GARDEN WAY

_ TRD_J_!LT"

Model

12213- 4.5HP

GARDEN WAYINCORPORATED

Owner'sManual

REAR-TINETILLER

• Safety

• Assembly

• Controls

• Operation

• Maintenance

• Parts List

DearOwner:

You now own one of the finest standard-rotating-tine tillers

available.Your new tiJJerallows you to tiJland cultivateyour

gardenwith ease,andaccomplish dozensof other property

managementprojects aswell. Your tiller is famous for its

ruggedness,performance and high-quality engineering. We

know you'll enjoyusing it.

Pleasecarefully readthis Manual. Ittells you howto safely

and easily assemble, operateand maintain your machine.

Besure that you and anyother operators carefully follow

the recommended safety practices atall times. Failureto

do so could result in personal injury or property damage.

Of course, if you should ever haveany problems or

questions, pleasecontact your local authorized dealeror

call the Factory (seehack cover of this Manual). We want to

be sore that you are completely satisfied at arttimes.

NOTE:Be sure to fill out and return the Warranty Registra-

tion Cardthat was supplied with this Manual.

See Back Cover for

Customer Service Information

Safety AlertSymbol

,_ This isa safety alert symbol. It is used in this

manualand on the unit to alertyou to

potential hazards. When you see this symbol,

readand obeythe messagethat follows it.

Failureto obeysafety messagescould result in personal

injury or property damage.

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

WARNING

The engine exhaust from this product contains

chemicals known te the State of California to cause

cancer, birth defects or other reproductive harm.

2

Tableof Contents

SECTION1: SAFETY........................................... 3

SafetyDecals .................................................................... 5

SECTION2: ASSEMBLY....................................... 6

Attach Handlebar............................................................... 7

Move Tiller Off Shipping Platform ...................................... 7

Install Forward Clutch Cable.............................................. 8

CheckLevel ofTransmission GearOil................................ 9

Add Motor Oil to Engine..................................................... 9

CheckHardwarefor Tightness........................................... 9

CheckAir Pressure in Tires................................................ 9

SECTION3: FEATURES& CONTROLS........................ 10

Wheel Drive Pins ............................................................... 10

Forward ClutchBail............................................................ 11

Depth Regulator................................................................. 11

HandlebarHeightAdjustment ............................................ 11

SECTION4: OPERATION...................................... 12

Break-in Operation.......................................................... 12

Starting and Stoppingthe Engine...................................... 12

Operatingthe Tifler ............................................................ 13

Tilling Tips & Techniques .................................................. 15

PowerComposting ............................................................ 17

Loadingand Unloading the Tiller ....................................... 17

SECTION5: MAINTENANCE.................................. 18

RequiredMaintenance Schedule........................................ 18

Tiller Lubdcation................................................................ 19

Checkfor Oil Leaks............................................................ 19

CheckHardware................................................................. 19

CheckTire Pressure........................................................... 19

Transmission GearOil Service........................................... 19

Bold Tines.......................................................................... 20

Checkingand Adjusting Forward Drive Belt Tension.......... 21

Forward ClutchBailAdjustment ......................................... 21

EngineCleaning................................................................. 22

Air CleanerService............................................................ 22

EngineOil Service.............................................................. 22

Spark Plug Service............................................................ 22

SparkArrestor Screen Service........................................... 22

CarburetodGovernor Control Adjustments ........................ 22

Off SeasonStorage............................................................ 22

Troubleshooting................................................................. 23

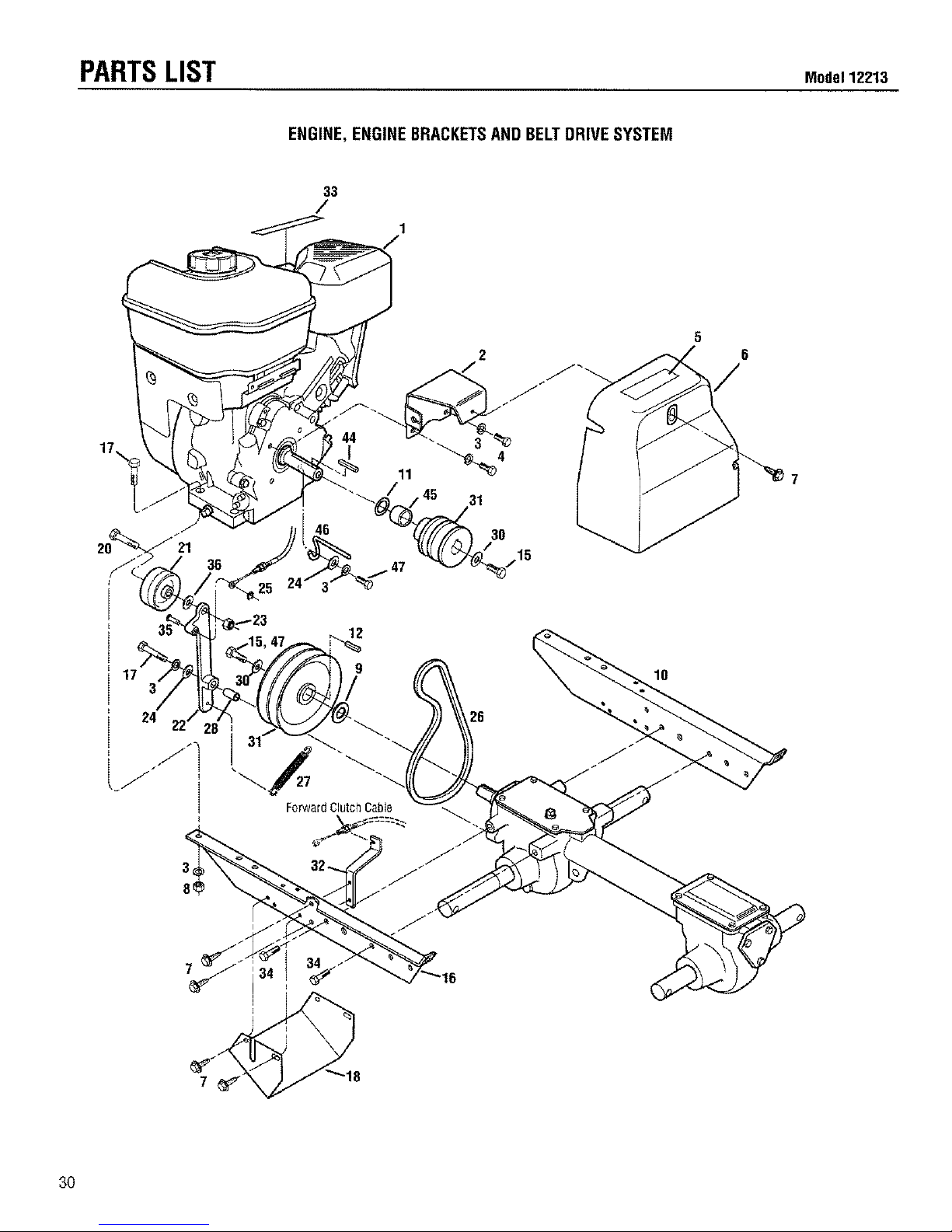

PARTSLIST ..................................................... 24

CUSTOMERSERVICEINFORMATION.............. BackCover

I1

Safety

SPARKARRESTERWARNINGTO RESIDENTSOFCALIFORNIA ANDSEVERAL OTHERSTATES

UnderCalifornialaw, and under the laws of severalother states, you are not permitted to operate an

internalcombustion engine using hydrocarbon fuels on any forest, brush, hay, grain, or grass

covered land; or land covered by anyflammable agricultural crop without anengine spark arrester in

continuous effective working order.

Theengine on the unit is an internal combustion engine which burns gasoline, a hydrocarbon fuel, and must be equipped with a

spark arrester muffler in continuous effectiveworking order. The spark arrester must beattached to the engine exhaustsystem in

such a mannerthat flames or heatfrom the system will not ignite flammable material. Failureof the owner/operator of the unit to

comply with this regulation is a misdemeanor under California law (and other states) and may alsobe a violation of other state

and/or federal regulations, laws, ordinances or codes. Contactyour local fire marshal or forest servicefor specific information

about which regulations apply in your area.

Training

1. Carefully readthis

Owner'sManual, the

separateEngineOwner's

Manual,and any other literature you may

receive.Bethoroughly familiar with the

controls and the proper useof the tiller

and its engine,Know how to stop the unit

and disengagethe controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthe area of operation clearof all

persons,particularly children and pets.

4. Keepin mind that the operator or user

isresponsible for accidents or hazards

occurring to other people,their property,

andthemselves.

Preparation

1. Thoroughly inspect the areawhere the

tiller is to be used and remove all foreign

objects.

2. Be sure all tiller controls arereleased

and both wheels are in the Wheel Drive

position before starting the engine.

3. Do not operate the tiller without

wearingadequate outer garments, Avoid

loose garments or jewelry that could get

caught in moving parts.

4. Do not operate the tiller when barefoot

or wearing sandals, sneakers,or light

footwear. Wear protective footwear that

will improve footing on slippery surfaces,

5. Do nottill nearunderground electric

cables, telephone lines, pipes or hoses. If

in doubt, contact your telephone or utility

company.

6. Warning: Handlefuel with care; it is

highly flammable and its vapors are

explosive. Besure to take the following

precautions:

a. Storefuel in containers specifically

designedfor this purpose.

b. The gas cap shall never be removed

or fuel added while the engine is

running. Allow the engine to cool

for several minutes beforeadding

fuel.

c. Keepmatches, cigarettes, cigars,

pipes, openflames, and sparks

away from the fuel tank and fuel

container.

d. Fillfuel tank outdoors with extreme

care.Neverfill fuel tank indoors.

Usea funnel or spout to prevent

spillage.

e. Replaceall fuel tank and container

caps securely.

f. Iffuel is spilled, do not attempt to

start the engine, but move the

machine awayfrom the area of

spillageand avoid creating any

source of ignition until fuel vapors

havedissipated.

7. Nevermake adjustments when engine

is running (unless recommended by

manufacturer).

Operation

1. Do not put handsor feet near or under

rotating parts.

2. Exerciseextreme caution when on or

crossing gravel drives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

not carry passengers.

3, After striking a foreign object, stop the

engine, removethe wire from the spark

plug wire and prevent it from touching

the spark plug. Thoroughly inspectthe

machinefor any damageand repairthe

damagebefore restarting and operating

the machine.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrate abnor-

mally,stop the engine, disconnect the

spark plug wire and prevent it from

touching the spark plug, and check

immediately for the cause.Vibration is

generallya warning of trouble.

6. Stop the engine, disconnect the spark

plug wire and prevent it from touching

the spark plug whenever you leavethe

operating position, beforeunclogging the

tines, or when making any repairs, adjust-

ments or inspections.

Section1: Safety

7. Take all possible precautions when

leavingthe machine unattended.Stop the

engine. Disconnectspark plugwire and

move it awayfrom the spark plug. Be

sure both wheels are in the Wheel Drive

position.

8. Before cleaning, repairing, or inspect-

ing, stop the engineand make certain all

moving parts havestopped. Disconnect

the spark plug wire and prevent it from

touching the spark plug to prevent acci-

dental starting.

9. The flap on the tine hood must be

down when operating the tiller.

10. Never usethe tiller unless proper

guards, plates,or other safety protective

devicesare in place.

