Page 1

TRUE

food service equipment, inc.

CONGRATULATIONS!

You have just purchased the finest commercial refrigerator

available. You can expect many years of trouble-free operation.

TABLE OF CONTENTS

SAFETY INFORMATION

Safety Precautions 1

Proper Disposal, Connecting Electricity, & Adapter Plugs 2

INSTALLATION

Ownership & Uncrating 3

Wire Gauge Chart & Electrical Installation 3

Locating and Leveling 5

Installation of Legs or Castors 6

Sealing Cabinet to the Floor 8

SETUP

Standard Accessories 9

Cabinet Adjustment 11

INSTALLATION MANUAL

gdm freezer/refrigerator

GDM-23

OPERATION

Startup 13

Mechanical Temperature Controls Sequence of Operation 13

Electronic Temperature Controls Sequence of Operation 19

MAINTENANCE, CARE, CLEANING

Cleaning Condenser Coil 29

Important Warranty Information 30

Stainless Steel Equipment Care and Cleaning 31

General Maintenance 32

WARRANTY

Warranty 33

GDM-49

GDM-69

gdm freezer/refrigerator

TRUE FOOD SERVICE EQUIPMENT, INC.

2001 East Terra Lane • O’Fallon, Missouri 63366-4434

(636)-240-2400 • FAX (636)-272-2408 • INT'L FAX (636)272-7546 • (800)-325-6152

Parts Department (800)-424-TRUE • Parts Department FAX# (636)-272-9471

Web: www.truemfg.com

INSTALLATION MANUAL

Page 2

TRUE

www

glass door merchandisers

.truemfg.com

NOTICE TO CUSTOMER

Loss or spoilage of products in your refrigerator/

freezer is not covered by warranty. In addition to

following recommended installation procedures

you must run the refrigerator/freezer 24 hours

prior to usage.

SAFETY INFORMATION

How to Maintain Your True Refrigerator to Receive the Most Efficient and Successful Operation.

You have selected one of the finest commercial refrigeration units made. It is manufactured under strict quality controls with only the best

quality materials available. Your TRUE cooler when properly maintained will give you many years of trouble-free service.

WARNING: Use this appliance for its intended purpose as described in this Owner Manual.

TO LOCATE REFRIGERANT TYPE, SEE SERIAL LABEL INSIDE CABINET. This cabinet may contain fluorinated greenhouse

gas covered by the Kyoto Protocol (please refer to cabinet’s inner label for type and volume, GWP of 134a= 1,300. R404a= 3,800).

FOR HYDROCARBON REFRIGERATION ONLY (R-290) SEE BELOW:

• DANGER - Risk of fire or explosion. Flammable refrigerant used. Do not use mechanical devices to defrost refrigerator. Do not

puncture refrigerant tubing.

• DANGER - Risk of fire or explosion. Flammable refrigerant used. To be repaired only by trained service personnel. Do not puncture

refrigerant tubing.

• CAUTION - Risk of fire or explosion. Flammable refrigerant used. Consult repair manual/owner’s guide before attempting to service

this product. All safety precautions must be followed.

• CAUTION - Risk of fire or explosion. Dispose of properly in accordance with federal or local regulations. Flammable refrigerant used.

• CAUTION - Risk of fire or explosion due to puncture of refrigerant tubing; follow handling instructions carefully. Flammable refrigerant

used.

• CAUTION - Keep clear of obstruction all ventilation openings in the appliance enclosure or in the structure for building-in.

SAFETY PRECAUTIONS

When using electrical appliances, basic safety precautions should be

followed, including the following:

• This refrigerator must be properly installed and located in

accordance with the Installation Instructions before it is used.

• Do not allow children to climb, stand or hang on the shelves

in the refrigerator. They could damage the refrigerator and

seriously injure themselves.

• Do not touch the cold surfaces in the freezer compartment

when hands are damp or wet. Skin may stick to these

extremely cold sur faces.

• Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance. Do not store

explosive substances such as aerosol cans with a flammable

propellant in this appliance.

• Keep f ingers out of the “pinch point” areas; clearances between

the doors and between the doors and cabinet are necessarily

small; be careful closing doors when children are in the area.

• Unplug the refrigerator before cleaning and making repairs.

• Setting temperature controls to the 0 position does not

remove power to the light circuit, perimeter heaters, or

evaporator fans.

NOTE: We strongly recommend that any servicing be preformed

by a qualified technician.

1

Page 3

TRUE

208-230/60/1

glass door merchandisers

www

.truemfg.com

WARNING!DANGER!

RISK OF CHILD

ENTRAPMENT

PROPER DISPOSAL OF THE REFRIGERATOR

Child entrapment and suffocation are not problems of the past.

Junked or abandoned refrigerators are still dangerous… even if they

will sit for “just a few days.” If you are getting rid of your old refrigerator, please follow the instructions below to help prevent accidents.

BEFORE YOU THROW AWAY YOUR OLD

REFRIGERATOR OR FREEZER:

• Take off the doors.

• Leave the shelves in place so that children may not easily climb

inside.

APPLIANCE DISPOSAL

When recycling appliance please make sure that the refrigerants are

handled according to local and national codes, requirements and

regulations.

REFRIGERANT DISPOSAL

Your old refrigerator may have a cooling system that uses “Ozone

Depleting” chemicals. If you are throwing away your old refrigerator,

make sure the refrigerant is removed for proper disposal by a qualified service technician. If you intentionally release any refrigerants you

can be subject to fines and imprisonment under provisions of the

environmental regulations.

USE OF EXTENSION CORDS

NEVER USE AN EXTENSION CORD! TRUE will not war-

ranty any refrigerator that has been connected to an extension cord.

REPLACEMENT PARTS

• Component parts shall be replaced with like components.

• Servicing shall be done by authorized service personnel, to

minimize the risk of possible ignition due to incorrect parts or

improper service.

• Lamps must be replaced by identical lamps only.

• If the supply cord is damaged, it must be replaced by a special

cord or assembly available from the manufacturer or its service

agent.

HOW TO CONNECT ELECTRICITY

DO NOT, UNDER ANY CIRCUMSTANCES, CUT OR

REMOVE THE GROUND PRONG FROM THE POWER

CORD. FOR PERSONAL SAFETY, THIS APPLIANCE

MUST BE PROPERLY GROUNDED.

The power cord from this appliance is equipped with a grounding

plug which minimizes the possibility of electric shock hazard.

Have the wall outlet and circuit checked by a qualified electrician to

make sure the outlet is properly grounded.

If the outlet is a standard 2-prong outlet, it is your personal responsibility and obligation to have it replaced with the properly grounded

wall outlet.

The refrigerator should always be plugged into it’s own individual

electrical circuit, which has a voltage rating that matches the rating

plate.

This provides the best performance and also prevents overloading

building wiring circuits which could cause a fire hazard from overheated wires.

Never unplug your refrigerator by pulling on the power cord. Always

grip plug firmly and pull straight out from the outlet.

Repair or replace immediately all power cords that have become

frayed or otherwise damaged. Do not use a cord that shows cracks

or abrasion damage along its length or at either end.

When removing the refrigerator away from the wall, be careful not

to roll over or damage the power cord.

If supply power cord is damaged it should be replaced with original

equipment manufacture parts. To avoid hazard this should be done

by a qualified service technician.

USE OF ADAPTER PLUGS

NEVER USE AN ADAPTER PLUG! Because of potential safety

hazards under certain conditions, we strongly recommend against the

use of an adapter plug.

The incoming power source to the cabinet including any adapters

used must have the adequate power available and must be properly

grounded. Only adapters listed with UL should be used.

NORTH AMERICA USE ONLY!

NEMA plugs

TRUE uses these types of plugs. If you do not have the right outlet

have a certified electrician install the correct power source.

NOTE: International plug configurations vary by voltage and country.

115/60/1

NEMA-5-15R

115/208-230/1

NEMA-14-20R

115/60/1

NEMA-5-20R

NEMA-6-15R

2

Page 4

TRUE

glass door merchandisers

INSTALLATION

OWNERSHIP

To ensure that your unit works properly from the first day, it must

be installed properly. We highly recommend a trained refrigeration

mechanic and electrician install your TRUE equipment. The cost of a

professional installation is money well spent.

www

.truemfg.com

Before you start to install your TRUE unit, carefully inspect it for

freight damage. If damage is discovered, immediately file a claim with

the delivery freight carrier.

TRUE is not responsible for damage incurred during shipment.

UNCRATING

TOOLS REQUIRED

• Adjustable Wrench

• Phillips Screwdriver

• Level

The following procedure is recommended for uncrating the unit:

A. Remove the outer packaging, (cardboard and bubbles or

styrofoam corners and clear plastic). Inspect for concealed

damage. Again, immediately file a claim with the freight carrier

if there is damage.

B. Move your unit as close to the final location as possible before

removing the wooden skid.

C. Remove door bracket on swinging glass door models (see

image 1-2). Do not throw the bracket or blocks away. For

future cabinet movement the bracket and blocks will need to

be installed so the glass door does not receive any damage.

(See image for bracket and shipping block removal)

NOTE: KEYS FOR COOLERS WITH DOOR LOCKS

ARE LOCATED IN WARRANTY PACKETS.

3 4

5 6

ELECTRIC INSTALLATION & SAFETY

INFORMATION

• If the supply cord is damaged, it must be replaced by a special

cord or assembly available from the manufacturer or its service

agent.

• Lamps must be replaced by identical lamps only.

• Appliance tested according to the climate classes 5 and 7

temperature and relative humidity.

ELECTRICAL INSTRUCTIONS

A. Before your new unit is connected to a power supply, check the

incoming voltage with a voltmeter. If anything less than 100% of

the rated voltage for operation is noted, correct immediately.

B. All units are equipped with a service cord, and must be

powered at proper operating voltage at all times. Refer to

cabinet data plate for this voltage.

TRUE RECOMMENDS THAT A SOLE USE CIRCUIT BE

DEDICATED FOR THE UNIT.

WARNING: Compressor warranties are void if compressor burns

out due to low voltage.

WARNING: Power supply cord ground should not be removed!

