 1 4 1 2 1 0 1 0 8 8 8 6 6 6 5 5

5 0 1 2 1 0 1 0 8 8 6 6 6 6 5 4 4

6 0 1 2 1 0 8 8 6 6 6 6 5 4 4 3

7 0 1 0 1 0 8 6 6 6 5 5 4 4 3 2

8 0 1 0 8 8 6 6 5 5 4 4 3 2 2

9 0 1 0 8 6 6 6 5 4 4 3 3 2 1

1 0 0 1 0 8 6 6 5 4 4 3 3 2 1 1

7

CABINET INSTALLATION AND SET UP CHECKLIST

1) Make sure cabinet is plugged into dedicated outlet. Before plugging in cabinet check to make sure

voltage is adequate for your cabinet. Do not use an extension cord, this will void cabinet

w a r r a n t y.

2) Follow installation instructions for your specific cabinet. Each cabinet is shipped with specific

installation and set up instructions. It is very important to read all information sent with your new

cabinet

3) Make sure shipping blocks (slide doors) and door support brackets (swing doors) are removed.

Doors will not function correctly if this step is not followed.

4) Make sure that your cabinet is leveled correctly. Follow specific instructions with your cabinet and

use castor shims were they are needed. Make sure that legs and castors are installed per instructions. If directions are not followed this may cause premature unwarranted failure of cabinet legs

or castors. If your cabinet is not level this can cause performance problems that will not be covered as warranty repairs.

5) When cabinet is set in its final location, make sure the specific clearance guidelines are followed.

These are very important for ventilation in the condensing unit area. If not followed can cause

premature compressor failure.

6) Follow altitude adjustment for temperature control if applicable.

7)

IF YOU HAVE ANY QUESTIONS ABOUT SET UP OR INSTALLATION OF YOUR

NEW CABINET PLEASE CALL OUR TECHNICAL SERVICE DEPARTMENT AT 1800-325-6152.

CABINET INSTALLATION AND SET UP CHECKLIST

8

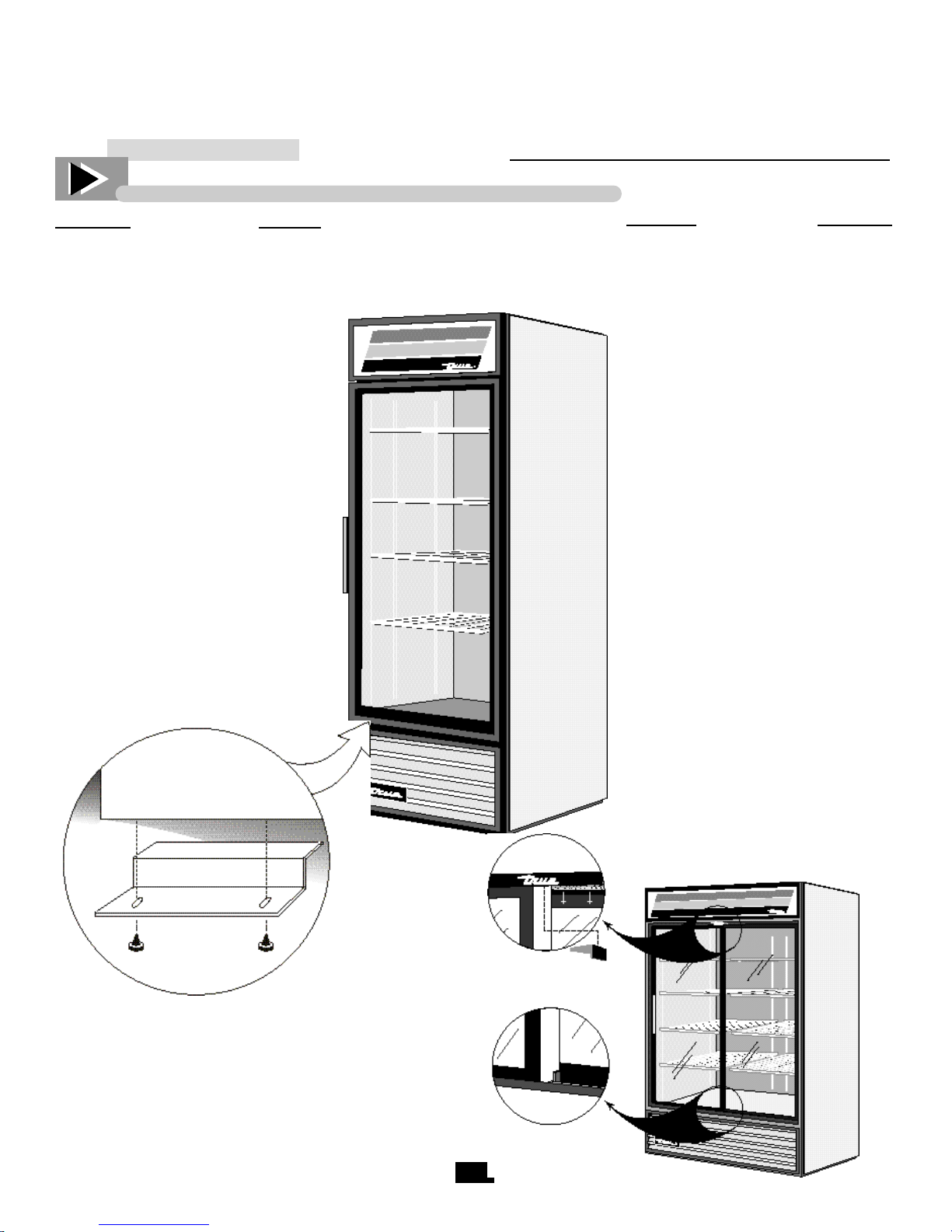

INSTALLATION INSTRUCTION

CABINET INSTALLATION AND SET-UP (SWING & SLIDE DOORS)

SWING DOORS

A. Remove all other tape securing

the doors to the cooler. Remove

the blue foam blocks approximately 1”x3”x1” (2.5 x 7.6 x 2.5 cm)

that are between the door and the

cooler. One foam block is located

on each side of the door frame. (left

and right).

NOTE

Your True Merchandiser has been

secured for safe shipping. During

installation, it is necessary to remove

the door support bracket.

SLIDE DOORS

A. Remove all transparent tape on the

door area. Remove the foam blocks in

top channel in front on the right door

approximately 1”x1”x20” (2.5 x 2.5 x

50 cm).

B . Remove both plastic brackets

secured by tape from under the left

door.

C. Open the left door.

D. Remove the foam block from the

top channel behind the left door.

B. Remove the two phillips screws

that secure the bracket to the door.

(see figure 1).

C. Remove bracket and save for

future shipping.

D. Replace screws securely into door.

E. Remove both plastic brackets from

under the right door (see figure 2).

NOTE

Door packing materials should NOT

be removed until cooler is placed on

location.

TRANSPORTATION OF THE

COOLER WITHOUT THE DOOR

PACKING MATERIALS IN

PLACE CAN RESULT IN DAM-

AGE TO DOORS, DOOR

ROLLERS AND V-TRACK

(figure 2)

(figure 1)

INSTALLATION INSTRUCTION

9

GDM / T-Series Freezers

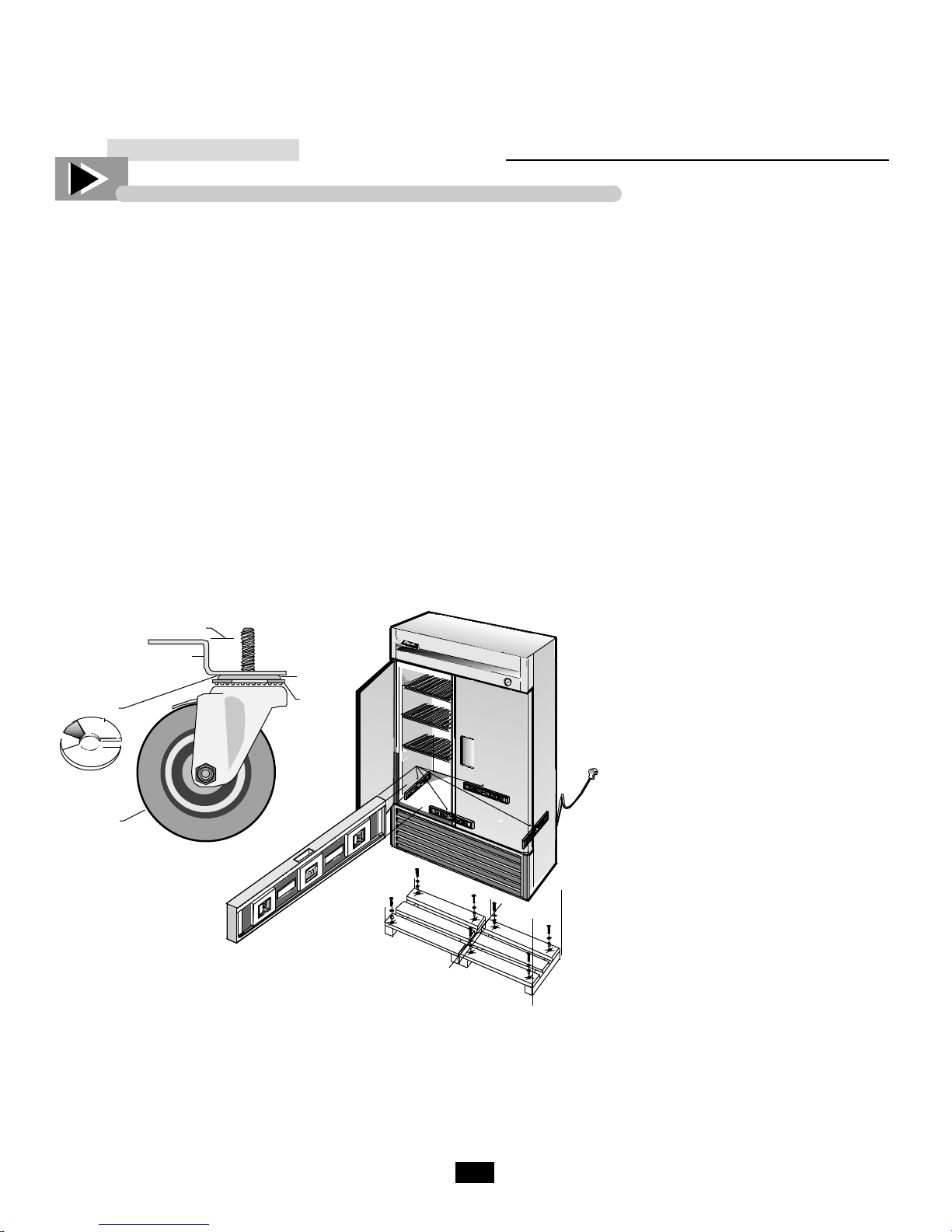

______ Installing Castors _______

Install castors in the bottom rail assembly

on the underside of the cooler. Castors

with brakes should be installed in front.

