Troybilt 21A-654J66 Owner’s Manual

OTRO_ n!_LT"

anual

Rear.tine Tiller

4 r T_

65 JmTho oughbred

IMPORTANT:READSAFETYRULESANDINSTRUCTIONSCAREFULLY

WARNING: This unit isequipped with aninternal combustion engine and should not be usedon or nearany unimproved forest-covered, brush-covered or

grass-covered land unless the engine's exhaust system is equipped with aspark arrester meetingapplicable local or state laws (if any). tf a spark arrester is used,it

should be maintained in effective working order by the operator. In the State of California the above is required by law (Section 4442 of the California Public

Resources Code). Other states may havesimilar laws, Federallaws applyon federallands, Aspark arrester for the muffler is availablethrough your nearestengine

authorizedservice dealer or contact theservice department, P,O,Box 361131 Cleveland,Ohio 44136-0019.

TROY-BILTLLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTEDINU.S.A. FORMNO. 769-01146

(3/17/2004)

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance and Adjustments 15

Safety 3 Off-season Storage 21

Assembly 6 Troubleshooting 22

Features and Controls 9 Parts List 23

Operation 11 Warranty Information Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new rear-tine tiller. It will help you assemble, prepare and maintain

the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

@

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by standing behind the unit and looking down at rear surface of the tine shield. This

information will be necessary to use the manufacturer's web site and/or help from the Customer Support

Department or an authorized service dealer.

iliii iii iilli!

www.t roybilt.com _1__ 5u_51180_ _

Copy the model number here:

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTreturnthe unit tothe retailer from whereit waspurchased,withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

_ Visit troy-bgt.com for many useful suggestions. Click on Customer Support button and youwill get the four options reproduced here. Click on the appropriate button and help is

_mmediately available.

7_e 8nswo_ you 8Fe " _e 8plswer you ale

_°_'"*__"°_*"°°'°*"_" _°"__*'"...... looking for could u_j_"-:u""

m_ho_Jf_/_r_IH mFLI_l_d_&, el update ye_lJ U_eJs#ll_l

8 mouse crick 8w8 S

, _o_o, a mouse crick away!

:

If you prefer to reach a Customer Support Representative, please call 1(800) 520-5520.

The engine manufacturer is responsible for all engine-related issues with regards to

_erformance, power-rating, specifications, warranty engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

and service. Please refer to the

SECTION1: IMPORTANTSAFEOPERATIONPRACTICES

WARNING: This symbol points out important safety instructions which, if not followed, could endanger

the personal safety and/or property of yourself and others. Read and follow all instructions in this manual

before attempting to operate this machine. Failure to comply with these instructions may result in personal

injury. When you see this symbol--heed its warning.

DANGER: This machine was built to be operated according to the rules for safe operation in this man-

ual. As with any type of power equipment, carelessness or error on the part of the operator can result in

serious injury. This machine is capable of amputating hands and feet and throwing objects. Failure to

observe the following safety instructions could result in serious injury or death.

California Proposition 65 Warning:

or emit chemicals known to the State of California to cause cancer and birth defects or other

WARNING: Engine exhaust, some of its constituents, and certain vehicle components contain

reproductive harm.

Training

1. Carefully read this Operator's Manual, the separate

Engine Owner/Operator's Manual, and any other

literature you may receive. Be thoroughly familiar

with the controls and the proper use of the tiller and

its engine. Know how to stop the unit and

disengage the controls quickly.

2. Never allow children to operate the tiller. Never

allow adults to operate the tiller without proper

instruction.

3. Keep the area of operation clear of all persons,

particularly children and pets.

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring to

other people, their property, and themselves.

Preparation

1. Thoroughly inspect the area where the tiller is to be

used and remove all foreign objects.

2. Be sure all control levers are released before

starting the engine.

3. Do not operate the tiller without wearing adequate

outer garments. Avoid loose garments or jewelry

that could get caught in moving parts.

