Page 1

$7.50

Owner/Operator

Manual

ECONO·HORSETM

PONY

Model

- Safety

- Assembly

- Controls

- Operation

-

Maintenance

®&

Tillers

JUNIOR

®

Page 2

TABLE

OF

CONTENTS

SECTION 1: SAFETY INSTRUCTIONS .4

Safety Alert Symbol .4

Training .4

Preparation .4

Operation .4

Maintenance and Storage 6

Decals 6

SECTION 2: EASY ASSEMBLY 7

SECTION 3: TILLER AND

ENGINE

Tiller Controls 18

Engine Controls 22

SECTIO N 4: OPERATION OF TILLER 24

Be

To Begin Tilling 25

Turning Around 25

Stopping the Tiller and Engine 25

Changing Speeds (Econo-Horss only) 26

Tilling in the Garden 27

CONTROLS

Wheel Gear Lever (Econo-Horse

Wheel Drive Pins (Junior only) 19

Forw

ard

Clutch 20

Maneuvering Clutch 20

Depth Regulator 21

Handlebar Height Adjustment 21

Starting Your Engine 22

Starting the Electric Start Engine

With the Recoil Starter Rope 23

Stopping the Engine 23

for

e Starting 25

Change

To

To Change from HIGH Speed to LOW 27

Guiding Your Tiller. 27

Tilling Depths 27

Tilling Patterns 28

Choosing Wheel and Tine Speeds 29

Avoid Making Footprints 29

Clearing Debris from the Tine Area 29

Power

Use Reverse to Turn in Tight Areas 30

Tilling Near Obstacles 30

Tilling Up and Down Slopes 31

Tilling Across Slopes Using Terraces 31

Tilling Across Slopes Without Terraces 32

Loading and Unloading the Tiller 32

from LOW Speed to HIGH 26

Comp

osting 30

& Pony) 18

18

SECTION 5: TILLER AND

ENGINE MAINTEN ANCE.

Lubrication , 33

Check for Oil Leaks 34

Tightening Nuts and Bolts , 34

Checking, Adding or Chang ing

Gear

Transmission

To Check the Transmission

Gear Oil Level 34

To Add Gear Oil to the

Transmission 35

To Drain and Refill the

Transmission 35

Checking Engine Oil Level 35

Changing Engine Oil 36

Air Cleaner Service 36

Spark Plug Maintenance 37

Ignition System Maintenance 37

Air Cooling System Maintenance 37

Bolo Tines 37

Removing Bolo Tine Assemblies 38

Removing Individu al Bolo Tines 38

Checking Tension on the Drive Belts 38

Forward Drive Belt Tension 39

Reverse Drive Belt Tension 39

Adjusting Forward Drive Belt Tension 39

Removing Forward Drive Bel

Installing Forward Drive Belt .. .41

Removing Reverse Drive Belt.. .42

Installing Reverse Drive

Adjusting Reverse Drive Belt Tension .43

Wheel Gear Cable Adjustment .43

Engine Throttle Cable Adjustment .44

Off-Season Storage .44

Troubleshoot Electric Start System .45

Starter Motor Won't

Ignition Switch Doesn't Stop Engine 46

Battery Care and Maintenance .47

Care in Service .47

Battery Storage .47

Carburetor Adjustment .47

Specifications .48

Recommended Maintenance Intervals .49

INDEX REFERENCE 52

Oil 34

t..

BelL

Turn Over .45

33

.41

.42

Page 3

TO THE OWNER:

Congratulations on the purchase of your new tiller! The ECONO-HORSE'" Model, the PONY®

Model and the JUNIOR ® Model, along with the rest of the TROY-BILT®models, make up the finest

family of tillers available anywhere.

The ECONO-HORSE'" , PONY® and JUNIOR®Tillers are covered in this manual. They have many

features in common, but there are substant ial differences too, and where differences occur, they are so

noted. Your new tiller is basically a simple machine to operate. However, as with all new equipment,

you should thoroughly read and understand this Owner/Operator Manual and any other product literature you received before you operate your tiller. Then,you should practice operating the tiller controls

and maneuvering the tiller in a safe area until you feel very comfortable using the tiller.

Your tiller was designed with the tines in the rear and the engine up front. This design, first perfected

in the larger Horse Model tiller, gives a superb balance combination which allows you to easily chop up,

shred, and bury all sorts of vegetation and organic matter directly into your garden's soil.

This is a rugged, dependable machine that will give you many years of use if properly maintained.

You can ensure long-lasting performance from your tiller by following the operating and maintenance

procedures in this manual and in the other literature sent to you.

Thank you,

afJ

UK

'/

edJ.

Dean Leith, Jr., Sales Manager

,

~

Page 4

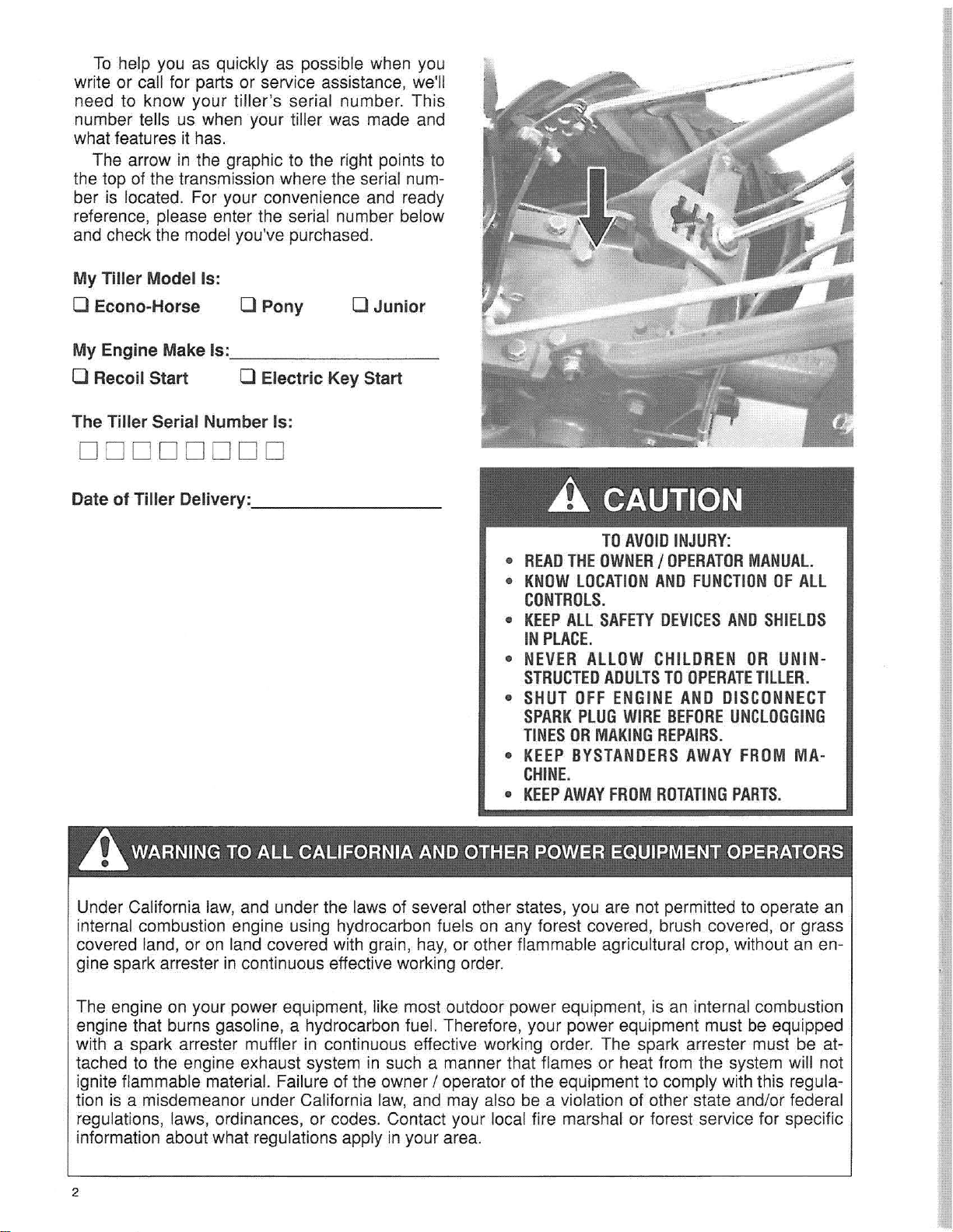

To help you as quickly as possible when you

write or call for parts or service assistance, we'll

need to know your tiller's serial number. This

number tells us when your tiller was made and

what features it has.

The arrow in the graphic to the right points to

the top of the transmission where the serial number is located. For your convenience and ready

reference, please enter the serial number below

and check the model you've purchased.

My Tiller Model Is:

o Econo-Horse 0 Pony

My Engine Make Is: _

o Junior

o Recoil Start 0 Electric Key Start

The Tiller Serial Number Is:

00000000

D

eli

ver

Date of Tiller

y:,

_

A CAUTION

TO

AVOID

•

READ

THE

OWNER/DPERATOR

•

KNOW

CONTROLS.

•

KEEPALL

IN

•

NEVERALLOWCHILOREN

STRUCTED

•

SHUT

SPARK

TINESOR

•

KEEP

CHINE

KEEP

•

LOCATION

SAFETY

PLACE.

ADULTSTOOPERATE

OFF

ENGINE

PLUG

MAKING

BYSTANDERS

.

AWAY

FROM

WIRE

INJURY:

AND

DEVICES

AND

BEFORE

REPAIRS.

ROTATING

FUNCT

AWAY

IONOFALL

ANO

ORUNIN-

DISCONNECT

UNCLOGGING

FROM

PART

MANUAL.

SHIELDS

TILLER.

MA·

S.

AWARNING TO ALL CALIFORNIA AND OTHER POWER EQUIPMENT OPERATORS

Under California law, and under the laws of several other states, you are not permitted to operate an

internal combustion engine using hydrocarbon fuels on any forest covered, brush covered, or grass

covered land, or on land covered with grain, hay, or other flammable agricultural crop, without an engine spark arrester in continuous effective working orde

The engine on your power equipment, like most outdoor power equipment, is an internal combustion

engine that burns gasoline, a hydrocarbon fuel. Therefore, your power equipment must be equipped

with a spark arrester muffler in continuous effective working order. The spark arrester must be attached to the engine exhaust system in such a manner that flames or heat from the system will not

ignite flammable material. Failure of the owner / operator of the equipment to comply with this regulation is a misdemeanor under California law, and may also be a violation of other state and/or fe

regulations, laws, ordinances, or codes. Contact your local fire marshal or forest service for specific

information about what regulations apply in your area.

2

r.

der

al

Page 5

ENGINE SERVICE

If your tiller engine ever needs service or repair, contact your nearest Briggs

Tecumseh Service Dealer.

To find the nearest Service Dealer, look in the

Yell ow

"Engines- Gasoline", or "Gasoline Engines."

If you have problems getting engine service or

parts locally, let us know so we can provide you

with the name of the nearest Service Dealer.

Page

s of your ph one

& Stratton or

book

under

QUESTIONS OR PROBLEMS?

1. Check

The answer to your question or problem may be

in this Manual. Refer to the index at the back of

this Manual to find the listing that concerns your

problem. Turn to that page and read the information provided.

this

OwnerlOperator Manual:

For Fa

In the U.S.A.:

Technical Service 1-800-833-6990

Parts Orders 1-800-648-6776

Customer Service 1·800-437-8686

In Canada:

Local only (416 Area Code) 624-8423

From Ontario and Quebec 1-800-387-3351

From Western Canada

st

est Service, Use The Toll-Free Numbers Below

& the Maritimes 1-800-387-3316

2. Call or write to us:

If you can't find the answer to your question or

problem in this Manual, please call us or write to

us. One of our helpful, friendly tiller experts will

gladly help you. Be sure to include your tiller

model name and the serial number of your tiller.

3. If you need a part:

Call or write to our Parts Department (see the

Toll-Free telephone number below). Please have

your tiller model name and serial number at

hand. Use the Parts Catalog to find the part

number

Remember that you can purchase many of the

common hardware items at your local hardware

store as well as ordering them from us.

and quantity of the part you need.

Our H

In the U.S.A. InCanada

Mon - Fri.- 8 A.M. to 7 P.M. Mon - Fr

Saturday- 9 A.M. to 4 P.M.

If you w

TROY-BILTMfg. Co. Garden Way Canada, Inc.

102nd S

Troy, New York 12180 Mississauga. Ontario L4W 2P5

IF YOU NOTICE any freight damage or missing parts, either at the time of delivery or later during

assembly, make sure that you put it in writing, within 15 days, and send your letter to the shipper

to confirm that you intend to file a claim.Tell thedriver, or inform the truck terminal, that you intend

to file a written claim. They will advise you as to how to proceed. HOWEVER, if you have any

problems with this procedure, please call us so that we can help you get satisfaction.

ould

In the U.S.A. In Canada

our

s are (Eastern Standard Time):

rather

1.

