Page 1

Safe Operation Practices • Assembly & Set-Up • Controls & Features • Operation • Maintenance • Warranty

OperatOr’s Manual

FLEX™ Pressure Washer Attachment — 23AADAAA711

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-10248

(February 2, 2015)

Page 2

To The Owner

Thank You

Thank you for purchasing the Troy-Bilt FLEX™ Pressure Washer

Attachment. It was carefully engineered to provide excellent

performance when properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator’s

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models.

Table of Contents

1

We reserve the right to change product specifications, designs

and equipment without notice and without incurring obligation.

If you have any problems or questions concerning the machine,

phone an authorized Troy-Bilt service dealer or contact us

directly. Troy-Bilt’s Customer Support telephone numbers,

website address and mailing address can be found on this page.

We want to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 7

Controls & Features ................................................10

Operation ................................................................11

Troubleshooting .....................................................17

Replacement Parts .................................................18

Warranty ................................................................. 19

Spanish ................................................................... 20

Maintenance & Adjustment .................................15

Record Product Information

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by looking at the pump side of the mounting plate.

This information will be necessary, should you seek technical

support via our web site, Customer Support Department, or with

a local authorized service dealer.

Model NuMber

Serial NuMber

Customer Support

Please do NOT return the machine to the retailer or dealer without first contacting the Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

◊ Visit us on the web at www.troybilt.com

See How-to Maintenance and Parts Installation Videos at www.troybilt.com/tutorials

◊ Call a Customer Support Representative at (800) 828-5500 or (330) 558-7220

◊ Write to Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

2

Page 3

Important Safe Operation Practices

WARNING: This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

DANGER: This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing objects. Failure to observe the following safety instructions could

result in serious injury or death.

CAUTION: The safety alert symbol indicates a potential personal injury hazard. A signal

word (DANGER, WARNING, or CAUTION) is used with the alert symbol to designate a degree

or level of hazard seriousness. A safety symbol may be used to represent the type of hazard.

NOTE: Is used to address practices not related to personal injury.

2

Operator Safety

Equipment Description

Read this manual carefully and become

familiar with your pressure washer

attachment.

Know its applications, its limitations, and any hazards involved.

This pressure washer operates at a maximum of 3,000 PSI (206.8

BARS) and a flow rate of up to 2.5 gallons per minute (9.46 liters

per minute).

Every effort has been made to ensure that information in this

manual is accurate and current. However, we reserve the right

to change, alter, or otherwise improve the product and this

document at any time without prior notice.

WARNING! POISONOUS GAS HAZARD. Engine

exhaust contains carbon monoxide, a poisonous gas

that could kill you in minutes. You CANNOT smell it,

see it, or taste it. Even if you do not smell exhaust

fumes, you could still be exposed to carbon

monoxide gas. Some chemicals or detergents could

be harmful if inhaled or ingested, resulting in death,

serious injury, nausea, fainting or poisoning.

• Operate this product ONLY outside far away from

windows, doors and vents to reduce the risk of carbon

monoxide gas from accumulating and potentially being

drawn towards occupied spaces.

• Install battery-operated carbon monoxide alarms or

plug-in carbon monoxide alarms with battery back-up

according to the manufacturer’s instructions. Smoke

alarms cannot detect carbon monoxide gas.

• DO NOT run this product inside homes, garages,

basements, crawl-spaces, sheds, or other partiallyenclosed spaces even if using fans or opening doors and

windows for ventilation. Carbon monoxide can quickly

build up in these spaces and can linger for hours, even

after this product has shut off.

• ALWAYS place this product downwind and point the

engine exhaust away from occupied spaces. If you start

to feel sick, dizzy, or weak while using this product,shut

it off and get to fresh air RIGHT AWAY. See a doctor. You

may have carbon monoxide poisoning.

• Use a respirator or mask whenever there is a chance that

vapors may be inhaled when using chemicals.

• Read all instructions with mask so you are certain the

mask will provide the necessary protection against

inhaling harmful vapors when using chemicals.

WARNING! Risk of electrocution. Contact with

power source could cause electric shock or burn

resulting in death or serious injury.

• NEVER spray near power source.

WARNING! Use of pressure washer could create

puddles and slippery surfaces causing you to fall

resulting in death or serious injury.

Kickback from spray gun could cause you to fall resulting in

death or serious injury.

• Operate pressure washer from a stable surface.

• The cleaning area should have adequate slopes and

drainage to reduce the possibility of a fall due to slippery

surfaces.

3

Page 4

• Be extremely careful if you must use the pressure washer

from a ladder, scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spray gun kicks back.

WARNING! Fuel and its vapors are extremely

flammable and explosive which could cause burns,

fire or explosion resulting in death or serious injury.

• NEVER use a spray gun which does not have a trigger

lock or trigger guard in place and in working order.

• Always be certain spray gun, nozzles and accessories are

correctly attached.

WARNING! Unintentional sparking could cause

fire or electric shock resulting in death or serious

injury.

When Operating Equipment:

• DO NOT operate this product inside any building,

carport, porch, mobile equipment, marine applications,

or enclosure.

• DO NOT tip engine or equipment at angle which causes

fuel to spill.

• DO NOT spray flammable liquids.

• After each starting attempt, where engine fails to run,

always point spray gun in safe direction, release the

red lever and squeeze spray gun trigger to release high

pressure.

• Firmly grasp spray gun with both hands when using

high pressure spray to avoid injury when spray gun kicks

back.

WARNING! Chemical Burn Hazard. Chemicals

could cause burns resulting in death or serious

injury.

• DO NOT use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents/soaps. Follow

all manufacturers instructions.

WARNING! The high pressure stream of water that

this equipment produces could cut through skin and

its underlying tissues, resulting in serious injury and

possible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected, which

could result in serious injury.

• If cut by fluid, call physician immediately. DO NOT treat

as a simple cut.

• DO NOT allow CHILDREN to operate pressure washer.

• NEVER repair high pressure hose. Replace it.

• NEVER repair leaking connections with sealant of any

kind. Replace O-ring or seal.

• NEVER connect high pressure hose to nozzle extension.

• Keep high pressure hose connected to pump and spray

gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red lever

and squeeze spray gun trigger to release high pressure,

every time you stop engine.

• NEVER aim spray gun at people, animals, or plants.

• DO NOT secure spray gun in open position.

• DO NOT leave spray gun unattended while machine is

running.

• NEVER operate pressure washer without protective

housing or covers.

WARNING! Risk of eye or bodily injury. Spray could

splash back or propel objects resulting in serious

injury.

• Always wear indirect vented (chemical splash) safety

goggles marked to comply with ANSI Z87.1 when using

or in vicinity of this equipment.

• NEVER substitute safety glasses or dry-condition goggles

for indirect vented safety goggles.

• Always wear protective clothing such as a long-sleeved

shirt, long pants and close-toed shoes.

• NEVER operate pressure washer when barefoot or

wearing sandals or shorts.

CAUTION: Excessively high operating speeds

could result in minor injury.

When Transporting, Moving Or Repairing Equipment:

• Disconnect the FLEX™ Pressure Washer attachment from

the power base prior to attempting to load, repair or

transport this device.

• Follow instructions in the FLEX™ Power Base operator’s

manual for Transporting the FLEX™ Power Base.

• Use care when loading or unloading this attachment

onto a trailer or truck.

• This attachment must be secured onto the trailer or

truck with straps, chains, cables, ropes, or other means

deemed adequate for that purpose.

Adjusting Or Making Repairs To Your Pressure Washer:

• Uncouple the FLEX™ Pressure Washer from the FLEX™

Power Base before making any major adjustments or

repairs.

Note: It is not necessary to uncouple the two devices in

the instance of changing spray tips. Simply power down

the FLEX™ Power Base, waiting for the engine to come to

a complete stop, engage the trigger lock, then change the

spray tip as instructed in the Assembly & Set-Up Section of

this manual.

4 Section 2 — important Safe operation practiceS

Page 5

Excessively low speeds impose a heavy load.

• DO NOT tamper with governor spring, links or other

parts to increase engine speed. Pressure washer supplies

correct rated pressure and flow when running at

governed speed.

• DO NOT modify pressure washer in any way

Note: High pressure spray could damage fragile items

including glass.

• DO NOT point spray gun at glass when using red (0°)

spray tip.

• NEVER aim spray gun at plants.

Note: Improper treatment of pressure washer could

damage it and shorten its life.

• If you have questions about intended use, ask dealer or

contact qualified service center.

• NEVER operate units with broken or missing parts, or

without protective housing or covers.

• DO NOT by-pass any safety device on this machine.

• DO NOT tamper with governed speed.

• DO NOT operate pressure washer above rated pressure.

• DO NOT modify pressure washer in any way.

• Before starting pressure washer in cold weather, check

all parts of the equipment to be sure ice has not formed

there.

• NEVER move machine by pulling on hoses. Use handle

provided on unit.

• This equipment is designed to be used with Troy-Bilt

authorized parts ONLY.

• If equipment is used with parts that DO NOT comply

with minimum specifications, user assumes all risks and

liabilities.

General Operation

1. Read this Operator’s Manual completely before starting the

machine. Study the controls and learn the proper sequence

of operation. Retain Operator’s Manual in a safe place for

future reference.

2. Do not allow anyone to operate or maintain this machine

who has not read the manual.

3. Always have your feet and hands clear of the controls when

starting the engine.

4. Do not remove any shields, guards, decals or safety devices.

If a shield, guard, decal or safety device is damaged or

does not function, repair or replace it before operating the

machine.

5. If truck or trailer mounted, make certain the sprayer is

securely bolted to the frame of the truck or trailer.

6. Wear a face shield and rubber gloves when handling

concentrates.

7. Always wear safety glasses, long pants and safety shoes

when operating or maintaining this unit. Do not wear

loose-fitting clothing.

8. Never run the engine indoors without adequate

ventilation. Exhaust fumes are deadly.

9. To avoid serious burns, do not touch the engine or muffler

while the engine is running or until it has cooled for at least

30 minutes after it has been shut off.

10. Keep adults, children and pets away from the sprayer and

the area to be sprayed.

11. Always check the area to be sprayed and remove debris

and other objects prior to spraying.

12. Always disconnect the spark plug wire to prevent the

engine from accidentally starting before performing any

maintenance on this machine.

13. Keep the machine and especially the engine/pump area

clean and free of grease, grass and leaves to reduce the

potential for over heating and fire.

General Requirements

1. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless,

and deadly gas.

2. Before cleaning, repairing, or inspecting, make certain all

moving parts have stopped. Disconnect the spark plug

wire and ground against the engine to prevent unintended

starting.

3. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

4. Never attempt to make adjustments or repairs to the

machine while the engine is running.

5. For safety protection, frequently check components

and replace immediately with original equipment

manufacturer’s (O.E.M.) parts only, listed in this manual.

“Use of parts which do not meet the original equipment

specifications may lead to improper performance and

compromise safety!”

6. Do not change the engine governor settings or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

7. Maintain or replace safety and instruction labels, as

necessary.

8. Observe proper disposal laws and regulations for gas, oil,

etc. to protect the environment.

5Section 2 — important Safe operation practiceS

Page 6

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read, understand, and follow all instructions in the manual(s) before attempting to

assemble and operate.

WARNING — BYSTANDERS

Keep bystanders away. ALWAYS point nozzle away and in a safe direction.

WARNING — FLUID INJECTION

Risk of fluid injection. Never spray yourself, others, or animals, as injury could result.

WARNING — KICK BACK

Spray gun kicks back. Hold securely with both hands when engaging trigger.

WARNING — EYE INJURY

Risk of eye injury. Always wear safety goggles. Spray can propel objects.

WARNING — SLIPPERY SURFACES

Use of pressure washer can cause slippery surfaces. Use extra care to avoid falling.

WARNING — ELECTROCUTION

Risk of electrocution. Never spray near power source.

WARNING — EXPLOSION

Risk of explosion. DO NOT spray flammable liquids.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTIONS!