4. Do not operate the tiller when barefoot or wearing

sandals, sneakers, or light footwear. Wear

protective footwear that will improve footing on

slippery surfaces.

5. Do not till near underground electric cables,

telephone lines, pipes or hoses. Ifin doubt, contact

your telephone or utility company.

6. Never make adjustments when engine is running

(unless recommended by the Engine

manufacturer).

WARNING: Handle fuel with care; it is highlyflammable

and its vapors are explosive. Take the following precautions:

a. Store fuel in containers specifically designed

for this purpose.

b. The gas cap shall never be removed or fuel

added while the engine is running. Allow the

engine to cool for several minutes before

adding fuel.

c. Keep matches, cigarettes, cigars, pipes,

open flames, and sparks away from the fuel

tank and fuel container.

d. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoors. Use a funnel or

spout to prevent spillage.

e. Replace all fuel tank and container caps

securely.

f. If fuel is spilled, do not attempt to start the

engine, but move the machine away from the

area of spillage and avoid creating any

source of ignition until fuel vapors have

dissipated.

Operation

1.

Do not put hands or feet near or under rotating

parts.

2. Exercise extreme caution when on or crossing

gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry passengers.

3. After striking a foreign object, stop the engine,

thoroughly inspect the machine for any damage,

and repair the damage before restarting and

operating the machine.

4. Exercise caution to avoid slipping or falling.

5. Ifthe unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration

is generally a warning of trouble.

6. Stop the engine before unclogging the tines, or

when making any repairs, adjustments or

inspections.

7. Take all possible precautions when leaving the

machine unattended. Stop the engine and move

the Wheel Shift Lever to FORWARD.

8. Beforecleaning,repairing,orinspecting,stopthe

engineandmakecertainallmovingpartshave

stopped.

9. Alwayskeepthetiller'sreartineshielddown.

10.Neverusethetillerunlessproperguards,plates,or

othersafetyprotectivedevicesareinplace.

11.Donotrunengineinanenclosedarea.Engine

exhaustcontainscarbonmonoxidegas,adeadly

poisonthatisodorless,colorless,andtasteless.

12.Keepchildrenandpetsaway.

13.Beawarethatthetillermayunexpectedlybounce

upwardorjumpbackwardifthetinesshouldstrike

extremelyhardpackedsoil,frozenground,or

buriedobstacleslikelargestones,roots,orstumps.

Ifindoubtaboutthetillingconditions,alwaysuse

thefollowingoperatingprecautionstoassistyouin

maintainingcontrolofthetiller:

a. Walkbehindandtoonesideofthetiller,

usingonehandonthehandlebars.Relax

yourarm,butuseasecurehandgrip.

b. Useslowerenginespeeds.

c. Clearthetillingareaofalllargestones,roots

andotherdebris.

d. Avoidusingdownwardpressureon

handlebars.Ifneedbe,useslightupward

pressuretokeepthetinesfromdiggingtoo

deeply.

e. Beforecontactinghardpackedsoilattheend

ofarow,reduceenginespeedandlift

handlebarstoraisetinesoutofthesoil.

f. Inanemergency,stoptinesandwheelsby

releasingtheWheelEngagementHandle.

Donotattempttorestrainthetiller.

15.Donotoverloadthetitler'scapacitybyattemptingto

tilltoodeeplyattoofastarate.

16.Neveroperatethetillerathightransportspeedson

slipperysurfaces.Lookbehindandusecarewhen

backingup.

17.Donotoperatethetilleronaslopethatistoosteep

forsafety.Whenonslopes,slowdownandmake

sureyouhavegoodfooting.Neverpermitthetiller

tofreewheeldownslopes.

18.Neverallowbystandersneartheunit.

19.Onlyuseattachmentsandaccessoriesthatare

approvedbyTroy-BiltLLC.

20.Neveroperatethetillerwithoutgoodvisibilityor

light.

