Troybilt 21A-634F063, 21A-634B063, 21A-630C063 Owner’s Manual

O TRO_ BILT

Operator's Manual

Rear-tine Tiller Models

630C Tuffy_

634Fm BroncoTM

634Bm Super BroncoTM

Model 634B Shown

IMPORTANT: READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

WARNING: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-

covered, brush-covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable

local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of

California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have similar laws.

Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or

contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

PRINTEDINU.S.A. FORM NO. 770-10594C

11/25/02

TABLEOFCONTENTS

Content Page

CallingCustomerSupport.......................................................................................................2

Safety......................................................................................................................................3

Assembly................................................................................................................................6

FreaturesandControls............................................................................................................lg

Operation................................................................................................................................12

Maintenance...........................................................................................................................17

Off-SeasonStorage.................................................................................................................21

Troubleshooting......................................................................................................................22

Parts List ................................................................................................................................23

WarrantyInformation..............................................................................................................BackCover

FINDINGMODELNUMBER

This Operator'sManualisan important partof your newRear-tineTiller. It will helpyouassemble, prepareandmaintain the unit for

best performance. Pleasereadand understandwhat it says.

information from itinthespace providedbelow.This information isvery importantif you needhelpfrom our Customer

Beforeyoustart assemblingyour new equipment,pleaselocatethe modelplateon the equipment andcopy the

Support Departmentor an authorizeddealer.

You can locatethe model number by lookingon the rearsurfaceof thetine shield.A sample model plate is explainedbelow. For

future reference,pleasecopy the modelnumber andtheserial numberof the equipment inthe spacebelow.

Copythe model numberhere:

Copythe serial numberhere:

O TRII_BILT • _."__-_ _. _

www.troybilt.com CLEVELAND,OH44136

• 866-840-648_

330-558-7220

ENGINEINFORMATION

Theengine manufacturer is responsiblefor allengine-relatedissueswith regardto performance,power-rating, specifications,

warrantyand service. Pleasereferto the enginemanufacturer's Owner's/Operator'sManualpackedseparatelywith your unitfor more

information.

CALLINGCUSTOMERSUPPORT

If you havedifficulty assemblingthis product or haveanyquestionsregarding thecontrols, operationor maintenanceofthis unit,

pleasecall the CustomerSupport Department.

Call1- (330) 558-7228 or 1- (866) 848-6483to reacha Customer Support representative.Pleasehaveyour unit's

model numberandserial number readywhen you call.Seeprevioussection to locatethis information. You will be

askedto enterthe serial

SECTION1: SAFETY

Thismachinemeetsvoluntarysafetystan-

dardB71.8-1996, whichissponsoredbythe

OutdoorPowerEquipmentInstitute,Inc.,

andis publishedbythe AmericanNational

StandardsInstitute.

WARNING

The engine exhaust from this productcontains

chemicals known to the State ofCalifornia to

cause cancer, birth defects or other reproduc-

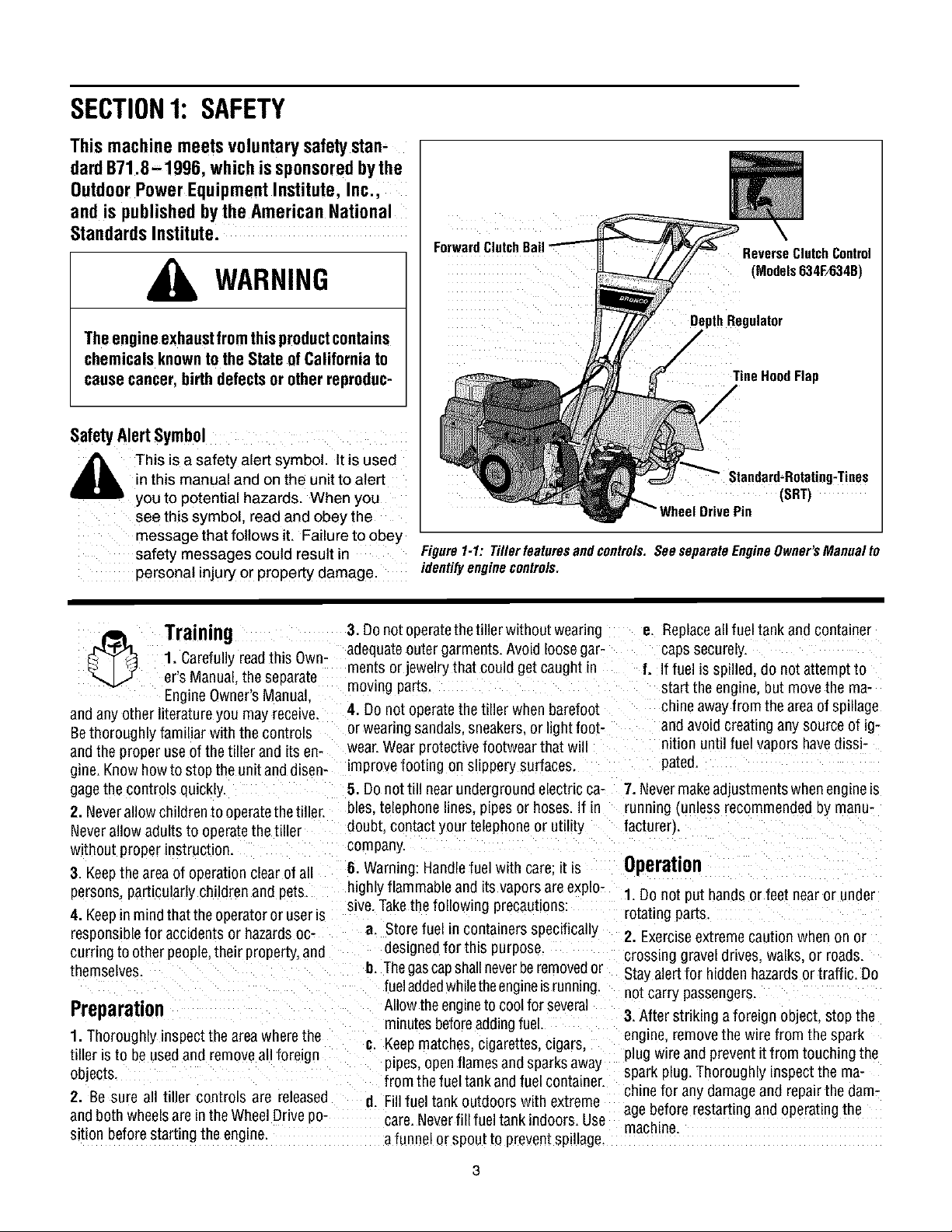

SafetyAlertSymbol

in this manual and on the unit to alert

This is a safety alert symbol. Itis used

you to potential hazards. When you

see this symbol, read and obey the

message that follows it. Failu re to obey

safety messages could result in

persona t injury or property damage.

