Troybilt 21A-665B063 Owner’s Manual

TRnV BILT'"

Operator's Manual

Rear, tine Tiller Model

665B

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any).

If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FROM NO. 770-10596

(11/2001)

TABLE OF CONTENTS

Content Page

Calling Customer Support .................................................... 2

Safety ................................................................... 3

Assembly ................................................................. 6

Features and Controls ....................................................... 9

Operation ................................................................ 11

Maintenance .............................................................. 15

Tiller Attachments .......................................................... 22

Troubleshooting ........................................................... 23

Parts List ................................................................. 24

Warrany Information ........................................................ Back Cover

FINDING MODEL NUMBER

This Operator's Manual is an important part of your new Rear-tine Tiller. It will help you assemble, prepare and main-

tain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the infor-

mation from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the equipment

in the space below

Copy Model Number Here

O BILT" TROY-BILT LL(

www.troybilt.com CLEVE_ND,OH_136

• 866-840-648_

P. O. BOX 361131

330-558-7220

Copy Serial Number Here

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, speci-

fications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's Manual packed sepa-

rately with your unit for more information.

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

your unit's model number and serial number ready when you call. See previous section to locate this

Call 1- (330) 558-7220 or 1- (866) 840-6483 to reach a Customer Support representative. Please have

information. You will be asked to enter the serial number in order to process your call.

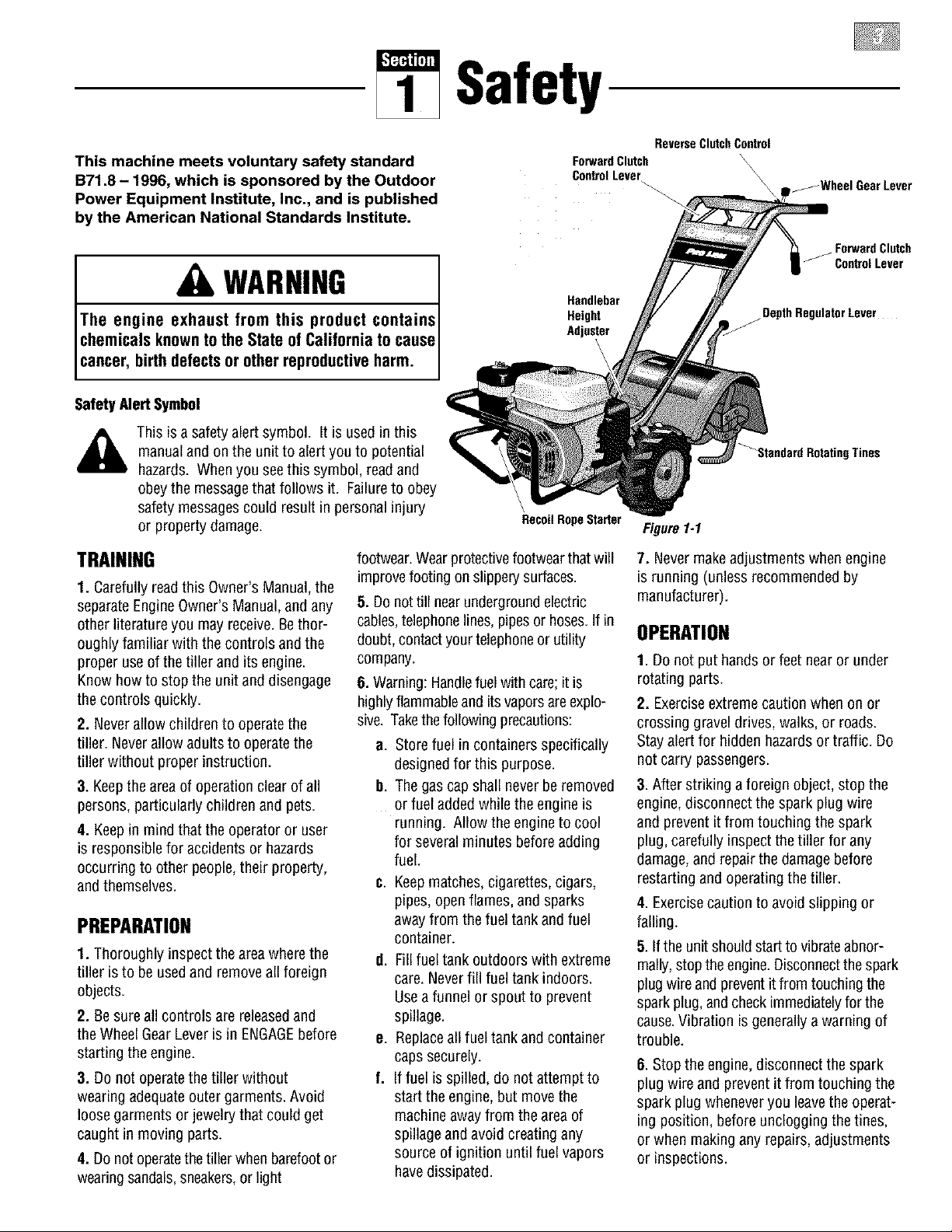

This machine meets voluntary safety standard

B71.8 - 1996, which is sponsored by the Outdoor

Power Equipment Institute, inc., and is published

by the American National Standards Institute.

WARNING

The engine exhaust from this product contains

chemicalsknowntotheStateofCaliforniato cause

cancer,birthdefectsor otherreproductiveharm.

SafetyAlert Symbol

This is a safety alert symbol. It is used inthis

manualand on the unit to alert you to potential

hazards. Whenyou seethis symbol, read and

obeythe messagethat follows it. Failureto obey

safety messagescould result in personalinjury

or propertydamage.

Safety

ForwardClutch

ControlLever

Handlebar

Height

Adjuster

\

\

Recoil Rope Starter

ReverseClutchControl

Figure1-1

\\\\\\

_Wheel Gear Lever

ForwardClutch

ControlLever

Depth Regulator Lever

J

_Standard RotatingTines

TRAINING

1. Carefullyread this Owner's Manual the

separate EngineOwner's Manual,and any

other literature you may receive. Bethor-

oughlyfamiliar with the controls andthe

proper use ofthe tiller and its engine.

Knowhow to stop the unit and disengage

the controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operate the

tiller without proper instruction.

3. Keepthe areaof operationclear ofall

persons,particularly children and pets.

4. Keepin mind that the operator or user

is responsiblefor accidentsor hazards

occurring to other people,their property,

and themselves.

PREPARATION

1. Thoroughly inspectthe areawherethe

tiller is to beusedand remove all foreign

objects.

2. Be sureall controls are releasedand

the WheelGearLeveris in ENGAGEbefore

starting theengine.

3. Do not operatethe tiller without

wearing adequateouter garments. Avoid

loosegarments or jewelry that could get

caught inmoving parts.

4. Donot operatethetiller when barefootor

wearingsandals,sneakers,orlight

footwear.Wearprotectivefootwearthatwill

improvefooting on slipperysurfaces.

5. Donottill nearundergroundelectric

cables,telephonelines,pipes or hoses.If in

doubt, contactyourtelephoneor utility

company.

6. Warning: Handlefuelwith care;it is

highlyflammableand its vaporsareexplo-

sive. Takethefollowing precautions:

a. Store fuel incontainers specifically

designedfor this purpose.

b. Thegascapshall never be removed

or fuel addedwhile the engine is

running. Allow the engineto cool

for severalminutes beforeadding

fuel.

c. Keepmatches, cigarettes, cigars,

pipes, openflames, and sparks

away from the fuel tankand fuel

container.

d. Fill fuel tank outdoorswith extreme

care. Neverfill fuel tankindoors.

Useafunnel orspout to prevent

spillage.

e. Replaceall fuel tank and container

caps securely.

f. If fuel is spilled, do not attempt to

start the engine, but movethe

machineawayfrom thearea of

spillageand avoid creatingany

source of ignition until fuel vapors

havedissipated.

7. Never makeadjustmentswhen engine

is running (unless recommended by

manufacturer).