& 9th Ave. 1

writ

e to us, our mailing addresses are:

IMPOR

i-

8 A.M. to 5 P.M.

51

5 Matheson Blvd.•Unit B11

TANT!

3

Page 6

Section

1:

Safety

Instructions

Your TROY-BILT Model Tiller has been designed w

anyother piece of powered equipment, the operator

rso

times. Failure to do so could result in pe

Before assembling , operating or

the

of

O

please call us'at one of the numbers listed on page 3 of this manual.

lows the Safety Instructions. Always use

safety instructions found in this Owner / Operator Manual, in the separate Engine

wner's

If you ever lend yo

Manual, and in any ot

ur

tiller

to so meone, make sure that he or she reads, understands, and

her

servicing

literature

nal

the

you

your

tiller carefully and keep safety in mind.

ith

many safety features. However, as w

mustfollow

injury

or damagetothe

tiller

or its engine, care

may receive. If

safe operating practices at all

you

A SAFETY ALERT SYMBOL. This symbol is used to alert you to

..

symbol, carefully read and follow its safety message. Failure to do so can

result in personal injury or property damage.

TRAINI NG

1. Carefully read this Owner/Operator Manual,

the separate Engine Owner's Manual, and any

other literature you may receive. Be thoroughly

familiar with the controls and the proper use of

the tiller and its engine. Know how to stop the

unit and disengage the controls quickly.

2. Never allow children to operate the tiller. Let

adults operate the tiller only if instructed properly.

3. Keep the area of operation clear of all persons

(particularly children) and pets.

PREPARATION

1. Thoroughly inspect the area where the tiller is

to be used and remove all foreign objects.

2. Be sure all control levers are released and the

ECONO-HORSE or PONY Model Wheel Gear

Lever is in "ENGAGE" before starting the engine.

On the JUNIOR Model, which does not have a

Wheel Gear Lever, be sure the Wheel Drive Pins

engage the wheels.

3. Do not operate the tiller without wearing ade-

quate outer garments. Avoid loose garments or

jewelry that could get caught in moving parts of

the tiller or its engine.

4. Do not operate the tillerwhen barefoot or wear-

ing sandals, sneakers , or light footwear. Wear

footwearwhichgripswell on slipperysurfaces.

5. Do not till near underground electric cables,

telephone lines,pipesor hoses. If in doubt,contact

yourtelephoneor utility company.

6. Handlefuel with care; it is highly flammable and

itsvapors areexplosive.

a. Use an approved fuel container.

b. Never add fuel to a running or hot engine.

4

important safety messages in this Manual and on decals which

are on your tiller regarding potential hazards. When you see this

c. Keep matches, cigarettes, cigars, pipes ,

open flames, and sparks away from the fuel

tank and fuel container.

d. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Use a funnel or

spout to prevent spillage.

e. Replace the fuel tank cap securely and

clean up any fuel before starting engine.

7. Never make adjustments when engine is running (unless recommended by manufacturer).

OPERATION

1. Do not put hands or feet near rotating parts.

2. Exercise extreme caution when on or crossing

gravel drives, walks, or roads. Stay alert for hidden hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine

(and remove the Ignition Switch Key on electric

start models), disconnect the spark plug wire and

prevent it from touching the spark plug, carefully

inspect the tiller for any damage, and repair the

damage before restarting and operating the tille

4. Exercise caution to avoid slipping or falling.

5. If the machine should start to vibrate abnormally, stop the engine (and remove the Ignition

Switch Key on electric start models). Disconnect

the spark plug wire and prevent it from touching

the spark plug, and check immediately for the

cause.Vibration is generally a warning of trouble.

6. Stop the engine (and remove the Ignition

Switch Key on electric start models), disconnect

the spark plug wire and prevent it from touching

the spark plug whenever you leave the operating

position, before unclogging the tines, or when

making any repairs, adjustments or inspections.

equipment or property.

fully

read and fo

ever have any questions,

llow

ith

tol

all

-

r.

Page 7

7. Before leaving the tiller unattended, stop the

engine. Remove the Ignition Key on electric start

models. Disconnect the spark plug wire and prevent it from touching the spark plug. Move the

Wheel Gea r

Lever

to "ENGAGE" on EconoHorse and Pony models. On Junior models, the

Wheel Drive Pins must engage the wheels.

8. Before cleaning, repairing, or inspecting, stop

the engine, remove the Ignition Switch Key on

electric start models, and make certain all moving

parts have stopped. Disconnect the spark plug

wire and prevent it from touching the spark plug

to prevent accidental starting. On electric start

models, always remove the cable from the nega-

-)

tive side (

of the battery.

9. Always keep the flap on the tine hood down

when operating the tiller, except when using the

hiller/furrower attachment.

Neveroperate

10.

the

till

er with

out

proper

guards, plates, or other protective safety devices

in place.

the

11. Do not run

engine indoors; exhaus t

fumes are dangerous.

12. Keep children and pets away.

13. Never operate the tiller under engine power if

the Econo-Horse or Pony Wheel Gear Lever is in

"DISENGAGE" (FREEWHEEL), or if the Junior

Wheel Drive Pins do not engage the wheels. In

this position, the wheels will not hold the tiller

back and the revolving tines could propel the

tiller rapidly, possibly causing loss of control.

Always move the Wheel Gear Lever to "EN-

GAGE" (or, on the Junior, ENGAGE the wheels

with the Wheel Drive Pins) before starting the

engine or engaging the tines / wheels with the

Forward Clutch or the Maneuvering Clutch.

14. Be aware that the tiller may unexpectedly

bounce

upward

or jump forward if the t

ines

should strike extremely hardpacked soil, frozen

round

g

, or

bur

ied

obstac

les such as

large

stones, roots, or stumps. If you are in doubt

about the tilling conditions, always use the following operating precautions to assist you in

maintaining control of the tiller:

a. Walk behind and to one side of the tiller,

using one hand on the handlebars. Relax

your arm, but use a secure hand grip.

b. Use sha llower depth regulator settings,

working gradually deeper with each pass.

c. Place the forwar d drive belt in its LOW

Range position (Econo-Horse only). Use

slower engine speeds.

d. Clear the tilling area of all large stones ,

roots and other debris.

e. Avoid using downward pressure on handle-

bars. If need be, use slight upward pressure

to keep the tines from digging too deeply.

f. Before contacting hardpacked soil at the end

of a row, reduce engine speed and lift handlebars to raise tines out of the soil.

g. In

wheels

Lever

you

to restrain the

ncy,stop

by

releasing

have engaged . Do

tiller

.

thetines

and

whicheverClutch

not

attempt

an

eme

rge

15. Do not overload the tiller's capacity by attempting to till too deeply at too fast a rate.

16. Never operate the tiller at high transport

speeds on slippery surfaces. Look behind and

use care when backing up.

17. Do not operate the tiller on a slope that is too

steep for safety. When on slopes, slow down and

make sure you have good footing. Never permit

the tiller to freewheel down slopes.

18. Never allow bystanders near the unit.

19. Only use attachments and accessories that

are approved by Troy-Bilt Manufacturing Co.

20. Use tiller attachments and accessories when

recommended.

21. Never operate the tiller without good visibility

or light.

22. Neveroperate the tillerif youare tired,or under

lcohol

the influenceofa

,drugsor medication.

23. Do not change the engine governor settings or

overspeed the engine.

24. Do not touch engine parts which may be hot

from operation. Allow parts to cool before inspecting,cleaningor repairing.

25. The battery on electric start model tillers con-

tains sulfuric acid. Avoid contactwith skin, eyes, or

clothing.Keepout of the reachof children.

Antidote-Externa l Contact: Flush immediately

with lotsof water.

Antidote-Internal: Drinklarge quantitiesofwater

or milk. Followwith milk of magnesia, beaten

egg orvegetable oil. CALL A PHYSICIAN IMMEDIATELY.

Antidote-Eye Contact: Flush with water for 15

minutes. GET PROMPT MEDICAL ATTENTION.

26. Batteries produce explosive gases. Keep

spar

ks, flame , and smoking materials away.

Ventilate when charging batteries or when using a

ALWA

batteryinan enclosed space.

goggleswhenworkingnearbatte

YS wearsafety

ries.

27. Please remember: You can always stop the

tines and wheels by releasing the Forward Clutch

Lever or the Maneuvering Clutch Lever (whichever

lever you have e

Control Leverto

ngaged

STOP.

) or by moving the T

hrottle

28.Toload or unload the tiller, see the instructions

in Section 4 ofthis Manual.

5

Page 8

MAINTENANCE AND STORAGE

1. Keep the tiller, attachments and accessories

in safe working condition.

2. Check all nuts, bolts, and screws at frequent

intervals

for

proper

tightness

to be sure the

equipment is in safe working condition.

3. Never store the tiller with fuel in the fuel tank inside a building where fumes may reach an open

flame or spark (hot water and space heaters, furnaces, clothes dryers,stoves,electricmotors, etc.).

4. Allow the engineto cool before storing it.

5. Toreduce the chances of a fire hazard, keep the

engine freeof grass, leaves,or excessive grease.

6. Store gasoline in a cool, well-ventilated area,

safely away from any spark or flame-producing

equipment. Store gasoline in an approved con-

tainer, safely away from the reach of children.

7. Refer to the Tiller and Engine Maintenance

section of this Manual for instructions if the tiller is

to be stored for an extended period.

8. Never perform maintenance while the engine

is running or the spark plug wire is connected, except when specifically instructed to do so.

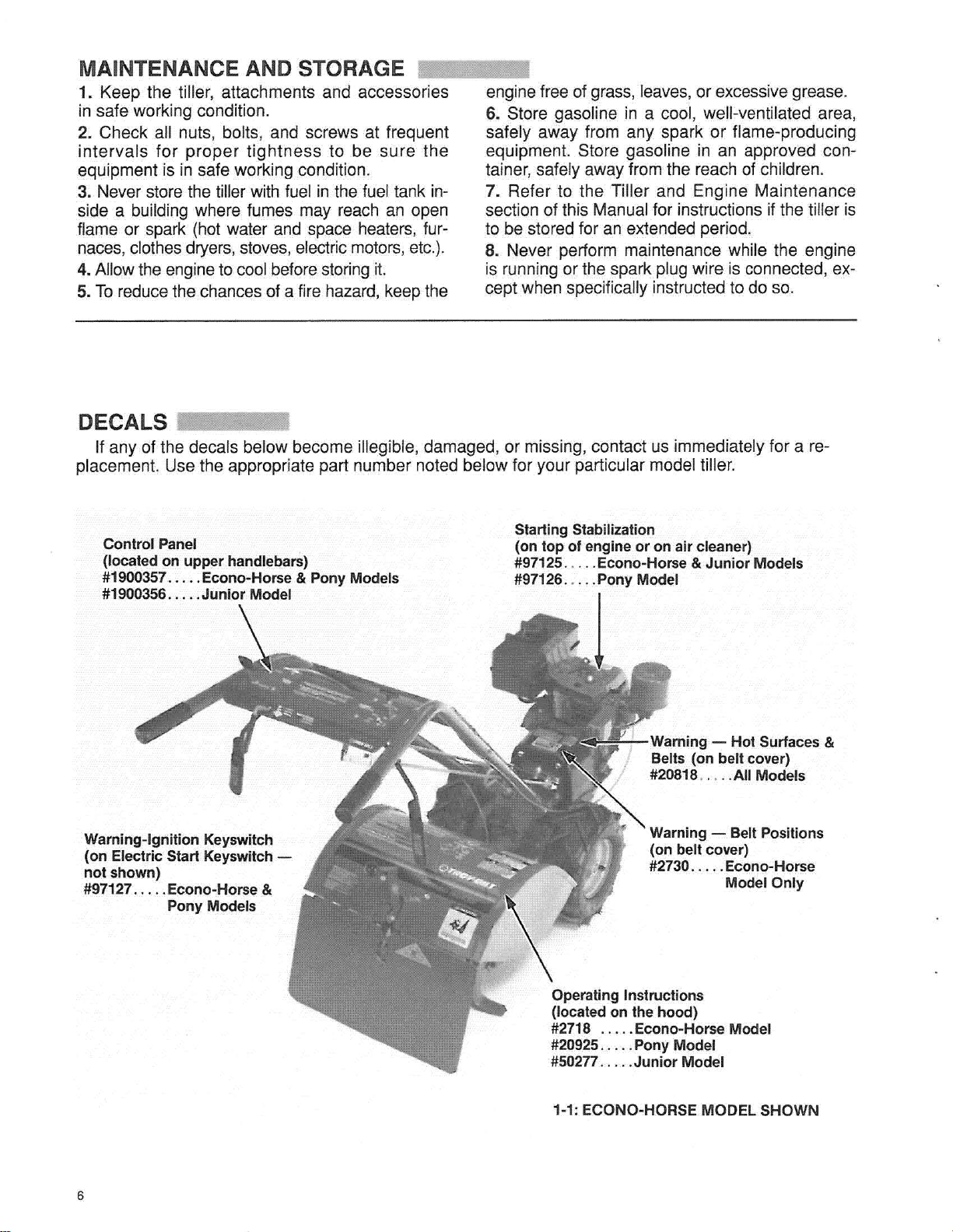

DECALS

If any of the decals below become illegible, damaged, or missing, contact us immediately for a re-

placement. Use the appropriate part number noted below for your particular model tiller.

