Troybilt 21A-634B063-2001, 21A-630B063 Owner’s Manual

0 TRnV BILT'"

Operator's Manual

Rear-tine Tiller Models

630B--Tufty _

634F--Bronco TM

634B--Super BroncoTM

Mode1634B Shown

IMPORTANT:READ SAFETY RULES AND INSTRUCTIONS CAREFULLY

Warning: This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-cov-

ered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if any). If a

spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required by law

(Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester

for the muffler is available by contacting the service department at Troy-Bilt LLC, P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OH 44136-0019

PRINTED IN USA FROM NO. 770-10594A

(12/2001 )

TABLE OF CONTENTS

Content Page

Calling Customer Support .................................................... 2

Safety ................................................................... 3

Assembly ................................................................. 6

Features and Controls ....................................................... 10

Operation ................................................................ 12

Maintenance .............................................................. 17

Off-Season Storage ........................................................ 21

Troubleshooting ........................................................... 22

Parts List ................................................................. 23

Warrany Information ........................................................ Back Cover

FINDINGMODELNUMBER

This Operator's Manual is an important part of your new Rear-tineTitter. It will help you assemble, prepare and main-

tain the unit for best performance. Please read and understand what it says.

Before you start assembling your new equipment, please locate the model plate on the equipment and copy the infor-

mation from it in the space provided below. This information is very important if you need help from our Customer

Support Department or an authorized dealer.

You can locate the model number by looking at the rear surface of the tine shield. A sample model plate is

explained below. For future reference, please copy the model number and the serial number of the equipment

in the space below

Copy Model Number Here

O BILT" TROY-BILT LL(

www.troybilt.com CLEVE_ND,OH_136

• 866-840-648_

P. O. BOX 361131

330-558-7220

Copy Serial Number Here

ENGINEINFORMATION

The engine manufacturer is responsible for all engine-related issues with regards to performance, power-rating, speci-

fications, warranty and service. Please refer to the engine manufacturer's Owner's/Operator's Manual packed sepa-

rately with your unit for more information.

CALLINGCUSTOMERSUPPORT

If you have difficulty assembling this product or have any questions regarding the controls, operation or maintenance

of this unit, please call the Customer Support Department.

your unit's model number and serial number ready when you call. See previous section to locate this

Call 1- (330) 558-7220 or 1- (866) 840-6483 to reach a Customer Support representative. Please have

information. You will be asked to enter the serial number in order to process your call ..

This machine meets voluntary safety standard

B71.8 - 1996, which is sponsored by the Outdoor

Power Equipment Institute, Inc., and is published

by the American National Standards Institute.

WARNING

Safety

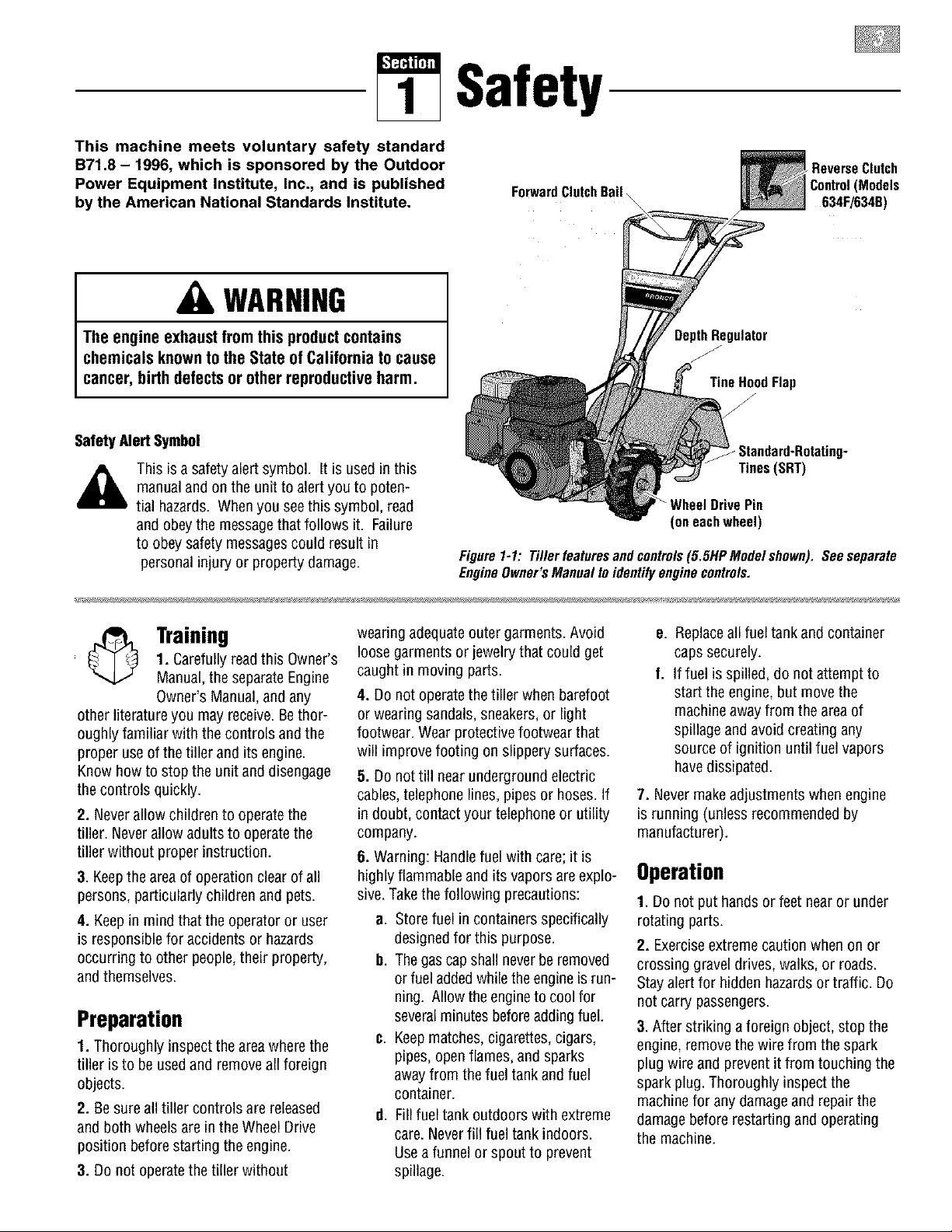

ForwardClutchBail

ReverseClutch

Control(Models

634F/634a)

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

SafetyAlert Symbol

This is a safety alertsymbol. It is used in this

manualand on the unit to alertyou to poten-

tial hazards. Whenyou seethis symbol, read

and obeythe messagethatfollows it. Failure

to obeysafety messagescould result in

personal injury or property damage.

wearing adequateouter garments. Avoid

1. Carefullyreadthis Owner's

Training

Manual,the separateEngine

Owner's Manual, and any

other literature you may receive. Bethor-

oughlyfamiliar with the controls andthe

proper use ofthe tiller and its engine.