21.Neveroperatethetillerifyouaretired,orunderthe

influenceofalcohol,drugsormedication.

22.Operatorsshallnottamperwiththeengine-

governorsettingsonthemachine;thegovernor

controlsthemaximumsafeoperatingspeedto

protecttheengineandallmovingpartsfrom

damagecausedbyoverspeed.Authorizedservice

shallbesoughtifaproblemexists.

23.Donottouchenginepartswhichmaybehotfrom

operation.Letpartscooldown

24.Pleaseremember:Youcanalwaysstopthetines

andwheelsbyreleasingtheWheelEngagement

Handle.

25.Useextremecautionwhenreversingorpullingthe

machinetowardsyou.

26.Starttheenginecarefullyaccordingtoinstructions

andwithfeetwellawayfromthetines.

27.Neverpickuporcarryamachinewhiletheengine

isrunning.

MaintenanceandStorage

1. Keep the tiller, attachments and accessories in safe

working condition.

2. Check all nuts, bolts, and screws at frequent

intervals for proper tightness to be sure the

equipment is in safe working condition.

3. Never store the tiller with fuel in the fuel tank inside

a building where ignition sources are present such

as hot water and space heaters, furnaces, clothes

dryers, stoves, electric motors, etc.). Allow engine

to cool before storing in any enclosure.

4. To reduce the chances of a fire hazard, keep the

engine free of grass, leaves, or excessive grease.

5. Store gasoline in a coot, well-ventilated area, safely

away from any spark- or flame-producing

equipment. Store gasoline in an approved

container, safely away from the reach of children.

6. Refer to the storage instructions in the

Maintenance section of this Manual and the

separate Engine Owner's Manual for instructions if

the tiller is to be stored for an extended period.

7. If the fuel tank has to be drained, do this outdoors.

,_ WARNING: YOUR RESPONSIBILITY Restrict the use of this power machine to persons who read,

understand and follow the warnings and instructions in this manual and on the machine.