To obtain maximum strength and stability

of the unit, it is important that you make

sure each castor is secured with a 3/4"

(19mm) open-end wrench. The bearing

race on the castor must make firm contact

with the rail.

______ Installing Leg Levelers _______

Screw leg levelers into the four corners of

the lower rail assembly (larger models

include levelers centered front and back

also).

CAUTION

To avoid damage to lower rail assembly,

raise unit slowly and carefully to upright

position.

LEVELING

A. Set unit in its final location. Be sure

there is adequate ventilation in your room.

Under extreme heat conditions, (100°F+,

38°C+), you may want to install an exhaust

fan.

Warning

Warranty is void if

ventilation is insuff i c i e n t .

B. Proper leveling of your True cooler is

critical to operating success. Effective

condensate removal and door operation

will be effected by leveling.

C . The cooler should be leveled front to

back and side to side with a level (see figure

4). Place the level in the interior floor of the

unit in the four positions illustrated.

For Castored Models:

Four shims have been provided in warranty packet for leveling castored units posi-

tioned on uneven floors. Shims must be

positioned between rail end and bearing

race. (see figure 3).

If the cabinet is not level use a 3/4" (19mm)

open-end wrench to turn the anchoring bolt

under the bearing race counter-clockwise until

the cabinet is level.

Install the desired number of shims, making

sure the slot of the shim is in contact with the

threaded stem of the castor.

If more than one shim is used, turn the slot at

a 90° angle so they are not in line.

Turn the anchoring bolt clockwise with a 3/4"

(19mm) open-end wrench to tighten and

secure the castor.

Leg Levelers For GDM Models:

If the cabinet is not level adjust leg levelers by

first relieving weight to leveler and adjusting

by either hand or wrench. Repeat with all leg

levelers until cabinet is level in all directions.

D . Ensure that the drain hose or hoses are

positioned in the pan.

I M P O R TA N T

Make certain the metal strap holding the

c o m p re s s o r during shipment is re m o v e d .

F a i l u re to cut strap could result in excessive

noise and vibration (fre e z e r ) .

E. Free plug and cord from inside the

figure 3.

l o w e r re a rof the cooler(do not plug in).

F. The unit should be placed close

enough to the electrical supply so that

extension cords are never used.

figure 4.

Warning

Compressor warranties are void if the

unit is more than 6-1⁄2 ft. (2m) from plugin connection.

10

INSTALLATION INSTRUCTION

Remote Condensing Unit

For cabinet installation, use installation instructions with cabinet.

Receiving: Upon receiving this

piece of equipment remove all

outer packaging and inspect for

concealed damage. If damage is

found, indicate such on the carriers

Bill of Lading for claim to be filed.

In order to minimize damage to this

equipment, it is recommended that

the packaging remains in place

until it is in its final location.

Condensing units located indoors

or in confined areas must have adequate ventilation. Condensing units

require 1000 cfm of air per ton of

refrigeration.

True Manufacturing Company

strongly recommends the use of

compressor crankcase heaters and

headmaster valves be used at all

times with a remote compressor

unit. Not using these components

may void the compressor warranty.

Refrigerant Lines: All refrigerant piping should be ACR type. It

is recommended that all brazed

joints be made with “hard solder”

such as Silphos or Unibraze.

Solder such as 95-5 or other soft

solders are not recommended.

All suction lines must be insulated, with at least 1/2” wall insulation. Keep all lines as short as possible.

Always pitch suction lines downward in the direction of flow.

Generally 1/2” pitch for each 10 ft.

of line is adequate for good oil

return. Field installation vibration

eliminators should be field installed

parallel with the compressor crank

shaft and as close to the compressor

as possible.

Leak Check and Evacuation:

After all refrigerant line connections

have been complete, the entire system should be leak checked. This

includes field and factory connections. Charge system with refrigerant

vapor and add enough nitrogen to

raise pressure to 150 PSIG maximum.

Leak check the entire system.

Make repairs as necessary.

Evacuation Process: To obtain

the proper level of dehydration in the

refrigeration system, a vacuum of at

least 500 microns must be drawn. Do

not use the system’s compressor as a

vacuum pump and do not operate

compressor while system is in a vacuum.

Open all system service valves to

discharge any pressure in the system.

Connect vacuum pump to high and

low side of system. Pull vacuum.

Break the vacuum with system

refrigerant. Pull vacuum again, down

to 500 microns or lower.

Shut valves before charging.

Charging Process: When initially

charging a system that is in a vacuum,

liquid refrigerant can be added directly into the receiver tank w i t h o u t

compressor running.

If you have difficulty charging the

correct amount of refrigerant into the

system you may start the system to

complete the charging process.

Add the correct amount or until the

sight glass indicates a full charge,

with a clear window, bubbles indicate

more refrigerant is required. Care

should be taken not to overcharge the

system at this point. The evaporator

fans must be operational while charging; cooler fans must run continuously, freezer fans will be delayed by the

fan control. Make sure freezer fans

are running during final charg i n g

process.

Keep a close check on suction and

discharge pressures. After system has

stabilized, check for excessive liquid

floodback to the compressor. If

flooding occurs (less than 8˚ superheat in freezers, 12˚ in coolers) adjust

expansion valve Clockwise, 1/2 a

turn at a time, recheck before leaving

installation.

Check full load amps on the compressor, this can be found on the compressors nameplate, Check compressor oil level. Normal charge is indicated by 1/2 of the sight glass having

oil in it.

Final Check: Check high and low

pressure control settings. Set thermostat to desired cabinet temperature.

Check defrost timer settings (if applicable). Check voltage, this must be

100% of the nameplate rated voltage

for operation. Anything more or less

should be corrected immediately.

Replace all service valve caps and

secure all unit covers.

11

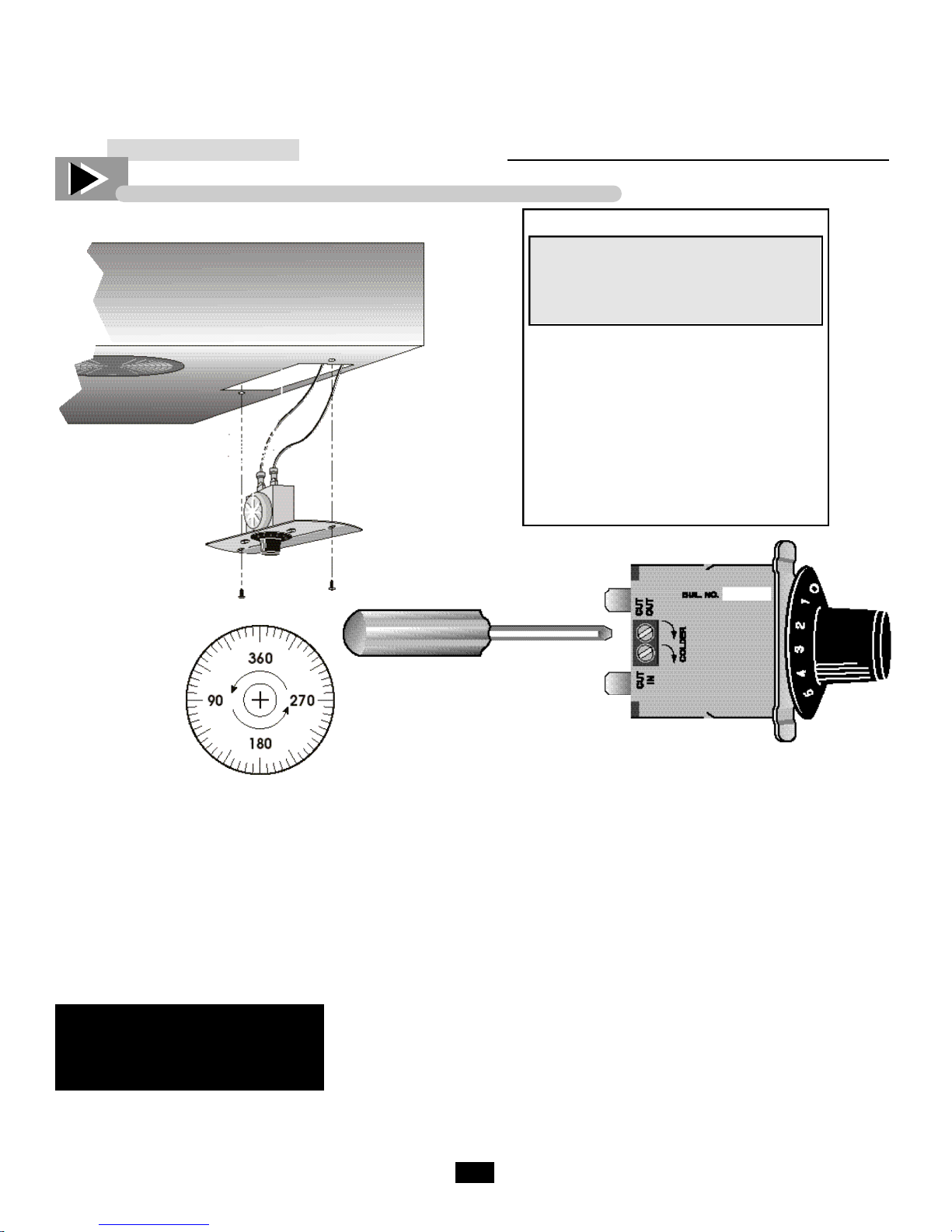

This scale may be

used as a guide

for measuring

degrees of rotation required for

altitude correction.

