Troy-Bilt 208cc FLEX Operator's Manual

Safe Operation Practices • Assembly & Set-Up • Controls & Features • Operation • Maintenance • Warranty

OperatOr’s Manual

208cc FLEX™ Power Base — 23A-1AXA711

WARNING

READ AND FOLLOW ALL SAFETY RULES AND INSTRUCTIONS IN THIS MANUAL

BEFORE ATTEMPTING TO OPERATE THIS MACHINE.

FAILURE TO COMPLY WITH THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

TROY-BILT LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-0019

Printed In USA

Form No. 769-10247

(January 15, 2015)

To The Owner

Thank You

Thank you for purchasing the Troy-Bilt FLEX™ Power Base. It was

carefully engineered to provide excellent performance when

properly operated and maintained.

Please read this entire manual prior to operating the equipment.

It instructs you how to safely and easily set up, operate and

maintain your machine. Please be sure that you, and any other

persons who will operate the machine, carefully follow the

recommended safety practices at all times. Failure to do so could

result in personal injury or property damage.

All information in this manual is relative to the most recent

product information available at the time of printing. Review

this manual frequently to familiarize yourself with the machine,

its features and operation. Please be aware that this Operator’s

Manual may cover a range of product specifications for various

models. Characteristics and features discussed and/or illustrated

in this manual may not be applicable to all models. We reserve

the right to change product specifications, designs and

equipment without notice and without incurring obligation.

Table of Contents

Safe Operation Practices ........................................ 3

Assembly & Set-Up .................................................. 9

Controls & Features ................................................13

Operation ................................................................15

Maintenance & Adjustment ................................ 20

1

If applicable, the power testing information used to establish

the power rating of the engine equipped on this machine can be

found at www.opei.org or the engine manufacturer’s web site.

If you have any problems or questions concerning the machine,

phone an authorized Troy-Bilt service dealer or contact us

directly. Troy-Bilt’s Customer Support telephone numbers,

website address and mailing address can be found on this page.

We want to ensure your complete satisfaction at all times.

Throughout this manual, all references to right and left side of the

machine are observed from the operating position

Troubleshooting .................................................... 27

Replacement Parts ................................................ 28

Attachments & Accessories .................................. 29

Emission Warranty ................................................ 30

Product Warranty .................................................. 32

Record Product Information

Before setting up and operating your new equipment, please

locate the model plate on the equipment and record the

information in the provided area to the right. You can locate the

model plate by standing at the operator’s position and looking

down at the rear of the power base. This information will be

necessary, should you seek technical support via our web site,

Customer Support Department, or with a local authorized service

dealer.

Model NuMber

Serial NuMber

Customer Support

Please do NOT return the machine to the retailer or dealer without first contacting the Customer Support Department.

If you have difficulty assembling this product or have any questions regarding the controls, operation, or maintenance of

this machine, you can seek help from the experts. Choose from the options below:

◊ Visit us on the web at www.troybilt.com

See How-to Maintenance and Parts Installation Videos at www.troybilt.com/tutorials

◊ Call a Customer Support Representative at (800) 828-5500 or (330) 558-7220

◊ Write to Troy-Bilt LLC • P.O. Box 361131 • Cleveland, OH • 44136-0019

2

Important Safe Operation Practices

WARNING: This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and follow

all instructions in this manual before attempting to operate this machine. Failure to comply

with these instructions may result in personal injury.

When you see this symbol. HEED ITS WARNING!

CALIFORNIA PROPOSITION 65

WARNING: Engine Exhaust, some of its constituents, and certain vehicle components

contain or emit chemicals known to State of California to cause cancer and birth defects

or other reproductive harm.

WARNING: Battery posts, terminals, and related accessories contain lead and lead

compounds, chemicals known to the State of California to cause cancer and reproductive

harm. Wash hands after handling.

DANGER: This machine was built to be operated according to the safe operation practices in

this manual. As with any type of power equipment, carelessness or error on the part of the

operator can result in serious injury. This machine is capable of amputating fingers, hands,

toes and feet and throwing objects. Failure to observe the following safety instructions could

result in serious injury or death.

2

General Operation

1. Read this operator’s manual carefully in its entirety before

attempting to assemble this machine. Read, understand,

and follow all instructions on the machine and in the

manual(s) before operation. Keep this manual in a safe

place for future and regular reference and for ordering

replacement parts.

2. Be completely familiar with the controls and the proper use

of this machine before operating it.

3. This machine is a precision piece of power equipment,

not a plaything. Therefore, exercise extreme caution at all

times. Do not use it for any other purposes other than what

it was designed for.

4. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand

the instructions and safe operation practices in this manual

and on the machine and should be trained and supervised

by an adult.

5. Only responsible individuals who are familiar with these

rules of safe operation should be allowed to use this

machine.

6. Thoroughly inspect the area where the equipment is to be

used. Remove all stones, sticks, wire, bones, toys and other

foreign objects, which could be tripped over or picked up

and thrown by the blade. Thrown objects can cause serious

personal injury.

7. Plan your mowing pattern to avoid discharge of material

toward roads, sidewalks, bystanders and the like. Also,

avoid discharging material against a wall or obstruction,

which may cause discharged material to ricochet back

toward the operator.

8. To help avoid blade contact or a thrown object injury,

stay in operator zone behind handles and keep children,

bystanders, helpers and pets at least 75 feet from mower

while it is in operation. Stop machine if anyone enters area.

9. Always wear safety glasses or safety goggles during

operation and while performing an adjustment or repair

to protect your eyes. Thrown objects which ricochet can

cause serious injury to the eyes.

10. Wear sturdy, rough-soled work shoes and close-fitting

slacks and shirts. Shirts and pants that cover the arms

and legs and steel-toed shoes are recommended. Never

operate this machine in bare feet, sandals, slippery or lightweight (e.g. canvas) shoes.

11. Do not put hands or feet near rotating parts or under the

cutting deck. Contact with blade can amputate fingers,

hands, toes and feet.

12. A missing or damaged discharge cover can cause blade

contact or thrown object injuries.

13. Many injuries occur as a result of the mower being pulled

over the foot during a fall caused by slipping or tripping.

Do not hold on to the mower if you are falling; release the

handle immediately.

3

14. Never pull the mower back toward you while you are

walking. If you must back the mower away from a wall or

obstruction first look down and behind to avoid tripping

and then follow these steps:

a. Step back from mower to fully extend your arms.

b. Be sure you are well balanced with sure footing.

c. Pull the mower back slowly, no more than half way

toward you.

d. Repeat these steps as needed.

15. Do not operate the mower while under the influence of

alcohol or drugs.

16. Do not engage the self-propelled mechanism on machines

so equipped while starting engine.

17. The blade control is a safety device. Never attempt to

bypass its operation. Doing so makes the safety device

inoperative and may result in personal injury through

contact with the rotating blade. The blade control must

operate easily in both directions and automatically return

to the disengaged position when released.

18. Never operate the mower in wet grass. Always be sure of

your footing. A slip and fall can cause serious personal

injury. If you feel you are losing your footing, release the

blade control handle immediately and the blade will stop

rotating within three seconds.

19. Mow only in daylight or good artificial light. Walk, never

run.

20. Stop the blade when crossing gravel drives, walks or roads.

21. If the equipment should start to vibrate abnormally, stop

the engine and check immediately for the cause. Vibration

is generally a warning of trouble.

22. Shut the engine off and wait until the blade comes to

a complete stop before removing the grass catcher or

unclogging the chute. The cutting blade continues to

rotate for a few seconds after the blade control is released.

Never place any part of the body in the blade area until you

are sure the blade has stopped rotating.

23. Never operate mower without proper trail shield,

discharge cover, grass catcher, blade control or other safety

protective devices in place and working. Never operate

mower with damaged safety devices. Failure to do so can

result in personal injury.

24. Muffler and engine become hot and can cause a burn. Do

not touch.

25. Never attempt to make a wheel or cutting height

adjustment while the engine is running.

26. Only use parts and accessories made for this machine by

the manufacturer. Failure to do so can result in personal

injury.

27. When starting engine, pull cord slowly until resistance

is felt, then pull rapidly. Rapid retraction of starter cord

(kickback) will pull hand and arm toward engine faster than

you can let go. Broken bones, fractures, bruises or sprains

could result.

28. If situations occur which are not covered in this manual, use

care and good judgement. Contact Customer Support for

assistance or the name of the nearest service dealer.

Slope Operation

Slopes are a major factor related to slip and fall accidents, which

can result in severe injury. Operation on slopes requires extra

caution. The machine is heavy and can speed up when going

downhill. Be prepared to maintain control of the machine. If you

feel uneasy on a slope, do not mow it. For your safety, use the

slope gauge included as part of this manual to measure slopes

before operating this machine on a sloped or hilly area. If the

slope is greater than 10 degrees, do not mow it.

Do:

1. Mow across the face of slopes; never up and down, to avoid

loss of control.

2. Exercise extreme caution when changing direction on slopes.

Turn uphill, not downhill.

3. Watch for holes, ruts, rocks, hidden objects, or bumps

which can cause you to slip or trip. Tall grass can hide

obstacles.

4. Always be sure of your footing. A slip and fall can cause

serious personal injury. If you feel you are losing your

balance, release the blade control handle immediately and

the blade will stop rotating within three (3) seconds.

Do Not:

1. Do not mow near drop-offs, ditches or embankments, you

could lose your footing or balance.

2. Do not mow slopes greater than 10 degrees as shown on

the slope gauge.

3. Do not mow on wet grass. Unstable footing could cause

slipping.

