Troybilt 21A-675B766 Owner’s Manual

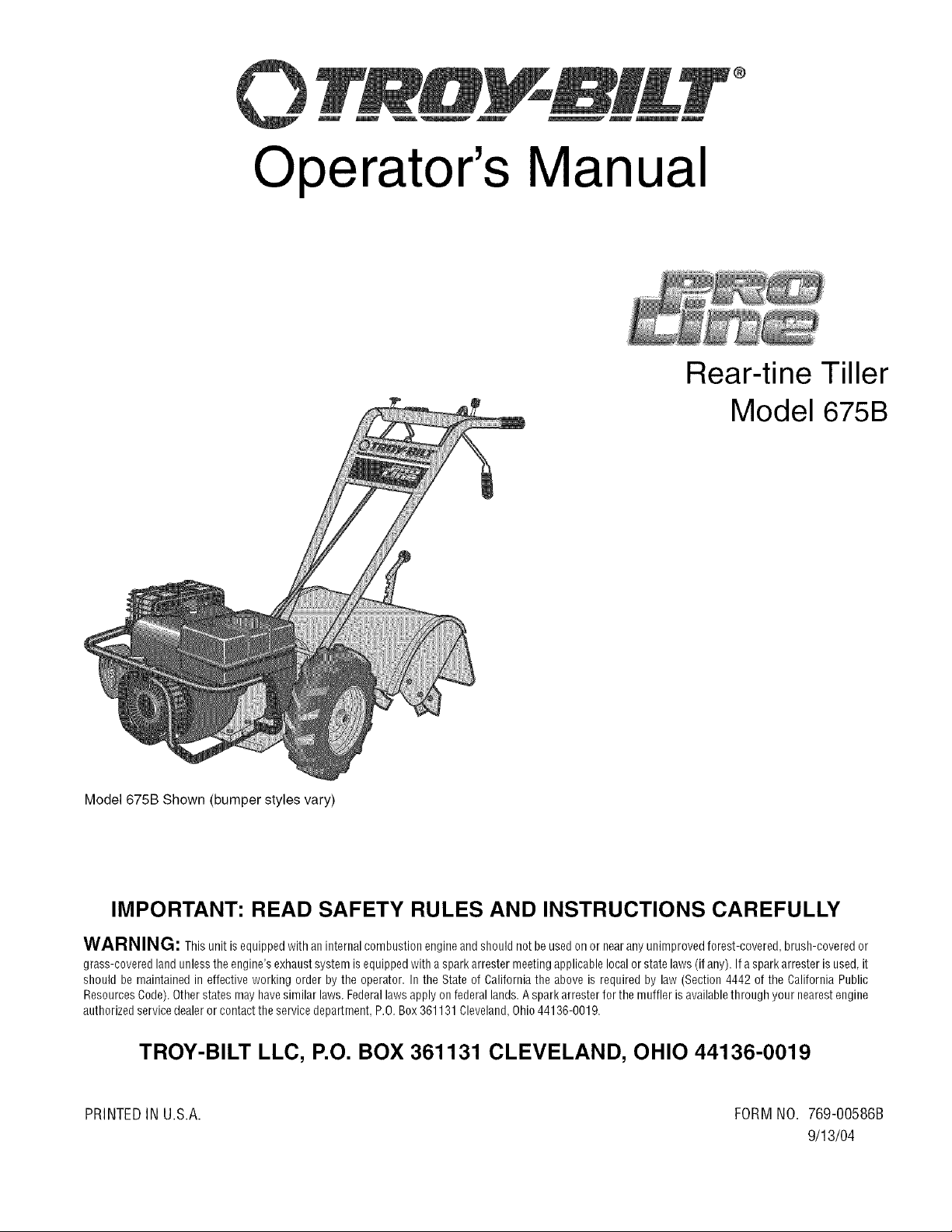

Operator's Manual

r®

Rear-tine Tiller

Model 675B

Model 675B Shown (bumper styles vary)

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

WARNING: This unit isequippedwith an internal combustion engineand should notbe usedon or near any unimproved forest-covered, brush-covered or

grass-covered land unless the engine's exhaust system isequipped with a spark arrester meeting applicablelocal or state laws(if any). If aspark arrester isused, it

should be maintained in effective working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

ResourcesCode). Otherstates may havesimilar laws. Federallaws apply on federal lands. A spark arrester for the muffler isavailable through your nearest engine

authorized servicedealer or contact the service department P.O. Box 361131Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTEDIN U.S.A. FORMNO. 769-00586B

9/13/04

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 16

Safety 3 Troubleshooting 23

Assembly 6 Parts List 24

Features and Controls 9 Warranty Back Cover

Operation 11

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new lawn tractor. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

Copy the model number here:

OTRDV-BILT T,OV-BmLTLLC

www.troybilt.com CLEVELAND,OH44136

,. 1-800-520-552_

P. O. BOX 361131

330-558-7220

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTreh/m thel/nit totheretailer withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

_ 7>,,,,

/;/ ,> ;'V }/ )

..... f ; @; t ;D

j;_ ?" #'s " 4t, ' F_ i/!s ,

* ;,, #FOX }_ j,"

,,, >,, rL;," ¢j ,_ <# ft, *x J ,7;; _

'_,-., _tf';_'ivc ,l

,v yO, ,_;7f'_;:'

If you prefer to reach a Customer Support Representative, please call 1(800) 520-5520.

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

SECTION1: SAFETY

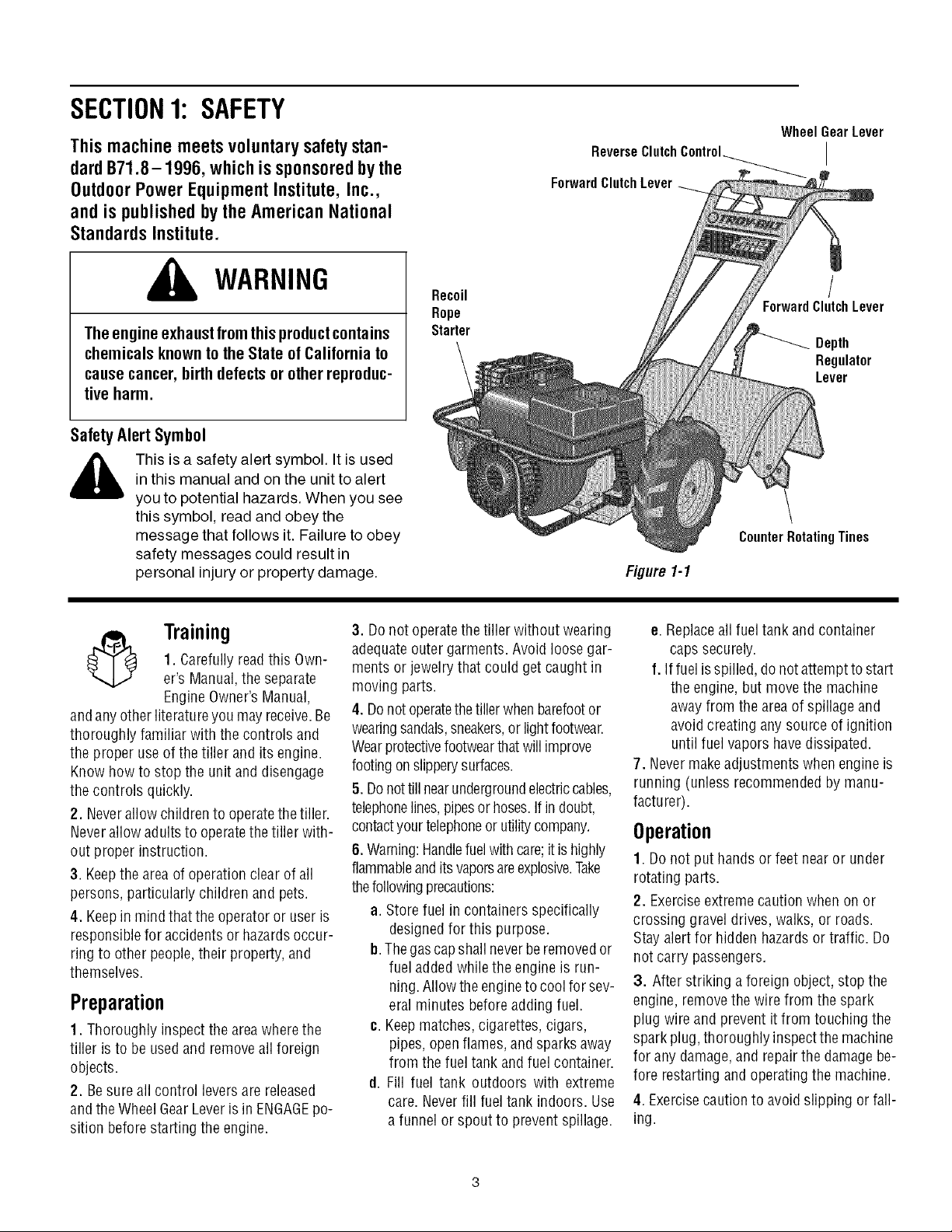

This machine meets voluntary safetystan-

dard B71.8-1996, which is sponsored bythe

Outdoor Power Equipment Institute, Inc.,

and is published by the American National

Standards Institute.