The arrows indicate

direction of screw

rotation.

REQUIRED TOOLS

• Phillips Head Screwdriver

• Hex Head Driver

• Jewelers Screwdriver

IMPORTANT

Upright models ordered with "High

Altitude" temperature controls

are pre-calibrated and do not

require adjustment.

___________ STEP 1 ___________

Unplug the cooler.

___________ STEP 2 ___________

Turn the temperature control to the "9"

position.

___________ STEP 3 ___________

Remove the screws that secure the

mounting plate to the evaporator top.

("A") See figure 1.

___________ STEP 4 ___________

Pull control down gently from housing.

___________ STEP 5 ___________

Turn screws counterclockwise (CCW)

See Chart and figure 2.

___________ STEP 6 ___________

Reassemble to cooler housing and

return the temperature control to the

"5" position.

INSTALLATION INSTRUCTION

TEMPERATURE CONTROL ALTITUDE ADJUSTMENT

Figure 1

Chart

CCW

Adjustment

(based on 360°/

Height complete turn)

2000' 42°

3000' 78°

4000' 114°

5000' 150°

6000' 186°

7000' 222°

8000' 258°

9000' 294°

10,000' 330°

Figure 2

12

INSTALLATION INSTRUCTION

Danfoss Temperature Control Adjustment for High Altitude Applications

Terms:

Cut-out - Temperature sensed by the

controller that shuts the compressor

off.

Cut-in - Temperature sensed by the

controller that turns the compressor on.

Instructions:

___________ STEP 1 ___________

Mechanical temperature controllers are

affected when functioning at high altitude. The cut-in and cut-out temperatures will be colder than when the controller function closer to sea level.

___________ STEP 2 ___________

For installations above 2,000 ft., it may

be necessary to “warm-up” the set

points. To make the adjustment, insert

the appropriate tool in each adjustment

screw and turn 1/4 of a revolution

clock-wise (to the right). This procedure will adjust both the cut-in and

cut-out about 2˚F warmer.

___________ STEP 3 ___________

Make sure to re-connect the pink wires

to the proper spade terminal when

re-installing.

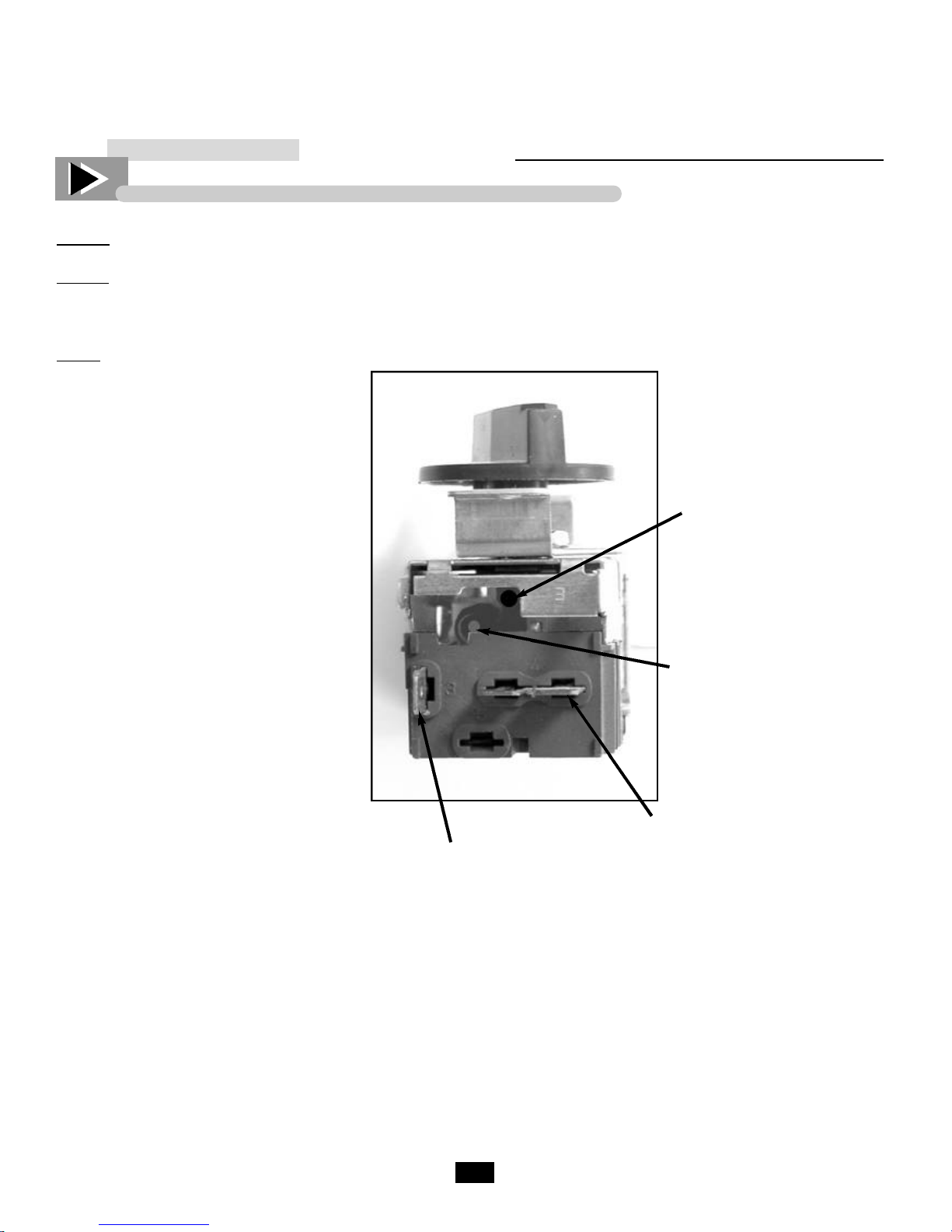

Cut-out Adjustment Screw

Allen (5/64” or 2 mm.)

Cut-in Adjustment

Screw Torx (T-7)

Compressor Connection (pink)

Compressor Connection (pink)

13

Recommended Defrost Settings

True Manufacturing has factory set your defrost time clock to a recommended time and duration defrost

scenario. All refrigeration equipment operating below 30˚F will accumulate frost on the evaporator coil

and will require routine defrost. Your True equipment has been designed for three defrost periods (8:00

a.m., 12:00 p.m. and 4:00 p.m.).

If you decide to deviate from these defrost time settings please follow the procedures and adjustment

below.

DEFROST CONTROLS

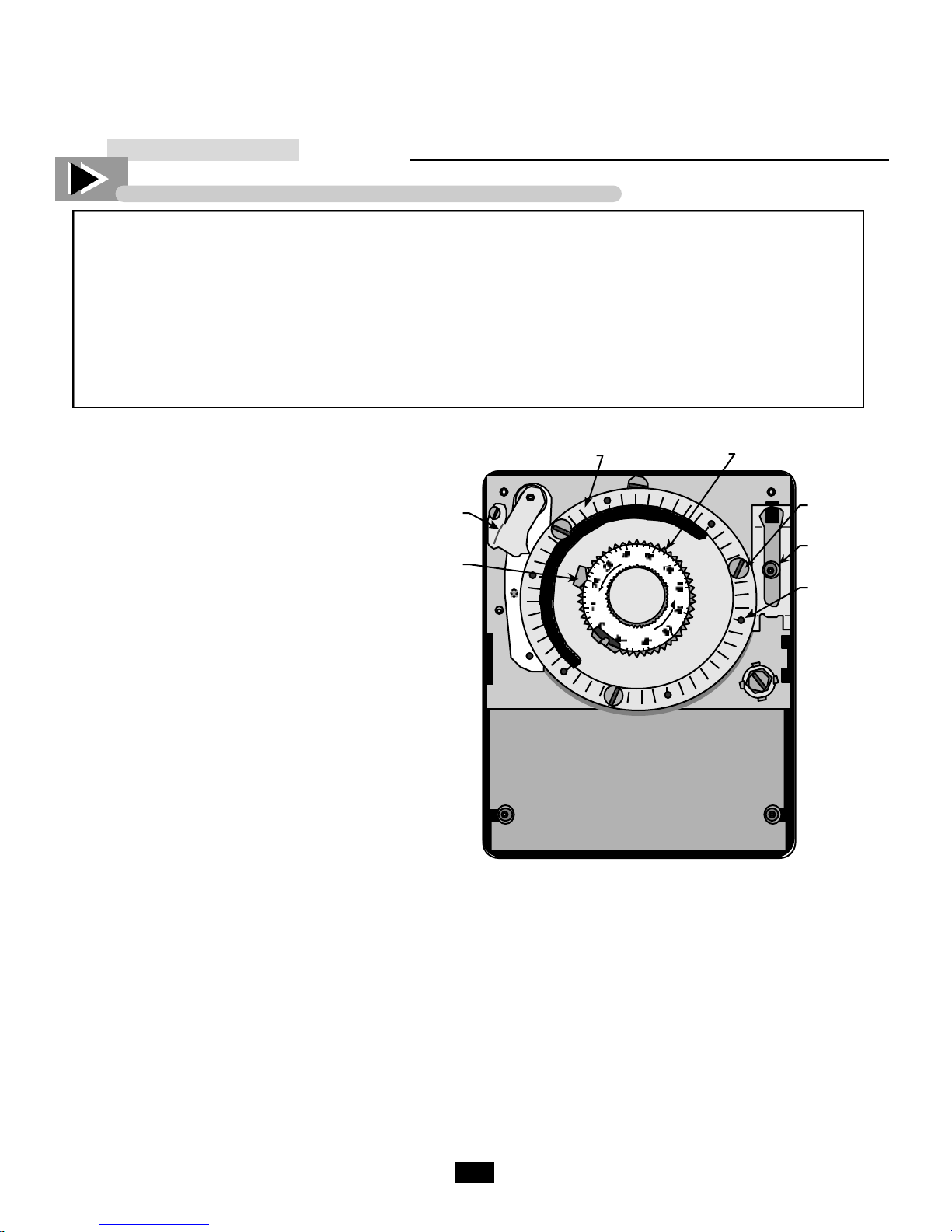

Defrost Time Clock Adjustment

REQUIRED TOOLS

Graduated

Time Disk

Adjusting

Knob

• Slotted Screwdriver

Locating The Defrost Timer

Take off lower grill assembly by removing

four (4) corner screws.