Children

Tragic accidents can occur if the operator is not alert to the

presence of children. Children are often attracted to the mower

and the mowing activity. They do not understand the dangers.

Never assume that children will remain where you last saw them.

1. Keep children out of the mowing area and under watchful

care of a responsible adult other than the operator.

2. Be alert and turn mower off if a child enters the area.

3. Before and while moving backwards, look behind and

down for small children.

4. Use extreme care when approaching blind corners,

doorways, shrubs, trees, or other objects that may obscure

your vision of a child who may run into the mower.

5. Keep children away from hot or running engines. They can

suffer burns from a hot muffler.

6. Never allow children under 14 years of age to operate this

machine. Children 14 and over should read and understand the

instructions and safe operation practices in this manual and on

the machine and be trained and supervised by an adult.

7. After stopping engine, remove Electric Start Push Key (if

equipped) and keep it in a safe place out of the reach of

children.

4 Section 2 — important Safe operation practiceS

Service

Safe Handling Of Gasoline:

1. To avoid personal injury or property damage use extreme

care in handling gasoline. Gasoline is extremely flammable

and the vapors are explosive. Serious personal injury can

occur when gasoline is spilled on yourself or your clothes,

which can ignite. Wash your skin and change clothes

immediately.

2. Use only an approved gasoline container.

3. Never fill containers inside a vehicle or on a truck or trailer

bed with a plastic liner. Always place containers on the

ground away from your vehicle before filling.

4. Remove gas-powered equipment from the truck or

trailer and refuel it on the ground. If this is not possible,

then refuel such equipment on a trailer with a portable

container, rather than from a gasoline dispenser nozzle.

5. Keep the nozzle in contact with the rim of the fuel tank or

container opening at all times until fueling is complete. Do

not use a nozzle lock-open device.

6. Extinguish all cigarettes, cigars, pipes and other sources

of ignition.

7. Never fuel machine indoors because flammable vapors will

accumulate in the area.

8. Never remove gas cap or add fuel while engine is hot or

running. Allow engine to cool at least two minutes before

refueling.

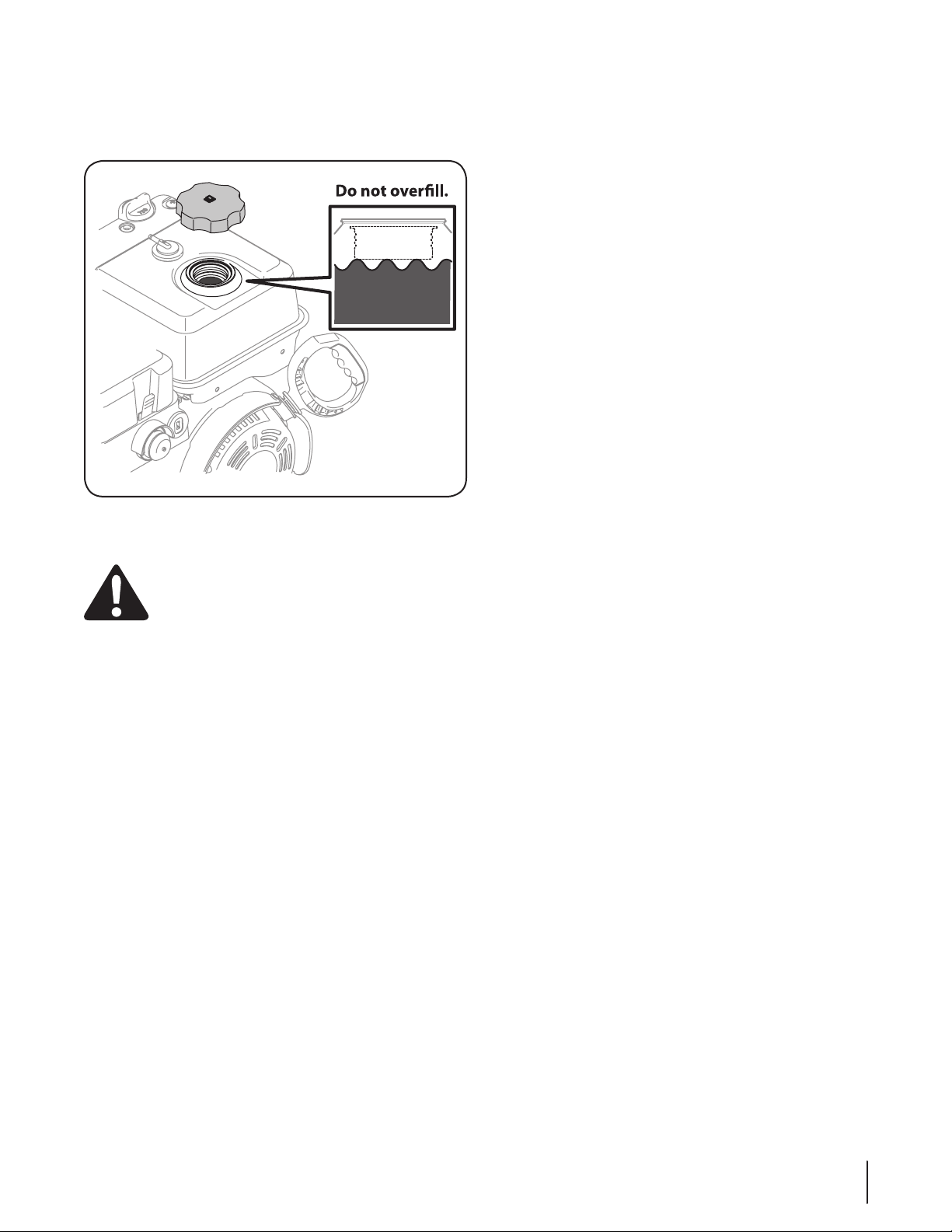

9. Never over fill fuel tank. Fill tank to the bottom of filler

neck, leaving space to provide for fuel expansion.

10. Replace gasoline cap and tighten securely until it clicks

indicating that it is properly tightened.

11. If gasoline is spilled, wipe it off the engine and equipment.

Move machine to another area. Wait 5 minutes before

starting engine.

12. Never store the machine or fuel container near an open

flame, spark or pilot light as on a water heater, space

heater, furnace, clothes dryer or other gas appliances.

13. To reduce fire hazard, keep machine free of grass, leaves,

or other debris build-up. Clean up oil or fuel spillage and

remove any fuel soaked debris.

14. Allow machine to cool at least 5 minutes before storing.

General Service:

1. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

2. Before cleaning, repairing, or inspecting, make certain the

blade and all moving parts have stopped. Disconnect the

spark plug wire and ground against the engine and remove

Electric Start Push Key (if equipped) to prevent unintended

starting.

3. Check the blade and engine mounting bolts at frequent

intervals for proper tightness. Also, visually inspect blade

for damage (e.g., bent, cracked, worn) Replace blade with

the original equipment manufacture’s (O.E.M.) blade only,

listed in this manual. “Use of parts which do not meet the

original equipment specifications may lead to improper

performance and compromise safety!”

4. Mower blades are sharp and can cut. Wrap the blade or

wear gloves, and use extra caution when servicing them.

5. Keep all nuts, bolts, and screws tight to be sure the

equipment is in safe working condition.

6. Never tamper with safety devices. Check their proper

operation regularly.

7. After striking a foreign object, stop the engine and

remove the key. Thoroughly inspect the power base and

attachment for any damage. Repair the damage before

starting and operating the equipment.

8. Never attempt to make a wheel or cutting height

adjustment while the engine is running.

9. Grass catcher components, discharge cover, and trail shield

are subject to wear and damage which could expose

moving parts or allow objects to be thrown. For safety

protection, frequently check components and replace

immediately with original equipment manufacturer’s

(O.E.M.) parts only, listed in this manual. “Use of parts which

do not meet the original equipment specifications may

lead to improper performance and compromise safety!”

10. Do not change the engine’s governor setting or over-speed

the engine. The governor controls the maximum safe

operating speed of the engine.

11. Check fuel line, tank, cap, and fittings frequently for cracks

or leaks. Replace if necessary.

12. Do not crank engine with spark plug removed.

13. Maintain or replace safety and instruction labels, as

necessar y.

14. Observe proper disposal laws and regulations. Improper

disposal of fluids and materials can harm the environment.

15. According to the Consumer Products Safety Commission

(CPSC) and the U.S. Environmental Protection Agency (EPA),

this product has an Average Useful Life of seven (7) years,

or 140 hours of operation. At the end of the Average Useful

Life have the machine inspected annually by an authorized

service dealer to ensure that all mechanical and safety

systems are working properly and not worn excessively.

Failure to do so can result in accidents, injuries or death.

Do not modify engine

To avoid serious injury or death, do not modify engine in any

way. Tampering with the governor setting can lead to a runaway

engine and cause it to operate at unsafe speeds. Never tamper

with factory setting of engine governor.

Notice Regarding Emissions

Engines which are certified to comply with California and federal

EPA emission regulations for SORE (Small Off Road Equipment)

are certified to operate on regular unleaded gasoline, and

may include the following emission control systems: Engine

Modification (EM), Oxidizing Catalyst (OC), Secondary Air

Injection (SAI) and Three Way Catalyst (TWC) if so equipped.

5Section 2 — important Safe operation practiceS

Spark Arrestor

WARNING: This machine is equipped with an

internal combustion engine and should not be used

on or near any unimproved forest-covered, brush

covered or grass-covered land unless the engine’s

exhaust system is equipped with a spark arrestor

meeting applicable local or state laws (if any).