WARNING: Do not use electrical appliances inside the food stor-

age compartments of the appliances unless they are of the type

recommended by the manufacturer.

NOTE: To reference wiring diagram, remove front louvered grill,

wiring diagram is positioned on the inside cabinet wall.

1

2

3

Page 5

TRUE

glass door merchandisers

WIRE GAUGE CHART

www

.truemfg.com

115 Volt s Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

2 14 14 14 14 14 14 14 14 14 14 14 14

3 14 14 14 14 14 14 14 14 14 14 14 12

4 14 14 14 14 14 14 14 14 14 12 12 12

5 14 14 14 14 14 14 14 12 12 12 10 10

6 14 14 14 14 14 14 12 12 12 10 10 10

7 14 14 14 14 14 12 12 12 10 10 10 8

8 14 14 14 14 12 12 12 10 10 10 8 8

9 14 14 14 12 12 12 10 10 10 8 8 8

10 14 14 14 12 12 10 10 10 10 8 8 8

12 14 14 12 12 10 10 10 8 8 8 8 6

14 14 14 12 10 10 10 8 8 8 6 6 6

16 14 12 12 10 10 8 8 8 8 6 6 6

18 14 12 10 10 8 8 8 8 8 8 8 5

20 14 12 10 10 8 8 8 6 6 6 5 5

25 12 10 10 8 8 6 6 6 6 5 4 4

30 12 10 8 8 6 6 6 6 5 4 4 3

35 10 10 8 6 6 6 5 5 4 4 3 2

40 10 8 8 6 6 5 5 4 4 3 2 2

45 10 8 6 6 6 5 4 4 3 3 2 1

50 10 8 6 6 5 4 4 3 3 2 1 1

230 Volts Distance In Feet To Center of Load

Amps 20 30 40 50 60 70 80 90 100 120 140 160

5 14 14 14 14 14 14 14 14 14 14 14 14

6 14 14 14 14 14 14 14 14 14 14 14 12

7 14 14 14 14 14 14 14 14 14 14 12 12

8 14 14 14 14 14 14 14 14 14 12 12 12

9 14 14 14 14 14 14 14 14 12 12 12 10

10 14 14 14 14 14 14 14 12 12 12 10 10

12 14 14 14 14 14 14 12 12 12 10 10 10

14 14 14 14 14 14 12 12 12 10 10 10 8

16 14 14 14 14 12 12 12 10 10 10 8 8

18 14 14 14 12 12 12 10 10 10 8 8 8

20 14 14 14 12 10 10 10 10 10 8 8 8

25 14 14 12 12 10 10 10 10 8 8 6 6

30 14 12 12 10 10 10 8 8 8 6 6 6

35 14 12 10 10 10 8 8 8 8 6 6 5

40 14 12 10 10 8 8 8 6 6 6 5 5

50 12 10 10 8 6 6 6 6 6 5 4 4

60 12 10 8 6 6 6 6 6 5 4 4 3

70 10 10 8 6 6 6 5 5 4 4 2 2

80 10 8 8 6 6 5 5 4 4 3 2 2

90 10 8 6 6 5 5 4 4 3 3 1 1

100 10 8 6 6 5 4 4 3 3 2 1 1

4

Page 6

TRUE

glass door merchandisers

www

.truemfg.com

LOCATING

A. Remove louver from the front of cabinet (see page 19 for

louver grill removal / reinstallation) and backguard (if applicable)

from rear of cabinet.

B. Skid bolts are located in each of 4 corners inside cabinet

bottom. (See photo A).

C. Remove skid bolts. (See photo B).

D. Cut straps if applicable. (See photo C).

E. Carefully lift cabinet off of skid.

F. Appliance tested according to the climate classes 5 and 7 for

temperature and relative humidity.

Removing skid from

A

bottom of cabinet.

LEVELING

A. Set unit in its final location. Be sure there is adequate ventilation

in your room. Under extreme heat conditions, (100°F+,

38°C+), you may want to install an exhaust fan.

WARNING: WARRANTY IS VOID IF VENTILATION IS

INSUFFICIENT.

B. Proper leveling of your TRUE cooler is critical to operating

success (for non-mobile models). Effective condensate removal

and door operation will be effected by leveling.

C. The cooler should be leveled front to back and side to side with

a level.

D. Ensure that the drain hose or hoses are positioned in the pan.

E. Free plug and cord from inside the lower rear of the cooler

(do not plug in).

F. The unit should be placed close enough to the electrical supply

so that ex tension cords are never used.

WARNING: CABINET WARRANTIES ARE VOID

IF OEM POWER CORD IS TAMPERED WITH. TRUE

WILL NOT WARRANTY ANY UNITS THAT ARE

CONNECTED TO AN EXTENSION CORD.

B

C

NOTE

When moving cabinet DO NOT push

on door hinges.

P

REMOVE COVER MAKE POWER CONNECTION

1227-5

NEPCO/CENTRALAB

5

Page 7

TRUE

Lower Rail

Assembly

g

Lower Rail Assembly

glass door merchandisers

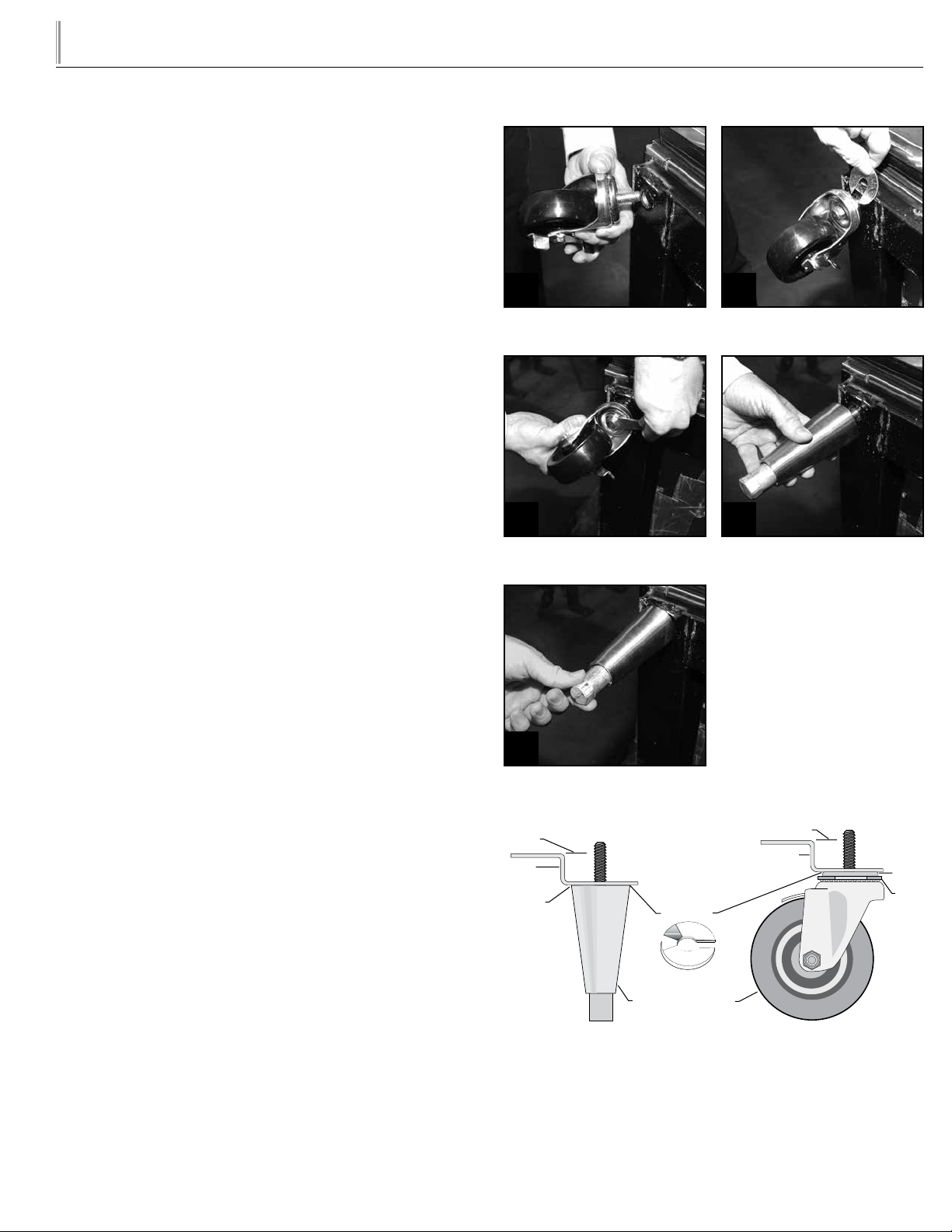

INSTALLATION OF CASTORS OR

OPTIONAL LEGS

Important Safeguard for installation of leg/castor. Images 1-5 demonstrate procedure.

SECURING CASTORS AND LEGS

To obtain maximum strength and stability of the unit, it is important

that you make sure each castor is secure. Optional legs are handtightened securely against the lower rail assembly see image 4-5. The

bearing race on the castor or the top edge of the leg must make firm

contact with the rail.

LEVELING SHIMS

Four leveling shims have been provided for leveling castored units

positioned on uneven floors. Shims must be positioned between rail

end and bearing race.

A. Turn the bearing race counter-clockwise until the cabinet is

level. Level front to back and side to side. (diagonally)

B. Install the desired number of shims, making sure the slot of the

shim is in contact with the threaded stem of the castor. See

image 2.

C. If more than one shim is used, turn the slot at a 90° angle so

they are not in line.

D. Turn the bearing race clockwise to tighten and secure the

castor by tightening the anchoring bolt with a 3/4 inch openend wrench or the tool provided. See image 3.

1

Thread castor into the underside of

cabinet frame rail.

3

Use the tool provided to tighten the

castor into place.

www

.truemfg.com

2

For leveling, insert the shim between

castor and frame rail.

4

Thread leg into cabinet bottom

frame rail.

CAUTION: TO AVOID DAMAGE TO LOWER RAIL

ASSEMBLY, SLOWLY RAISE UNIT TO UPRIGHT

POSITION.