Control

(located on

#1900357 Econo-Horse & Pony Models

#1900356 Junior Model

Warning-Ignition Keysw itch

(on Electric Start Keysw

not

shown)

#97127

Panel

upper

.....

Econo-Horse &

Pony Models

handlebars)

itch

-

Starting Stabilizat

(on top01engine or on

#97125 Econo-Horse & Jun

#97126 Pony Model

ion

air

cleaner)

,j

Warning - Hot Surfaces &

Belts (on belt cover)

#20818 .... .AII Models

Warning - Belt Positions

(on belt cover)

#2730 ... . .Eco

ior

Models

no-

Horse

Model Only

Operat

ing

Instructions

(located on the

#2718 Econo-Horse Model

#20925 Pony Model

#50277

1-1: ECONO-HORSE MODEL SHOWN

6

hood)

Junio

r Model

Page 9

Section

2:

Ea

sy

Assembly

Please

Model tiller and prepare it for use. Due to assembly similarities , we show one model in the assembly photos to represent the three tiller models. Steps unique to any single model(s) are

noted.These steps will

We recommend you read thi s Section all the way through

follow

the steps in this Section to assemble your ECONO·HORSE" , PONY" or JUNIOR®

not

take long and will assure correct assemblyofyour new tiller.

firs

t. Then begin the assemb ly steps.

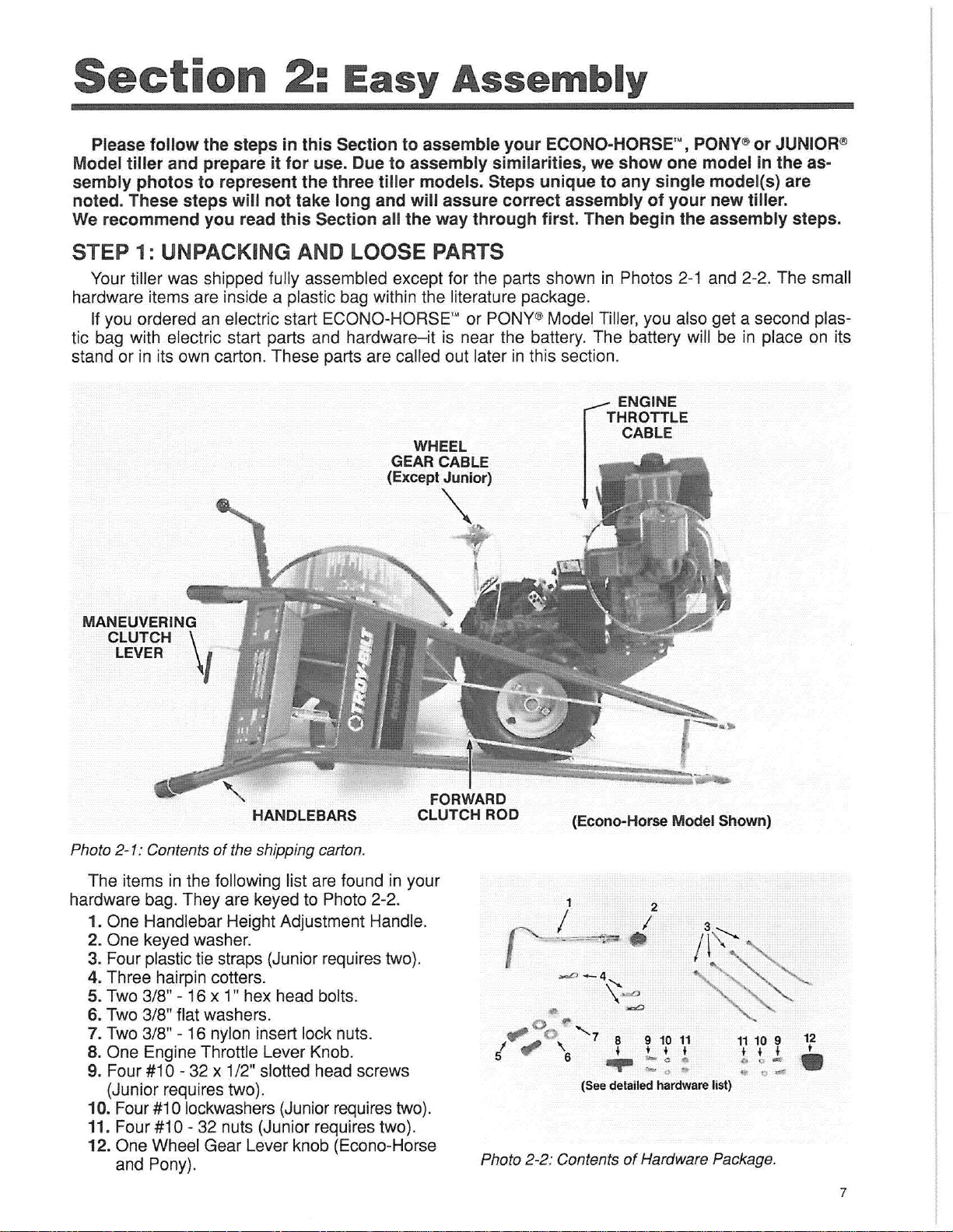

STEP 1: UNPACKING AND LOOSE PARTS

Your tiller was shipped fully assembled except for the parts shown in Photos 2-1 and 2-2. The small

hardware items are inside a plastic bag within the literature package.

If you ordered an electric start ECONO-HORSE'" or PONY®Model Tiller, you also get a second plastic bag with electric start parts and hardware- it is near the battery. The battery will be in place on its

stand or in its own carton . These parts are called out later in this section.

ENGINE

THROTTLE

WHEEL

GEAR CABLE

(Except Junior)

CABLE

-,

MANEUVERING

CLUTCH \

LEVER

Photo 2-1: Contents of the shipping carton.

The items in the following list are found in your

hardware bag. They are keyed to Photo 2-2.

1. One Handlebar Height Adjustment Handle.

2. One keyed washer.

3. Four plastic tie straps (Junior requires two).

4. Three hairpin cotters.

5. Two 3/8" - 16 x 1" hex head bolts.

6. Two 3/8" flat washers.

7. Two 3/8" - 16 nylon insert lock nuts.

8. One Engine Throttle Lever Knob.

9. Four #10 - 32 x 1/2" slotted head screws

(Junior requires two).

10. Four

11.

12. One Wheel Gear Lever knob (Econo-Horsa

#1

Four#10

and Pony).

I

HANDLEBARS

0 lockwashers (Junior requires two).

- 32 nuts (Junior requires two).

FORWARD

CLUTCH ROD

"-°0'"

/

5

Photo

(Econo-Horse Model Shown)

2

I

•

-0

- 4

•

fI'""

~

,

"'6

2-2

: Contents of Hardware Package.

'\-a

-a

7 8 9 10 11

1

' t .

-

....

(See detailed hardware list)

0"

""

0 •

11 10 9

• • I

b

0-

..

.-

12

t

•

7

Page 10

Compare the parts that you received to Photos 2-1 and 2-2. If you are missing any items, please call

us at one of the telephone numbers listed on page 3 of this Manual.

If you notice any freight damage, either at the time of delivery or later during assembly, contact the

freight terminal and tell them you will be filing a written claim (do so within 15 days). The terminal will

advise you as to how to proceed. However, if you meet any problems with this procedure, please call

us so we can provide assistance.

Before you attempt to move the tiller off the shipping carton, please install the handlebars (Step 2).

With the handlebars installed, you'll have better leverage and be more easily able to move the tiller to a

level area so you can continue the assembly.

You'll need the following tools to assemb le your tiller:

1. Two 9/16" wrenches.

2. One medium-size flat blade screwdriver.

3. One open end 3/8" wrench.*

4. Scissors (to trim the plastic ties).

5. One 7/16" wrench (electric models only).*

6. A piece of wood to tap the knobs securely on

*

the control levers.

7. Automotive-type tire pressure gauge.

8. Ruler.

9. Sturdy wood box or block 2-1/2"

-3

-1/2" high

(Junior Model only).

•

You

may

substitu

te adj

ustablewrenche

s.

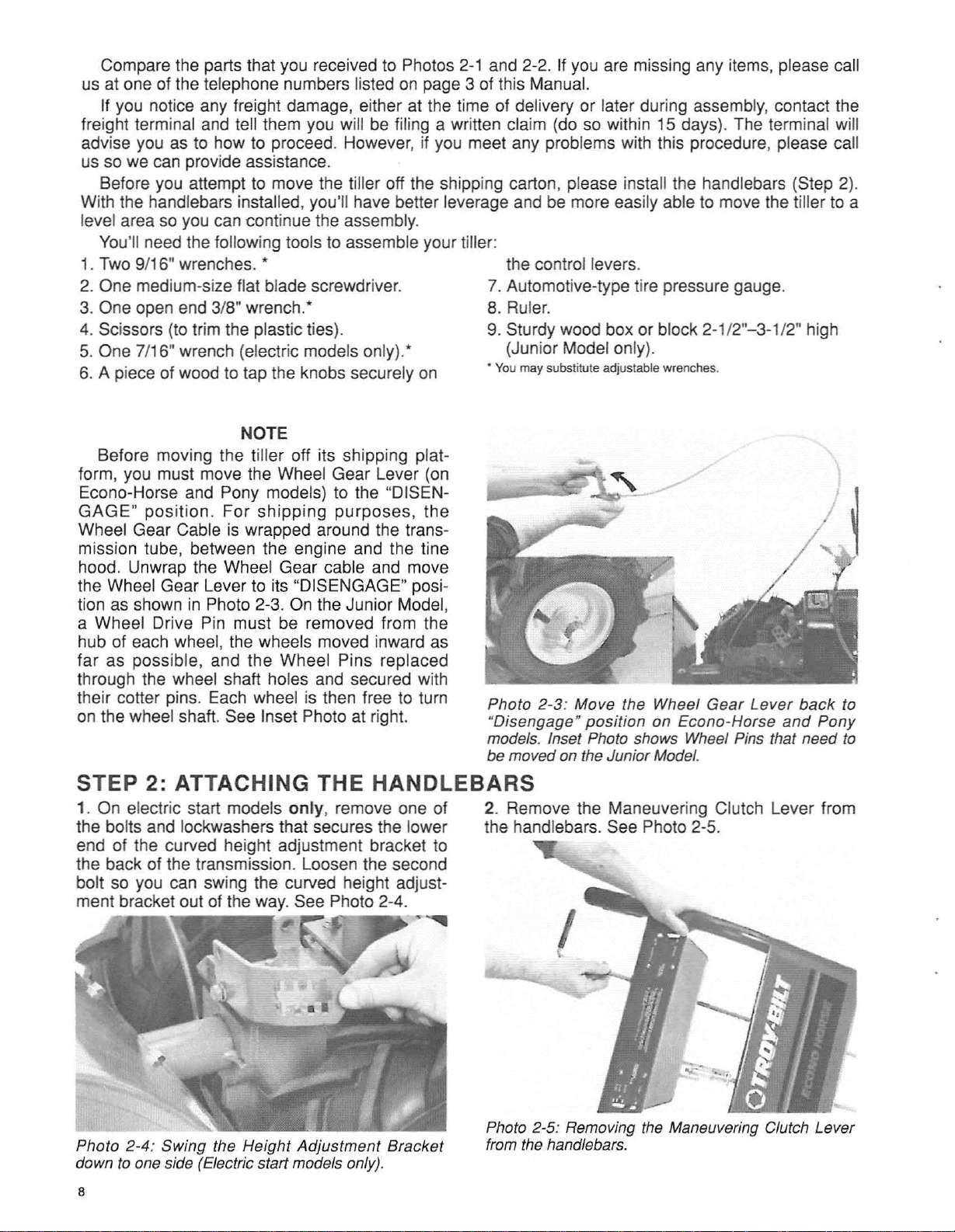

NOTE

Before moving the tiller off its shipping platform, you must move the Wheel Gear Lever (on

Econo-Horse and Pony models) to the "DISENG

AGE"position

. For shipping purposes, the

Wheel Gear Cable is wrapped around the transmission tube, between the engine and the tine

hood. Unwrap the Wheel Gear cable and move

the Wheel Gear Lever to its "DISENGAGE" position as shown in Photo 2-3. On the Junior Model,

a Wheel Drive Pin must be removed from the

hub of each wheel, the wheels moved inward as

far as possible , and the Wheel Pins replaced

through the wheel shaft holes and secured with

their cotter pins. Each wheel is then free to turn

on the wheel shaft. See Inset Photo at right.