If a spark arrestor is used, it should be maintained in effective

working order by the operator. In the State of California the

above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws

apply on federal lands.

A spark arrestor for the muffler is available through your

nearest engine authorized service dealer or contact the service

department, P.O. Box 361131 Cleveland, Ohio 44136-0019.

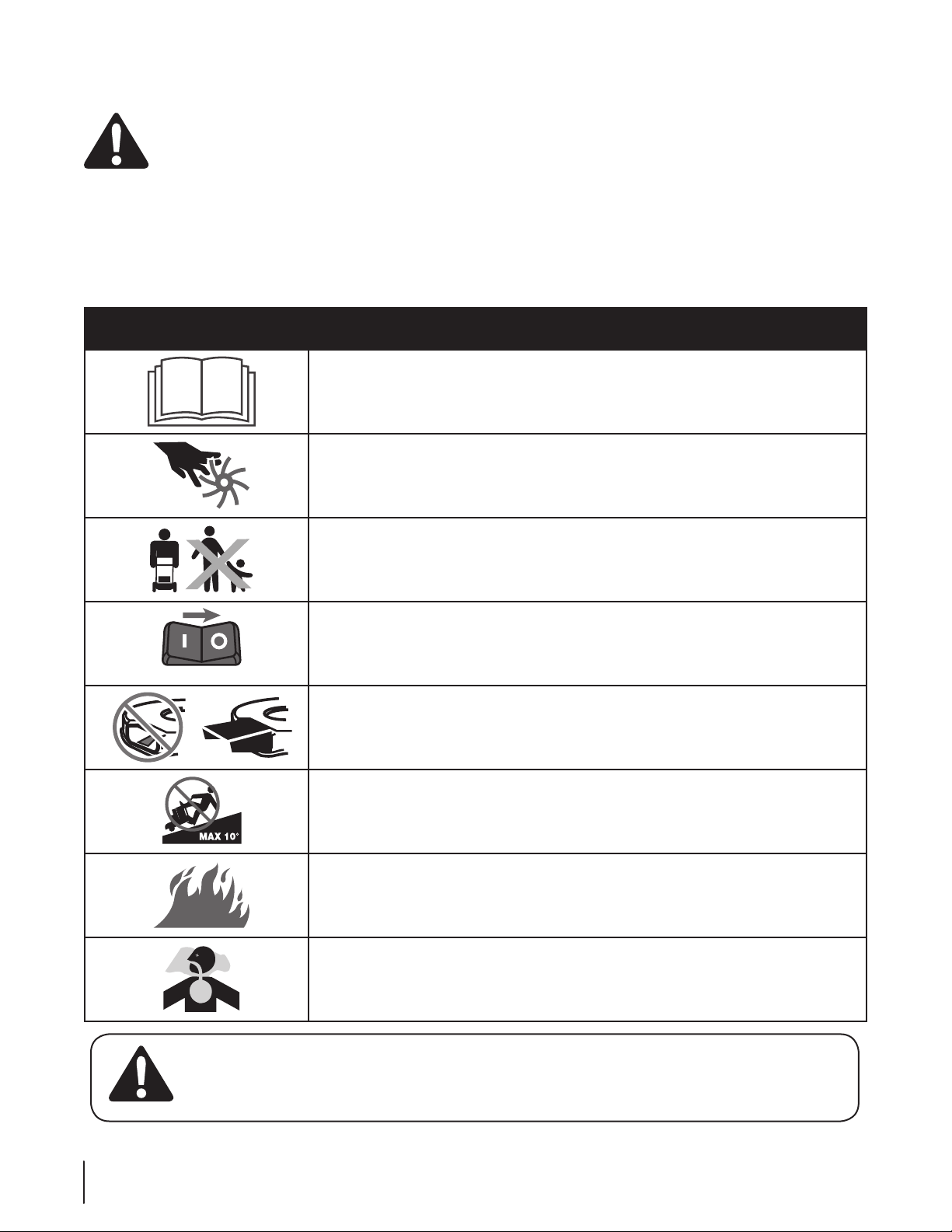

Safety Symbols

This page depicts and describes safety symbols that may appear on this product. Read, understand, and follow all instructions on the

machine before attempting to assemble and operate.

Symbol Description

READ THE OPERATOR’S MANUAL(S)

Read the power base and attachment operator’s manuals before operating.

DANGER — MOVING PARTS

Keep hands and feet away from moving parts.

ON OFF

DANGER — BYSTANDERS

Keep bystanders away. Look behind while backing.

CAUTION — STOP ENGINE

Wait for engine to come to a complete stop before removing attachment. Another means

for stopping the engine is to remove the key.

DANGER — ROTATING BLADES

Keep safety devices in place and working. If damaged, repair or replace immediately.

DANGER — SLOPES

Use extra c aution on slopes. The machine is heav y and can speed up when going downhill. Be prepared to

maintain control of the machine. To avoid loss of control, operate across slop es, not up and down. When turning,

turn uphill, not down. Do not operate on slo pes greater than 10°. Operate across slopes, never up and down.

WARNING—GASOLINE IS FLAMMABLE

Allow the engine to cool at least two minutes before refueling.

WARNING— CARBON MONOXIDE

Never run an engine indoors or in a poorly ventilated area. Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

WARNING: Your Responsibility—Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

6 Section 2 — important Safe operation practiceS

SAVE THESE INSTRUCTIONS!

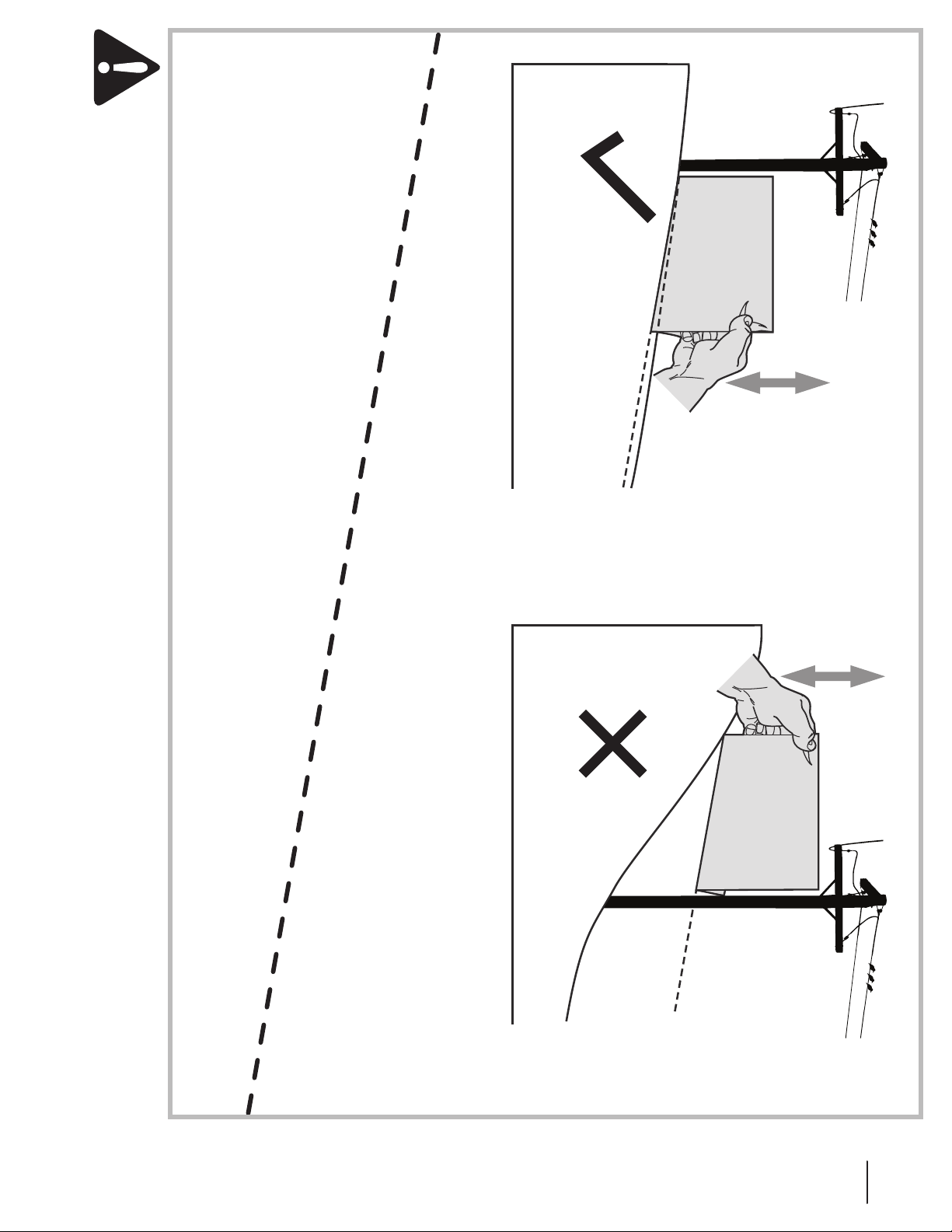

To check the slope, proceed as follows:

1. Remove this page and fold along the dashed line.

2. Locate a vertical object on or behind the slope (e.g. a pole, building, fence, tree, etc.)

3. Align either side of the slope gauge with the object (See Figure 1 and Figure 2 ).

4. Adjust gauge up or down until the left corner touches the slope (See Figure 1 and Figure 2).

5. If there is a gap below the gauge, the slope is too steep for safe operation (See Figure 2 above).

WARNING! Slopes are a major factor related to tip-over and roll-over accidents which can result in severe injury or death.

