Troybilt 21A-634A766 Owner’s Manual

®

O m m 'W//////aI&_AIIIIIIIIIIIIIF

Operator's Manual

/ m mllllllllllllllllml m

Rear-tine Tiller Models

630C--Tuffy

634AmSuper BroncoTM

Mode1634A Shown

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark attester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-0019.

Troy-Bilt LLC,P.O.BOX361131CLEVELAND,OHIO44136-0019

PRINTEDINU.S.A. FORMNO. 770-10594E

9/9/04

TABLEOFCONTENTS

Content Page Content Page

Customer Support 2 Maintenance 17

Safety 3 Off-season Storage 21

Assembly 6 Troubleshooting 22

Features and Controls 10 Parts List 23

Operation 12 Warranty Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new lawn tractor. It will help you assemble, prepare and maintain the

unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and

copy the information from it in the space provided below. A sample model plate is also given below. You can

locate the model plate by looking at the rear of the tine shield. This information will be necessary to use the

manufacturer's web site and/or help from the Customer Support Department or an authorized service dealer.

Copy the model number here:

OTRDV-BILT T,OV-BmLTLLC

www.troybilt.com CLEVELAND,OH44136

,. 1-800-520-552_

P. O. BOX 361131

330-558-7220

Copy the serial number here:

CUSTOMERSUPPORT

PleasedoNOTreh/m thel/nit totheretailer withoutfirstcontactingCustomerSupport.

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance of

this unit, you can seek help from the experts. Choose from the options below:

Visit troy-bilt.com for many useful suggestions. Click on Customer Support button and you

will get the four options reproduced here. Click on the appropriate button and help is

immediately available.

_ 7>,,,,

/;/ ,> ;'V }/ )

..... f ; @; t ;D

j;_ ?" #'s " 4t, ' F_ i/!s ,

* ;,, #FOX }_ j,"

,,, >,, rL;," ¢j ,_ <# ft, *x J ,7;; _

'_,-., _tf';_'ivc ,l

,v yO, ,_;7f'_;:'

If you prefer to reach a Customer Support Representative, please call 1(800) 520-5520.

The engine manufacturer is responsible for all engine-related issues with regard to

performance, power-rating, specifications, warranty and service. Please refer to the engine

manufacturer's Owner's/Operator's Manual, packed separately with your unit, for more

information.

SECTION1: SAFETY

This machine meets voluntary safety stan-

dard B71.8-1996, which is sponsoredbythe

Outdoor Power Equipment Institute, Inc.,

and is published by the American National

Standards Institute.

WARNING

The engine exhaustfromthisproductcontains

chemicals known to the State of California to

cause cancer, birth defects or other reproduc-

SafetyAlertSymbol

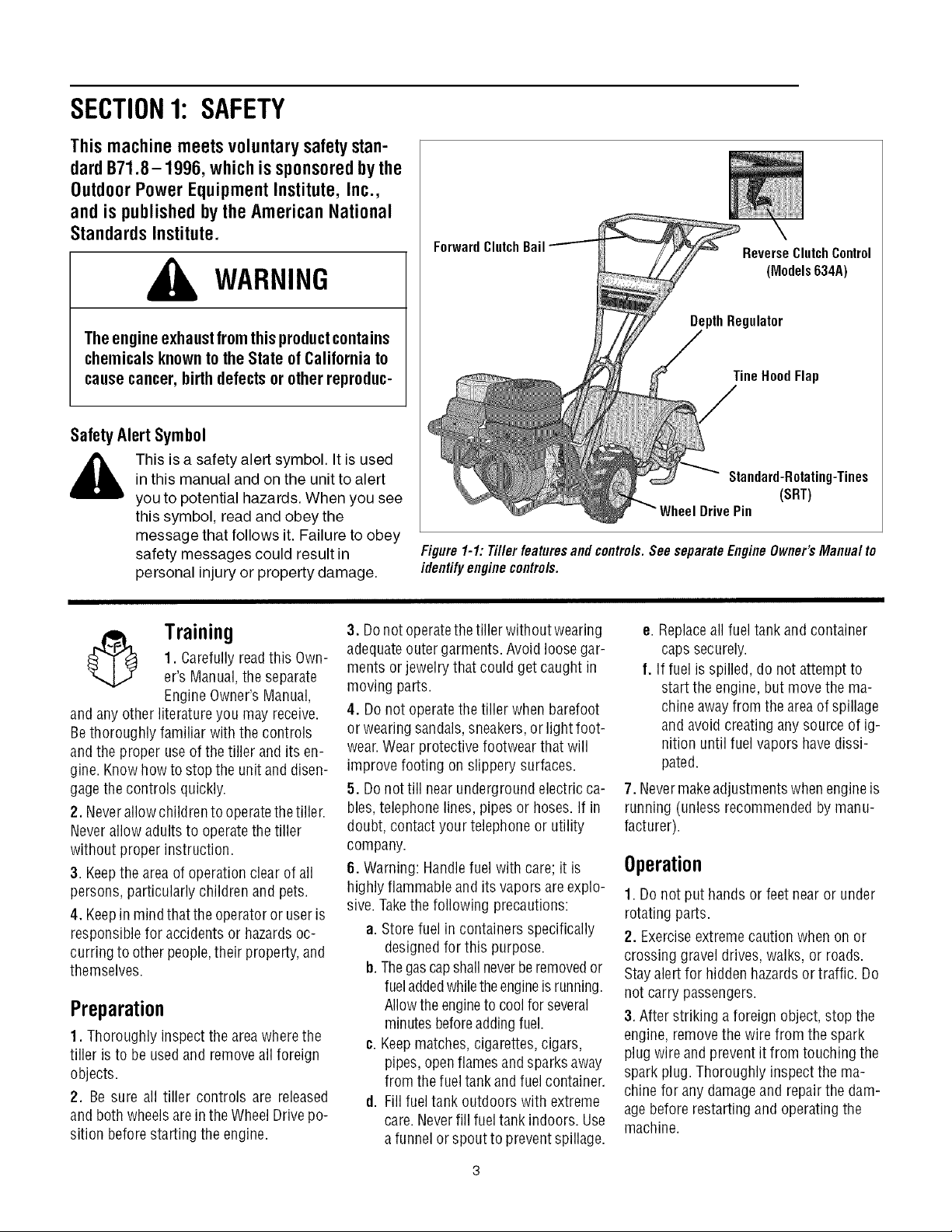

ForwardClutchBail

ReverseClutchControl

(Models634A)

DepthRegulator

TineHoodFlap

,_ This is a safety alert symbol. It is used

and anyother literature you may receive.

Bethoroughly familiar with the controls

andthe proper useof the tiller and its en-

gine. Knowhowto stopthe unit and disen-

gagethe controls quickly.