Knowhow to stop the unit anddisengage

the controls quickly.

2. Neverallow children to operatethe

tiller. Neverallow adults to operatethe

tiller without proper instruction.

3. Keepthe areaof operation clear ofall

persons,particularly children and pets.

4. Keepin mind that the operatoror user

is responsiblefor accidents or hazards

occurring to other people,their property,

and themselves.

Preparation

1. Thoroughly inspectthe areawhere the

tiller is to be usedand remove all foreign

objects.

2. Be sureall tiller controls arereleased

and both wheelsare in the Wheel Drive

position beforestarting the engine.

3. Do not operatethe tiller without

loosegarments or jewelry that could get

caught in moving parts.

4. Do not operatethe tiller when barefoot

or wearingsandals, sneakers,or light

footwear. Wear protectivefootwear that

will improve footing on slippery surfaces.

5. Do not till near undergroundelectric

cables,telephonelines, pipesor hoses. If

in doubt, contact your telephoneor utility

company.

6. Warning: Handlefuel with care; it is

highlyflammable and its vapors are explo-

sive. Takethe following precautions:

a. Storefuel in containers specifically

designedfor this purpose.

b. Thegascapshall neverbe removed

or fuel addedwhilethe engineis run-

ning. Allowthe engineto cool for

severalminutesbeforeaddingfuel.

¢. Keepmatches,cigarettes, cigars,

pipes, openflames,and sparks

away from the fuel tank and fuel

container.

d. Fillfuel tank outdoors with extreme

care. Neverfill fuel tank indoors.

Useafunnel or spout to prevent

spillage.

DepthRegulator

TineHoodFlap

f

Standard-Rotating-

Tines(SRT)

WheelDrivePin

(on eachwheel)

Figure1-1: Tillerfeaturesandcontrols(5.SHPModelshown),Seeseparate

EngineOwner'sManualtoidentifyenginecontrols.

e.

Replaceall fuel tankand container

caps securely.

f.

If fuel is spilled, do not attempt to

start the engine, but movethe

machine awayfrom the area of

spillageand avoid creating any

source of ignition until fuel vapors

havedissipated.

7. Never makeadjustmentswhen engine

is running (unless recommendedby

manufacturer).

Operation

1. Donot put handsor feet nearor under

rotating parts.

2. Exerciseextreme caution when on or

crossing graveldrives, walks, or roads.

Stay alertfor hidden hazardsor traffic. Do

notcarry passengers.

3. After striking a foreign object,stop the

engine, removethe wire from the spark

plug wire and prevent it from touching the

spark plug.Thoroughly inspect the

machinefor any damageand repair the

damagebeforerestarting and operating

the machine.

4. Exercisecaution to avoid slipping or

falling.

5. If the unit should start to vibrateabnor-

mally, stop the engine, disconnect the

spark plug wire and prevent it from

touching the spark plug, and checkimme-

diatelyfor the cause. Vibration is gener-

ally a warning oftrouble.

6. Stop the engine,disconnect the spark

plug wire and prevent it from touching the

spark plug, wheneveryou leavethe oper-

ating position, before unclogging the tines,

or when making any repairs, adjustments

or inspections.

7. Takeall possible precautionswhen

leavingthe machine unattended. Stopthe

engine. Disconnectthe spark plug wire

and move it awayfrom the spark plug. Be

surethat both wheelsare in the Wheel

Drive position.

8. Beforecleaning,repairing, or

inspecting, stop the engineand make cer-

tain all moving parts havestopped. Dis-

connectthe spark plug wire and prevent it

from touching thespark plug to prevent

accidentalstarting.

9. The flap on the tine hood must bedown

when operating thetiller.

lB. Neverusethe tiller unless proper

guards, plates,or other safety protective

devicesare in place.

11. Donot run the engine in an enclosed

area. Engineexhaustcontains carbon

monoxide gas,a deadlypoison that is

odorless,colorless, and tasteless.

12. Keepchildren and petsaway.

13. Neveroperatethe tiller underengine

powerif the wheels are in the Freewheel

position.Inthe Freewheelposition, the

wheels will not hold thetiller backandthe

revolving tines could propel the tiller

rapidly, possibly causing loss of control.

Always engagethewheels with the wheel

drive pins in the WheelDrive position

beforestarting the engineor engaging the

tines/wheels with the Forward ClutchBail

(all models) or the ReverseClutchcontrol

(Models 634F/634B only).

14. Beaware that thetiller may unex-

pectedlybounceupwardor jump forward

ifthe tinesshouldstrike extremelyhard

packedsoil, frozenground,orburied

obstacleslike large stones,roots,or

stumps.If in doubtaboutthe tilling con-

ditions,alwaysusethe following

operatingprecautionsto assistyouin

maintainingcontrolofthetiller:

a. Walk behindandto oneside ofthe

tiller, usingonehandon thehan-

dlebars. Relaxyour arm, butusea

securehandgrip.

b. Useshallower depth regulatorset-

tings, workinggraduallydeeper

with eachpass.

c. Use slowerenginespeeds.

d. Clearthe tilling area ofall large

stones,rootsandotherdebris.

e. Avoidusingdownwardpressureon

the handlebars.If need be, use

slight upwardpressureto keepthe

tines fromdiggingtoo deeply.

f. Beforecontactinghardpackedsoil

at the end ofa row, reduceengine

speedandlift the handlebarsto

raise thetines outofthe soil.

g. In an emergency,stopthe tines and

wheels byreleasingwhichever

clutchcontrolis engaged. Do not

attempttorestrainthe tiller.

15. Donot overloadthe tiller's capacity by

attempting to till too deeplyat too fast a

rate.

16. Neveroperatethetiller at high trans-

port speeds onhard or slippery surfaces.

Look behind andusecarewhen backing

up.

17. Donot operatethe tiller on a slope

that is too steepfor safety.When on

slopes,slow down and make sure you

havegood footing. Neverpermit the tiller

to freewheeldown slopes.

18. Neverallow bystanders nearthe unit.

19. Onlyuseattachments and accessories

that are approvedby the manufacturer of

the tiller.

20. Usetiller attachments and accessories

when recommended.

21. Neveroperatethetiller without good

visibility or light.

22. Neveroperatethetiller if you are tired;

or underthe influence ofalcohol, drugs or

medication.

23. Operatorsshall not tamper with the

engine-governorsettings on the machine;

the governor controls the maximum safe

operatingspeedto protect theengine and

all moving parts from damagecausedby

overspeed. Authorized service shall be

sought if a problem exists.

24. Donot touch engine parts which may

be hot from operation. Let parts cool down

sufficiently.

25. Pleaseremember: You canalways

stop the tinesand wheels by releasingthe

ForwardClutch Bail or on Models 634F

and 634Bthe ReverseClutch control,

(whichever control is engaged),or by

moving the ignition switch and/or throttle

control leveron the engineto "OFF"or

"STOP".