ForwardClutchB_

DepthRegulator

ReverseClutchControl

(Models634F/634B)

TineHoodFlap

/

(SRT)

Figure1-1:Tillerfeaturesandcontrols.SeeseparateEngineOwner'sManualto

identifyenginecontrols.

3. Donot operatethetiller without wearing

1. Carefullyreadthis Own-

Training

er's Manual.the separate

EngineOwner'sManual

andany other literatureyou may receive.

Bethoroughly familiar withthe controls

andthe proper use of the tiller and its en-

gine.Know howto stop the unitand dlsen- improve footing on slippery surfaces.

gagethe controls quickly.

2. Neverallow children to operatethetiller.

Neverallow adults to operatethe tiller

without proper instruction.

3. Keepthe area of operation clear of all

persons,particularly children and pets

4. Keepin mindthat theoperatoror useris

responsiblefor accidents or hazardsoc-

curring to other people,their property,and

themselves.

Preparation

1.Thoroughly inspectthe areawherethe

tiller isto be usedand removeall foreign

objects.

2. Be sure all tiller controls are released

andboth wheelsare in theWheelDrive po-

sition beforestarting the engine.

adequateouter garments. Avoid loosegar-

ments or jewelry that could get caught in

moving parts.

4. Do not operatethe tiller when barefoot

or wearing sandals,sneakers,or light foot-

wear.Wearprotective footwear that wi

5. Donottill near underground electricca- 7. Nevermakeadjustments when engine_s

bles. telephone lines, pipes or hoses.If in running {unlessrecommended oy manu-

doubt contact your telephoneor utility facturer).

company.

6. Warning: Handlefuel with care: it is Operation

highly flammableand its vaporsare explo-

sive.Takethe following precautions:

a. Storefuel in containersspecifically

desLgnedfor this 3urpose.

I]. Thegascapshallneverberemovedor

fueladdedwhiletheengineis running.

Allow theengineto coolfor several

m_nutesbeforeaddingfuel.

#. Keepmatches, cigarettes, cigars,

ptpes,openflames and sparksaway

from the fueltank and fuel container.

d. Fillfuel tank outdoors with extreme

care.Neverfill fueltank indoors. Use

a funnel orspou[ to preventspillage.

e. Replaceall fuel tank and container

caps securely.

f. If fuel is spilled, do not attempt to

start the engine, but movethe ma-

chine awayfrom the areaof sp_llage

and avoid creating any source of ig-

lit{on until fuel vapors havedissi-

pated.

1. Do not put hands or feet near or under

rotating parts

2. Exerciseextremecaution when on or

crossing gravel drives, walks, or roads.

Stayalertfor hidden hazardsor traffic. Do

not carry passengers.

3.Nter striking a foreign object, stop the

engine,removethe wire from the spark

plug wire andpreventitfrom touching the

spark plug. Thoroughly inspectthe ma-

chinefor any damageand repairthe dam-

agebefore restarting andoperatingthe

machine.

4. Exercisecautionto avoid slippingor fall- If indoubtaboutthetilling conditions,al- 24. Donot touch engine parts which may

ing.

5. If the unit should start to vibrate aonor-

really,stop the engine,disconnect the

spark plug wire and prevent itfrom touch-

ing the sparkplug,and checkimmediately

for the cause. Vibration is generally a

warning of trouble.

6. Stopthe eng he.disconnectthe spark

plugwire and prevent itfrom touching the

spark plug, whenever you leavethe oper-

atingposition, beforeuncloggingthetines.

or whenmaking any repairs, adjustments

or inspections.

7. Takeall possible precautionswhen leav-

ing the machineunattended. Stop the en-

gine. Disconnectthe spark plug wire and

move it awayfrom thespark plug. Besure

that both wheelsare inthe Wheel Drive po-

sition.

8. Beforecleaning, repairing, or inspect-

ing, stop the engine and makecertain all

mowng parts havestopped. Disconnect

thespark plugwire and prevent itfrom

touching the spark plug to preventacci-

dentalstarting.

9. Theflapon thetine hood must bedown

when operatingthetiller.

tO. Neverusethetiller unless proper

guards, plates, or other safety protective

devicesare in place.

11. Donot run the engineman enclosed

area. Engineexhaust contains careen

monoxide gas. a deadlypoison that is

odorless, colorless, and tasteless.

12. Keepchildren andpetsaway.

13.Neveroperatethetiller underengine wheeldown slopes.

powerif the wheels are in theFreewheel

position.Inthe Freewheelposition, the

wheelswill not holdthe tiller backand the

revolving Linescould propelthetiller rapid-

ly,possibly causingloss of control. Always

engagethe wheels with the wheeldrive

pins in the Wheel Drive position before

starting the engineor engagingthe

tines/wheelswith the Forward ClutchBail

(all models_orthe ReverseClutchcontrol

(Models 634F/634Bonly}.

14. Be aware that the tiller may unex-

pectedlybounceupwardorjumpforward

if the tines shouldstrikeextremelyhard

packedsoil, frozenground,or buriedob-

stacleslike large stones, roots,or

stumps.

waysusethe followingoperatingprecau- behot from operation. Letparts cool down

tionsto assistyou inmaintainingcontrol sufficiently.

ofthe tiller: 25. Pleaseremember:Youcanalwaysstop

a. Walk behindandto oneside of the thetines andwheels by releasingthe For-

tiller, usingonehandonthe handle ward Clutch Bailor on Models 634Fand

barsRelax your arm, but usea 634B the ReverseClutchcontrol. _which-

securehandgrip.

b. Useshallower depthregulator

settings,workinggraduallydeeper

with each pass.

c. Useslowerenginespeeds.

d. Clearthe tilling area of all large

stones,rootsorotherdebris.

e. Avoidusingdownwardpressureon

thehandlebars.If needbe, use

slightupwardpressureto keep the

tines from diggingtoodeeply.

f. Beforecontactinghardpackedsoil

at the end of a row.reduceengine

speedandlift the handlebarsto

raise the tines outof the soil.

g. Inanemergency,stopthetinesand

wheels byreleasingwhichever

clutchcontrolis engaged.Do not

attemptto restrainthetiller.

15. Donot overloadthe tiller's capacityDy

attempting to till too deeplyattoo fast a

rate

16. Neveroperatethe tiller at high trans-

port speeds on hard or slippery surfaces.

Look behindand usecarewhen backing

up

17. Do not operatethetiller ona slopethai

is too steepfor safety.When onslopes,

slow down and makesure you havegood

footing. Never permit the tiller to free-

18. Neverallow bystandersnearthe umt.

19. Onlyuseattachments andaccessories

that areapprovedby the manufacturero1

the tiller.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethe tiller without good

wsibility orlight.

22. Neveroperatethe tiller if you aretired:

or underthe influence ofalcohol, drugs or

medication.