2. Neverallow childrento operatethe tiller.

Neverallow adults to operatethe tiller

without proper instruction.

3. Keepthe areaof operationclear of all

persons, particularly children and pets.

4. Keepin mindthattheoperatoror useris

responsible for accidents or hazardsoc-

curring to otherpeople,their property,and

themselves.

in this manual and on the unit to alert

you to potential hazards. When you see

this symbol, read and obey the

message that follows it. Failure to obey

safety messages could result in

personal injury or property damage.

3. Donot operatethetiller without wearing

1. Carefully readthis Own-

Training

er's Manual,the separate

Engine Owner'sManual,

adequateouter garments.Avoid loosegar-

ments or jewelry that could get caught in

moving parts.

4. Do not operatethe tiller when barefoot

or wearingsandals, sneakers,or light foot-

wear.Wear protective footwear that will

improve footing on slippery surfaces.

5. Do nottill nearundergroundelectric ca-

bles,telephone lines, pipes or hoses.If in

doubt, contact your telephoneor utility

company.

6. Warning: Handlefuel with care; it is

highly flammableandits vapors areexplo-

sive.Takethe following precautions:

a. Storefuel in containers specifically

b. Thegascapshall neverberemovedor

Preparation

1. Thoroughly inspect the areawherethe

tiller is to be usedand removeallforeign

objects.

2. Be sure all tiller controls are released

and bothwheels arein theWheelDrive po-

sition beforestarting the engine.

c. Keepmatches,cigarettes, cigars,

d. Fillfuel tank outdoors with extreme

Standard-Rotating-Tines

(SRT)

DrivePin

Figure 1-1: Tiller featuresand contre/s. SeeseparateEngine Owner'sManua/ to

identifyenginecontre/s.

e. Replaceall fueltank and container

caps securely.

f. If fuel isspilled, do not attempt to

start the engine,but move the ma-

chineawayfrom the areaof spillage

and avoidcreating any source of ig-

nition until fuel vapors havedissi-

pated.

7. Nevermakeadjustments whenengineis

running (unless recommendedby manu-

facturer).

Operation

1. Do not put hands or feet nearor under

rotating parts.

designedfor this purpose.

fueladdedwhiletheengineis running.

Allowthe engineto coolforseveral

minutesbeforeaddingfuel.

pipes, openflamesandsparks away

from thefueltank andfuelcontainer.

care.Neverfill fuel tank indoors. Use

a funnelor spout to preventspillage.

2. Exerciseextremecautionwhen on or

crossing gravel drives,walks, or roads.

Stayalert for hiddenhazardsor traffic. Do

not carry passengers.

3. After striking a foreign object, stop the

engine,removethe wire from the spark

plug wire and prevent it from touching the

spark plug. Thoroughly inspectthe ma-

chine for any damageand repairthe dam-

agebefore restarting and operatingthe

machine.

4.Exercisecautiontoavoidslippingorfall-

ing.

5.Iftheunitshouldstarttovibrateabnor-

mally,stoptheengine,disconnectthe

sparkplugwireandpreventitfromtouch-

ingthesparkplug,andcheckimmediately

forthecause.Vibrationisgenerallya

warningoftrouble.

6. Stopthe engine, disconnectthe spark

plug wire and prevent it from touching the

spark plug,wheneveryou leavethe operat-

ing position, before unclogging thetines,

or whenmakingany repairs, adjustments

or inspections.

7. Takeall possible precautionswhen leav-

ing the machine unattended.Stopthe en-

gine. Disconnectthespark plug wire and

move it awayfrom thespark plug. Besure

that both wheelsarein the WheelDrive po-

sition.

8. Before cleaning,repairing,or inspect-

ing, stop the engine and make certain all

moving parts havestopped. Disconnect

the spark plug wire and prevent it from

touching thespark plug to preventacci-

dentalstarting.

9. Theflapon thefine hood must bedown

when operatingthetiller.

10. Neverusethetiller unless proper

guards, plates,or other safety protective

devicesare in place.

11. Do not run the engine in an enclosed

area.Engineexhaust containscarbon

monoxide gas,adeadlypoison that is

odorless, colorless, and tasteless.

12. Keepchildren and pets away.

13. Never operate the tiller underengine

powerif thewheels areinthe Freewheel

position.In the Freewheelposition, the

wheelswill not hold the tiller back andthe

revolvingtines could propel thetiller rapid-

ly,possibly causingloss of control. Always

engagethe wheels with the wheel drive

pins in theWheel Drive position before

starting the engineorengagingthe

tines4Nheelswith the Forward Clutch Bail

(all models) or the ReverseClutchcontrol

(Models 634A only).

14. Be awarethat the tiller may unex-

pectedlybounceupwardorjumpforward

if the tinesshouldstrike extremelyhard

packedsoil, frozen ground,or buriedob-

stacleslike large stones,roots,or

stumps.

If indoubtaboutthetilling conditions, al-

ways usethe following operating precau-

tionsto assistyouin maintainingcontrol

of the tiller:

a. Walk behindandto one side of the

tiller, usingone handonthehandle

barsRelax yourarm, but use a

securehandgrip.

b. Useshallowerdepthregulator

settings,working graduallydeeper

with eachpass.

¢. Useslowerenginespeeds.

d. Clearthetilling area of all large

stones,rootsor other debris.

e. Avoidusingdownwardpressureon

thehandlebars. If needbe, use

slight upwardpressuretokeep the

tinesfrom diggingtoodeeply.

f. Beforecontacting hardpackedsoil

at the endof a row, reduceengine

speedand lift thehandlebarsto

raise thetines out of the soil.

g. In anemergency,stopthetinesand

wheels byreleasingwhichever

clutch controlis engaged.Do not

attemptto restrainthetiller.

15. Do not overloadthe tiller's capacityby

attempting to till too deeply at too fast a

rate.

16. Neveroperatethetiller at high trans-

port speeds on hard or slippery surfaces.

Look behind and usecare when backing

up.

17. Donot operatethetiller on aslopethat

is too steepfor safety.When onslopes,

slow down and makesure you havegood

footing. Neverpermit thetillerto freewheel

down slopes.

18. Neverallowbystandersnearthe unit.

19. Onlyuseattachmentsand accessories

that are approved bythe manufacturerof

the tiller.

20. Usetiller attachmentsand accessories

when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethe tiller ifyou aretired;

or underthe influence ofalcohol, drugs or

medication.

23. Operatorsshall nottamper with theen-

gine-governor settings onthe machine;

the governor controls the maximum safe

operatingspeed to protect the engine and

all moving parts from damagecaused by

overspeed.Authorized serviceshall be

sought if a problem exists.

24. Do nottouch engine parts which may

behot from operation.Let partscool down

sufficiently.