26. To load or unloadthe tiller, seethe

instructions in Section 4 of this Manual.

27. Useextremecaution when reversing

or pulling the machinetowards you.

28. Start the enginecarefully according to

instructions and with feet well awayfrom

thetines.

29. Never pick up or carry a machine

while the engine is running.

MaintenanceandStorage

1. Keepthe tiller, attachments and acces-

sories in safeworking condition.

2. Checkall nuts, bolts, and screwsat

frequent intervalsfor proper tightness to

be surethe equipment is in safe working

condition.

3. Neverstorethe tiller with fuel in the fuel

tank inside a building where ignition

sourcesare present such as hot water and

spaceheaters,furnaces, clothesdryers,

stoves,electric motors, etc.). Allow the

engineto cool beforestoring the unit in

anyenclosure.

4. To reduce the chances of a fire hazard,

keepthe engine free of grass, leaves,or

excessivegrease.

5. Storegasoline in a cool, well-ventilated

area,safely away from any spark- or

flame-producing equipment. Storegaso-

line in an approved container, safelyaway

from the reachof children.

6. Referto the Maintenancesections of

this Manualand the separateEngine

Owner's Manualfor instructions if the unit

is to bestored for an extended period.

7. Neverperform maintenancewhile the

engine is running orthe spark plug wire is

connected,exceptwhen specifically

instructed to do so.

8. If thefuel tank hasto be drained,do

this outdoors.

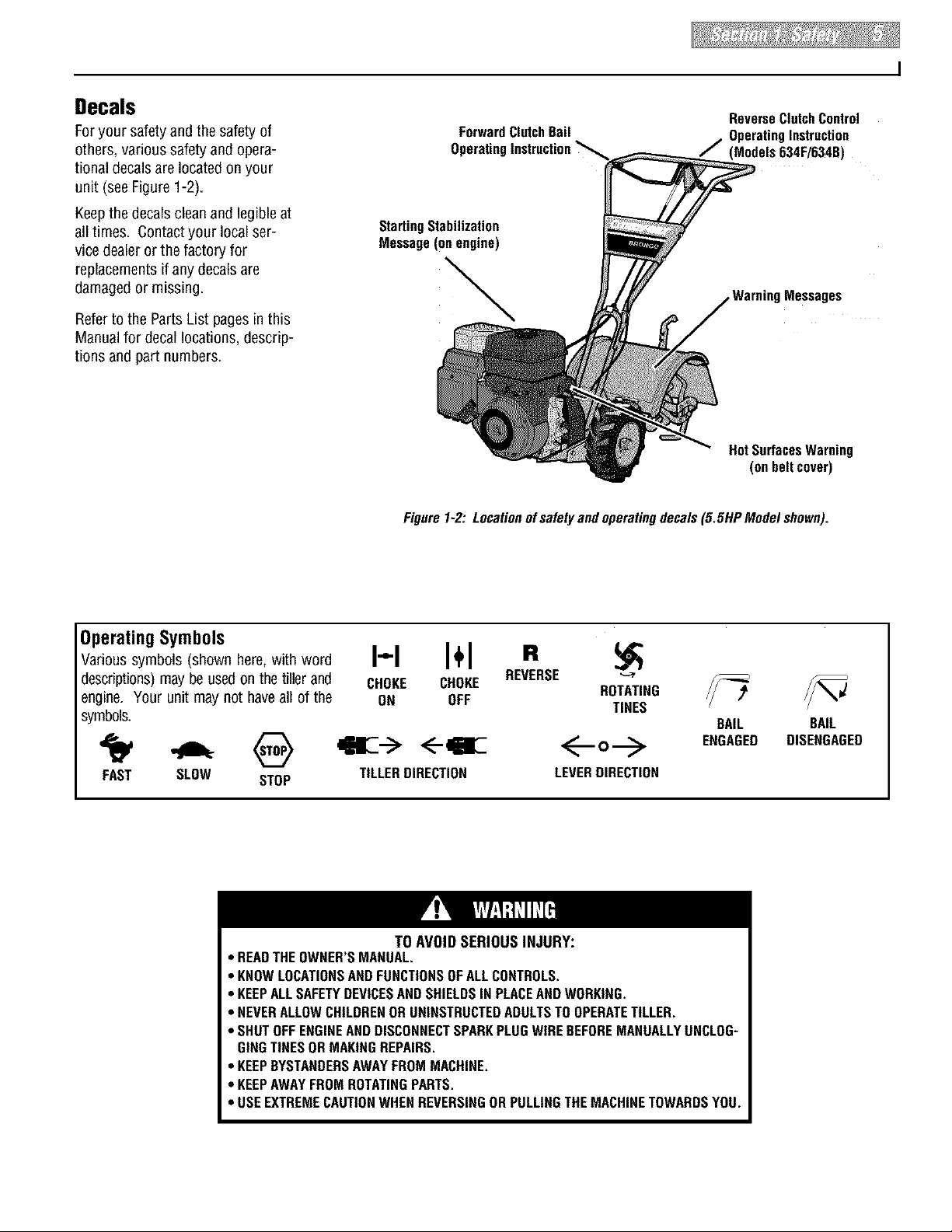

Decals

Foryour safety and the safety of

others, various safetyand opera-

tional decalsare located on your

unit (seeFigure1-2).

Keepthe decals cleanand legible at

all times. Contactyour local ser-

vice dealerorthe factoryfor

replacements ifany decalsare

damagedor missing.

Referto the Parts List pagesin this

Manualfor decallocations, descrip-

tions and part numbers.

ForwardClutchBail

OperatingInstruction

Starting Stabilization

Message (on engine)

ReverseClutchControl

OperatingInstruction

(Models 634F/634B)

\

Rot SurfacesWarning

(onbelt cover)

Figure1-2: Locationof safety and operatingdecals(5.5HP Model shown).

Messages

OperatingSymbols

Varioussymbols (shown here,with word

descriptions)may beusedon the tillerand

engine. Your unit may not haveall of the

symbols.

FAST SLOW STOP

• READTHEOWNER'SMANUAL.

• KNOWLOCATIONSAND FUNCTIONSOFALLCONTROLS.

• KEEPALL SAFETYDEVICESANDSHIELDSIN PLACEANDWORKING.

• NEVERALLOWCHILDRENORUNINSTRUCTEDADULTSTO OPERATETILLER.

• SHUT OFFENGINEANDDISCONNECTSPARKPLUGWIREBEFOREMANUALLYUNCLOG-

GINGTINESORMAKINGREPAIRS.

• KEEPBYSTANDERSAWAYFROMMACHINE.

• KEEPAWAY FROMROTATINGPARTS.

• USEEXTREMECAUTIONWHENREVERSINGORPULLINGTHEMACHINETOWARDSYOU.

