Troybilt 21A-675B063 Owner’s Manual

_i_)iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

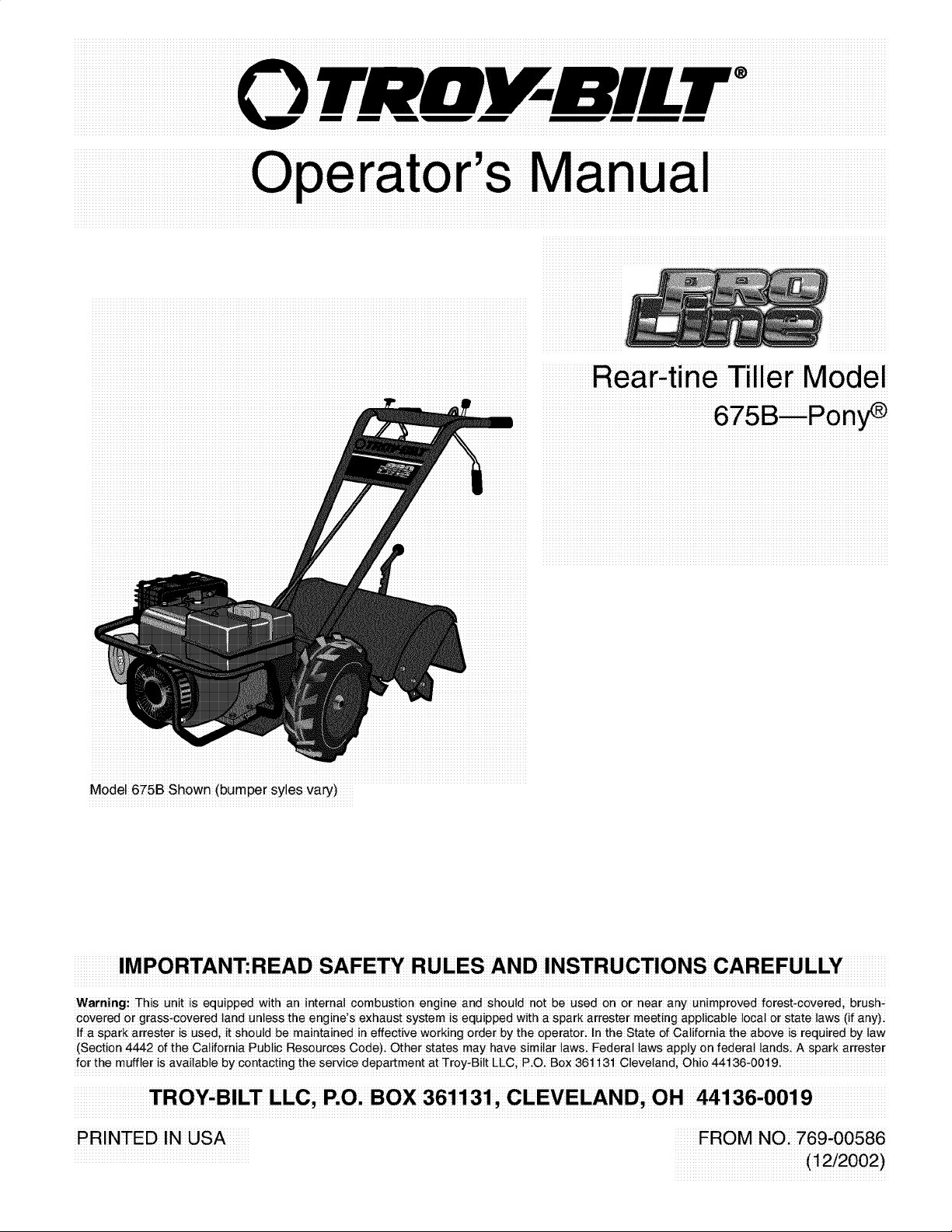

Rear, tineTillerModel

M0del 675B ShOwn(bumper sy!eSVa_)

I MPO RTANT:READ SAFETY RUL ES AND INSTRUCTIONS CAR EFULLY

Warning: This unit is equipped with an interna ! combustion engine and shou!d not be used on or near any un!mproved forest-covered; brush-

covered or grass-covered land unless the eng!nels exhaust system !sequip_d with a spark arrester meet!ng app]!cab!e Iota! or state laws (if any) i

!f a spark arrester is used, !t shou!d be maintained in effect_e working order by the operatori In the State of California the above is requ!red by law

(Sect!on 4442 of the California Pub!ic Resources Code)i Other states may have s!mi!ar !awsi Federa! !aws apply on federal landsi A spark arrester

for the muff!er is ava!lab!e by contacting the service department at Troy-Bi!t LLC; PiOi Box 361131 Cleveland, Ohio 44136-0019i

TROY-BILT LLC, ROi BOX 361131i CLEVELAND, OH 44136,0019

PRINTED IN USA FROM NO: 769,00586

TABLEOFCONTENTS

Content Page

Calling Customer Support : : i i..i i :: : : i i.i i : :: : i i..i i : : : i i i.i i : : : : i i.i i i :: :2

Safety::::.i;:; ; ; ; ; ;; ;:3

Assemblyi i. i ; i ; ; ; ; ; ;; ; i6

Features and Controls:.:::;: : : :..: : : : : : : :.: : : :: : : :..: : : : : : : :.: : : : : : : :.: : : : : :8

Operation : : : : : :: : :t t

Maintenance iii ; iiii.iiii; iii..iii; iiii.iiii; iii.iiii; iiii.iii;; iii.iiii; it6

Troubleshooting ::::i.;;;::::i..;;:::::i.;;:::::i.;;;::::ii.;;:::::i.;;;::;22

Parts List : : : : : : : :24

War,any Information : :. i i i :; ; ; ; ;; ; :Back Co_er

FINDING

This Operator's Manual is an important part of your new Rear,tine Tillerilt will help you assemble; prepare and main,

tain the unit for best performance: Please read and understand what it says:

Before you start assem bling you r new eq uipment; please locate the model plate on the equipment and copy the infor,

mation from it in the space provided below: This information is ve_ important if you need help from our Customer

Support Department oKan authorized dealeri

• You can locate the model number by looking at the rear surface of the tine shield: A sample model plate is

explained below. For futu re refefence; please copy the model number and the serial number of the equipment

in the space below

Copy Model Number Here

www:t rovbilt:com CLEVELANDi0H44136

_ 866-840-6483

_ 330;558,7220

ENGINEINFORMATION

_he engine manufacturer is responsible for all engine-related issues with regards to performance; power-_ating, speci-

ficationsi warranty and servicei Please refer to the engine manufactureCs Owner's/Operator's Manual packed sepa,

rarely with your unit for more informationi

CALLINGCUSTOMER

If you have difficulty assembling this product or have any questions regarding the controls; operation or maintenance

of this unit, please call the Customer Support Department;

Call 1-(330)558,7220 or 1, (866) 840-6483 to reach a Custome r Support representativei Please have

'_ your unit!s model number and serial number ready when you Call:See previous section to locate this infor,

mationi You will be asked to enter the seiial numbei in oidei to piocess your call

SPARK ARRESTER WARNINGTO RESIDENTS OF

CALIFORNIAAND SEVERALOTHERSTATES

Under Oalifornialawiand Under the laws of several

other states; you are not permitted to operate an inter.

halcombustion engine usinghyd rocarbon fuels on any

foresL brushi hay;grainiorg rass covered land;or land

Covered by any flammable agtic ultural Ctop without an

engine spark arrester in continuous effective working

order.

Theengine on theunit is aninternal cornbustionengine

which burns gasolinei a hydrocarbon fueli and must be

eq uipped with aspark arrester muffler in continuous

effective working orderi The spark arrester must be

attached to the engine exhaust sYstem in such a

manner that flames or heatfrom the system willnot

ignite flammable material: Failureof the owner/opera-

tor of the unit to cornply with this regulation is a mis,

demeanor under California law (and other states) and

may also be a violation of other state and!or federal

reg ulations, laws; ordinances or codesi Conrad your

localfi remarshal or forest servicefor specific informa,

tion aboutwhich regulations apply inyour area.