The machine is heavy and can speed up when going downhill. Be prepared to maintain control of the machine. To avoid loss

of control, operate across slopes, not up and down. When turning, turn uphill, not down. Do not operate machine on slopes

in excess of 10 degrees.

(OK) (TOO STEEP)

IF A SLOPE IS TOO STEEP FOR SAFE OPERATION!

USE THIS SLOPE GAUGE TO DETERMINE

10° dashed line

10° Slope

Slope Gauge

Figure 2Figure 1

10° Slope

7Section 2 — important Safe operation practiceS

Assembly & Set-Up

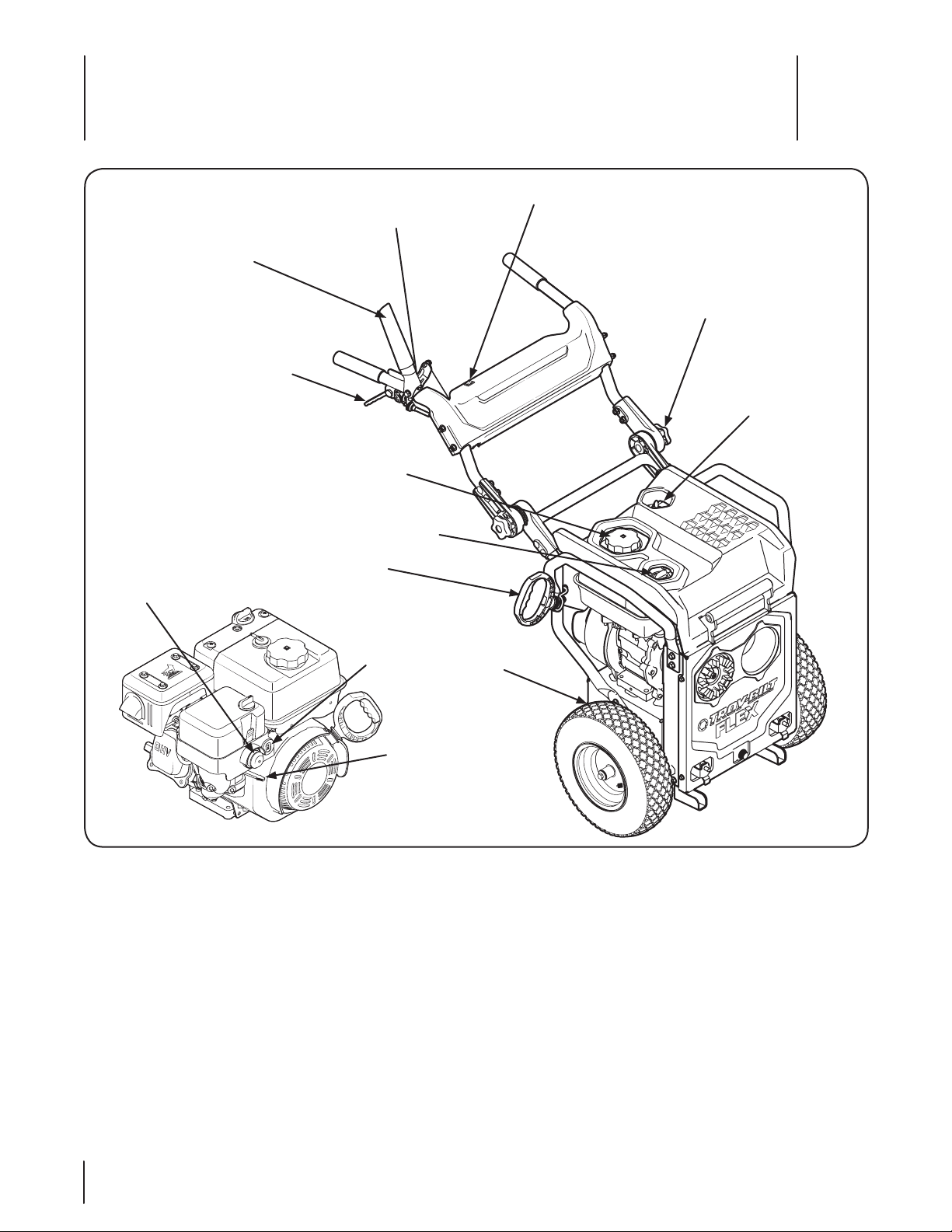

A

A

B

C

C

NOTE: All references in this manual to the left or right side

of the FLEX™ Power Base is from the operating position only.

Exceptions, if any, will be specified.

IMPORTANT: This unit is shipped WITHOUT the engine full of

oil.

FLEX™ Power Base Parking Position

To rest the FLEX™ Power Base after unpacking it from the

shipping carton, and/or when no attachment is present, a

convenient Latch’n Lock™ kickstand has been provided on the

rear of the unit. Simply deploy the Latch’n Lock™ kickstand to

park the FLEX™ Power Base when no attachment is present. See

Figure 3-1.

3

Figure 3-2

3. Tighten the two star knobs (C) to firmly secure the upper

handle and support tubes. See Figure 3-3.

Figure 3-1

Installing and Adjusting the Handle

1. Remove any packaging material from the upper handle.

2. Loosen the star knobs (A) as shown in Figure 3-2, and pivot

the upper handle assembly upwards (B) until it reaches

the optimal operating position based on the operator’s

preference.

Note: The handle adjustment range is not infinate, and

can only be adjusted within a range. Once reaching the

stop point in either the upward or downward position, it is

imporant not to attempt for force the handle any further.

8

Figure 3-3

Note: The convenient star knobs, detailed in C of Figure 3-3, are

available for the operator to simply make a handle adjustment,

based on preference and/or application, quickly, and easily.

Placing Upper Handle Into the “Stowed” Position

A

A

B

Cold Weather

(Below 32 F.)

Warm Weather

(Above 32 F. )

WARNING! DO NOT attempt to fold the handle

down while the engine is hot!

1. Loosen the star knobs (A) as shown in Figure 3-4, and pivot

the upper handle assembly downwards (B) until it reaches

the bottom of it’s pivot motion.

Figure 3-5

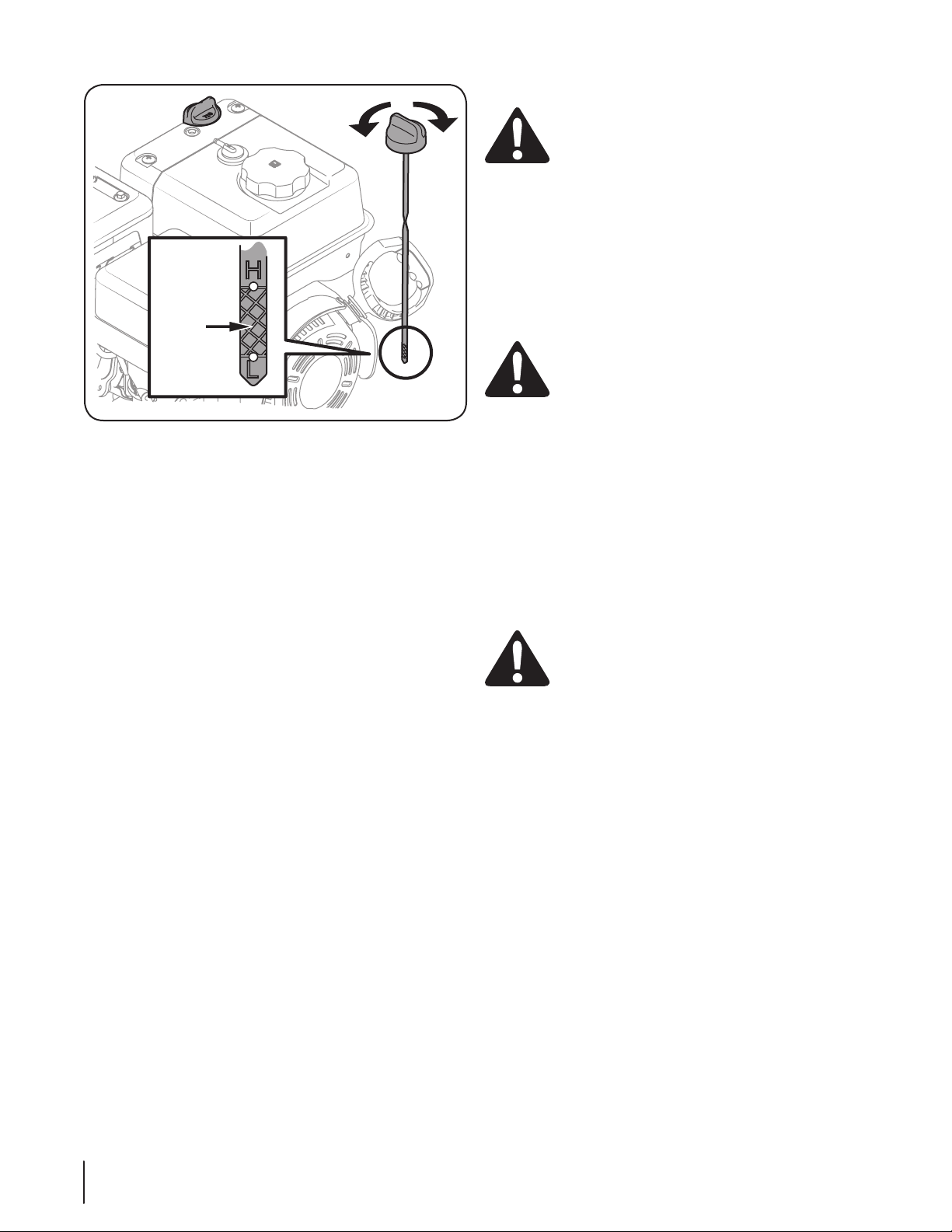

Checking the Oil Level

NOTE: Be sure to check the oil while on a level surface with the

engine stopped.