OPERATION

1. Donot put handsor feet nearor under

rotating parts.

2. Exerciseextremecaution when onor

crossing graveldrives, walks, or roads.

Stay alert for hidden hazardsor traffic. Do

notcarry passengers.

3. After striking a foreign object, stop the

engine,disconnect the spark plugwire

and prevent itfrom touching thespark

plug,carefully inspectthetiller for any

damage,and repair the damagebefore

restartingand operating thetiller.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit shouldstart to vibrateabnor-

mally,stop theengine.Disconnectthe spark

plugwireand preventit from touchingthe

spark plug,and checkimmediatelyforthe

cause.Vibration is generallya warning of

trouble.

6. Stopthe engine, disconnect the spark

plug wire andprevent it from touching the

spark plugwheneveryou leavethe operat-

ing position, beforeunclogging the tines,

or when making any repairs,adjustments

or inspections.

7. Takeall possible precautionswhen

leavingthe machine unattended.Stop the

engine. Disconnectspark plug wire and

move it awayfrom the spark plug. Move

Wheel GearLeverto ENGAGE.

8. Beforecleaning,repairing, or inspect-

ing, stop the engineand makecertainall

moving partshavestopped.Disconnect

the spark plug wire andprevent itfrom

touching the spark plugto preventacci-

dental starting.

9. Always keepthe tiller tine hood flap

down, unless using the hiller/furrower

attachment.

10. Neveruse the tiller unless proper

guards, plates,or othersafetyprotective

devicesare in place.

11. Donot run engine in an enclosed area.

Engineexhaustcontains carbon monoxide

gas, a deadly poisonthat is odorless, col-

orless,and tasteless.

12. Keepchildren and petsaway.

13. Never operatethe tiller underengine

powerifthe Wheel Gear Lever is in DIS-

ENGAGE(FREEWHEEL).In this position,

the wheelswill notholdthe tiller back

and the revolvingtinescouldpropelthe

tiller rapidly,possiblycausinglossof

control.Alwaysmove the Wheel Gear

Leverto ENGAGEbefore starting the

engine or engaging thetines/wheelswith

ForwardClutch Control or ReverseClutch

Control.

14. Beawarethat the tiller may unexpect-

edly bounceupward or jump forward if the

tines should strike extremely hard packed

soil, frozen ground, or buried obstacles

like largestones, roots, or stumps. If in

doubt aboutthe tilling conditions, always

usethefollowing operating precautionsto

assist you in maintainingcontrol of the

tiller:

a. Walk behindandto oneside of the

tiller, usingonehand onthe han-

dlebars.Relaxyour arm, butuse a

securehandgrip.

b. Useshallowerdepthregulatorset-

tings, workinggraduallydeeper

with each pass.

c. Use slower enginespeeds.

d. Clearthe tillingarea ofall large

stones,rootsand otherdebris.

e. Avoidusingdownwardpressureon

handlebars.If needbe, useslight

upwardpressureto keepthetines

from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the endofa row, reduceengine

speedand lift handlebarsto raise

tines outofthesoil.

g. In an emergency,stoptinesand

wheels byreleasingwhichever

ClutchLever is engaged. Do not

attemptto restrainthetiller.

15. Do not overloadthe tiller's capacityby

attempting to till too deeplyat too fast a

rate.

16. Neveroperate tiller at high transport

speedson hard or slippery surfaces. Look

behind and usecare when backingup.

17. Do not operatethe tiller ona slope

that istoo steepfor safety.When on

slopes,slow down and makesure you

havegood footing. Neverpermit the tiller

to freewheel down slopes.

18. Neverallow bystandersnearthe unit.

19. Only useattachments and accessories

that areapproved by the tiller

manufacturer.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethetiller without good

visibility orlight.

22. Neveroperatethetiller ifyou aretired, or

undertheinfluenceofalcohol,drugs or

medication.

23. Operatorsshallnottamperwith the

engine-governorsettingson themachine;

the governorcontrolsthemaximumsafe

operatingspeedto protecttheengineandall

moving partsfrom damagecausedby over-

speed. Authorizedserviceshallbesought if

a problemexists.

24. Donot touch enginepartswhich may be

hotfrom operation.Letpartscooldownsuf-

ficiently.

25. Thebatteryonelectricstart modeltillers

(if soequipped)containssulfuricacid.Avoid

contactwith skin,eyes,or clothing.Keepout

ofthe reachofchildren.

Antidote-ExternalContact:Flushimme-

diatelywith lotsofwater.

Antidote-Internal:Drink largequantities

ofwater or milk. Followwith milk of mag-

nesia,beateneggs or vegetable oil. Call

a doctor immediately.

Antidote-EyeContact:Flushwith water

for 15 minutes.Getpromptmedical

attention.

26. Batteriesproduceexplosivegases.Keep

sparks,flame,andsmokingmaterialsaway.

Ventilatewhencharging batteriesor when

usinga batteryin anenclosedspace.

ALWAYSwearsafetygoggleswhenworking

nearbatteries.

27. Pleaseremember:Youcanalwaysstop

thetinesand wheelsby releasingthe

ForwardClutchControlLeverorthe Reverse

ClutchControlknob(whichevercontrolyou

haveengaged),or by movingthe engine

switch (locatedonengine)to the OFF

position.

28.To loador unloadthe tiller, seethe

instructionsin Section4 ofthis Manual.

29. Useextremecautionwhen reversingor

pullingthemachinetowardsyou.

30. Startenginecarefullyaccordingto

instructionsandwith feet awayfrom tines.

31. Neverpick upor carrya machinewhile

theengineis running.

MAINTENANCEANDSTORAGE

1. Keepthe tiller, attachments and acces-

sories in safeworking condition.

2. Checkall nuts, bolts, andscrews atfre-

quentintervals for proper tightness to be

surethe equipment is in safeworking con-

dition.

3. Neverstorethe tiller with fuel inthefuel

tank insidea buildingwhereignitionsources

are presentsuchashotwaterandspace

heaters,furnaces,clothesdryers, stoves,

electricmotors,etc. Allowengineto cool

beforestoring inany enclosure.

4. Toreducethechancesof a fire hazard,

keepthe enginefree of grass,leaves,or

excessivegrease.

5. Storegasoline inacool, well-ventilated

area,safelyawayfrom anyspark- or flame-

producingequipment. Store gasoline in an

approvedcontainer,safelyawayfrom the

reachof children.

6. Referto the storageinstructions inthe

Maintenancesection of this Manualand in

the separateEngineOwner's Manualfor

instructions if the tiller isto bestored for

an extendedperiod.

7. Never perform maintenancewhile the

engineis running or the spark plug wire is

connected,exceptwhenspecifically

instructed to doso.

8. If thefuel tank has to bedrained,do this

outdoors.