6 Section 2 — important Safe operation practiceS

Page 7

Assembly & Set-Up

Soap Inlet

Port

3

Read entire operator’s manual before you attempt to

assemble or operate your new pressure washer.

If you have any problems with the assembly of your pressure

washer, please call (800) 828-5500. If calling for assistance, please

have the model and serial number from the identification label

available.

Unpack Pressure Washer

1. Remove the parts bag, any accessories, and cardboard

inserts included with pressure washer.

2. Open carton completely by cutting each corner from top

to bottom.

3. Ensure you have all included items prior to assembly.

Items in the carton include:

• Main Unit

• High Pressure Hose

• Spray Gun

• Nozzle Extension with Quick Connect Fitting

• Operator’s Manual

• Owner’s Registration Card

• Bag containing 5 Multi–Colored Spray nozzles

• Bag containing soap inlet tube with 2 clamps

Set-Up

To prepare this pressure washer attachment for operation,

perform these tasks:

1. Remove the five plastic caps shown in Figure 3-1.

Note: The first four caps pull off as shown. The plastic cap

in the inset of Figure 3-1, rotates counter clockwise to

remove. If choosing not to install the soap inlet tube at this

time, the plastic cap on the soap inlet port of the pressure

washer pump may remain in place.

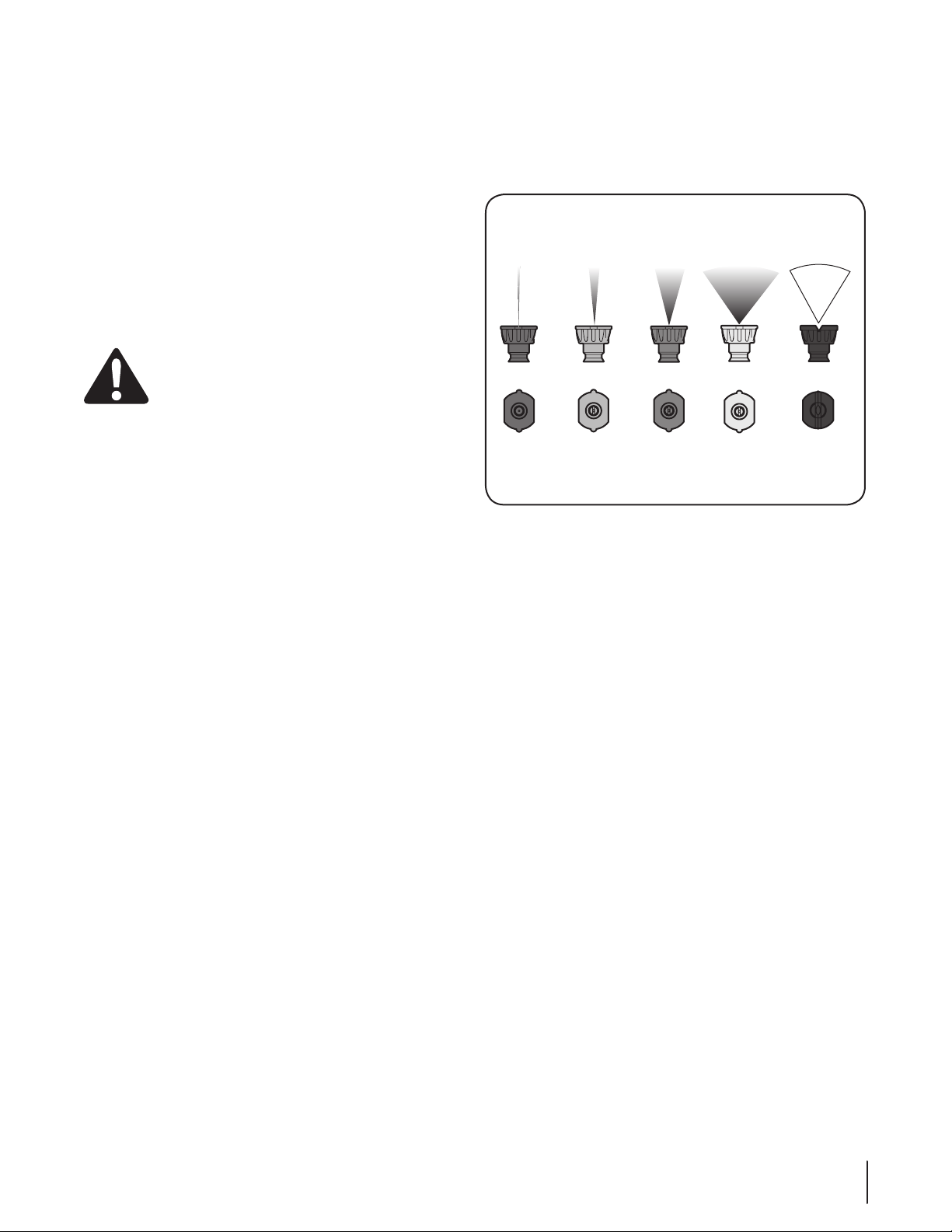

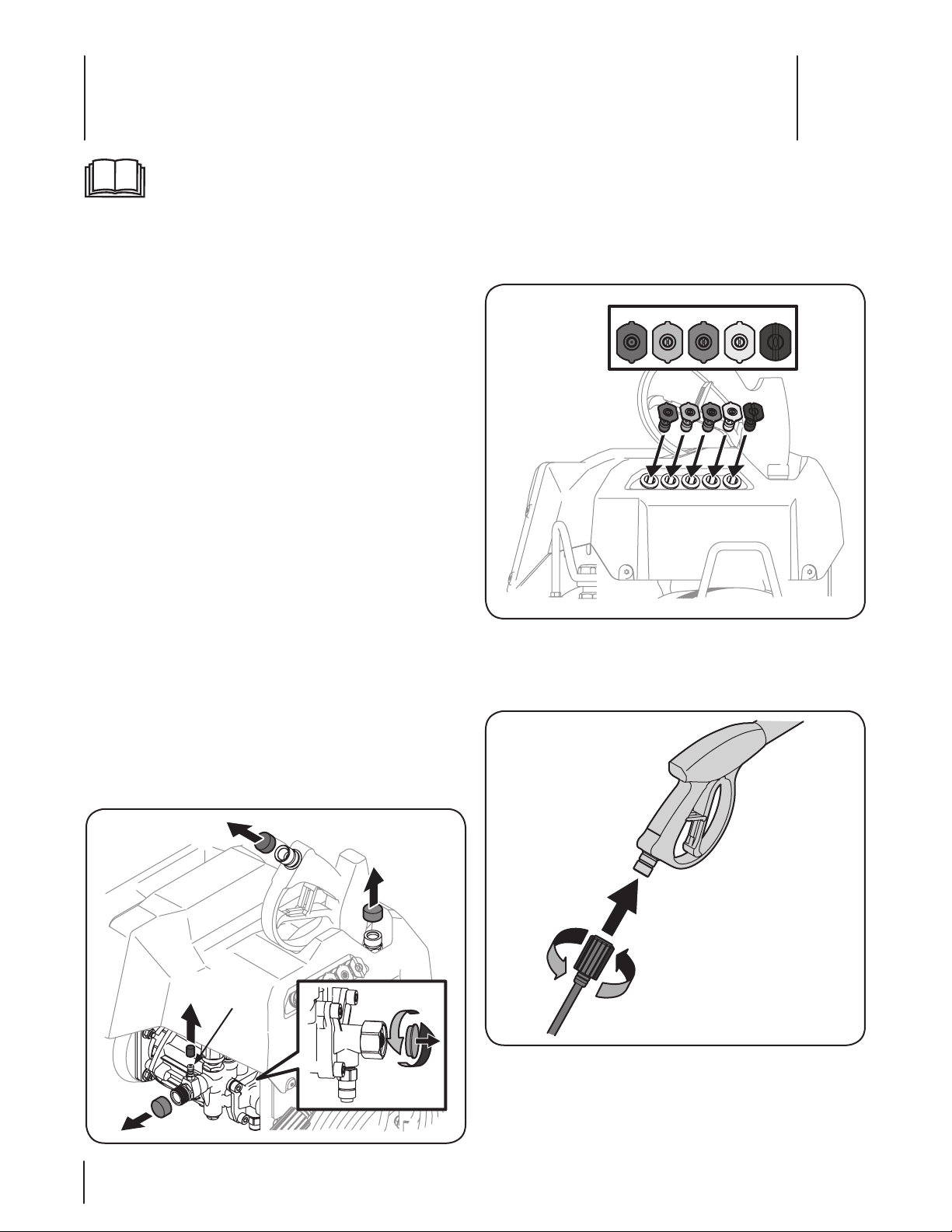

2. Locate the bag containing the 5 multi-colored spray

nozzles, included with the loose parts in the carton. Insert

the tips into the provided mounting holes on the pressure

washer main unit. Follow the color pattern provided on

the label on the unit for the proper order in which to install

these tips. See Figure 3-2.

Figure 3-2

3. Connect high pressure hose to spray gun handle by

threading the hose onto the spray gun as shown in Figure

3-3.

Figure 3-3

Figure 3-1

7

Page 8

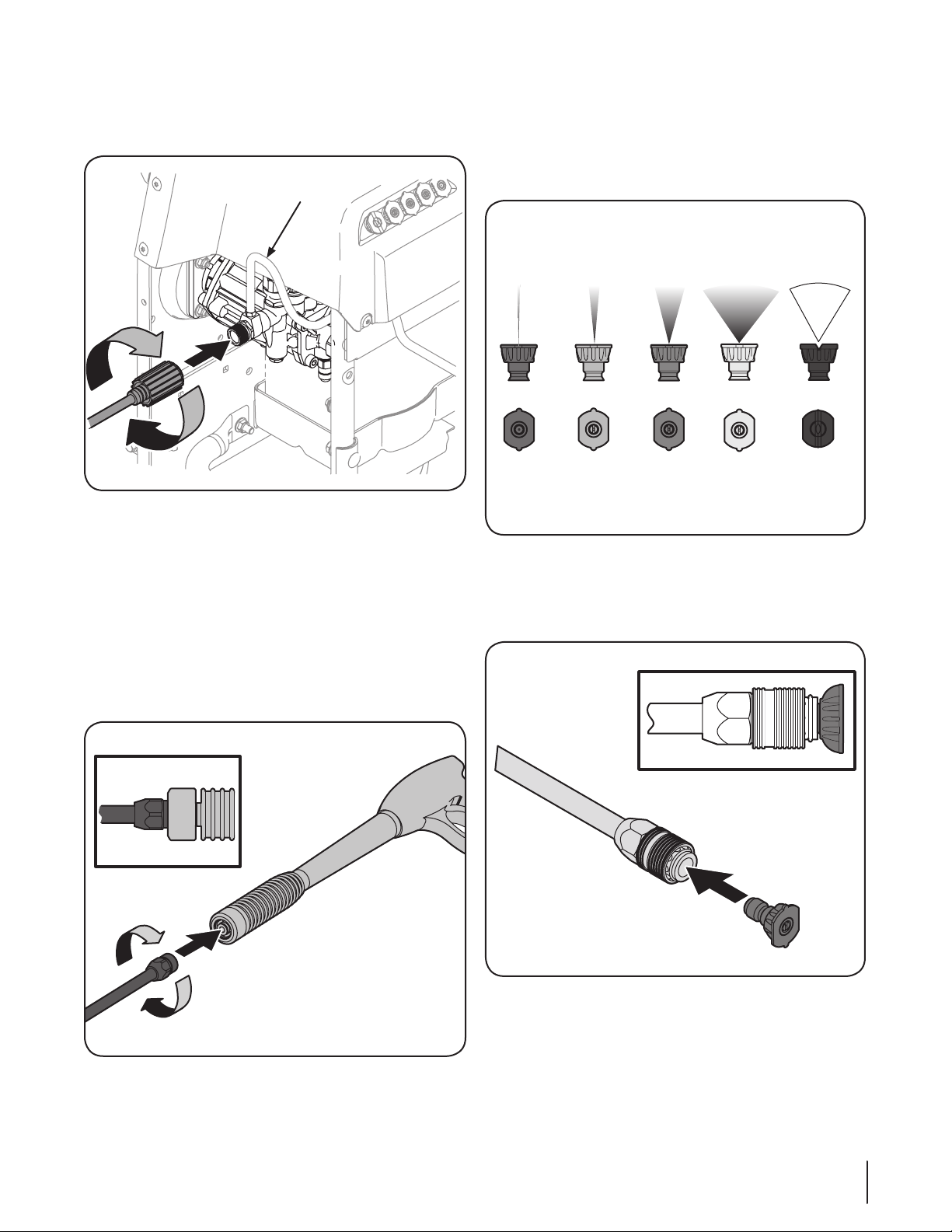

4. Uncoil and connect the other end of the high pressure hose

Soap Inlet Tube

0º

15º

25º

40º

Soap

black

white

green

yellow

red

to the pressure washer main unit by threading the hose

onto the hose port as shown in Figure 3-4.