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating

hours when engine is warm.

• Keep oil level between “H” and “L” marks on dipstick.

Figure 3-4

2. Lightly tighten the two star knobs (C) to secure the upper

handle into the stowed position. See Figure 3-3.

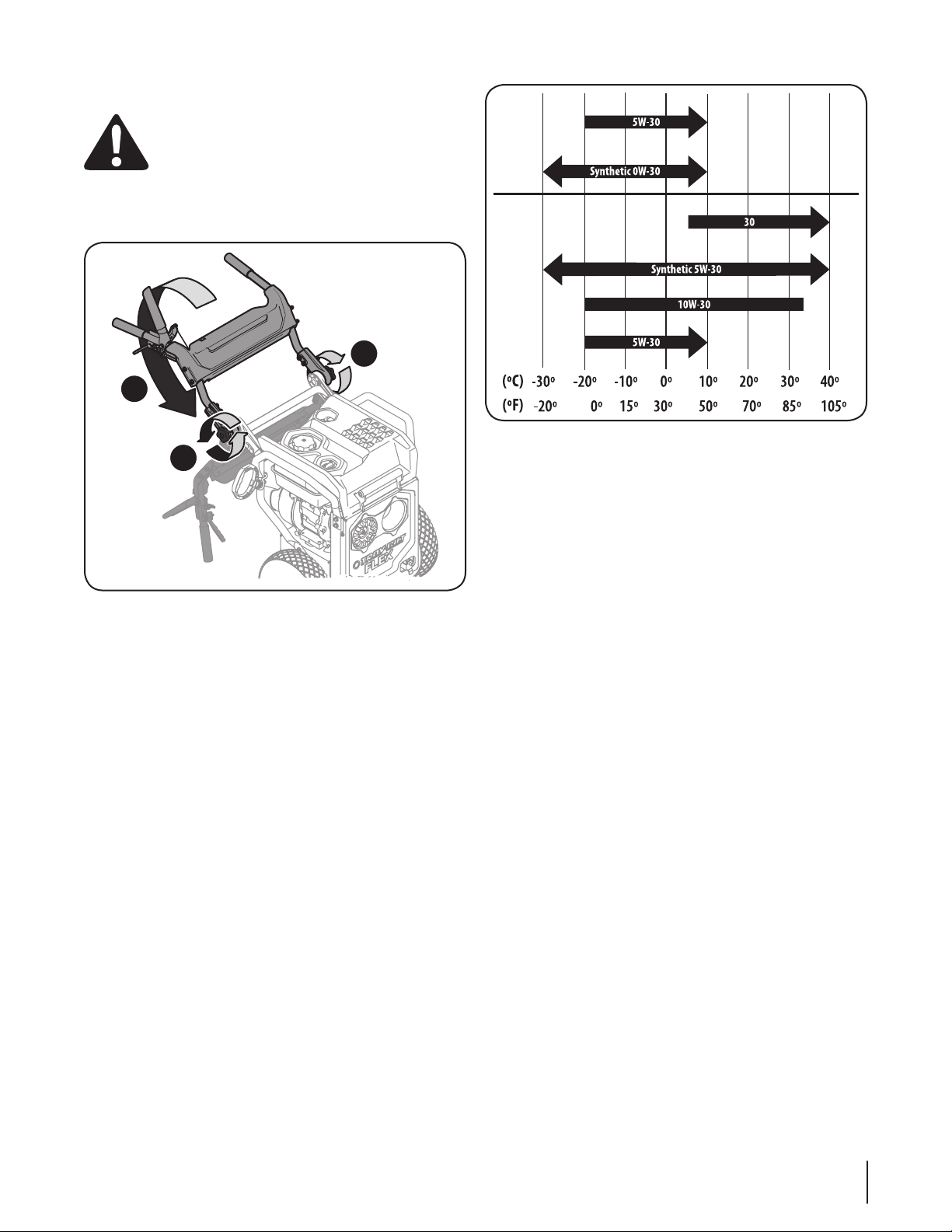

Oil & Fuel Specifications

IMPORTANT: The engine is shipped without oil and gasoline

in the engine. See the following instructions for adding oil and

gasoline.

1. Remove the oil filler cap/dipstick and wipe the dipstick

2. Insert the cap/dipstick into the oil filler neck, and tighten

3. Remove the oil filler cap/dipstick. If the level is low, slowly

IMPORTANT: It is very important to check the oil level before

operating the engine and to add oil if necessary. Running the

engine with insufficient oil can cause serious engine damage and

void the engine warranty

4. Replace and tighten cap/dipstick firmly before starting

Oil Recommendations

The FLEX Power Unit is shipped with a container of oil, to be

added before its first usage. Follow the instructions below for

adding oil, and oil types thereafter.

Before starting engine, fill with motor oil, capacity is 600

ml/20 oz. Refer to the viscosity chart (Figure 3-5) for oil

recommendations. Do not over-fill. Use a 4-stroke, or an

equivalent high detergent, premium quality motor oil certified to

meet or exceed U.S. automobile manufacturer’s requirements for

service classification of a minimum level SJ (higher letter ratings

are acceptable such as SL and SM grades). Motor oil will display

this designation on the container.

NOTE: Do not use non-detergent oil or 2-stroke engine oil. It

could shorten the engine’s service life.

NOTE: To change the oil, see Changing Oil instructions in the

Maintenance Section of this manual.

See Figure 3-6.

• Be sure oil fill cap/plug is tightened securely when

checking.

clean. See Figure 3-6.

the cap until seated.

add oil until oil level registers between high (H) and low (L),

Figure 3-6.

engine.

NOTE: Do not overfill. Overfilling with oil may cause

smoking, hard starting, or spark plug fouling.

NOTE: DO NOT allow oil level to fall below the “L” mark

on the dipstick. Doing so may result in equipment

malfunctions or damage.

9Section 3 — ASSembly & Set-Up

Fill

between

high

and low

marks

Figure 3-6

Adding Oil (If Needed)

IMPORTANT: This unit is shipped WITHOUT the engine full of

oil. Using the oil included with the FLEX™ Power Base, follow the

instructions below to add oil to the engine for it’s first time use.

1. Be sure the engine is upright and level.

2. Remove the oil fill cap dipstick from oil filler tube by

rotating counter-clockwise and lifting the dipstick out of

the engine. Wipe the dipstick clean with a shop rag.

3. Insert oil fill cap dipstick back into oil filler tube. On quarterturn oil fill caps, tighten by rotating the cap clockwise until

firmly seated.

4. Loosen and remove the oil fill cap dipstick from the oil

filler tube. Note the oil level, if oil reading on the dipstick

is below the “L” mark, slowly add oil to reach the “H” level.

See Figure 3-6.

5. Insert oil fill cap dipstick back into oil filler tube. Tighten by

rotating the cap clockwise until firmly seated.

6. Wipe away any spilled oil.

NOTE: To change the oil, see Changing Oil instructions in the

Maintenance Section of this manual.

Fuel Recommendations

CAUTION: Operating the engine with E15 or E85

fuel, an oil/gasoline mixture, dirty gasoline, or

gasoline over 30 days old that has not been

stabilized using a fuel additive, may result in

damage to your engine’s carburetor. Subsequent

damage would not be covered under the

manufacturer’s warranty.

Use automotive gasoline (unleaded or low leaded to minimize

combustion chamber deposits) with a minimum of 87 octane.

Gasoline with up to 10% ethanol or 15% MTBE (Methyl Tertiary

Butyl Ether) can be used. Never use an oil/gasoline mixture or

dirty gasoline. Avoid getting dirt, dust, or water in the fuel tank.

DO NOT use E15 or E85 gasoline.

WARNING! Gasoline is extremely flammable and is

explosive under certain conditions.

• Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks in the area where

the engine is refueled or where gasoline is stored.

• Do not overfill the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

• Be careful not to spill fuel when refueling. Spilled fuel or

fuel vapor may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

• Avoid repeated or prolonged contact with skin or

breathing of vapor.

Adding Fuel

WARNING! An adult should fuel this engine. NEVER

allow children to refuel this engine. Gasoline (fuel)

vapors are highly flammable and can explode. Fuel

vapors can spread and be ignited by a spark or flame

many feet away from engine. To prevent injury or

death from fuel fires, follow these instructions:

• DO NOT use leaded fuel.

• Fuel must be fresh and clean. NEVER use fuel left over

from last season or stored for longer than 30 days.

• NEVER mix oil with fuel.

• DO NOT use fuel containing Methanol (Wood

Alcohol)

1. Before refueling, allow the engine to cool for two minutes.

2. Be sure engine is outdoors and in a well-ventilated area.

3. Clean area around the fuel fill cap and remove the fuel fill cap.

4. Using an approved red GASOLINE container, add fuel

slowly, being careful to avoid spilling. Fill tank until the fuel

reaches the bottom of the filler neck to allow space for fuel

expansion. Be careful not to overfill.

10 Section 3 — ASSembly & Set-Up

5. Replace the fuel cap and tighten securely. Wipe up spilled

fuel before starting engine. If fuel is spilled DO NOT start

engine. Move machine away from area of spillage. Avoid

creating any source of ignition until fuel vapors are gone.