23. Operatorsshall not tamper with the en-

gine-governor settings onthe machine:

the governor controls the maximum safe

operatingspeedto protectthe engine and

all movingparts from damagecaused by

overspeed. Authorized serviceshall be

sought if a problem exists.

evercontrol isengaged),or by movingthe

_gnitionswitch and/orthrottle control lever

on the engineto "OFF"or "STOP".

26. To load or unloadthe tiller, seethe in-

structions in Section4 of this Manual.

27. Useextreme caution when reversing

or pullingthe machinetowards you.

28. Start the enginecarefullyaccording to

instructionsand with feet well awayfrom

thetines.

29. Neverpickupor carry amachinewhile

theengine is running.

MaintenanceandStorage

1. Keepthe tiller, attachmentsand acces-

sories insafeworking condition.

2. Checkall nuts bolts, andscrews at

ervalsfor proper t_ghtnessto be surethe

equipment is insafeworking condition.

3. Neverstore thetiller with fuel inthefuel

tank insidea building where ignition sourc-

esare presentsuchashotwater andspace

heaters,furnaces, clothesdryers, stoves,

electric motors, etc.L Allow the engineto

cool neforestoring the unit inan'yenclo-

sure.

4. To reducethe chancesof afire hazard.

keepthe enginefree ofgrass, leaves,or ex-

cessivegrease.

5. Storegasolinein a cool. well-ventilated

area,safelyaway from any spark- or

flame-producing equLpment. Store gaso-

line in an approvedcontainer,safelyaway

from the reachof children.

6. Refedto the Maintenancesections of

this Manualand the separateEngineOwn-

er'sManualfor instructions if the unit isto

be stored for an extendedperiod.

7. Neverperform maintenancewhilethe

engineis runmng orthe spark plug wire is

connected,exceptwhen specificahy in-

structed to doso.

8. Ifthefueltankhastobedrained dothis

outdoors.

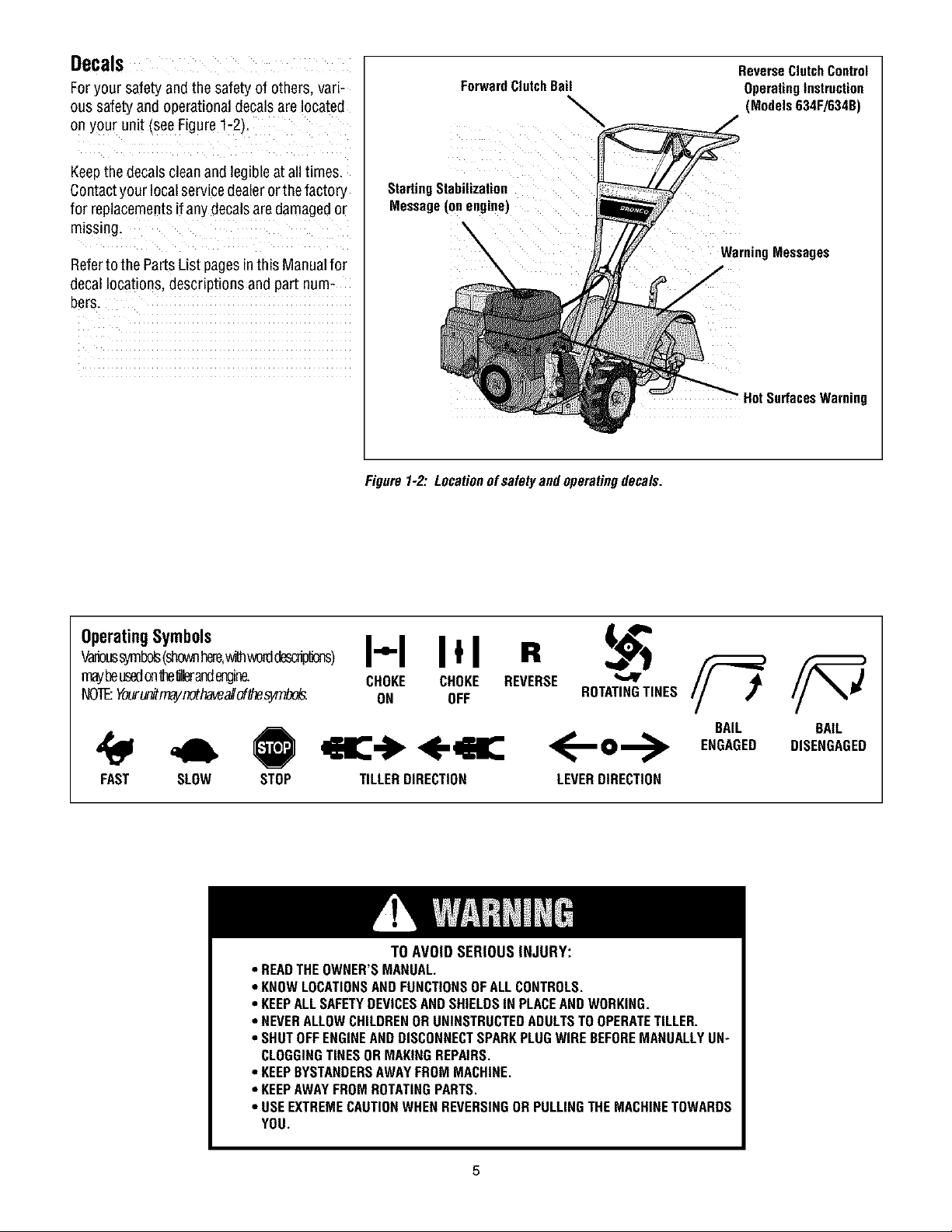

Decals

Foryour safety and the safetyof others, vari-

ous safetyand operationaldecalsare located

on your unit (seeFigure1-2)t

Keepthe decalsclean and legibleat alltimes.

Contactyour localservicedealerorthefactory

for replacementsif any decalsare damagedor

missing.

Referto the PartsList pagesinthis Manualfor

decallocations, descriptions and part num-

bers.

ForwardClutchBail

StartingStabilization

Message(onengine)

Figure1-2:Locationofsafetyandoperatingdecals.