Wheel GearLever

ReverseClutch Control_ I

ForwardClutch Lever

WARNING

The engine exhaustfrom this productcontains

chemicals known to the State of California to

cause cancer, birth defects or other reproduc-

tive harm.

SafetyAlertSymbol

,_ This is a safety alert symbol. It is used

andanyotherliteratureyou mayreceive.Be

thoroughly familiar with the controls and

the proper use ofthe tiller and its engine.

Know howto stop the unit and disengage

the controls quickly.

2. Neverallow childrento operatethetiller.

Neverallow adultsto operatethetiller with-

out proper instruction.

3. Keepthe area of operationclear of all

persons, particularly children and pets.

4. Keepin mind that the operatoror user is

responsiblefor accidents or hazardsoccur-

ring to other people,their property, and

themselves.

Preparation

1. Thoroughly inspect the areawherethe

tiller is to be usedand removeall foreign

objects.

2. Besure allcontrol leversare released

andthe WheelGearLever isin ENGAGEpo-

sition beforestarting the engine.

in this manual and on the unit to alert

you to potential hazards. When you see

this symbol, read and obey the

message that follows it. Failure to obey

safety messages could result in

personal injury or property damage.

3. Donot operatethetiller without wearing

1. Carefullyreadthis Own-

Training

er's Manual,the separate

EngineOwner's Manual,

adequateouter garments. Avoid loosegar-

ments orjewelry that could getcaught in

moving parts.

4. Donotoperatethetillerwhenbarefootor

wearingsandals,sneakers,or light footwear.

Wearprotectivefootwearthatwill improve

footingonslipperysurfaces.

5. Donottillnearundergroundelectriccables,

telephonelines,pipesor hoses.If indoubt,

contactyour telephoneorutilitycompany.

6.Warning:Handlefuelwith care;itis highly

flammableandits vaporsareexplosive.Take

thefollowingprecautions:

a. Storefuel in containers specifically

b.Thegascapshall neverberemovedor

c. Keepmatches,cigarettes, cigars,

d. Fill fuel tank outdoors with extreme

Recoil

Rope

Starter

designedfor this purpose.

fuel addedwhile the engine is run-

ning.Allow theengineto coolfor sev-

eral minutes beforeadding fuel.

pipes, openflames, andsparksaway

from the fueltank and fuel container.

care. Neverfill fueltank indoors. Use

a funnel or spout to prevent spillage.

/

ForwardClutchLever

Depth

Regulator

Lever

CounterRotatingTines

Figl/re 1-1

e. Replaceall fueltank and container

caps securely.

f. If fuel isspilled, donot attemptto start

the engine,but move the machine

awayfrom the area of spillageand

avoidcreating anysource of ignition

until fuelvapors havedissipated.

7. Nevermakeadjustments whenengineis

running (unless recommendedby manu-

facturer).

Operation

1. Do not put hands orfeet near or under

rotating parts.

2. Exerciseextreme caution when on or

crossing gravel drives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine,remove thewire from the spark

plug wire and prevent it from touching the

spark plug,thoroughly inspectthe machine

for any damage,and repairthe damagebe-

fore restarting and operatingthe machine.

4. Exercisecautionto avoidslipping or fall-

ing.

5.Iftheunitshouldstarttovibrateabnormally,

stoptheengine,disconnectthesparkplug

wireandpreventitfromtouchingthespark

plug,andcheckimmediatelyforthecause.Vi-

brationisgenerallyawarningoftrouble.

6.Stoptheengine,disconnectthespark

plugwireandpreventitfromtouchingthe

sparkplugwheneveryouleavetheoperat-

ingposition,beforeuncloggingthetines,

orwhenmakinganyrepairs,adjustments

orinspections.

7.Takeallpossibleprecautionswhenleav-

ingthemachineunattended.Stoptheen-

gine.Disconnectsparkplugwireandmove

itawayfromthesparkplug.MoveWheel

GearLevertoENGAGE.

8.Beforecleaning,repairing,orinspect-

ing,stoptheengineandmakecertainall

movingpartshavestopped.Disconnect

thesparkplugwireandpreventitfrom

touchingthesparkplugtopreventacci-

dentalstarting.

9.Alwayskeepthetillertinehoodflap

down.

10.Neverusethetillerunlessproper

guards,plates,orothersafetyprotectivede-

vicesareinplace.

11.Donotrunengineinanenclosedarea.

Engineexhaustcontainscarbonmonoxide

gas,adeadlypoisonthatisodorless,col-

orless,andtasteless.

12.Keepchildrenandpetsaway.

13. Neveroperate thetiller underengine

powerif the WheelGearLever is in DIS-

ENGAGE(FREEWHEEL).Inthis position,

thewheels will notholdthe tiller back

andthe revolvingtines could propelthe

tiller rapidlybackward,possiblycausing

lossofcontrol. Always move theWheel

GearLeverto ENGAGEbefore starting the

engine or engagingthe tines4Nheelswith

the Forward Clutch or the ReverseClutch.

14. Beawarethat the tiller may unexpect-

edly bounceupward or jump backward if

the tines should strike extremely hard

packedsoil, frozen ground, or buried ob-

stacleslike largestones, roots, or stumps.

If in doubt aboutthe tilling conditions, al-

ways usethe following operating precau-

tions to assist you in maintaining control

of thetiller:

a. Walkbehindand to one sideof the

tiller, usingone handon thehan-

dlebars.Relax yourarm, butuse a

securehandgrip.

b. Use slower enginespeeds.

c. Clear thetilling areaof all large

stones,rootsand other debris.

d. Avoidusingdownwardpressureon

handlebars.If needbe, useslight

upwardpressureto keepthe tines

from diggingtoo deeply.

e. Beforecontacting hardpackedsoil

at the endof a row,reduceengine

speedand lift handlebarsto raise

tines out of thesoil.

f. In an emergency, stoptines and

wheels by releasingwhichever

ClutchLeverisengaged.Donotat-

temptto restrainthe tiller.

15. Donot overloadthe tiller's capacityby

attempting to till too deeplyat too fast a

rate.

16. Neveroperatethetiller at hightrans-

port speedsonslippery surfaces. Lookbe-

hind and use care when backing up.

17. Donot operatethetiller on aslopethat

is too steep for safety.When onslopes,

slow down and makesure you havegood

footing. Neverpermit thetiller to freewheel

down slopes.

18. Neverallow bystandersnearthe unit.

19. Onlyuse attachmentsand accessories

that are approved byGardenWay Inc.

20. Usetiller attachmentsandaccessories

when recommended.

21. Neveroperatethetiller withoutgoodvis-

ibility or light.

22. Neveroperatethetillerif youaretired,or

underthe influenceofalcohol,drugsormedi-

cation.

23.Operatorsshallnottamperwiththeengine-

governorsettingsonthemachine;thegovernor

controlsthemaximumsafeoperatingspeedto

protecttheengineandallmovingpartsfrom

damagecausedby overspeed.Authorizedser-

viceshallbesoughtif a problemexists.

24. Donottouchenginepartswhichmaybe

hotfromoperation.Letpartscooldown

25.Pleaseremember:Youcanalwaysstopthe

tinesandwheelsby releasingtheForward

ClutchLeverortheReverseClutchControl

(whicheverleveryou haveengaged)orbymov-

ingtheThrottleControlLeverto STOP.

26.Toloador unloadthetiller,seetheinstruc-

tionsinSection4ofthisManual.

27. Useextremecautionwhenreversingor

pullingthe machinetowardsyou.

28.Starttheenginecarefullyaccordingtoin-

structionsandwithfeetwellawayfromthe

tines.

29.Neverpickupor carryamachinewhilethe

engineis running.

MaintenanceandStorage

1. Keepthe tiller, attachmentsand acces-

sories in safeworking condition.

2. Checkall nuts, bolts, andscrews at fre-

quent intervalsfor proper tightness to be

surethe equipment is in safeworking con-

dition.