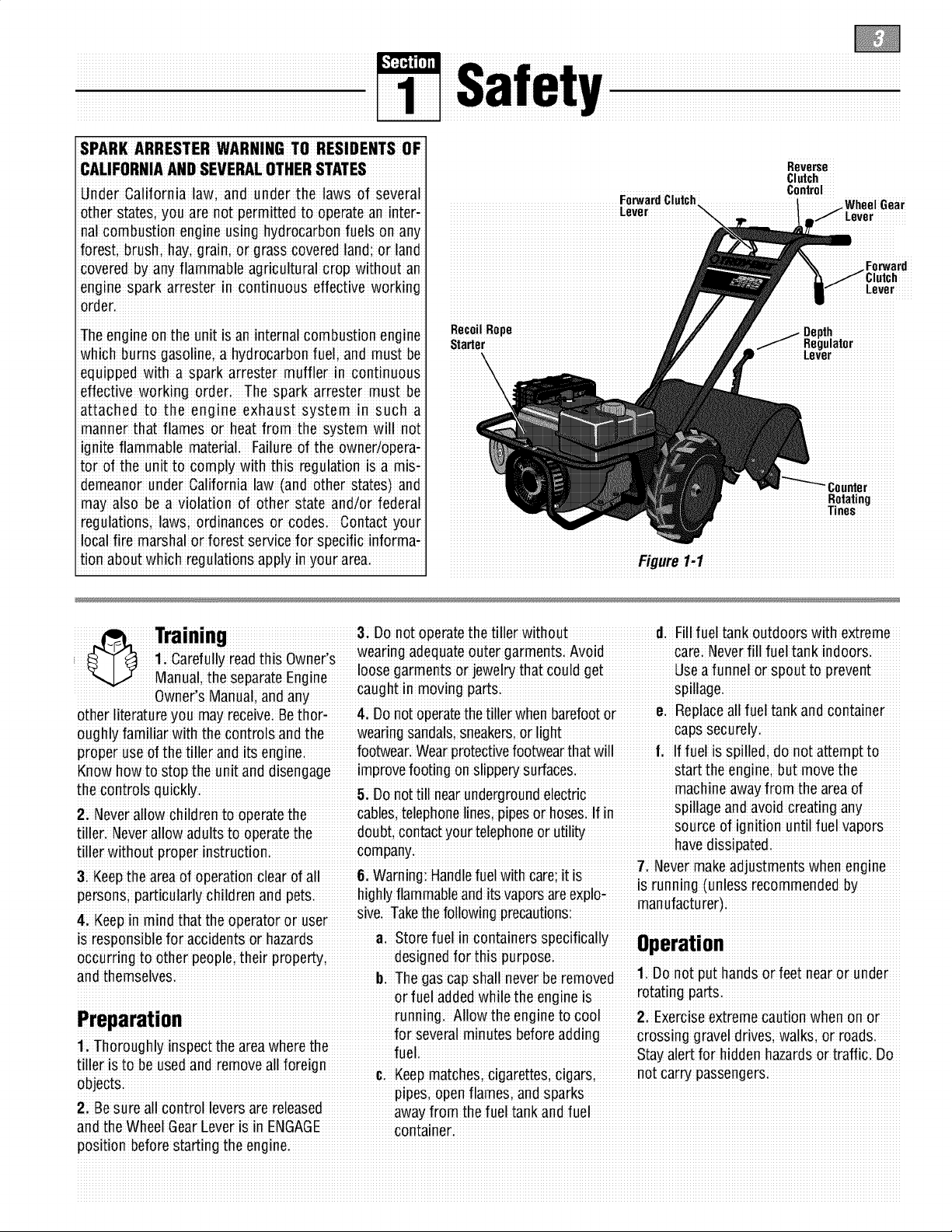

Reverse

Clutch

ForwardClutch i ...... luh,,,, n,,_,_

Leve I ..............

RecoilRope

Starter lulator

Control

Forward

iiiiiiiiiiiiil

Rotatingiiiiiiii

Tines

iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii_urei1i.1iiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiiii

h

Training 3: Donot operatethe tiller without d. Fill fuel tankoutdoorswith extreme

1 r f ii-i ihi wn r, wear'ng adequateouter garmentS Avo'd care Neverf ' fue tank'ndoors

,,Ca e u y Bad sO e

Manual, the separateEngine ........ .......

............... wnii Mn I nd n................caught in moving parts...........................................................spillage............................................................

0 e s ia ua,a a

other literature you may receive Bethori 4: Donotoperatethetiller whenbarefootore. Replaceall fuel tank andcontainer

oughlyfamiliar with the controls and the wear ngsandals;Sneakersior light capssecurely

proper useof the tiller andits engine: footwear.Wearprotectivefootwear that will l, lffuel is spilledi donor attempt to

Know how to Stopthe unit and disengage improvefooting onslippe_ surfaces, start the enginei butmove the

thecontrols .machine away from the areaof

• 5, Donott!ll nearundergroundelectnc :

2, Neverallow children to operatethe cables,telephone nesiplpeso hose& If n,, : :

iiller Neverallow adultsto operatethe doubt contactyourtelephoneor utility !

r': r coman havedissipated

tille withoutproperlnstuctloni P Yi _ i i ,: il i i :

&Keep the areaof operation clearof all&Warning: Handlefuelwith care;it isis r_nnin" _unless"_ _"_'_ _:

pe#sons;pa#ticuladychildren and pets highlyflammableanditsvaporsareeXplo; _, ;,_; ;_

4 KeG inmin thtth oertor r......er..........slve taKe[neToliowlngprecau1:ions..............................................................................................................

p d a: e p a: o us

is responsiblefor accidentsor hazards a; Storefuel in containers specifically 88eratiGn

occurring to other people;their property; designedfor th s purposei _,-c--_-_

and themselves Th h II n v r r m v 1 Donot put hands or feet nearor under

i iii i i!. b; egascapsiaii ieeibe e ioed.

............. ........ running AIIow the engine to cool 2 ExerciseextremeCautionwhen onor

Preparation ...... ............

1/horoughly inspect the areawherethe

fue Stay alertfor hidden hazardsor traffic. Do

; i. for several rainutes beforeadd gravel drives; walksi or roads

tiller is to beused andremove all foreign _ _L_LL_ Li_L_L_,._ not cai"' _assen'_ers

UUJUUL;5.............................................................................................. ....................................................................................................................................................................

2; Be Sureall control leversare released awayfrom thefuel tank andfuel

andihe WheelGearLe_er iSin ENGAGE cont'aineri

position beforestarting the engine.

loosegarmentsor ]ewel_ that could get Useafunnel or spout toprevent

li' r i spillage ariaavOIOcrea:lngany.............

source of ignition until fuel vapors

. : ; t\Jevermake aejusl:menl:swnen engine

g _ ruuul_mluuuuu uy

÷ _. I I IdllU_dbLU EUE,li

or fueladded while the engine iS rotat!ngparts.

pipes,open flamesi and

3. After striking a foreign object, stopthe 14: Beawarethat the tiller may unexpeCb Speed:Authorizedserviceshallbesoughtif

engirle,remove the wire from the ;spark edly bounceupward or jump backward if a problemexistsi

plug wire and preVentit from touchingthe thetinessh ould strikeextremel!i hard 24 DonoitouchengineDa_swhichmavbe

spark plugi thoroughly respectthe packedsoil, frozengroundi or buried hoifrom oDerationiLet Da2rtscool down

machinefor any damagei and repair the obstacles likelarge stones, roots; or sufficientli

damagebefore restart!ng and operating stumps; If !ndoubt about the t!lhng cond!-L _

the machinei tionsi alwaysuse thefollowing operating 2_i _!easeremem_e_:_ou cana_waysStop

the l:lnesandWlleelsby releasingtile

4i E×ercisecautiontoavoid slipping or precaut!°nst° ass!st Y°u !n mamta!mng F_rw_P"1 i_h L"v_i _iih" RXv_r_ _1 i_h

_.i_ control of the tiller: U _u_u_ u _ _u

Control(whicheverleveryouhave engaged)

5i Ifthou nit shouIdstartto Vibrateabnori a+ Walk beh_ndand to ones_dee! the orbYmo_ingtheThiottle ControlLeVei to

mallv sfonfhe ermine disconnectfhesnark tiller, usingone handon the han-

p"iug'wiieandpie've'ntlit from'i"ou_h_"rlgihe_ i Relaxyourarm; but pi_ thi tillii iii thi

's_anu_i

causei Vibiaiion isgeneially a waining of Useslower engine speodsi ,

troublei Clearthe tilling area otall large i

6Sto L ihe engine disconneciihe s_aik stonesi roots and otherdebris:pull! ngthe machinetowardsyoui

• _ i ; !lJ

zt use extremecaul:lOnwren reversingor

plug wire and preventit from touching the d; Avoid usingdownward pressure on 28: Sta_the enginecare!ull_accord[rlgto

spaik plugwhe neveryou leavethe opeiaii handlebarsi I1need bei useslight nstruo:lonsandwireTee_WellawayTromme

ing positiom before unclogging thetines, upwardpressure to keepthe tines ! nes

or when making any repairs;adjustments lrom digging too deeply; 29: Neverpick upor car_ a machinewhile

or inspectionsi e; Beforecontactinghardpackedsoil theengineis runningi

moving partshavestoppedi Disconnect 15: Donot o_erloadthe tiller's capaci_ by dition

the sparkplug wire andprevent it from attempting totill too deeplyat too fast a __