Figure 3-7

Tire Pressure

WARNING: Under any circumstance do not exceed

manufacturer’s recommended psi. Equal tire

pressure should be maintained at all times. Excessive

pressure when seating beads may cause tire/rim

assembly to burst with force sufficient to cause

serious injury. Refer to sidewall of tire for

recommended pressure.

The tires are over-inflated for shipping purposes. Check the tire

pressure before operating the FLEX™ Power Base. Refer to the tire

side wall for tire manufacturer’s recommended psi and deflate

(or inflate) the tires as necessary. Use a manual pump or portable

electric tire inflator to prevent over-inflation. NEVER USE AN AIR

COMPRESSOR!

Note: Equal tire pressure is to be maintained at all times for

performance purposes.

11Section 3 — ASSembly & Set-Up

Controls & Features

Attachment Control Safety Lock

Kickstand

Cold Weather/Warm

Weather Control

Handle Adjustment Knob

On/Off Switch

Attachment Control Lever

Drive Control Lever

Fuel Cap

Oil Fill Cap

Recoil Starter

Choke

Key

Primer

4

Attachment Control Lever

The attachment control lever is for deploying power to the

various available attachments. See also Figure 4-2.

Handle Adjustment Knobs

Utilize these two knobs to adjust the height and position of the

FLEX™ Power Base’s handle assembly. Refer to Installing and

Adjusting the Handle in the Assembly and Setup Section of this

manual for specific instructions regarding adjusting the handle.

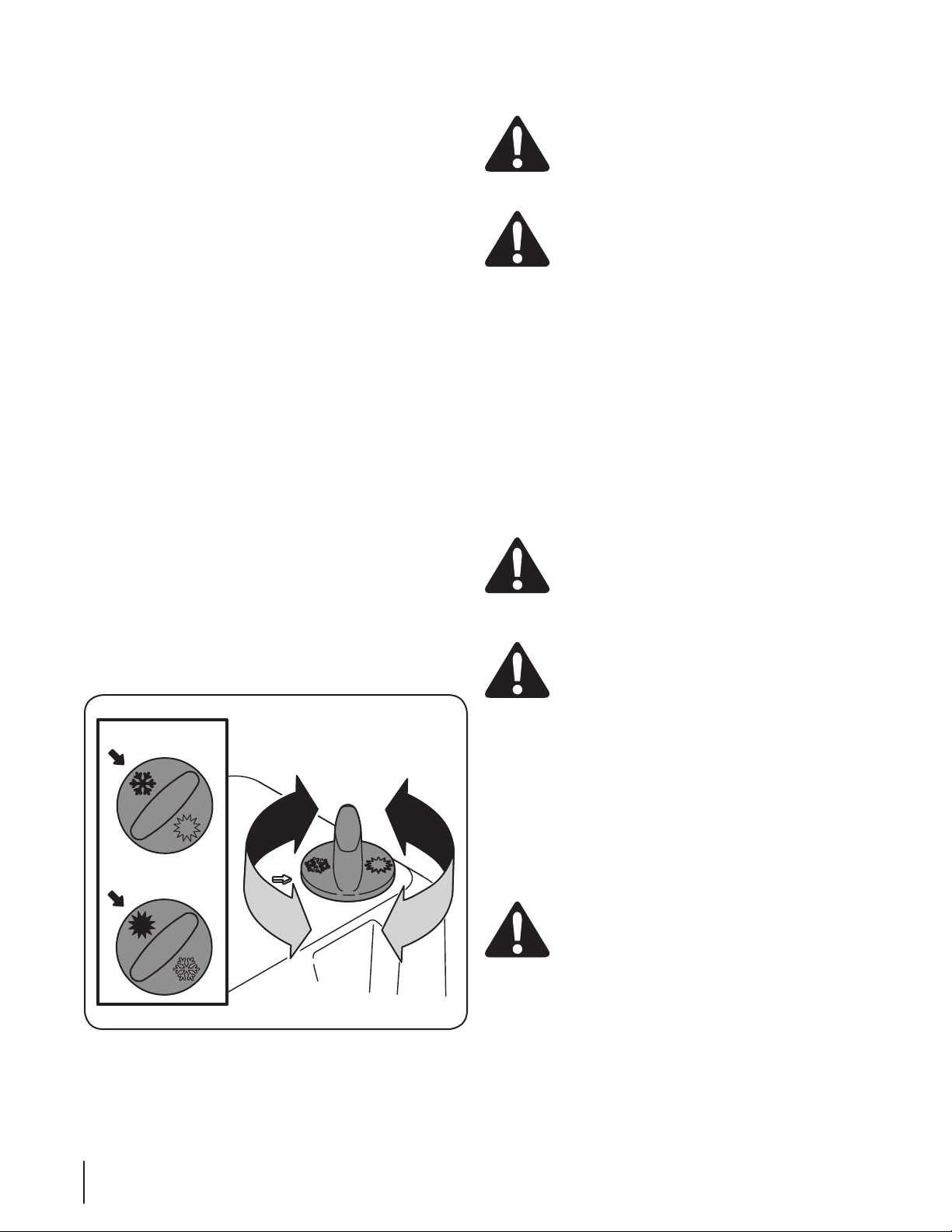

Cold Weather/Warm Weather Control

This control is utilized throughout the year. Turn the control to

Winter for Winter operation (below 32F, and Summer (above

32F for Summer operation.

Figure 4-1

Kickstand

The kickstand is utilized to hold the FLEX™ Power Base in an

upright and parked position when there is NO attachment

present. It also locks the attachment to the power base (when in

“Up” position) and unlocks the attachment when placed in the

down position.

Recoil Starter

The recoil starter employs a starter rope and handle used to pullstart the engine.

12

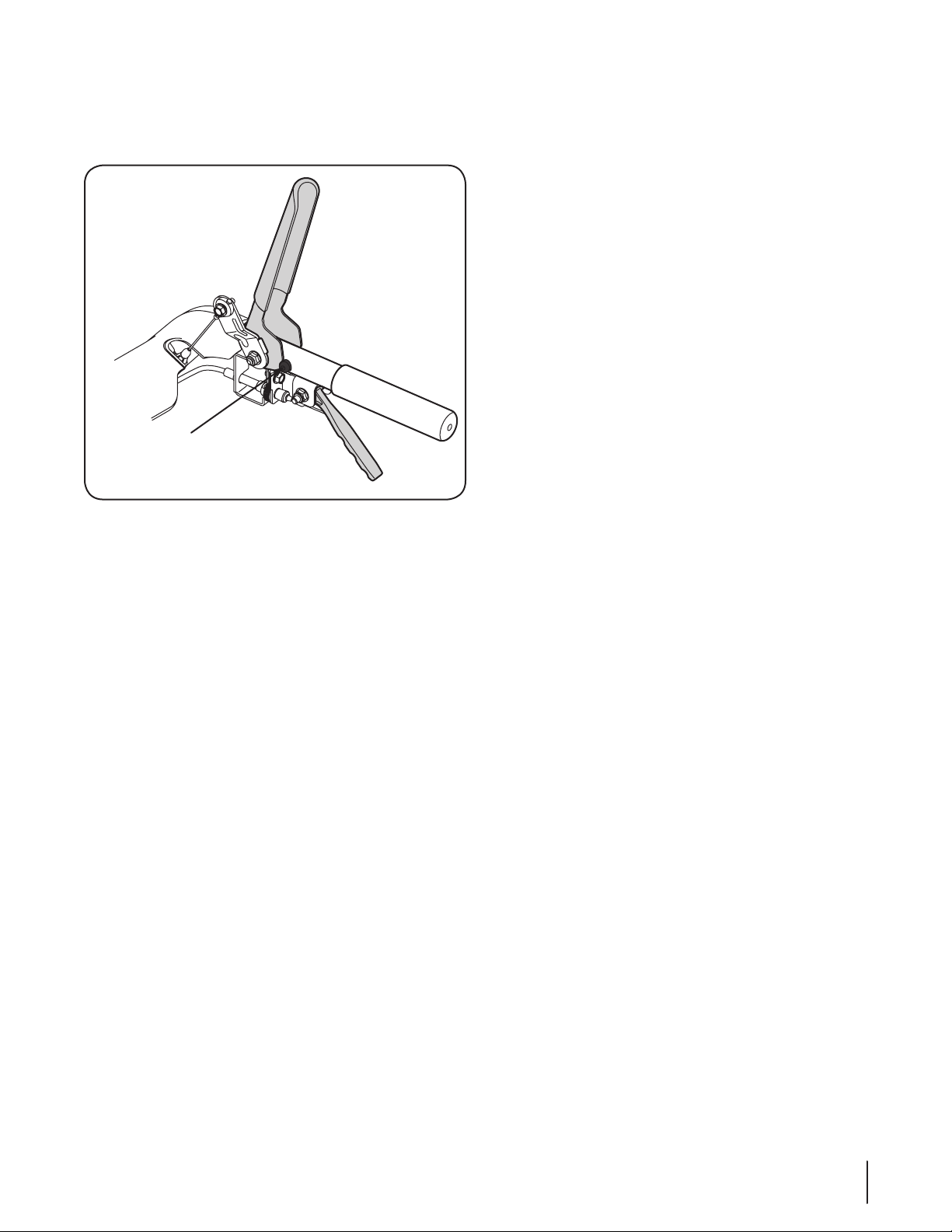

Attachment Control Safety Lock

Drive Control

Lever

Attachment Control

Safety Lock

Attachment Control

Lever

The attachment control safety lock is a red button beside the

lever that must be pressed in order to actuate the attachment

control lever. See Figure 4-2.