11. Do not run engine in an enclosed

area. Engineexhaust contains carbon

monoxide gas, a deadlypoison that is

odorless, colorless, and tasteless.

12. Keepchildren and pets away.

13. Never operatethe tiller under

engine powerif the wheels are in the

Freewheel position.In the Freewheel

position, the wheels will not hold the tiller

back and the revolving tines could propel

the tiller rapidly, possibly causing loss of

control. Always engagethe wheels with

the wheel drive pins in theWheel Drive

position beforestarting the engine or

engaging the tines/wheels with the

Forward Clutch Bail.

14. Be aware that the tiller may unex-

pectedlybounceupwardor jump

forwardif the tines shouldstrike

extremely hardpackedsoil, frozen

ground,or buried obstacleslike large

stones,roots, or stomps. If in doubt

aboutthe tilling conditions,alwaysuse

the following operatingprecautionsto

assistyouin maintaining controlof the

tiller:

a. Walk behindand to oneside ol the

tiller, usingone hand onthe han-

dlebars. Relaxyour arm, butusea

securehandgrip.

b. Use shallowerdepth regulator

settings,workinggradually

deeperwith each pass.

c. Useslower enginespeeds.

d. Clear thetilling area ofall large

stones,rootsand otherdebris.

e. Avoidusingdownwardpressure

on handlebars.If need be, use

slight upwardpressureto keep the

tines lrom diggingtoodeeply.

f. Beforecontactinghardpackedsoil

atthe end of a row, reduceengine

speedand lift handlebarsto raise

tines outofthe soil.

go In an emergency, stoptines and

wheels byreleasing whichever

clutchcontrol isengaged. Donot

attemptto restrainthetiller.

15. Do not overload the tiger's capacity

by attempting to till too deeplyat too fast

a rate.

16. Never operate thetiller at high

transport speeds on hard or slippery

surfaces. Look behind and usecare when

backing up.

17. Do not operate the tiller on a slope

that is too steepfor safety. When on

slopes, slow down and makesure you

havegood footing. Neverpermit the tiller

to freewheel down slopes.

18. Never allow bystanders nearthe unit.

19. Only useattachments and acces-

sories that are approvedby the manufac-

turer of the tiller.

20. Usetiller attachments and acces-

sories when recommended.

21. Neveroperate the tiller without good

visibility or lighL

22. Neveroperate the tiller ifyou are

tired, or under the influence of alcohol,

drugs or medication.

23. Operatorsshall not tamper with the

engine-governor settings on the machine;

the governor controls the maximum safe

operating speed to protect the engineand

all moving parts from damagecausedby

overspeed. Authorized service shall be

sought if a problem exists.

24. Do not touch engine partswhich may

behot from operation, Let parts cool

down sufficiently,

25. Pleaseremember: You can always

stop the tines and wheels by releasingthe

Forward Clutch Bail or by moving the

Throttle Control Lever on theengine to

"OFF"or "STOP".

26. To load or unload the tiller, see the

instructions in Section 4 of this Manual.

27. Use extreme caution when reversing

or pulling the machine towards you.

28. Start the engine carefully according to

instructions and with feet well away from

thetines.

29. Neverpick upor carry amachine

while the engine is running.

Maintenance and Storage

1. Keepthe tiller, attachments and acces-

sories in safe working condition.

2. Checkall nuts, bolts, and screws at

frequent intervals for proper tightness to

besure the equipment is in safeworking

condition.

3. Neverstore the tiller with fuel in the

fuel tank inside a building where ignition

sources are present such as hot water

and spaceheaters,furnaces, clothes

dryers, stoves, electric motors, etc.).

Allow engineto cool before storing in any

enclosure.

4. To reducethe chances of afire hazard,

keepthe engine free ofgrass, leaves,or

excessivegrease.

5. Store gasolinein a cool, welI-ventilated

area,safely away from anyspark- or

flame-producing equipment. Store

gasoline in an approved container, safely

awayfrom the reach of children.

6. Referto the Maintenance sections of

this Manual and the separateEngine

Owner's Manual for instructions if the

tiller is to be stored for an extended

period.

7. Neverperform maintenancewhile the

engine is running or the spark plug wire

is connected, except when specifically

instructed to do so.

8. If the fuel tank has to be drained, do

this outdoors,

Section1: Safety

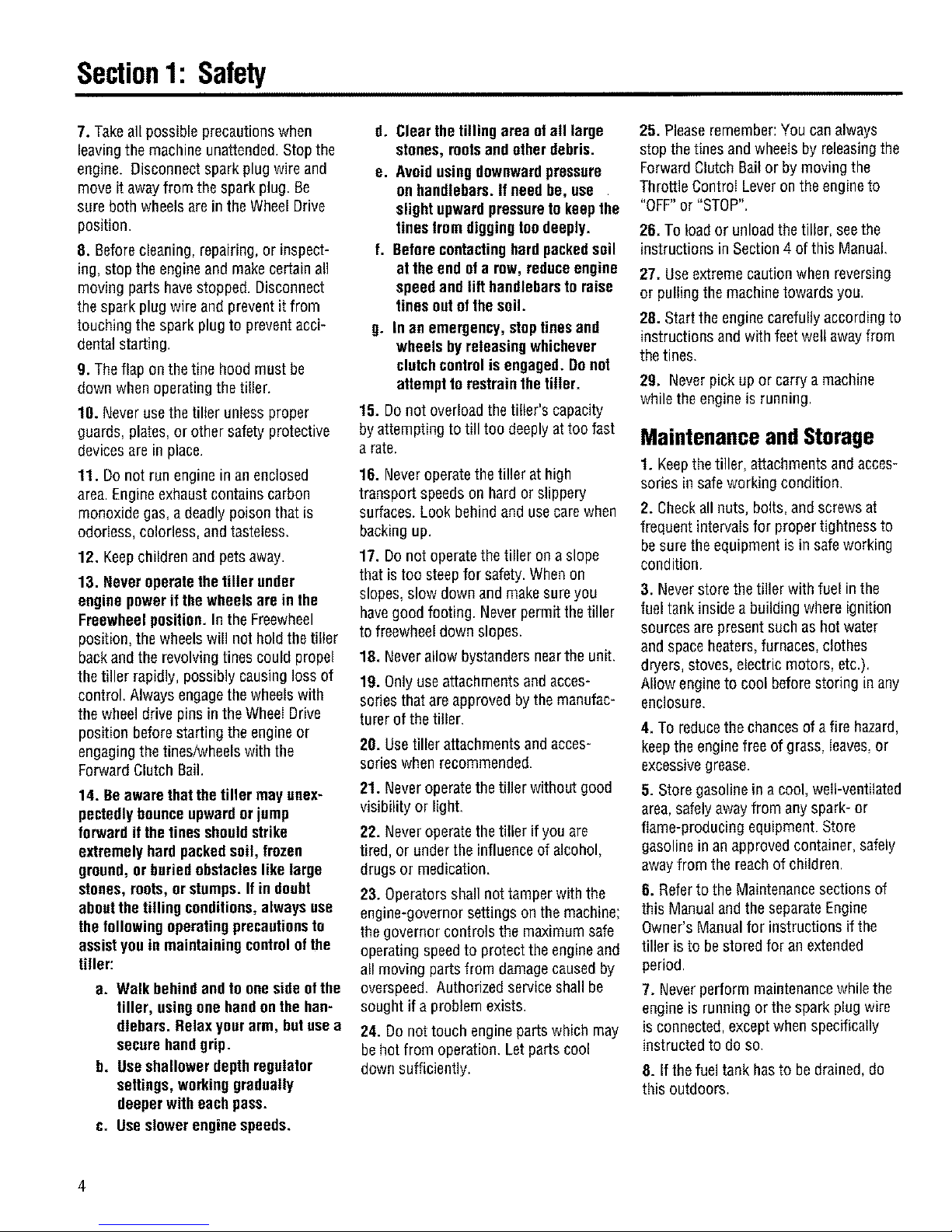

Decals

Foryour safety and the safety of

others, various safetyand opera-

tional decalsare located on your

unit (see Figure 1).

Keepthe decals clean and legible at

al!times. Contactyour local

service dealer or the factory for

replacementsif any decalsare

damaged or missing.

Referto the Parts List pagesin this

Manualfor decallocations, descrip-

tions and part numbers.

ForwardClutchBail

OperatingInstruction

Starting Stabilization

Message(on engine)

WarningMessages

HotSurfaces/MovingBelts

Warning(onbeltcover)

Figure1: LocationofSafetyand OperatingDecals.

OperatingSymbols

Various symbols (shown here, with word

desndptions)areused onthe tiller and engine.

Your unit may not haveall of the symbols.

FAST SLOW STOP

I-,,-I I+1

CHOKE CHOKE ROTATING

ON OFF TINES

TILLERDIRECTION LEVERDIRECTION

BAIL

ENGAGED

BAIL

DISENGAGED

TO AVOID SERIOUS INJURY:

• READTHEOWNER'S MANUAL,

• KNOWLOCATIONSANDFUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESAND SHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINES OR MAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE,

• KEEPAWAYFROMROTATINGPARTS,

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHE MACHINETOWARDSYOU.

I1

Assembly

To preventpersonal injury or property

damage, do net start fhe engine until

all assembly steps are complete and

you have read and understand the

safety and operatinginstructionsinthis

manual.

Introduction

Carefullyfollow these assembly steps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety before beginning assembly.

Inspectunit

Inspect the unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail acopy to the

carrier within 15 days after the unit has

been delivered.Contact us at the factory if

you needassistance in this matter.

STEP1: UnpackingInstructions

NOTE:Becareful not to severely bend any

of the control cableson the unit.

1. Removeanycardboard inserts and

packagingmaterial from the carton.

Removeany staples from the bottom of

the carton and remove the carton.

2. The tiller is heavy (approximately 133

]bs.). Oonot attempt to remove it from

the shipping platform until instructed to

do so in these Assembly steps.