Figure 3-4

5. Attach the nozzle extension to spray gun by threading it

into the spray gun handle as shown in Figure 3-5. Firmly

hand-tighten the two components together.

Note: It may be necessary to use an adjustable wrench

to further tighten the nozzle extension to the spray gun

handle if the operator notices water seeping or leaking

from the connection point during operation. Be careful

not to overtighten. Do not use an adjustable wrench or

adjustable pliers to tighten either end of the high pressure

hose onto the spray gun or the main pressure washer unit.

6. Select the tip to use for the particular application this

pressure washer is to be used for. See Figure 3-6.

Note: See the Operation Section for more details regarding

each spray nozzle’s usage.

Figure 3-6

7. Install the desired spray nozzle into the end of the spray

handle assembly as shown in Figure 3-7. Simply align the

tip into the end of the spray handle and push. It will click

into place. See Figure 3-7.

8 Section 3— ASSembly & Set-Up

Figure 3-5

Figure 3-7

8. To remove a spray nozzle, simply pull back on the spray

gun collar (A) in Figure 3-8.

Page 9

A

B

Figure 3-8

Installing the Soap Inlet Tube

If planning to utilize the “Soap” tip, and apply soap using the

spray handle, follow these steps:

1. Remove the plastic cap on the soap inlet port of the

pressure washer pump, if not already done so. Refer to

Figure 3-1.

Note: If choosing not to install the soap inlet tube at this

time, the plastic cap on the soap inlet port of the pressure

washer pump may remain in place.

2. Install the two plastic hose clips packed with the soap inlet

tube, into the frame holes provided. See Figure 3-9.

Note: Clip types may vary, but all function the same.

3. Push the soap inlet tube onto the inlet port on pressure

washer pump. Refer to Figure 3-1 for location of where the

inlet tube attaches.

Note: The soap inlet hose has enough additional length so

that instead it can be routed into a bucket that sits beside

the unit that contains a soap mixture.

Figure 3-10

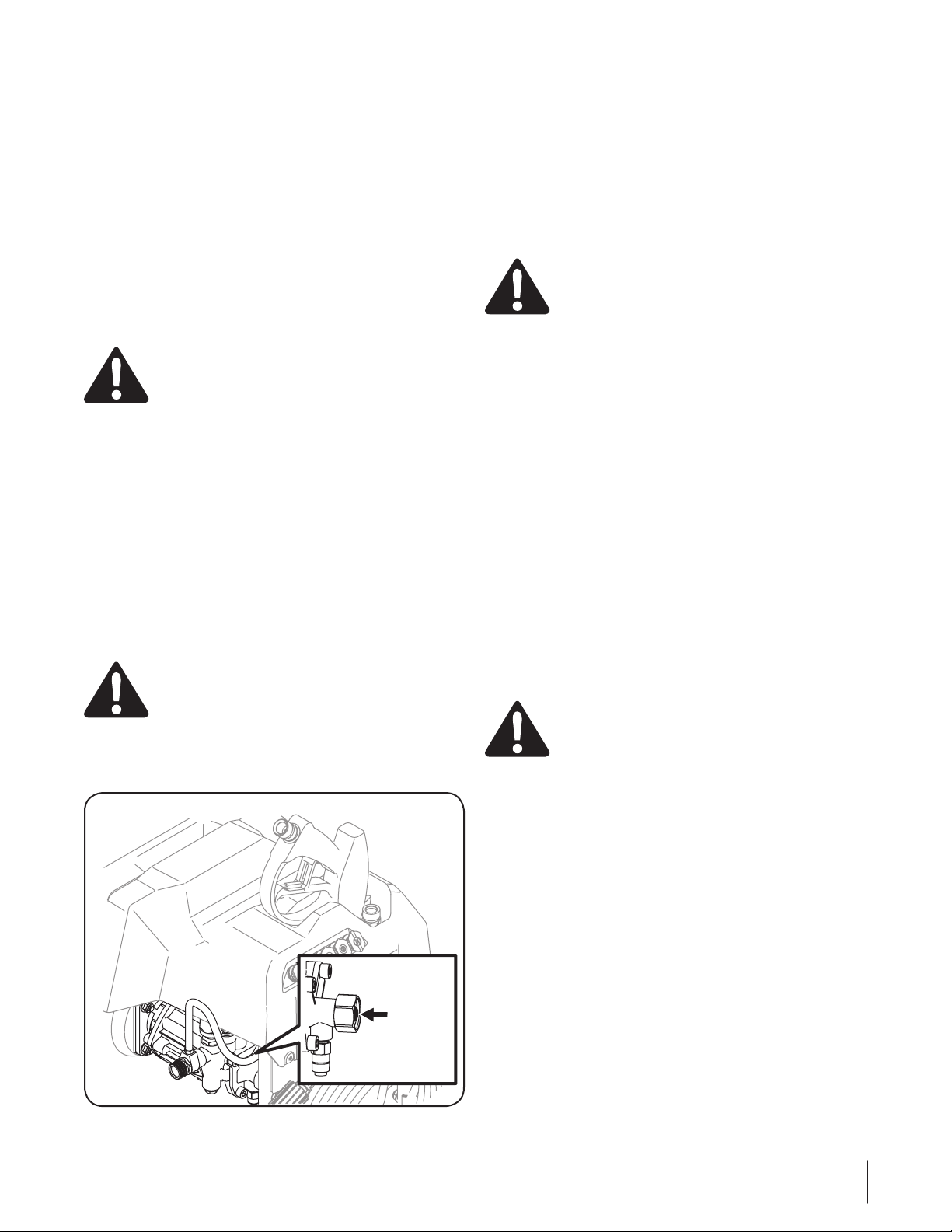

6. A pressure control valve has been supplied to adjust the

pressure of the spray being dispensed through the spray

gun by the pressure washer. From the factory, the unit has

been set at maximum pressure. To lower pressure, rotate

knob counter-clockwise. See Figure 3-11.

Figure 3-9

4. Route the soap inlet tube through the two clips installed in

Step 2. See the inset of Figure 3-9.

5. Install the bottle of soap into the soap holding tray and

insert the soap inlet tube into the bottle as shown in Figure

3-10. Soap bottle NOT included.

Figure 3-11

7. If the pressure control has been lowered by turning the

knob counter-clockwise, then turn the knob clockwise to

increase the pressure.

WARNING! Do not tighten or force the pressure

control knob once it reaches the stop at either end

of the pressure control spectrum. It is best to have

the knob slightly backed off in either direction once

reaching the stop either at min. or max. pressure.

Your FLEX™ Pressure Washer is now setup and ready to be used

in a wide variety of applications. Proceed to the next section

in this manual to learn about the controls and operation of the

FLEX™ Pressure Washer.

9Section 3 — ASSembly & Set-Up

Page 10

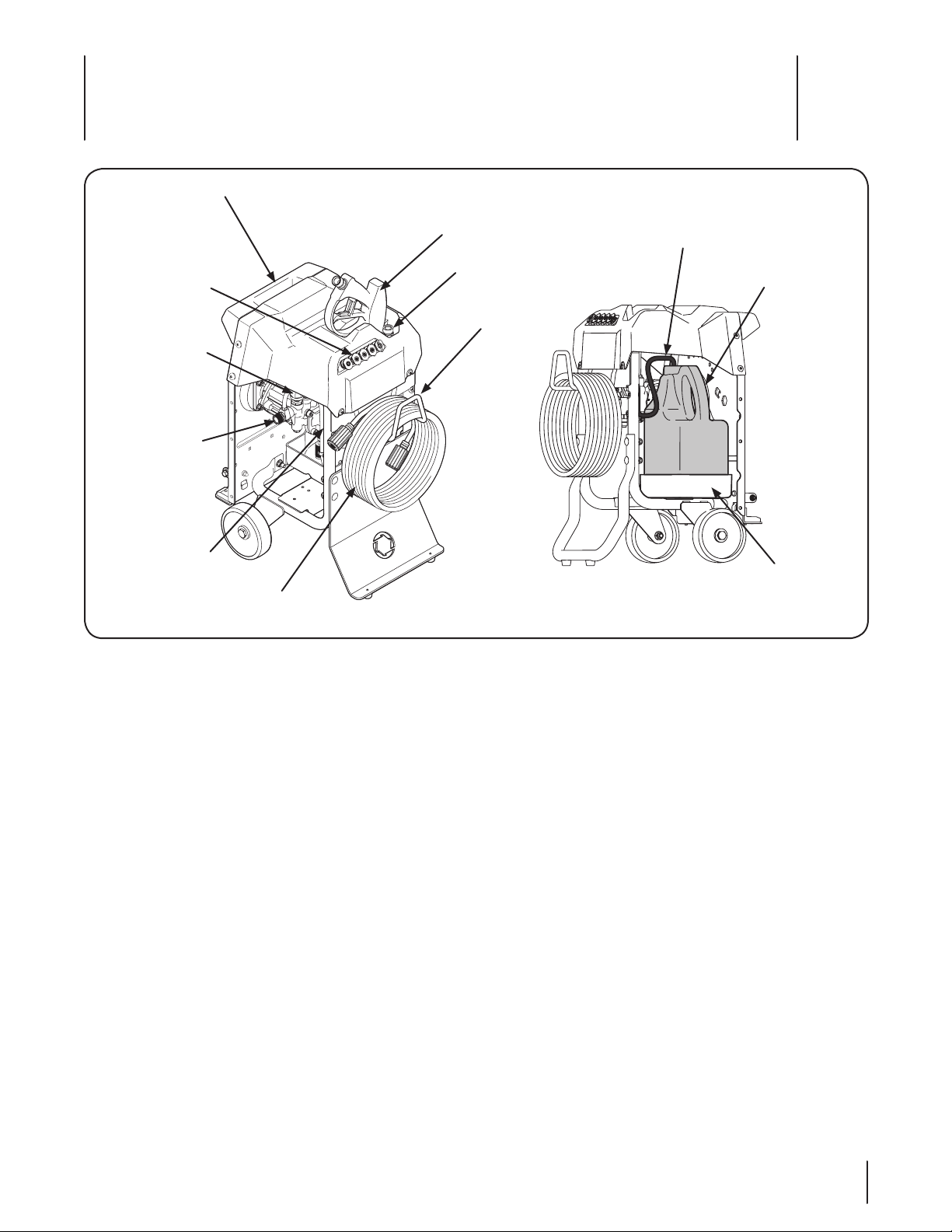

Controls & Features

Rear Handle

Spray Nozzles

Pressure Valve

Spray Handle

Hose Storage

Hanger

High Pressure

Hose

High Pressure

Outlet

Water Inlet Port

Spray Handle Extension

Soap Inlet Tube

Soap Bottle

(Not included)

Soap Retaining Tray

4

Rear Handle

The rear handle can be used to move the pressure washer

around when NOT attached to the FLEX™ Power Unit.

Spray Nozzles

Five spray nozzles have been included for various applications

ranging from applying soap to different gauge pressure streams.