Single door models:

Defrost timer is located in the lower right

corner behind the louvered grill.

Two door models:

Defrost timer is located in the middle of

the cabinet, behind the louvered grill.

Timer is mounted to the left of the centered

ballast box.

Three door models:

Defrost timer is located on the left upright

post behind the louvered grill.

Adjusting The Defrost Control

(time initiated, temperature terminated)

Your True freezer contains a defrost

system that is temperature terminated,

however the time clock has been designed

with a time termination back-up so that the

defrost period will not exceed twenty

minutes. While True recommends 3

defrost periods not to exceed 20 minutes

the procedure below should be followed to

customize your specific needs.

Time

Indicator

Duration

Indicator

Warning

Always follow the manufactures

recommended settings when program-

ming the amount and duration of the

defrost cycles.

___________ STEP 1 ___________

Referencing the outer graduated time disk,

position the current time of day to align

with the “TIME” indicator. To move the

graduated time disk, grasp the adjusted

knob and turn counter clockwise until the

current time of day aligns with the “TIME

indicator.

Trip Pin

Extra Trip

Pin

Trip Pin

Hole

___________ STEP 2 ___________

In order to program the time to begin the

defrost cycle, insert threaded trip pins into

the graduated time disk hole that

corresponds to your customized defrost

needs.

___________ STEP 3 ___________

True recommends a 20 minute defrost

cycle three times per day. Changing the

recommended duration requires pressing

down and sliding the copper duration

indicator.

14

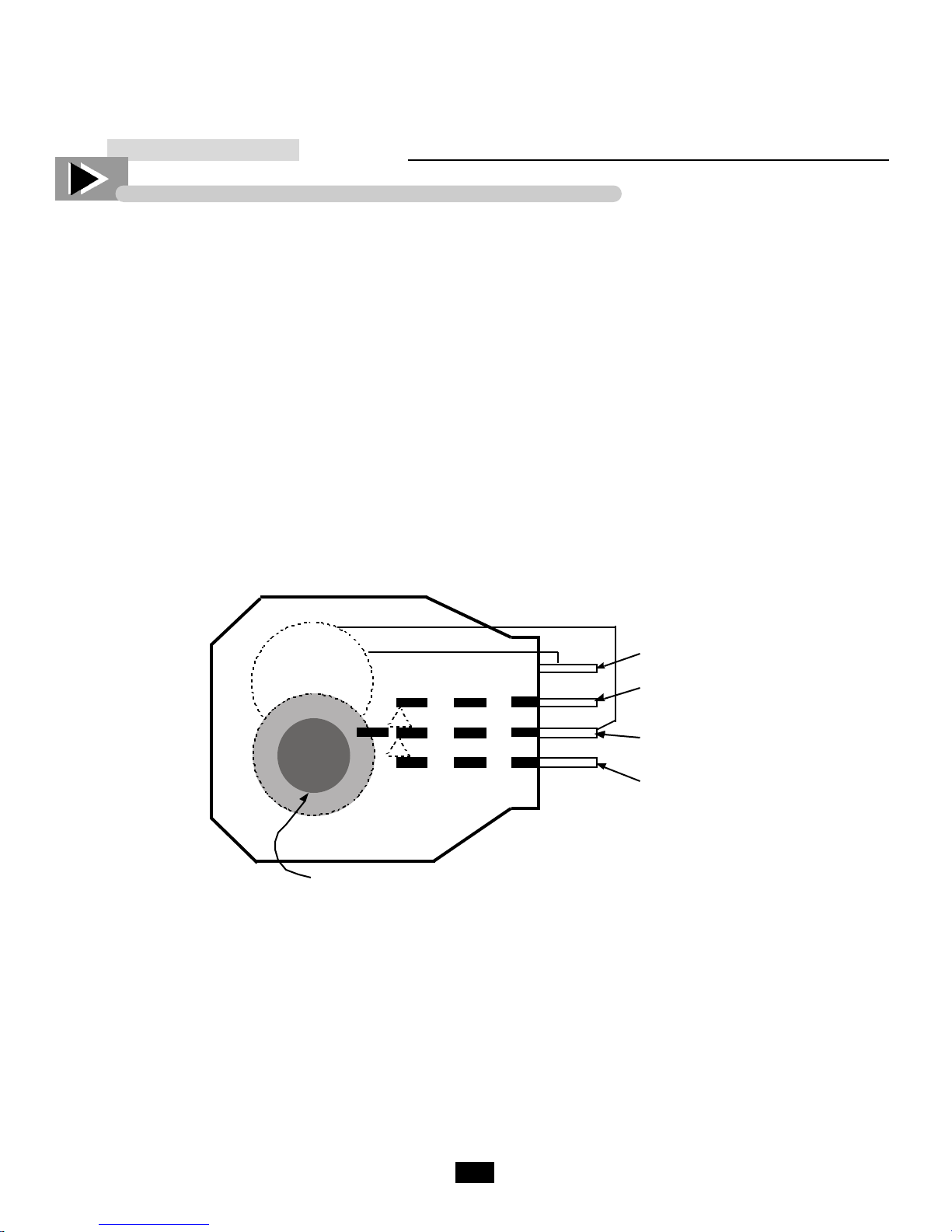

2. TIME INITIATED, TIME TERMINATED

Like in the time initiated, temperature terminated controls; these systems have a temperature sensor that will

disconnect the heaters to keep the cabinet from over heating. However it won’t restart the freezing cycle until

the control completes the factory set time, which in our case is usually 20 minutes. These systems are also

equipped with temperature sensors to delay the fan motors once the defrost cycle has been completed, to prevent the circulation of warm air inside the cabinet.

To adjust the defrost cycle time there is only one possible adjustment; Once the cabinet has reach the design

temperature, pick the time of the day that you want the unit to defrost. T urn the actuating gear clockwise until

the contacts change position initiating the defrost c y c l e .

MOTOR

DEFROST CONTROLS

3 Line

4 Compressor

1 Comun

2 Heaters

Actuating Gear

Common

Notes

16

Please read these instructions. Failure to follow maintenance

guidelines may cause a n o n - w a r r a n t e d cabinet repair service.

PREVENTATIVE

MAINTENANCE

17

CABINET MAINTENANCE SCHEDULE

MONTHLY

1. Check product temperature.

2. Brush off condenser coil.

3. Inspect lamps and lamp holder connections.

QUARTERLY

1. Check physical condition of condenser coil and evaporator coil (straighten fins if necessary.

2. Blow out condenser coil with compressed air.

3. Brush off evaporator coil if needed.

4. Check physical condition of gaskets and also make sure they are sealing correctly.

YEARLY

1. Check operation of all moving parts (fan motors, doors, defrost timers, & IDL door cords)

2. Check all electrical connections, make sure they are all tight and crimps in good condition.

3. Check defrost timer contacts, make sure they are not pitted.

4. Check rear condenser coil screen (clean if necessary).

CABINET MAINTENANCE SCHEDULE

Monthly, Quarterly, and Yearly

GENERAL MAINTENANCE

18

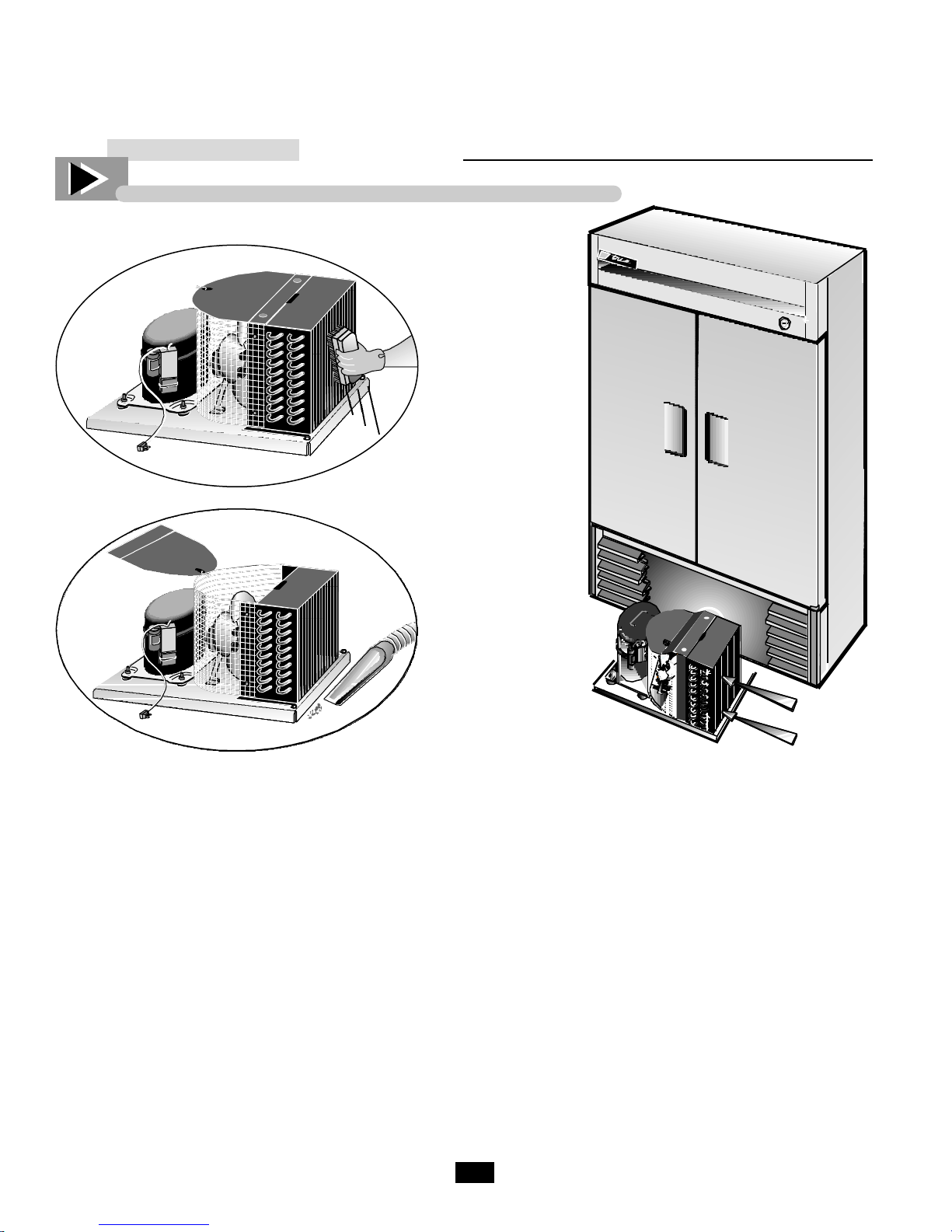

CONDENSER CLEANING

Step 4

Step 6

REQUIRED TOOLS

• Phillips Screwdriver

• Stiff Bristle Brush

• Adjustable Wrench

____________ STEP 1 ____________

Disconnect power to unit.