3. Removeall unassembledparts and

the separatehardware bagfrom the

carton, Checkthat you havethe items

listed below(contact your local dealeror

the factory if anyitems are missing or

damaged). NOTE: Usethe screw length

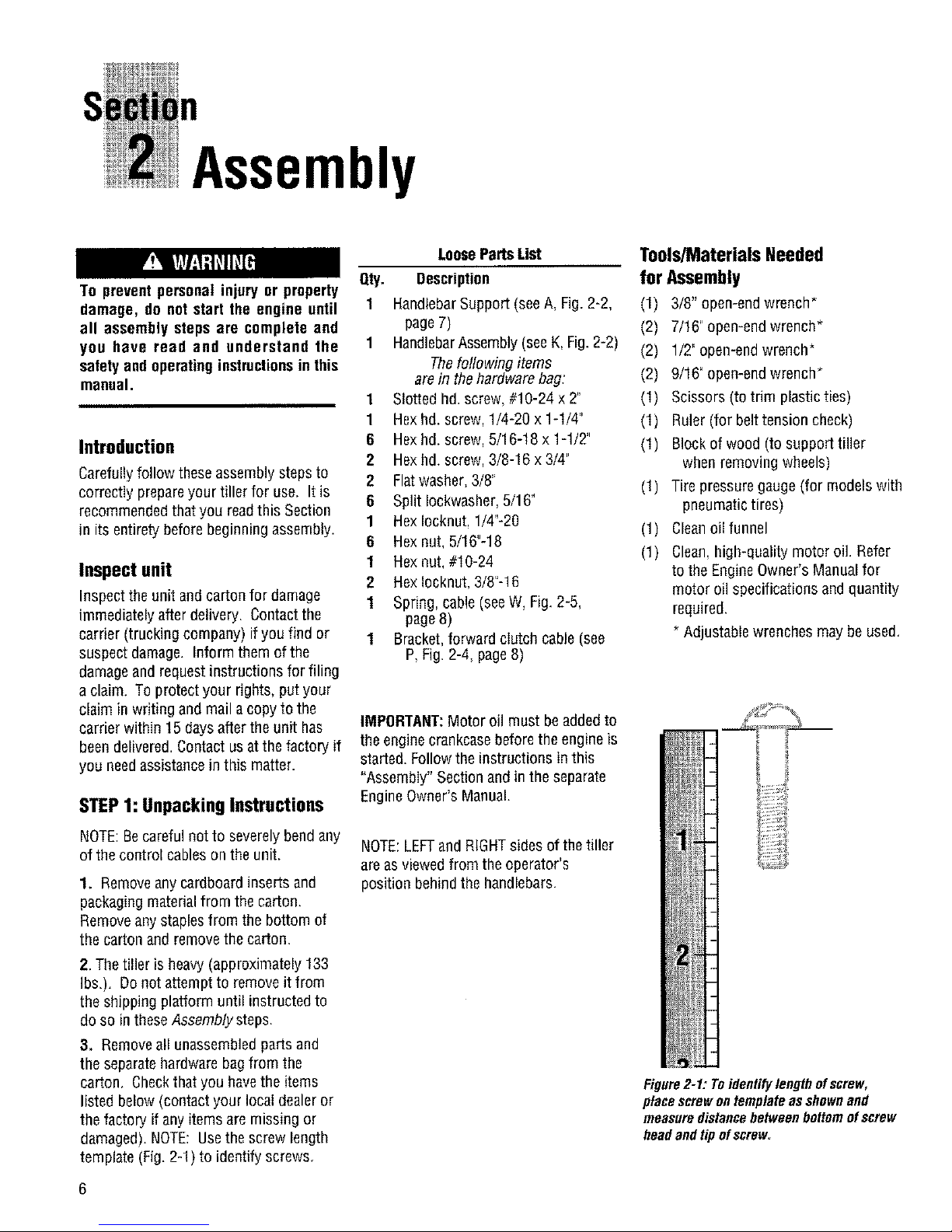

template (Fig. 2-1) to identify screws.

LooseParts List

Qty. Description

1 HandlebarSupport (seeA, Fig. 2-2,

page 7)

1 HandlebarAssembly(see K,Fig.2-2)

Thefollowing items

are in the hardware bag:

1 Slotted hd. screw, #10-24 x 2"

1 Hexhd. screw, 1/4-20 x 1-1/4"

6 Hexhd. screw, 5/16-t8 x 1-1/2"

2 Hexhd screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

6 Split Iockwasher,5/16"

1 Hex Iocknut, 1/4'-20

6 Hex nut, 5/16"-18

1 Hex nut,#10-24

2 Hexlocknut, 3/8"-16

1 Spring, cable (seeW, Fig. 2-5,

page8)

1 Bracket,forward clutch cable (see

P,Fig. 2-4, page8)

IMPORTANT:Motor oil must be addedto

the enginecrankcase before the engine is

started. Follow the instructions in this

"Assembiy" Section and in the separate

EngineOwner's Manual.

NOTE:LEFTandRIGHTsides of thetiller

are asviewed from the operator's

position behind the handlebars,

Tools/MaterialsNeeded

for Assembly

(1) 3/8" open-endwrench*

(2) 7/16"open-end wrench*

(2) 1/2" open-endwrench*

(2) 9/16" open-endwrench*

(1) Scissors (to trim plasticties)

(1) Ruler(for belt tension check)

(1) Blockof wood (to support tiller

when removing wheels)

(1) Tire pressure gauge (for models with

pneumatic tires)

(1) Cleanoil funnel

(1) Clean,high-quality motor oil. Refer

to the EngineOwner's Manual for

motor oil specifications and quantity

required.

* Adjustable wrenches may be used,

Figure2-1: Toidentifylengthofscrew,

placescrewontemplateasshownand

measuredistancebetweenbottomofscrew

headandtipofscrew

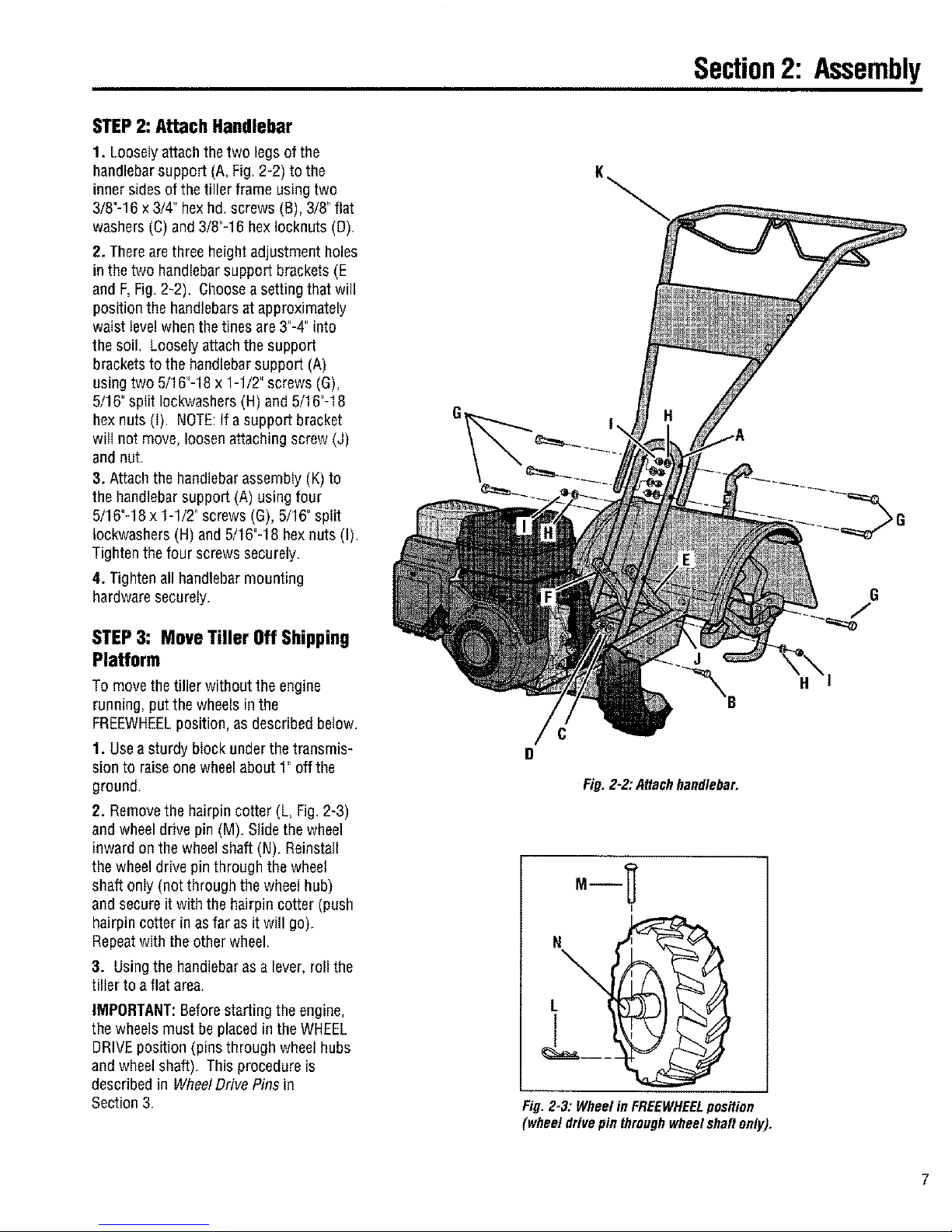

STEP2: Attach Handlebar

1. Looselyattach the two legs of the

handlebarsupport (A,Fig. 2-2) to the

inner sides of the tiller frame using two

3/8"-16 x3/4" hexhd, screws (B), 3/8' flat

washers (C) and 3/8"-16 hexIocknuts (D)

2. There are three height adjustment holes

in the two handlebar support brackets (E

and F,Fig. 2-2). Choosea setting that will

position the handlebars at approximately

waist level when the tines are 3"-4" into

the soil, Looselyattachthe support

bracketsto the handlebar support (A)

using two 5/16"-18 x 1-1/2' screws (G),

5/16" split Iockwashers (H) and5/16"-18

hexnuts (I) NOTE:If a support bracket

will not move, loosen attaching screw (J)

and nut.

3. Attach the handlebarassembly (K) to

the handlebar support (A) using four

5/16"-18 x 1-1/2' screws (G), 5/16" split

Iockwashers (H) and 5/16"-18 hexnuts (I).

Tighten the four screws securely

4. Tighten all handlebar mounting

hardware securely.

STEP3: MoveTiller OffShipping

Platform

To move the tiller without the engine

running, put the wheels inthe

FREEWHEELposition, as described below.

1. Use asturdy block under the transmis-

sion to raiseone wheel about 1' off the

ground.

2. Remove the hairpin cotter (L, Fig.2-3)

and wheel drive pin (M). Slide the wheel

inward on the wheel shaft (N). Reinstall

the wheel drive pin through the wheel

shaft only (not through the wheel hub)

and secure it with the hairpin cotter (push

hairpin cotter in as far as it will go).

Repeatwith the other wheel.

3. Usingthe handlebaras a lever, roll the

tiller to a flat area.

IMPORTANT:Beforestarting the engine,

the wheels must be placedin the WHEEL

DRIVEposition (pins through wheel hubs

and wheelshaft). Thisprocedure is

described in WheelDrive Pins in

Section 3.

Section2: Assembly

K

J

Fig. 2-2:A_achhnndleba_

H

L

Fig.2-3: WheelinFREEWHEELposition

(wheeldrivepinthroughwheelshaftonly).