3. Neverstorethetillerwithfuelinthefueltank

insideabuildingwhereignitionsourcesare

presentsuchashotwaterandspaceheaters,

furnaces,clothesdryers,stoves,electricmo-

tors,etc.).Allowenginetocoolbeforestoringin

anyenclosure.

4.Toreducethechancesofafirehazard,keep

theenginefreeofgrass,leaves,or excessive

grease.

5. Storegasoline in acool, well-ventilated

area,safelyawayfrom any spark- orflame-

producingequipment. Store gasolinein an

approvedcontainer,safelyawayfrom the

reachof children.

6. Referto the storageinstructions in the

Maintenancesectionof this Manualandthe

separateEngineOwner'sManualfor in-

structions ifthe tiller is to be storedforan

extendedperiod.

7. Neverperformmaintenancewhiletheen-

gine is running orthe spark plugwire is

connected,exceptwhen specificallyin-

structedto do so.

8. If the fueltank hasto be drained,dothis

outdoors.

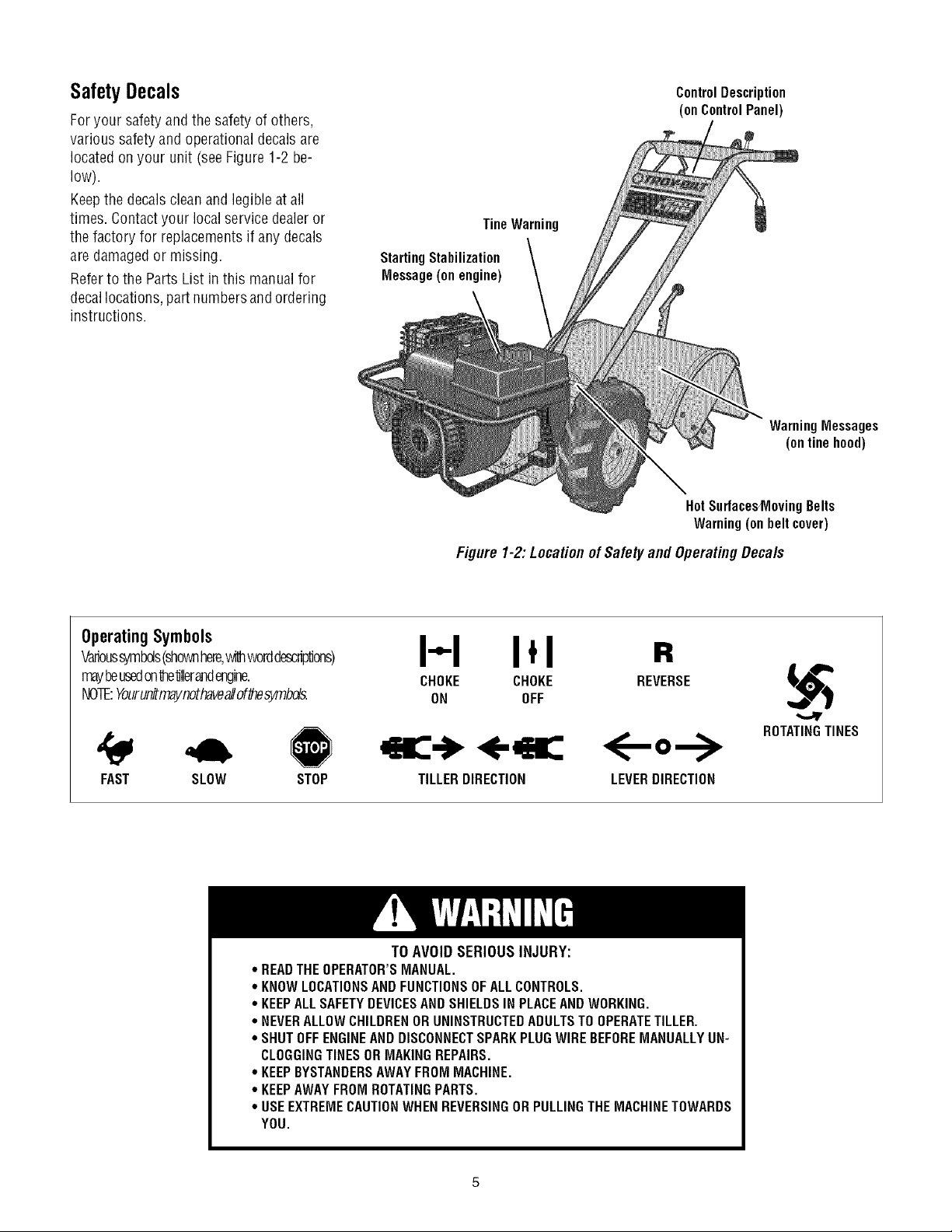

SafetyDecals

Foryour safety andthe safety of others,

various safety andoperationaldecals are

located on your unit (seeFigure 1-2be-

low).

Keepthe decalscleanand legible atall

times. Contactyour local service dealeror

the factory for replacementsif anydecals

are damagedor missing.

Referto the Parts List in this manual for

decallocations, partnumbersand ordering

instructions.

ControlDescription

(onControlPanel)

TineWarning

StartingStabilization

Message(onengine)

WarningMessages

(onlinehood)

HotSurfacesMovingBelts

Warning(onbeltcover)

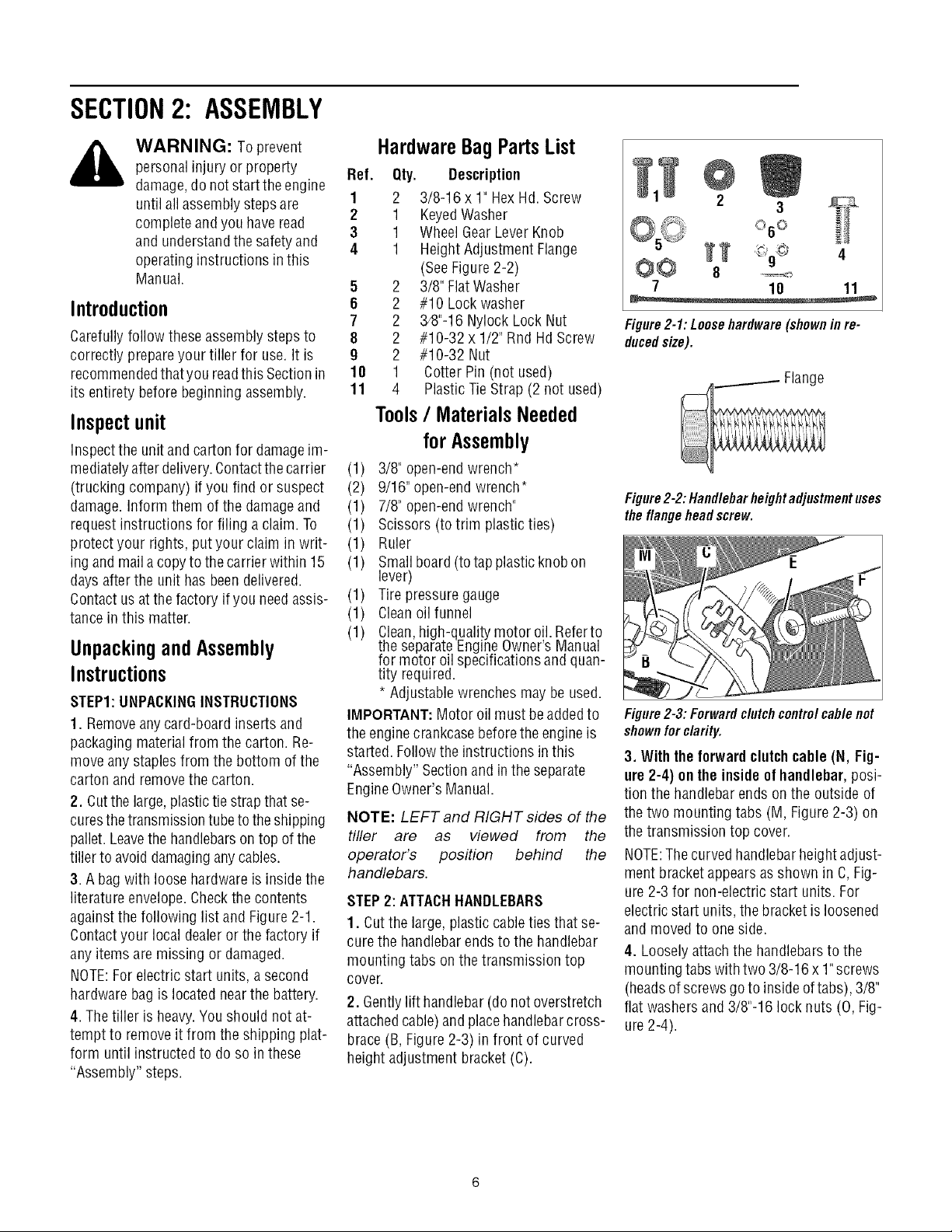

OperatingSymbols

Varioussymbds(shownhere,withworddescriptions)

mayheusedon'dle'dllerandengine.