SAFETYLABELSFOUNDONYOURTILLER

SECTION2: ASSEMBLINGTHETILLER

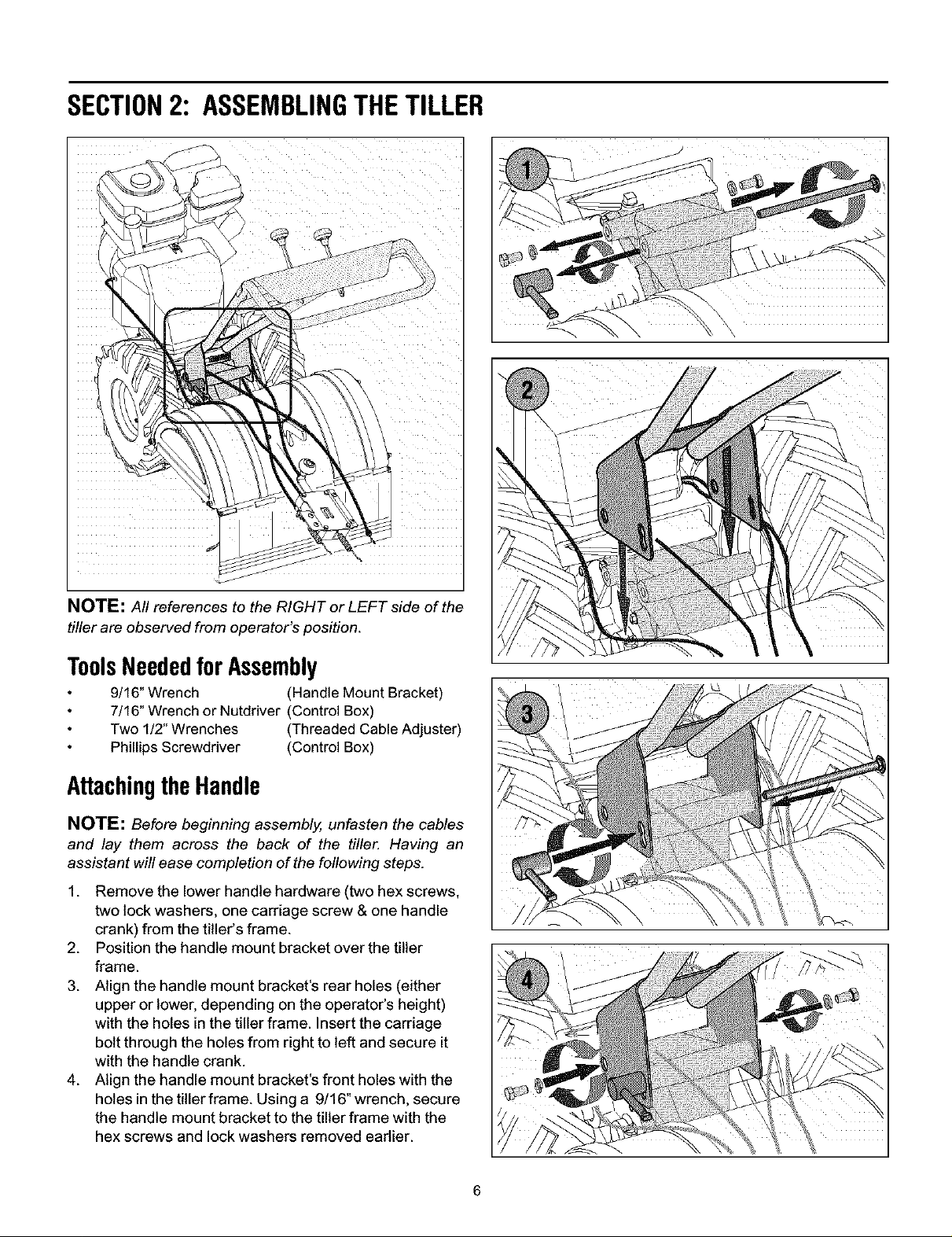

NOTE: All references to the RIGHT or LEFT side of the

tiller are observed from operator's position.

ToolsNeededforAssembly

9/16" Wrench (Handle Mount Bracket)

7/16" Wrench or Nutdriver (Control Box)

Two 1/2"Wrenches (Threaded Cable Adjuster)

Phillips Screwdriver (Control Box)

AttachingtheHandle

NOTE: Before beginning assembly, unfasten the cables

and lay them across the back of the tiller. Having an

assistant will ease completion of the following steps.

1. Remove the lower handle hardware (two hex screws,

two lock washers, one carriage screw & one handle

crank) from the titler's frame.

2. Position the handle mount bracket over the tiller

frame.

3. Align the handle mount bracket's rear holes (either

upper or lower, depending on the operator's height)

with the holes in the tiller frame. Insert the carriage

bolt through the holes from right to left and secure it

with the handle crank.

4. Align the handle mount bracket's front holes with the

holes in the tiller frame. Using a 9/16" wrench, secure

the handle mount bracket to the tiller frame with the

hex screws and lock washers removed earlier.