25. Pleaseremember:Youcan alwaysstop

thetines andwheelsby releasingthe For-

ward ClutchBailoron Model634Athe Re-

verseClutchcontrol, (whichevercontrol is

engaged),or bymovingthe ignition switch

and/orthrottle control lever on the engine

to "OFF" or"STOP".

26. To loador unloadthe tiller, seethe in-

structions in Section4 of this Manual.

27. Useextremecaution when reversing

or pulling the machinetowards you.

28. Starttheenginecarefully accordingto

instructions and with feet well away from

thetines.

29. Neverpick up or carry a machinewhile

the engineis running.

MaintenanceandStorage

1. Keepthe tiller, attachmentsand acces-

sories in safeworking condition.

2. Checkall nuts, bolts, and screws for

proper tightnessto besurethe equipment

is in safeworking condition.

3. Neverstore thetiller with fuel in thefuel

tank insidea building whereignition sourc-

esare presentsuchas hot waterandspace

heaters,furnaces, clothes dryers, stoves,

electric motors, etc.). Allow the engineto

cool beforestoring the unit in anyenclo-

sure.

4. To reducethe chancesof a fire hazard,

keepthe enginefreeof grass, leaves,or ex-

cessivegrease.

5. Store gasolinein acool, well-ventilated

area,safely awayfrom any spark- or

flame-producing equipment. Store gaso-

line in anapprovedcontainer,safelyaway

from the reachof children.

6. Refertothe Maintenancesectionsof

this Manualandthe separateEngineOwn-

er'sManualfor instructions ifthe unitis to

bestored for an extendedperiod.

7. Neverperform maintenancewhilethe

engineis running orthe spark plug wire is

connected,exceptwhen specifically in-

structed to do so.

8. Ifthefueltank hasto be drained,dothis

outdoors.

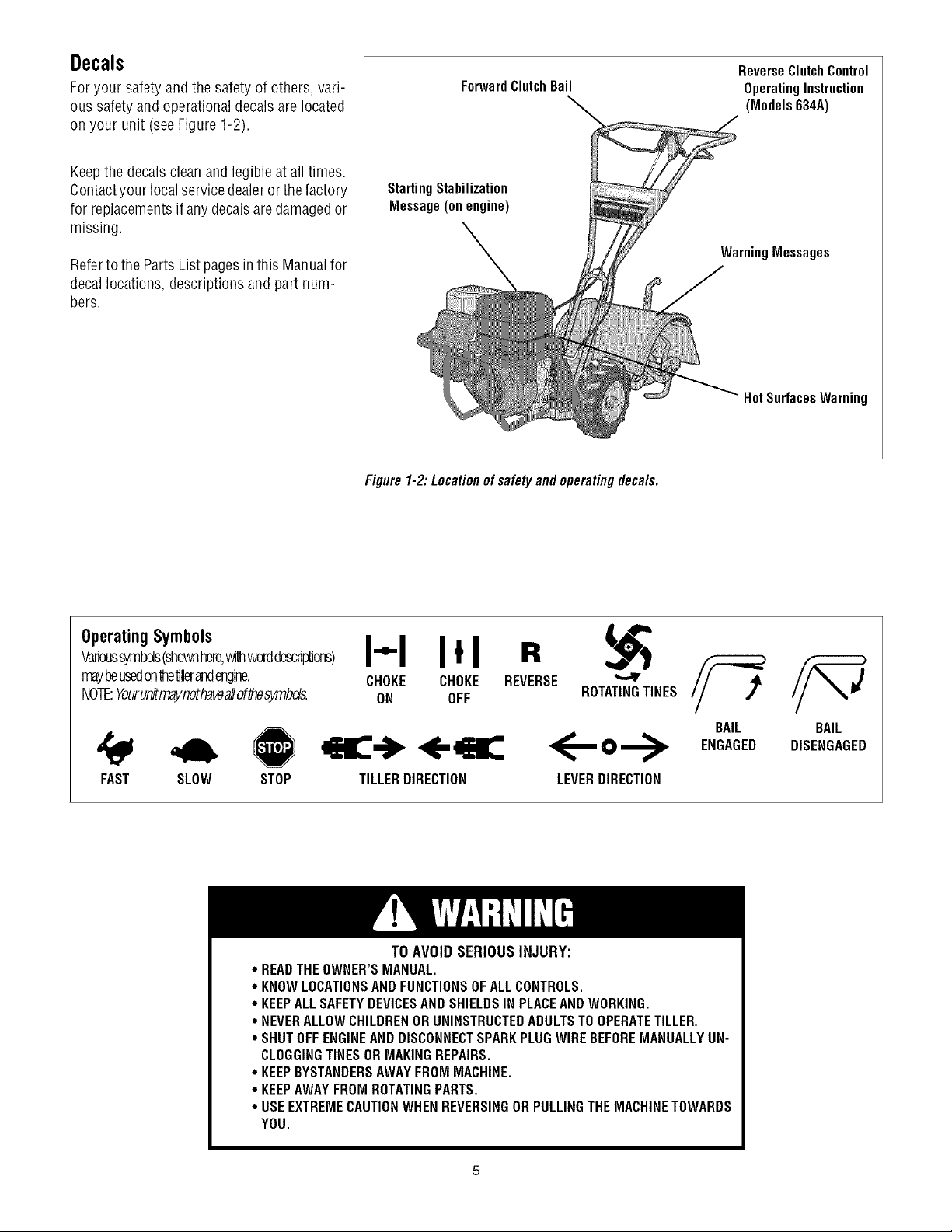

Decals

Foryour safety and the safety of others, vari-

ous safety and operationaldecalsarelocated

on your unit (seeFigure 1-2).

Keepthe decalsclean and legibleatall times.

Contactyour localservicedealeror thefactory

for replacementsif anydecalsaredamagedor

missing.

Referto the PartsListpagesin this Manualfor

decallocations, descriptionsandpart num-

bers.

ForwardClutchBail

StartingStabilization

Message(on engine)

Figure 1-2: Locationofsafety and operatingdeca/s.