H I÷1 R

CHOKE CHOKE REVERSE '_'

ON OFF TINES

41E-->

TILLERDIRECTION LEVERDIRECTION

TO AVOID SERIOUS INJURY:

ROTATING

BAIL BAIL

ENGAGED DISENGAGED

Assembly

ASSEMBLYSTEPS

To prevent personal injury or property

damage, do not start the engine until

all assembly steps are complete and

you have read and understand the

safetyandoperatinginstructionsin this

manual.

INTRODUCTION

Carefullyfollow these assembly stepsto

correctly prepareyour tiller for use. It is

recommendedthat you readthis Section

in its entirety before beginning assembly.

NOTE:Varioustiller models arepresented

in this Manual.Useonlythe information

appropriate for your tiller model.

INSPECTUNIT

Inspect the unit and carton for damage

immediately after delivery. Contactthe

carrier (trucking company) if you find or

suspectdamage. Inform them of the

damageand request instructions for filing

a claim. To protect your rights, put your

claim in writing and maila copy to the car-

rier within 15days after the unit has been

delivered.Contactthe factory if you need

assistance in this matter.

TOOLS/MATERIALSNEEDED

FORASSEMBLY

(1) 3/8" open-endwrench*

(2) 7/16"open-endwrench*

(2) 1/2"open-endwrench*

(2) 9/16"open-endwrench*

(1) Largeadjustablewrench (Models

634F/634Bonly)

(1) Scissors(to trim plastic ties)

(1) Ruler(for belt tension check)

(1) Blockof wood (to support tiller

when removing wheels)

(1) Tire pressure gauge (for models with

pneumatictires)

(1) Cleanoilfunnel

(1) Motoroil. Referto the EngineOwner's

Manualfor oil specificationsand

quantityrequired.

* Adjustablewrenches may be used.

STEP1: UNPACKINGINSTRUCTIONS

NOTE: While unpacking,do not severely

bend any control cables.

1. The tiller weighs approximately 133 Ibs.

Do not attempt to remove it from the ship-

ping platform until instructed to do so in

theseAssembly steps.

2. Removeany packagingmaterialfrom

the carton. Removeanystaplesfrom the

bottom of the carton and removethe

carton from the shipping platform.

3. Removeall unassembledparts andthe

separatehardwarebag from the carton.

Checkthat you havethe items listed in the

LooseParts List (contact your localdealer

or the factory items are missing or dam-

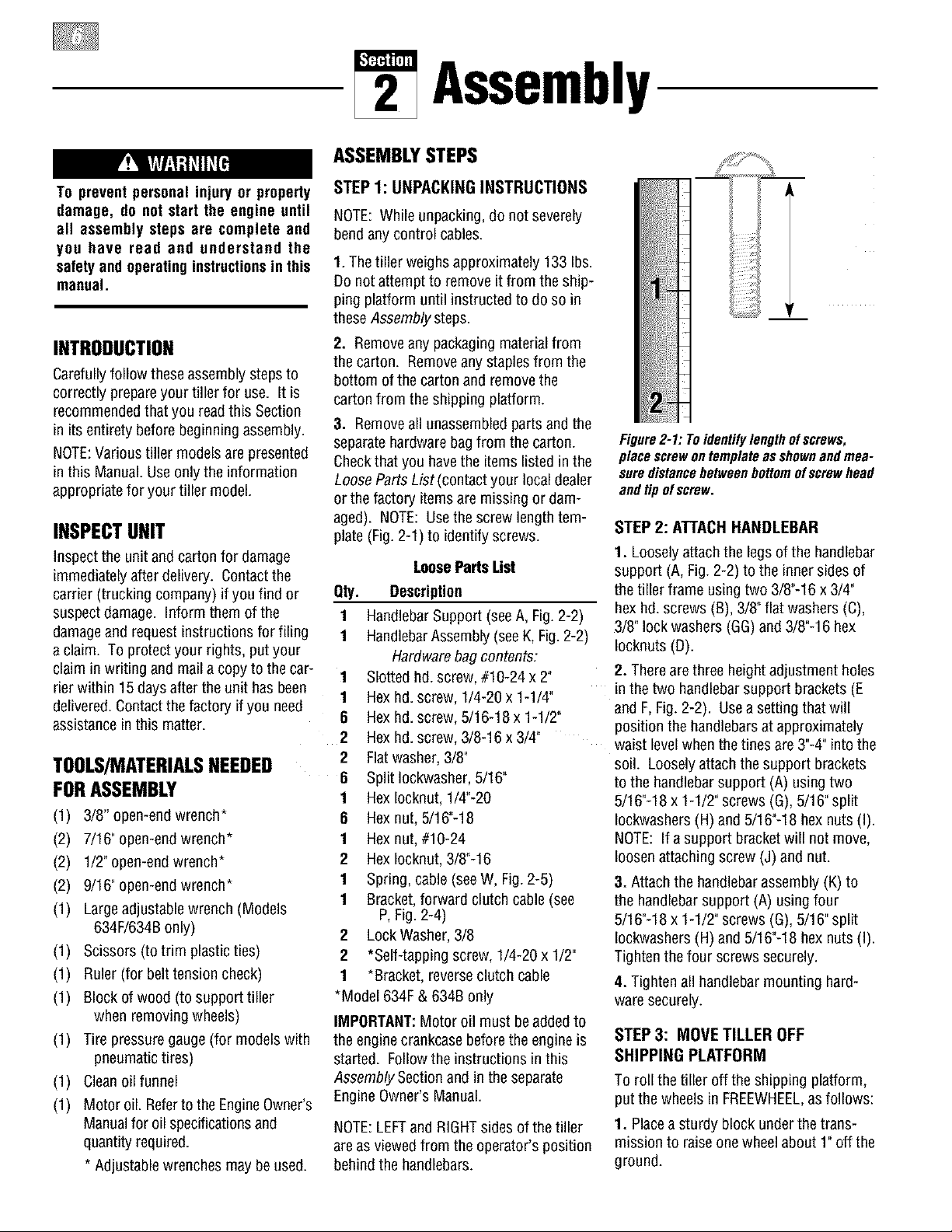

aged). NOTE: Usethe screw lengthtem-

plate (Fig. 2-1)to identify screws.

LoosePartsList

Qty. Description

1 HandlebarSupport (seeA, Fig.2-2)

1 HandlebarAssembly(seeK,Fig.2-2)

Hardwarebagcontents:

1 Slottedhd. screw, #10-24 x 2"

1 Hexhd. screw, 1/4-20 x 1-1/4"

6 Hexhd. screw, 5/16-18 x 1-1/2"

2 Hexhd. screw, 3/8-16 x 3/4"

2 Flatwasher,3/8"

6 Split Iockwasher,5/16"

1 HexIocknut, 1/4"-20

6 Hexnut, 5/16"-18

1 Hexnut,#10-24

2 HexIocknut, 3/8"-16

1 Spring, cable(seeW, Fig. 2-5)

1 Bracket,forward clutch cable (see

P,Fig.2-4)

2 LockWasher, 3/8

2 *Self-tapping screw, 1/4-20 x 1/2"

1 *Bracket, reverseclutch cable

*Model 634F& 634B only

IMPORTANT:Motor oil must beaddedto

the enginecrankcase beforethe engineis

started. Follow the instructions in this

Assembly Section and in the separate

Engine Owner's Manual.