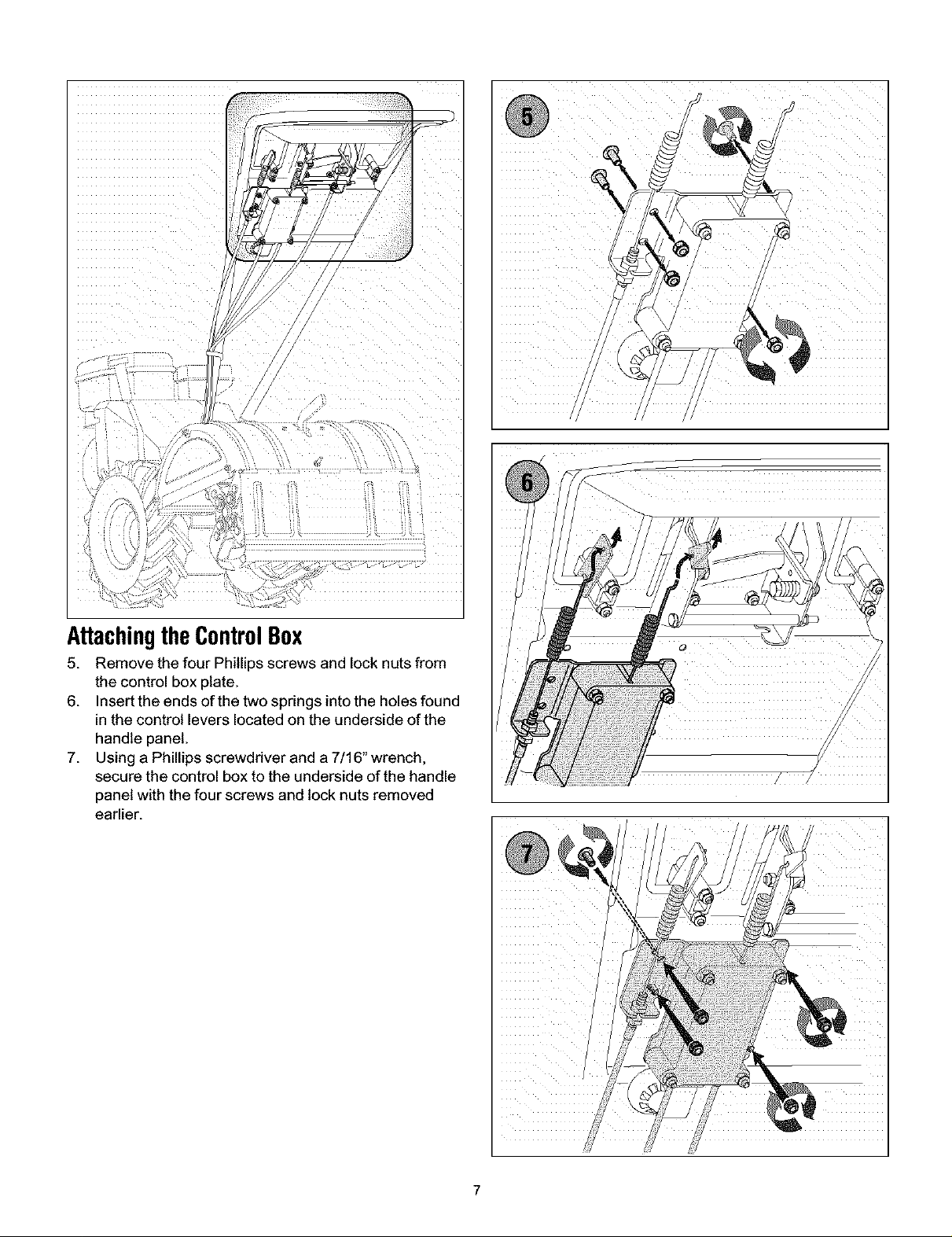

AttachingtheControlBox

5. Remove the four Phillips screws and lock nuts from

the control box plate.

6. Insert the ends of the two springs into the holes found

in the control levers located on the underside of the

handle panel.

7. Using a Phillips screwddver and a 7/16" wrench,

secure the control box to the underside of the handle

panel with the four screws and lock nuts removed

earlier.

XXXXXXXXXXXXXXXXX r¸ J---- --_

/

AttachingtheShiftCable

8. Place the shift lever in the forward position. Insert the

end of the shift cable into the hole in shift lever

located on the underside the handle panel.

9. Position the shift cable's threaded adjuster in the slot

found on the shift lever mount bracket. (one nut below

the mount bracket and the flat washer, lock washer

and second nut above the mount bracket. See Inset).