7

Section2: Assembly

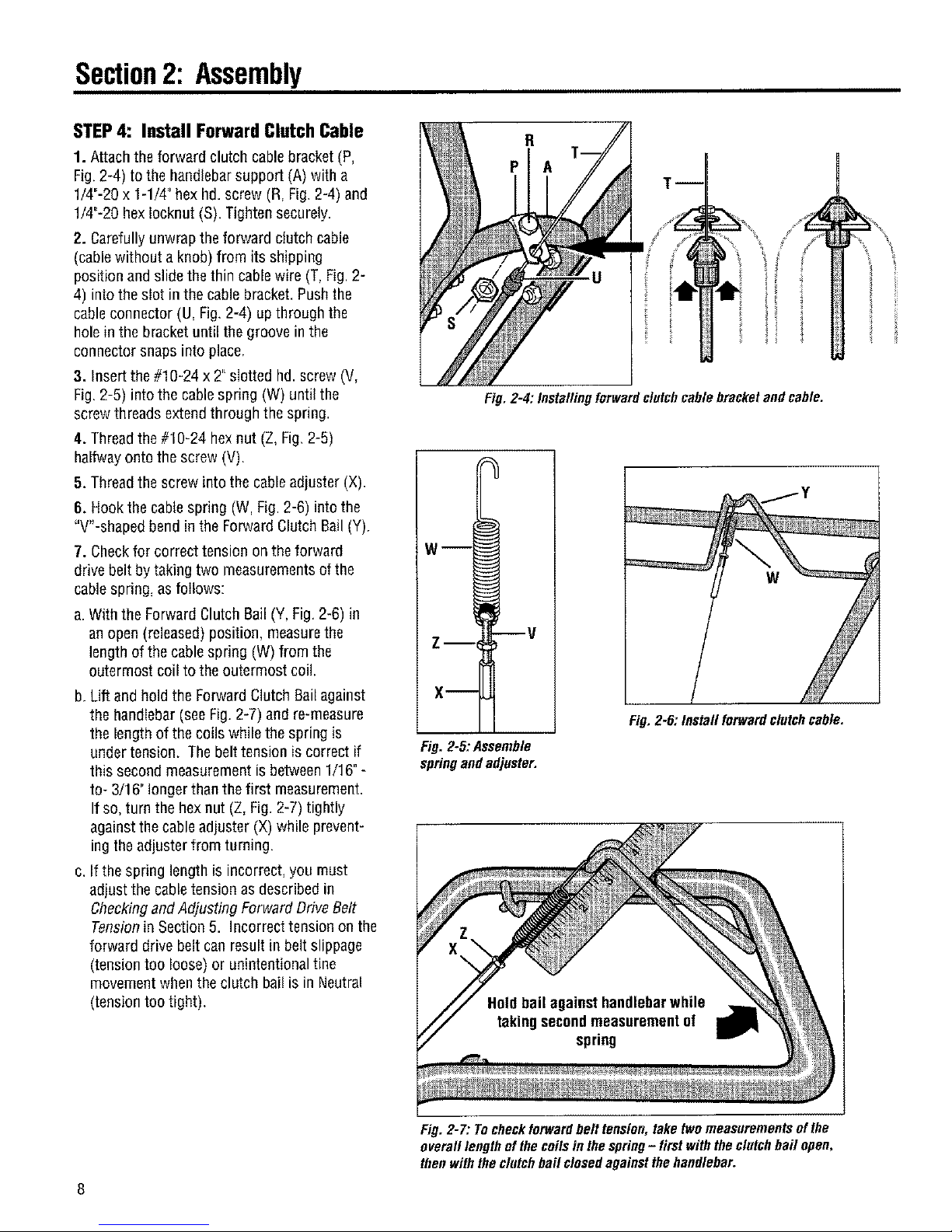

STEP4: Install ForwardClutchCable

1. Attach the forward clutch cablebracket (P,

Fig. 2-4) to the handlebarsupport (A) with a

1/4"-20 x 1-1/4" hex hd. screw (R, Fig. 2-4) and

1/4"-20 hexIocknut (S). Tighten securely.

2. Carefully unwrap the forward clutch cable

(cablewithout a knob) from its shipping

position and slide the thin cable wire (T, Fig.2-

4) into the slot in the cable bracket. Pushthe

cableconnector (U, Fig,2-4) up through the

hole in the bracket until the groove in the

connector snaps into place,

3. Insert the #10-24 x 2"slotted hd.screw (V,

Fig. 2-5) intothe cablespring (W) until the

screw threads extend through the spring.

4. Thread the #10-24 hex nut (Z, Fig.2-5)

halfwayonto the screw (V).

5. Thread the screw into the cableadjuster (X).

6. Hook the cable spring (W, Fig. 2-6) into the

"W-shaped bend inthe Forward Clutch Bail(Y).

7. Checkfor correct tension on the forward

drive belt bytaking two measurements ofthe

cable spring, as follows:

a. With the Forward Clutch Sail (Y, Fig.2-6) in

an open (released) position, measurethe

length of the cable spring (W) from the

outermost coil to the outermost coi!.

b. Lift and hold the Forward Clutch Bail against

the handlebar (see Fig. 2-7) and re-measure

the length of the coils while the spring is

under tension. Thebelt tension is correct if

this second measurement is between 1/16"-

to- 3/16" longer than thefirst measurement.

If so, turn the hex nut (Z, Fig. 2-7) tightly

against thecable adjuster (X) while prevent-

ing theadjuster from turning.

c. If the spring length is incorrect, you must

adjust the cable tension asdescribed in

Checkingand Adjusting Forward Drive Belt

Tension in Section 5. Incorrect tension on the

forward drive belt can result in belt slippage

(tension too loose) or unintentional tine

movement whenthe clutch bail is in Neutral

(tension too tight),

Fig, 2-4: Installingforward clutchcable bracketand cable.

w--I

Z-- V

X--

Fig. 2-5:Assemble

springand adjuster.

w

Fig, 2-6: Install forwardclutchcable,

ii

Fig. 2-7: Tocheckforwardbelt tension, take twomeasurements ofthe

overall length of the coilsin the spring- first with the clutch bail open,

then withthe clutch bail closedagainstthe handlebar.

Section2: Assembly

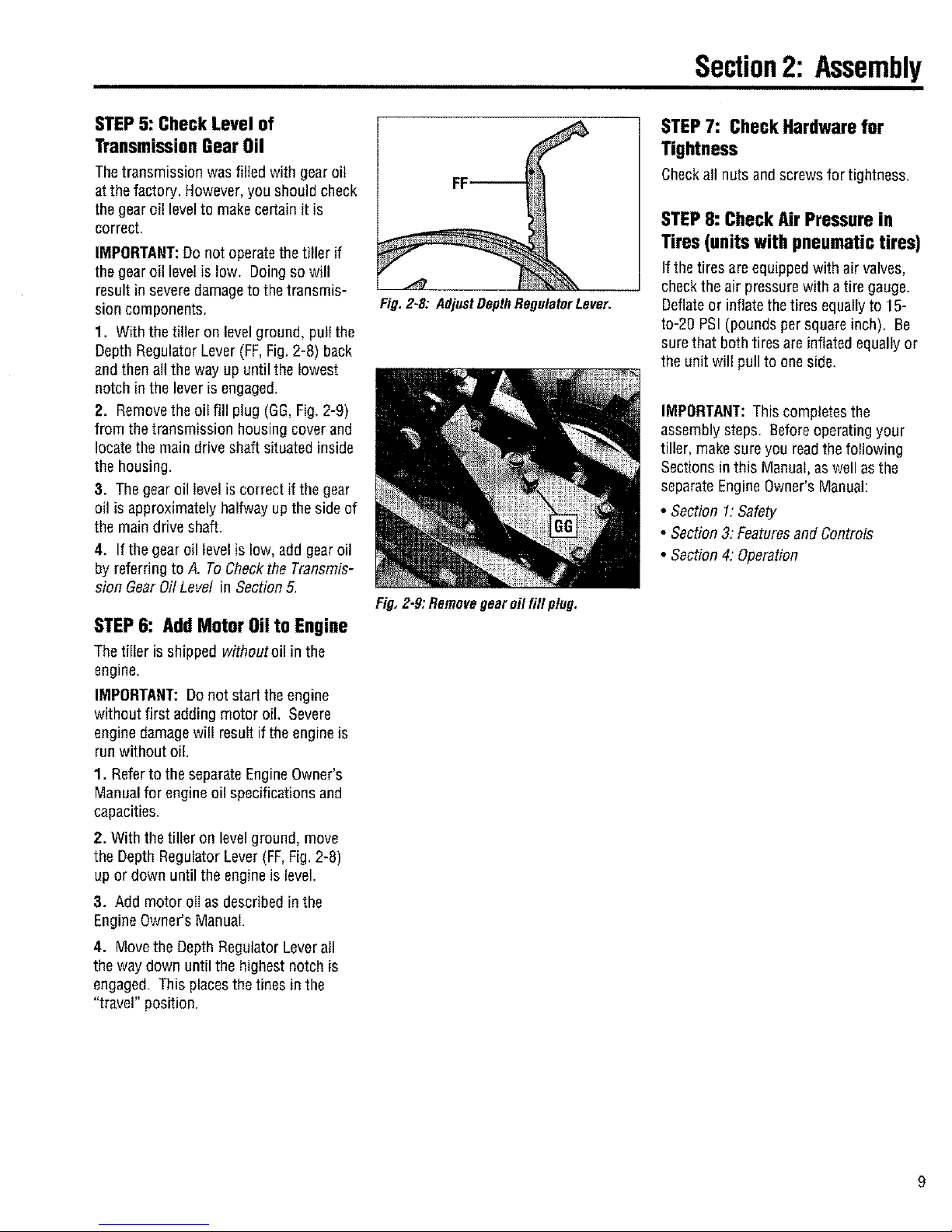

STEP5: Check Level of

Transmission Gear Oil

Thetransmissionwasfilledwithgearoil

atthefactory.However,youshouldcheck

thegearoillevelto makecertainit is

correct,

IMPORTANT:Do not operate the tiller if

thegear oil level is low. Doingso will

result in severe damageto the transmis-

sion components,

1. With the tiller on levelground, pull the

Depth Regulator Lever (FF,Fig. 2-8) back

and thenall the way up until the lowest

notch in the lever is engaged.

2. Removethe oil fill plug (GG,Fig.2-9)

from the transmission housing coverand

locate the main drive shaft situated inside

the housing.

3. Thegear oil level is correct if the gear

oil is approximately halfway up the side of

the main drive shaft.

4. If the gear oil levelis low, add gear oil

by referring to A. ToCheckthe Transmis-

sion Gear Oil Level in Section 5,

STEP6: Add Motor Oil to Engine

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do not start the engine

without first adding motor oil Severe

engine damagewill result if the engineis

run without oil.

1. Referto the separate EngineOwner's

Manual for engine oil specifications and

capacities,

2. With the tiller on level ground, move

the Depth Regulator Lever (FF,Fig, 2-8)

up or down until the engine is level.

3. Add motor eli as described in the

EngineOwner's Manual.

4. Movethe Depth Regulator Leverall

the way down until the highest notch is

engaged. This placesthe tines in the

"travel" position.

Fig. 2-8: Adjust DepthRegulator Lever.

Fig,Z-9:Removegearoilfill plug.

STEP7: Check Hardware far

Tightness

Checkall nutsandscrewsfortightness,

STEP 8: Check Air Pressure in

Tires(unitswith pneumatictires)

If the tires areequipped with air valves,

checkthe air pressurewith a tire gauge.

Deflateor inflate the tires equallyto 15-

to-2g PSI (pounds per square inch), Be

surethat both tires are inflated equallyor

the unit will pull to oneside.

IMPORTANT: This completes the

assembly steps, Beforeoperatingyour

tiller, make sure you readthe following

Sections in this Manual, as well as the

separate Engine Owner'sManual:

• Section 1:Safety

• Section3: FeaturesandControls

• Section4: Operation

9

FeaturesandControls

Before operating your machine,

carefully read end understand all

safety, controls and operating instruc-

tions in this Manual, the separate

Engine Owner's Manual, and on the

decalson the machine.

Failure to follow these instructionscan

resultin seriouspersonal injury.