ReverseClutchControl

OperatingInstruction

(Models634F/634B)

WarningMessages

HotSurfacesWarning

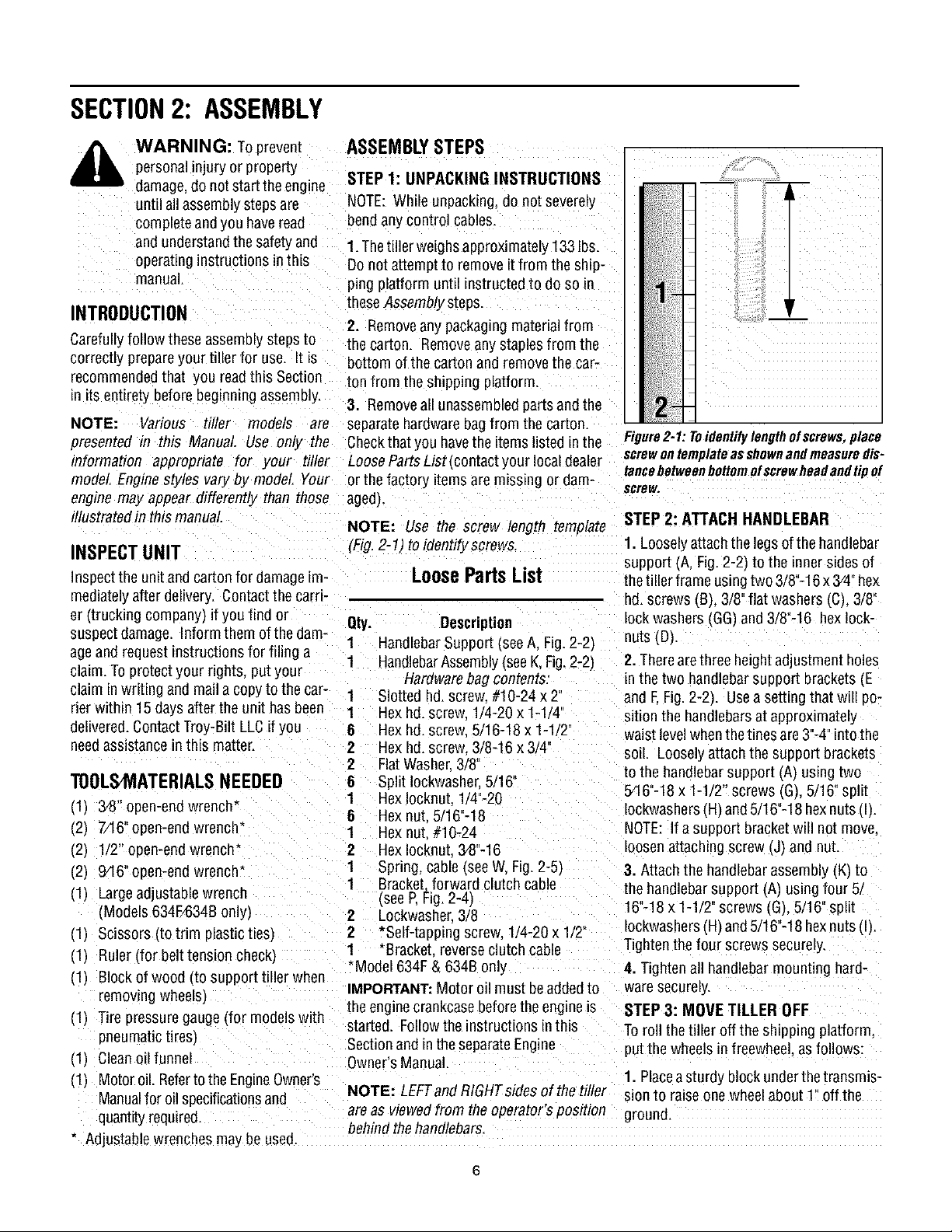

OperatingSymbols

w_s _bo_ (shownr_re,_ _crd_)

maybeusedonthellera_lmgine.

NOTEYour_mayr_thavealiof_s_.

FAST SLOW

STOP TILLERDIRECTION LEVERDIRECTION

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

• KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEAND WORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTOOPERATETILLER.

• SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUN"

CLOGGINGTINESORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE.

• KEEPAWAYFROMROTATINGPARTS.

• USEEXTREMECAUTIONWHEN REVERSINGOR PULLINGTHEMACHINETOWARDS

YOU.

I-'-I Itl R

CHOKE CHOKE REVERSE

ON OFF ROTATINGTINES

<--o-->

TO AVOID SERIOUS INJURY:

BAIL BAIL

ENGAGED DISENGAGED

SECTION2: ASSEMBLY

WARNING: To prevent

personalinjury or property

damage,do notstart the engine

until all assemblysteps are

completeandyou have read

and understandthe safetyand

operatinginstructions in this

manual.

INTRODUCTION

Carefullyfollow these assemblysteps to

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in itsentirety before beginning assembly.

NOTE: Various tiller models are

presented in this Manual Use only the Checkthat you havethe items listedin the

information appropriate for your tiller LooseParts List (contactyour localdealer

model Engine styles varyby model Your or the factory itemsare missing or dam-

engine may appear differently than those aged).

illustratedin thismanual.

INSPECTUNIT

Inspectthe unitand carton for damageLm-

mediatelyafter delivery. Contactthe cam-

er (trucking company) if you find or

suspectdamage. Inform them of the dam-

ageand request instructions for filing a 1

claim. Toprotect your rights, put your

claim inwriting andma_la copyto the car- 1

rier within 15 days after the unit has been 1

delive'ed. Contact Troy-Bilt LLCil you 6

needassistancein this matter. 2

TOOLSMATERIALSNEEDED

Ill 3,8" open-endwrench* 6 Hex nut. 5/16"-18 Iockwashers(.H)and5/16"-18 hexnuts (I).

(.2) 7/16' open-end wrench" 1 Hexnut #10-24 NOTE: If a support bracketwill not move

12_ 1/2" open-endwrench* 2 HexIocknut.3,8"-16 loosenattaching screw (J) and nut.

(2) 946"open-end wrench* 1 Spring, cable(see W, Fig.2-5_ 3. Attach the handlebarassembly (.K_to

(1) Largead Jstablewrench (.seeP, Fig.2-4_ 16"-18x 1-1/2" screws (.G_,5/16" split

_Models634F/634Bonly} 2 Lockwasher 3/8

(.1J Scissors to trim plasticties/

(1) Ruler (for belttension check_

111 Blockof wood (to support tiller when

remowng wheels)

111 Tire pressure gauge(for modelswith

pneumatictires_

Ill Cleanoil funnel

111 Motoroil Refertothe Engine0wner's

Manualfor oilspecificationsand

quantityrequired.

* Adjustablewrenches mayDeused,

ASSEMBLYSTEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE:While unpacking, do not severely

bendany control cables.

1.Thetiller weighsapproximately133 lbs.

Donot attempt to remove it from the ship-

ping platform until instructed to do so m

these Assembly steps.

2. Removeanypackagingmaterialfrom

the carton. Removeany staplesfrom the

bottom ofthe carton and removethe car-

ton from the shipping platform.

3. Removeall unassembledpartsand the

separatehardwarebagfrom the carton.

NOTE: Use the screw length template

(Fig.2-1) toidentify screws

LoosePartsList

Qty. Description

1

HandlebarSupport (seeA, Fig. 2-2_

HandlebarAssembly(seeK,Fig.2-2)

Hardwarebag contents:

Slotted hd. screw #10-24 x 2'

Hex hd. screw 1/4-20 x 1-1 '4

Hex hd. screw 5/16-18 x 1-1 2"

Hex hd. screw. 3/8-16 x 3/4

2

FlatWasher.3/8

6 Split Iockwashe_5/16"

1 HexIocknut. 1/4"-20 5Pi6"-18x 1-1/2" screws (G).5/16" split

1 Bracket.forward clutchcable the handlebarsupport (A) usingfour 5.

2

*Self-tappingscrew.1/4-20 x 1/2" IockwashersIHI and5/16"-18 hexnuts (I).