NOTE: OPEN HOLES LOCATED ON THE CROSS

MEMBERS OF THE FRAME RAIL SHOULD BE

PLUGGED BEFORE UNIT IS IN USE.

5

The end of the leg is adjustable for

easy leveling.

Rail End

Snug Fit

Here

Leveling Shim

Rail End

CastorLeg

Snug Fit

Here

Bearin

Race

6

Page 8

TRUE

glass door merchandisers

INSTALLING OPTIONAL CASTORS ON

GDM-10 AND GDM-12 MODELS

FINAL LOCATION

A. Place Styrofoam corners behind cooler for cushion and carefully

tilt unit on it’s back.

B. Remove the louvered grill by removing four phillips-head

screws.

C. Remove the four bolts from the skid with an adjustable wrench,

and locate the four castors. Castors are placed inside cooler,

within the bubble wrap.

D. Install one castor in each of the four female threaded areas as

indicated.

NOTE: Two out of the four castors are designated with an “F” for

front. These are provided with hand-brakes. Position these castors in

FRONT of the unit.

E. When all castors have been threaded fully, replace grill and lift

unit; positioning it into its final location.

F. Ensure that the two front castors are positioned FORWARD

as illustrated and locked down with the hand-brakes.

WARNING: Unit may tip forward if procedure “F” is not strictly

followed.

www

.truemfg.com

G. Units f inal location should be adequately ventilated. Conditions

where heat exceeds 100ºF require an exhaust fan.

H. Ensure that the drain hose for hoses are positioned in the pan.

I. Free plug and cord from inside the lower rear of the cooler (Do

Not Plug In.)

WARNING: Warranty is VOID if ventilation is insufficient.

J. The unit should be placed close enough to the electrical supply

so that ex tension cords are NEVER used.

WARNING: Cabinet warranties are void if OEM power cord is

tampered with. TRUE will not warranty any units that are connected

to an extension cord.

K. Proper leveling of your TRUE cooler is critical to operating

success. Effective condensate removal and door operation will

be effected by leveling. Adjust castors or add shims.

POSITIONING OF THE

CASTOR IS CRITICAL.

ORIENT THE CASTOR IN

THE FORWARD POSITION

AS SHOWN.

7

Page 9

TRUE

glass door merchandisers

www

.truemfg.com

SEALING CABINET TO FLOOR

STEP 1 - Position Cabinet - Allow one inch between the wall and

rear of the GDM refrigerator to assure proper ventilation. For GDM

freezers 3 inches between the wall and rear of the cabinet will assure

proper ventilation.

STEP 2 - Level Cabinet - Cabinet should be level, side to side and

front to back. Place a carpenter’s level in the interior floor in four

places:

A. Position level in the inside floor of the unit near the doors.

(Level should be parallel to cabinet front). Level cabinet.

B. Position level at the inside rear of cabinet. (Again level should

be placed parallel to cabinet back).

C. Perform similar procedures to steps A & B by placing the level

on inside floor (left and right sides - parallel to the depth of the

cooler). Level cabinet.

STEP 3 - Draw an outline on the base on the floor.

STEP 4 - Raise and block the front side of the cabinet.

STEP 5 - Apply a bead of “NSF Approved Sealant”, (see list below),

to floor on half inch inside the outline drawn. The bead must be heavy

enough to seal the entire cabinet surface when it is down on the

sealant.

STEP 6 - Raise and block the rear of the cabinet

STEP 7 - Apply sealant on floor as outlined in Step 5 on other

three sides.

STEP 8 - Examine to see that cabinet is sealed to floor around

entire perimeter.

NOTE: Asphalt floors are very susceptible to chemical attack. A

layer of tape on the floor prior to applying the sealant will protect

the floor.

NSF APPROVED SEALANTS:

1. Minnesota Mining #ECU800 Caulk

2. Minnesota Mining #ECU2185 Caulk

3. Minnesota Mining #ECU1055 Bead

4. Minnesota Mining #ECU1202 Bead

5. Armstrong Cork - Rubber Caulk

6. Products Research Co. #5000 Rubber Caulk

7. G.E. Silicone Sealer

8. Dow Corning Silicone Sealer

8

Page 10

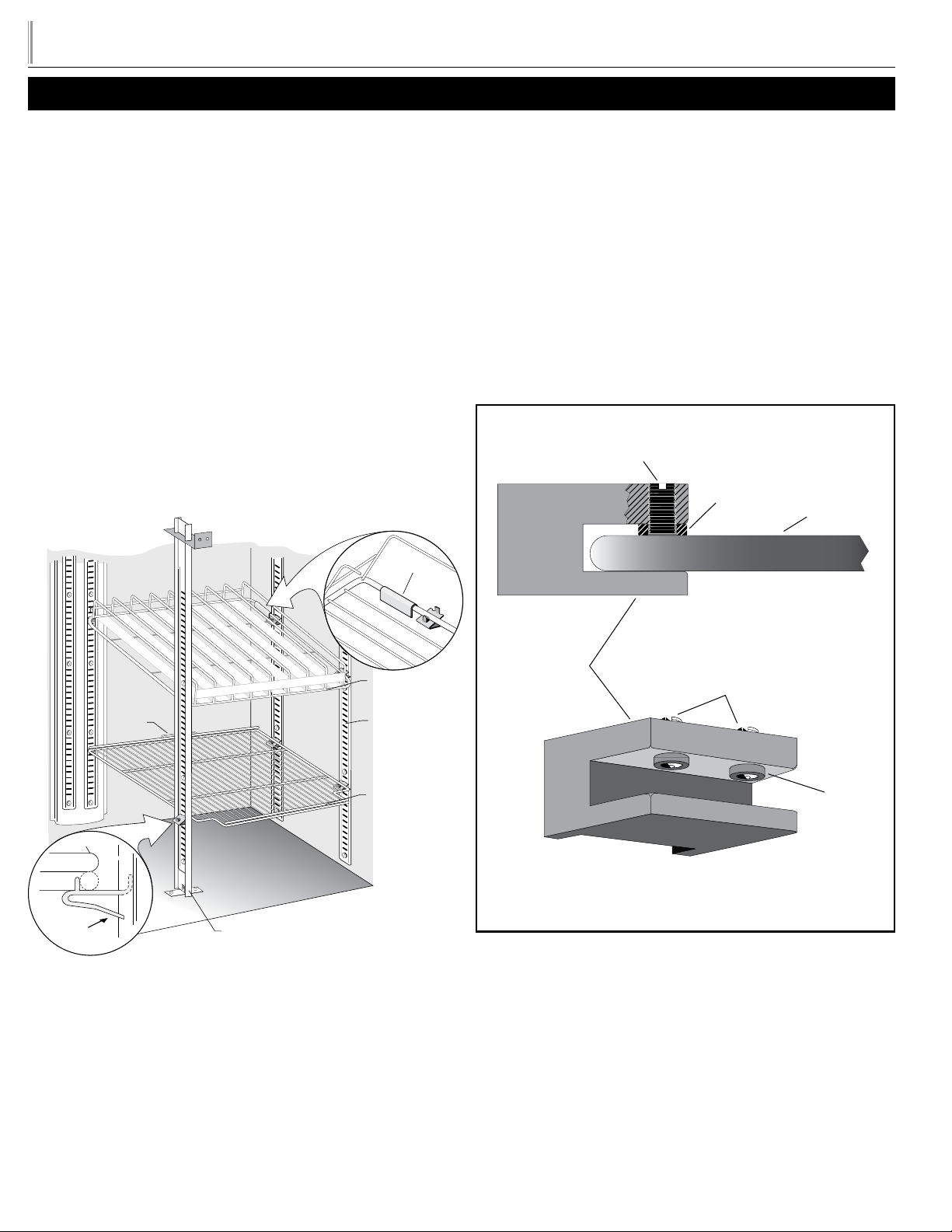

TRUE

G4SM-23RGS SHELF BRACKET ASSEMBLY

glass door merchandisers

SETUP

STANDARD ACCESSORIES

SHELVING INSTALLATION / OPERATION

SHELF INSTALLATION:

A. Hook shelf clips onto shelf standards.

B. Position all four shelf clips equal in distance from the floor for

flat shelves.

C. Lower front of gravity feed TrueTrac organizers to enable

proper feed.

D. Place shelves on shelf clips making sure all corners are seated

properly.

WIRE SHELVES: Wire shelves are oriented so that cross support

bars are facing down.

NOTE: GDM-5 models include an airflow guard on the rear of

shelves to maintain an air space at the rear of the cabinet. (see illustration).

www

.truemfg.com

TRUETRAC ORGANIZERS: TrueTrac organizers for Glass

Door Merchandisers come with a package of shelf retainer clips.

Install clip on the side to the rear of organizer (see illustration) to end

of organizer that rests against left or right outside wall.

With correct installation, the retainer clip should separate the rear of

the organizer from the rear interior wall of the cabinet.

NOTE:

No retainer clips needed on center organizers of a GDM-69.