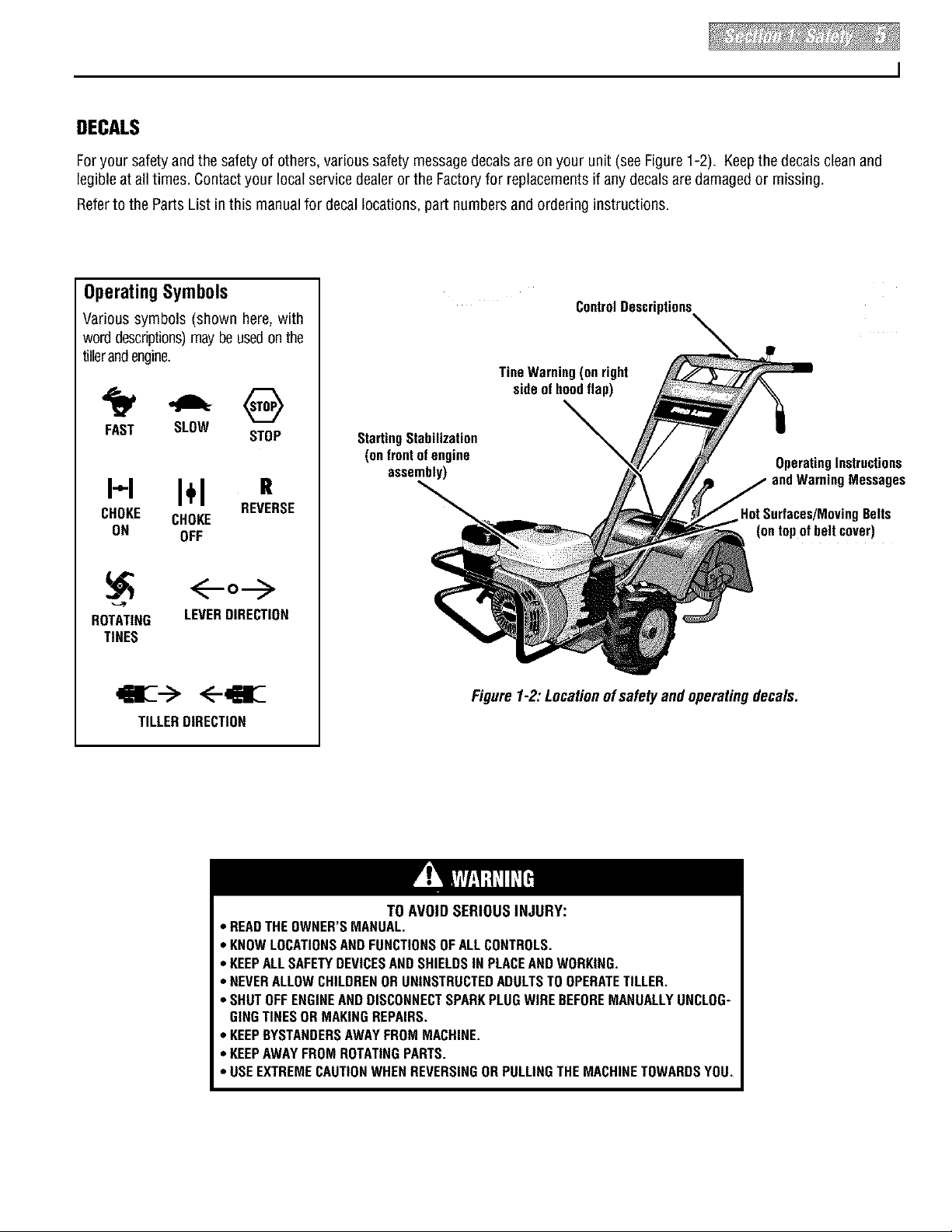

DECALS

Foryour safety and the safety of others, various safety messagedecalsare on your unit (see Figure1-2). Keepthe decalsclean and

legible at all times. Contact your local service dealer or the Factory for replacements if any decals are damaged or missing.

Refer to the Parts List in this manual for decal locations, part numbers and ordering instructions.

OperatingSymbols

Various symbols (shown here,with

word descriptions) may be used on the

tillerand engine.

FAST SLOW

STOP

H I÷1 R

CHOKE CHOKE REVERSE

ON OFF

ROTATING LEVERDIRECTION

TINES

<--qHE

TILLERDIRECTION

StartingStabilization

(onfrontofengine

assembly)

Figure1-2".Locationofsafetyand operatingdecals.

ControlDescriptions

TineWarning(onright

sideofhoodflap)

OperatingInstructions

andWarningMessages

HotSurfaces/MovingBelts

(ontopofbeltcover)

TO AVOID SERIOUS INJURY:

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALL CONTROLS.

• KEEPALL SAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIRE BEFOREMANUALLYUNCLOG-

GINGTINES ORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROM MACHINE.

• KEEPAWAY FROMROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHE MACHINETOWARDSYOU.

Assembly

HARDWARE BAG PARTS LIST

To prevent personal injury or property

damage, do notstart the engine untilall

assembly steps are complete and you

haveread and understandthe safetyand

operatinginstructionsin thisManual.

INTRODUCTION

Carefullyfollow these assembly steps to

correctly prepareyour tiller for use. It is

recommendedthat you read this Section

in itsentirety before beginning assembly.

INSPECTUNIT

Inspect the unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspect damage. Informthem ofthe

damageand requestinstructions for filing

a claim. To protect your rights, put your

claim inwriting and maila copy to the

carrier within 15days after the unit has

beendelivered. Contactus atthe factory if

you needassistance in this matter.

UNPACKINGANDASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Removeany cardboard insertsand

packagingmaterial from the carton.

Removeany staplesfrom the bottom of

the carton and remove the carton.

2. Cutthe large, plastic tie strapthat

securesthetransmission tube to the ship-

ping pallet. Leavethe handlebarson top of

the tiller to avoid damagingany cables.

3. A bagwith loose hardwareis insidethe

literature envelope. Checkthe contents

against the following list and Figure2-1.

Contactyour local dealer or the factory if

any items aremissing or damaged.

4. Thetiller is heavy. Youshould not

attempt to removeit from the shipping

platform until instructed to do so inthese

"Assembly" steps.

Fig.

Ref. Qty. Description

1 2 3/8-16x 1"Hex Hd. Screw

2 1 KeyedWasher

3 1 Wheel GearLeverKnob

4 1 HeightAdjustment Flange

Screw (SeeFigure2-1A)

5 2 3/8"FlatWasher

6 2 #10 Lockwasber

7 2 3/8"-16Nylock Lock Nut

8 2 #10-32 x 1/2" Round Hd.

Screw

9 1 CotterPin (not used)

10 4 PlasticTie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8"open-end wrench*

(2) 9/16"open-end wrench*

(1) 7/8" open-endwrench or 8"long

adjustablewrench

(1) Scissors (to trim plastic ties)

(1) Ruler

(1) Smallboard (to tap plastic knob on

lever)

(1) Tire pressure gauge

(1) Cleanoilfunnel

(1) Clean,high-quality motor oil. Referto

the separateEngineOwner's Manual

for motor oilspecifications and

quantity required.

* Adjustablewrenches maybe used.

IMPORTANT:Motor oil must beaddedto

the engine crankcasebefore the engineis

started. Followthe instructions in this

"Assembly" Section and in the separate

EngineOwner's Manual.

NOTE:LEFTandRIGHTsides of thetiller

are as viewedfrom the operator's position

behind the handlebars.