1 *Bracket reverseclutch cable

*Model 634F& 634B only

IMPORTANT:Motor oil must beaddedto

the enginecrankcase beforetheengine is

started. Followthe instructions inthis

Sectionand in the separateEngine

Owner'sManual.

NOTE: LEFTandRIGHTsidesofthetiller sion to raise one wheelabout l" off the

are as viewedfrom the operator's position ground.

behind the handlebars.

Figure2-1: Toidentifylengthofscrews,place

screwontemplateasshownandmeasuredis-

tancebetweenbottomofscrewheadandtipof

scrBw,

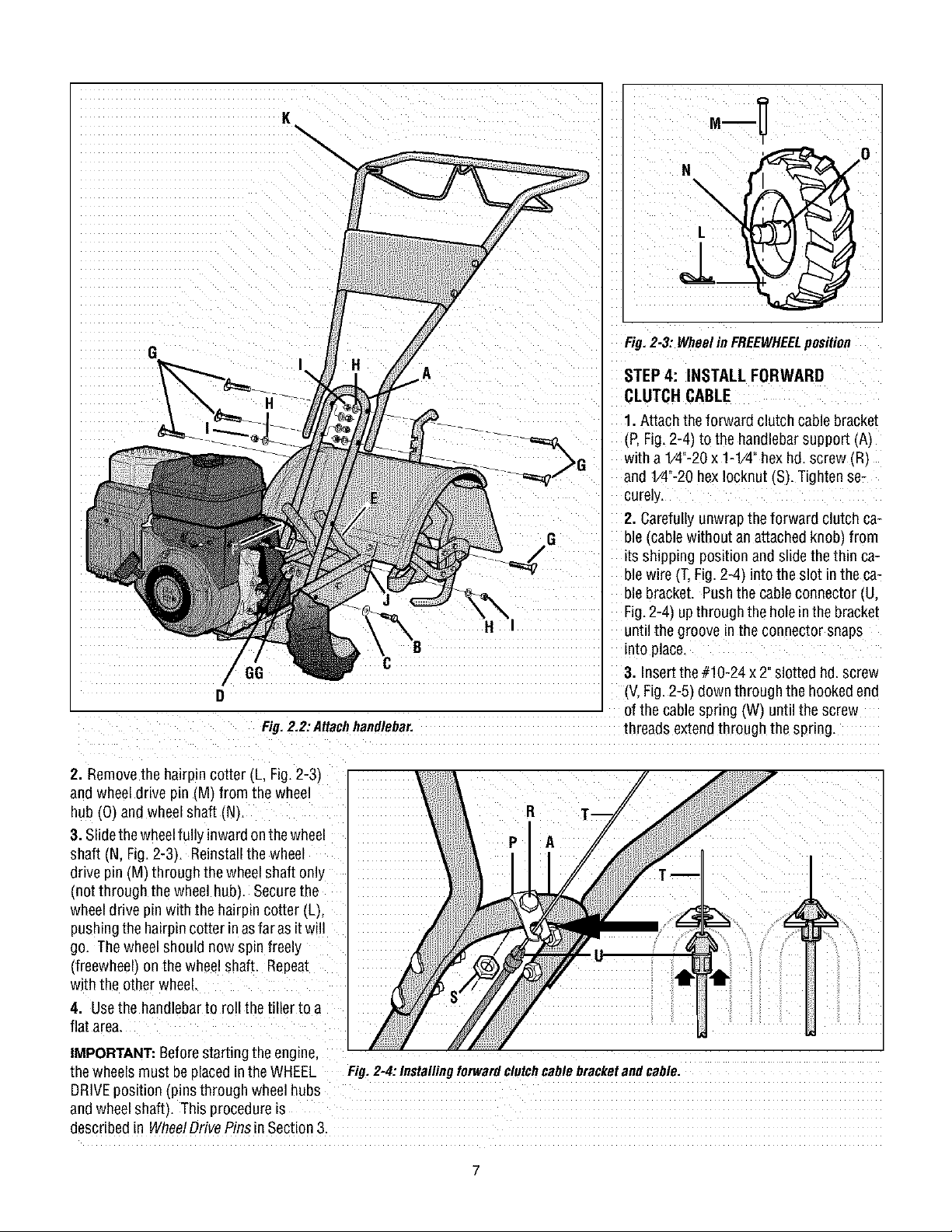

STEP 2: ATTACH HANDLEBAR

1. Looselyattach the legsof the handlebar

support (A, Fig.2-2) to the innersides of

thetiller frame usingtwo 3/8"-16x 3/4"hex

hd. screws (B), 3/8"flat washers(C), 3/8"

lock washers (GG_,and 3/8"-16 hexlock-

nuts (D_,

2. Therearethree height adjustment holes

in the two handlebarsupport brackets (.E

and E Fig. 2-2). Usea setting that will po-

sition the handlebarsat approximately

waist levelwhenthetines are3"-4"intothe

so_l. Looselyattachthe support brackets

to the handlebarsupport (.A_using two

Tightenthe four screwssecurely

4. Tighten all handlebarmounting hard-

waresecurely.

STEP3: MOVE TILLER OFF

Toroll thetiller off the shipping platform.

put the wheels in freewhee asfollows:

1. Placeasturdy block underthe transmis-

m

Fig.2,2:AHachhandlebar, threads extendthrough the spring.

2. Removethe hairpin cotter (L, Fig.2-3)

and wheel drive pin (M) from the wheel

hub (0) and wheel shaft (N).