ReverseClutch Control

OperatingInstruction

(Models 634A)

WarningMessages

HotSurfacesWarning

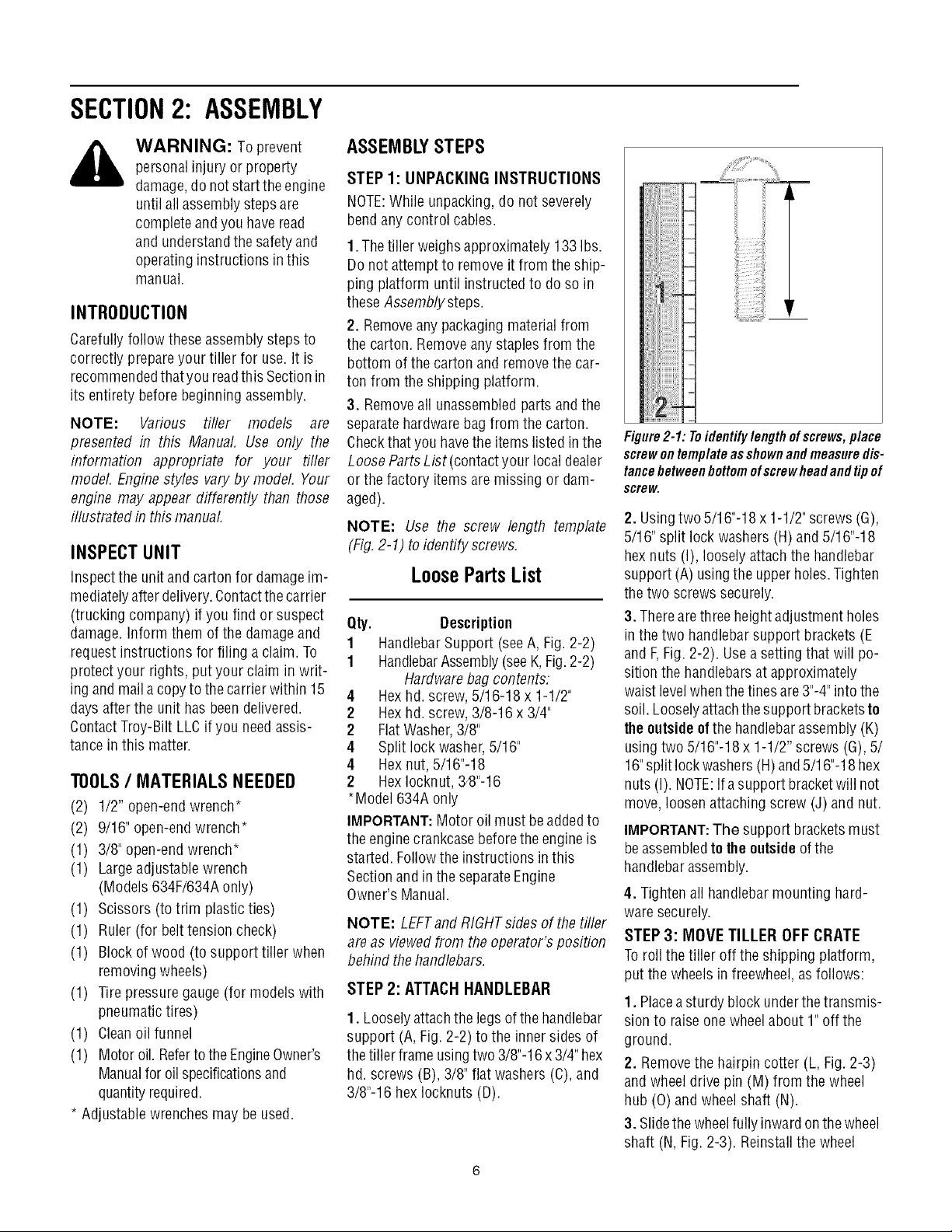

OperatingSymbols

Varioussymbols(shownhere,withworddescriptions)

mayheusedonte'dllerandengine.

NOTE:Yourunitmaynothaveallof_esymbds.

FAST SLOW STOP

* READTHEOWNER'SMANUAL.

* KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

* KEEPALLSAFETYDEVICESANDSHIELDSIN PLACEAND WORKING.

° NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

° SHUTOFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUN-

CLOGGINGTINESORMAKINGREPAIRS.

° KEEPBYSTANDERSAWAYFROMMACHINE.

° KEEPAWAYFROM ROTATINGPARTS.

° USEEXTREMECAUTIONWHENREVERSINGOR PULLINGTHEMACHINETOWARDS

YOU.

I"1 I*1 R

CHOKE CHOKE REVERSE

ON OFF ROTATINGTINES

TILLERDIRECTION LEVERDIRECTION

TO AVOID SERIOUS INJURY:

BAIL

ENGAGED

BAIL

DISENGAGED

SECTION2: ASSEMBLY

WARNING: Toprevent

personalinjury or property

damage,do notstart the engine

until all assemblysteps are

completeandyou haveread

and understandthesafety and

operatinginstructions in this

manual.

INTRODUCTION

Carefullyfollow theseassemblysteps to

correctly prepareyour tiller for use. It is

recommendedthatyou readthis Sectionin

its entirety beforebeginning assembly.

NOTE: Various rifler models are

presented in this Manual. Use only the

information appropriate for your tiller

model. Engine styles vary by model, Your

engine may appear differently than those

illustrated in this manual

INSPECTUNIT

Inspect the unitandcarton for damageim-

mediatelyafter delivery.Contactthe carrier

(trucking company) if you find or suspect

damage. Inform them of the damageand

request instructions for filing a claim. To

protect your rights, put your claim in writ-

ing andmaila copyto the carrierwithin 15

days afterthe unit has beendelivered.

ContactTroy-Bilt LLCif you needassis-

tance in this matter.

TOOLS/ MATERIALSNEEDED

(2) 1/2" open-end wrench*

(2) 9/16" open-endwrench*

(1) 3/8" open-endwrench*

(1) Largeadjustable wrench

(Models 634F/634Aonly)

(1) Scissors (totrim plasticties)

(1) Ruler (for belttension check)

(1) Block of wood (to support tiller when

removing wheels)

(1) Tirepressuregauge (for models with

pneumatictires)

(1) Cleanoil funnel

(1) Motor oil. Refertothe EngineOwner's

Manualfor oil specificationsand

quantityrequired.

* Adjustable wrenchesmay be used.

ASSEMBLYSTEPS

STEP 1: UNPACKING INSTRUCTIONS

NOTE:While unpacking,do not severely

bend anycontrol cables.

1.The tiller weighs approximately 133 Ibs.

Do notattemptto remove it from the ship-

ping platform until instructed to do so in

these Assemblysteps.

2. Removeany packagingmaterial from

the carton. Removeany staplesfrom the

bottom of the carton and removethe car-

ton from the shipping platform.

3. Removeall unassembledpartsandthe

separatehardwarebagfrom the carton.

Checkthat you havethe items listed in the

LooseParts List (contactyour local dealer

or the factory items aremissing or dam-

aged).

