Troybilt 21A-664D063 Owner’s Manual

'0 TRO BI£T°----

Operator's Manual

Rear-tine Tiller Model

664DmPony_

E666MmPony _

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark attester meeting applicable local or state laws (if any).

If a spark attester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, p.o. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FROM NO. 770-10597A

(11/2002)

TABLEOFCONTENTS

Content Page

Calling Customer Support .................................................... 2

Safety ................................................................... 3

Assembly ................................................................. 6

Features and Controls ....................................................... 11

Operation ................................................................ 14

Maintenance .............................................................. 20

Tiller Attachments .......................................................... 28

Troubleshooting ........................................................... 29

Parts List ................................................................. 30

Warrany Information ........................................................ Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new Rear-tine Tiller. It will help you assemble, prepare and main-

tain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the infor-

mation from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the equipment

in the space below

Copy Model Number Here

O]_II__IpD,m...]_. TROY-BILT LLC

www.troybilt.com CLEVELAND, OH 44136

P. O. BOX 361131

330-558-7220

866-840-6483

Copy Serial Number Here

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, speci-

fications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's Manual packed sepa-

rately with your unit for more information.

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

Call 1- (330) 558-7220 or 1- (866) 840-6483 to reach a Customer Support representative. Please have

your unit's model number and serial number ready when you call. See previous section to locate this

information. You will be asked to enter the serial number in order to process your call.

SafetyAlert Symbol

safety

This machine meets voluntary safety standard B71.8

- 1996, which is sponsored by the Outdoor Power

Equipment Institute, Inc., and is published by the

American National Standards Institute.

_ his isasafetyalert symbol. It is usedin this

TRAINING

1. Carefullyreadthis

Owner's Manual,the sepa-

rateEngineOwner's

Manual,and anyother literatureyou may

receive.Bethoroughly familiar with the

controls andthe proper useofthe tiller

and itsengine. Knowhow to stop the unit

and disengagethe controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adultsto operatethe

tiller without proper instruction.

3. Keepthe areaof operation clear ofall

persons,particularly children and pets.

4. Keepin mind thatthe operator or user

is responsiblefor accidents or hazards

occurring to other people,their property

and themselves.

PREPARATION

1. Thoroughly inspectthe areawherethe

tiller is to be usedand removeall foreign

objects.

2. Besure all controls are releasedand

the WheelGearLeveris in ENGAGE

beforestarting the engine.

3. Do not operatethetiller without

wearing adequateouter garments. Avoid

loosegarments or jewelry that could get

caught inmoving parts.

4. Donotoperatethetiller when barefoot

or wearing sandals,sneakers,or light

footwear.Wearprotectivefootwearthat will

improvefooting onslipperysurfaces.

manualand on the unit to alertyou to potential

hazards. Whenyou seethis symbol, readand

obeythe messagethat follows it. Failureto

obeysafety messagescould result in personal

injury or property damage.

5. Donottill nearundergroundelectric

cables,telephonelines, pipesor hoses.If in

doubt, contactyourtelephoneor utility

company.

6. Warning: Handlefuel with care; it is

highlyflammableand itsvaporsareexplo-

sive. Takethefollowing precautions:

a. Storefuel in containersspecifically

designedfor this purpose.

b. Thegascap shall neverbe removed

or fuel addedwhile the engine is

running. Allow the engineto cool

for several minutes beforeadding

fuel.

c. Keepmatches,cigarettes,cigars,

pipes, open flames, and sparks

awayfrom the fuel tankand fuel

container.

d. Fillfuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Usea funnel or spout to prevent

spillage.

e.

Replaceall fuel tankand container

caps securely.

f.

If fuel is spilled, do not attemptto

start the engine, but move the

machine awayfrom the area of

spillageand avoid creating any

source of ignition until fuel vapors

havedissipated.

7. Nevermakeadjustments when engine unclogging thetines, or when making any

is running (unless recommendedby repairs, adjustments or inspections.

manufacturer).

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

OPERATION

1. Donot put handsor feet nearor under

rotating parts.

2. Exerciseextremecaution when on or

crossing graveldrives, walks, or roads.

Stayalert for hidden hazardsor traffic. Do

not carry passengers.

3. After striking aforeign object, stop the

engine (andremovethe ignition key on

electric start models), disconnect the

spark plugwire and prevent it from

touching the spark plug,carefully inspect

the tiller for any damage,and repair the

damagebeforerestarting and operating

the tiller.

4. Exercisecaution to avoid slipping or

falling.

5. Ifthe unitshould startto vibrateabnor-

mally,stop the engine(andremovethe

ignition keyon electric start models). Dis-

connectthespark plugwire andpreventit

from touchingthe spark plug,and check

immediatelyfor thecause.Vibration is

generallya warning of trouble.

6. Stopthe engine(and removethe igni-

tion key on electric start models), discon-

nectthe spark plug wire and prevent it

from touching thespark plugwhenever

you leavethe operating position, before

7. Takeall possible precautionswhen

leavingthe machineunattended.Stopthe

engine. Removeignition key on electric

start models. Disconnect sparkplug wire

and moveit awayfrom the spark plug.

MoveWheelGear Leverto ENGAGE.

8. Beforecleaning, repairing, or inspect-

ing,stop the engine,remove the ignition

keyon electric start models,and make

certain all moving parts havestopped.

Disconnectthe spark plug wire and

preventit from touchingthe spark plug to

preventaccidentalstarting. Onelectric

start models,always removethe cable

from the negativeside (-) of the battery.

9. Always keepthe tiller tine hood flap

down, unlessusing the hiller/furrower

attachment.

10. Never usethe tiller unless proper

guards, plates,or othersafetyprotective

devicesarein place.

11. Do not run enginein an enclosed

area.Engineexhaustcontains carbon

monoxide gas,a deadly poisonthat is

odorless, colorless, and tasteless.

12. Keepchildren and pets away.

13. Never operatethe tiller under

engine powerif theWheel GearLeveris

in DISENGAGE(FREEWHEEL).In this

position,the wheelswill notholdthe

tiller backand therevolvingtines could

propelthe tiller rapidly, possibly

causinglossof control.Always movethe

WheelGearLeverto ENGAGEbefore

starting the engine or engagingthe

tines/wheelswith the ForwardClutch

Control orthe ReverseClutch Control.

14. Be aware that the tiller mayunex-

pectedlybounceupwardorjump

forwardif the tinesshouldstrike

extremelyhard packedsoil, frozen

ground,or buried obstacleslike large

stones,roots,or stumps.If in doubt

aboutthe tilling conditions,always use

thefollowingoperatingprecautionsto

assistyou in maintainingcontrolof the

tiller:

Walk behindandto oneside of the

a.

tiller, usingone handonthe han-

dlebars. Relaxyour arm, butusea

securehand grip.

b. Use shallowerdepth regulatorset-

tings, working graduallydeeper

with eachpass.

c. Useslowerenginespeeds.

d. Clearthe tilling area ofall large

stones,rootsandotherdebris.

e. Avoidusingdownwardpressure

on handlebars.If needbe, use

slightupwardpressureto keepthe

tines from diggingtoo deeply.

f. Beforecontactinghardpackedsoil

at the endof a row, reduceengine

speedand lift handlebarsto raise

tines out of the soil.

g. In an emergency,stoptinesand

wheels by releasing whichever

ClutchLever is engaged. Donot

attemptto restrainthetiller.

15. Do not overloadthetiller's capacity

by attempting to till too deeplyattoo fast

a rate.

16. Neveroperate thetiller at high trans-

port speeds on hardor slippery surfaces.

Look behind and use carewhen backing

up.

17. Do not operatethe tiller on a slope

that istoo steepfor safety.When on

slopes,slow down and makesureyou

havegood footing. Never permit the tiller

to freewheel down slopes.

18. Neverallow bystanders nearthe unit.

19. Onlyuseattachments and acces-

sories that areapproved bythe tiller

manufacturer.

20. Usetiller attachments and acces-

sories when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethetiller ifyouaretired,

or undertheinfluenceof alcohol,drugs or

medication.

23. Operatorsshallnottamperwith the

engine-governorsettingsonthe machine;

the governorcontrolsthemaximumsafe

operatingspeedto protecttheengineand

all movingpartsfrom damagecausedby

overspeed.Authorizedserviceshallbe

soughtif a problemexists.

24. Donottouch enginepartswhich may

be hotfrom operation.Letpartscool down

sufficiently.

25. Thebatteryon electricstart modeltillers

containssulfuricacid.Avoidcontactwith

skin,eyes,or clothing.Keepoutof the

reachof children.

Antidote-External Contact:Flushimme-

diatelywith lotsof water.

Antidote-Internal: Drinklargequantities

ofwateror milk.Followwith milk of

magnesia,beateneggs or vegetableoil.

Calla doctor immediately.

Antidote-EyeContact:Flushwith water

for 15 minutes.Getpromptmedical

attention.

26. Batteriesproduceexplosivegases.Keep

sparks,flame,andsmoking materialsaway.

Ventilatewhencharging batteriesor when

usinga batteryinanenclosedspace.

ALWAYSwearsafetygoggleswhen

working nearbatteries.

27. Pleaseremember:Youcanalwaysstop

thetines andwheelsby releasingthe

ForwardClutchControlLeverorthe

ReverseClutchControlknob(whichever

control you haveengaged),or by moving

the EngineThrottleControlLever(located

onengine)to STOPon recoilstart models

or by turning the ignitionkeyto OFFon

electricstartmodels.

28. To loador unloadthetiller, seethe

instructionsinSection4 ofthis Manual.

29. Useextremecautionwhen reversingor

pullingthemachinetowardsyou.

30. Starttheenginecarefullyaccordingto

instructionsandwith feetwellawayfrom

thetines.

31. Neverpick up or carrya machinewhile

theengineis running.

MAINTENANCEANDSTORAGE

1. Keepthe tiller, attachments and acces-

sories insafe working condition.