NOTE:Yourunitmaynothaveallof_esymbds.

FAST SLOW STOP

* READTHEOPERATOR'SMANUAL.

* KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

* KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

. NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

° SHUTOFFENGINEAND DISCONNECTSPARKPLUGWIREBEFOREMANUALLYUN-

CLOGGINGTINESORMAKINGREPAIRS.

. KEEPBYSTANDERSAWAYFROM MACHINE.

. KEEPAWAYFROM ROTATINGPARTS.

° USEEXTREMECAUTIONWHENREVERSINGOR PULLINGTHEMACHINETOWARDS

YOU.

Figure 1-2:Locationof Safetyand OperatingDecals

I-.-I I,I

CHOKE CHOKE

ON OFF

TILLERDIRECTION

TO AVOID SERIOUS INJURY:

R

REVERSE

ROTATINGTINES

<--

LEVERDIRECTION

SECTION2: ASSEMBLY

WARNING: Toprevent

personalinjury or property

damage,do notstartthe engine

until allassemblysteps are

completeandyou haveread

and understandthe safety and

operatinginstructions in this

Manual.

Introduction

Carefullyfollow these assemblysteps to

correctly prepareyour tiller for use. It is

recommendedthatyou readthis Sectionin

its entirety beforebeginning assembly.

Inspect unit

Inspect the unitand carton for damageim-

mediatelyafter delivery.Contactthe carrier

(trucking company) if you find or suspect

damage. Inform them of the damageand

request instructions for filing a claim. To

protect your rights, put your claim in writ-

ing and maila copyto the carrierwithin 15

days after the unit has beendelivered.

Contact usatthe factory ifyou needassis-

tance in this matter.

Unpackingand Assembly

Instructions

STEP1:UNPACKINGINSTRUCTIONS

1. Removeanycard-board inserts and

packaging materialfrom the carton. Re-

move anystaples from the bottom ofthe

carton and removethe carton.

2. Cutthe large,plastictie strapthat se-

curesthe transmissiontubeto theshipping

pallet. Leavethe handlebarson top ofthe

tiller to avoid damaginganycables.

3. Abag with loosehardware is inside the

literature envelope.Checkthe contents

againstthe following list and Figure2-1.

Contactyour local dealeror the factory if

anyitems are missing or damaged.

NOTE:Forelectric start units, a second

hardwarebag is locatednearthe battery.

4. Thetiller is heavy.Youshould not at-

tempt to removeit from the shipping plat-

form until instructed to do so in these

"Assembly" steps.

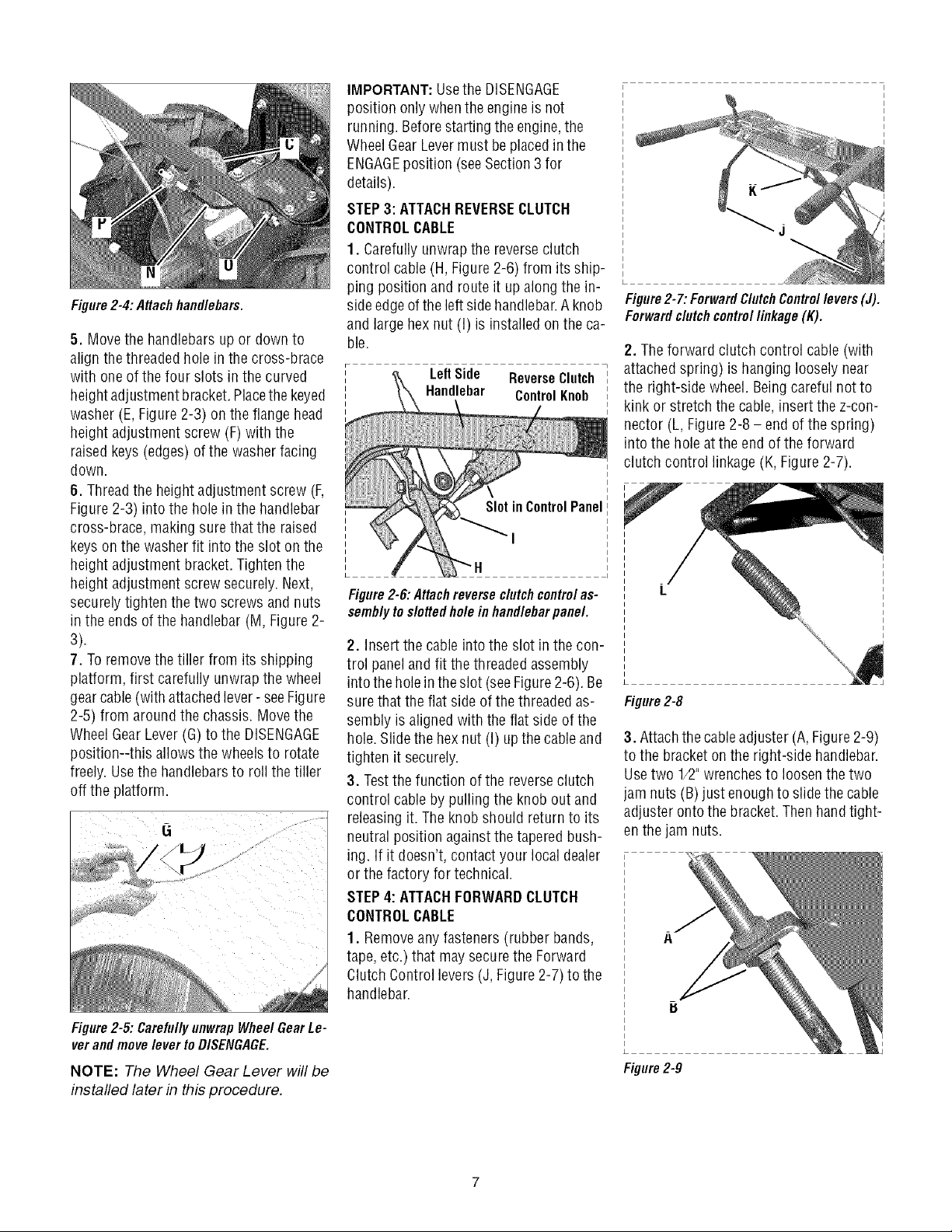

HardwareBagPartsList

Ref. Qty. Description

1 2 3/8-16 x 1" HexHd. Screw

2 1 KeyedWasher

3 1 WheelGearLeverKnob

4 1 Height Adjustment Flange

(SeeFigure2-2)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16Nylock Lock Nut

8 2 #10-32 x 1/2" Rnd HdScrew

9 2 #10-32 Nut

18 1 CotterPin (not used)

11 4 PlasticTieStrap (2 not used)

Tools/ MaterialsNeeded

forAssembly

(1) 3/8" open-endwrench*

(2) 9/16" open-endwrench*

(1) 7/8" open-endwrench"

(1) Scissors (totrim plasticties)

(1) Ruler

(1) Smallboard (totap plastic knobon

lever)

(1) Tirepressure gauge

(1) Cleanoil funnel

(1) Clean,high-quality motor oil. Referto

the separateEngineOwner'sManual

for motor oil specificationsand quan-

tity required.

* Adjustablewrenchesmay be used.

IMPORTANT:Motor oil must beaddedto

the enginecrankcasebeforethe engine is

started. Followthe instructions inthis

"Assembly" Sectionand in the separate

EngineOwner'sManual.

NOTE: LEFT and RIGHT sides of the

tiller are as viewed from the

operator's position behind the

handlebars.

STEP2: ATTACHHANDLEBARS

1. Cutthe large, plastic cableties that se-

curethe handlebarends to the handlebar

mounting tabs onthe transmission top

cover.

2. Gentlylift handlebar(do not overstretch

attachedcable) and placehandlebarcross-

brace(B, Figure2-3) in front of curved

height adjustmentbracket (C).

4

O@ 8

7 10 11

Figure2-1:Loosehardware(shownin re-

ducedsize).

Figure2-2: Handlebarheightadjustmentuses

the flangehead screw.