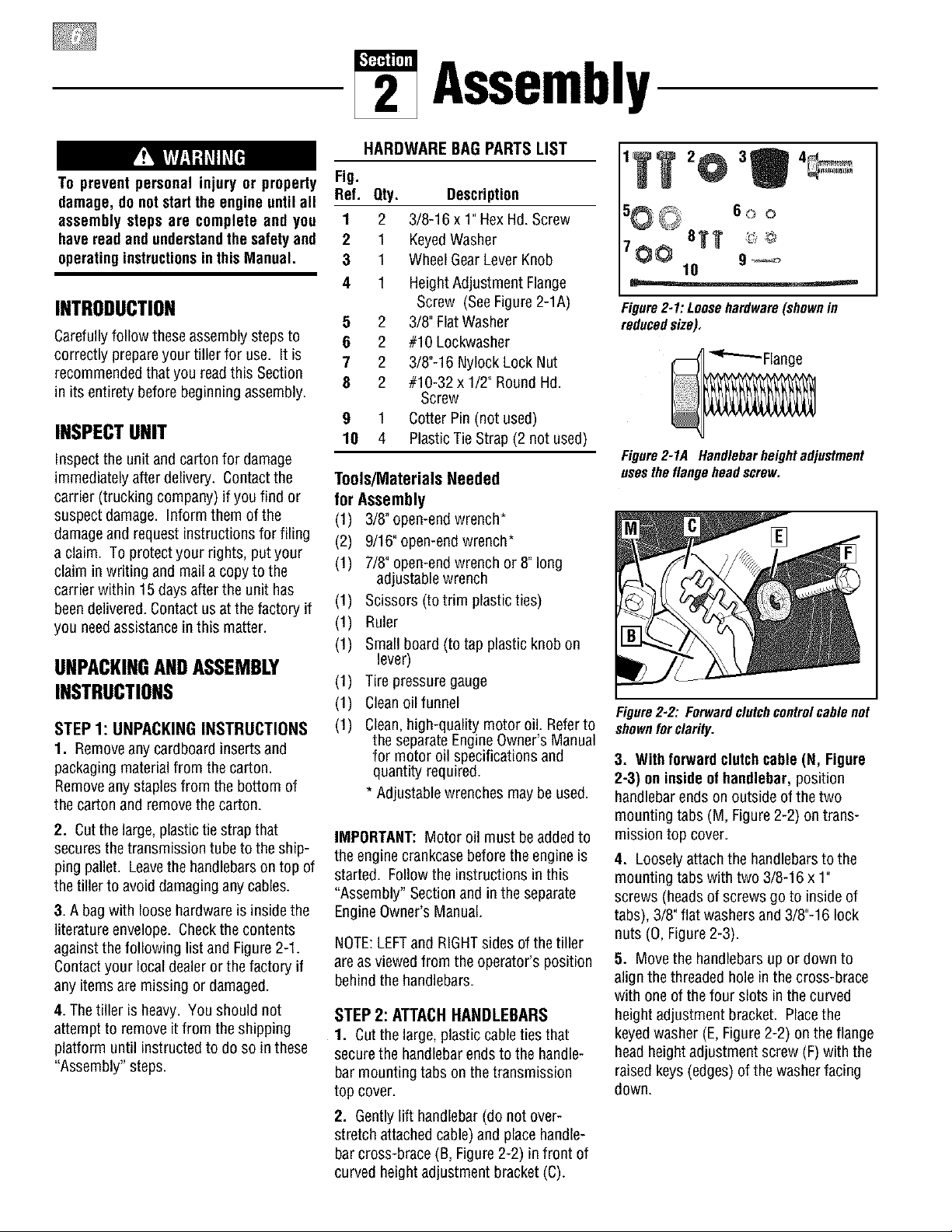

STEP 2: ATTACHHANDLEBARS

1. Cut the large,plastic cableties that

securethe handlebarendsto the handle-

bar mounting tabs on the transmission

top cover.

2. Gently lift handlebar (do not over-

stretch attached cable) and placehandle-

bar cross-brace (B, Figure2-2) in front of

curved height adjustmentbracket (C).

Figure2-1:Loosehardware(shownin

reducedsize).

Figure2-1A Handlebarheightadjustment

usestheflangeheadscrew.

Figure2-2: Forwardclutchcontrolcablenot

shownforclarity.

3. With forwardclutchcable (N, Figure

2-3) oninsideof handlebar, position

handlebarends on outside of the two

mounting tabs (M, Figure2-2) ontrans-

mission top cover.

4. Loosely attachthe handlebarsto the

mounting tabswith two 3/8-16 x 1"

screws (heads of screws goto insideof

tabs), 3/8"flat washersand 3/8"-16 lock

nuts (0, Figure2-3).

5. Move the handlebarsup or down to

align the threadedhole in the cross-brace

with oneof the four slots in the curved

heightadjustment bracket. Placethe

keyedwasher (E, Figure2-2) on theflange

headheight adjustment screw (F) with the

raisedkeys (edges) of thewasher facing

down.

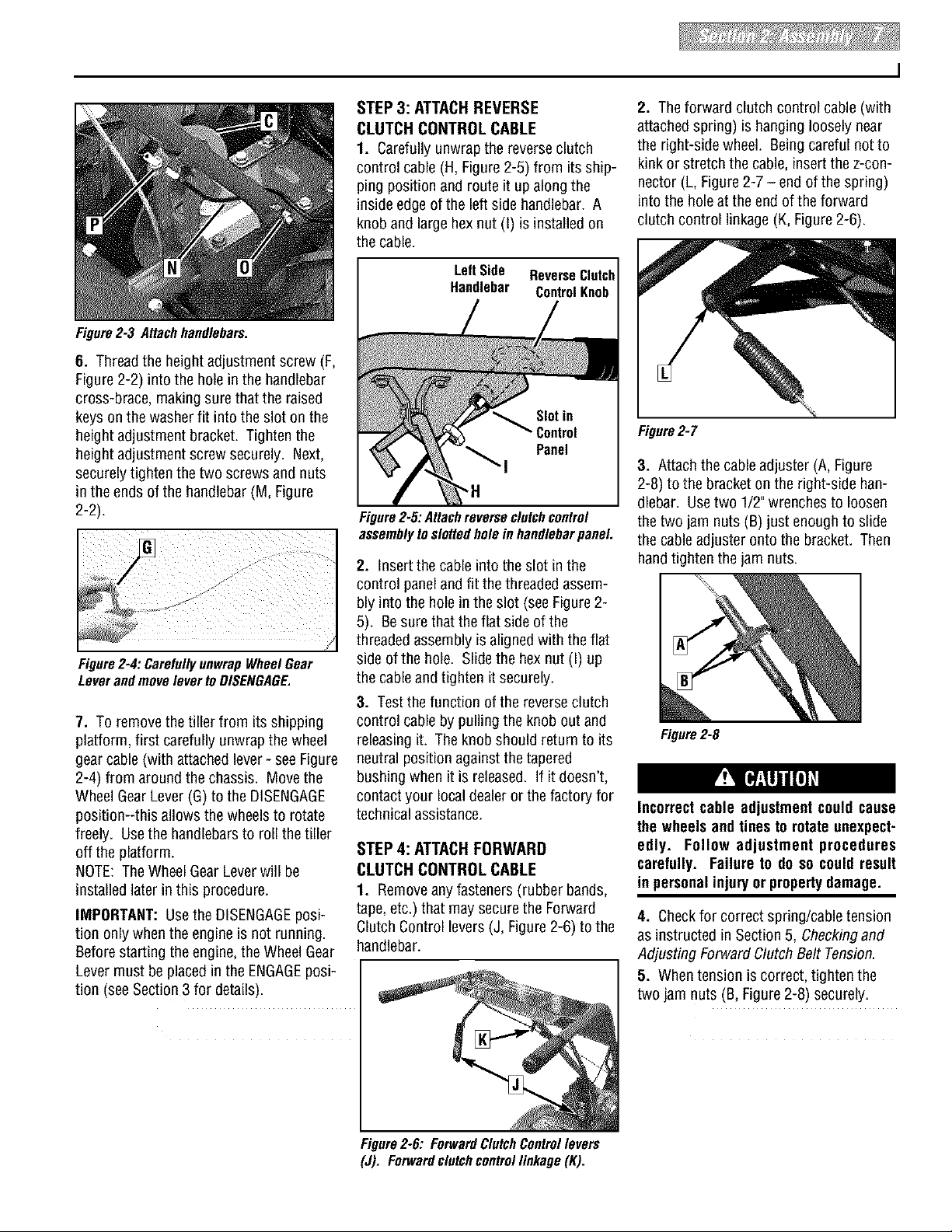

STEP 3: ATTACHREVERSE

CLUTCH CONTROL CABLE

1. Carefully unwrap the reverseclutch

control cable(H, Figure2-5) from its ship-

ping positionand route it up alongthe

inside edgeof the left side handlebar. A

knob and large hexnut (I) is installedon

the cable.

LeftSide ReverseClutch

Handlebar ControlKnob

Figure2-3 Attachhandlebars,

6. Thread the height adjustment screw (F,

Figure2-2) intothe holein the handlebar

cross-brace, making sure that the raised

keys on the washerfit into the slot on the

height adjustment bracket. Tightenthe

height adjustment screwsecurely. Next,

securelytighten the two screwsand nuts

in the endsof the handlebar (M, Figure "-H

2-2). Figure2-5: Attach reverse clutchcontrol

assemblytoslottedholeinhandlebarpanel.