2. Checkall nuts, bolts, andscrews at

frequent intervalsfor proper tightness to

besure the equipment is in safeworking

condition.

3. Neverstorethe tillerwith fuel inthefuel

tank insidea buildingwhere ignition

sourcesare presentsuchas hotwaterand

spaceheaters,furnaces,clothesdryers,

stoves,electric motors,etc. Allow engineto

cool beforestoring inanyenclosure.

4. To reducethe chancesof a fire

hazard,keeptheenginefree of grass,

leaves,orexcessivegrease.

5. Storegasolinein acool, well-venti-

latedarea, safelyawayfrom anyspark-

or flame-producingequipment. Store

gasolinein an approved container,

safelyawayfrom the reach of children.

6. Referto the Maintenancesectionof

this Manualand in the separateEngine

Owner's Manualfor instructions if the

tiller isto bestored for an extended

period.

7. Neverperform maintenancewhile

the engineis running orthe spark plug

wire is connected,exceptwhenspecifi-

cally instructed to do so.

8. If thefuel tankhasto bedrained,do

this outdoors.

OperatingSymbols

Various symbols (shown here, with

word descriptions)maybe usedonthe

tillerandengine.

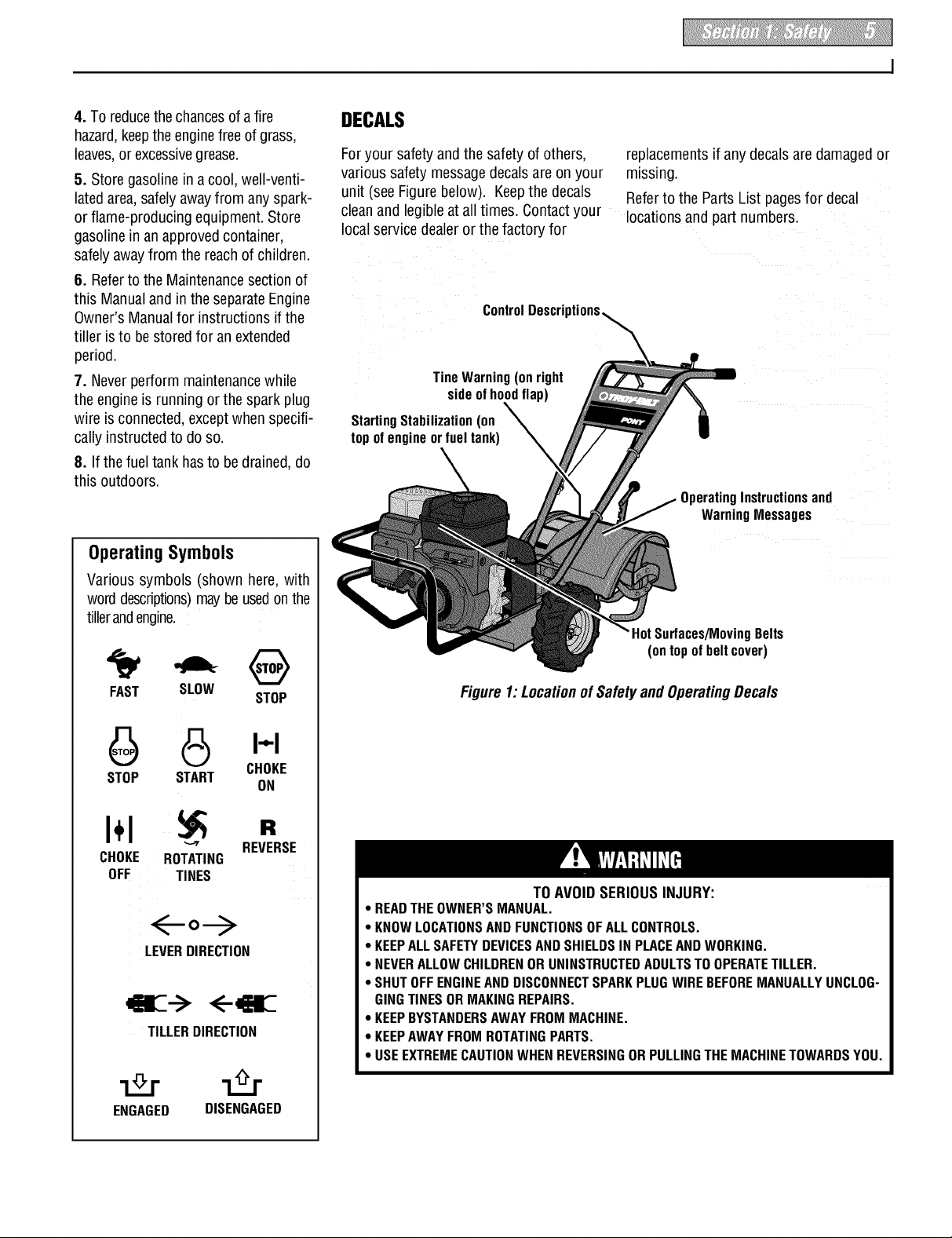

DECALS

Foryour safetyand the safety of others, replacementsif any decalsare damagedor

various safety messagedecalsare on your missing.

unit (seeFigurebelow). Keepthe decals Referto the Parts List pagesfor decal

cleanand legibleat all times. Contactyour locations and partnumbers.

localservicedealer or the factoryfor

ControlDescri

TineWarning (onright

side of hoodflap)

StartingStabilization (on

top of engine or fuel tank)

OperatingInstructionsand

WarningMessages

/MovingBelts

(ontopofbeltcover)

FAST SLOW

STOP

6 I-'-I

STOP START

CHOKE

ON

I÷1

CHOKE ROTATING

OFF TINES

o--.>

LEVERDIRECTION

TILLERDIRECTION

ENGAGED DISENGAGED

REVERSE

<--

Figure 1:Locationof SafetyandOperatingDecals

R

TO AVOID SERIOUS INJURY:

• READTHEOWNER'S MANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUNCLOG-

GINGTINESOR MAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHEN REVERSINGORPULLINGTHEMACHINETOWARDSYOU.

2 Assembly

HARDWARE BAG PARTSLIST

To prevent personal injury or property

damage,do notstartthe engine until all

assembly steps are complete and you

havereadand understandthe safetyand

operatinginstructionsin this Manual.

INTRODUCTION

Carefullyfollow theseassembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety before beginningassembly.

INSPECTUNIT

Inspectthe unit andcarton for damage

immediatelyafter delivery. Contactthe

carrier (trucking company) ifyou find or

suspect damage. Inform them ofthe

damageand request instructions for filing

a claim. To protectyour rights, put your

claim inwriting and mail a copy to the

carrier within 15 days after the unit has

beendelivered.Contact us at the factory if

you needassistancein this matter.

UNPACKINGANDASSEMBLY

INSTRUCTIONS

STEP 1: UNPACKING INSTRUCTIONS

1. Removeanycardboard inserts and

packagingmaterialfrom the carton.

Removeany staples from the bottom of

the carton and removethe carton.

2. Cutthe large,plastictie strap that

securesthe transmission tubeto the ship-

ping pallet. Leavethe handlebarson top

of the tiller to avoid damaginganycables.

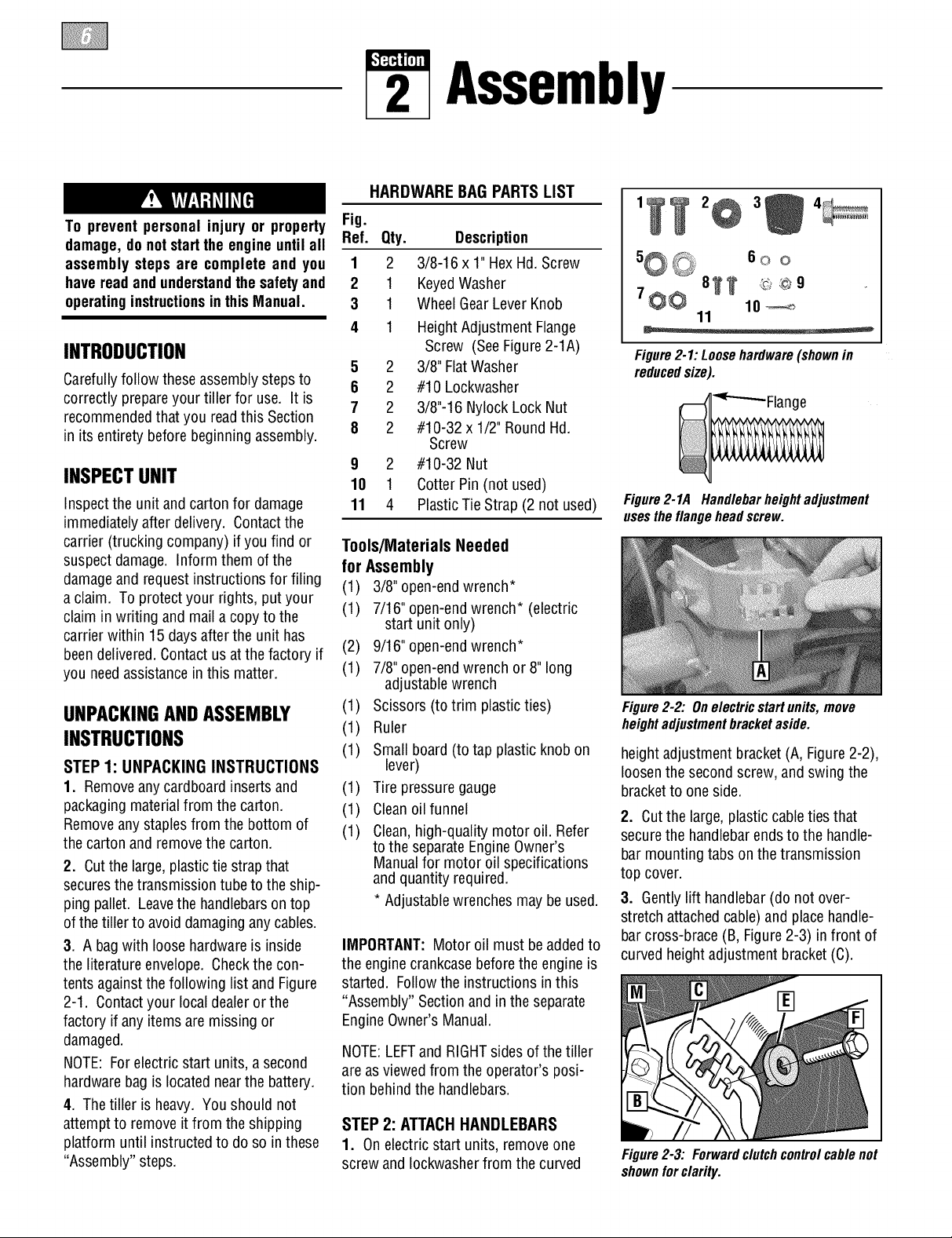

3. A bag with loose hardware is inside

the literature envelope. Checkthe con-

tents against thefollowing list and Figure

2-1. Contactyour local dealeror the

factory if any items aremissing or

damaged.