Photo 2-3 : Move the Wheel

"Disengage"

models. Inset Photo shows Wheel Pins that need to

be moved on the Junior Model.

posit

ion on Econo-Horse

Gear

Lever

and

back

Pony

to

STEP 2: ATTACHING THE HANDLEBARS

1. On electric start models only, remove one of

the bolts and lockwashers that secures the lower

end of the curved height adjustment bracket to

the back of the transmission. Loosen the second

bolt so you can swing the curved height adjustment bracket out of the way. See Photo 2-4.

~

Photo 2-4: SWing the HeightAdjustm

down to one side (Electric start models only).

8

ent

Bracket

2. Remove the Maneuvering Clutch Lever from

the handlebars. See Photo 2-5.

Photo 2-5: Removing the Maneuvering Clutch Lever

from the handlebars.

Page 11

3. Place the lower end of the handlebars on the

outside of the two mounting tabs on the top of

the transmission. Make sure that the handlebar

crossbrace (on the lower end of the handlebars)

goes underneath the curved height adjustment

bracket.

4. Secure the lower ends of the handlebar to the

two mounting tabs with a 3/8"-16 x 1" bolt, a 3/8"

flat washer, and a 3/8"-16 nylon insert lock nut.

Use 9/16" wrenches. The bolt head should be to

The

the inner side of the mounting tab.

flat

washer and lock nut must face out.

5. On electric start models, move the curved

heig

ht adjustment

brac

ket

back

in pl ace.

Reinstall the bolt and lockwasher you previously

removed. Tighten both bolts very securely.

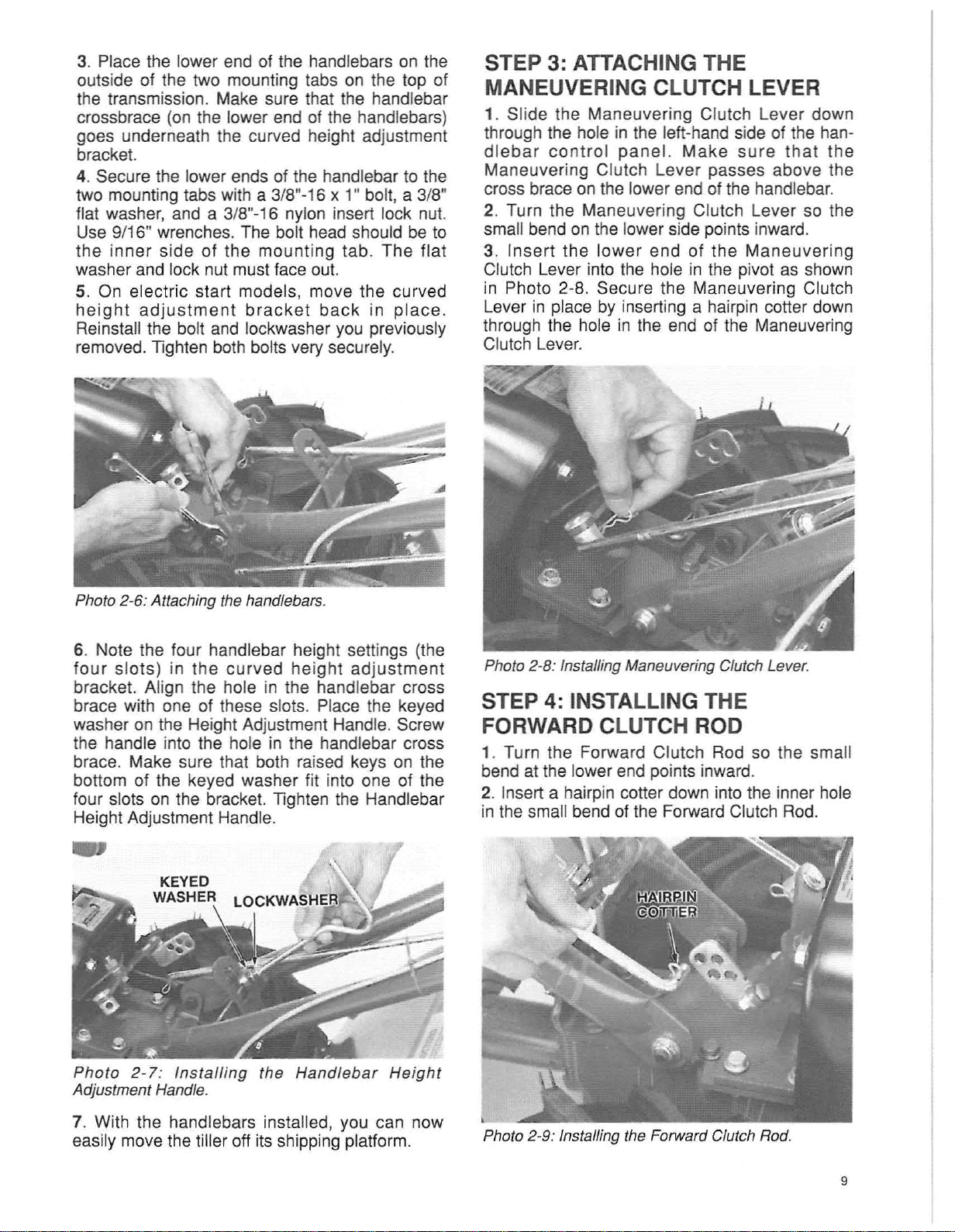

STEP 3: ATTACHING THE

MANEUVERING CLUTCH LEVER

1. Slide the Maneuvering Clutch Lever down

through the hole in the left-hand side of the handlebar

Maneuvering Clutch Lever passes above the

cross brace on the lower end of the handlebar.

2. Turn the Maneuvering Clutch Lever so the

small bend on the lower side points inward.

3. I

Clutch Lever into the hole in the pivot as shown

in Photo 2-8. Secure the Maneuvering Clutch

Lever in place by inserting a hairpin cotter down

through the hole in the end of the Maneuvering

Clutch Lever.

nsert

control

panel.Make

the lower end of the

sure

that

Maneuvering

the

Photo 2-6: Attaching the handlebars.

6. Note the four handlebar height settings (the

four

slots) in

the

curved

height ad

justment

bracket. Align the hole in the handlebar cross

brace with one of these slots. Place the keyed

washer on the Height Adjustment Handle. Screw

the handle into the hole in the handlebar cross

brace. Make sure that both raised keys on the

bottom of the keyed washer fit into one of the

four slots on the bracket. Tighten the Handlebar

Height Adjustment Handle.

Photo 2-8: Installing Maneuvering Clutch Lever.

STEP 4: INSTALLING THE

FORWARD CLUTCH ROD

1. Turn the Forward Clutch Rod so the small

bend at the lower end points inward.

2. Insert a hairpin cotter down into the inner hole

in the small bend of the Forward Clutch Rod.

Phot

o

2-7

: Insta

Adjustment Handle.

ll

ing the Ha

ndlebarHeight

7. With the handlebars installed, you can now

easily move the tiller off its shipping platform.

Photo 2-9: Installing the Forward Clutch Rod.

9

Page 12

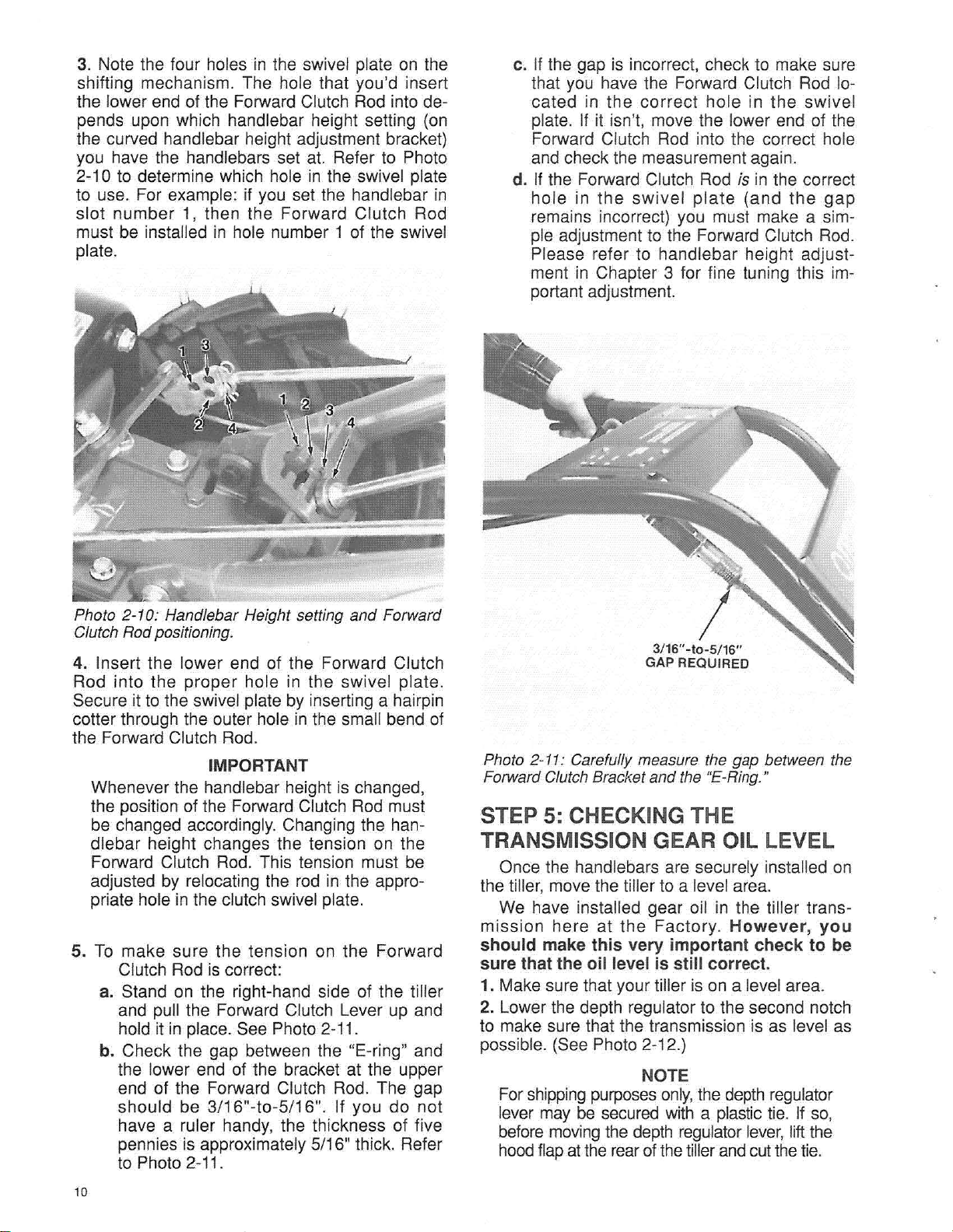

3. Note the four holes in the swivel plate on the

shifting mechanism. The hole that you'd insert

the lower end of the Forward Clutch Rod into de-

pends upon which handlebar height setting (on

the curved handlebar height adjustment bracket)

you have the handlebars set at. Refer to Photo

2-10 to determine which hole in the swivel plate

to use. For example: if you set the handlebar in

slot number 1, then the Forward Clutch Rod

must be installed in hole number 1 of the swivel

plate.

c. If the gap is incorrect, check to make sure

that you have the Forward Clutch Rod located in the correct hole in the swivel

plate. If it isn't, move the lower end of the

Forward Clutch Rod into the correct hole

and check the measurement again.

d. If the Forward Clutch Rod is in the correct

hole in

swivel

plate

(and

the

gap

the

remains incorrect) you must make a simple adjustment to the Forward Clutch Rod.

Please refer to handlebar height adjustment in Chapter 3 for fine tuning this important adjustment.

Photo 2-10: Handlebar Height setting

Clutch Rod positioning.

and

Forward

4. Insert the lower end of the Forward Clutch

Rod into the proper hole in the swivel plate.

Secure it to the swivel plate by inserting a hairpin

cotter through the outer hole in the small bend of

the Forward Clutch Rod.

IMPORTANT

Whenever the handlebar height is changed,

the position of the Forward Clutch Rod must

be changed accordingly. Changing the handlebar height changes the tension on the

Forward Clutch Rod. This tension must be

adjusted by relocating the rod in the appropriate hole in the clutch swivel plate.

5. To make sure the tension on the Forward

Clutch Rod is correct:

a. Stand on the right-hand side of the tiller

and pull the Forward Clutch Lever up and

hold it in place. See Photo 2

-11.

b. Check the gap between the "E-ring" and

the lower end of the bracket at the upper

end of the Forward Clutch Rod. The gap

should be 3/16"-to-5/16". If you do not

have a ruler handy, the thickness of five

pennies is approximately 5/16" thick. Refer

to Photo 2-11.

3/16" -10-5/16"

GAP REQUIRED

Photo 2-11: Carefully measure the gap between the

Forward Clutch

Bracket and the "E-Ring."

STEP 5: CHECKING THE

TRANSMISSION GEAR OIL LEVEL

Once the handlebars are securely installed on

the tiller, move the tiller to a level area.