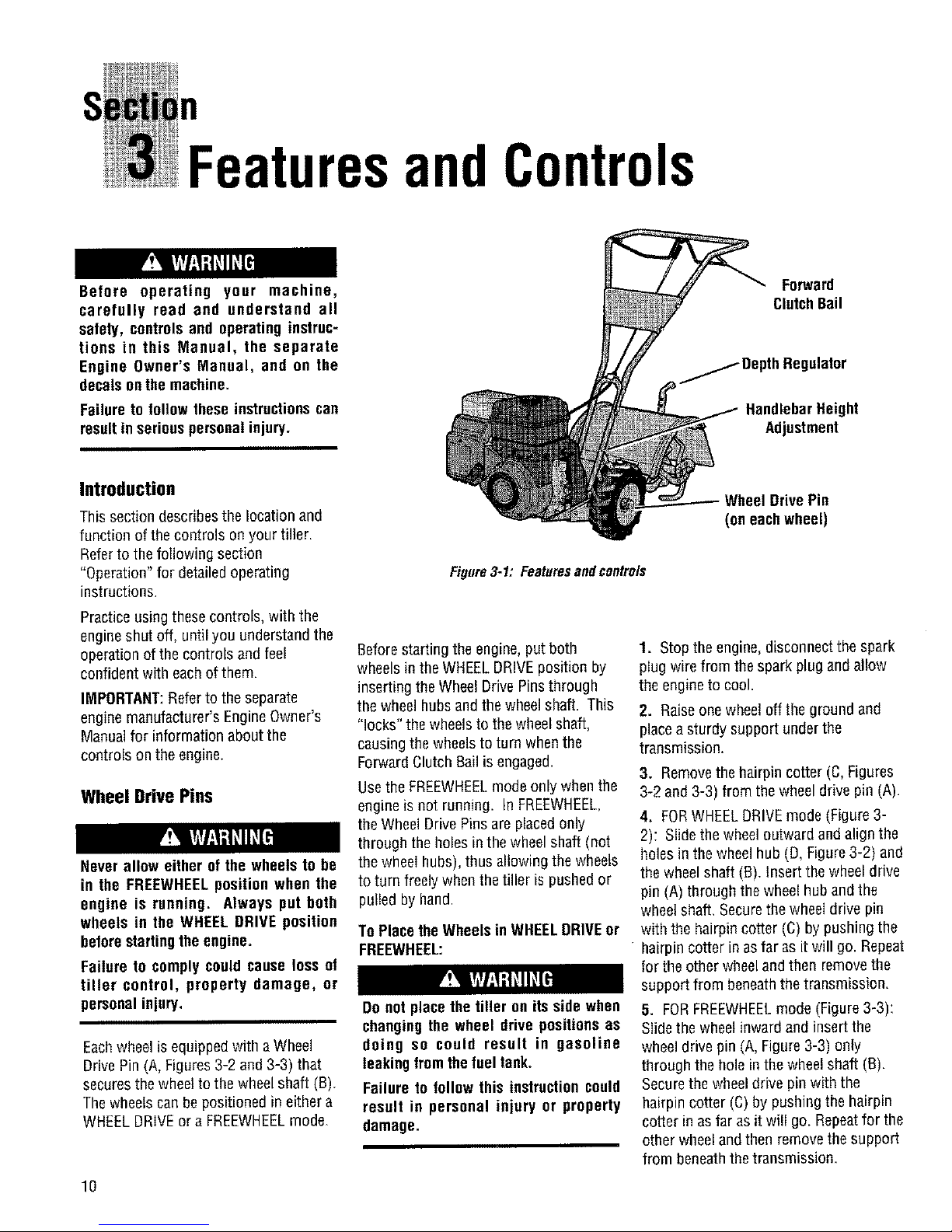

Forward

ClutchBail

_ DepthRegulator

HandlebarHeight

Adjustment

Introduction

This section describes the location and

function of the controls on your tiller.

Referto the following section

"Operation" for detailed operating

instructions.

Practiceusing these controls, with the

engine shut off, until you understand the

operation of the controls and feel

confident with each of them.

IMPORTANT:Refer to the separate

enginemanufacturer's EngineOwner's

Manualfor informationabout the

controls on the engine.

Wheel Drive Pins

Never allow either of the wheels to be

in the FREEWHEELposition when the

engine is running. Always put both

wheels in the WHEEL DRIVE position

beforestartingthe engine.

Failure to comply could cause loss of

tiller control, property damage, or

personalinjury.

Eachwheel is equipped with aWheel

Drive Pin (A, Figures3-2 and 3-3) that

securesthe wheelto thewheel shaft (B),

Thewheels can be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

10

Figure3-1: Featuresandcontrols

Beforestarting the engine, putboth

wheels in the WHEELDRIVEposition by

inserting the Wheel Drive Pinsthrough

the wheel hubsand the wheel shaft. This

"locks" the wheelsto thewheel shaft,

causing the wheels to turn when the

Forward ClutchBail is engaged.

Use the FREEWHEELmodeonly when the

engine is not running. In FREEWHEEL,

the Wheel Drive Pinsare placed only

through the holes in the wheel shaft (not

the wheel hubs), thus allowing the wheels

to turn freely whenthe tiller is pushedor

pulled by hand.

To Place the Wheels in WHEELDRIVEor

FREEWHEEL:

Do not placethe tiller on its side when

changing the wheel drive positions as

doing so could result in gasoline

leaking fromfhefueltanko

Failure to follow this instructioncould

result in personal injury or property

damage.

Wheel Drive Pin

(on eachwheel)

1. Stop the engine,disconnect the spark

plug wire from the spark plug and allow

the engine to cool.

2. Raiseone wheel off the ground and

placea sturdy support under the

transmission,

3. Removethe hairpin cotter (C, Figures

3-2 and 3-3) from the wheel drive pin (A).

4. FORWHEELDRIVEmode (Figure 3-

2): Slide the wheel outward and align the

holes in the wheelhub (D, Figure3-2) and

thewheel shaft (B), Insert the wheel drive

pin (A) through the wheelhub and the

wheel shaft, Securethe wheel drive pin

with the hairpin cotter (C) by pushing the

hairpin cotter in as far as it will go. Repeat

for the other wheel and then removethe

support from beneaththe transmission.

5. FORFREEWHEELmode (Figure3-3):

Slide the wheel inward and insert the

wheeldrive pin (A, Figure 3-3) only

through the hole in the wheel shaft (B),

Securethe wheeldrive pin with the

hairpin cotter (C) by pushing the hairpin

cotter in as far as it will go. Repeatfor the

other wheel and then removethe support

from beneaththe transmission.

Section3: FeaturesandControls

0 1

Figure3-2: WHEELDRIVEposition.

01

B

Figure33: FREEWHEELposition.

Beforestarting the engine, be sure that

both wheels are in the WHEEL DRIVE

position. See "Wheel Drive Pins" for

instructions.

Engagingthe Forward ClutchBail when

the wheels are not in the WHEELDRIVE

positioncould allowthe tines to rapidly

propelthe tiller forward.

Failure to comply couldcause loss of

tiller control, property damage, or

personalinjury.

Forward Clutch Bail

TheForward Clutch Bail (E, Figure3-4)

controls the engagementof forward drive

to the wheels and tines.

To Operatethe ForwardClutchBail:

1. Put the wheels in the WHEELDRIVE

position (seethe "WARNING"statement

above),

2. Lift and hold the bail against the

handlebar. The wheels and tines wilt

rotate in a forward direction.

3. Releasethe bail to disengage (stop)

the wheels andtines. All forward motion

will stop (the engine will continue to run).

'E

Figure34: ForwardClutchBail(E).

DepthRegulatorLever

This lever (G, Figure 3-5) controls the

tilling depth of the tines. Pull the lever

straight back and slide it up or down to

engagethe notched height settings.

Thehighest notch (lever all the way down)

raisesthe tines approximately 1-1/2' off

the ground. This "travel" setting allows

the tiller to be moved without the tines

digging into the ground. Also usethis

setting when starting the engine.

Move the lever upwardto increasethe

tilling depth. Thelowest notch allows a

tilling depth of approximately 6",

depending on soi! conditions.

Forbest results,always begintilling at

a veryshallow depthsettingand

graduallyincreasethe tilling depth.

Travel

Position ,_ G

Deep

gs

Figure3-5,"DepthRegulatorLever (G).

• Do notattemptto till 1o0deeplytoo

quickly.Graduallyworkdownto

deepertilling depths.

• Place the Depth Regulator Lever in

the "travel" position before starting

the engine. This position prevents

the tines from touching the ground

until youare readyto begintilling.

Failure to follow this warning could

result in personal injury or property

damage.

HandlebarHeightAdjustment

The handlebar height is adjustable to

three different settings (see Figure 3-6).

As a generalrule, adjust the handlebars

so they are at waist levelwhen the tines

are 3"-4"into the soil.

To AdjusttheHandlebars:

1. Stop the engine,disconnect the spark

plug wire from the spark plug and allow

the engineto cool.

2. Removethe screws, Iockwashers and

nuts, reposition the handlebars,and

reinstall the hardware.

Figure3-6:Handlebarheightadjustment.

ENGINECONTROLS

Referto the enginemanufacturer's Engine

Owner's Manual (included in the tiller lit-

eraturepackage)to identify the controls

on your engine,

IMPORTANT:Thecontrol for stopping the

engine islocatedon the engine.

11

n

Operation

Before operating your machine,

carefully read and understandall safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner'sManual, and on the decals on

the machine.

Failureto follow these instructionscan

resultin seriouspersona]injury.

\

ForwardClutchBail

_lator Lever

INTRODUCTION

Readthis Section of the manual thor-

oughly before you start the engine, Then,

takethe time to familiarizeyourself with

the basic operation of the tiller before

using it in the garden, Findanopen, level

areaand practice using thetiller controls

without the tines engaging the soil (put

tines in "travel" setting), Onlyafter

you've becomecompletely familiar with

the tiller should you begin using it in the

garden.

BREAK-IN OPERATION

Perform the following maintenance

during thefirst hours of new operation

(see"Maintenance" Section in this

Manualand in the Engine Owner's

Manual).

1. Changeengine oil after first 2 hours of

new engineoperation,

2. Checkfor looseor missing hardware

on unit. Tighten or replaceas needed.

3. Checktension on forward drive belt

after first 2 hours of operation.

4. Checktransmission gearoil level after

first 2 hours of operation.

Recoil Starter

Figure4-1

STARTINGANDSTOPPING

THE ENGINE

Pro-StartChecklist

Makethe following checks and perform

thefollowing services beforestarting the

engine.

1. Readthe "Safety" and "Controls"

Sections in this Manual. Readthe

separateEngineOwner's Manualprovided

bythe engine manufacturer.

2. Checkthat the wheels are in the

WHEELDRIVEposition (wheel pins must

be through the wheel hubs and thewheel

shaft holes).

3. Checkunit for looseor missing

hardware. Serviceas required.

4. Checkengine oil level. SeeEngine

Owner's Manual.

5. Checkthat all safety guards and

covers are in place,

6. Checkair cleanerandenginecooling

system. SeeEngineOwner's Manual,

7. Attach spark plug wire to spark plug.

Wheel Drive Pin

(on eachwheel)

GASOLINEIS HIGHLYFLAMMABLEAND

ITS VAPORSAREEXPLOSIVE.

Follow gasoline safety rules in this

Manual (see Section 1) and in the

separateEngineOwner'sManual.

Failure to follow gasoline safety

instructions can result in serious

personalinjury and propertydamage.

8. Fillthefuel tank with gasoline

according to the directions in the separate

EngineOwner's Manual, Follow all

instructions and safety rules carefully.