Pressure Valve

Used to increase and decrease the pressure of the water being

dispensed from the spray handle.

High Pressure Outlet

Use this port to attach the high pressure hose, while the other

end attaches to the spray handle.

Water Inlet Port

Use this port to attach the water hose/feed line.

High Pressure Hose

Connect one end to the high pressure hose port, the other end

to the spray gun.

Hose Storage Hanger

Used for storing the high pressure hose when not in use.

Figure 4-1

Spray Handle Extension with Quick Connect

Threads onto the end of the spray handle, extending the spray

handle and includes the spray nozzle quick connect fitting.

Spray Handle

Controls the application of water onto cleaning surface with

trigger device. Includes a trigger lock.

Soap Inlet Tube

Used to supply soap when utilizing the “Soap” nozzle. Simply

feed the line down into the soap in the container.

Soap Bottle (Not Included)

A space has been supplied to accommodate either an oblong or

rounded pressure washer detergent bottle. Bottle shown is for

reference purposes and not included.

10

Page 11

Operation

1

2

WARNING! When the FLEX™ Pressure Washer attachment is attached to the FLEX™ Power Base, the engine must only

be started after the water supply is connected and turned on with water flowing through the pressure washer. Failure

to have the water source connected with water flowing through he pressure washer prior to starting the engine of the

FLEX™ Power Base will cause irreparable damage to the pressure washer pump.

Starting The Engine

Refer to the FLEX™ Power Base’s Operator’s Manual for engine

starting and operating instructions.

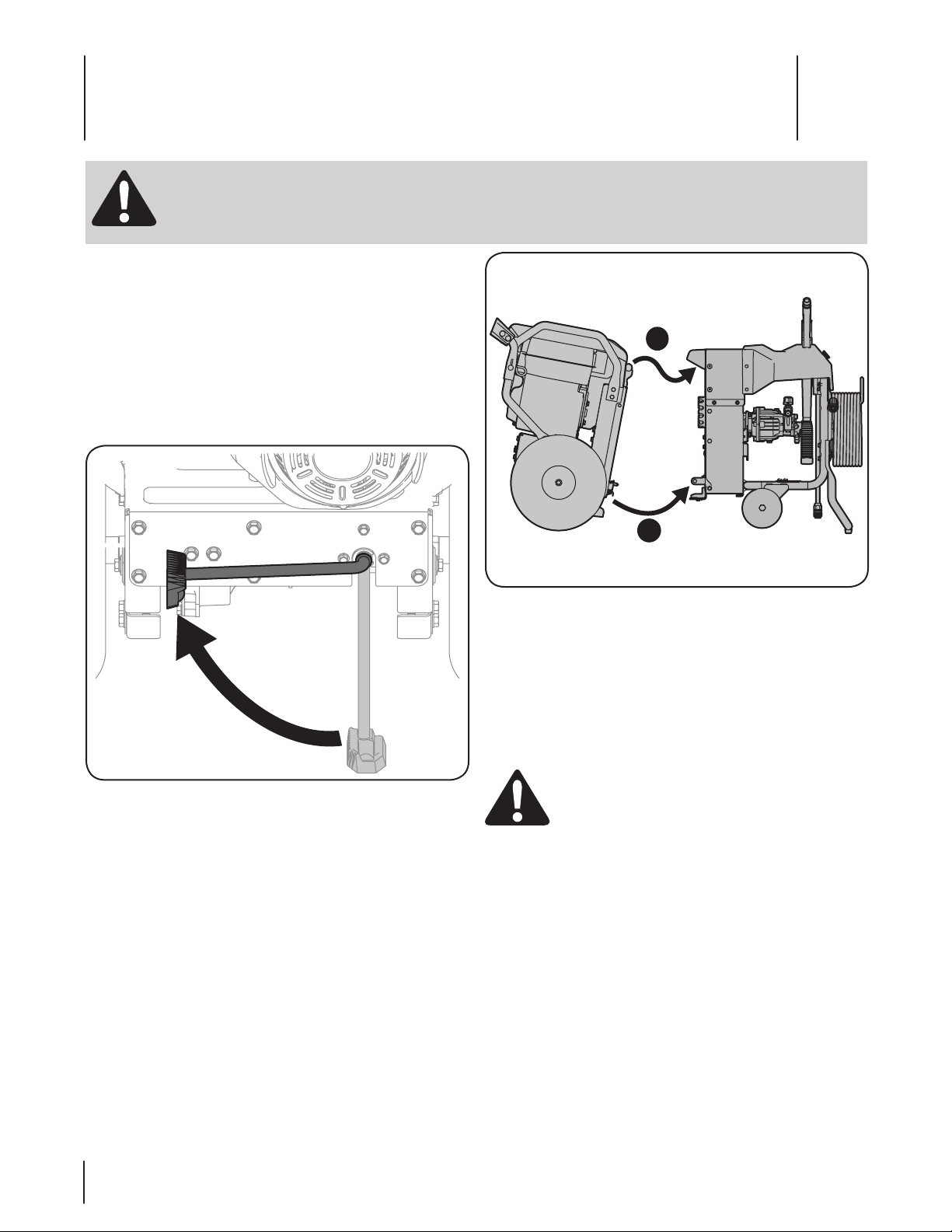

Couple Pressure Washer Attachment to Power

Base

1. With the kickstand UP on the FLEX™ Power Base, as shown

in Figure 5-1, roll it over to the pressure washer attachment.

5

Figure 5-1

2. Tip the FLEX™ Power Base forward until the power base

hinge is in place under the mounting handle (1), and push

down firmly on both handles until you hear the Latch-nLock™ System click into place (2) on the pressure washer

attachment. See Figure 5-2.

Note: The operator will be able to hear the Latch-n-Lock™

system engage and lock (latching sound) when coupled

properly. To test if coupled properly, lift up on the handles.

If the unit comes apart, the connection was not made.

Double check that the kickstand is still in the UP position,

and repeat steps 1 and 2.

Figure 5-2

Note: The operator will be able to hear the Latch-n-Lock™

system engage and lock when coupled properly.

Uncouple the Pressure Washer Attachment from Power Base:

Fully stop the Power Base engine before attempting to perform

any maintenance steps or uncoupling of the attachment. Never

attempt to uncouple the Power Base from the pressure washer

attachment WITH the engine running.

WARNING! Always turn off the FLEX™ Power Base

engine and remove the key prior to attempting to

perform any maintenance or adjustments and/or

uncoupling of the Power Base from the attachment.

1. Position the kickstand down.

2. Tip the FLEX™ Power Base forward to disengage the Latchn-Lock™ mechanism, then the power base hinge.

3. Move the FLEX™ Power Base away from the pressure

washer attachment.

Note: With the kickstand deployed in the downward (unlocking)

position, the FLEX™ Power Base will rest comfortably in a parked

position.

11

Page 12

FLEX™ Pressure Washer Operation

Connect

garden

hose

here.

To use this pressure washer for the first time, follow these stepby-step instructions.

1. Place pressure washer near an outside water source

capable of supplying water at a flow rate greater than 3.3

gallons per minute (12.5 liters per minute) and no less than

20 PSI (1.38 BARS) at pressure washer end of garden hose.

Do not use the self-propelled feature on the FLEX™ Power

Base to drive the attachment to the location in which it

will be used. The water source must be connected to

the pressure washer and turned on with water flowing

through the pressure washer attachment, before

attempting to start the FLEX™ Power Base.

WARNING! DO NOT run the FLEX™ Power Base,

and pressure washer attachment, without the water

supply connected and turned on with water flowing

through the Pressure Washer. Damage to this

equipment resulting from failure to follow this

instruction will void the warranty.

2. Check that the spray gun extension tube with nozzle quick

connect is tightly connected to the spray gun handle. See

the Assembly & Set-Up section for detailed instructions.

3. Check that high pressure hose is tightly connected to both

the spray gun and the water pump. See the Assembly &

Set-Up section for detailed instructions.

4. Choose the spray nozzle that you want to use, and insert it

into the end of the spray handle extension by pushing until

it can be heard clicking into place. Tug on spray nozzle to

make sure it is securely in place.

WARNING! Never change a spray nozzle without

the trigger lock engaged.

5. Make sure that the complete unit is in a level position.

6. Connect a garden hose to the water inlet on the pressure

washer pump. See Figure 5-3.

Note: Make sure the garden hose is not kinked or restricted

in any way and that water can flow freely once turned on.

7. Point spray gun in a safe direction, and then turn the water

ON.

8. Release the spray gun lock lever, if locked, and squeeze

the trigger to purge the pump system of any air and/or

impurities.

Note: Before starting the pressure washer, be sure you are

wearing safety goggles as described below.

CAUTION: Risk of eye injury. Spray could splash

back or propel objects resulting in serious injury.

• Always wear indirect vented (chemical splash)

safety goggles marked to comply with ANSI

Z87.1 when using or in vicinity of this

equipment.

• NEVER substitute safety glasses or dry condition goggles for indirect vented safety

goggles.

9. Start the FLEX™ Power Base in accordance with the starting

instructions in the FLEX™ Power Base’s Operator’s Manual.

How to Stop Your Pressure Washer

1. Release the spray gun trigger and let the engine idle for

two minutes.

2. Push down and hold the engine rocker on/off switch on

the FLEX™ Power Base, to the OFF position, until the engine

comes to a complete stop.

3. ALWAYS point the spray gun in a safe direction, release

the spray lock lever if applied, then squeeze the spray gun

trigger to release any retained high water pressure.

4. Turn off the water source.

WARNING! The high pressure stream of water that

this equipment produces could cut through skin and

its underlying tissues, resulting in serious injury and

possible amputation. Spray gun traps high water

pressure, even when engine is stopped and water is

disconnected, which could result in serious injury.

• Keep the high pressure hose connected to the

pump and the spray gun while the system is

pressurized.

• ALWAYS point the spray gun in a safe direction,

release the trigger lock if applied, and squeeze

the spray gun trigger to release any built-up

high pressure, every time you stop engine.

12 Section 5— operation

Figure 5-3

How to Use The Accessory Tray

The unit is equipped with an accessory storage system with

places to store your spray gun, nozzle extension, high pressure

hose and quick connect spray nozzles.

1. Place the nozzle extension into the hole on the front, top,

left side of accessory tray as shown in Figure 4-1 of the

Controls & Features Section of this manual. Clip the nozzle

extension into place by moving it towards the front of the

unit.

2. Place the spray gun into the same hole, located just behind

the nozzle extension, and allow it to rest on its handle.

Page 13

3. Insert the five (5) multi–colored spray nozzles into the

0º

15º

25º

40º

Soap

black

white

green

yellow

red

color-coded spaces provided in the accessory tray.

4. Coil and hang the high pressure hose onto the hose

storage hanger, once both ends are detached from the

spray gun and the pressure washer pump.

How to Use Spray Nozzles

The quick–connect on the nozzle extension allows you to switch

between five (5) different quick-connect spray nozzles. Spray

nozzles can be changed while the pressure washer is running

once the spray gun trigger lock has been engaged. The spray

nozzles vary the spray pattern as shown. Refer to Figure 5-4.

Follow these instructions to change spray nozzles:

1. Engage the trigger lock lever on the spray gun handle.

WARNING! The high pressure stream of water that

this equipment produces could cut through skin and

its underlying tissues, resulting in serious injury and

possible amputation. NEVER exchange spray nozzles

without the trigger lock being engaged on the spray

gun.

• DO NOT twist spray nozzles while spraying.

2. Pull the quick–connect collar back and pull the current

spray nozzle off. Store spray nozzles in the holder provided

on the accessory tray.

3. Select the desired spray nozzle:

• For delicate rinse, for gentle cleaning of cars/trucks,

boats, RV’s, patio furniture, lawn equipment, etc.;

select the white 40° spray nozzle.

• For a little more pressure, ideal for dried-on debris;

select the green 25° spray nozzle.

• For general rinsing, ideal for most all purpose

cleaning such as home siding, brick patios, wood

decks, driveways and sidewalks, garage floors, etc.;

select the yellow 15° spray nozzle.