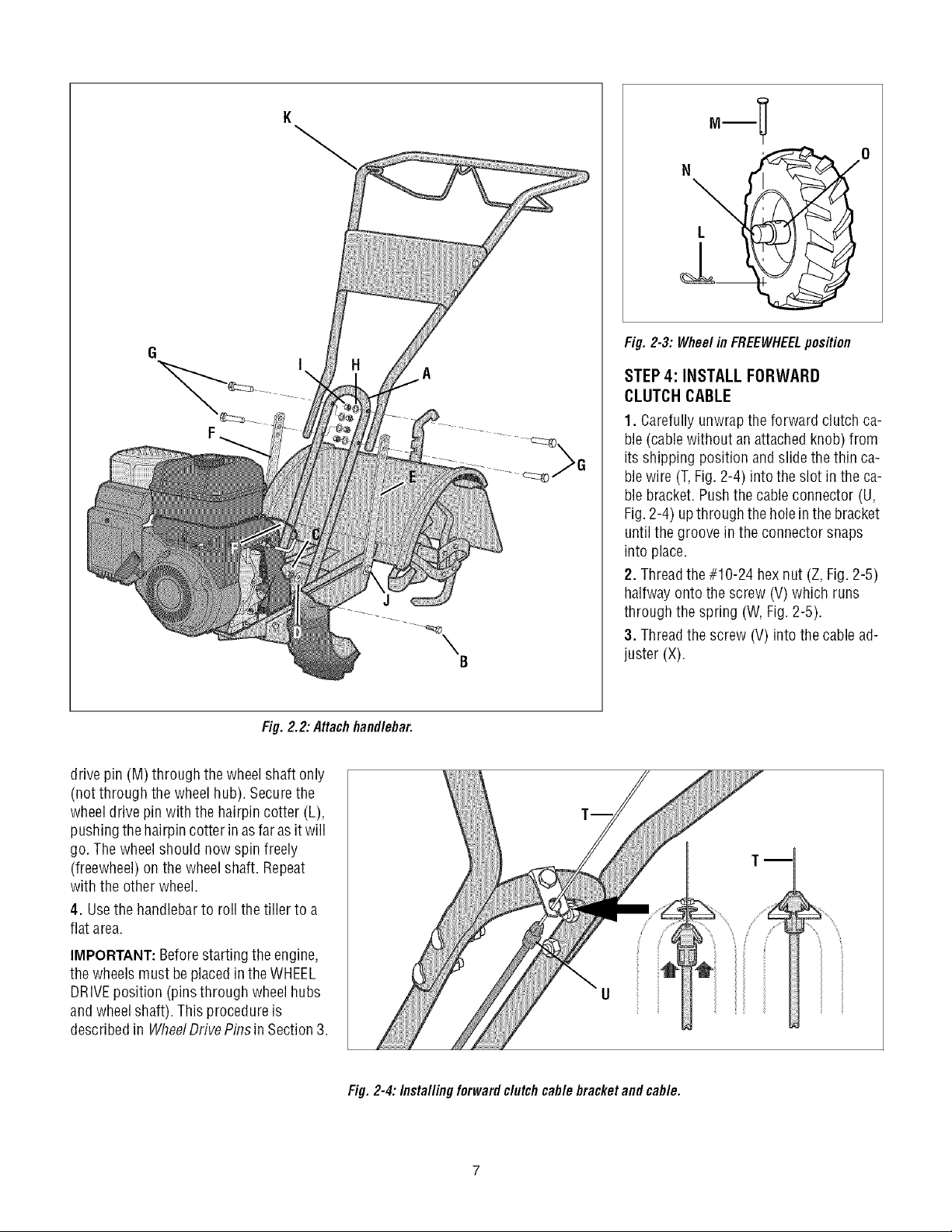

NOTE: Use the screw length template

(Fig,2-1) to identify screws,

LoosePartsList

Qty. Description

1 HandlebarSupport (seeA, Fig. 2-2)

1 HandlebarAssembly(seeK,Fig.2-2)

Hardwarebag contents:

4 Hexhd. screw,5/16-18 x 1-1/2"

2 Hexhd. screw,3/8-16 x 3/4"

2 FlatWasher,3/8"

4 Split lockwasher,5/16"

4 Hex nut, 5/16"-18

2 HexIocknut, 34}"-16

*Model 634A only

IMPORTANT:Motor oil must beaddedto

the enginecrankcasebefore theengine is

started. Followthe instructions inthis

Sectionand in the separateEngine

Owner's Manual.

NOTE: LEFTand RIGHTsidesof thetiller

are as viewedfrom the operator's position

behind thehandlebars.

STEP 2: ATTACHHANDLEBAR

1. Looselyattachthe legsof thehandlebar

support (A, Fig. 2-2) to the inner sides of

the tiller frameusingtwo 3/8"-16x3/4" hex

hd. screws (B), 3/8" flat washers(C), and

3/8"-16 hex Iocknuts (D).

_iiii

Figure2-1: Toidentifylengthofscrews,place

screwontemplateasshownandmeasuredis-

tancebetweenbottomofscrewheadandtipof

screw.

2. Usingtwo5/16"-18 x 1-1/2"screws(G),

5/16" split lock washers (H) and 5/16"-18

hexnuts (I), loosely attachthe handlebar

support (A) usingthe upperholes.Tighten

thetwo screws securely.

3. Therearethree height adjustmentholes

in the two handlebar support brackets (E

and F,Fig.2-2). Usea setting that will po-

sition the handlebarsat approximately

waist levelwhenthe tines are3"-4"intothe

soil. Looselyattachthe support bracketsto

theoutsideofthe handlebarassembly(K)

usingtwo 5/16"-18x 1-1/2" screws (G),5/

16"split lockwashers(H)and5/16"-18 hex

nuts (I). NOTE:Ifa support bracketwill not

move, loosenattaching screw (J) and nut.

IMPORTANT:The support bracketsmust

beassembledto theoutsideof the

handlebarassembly.

4. Tightenall handlebarmounting hard-

waresecurely.

STEP 3: MOVE TILLER OFF CRATE

Toroll the tiller off the shipping platform,

put the wheelsinfreewheel,asfollows:

1. Placeasturdy block underthetransmis-

sion to raiseonewheel about 1" off the

ground.

2, Removethe hairpin cotter (L, Fig.2-3)

and wheeldrive pin (M) from the wheel

hub (0) and wheelshaft (N).

3. Slidethe wheelfully inward onthewheel

shaft (N, Fig.2-3). Reinstallthe wheel

°-! °

Fig. 2-3: Wheel in FREEWHEELposition

Fig. 2.2: Attachhandlebar.

drive pin (M) through thewheelshaft only

(not through the wheel hub). Securethe

wheeldrive pin with the hairpin cotter (L),

pushingthe hairpincotter in as faras it will

go. Thewheelshould now spin freely

(freewheel) onthe wheelshaft. Repeat

with the other wheel.

4. Usethehandlebarto roll the tiller to a

flat area.