____________ STEP 2 ____________

Take off lower grill assembly by removing

four (4) corner screws.

____________ STEP 3 ____________

Remove bolts anchoring compressor

assembly to frame rails and carefully slide

out. (tube connections are flexible)

____________ STEP 4 ____________

Clean off accumulated dirt from condensing

coil with a stiff bristle brush.

____________ STEP 5 ____________

Lift cardboard cover above fan at plastic

plugs and carefully clean condenser coil

and fan blades.

____________ STEP 6 ____________

After brushing condenser coil vacuum dirt

from coil, and interior floor.

____________ STEP 7 ____________

Replace cardboard cover. Carefully slide

compressor assembly back into position

and replace bolts. When reinstalling

condensing unit becareful not to crimp

or damage the tubing between the condensing unit and the cabinet.

____________ STEP 8 ____________

Reinstall louver assembly onto unit with

appropriate fastener and clips. Tighten all

screws.

____________ STEP 9 ____________

Connect unit to power and check to see if

compressor is running.

Notes

20

In this section you can find information that is helpful for the

customer and the service technician to help you understand how

our refrigeration system works along with how to diagnose

and correct any problems that might arise.

REFRIGERATION

SECTION

21

Polyol Ester Lubricant

After exhaustive research and testing, Copeland has

determined that PolyolEster (POE) lubricants provide the best combination of characteristics for use

with the new generation of chlorine-free refrigerant.

In addition to providing superior lubrication. POE

has other advantages which increase its attractiveness for use in refrigeration.

Polyol Ester is a synthetic lubricant used primarily

for jet engine lubrication. It is manufactured by

numerous companies and there are various types and

grades available. Therefore, it is important to recognize that all POE's are not the same.

Since POE is synthetic, it has better resistance to

high temperature degradation than refrigeration mineral oils. POE is also made from more expensive

base stocks making it significantly more expensive

than other refrigeration oils. Furthermore, POE is

compatible with common refrigerant and mineral oil.

Therefore, a compressor containing the oil can be

installed in a system containing HCFC's or HFC's. In

short, POE provides significant flexibility in the face

of changes brought on by the CFC issue.

HFC refrigerant require the use of POE for all

Copeland compressors. This is necessary for two

specific reasons. First, mineral oils are not readily

miscible in HFC's. When using HFC's conventional

oils will not return to the compressor. Secondly, the

chlorine contained in CFCs and HCFCs aids in the

lubricity of mineral oil.

One drawback from using POE is that they absorb

moisture from the air at a much greater rate than do

mineral oils. As a result, they must be handled and

packaged with much more care than conventional

oils. Copeland has not tested all types of compressors

or all combinations of refrigerant and con-Industry

knowledge of POE must rapidly increase in order to

maintain and improve expected reliability.

After conducting extensive tests for both compressor

durability and reliability on more than 40 refrigerant/oil combinations, Copeland identified Mobil Oil

Corporation as our preferred U.S. supplier of polyol

ester oil in terms of both the oil itself and Mobil's

ability to package and deliver the oil with acceptable

low moisture levels. Because of its technical superiority. Copeland has approved Mobil's EAL Artic 22

CC polyol ester oil for use in our compressors.

To serve our customers, Copeland will distribute

E A L Artic 22 CC to the after market through

Copeland's network of 800 authorized wholesalers.

The lubricant will be charged into our new production compressors whenever a polyol ester is specified.

C u r r e n t l y, certain approved compressor models sold

to OEMs are available with this oil installed during

manufacture. Refrigeration service compressors

charged with POE will be supplied in the near future.

POLYOL ESTER LUBRICANT

THE CFC REPORT - LEADING THE WAY INTO A NEW AGE

22

SERVICE CONTRACTORS

..... ATTENTION PLEASE .....

SERVICE CONTRACTORS

..... ATTENTION PLEASE .....

This is a Tecumseh hermetic compressor specifically designed for use with environmentally

friendly HFC refrigerant R404A. However, it is acceptable to use this compressor as a service

replacement with R502.

The Tecumseh approved polyolester (POE) oil contained in this compressor is compatible

with all internal component materials and is miscible (mixes) with R502 to effect proper oil

return. Using R502 with this R404A compressor will result in very similar performance to

the replaced R502 compressor. But, the following precautions should be taken.

1) Care must be taken to assure that most of the mineral oil is removed from the system

before the new compressor is installed. Small amounts of mineral oil (up to 5%) left in

the system are acceptable but 1% or less if achievable is desired.

2) POE oils are 100 times more hygroscopic (ability to absorb moisture) than mineral oils

thus the utmost care must be taken to prevent moisture from entering the system. The

compressor or system should not be left open to the atmosphere for longer than 15 minutes maximum.

3) The appropriate new drier provided must be installed in the system.

4) Established industry procedures for recovery, evacuation, refrigerant charging and leak

testing should be followed.