Figure2-3:Forwardclutchcontrolcablenot

shownforclarity.

3. Withtheforwardclutchcable (N, Fig-

ure 2-4) ontheinside of handlebar,posi-

tion the handlebarends onthe outside of

thetwo mounting tabs (M, Figure 2-3) on

thetransmission top cover.

NOTE:Thecurved handlebarheightadjust-

ment bracket appearsas shown in C, Fig-

ure 2-3 for non-electric start units. For

electricstart units, the bracketisloosened

and moved to one side.

4. Loosely attach the handlebarsto the

mounting tabs withtwo 3/8-16 x 1"screws

(headsof screws goto inside of tabs), 3/8"

flat washersand 3/8"-16 lock nuts (O, Fig-

ure2-4).

Figure2-4: Attachhandlebars.

5. Move the handlebarsup or downto

align thethreaded hole in the cross-brace

with one of thefour slots in the curved

heightadjustment bracket.Placethekeyed

washer (E, Figure2-3) on the flange head

height adjustmentscrew (F)with the

raised keys(edges)of the washerfacing

down.

6. Threadthe height adjustment screw (F,

Figure2-3) into the holein the handlebar

cross-brace, makingsurethat the raised

keyson the washerfit intothe slot on the

height adjustmentbracket. Tightenthe

height adjustmentscrew securely.Next,

securelytighten thetwo screws and nuts

in the ends of the handlebar (M,Figure2-

3).

7. Toremovethe tiller from its shipping

platform, first carefully unwrap the wheel

gearcable(with attached lever- seeFigure

2-5) from around the chassis. Movethe

WheelGearLever(G) to the DISENGAGE

position--this allows the wheelsto rotate

freely. Usethe handlebarsto roll the tiller

off the platform.

IMPORTANT:Usethe DISENGAGE

position onlywhenthe engineis not

running. Beforestartingthe engine,the

WheelGear Levermust be placedin the

ENGAGEposition (seeSection3 for

details).

STEP3: ATTACHREVERSECLUTCH

CONTROLCABLE

1. Carefullyunwrap the reverseclutch

control cable(H, Figure 2-6) from its ship-

ping position and route it upalong the in-

sideedgeofthe left sidehandlebar.Aknob

and large hexnut (I) is installed on theca-

ble.

Left Side ReverseClutch

Handlebar Control Knob

SlotinControlPanel

'1

Figure2-6:Attachreverseclutchcontrolas-

semblytodotted holeinhandlebarpanel.

2. Insert the cableinto the slot inthe con-

trol paneland fit the threaded assembly

intothe holein theslot (seeFigure2-6). Be

surethat the flat sideof the threaded as-

sembly is aligned with theflat side of the

hole.Slide the hexnut (I) upthecable and

tighten it securely.

3. Testthe function ofthe reverseclutch

control cableby pulling the knob out and

releasingit. Theknob should return to its

neutral position againstthe taperedbush-

ing. If it doesn't, contact your local dealer

or the factory for technical.

STEP4: ATTACHFORWARDCLUTCH

CONTROLCABLE

1. Removeany fasteners (rubber bands,

tape, etc.) that may securethe Forward

ClutchControl levers(J, Figure 2-7) to the

handlebar.

Figure2-7: ForwardClutchControllevers(J).

Forwarddutch controllinkage (K).

2. Theforward clutch control cable (with

attachedspring) is hanging looselynear

the right-side wheel. Beingcareful not to

kink or stretch the cable,insert the z-con-

nector (L, Figure2-8 - end of the spring)

into the hole atthe end ofthe forward

clutch control linkage(K, Figure2-7).

Figure2-8

3. Attachthecableadjuster (A, Figure2-9)

to the bracketon the right-side handlebar.

Usetwo 1/2"wrenchesto loosenthe two

jam nuts (B)just enoughto slidethe cable

adjuster ontothe bracket.Then handtight-

enthe jam nuts.

Figure2-5:CarefullyunwrapWheelGearLe-

verandmoveleverto DISENGAGE.

NOTE: The Wheel Gear Lever will be

installed later in this procedure.

Figure2-9

CAUTION: Incorrect cable

adjustment couldcausethe

wheelsandtines to rotate

unexpectedly.Follow

adjustment procedures

carefully. Failureto dosocould

result in personal injury or

property damage.

4. Checkfor correct spring/caNetension

as instructedin Section 5, Checkingand

Adjusting Forward Clutch Belt Tension.

5. Whentension is correct, tightenthe two

jam nuts (B) securely.

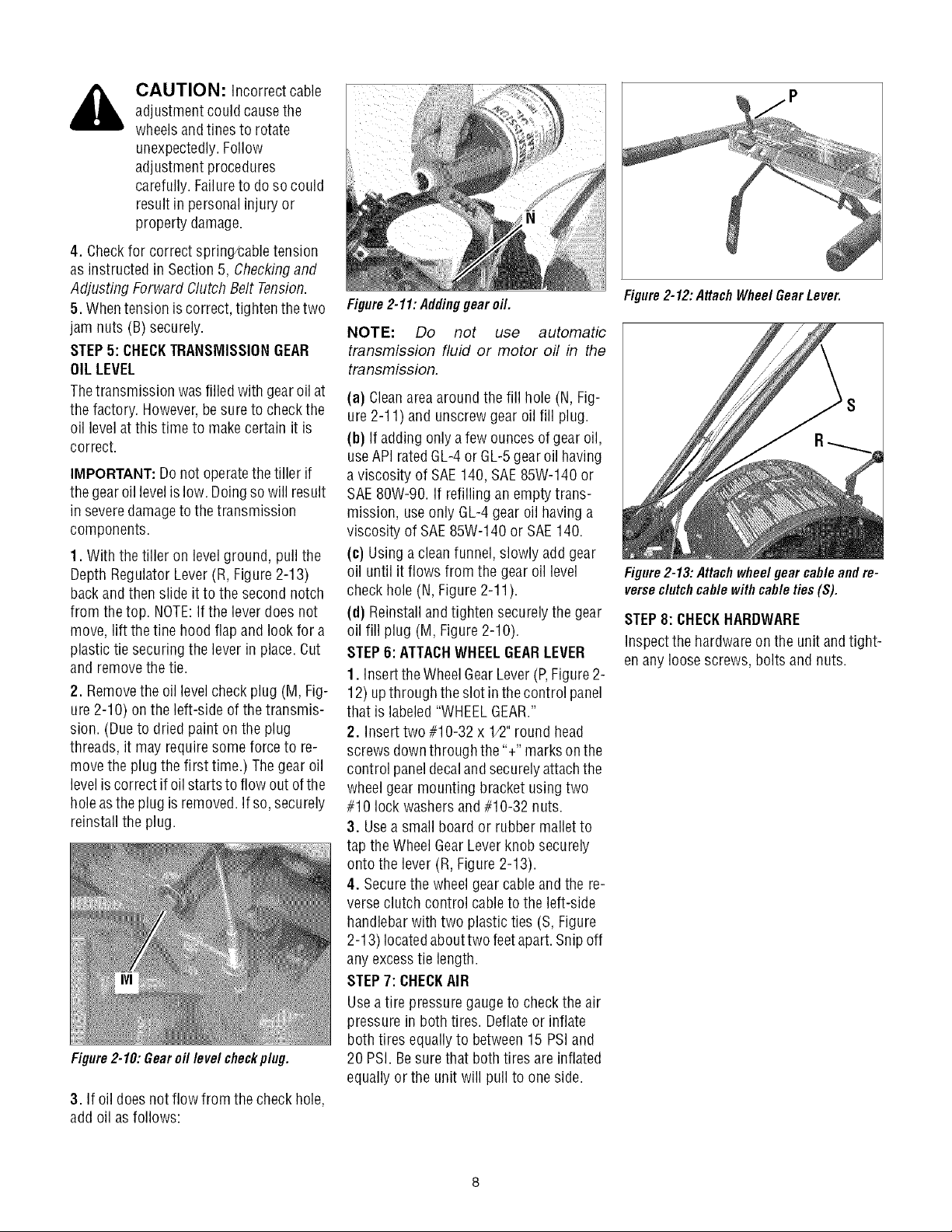

STEP5: CHECKTRANSMISSIONGEAR

OILLEVEL

Thetransmission was filled with gearoil at

the factory. However,besure to checkthe

oil levelatthis time to makecertain it is

correct.

IMPORTANT:Do not operatethe tiller if

the gearoillevelislow. Doingso will result

in severedamagetothe transmission

components.