A

J

B

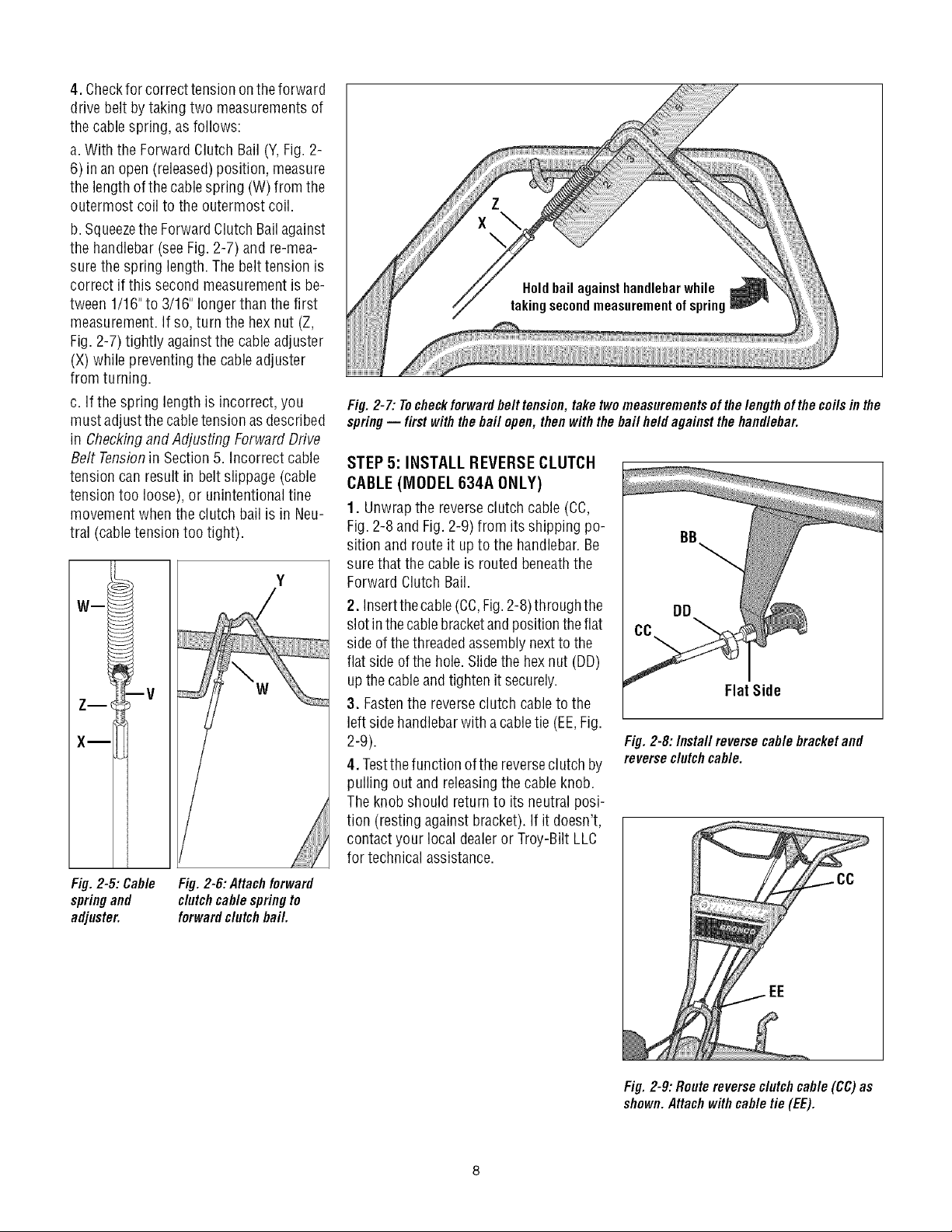

STEP 4: INSTALL FORWARD

CLUTCH CABLE

1. Carefully unwrapthe forward clutch ca-

ble(cablewithout an attachedknob) from

its shipping position and slide the thin ca-

blewire (T,Fig. 2-4) into the slot in the ca-

blebracket. Pushthe cableconnector (U,

Fig.2-4) upthrough the holein thebracket

untilthe groove in the connector snaps

into place.

2. Threadthe#10-24 hex nut (Z, Fig. 2-5)

halfway ontothe screw (V) which runs

through the spring (W, Fig.2-5).

3. Threadthe screw (V) into the cablead-

juster (X).

IMPORTANT: Beforestartingthe engine,

the wheels must beplacedin theWHEEL

DRIVEposition (pins through wheel hubs

andwheelshaft). This procedureis

describedin WheelDrivePinsin Section3.

Fig. 2-4: Installingforward clutchcable bracketand cable.

4. Checkfor correcttensionontheforward

drive belt bytaking two measurements of

the cablespring, as follows:

a.With the Forward Clutch Bail (Y,Fig. 2-

6) inanopen(released)position, measure

the length ofthe cablespring (W) from the

outermost coil to the outermost coil.

b. Squeezethe ForwardClutch Bailagainst

the handlebar(see Fig. 2-7) andre-mea-

surethe spring length. Thebelt tension is

correct if this second measurementis be-

tween 1/16"to 3/16" longer thanthe first

measurement.If so,turn the hex nut (Z,

Fig. 2-7)tightly against the cable adjuster

(X) while preventingthe cableadjuster

from turning.

c. If the spring lengthis incorrect, you

must adjustthe cabletension asdescribed

in Checkingand Adjusting Forward Drive

Belt Tensionin Section 5. Incorrect cable

tension can result in belt slippage (cable

tension too loose), or unintentional tine

movement whenthe clutch bail is in Neu-

tral (cabletension too tight).

Wm

W

iiiiiiiiiiiiiiii

Fig. 2-7: Tocheckforwardbelttension,take twomeasurementsofthelengthof the coilsinthe

spring-- first withthebail open, then withthe bail held against thehandlebar.

STEP 5: INSTALL REVERSECLUTCH

CABLE (MODEL 634A ONLY)

1. Unwrapthe reverseclutch cable (CC,

Fig.2-8 and Fig.2-9) from its shipping po-

sition and route it up to the handlebar. Be

surethat the cableis routedbeneaththe

Forward Clutch Bail.

2. Insertthecable(CC,Fig.2-8)through the

slot inthecablebracketandpositiontheflat

sideof thethreadedassemblynextto the

flat side ofthe hole.Slidethe hexnut (DD)

up thecable andtighten it securely.

Flat Side

3. Fastenthe reverseclutch cableto the

left sidehandlebarwith acabletie (EE,Fig.

2-9).

4. Testthefunction ofthe reverseclutch by

Fig. 2-8:/nsta//reverse cablebracketand

reverseclutchcable.

pulling out and releasingthe cableknob.

Theknob should return to its neutral posi-

tion (resting againstbracket).Ifit doesn't,

contact your local dealeror Troy-Bilt LLC

for technical assistance.

Fig.2-5: Cable

springand

adjuster.

Fig. 2-6: Attachforward

clutchcable springto

forwardclutch bail.

Fig. 2-9: Route reverseclutchcable (CC)as

shown.Attach withcable tie (EE).