[OUgrllng£nespark plugI:oprevemaccl-a

aen_als[amng

: r:t: _. t_Jevers_orethe[lller wenTUelIn[ReTUel

[aRK InsIge a OUIIOlng wnere Ignl£10n sources

16; Neveroperate thetiller at high transi arepresent suchashot waterandspace

9. Alwayskeep the tiller tinehood flap port speedson Slippe_ su_aces. Look heaters;furnaces;clothesdryers;stoves

down behineand usecare when backing uP electricmotors;etc;)Allow engineto Cool

10: Neveruse thetiller unlesSproper 17: Donot operatethe tiller ona Slope befo[estoringinany enclosu[e:

gaards; plates;orother Safe_ protective that is too Steepfor safety:When o[14. Toreducethechancesof a fire hazard;

devicesare in placei slopesi slow down and make sureyou keepthe enginefree Ofgrass,leaves;or

11i Donot Curlengine in anenclosed aiea. i i !i i ii

Erlgne exhaustcontains carborl monox!de 5_Storegasohrle macool, well-verlblated

havegood footing Never permetthe teller excesseverease

: to freewheeldown Slopesi i.

gas; a deadlypc isonthat is odorless coI-18 :Never allow bystandersnearthe unit: areaisafely awayfrom anyspark: or flame:

oflessi and !as!eless. 19: Only useattachments and accessories p[oducing equipment store gasoline in an

12: Keepchild tenandpets away. that areapproved by GardenWay Inci approvedcontainer,safelyawayfrom the

ENGAGEtFREEWHEE[_ In this-osition :.ii ..: Maintenancesection ofthis ManUaland

thewheelswill not hold thetiller back visibilih_or linht e ,_e_:: u _ _ a u,,

...... ,, Z'l, Neveropera_:eme_:lllerwl_:nou_gooa thx _r_t. ,Enfin" nwnXi'_ M_ni_1f"r

andthe revolvingtines cozddpropelthe " _' instructionsif thetiller iSto be Storedfor

tiller rapidly bac_ardi possiblycausing 22i Neveroperatethetiller ifyou aretired, or an extendedperiod

loss ofcontrol Alwa"s movethe Wheel undertheinflUenCeof alcoholidrugsor ,.

Gear Leverto ENGAGEbeforesta_ing iurlning or thespaik plug wiie

mealcaEiofl

engineo[ engagingthe tines/wheels with 23i Operatorsshallnot tampei withthe _onnected,except whensPecificall7

the Forward Clutch orthe ReverseClutch: engine-governorse_ingson themachine; instructedto dosoi

!he_;m° ic_ln_r°lsthett_ximu mSafned & If thefuel tank hasto bedrained,do this

ope_ g;_ ;_ _ outdoors

!o gpa!s o !oa agecauseeD_oe- i

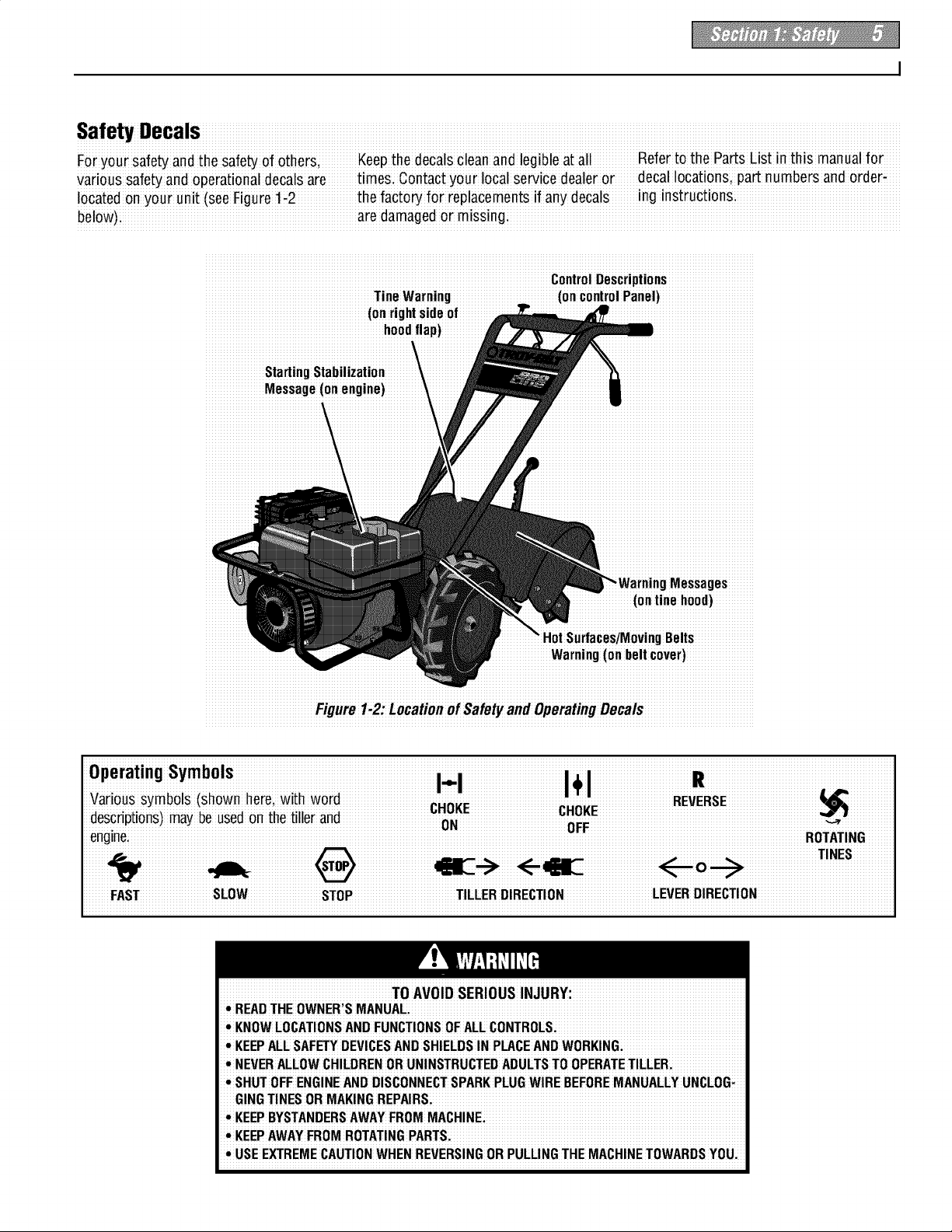

Safety Decals

For your safety and the safe_ of others, Keep the decals €lean and legible at all Refer to the Parts List in thisman ual for

various safetyand operationaldecalsare times. Contactyour local Servicedealeror decalIocations, partnumbers and order-

located on your unit (see Figure1-2 thefactop¢for replacementsif any decals ing instructions

below)i aredamagedor missing:

Con#ol Descriptions

TineWarning(on controlPanel)

(onright side of

hoodflap)

Message(on engine)

(ontine hood)

Belts

Warning(on belt cover)

Figure1,2: LocationofSafetyand OperatingDecals

FAST SLOW STOP TILLERDIRECTION LEVERDIRECTION

TO AVOID SERIOUS INJURY:

• READTHE OWNER'SMANUAL

• KNOWLOCATIONSAND FUNCTIONSOFALL CONTROLS:

• KEEPALLSAF_Y DEVICESANDSHIELDSIN PLACEANDWORKING:

• NEVERALLOWCHILDRENOR UNINSTRUCTEDADULTSTOOPERATETILLER.

!•SHUTOFF ENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG_

GING TINESOR MAKINGREPAIRS:

• KEEPBYSTANDERSAWAYFROMMACHINE:

• KEEPAWAYFROM ROTATINGPARTS.

!• USEEXTREMECAUTIONWHENREVERSINGOR PULLINGTHE MACHINETOWARDSYOU;

To prevent personal injury or property

damagei do notstart the engine until aII

assembly steps are complete and you

haveread andunderstandthe safetyand

operatinginstructionsinthis Manual:

INTRODUCTION

Carefullyfollow theseassembly steps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in itsentirety beforebeginning assembly.

INSPECTUNIT

Inspect the unit andcartonfor damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Inform them of the

damageand request instructions for filing

a claim. To protect your rights, put your

claim inwriting and mail a copyto the

carrier within 15 daysafter the unit has

beendelivered. Contactus at the factory if

you needassistanceinthis matter.

UNPACKINGANDASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Removeanycardboard inserts and

packaging materialfrom the carton.

Removeany staplesfrom the bottom of

the carton and removethe carton.

2. Cutthe large,plastictie strap that

securesthe transmission tube to the ship-

ping pallet. Leavethe handlebarson top of

the tiller to avoid damaginganycables.