• For maximum rinsing, for stubborn or hard to reach

surface such as second story surfaces, paint removal,

oil stains, rust removal or other stubborn substances

(tar, gum, grease, wax, etc.); select the red 0° spray

nozzle.

• To apply detergent, apply project specific cleaners

to help break down stubborn dirt and grime on a

variety of surfaces; select the black detergent spray

nozzle.

4. Insert new spray nozzle by pushing it into the spray

nozzles. The spray nozzles are quick connect and simply

push-and-click into place. It is not necessary to pull back

on the nozzle collar to install the spray nozzles. Tug on

spray nozzle once installed to make sure that it is securely

in place.

Figure 5-4

Usage Tips

• For most effective cleaning, keep spray nozzle from 8 to 24

inches (20 to 61 cm) away from cleaning surface.

• If you get spray nozzle too close, especially when using

spray nozzles with less than a 40 fan.; you may damage

the surface being cleaned.

• DO NOT get closer than 6 inches (15 cm) when cleaning

tires.

13Section 5 — oper ation

Page 14

Applying Detergent

WARNING! Chemical Burn Hazard. Chemicals

could cause burns resulting in death or serious

injury.

• DO NOT use caustic liquid with pressure washer.

• Use ONLY pressure washer safe detergents/soaps.

Follow all manufacturers’ instructions.

To apply detergent, follow these steps:

1. Review use of the spray nozzles.

2. Prepare the detergent solution as required by job.

3. Install the detergent container into the soap retaining tray,

refer back to Figure 4-1 in the Controls & Features Section

for the location of soap retaining tray.

4. Remove the cap on the detergent container and insert the

soap inlet tube down INTO the detergent.

5. Make sure black “Soap” spray nozzle is installed.

Note: Detergent cannot be applied with any other spray

nozzle other than the “Soap” spray nozzle.

6. Make sure that a garden hose is connected to the water

inlet on the pressure washer.

7. Check that the high pressure hose is connected to the

spray gun and pump.

8. Turn the water ON to FULL.

WARNING! You must attach all hoses before you

start the engine.

• Starting the engine without all the hoses

connected and without the water turned ON

and water flowing through the pressure

washer will damage the pump.

• Damage to equipment resulting from failure

to follow this instruction will void warranty.

9. Start engine in accordance with the starting instructions in

the FLEX™ Power Base Operator’s Manual.

10. Apply detergent to a dry surface, starting at lower portion

of area to be washed and work upward, using long, even,

overlapping strokes.

11. Allow detergent to “soak in” for 3-5 minutes before

washing and rinsing. Reapply as needed to prevent surface

from drying. DO NOT allow detergent to dry on (prevents

streaking).

WARNING! Kickback from the spray gun could

cause you to fall resulting in death or serious injury.

• Operate pressure washer from a stable surface.

• Be extremely careful if you must use the pressure

washer from a ladder, scaffolding, or any other

similar location.

• Firmly grasp spray gun with both hands when

using high pressure spray to avoid injury when

spray gun kicks back.

4. Apply a high pressure spray to a small area, then check

the surface for damage. If no damage is found, it is okay to

continue cleaning.

5. Start at the top of the area to be rinsed, working down with

same overlapping strokes as you used for washing and

applying detergent.

Automatic Cool Down System (Thermal Relief)

If you run the engine on your pressure washer for 3-5 minutes

without pressing the trigger on the spray gun, circulating water

in the pump can reach temperatures above 125°F (51°C). The

system engages to cool the pump by discharging the warm

water onto the ground.

Pressure Washer Rinsing

1. Remove the black detergent spray nozzle from the nozzle

extension.

2. Select and install the desired high pressure spray nozzle

following the instructions for How to Use Spray Nozzles.

3. Keep the spray gun a safe distance from the area you plan

to spray.

14 Section 5— operation

Page 15

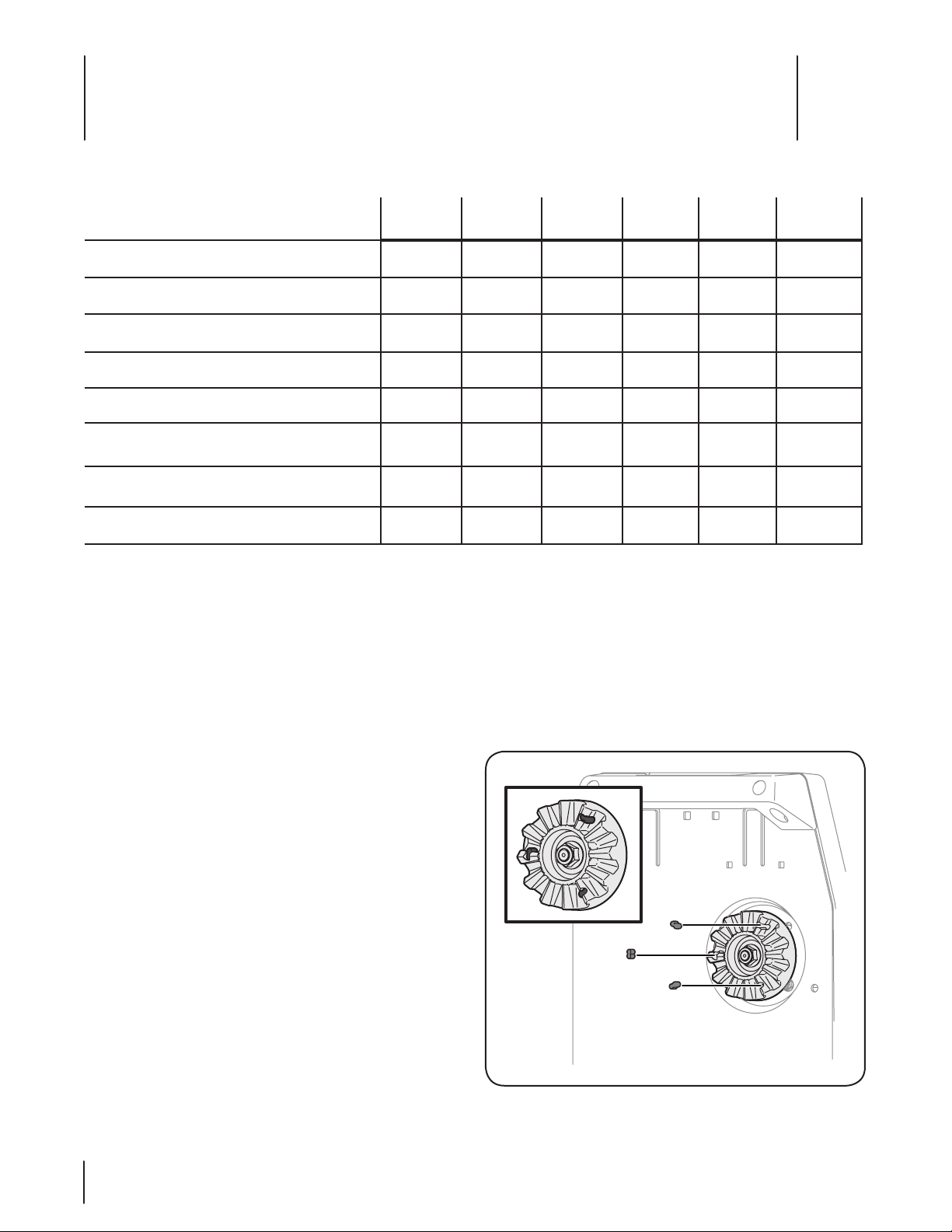

Maintenance & Adjustments

Maintenance Schedule

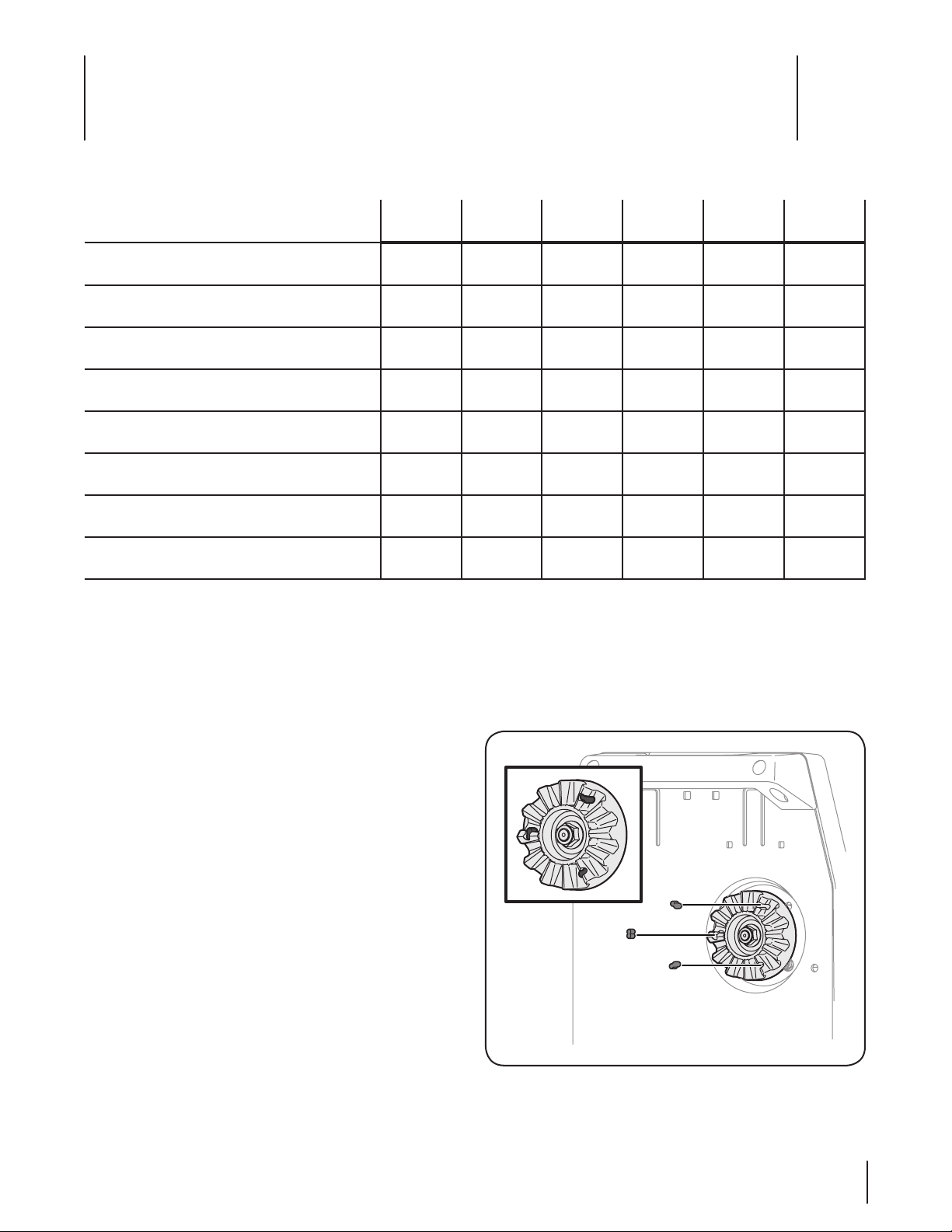

6

Before

Each use

Check clutch bumpers

Check engine oil level

Check / clean water inlet screen

Check high pressure hose

Check detergent siphoning tube

Check spray gun and assembly for leaks

Clean debris

Lube Pivot Points

P

P P

General Recommendations

Regular maintenance will improve the performance and extend

the life of the pressure washer. See any authorized service dealer

for service.

The pressure washer’s warranty does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, the operator must maintain the

pressure washer as instructed in this manual, including proper

storage as detailed the Winter and Long Term Storage sections.

Note: Should you have questions about replacing components

on your pressure washer, please call (800) 828-5500 or (330) 5587220 for assistance.

Some adjustments will need to be made periodically to properly

maintain your pressure washer.