NOTE:LEFTand RIGHTsides of the tiller

areas viewed from the operator's position

behind the handlebars.

Figure2-1: Toidentitylengthofscrews,

placescrewontemplateasshownandmea-

suredistancebetweenbottomof screwhead

andtipofscrew.

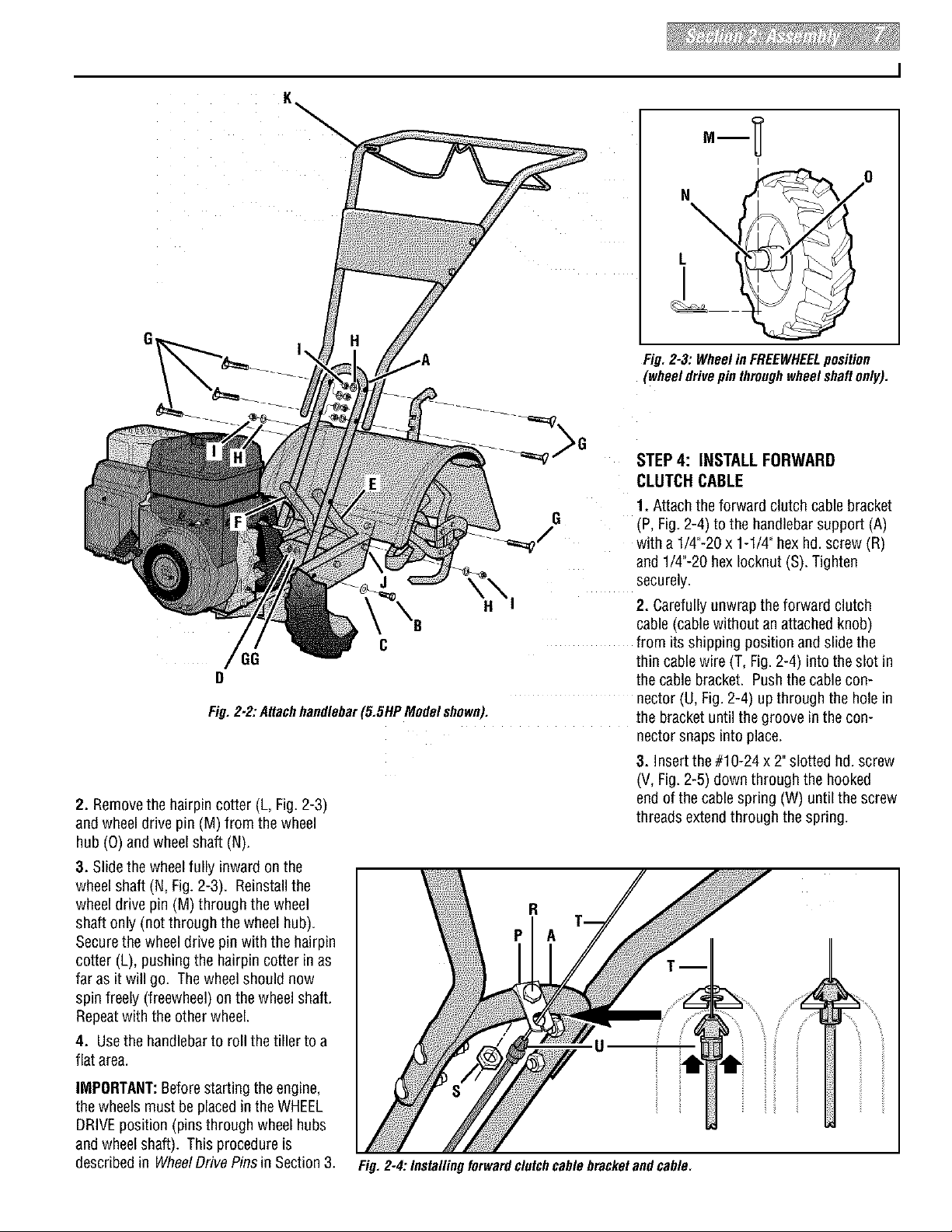

STEP 2: ATTACHHANDLEBAR

1. Looselyattach the legsof the handlebar

support (A, Fig. 2-2) to the inner sides of

the tiller frame usingtwo 3/8"-16 x3/4"

hexhd. screws (B), 3/8"flat washers (C),

3/8" lock washers (GG)and 3/8"-16 hex

Iocknuts (D).

2. Thereare three heightadjustment holes

in the two handlebarsupport brackets (E

and F,Fig. 2-2). Usea setting that will

position the handlebarsat approximately

waist levelwhenthe tines are 3"-4"into the

soil. Loosely attach the support brackets

to the handlebarsupport (A) using two

5/16"-18 x 1-1/2" screws (G),5/16"split

Iockwashers(H) and 5/16"-18 hexnuts (I).

NOTE: If a support bracket will not move,

loosenattaching screw (J) and nut.

3. Attach the handlebarassembly (K) to

the handlebarsupport (A) using four

5/16"-18 x 1-1/2" screws (G),5/16"split

Iockwashers(H) and 5/16"-18 hexnuts (I).

Tighten the four screws securely.

4. Tighten all handlebar mounting hard-

ware securely.

STEP3: MOVE TILLER OFF

SHIPPING PLATFORM

To roll the tiller off the shipping platform,

put the wheels in FREEWHEEL,asfollows:

1. Placea sturdy block underthe trans-

mission to raiseonewheelabout 1"off the

ground.

K

D

Fig.2-2:Attachhandlebar(5.5HPModelshown).

2. Removethe hairpin cotter (L, Fig. 2-3)

and wheel drive pin (M) from the wheel

hub (0) andwheelshaft (N).

3. Slide the wheelfully inward on the

wheel shaft (N, Fig. 2-3). Reinstallthe

wheel drive pin (M) through the wheel

shaft only (not through the wheel hub).

Securethe wheeldrive pin with the hairpin

cotter (L), pushingthe hairpin cotter inas

far as it will go. The wheelshould now

spin freely (freewheel) on thewheel shaft.

Repeatwith the other wheel.

4. Usethe handlebarto roll the tiller to a

flat area.

MI

Fig.2-3: Wheelin FREEWHEELposition

(wheeldrivepinthroughwheelshaftonly).