Figure 4-2

Engine Controls

Primer Bulb

Pressing the primer bulb forces fuel directly into the engine’s

carburetor to aid in starting a “Cold” engine.

Key

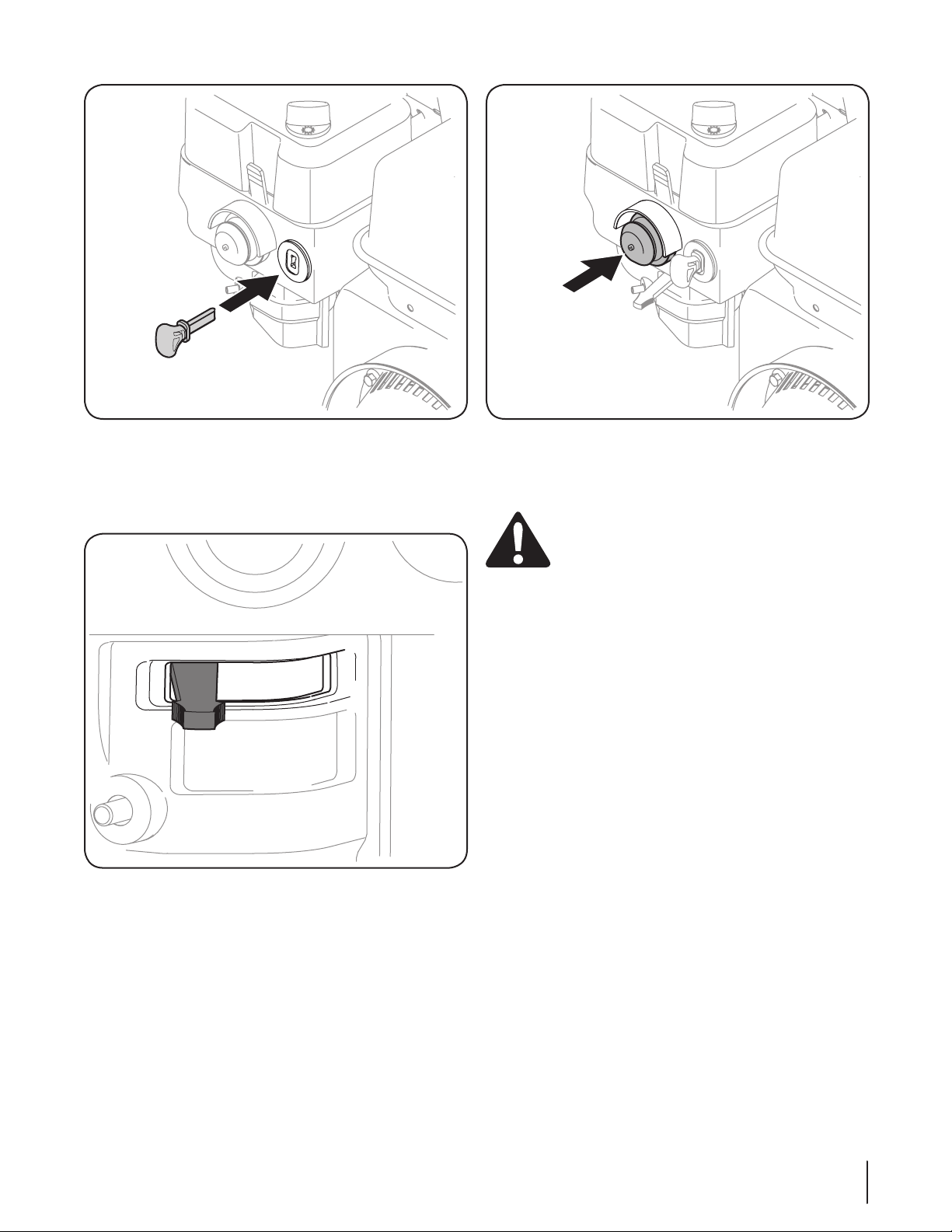

The key is a safety device. It must be fully inserted in order for the

engine to start. Remove the key when the power base is not in

use.

IMPORTANT: Do not attempt to turn the key once inserted into

the FLEX™ Power Base engine. For the engine to be in the “Run”

position, the key only need be fully inserted into the engine key

hole. Do not turn the key in an attempt to start the engine. Doing

so may cause it to break.

Choke

Activating the choke closes the choke plate on the carburetor

and aids in starting the engine.

Fuel Cap

Remove the fuel cap to fill the FLEX™ Power Base with gasoline.

Refer to the Assembly & Set-Up section of this manual for

complete fuel type and filling instructions.

Oil Fill Cap

Remove the oil fill cap to check and/or fill the FLEX™ Power

Base with engine oil. Refer to Adding Oil in the Assembly &

Set-Up section of this manual for complete fuel type and filling

instructions.

On/Off Switch

The On/Off Switch is used to remove the power to the engine,

causing the engine to come to a complete stop. Once pressed

and held, the engine will shut down. Upon releasing the On/Off

Switch, the switch will return to the ON position.

Note: The On/Off switch is a “Momentary Switch” which means

the operator must hold the switch in the OFF position until the

motor comes to a complete stop.

Note: Another way to remove power to the engine is to remove

the key by pulling it outward. DO NOT attempt to turn the key.

13Section 4 — controlS & FeatureS

Operation

ChokeRun

Fast Slow/Idle Engine Off

Primer

5

Pre-Operation Check

IMPORTANT: The engine is shipped without gasoline in the

engine. See the Set-Up Section of this manual for instructions on

adding gasoline.

IMPORTANT: Some engines are shipped with oil already in

the engine, others without oil already in the engine. It is very

important to check the oil before operating the engine and

to add if necessary. See the Set-Up Section of this manual for

instructions on checking and adding oil.

For your safety, and in order to maximize the service life of this

equipment, it is very important to check its condition before you

operate this engine. Make certain to service, correct or fix any

problem that might be identified before attempting to operate

this engine.

WARNING! Improperly maintaining this engine, or

failure to correct any problem before operation can

cause a malfunction which could result in serious

injury or even death.

Always perform a pre-operation inspection before

each operation, and correct any problem.

Before you start the engine, always check the following items:

1. Fuel Recommendations (See Set-Up Section)

2. Checking Oil Level (See Set-Up Section)

3. Air filter (if equipped) (See Maintenance Section)

4. General Overall Inspection. Check for any fluid leaks or

discharges, and loose or damaged parts.

5. Review this owner’s manual for any precautions and

procedures that should be followed before starting the

engine.

Starting the Engine

WARNING! Always keep hands and feet clear of

moving parts. Do not use a pressurized starting

fluid. Vapors are flammable.

WARNING! An adult should start the engine. Only

allow children to start the engine if an adult has

determined they are experienced and capable of

such operation.

WARNING! If you are unable to start this engine

after following instructions in this manual, contact

an authorized Troy-bilt Service Dealer. To avoid

serious burn injuries or damage to your engine, DO

NOT attempt to start or troubleshoot this engine in

any other way. For example:

• DO NOT use starting fluid.

• DO NOT spray flammable vapors into the

carburetor.

• DO NOT put flammable liquids into carburetor.

• DO NOT operate engine or pull on starter rope

with spark plug removed. Fuel can spray from

spark plug hole and ignite.

NOTE: Allow the engine to warm up for a few minutes after

starting. The engine will not develop full power until it reaches

operating temperatures.

Familiarize yourself with the engine symbols shown in Figure

5-1 before attempting to start this engine.

Figure 5-1

NOTE: The following starting instructions are for several different

types of engines. In order to locate the instructions that apply to

your engine, first determine what type of starter you have. If you

have an electric starter, see Engines With Electric Starters. If you

have a manual recoil starter, see Engines with Recoil Starters later

in this section.

The Recoil Starter

WARNING! DO NOT pull starter rope with engine

running. Doing so may VOID YOUR WARRANTY.

IMPORTANT: The FLEX™ Power Base will not start without an

attachment fully installed onto the unit.

1. To avoid carbon monoxide poisoning, be sure engine is

outdoors in a well-ventilated area.

2. Insert key into slot. Make sure it snaps into place. Do not

attempt to turn the key. See Figure 5-2.

NOTE: The engine cannot start without the key fully

inserted into the switch.

NOTE: The engine will not start without an attachment

installed onto the power base.

3. Set the unit’s On/Off switch to the “On” position.

14

Figure 5-2

4. Be sure fuel valve, if present (see the Engine Operator’s

Manual instructions), is open.

5. Set the choke control to “FULL CHOKE” position. See Figure

5-3.

Figure 5-3

6. Hold the primer bulb in for one full second each time you

press it.

• Make sure you cover the vent hole with your

thumb.

• Prime between 3 and 5 times.

Note: Primer bulb should only be used in cold weather.

Figure 5-4

NOTE: DO NOT use the primer bulb to restart a warm

engine after a short shutdown. Doing so will flood the

engine and may result in equipment malfunction.

WARNING! When pulling the starter rope, the

rope can unexpectedly jerk back toward the engine

causing serious injury. To avoid this risk, carefully

follow these instructions:

7. Grasp the starter cord handle.

• Pull rope out slowly until you feel drag.

• Without allowing the rope to retract, continue

pulling the rope with one rapid full arm stroke.

• Return the rope slowly to the original position.

NOTE: Following the instructions listed in the steps above

avoids potential damage to the recoil mechanism.