NOTE:Forelectric start units, a second

hardwarebag is located nearthe battery.

4. The tiller is heavy. You should not

attempt to remove it from theshipping

platform until instructed to do so in these

"Assembly" steps.

Fig.

Ref. Qty. Description

1 2 3/8-16 x 1" HexHd. Screw

2 1 KeyedWasher

3 1 WheelGearLeverKnob

4 1 Height Adjustment Flange

Screw (SeeFigure 2-1A)

5 2 3/8" FlatWasher

6 2 #10 Lockwasher

7 2 3/8"-16 Nylock Lock Nut

8 2 #10-32 x 1/2" Round Hd.

Screw

9 2 #10-32 Nut

10 1 Cotter Pin (not used)

11 4 PlasticTie Strap (2 not used)

Tools/Materials Needed

for Assembly

(1) 3/8" open-endwrench*

(1) 7/16" open-endwrench* (electric

start unit only)

(2) 9/16" open-endwrench*

(1) 7/8" open-endwrench or 8" long

adjustable wrench

(1) Scissors(to trim plasticties)

(1) Ruler

(1) Small board (to tap plastic knob on

lever)

(1) Tire pressuregauge

(1) Cleanoilfunnel

(1) Clean,high-quality motor oil. Refer

to the separateEngineOwner's

Manualfor motor oil specifications

and quantity required.

* Adjustablewrenches may be used.

IMPORTANT:Motor oil must beaddedto

the enginecrankcasebeforethe engine is

started. Followthe instructions in this

"Assembly" Sectionand inthe separate

EngineOwner's Manual.

NOTE:LEFTandRIGHTsides of thetiller

are as viewedfrom the operator's posi-

tion behindthe handlebars.

STEP 2: ATTACHHANDLEBARS

1. On electric start units, removeone

screw and Iockwasherfrom the curved

5@_, 60 o

8_ @©9

7_ 10_

11

Figure2-1:Loosehardware(shownin

reducedsize).

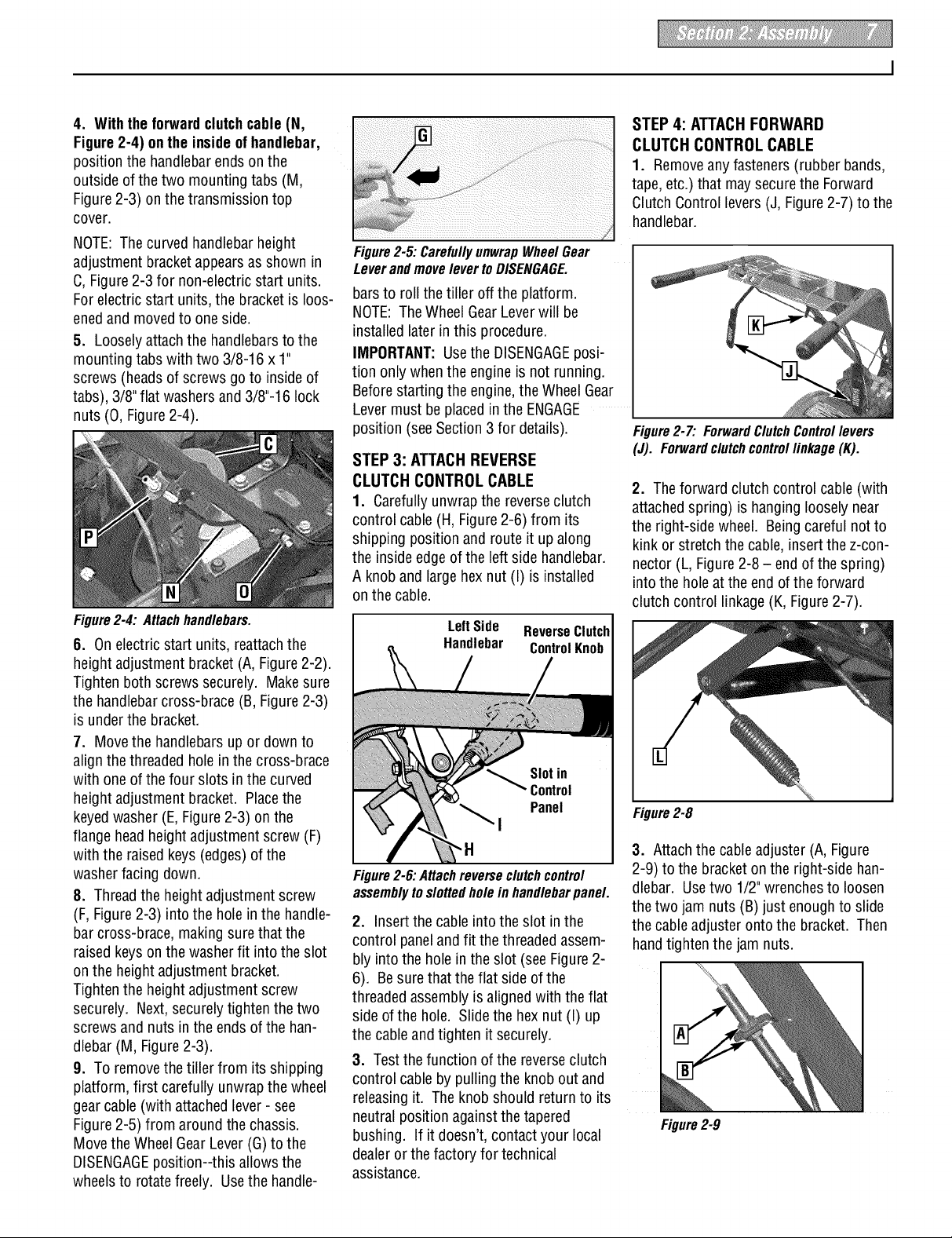

Figure2-1A Handlebarheightadjustment

usestheflangeheadscrew.

Figure2-2: Onelectric start units, move

heightadjustmentbracket aside.

heightadjustment bracket (A, Figure2-2),

loosenthe secondscrew, andswing the

bracketto one side.

2. Cutthe large, plastic cableties that

securethe handlebarendsto the handle-

bar mounting tabs on the transmission

top cover.

3. Gently lift handlebar (do not over-

stretch attached cable) and placehandle-

bar cross-brace (B, Figure2-3) in front of

curved height adjustment bracket (C).

Figure2-3: Forwardclutchcontrolcable not

shownfor clarity.

4. With the forwardclutchcable (N,

Figure2-4) onthe inside of handlebar,

position the handlebarendson the

outside of thetwo mounting tabs (IVI,

Figure2-3) on the transmission top

cover.

NOTE:Thecurved handlebarheight

adjustment bracketappears asshown in

C,Figure2-3 for non-electricstart units.

Forelectricstart units, the bracket is loos-

ened and moved to one side.

5. Loosely attachthe handlebars to the

mounting tabs with two 3/8-16 x 1"

screws (headsof screws go to insideof

tabs), 3/8" flat washersand 3/8"-16 lock

nuts (0, Figure2-4).

Figure 2-4: Attachhandlebars.

6. Onelectric start units, reattach the

heightadjustment bracket(A, Figure2-2).

Tighten both screws securely. Makesure

the handlebarcross-brace (B, Figure2-3)

is under the bracket.

7. Move the handlebarsup or down to

align the threaded hole in the cross-brace

with one of thefour slots in the curved

heightadjustment bracket. Placethe

keyedwasher (E,Figure2-3) on the

flange head heightadjustment screw (F)

with the raisedkeys(edges) of the

washer facing down.

8. Threadthe height adjustment screw

(F, Figure2-3) into the hole in the handle-

bar cross-brace, makingsure that the

raisedkeyson the washer fit into theslot

on the height adjustment bracket.

Tighten the heightadjustment screw

securely. Next,securely tighten the two

screws andnuts in the endsof the han-

dlebar (M, Figure2-3).

9. To removethe tiller from its shipping

platform, first carefully unwrap the wheel

gear cable (with attachedlever - see

Figure2-5) from around the chassis.

Movethe Wheel GearLever (G)to the

DISENGAGEposition--this allows the

wheels to rotatefreely. Usethe handle-

Figure2-5: CarefullyunwrapWheelGear

LeverandmovelevertoDISENGAGE.

barsto roll thetiller off the platform.

NOTE:TheWheelGearLever will be

installed later inthis procedure.

IMPORTANT: Usethe DISENGAGEposi-

tion only when the engine is not running.

Beforestarting the engine,the Wheel Gear

Levermust be placed inthe ENGAGE

position (seeSection 3 for details).