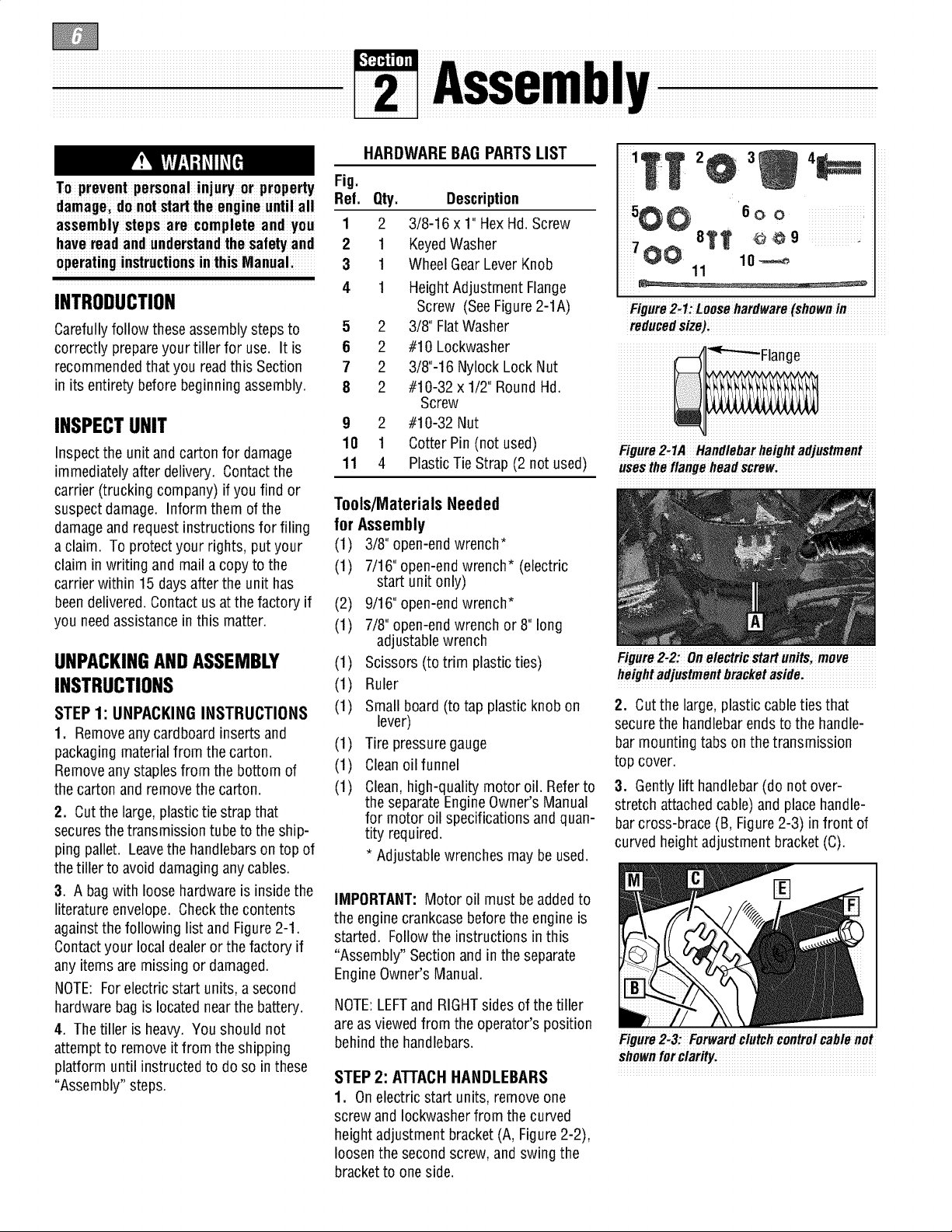

3. A bagwith loosehardwareis insidethe

literature envelope. Checkthe contents

againstthe following list and Figure2-1.

Contactyour localdealerorthe factory if

anyitemsare missing or damaged.

NOTE: Forelectric start units, a second

hardwarebag is located nearthe battery.

4. The tiller is heavy. You should not

attempt to remove itfrom the shipping

platform until instructed to do so in these

"Assembly" steps.

HARDWARE BAG PARTS LIST

Fig.

Ref. Qty. Description

1 2 3/8-16 x 1"HexHd.Screw

2 1 KeyedWasher

3 1 WheelGearLever Knob

4 1 HeightAdjustment Flange

Screw (SeeFigure2-1A)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16 Nylock Lock Nut

8 2 #10-32 x 1/2" RoundHd.

Screw

9 2 #10-32 Nut

10 1 Cotter Pin (not used)

11 4 Plastic Tie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8" open-end wrench*

(1) 7/16" open-end wrench* (electric

start unit only)

(2) 9/16" open-endwrench*

(1) 7/8" open-end wrench or 8" long

adjustablewrench

(1) Scissors (to trim plasticties)

(1) Ruler

(1) Small board (to tap plastic knob on

lever)

(1) Tire pressuregauge

(1) Cleanoilfunnel

(1) Clean,high-quality motor oil. Referto

the separateEngineOwner's Manual

for motor oil specifications and quan-

tity required.

* Adjustablewrenches maybe used.

IMPORTANT:Motor oil must beaddedto

the engine crankcasebefore the engine is

started. Followthe instructions in this

"Assembly" Sectionand in theseparate

EngineOwner's Manual.

NOTE:LEFTandRIGHTsides ofthe tiller

areasviewed from the operator's position

behind the handlebars.

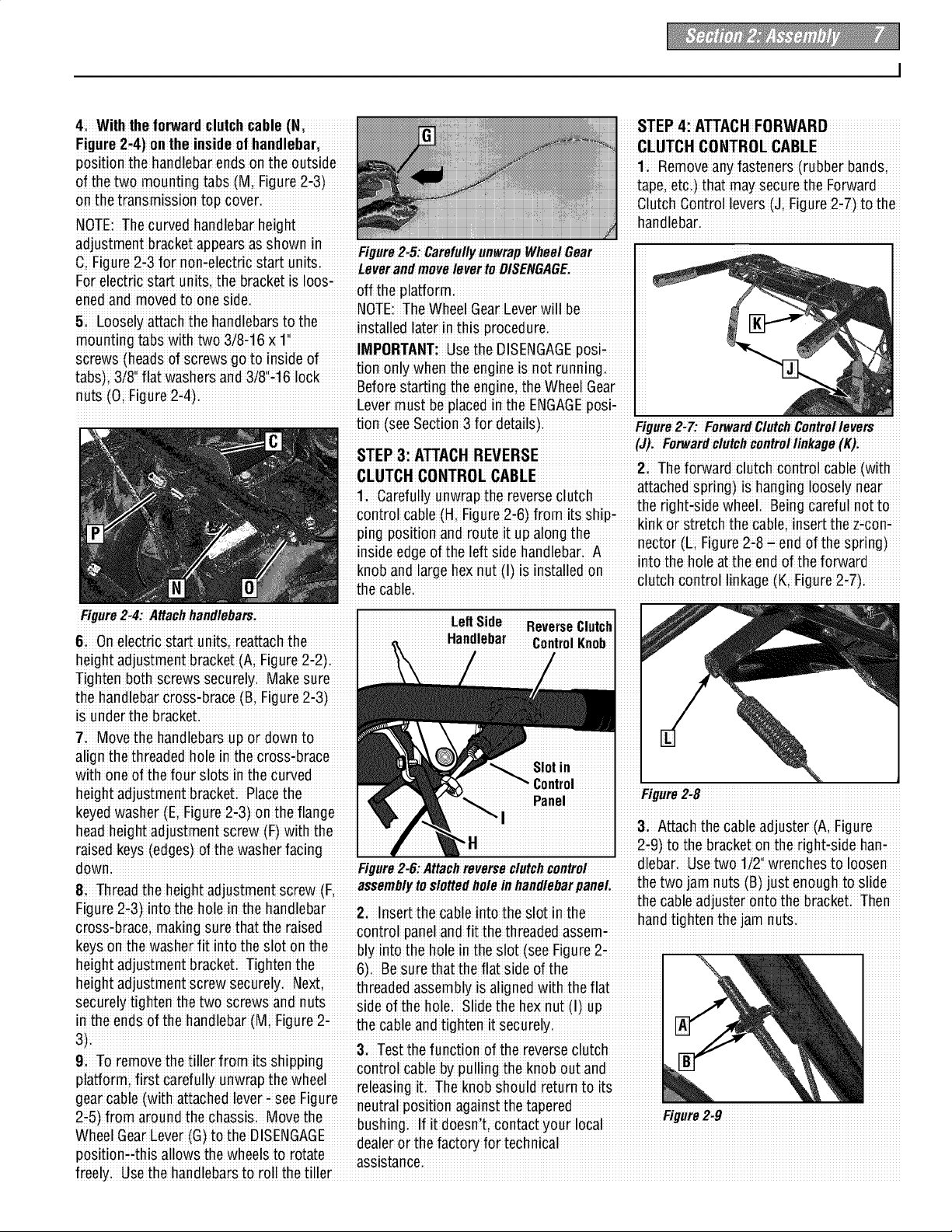

STEP2: ATTACHHANDLEBARS

1. Onelectric start units, removeone

screwand Iockwasherfrom the curved

heightadjustment bracket (A, Figure2-2),

loosenthe secondscrew,andswing the

bracketto oneside.