TRUE MANUFACTURING COMPANY

23

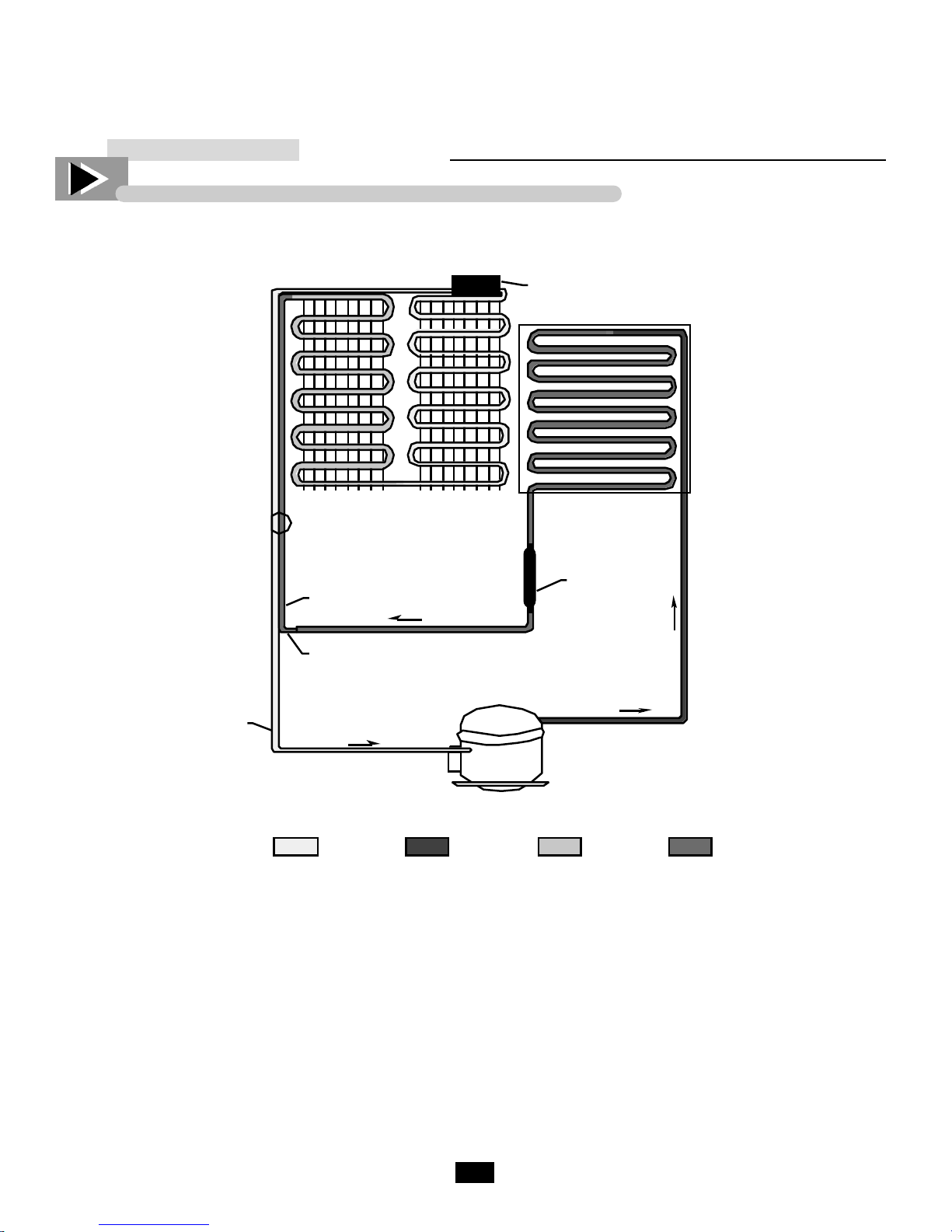

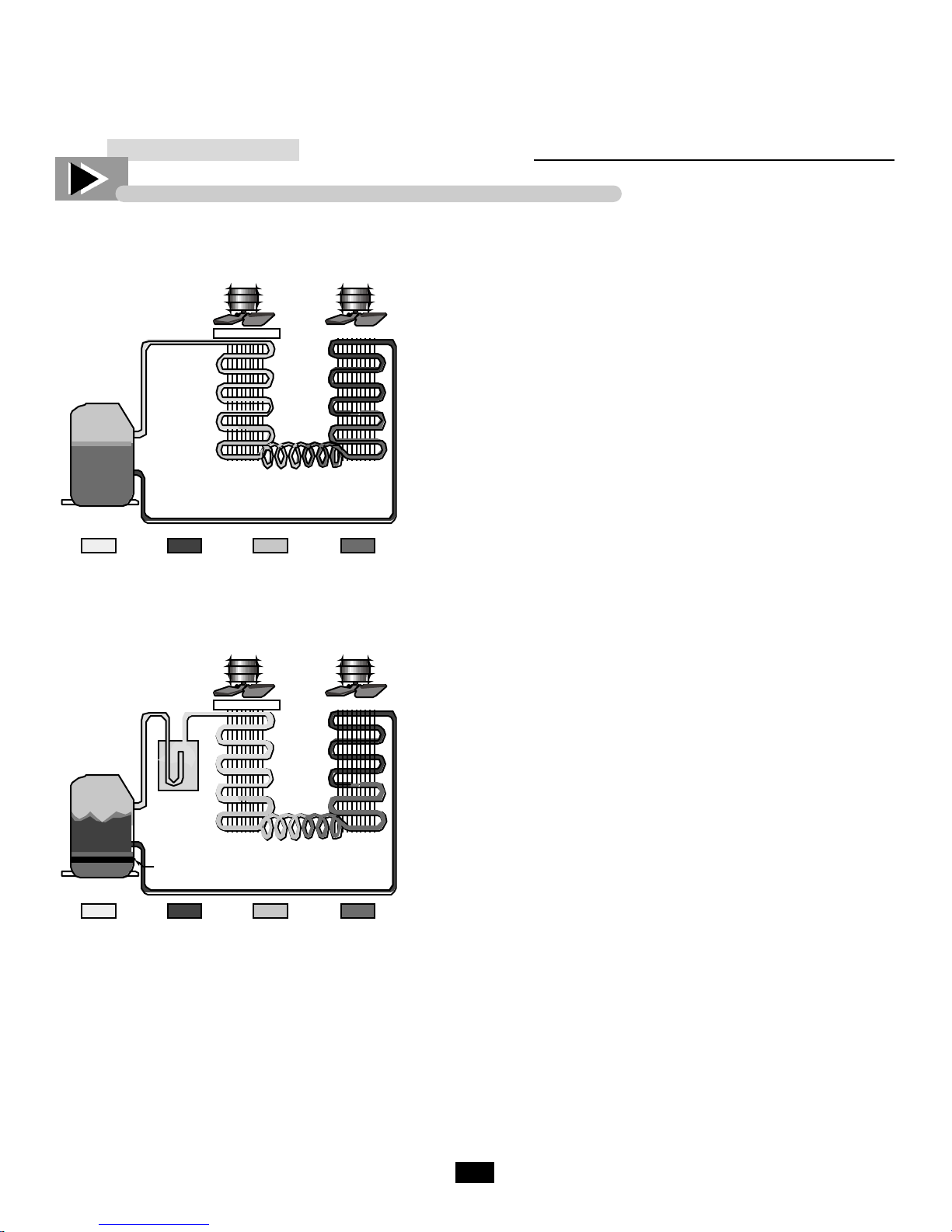

CFC & Refrigeration Basics

BASIC REFRIGERATION

THE CAPILLARY TUBE SYSTEM

Suction

Line

Capillary

Tube

Heat

Exchanger

Evaporator

Accumulator

Condenser

FilterDrie

Motor Compressor

LOW PRESSURE

GAS

Starting at the Capillary Tube, refrigerant flows into

the evaporator and changes from a liquid to a gas. As it

absorbs heat, after leaving the evaporator, it flows

through the accumulator. The accumulator is a part

that is designed like a reservoir to allow any refrigerant,

that has not changed from a liquid to a gas, space to do

so before returning to the compressor. After flowing

through the accumulator, refrigerant flows through the

s u c t i o n line as a low pressure gas into the compressor.

The compressor pumps the refrigerant from a low pressure gas to a high pressure gas and forces it into the

condenser. In the condenser with a fan circulating air

over it the refrigerant condenses from high pressure

HIGH PRESSURE

GAS

LOW PRESSURE

LIQUID

HIGH PRESSURE

LIQUID

gas to high pressure liquid. After leaving the condenser

refrigerant flow through the drier which is designed to

remove any particles or moisture in the system.

Refrigerant then flows through the liquid line into the

capillary tube. The capillary tube is designed to allow

a certain amount of refrigerant to flow through it to

keep the evaporator evenly flooded. The capillary tube

is taped to the suction line to cool the liquid to allow

the best heat transfer. When the refrigerant enters the

evaporator as a liquid, warm air from inside the cabinet

is circulated through the evaporator coil and the heat

from the air is then absorbed in the refrigerant.

Thermostat

Senses evaporator

temperature

@40°F cuts in starts compressor

@18°F cuts out shuts compressor

off

Evaporator

As air is pushed

through the

evaporator by the

fan motors liquid

refrigerant absorbs

heat through the

walls of the

evaporator coils and

vaporizes - thus

becoming a low

pressure gas.

®

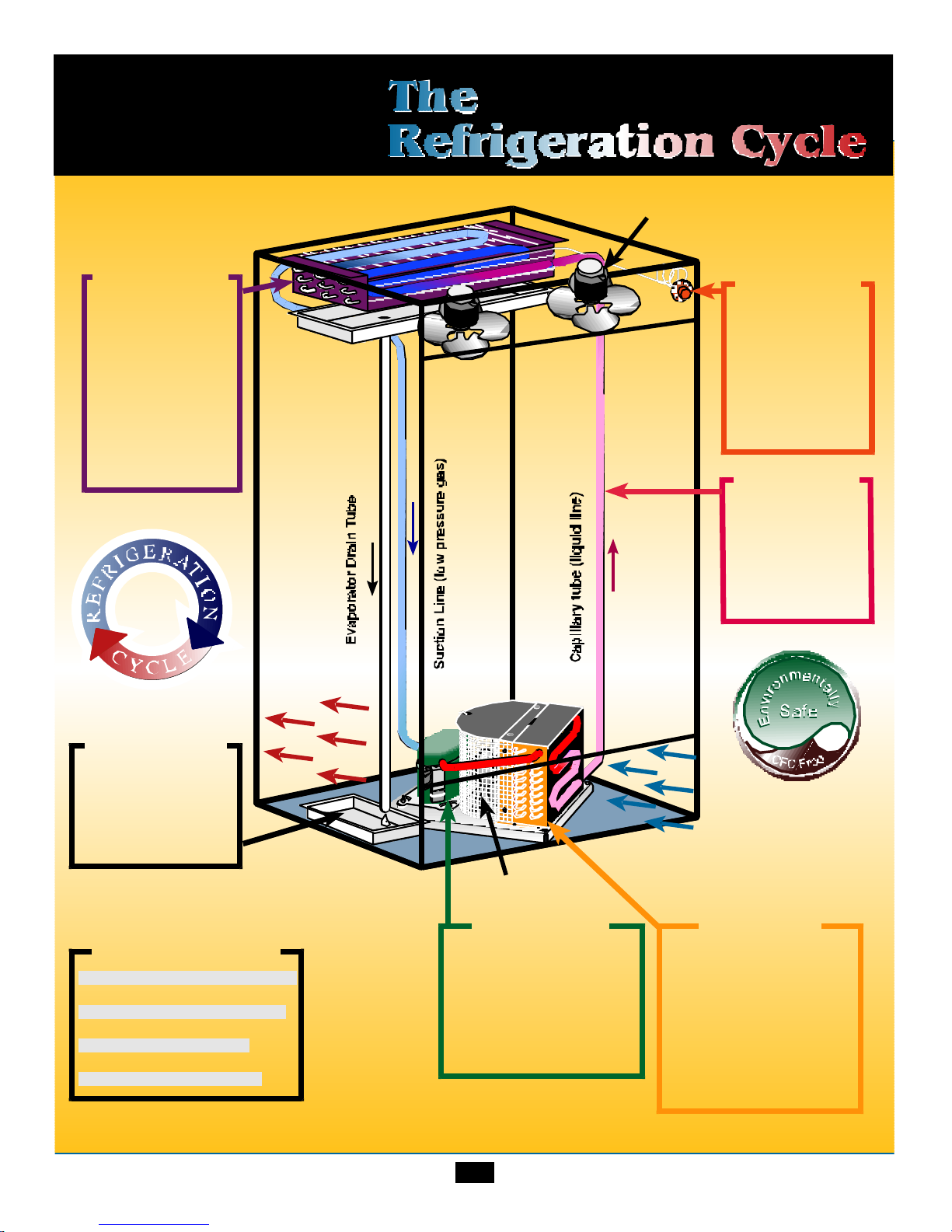

24

®

Evaporator

Fan Motor

Condensate

Pan

The resulting warm air

from the condensor

blows over the

condensate pan and

evaporates the water.

Hot air out

Cool air in

Capillary

Tube

Meters the amount

of liquid refrigerant

into the evaporator

where it absorbs

heat.

Color Chart

Dark Blue = Low pressure liquid

Light Blue = Low pressure gas

Red = High pressure gas

Pink = High pressure liquid

Compressor

Fan Motor

Compressor

Combines heat absorbed

in the evaporator coils with

heat of compression from

the piston stroke then

pushes high pressure gas

(vapor) on into the

condenser.

Condenser

High pressure gas is

condensed into a high

pressure liquid when the

heat is removed. By pulling

air in the front of the

condenser by means of the

fan motor. The air will be

used to evaporate the drain

pan water.