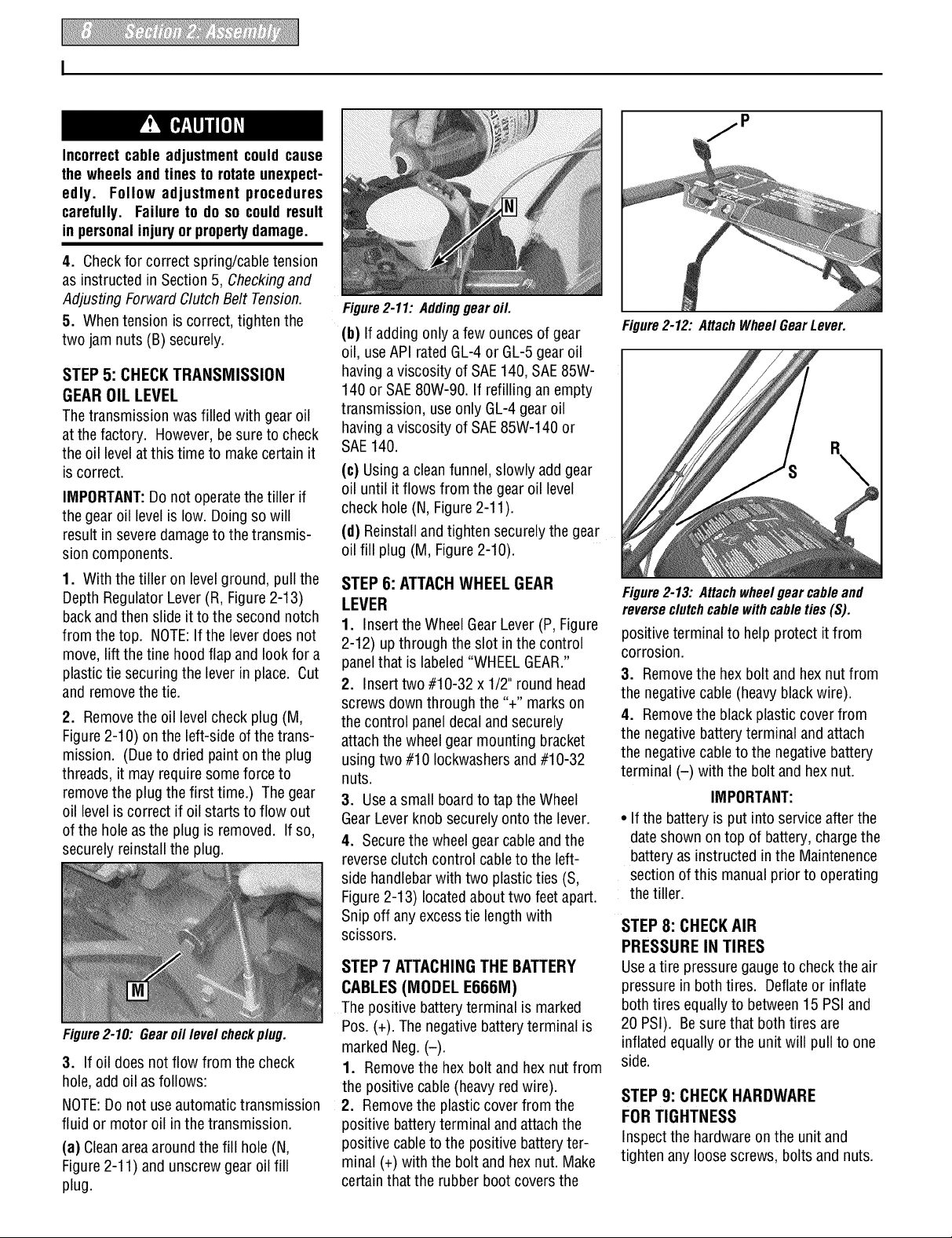

STEP3: ATTACH REVERSE

CLUTCH CONTROL CABLE

1. Carefullyunwrapthe reverseclutch

control cable(H, Figure2-6) from its

shipping position and route it up along

the insideedge ofthe left side handlebar.

A knoband large hexnut (I) is installed

on the cable.

I

Figure2-6: Attachreverse clutch control

assemblyto slottedhole in handlebarpanel.

2. Insertthe cable into the slot in the

control paneland fit the threadedassem-

bly into the holein theslot (see Figure2-

6). Besure that theflat side of the

threadedassembly is aligned with the flat

side of the hole. Slide the hex nut (I) up

the cableand tighten it securely.

3. Testthefunction of the reverseclutch

control cableby pulling the knob out and

releasingit. Theknob should return to its

neutral position against the tapered

bushing. If it doesn't, contact your local

dealeror the factory for technical

assistance.

LeftSide ReverseClutch]

Handlebar ControlKnob

STEP 4: ATTACHFORWARD

CLUTCH CONTROL CABLE

1. Removeanyfasteners (rubber bands,

tape, etc.) that maysecurethe Forward

Clutch Control levers (J, Figure2-7) to the

handlebar.

Figure2-7: ForwardClutchControllevers

(J). Forwardclutchcontrollinkage(K).

2. Theforward clutch control cable(with

attachedspring) is hanging loosely near

the right-side wheel. Being careful not to

kink orstretch the cable, insert thez-con-

nector (L, Figure2-8 - end of the spring)

into the hole at the end of the forward

clutch control linkage(K, Figure2-7).

I

Figure2-8

3. Attachthe cableadjuster (A, Figure

2-9) to the bracket onthe right-side han-

dlebar. Usetwo 1/2"wrenchesto loosen

the two jam nuts (B) just enoughto slide

the cableadjuster onto the bracket. Then

hand tighten the jam nuts.

Figure2-9

Incorrectcable adjustment could cause

the wheels andtines to rotate unexpect-

edly. Follow adjustment procedures

carefully. Failure to do so could result

in personalinjury orpropertydamage.

4. Checkfor correct spring/cable tension

as instructed in Section5, Checkingand

Adjusting ForwardClutch Belt Tension.

5. Whentension is correct, tighten the

two jam nuts (B) securely.

STEP5: CHECKTRANSMISSION

GEAROIL LEVEL

Thetransmission was filled with gear oil

at the factory. However,be sureto check

the oil levelat this time to makecertain it

iscorrect.

IMPORTANT:Do not operatethe tiller if

the gear oil level is low. Doingso will

result inseveredamageto the transmis-

sion components.

1. With the tiller on levelground, pull the

Depth Regulator Lever(R, Figure2-13)

backand then slide it to the second notch

from the top. NOTE:If the lever does not

move,lift the tine hoodflap and look for a

plastictie securing the lever in place. Cut

and removethe tie.

2. Removethe oil levelcheck plug (M,

Figure2-10) on the left-side of the trans-

mission. (Dueto dried painton the plug

threads, it may require some force to

removethe plug the first time.) The gear

oil levelis correct if oil starts to flow out

ofthe hole asthe plug is removed. If so,

securely reinstall the plug.

Figure2-10: Gearoil level checkplug.

3. If oil does notflow from the check

hole,add oil as follows:

NOTE:Donot use automatic transmission

fluid or motor oil inthe transmission.

(a) Cleanareaaround the fill hole (N,

Figure2-11) and unscrewgear oil fill

plug.

Figure2-11: Addinggearoil.

(b) If adding only a few ouncesof gear

oil, useAPI ratedGL-4 or GL-5 gear oil

havinga viscosity of SAE140, SAE85W-

140 or SAE80W-90. If refilling anempty

transmission, useonly GL-4 gear oil

havinga viscosity of SAE85W-140 or

SAE140.

(c) Usinga cleanfunnel, slowly add gear

oil until itflows from the gearoil level

check hole (N, Figure2-11).

(d) Reinstalland tighten securelythe gear

oil fill plug (M, Figure2-10).

STEP 6: ATTACHWHEEL GEAR

LEVER

1. Insert the Wheel GearLever(P, Figure

2-12) up through theslot in the control

panelthat is labeled"WHEELGEAR."

2. Insert two #10-32 x 1/2" round head

screws down through the "+" marks on

the control paneldecal and securely

attach thewheel gear mounting bracket

usingtwo #10 Iockwashersand #10-32

nuts.

3. Usea small board to tap the Wheel

GearLeverknobsecurely onto the lever.

4. Securethe wheelgear cableand the

reverseclutch control cableto the left-

side handlebarwith two plastic ties (S,

Figure2-13) locatedabout two feet apart.

Snip off anyexcesstie lengthwith

scissors.

STEP7 ATTACHINGTHE BATTERY

CABLES(MODEL E666M)

The positive battery terminal is marked

Pos. (+). The negativebattery terminal is

marked Neg.(-).

1. Removethe hex bolt and hex nut from

the positive cable (heavy red wire).

2. Removethe plastic cover from the

positive batteryterminal and attachthe

positive cableto the positive batteryter-

minal (+) with the bolt and hex nut. Make

certain that the rubber boot coversthe

Figure2-12: AttachWheel GearLever.

Figure2-13: Attach wheel gear cable and

reverseclutchcable with cable ties (S).

positive terminal to help protect it from

corrosion.

3. Removethe hexbolt and hex nut from

the negativecable (heavyblackwire).

4. Removethe black plastic cover from

the negativebattery terminal andattach

the negativecableto the negativebattery

terminal (-) with the bolt and hex nut.

IMPORTANT:

• If the battery is put into serviceafter the

dateshown ontop of battery, chargethe

batteryas instructed in the Maintenence

sectionof this manualprior to operating

the tiller.

STEP 8: CHECKAIR

PRESSURE IN TIRES

Usea tire pressuregaugeto check the air

pressure in bothtires. Deflateor inflate

both tires equallyto between15 PSI and

20 PSI). Besure that both tires are

inflated equally orthe unit will pull to one

side.

STEP 9: CHECK HARDWARE

FOR TIGHTNESS

Inspect the hardwareon the unit and

tighten anyloose screws, bolts and nuts.

3 Featuresand Controls

Before operating your machine, care-

fully read and understand all safety,

controls and operating instructions in

this Manual, the separate Engine

Owner's Manual, and on the decals on

the machine.

Failure to follow these instructionscan

resultin seriouspersonalinjury.