4_

_iiiiiiiiiiiiiii_ iii

11

iiiiii iii

Figure2-1:Loosehardware(shownin

reducedsize):

Figure2,1A Handlebarheightadjustment

usestheflange headscrewi

Figure2:2:0n electric start unitsi move

height adjustmentbracket aside:

2. Cut the large,plastic cableties that

securethe handlebar ends to the handle-

bar mounting tabs onthe transmission

top cover.

3. Gently lift handlebar(do not over-

stretch attachedcable) andplace handle-

bar cross-brace (B, Figure2-3) infront of

curved height adjustment bracket(C).

Figure2.3: Forwardclutchcontroicable not

shownforclarity.

4: Withtheforwardclutchcable(N,

Figure2-4)on the insideofhandlebar,

position the handlebarends onthe outside

ofthe two mounting tabs (M, Figure2-3)

onthe transmission top covc

NOTE:The curved handlebar height

adjustment bracketappearsasshown In Fi..ure2 5: Carefull;unwra"Wheel r

....... _.............................................. ..................... ;................. y _ , y p U_a: ..................

C; Figure2i3 for non-electric start un!tSl_everan #moveleverto

Forelectric stag units, the bracket is Ioos-of f the la_oim _

ened and movedto oneside P

' NOTE:The WheelGearLeverwill be

handlebari

5i Loosely attach the handlebarsto the installed later inins p¢oceduie I

mounting tabs with two 3/8#16×1 1 I

screws (headsof screwsgoto Inside of : ....

_,_ ._0ii_1_ _,_._ _ only when the engineis riot running

tau_.l;,_/o mw<_s,ers<_nao/o!, v,OuK'

,. _i_;;_ ,, Before starting theengine; theWheelGear

i : IMPORTANT' Usethe DISENGAGEposi.

,uL_!ui rluu_ 5i_!' Levermust be placedin the ENGAGEposii

tion (seeSection 3 for details). Figure2;7:FetwardClMcfl Controllevers

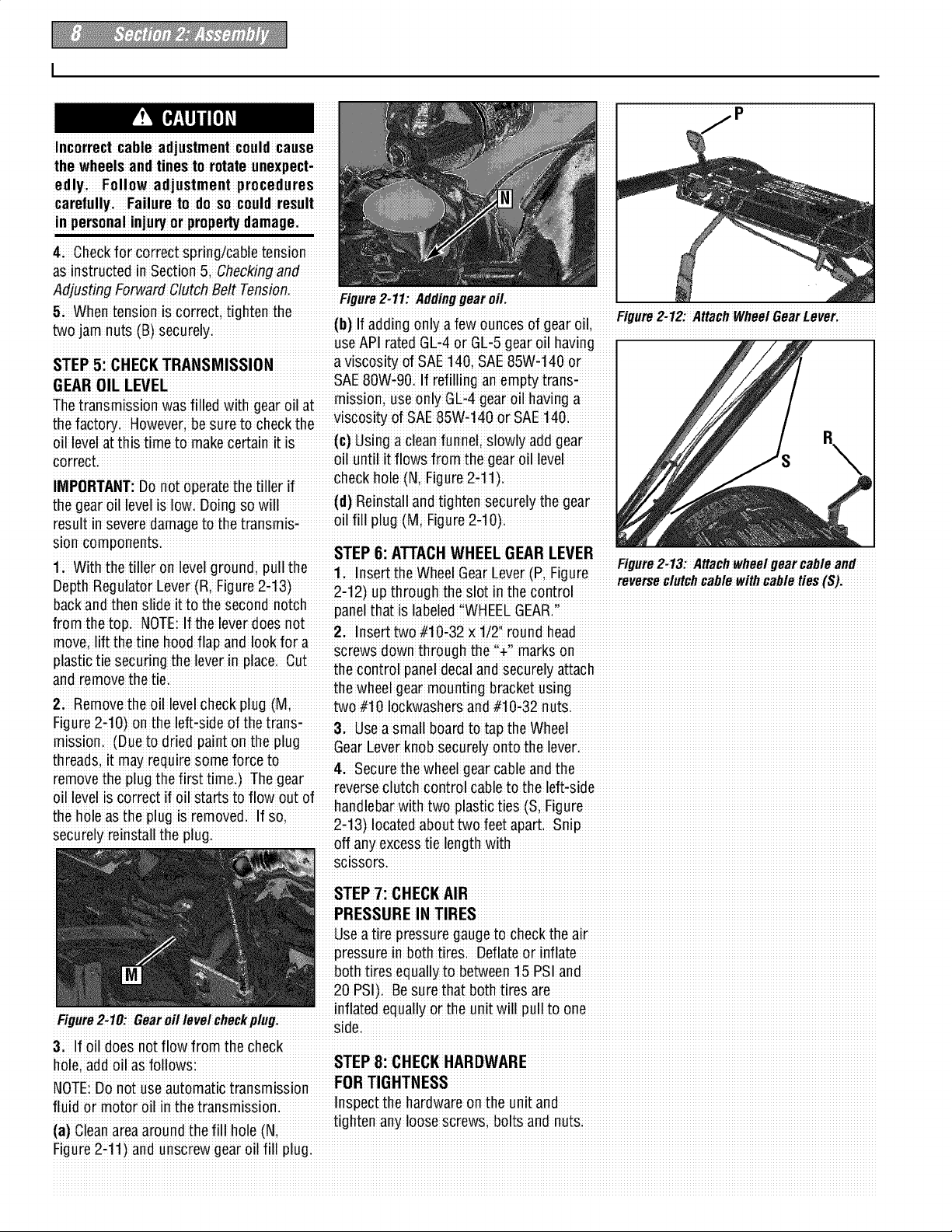

CLIITCH CONTROLCABLE 2: Theforward clUtChcontrol cable(with

STEP4: ATTACH FORWARD

CLUTCH CONTROL CABLE

1: Removeany fasteners (rubber bands;

tape, etci) that maysecurethe Forward

ClutchControl levers (JiFigure2-7)to the

control cable(H,F gure2:6)from its Sh i22 _ _i_.2_22_ _2,1 ,u :_

ping posll:lOnano rou[e i[ upalong [ne x,x..x; r=xi;, _o _ _.__., xx;i

', ;_ kink or s[reLcnthecal_,eiinset[ [l]e z-con-

inslde edgeof the left slde handlebar: A :: :_ ;

isinstalled on 'n[° me no,eal:me eno

the cable, Je(Ki Figuie2i 7)

Left Side ReverseClutch

61 Onelectric start units, reattachthe

Handlebar ControlKnob

heightadjustment bracket (A; Figure2-2)

Tighten bothscrews securelyi Makesure

the handlebarcross-brace (B; Figure2-3)

isunder the bracket.

7: Movethe handlebars u) or downto

align the threadedhole inthe cross-brace

with oneof the four slots in the curved

heightadjustment bracket: Placethe

Slotin

Control

Figure2,8

keyedwasher (E Figure2-3)onthe flange

headheightadjustment screw (F)with the 3; Attachthe cableadjuster (A; Figure

raisedkeys (edges)of thewasher facing 2-9)to the bracketonthe right-side han-

downi Figure2,6:Attach reverseclutch control !n

Thi._ih _h_inhi _rli,mtm_ni _r_w i assemblytoslottedholeinhandlebar the two jam nuts (B}jast enough to slid

Fiour'e2"3: i_o _ hole'_nthe hand eba'r' the Cableadjusteronto the bracket: Then

g-) 2i Insert the cable intothe slot in the handti, htenthe iam nuts

crossfbrace; making suie !hat !he raised coniiol paneland fii the threadedassemi

keysonthe washerfit into theslot onthe bly into the holeinthe slot (seeFigure2-

heightadjustment bracketi Tightenthe 6)Be surethat the flat side ofthe

heightadjustment screw securely. Nexti threadedassembly is aligned with theflat

securelytighten thetwo screws andnuts side of the holei Slidethe hexnut (I)up

in theends of the handlebar(Mi Figure2- the cableand tighten it securely

3)

9 To removethe tiller from its shipp ng

pla_ormi first carefully unwrap the wheel il in it TI_ h I r t rnt it

gear cable(wzth attachedlever, see Rgure :i : r

2:5) from aroundthe chassis Movethe :. Figure 2_9

_,,7 ;" _.Z_C2_.._ bushingi If It doesnt, contactyour local

wnee bear Lever_Ll_:omeu_l:i'_L1ALll: ir it h f t f r t hni I

.;idea e o e ac o_ o ec ca

...... eeas g. e obs cud eu o s

...... ...... .... neutralpositon againstthe tape ed .................................................................................

control cable bypulhngthe knob out and

pos!t!oni4h!s allowsthe wheels to rotate assistance'

freely;Use thehandlebars to roll the tiller

Incorrect cable adjustmentcouId cause

the wheels andtines to rotate unexpect-

edlyi Follow adjustment procedures

carefullyi Failure to do so could result

in personalinlu_ or prope_ damage.