1. With the tiller on level ground, pull the

Depth Regulator Lever(R, Figure 2-13)

backand then slide it to the second notch

from thetop. NOTE:Ifthe lever does not

move, lift thetine hood flapand look for a

plastic tie securing the lever in place.Cut

and removethe tie.

2. Removethe oil levelcheck plug (M, Fig-

ure 2-10) on the left-side of thetransmis-

sion. (Dueto dried paint onthe plug

threads, it mayrequire some forceto re-

move the plug the first time.) Thegear oil

levelis correct if oilstarts to flow out ofthe

holeastheplug isremoved.If so, securely

reinstall the plug.

Figure2-10: Gear oil level checkplug.

3. If oil doesnot flow from the checkhole,

add oil as follows:

Figure2-11:Addinggearoil.

NOTE: Do not use automatic

transmission fluid or motor oil in the

transmission.

(a) Cleanareaaround the fill hole (N, Fig-

ure 2-11) and unscrewgear oil fill plug.

(b) If adding onlya fewounces ofgear oil,

useAPI rated GL-4or GL-5gearoil having

a viscosity of SAE140, SAE85W-140 or

SAE80W-90. If refilling an emptytrans-

mission, useonly GL-4gear oil havinga

viscosity of SAE85W-140 or SAE140.

(c) Using aclean funnel, slowly add gear

oil until it flows from the gear oil level

checkhole (N, Figure 2-11).

(d) Reinstalland tighten securelythe gear

oil fill plug (M, Figure2-10).

STEP6: ATTACHWHEELGEARLEVER

1. Insertthe WheelGearLever(P,Figure2-

12) upthrough theslot in thecontrol panel

that is labeled"WHEELGEAR."

2. Insert two#10-32 x 1/2"round head

screws downthrough the'%" marks onthe

control paneldecalandsecurelyattachthe

wheelgear mounting bracket usingtwo

#10 lock washersand #10-32 nuts.

3. Usea small board or rubber malletto

tap the Wheel GearLever knob securely

onto the lever (R, Figure2-13).

4. Securethe wheelgear cable and the re-

verseclutch control cableto the left-side

handlebarwith two plastic ties (S, Figure

2-13) locatedabouttwo feetapart.Snip off

anyexcesstie length.

STEP7: CHECKAIR

Usea tire pressuregauge to checkthe air

pressure in both tires. Deflateor inflate

both tires equallyto between15 PSiand

20 PSI. Besure that both tires are inflated

equallyor the unit will pull to one side.

Figure2-12: Attach Wheel GearLever.

Figure2-13:Attachwheelgearcableandre-

verseclutchcablewithcableties(S).

STEP8: CHECKHARDWARE

Inspectthe hardwareon the unit andtight-

en anyloose screws, boltsand nuts.

SECTION3: FEATURESANDCONTROLS

_ ARNING: Before

Tiller Features

This section describesthe locationand

function ofthecontrols on yourtiller. Refer

to Section4: Operationfor detailedoperat-

ing instructions.

Practice usingthese controls, with the en-

gine shut off, until you understandthe op-

eration ofthe controls and feel confident

with eachof them.

IMPORTANT:Referto theseparateengine

manufacturer's EngineOwner's Manual

for information about thecontrols onthe

engine.

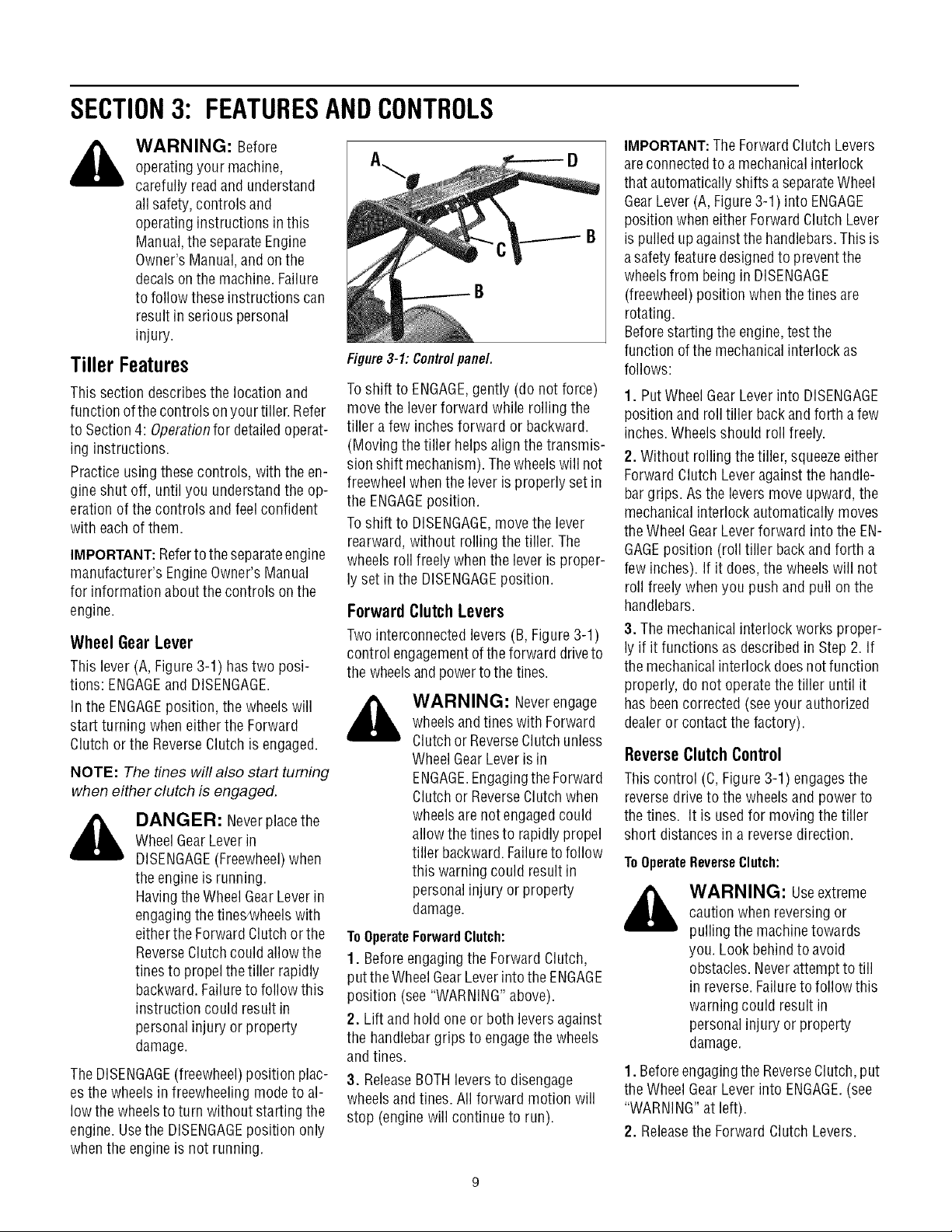

Wheel Gear Lever

This lever (A,Figure3-1) hastwo posi-

tions: ENGAGEand DISENGAGE.

In the ENGAGEposition, the wheelswill

start turning when either the Forward

Clutch orthe ReverseClutch is engaged.

NOTE: The tines will also start turning

when either clutch is engaged.

,_ DANGER: Neverplacethe

TheDISENGAGE(freewheel)position plac-

esthe wheels infreewheeling modeto al-

low thewheelsto turn without starting the

engine.Usethe DISENGAGEposition only

whenthe engine is not running.

operatingyour machine,

carefully readand understand

all safety,controls and

operatinginstructions in this

Manual,the separateEngine

Owner's Manual,andon the

decalson the machine.Failure

to follow these instructions can

result in serious personal

injury.

WheelGearLever in

DISENGAGE(Freewheel)when

the engineis running.

HavingtheWheelGearLeverin

engagingthetines_vheelswith

eitherthe Forward Clutchorthe

ReverseClutch couldallow the

tines to propel thetiller rapidly

backward.Failureto follow this

instruction could result in

personalinjury or property

damage.

Figure3-1: Controlpanel.

Toshift to ENGAGE,gently (do not force)

move the leverforward while rolling the

tiller afew inches forward or backward.

(Moving thetiller helpsalign the transmis-

sionshift mechanism). Thewheelswill not

freewheelwhenthe leveris properly setin

the ENGAGEposition.

Toshift to DISENGAGE,move the lever

rearward, without rolling the tiller.The

wheels roll freelywhen the leveris proper-

ly setin the DISENGAGEposition.

ForwardClutchLevers

Twointerconnected levers (B, Figure3-1)

control engagementofthe forward driveto

the wheelsandpowerto the tines.