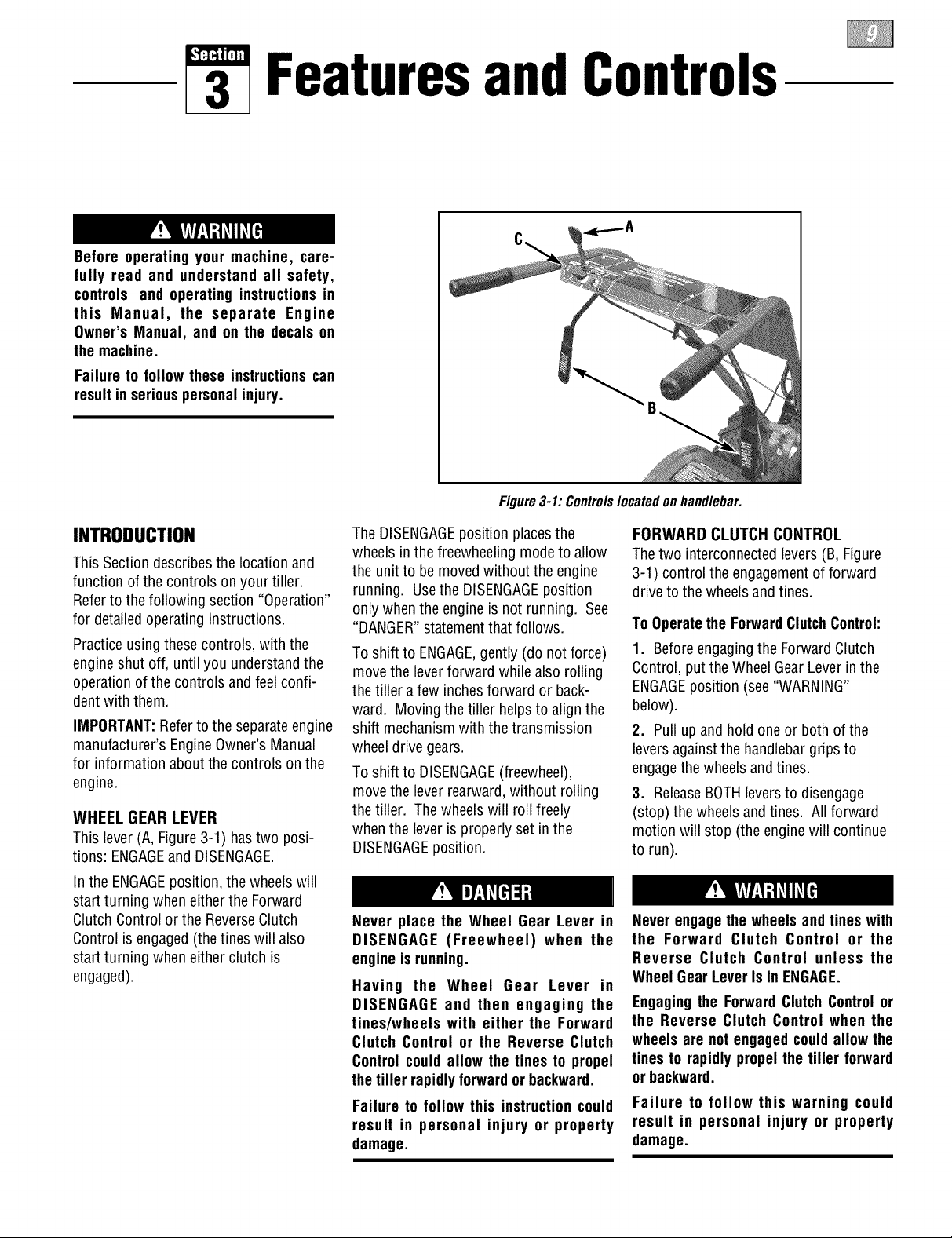

Figure3-1: Controlslocatedon handlebar.

INTRODUCTION

This Sectiondescribesthe location and

function of the controls on your tiller.

Referto thefollowing section "Operation"

for detailedoperating instructions.

Practiceusingthese controls, with the

engine shut off, until you understandthe

operation of the controls and feel confi-

dent with them.

IMPORTANT:Referto the separateengine

manufacturer'sEngineOwner's Manual

for information about the controls on the

engine.

WHEEL GEAR LEVER

This lever(A, Figure3-1) has two posi-

tions: ENGAGEand DISENGAGE.

Inthe ENGAGEposition, the wheels will

start turning when eitherthe Forward

Clutch Control or the ReverseClutch

Control is engaged(the tines will also

start turning when eitherclutch is

engaged).

The DISENGAGEposition placesthe

wheels inthefreewheeling modeto allow

the unitto be moved without the engine

running. Usethe DISENGAGEposition

only whenthe engine is not running. See

"DANGER"statementthat follows.

To shift to ENGAGE,gently (do not force)

movethe leverforward while also rolling

the tiller afew inchesforward or back-

ward. Moving the tiller helpsto align the

shift mechanismwith the transmission

wheel drive gears.

To shift to DISENGAGE(freewheel),

movethe lever rearward, without rolling

the tiller. Thewheels will roll freely

when the lever is properly set in the

DISENGAGEposition.

Never place the Wheel Gear Lever in

DISENGAGE (Freewheel) when the

engine is running.

Having the Wheel Gear Lever in

DISENGAGE and then engaging the

tines/wheels with either the Forward

Clutch Control or the Reverse Clutch

Control could allow the tines to propel

thetiller rapidlyforwardor backward.

Failure to follow this instruction could

result in personal injury or property

damage.

FORWARD CLUTCH CONTROL

The two interconnected levers (B, Figure

3-1) control the engagementof forward

drive to the wheelsand tines.

To Operatethe ForwardClutchControl:

1. Beforeengagingthe ForwardClutch

Control, put the WheelGearLeverin the

ENGAGEposition (see"WARNING"

below).

2. Pull up and hold one or both of the

levers againstthe handlebar grips to

engagethe wheels and tines.

3. ReleaseBOTHleversto disengage

(stop) the wheels andtines. All forward

motion will stop (the enginewill continue

to run).

Never engagethe wheels andtines with

the Forward Clutch Control or the

Reverse Clutch Control unless the

Wheel GearLeveris in ENGAGE.

Engagingthe ForwardClutch Controlor

the Reverse Clutch Control when the

wheels are not engagedcouldallow the

tines to rapidlypropelthe tiller forward

or backward.

Failure to follow this warning could

result in personal injury or property

damage.

REVERSE CLUTCH CONTROL

The ReverseClutchControl (C, Figure

3-1) controls the engagementof reverse

driveto thewheels and tines. The revers-

ingfeature is usedfor maneuveringthe

tiller only- neverengagethe tines in

the groundwhile goingin the reverse

direction.

• Use extreme caution when reversing

or pulling the machine towards you.

Lookbehindto avoid obstacles.

• Neverattemptto till in reverse.

Failure to follow this warning could

result in personal injury or property

damage.

To Operatethe ReverseClutchControl:

1. Putthe WheelGearLeverin the

ENGAGEposition (seethe "WARNING"

statementon previouspage).

2. Stopall tiller motion by releasingthe

ForwardClutch Control levers.

3. Lift upthe handlebarsuntil thetines

clearthe ground, look behindyou to avoid

anyobstacles,and then pull the Reverse

ClutchControl knob out. Thetines and

wheelswill rotate in a reverse direction.

4. Releasethe ReverseClutch Control

knobto disengage(stop) the wheels and

tines. All reversemotion will stop (the

enginewill continue to run).

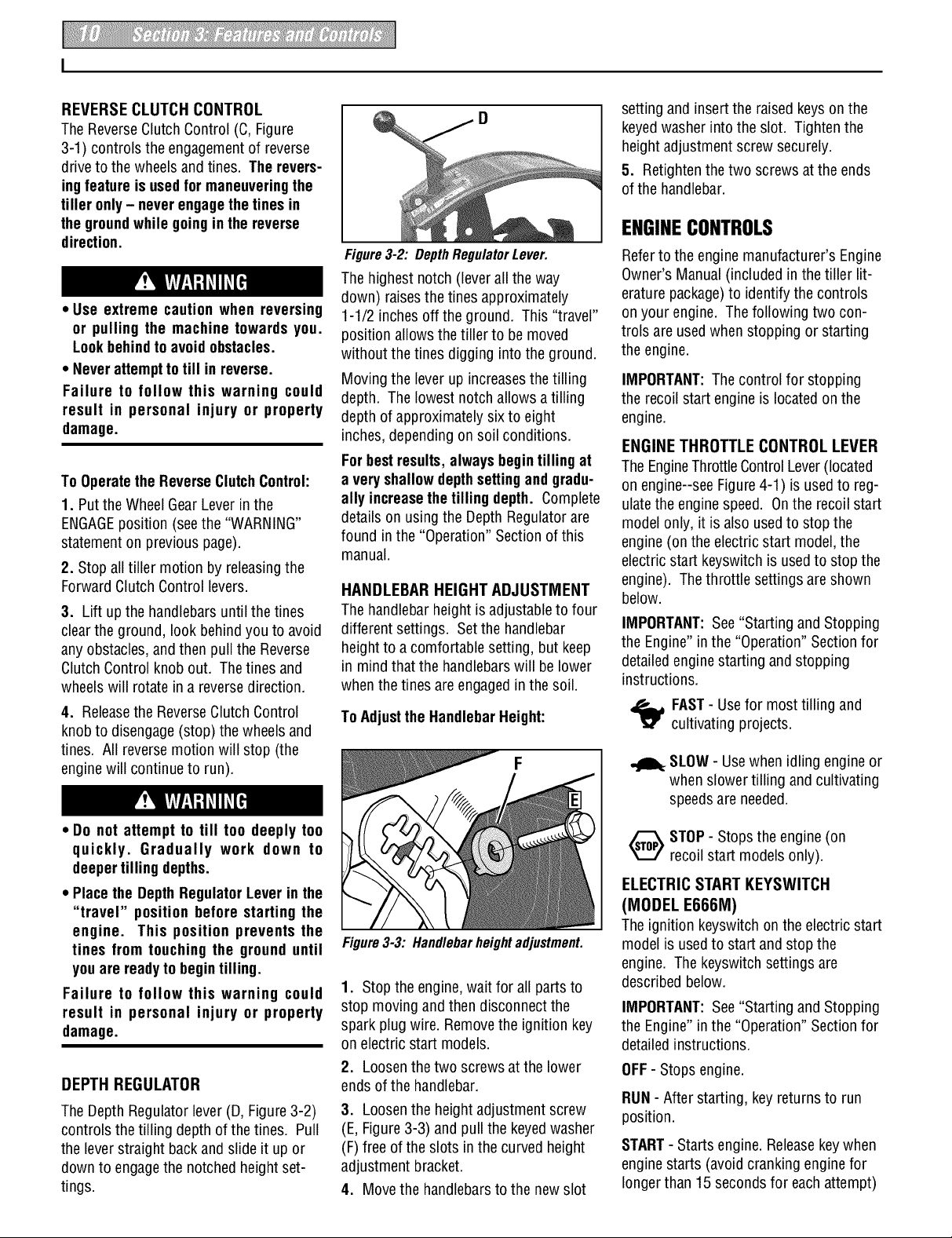

Figure3-2: DepthRegulatorLever.