4 Checkfor correct spring/cable tension

aSinstructedinSection5;Checkingand

Adjusting ForwardClutchBelt Tension. ,,, ..., __ ,,_,,, .,,, ,.,

..

5. Whentension is correct; tighten the Figure2.12: AttachWfleei Gear Lever

two iam nuts (B_securely (b)If adding only a few ounces of gearoil

_ uSeAP iaied GLi4 oi GEi5geai oil havng

STEP 5: CHECKTRANSMISSION a viscosity of SAE 140;SAE85W,140or

• : mission useonly GL,4gear oil having a...........

Thetransmiss!on was f!lled w!th gearo!lat. i., k,; _;:

the factoryi However;besure to checkthe-

VISOOSll:yOf hAL UbVV14U or bat: ]qU

oil levelatth istime to makecertainit is (c)Usi ngacleanfunnel; slowly add gear R

correct, oil until it flows from the gearoil level i

IMPORTANTiDo noi oieraie i heiiller if checkh ole(N, Figure 2-11)

the gear oil levelis Iowi going so will (d) Reinstalland tighten securelythegear

iesuli in seveie damageto thetransmisi oilfill plug (Mi Figure2-1 O)

sloncomponents.

1 With the tiller o e egou d;pu '

DepthRegulatorLe (R, F!gu e 2,12)up through the slot !n thecontrol

n I v I r n Ilth Figure2 13 Attachwheelgear cable and

v r " r utchcablewlthcab eties(S).

backand then slide it to the second notch .....

.fromthe mp NOTP If the roverdoes _i_ _C _}_i _X,_

:1 ..' i'. Insert two#_U-o/x UZ round Ilead

move, h.fttne tlne hOOdflap ano lOOK.foraii _..#X

plastictlesecurlngtheeverlnplac Cut th cntil ne I nd e reI tt h

_:.:.'e _o o pa e _aa scu ya ac

i screwsdown through the irl_o M,,

STEP6: ATTACHWHEEL GEARLEVER

1, Insert the WheelGearLever(Pi Figure i . i .

: panel that is labeled WHEELGEA&

and removeme _mi ihe wheel geai mouniing biacket using

2i Removethe oil levelCheckplug (M; two #t0 Iockwashersand #10:32 nutS:

Figure2-10)on the left-side of thetrans-3 Used small board to tad theWheel

mission. (Dueio dried paint onihe plug Gear Leverknobsecurely onto the levei.

threads itmay require some forceto

..... ...... 4 Secure the wheelgearcable and the

removethe plug the first time )The gear

: :i reverseclutch control cableto the left-side

011level is correc[ i.f Oll sEar[s £o TIOWOU£01" ;.-

_i; _ ,._; _i;_ nanaleoarWl1:nl:woplasl:lCl:les i-igure

then°iea_tu_piuui_'em°veu "Su' 2 1 Itd ottw let _

securelyreinstall the plug

. ' -3) ocaeab u o eapa 4S p

' offany excesstie length with

SClSSOrS_

STEP7: CHECKAIR

PRESSUREIN TIRES

Useatire pressuregauge to check theair

pressurein bothtire& Deflateor inflate

bothtires equally to between15PSI and

20 PSI)i Be surethat bothtires are

,,,inflated equally or the unit will pull to one

I-#gurez-Tu: _earo# mve#cnecKpmgi sidei

3; If oil doesnot flow from the check

fluid or motor oil inthe transmissioni Inspect the hardwareon the unit and

Li _'_ _ _i _ ;_ _iiiL_i_ tighten any loose Screws;bolts and nuts

(a] umanareaaround _nefin Ilo_e tin,

Figure2,11)and unscrew gear Oilfill plug:

Before operating your machinei care,

fully read and understand all safetyi

controls and operating instructions in

this Manual, the separate Engine

Owner,sManuali and on the decals on

the machinei

Failureto follow these instructionscan

resultin seriouspersonalinjury,

TILLERFEATURES

ANDCONTROLS

This section describesthe location and

function of the controls on your tiller.

Referto Section4: Operationfor detailed

operating instructions.

Practiceusing thesecontrols, withthe

engine shut off, until you understandthe

operation of the controls and feelconfi-

dentwith eachof them.

IMPORTANT:Referto the separateengine

manufacturer's EngineOwner's Manualfor

information aboutthe controls on the

engine.

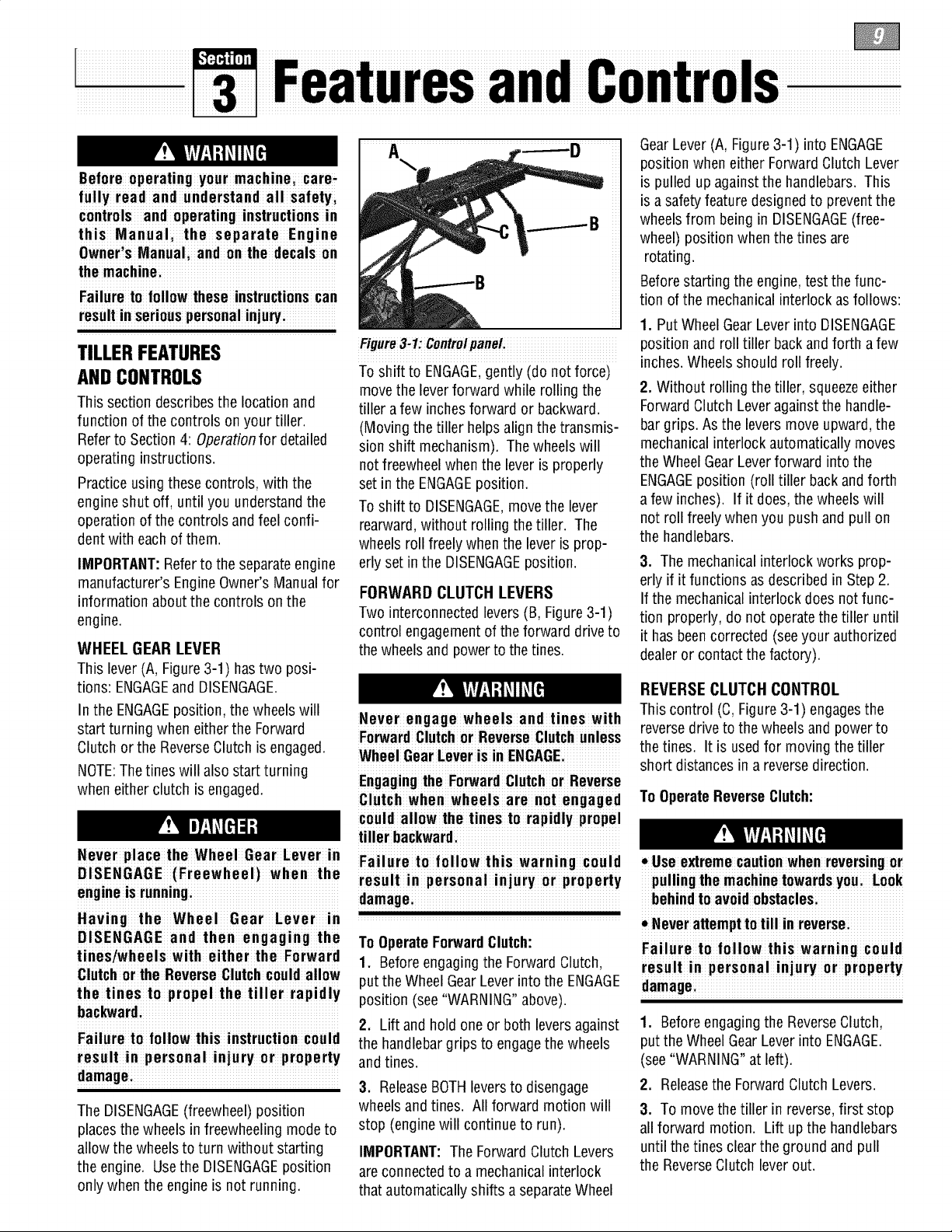

WHEEL GEAR LEVER

This lever(A, Figure3-1) hastwo posi-

tions: ENGAGEand DISENGAGE.