25

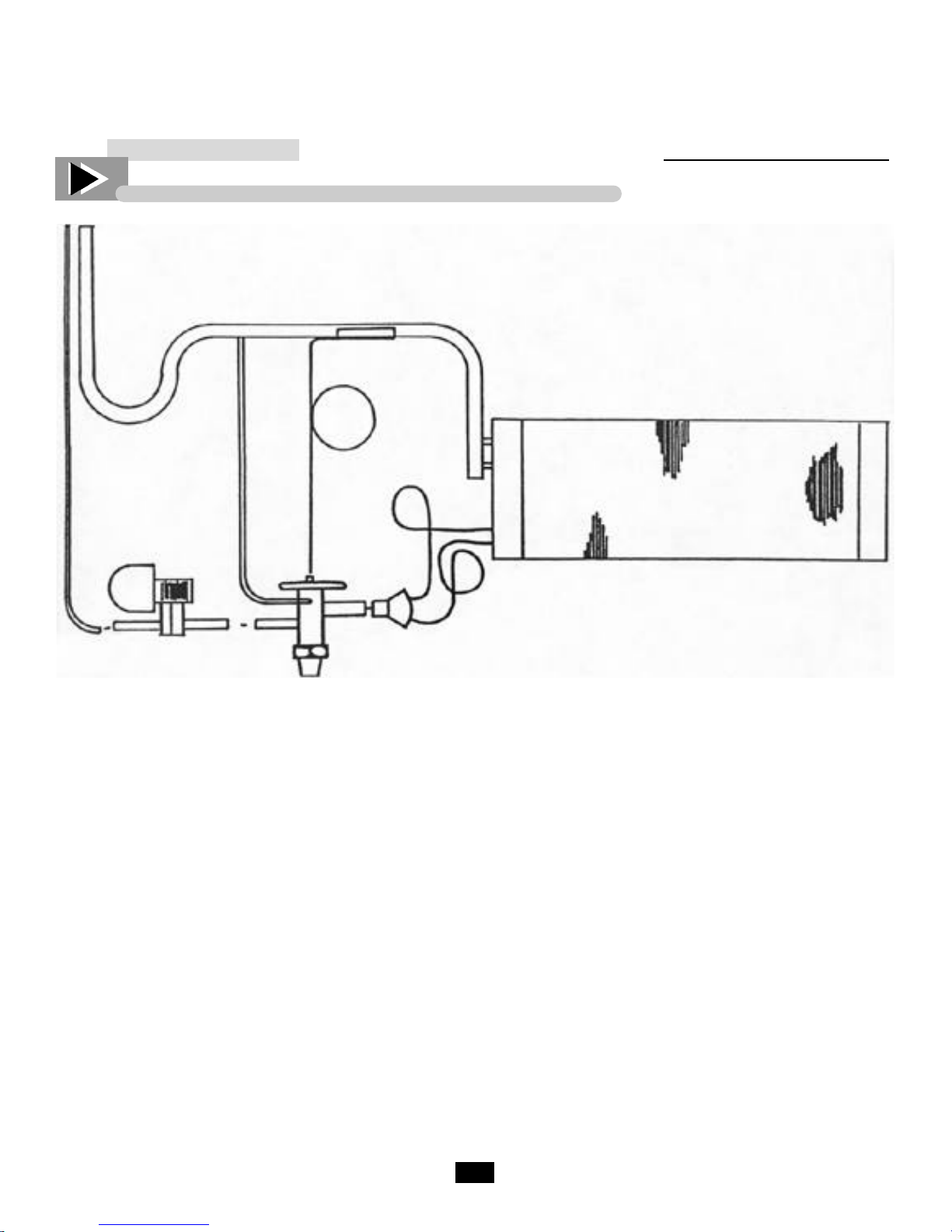

TRUE’S REMOTE SYSTEM - HOW IT WORKS

Liquid and Suction

Tubing

‘P’ Trap

TXV Bulb

Suction Line

External

Equalizer

Refrigeration Schematic Diagram

TXV

Liquid Line

Solenoid

Distributor

with Nozzle

The suction line will exit the evaporator coil as usual

for self-contained models, except it shall include an

Oil “P” trap. This is used to trap oil in low velocity

suction gases at a point just prior to a vertical rise.

Whether the compressor is to be located above or

below the evaporator, (True does not have control

over this), the suction will always have a “P” trap in

case the compressor is installed overhead.

The liquid line shall enter the cabinet and go directly to the liquid line solenoid, this is a normally

closed refrigerant valve which will be energized and

wired in series with the thermostat. When the thermostat is closed (requires refrigeration) the solenoid

will be energized to open, allowing refrigerant to

pass to the “thermal expansion valve” (TXV). The

TXV allows refrigerant through to the evaporator

coil. If the evaporator has more than one circuit, a

Feeder

Tubes

Evaporator

Coil

distributor is used which evenly distributes refrigerant to each circuit. The TXV is made to open and

close by its sensing bulb which senses suction line

temperature on the other side of the evaporator. The

sensing bulb has the same refrigerant that is used in

the refrigeration system. When hot air passes over

the evaporator coil and warms the refrigerant, the

sensing bulb senses the warm condition and pushes

the sensing valve open. When too much refrigerant

flows into the evaporator, the sensing bulbs refrigerant cools and contracts allowing the diaphragm to

ease away the needle valve, thus closing the valve.

The external equalizer is another sensing element

which helps the sensing bulb to more accurately feed

refrigerant. The external equalizer line must be

down-stream of the TXV bulb. The TXV bulb

should be insulated with corktape.

CFC & REFRIGERATION BASICS

26

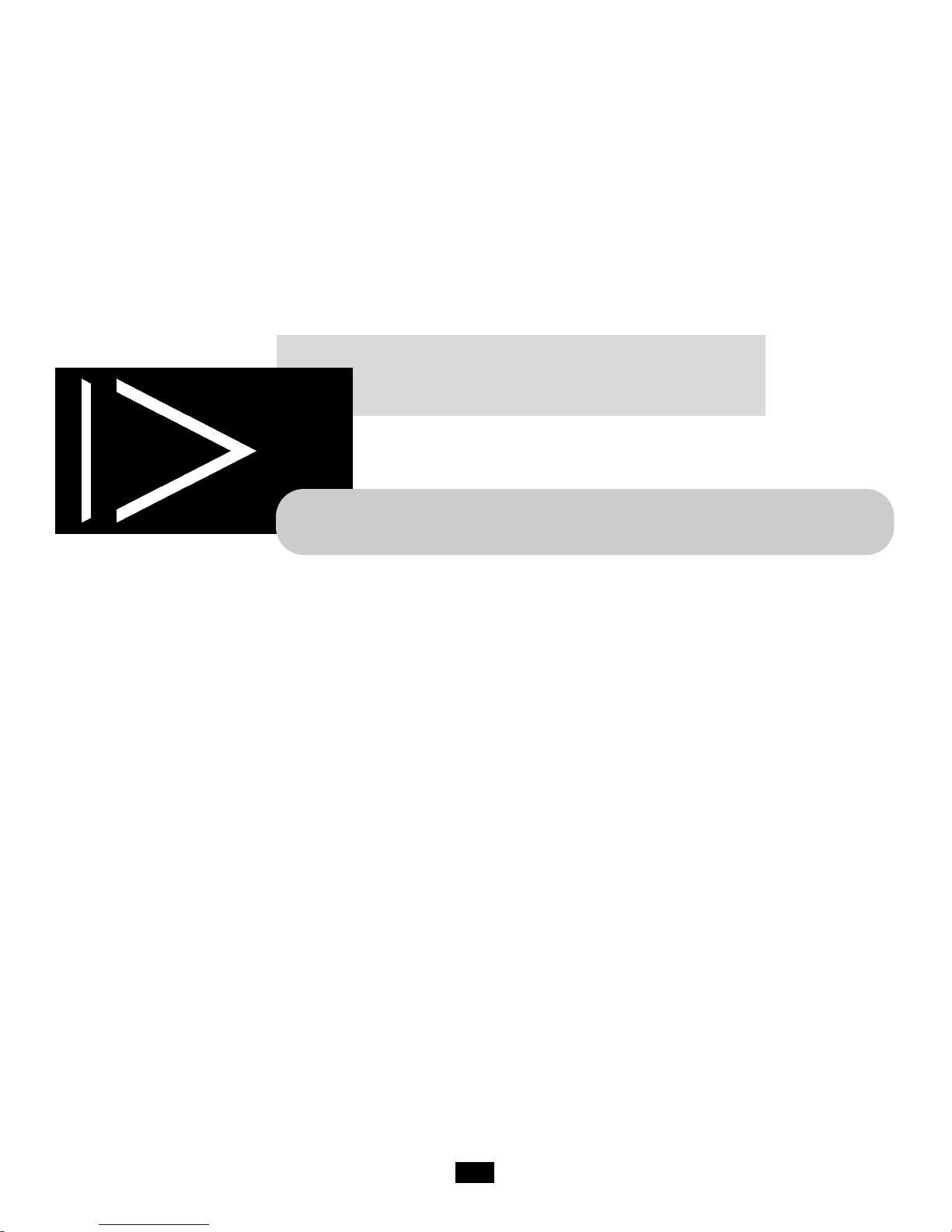

BASIC REFRIGERATION

Control of Liquid Refrigerant Floodback To The Compressor During Operation

Compressor

LOW PRESSURE

GAS

Compressor

HIGH PRESSURE

GAS

Accumulator

Crankcase

Heater

Fan Fan

Filter

Evaporator Condenser

Expansion Device

LOW PRESSURE

LIQUID

Fan Fan

Filter

Evaporator Condenser

Expansion Device

HIGH PRESSURE

LIQUID

Liquid floodback during operation can be caused by fan

failure, or dirty clogged filters that can reduce the heat

transfer rate to such a point that the liquid refrigerant

floods through, instead of vaporizing. When this situation

occurs, liquid refrigerant may enter the compressor under

conditions which result in separation of the oil and refrigerant. This separation may result in an accumulation of the

refrigerant under the oil. Thus, when the compressor is

started, the first liquid to be pumped to the bearings will

probably be refrigerant, not oil. Even if this oil-refrigerant

separation does not occur, the large amount of liquid refrigerant in the crankcase will instantly vaporize and boil away

the oil charge when the compressor starts. Thereby leaving

the compressor oil-starved for many seconds.

Liquid floodback can be prevented by the application of a

properly designed and sized suction line accumulator.

Using a totally new concept, Tecumseh engineers have

designed a suction line accumulator available in eight basic

sizes covering a full range of system applications and

refrigerant. When properly selected based upon system

c h a rge, a Tecumseh suction line accumulator will improve

compressor reliability and endurance by preventing damaging liquid refrigerant floodback.