2. Insert the cable intothe slot in the

control paneland fit thethreadedassem-

bly into the holein the slot (seeFigure2-

5). Besure that the flat side of the

threaded assembly is alignedwith theflat

Figure2-4:CarefullyunwrapWheelGear side ofthe hole. Slidethe hex nut (I) up

Leverandmoveleverto DISENGAGE. the cableand tighten it securely.

3. Test the function of the reverseclutch

7. To removethetiller from itsshipping control cable by pullingthe knob out and

platform,first carefully unwrapthe wheel releasing it. The knobshould return to its

gear cable (with attached lever- seeFigure neutral position against the tapered

2-4) from around the chassis. Movethe bushing when itis released. If itdoesn't,

WheelGearLever(G) to the DISENGAGE contact your localdealer or the factory for

position--thisallows the wheelsto rotate technical assistance.

freely. Usethe handlebarsto roll thetiller

off the platform. STEP 4: ATTACHFORWARD

NOTE: TheWheel GearLeverwill be CLUTCH CONTROL CABLE

installed later in this procedure. 1. Removeanyfasteners (rubber bands,

IMPORTANT: Usethe DISENGAGEposi- tape, etc.) that may securethe Forward

tion only when the engineis not running. Clutch Control levers (J, Figure2-6) to the

Beforestarting theengine,the WheelGear handlebar.

Lever must beplacedin the ENGAGEposi-

tion (seeSection 3 for details).

2. Theforward clutch control cable (with

attachedspring) is hanging loosely near

the right-side wheel. Beingcareful not to

kink or stretch the cable, insert the z-con-

nector (L, Figure2-7 - end of the spring)

into the holeatthe end of the forward

clutch control linkage (K, Figure2-6).

Figure2-7

3. Attach the cableadjuster (A,Figure

2-8) to the bracketon the right-side han-

dlebar. Usetwo 1/2"wrenches to loosen

the two jam nuts (B) just enoughto slide

the cableadjuster ontothe bracket. Then

handtighten the jam nuts.

Figure2-8

Incorrectcable adjustmentcould cause

the wheels and tines to rotate unexpect-

edly. Follow adjustment procedures

carefully. Failure to do so couldresult

in personalinjury or propertydamage.

4. Checkfor correct spring/cabletension

as instructed in Section5, Checkingand

Adjusting ForwardClutch Belt Tension.

5. When tension iscorrect, tighten the

two jam nuts (B,Figure2-8) securely.

Figure2-6: ForwardClutchControllevers

(J), Forwardclutchcontrollinkage(K).

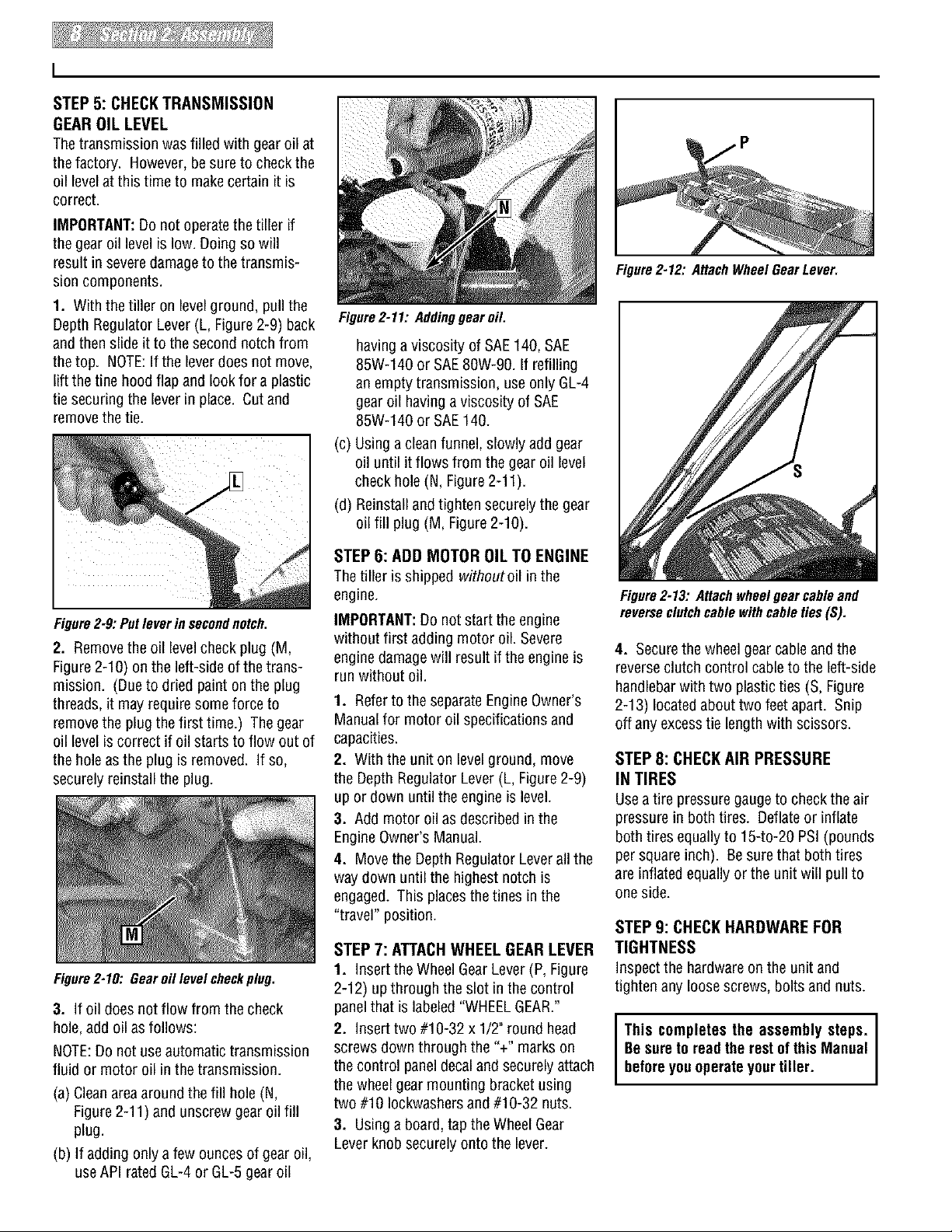

STEP 5: CHECKTRANSMISSION

GEAROIL LEVEL

Thetransmission was filled with gearoil at

the factory. However,besure to checkthe

oil levelat this time to makecertain it is

correct.

IMPORTANT:Do not operatethe tiller if

the gear oil level is low.Doing so will

result inseveredamageto the transmis-

sion components.

1. With thetiller on levelground, pull the

Depth Regulator Lever (L, Figure2-9) back

and then slide it to thesecond notch from

the top. NOTE:If the lever does not move,

lift the tine hood flap and look for aplastic

tie securing the lever in place. Cutand

removethe tie.

Figure2-12: Attach Wheel GearLever.

Figure2-11: Addinggear oil,

havinga viscosity of SAE140, SAE

85W-140 or SAE80W-90. if refilling

an empty transmission, use only GL-4

gear oil havingaviscosity of SAE

85W-140 or SAE140.

(c) Using a cleanfunnel, slowly add gear

oil until it flows from the gear oil level

checkhole (N, Figure2-11).

(d) Reinstalland tighten securely thegear

oil fill plug(M, Figure2-10).

Figure2-9:Putleverin secondnotch.

2. Removethe oil levelcheck plug (M,

Figure2-10) onthe left-side of the trans-

mission. (Dueto dried paint onthe plug

threads, it may require some force to

removethe plug thefirst time.) The gear

oil levelis correct if oil starts to flow out of

the hole asthe plug is removed. If so,

securelyreinstall the plug.

Figure2-10: Gear oil level checkplug.

3. If oil doesnot flow from the check

hole,add oil asfollows:

NOTE:Do not useautomatic transmission

fluid or motor oil in the transmission.

(a) Cleanareaaround the fill hole (N,

Figure2-11) andunscrew gearoil fill

plug.

(b) If adding only afew ouncesof gear oil,

useAPI rated GL-4 or GL-5 gearoil

STEP 6: ADD MOTOR OIL TO ENGINE

Thetiller is shipped withoutoil in the

engine.