Shelf Retaining Screw

Shelf

Clip

T-Series

& GDM-5

Airflow

Guard

Shelf

Pillaster

(I-beam)

Organizer

Shelf

Standards

Shelf

O-Ring

Glass Shelf

Retainer

Clip

Shelf Bracket

Shelf Retaining Screw

O-Ring

9

Page 11

TRUE

glass door merchandisers

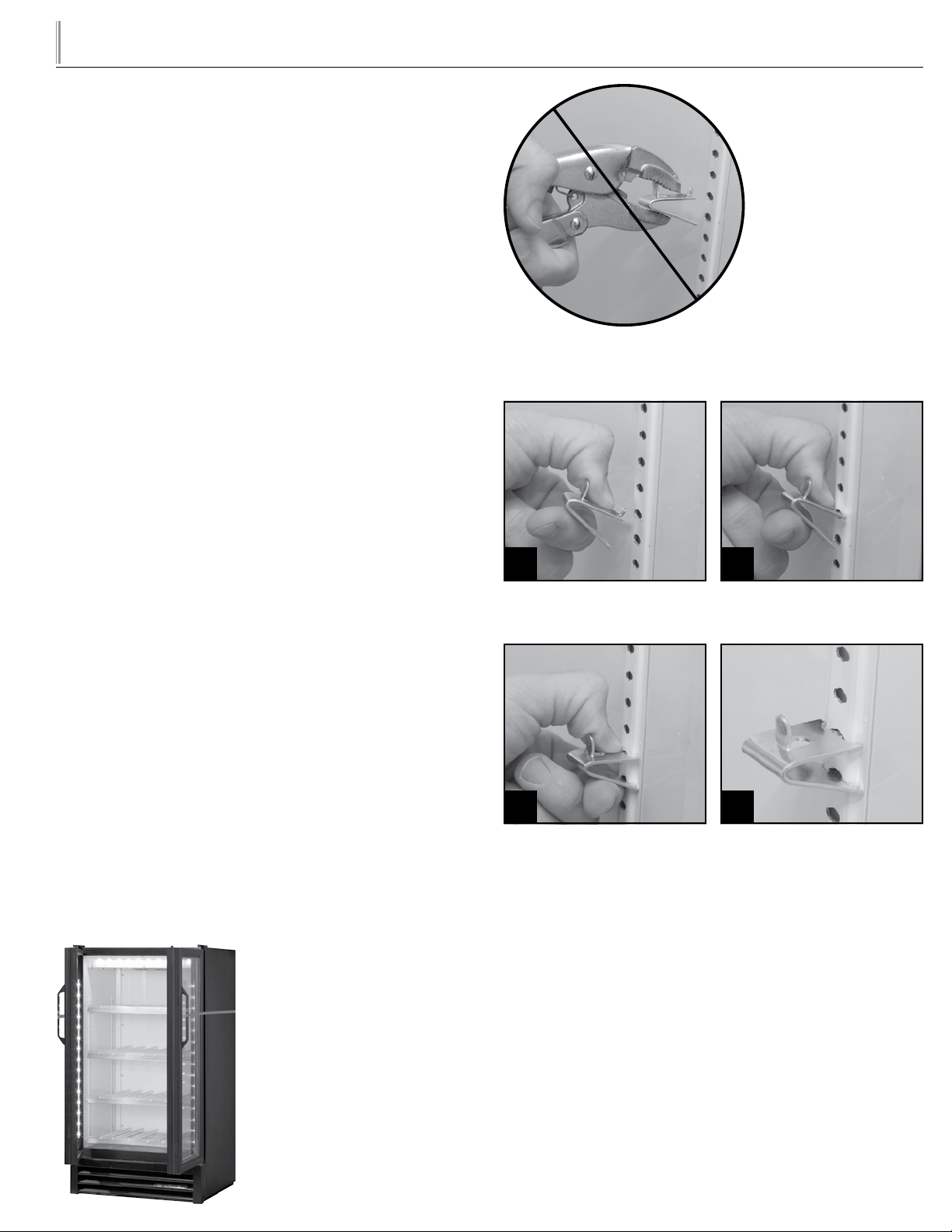

WARNING!

Do not use pliers or any crimping tools when installing shelf clips.

Altering shelf clips in any way can lead to shelving instability.

SHELF INSTALLATION:

For Proper Shelf Clip Installation Please Read The Following

Instructions.

STEP 1

Install the top tab of the shelf clip into the proper hole. Push up on

the bottom of the clip. (See image 1).

www

.truemfg.com

STEP 2

Bottom tab of the shelf clip will fit tightly. You may need to squeeze or

twist the bottom of the shelf clip to install. (See image 2 & 3).

STEP 3

After installation, the shelf clip will fit snug into the shelf standard.

The shelf clip should not be loose or able to wiggle out of the shelf

standard.

SHELF INSTALLATION TIPS

1. Install all the shelf clips before installing the shelves.

2. Start at the bottom in terms of shelf installation and work your

way up.

3. Always lay the back of each shelf down on the rear clips before

the front.

INSTALLING SHELVES

(GDM-30 ONLY)

Tape door handles back to the cabinet when installing shelves

1

Installing top tab of shelf clip

3

You may need to squeeze or twist

the bottom of the shelf clip to

install

2

Installing bottom of the shelf

clip

4

Shelf clip installation complete

10

Page 12

TRUE

glass door merchandisers

SLIDE DOOR OPERATION (CABINET ADJUSTMENT)

www

.truemfg.com

STEP 1 - Before removing slide door do not use the side latch.

Tension on the door cord is needed to execute these operation

instructions. Doors can not be removed unless placed in specific locations stated in these instructions.

STEP 2

Two Door Units: Slide the front door so it is centered on the

cabinet. The door can not be removed unless it is centered. See

image 1 for door channel openings and image 2 for centering

door.

1

(Two Door Units ONLY)

STEP 3 - After centering the door lift it up and tilt top of door towards

the back of the unit so the rollers are out of the top channel. Swing

the bottom of the door out of the bottom channel. Then remove the

door and set it down. See image 4.

4

(TWO DOOR UNITS SKIP TO STEP 6)

CENTERED DOOR

2

(Two Door Units ONLY)

Three Door Units: Slide the middle door to the right so it is

centered with the left edge of the right door. See image 3.

STEP 4 - Slide right door to the left so left edge lines up with the

left edge of TRUE Logo located above the door. See image 5. Then

lift door out of track same way as image 4.

TRUE Logo

5

(Three Door Units ONLY)

11

3

(Three Door Units ONLY)

Page 13

TRUE

glass door merchandisers

www

.truemfg.com

STEP 5 - Slide left door to the right so right edge lines up with the

end of the TRUE Logo located at the top of the door frame. See

image 6. Then lift door out of track same way as image 4.

TRUE Logo

6

(Three Door Units ONLY)

NOTE: Door cord will either be nylon cord or metal cable.

STEP 6 - Remove door cord from roller bracket. The black plastic

tab holding the door cord slides out the back. See images 7 & 8.

TO ADJUST SLIDE DOOR

STEP 1 - After cabinet is installed in a final location and correctly lev-

eled check for any openings when the slide doors are completely closed.

If there are any gaps/openings between the closed doors and cabinet,

the doors will need to be adjusted.

STEP 2 - Using a 7/16" wrench or adjustable wrench and 1/8" Allen

wrench loosen roller and move along slotted hole. After adjustment

has been made tighten the roller into place. See image 10.

10

SLIDE DOOR UNITS WITH HOLD OPEN FEATURE

These instructions explain how to keep door in open position.

A. Slide the door open.

B. Latch the door in the open position from the back side of door

(notch in track).

C. Door latch in image 1 is in the open position.

D. Door latch in image 2 is in the closed position.

7

Door roller bracket with metal cable.8Door roller bracket with nylon cord.

STEP 7 - Let the door cord slowly retract back into the door side

channel.

STEP 8 - When reinstalling door, make sure door cord grommet

attaches to roller slot closest to pulley. See image 9.

9

Door closing to the left

1 2

Rear view of door & track

12

Page 14

TRUE

glass door merchandisers

OPERATION

www

.truemfg.com

STARTUP

A. The compressor is ready to operate. Plug in the cooler.

B. Temperature controls are factory-set to give refrigerators

an approximate temperature of 35°F (1.7°C) and freezers

an approximate temperature of -10°F (-23.3°C). Allow unit

to function several hours, completely cooling cabinet before

changing the control setting.

Temperature Control Location and Settings.

• Electronic temperature control is located on rear of unit or

behind access grill.

• LAE temperature control is located on the front of cabinet

counter top or in/behind louvered grill.

• Mechanical temperature control is located inside of unit.

See website for adjustments, sequence of operation, and more

information.

C. Excessive tampering with the control could lead to service

difficulties. Should it ever become necessary to replace

temperature control, be sure it is ordered from your TRUE

dealer or recommended service agent.

D. Good air flow in your TRUE unit is critical. Be careful to

load product so that it neither presses against the back wall,

nor comes within four inches of the evaporator housing.

Refrigerated air off the coil must circulate down the back wall.

NOTE: If the unit is disconnected or shut off, wait five minutes

before starting again.

RECOMMENDATION - Before loading product we recommend

you run your TRUE unit empty for two to three days. This allows you

to be sure electrical wiring and installation are correct and no shipping damage has occurred. Remember, our factory warranty does not

cover product loss!

LIGHT SWITCH LOCATION: Light switch location depends

upon the GDM model. Most GDM models will have the light switch

located on the right side of the ceiling inside the unit. Most instances

the switch is located next to the temperature control. GDM-49’s and

72’s have the switch located on the right side of the evaporator housing along the interior ceiling. GDM-9’s, 5’s, and GDM-5PT’s have the

switch located on the left side of the ceiling. Some convenience store

GDM’s have the switch located behind the sliding doors above the

light bulb for example the GDM-33SSL-54 and the GDM-33CPT-54.

G4SM-23 models have an additional switch for the rotating display

shelves. The switch for the rotating shelves in the G4SM-23 models is

located under the sign frame.

MECHANICAL TEMPERATURE CONTROLS

COIL SENSING

An evaporator coil sensing temperature control ensures that the evaporator coil will remain clear

of frost and ice by not allowing the compressor to restar t until the coil temperature is above the

freezing temperature. This is considered an off cycle defrost.

AIR SENSING

An air sensing temperature control used in a freezer application will require a defrost cycle with

heaters to ensure that the evaporator coil is kept clear of frost and ice.

13

Page 15

TRUE

www

glass door merchandisers

MECHANICAL TEMPERATURE CONTROL GENERAL SEQUENCE OF OPERATION

MECHANICAL CONTROL REFRIGERATOR GENERAL SEQUENCE OF OPERATION

1. Cabinet is plugged in.

a. Interior lights will illuminate on Glass Door Models only. If lights do not come on verify the light switch is in the “ON”

position. Solid door cabinets may or may not have lights that may be controlled by the door switch.

2. The compressor and evaporator fans will star t if the temperature control is calling for cooling. (If the compressor does not

start, verify that the temperature control is not in the “OFF” or “0” position.)

3. The temperature control may cycle the compressor and evaporator fan(s) on and off together.

a. The temperature control is sensing the evaporator coil temperature.

b. The temperature control should be set on the #4 or #5.

c. The warmest setting is #1, the coldest is #9, and #0 is the off position.

d. The thermometer is designed to read and display a cabinet temperature not a product temperature.