5! 6: CHECKTRAHSMiSSiOH

OILLEVEL

Thetransmission was filledwith gearoil at

thefactory. However,you shouldcheckthe

gear oillevelatthis time to makecertain it

is correct.

IMPORTANT:Donot operatethe tiller ifthe

gear oillevel islow. Doingso will result in

severedamageto the transmission com-

ponents.

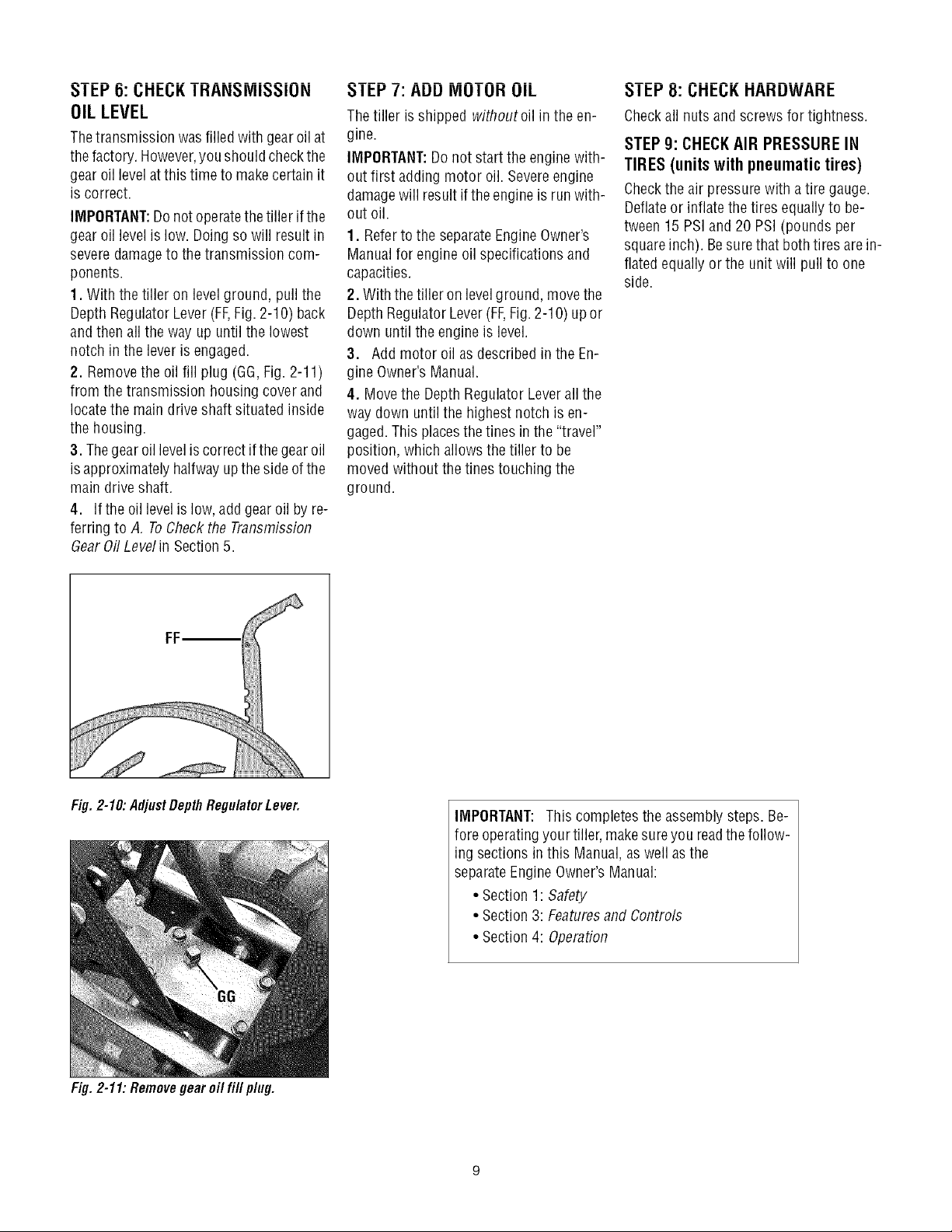

1. With the tiller on level ground, pull the

Depth RegulatorLever(FF,Fig. 2-10) back

andthen all the way up until the lowest

notch in the lever is engaged.

2. Removethe oil fill plug (GG,Fig. 2-11)

from the transmission housing cover and

locatethe maindrive shaft situated inside

the housing.

3. Thegear oilleveliscorrect ifthegear oil

isapproximately halfway upthe sideofthe

main driveshaft.

4. Ifthe oil levelislow, addgearoilby re-

ferring to A. ToCheckthe Transmission

dear 0il Levelin Section5.

I El-'/: AUU IVlUI UH UIL

Thetiller is shipped withoutoil in the en-

gine.

IMPORTANT:Donot start the engine with-

out first adding motor oil. Severeengine

damagewill result ifthe engineis run with-

out oil.

1. Refertothe separateEngineOwner's

Manualfor engine oil specifications and

capacities.

2. With thetiller on levelground, movethe

Depth RegulatorLever(FF,Fig.2-1O)up or

down until the engine is level.

3. Addmotor oil as describedin the En-

gine Owner's Manual.

4. Movethe DepthRegulator Leverall the

way down untilthe highest notch is en-

gaged.This placesthe tines in the"travel"

position, which allows the tiller to be

moved without thetines touching the

ground.

_1 El-'8: I.;HEI.;K HAHUWAHE

Checkall nuts and screws for tightness.

STEP g: CHECKAIR PRESSURE IN

TIRES (unitswithpneumatictires)

Checkthe air pressurewith a tire gauge.

Deflateor inflatethetires equally to be-

tween 15 PSIand 20 PSI (pounds per

squareinch). Besurethat both tires arein-

flated equallyor the unit will pull to one

side.

Fig. 2-10: AdjustDepth RegulatorLever.

Fig. 2-11: Removegear oil fill plug.

IMPORTANT: This completesthe assemblysteps. Be-

fore operatingyour tiller, makesureyou readthefollow-

ing sections inthis Manual,as well asthe

separateEngineOwner'sManual:

• Section1: Safety

• Section3: Featuresand Controls

• Section4: Operation

SECTION3: FEATURESANDCONTROLS

_ ARNING: Before

operatingyour machine,

carefully readand understand

all safety,controls and

operatinginstructions in this

Manual,the separateEngine

Owner's Manual,and on the

decalson the machine.

Failureto follow these

instructions can resultin

serious personalinjury.

INTRODUCTION

This Sectiondescribesthe locationand

function ofthecontrols on your tiller.Refer

to the following Section, Operationfor de-

tailed operating instructions.

Practice usingthesecontrols, with the en-

gine shut off, until you understandthe op-

eration ofthe controls and feel confident

with eachofthem.