10. Adjust the shift cable as follows:

a. Using a ½" wrench, thread the bottom nut

upward until the cable is taut.

b. Using a ½" wrench, thread the top nut

downward to secure the adjuster to the mount

bracket.

Position the shift cable (and three other cables)

against the left handle tube. Secure them to the

handle with the cable tie provided as shown in the

illustration at the top of the page.

GasandOilFill-up

Gasoline

Service the engine with gasoline as instructed in the

separate Briggs & Stratton Operator/Owner Manual

packed with your tiller. Read instructions carefully.

0il

f

IMPORTANT:Pour the entire contents of the provided oil

bottle into the engine's oil fill.

SECTION3: KNOWYOURTILLER

Wheel ShiftLever

Tine DirectionSelector

Engine J

Starter Handle

Read this operator's manual and safety rules before

operating your tiller. Compare the illustrations above with

your unit to familiarize yourself with the location of vadous

controls. Save this manual for future reference.

Engine

See the Briggs & Stratton Owner!Operator manual

packed with your unit for the location and function of the

controls on the engine.

Starter Handle

The starter handle is located on the engine. Pull the

starter handle to start engine.

WheelShiftLever

The shift lever is located on the

dght side of the handle panel

and has three positions,

FORWARD, NEUTRAL and

REVERSE. Place the wheel

shift lever in either FORWARD

or REVERSE before engaging

the drive handle. Always bring

the tiller to a complete stop

prior to moving the shift lever

from FORWARD to REVERSE

or vice-versa.

IMPORTANT: Never force the

shift lever. Doing so may result

in serious damage to the tiller's

transmission.

Wheel EngagementHandle

_Tine EngagementLever

DepthRegulatorLever

(DepthStake)

HandleHeightAdjuster

WheelEngagementHandle

The wheel engagement handle

is located below the tilter's

upper handle.

Closing the wheel engagement

handle with the wheel shift

lever in either FORWARD or

REVERSE will cause the tiller's

wheels to drive.

Releasing/Opening the wheel

engagement handle

automatically stops the tiller's

wheels from driving

NOTE: If the tiller's tines and

wheels are engaged, releasing/

opening the wheel engagement

handle automatically stops

BOTH the tiller's tines and the

tiller's wheels from driving.

Tine DirectionSelector

The tine direction selector (found in the lower left area the

handle panel) is used to alternate tine rotation between

FRT mode (Forward Rotating Tines) to CRT mode

(Counter Rotating Tines).

Operate the tiller inCRT mode when tilling virgin

ground, sod or hard soil.

Operate the tiller inFRT mode when cultivating or

tilling soft ground or previously tilled soil.

IMPORTANT: When operating the tiller in FRT mode,

always lower the depth regulator lever (for a shallower

tilling depth).

DepthRegulatorLever

The highest notch (lever all the

way down) raises the tines

approximately 1/2-inch off the

ground. This "travel" position

allows the tiller to be moved

without the tines digging into

the ground.

Moving the lever up increases

the tilling depth. The lowest

notch allows a tilling depth of

approximately six to eight

inches, depending on soil

conditions.

Tine EngagementLever

The tine engagement lever is

located on the left side of the

handle panel and has two

positions, ON and OFF. To

engage the tines and begin

tilling, place the lever in the ON

position. To disengage the

tines, move the lever into the

OFF position.

NOTE: The tlne engagement

lever cannot be placed in the

ON position without first closing

the wheel engagement handle.

Also, the tlne engagement

lever cannot be placed in the

ON position unless the wheel

shift lever is in the FORWARD

position. Refer to SafetyInterlock

Systemon Page 11.

HandleHeightAdjuster

The handle mount bracket can be adjusted downward (for

shorter operators) or upward (for taller operators) using

the handle height adjuster. Align the handle mount

bracket's rear holes with the holes in the tiller frame. Insert

the carriage bolt through the holes from right to left and

secure it with the handle crank.

10

Loading...

Loading...