The thermometer may reflect the refrigeration cycle swings of up and down temperatures.

The most accurate temperature on a cabinet's operation is to verify the product temperature.

4. There is not a defrost timer as the temperature control will initiate the off-cycle defrost during each refrigeration cycle.

a. At this time, the compressor will and the evaporator fan(s) may turn off. Defrost heaters are not installed on refrigerators

and therefore will not be energized.

b. After the evaporator coil temperature has been reached, as determined by the temperature control, the compressor will

restart.

5. There may be a timer located on the condensing unit base. This timer is not used for a defrost event. The timer will change

the rotation of the reversing condenser fan motor.

.truemfg.com

MECHANICAL CONTROL FREEZER GENERAL SEQUENCE OF OPERATION

1. Cabinet is plugged in.

a. Interior lights will illuminate on glass door models only. If lights do not come on, verify the light switch is in

the “ON” position. Solid door cabinets may or may not have lights that may be controlled by the door switch.

2. The compressor only will star t if the temperature control is calling for cooling. (If the compressor does not start, verify that

the temperature control is not in the “OFF” or “0” position or the cabinet is not in a defrost event.)

a. The evaporator fan(s) will remain off until a specific temperature of the evaporator coil is reached.

3. The temperature control may cycle the compressor and evaporator fan(s) on and off together.

a. The temperature control is sensing the air temperature.

b. The temperature control should be set on the #4 or #5.

c. The warmest setting is #1, the coldest is #9, and #0 is the off position.

d. The thermometer is designed to read and display a cabinet temperature not a product temperature.

The thermometer may reflect the refrigeration cycle swings of up and down temperatures.

The most accurate temperature on a cabinet's operation is to verify the product temperature.

4. The defrost timer will initiate defrost during specific times of day.

a. At this time, the compressor and evaporator fan(s) will turn off and the evaporator coil heater and drain tube heater will

be energized. Some cabinets may also change the rotation of the reversing condenser fan motor.

b. After the predetermined evaporator coil temperature has been reached or duration for defrost has expired, the

compressor will restart and the evaporator fan(s) will remain off until a specific temperature of the evaporator coil is

reached.

14

Page 16

TRUE

60

45

15

glass door merchandisers

WHEN TO MAKE AN ADJUSTMENT TO A MECHANICAL TEMPERATURE CONTROL

We advise to make a mechanical temperature control adjustment only for a high altitude location.

HOW TO ADJUST A MECHANICAL TEMPERATURE CONTROL

www

.truemfg.com

OPERATION INSTRUCTIONS:

REQUIRED TOOLS:

• Jewelers Screw Driver (Small Screw Driver)

GE CONTROL INSTRUCTIONS:

The scale to the right may be used as a guide for measuring

degrees of rotation required for altitude correction. See Figure 1.

The arrows indicate direction of screw rotation. Turn calibration

screw clockwise to obtain warmer operating temperatures.

NOTE: Each 1/4 turn of the calibration screw is equal to

approximately 2 degrees F. Do not make more than 3/4 turn.

After making adjustment, measure temperature during three

cycles before adjusting again.

ALTITUDE CORRECTION TABLE:

NOTE: Only adjust the screw

(small flathead) on the face of

the control (next to the cam).

See Figure 3.

Follow the Altitude Correction

Table to the right.

CALIBRATION SCREW ADJUSTS

BOTH CUT-IN AND CUT-OUT

Altitude (Feet)

2000

3000

4000

5000

6000

7000

8000

9000

10,000

Clockwise Turns

7/60

11/60

15/60

19/60

23/60

27/60

30/60

34/60

37/60

Scale Guide for Measuring Back of Temperature Control

Compressor

55

50

5

M

R

A

W

10

E

R

Ter min a ls

Ground

C

R

O

E

L

40

D

35

30

20

25

Ter min a l

1 2

Altitude Correction

3

Front of Temperature Control

Calibration

Screw

To adjust the temperature control

take the control knob off to view the

cut-in screw. (See Photo Above)

INSTALLATION INSTRUCTIONS

DANFOSS TEMPERATURE CONTROL ADJUSTMENT

FOR HIGH ALTITUDE APPLICATIONS:

REQUIRED TOOLS:

• Allen Wrench (5/64")

• Torx Screw (T-7)

TERMS:

Cut-out - Temperature sensed by the controller that shuts the

compressor off.

Cut-in - Temperature sensed by the controller that turns the

compressor on.

15

Bottom of Temperature Control

Cut-out Adjustment

Screw Allen (5/64" or 2 mm.)

Cut-in Adjustment

Screw Torx (T-7)

Compressor

Connection

Compressor Connection

(double terminal)

1

Page 17

TRUE

www

glass door merchandisers

INSTRUCTIONS: DANFOSS TEMPERATURE CONTROL ADJUSTMENT FOR

HIGH ALTITUDE APPLICATIONS

STEP 1 - Unplug cooler.

STEP 2 - Remove the screws that secure the temperature control to the inset box.

STEP 3 - To make these adjustments it may be necessary to remove the temperature control from the housing.

NOTE: You may have to remove the wires attached to the control. Take note as to which wire is on which spade terminal.

STEP 4 - Pull out gently from cabinet.

NOTE: Mechanical temperature controllers are affected when functioning at high altitude.

The cut-in and cut-out temperatures will be colder than when the controller functions closer to sea level.

STEP 5 - For high elevation installations, it may be necessary to “warm-up” the set points. To make the adjustment, inser t the

appropriate tool in each adjustment screw and turn 1/4 of a revolution clockwise (to the right). This procedure will adjust both

the cut-in and cut-out about 2˚F warmer.

.truemfg.com

STEP 6 - Make sure to reconnect the wires to the proper spade terminal when reinstalling.

INSTALLATION INSTRUCTIONS

TEMPERATURE CONTROL ALTITUDE ADJUSTMENT:

REQUIRED TOOLS:

• Allen Wrench (5/64”)

• Torx Screw (T-7)

The scale to the right may be used as a guide for measuring degrees of rotation required for altitude

correction. The arrows indicate direction of screw rotation. See Figure 1.

IMPORTANT: Upright models ordered with “High Altitude” temperature controls are

pre-calibrated and do not require adjustment.

INSTRUCTIONS: CUTLER HAMMER TEMPERATURE CONTROL ALTITUDE ADJUSTMENT

STEP 1 - Unplug cooler.

STEP 2 - Turn the temperature control to the “9” position.

Scale Guide for Measuring

360

90

270

180

1

STEP 3 - Remove the screws that secure the mounting plate to the evaporator top. See Figure 2.

STEP 4 - Pull control down gently from housing.

STEP 5 - Turn screws counterclockwise (CCW).

STEP 6 - Reassemble to cooler housing and return the temperature control to the “5” position.

16

Page 18

TRUE

O

9

8

7

6

5

4

3

2

1

glass door merchandisers

www

.truemfg.com

CHART

CCW Adjustment

(based on 360°/

complete turn)Height

2000' 42°

3000' 78°

4000' 114°

5000' 150°

6000' 186°

7000' 222°

8000' 258°

9000' 294°

10,000' 330°

BUL. NO.

CUT

OUT

COLDER

IN

CUT

O

1

9

2

8

3

7

4

5

17

2

Page 19

TRUE

glass door merchandisers

www

.truemfg.com

DEFROST TIMER

DEFROST TIME CLOCK OPERATION FOR UNITS

WITH MECHANICAL CONTROL

RECOMMENDED DEFROST SETTINGS:

TRUE Manufacturing has factory set your defrost time clock to a

recommended time and duration defrost scenario. All refrigeration

equipment operating below 30°F will accumulate frost on the evaporator coil and will require routine defrost. Your TRUE equipment has

been designed for three defrost periods (6:00 a.m., 2:00 p.m. and

10:00 p.m.). If you decide to deviate from these defrost time settings

please follow the procedures for adjustment below.

TOOLS REQUIRED

• Phillips Head Screwdriver

• 1/4" Nut Driver or Socket

SETTING THE TIMER:

UNPLUG UNIT FROM POWER SUPPLY! DO NOT SET THE TIME

BY ROTATING THE “OUTER” DIAL.

Turn the minute hand clockwise until the time of day on the outer

dial is aligned with the triangle marker on the inner dial (two o’clock

position).

NOTICE: If timer is not set for a minimum of 3 defrost per day

for 30 minutes each, the coil may develop excessive frost. This may

lead to system failure and product loss, which is not covered under

warranty.

The following procedure may be followed to customize your needs.

High usage, high temperature, and high humidity may require 4

defrost settings per day.

WARNING: Always follow the manufacturer’s recommended

settings when programming the amount and duration of the defrost

cycles.

STEP 1: The white tabs located on the outmost area of the time

clock have been factory set for (6:00 a.m., 2:00 p.m., and 10:00

p.m.). Each tab represents 15 minutes of defrost time. Notice that at

each defrost time two white tabs are set for 15 minutes each for a

total of 30 minutes of defrost.

STEP 2: In order to program the time to begin the defrost cycle,

flip the white tabs out to set the defrost time. To eliminate a defrost

time flip the white tabs back toward the center of the Defrost

Timer.

STEP 3: TRUE recommends a 30 minute defrost cycle three times

per day.

ADJUSTING THE DEFROST TIMER:

Your TRUE freezer contains a defrost system that is temperature

terminated, however the time clock has been designed with a time

termination back-up so that the defrost period will not exceed thir ty

minutes. While TRUE requires a minimum 3 defrost periods not to

exceed 30 minutes the procedure on this page should be followed

to customize your specific needs.

1

2

Outer most dial.

White tabs represent 15

minutes of defrost time.

Time of day.

Inner most dial.

18

Page 20

TRUE

glass door merchandisers

ELECTRONIC TEMPERATURE CONTROLS

LAE ELECTRONIC TEMPERATURE CONTROL GENERAL SEQUENCE OF OPERATION

www

.truemfg.com

t1 = supply air / return air* (thermostat)

t2 = coil / copper line (defrost)

t3 = return air / supply air* (display)

t3 probe is not installed and / or activated in all applications

with t3 is not installed and / or activated, the display probe is t1.