IMPORTANT:Do notstart the engine

without first adding motor oil. Severe

engine damagewill result if the engine is

run without oil.

1. Referto the separateEngine Owner's

Manualfor motor oil specifications and

capacities.

2. With the unit on levelground, move

the DepthRegulator Lever(L, Figure2-9)

up or down until the engine is level.

3. Add motor oil asdescribed in the

EngineOwner's Manual.

4. Move the DepthRegulator Leverall the

way down until the highest notch is

engaged. This placesthetines inthe

"travel" position.

STEP 7: ATTACHWHEEL GEARLEVER

1. Insert theWheel GearLever (P, Figure

2-12) upthrough the slot in the control

panelthat is labeled"WHEELGEAR."

2. Insert two #10-32 x 1/2" round head

screws downthrough the "+" marks on

the control paneldecaland securelyattach

the wheelgear mounting bracketusing

two #10 Iockwashersand #1g-32 nuts.

3. Using a board,tap the Wheel Gear

Leverknob securely onto the lever.

Figure2-13: Attachwheelgearcableand

reverseclutchcablewithcableties(S).

4. Secure the wheelgear cableand the

reverseclutch control cableto the left-side

handlebarwith two plasticties (S, Figure

2-13) locatedabout two feetapart. Snip

off anyexcesstie lengthwith scissors.

STEP 8: CHECKAIR PRESSURE

IN TIRES

Usea tire pressuregauge to checkthe air

pressurein both tires. Deflateor inflate

bothtires equallyto 15-to-20 PSi(pounds

persquare inch). Besure that both tires

are inflated equally or the unit will pull to

one side.

STEP 9: CHECKHARDWARE FOR

TIGHTNESS

Inspectthe hardwareon the unit and

tighten any loosescrews, bolts and nuts.

This completes the assembly steps.

Besureto readtherest of thisManual

beforeyou operateyourtiller.

FeaturesandControls

Before operating your machine, care-

fully read and understand all safety,

controls and operating instructions in

this Manual, in the separate Engine

Owner's Manual, and on the decals on

the machine.

Failure to follow these instructionscan

resultin seriouspersonal injury.

INTRODUCTION

This section describesthe locationand

function of the controls on your tiller.

Referto Section 4: Operationfor detailed

operating instructions.

Practiceusing these controls, with the

engine shut off, until you understandthe

operation ofthe controls andfeel confi-

dentwith eachof them.

IMPORTANT:Referto the separateengine

manufacturer's EngineOwner's Manualfor

information aboutthe controls onthe

engine.

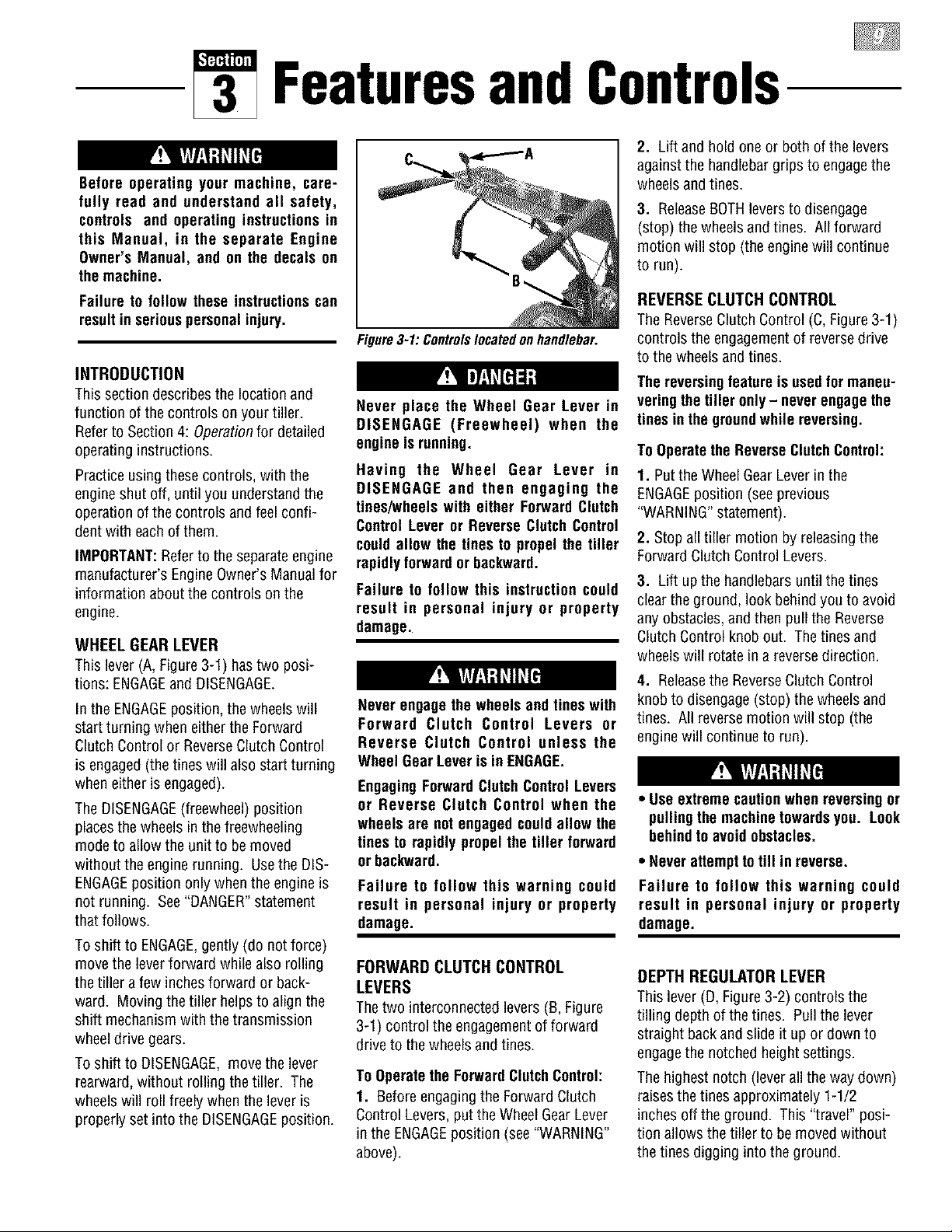

WHEEL GEAR LEVER

This lever (A,Figure 3-1) hastwo posi-

tions: ENGAGEand DISENGAGE.

In the ENGAGEposition, thewheels will

start turning when eitherthe Forward

ClutchControl or ReverseClutchControl

is engaged(the tineswill also start turning

when eitheris engaged).

TheDISENGAGE(freewheel) position

placesthe wheels in the freewheeling

modeto allow the unit to bemoved

without the enginerunning. Usethe DIS-

ENGAGEposition only when the engineis

not running. See"DANGER"statement

that follows.

Toshift to ENGAGE,gently (do not force)

move the leverforward while also rolling

thetiller a few inchesforward or back-

ward. Moving the tiller helpsto align the

shift mechanismwith thetransmission

wheeldrive gears.

Toshift to DISENGAGE,movethe lever

rearward, without rolling the tiller. The

wheelswill roll freely whenthe lever is

properly set into the DISENGAGEposition.

Figure3-1: Controlslocated on handlebar.

Never place the Wheel Gear Lever in

DISENGAGE (Freewheel) when the

engineis running.

Having the Wheel Gear Lever in

DISENGAGE and then engaging the

tines_heels with either ForwardClutch

ControlLever or ReverseClutch Control

couldallow the tines to propelthe tiller

rapidlyforwardor backward.

Failure to follow this instruction could

result in personal injury or property

damage.

Never engage the wheels andtines with

Forward Clutch Control Levers or

Reverse Clutch Control unless the

WheelGearLever is in ENGAGE.

EngagingForwardClutchControlLevers

or Reverse Clutch Control when the

wheels are notengaged couldallow the

tines to rapidly propelthe tiller forward

or backward.