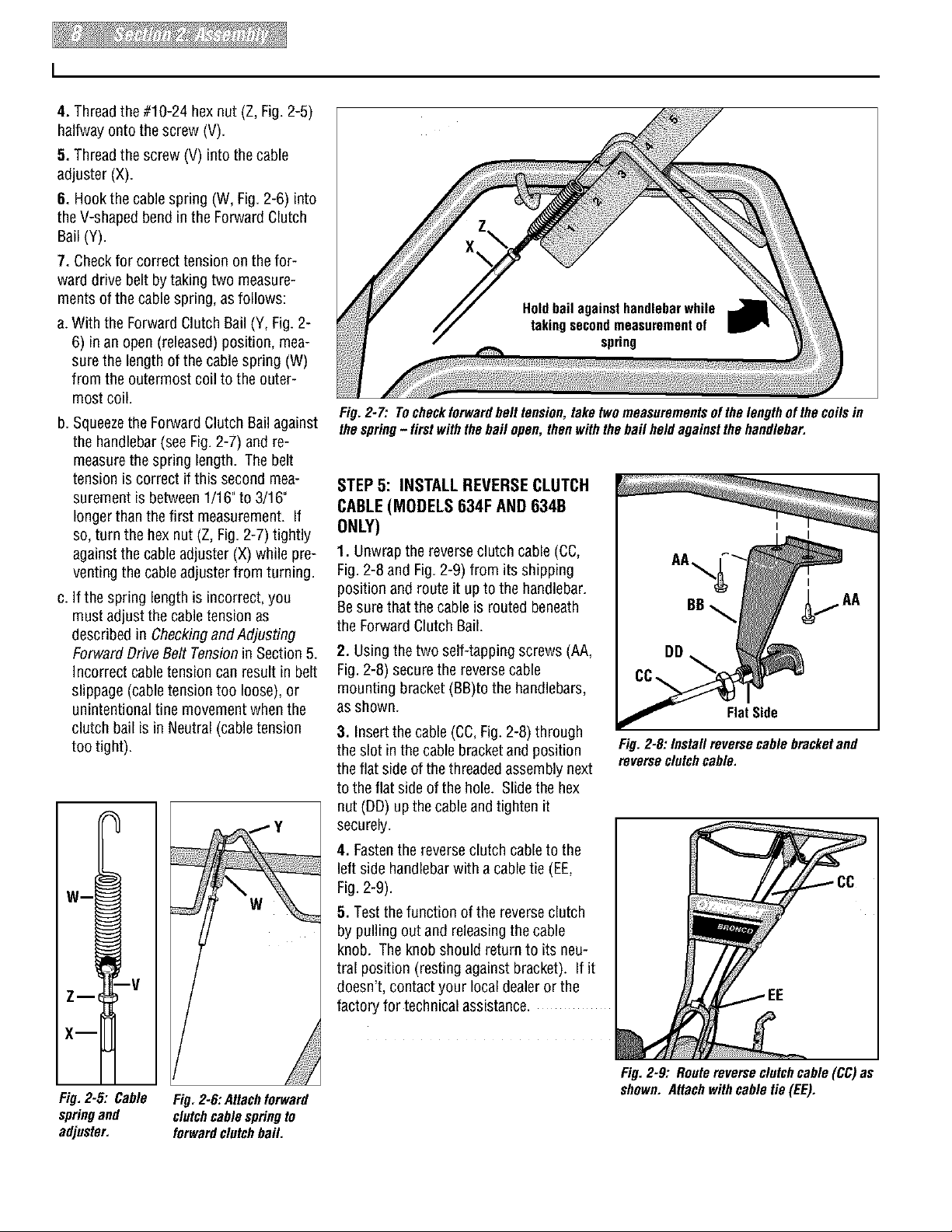

' STEP4: INSTALLFORWARD

CLUTCHCABLE

1. Attach the forward clutch cable bracket

G (P, Fig.2-4) to the handlebarsupport (A)

J

_-_17" with a 1/4"-20 x 1-1/4" hex hd. screw(R)

and 1/4"-20 hex Iocknut (S). Tighten

securely.

H I 2. Carefullyunwrapthe forward clutch

cable(cablewithout an attachedknob)

C

from its shipping position andslide the

thin cablewire (T, Fig.2-4) into the slot in

the cablebracket. Pushthe cablecon-

nector (U, Fig. 2-4) up through the hole in

the bracketuntil the groove in the con-

nector snaps into place.

3. Insertthe #10-24 x 2" slotted hd.screw

(V, Fig.2-5) downthrough the hooked

end of the cable spring (W) until the screw

threads extendthrough the spring.

IMPORTANT:Beforestarting the engine,

the wheels must be placedinthe WHEEL

DRIVEposition (pins through wheel hubs

and wheelshaft). This procedureis

described in WheelDrive Pinsin Section3.

Fig.2-4:Installingforwardclutchcablebracketandcable,

4.Threadthe#10-24 hexnut (Z, Fig.2-5)

halfwayonto the screw (V).

5. Thread the screw (V) into thecable

adjuster (X).

6. Hookthe cable spring (W, Fig.2-6) into

the V-shaped bend in the ForwardClutch

Bail (Y).

7. Check for correct tension on the for-

ward drive belt by taking two measure-

ments of the cablespring, as follows:

a. With the Forward ClutchBail (Y, Fig.2-

6) in an open (released)position, mea-

surethe length ofthe cablespring (W)

from the outermost coil to the outer-

most coil.

b. Squeezethe ForwardClutch Bail against

the handlebar(seeFig.2-7) and re-

measurethe spring length. Thebelt

tension is correct ifthis second mea-

surement is between1/16"to 3/16"

longer thanthe first measurement. If

so, turn the hexnut (Z, Fig.2-7) tightly

against the cableadjuster (X) while pre-

venting the cableadjuster from turning.

c. If the spring lengthis incorrect,you

must adjust the cabletension as

described in CheckingandAdjusting

Forward Drive Belt Tensionin Section5.

Incorrect cabletension can result in belt

slippage (cabletensiontoo loose), or

unintentional tine movementwhen the

clutch bail is in Neutral (cabletension

too tight).

Wm

v

Fig.2-7: Tocheckforwardbelttension,taketwomeasurementsofthelengthofthecoilsin

thespring- firstwiththebailopen,thenwiththebailheldagainstthehandlebar,

STEP5: INSTALLREVERSECLUTCH

CABLE(MODELS634FAND634B

ONLY)

1. Unwrap the reverseclutch cable (CC,

Fig.2-8 and Fig.2-9) from its shipping

position and route it up to the handlebar.

Besurethat the cableis routed beneath

the Forward Clutch Bail.

2. Using the two self-tapping screws (AA,

Fig.2-8) securethe reversecable

mounting bracket(BB)to the handlebars,

as shown.

3. Insertthe cable(CC,Fig.2-8) through

the slot in the cablebracketandposition

the flat side of the threadedassemblynext

to the flat side of the hole. Slide the hex

nut (DD) upthe cableand tighten it

securely.

4. Fastenthe reverseclutch cable to the

left side handlebarwith a cabletie (EE,

Fig.2-9).

5. Testthe function of the reverseclutch

bypulling outand releasingthe cable

knob. The knobshould returnto its neu-

tral position (resting against bracket). If it

doesn't, contact your local dealeror the

factory for technical assistance.