3. Slidethe wheelfully inwardonthewheel

shaft (N, Fig.2-3). Reinstallthe wheel

drive pin (M) through the wheelshaft only

(not through the wheel hub). Securethe

wheeldrive pin with the hairpin cotter (L),

pushingthe hairpincotter inasfar asit will

go. Thewheel should now spin freely

(freewheel) on the wheel shaft. Repeat

with the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

Fig. 2-3: Wheelin FREEWHEELposition

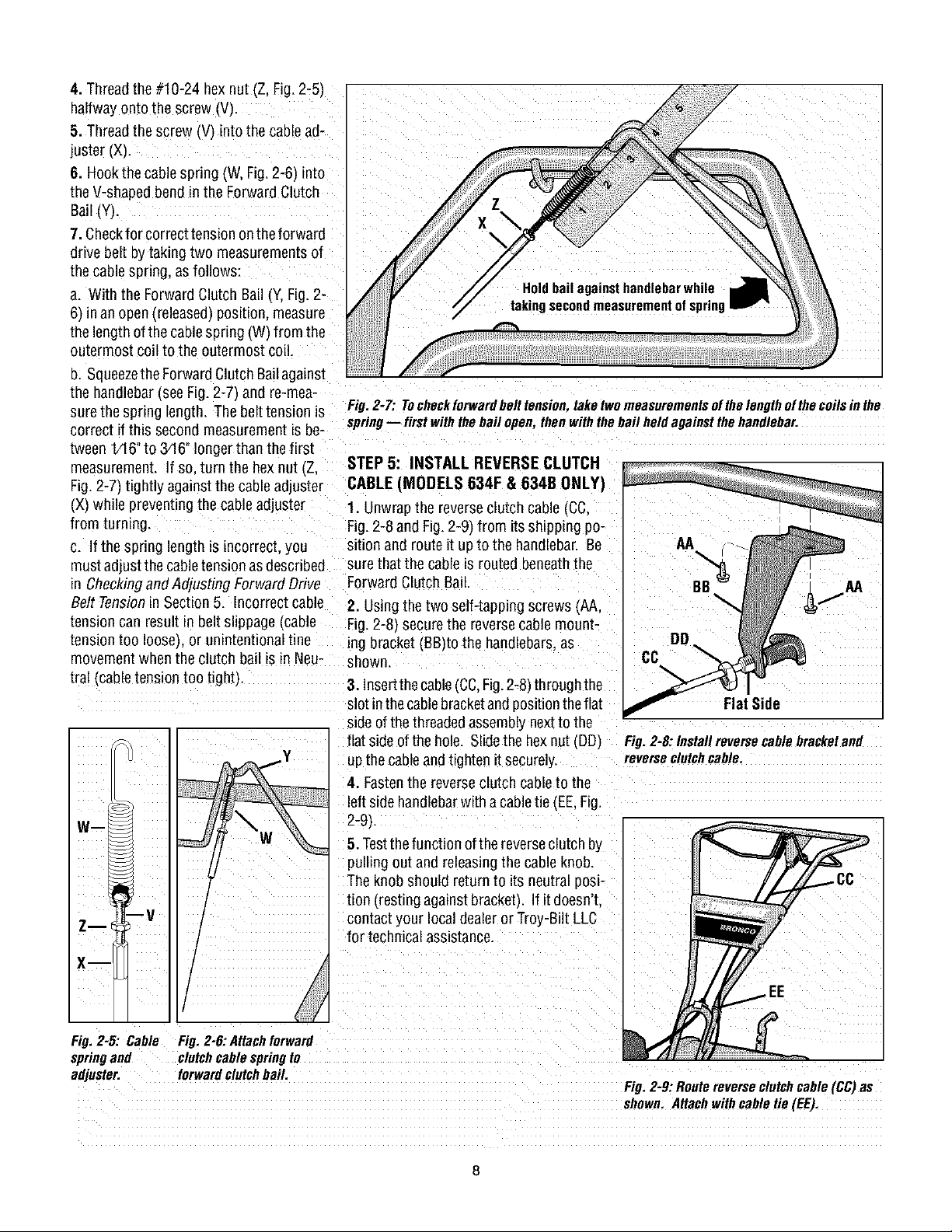

STEP4: INSTALL FORWARD

CLUTCH CABLE

1. Attach the forward clutch cablebracket

(P,Fig.2-4) to the handlebarsupport AI

with a1/4"-20x 1-1/42hexhd. screw (R)

and V4"-20 hexIocknut (S). Tightense-

curely.

2. Carefullyunwrapthe forward clutch ca-

ble (cable without anattachedknob, from

its shipping position and slidethe thin ca-

ble wire (T.Fig.2-4 intothe slot in the ca-

ble bracket. Pushthe cable connector (U.

Fig.2-4) upthrough the holein the bracket

until the groove inthe connector snaps

into place.

3. Insertthe #10-24 x 2"slotted hd.screw

(V,Fig.2-5) downthrough the hookedend

of the cable spring (W) until the screw

IMPORTANT:Beforestarting theengine,

thewheels must beplacedin the WHEEL Fig.2=4:Installingforwardclutchcablebracketandcable.

DRIVEposition (pins through wheelhubs

andwheelshaft). This procedureis

described in WheelDrivePinsin Section3.

4. Threadthe #10-24 hexnut (Z,Fig. 2-5)

halfwayonto the screw (V).

5. Threadthe screw IV_into thecable ad-

juster (X).

6. Hookthe cable spring (W,Fig.2-6) into

theV-shaoedbend in the ForwardClutch

Bail _Y).

7. Checkfor correcttension ontheforward

drive belt by taking two measurementsof

thecablespnng, asfollows:

a. With the ForwardClutch Bail(Y,Fig.2-

6/in an open(released)position, measure

thelength ofthecablespring (W from the

outermost coil to the outermost coil.

n. Squeezethe ForwardClutchBailagainst

the handlebar(see Fig. 2-7_and re-mea-

surethe spring length, Thebelt tensionis

correct if this second measurementis be-

Fig.2-7: Tocheckforwardbelttension,taketwomeasurementsofthelengthofthecoilsinthe

spring-- firstwiththebailopen,thenwiththebailheldagainstthehandlebar.

tween 1/16"to 3/16"longer than thefirst

measurement. If so. turn the hexnut (Z.

Fig.2-7) tightly against the cableadjuster

(X_while preventingthe cableadjuster

from turnmg.

c. Ifthe spring length is incorrect, you

mustadjust the cabletension asdescribed

STEP 5: INSTALL REVERSECLUTCH

CABLE (MODELS 634F & 634B ONLY)

1. Unwrapthe reverseclutch cable(CC.

Fig.2-8 and Fig.2-9_from itsshipping po-

sition and route it upto the handlebar. Be

surethat the cableis routed beneaththe

in Checkingand Adjustin_ ForwardDrive Forward Clutch Bail.

Belt Tensionin Section 5. Incorrectcable

tension can result in belt slippage Icable

tension too IooseLor unintentional tine

movement when the clutch bail is in Neu-

tral Icable tension too tight}

2. Usingthe two self-tapping screws (AA,

Fig.2-8) securethe reversecable mount-

ing bracket(BB)to the handlebars,as

show_

3. Insertthe cable(CC,Fig.2-8) through the

slot inthecablebracketandpositiontheflat

sideofthe threadedassemblynextto the

flat sideof the hole. Slidethe hex nut (DD/

up the cable andtighten it securely

4. Fastenthe reverseclutch cable to the

left side handlebarwith a cabletie (EE,Fig.

Wm

2-9L

5. Testthefunction ofthe reverseclutch by

pulling out and releasing the cableknob.

Theknob should return to its neutral posi-

tion (resting against bracketL Ifit doesn't.

Zm

contact your localdealer or Troy-Bilt LLC

for technical assistance.