LOW PRESSURE

GAS

HIGH PRESSURE

GAS

LOW PRESSURE

LIQUID

HIGH PRESSURE

LIQUID REFRIGERANT ACCUMULATION IN THE COMPRESSOR CAN ALSO BE CAUSED BY

LIQUID MIGRATION TOTHE COMPRESSOR DURING PERIODS OF SHUTDOWN. THIS CONDITION CAN BE CONTROLLED BY THE APPLICATION OF A CRANKCASE HEATER. A SUCTION

LINE ACCUMULATOR DOES NOTHING TO PREVENT LIQUID MIGRATION AND ACRANKCASE

HEATER DOES NOTHING TO PREVENT LIQUID FLOODBACK. EACH WITHOUT THE OTHER

IS HALF A JOB - BOTH TOGETHER PROVIDE BALANCED COMPRESSOR PROTECTION.

LIQUID

Notes

28

Using the following instructions you will be able to make cabinet

exterior repairs along with other general cabinet repairs.

GENERAL CABINET

MAINTENANCE

AND REPAIRS

29

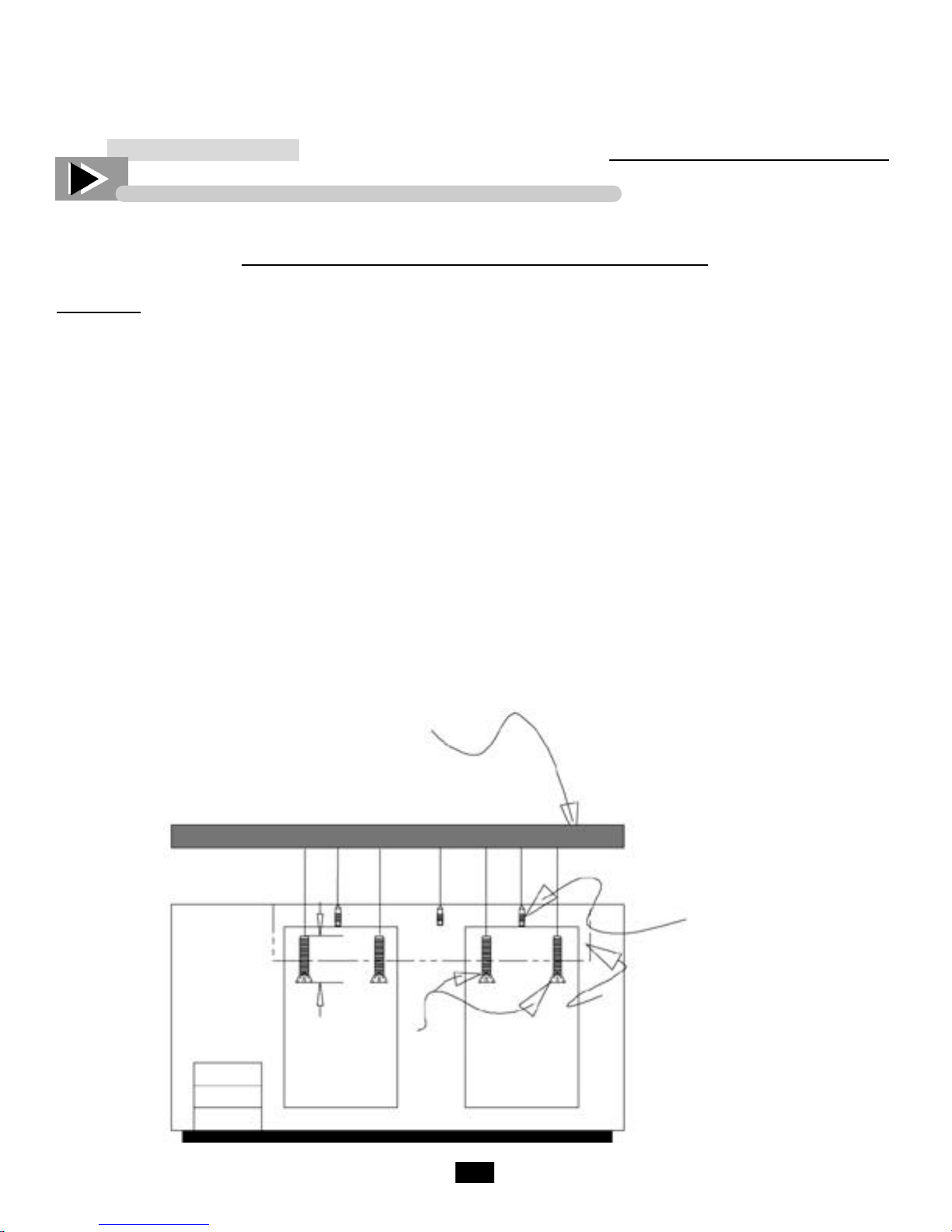

TOP REMOVAL FOR TBB & TDD UNITS

TOP REMOVAL FOR TBB & TDD UNITS

Disconnect the power to the unit.

Locate and remove screws on the inside of the cabinet going through the evaporator housing and into the bottom of the counter top.

Locate and remove the screws securing the line set cover to the top located to the left of the evaporator housing.

Remove the two screws inside the door jamb going through the jamb into the bottom of the top. There will be

two screws in each door on multiple door units.

Cut the silicone seal that runs along both ends and along the back of the unit. Silicone seal is wrapped around

the front wall of multiple door units.

To remove top lift front up approximately 2-3 inches and push backward to unlock lip in back of top.

To reinstall top, carefully align the groove in the back with lip on cooler base. Slide forward, reinstall all

screws and re-silicone around cabinet edge.

3”

Top Screws

Top

Evaporator

Housing Screws

Evaporator Housing

30

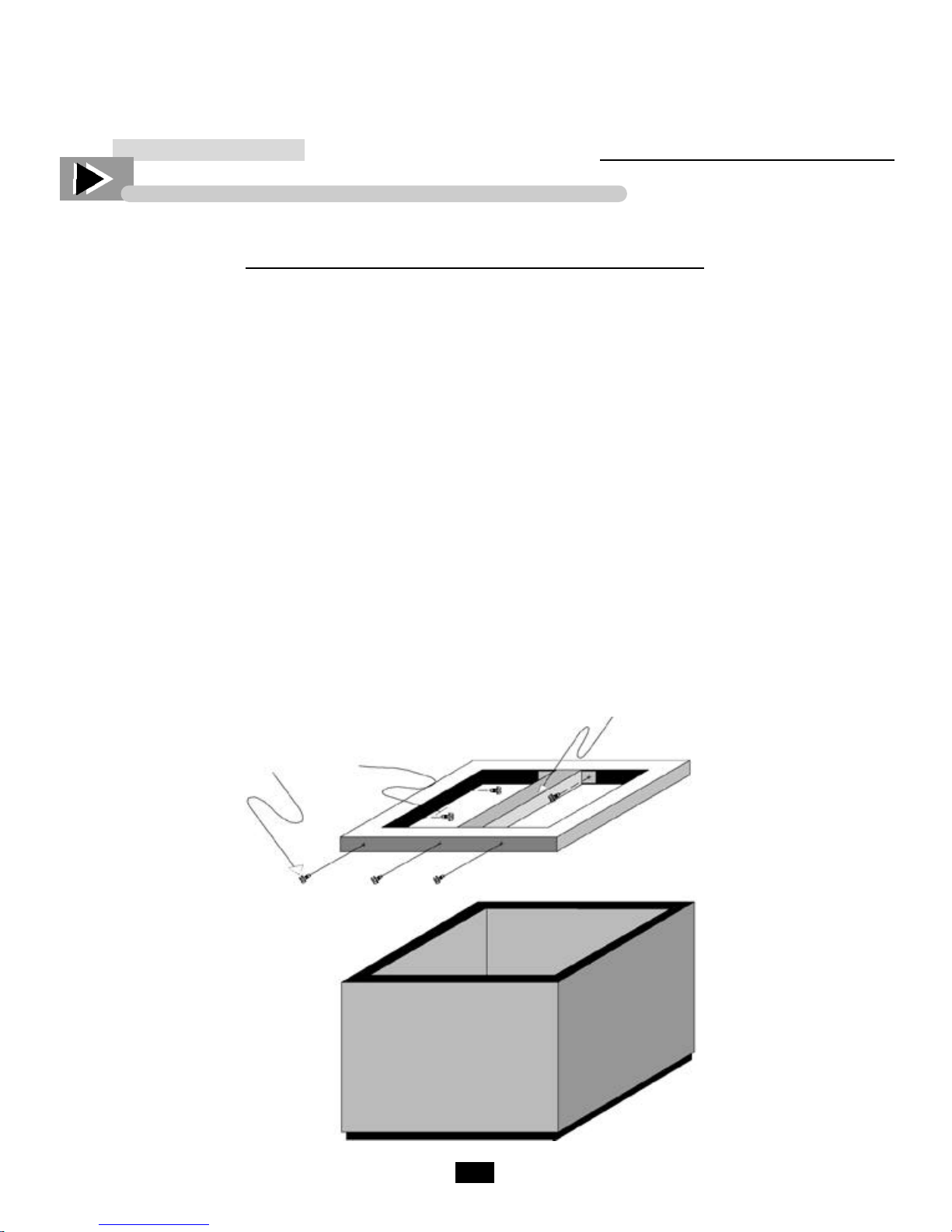

TOP REMOVALFOR TD & T-GC UNITS

TOP REMOVAL FOR TD & T-GC UNITS

1. Turn unit off and remove lids.

2. Remove screws along back of cabinet top.

3. Remove screws on each side, going through lid slide rails, inside cooler.

4. Remove screws along front of top under inside ledge, also remove the two screws holding center trunion

on units with more than one door.

5. Lift top to approximately 45 degrees while pushing top forward at same time. Top will lift off lip in front.

T-50-GC has heater wire looped through center trunion. Please becareful when removing top. Before

reinstalling, inspect heater wire to make sure it is not damaged.

6. To reinstall top, while holding top at 45 degree angle hook top on lip at front of cabinet and lay down while

pushing backwards on top, when laid completely down press firmly on top to provide a good seal.

7. Reinstall all screws along inside of cabinet and along back of top on outside of cabinet.

8. Reinstall doors and turn unit on.

Lid

Trunion

Top Screws

Loading...

Loading...