The highest notch (leverall the way

down) raisesthe tines approximately

1-1/2 inches off the ground. This "travel"

position allowsthetiller to be moved

without the tines digging into the ground.

Moving the lever up increasesthe tilling

depth. Thelowest notch allows a tilling

depth of approximately six to eight

inches,depending on soil conditions.

Forbest results,always begintilling at

a very shallowdepthsettingand gradu-

ally increasethe tilling depth. Complete

details onusing the Depth Regulatorare

found in the "Operation" Section of this

manual.

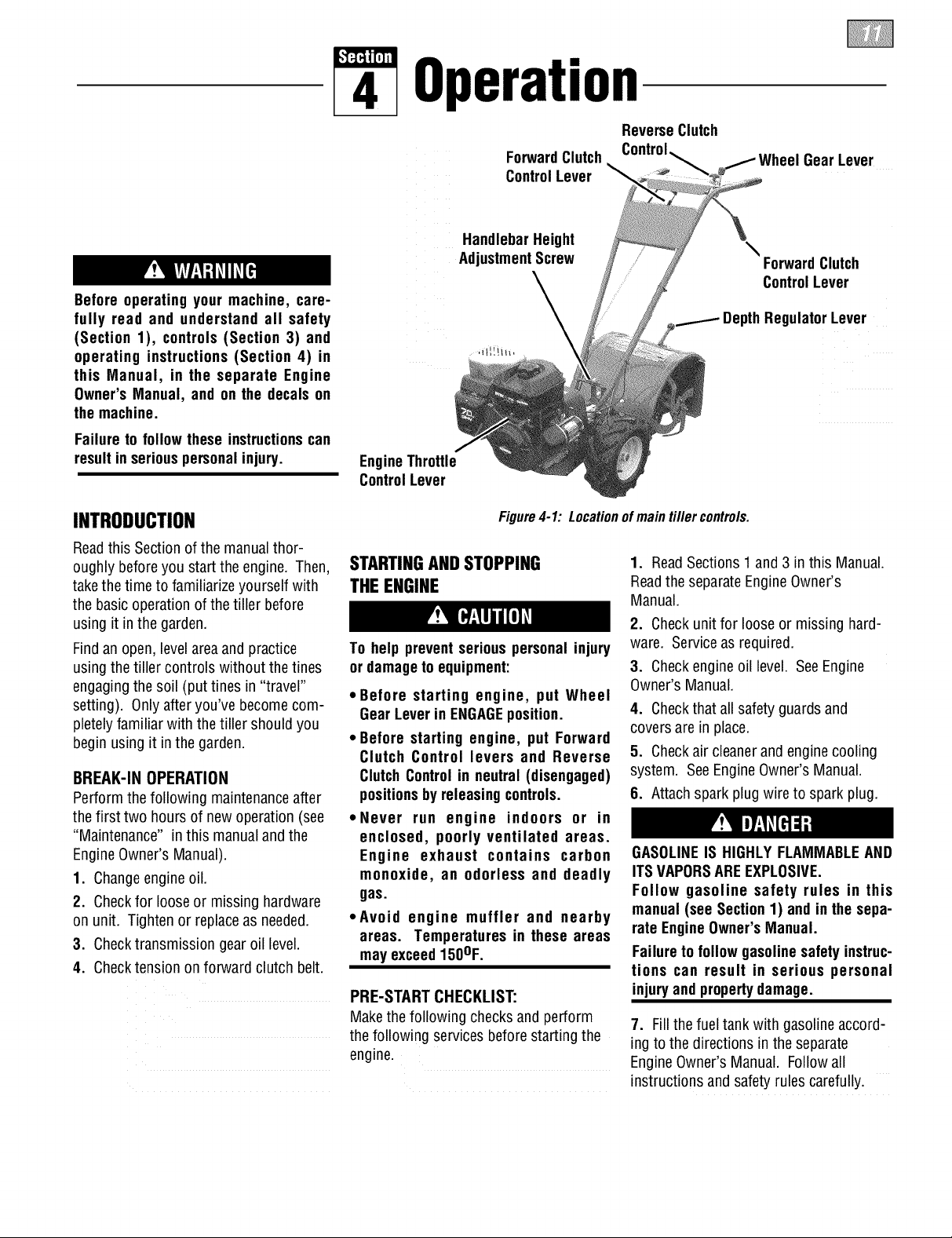

HANDLEBAR HEIGHT ADJUSTMENT

The handlebarheight is adjustableto four

different settings. Setthe handlebar

heightto a comfortable setting, but keep

in mindthat the handlebarswill be lower

when thetines are engagedin the soil.

ToAdjustthe HandlebarHeight:

F

setting and insert the raisedkeyson the

keyedwasher into the slot. Tighten the

height adjustment screw securely.

5. Retightenthe two screws at the ends

of the handlebar.

ENGINECONTROLS

Referto the engine manufacturer'sEngine

Owner's Manual(included in thetiller lit-

erature package)to identify the controls

on your engine. The following two con-

trols areusedwhen stopping or starting

the engine.

IMPORTANT:The control for stopping

the recoil start engineis locatedon the

engine.

ENGINE THROTTLE CONTROLLEVER

TheEngineThrottleControlLever(located

on engine--see Figure 4-1) is usedto reg-

ulatethe engine speed. Onthe recoil start

model only, it is also usedto stop the

engine (on the electric start model,the

electric start keyswitch is usedto stop the

engine). The throttle settings are shown

below.

IMPORTANT:See"Starting and Stopping

the Engine" in the "Operation" Sectionfor

detailedenginestarting andstopping

instructions.

FAST- Usefor most tilling and

cultivating projects.

-l_ SLOW- Usewhen idling engineor

when slower tilling and cultivating

speeds are needed.

• Do not attempt to till too deeply too

quickly. Gradually work down to

deepertilling depths.

• Placethe DepthRegulatorLever inthe

"travel" position before starting the

engine. This position prevents the

tines from touching the ground until

youare readytobegintilling.

Failure to follow this warning could

result in personal injury or property

damage.

DEPTH REGULATOR

The Depth Regulator lever(D, Figure3-2)

controls the tilling depth of the tines. Pull

the leverstraight backand slide it upor

downto engagethe notched height set-

tings.

Figure3-3: Handlebarheightadjustment.

1. Stopthe engine, wait for all parts to

stop moving and then disconnectthe

spark plugwire. Removethe ignition key

on electric start models.

2. Loosenthetwo screws atthe lower

ends of the handlebar.

3. Loosenthe height adjustment screw

(E,Figure3-3) and pull the keyedwasher

(F)free ofthe slots in the curved height

adjustment bracket.

4. Movethe handlebarsto the newslot

_) TOP- Stops the engine (on

recoil start models only).

ELECTRIC START KEYSWITCH

(MODEL E666M)

Theignition keyswitch on the electric start

model is used to start and stop the

engine. The keyswitch settings are

described below.

IMPORTANT:See"Starting and Stopping

the Engine" in the "Operation" Sectionfor

detailedinstructions.

OFF- Stops engine.

RUN- After starting, keyreturns to run

position.

START- Startsengine. Releasekeywhen

engine starts (avoidcranking engine for

longer than 15 secondsfor eachattempt)