LAE ELECTRONIC CONTROL GENERAL SEQUENCE OF OPERATION

1. Cabinet is plugged in.

a. Display will illuminate.

b. Interior light will illuminate on Glass Door Models only. Solid door cabinet lights are controlled by the door switch.

2. Af ter the LAE control preprogrammed time delay of up to 6 minutes, the compressor and evaporator fan(s) will

start if the control is calling for cooling.

a. Control or condenser fans may be already pre-programmed from the factory so at the start of every compressor cycle or

during a defrost cycle, the condenser fan(s) will reverse for 30 seconds to blow dir t off the condensing coil.

3. The LAE control will cycle the compressor but may also cycle evaporator fan(s) on and off determined by the

Set-Point and Differential temperatures.

a. The Set-Point is the adjustable preprogrammed temperature which shuts off the compressor and evaporator fan(s).

This is not the programmed cabinet temperature.

b. The Differential is the non adjustable preprogrammed temperature that is added to the Set-Point temperature that

will restar t the compressor and evaporator fan(s).

c. The LAE control is designed to read and display a cabinet temperature not a product temperature.

This cabinet temperature may reflect the refrigeration cycle of the Set-Point and it’s Differential.

The most accurate temperature on a cabinets operation is to verify the product temperature.

* STA, STG, STM, STR Models.

Example: If the Set-Point is -9°F/-23°C and the Differential is 10°F/5°C

(Set-Point) -9°F + 10 (Differential) = 1°F

Or

(Set-Point) -23°C + 5 (Differential) = -18°C

The compressor and evaporator fan(s) will cycle off -9°F/-23°C and back on at 1°F/-18°C

4. The L AE control may be preprogrammed to initiate defrost by inter val or at specific times of day.

a. At this time the “dEF” will appear on the display and compressor will turn off until a preprogrammed temperature

or duration is reached. During this time for freezers only, evaporator fan(s) will also turn off and the coil heater and

drain tube heaters will also be energized. Some cabinets may also change the rotation of the reversing condenser

fan motor.

b. After the preprogrammed temperature or duration for defrost has been reached there may be a shor t delay

for both the compressor and evaporator fans to restar t. At this time “dEF” may still appear on the display for a

short time.

19

Page 21

TRUE

glass door merchandisers

HOW TO DIAGNOSE AN LAE ELECTRONIC CONTROL

Indicator lights for Refrigeration/Heating Mode, Fan Operation, Defrost Mode.

www

.truemfg.com

LAE Control

Info / Set Point

Button

USING THE LAE ELECTRONIC CONTROL

LOCKING AND UNLOCKING THE LAE CONTROLLER:

WHY: Locking of control is necessary to prevent changes to program that may affect

cabinet operation.

Manual Defrost /

Down Button

Manual Activation

Up Button

Stand- By

Button

LAE Control Icons

Compressor Running

Evaporator Fan Running

Cabinet in Defros t

Activation of 2nd Parameter Set

Alarm

1

HOW TO LOCK AND UNLOCK LAE CONTROLLER:

STEP 1 - To change lock setting press and release the Info button .

“t1” will appear. See image 1.

STEP 2 - Press the Down button

STEP 3 - While pressing and holding the Info button

or Down button to change the lock settings. If “no” appears,

the controller is unlocked. If “yes” appears, the controller is locked. See

images 3 and 4.

STEP 4 - Once the lock setting has been set correctly release the

info button . Wait 5 seconds for the display to show temperature.

See image 5.

until “Loc” appears. See image 2.

press the Up

2

3

Image 3: If “no” appears on screen,

the controller is unlocked.

4

Image 4: If “yes” appears on screen, the

controller is locked.

5

20

Page 22

TRUE

glass door merchandisers

LAE Control

www

.truemfg.com

HOW TO TURN OFF THE LAE ELECTRONIC CONTROL:

May need to unlock control.

WHY: Turning off the control will deactivate all electrical components.

CAUTION: Turning off the control will not shut off power to the cabinet. Cabinet

must be unplugged prior to any repair.

HOW TO TURN OFF THE LAE ELECTRONIC CONTROL:

STEP 1 - To turn off control, press and hold the Stand-by button until

"OFF" appears. Release Stand-by button. See Image 2.

STEP 2 - To turn on control, repeat prior steps and a temperature will appear.

Info / Set Point

Button

Manual Activation

Up Button

Manual Defrost /

Down Button

Stand- By

Button

1

2

TURNING THE GLASS DOOR MODEL LIGHTS ON AND OFF:

May need to unlock control.

WHY: Light may be controlled by LAE Controller or interior light switch.

HOW TO TURN THE GLASS DOOR MODEL LIGHT ON

AND OFF:

STEP 1 - To control interior / sign lights by the LAE Controller, press and

release the Manual Activation button .

STEP 2 - To control interior / sign lights by the interior door switch, depress

the rocker switch to the “ON” position. Light switch is located on inside top

right of the ceiling.

ON Position

(Solid Door model lights are controlled by a

door switch)

21

Page 23

TRUE

glass door merchandisers

LAE Control

www

.truemfg.com

CHANGING THE "SET POINT":

May need to unlock control.

WHY: The set point is the temperature at which the compressor will shut off.

NOTE: The “set point” IS NOT the cabinet holding temperature.

HOW TO CHANGE THE “SET POINT”:

STEP 1 - To see the set point, press and hold the Info button .

See image 1.

STEP 2 - While still holding the Info button , press the Up or

Down button to change the “set point”.

STEP 3 - Once the “set point” has been set correctly release the Info

button . The display will show temperature. See image 2.

Info / Set Point

Button

Manual Activation

Up Button

Manual Defrost /

Down Button

Stand- By

Button

1

2

22

Page 24

TRUE

glass door merchandisers

LAE Control

www

.truemfg.com

Info / Set Point

Button

Manual Activation

Up Button

Manual Defrost /

Down Button

Stand- By

Button

INITIATE A MANUAL DEFROST:

May need to unlock control.

WHY: A one time additional defrost may be necessary to clear accumulated frost / ice from evaporator coil.

HOW TO INITIATE A MANUAL DEFROST:

The method to initiate a manual defrost is determined by the Defrost Mode Parameter “DTM” preprogrammed in the controller.

REGULAR TIME DEFROST (TIM)

If controller is preprogrammed for “TIM”, press and release the Manual Defrost button until “dEF” appears.

REAL TIME CLOCK (RTC)

If controller is preprogrammed for “RTC” press the and hold the Manual Defrost button for 5 seconds until “dh1” appears.

Release the Manual Defrost button and then press and hold for an additional 5 seconds until “dEF” appears.

NOTE: Defrost will only terminate once a specific preset temperature or a preset time duration is reached.

23

Page 25

TRUE

glass door merchandisers

LAE Control

www

.truemfg.com

CHANGING “DEFROST INTERVALS”:

May need to unlock control.

This can only be changed if defrost mode parameter “DFM” is set for “TIM”.

WHY: The defrost interval is the time duration between defrost cycles. The defrost

interval time starts when the cabinet is supplied power or after a manual defrost.

HOW TO CHANGE “DEFROST INTERVALS":

STEP 1 - To see the set point, press and hold the Info button

Stand-by button

NOTE: Depending on the version of control, one of three parameters will

appear: “ScL” image 1a, “SPL” image 1b, “MdL” image 1c.

at the same time.

and the

Info / Set Point

Button

Manual Activation

Up Button

Manual Defrost /

Down Button

Stand- By

Button

1a

1b

1c

STEP 2 - Push the Up button

STEP 3 - Press and hold the Info button

time. See image 3.

STEP 4 - While pressing and holding the Info button

Up

the number the less frequent the cabinet will defrost).

STEP 5 - Once the defrost interval time has been changed, release the Info

button

STEP 6 - Wait 30 seconds for the display to show temperature.

See image 4.

or Down button to change the defrost interval times (higher

.

until “dFt” appears. See image 2.

to see the defrost interval

, press the

2

3

4

24

Page 26

TRUE

glass door merchandisers

LAE Control

www

.truemfg.com

HOW TO CHANGE DISPLAY READOUT FROM

FAHRENHEIT TO CELSIUS:

May need to unlock control.

This can only be changed with the LAE model BR1 version of the control.

WHY: Changing readout will assist with customer application.

HOW TO CHANGE DISPLAY READOUT FROM

FAHRENHEIT TO CELSIUS:

STEP 1 - To change the display, press and hold the Info button and

the Stand-by button at the same time. “MdL” will appear. See image 1.

STEP 2 - Push the Down button until “ScL” appears. See image 2.

Info / Set Point

Button

Manual Activation

Up Button

Manual Defrost /

Down Button

Stand- By

Button

1

2

3

STEP 3 - Press and hold the Info button to see the “readout scale”.

See image 3.

STEP 4 - While pressing and holding the Info button , press the up

or down button to change the “readout scale". See image 4.

STEP 5 - Once the “readout scale” has been changed, release the info button .

STEP 6 - Wait 30 seconds for the display to show temperature. See image 5.

4

5

25

Page 27

TRUE

glass door merchandisers

LAE Control

www

.truemfg.com

DISPLAYING TEMPERATURE PROBES, T1, T2, T3:

WHY: To display temperature probe readings in different locations of the cabinet.

HOW TO DISPLAY PROBE TEMPERATURES:

STEP 1 - To display T1 temperature, press and release the info button

. “t1” will appear. See image 1.

STEP 2 - Press and hold the info button . This is the temperature of

the T1 Probe. See image 2.

STEP 3 - By releasing the info button , “t2” will appear. Press and hold

the info button to display the temperature of the T2 probe.

Info / Set Point

Button

Manual Activation

Up Button

Manual Defrost /

Down Button

Stand- By

Button

1

2

STEP 4 - By releasing the info button again, “t3” will appear. Press and

hold the info button to display the temperature of the T3 probe. (If

probe T3 is not activated, “t3” will not appear of the display.)