,_ WARNING: Neverengage

ToOperateForwardClutch:

1. Beforeengagingthe ForwardClutch,

putthe Wheel GearLeverintothe ENGAGE

position (see "WARNING"above).

2. Lift and holdone or both leversagainst

the handlebargrips to engagethe wheels

andtines.

3. ReleaseBOTHleversto disengage

wheelsand tines. All forward motion will

stop (engine will continue to run).

wheelsandtines with Forward

Clutchor ReverseClutchunless

WheelGearLever is in

ENGAGE.EngagingtheForward

Clutchor ReverseClutchwhen

wheelsare not engagedcould

allowthe tinesto rapidly propel

tiller backward.Failureto follow

this warning could result in

personalinjury or property

damage.

IMPORTANT:The ForwardClutch Levers

areconnectedto amechanicalinterlock

that automaticallyshifts a separateWheel

GearLever(A,Figure3-1) into ENGAGE

position when eitherForwardClutch Lever

is pulledupagainstthe handlebars.This is

asafety featuredesignedto preventthe

wheelsfrom being in DISENGAGE

(freewheel)position when the tines are

rotating.

Beforestarting the engine,testthe

function ofthe mechanicalinterlock as

follows:

1. PutWheel GearLeverinto DISENGAGE

position and roll tiller backand forth a few

inches.Wheels should roll freely.

2. Without rollingthe tiller, squeezeeither

Forward Clutch Leveragainst the handle-

bargrips. Asthe levers move upward,the

mechanicalinterlock automatically moves

theWheel GearLeverforward into the EN-

GAGEposition (roll tiller backand forth a

few inches). If it does,the wheels will not

roll freely whenyou push and pull on the

handlebars.

3. The mechanicalinterlock works proper-

ly if it functions as describedin Step 2. If

themechanical interlock does not function

properly, do not operatethe tiller until it

hasbeencorrected (seeyour authorized

dealeror contact the factory).

Reverse Clutch Control

This control (C,Figure3-1) engagesthe

reversedrive to the wheels andpower to

thetines. It is usedfor moving thetiller

short distances in a reversedirection.

ToOperateReverseClutch:

_ ARNING: Useextreme

1. Beforeengagingthe ReverseClutch,put

theWheel GearLever into ENGAGE.(see

"WARNING"at left).

2. Releasethe Forward ClutchLevers.

caution whenreversing or

pulling the machinetowards

you. Look behindto avoid

obstacles.Neverattemptto till

in reverse.Failureto follow this

warningcould result in

personalinjury or property

damage.

3.Tomovethetillerinreverse,firststopall

forwardmotion.Liftupthehandlebarsun-

tilthetinesclearthegroundandpullthe

ReverseClutchleverout.

Thewheelswillrotateinareversedirection

aslongastheleverisheldinREVERSE.To

stopthewheelsandtines,releasethelever

anditwillreturntoNEUTRAL.Neverat-

temptto till whilemovingin reversedi-

rection.

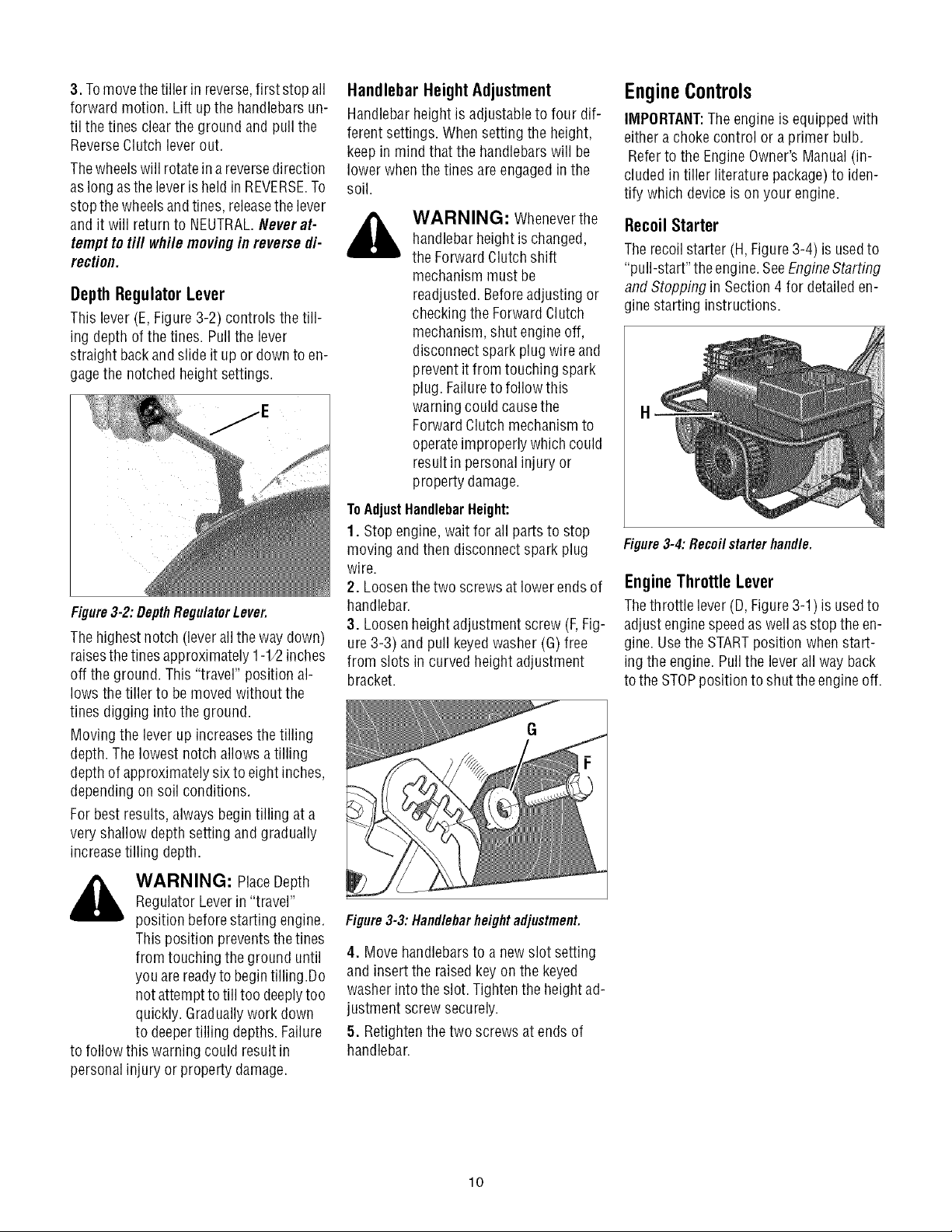

DepthRegulatorLever

This lever (E,Figure3-2) controls the till-

ing depthof the tines. Pullthe lever

straight backandslide it upor downto en-

gagethe notchedheight settings.

Figure3-2:DepthRegulatorLever.

Thehighest notch(leverall the way down)

raisesthe tinesapproximately1-1/2inches

off the ground. This"travel" position al-

lows the tiller to bemoved without the

tines digging into the ground.

Moving the lever up increasesthetilling

depth. Thelowest notch allows a tilling

depthof approximatelysix to eight inches,

dependingon soil conditions.

Forbest results, always begin tilling at a

very shallow depth setting and gradually

increasetilling depth.

Handlebar HeightAdjustment

Handlebarheight is adjustableto four dif-

ferent settings. Whensetting the height,

keepin mindthat the handlebarswill be

lower whenthe tines areengagedin the

soil.

WARNING: Wheneverthe

handlebarheight ischanged,

the ForwardClutchshift

mechanism must be

readjusted.Beforeadjusting or

checkingthe ForwardClutch

mechanism,shut engineoff,

disconnect spark plugwire and

prevent itfrom touching spark

plug. Failureto follow this

warningcould causethe

ForwardClutch mechanismto

operateimproperly which could

result in personal injury or

property damage.

ToAdjustHandlebarHeight:

1. Stopengine, wait for all parts to stop

moving andthen disconnectspark plug

wire.

2. Loosenthe two screws atlower endsof

handlebar.

3. Loosenheight adjustment screw (F,Fig-

ure 3-3) and pull keyedwasher (G)free

from slots in curved height adjustment

bracket.

EngineControls

IMPORTANT:Theengineis equippedwith

eithera chokecontrol ora primer bulb.

Referto the EngineOwner's Manual(in-

cluded intiller literature package)to iden-

tify which deviceis on your engine.

Recoil Starter

Therecoil starter (H, Figure3-4) is usedto

"pull-start" theengine.SeeEngineStarting

and Stopping in Section4 for detaileden-

gine starting instructions.