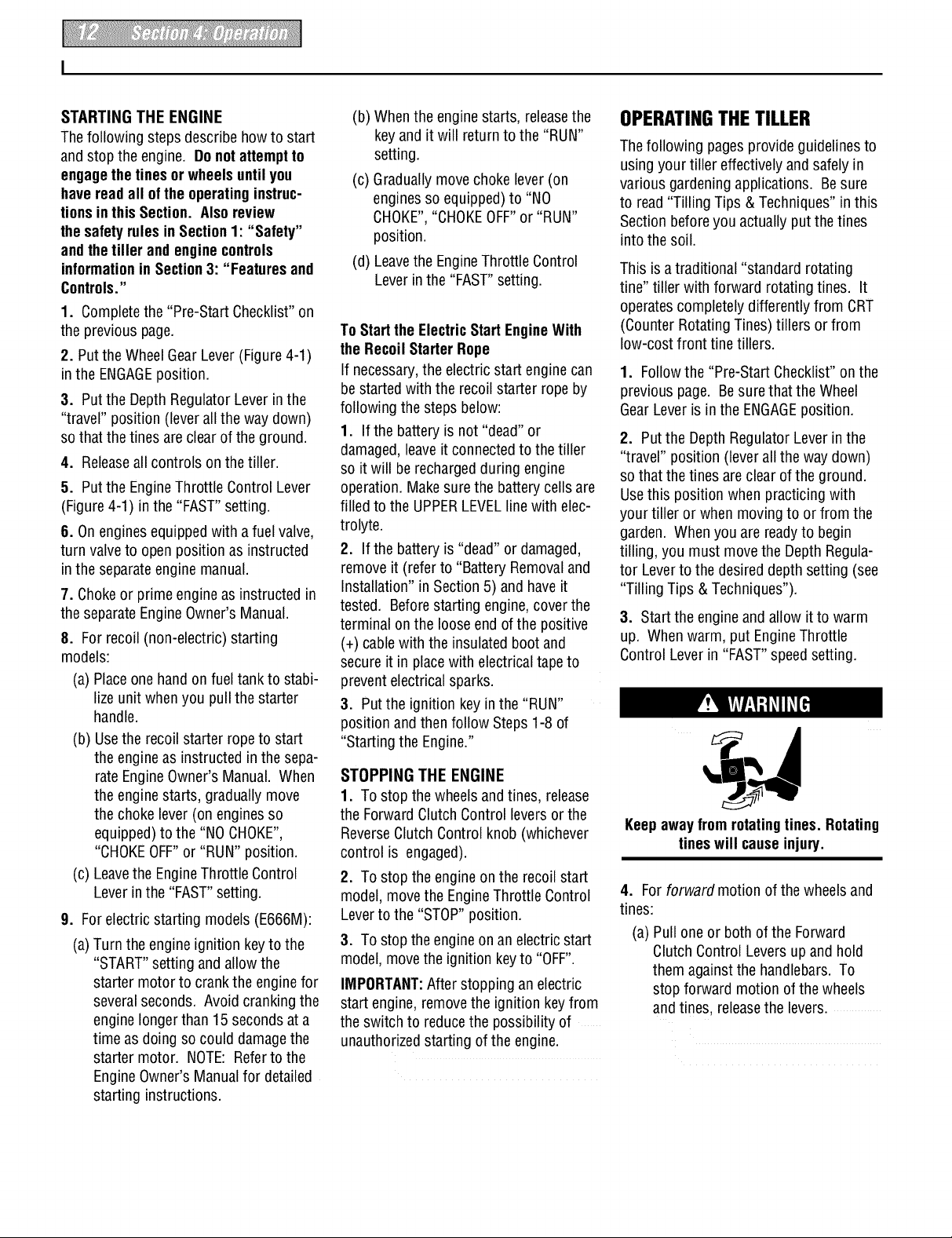

Operation

ReverseClutch

ForwardClutch

ControlLever

Wheel GearLever

Before operating your machine, care-

fully read and understand all safety

(Section 1), controls (Section 3) and

operating instructions (Section 4) in

this Manual, in the separate Engine

Owner's Manual, and on the decals on

the machine.

Failureto follow these instructionscan

resultin seriouspersonalinjury.

INTRODUCTION

Readthis Section ofthe manual thor-

oughly beforeyou start the engine. Then,

takethe time to familiarize yourself with

the basic operation of thetiller before

using it in the garden.

Findan open,levelareaand practice

usingthe tiller controls without the tines

engagingthe soil (put tines in "travel"

setting). Only after you've becomecom-

pletelyfamiliar with the tiller should you

begin using it in the garden.

BREAK-IN OPERATION

Perform the following maintenanceafter

thefirst two hours of newoperation (see

"Maintenance" in this manualand the

EngineOwner's Manual).

1. Changeengineoil.

2. Checkfor looseor missing hardware

on unit. Tighten or replace as needed.

3. Checktransmission gear oil level.

4. Checktension on forward clutch belt.

HandlebarHeight

AdjustmentScrew

,ill!iih,

EngineThrottle

ControlLever

Figure4-1: Locationof main tiller controls.

STARTINGANDSTOPPING

THE ENGINE

To help preventserious personal injury

or damageto equipment:

*Before starting engine, put Wheel

GearLever in ENGAGEposition.

* Before starting engine, put Forward

Clutch Control levers and Reverse

ClutchControl in neutral (disengaged)

positionsbyreleasingcontrols.

*Never run engine indoors or in

enclosed, poorly ventilated areas.

Engine exhaust contains carbon

monoxide, an odorless and deadly

gas.

*Avoid engine muffler and nearby

areas. Temperatures in these areas

may exceed150OF.

PRE-START CHECKLIST:

Makethe following checksand perform

the following services beforestarting the

engine.

\

ForwardClutch

ControlLever

DepthRegulatorLever

1. ReadSections1 and 3 in this Manual.

Readthe separateEngineOwner's

Manual.

2. Checkunit for looseor missing hard-

ware. Serviceas required.

3. Checkengine oil level. SeeEngine

Owner's Manual.

4. Checkthat all safety guards and

coversare in place.

5. Checkair cleanerand enginecooling

system. SeeEngineOwner's Manual.

8. Attachspark plugwire to spark plug.

GASOLINEIS HIGHLYFLAMMABLEAND

ITSVAPORSAREEXPLOSIVE.

Follow gasoline safety rules in this

manual(see Section1) andin the sepa-

rateEngineOwner'sManual.

Failureto follow gasolinesafety instruc-

tions can result in serious personal

injuryand propertydamage.

7. Fillthe fueltank with gasolineaccord-

ing to the directions in the separate

EngineOwner's Manual. Follow all

instructions and safety rules carefully.

STARTINGTHE ENGINE

Thefollowing steps describe howto start

and stop the engine, go notattempt to

engagethe tines orwheels untilyou

haveread all ofthe operatinginstruc-

tionsin this Section. Alsoreview

the safetyrules in Section1: "Safety"

and the tiller and enginecontrols

informationin Section3: "Features and

Controls."

1. Completethe "Pre-Start Checklist" on

the previous page.

2. Put the WheelGearLever(Figure4-1)

in the ENGAGEposition.

3. Putthe DepthRegulator Lever inthe

"travel" position (leverall the way down)

so that the tines are clearof the ground.

4. Releaseall controls on the tiller.

5. Putthe EngineThrottle Control Lever

(Figure4-1) inthe "FAST"setting.

6. On enginesequippedwith afuel valve,

turn valveto open position as instructed

in the separateengine manual.

7. Chokeor prime engineas instructed in

the separateEngineOwner's Manual.

8. Forrecoil (non-electric) starting

models:

(a) Placeone hand onfuel tankto stabi-

lizeunit whenyou pull the starter

handle.

(b) Usethe recoil starter ropeto start

the engineas instructed inthe sepa-

rate EngineOwner's Manual. When

the enginestarts, graduallymove

the choke lever(on enginesso

equipped) to the "NO CHOKE",

"CHOKEOFF"or "RUN" position.

(c) Leavethe EngineThrottle Control

Leverinthe "FAST"setting.

9. Forelectric starting models (E666M):

(a) Turn the engine ignition keyto the

"START"setting andallow the

starter motor to crank the enginefor

several seconds. Avoid cranking the

engine longer than 15seconds at a

time as doing so could damage the

starter motor. NOTE: Referto the

EngineOwner's Manualfor detailed

starting instructions.

(b) When the engine starts, releasethe

keyand it will returnto the "RUN"

setting.

(c) Graduallymovechoke lever(on

enginesso equipped)to "NO

CHOKE","CHOKEOFF"or "RUN"

position.

(d) Leavethe EngineThrottle Control

Leverinthe "FAST"setting.

To Start the ElectricStart EngineWith

the Recoil StarterRope

If necessary,the electric start engine can

be started with the recoilstarter rope by

following the steps below:

1. If the battery is not "dead" or

damaged,leaveit connectedto the tiller

so it will be rechargedduring engine

operation. Makesure the battery cells are

filled to the UPPERLEVELline with elec-

trolyte.

2. If the battery is "dead" or damaged,

remove it (referto "Battery Removal and

Installation" in Section 5) and have it

tested. Beforestarting engine, coverthe

terminal on the looseend of the positive

(+) cable with the insulatedboot and

secure it in placewith electricaltape to

prevent electrical sparks.

3. Put the ignition key in the "RUN"

position andthenfollow Steps 1-8 of

"Starting the Engine."

STOPPING THE ENGINE

1. Tostop the wheels andtines, release

the ForwardClutch Control levers or the

ReverseClutch Controlknob (whichever

control is engaged).

2. Tostop the engine on the recoil start

model, move the EngineThrottle Control

Leverto the "STOP" position.

3. Tostop theengine on an electricstart

model, move the ignition keyto "OFF".

IMPORTANT:Afterstopping anelectric

start engine, removethe ignition keyfrom

the switch to reduce the possibility of

unauthorizedstarting of the engine.

OPERATINGTHETILLER

Thefollowing pagesprovideguidelines to

usingyour tiller effectively and safely in

various gardening applications. Besure

to read"Tilling Tips &Techniques" in this

Section before you actually put the tines

intothe soil.

This isa traditional "standard rotating

tine" tiller with forward rotating tines. It

operatescompletely differently from CRT

(CounterRotating Tines)tillers or from

low-cost front tine tillers.

1. Followthe "Pre-Start Checklist" on the

previous page. Besure thatthe Wheel

GearLeveris in the ENGAGEposition.

2. Putthe Depth Regulator Leverin the

"travel" position (lever all the way down)

so that the tines areclear of the ground.

Usethis position when practicingwith

your tiller or when movingto orfrom the

garden. When you are readyto begin

tilling, you must movethe Depth Regula-

tor Leverto the desireddepth setting (see

"Tilling Tips & Techniques").

3. Start theengine and allow it to warm

up. When warm, put EngineThrottle

Control Leverin "FAST"speedsetting.

Keepawayfrom rotatingtines. Rotating

tines will causeinjury.

4. For forward motion of the wheelsand

tines:

(a) Pull one or both of the Forward

Clutch Control Levers up and hold

them against the handlebars.To

stop forward motion of the wheels

and tines, releasethe levers.

Figure4-2: Useone handtoguide tiller

whenmovingforward.