We have installed gear oil in the tiller transmission here at the

shou

ld make t

his

Factory

very important checkto be

sure that the oil level is sti ll correct.

1. Make sure that your tiller is on a level area.

2. Lower the depth regulator to the second notch

to make sure that the transmission is as level as

possible. (See Photo 2-12.)

NOTE

For

shipping

purposes

only, the

lever may be secured with a plastic tie. If so,

before

moving

the

depth

hoodflapattherearofthetillerandcutthetie.

. However,you

depth

reguiator

lever,

regulator

liftthe

10

Page 13

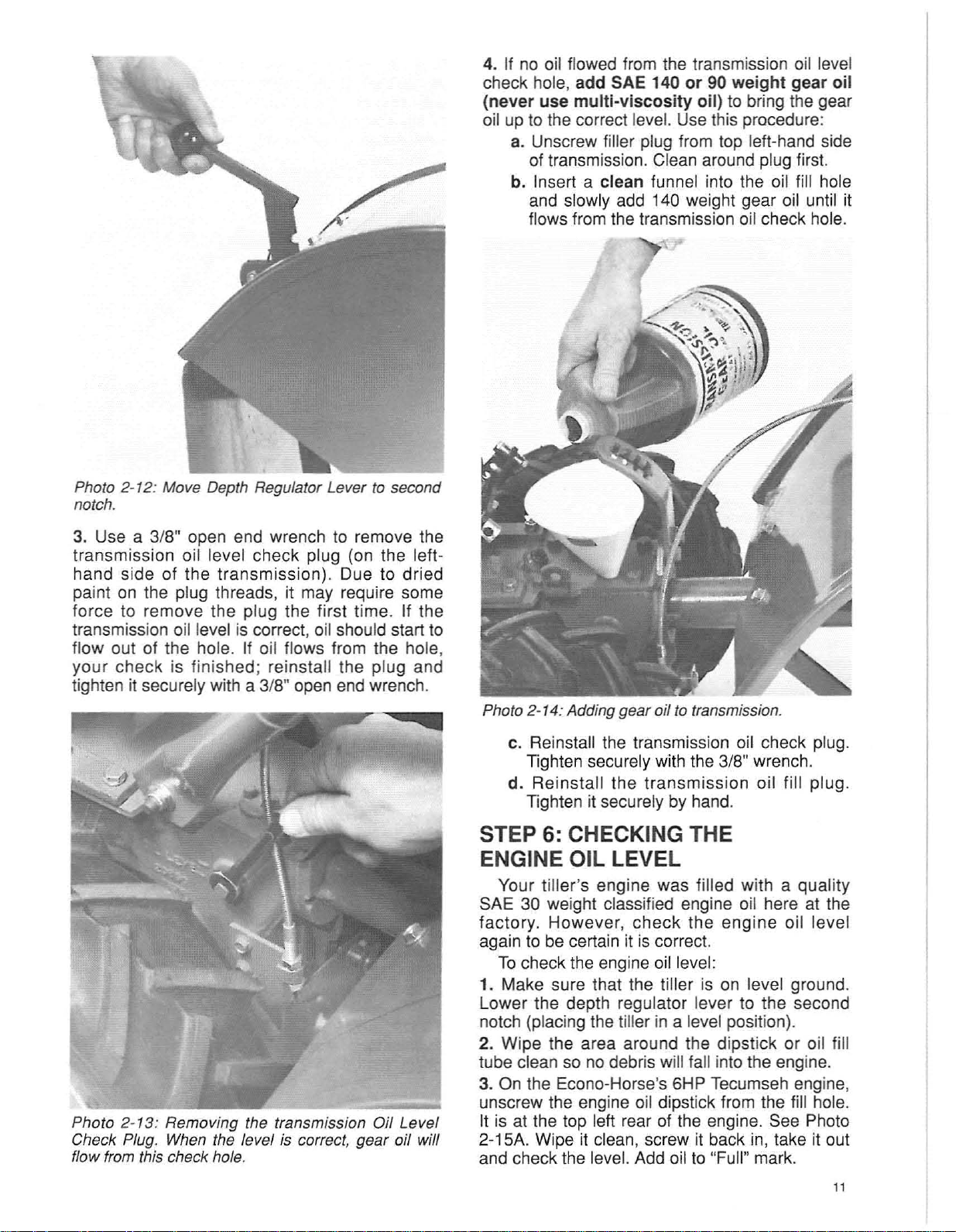

Photo 2-12: Move Depth Regulator Lever to second

notch.

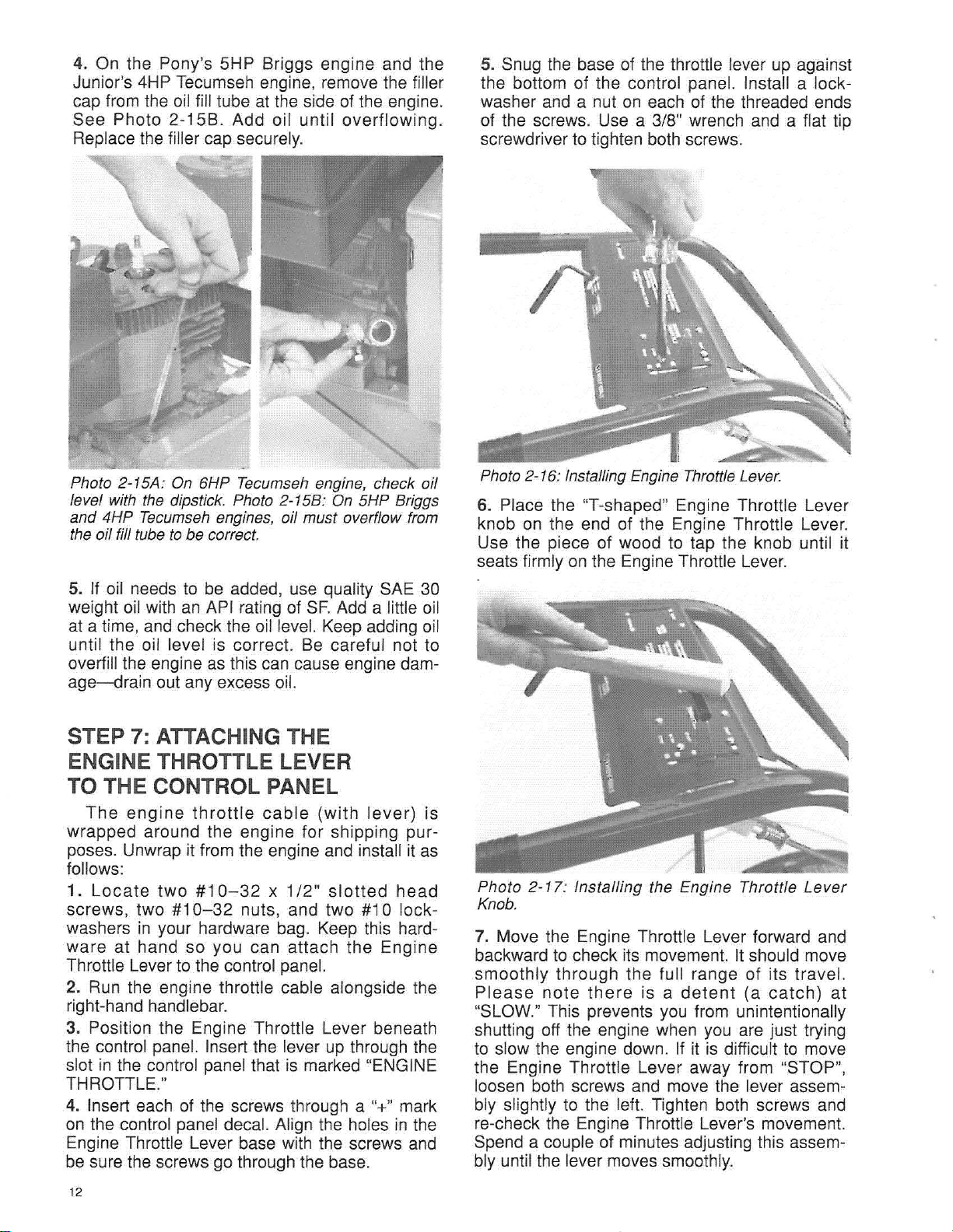

4. If no oil flowed from the transmission oil level

igh

check hole, add SAE 140 or 90 we

(never use multi-v

iscosity

oil) to bring the gear

t gear oil

oil up to the correct level. Use this procedure:

a. Unscrew filler plug from top left-hand side

of transmission. Clean around plug first.

b. Insert a clean funnel into the oil fill hole

and slowly add 140 weight gear oil until it

flows from the transmission oil check hole.

3. Use a 3/8" open end wrench to remove the

transmission oil level check plug (on the lefthand side of the transmiss ion). Due to dried

paint on the plug threads, it may require some

force to remove the plug the first time. If the

transmission oil level is correct, oil should start to

flow out of the hole. If oil flows from the hole,

your check is finished; reinstall the plug and

tighten it securely with a 3/8" open end wrench.

Photo 2- 13: Removing the transmis sion Oil Level

Check Plug. When the level

flow from this check hole.

is correct, gear oil will

Photo 2-14:

Add

ing gear oil to transmission.

c. Reinstall the transmission oil check plug.

Tighten securely with the 3/8" wrench.

d. Reinstall the transmission oil fill plug.

Tighten it securely by hand.

STEP 6: CHECKING THE

ENGINE OIL LEVEL

Your till

SAE 30 weight classified engine oil here at the

factory. However, check the engine oil level

again to be certain it is correct.

Tocheck the engine oil level:

1. Make sure that the tiller is on level ground.

Lower the depth regulator lever to the second

notch (placing the tiller in a level position).

2. Wipe the area around the dipstick or oil fill

tube clean so no debris will fall into the engine.

3. On the Econo-Horse's 6HP Tecumseh engine,

unscrew the engine oil dipstick from the fill hole.

II is at the top left rear of the engine. See Photo

2-15A. Wipe it clean, screw it back in, take it out

and check the level. Add oil to "Full" mark.

er'

s engine was filled with a quality

11

Page 14

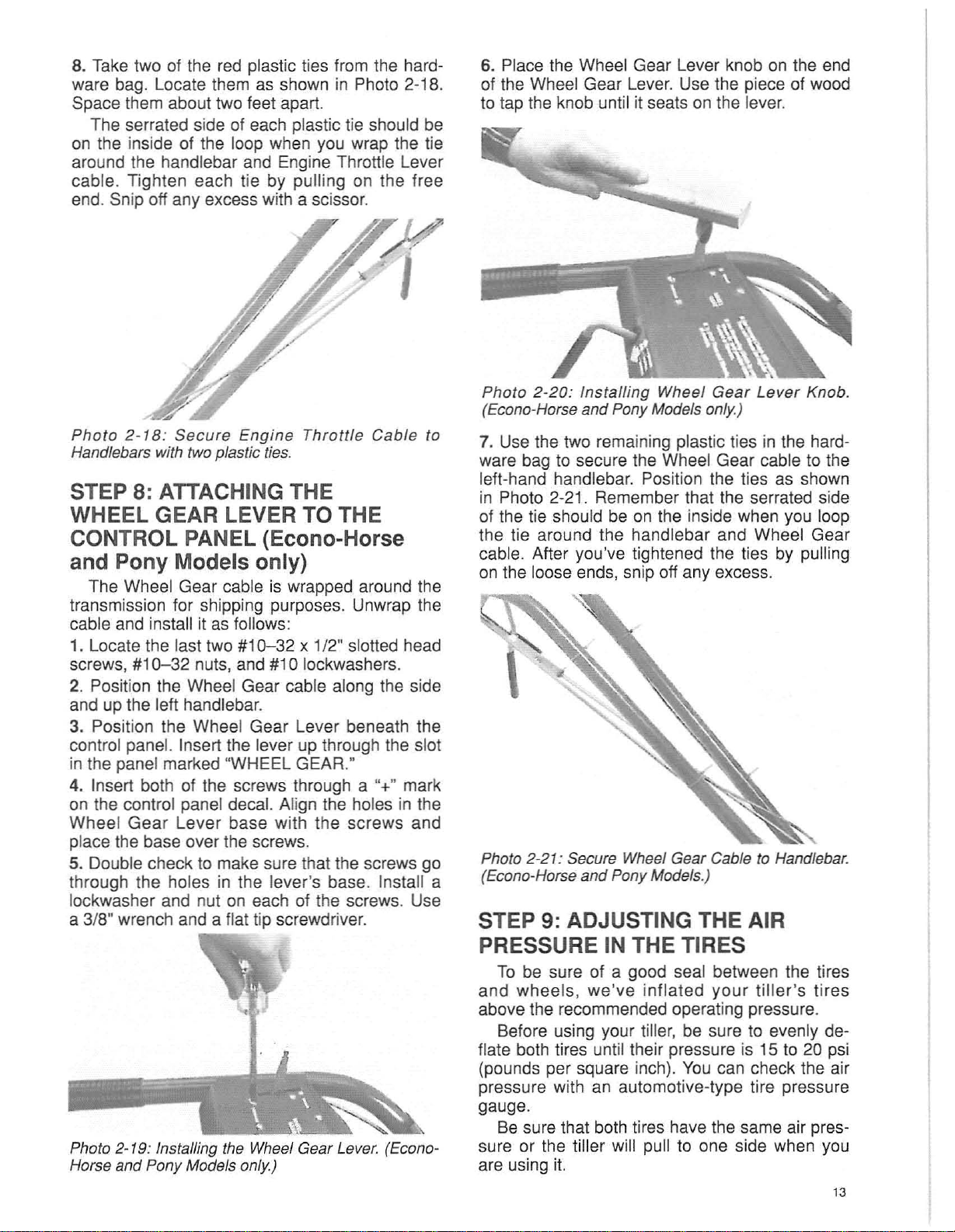

4. On the Pony's 5HP Briggs engine and the

Junior's 4HP Tecumseh engine, remove the filler

cap from the oil fill tube at the side of the engine.