12

Section4: Operation

Starting the Engine

Thefollowing steps describe how to start

and stop the engine. Do notattempt to

engagefhe tines or wheelsuntil you

haveread all of the operatinginstruc-

tionsin this Section. Also review

the safetyrules in Section1: Safetyand

thetiller and engine controls

informaUonin Section 3: Featuresand

Controls.

To help prevent serious

personal injury or damage to

equipment:

• Before starting engine, put both

wheels in the WHEEL DRIVEposition.

Never have the wheels in the

FREEWHEEL position when the

engine is running. When the wheels

are in FREEWHEEL,they do not hold

back the tiller and the tines could

propelthe tiller rapidlyforward.

• Before starting engine, put Forward

Clutch Bail in neutral (disengaged)

positionby releasing lever.

• Never run engine indoors or ifl

enclosed, poorly ventilated areas.

Engine exhaust contains carbon

monoxide, an odorless and deadly

gas.

*Avoid engine muffler and nearby

areas. Temperatures in these areas

may exceed150°F.

1. Completethe Pre-StartCheckliston

the previous page.

2. Put the wheels in the WHEELDRIVE

position (see Wheel Drive Pinsin

Section 3).

3. Putthe DepthRegulator Leverin the

"travel" position (lever all the way down)

so that the tines are clear of the ground.

4. Releaseall controls on the tiller.

5. If engineis equipped with a fuel valve,

turn valve to open position as instructed

in the separateEngine Owner's Manual.

6. PutThrottle Control Leveron engine in

"ON", "RUN", "FAST"or "START"position

asinstructed in the separateEngine

Owner's Manual.

7. Chokeor prime engineas instructed in

the separate EngineOwner's Manual.

8. Placeone hand on the fuel tank to

stabilizethe unit when you pull the starter

handle. Usethe recoil starter rope to start

the engine as instructed in the separate

EngineOwner's Manual. When engine

starts, gradually move choke lever(on

enginesso equipped)to "NO CHOKE",

"CHOKEOFF"or "RUN" position.

9. Usethe "FAST"throttle speedsetting

when tilling.

Keepaway from rotatingtines. Rotating

tines will cause injury.

Stoppingthe Engineend Tiller

1. To stop the wheels andtines, release

the Forward Clutch Bail,

2. To stop the engine,put the Throttle

Control Leveron the engine in the "OFF"

or "STOP" position.

OPERATINGTHETILLER

The following pages provide guidelines to

using your tiller effectively and safely in

various gardening applications. Besure

to read Tilling Tips & Techniquesin this

Section beforeyou actually put the tines

into the soil,

This is a traditional "standard-rotating-

tine" (SRT)tiller with forward rotating

tines. It operates completely differently

from "counter-rotating-tine" (CRT)tillers

or from front-tine tillers.

1. Followthe Pre-StartCheckliston the

previous page. Besure that thewheels

are in the WHEELDRIVE position.

2. Putthe DepthRegulatorLever in the

"travel" position (lever all the way down)

sothat the tines are clear of the ground,

Usethis position when practicing with

your tiller or when moving to or from the

garden. When you are readyto begin

tilling, you must move the Depth

Regulator Leverto the desired depth

setting (see Tilling Tips & Techniques).

3. Startthe engineand allow itto warm

up. When warm, put throttle control in

fast speed setting,

4. For forward motion of thewheels and

tines:

Figure4-2: Useonehandtoguidetiller

whenmovingforward.

(a)

(b)

Pull the Forward Clutch Bail up and

hold it againstthe handlebar. Release

the bail to stop forward motion of the

wheels and tines.

Asthe tiller moves forward, relax and

letthe wheels pui! the unit along while

the tines dig. Walk behind and a little

to one side of the tiller. Usea light

but secure grip with one hand onthe

handlebars, but keep your arm loose,

See Figure4-2. Letthe tiller move

aheadat its own paceand do not push

down on the handlebarsto try and

force the tiller to dig deeper-this

takesweight off the wheels, reduces

traction, and causesthe tines to try

and propel thetiller.

13

Section4: Operation

Donot pushdownonthe handlebarsto

tryto make thetiller till more deeply.

Thispreventsthewheels from holding

thetiller back andcanallow thetines

to rapidly propelthe filler forward,

whichcouldresult in lossofcontrol,

properlydamage, or personal injury.

5. To move the unit rearward:

(a) Look behind and exercise caution

when moving in reverse. Do nottill

while in reverse.

(b) Releasethe Forward Clutch Bail.

(c) Tilt the handlebar slightly upward until

the tines are out of the soil.

(d) Swingthe handlebarto the left so the

right wheel takesa "step" backward.

Next movethe handlebarto the right so

the left wheel takesa "step" backward.

(e) Repeatto "walk" the tiller rearward. If

longer distances needto be covered in

reverse,shut off the engine,then place

thetwo wheels in FREEWHEEL.

6. ToTurn the Tiller Around:

(a) Practiceturning the tiller in a level,

open area. Bevery careful to keep

your feet and legs away fromthe tines.

(b) To makea turn, lift the handlebars

until the engineand tines are balanced

over the wheels (Figure4-4). The

tines must beout of the ground while

turning the tiller.

(c) With the tiller balanced,push sideways

on the handlebar to move the tiller in

the direction of the turn (Figure4-5).

After completing the turn, slowly lower

the tines into the soil to resume tilling.

Figure4-3: Raise tines offgroundand look

behind whenmoving in reverse. Unitcan be

"fishtailed" backwardmanually fora short

distance, orrolled backward whenwheels

are in FREEWHEEL.)

Steppingthe Tiller andEngine

1. To stop the wheels and tines, release

the ForwardClutch Bail.

2. To stop the engine, put theThrottle

Control Leveron the engine in the "OFF"

or "STOP" position.

Beforetilling, contactyourtelephone or

utilities companyand inquire if under-

groundequipmentor lines are used in

your area. Their representativewill be

glad to answer your questionsand tell

yon if any of their equipment or lines

are buried underground on your

property.

I Turningthe Tiller Around

Figure4-4: Tobeginturn, lift handlebars

until engineand tinesare balanced over

wheels. Besure tinesare outofground.

Figure4-5". Withtiller balancedover

wheels (andtines outof the ground),

push handlebarssideways to turn ti!ler.

14

Section4: Operation

TillingTips& Techniques

Letthe tiller dothework

• Whiletilling, relax and letthe wheels

pull the tiller along while the tines do

the digging. Walk on the sidethat is

not yet finished (to avoid making foot-

prints in the freshly tilled soil) and

lightly, but securely grip the handlebar

with just one hand.See Figure4-2.

• Avoid pushing down on the handlebars

in an attempt to force the tiller to dig

deeper. Doing so takes the weight off

the powered wheels,causing them to

lose traction. Without the wheels

helping to hold the tiller back, the tines

will attempt to propelthetiller - often

causing the tiller to skip rapidly across

the ground. (Sometimes, slight

downward pressure on the handlebars

will help get through a particularly

tough section of sod or unbroken

ground, but in most casesthis won't be

necessaryat all.)

Tilling depths

• Avoid trying to dig too deeplytoo

quickly, especially when busting sod or

tilling soil that hasn't been tilled for

some time. Use shallow depth settings

(only an inch or two deep) for the first

passesthrough the garden area. With

eachsucceeding pass,adjust the depth

regulatorto dig another inch or two

deeper, (Watering the garden area a

few days prior to tilling will make tilling

easier, aswill letting the newlyworked

soil set for a day or two before making

a final, deeptilling pass.)

• Whencultivating (breakingupthe

surfacesoil around plants to help

destroy weeds), useveryshallow depth

settings to preventinjury to plantswhose

rootsoften growcloseto the surface. If

needed,lift up on the handlebarsslightly

to preventthe tines from diggingtoo

deeply. Cultivatingon a regularbasisnot

onlyeliminatesweeds,it alsoloosens

andaeratesthesoil for bettermoisture

absorptionandfasterplant growth.)

Avoidtillingwet, soggysoil

Tilling wet soil often results in large,

hard clumps of soil that can interfere

with planting. If time permits, wait a day

or two after heavyrainsto allow the soil

to dry beforetilling. Testthe soil by

squeezingit into a ball. If it compresses

too easily, it is too wet to till.

Avoidmakingfootprints

Whenpossible,walk on the untilled side

of the unitto avoid makingfootprints in

thefreshly tilled soil. Footprintscause

soil compaction that can hamperroot

penetrationand contributeto soil erosion.

Theycanalso "plant" unwantedweed

seedsbackinto the newlytilled soil.

Choosingcorrectwheel

and tinespeeds

With experience,you will find the "just

right" tilling depth and tilling speed com-

bination that is best for your garden.

Setthe engine throttle lever ata speed to

givethe engine adequatepower and yet

allow it to operate at the slowest possible

speed...atleast until you haveachieved

the maximum tilling depth you desire.

Fasterenginespeeds may be desirable

when making final passesthrough the

seedbedor when cultivating. Selection of

the correct engine speed, in relation to

the tilling depth, witl ensure a sufficient

power level to do the job without causing

the engineto labor.

Suggestedtilling patterns

When preparing a seedbed,go over the

same pathtwice in the first row, then

overlapone-half the tiller width on the

rest of the passes(see Figure4-6).

Whenfinished in one direction, make a

second pass ata right angle as shown

in Figure4-7. Overlapeachpass for

best results (in very hardground it

may takethree or four passesto thor-

oughly pulverizethe soil).

• If the garden sizewill not permit

lengthwise and then crosswise tilling,

then overlap the first passesby one-

half a tiller width, followed by succes-

sive passesat one-quarter width (see

Figure4-8),

• With planning, you can allow enough

room betweenrows to cultivate (see

Figure4-9). Leaveroom for the hood

width, plus enough extra room for

future plant growth.

Figure4-6

Figure4.7

.d

Figure4-8

.guro,-gIOI@I®I

15

Section4: Operation

TillingTips& Techniques

Clearingthe tines

Thetines have a self-clearing action

which helps to eliminate most tangling

of debris. However, occasionally dry

grass, stringy stalks or tough vines may

become tangled. Follow these proce-

dures to help avoid tangling andto clear

the tines, if necessary.

• To reducetangling, setthe depth

regulator deepenough to get maximum

"chopping" action asthe tines chop the

material againstthe ground. Also, try

to till under crop residues or cover

crops while they are green, moist and

tender.

• While power composting, try swaying

the handlebarsfrom side to side (about

6"to 12°). This "fishtailing" action

often clears the tines of debris.

• If tangling occurs on modelsequipped

with a poweredreverse, lift the tines

out of the soil and run thetiller in

reversefor a few feet. This reversing

action should unwind a good deal of

debris.

• It may benecessaryto remove the

debris by hand (a pocket knife will help

you to cut away the material).

Beforeclearing the tines by hand, stop

the engine, allow all moving partsto

stop and disconnect the spark plug

wire.

Failure to follow this warning could

resultin personal injury.

Tilling on slopes

If you must garden on sloping ground,

deasefollow two very important guide-

lines:

1.Till only on moderate slopes, neveron

steepinclines wherefooting is difficult

(review safety rules in the "Safety"

Section of this Manual).

2. We recommend tilling up and down

slopes rather than terracing. Tilling

vertically on a slope allows maximum

planting area andalso leavesroom for

cultivating.