(b) Asthe tiller movesforward, relax

and let the wheels pull the unit along

while the tines dig. Walk behind and

a little to oneside of the tiller. Usea

light but secure grip with one hand

on the handlebars,but keepyour

arm loose. SeeFigure4-2. Letthe

tiller move aheadat its own pace

and do not push down on the han-

dlebarsto try andforce the tiller to

dig deeper- this takesweight off the

wheels, reducestraction, and causes

the tines to try and propel the tiller.

Do not push down on the

handlebars to try to make the tiller till

more deeply. This preventsthe wheels

from holding the tiller back and can

allow the tines to rapidly propel the

tiller forward,whichcould resultin loss

of control,propertydamage, or personal

injury.

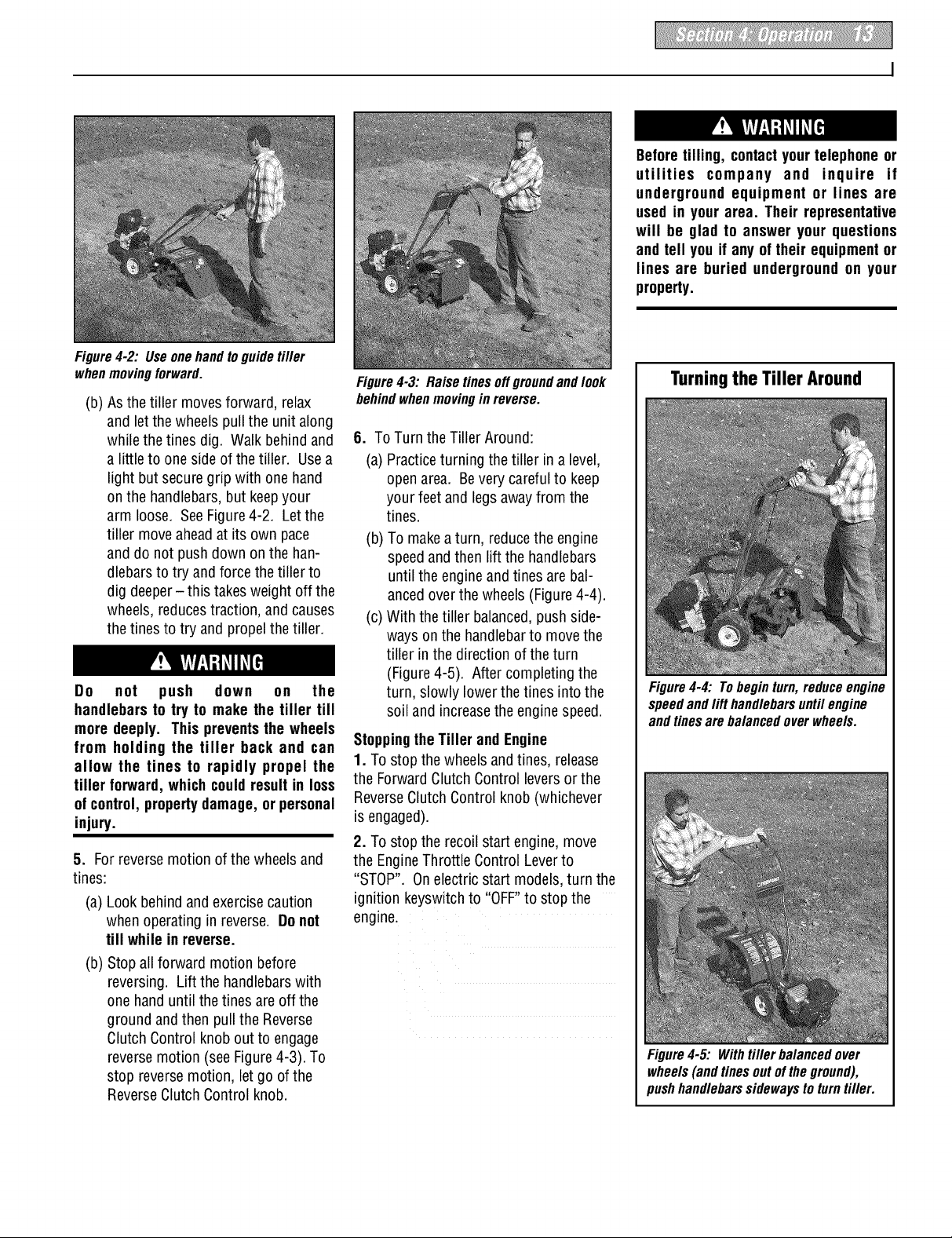

5. Forreverse motion of the wheelsand

tines:

(a) Look behind andexercisecaution

when operating in reverse. Do not

till while in reverse.

(b) Stop all forward motion before

reversing. Lift the handlebarswith

one hand until the tines areoff the

ground andthen pull the Reverse

Clutch Control knob out to engage

reverse motion (seeFigure 4-3). To

stop reversemotion, let go ofthe

ReverseClutch Control knob.

Figure4-3: Raise tinesoffgroundand look

behindwhen movingin reverse.

6. To Turn the Tiller Around:

(a) Practiceturning the tiller in a level,

open area. Bevery careful to keep

your feet and legsawayfrom the

tines.

(b) To makea turn, reducethe engine

speedandthen lift the handlebars

until the engine and tines are bal-

ancedoverthe wheels (Figure4-4).

(c) With the tiller balanced,pushside-

ways on the handlebarto move the

tiller in the direction ofthe turn

(Figure4-5). After completing the

turn, slowly lower the tines into the

soil and increasethe enginespeed.

StoppingtheTiller and Engine

1. To stop the wheelsandtines, release

the Forward ClutchControl levers or the

ReverseClutch Control knob whichever

isengaged).

2. To stop the recoil start engine, move

the EngineThrottle Control Leverto

"STOP". Onelectric start models,turn the

ignition keyswitchto "OFF"to stop the

engine.

Beforetilling, contactyour telephoneor

utilities company and inquire if

underground equipment or lines are

used in your area. Their representative

will be glad to answer your questions

and tell you if any oftheir equipmentor

lines are buried underground on your

property.

Turningthe Tiller Around

Figure4-4: Tobegin turn,reduce engine

speedand lift handlebars until engine

and tines are balancedover wheels.

Figure4-5: Withtiller balanced over

wheels(and tines outof the ground),

pushhandlebarssidewaysto turn tiller.

TillingTips& Techniques

Letthetiller dothe work

• While tilling, relaxand let the wheels

pull the tiller along while thetines do

the digging. Walk on the sidethat is

notyet finished (to avoid making foot-

prints inthe freshly tilled soil) and

lightly, butsecurely gripthe handlebar

with just one hand.

• Avoid pushing down on the handlebars

in an attempt to force the tiller to dig

deeper. Doing so takesthe weight off

the poweredwheels,causing them to

losetraction. Without the wheels

helpingto hold the tiller back,the tines

will attempt to propel the tiller - often

causing the tiller to skip rapidly across

the ground. (Sometimes, slight down-

ward pressureon the handlebarswill

helpget through a particularly tough

section of sod or unbrokenground, but

in mostcases this won't be necessary

at all.)

Tilling depths

• Avoid trying to dig too deeplytoo

quickly, especiallywhen busting sod or

when tilling soil that hasn't beentilled

for some time. Useshallow depth reg-

ulator settings (only an inch or two

deep) for the first passesthrough the

garden area. With eachsucceeding

pass,adjust the depth regulatorto dig

another inch or two deeper. (Watering

the garden areaa few days prior to

tilling will maketilling easier,as will

letting the newlyworked soil set for a

day or two beforemaking a final, deep

tilling pass.)

• When cultivating (breaking up the

surfacesoil around plantsto help

destroyweeds),usevery shallow depth

settingsto preventinjury to plantswhose

rootsoftengrow closetothesurface. If

needed,lift uponthe handlebarsslightly

to preventthetinesfrom diggingtoo

deeply. (Cultivatingona regularbasis

notonlyeliminatesweeds,it also loosens

andaeratesthesoil for bettermoisture

absorptionandfaster plantgrowth.)

Avoidtillingsoggy,wetsoil

Tilling wet soil often results in large,

hardclumps of soil that can interfere

with planting. Iftime permits, wait a day

or two after heavyrainsto allow the soil

to dry before tilling. Test soil by squeez-

ing it into a ball. If it compresses too

easily, it is too wet to till.

Avoid making footprints

When possible,walk on the untilledside

of the unit to avoid makingfootprints in

thefreshly tilled soil. Footprintscause

soil compaction that canhamperroot

penetrationandcontribute to soil

erosion. They can also"plant" unwanted

weedseedsback intothe freshly tilled

ground.

Choosing correctwheel

and tine speeds

With experience,you will find the "just

right" tilling depth andtilling speed com-

binationthat is best for your garden.

Setthe EngineThrottle Control Lever to

a speed to give the engineadequate

powerand yet allow it to operate at the

slowest possiblespeed...atleast until

you haveachievedthe maximum tilling

depth you desire. Fasterengine speeds

may bedesirablewhen making final

passesthrough the seedbedor when

cultivating. Selectionof the correct

engine speed, in relationto the tilling

depth, will ensurea sufficient power

levelto do the job without causingthe

engine to labor.

Suggestedtilling patterns

• When preparinga seedbed,go overthe

same path twice in thefirst row, then

overlapone-half thetiller width on the

rest ofthe passes(see Figure4-6).

Whenfinished in onedirection, make a

second pass ata right angle asshown

in Figure4-7. Overlapeach passfor

best results (in very hardground it may

takethree or four passesto thoroughly

pulverizethe soil).

• Ifthe gardensizewill not permit

lengthwiseand then crosswisetilling,

then overlapthe first passesby one-

halfa tiller width, followed by succes-

sive passesat one-quarter width (see

Figure4-8).

• With planning,you canallow enough

room between rows to cultivate (see

Figure4-9). Leaveroom for the hood

width, plus enough extra room for

future plantgrowth.

Figure4-6

r y V

Figure4-7

Figure4-8

Figure4-9

Loading...

Loading...