DISPLAY CODES

DISPLAY

Defrost in progress Room high temperature alarm

Controller in stand-by Room low temperature alarm

Door open alarm Probe T1 failure

Instant Probe 1 temperature Probe T2 failure

Instant Probe 2 temperature Probe T3 failure

Instant Probe 3 temperature Maximum probe 1 temperature recorded

Minutes of the Real Time Clock Minimum probe 1 temperature recorded

Hours of the Real Time Clock Keypad state lock

26

Page 28

TRUE

SUBJECT TO CHANGE

glass door merchandisers

LAE Controller Parameter Settings

for Celsius

For every model / version of the LAE controller,

ALL parameters with a formula shown need to be

converted for Celsius applications.

EXCEPT MODEL: BR1

EXAMPLE:

If current SPL is set for 20 degrees F,

the formula is (X-32) / 1.8

(20-32) / 1.8 = -6.7 Celcius

AR2-28

SCL

SPL

SPH

SP

HYS

DLI

FDD

FDT

FDH

FT3 DLTFP

ATM LCSDSH

ALA

AHA

ALR

AHR

ATI AHR

ATD ATD

1C

(X-32) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X) / 1.8

AHT

IISL

HSIITRC

PSII1TC

YHII2TC

2AOYTD

1SOMDD

2SODIF

3SOOTF

(X-32) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X) / 1.8

(X) / 1.8

(X) / 1.8

SPL

SPH

SP

HYS

DLI

FDD

FDT

SP

HYS

ALA

AHA

ALR

HDFCFIIDSC

ALAMSD3HD

AHA2ID4HD

RLATTS5HD

RHATDE6HD

ITAMSL

DTA1AOOTD

LPSDCDPD

HPSPNINRD

(X-32) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X-32) / 1.8

(X-32) / 1.8

(X) / 1.8

(X) / 1.8

BIT25

BIT25 Heating

ADO

AHM

AHT

ACC

SB

LSM

OS1

T2

MISMTASD2HD

ADR

ADO

SB

DI1

PSL

MISMTA

ADR

www

.truemfg.com

(X-32) / 1.8

LSII1TC

(X-32) / 1.8

HSII2TC

(X-32) / 1.8

PSIIDSC

(X-32) / 1.8

YHIIMFD

CFIITFD

FDIIBFD

1IDOTD

2IDYTD

M3TDPDODA

3SONRDMHA

LSPMDD

(X-32) / 1.8

RSPYDDCCA

(X-32) / 1.8

FOPDIFMSIIH-C

1AOOTF

2AOMCF

2SO1TFSDHMFD

DLT2TFFDIITFD

LCS3TFBS1HD

2IDMC2TYDD

(X-32) / 1.8

RSPNOT3T

(X-32) / 1.8

FOPFOT

MSDBPDLTMCF

MSLTISDT

1AOTDGVA

2AORAMIS1TF

1SOTCRDA2TF

(X) / 1.8

(X) / 1.8

(X) / 1.8

(X) / 1.8

1C

(X) / 1.8

1C

27

Page 29

TRUE

glass door merchandisers

SOLLATEK ELECTRONIC TEMPERATURE CONTROL GENERAL SEQUENCE OF OPERATION

control probe = return air

defrost probe = coil

SOLLATEK ELECTRONIC TEMPERATURE CONTROL GENERAL SEQUENCE OF OPERATION

1. Cabinet is plugged in.

a. Interior lights will illuminate on glass door models only. If the lights do not come on verify the light switch is in the “ON”

position. Solid door cabinets may or may not have lights that may be controlled by the door switch.

2. The compressor and evaporator fans will star t if the temperature control is calling for cooling. (If the compressor does not

start verify that the temperature control is not in the “off ” or “0” position.)

a. Control or condenser fan(s) may be already preprogrammed from the factory so at the start of every compressor cycle,

the condenser fan(s) will reverse for 30 seconds to blow dirt off the condensing coil.

www

.truemfg.com

3. The Sollatek control will cycle the compressor and the evaporator fan(s) on and off together.

a. The temperature control is sensing the discharge air temperature.

b. The temperature control should be set on the #4 or #5.

c. The warmest setting is #1, the coldest is #9, and #0 is the off position.

d. The thermometer is designed to read and display a cabinet temperature not a product temperature.

This cabinet temperature may reflect the refrigeration cycle determined by the temperature control.

The most accurate temperature on a cabinets operation is to verify the product temperature.

4. The Sollatek control is preprogrammed to initiate defrost ever y 4 hours of compressor run time.

If deemed necessary by the Sollatek control additional defrost may occur at unspecified times.

a. At this time, the evaporator fans will continue to run but the compressor will turn off.

Some cabinets may also change the rotation of the reversing condenser fan motor.

b. Once a preprogrammed temperature of the evaporator coil is reached, the Defrost Cycle will terminate and the

2 minute delay will star t.

c. After the 2 minute delay the compressor will restart.

28

Page 30

TRUE

glass door merchandisers

MAINTENANCE, CARE, CLEANING

www

.truemfg.com

CLEANING THE CONDENSER COIL

When using electrical appliances, basic safety precautions should be

followed, including the following:

TOOLS REQUIRED

• Phillips Screwdriver

• Stiff Bristle Brush

• Adjustable Wrench

STEP 1 - Disconnect power to unit.

STEP 2

SLIDE DOOR MODELS:

Remove louver grill by removing

Phillips screw located on either

side of the louver grill. (See image

1). Pull the louver grill out from

the cabinet front. (See image 2).

(To reinstall grill, place louver grill

back into brackets located at the

base of the unit (See image 3).

Snap top of louver grill into place.

Replace screws).

• Air Tank or CO2 Tank

• Vacuum Cleaner

1

2

STEP 3 - Remove bolts anchoring compressor assembly to frame

rails and carefully slide out. (tube connections are flexible)

STEP 4 - Clean off accumulated dirt from condensing coil with a

stiff bristle brush.

STEP 5 - Lift cardboard cover above fan at plastic plugs and carefully

clean condenser coil and fan blades.

STEP 6

INDOOR LOCATION:

After brushing condenser coil vacuum dir t from coil, and interior

floor.

OUTDOOR LOCATION:

(GDM-33, GDM-47, and GDM-49 only) After brushing condenser

coil blow CO2 through condenser from fin side to fan.

STEP 7 - Replace cardboard cover. Carefully slide compressor

assembly back into position and replace bolts.

STEP 8 - Reinstall louver assembly onto unit with appropriate fasteners and clips. Tighten all screws.

STEP 9 - Connect unit to power and check to see if condenser is

running.

SWING DOOR MODELS:

Take off lower grill assembly by removing four (4) screws.

(See images 4 & 5.)

4

Loosen but do not remove

4 Phillips screws inside the

grill frame.

5

Lift the grill up until it clears the

screw key hole slots.

3

Indoor Location

Outdoor Location

29

Page 31

TRUE

Condenser

glass door merchandisers

www

.truemfg.com

IMPORTANT WARRANTY INFORMATION

Condensers accumulate dirt and require cleaning every 30 days.

Dirty condensers result in compressor failure, product loss, and lost

sales, which are not covered by warranty.

If you keep the Condenser clean you will minimize your service

expense and lower your electrical costs. The Condenser requires

scheduled cleaning every thir ty days or as needed.

Air is pulled through the Condenser continuously, along with dust,

lint, grease, etc.

A dirty Condenser can result in NON-WARRANTEED part &

Compressor Failures, Product Loss, and Lost Sales.

Proper cleaning involves removing dust from the Condenser. By using

a soft brush, or vacuuming the Condenser with a shop vac, or using

CO2, nitrogen, or pressurized air.

If you cannot remove the dirt adequately, please call your refrigeration service company.

On most of the reach-in units the condenser is accessible in the

rear of the unit. You must remove the cabinet grill to expose the

Condenser.

The Condenser looks like a group of vertical fins. You need to be able

to see through the condenser for the unit to function at maximum

capacity. Do not place filter material in front of condensing coil. This

material blocks air-flow to the coil similar to having a dirty coil.

THE CLEANING OF THE CONDENSER IS NOT

COVERED BY THE WARRANTY!

HOW TO CLEAN THE CONDENSER:

1. Disconnect the electrical

power to the unit.

2. Remove the louvered

grill.

3. Vacuum or brush the dir t,

lint, or debris from the

finned condenser coil.

4. If you have a significant dirt build up you can blow out the

condenser with compressed air.

(CAUTION MUST BE USED TO AVOID EYE INJURY.

EYE PROTECTION IS RECOMMENDED.)

5. When finished be sure to replace the louvered grill. The grill

protects the condenser.

6. Reconnect the electrical power to the unit.

If you have any questions, please call TRUE Manufacturing at 636240-2400 or 800-325-6152 and ask for the Service Depar tment.

Direct to Service Department 1(855)372-1368. Service Department

Availability Monday-Thursday 7:00 a.m. to 7:00 p.m., Friday 7:00 a.m.

to 6:00 p.m. and Saturday 8:00 a.m. to 12:00 p.m. CST.

Condensing Unit

Airflow

30

Page 32

TRUE

glass door merchandisers

www

.truemfg.com

STAINLESS STEEL EQUIPMENT CARE

AND CLEANING

CAUTION: Do not use any steel wool, abrasive or chlorine based

products to clean stainless steel surfaces.

STAINLESS STEEL OPPONENTS

There are three basic things which can break down your stainless

steel’s passivity layer and allow corrosion to rear its ugly head.

1. Scratches from wire brushes, scrapers, and steel pads are just

a few examples of items that can be abrasive to stainless steel’s

surface.

2. Deposits left on your st ainless steel can leave spots. You may have

hard or sof t water depending on what part of the country you live

in. Har d water can leave spot s. Hard water that is heated can le ave

deposits if left to sit too long. These deposits can cause the

passive layer to break down and rust your stainless steel.

All deposits left from food prep or service should be removed

as soon as possible.

3. Chlorides are present in table salt, food, and water. Household

and industrial cleaners are the worst type of chlorides

to use.