All service and adjustments should be made at least once each

season. Follow the requirements in the Maintenance Schedule

chart above.

Note: Once a year you should clean or replace the spark plug,

clean or replace the air filter, and check the spray gun and nozzle

extension assembly for wear. A new spark plug and clean air filter

assure proper fuel-air mixture and help your engine run better

and last longer.

Every

8 Hours

Every

50 Hours

Every

200 Hours

Yearly

Prior

to Storing

P

P

P

P

P

P P

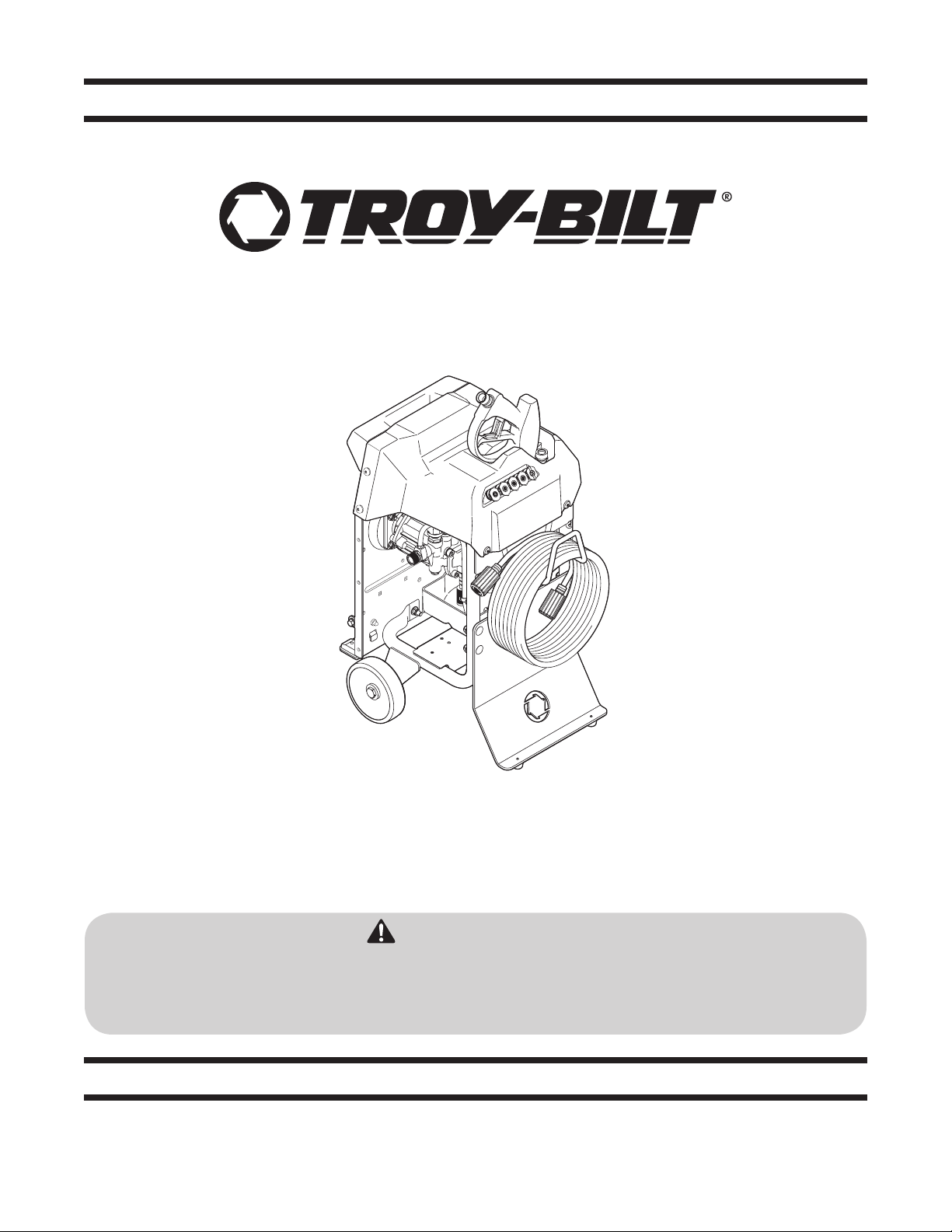

Clutch Bumpers

It is necessary to check the clutch bumpers, installed on the

dog clutch assembly, before each use. The clutch bumpers are

wearable parts that will need to be replaced periodically after

extended usage.

To replace the clutch bumpers, follow these instructions:

1. Gently pry each clutch bumper out of the dog clutch using

a standard screw driver. See Figure 6-1.

Pump Oil

DO NOT attempt any oil maintenance on this pump. The pump

is pre-lubricated and sealed from the factory, requiring no

additional maintenance for the life of the pump.

Figure 6-1

2. Replace the clutch bumpers (Kit Part No. 753-08457) by

fully pressing them into place.

15

Page 16

Pressure Washer Maintenance

Clean Debris

Daily or before use, clean accumulated debris from pressure

washer. Keep linkage, spring and controls clean. Keep area

around and behind muffler free from any combustible debris.

Inspect cooling air slots and openings on the pressure washer.

These openings must be kept clean and unobstructed.

Pressure washer parts should be kept clean to reduce the risk of

overheating and ignition of accumulated debris.

• Use a damp cloth to wipe exterior surfaces clean.

Note: Improper treatment of pressure washer could

damage it and shorten its life.

• DO NOT insert any objects through cooling slots.

• Use a soft bristle brush to loosen caked on dirt, oil, etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

Check and Clean Inlet Screen

Examine the screen on the pump’s water inlet. Clean it if the

screen is clogged or replace it if screen is damaged.

Check High Pressure Hose

The high pressure hose can develop leaks from wear, kinking, or

abuse. Inspect the hose each time before using it. Check for cuts,

leaks, abrasions or bulging of cover, damage or movement of

couplings. If any of these conditions exist, replace the hose.

WARNING! The high pressure stream of water that

this equipment produces could cut through skin and

its underlying tissues, resulting in serious injury and

possible amputation.

• NEVER repair leaking connections with sealant of any kind.

Replace O-ring or seal.

After Each Use

Water should not remain in the unit for long periods of time.

Sediments or minerals can deposit on pump parts and freeze

pump action. Follow these procedures after every use:

3. Flush detergent system by removing the detergent

siphoning tube from the cleaning tank and run pressure

washer with black spray nozzle. Flush for one to two

minutes.

WARNING! The high pressure stream of water that

this equipment produces could cut through skin and

its underlying tissues, resulting in serious injury and

possible amputation. Spray gun traps high water

pressure, even when engine is stopped and water is

disconnected, which could result in serious injury.

• Keep high pressure hose connected to pump and

spray gun while system is pressurized.

• ALWAYS point spray gun in safe direction, press red

lever and squeeze spray gun trigger to release high

pressure, every time you stop engine.

4. Shut off engine, turn off water supply, point gun in a safe

direction, press red lever and squeeze trigger to relieve

trapped pressure, and let engine cool.

5. Disconnect hose from spray gun and high pressure outlet

on pump. Drain water from hose, spray gun, and nozzle

extension. Use a rag to wipe off the hose.

6. Place the spray gun, nozzle extension and spray nozzles

in the accessory tray. Hang high pressure hose on hook

attached to accessory tray.

7. Empty pump of all pumped liquids by pulling recoil handle

about six times. This should remove most liquid in pump.

8. Store unit in a clean, dry area.

9. If storing for more than 30 days, see Off-Season Storage

later in this section.

WARNING! Fuel and its vapors are extremely

flammable and explosive which could cause burns,

fire or explosion resulting in death or serious injury.

When Storing Fuel Or Equipment With Fuel In Tank

• Store away from furnaces, stoves, water heaters,

clothes dryers, or other appliances that have pilot

light or other ignition source because they could

ignite fuel vapors.

Winter Storage

Note: You must protect your unit from freezing temperatures.

• Failure to do so will permanently damage your pump and

render your unit inoperable.

• Freeze damage is not covered under warranty.

To protect the unit from freezing temperatures:

1. Follow steps 2-5 in the previous section After Each Use.

2. Use PumpSaver, Model BS-6151, to treat pump. This

minimizes freeze damage and lubricates pistons and seals.

3. If pump saver is not available, connect a 3-foot (1 m)

section of garden hose to water inlet adapter. Pour RVantifreeze (antifreeze without alcohol) into hose. Pull recoil

handle twice. Disconnect 3-foot (1 m) hose.

4. Store unit in a clean, dry area.

Long Term Storage

If you do not plan to use the pressure washer for more than 30

days, you must prepare the engine and pump for long term

storage.

Protecting the Pump

To protect the pump from damage caused by mineral deposits

or freezing, use PumpSaver, Model BS-6151, to treat pump. This

prevents freeze damage and lubricates pistons and seals.

Note: PumpSaver is available as an optional accessory. It is

not included with the pressure washer. Contact the nearest

authorized service dealer to purchase PumpSaver.

Note: You must protect your unit from freezing temperatures.

• Failure to do so will permanently damage your

pump and render your unit inoperable.

• Freeze damage is not covered under warranty.

To use PumpSaver, make sure the pressure washer is turned

off and disconnected from supply water. Read and follow all

instructions and warnings given on the PumpSaver container.

Other Storage Tips

1. Cover unit with a suitable protective cover that does not

retain moisture.

WARNING! Storage covers could cause a fire

resulting in death or serious injury.

• DO NOT place a storage cover over a hot pressure

washer.

• Let equipment cool for a sufficient time before

placing the cover on the equipment.

16 Section 6— Maintenance & adjuStMentS

Page 17

Troubleshooting

Problem Cause Remedy

7

Pump has following

problems: failure to produce

pressure, erratic pressure,

chattering, loss of pressure,

low water volume.

Detergent fails to mix with

spray.

Excessive vibration or noise

when the Attachment

Control Lever is applied.

1. Low pressure spray nozzle installed.

2. Water inlet is blocked.

3. Inadequate water supply.

4. Inlet hose is kinked or leaking.

5. Clogged inlet hose screen.

6. Water supply is over 100°F (38°C).

7. High pressure hose is blocked or leaks.

8. Spray gun leaks.

9. Spray nozzle is obstructed.

10. Pump is faulty.

1. Detergent siphoning tube is not submerged.

2. Detergent siphoning tube is clogged or

cracked.

3. Non-soap spray nozzle installed.

4. Check ball stuck in detergent siphoning

system.

1. One or more of the clutch bumpers is missing

or worn.

1. Replace with high pressure spray nozzle.

2. Clear inlet.

3. Provide adequate water flow.

4. Straighten inlet hose, patch leak.

5. Check and clean inlet hose screen.

6. Provide cooler water supply.

7. Clear blocks in outlet hose.

8. Replace spray gun.

9. Clean spray nozzle.

10. Contact an authorized service dealer .

1. Insert detergent siphoning tube into

detergent.

2. Clean or replace detergent siphoning tube.

3. Replace with soap spray nozzle.

4. Unstick check ball as described in Detergent

Siphoning Check Ball.

1. Replace the three cluctch bumpers with

replacement kit part no. 753-08457.

17

Page 18

Replacement Parts

Component Part Number and Description

8

687-05118 Spray Nozzle Kit (5)

753-08457 Clutch Bumper Kit (6)

737-05046 High-Pressure Hose

Phone (800) 828-5500 to order replacement parts or a complete Parts Manual (have your full model number and serial number ready).

Parts Manual downloads are also available free of charge at www.troybilt.com.

18

Page 19

LIMITED WARRANTY FOR FLEX ATTACHMENT PRODUCT

The limited warranty set forth herein is given by Troy-Bilt LLC to the Initial

Purchaser (as defined herein) with respect to a new Troy-Bilt-branded FLEX

attachment product consisting of one of the following four (4) attachments

to the FLEX Power Base (referred to hereaf ter as the “Attachment”): (i) wide

area mower, (ii) snow-thrower, (iii) pressure washer or (iv) leaf blower. This

limited warranty does not cover Emission Control Systems and is not a

Federal Emission Control Warranty Statement as defined by U.S. federal

law. Please refer to the Federal Emission Control Warranty Statement in

the operator’s manual for the FLEX Power Base product (“Power Base”) for

warranties covering Emission Control Systems.