Fig.2-8:Installreversecablebracketand

reverseclutchcable,

FlatSide

Fig.25: Cable

springand

adjuster,

Fig,2-6:Attachforward

clutchcablespringto

forwardclutchbail.

Fig. 2-9: Route reverse clutchcable (CC)as

shown. Attachwith cabletie (EE).

STEP6: CHECKLEVELOF

TRANSMISSIONGEAROIL

STEP7: ADDMOTOROIL

TO ENGINE

Thetransmission was filled with gear oil at

the factory. However,you should check

the gear oil levelat this time to makecer-

tain it is correct.

IMPORTANT:Do notoperatethe tiller if

the gear oil levelis low. Doing so will

result in severedamageto the transmis-

sion components.

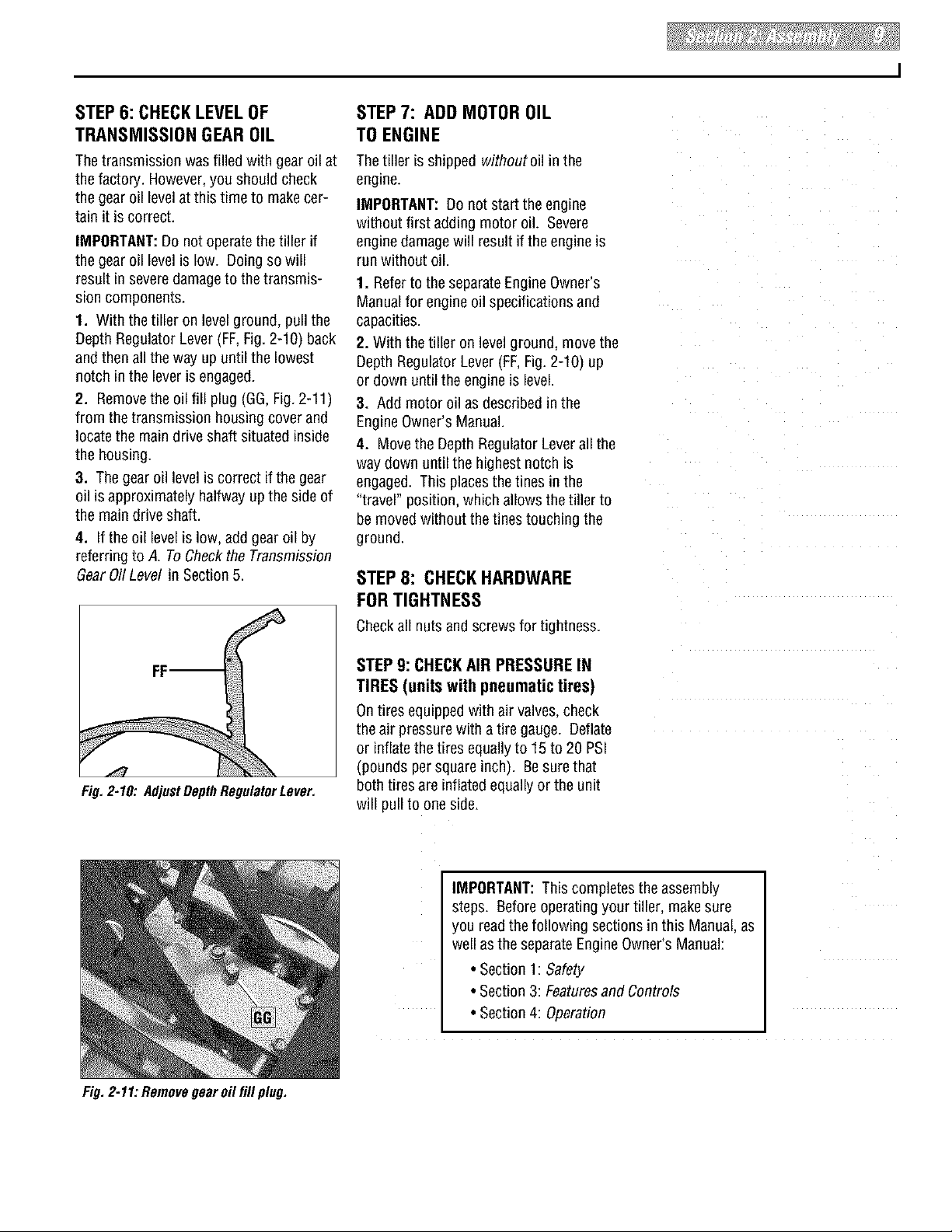

1. With the tiller on level ground, pull the

Depth Regulator Lever(FF,Fig.2-10) back

and then all the way up until the lowest

notch in the lever is engaged.

2. Removethe oil fill plug (GG, Fig.2-11)

from the transmission housing cover and

locate the main drive shaft situated inside

the housing.

3. Thegear oil level is correct if the gear

oil is approximately halfway up the side of

the main drive shaft.

4. If the oil levelis low, add gearoil by

referring to A. To Checkthe Transmission

GearOilLevel in Section5.

Thetiller is shipped withoutoil in the

engine.

IMPORTANT: Donot start the engine

without first adding motor oEI.Severe

enginedamagewill result if the engine zs

run without oil.

1. Referto the separateEngineOwner's

Manualfor engine oil specifications and

capacities.

2. With the tiller on level ground, move the

Depth Regulator Lever/FF. Fig. 2-10) up

or down until the engine is level.

3. Add motor oil as described in the

EngineOwner's Manual.

4. Movethe Depth Regulator Leverall the

way down until the hEghestnotch is

engaged. This placesthe tines in the

"travel" position which allows thetiller to

be moved without thetines touching the

ground.

STEP8: CHECKHARDWARE

FORTIGHTNESS

Checkall nuts and screws for tightness.

Fig. 2-10: AdjustDepthRegulatorLever.

Fig.2-11:Removegearoilfillplug.

STEP 9: CHECKAIR PRESSURE IN

TIRES (units with pneumatic tires)

Ontires equEppedwith airvalves, check

the a_rpressure with a tire gauge. Deflate

or inflate the tires equally to 15 to 20 PSI

(pounds per square inch). Besure that

9othtires are inflated equallyor the unit

will pull to one side.

IMPORTANT:This completes the assembly

steps. Before operating your tiller, make sure

you readthe following sections in this Manual.as

well as the separate EngineOwner's Manual:

• Section 1: Safety

• Section 3: FeaturesandControls

• Section 4: Operation

T FeaturesandControls

Before operating your machine, care-

fully read and understand all safety,

controls and operating instructions in

this Manual, the separate Engine

Owner's Manual, and on the decals on

themachine.

Failure to follow theseinstructionscan

resultin seriouspersonalinjury.

INTRODUCTION

This Sectiondescribes the location and

function of the controls on your tiller.

Referto the following Section, Operation

for detailed operatinginstructions.