In the ENGAGEposition, the wheels will

start turning when either the Forward

Clutchor the ReverseClutch is engaged.

NOTE:Thetines will alsostart turning

when either clutch isengaged.

Never place the Wheel Gear Lever in F il r I II w hi w rnin I

DISENGAGE (Freewheel) when the

engme is running, damage

Having the Wheel Gear Lever in

DISENGAGE and then engaging the

tines/whe els with eithe r the Forward

Clutchor the ReverseCIutchcouId allow

the tines to propel the tiller rapidly

hac_ard:

Failure to follow thisi nstruction couId

result in personal injury or property

damagei

The DISENGAGE(freewheel) position

placesthe wheels in freewheeling mode to

allow the wheelsto turn without starting

the engine. Usethe DISENGAGEposition

only when the engine is not running.

Figure3-1:ControipaneL

To shift to ENGAGE,gently (do not force)

movethe leverforward while rolling the

tiller a few inchesforward or backward.

(Moving the tiller helps align the transmis-

sion shift mechanism). Thewheelswill

notfreewheel when the leveris properly

set inthe ENGAGEposition.

To shift to DISENGAGE,movethe lever

rearward,without rolling thetiller. The

wheels roll freelywhen the lever is prop-

erly set in the DISENGAGEposition.

FORWARD CLUTCH LEVERS

Two interconnectedlevers(B, Figure3-1)

control engagementof the forward drive to

the wheelsand power to the tines.

Never engage wheels and tines with

ForwardClutchor Reverse Clutchunless

Wheel Gear Leveris in ENGAGE:

Engagingthe Forward CIutch or Reverse

Clutch when wheelsarenotengaged

could allow the tines to rapidly propel

tiller backward.

a u eto o o t s a gcou d

result in personal injury or property

!

To OperateForwardClutch:

1. Before engagingthe Forward Clutch,

putthe Wheel GearLever intothe ENGAGE

position (see"WARNING"above).

2. Lift andhold oneor both leversagainst

the handlebargrips to engagethe wheels

and tines.

3. ReleaseBOTHleversto disengage

wheels and tines. All forward motion will

stop (enginewill continue to run).

IMPORTANT:The Forward Clutch Levers

are connectedto a mechanicalinterlock

that automaticallyshifts a separateWheel

GearLever(A, Figure3-1) into ENGAGE

position when either ForwardClutch Lever

is pulled up against the handlebars. This

isa safety feature designedto prevent the

wheelsfrom being in DISENGAGE(free-

wheel) position whenthe tines are

rotating.

Beforestarting the engine,test the func-

tion ofthe mechanicalinterlock asfollows:

1. Put WheelGearLeverinto DISENGAGE

position and roll tiller backandforth a few

inches.Wheelsshould roll freely.

2. Without rolling the tiller, squeezeeither

ForwardClutch Leveragainst the handle-

bargrips. Asthe levers move upward, the

mechanicalinterlock automatically moves

the Wheel GearLeverforward into the

ENGAGEposition (roll tiller back andforth

a few inches). If it does, the wheelswill

not roll freely whenyou pushand pull on

the handlebars.

3. The mechanicalinterlock works prop-

erly if it functions as describedin Step 2.

If the mechanical interlock does notfunc-

tion properly, do not operate thetiller until

it has beencorrected (seeyour authorized

dealer or contact the factory).

REVERSECLUTCH CONTROL

This control (C, Figure3-1) engagesthe

reversedriveto the wheels and power to

the tines. It is used for moving the tiller

short distancesin areversedirection.

To OperateReverseClutch:

• Use extremecautionwhen reversingor

pulling the machinetowardsyou Look

behindto avoidobstaclesi

• Neverattemptto till in reversei

Failure to follow this warning could

result in personal injury or property

damagei

1. Beforeengaging the ReverseClutch,

putthe WheelGearLeverinto ENGAGE.

(see"WARNING"at left).

2. Releasethe ForwardClutch Levers.

3. To movethetiller in reverse,first stop

all forward motion. Lift up the handlebars

until the tines clearthe ground and pull

the ReverseClutch lever out.

Thewheelswillrotateinareversedirec-

tionaslongastheleverisheldin

REVERSE.Tostopthewheelsandtines,

releasetheleveranditwillreturnto

NEUTRAL.Neverattemptto till while

movingin reversedirection.

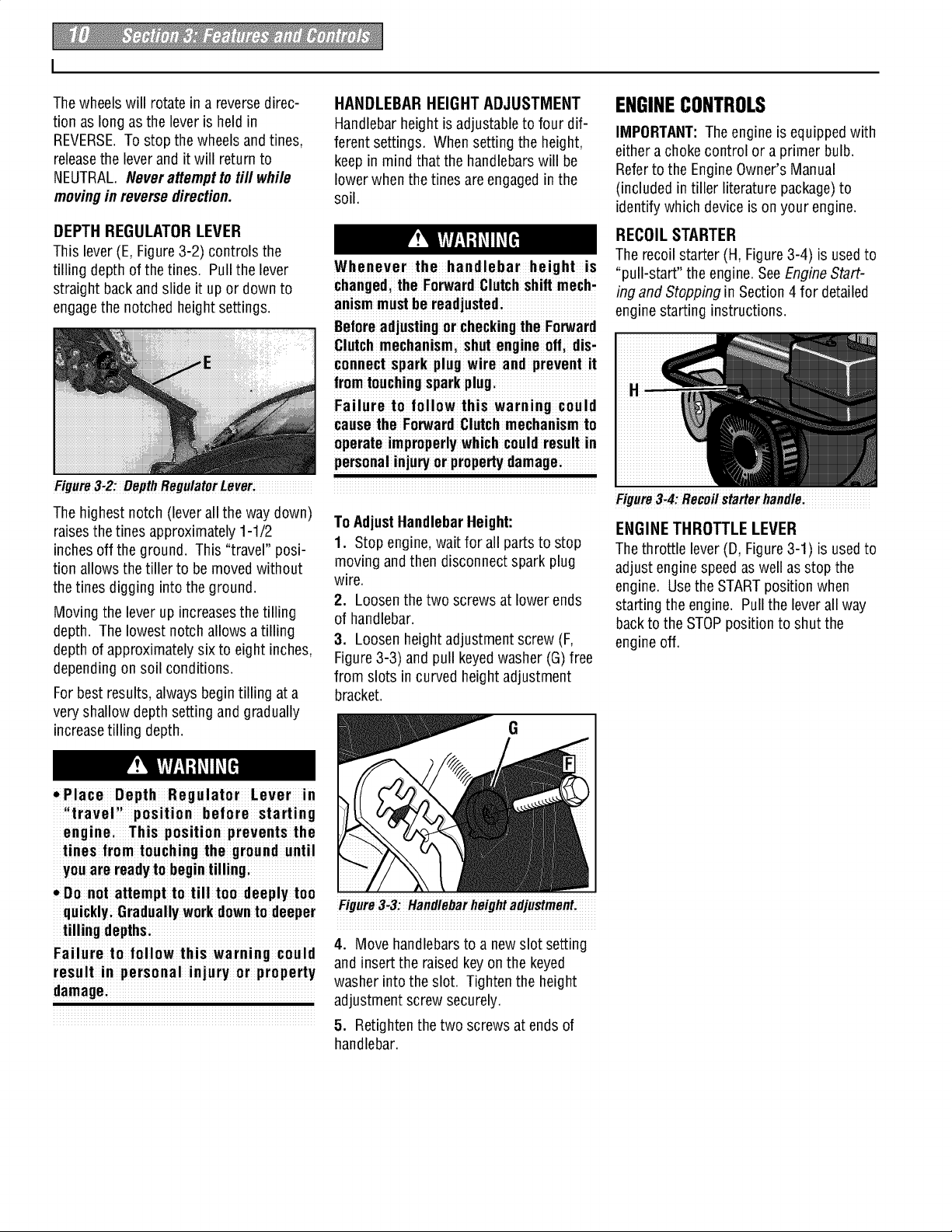

DEPTH REGULATOR LEVER

This lever (E, Figure3-2) controls the

tilling depth of thetines. Pull the lever

straight backand slide it upor down to

engagethe notched heightsettings.

Figure3-2: Depth RegulatorLever:

Thehighest notch (lever allthe waydown)

raisesthe tines approximately 1-1/2

inches off the ground. This "travel" posi-

tion allows the tiller to be moved without

thetines digging into the ground.