Failure to follow this warning could

result in personal injury or property

damage.

FORWARD CLUTCHCONTROL

LEVERS

Thetwo interconnectedlevers(B, Figure

3-1) control the engagementofforward

drive to the wheels and tines.

To OperatetheForwardClutchControl:

1. Before engagingthe ForwardClutch

Control Levers, put the WheelGearLever

in the ENGAGEposition (see "WARNING"

above).

2. Lift and hold oneor both of the levers

against the handlebargrips to engagethe

wheels and tines.

3. ReleaseBOTHleversto disengage

(stop) the wheelsand tines. All forward

motion will stop (the enginewill continue

to run).

REVERSE CLUTCH CONTROL

The ReverseClutchControl (C,Figure3-1)

controls the engagementof reversedrive

to the wheelsand tines.

The reversingfeatureis usedfor maneu-

veringthetiller only- neverengagethe

tines in the groundwhile reversing.

To Operatethe ReverseClutchControl:

1. Putthe WheelGearLever in the

ENGAGEposition (seeprevious

"WARNING"statement).

2. Stop all tiller motion by releasingthe

ForwardClutch Control Levers.

3. Lift up the handlebars until thetines

clearthe ground, look behindyou to avoid

any obstacles,andthen pull the Reverse

ClutchControl knobout. The tines and

wheels will rotatein a reversedirection.

4. Releasethe ReverseClutchControl

knobto disengage(stop) the wheels and

tines. All reversemotion will stop (the

engine will continueto run).

• Use extreme cautionwhen reversingor

pullingthe machinetowardsyou. Look

behindto avoid obstacles.

• Neverattempttotill in reverse.

Failure to follow this warning could

result in personal injury or property

damage.

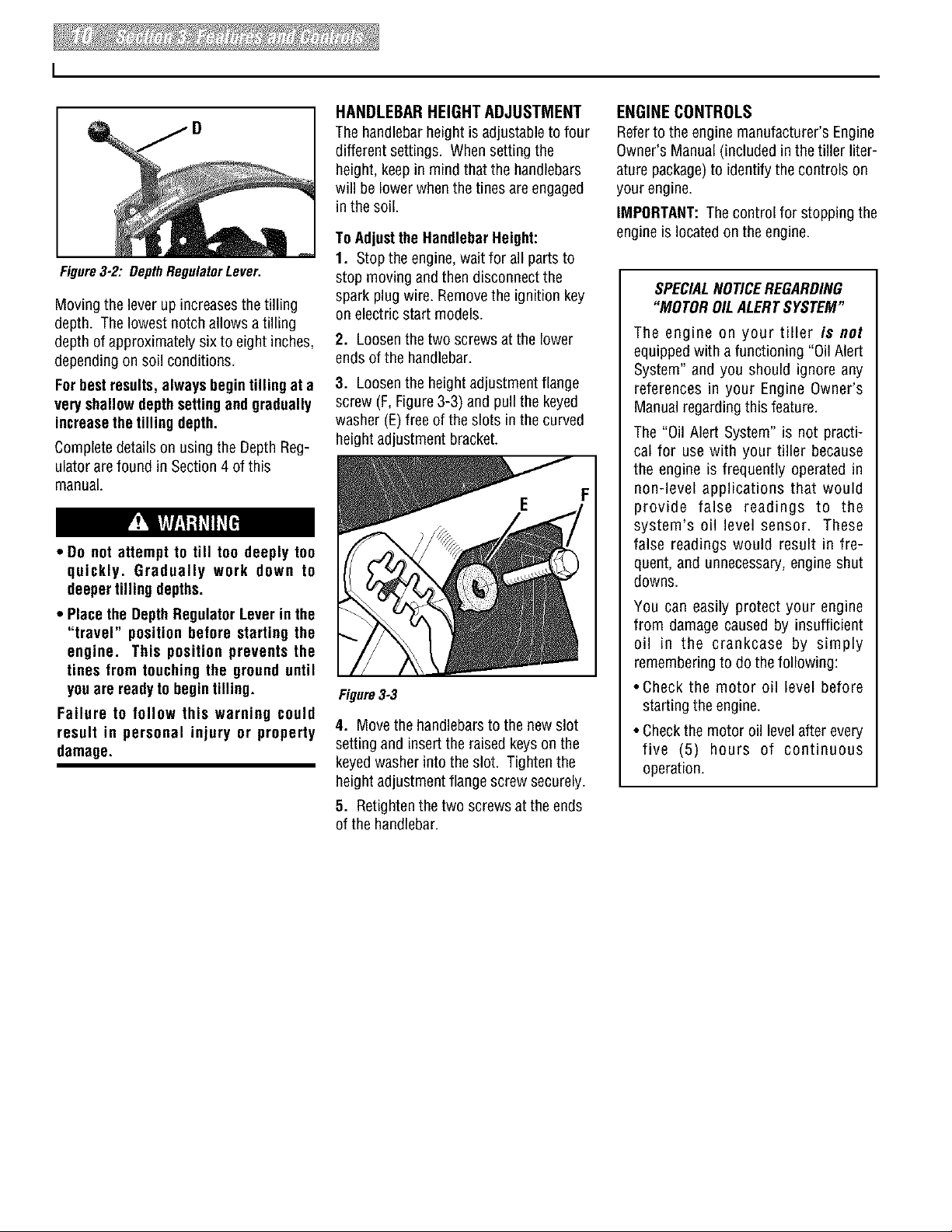

DEPTH REGULATORLEVER

This lever(D, Figure3-2) controls the

tilling depth of the tines. Pullthe lever

straight backand slide it up or down to

engagethe notched height settings.

Thehighest notch (lever all the waydown)

raisesthe tines approximately 1-1/2

inches off the ground. This "travel" posi-

tion allows the tiller to bemoved without

the tines digging into the ground.

Figure3-2: DepthRegulator Lever.

Moving the leverup increasesthe tilling

depth. The lowest notch allows atilling

depth ofapproximately six to eight inches,

dependingon soil conditions.

Forbestresults, always begintilling at a

very shallowdepth settingand gradually

increasethe tilling depth.

Completedetails on using the DepthReg-

ulator arefound in Section4 of this

manual.

• Do not attempt to till too deeply too

quickly. Gradually work down to

deepertilling depths.

• Place the DepthRegulatorLeverin the

"travel" position before starting the

engine. This position prevents the

tines from touching the ground until

youare readytobegintilling.

Failure to follow this warning could

result in personal injury or property

damage.