Practiceusing thesecontrols, with the

engineshut off, until you understandthe

operationof the controls and feelconfi-

dentwith eachof them.

ENGINE CONTROLS

Referto the engine manufacturer's Engine

Owner's Manual(included in the tiller liter-

ature package)to identify thecontrols on

your engine.

IMPORTANT:Thecontrol for stopping the

engine is locatedonthe engine.

ForwardClutchBail

ReverseClutch

Control(Models

634F/634B)

ulator

Height

Adjustment

WheelDrivePin

(oneachwheel)

Figure3-1: Tillerfeaturesandcontrols(5.5HPModelshown),SeeseparateEngineOwner's

Manualtoidentifyenginecontrols.

Forward Clutch Bail (all models) or the

ReverseClutch Control (Models 634Fand

634B) is engaged.

Usethe FREEWHEELmode only whenthe

engine is not running. In FREEWHEEL,the

wheeldrive pinsare placed only through

the holes in the wheelshaft (not thewheel

hubs), thus allowing the wheels to turn

freely when you manually move the tiller.

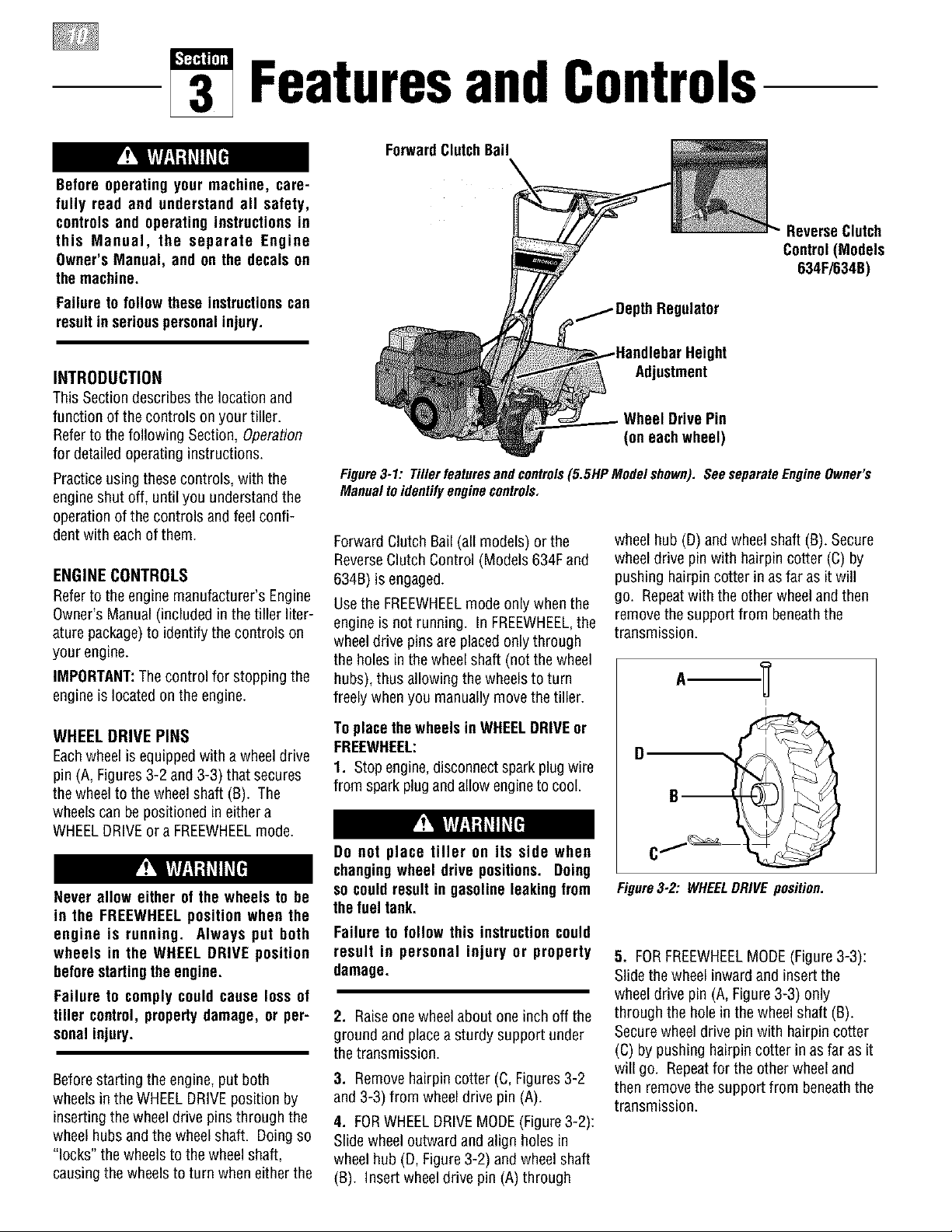

wheel hub (D) and wheelshaft (B). Secure

wheel drive pin with hairpin cotter (C) by

pushing hairpin cotter in as far as it will

go. Repeatwith the other wheeland then

removethe support from beneaththe

transmission.

I

WHEEL DRIVE PINS

Eachwheel is equippedwith a wheeldrive

pin (A, Figures3-2 and 3-3) that secures

the wheel to the wheelshaft (B). The

wheels can be positioned in either a

WHEELDRIVEor a FREEWHEELmode.

Never allow either of the wheels to be

in the FREEWHEELposition when the

engine is running. Always put both

wheels in the WHEEL DRIVE position

beforestartingthe engine.

Failure to comply could cause loss of

tiller control, propertydamage, or per-

sonalinjury.

Beforestarting the engine,put both

wheels in the WHEELDRIVEposition by

inserting the wheeldrive pinsthrough the

wheel hubs andthe wheel shaft. Doingso

"locks" the wheels to thewheel shaft,

causingthe wheels to turn wheneither the

To placethewheels in WHEELDRIVEor

FREEWHEEL:

1. Stop engine,disconnectspark plug wire

from spark plugand allow engineto cool.

Do not place tiller on its side when

changingwheel drive positions. Doing

so couldresult in gasoline leakingfrom

thefuel tank.

Failure to follow this instruction could

result in personal injury or property

damage.

2. Raiseonewheel about one inch off the

ground and placea sturdy support under

the transmission.

3. Remove hairpin cotter (C, Figures3-2

and 3-3) from wheel drive pin (A).

4. FORWHEELDRIVEMODE(Figure3-2):

Slide wheel outwardand align holes in

wheel hub (D, Figure3-2) and wheel shaft

(B). Insert wheeldrive pin (A) through

D

Figure3-2: WHEELDRIVE position,

5. FORFREEWHEELMODE(Figure 3-3):

Slidethe wheel inward and insert the

wheel drive pin (A, Figure3-3) only

through the holein the wheelshaft (B).

Securewheel drive pin with hairpincotter

(C) by pushing hairpin cotter in as far asit

will go. Repeatfor the other wheel and

then removethe support from beneaththe

transmission.

Loading...

Loading...