X--

CC

Flat Side

Fig. 2-8: Install reverse cable bracketand

reverseclutch cable,

Fig, 2-5: Cable

springand

adjuster.

Fig. 2-6: Attachforward

clutch cable spring to

forwardclutchbail.

Fig.2-9:Routereverseclutchcable(CC)as

shown.Attachwithcabletie(EL:).

31bY I_: L;I'IEL;KLEVEL UI-

Thetransmission wasfilled with gearoil at

thefactory.However,youshouldcheckthe

gearoil levelatthis timeto makecertain it

is correct.

IMPORTANT:Donot operatethe tiller if the

gearoil levelis low. Doingso will result in

severedamageto thetransmission com-

ponents.

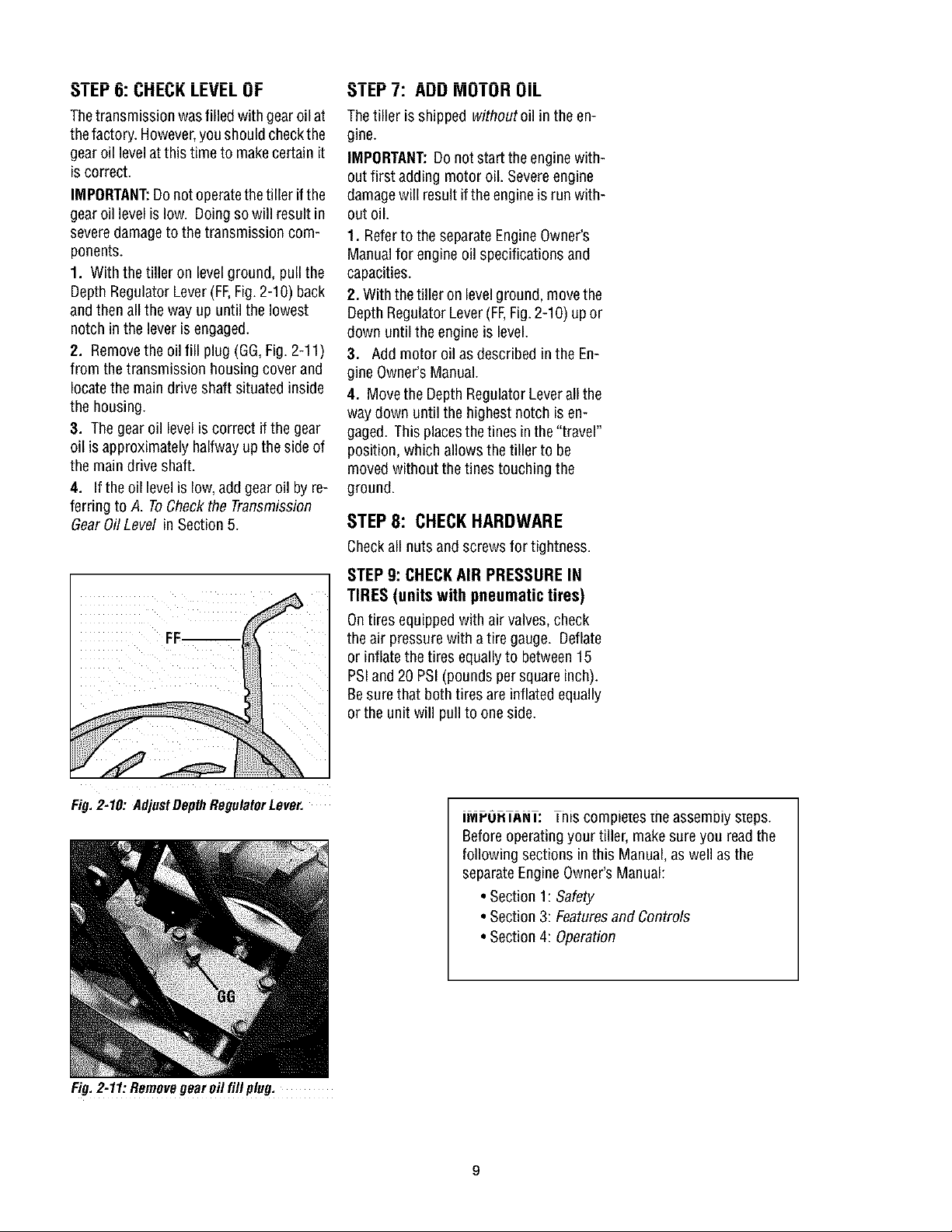

1. With the tiller on levelground, pull the

Depth RegulatorLever(FF,Fig.2-10) back

andthen all the way up until the lowest

notch inthe lever isengaged.