ENGINE CONTROLS

Referto the enginemanufacturer's Engine

Owner'sManual(included in the tiller liter-

aturepackage)to identify the controls on

your engine.

IMPORTANT:Thecontrol for stopping the

engine is located onthe engine.

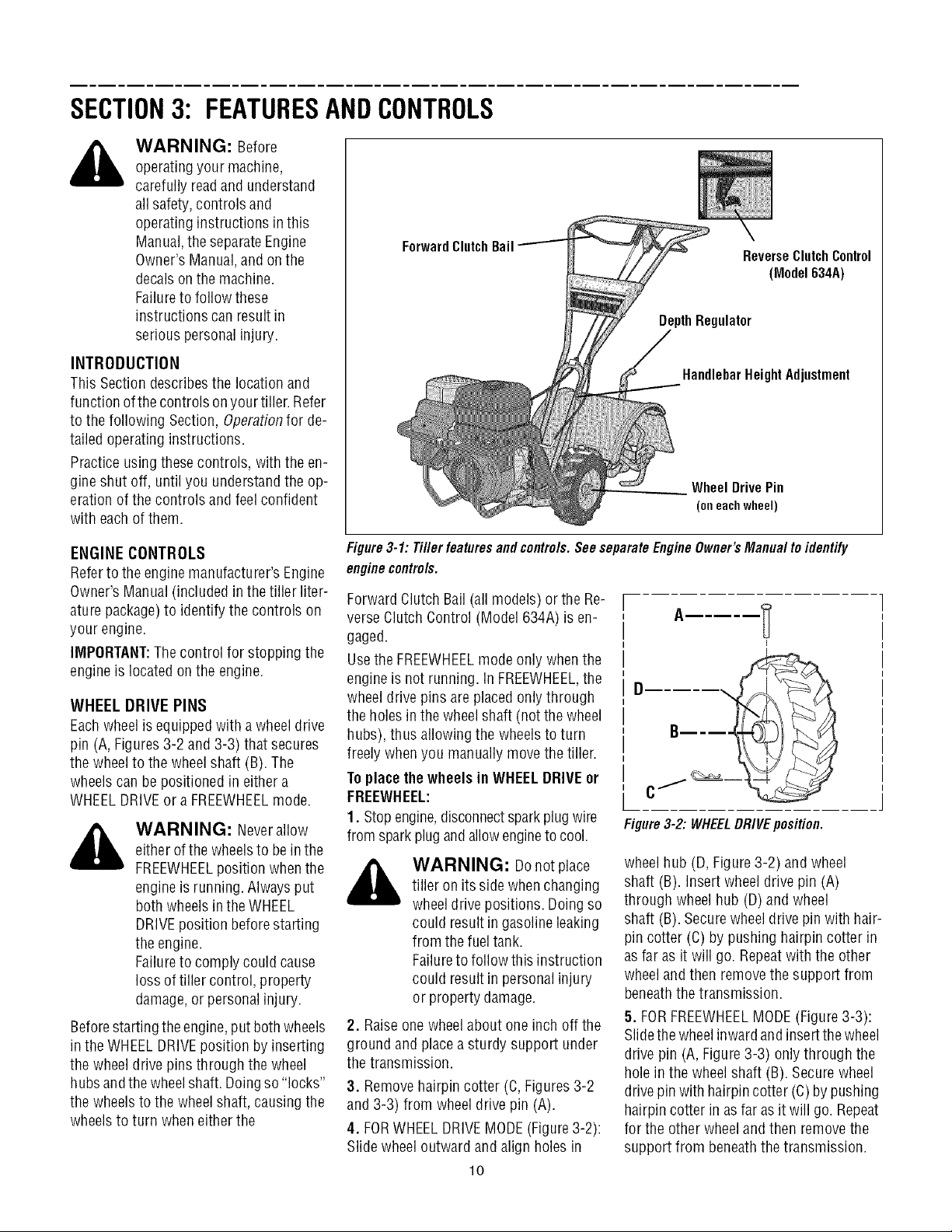

WHEEL DRIVE PINS

Eachwheel is equippedwith a wheeldrive

pin (A, Figures3-2 and 3-3) that secures

the wheelto the wheel shaft (B). The

wheelscan be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

_ WARNING: Neverallow

either ofthewheelsto bein the

FREEWHEELposition whenthe

engineis running. Alwaysput

both wheelsin theWHEEL

DRIVEposition beforestarting

the engine.

Failureto comply could cause

loss of tiller control, property

damage,or personalinjury.

Beforestarting the engine,put bothwheels

in the WHEELDRIVEposition byinserting

the wheel drive pins through the wheel

hubsandthewheelshaft.Doingso "locks"

the wheels to the wheelshaft,causing the

wheelsto turn when either the

ForwardClutch

Figure3-1: Tiller features and controls.See separateEngineOwner's Manual to identify

enginecontrols.

Bail ReverseClutchControl

(Model 634A)

gulator

HandlebarHeight Adjustment

Wheel Drive Pin

(oneachwheel)

Forward ClutchBail (all models) or the Re-

verse ClutchControl (Model 634A) is en-

gaged.

Usethe FREEWHEELmode only whenthe

engineis not running, in FREEWHEEL,the

wheeldrive pins are placedonly through

the holes inthewheelshaft (notthe wheel

hubs), thus allowing the wheels to turn

freely whenyou manually movethe tiller.

ToplacethewheelsinWHEELDRIVEor

FREEWHEEL:

1. Stop engine,disconnectsparkplug wire

Figure3-2: WHEELDRIVEposition.

from sparkplug andallowengineto cool.

wheelhub (D, Figure3-2) and wheel

_ WARNING: Donotplace

tiller on its side whenchanging

wheeldrive positions. Doingso

could result in gasolineleaking

from the fuel tank.

Failureto follow this instruction

could result in personalinjury

or property damage.

2. Raiseonewheel about one inch off the

ground and placeasturdy support under

the transmission.

shaft (B). Insertwheel drive pin (A)

through wheel hub (D)and wheel

shaft (B). Securewheeldrive pin with hair-

pin cotter (C) by pushing hairpin cotter in

asfar as it will go. Repeatwith the other

wheeland then removethe support from

beneaththe transmission.

5. FORFREEWHEELMODE(Figure3-3):

Slidethewheelinwardandinsertthe wheel

drive pin (A, Figure3-3) onlythrough the

hole inthe wheel shaft (B). Securewheel

3. Removehairpin cotter (C,Figures3-2

and 3-3) from wheel drive pin (A).

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheeloutward and align holes in

lO

drivepin with hairpincotter (C)by pushing

hairpin cotter in asfar asit will go. Repeat

for the other wheelandthen removethe

support from beneaththetransmission.

Loading...

Loading...