See Photo 2-15B. Add oil unti l overflowing.

Replace the filler cap securely.

5. Snug the base of the throttle lever up against

the bottom of the control panel. Install a lockwasher and a nut on each of the threaded ends

of the screws. Use a 3/8" wrench and a flat tip

screwdriver to tighten both screws.

Photo 2-15A: On 6HP Tecumseh engine, check oil

level with the dipstick. Photo 2-15B: On 5HP Briggs

and 4HP Tecumseh engines, oil must overflow from

the oil fill tube to be correct.

5. If oil needs to be added, use quality SAE 30

SF.

weight oil with an API rating of

Add a little oil

at a time, and check the oil level. Keep adding oil

until the oil level is cor rect. Be careful not to

overfill the engine as this can cause engine damage-drain

out any excess oil.

STEP 7: ATTACHING THE

TT

ENGINE THRO

LE LEVER

TO THE CONTROL PANEL

The

engine

wrapped around the engine for shipping purposes. Unwrap it from the engine and install it as

follows:

Locate

1.

screws, two

washers in your hardware bag. Keep this hardware at hand so you can attach the Engine

Throttle Lever to the control panel.

2. Run the engine throttle cable alongside the

right-hand handlebar.

3. Position the Engine Throttle Lever beneath

the control panel. Insert the lever up through the

slot in the control panel that is marked "ENGINE

THROTTLE."

4. Insert each of the screws through a

on the control panel decal. Align the holes in the

Engine Throttle Lever base with the screws and

be sure the screws go through the base.

two

#10-32

throttle

#10-32

cable

x 1

/2"

(with

slotted

lever)

head

is

nuts, and two #10 lock-

"+" mark

Photo 2-16: Installing Engine Throttle Lever.

6. Place the "T-shaped" Engine Throttle Lever

knob on the end of the Engine Throttle Lever.

Use the piece of wood to tap the knob until it

seats firmly on the Engine Throttle Lever.

Photo 2

Knob.

-17

: Installing the Engine Throttle

Lever

7. Move the Engine Throttle Lever forward and

backward to check its movement. It should move

smoothly through the full range of its travel.

lease

P

note

there

is a

detent

(a

catch)

at

"SLOW." This prevents you from unintentionally

shutting off the engine when you are just trying

to slow the engine down. If it is difficult to move

the Engine Throttle Lever away from "STOP",

loosen both screws and move the lever assembly slightly to the left. Tighten both screws and

re-check the Engine Throttle Lever's movement.

Spend a couple of minutes adjusting this assembly until the lever moves smoothly.

12

Page 15

8. Take two of the red plastic ties from the hardware bag. Locate them as shown in Photo

Space them about two feet apart.

The serrated side of each plastic tie should be

on the inside of the loop when you wrap the tie

around the handlebar and Engine Throttle Lever

cable. Tighten each tie by pulling on the free

end. Snip off any excess with a scissor.

2-18.

6. Place the Wheel Gear Lever knob on the end

of the Wheel Gear Lever. Use the piece of wood

to tap the knob until it seats on the lever.

Photo

Handlebars with two plastic ties.

2-

18: Se

cure

Engine

Throttle

Cable

to

STEP 8: ATTACHING THE

WHEELGEARLEV

ER

TOTHE

CONTROL PANEL (Econo-Horse

and Pony Models only)

The Wheel Gear cabie is wrapped around the

transmission for shipping purposes. Unwrap the

cable and install it as follows:

1. Locate the last two

#10

screws,

2. Position the Wheel Gear cable along the side

and up the left handlebar.

3. Position the Wheei Gear Lever beneath the

control panel. Insert the lever up through the slot

in the panel marked "WHEEL GEAR."

4. Insert both of the screws through a

on the control panel decal. Align the holes in the

Wheel Gear Lever base with the screws and

place the base over the screws.

5. Double check to make sure that the screws go

through the holes in the lever's base. Install a

lockwasher and nut on each of the screws. Use

3/8"wrench and a flat tip screwdriver.

a

Photo 2-19: Installing the Wheel Gear Lever. (EconoHorse and Pony Models

-32

#10-32

nuts, and #10 lockwashers.

only)

x 1/2" slotted head

"+" mark

Photo2-20:

(Econo-Horse and Pony Models only.)

7. Use the two remaining plastic ties in the hardware bag to secure the Wheel Gear cable to the

left-hand handlebar. Position the ties as shown

in Photo

of the tie should be on the inside when you loop

the tie around the handlebar and Wheel Gear

cable. After you've tightened the ties by pulling

on the loose ends, snip off any excess.

Photo 2-21: Secure Wheel Gear Cable to Handlebar.

IEcono-Horse

Installing

Wheel Gea r

Lever

Knob

2-21. Remember that the serrated side

and

Pony Models.)

STEP 9: ADJUSTING THE AIR

PRESSURE IN THE TIRES

To be sure of a good seal between the tires

and wheels, we've inflated you r till er's tires

above the recommended operating pressure.

Before using your tiller, be sure to evenly deflate both tires until their pressure is 15 to

(pounds per square inch). You can check the air

pressure with an automotive-type tire pressure

gauge.

Be sure that both tires have the same air pressure or the tiller wilt pull to one side when you

are using it.

20 psi

13

.

Page 16

If you have a standard start ECONO-HORSE'", PONY'"

or JUNIOR"'Tiller, it is now completely assembled and

ready to be used.

Please read the rest of this Owner/Operator Manual

before you begin to operate your tiller.

You should become very familiar with, and follow all

the safety rules, the tiller operating instructions, and

the engine operating instructions at all times.

If yo u have an E

PONY

steps to assemble the electric starting system on your

tiller.

'"

Tiller, you will have to perform the following

lectricStart

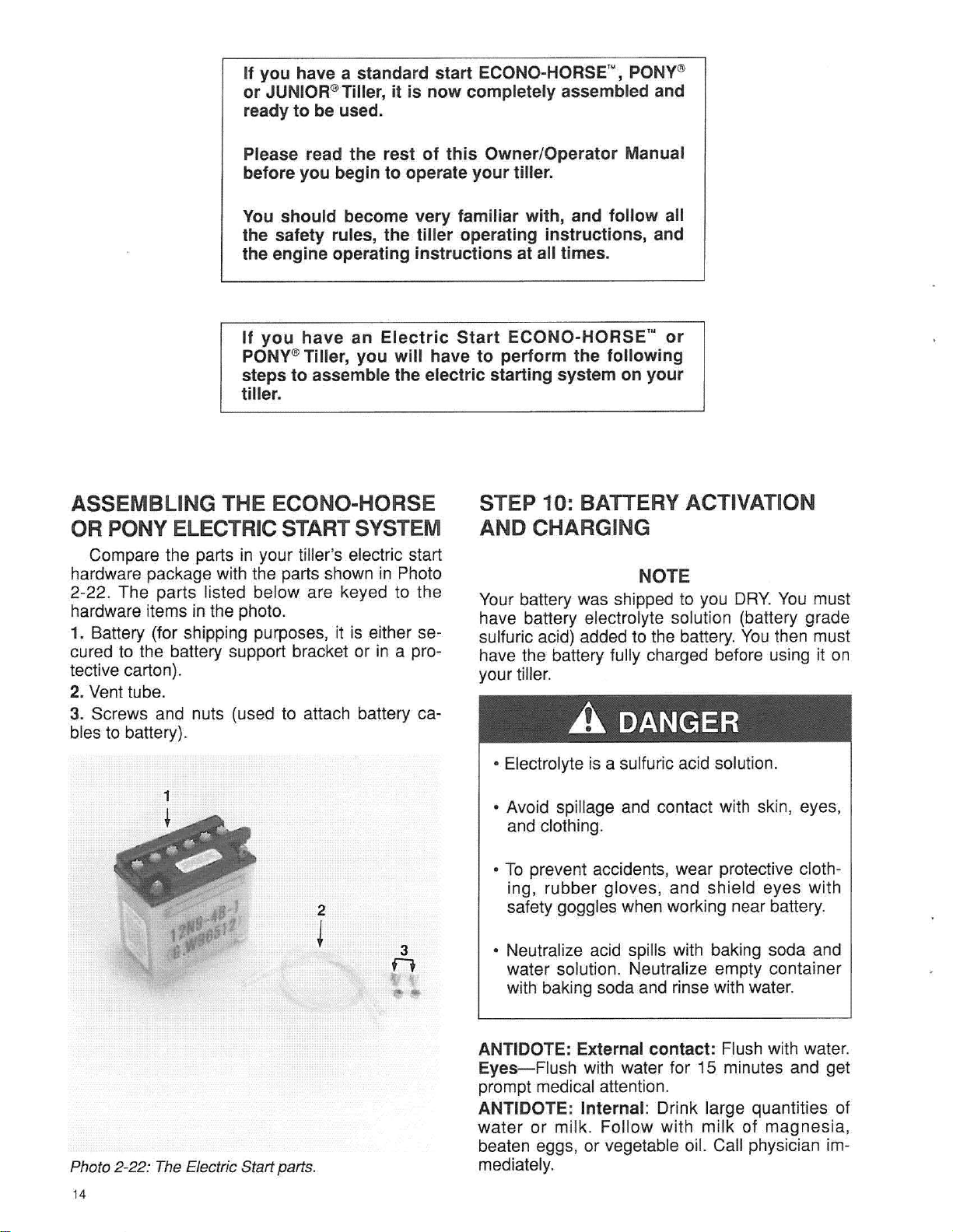

ASSEMBLING THE ECONO-HORSE

OR PONY ELECTRIC START SYSTEM

Compare the parts in your tiller's electric start

hardware package with the parts shown

2-22. The parts listed below are keyed to the

hardware items in the photo.

1. Battery (for shipping purposes, it is either se-

cured to the battery support bracket or

tective carton).

2. Vent tube.

3. Screws and nuts (used to attach battery ca-

bles to battery).

in Photo

in

a pro-

ECONO-HORSE'" or

STEP 10: BATTERY ACTIVATION

AND CHARGING

NOTE

Your battery was shipped to you

have battery electrolyte solution (battery grade

sulfuric acid) added to the battery.

have the battery fully charged before using it on

your tiller.

A

• Electrolyte is a sulfuric acid solution.

DANGER

DRY.

You

You must

then must

Photo 2-22: The Electric Start parts.

14

• Avoid spillage and contact with skin, eyes,

and clothing.

• To prevent accidents, wear protective clothing, rubber gloves, and shield eyes with

2

t

3

n

•

safety goggles when working near battery.

• Neutralize acid spills with baking soda and

water solution. Neutralize empty container

with baking soda and rinse with water.

ANTIDOTE: External contact: Flush with water.

s-

Eye

prompt medical attention.

ANTIDOTE : Internal: Drink large quantities of

wate r or milk . Follow with milk of magnesia,

beaten eggs, or vegetable oil. Call physician immediately.

Flush with water for 15 minutes and get

Page 17

A

BATTERIES PRODUCE

EXPLOSIVE

• Keep sparks, flame, and cigarettes away.

• Ventilate area when charging or using battery in an enclosed space.

DANGER

GAS

ES!

5. Allow the battery to stand for thirty minutes.

Then check the electrolyte level in each cell. If

needed, add more electrolyte to bring the electrolyte level up to the "UPPER LEVEL" line on

the battery. Do not overfill the battery as this

could lead to flooding from the cells when the

battery is being charged.

6. Charge the battery by following the next set of

instructions.

• Make sure venting path of battery is always open once battery is filled with acid.

Adding electrolyte to the battery and charging

the battery can be dangerous. The sulfuric acid

in the electrolyte can severely burn you or blind

you. Also, a battery that is charging gives off

gases that could explode if a spark or flame

should contact the gases.

We strongly recommend that you take your

battery to a TROY-BILT tiller dealer, a reliable

service station, battery store, or farm equipment

store where a trained battery technician can

complete the job safely.

PL

EASE

VATE THE BATTERY U

FULLY EXPERIENCED IN BATTERY SET-

AND

UP

To ensure proper activation of your battery, we

suggest you review the following activating and

charging instructions with your battery technician

and make sure that he follows the instructions.