H

Figure3-4: Recoil starter handle.

EngineThrottle Lever

Thethrottle lever (D, Figure3-1) is usedto

adjust enginespeedas wellas stop the en-

gine. Usethe STARTposition whenstart-

ing the engine. Pullthe lever all way back

tothe STOPpositionto shut the engineoff.

,_ WARNING: PlaceDepth

to follow this warning could result in

personalinjury or property damage.

Regulator Leverin "travel"

position beforestarting engine.

This position preventsthetines

from touching the ground until

you arereadyto begintilling .Do

notattempt to till too deeplytoo

quickly. Graduallywork down

to deepertilling depths.Failure

Figure3-3: Handlebarheight adjustment.

4. Move handlebarsto a new slot setting

and insert the raisedkeyon the keyed

washer intothe slot. Tightenthe heightad-

justment screw securely.

5. Retightenthe two screws atends of

handlebar.

lO

SECTION3: OPERATION

WARNING: Before

operatingyour machine,

carefully readand understand

all safety (Section1),controls

(Section 3) andoperating

instructions (Section4) inthis

Manual,in the separateEngine

Owner's Manual,andon the

decalson the machine.Failure

to follow these instructions can

result in serious personal

injury.

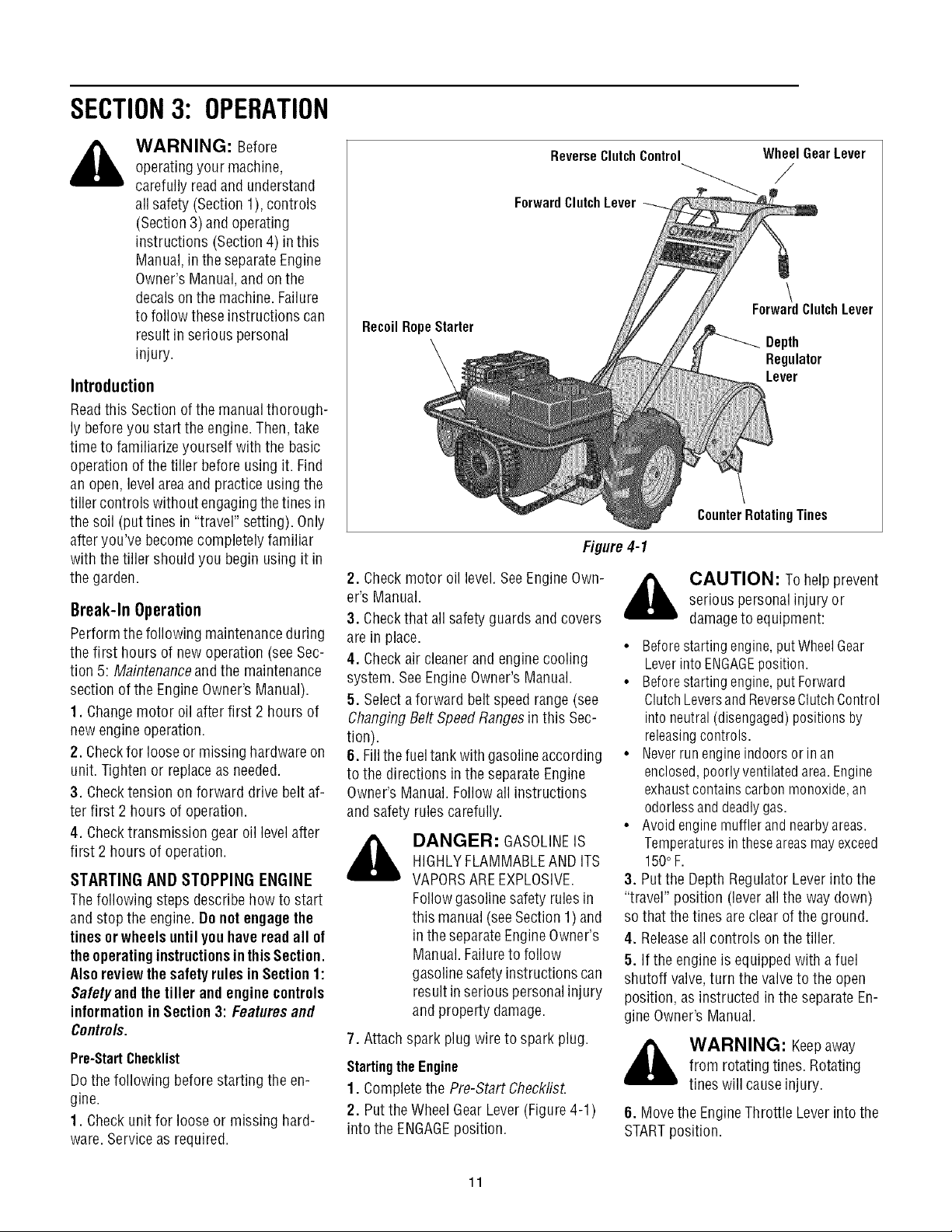

Introduction

Readthis Section of the manualthorough-

ly beforeyou start the engine.Then,take

time to familiarizeyourself with the basic

operation of the tiller before using it. Find

an open, levelareaand practiceusing the

tiller controls without engagingthe tines in

the soil (put tines in "travel" setting). Only

after you've becomecompletely familiar

with thetiller should you begin using it in

the garden.

Break-In Operation

Perform thefollowing maintenanceduring

the first hours of newoperation (seeSec-

tion 5: Maintenanceandthe maintenance

section of the EngineOwner'sManual).

1. Changemotor oil after first 2 hours of

newengine operation.

2. Checkfor loose or missinghardwareon

unit. Tighten or replaceas needed.

3. Checktension on forward drive belt af-

ter first 2 hours of operation.

4. Checktransmission gear oil levelafter

first 2 hours of operation.

STARTING AND STOPPING ENGINE

Thefollowing steps describehow to start

and stop the engine. Donot engagethe

tinesorwheels untilyouhavereadall of

theoperatinginstructionsinthisSection.

Alsoreviewthe safetyrules in Section1:

Safetyand the tiller andenginecontrols

informationin Section3: Featuresand

Controls.

Pre-StartChecklist

Dothe following beforestarting the en-

gine.

1. Checkunit for looseor missing hard-

ware. Serviceas required.

ReverseClutchControl

ForwardClutchLever

RecoilRopeStarter

Figure4-1

2. Checkmotor oil level.SeeEngineOwn-

er's Manual.

3. Checkthat allsafety guards andcovers

are in place.

4. Checkair cleanerand enginecooling

system. SeeEngineOwner's Manual.

5. Selectaforward belt speedrange (see

ChangingBelt SpeedRangesin this Sec-

tion).

6. Fillthefueltank with gasolineaccording

to the directions inthe separate Engine

Owner's Manual.Follow allinstructions

and safety rules carefully.

_k ANGER: GASOLINEIS

7. Attachspark plug wire to spark plug.

Startingthe Engine

1. Completethe Pre-Start Check/isL

2. Putthe WheelGear Lever(Figure4-1)

into the ENGAGEposition.

HIGHLYFLAMMABLEAND ITS

VAPORSAREEXPLOSIVE.

Followgasolinesafety rules in

this manual (seeSection 1)and

in the separateEngineOwner's

Manual.Failureto follow

gasolinesafety instructions can

result in seriouspersonalinjury

and property damage.

WheelGearLever

/

\

ForwardClutchLever

Depth

Regulator

Lever

CounterRotatingTines

_, AUTION: To helpprevent

• Beforestartingengine,putWheelGear

• Beforestartingengine,putForward

• Neverrunengineindoorsor inan

• Avoid enginemufflerand nearbyareas.

3. Putthe DepthRegulatorLeverinto the

"travel" position (lever all the way down)

sothat the tinesare clear ofthe ground.

4. Releaseall controls on the tiller.

5. If the engine is equipped with afuel

shutoff valve,turn the valveto the open

position, asinstructed in the separateEn-

gine Owner's Manual.

_ WARNING: Keepaway

6. Movethe EngineThrottle Leverinto the

STARTposition.

serious personalinjury or

damageto equipment:

LeverintoENGAGEposition.

ClutchLeversandReverseClutchControl

intoneutral (disengaged)positions by

releasingcontrols.

enclosed,poorlyventilatedarea.Engine

exhaustcontainscarbonmonoxide,an

odorlessanddeadlygas.

Temperaturesintheseareasmayexceed

150oF.

from rotating tines. Rotating

tines will causeinjury.

11

Loading...

Loading...