IMPORTANT: When tilling on slopes, be

;urethe correct oil level is maintained in

the engine (check every one-half hour of

operation). The inclineof the slopewill

causethe oil to slant awayfrom its

normal level andthis canstarve engine

_artsof required lubrication. Keepthe

engine eli levelat thefull point at all

times!

A. Tilling up and downslopes:

-To keepsoil erosion to a minimum, be

sureto add enough organic matter to

the soil so that it hasgood moisture-

holding texture and try to avoid leaving

footprints or wheel marks.

• Whentilling vertically, try to makethe

first pass uphill as the tiller digs more

deeplygoing uphill than it does

downhill. In soft soil or weeds,you

may haveto lift the handlebars slightly

while going uphill. When going

downhill, overlapthe first pass by

aboutone-half the width of thetiller.

B. TerraceGardening:

• Whena slope is too steepor too short

for vertical tilling, it maybe necessary

to till acrossthe slope and create

terraced rows. Terraces are rows that

are cut intothe side of a slope, creating

a narrow, but flat areaon which to

plant.

• Ona longslope, you can makeseveral

terraces, one below the other.

• Terracesshould beonly 2-to-3 feet

wide. Diggingtoo far into the side of

the slope will expose poor subsoil that

is unproductive for plants.

• To create a terrace,start at thetop of

the slope and work down. Go back and

forth across the first row as shown in

Figure4-10.

• Eachsucceeding lower terrace is

started by walking below the terrace

you're preparing. For added stability of

the tiller, always keepthe uphill wheel

in the soft, newly tilled soil Do not till

the last 12" or more of the downhill

outside edgeof eachterrace. This

untilled strip helps prevents the

terracesfrom breaking apart and

washing downhill. It also provides a

walking path between rows.

o::ll *

O _ _""EPEAT

Figure4.10

C.Tilling across slopeswithout using

terraces:

• Ifvertical or terracing gardening aren't

practical for you, then you cantill

laterally across a slope. We don't

reallyrecommend this method as it can

create unsurefooting and invites soil

erosion.

• As in terrace gardening, start atthe top

of the slope and overlap the first pass

by half the width of the tiller. For added

stability of the tiller, always keepthe

uphill wheel in the soft, newlytilled soil.

16

Section4: Operation

POWERCOMPOSTING

Power composting simply meanstilling

under and burying in the soil all manner

of organic matter such as crop residues,

leaves,grass clippings and cover crops.

This materialwill decompose during the

non-growing season and add important

natural nutrients to the soil.

When power composting,do not keep

the Depth Regulator Lever at a deep

settingif the tiller jumps orbucks.

Ifjumping or buckingoccurs,movethe

DepthRegulator Lever down to one of

the shallower settingsand then slowly

increase the tilling depth on later

passes.

Failure to comply could result in loss

of tiller control, property damage or

personalinjury.

The firstplaceto begin iswith crop

residues such asleftover vines, stalks,

stems and roots. Powercompost these

crop residues as soon as they finish

bearing. The sooner this is done,the

better, as tender green matter is easierto

till under. Usethe deepest depth

regulator setting possible without causing

the engineto labor or the tiller to jump

ahead.

Standing cornstalks of reasonableheight

can be power composted. Pushing over

(but not uprooting) cornstalks will often

make it easier for your tiller to chop up

the stalks. Keepthe tines clearof

excessivetangling by "fishtailing" or fre-

quently using reverse. Make several

passes,then return a few days laterto

finish off any remaining stubble.

After tilling under crop residues,add more

organic matter such as leaves,grass

clippings and even kitchen scraps. When

tilled into the soil, this organic matterwill

decompose and add even more important

nutrients to the soil.

After power composting, you may want to

plant a "green manure" cover crop to

protect the soil during the off-season.

You simply grow a crop of clover, alfalfa,

buckwheat, peas,beans, rye grass, grain,

or kaleand then till it into the soi! prior to

the planting season.

LOADINGAND UNLOADINGTHE

TILLER

Loadingand unloadingthe tiller intoa

vehicle is potentially hazardous and

we don't recommend doing so unless

absolutely necessary, as this could

result in personal injury or property

damage.

However, if you must load or unload

the tiller, to!low the guidelines given

next.

• Beforeloading or unloading, stopthe

engine,wait for all parts to stop moving,

disconnect the spark plug wire and let

the engine and muffler cool.

• The tiller is too heavyandbulky to lift

safely by one person. Two or more

people should share the load.

• Usesturdy ramps and manually (engine

shut off) roll the tiller into andout of the

vehicle. Two or more peopleare needed

to do this.

• Ramps must bestrong enoughto

support the combined weight of the tiller

and any handlers. The ramps should

provide good traction to prevent

slipping; they should haveside rails to

guide the tiller along the ramps; andthey

should have a locking device to secure

them to the vehicle.

•The handlersshould wear sturdy

footwear that will help to prevent

slipping.

• Position the loading vehicle sothat the

ramp angle is asfiat as possible (the

less incline to the ramp, the better).

Turn the vehicle's engineoff andapply

its parking brake.

• When going up ramps, stand inthe

normal operating position and push the

tiller ahead of you. Havea personat

eachside to turn the wheels.

* When going down ramps, walk

backwardwith the tiller following you.

Keepalertfor any obstacles behindyou.

Position a person at eachwheel to

control the speed of the tiller. Nevergo

down ramps tilter-first, asthe tiller could

tip forward.

• Usewooden blocks to placeon the

downhill side of the wheels if you need

to stop the tiller from rolling down the

ramp. Also, usethe blocks to temporar-

ily keep the tiller in placeon the ramps

(if necessary), and to chock the wheels

in placeafter the tiller is in the vehicle.

• Whenthe tiller is inthe vehicle, prevent

it from rolling by engaging thewheels in

the WHEELDRIVE position. Chockthe

wheels with blocks and securely tie the

tiller down.

17

n

Maintenance

Before inspecting, cleaning or

servicingthe machine, shutoffengine,

wait for all moving partsto come to e

complete stop, disconnectspark plug

wire and move wire away from spark

plug. Remove ignition key on electric

start models.

Failureto followthese instructionscan

result in serious personal injury or

propertydamage.

REQUIRED MAINTENANCE SCHEDULE

Before Eve_ Eve_ As

PROCEDURE Each 10 30 Noted

Use Hou_ Hon_

Checkengine oil level

Cleanengine

Checkdrive belttension

Checknuts and bolts

Changeengine oil

Lubricate tiller

Service engineair cleanersystem

Checkgearoil levelin

transmission

Checktines for wear

Checktire pressure

(pneumatic tires only)

Service spark plug

And every5

operating hours

-r

* Changemorefrequentlyindustyordirtyconditions. Changeafterfirst2hoursof

break-in operation,

_ Check after first 2 hours of break-in operation.

• SeeEngine Owner'sManual forservice intervalsand instructions.

18

Section5: Maintenance

WARNINGBelore inspecting, cleaning or servicing the unit, shut off engine, wait for all t =,.-.,.

partsto come to a complete stop, disconnectspark plug wire and movewire away from spark

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

TILLER LUBRICATION

Proper lubrication of the tiller is an

essential part of your maintenance

program. After every t0 operating

hours, oil or greasethe lubrication points

shown in Figure5-1 and described

below.

Usea good quality lubricating oil (#30

weight engine oil is suitable) and agood

quality general purpose grease (grease

that has a metal lubricant is preferred, if

available).

• Removewheels, cleanwheel shaft (A,

Fig.5-1) and apply thin coating of

greaseto shaft.

• Greaseback,front and sides of depth

regulator lever (g, Fig. 5-1).

• Removetines, clean tine shafts (C, Fig.

5-1) and inspect for rust, rough spots

or burrs (especially around holes). File

or sand smooth and coat ends of shaft

with grease.

• Oilthe threads on the handlebar height

adjustment screws and the handlebar

attachingscrews (D, Fig. 5-1).

D

A

Figure5-I

CHECKFOR OILLEAKS

Beforeeach use, checkyour tiller for

signs of an oil leak - usually a dirty, oily

accumulation either on the unit or on the

floor where it has beenparked.

A little seepagearound a cover or oil sea]

is usually not a cause for alarm. However,

ifthe oil drips overnight then immediate

attention is neededas ignoring a leak can

result in severetransmission damage.

If a cover isleaking, check for loose

screws. If the screws are tight, a new

gasket or oil seal may be required. If the

leakis from around a shaft and oil seal,

the oil seal probably needs to be replaced.

Seeyour authorized dealer or contact the

factory for service or advice.

IMPORTANT:Neveroperate the tiller if the

transmission is low on oil. Checkthe oil

levelafter every30 hours of operation and

whenever there is any oil leakage.

CHECK HARDWARE

Checkfor looseor missing hardwareafter

every10 operating hours. Tighten or

replacehardware beforeusing the tiller.

Besureto checkthe screws underneath

the tiller hood (lift the hood flap) that

securethe transmission cover andthe

Depth Regulator Leverto the transmis-

sion.

CHECKTIREPRESSURE(Models

withpneumatictires)

Checkthe air pressure in both tires.

Deflateor inflate both tires evenly from

t 5-to-20 PSI (pounds per square inch).

Besure that both tires havethe same air

pressure or the unit will tend to pull to

one side.

TRANSMISSIONGEAROIL SERVICE

Checkthe transmission gear oil levei after

every 30 hours of operation or whenever

you notice any oil leak, Operatingthe

tiller when the transmission is low on oil

canresult in severe damage.

A. To Checkthe Transmission

GearOil Level:

1. Checkthe gear oil levelwhen the trans-

mission is cool. Gearoil will expandin

warm operating temperatures and this

expansion will provide an incorrect oil

levelreading.

2. With the tiiler on level ground, pull the

Depth Regulator Leverall the way up.

3. Removethe oil fill plug (A, Fig.5-2)

from the transmission housing and locate

the main drive shaft situated inside the

housing.

4. Thegear oil level is correct ifthe gear

oil is approximately halfway up the side of

the main drive shaft.

5. Ifthe gear oil levelis low, add gear oil

as described next. If the gear oil levelis

okay,securely replacethe oil fill plug.

IMPORTANT:Do not operate the tiller if

the gear oil level is Iow. Doing so will

result in severedamageto the transmis-

sion components.

8. If addingonly afew ounces of gear

oil, use API rated GL-4 or GL-5 gear oil

having a viscosity of SAE140, SAE85W-

140 or SAE80W-90. if refilling an empty

transmission, use only GL-4 gear oil

having a viscosity of SAE85W-140 or

SAE140.

IMPORTANT: Do not use automatic

transmission fluid or motor oil inthe

transmission.

7. While checking frequently to avoid

overfilling, slowly add gear oil into the oil

fill hole until it reaches the halfway point

on the drive shaft.

8. Securelyreplacethe oiI fill plug,

B. To Drainthe TransmissionGearOil:

Thetransmission gear oil does not need

to be changed unless it has been contam-

inated with dirt, sand or metal particles.

1. Drain gasoline from the fuel tank or

run the engine until the fueI tank is

empty_See"DANGER" statement that

follows.

19

Section5: Maintenance

WARNING Before inspecting,cleaning or servicingthe unit, shut off engine, wait for all i

partsto come to a completestop, disconnectsparkplug wire and movewire away fromspark

plug. Failure to foliowthese instructions can result in serious personal injury or

propertydamage.

Gasoline is highly flammable and its

vapors are explosive. Follow these

safety practices to prevent personal

injury or propertydamage from fire or

explosion.