Activate the Batte ry:

To

1. Placethe battery on a level area awayfrom any

spark- or flame-producing sources such as a gas

stove, heater,electricalswitch, pilotlight, (etc.).

DO N

CHARGING PROCEDURES.

OT

ATTEMPT

NLESS

TO

YOU ARE

ACTI-

2. Remove and discard the short sealing tube (if

installed) on the battery side vent.

3. Remove the six filler caps that are on top of

the battery. Leave the caps off while activating

and charging the battery.

4. Carefully fill each of the six cells in the battery

with electrolyte (battery grade sulfuric acid that

has a specific gravity of 1.265) until the level

reaches the "UPPER LEVEL" line on the battery.

To Charge the Battery

To obtain maximum battery life, charge the

battery by the following method until all cells are

gassing freely. A battery is gassing freely when

the surface of the electrolyte is covered with tiny

bubbles.

A

When checking the battery for gassing, ALWAYSwear safety goggles and use a flashlight to look down into the cells.

Failure to do so could result in serious personalinjury.

Be sure to follow all instructions given by the

manufacturer of the battery charging equipment

that is being used to charge the battery.

1. Hook up the battery charger and charge the

battery approximately three to five hours at one

to two amperes. Turn the battery charger

2. If the electrolyte level has fallen after charging,

refill the battery with distilled water until the electrolyte level reaches the "UPPER LEVEL" line on

the battery.

3. After charging, reinstall the six filler caps on

the battery.

4. Unplug the battery charger from the electrical

outlet (or turn the battery charger OFF). Then

disconnect the cables from the battery posts.

DANGER

OFF.

5. Wash any acid spillage off the battery with

water. Then dry the battery.

NOTE

• The battery and electrolyte should be between

0

and 800F for best results.

60

• Do not add water or any other liquid to activate

the battery.

15

Page 18

STEP11: INSTALLING THE

BATTERY ON THE TILLER

Photo 2-

1. Use both hands to carefully place the battery

on the battery mounting bracket. The battery

posts should face to the rear of the tiller. The

positive

of the tiller and the negative (-) post should be

on the right-hand side of the tiller.

23

: Installing the Battery.

(+) post should be on the left-hand side

3. Use the two 1/4" -20 x 1 1/4" carriage bolts,

1/4" lockwashers, and 1/4"-20 nuts to secure the

hold-down bracket to the b

bracket. Insert the bolts from beneath the battery

mounting bracket, up through the battery holddown bracket, and secure them with the lockwashers and nuts. Use a 7/16-inch wrench to

evenly tighten both nuts. Do not tighten the nuts

so that the tabs on the battery hold-down bracket

become bent.

attery

mo

unt

ing

STEP 12: INSTALLING

THE BATTERY CABLES

1. The Positive battery cable is already conleno

nected at one end to the so

mounted a few inches below the battery on a

post. You are to connect the loose end of the

positive cable to the positive

tery. Use a bolt and nut from the hardware bag.

Use a screwdriver and a

the bolt. See Photo 2-25.

(+) post on the bat-

3/8" wrench to tighten

id which is

A WARNING

• Be sure that the battery is positioned on

the tiller as explained in Step 1. Hooking the

battery cables to the wrong posts could re-

sult

in damage to the battery and other

electrical parts.

• Do not touch the positive (+) battery post

and any surrounding metal with tools, jewelry, or other metal objects. Doing so could

cause a short circuit that could result in

electrical burns or an explosion of battery

gases.

2. Place the battery hold-down bracket over the

battery. Center the bolt holes in the lower part of

the hold-down bracket with the bolt holes in the

battery mounting bracket. Make sure that the

Engine Ignition Switch is on the forward side of

the battery.

Photo 2-25: Attach Positive Cable to Battery.

2. Slide the black rubber boot up the positive

cable and slip it over the positive battery post.

3. The Negative cable is already connected at

one end to one of the mounting bolts securing

the solenoid to the post. This is the grounding

point for the negative

cable-connect

end of the negative (-) cable to

the negative battery

the last nut and

last bolt to securely attach the

negative battery

cable to the negative (-) battery

post.

the loose

pos

t. Use

Photo 2-24:Securing the Battery in Place.

16

Photo 2-26: Attach the Negative

Battery Cable to

the battery.

Page 19

4. Use a 3/8" wrench to check the tightness of

the upper mounting bolt on the starter solenoid.

This bolt

ground location. Scrape away any paint between

the cable and the bolt as this would prevent a

proper electrical ground.See Photo 2-27.

secures

the Negative Cable to its

-1

Photo

2-27

: The Negative Battery Cable must be se-

curely grounded to the Upper Mounting Bolt on the

Solenoid.

STEP 14: CONNECT WIRING HARNESS TO IGNITION KEYSWITCH

Slide the wiring harness connector over the

prongs on the back of the Ignition Keyswitch .

You

r keyswitch has either a 3-prong or 5-prong

design. See Sketch 2-29 or 2-29A.

•

STEP 13: INSTALLING THE

BATTERY VENT TUBE

1. Push the battery vent tube down into the vent

tube sheath. Attach the upper end of the vent

tube to the side vent on right side of battery.

A WARNING

Be sure that the vent tube does not become

kinked, folded, or pinchedwhen you install it.

Improper venting could cause the battery to

explode, resulting in personal injury or property damage.

Sketch

Ignition Keyswitch . The 5-prong design is shown.

Inset Sketch 2-29A

you may have instead 01the 5-prong type.

HORSE'" or PONY

begin to operate the tiller, please read the rest of

this Owner/Operator Manual so that you become

familiar with the location of, and the operation of,

the various tiller and engine controls.

the tiller controls so that you understand what

each one does. After you've done this, move the

tiller to a safe, level area to practice starting the

engine and maneuvering the tiller without actually tilling. Make sure that the depth regulator

lever is in the "travel" position (one of the higher

notches) while you're becoming fami liar with

your newtiller.

while you 're practicing in case you have any

questions about operating your tiller.

2-29:

Connect the Wiring Harness to the

-sh

ows the 3-prong type which

You

're now finished assembling your ECONO-

®Til

ler.

Before you add gasoline to the gas tank and

Without starting your tiller's engine, operate

Take this Manual along for ready reference

l!o...

Photo 2-28: Installing the Battery Vent Tube.

A WARNING

To avoid serious personal injury or damage

to equipment, do not attempt to operate the

tiller or its engine until after you've read and

understood all of the Safety, Controls, and

Operating Instructions in this Manual, in the

Engine Owner's Manual, and in other litera-

ture you may receive.

17

Page 20

Section

T

ill

er

And

3:

Eng

...

in

...e......C....o....

n....,t_r

...

o....,ls

......

_

Before attempting to operate

functionofall the operational c

and

Practice

of

the

using

controls

thesecontrols-with

and feel

conf

ident

you

r new tiller, become

ontr

ols.

the engine

with

each one of them.

shut

thoroug

off-until

hly

familiar with the location of

you

unders

tand the operation

TILLER CONTROLS

There are four tiller controls you will be using when you operate your tiller. These controls are: the

Wheel Gear Lever (ECONO-HORSE and PONY Models only). the Forward Clutch, the Maneuvering

Clutch, and Depth Regulator Lever. Referto Photos below for the location of these controls.

MANEUVERING WHEELGEAR

CLUTCH , /

.~

,!:

-

~

~~~

LE

VER

ECON O

-HOR

ENGINETHROn l E

LEVER

HANDLEBAR

HEIGHT

ADJU STMENT

/

SE and PON Y M

ODEL

COf'l

\lol

s

HANDLEBAR

HEIGHT

"D

i TMENT

DEPTH

REGULATOR

LEVER-

DEPTH

RE

GULATOR

LEVER

RECO IL

STARTER

Photo

3-t

: Location of controls on ECONO-HORSE

and PONYModels.

Wh

eel

Gear Lever

(Ec

ono-Horseand P

This lever is located on the left-hand side of

the handlebar control panel. It has two positions:

ENGAGE and DISENGAGE (FREE WHEEL).

The ENGAGE position allows power from the

engine to turn the wheels and tines whenever:

a. The Forward Clutch is engaged. OR

b. The Maneuvering Clutch is engaged in either

forward or reverse.

The DISENG AGE (FREE WHEEL) position

should only be used when the engine is not running. Use the DISENGAGE (FREE WHEEL) position ONLY when you are rolling the tiller to another location.

ony

Models only)

AIR ClEANER

Photo

Model tiller.

3-t

A: Location

.A

NEVER place the Wheel Gear Lever in DISENGAGE (FREE WHEEL) when the engine

is running.

Having the Wheel Gear Lever in DISEN-

GAGE (FREE WHEEL) and then engaging

the tines/wheels with either the Forward

Clutch or the Maneuvering Clutch could

allow the tines to propel the tiller rapidly forward or backward.

Failure to follow this instruction could result

in personal injury or property damage.

of

controls on the

DANGER

JUN

IOR

18

Page 21

To operate the Wheel Gear Lever:

1. Roll the tiller a few inches forward or back-

ward while you gently move the Wheel Gear

Lever ahead to ENGAGE. Don't force the lever

into ENGAGE (see Pg 43 for lever adjustment).

2. To place the Wheel Gear Lever in DISENGAGE (FREE WHEEL), simply move the lever

rearward. You don't have to move the tiller when

you move the Wheel Gear Lever into DISENGAGE (FREE WHEEL).

-\

\-.~

- . ,

+ ii .

--.:

,-

;,"=

I !

To Engage

A. Make certain the engine is stopped and the

spark plug wire is disconnected.

B. Raise one wheel off the ground and place a

sturdy block beneath the transmission.

C. Remove the hair pin cotter and pull the Wheel

Drive Pin out.

D. Slide the wheel outward on the shaft and re-

place the Wheel Drive Pin through the hole in

the wheel hub AND the hole in the wheel shaft.

Replace the hair pin cotter through the Wheel

Drive Pin, pushing the cotter pin in as far as it

will go. See Photo 3-2A.

E. Repeat these steps with the other wheel.

the

Wheels in WHEEL DRIVE:

A WARNING

Photo 3-2: The Wheel Gear Lever in "ENGAGE" po-

sition. Econo-Horse and Pony Models only.

Wheel

place by a Wheel Drive Pin (Photo 3-2A). The

pins are used to engage and disengage drive

power to the wheels. Before starting the engine,

the Wheel Pins must be in the WHEEL DRIVE

position. Do this by inserting the pins through the

holes in the wheel hubs AND the holes in the

wheel shaft. This "locks" the wheels to the wheel

shaft, so they will turn when either the Forward

Clutch or the Maneuvering Clutch is engaged.

ning, the

WHEEL". To permit this, insert the Wheel Drive

Pins through the wheel shaft holes only. When

this is done, the pins will keep the wheels on the

wheel shaft, but the wheels will be free to rotate

as they are no longer "locked" to the shaft.

DrivePins

Both wheels on the Junior tiller are held in

To move the tiller when the engine is not run-

wheelsmust

(Junior

Model

be able to "FREE

only)

A WARNING

NEVER

power if the wheels are in FREE WHEEL

position(Wheel Pins through wheel shaft

only). In FREE WHEEL, the wheels will not

hold the tiller back and the tines could propel the tiller rapidly, possibly causing loss of

control and serious injury or property dam-

age. Always engage the wheels in WHEEL

DRIVE position before starting the engine or

engaging

Clutch.

operate

the

Forward

thetiller

Clutch

under

or Maneuvering

engine

To avoid personal inju

on its side while adjusting the wheels. This

could cause gasoline to leak from the fuel

tank, resulting in an unsafe condition.

Photo 3-2A : Install Wheel Drive Pin through wheel

hub and shaft for WHEEL DRIVE position.

To Engage the Wheels in FREE WHEEL:

A. Repeat Steps A, B, and C of the previous

"Wheel Drive" engagement instructions.

B. Slide the wheel fully inward on the shaft.

C. Place Wheel Drive Pin through hole in wheel

shaft only, as shown in Photo 3-28.

D. Replace the hair pin cotter through the Wheel

Drive Pin. Push it in as far as possible.

E. Repeat Steps A through D with the other

wheel. Remove the support block.

Photo

shaft only for FREE WHEEL position.

3-2

8 : Install Wheel Drive Pin through wheel

ry,

do not lay the tiller

19

Page 22

Forward Clutch

This control is the two interconnected "paddies" that hang down beneath the control panel.

It is used to engage and disengage both the

wheels and the tines in forward motion.

To operate the Forward Clutch:

Before engaging the Forward Clutch, first

make sure that the Wheel Gear Lever (EconoHorse and Pony Models only) is in ENGAGE. On

the Junior Model, the Wheel Drive Pins must be

through the holes in the wheel hubs and the

wheel shaft. Then lift up on either or both of the

"paddles" and hold it (or them) against the underside of the handlebar grips. As long as you hold

the "paddles" in this position, both the wheels

and tines will turn.

Tostop forward motion of the tines and wheels

when you have the Forward Clutch engaged,

simply release the "paddles" and allow them to

drop downward. Both the wheels and tines will

stop rotating

-the

engine will continue to run.

Maneuvering Clutch

This control is located at the rear of the left-

hand side of the control panel. It is the rod hav-

ing a 90° bend and a black plastic grip.

The Maneuvering Clutch is used to precisely

maneuver the tiller in either a forward or backward direction. Pulling the Maneuvering Clutch

out (for REVERSE) or pushing the Maneuvering

Clutch in (for FORWARD) engages both the

wheels and tines.

If you want to precision till near an obstacle,

release the Forward Clutch "paddles" and push

in the Maneuver ing Clutch Lever. When you

want to stop tilling with the Maneuvering Clutch

-it

Lever, release it

NEUTRAL

If you want to move the tiller forward for a

short distance or in close quarters, release the

Forward Clutch paddles , lift up on the handlebars until the tines clear the ground. Then push

the Maneuvering Clutch in. To stop forward motion, release the Maneuvering Clutch Lever.

The only way you can make the tiller move in

reverse is by using the Maneuver ing Clutc h

Lever. Lift up on the handlebars until the tines

clear the ground and then pull the Maneuvering

Clutch Lever out. The tines and wheels will both

move in reverse direction for as long as you hold

the Maneuvering Clutch Lever in REVERSE. To

stop reverse motion of the tines and wheels, simply release the Maneuvering Clutch Lever.

will automatically return to

Photo 3-3: The Forward Clutch.

A WARNING

NEVER move the Maneuvering Clutch into

either FORWARD or REVERSE unless the

Wheel Gear Lever on Econo-Horse and

Pony Models is in ENGAGE. On

Models, the Wheel Drive Pins must be in

WHEEL DRIVE POSITION.

Placing the Maneuvering Clutch in either

FORWARD or REVERSE when the wheels

are not engaged could allow the tines to

rapidly propel the tiller forward or backward.

Failure to follow this warning could result in

personal injury or property damage.

20

Junior

A WARNING

• When moving the tiller in reverse, always

look behind you to check for, and avoid,

obstacles.

• Never attempt to till in reverse.

Failure to follow these instructions could result in personal injury.

Photo 3-4: The Maneuvering Clutch.

Page 23

Depth Regulator

The lever at the rear of the tine hood is the

Depth Regulator Lever. Pulling back on this lever

and moving it either up or down allows you to

control the depth of tine penetration in the soil.

When you move the Depth Regulator Lever all

the way down (engaging the highest notch on

the depth regulator), you put the tiller in the

"travel" pos ition . This position allows you to

move the tiller without damage to your lawn by

allowing the tines to clear the ground by approximately

the way up (engaging the lowest notch on the

depth regu

depth (approximately six to eight inches, depending on soil conditions).

lower Depth Regulator Lever settings and

gradually increase the tilling depth and not

attempt to t

1-1/2 inches.

When you move the Depth Regulator Lever all

lator

), you

You

should begin tilling at one of the shal-

ill

too deeply too soon.

get

the

deepest

tilling

A WARNING

Handlebar Height Adjustment

To adjust

the

handlebar height:

1. Loosen the handlebar height adjustment han-

dle until the keys on the bottom of the keyed

washer can clear the slots in the curved handlebar height adjustment bracket.

2. Move the handlebar up or down to the height

you desire. Align the hole in the handlebar crossbrace with one of the four slots in the curved

handlebar height adjustment bracket.

3. Align the keys on the bottom of the keyed

washer with the slot in the curved handlebar

height adjustment bracket. Screw the handlebar

height adjustment handle into the hole in the

handlebar crossbrace. Tighten it securely.

To avoid injury, always place the Depth

Regulator Lever in the TRAVEL position before starting the engine. This position prevents the tines from touch ing the ground

until you are ready to begin tilling.

Photo 3-6: Adjusting the Handlebar height.

A WARNING

• When you change the handlebar height,

you MUST readjust the Forward Clutch

mechanism.

• When ad

Clutch mechanism, shut engine off, disconnect spark plug wire and prevent it from

touching the spark plug.

Failure to do this could allow the Forward

Clutch mechan ism to operate improperly,

which could resu lt in personal i

property damage.

justing

or

checking

Forward

njur

y or

Photo 3-5: The Depth Regulator Lever.

4. Readjust the Forward Clutch mechanism by

performing the following steps:

a. Remove the inner hairpin cotter from the

lower end of the Forward Clutch Rod.

21

Page 24

b. Use Photo 3-7 to determine which hole in

the swivel plate you should insert the lower

end of the Forward Clutch Rod into. For example, if you have the handlebar height setting at

position number 1 (on the curved handlebar

height adjustment bracket) insert the lower

end of the Forward Clutch rod into hole number 1 on the swivel plate.

Photo 3-7: Handlebar Height setting

Clutch positioning.

C. Insert the lower end of the Forward Clutch

and

Forward

Rod into the proper hole in the swivel plate.

Secure it in place by reinstalling the hairpin

cotter in the inner hole in the Forward Clutch

Rod.

d. To make sure that you have selected the

correct hole in the swivel plate:

(1). Stand on the right-hand side of the tiller.

Pull the Forward Clutch Lever up and hold it

in place.

(2). Check the gap between the E-Ring and

the lower end of the bracket on the Forward

Clutch Lever. The gap should be 3/16" to

5/16". If you do not have a ruler handy, five

pennies

are

approximately

5/16"

Refer to Photo 3-8.

e. If you are unable to get the 3/16" to 5/16"

gap, you'll have to readjust the Forward Clutch

Rod as follows:

(1). Refer to Photo 3-7 and make sure that

you have the Forward Clutch Rod in the

correct hole in the swivel plate.

thick.

3/16 "-10-5 /16"

REQUIRED GAP

Photo 3-8: Measuring the gap between the Forward

Clutch Bracket and the E-Ring.

(2). Insert the lower end of the Forward

Clutch Rod into this hole.

(3). Pull the Forward Clutch Lever up and

hold it in place.

(4). Check the gap between the E-Ring and

the

lower

end

of

the

Forward

Clutch

bracket.

If the gap is greater than 5/16", you'll have

to release the Forward Clutch Lever, re-

move the hairpin cotter from the inner hole

in the lower end of the Forward Clutch Rod,

move the Forward Clutch Rod away from

the swivel plate, and turn the rod counterclockwise (as viewed from the front of the

tiller) to decrease the gap.

If the gap is less than 3/16", you'll have to

release the Forward Clutch Lever, remove

the hairpin cotter from the inner hole in the

lower end of the Forward Clutch Rod, move

the Forward Clutch Rod away from the

swivel plate, and turn the rod clockwise (as

viewed from the front of the tiller) to increase the gap.

f. After getting the correct gap, make sure that

you reinstall the hairpin cotter in the inner hole

in the lower end of the Forward Clutch Rod.

ENGINE CONTROLS

Please read the following information about engine controls and operation.

Engine Owner's Manual that you received in your literature package.

Start

Electric Start Models

1. Check to make sure that the spark plug wire is

securely attached to the spark plug.

2. Make sure that the Wheel Gear Lever is in

"ENGAGE" on Econo-Horse and Pony Models.

22

ing

YourEng

ine-Recoi

l

Startand

On Junior Models, there is no Wheel Gear Lever,

but the Wheel Drive Pins should be through the

wheel hubs and wheel shaft holes in "ENGAGE."

3. Move the Depth Regulator Lever all the way

DOWN so the tines are in the "travel" position

(they should clear the ground by about

You

should also read the

1'

12")

.

Page 25

4. Move the Carburetor Choke Lever to "FULL

CHOKE" position (in the direction of the arrow on

Tecumseh engines; toward "Choke" on Briggs

Stratton engines). See Photo 3-9 for the EconoHorse's Tecumseh engine choke control; Photo

3-10 for the Pony's Briggs

& Stratton engine

choke control; and Photo 3-11for the Junior's

Tecumseh engine choke control.

Photo 3-9:

Econo-Horse

Model-ehoke

lever on the 6

Horsepower

Tecumseh

gine.

Photo 3-10:

Pony Modelchoke lever on

the 5HP Briggs

engine.

en-

pull the rope outward, be sure that nothing is

hind you.

&

Photo.3-13: Use

starter rope to start

engine.

7. For Electric Start models, turn the Engine

Ignition Switch to "START."Don't keep the switch

in START for longer than ten seconds. You may

have to try this several times before the engine

starts - allow the engine to come to a complete

stop before you turn the switch to START again.

When the engine starts, release the key; it will

automatically return to "RUN."

8. After the engine is running, gradually move

the Carburetor Choke Lever to NO CHOKE (in

the opposite direction of Choke).

be-

3-11: the

Photo

Junior Mode

choke lever on

the 4HP

Tecumseh

gi

ne.

l-

en-

5. Move the Engine Throttle Lever (on the righthand side of the control panel) to "START."

Photo 3-12: Engine Throttle Lever.

6. For Standard Start models, grasp the starter

rope handle with one hand. Brace the tiller by

placing your free hand on the gas tank. Pull the

starter rope slowly until you feel resistance. Then

pull the starter rope out rapidly...but let it rewind

slowly. You may have to repeat this procedure

several times until the engine starts. When you

Start

ing

theElectric

Start

Engine

with

the

Recoil Starter Rope

If necessary, the electric start engine can be

started with the recoil starter rope. Before doing

so, be sure to follow the procedure below.

1. If the battery is in good condition (not "dead"

or damaged), keep it on the tiller. This lets it

recharge during engine operation. However,

be-

fore starting the engine with the recoil starter

rope, make sure the

UPPER LEVEL line with electrol

batte

ry is filled to the

y1

e.

2. If the battery is "dead" or damaged, remove it

from the tiller and have it tested by a qualified

technician. Before using the starter rope to start

the engine, disconnect the positive battery cable

from the starter solenoid. Reinstall it after replac-

ing the battery.

IMPORTANT-When starting the engine with the

starter rope, turn the Ignition Key Switch to RUN.

Also move the Engine Throttle Lever to

START.

Stopping the Engine

To stop the wheels/tines at any time, simply

release the Forwa rd Clutch "paddles" or the

Maneuvering Clutch Lever (whichever one you

have engaged).

1. Tostop the engine on a Standard Start model,

move the EngineThrottle Lever to STOP.

2. To stop the engine on an Electric Start model,

you can either move the Ignition Key Switch to

OFF or you can move the Engine Throttle Lever

to STOP.

23

Page 26

Section

4:

.Q.p

(Section 1 ) and the Tiller and Engine operating in

tempttooperate your tille r.

use it in

ning the tiller

sit

yo

er

at

ion

Please be sure

Take a few mi

the

ion (Depth Regulator Lever p

Only after

ur

garden.

MANEUVERING WHEEL GEAR

CLUTCH

that

nutes

garden. Locate a clear, level area and practice engaging the

back

and forth. When you do this, make sure that the tines are in the

you

've

Of

you've

to familiarize yourselfwith the basic operationofyour

become

./

T

read, fu

ushe

comp

LEVER

ill

er

lly

understand, and a

d all the way down).

letely fa

mil

iar

struct

wit

ECONO-

ions (Sect

h your tille r

lways

HORSE

follow the Safety In

ions

3 and 4) before you at-

tiller

till

er controls and run-

shou

ld you begin

and PONYMODEL controls

stru

cti

before you

"tr

avel" po-

using

ons

it in

FORWARD

CLUTCH

LEVERS

,/

ool

~~

=:

I

.., LEVER

DEPTH

REGULATOR

LEVER

~~------

-

ENGINE THROTTLE

HANDLEBAR

HEIGHT

ADJUSTMENT

CHOKE

VER

LE

Photo 4-1: Operating

24

I

your

TROY-BILT Rototiller is easy

and

so rewarding .

Page 27

BEFORE STARTING, ALWAYS:

1. Check the engine oil level; add oil as necessary to bring the level up to the FULL mark on

the dipstick or to the point of overflowing if your

engine has an oil fill tube.

2. Make sure the engine air cleaner element is

clean and the air cleaner assembly is tight.

3. Be sure the gas tank has clean, fresh gasoline.

The gas tank cap must be screwed on tightly.

4. Check the spark plug wire; make sure that it is

securely attached to the spark plug.

5. Put the Wheel Gear Lever (on Econo-Horse

and Pony Models) in ENGAGE. On Junior tillers,

the

Wheel

Dri ve

Pins

must be ENG

AGED

through the wheel hubs and the wheel shaft.

TO BEGIN TILLING:

1. Make sure that the Wheel Gear Lever is in

ENGAGE on Econo-Horse and Pony Models. On

the Junior Model, the Wheel Drive Pins have to

be engaged.

2. Move the Depth Regulator Lever to the de-

sired position.

When practicing with your tiller or when moving the tiller to or from the garden, keep the tines

in the "travel" position.

When till ing, you

must

move

the

Depth

Regulator Lever to the desired setting, increase

the engine speed, and then begin tilling.