RECOMMENDED CLEANERS FOR CERTAIN

SITUATIONS / ENVIRONMENTS OF STAINLESS

STEEL

A. Soap, ammonia and detergent medallion applied with a cloth or

sponge can be used for routine cleaning.

B. Arcal 20, Lac-O-Nu Ecoshine applied provides barrier f ilm for

fingerprints and smears.

C. Cameo, Talc, Zud First Impression is applied by rubbing in

the direction of the polished lines for stubborn stains and

discoloring.

D. Easy-off and De-Grease It oven aid are excellent for removals

on all finishes for grease-fatty acids, blood and burnt-on foods.

E. Any good commercial detergent can be applied with a sponge

or cloth to remove grease and oil.

F. Benef it, Super Sheen, Sheila Shine are good for restoration /

passivation.

NOTE: The use of stainless steel cleaners or other such solvents is

not recommended on plastic parts. Warm soap and water will suffice.

8 STEPS THAT CAN HELP PREVENT RUST ON

STAINLESS STEEL:

1. USING THE CORRECT CLEANING TOOLS

Use non-abrasive tools when cleaning your stainless steel

products. The stainless steel’s passive layer will not be harmed

by soft cloths and plastic scouring pads. Step 2 tells you how to

find the polishing marks.

2. CLEANING ALONG THE POLISH LINES

Polishing lines or “grain” are visible on some stainless steels.

Always scrub parallel to visible lines on some stainless steels.

Use a plastic scouring pad or soft cloth when you cannot see

the grain.

3. USE ALKALINE, ALKALINE CHLORINATED OR

NON-CHLORIDE CONTAINING CLEANERS

While many traditional cleaners are loaded with chlorides, the

industry is providing an ever increasing choice of non-chloride

cleaners. If you are not sure of your cleaner’s chloride content

contact your cleaner supplier. If they tell you that your present

cleaner contains chlorides, ask if they have an alternative. Avoid

cleaners containing quaternary salts as they can attack stainless

steel, causing pitting and rusting.

4. WATER TREATMENT

To reduce deposits, soften the hard water when possible.

Installation of certain filters can remove corrosive and distasteful

elements. Salts in a properly maintained water softener can be

to your advantage. Contact a treatment specialist if you are not

sure of the proper water treatment.

5. MAINTAINING THE CLEANLINESS OF YOUR

FOOD EQUIPMENT

Use cleaners at the recommended strength (alkaline chlorinated

or non-chloride). Avoid build-up of hard stains by cleaning

frequently. When boiling water with your stainless steel

equipment, the single most likely cause of damage is chlorides in

the water. Heating any cleaners containing chlorides will have

the same damaging effects.

6. RINSE

When using chlorinated cleaners you must rinse and wipe dry

immediately. It is better to wipe standing cleaning agents and

water as soon as possible. Allow the stainless steel equipment

to air dry. Oxygen helps maintain the passivity film on stainless

steel.

31

7. HYDROCHLORIC ACID (MURIATIC ACID)

SHOULD NEVER BE USED ON STAINLESS STEEL

8. REGULARLY RESTORE/PASSIVATE STAINLESS

STEEL

Page 33

TRUE

glass door merchandisers

www

.truemfg.com

GENERAL MAINTENANCE

LIGHT BULB REPLACEMENT (IDL)

INTEGRATED DOOR LIGHTING

WARNING: When replacing a light bulb make sure power to the

unit is either turned off or unplugged.

IDL (INTEGRATED DOOR LIGHTING):

• Squeeze the plastic lampshield together and pull away from the

door (See Image 1).

• Push the bulb down while pulling the spring activated lampholder

up. This will give you enough clearance to take the bulb out

(See Image 2).

LIGHT COVER INSTALLATION FOR

GDM-10F & GDM-12F

IMPORTANT

Before installing lamp cover turn cabinet on and allow it to reach

temperature.

STEP 1

Locate rubber gasket behind lamp holder mounted to evaporator

housing. (See Image 1).

Rubber

Gasket

Lamp

Holder

1

STEP 2

Fit the bottom edge of the lamp cover into the bottom groove of

the rubber gasket and rotate upwards while working the edges into

the rest of the rectangular groove. (See Images 2-3). (slide fingers

underneath top edges of rubber gasket and push rubber over the

top lip of the lamp shield).

1

Remove the lampshield to reveal the

bulb. Squeeze the sides of the lampshield at the same time pulling it away

from the bulb.

2

The lamp holders are spring activated. Pull

the top lamp holder up and push the bulb

down at the same time. This will leave

enough clearance to remove the bulb.

2

STEP 3

Be sure lamp cover is seated properly in rubber gasket.

NOTE

If cabinet is turned off and interior allowed to warm up lamp cover

may become loose and require reinstallation. Follow directions above.

FOR ADDITIONAL MAINTENANCE INSTRUCTION,

PLEASE VISIT THE MEDIA CENTER AT

WWW.TRUEMFG.COM

Lamp Cover

3

32

Page 34

www.truemfg.com

T

R

RUE

EFRIGERATION

MADE IN

U.S.A.

SINCE 1945

®

WARRANTY INFORMATION (U.S.A & CANADA ONLY!)

THIS WARR ANTY ONLY APPLIES TO UNITS SHIPPED FROM TRUE’S MANUFACTURING FACILITIES AFTER JULY 1, 2014.

THREE YEAR PARTS & LABOR WARRANTY

TRUE warrants to the original purchaser of every new TRUE refrigerated unit, the cabinet and all parts thereof, to be free from defects in material or workmanship, under normal and

proper use and maintenance service as specified by TRUE and upon proper installation and start-up in accordance with the instruction packet supplied with each TRUE unit. TRUE’s

obligation under this warranty is limited to a period of three (3) years from the date of original installation or 39 months after shipment date from TRUE, whichever occurs first.

Any part covered under this warranty that are determined by TRUE to have been defective within three (3) years of original installation or thir ty-nine (39) months after shipment date

from manufacturer, whichever occurs first, is limited to the repair or replacement, including labor charges, of defective parts or assemblies. The labor warranty shall include standard straight

time labor charges only and reasonable travel time, as determined by TRUE.

Warranty does not cover standard wear parts which include door gaskets, incandescent bulbs or fluorescent bulbs. Warranty also does not cover issues caused by improper installation

or lack of basic preventative maintenance which includes regular cleaning of condenser coils.

ADDITIONAL TWO YEAR COMPRESSOR WARRANTY

In addition to the Three (3) year warranty stated above, TRUE warrants its hermetically and semi-hermetically sealed compressor to be free from defects in both material and workman

ship under normal and proper use and maintenance service for a period of two (2) additional years from the date of original installation but not to exceed five (5) years and three (3)

months after shipment from the manufacturer.

Compressors determined by TRUE to have been defective within this extended time period will, at TRUE’s option, be either repaired or replaced with a compressor or compressor parts

of similar design and capacity.

The two (2) year extended compressor warranty applies only to hermetically and semi-hermetically sealed parts of the compressor and does not apply to any other parts or components,

including, but not limited to: cabinet, paint finish, temperature control, refrigerant, metering device, driers, motor starting equipment, fan assembly or any other electrical component, etcetera.

-

404A/134A COMPRESSOR WARRANTY

The two year compressor warranty detailed above will be voided if the following procedure is not carefully adhered to:

1. This system contains R404A or R134A refrigerant and polyol ester lubricant. The polyol ester lubricant has rapid moisture absorbing qualities. If long exposure to

the ambient conditions occur, the lubricant must be removed and replaced with new. For oil amounts and specifications please call TRUE technical ser vice depar tment

(855-372-1368). Failure to comply with recommended lubricant specification will void the compressor warranty.

2. Drier replacement is very impor tant and must be changed when a system is opened for servicing. A drier using XH-7 desiccant or an exact replacement solid core drier

must be used. The new drier must also be the same capacity as the drier being replaced.

3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower must be obtained.

WARRANTY CLAIMS

All claims for labor or parts must be made directly through TRUE. All claims should include: model number of the unit, the serial number of the cabinet, proof of purchase, date of installation, and all pertinent information suppor ting the existence of the alleged defect.

In case of warranty compressor, the compressor model tag must be returned to TRUE along with above listed information.

Any action or breach of these warranty provisions must be commenced within one (1) year after that cause of action has occurred.

WHAT IS NOT COVERED BY THIS WARRANTY

TRUE’s sole obligation under this warranty is limited to either repair or replacement of parts, subject to the additional limitations below. This warranty neither assumes nor authorizes any

person to assume obligations other than those expressly covered by this warranty.

NO CONSEQUENTIAL DAMAGES. TRUE IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT LOSS; OR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING

WITHOUT LIMITATION, LOSSES OR DAMAGES ARISING FROM FOOD OR PRODUCT SPOILAGE CLAIMS WHETHER OR NOT ON ACCOUNT OF REFRIGERATION FAILURE.

WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the original purchaser/user to whom delivered. ANY SUCH ASSIGNMENT OR

TRANSFER SHALL VOID THE WARRANTIES HEREIN MADE AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE.

IMPROPER USAGE. TRUE ASSUMES NO LIABILITY FOR PARTS OR LABOR COVERAGE FOR COMPONENT FAILURE OR OTHER DAMAGES RESULTING FROM IMPROPER

USAGE OR INSTALLATION OR FAILURE TO CLEAN AND/OR MAINTAIN PRODUCT AS SET FORTH IN THE WARRANTY PACKET PROVIDED WITH THE UNIT.

RELOCATION OF CABINET FOR REPAIR: True is not responsible for the cost to move a cabinet for any reason from its position of operation on the customer’s premises to make a

warranty repair.

RESIDENTIAL APPLICATIONS: TRUE assumes no liability for par ts or labor coverage for component failure or other damages resulting from installation in non-commercial or residential

applications.

ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION, FIRE, FLOOD, ACTS OF GOD. TRUE is not responsible for the repair or

replacement of any parts that TRUE determines have been subjected after the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during transit or installation, fire,

flood, or act of God.

IMPROPER ELECTRICAL CONNECTIONS. TRUE IS NOT RESPONSIBLE FOR THE REPAIR OR REPLACEMENT OF FAILED OR DAMAGED COMPONENTS RESULTING FROM