,, Allow the engine and muffler to cool

for at leasttwo minutesbefore draining

thetiller's gasolinetank.

• Do not allow open flames, sparks,

matchesor smokingin the area.

* Wipe away spills and pushtiller away

fromspilled fuel.

• Use only an approved fuel container

and store it safely out of the reach of

children.

• Do not store gasoline in an area

where its vapors could reach an open

flame or spark, or where ignition

sourcesare present(such as hot water

and space heaters, furnaces, clothes

dryers,stoves, electricmotors,etc.)

2. Drain the oil from the engine.

3. Removefour screws (B, Figure5-2) and

removetransmission cover and gasket.

4. Remove the left-side wheel.

5. Tilt the left-side wheel shaft into a

drain pan and allow the gear oil to drain

through the top of the transmission,

6. Reinstall the wheel, install a new

gasketcover (do not reuseold gasket)

and reinstall the transmission cover.

7. Refillthe transmission using GL-4

gear oil (SAE85W-140 or SAE 140).

8. Refillthe engine with motor oil and

replenish the fuel tank with gasoline.

BOLOTINES

The bolo tines will wearwith useand they

should be inspected atthe beginning of

eachtilling seasonand after every 30

operating hours. The tines can be

replacedindividually or as a complete set.

Seethe Parts Listfor tine identification

and part numbers,

2O

Figure5-2: Remove oil fiRplug (A) to check

gear ofl level and to addgear niL Remove

fourcoverscrews(B) todrain gear oil.

A, Tine Inspection:

With use,thetines will becomeshorter,

narrowerand pointed. Badlyworn tines

will result in a loss of tilling depth and

reducedeffectiveness whenchopping up

and turning under organic matter.

B. Removinga Single Tine:

1. With the engine shot offandthe spark

plug wire disconnected, removethe two

screws (A, Figure 5-3) and Iocknuts (B)

that attach a single tine to the tine holder.

If needed,use penetrating oil on the nuts.

2. When installing a single tine, besure to

position it so that its cutting edge will

enter the soil first asthe tiller moves

forward.

C. Removinga Tine Assembly:

1. A tine assembly consists of eight tines

mounted on atine holder.

2. If removing both tine assemblies, mark

them "left" and "right" before removal.

Removethe screw (C, Figure 5-3) and

Iocknut (D)that secure the tine assembly

to the tine shaft. If necessary,use a

rubber mallet to tap the tine assembly

outward off the shaft.

3. Before reinstalling thetine assembly,

inspect the tine shaft for rust, rough

spots or burrs andfile or sand as needed.

Apply a thin coat of greaseto the shaft.

4. Install eachtine assembly so that the

cutting edge of the tines will enter the

soil first when the tiller moves forward.

Securethe tine assembly to thetine shaft

using the screw and Iocknut previously

removed.

ENGINE

C

B

Figure5-3: Install tinesso thatcutting edgeof tinesenter softfirst whentiller moves forward.

Section5: Maintenance

WARNINGBefore inspecting,cleaning or servicingthe unit, shut off engine, wait for all 1_

parts to come to a complete stop, disconnectspark plugwire and movewire away from spark _,L._/

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

CHECKINGAND ADJUSTING

FORWARDDRIVE BELTTENSION

Maintaining correct tension on the

forward drive bett is important to good

tilling performance and Iong belt life.

A loosebelt will slip on the engine and

transmission pulleys and causethe tines

and wheels to slow down - or stop com-

pletely- eventhough the engineis

running atfull speed. A beltthat is too

tight can result in unintentional tine

movement whenthe clutch bail is in the

Neutral (released)position.

Also check the belt for cracks, cuts or

frayed edgesand replace it as soon as

possible.

• Checkbelt tension afterthe first two

hours of break-inoperation (new belt).

• Checkbelt tension after every10

operating hour.

To CheckForwardBeltTension:

1. Stop the engine,wait for al! parts to

stop moving and disconnectthe spark

plug wire.

2. With the forward clutch bail inan open

(released)position, measureand carefully

notethe overall length of the cablespring

(A, Figure 5-4) by measuringfrom the

outermost coil to the outermost coil.

3. Lift and holdthe forward clutch bail

against the handlebar (see Figure5-4) and

re-measurethe overall lengthof the coils

while the spring is under tension. The belt

tension is correct if this second measure-

ment is between1/16"-to- 3/16" longer

than the first measurement.

4. If the spring is too short (less than

1/16" greaterthan the first measurement),

the tension is too loose. If the spring is

too long (more than 3i1B"greater than the

first measurement), the tension is too

tight.

5. To adjust the length of the spring:

a. Releasethe Forward Clutch Bail.

b. Unthread the hex nut (C, Figure5-4)

about halfway up the adjustment

screw (D).

c. Unhook the top of the spring from

the forward clutch bail.

d. Use pliers to preventthe adjuster (B)

from turning and turn the slotted

screw located inside the screw

clockwise (viewed from operator's

position) to increasetension on the

spring. Turn the screw counter-

clockwise to decreasetension on the

spring. Onceadjusted, re-hookthe

top of the spring to the forward

clutch bail. (Continue to Step 5e.)

e. RepeatSteps 2 and 3 to re-measure

thelength of the spring coils. When

the second measurement(with bail

closedagainst handlebar)is between

1/16"-to- 3/16" longerthan the first

measurement,retightenthe hexnut

(C)against the top of the adjuster (B).

ReplacementBelt Information

If the drive belt needsto be replaced,see

your local authorized dealeror referto the

Parts Listfor ordering information. Use

only afactory-authorized belt asan "over

the counter" belt maynot perform satis-

factorily. Theprocedure requiresaverage

mechanicaiability and commonly

availabletools.

FORWARDCLUTCH

BAILADJUSTMENT

If the Forward Clutch Baildoes not

function properly, first check that the

forward drive belt is adjusted properly

(see Checkingand Adjusting Forward

Drive Belt Tension). If this fails to correct

the problem, contact the factory technicai

servicedepartment or your authorized

dealerfor service advice.

Figure5-4: Tocheck forwardbelt tension, take two measuremenls of

the overall length of the coilsin the spring - first withthe clutchbai!

open, thenwith the clutchbail closedagainst the handlebar.

21

Section5: Maintenance

WARNING Before inspecting,cleaning or servicingthe unit, shut off engine, wait for all 1"

pads to come to a completestop, disconnectsparkplug wire and movewire away from spark ...._.../

plug. Failure to follow these instructions can result in serious personal injury or

propertydamage.

ENGINECLEANING

Keepthe engineclean to assure smooth

operation and to preventdamagefrom

overheating. Referto the separateEngine

Owner's Manualfor specific repair and

cleaning instructions. All inspections and

services must be done with the engine

shut off and cool to the touch.

AIR CLEANERSERVICE

Theengine air cleaner filters dirt and dust

out of the air before it enters the carbure-

tor. Operatingthe engine with a dirty,

clogged air filter can cause poor perfor-

manceand damageto the engine. Never

operatethe enginewithout the air cleaner

installed. Inspect and servicethe air

cleaner more often if operating in very

dusty or dirty conditions.

Service the air cleaner asinstructed in the

separate EngineOwner's Manual.

ENGINEOIL SERVICE

Checkthe engine oil level before starting

the engine each dayand check it after

each 5 hours of continuous operation.

Runningthe enginewhen it is low on oil

will quickly ruin the engine.

It is recommended that you change the

engine oil after every 10 hours of

operation and even sooner when

operating in extremely dirty or dusty con-

ditions. Refer to the separate Engine

Owner's Manualfor detailed service

instructions.

A. To Checkthe EngineOil Level:

1. Move the tiller to a levelareaand shut

off the engine.

2. Level the engine by putting the Depth

Regulator Leverin the second notch from

the top,

3. Cleanthe areaaround the oil dipstick

or oil fill tube to prevent dirt from falling

into the crankcase.

4. On engines with an oil fill tube, remove

thefiller cap, add oil (if required) until it

reachesthe top ofthe tube and reinstall

thefiller cap.

5. On engines with a dipstick, remove it,

wipe it clean, and reinstall it finger-tight.

Removethe dipstick and checkthe

reading. Add oil (if required) to bring the

levelto the FULLmark. Do not overfill.

B. To Changethe EngineOil:

Changethe engine oil asinstructed in the

separateEngineOwner'sManual.

SPARKPLUGSERVICE

inspect and clean or replacethe spark

plug after every 100 operating hours or

annually. Cleanthe plug and set the gap

asdescribed in the separateEngine

Owner's Manual.

In some areas,local lawrequires using

resistor spark plugsto suppress ignition

signals. If the engine was originally

equipped with a resistor spark plug, use

the same type for replacement.

SPARKARRESTERSCREEN

SERVICE

If the engine muffler is equippedwith a

spark arrestor screen, removeand clean

it according to the time intervals and

instructions in the separateEngine

Owner's Manual.

Operators shall not tamper with the

engine governor settings on the

machine; the governor controls the

maximum safe operating speed to

protect the engine and all moving

parts from damage caused by

overspeed.Authorizedserviceshall he

soughtit a problemexists.

THROTTLELEVERADJUSTMENT

If the enginedoes not respond to various

throttle lever settings, refer to the

separateEngineOwner's Manualfor

serviceinformation or contact your local

authorized engine servicedealer.

CARBURETOR/GOVERNOR

CONTROLADJUSTMENTS

Thecarburetor was adjusted atthe

factory for best operating speed. Referto

the separateEngineOwner's Manualfor

anyadjustment information or seeyour

authorized engine servicedealer.

Thegovernor controls the maximum safe

operating speed and protects the engine

and all moving parts from damage

causedby overspeeding Donot tamper

with the engine governor settings.

OFF SEASONSTORAGE

Whenthe tiller won't be usedfor

extendedperiods, prepare it for storage

asfollows:

1. Cleanthe tiller and engine.

2. Do routine tiller lubrication and check

for loose parts and hardware.

3. Protect the engine and perform recom-

mended engine maintenance byfollowing

the engine storage instructions found in

the separateEngine Owner's Manual.

NOTE:Besure to protect thefuel lines,

carburetor and fuel tank from gum

deposits by removing fuel or by treating

fuel with afuel stabilizer (follow engine

manufacturer's recommendations).

4. Store unit in a clean,dry area.

5. Neverstore the tiller with fuel in the

fuel tank in an enclosedarea where gas

fumes could reachan open flame or

spark, or where ignition sources are

present (space heaters,hot water

heaters,furnaces, etc.).

22

Section5: Maintenance

TROUBLESHOOTING

Beforeperforming any corrections, refer to the appropriate information in this Manual, or in the EngineOwner's Manual, for the

correct safety precautions and operating or maintenance procedures. Contactyour local authorized EngineService Dealerfor

engine service. Contactyour localauthorized equipment dealer or the factory for all other service problems.

PROBLEM POSSIBLE CAUSE CORRECTION

Enginedoes

not start.

!. Sparkplugwire disconnected.

2. EngineThrottleControILeverincorrectlyset.

3. FueItank empty.

4. ChokecontroI (if soequipped)in incorrect position.

5. StalegasoIine.

6. Dirty air filter(s).

7. Defectiveor incorrectlygappedsparkplug.

8. Carburetorout of adjustment.

9. Misadjustedthrottle control

10.Dirt or waterinfuel tank.