Moving the leverup increasesthetilling

depth. The lowest notchallows atilling

depth of approximatelysixto eight inches,

depending on soil conditions.

Forbest results, alwaysbegintilling at a

very shallow depthsetting andgradually

increasetilling depth.

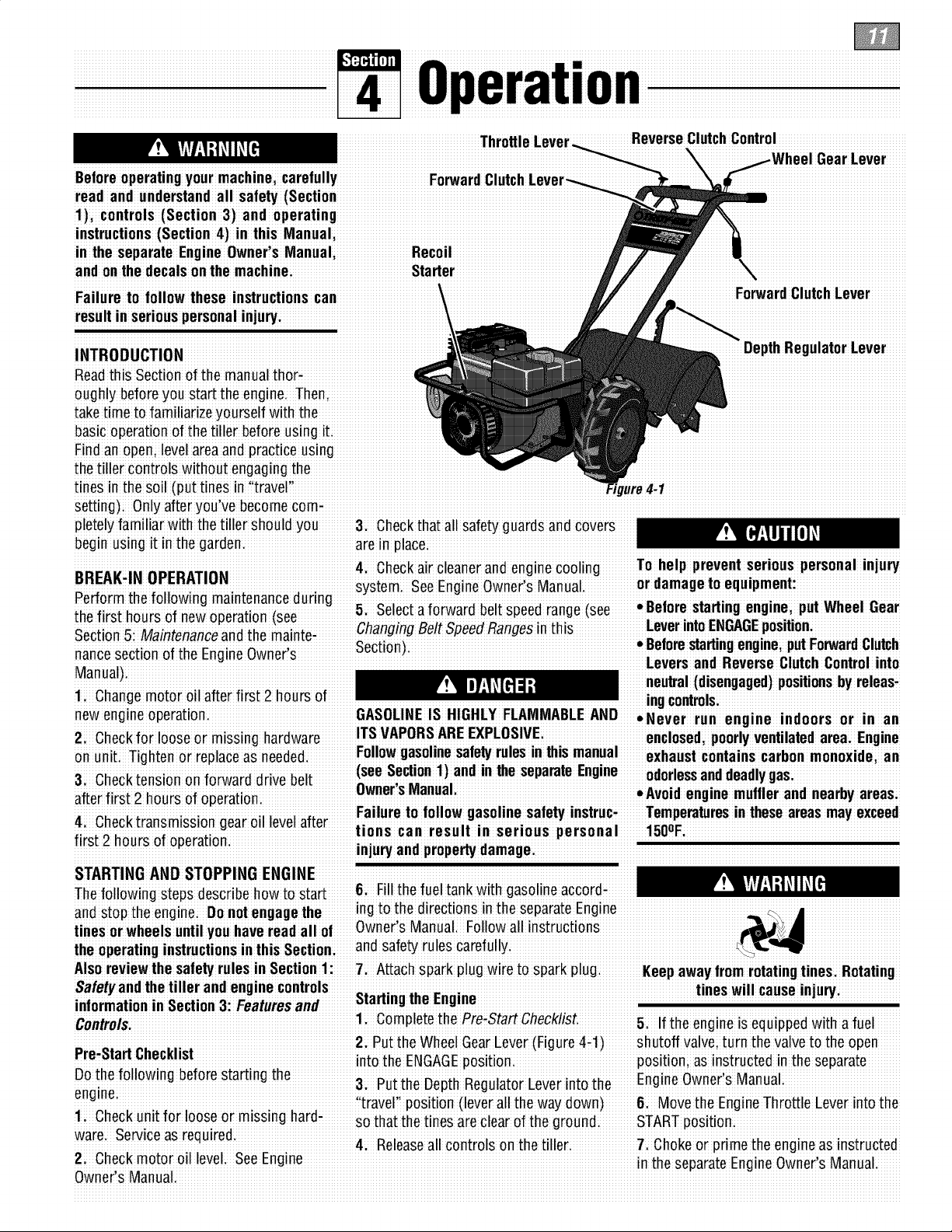

HANDLEBAR HEIGHT ADJUSTMENT

Handlebarheight is adjustableto four dif-

ferent settings. When setting the height,

keepin mind that the handlebarswill be

lower when the tines are engagedinthe

soil.

Whenever the handlebar height is

changed,the ForwardClutchshift mech,

anismmustbe readjusted:

Beforeadjustingor checkingthe Forward

Clutchmechanismi shut engine oil dis,

connectspark plug wire and prevent it

fromtouchingsparkplug:

Failureto follow this warning could

causethe ForwardClutchmechanismto

operateimproperlywhich could result in

personalinjuryor prope_y damagei

To AdjustHandlebarHeight:

1. Stop engine,wait for all parts to stop

moving and then disconnect spark plug

wire.

2. Loosen the two screws at lower ends

of handlebar.

3. Loosen heightadjustment screw (F,

Figure3-3) and pull keyedwasher (G) free

from slots incurved heightadjustment

bracket.

G

ENGINECONTROLS

IMPORTANT:The engine is equippedwith

either a choke control or a primer bulb.

Referto the EngineOwner's Manual

(included intiller literature package)to

identifywhich deviceison your engine.

RECOIL STARTER

The recoil starter (H, Figure3-4) is usedto

"pull-start" the engine. SeeEngineStart-

ing and Stopping in Section 4 for detailed

engine starting instructions.

Figure3_4:Recoilstarterhandle:

ENGINETHROTTLE LEVER

Thethrottle lever(D, Figure 3-1) is usedto

adjust enginespeedaswell as stopthe

engine. Usethe STARTposition when

starting the engine. Pullthe leverall way

backto the STOPposition to shut the

engine off.

• Place Depth Regulator Lever in

iltraveli' position before starting

enginei This position prevents the

tines from touching the ground until

youare readyto begintilling;

• Do not attempt to tilltoo deeplytoo

quicklyi Graduallywork downto deeper

tilling depthsi

Failureto follow this warning could

result in personal injury or property

damagei

Figure3_3!Handlebarheightadjustment!

4. Move handlebars to a newslot setting

and insert the raised keyonthe keyed

washer into the slot. Tighten the height

adjustment screw securely.

5. Retighten thetwo screws at endsof

handlebar.

Beforeoperatingyour machinei carefull!

read and understandalI safety (Section

1), controls(Sect ion 3) and operating

instructions (Section 4) in this Manual

in the separate EngineOwner's Manual Recoil

and onthedecalson the machine: Starter

Failure to follow these instructionscan

resuIt in seriouspersonalin]ury

Thr

ReverseClutchControl

INTRODUCTION

DepthRegulatorLever

Readthis Section ofthe manualthor

oughlybefore you start the engine. Then,

take time to familiarizeyourself with the _

basic o Fit

Findan open; levelarea and practiceusing

thetiller controls withoutengagingthe

tines inthe soil (put tines in "traver' FJ ,re4.1

Setting)i Onlyafter'you've becomecom-

pletely uardSand covers

begin using it in the garden, are m place

.r,r_,s i...r..-,-,.. 4i Checkair cleanei andenginecooling To help prevent serious personalinju_

Dnz:MA-II_ urEn_llu. System. SeeEngineOwner's Manual. or damagetoequipment:

venorm 1:neTonowmgmalm:enanceeunn0 _. Belore startin" endne "ut Wheel Gear

th_ first hm,r_ _f n_w _,r_ti_n (_, _; _e!ec_a xorwaroDe!_speeorange _see u u

Secti_5_Maintenanceandt'he mai'niei ChangingBelt SpeedRangesinthis. _e_erintoE:GAGEiP_sitionFrw r :1 ih

noncesection ofihe Engine Owneris Secti°n) L:[,°erresSZanr__eev_U_c_°C_rt_o_ ui_Cto

Manual)

i neutral(disengaged)positionsby releasi

STARTING AND STOPPING ENGINE

the operatinginstructionsinthis Section: and safetyrules carefully

Control&li Oomple!e!he PreiStartChecklist. 5: If the engine isequipped with a fuel

:::: 2:Put the WheelGearLever (Figure4-1)shutoff Valve;turnthe valve to the open

re,atan L;neCKB_SZ nto the ENGAGEposit oni positioni as instructed in theseparate

eDn°4hnef° I°win! bef°re star!ing !he & Put the Depih RegulatoiEeverinto the EngineOwnerls Manua

'iiiavelii position (leveiall the way downi 6. Moveihe EngineThiottle Eeveiinto the

1 Checkunit for looseor missing hardi Sothat thetinesareclear of the groundi STARTposition:

ware. Service as r.equired. 4. Releaseall conirols on ihe tillei 7. Chokeoi prime ihe engine as instiucted

2 Checkmotor oll level SeeEngme Rnth rt En in wn r' M n I

...... ...... esepaia!e! igiieO ie s !aiaa!.

Owner'sManual.

Loading...

Loading...