Scope of the Limited Warranty

Troy-Bilt LLC offers the following limited warranty to the Initial Purchaser for

residential or otherwise non-commercial use of the Attachment on the FLEX

Power Base: except for the Exclusions (defined herein), during the Warrant y

Period (defined herein), the Attachment will be free from manufacturing

defects (including workmanship and materials). The “Initial Purchaser” is the

first person to purchase a new Attachment from an authorized Troy-Bilt dealer,

distributor and/or retailer of such attachment products. This limited warranty

is non-transferrable. Except as otherwise set forth herein, the limited warranty

period for this new Attachment purchased by the Initial Purchaser is two (2)

years from the date of purchase as shown on the original sales receipt for the

Attachment (“Warranty Period”).

Defects in Workmanship or Materials

Except for the Exclusions, the Attachment is warranted to be free from

manufacturing defects in either workmanship or materials for the Warranty

Period. During the Warranty Period, Troy-Bilt LLC will, at its option, either

repair or replace any original part that is covered by this limited warranty and

is determined to be defective in workmanship or material.

To qualify for this limited warranty the FLEX™ Base Unit:

1. Must have been purchased from an authorized Troy-Bilt retailer.

2. Must have been purchased within the United States by the Initial

Purchaser.

3. Must have been used for residential or otherwise non-commercial

purposes.

4. Must have been used in a manner consistent with the normal and

proper intended use for the Attachment. This Attachment is not

intended for rental or commercial use.

Who can perform repairs under this warranty?

In order to qualif y for the limited warranty as set forth herein, the repairs made

under this warranty must be performed by an authorized Troy-Bilt service

provider.

How to get service under this limited warranty:

To locate a Troy-Bilt warranty service provider, contact your authorized

Troy-Bilt dealer, distributor and/or retailer or contact Troy-Bilt LLC at P.O. Box

361131, Cleveland, Ohio 44136-0019 or call 1-877-282-8684 or log on to our

Website at www.troybilt.com. This limited product warranty is provided

by Troy-Bilt LLC and is the only product warranty provided by Troy-Bilt LLC

for this Attachment. A COPY OF YOUR SALES RECEIPT IS REQUIRED FOR

WARRANTY SERVICE.

What this limited warranty does not cover.

This limited warranty does not cover the following (the “Exclusions”):

1. Attachment purchased outside of the United States.

2. Damage due to lack of maintenance and/or improper maintenance as

described in the operator’s manual.

3. Normal wear and tear resulting from use of the Attachment.

4. Use of the Attachment that is not consistent with the intended use

thereof as described in the operating instructions, including, but not

limited to, abuse, misuse and/or neglect of the Attachment or any use

inconsistent with and/or non-compliant with instructions contained in

the Operator’s Manual.

5. Any expendable, consumable, or routine maintenance item which

needs replacement or service as part of normal maintenance, unless

such items have defects that cause failure or premature wear within

the first thirty (30) days. Where applicable, normal wear items include

but are not limited to, blades, tires, belts, filters, fuses, and other

consumable items

6. Any Attachment that has been altered or modified in a manner not

consistent with the original design of the product or in a manner not

otherwise approved by Troy-Bilt LLC.

7. Paint repairs or replacements for defective paint (including materials

and application) are covered for a period of three (3) months.

8. Wheel rims are covered for a period of three (3) months for

manufacturing defects.

9. The FLEX Power Base is covered by a separate limited warranty which

is contained in the operator’s manual for the FLEX Power Base.

This warranty does not cover and Troy-Bilt LLC disclaims any

responsibility for:

1. Loss of time or loss of use of the Attachment.

2. Transportation costs and other expenses incurred in connection with

the transport of the Attachment to and from the authorized Troy-Bilt

service provider.

3. Any loss or damage to other equipment or personal items.

4. Damage caused by performance or use of the Attachment in

connection with any product other than the FLEX Power Base.

Limitations:

1. THERE ARE NO IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED

TO, ANY IMPLIED WARRANT Y OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. NO WARRANTY APPLIES AFTER THE APPLICABLE

WARRANTY PERIOD AS SET FORTH ABOVE AS TO THE PARTS AS

IDENTIFIED. NO OTHER E XPRESS WARR ANTY OR GUARANTY, WHETHER

WRITTEN OR ORAL , EXCEPT AS MENTIONED ABOVE, GIVEN BY ANY

PERSON OR ENTITY, INCLUDING A DEALER OR RETAILER, WITH RESPECT

TO ANY PRODUCT SHALL BIND TROY-BILT LLC. DURING THE WARRANTY

PERIOD, THE EXCLUSIVE REMEDY IS REPAIR OR REPLACEMENT OF THE

DEFECTIVE PART, AS SET FORTH ABOVE. (SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.)

2. THE PROVISIONS AS SET FORTH HEREIN PROVIDE THE SOLE AND

EXCLUSIVE REMEDY ARISING FROM THE SALE. TROY-BILT SHALL NOT

BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGES

INCLUDING, WITHOUT LIMITATION, FOR TRANSPORTATION OR FOR

RELATED EXPENSES, OR FOR RENTAL EXPENSES TO TEMPORARILY

REPLACE A WARRANTED PRODUCT. (SOME STATES DO NOT ALLOW

THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THE ABOVE E XCLUSION OR LIMITATION MAY NOT APPLY

TO YOU.)

3. In no event shall recover y of any kind be greater than the amount of the

purchase price of the product sold. Alteration of the safety features of the

product shall void this limited warranty. You assume the risk and liability

for loss, damage, or injury to you and your property and/or to others

and their property arising out of the use or misuse or inability to use the

product.

How State Law Relates to this Warranty:

This limited warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

079221 REV. A

Troy-Bilt LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019; Phone: 1-800-828-5500, 1-330-558-7220

MTD Canada Limited - KITCHENER, ON N2G 4J1; Phone 1-800-668-1238

Page 20

Medidas de seguridad • Conguración • Funcionamiento • Mantenimiento • Servicio • Solución de problemas • Garantía

Manual del OperadOr

Accesorio de lavadora a presión FLEX™ — 23AADAAA711

ADVERTENCIA

LEA Y OBSERVE TODAS LAS NORMAS E INSTRUCCIONES DE SEGURIDAD INCLUIDAS

EN ESTE MANUAL ANTES DE PONER EN FUNCIONAMIENTO LA MÁQUINA.

SI NO SIGUE ESTAS INSTRUCCIONES PUEDE PROVOCAR LESIONES PERSONALES.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Impreso en EE.UU.

Page 21

Al propietario

Gracias

Gracias por comprar el Accesorio de lavadora a presión FLEX™

Troy-Bilt. La misma ha sido cuidadosamente diseñada para brindar

excelente rendimiento si se la opera y mantiene correctamente.

Por favor lea todo este manual antes de hacer funcionar el equipo.

El manual le indica cómo configurar, operar y mantener la máquina

con seguridad y fácilmente. Por favor asegúrese de que usted,

y cualquier otra persona que haga funcionar la máquina, sigue

atentamente y en todo momento las medidas de seguridad

recomendadas. En caso de no hacerlo podrían producirse lesiones

personales o daños materiales.

Toda la información contenida en este manual hace referencia a la

más reciente información de producto disponible en el momento de

la impresión. Revise el manual frecuentemente para familiarizarse

con la máquina, sus características y funcionamiento. Por favor

tenga en cuenta que este Manual del Operador puede cubrir una

gama de especificaciones para productos de varios modelos. Es

posible que las características y funciones incluidas y/o ilustradas en

este manual no se apliquen a todos los modelos. Nos reservamos

el derecho de modificar las especificaciones de los productos,

Índice

Medidas de seguridad .......................................... 22

Montaje y Conguración ...................................... 26

Controles y Características ................................... 29

Operación .............................................................. 30

1

diseños y equipos sin previo aviso y sin generar responsabilidad por

obligaciones de ningún tipo.

Si tiene algún problema o duda respecto a la máquina, llame a

un distribuidor de servicio Troy-Bilt autorizado o comuníquese

directamente con nosotros. En esta página encontrará los números

de teléfono, dirección del sitio web y dirección postal de Atención

al cliente de Troy-Bilt. Queremos garantizar su entera satisfacción en

todo momento.

En este manual, todas las referencias al lado derecho e izquierdo de la

máquina se observan desde la posición del operador

Mantenimiento y ajustes ...................................... 34

Solución de problemas ......................................... 37

Piezas de Repuesto ................................................ 38

Garantía ................................................................. 40

Registro de información de producto

Antes de configurar y hacer funcionar su equipo nuevo, por favor

localice la placa de modelo en el equipo y registre la información

en el espacio de la derecha. Podrá localizar la placa de modelo si la

busca en la placa de montaje en el lado correspondiente a la bomba.

Si tiene que solicitar soporte técnico a través de nuestro sitio web,

el Departamento de Asistencia al Cliente, o de un distribuidor de

servicio autorizado local, necesitará esta información.

NúMero de Modelo

NúMero de Serie

Asistencia al Cliente

Por favor, NO devuelva la máquina al minorista o distribuidor sin ponerse

en contacto primero con el Departamento de Asistencia al Cliente.

Si tiene dificultad para armar este producto o tiene dudas respecto a los controles, el funcionamiento o el mantenimiento de

esta máquina, puede solicitar la ayuda de expertos. Seleccione una de las opciones siguientes:

◊ Visite nuestro sitio web en www.troybilt.com

Vea videos instructivos sobre el mantenimiento y la instalación de piezas en www.troybilt.com/tutorials

◊ Llame a un representante de Asistencia al Cliente al (800) 828-5500 ó (330) 558-7220

◊ Escriba a Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

21

Page 22

Importantes medidas de seguridad

ADVERTENCIA: La presencia de este símbolo indica que se trata de instrucciones de seguridad

importantes que se deben respetar para evitar poner en peligro su seguridad personal y/o material

y la de otras personas. Lea y cumpla todas las instrucciones de este manual antes de intentar operar

esta máquina. Si no respeta estas instrucciones puede provocar lesiones personales.

CUANDO vea este símbolo. TENGA EN CUENTA LA ADVERTENCIA!

PELIGRO: Esta máquina está diseñada para ser utilizada respetando las normas de seguridad

contenidas en este manual. Al igual que con cualquier tipo de equipo motorizado, un descuido

o error por parte del operador puede producir lesiones graves. Esta máquina es capaz de amputar

dedos, manos y pies y de arrojar objetos. De no respetar las instrucciones de seguridad siguientes

se pueden ocasionar lesiones graves o la muerte.

PRECAUCIÓN: El símbolo de alerta de seguridad indica un riesgo potencial de que se produzcan

lesiones. Se utiliza una palabra indicadora (PELIGRO, ADVERTENCIA o PRECAUCIÓN) con el símbolo

de alerta para designar un grado o nivel para la gravedad del riesgo. Se puede usar un símbolo de

seguridad para representar el tipo de riesgo.

NOTA: Se utiliza para abordar prácticas que no están relacionadas con que se produzcan lesiones.

2

Seguridad del operador

Descripción del equipo

Lea este manual con atención

y familiarícese con el accesorio

de lavadora a presión.

Conozca sus aplicaciones, limitaciones y los riesgos que conlleva. Esta

lavadora a presión funciona a un máximo de 3,000 PSI

(206.8 BARS) y un caudal de hasta 2.5 galones por minuto

(9.46 litros por minuto).

Se ha hecho todo lo posible para asegurar que la información que se

incluye en el presente manual sea precisa y actual. Sin embargo, nos

reservamos el derecho de cambiar, modificar o mejorar de cualquier

otra manera el producto y este documento en cualquier momento

sin aviso previo.