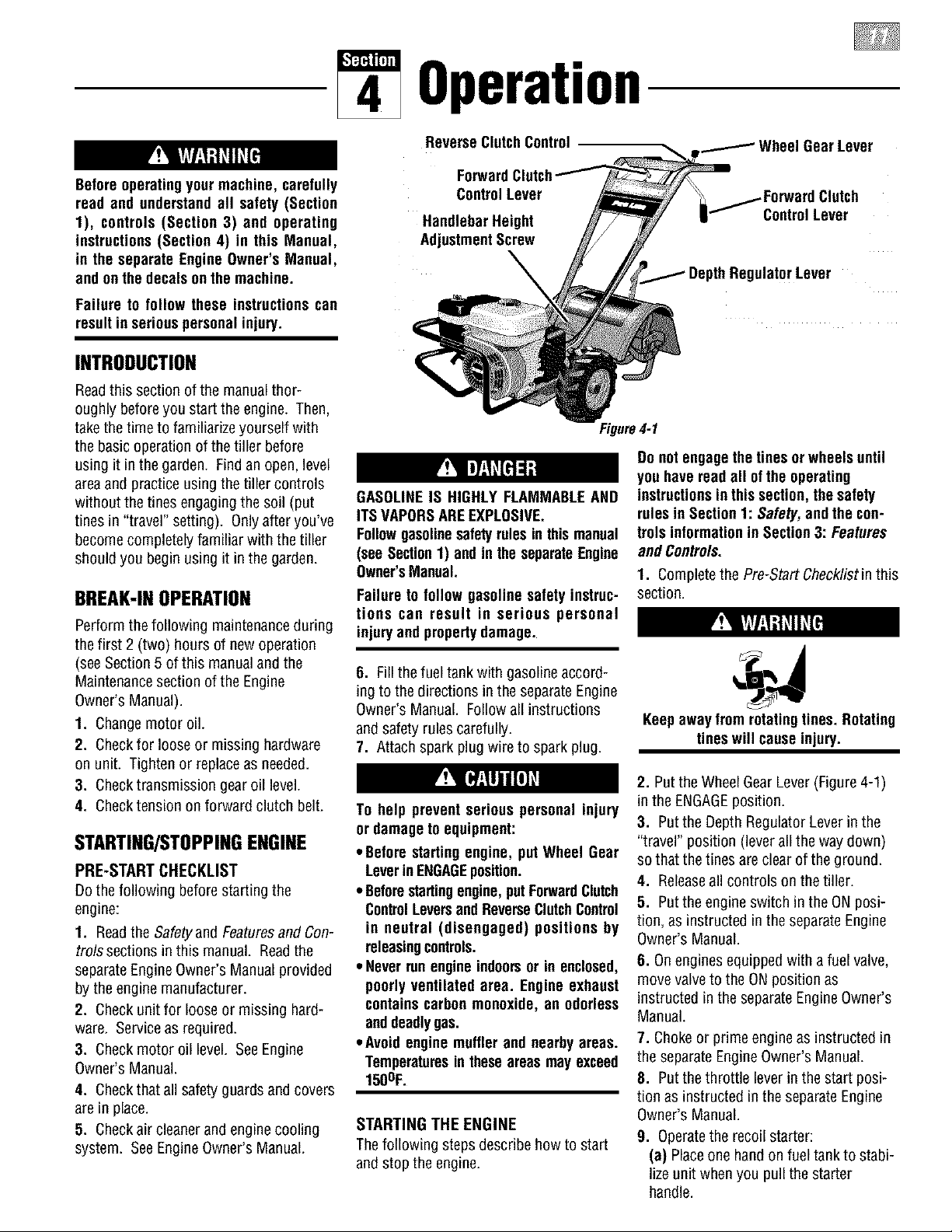

HANDLEBAR HEIGHT ADJUSTMENT

The handlebarheight is adjustable to four

different settings. When settingthe

height, keep in mind thatthe handlebars

will be lowerwhen the tines are engaged

in the soil.

To Adjustthe HandlebarHeight:

1. Stop the engine,wait for all parts to

stop moving and then disconnect the

spark plug wire. Removethe ignition key

on electric start models.

2. Loosen the two screws at the lower

ends of the handlebar.

3. Loosen the height adjustment flange

screw(F, Figure 3-3) andpull the keyed

washer (E) free of the slots in the curved

heightadjustment bracket.

Figure3-3

4. Move the handlebarsto the new slot

settingand insertthe raisedkeys on the

keyedwasher into the slot. Tighten the

heightadjustment flange screw securely.

5. Retighten the two screws at the ends

of the handlebar.

ENGINE CONTROLS

Referto theengine manufacturer's Engine

Owner's Manual(included in thetiller liter-

ature package)to identify the controls on

your engine.

IMPORTANT:The control for stoppingthe

engine is locatedon the engine.

SPECIALNOTICEREGARDING

"MOTOROILALERTSYSTEM"

The engine on your tiller is not

equipped with a functioning "Oil Alert

System" and you should ignore any

references in your Engine Owner's

Manual regarding this feature.

The "Oil Alert System" is not practi-

cal for use with your tiller because

the engine is frequently operated in

non-level applications that would

provide false readings to the

system's oil level sensor. These

false readings would result in fre-

quent, and unnecessary, engine shut

downs.

You can easily protect your engine

from damage caused by insufficient

oil in the crankcase by simply

remembering to dothe following:

• Check the motor oil level before

starting the engine.

• Checkthe motor oil levelafter every

five (5) hours of continuous

operation.

Operation

Beforeoperatingyourmachine, carefully

read and understandaii safety (Section

1), controls (Section 3) and operating

instructions(Section 4) in this Manual,

in the separate EngineOwner's Manual,

and onthedecals onthe machine.

Failure to follow these instructionscan

resultin seriouspersonalinjury.

INTRODUCTION

Readthis section of the manualthor-

oughly beforeyou start the engine. Then,

takethe time to familiarizeyourself with

the basic operation of the tiller before

using it in the garden. Findan open, level

areaand practice using the tiller controls

without the tines engagingthe soil (put

tines in "travel" setting). Onlyafter you've

becomecompletely familiar with the tiller

should you beginusing it inthe garden.

BREAK-INOPERATION

Perform the following maintenanceduring

thefirst 2 (two) hours of new operation

(seeSection 5 of this manual and the

Maintenancesection of the Engine

Owner's Manual).

1. Changemotor oil.

2. Checkfor loose or missing hardware

on unit. Tighten or replaceas needed.

3. Checktransmission gear oil level.

4. Checktension onforward clutch belt.

STARTING/STOPPINGENGINE

PRE-START CHECKLIST

Dothe following beforestarting the

engine:

1. Readthe Safetyand Featuresand Con-

trolssections in this manual. Readthe

separateEngineOwner's Manual provided

by theengine manufacturer.

2. Check unit for looseor missing hard-

ware. Serviceas required.

3. Check motor oil level. SeeEngine

Owner's Manual.

4. Checkthat all safetyguards andcovers

are in place.

5. Checkair cleanerand enginecooling

system. SeeEngineOwner's Manual.

ReverseClutchControl

ControlLever

HandlebarHeight

AdjustmentScrew

GASOLINEIS HIGHLY FLAMMABLEAND

ITSVAPORSAREEXPLOSIVE.

Followgasolinesafetyrules inthis manual

(see Section1) and in the separateEngine

Owner'sManual.

Failure to followgasoline safetyinstruc-

tions can result in serious personal

injuryandpropertydamage.

6. Fill the fuel tank with gasoline accord-

ing to the directions in the separateEngine

Owner's Manual. Followall instructions

and safety rulescarefully.

7. Attach sparkplug wire to sparkplug.

To help prevent serious personal injury

or damagetoequipment:

*Before starting engine, putWheel Gear

Leverin ENGAGEposition.

. Beforestartingengine,putForwardClutch

ControlLeversandReverseClutchControl

in neutral (disengaged) positions by

releasingcontrols.

. Neverrunengineindoorsorin enclosed,

poorlyventilated area. Engine exhaust

containscarbonmonoxide,an odorless

anddeadlygas.

*Avoid enginemuffler and nearby areas.

Temperaturesin these areas mayexceed

150OF.

STARTING THE ENGINE

Thefollowing steps describe howto start

and stop the engine.

eel Gear Lever

_Forward Clutch

ControlLever

Jlator Lever

Donotengagethe tines orwheels until

youhaveread all ofthe operating

instructionsin thissection,the safety

rulesin Section1: Safety,andthe con-

troisinformationin Section3: Features

andControls.

1. Completethe Pre-Start Checklistin this

section.

Keepawayfrom rotatingtines. Rotating

tines will causeinjury.

2. Putthe Wheel GearLever(Figure4-1)

in the ENGAGEposition.

3. Put the DepthRegulator Leverin the

"travel" position (leverall the way down)

so that the tines areclear of the ground.

4. Releaseall controls on the tiller.

5. Put the engineswitch in the ONposi-

tion, as instructed inthe separateEngine

Owner'sManual.

6. On enginesequippedwith a fuel valve,

movevalve to the ONposition as

instructed inthe separateEngineOwner's

Manual.

7. Chokeor prime engineas instructed in

the separateEngineOwner's Manual.

S. Put the throttle lever in the start posi-

tion as instructed in the separateEngine

Owner'sManual.

9. Operatethe recoil starter:

(a) Placeone handon fuel tank to stabi-

lizeunit whenyou pull the starter

handle.

Loading...

Loading...