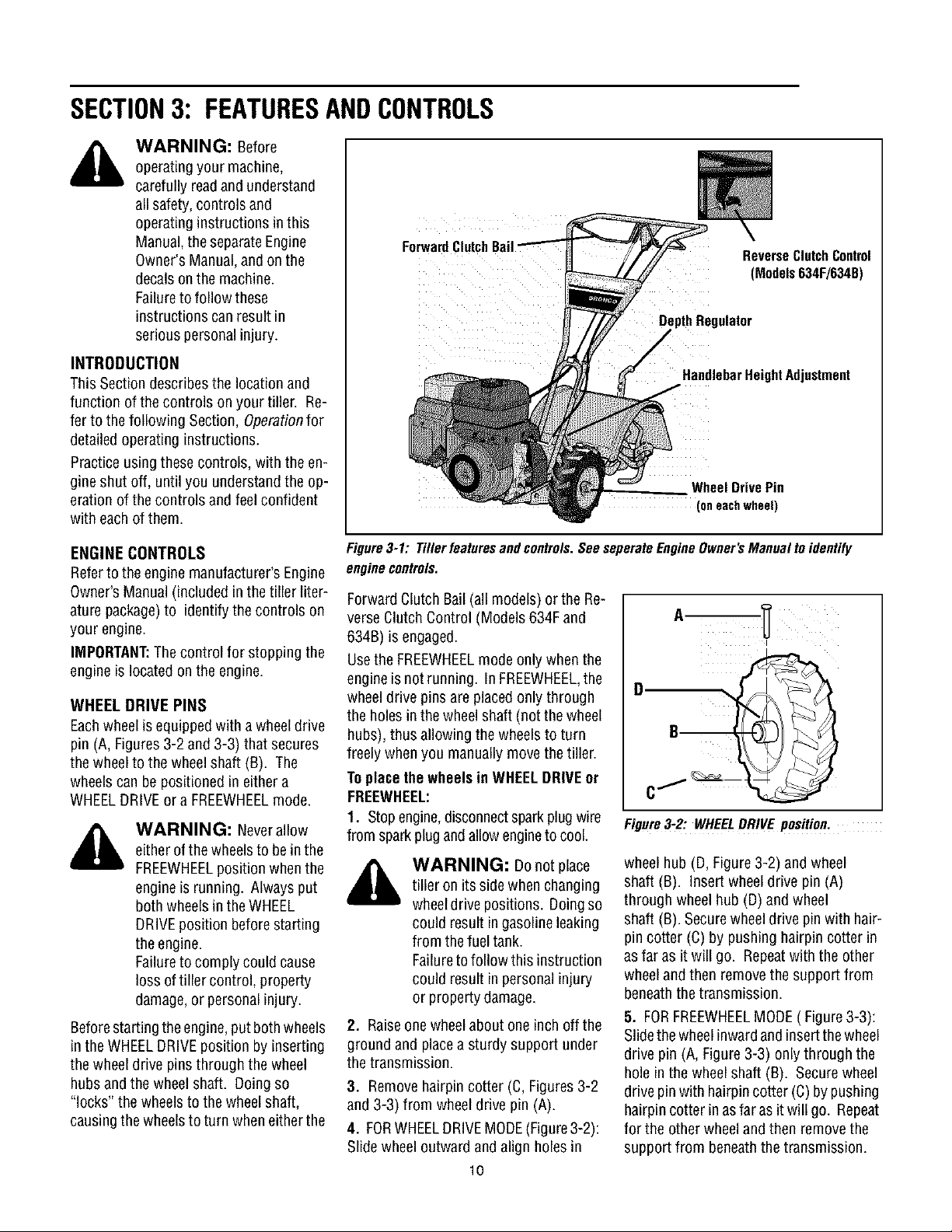

2. Removethe oil fill plug (GG,Fig.2-11)

from the transmission housingcover and

locatethe main drive shaft situated inside

the housing.

3. Thegear oil level is correct ifthe gear

oil isapproximately halfwayup theside of

the maindrive shaft.

4. If the oil levelis low,add gear oil byre-

ferring to A. ToCheckthe Transmission

GearOil Level inSection 5.

_IbY I: AUU MUIUH UIL

Thetiller isshipped withoutoil in theen-

gine.

IMPORTANT:Do not start theengine with-

outfirst adding motor oil. Severeengine

damagewill resultifthe engineis run with-

out oil.

1. Referto the separateEngineOwner's

Manualfor engine oil specifications and

capacities.

2. With thetiller on levelground, movethe

Depth RegulatorLever(FF,Fig.2-10) upor

down until the engineis level.

3. Add motor oil asdescribed in the En-

gine Owner'sManual.

4. Movethe DepthRegulatorLeverall the

way down until the highest notch is en-

gaged. This placesthetines in the "travel"

position, which allows the tiller to be

moved without thetines touching the

ground.

STEP8: CHECKHARDWARE

Checkall nuts and screws for tightness.

STEP 9: CHECKAIR PRESSURE IN

TIRES (units with pneumatic tires)

Ontires equipped with air valves, check

theair pressurewith atire gauge. Deflate

or inflatethe tires equallyto between15

PSIand20 PSI(pounds per squareinch).

Besure that both tires are inflated equally

orthe unit will pullto one side.

Fig. 2-10: AdjustDepth RegulatorLever.

Fig.2-11:Removegearoil fill plug,

IMrU. lANl: his compie[esme assemoiy steps.

Beforeoperatingyour tiller, makesure you readthe

following sections in this Manual,as well as the

separateEngineOwner'sManual:

• Section1: Safety

• Section3: Featuresand Controls

• Section4: Operation

SECTION3: FEATURESANDCONTROLS

WARNING: Before

operatingyour machine,

carefully readand understand

all safety, controls and

operatinginstructions in this

Manual,the separateEngine

Owner's Manual,and on the

decalson the machine.

Failureto follow these

instructions canresult in

serious personal injury.

INTRODUCTION

This Section describesthe location and

function of the controls onyour tiller. Re-

ferto thefollowing Section,Operationfor

detailedoperating instructions.

Practiceusing these controls, with the en-

gine shut off, until you understandthe op-

eration ofthe controls andfeelconfident

with eachof them.

Forward

Reverse ClutchControl

(Models634F/634B)

DepthRegulator

Handlebar HeightAdjustment

Wheel Drive Pin

(oneachwheel)

ENGINE CONTROLS

Referto the engine manufacturer's Engine

Owner'sManual (included inthe tiller liter-

ature package)to identify the controls on

your engine.

IMPORTANT:Thecontrol for stopping the

engine is locatedon the engine.

WHEEL DRIVE PINS

Eachwheel is equippedwith awheeldrive

pin (A, Figures3-2 and 3-3) that secures

thewheelto the wheel shaft (B). The

wheelscan be positioned ineither a

WHEELDRIVEora FREEWHEELmode.

WARNING: Neverallow

eitherof thewheelsto bein the

FREEWHEELposition whenthe

engineis running. Alwaysput

both wheelsin theWHEEL

DRIVEposition beforestarting

theengine.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

Beforestarting theengine,put both wheels

in the WHEELDRIVEposition byinserting

thewheel drive pins through the wheel

hubsand the wheel shaft. Doingso

"locks" the wheels to the wheel shaft,

causingthe wheelsto turn wheneitherthe

Figure3-1: Tillerfeaturesandcontrols.SeeseperateEngineOwner'sManualtoidentify

enginecontrols.

Forward Clutch Bail (all models) or the Re-

verseClutch Control (Models 634Fand

634B) is engaged.

Usethe FREEWHEELmode only whenthe

engineis not running. In FREEWHEEL,the

wheeldrive pins are placed only through

theholes in thewheelshaft (not the wheel

hubs), thus allowing the wheelsto turn

freely whenyou manuallymovethe tiller.

Toplacethe wheels in WHEELDRIVEot

FREEWHEEL:

1. Stopengine,disconnectsparkplugwire

from sparkplug andallowengineto cool.

WARNING: Donot place

tiller on its side when changing

wheeldrive positions. Doing so

could result in gasoline leaking

from thefuel tank.

Failureto follow this instruction

could result in personal injury

or propertydamage.

2. Raiseonewheelabout one inch off the

ground and placea sturdy support under

thetransmission.

3. Removehairpin cotter (C, Figures3-2

and 3-3) from wheel drive pin (A).

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheel outward and align holes in

10

Figure3-2: WHEELDRIVE position.

wheelhub (D,Figure3-2) and wheel

shaft (B). Insert wheeldrive pin (A)

through wheel hub (D)and wheel

shaft (B). Securewheeldrive pinwith hair-

pin cotter (C) by pushing hairpincotter in

asfar as it will go. Repeatwith the other

wheeland then removethesupport from

beneaththe transmission.

5. FORFREEWHEELMODE( Figure3-3):

Slidethe wheelinwardand insertthewheel

drive pin (A, Figure3-3) onlythrough the

hole in the wheel shaft (B). Secure wheel

drive pinwith hairpincotter (C)by pushing

hairpin cotter inasfaras it will go. Repeat

for the other wheeland then removethe

support from beneaththe transmission.

Loading...

Loading...