ADVERTENCIA! PELIGRO DE GASES VENENOSOS. El

escape del motor contiene monóxido de carbono,

un gas venenoso que podría matarlo en minutos.

NO puede olerlo, mirarlo ni probarlo. Incluso si no huele

los gases del escape, igual podría quedar expuesto al

gas de monóxido de carbono.

Algunos productos químicos o detergentes podrían

ser perjudiciales si se inhalan o ingieren, podrían

producir la muerte, lesiones graves, náuseas,

desmayos o envenenamiento.

• Opere este producto ÚNICAMENTE en exteriores bien

alejado de ventanas, puertas y ventilaciones a fin de

reducir el riesgo de que se acumulen emanaciones de

gas de monóxido de carbono y sean atraídas hacia

espacios ocupados.

• Instale alarmas de monóxido de carbono operadas a batería

o alarmas de monóxido de carbono conectable con batería de

reserva según las instrucciones del fabricante. Las alarmas de

humo no pueden detectar el gas de monóxido de carbono.

• NO utilice este producto en el interior de una casa, garaje,

sótano, entrepisos, graneros ni otros espacios parcialmente

cerrados incluso si utiliza ventiladores o si abre puertas y

ventanas para ventilar. El monóxido de carbono se acumula

rápidamente en dichos espacios y puede quedar acumulado

por horas, incluso después de haber apagado este producto.

• Ubique SIEMPRE este producto en la dirección del viento

y apunte el escape del motor de manera que quede alejado

de espacios ocupados. Si empieza a sentirse descompuesto,

mareado o débil mientras utiliza este producto, apáguelo

y salga al aire libre DE INMEDIATO. Consulte a un médico.

Puede sufrir envenenamiento por monóxido de carbono.

• Utilice un respirador o una máscara cuando haya posibilidad

de que puedan inhalarse los vapores al

usar productos químicos.

• Lea todas las instrucciones que se adjuntan con la

máscara de manera de estar seguro de que la máscara

proveerá la protección necesaria contra la inhalación

de vapores perjudiciales al usar productos químicos.

ADVERTENCIA! Riesgo de electrocución.

El contacto con la fuente de alimentación de energía

podría causar una descarga eléctrica o quemaduras que

podrían producir la muerte o lesiones graves.

• NUNCA rocíe cerca de la fuente de alimentación de energía.

ADVERTENCIA! El uso de la lavadora a presión podría

crear charcos y superficies resbaladizas que podrían

hacerlo caer y provocarle la muerte o lesiones graves.

El retroceso del gatillo rociador podría hacerlo caer provocándole la

muerte o lesiones graves.

• Opere la lavadora a presión desde una superficie estable.

• La zona de limpieza debe tener pendientes y drenaje que

sean adecuados para reducir la posibilidad de una caída

por superficies resbaladizas.

22

Page 23

• Sea extremadamente precavido si debe usar la lavadora

a presión desde una escalera, andamio o cualquier otro

lugar similar.

• Tome con firmeza el gatillo rociador con ambas manos

cuando use el rociado a alta presión para evitar lesiones

si el gatillo rociador retrocede.

ADVERTENCIA! El combustible y sus vapores

son extremadamente inflamables y explosivos,

lo que podría producir quemaduras, incendios

o explosiones provocando la muerte o lesiones graves.

Al operar el equipo:

• NO opere este producto en el interior de construcciones,

garajes, porches, equipos móviles, aplicaciones marítimas

o lugares cerrados.

• NO incline el motor ni el equipo en un ángulo que provoque

que se derrame combustible.

• NO rocíe líquidos inflamables.

• Después de cada intento de arranque, si el motor no

funciona, oriente siempre el gatillo rociador en una

dirección segura, suelte la palanca roja y oprima el

gatillo del rociador para descargar la presión alta.

• Tome con firmeza el gatillo rociador con ambas manos

cuando use el rociado a alta presión para evitar lesiones

si el gatillo rociador retrocede.

ADVERTENCIA! Peligro de quemaduras con

productos químicos. Los productos químicos podrían

producir quemaduras que provocaran la muerte

o lesiones graves.

• NO utilice líquido cáustico con la lavadora a presión.

• Utilice ÚNICAMENTE los detergentes/jabones seguros

para lavadora a presión. Siga todas las instrucciones

del fabricante.

ADVERTENCIA! El caudal de alta presión de agua

que produce este equipo podría producir cortes en la

piel y los tejidos subyacentes, con lo que se pueden

producir lesiones graves y una posible amputación.

El gatillo rociador contiene alta presión de agua, incluso

cuando el motor está parado y se ha desconectado el

agua, con lo que se podrían producir lesiones graves.

• Si sufre un corte producido por líquidos, debe llamar a un

médico de inmediato. NO lo trate como a un simple corte.

• NO permita que NIÑOS operen la lavadora a presión.

• NUNCA repare la manguera a alta presión. Debe reemplazarla.

• NUNCA repare con ningún tipo de sellador las conexiones

que presenten pérdidas. Reemplace la junta tórica o el sello.

• NUNCA conecte la manguera de alta presión a la extensión

de la boquilla.

• Mantenga la manguera de alta presión conectada a la bomba

y el gatillo rociador mientras el sistema esté presurizado.

• SIEMPRE debe apuntar el gatillo rociador en una dirección

segura, oprima la palanca roja y oprima el gatillo del rociador

para descargar la presión alta, cada vez que pare el motor.

• NUNCA apunte el gatillo rociador a personas, animales

ni plantas.

• NO asegure el gatillo rociador en la posición open (abierto).

• NO deje el gatillo rociador sin prestarle atención mientras

la máquina está en funcionamiento.

• NUNCA use un gatillo rociador que no tenga una traba para

el gatillo o una protección para el gatillo en su lugar y en

buenas condiciones de funcionamiento.

• Asegúrese siempre de que el gatillo rociador, las boquillas

y los accesorios estén correctamente conectados.

ADVERTENCIA! Las chispas accidentales podrían

causar incendio o electrocución que produjeran la

muerte o lesiones graves.

• NUNCA opere la lavadora a presión sin un alojamiento

o cubiertas de protección.

ADVERTENCIA! Riesgo de lesiones oculares

o corporales. El rociado podría rebotar y salpicar

al operador o podría mover objetos con lo que

podrían producirse lesiones graves.

• Utilice siempre gafas de seguridad con ventilación indirecta

(para salpicaduras de productos químicos) que tengan la

marca de que cumplen con la norma ANSI Z87.1 al usar este

equipo o al estar cerca de él.

• NUNCA sustituya las gafas de seguridad con ventilación indirecta por gafas de seguridad o gafas para condiciones secas.

• Utilice siempre vestimenta que lo proteja como camisa

de mangas largas, pantalones largos y zapatos de punta

cerrada.

• NUNCA opere la lavadora a presión cuando esté descalzo

o con sandalias o pantalones cortos.

PRECAUCIÓN: Como resultado de velocidades

de funcionamiento excesivamente elevadas, podrían

producirse lesiones menores.

Al transportar, desplazar o reparar equipos:

• Desconecte el accesorio de lavadora a presión FLEX™

de la base de potencia antes de intentar cargar, reparar

o transportar este dispositivo.

• Siga las instrucciones del manual del operador de la base

de potencia FLEX™ para transportar dicha base.

• Tenga cuidado al cargar o descargar este accesorio en

un remolque o camión.

• Una vez que esté en el en el remolque o camión, se debe

sujetar este accesorio con correas, cadenas, cables, sogas

u otros medios que se consideren adecuados al efecto.

Realización de ajustes o reparaciones de la lavadora a presión:

• Desacople la lavadora a presión FLEX™ de la base de

potencia FLEX™ antes de realizar algún ajuste o alguna

reparación de importancia.

Nota: No es necesario desacoplar los dos dispositivos cuando

se cambian las puntas de rociado. Sólo debe apagar la base

de potencia FLEX™, esperar a que el motor se detenga por

completo, poner la traba para el gatillo, y luego cambiar la

punta de rociado como se indica en la sección Montaje y

Configuración del presente manual.

23Sección 2 — importanteS medidaS de Seguridad

Page 24

Las velocidades excesivamente lentas imponen una carga

pesada.

• NO manipule indebidamente el resorte ni el enlace del

regulador, ni otras piezas para incrementar la velocidad

del motor. La lavadora a presión suministra la presión y

el flujo nominales correctos cuando la máquina funciona

a velocidad controlada.

• NO modifique la lavadora a presión de ninguna manera

Nota: El rociado a alta presión podría dañar artículos frágiles,

incluidos aquellos de vidrio.

• NO apunte el gatillo rociador a vidrios cuando use la

punta de rociado roja (0°).

• NUNCA apunte el gatillo rociador a las plantas.

Nota: Si se trata de manera inadecuada la lavadora a presión

podría dañarla y reducir su vida útil.

• Si tiene dudas en relación con el propósito para el que fue

diseñada, pregúntele al distribuidor o comuníquese con

el centro de servicio calificado.

• NUNCA opere las unidades que tengan piezas rotas

o faltantes, o que no tengan los alojamientos o las

cubiertas de protección.

• NO omita ningún dispositivo de seguridad en esta máquina.

• NO utilice de manera indebida la velocidad controlada.

• NO opere la lavadora a presión a una velocidad que supere

la nominal.

• NO modifique la lavadora a presión de ninguna manera.

• Antes de poner en marcha la lavadora a presión en climas

fríos, controle todas las piezas del equipo para comprobar

que no se haya formado hielo allí.

• NUNCA tire de las mangueras para mover la máquina.

Utilice la manija que se provee en la unidad.

• El presente equipo está diseñado para usarse con piezas

Troy-Bilt autorizadas ÚNICAMENTE.

• Si se usa el equipo con piezas que NO cumplen con las

especificaciones mínimas, el usuario asume todos los riegos

y las responsabilidades.

Funcionamiento general

1. Lea este manual del operador en su totalidad antes de poner

en funcionamiento la máquina. Estudie los controles y aprenda

la secuencia operativa adecuada. Conserve este Manual del

operador en un lugar seguro para consultas futuras.

2. No deje que nadie que no haya leído este manual opere

o realice el mantenimiento de esta máquina.

3. Siempre mantenga sus pies y manos alejados de los controles

cuando ponga en marcha el motor.

4. No retire las protecciones, las calcomanías o los dispositivos

de seguridad. Si una protección, calcomanía o un dispositivo

de seguridad está dañado o no funciona, repárelo o

reemplácelo antes de operar la máquina.

5. Si se la monta en un remolque o camión, debe asegurarse de

que el rociador esté bien sujeto al bastidor de dicho remolque

o camión.

6. Utilice una máscara que cubra el rostro y guantes de goma

cuando manipule productos concentrados.

7. Siempre use gafas de protección, pantalones largos y zapatos

de seguridad cuando opere o realice el mantenimiento de

esta unidad. No use vestimenta demasiado holgada.

8. Nunca encienda el motor en un lugar cerrado sin ventilación

adecuada. Los humos de escape son venenosos.

9. Para evitar quemaduras graves, no toque el motor o silenciador

mientras el motor esté en funcionamiento o hasta que se haya

enfriado por lo menos durante 30 minutos luego que se haya

apagado.

10. Mantenga a adultos, niños y mascotas alejados del rociador

y del área a ser rociada.

11. Siempre realice un control del área a ser rociada y retire los

residuos u otros objetos antes de rociar.

12. Antes de realizar las tareas de mantenimiento de la máquina

desconecte siempre el cable de la bujía para evitar que el

motor se ponga en marcha de forma accidental.

13. Mantenga la máquina y especialmente la zona del motor/

la bomba limpia y libre de grasa, césped y hojas para reducir

la posibilidad de que se produzca un sobrecalentamiento

e incendio.

Requerimientos generales

1. Nunca encienda el motor en espacios cerrados o en una zona

con poca ventilación. El escape del motor contiene monóxido

de carbono, un gas inodoro y letal.

2. Antes de limpiar, reparar o inspeccionar la máquina,

compruebe que todas las piezas móviles se hayan detenido.