NOTE: If the recoil starter handle is frozen and will not

operate the engine, proceed as follows:

• Pull as much rope out of the starter as possible.

• Release the starer handle and let it snap back

against the starter to break up ice; these two

steps should only be done when the starter is

frozen.

8. If the engine fails to start after 3 attempts, repeat steps 1

through 7 and try again.

9. When the Engine starts:

• Move the choke control to 1/2 “CHOKE” position

until the engine runs smoothly.

• Next, move the choke control to the NO CHOKE

position.

NOTE: If the engine starts but falters when the choke

control is moved to the “NO CHOKE” position:

15Section 5 — oper ation

• Momentarily move choke control back to “FULL

Cold Weather

Warm Weather

CHOKE” position.

• Next, move the choke control to “1/2 CHOKE”

position until engine runs smoothly.

• Finally, move the choke control to the NO

CHOKE position.

If the engine shots down after choke control is moved to “NO

CHOKE” position, repeat steps 3 through 10 to restart engine.

10. If the engine fails to start after 3 attempts in the “NO

CHOKE” position, move the choke control to “FULL CHOKE”

position and start engine.

11. If engine does not start after following steps 1 through 11,

contact your Authorized Troy-bilt Service Dealer. DO NOT

attempt to troubleshoot this engine in any other way.

Cold Weather / Warm Weather Control

A weather control knob is available on the topside of the air filter.

This control is utilized to control the flow of air during the warm

and cold months of the year.

Note: 32 F is the general recommendation to switch

between the warm and cold setting.

To set the weather control knob:

1. In colder months, especially when operating the snow

throwing attachment, turn the knob to the position in

which the snow flake on the knob aligns with the arrow on

the air filter cover. See the top portion of the inset in Figure

5-5.

2. In warmer months, most likely when operating the

pressure washer, cutting deck, etc., place the weather

control knob in which the Sun image on the knob aligns

with the arrow on the air filter cover. See the bottom of the

inset in Figure 5-5.

Stopping the Engine & Short Term Storage

WARNING! To avoid unsupervised engine

operation, especially by children, NEVER leave the

engine unattended while running. Always turn off

the engine after use and remove the key, if

equipped.

WARNING! NEVER store the engine with fuel in the

fuel tank inside a building with potential sources of

ignition such as hot water tank and space heaters,

clothes drivers, electric motors, etc.

Stopping The Engine

1. If operating the engine in the snow or rain, run the engine

for a few minutes to help dry off any moisture.

2. Push the On/Off switch to the off position and hold until

the engine comes to a c complete stop.

Note: It is also possible to stop the engine by removing the

key, as shown in the Controls section of this manual.

3. Remove the key, if provided (see equipment Operator’s

Manual).

NOTE: Removing the key will reduce the possibility of

unauthorized starting of the engine while equipment is not

in use.

WARNING! NEVER store the engine with fuel in the

fuel tank inside a building with potential sources of

ignition such as hot water tank and space heaters,

clothes dryers, electric motors, etc.

After the Engine is Stopped

WARNING! To prevent the possible freeze-up of

engine controls, follow instructions with engine

STOPPED, listed below:

1. Wipe all snow and moisture from the engine control lever

and choke areas.

2. Move the engine choke back and forth several times and

leave in the “FULL CHOKE” position.

3. Be sure the Fuel Shut-Off Valve, if present, is off.

16 Section 5— operation

Operating Tips

NOTE: Allow the engine to warm up for a few minutes. The

engine will not develop full power until it reaches operating

temperature.

WARNING: The temperature of the muffler and

the surrounding areas may exceed 150° F. Avoid

these areas.

Figure 5-5

Connecting an Attachment

1

2

1

2

Drive Control

Lever

Note: This FLEX™ Power Base is designed to couple with a series

of attachments that will be powered by this unit. The coupling of

the various attachments are engineered with precise tolerances.

It is imperative that the operator keeps the coupling mechanisms

free from dirt and debris. Refer to the individual attachment

manuals for detailed instructions for connecting the various

attachments.

If you experience difficulty coupling these devices, possible

reasons could be dirt or debris affecting mounting pins and

latches. Clean and inspect the mounting points regularly.

The FLEX™ Power Base incorporates a special locking system,

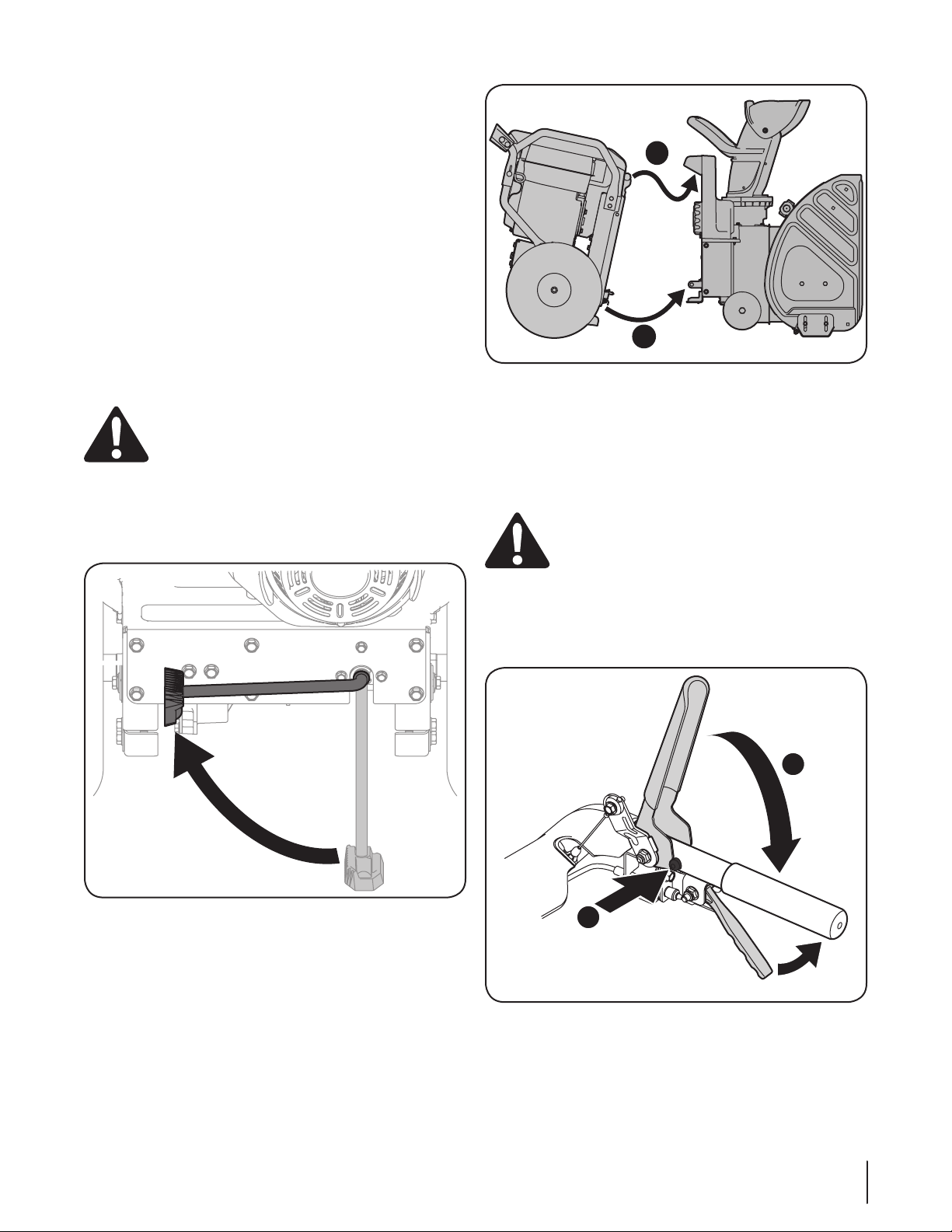

called the Latch’n Lock™. To connect the FLEX™ Power Base to an

attachment, follow these simple steps:

1. Be sure to release the Attachment Control Lever before

attempting to connect or disconnect the FLEX™ Power

Base from any of the various attachments.

WARNING! Always be sure to release the

Attachment Control Lever before attempting to

couple or uncouple the power base from an

attachment. Failure to do so can result in damage to

your equipment, as well as possible injury resulting from

accidentally activating an attachment.

2. Put the Latch’n Lock™ kickstand into the lock (Up) position,

see Figure 5-6.

Figure 5-7

To Engage the PTO (Power Take Off)

To apply power to a FLEX attachment, follow these instructions:

NOTE: For complete operator control instructions, see the

accompanying manual included with each of the various

available attachments.

CAUTION: NEVER deploy the operator’s bail

without first putting the Latch’n Lock™ kickstand up

into its attachment lock position. Failure to do so

can cause damage to the FLEX™ Power Base.

1. Press the Attachment Control Safety Lock(red button) on

the right handle, as shown in 1 of Figure 5-8.

2. With the red button pressed in, pivot the Attachment

Control Lever downward towards the handle (2).

Figure 5-6

3. Tip the FLEX™ Power Base forward and engage the top

locking handle on the various attachment.

4. Rock the FLEX™ Power Base backwards to lock in the

bottom mounts. The operator should feel it engage and

hear an audible “click,” indicating that the attachment has

been properly connected.

Note: Try pivoting the FLEX™ Power Base forward to make

sure a connection has been established.

Figure 5-8

17Section 5 — operation

Propelling the Power Base Forward

To propel the power base forward, simply pull up on the Drive

Control Lever. To stop, simply release the lever.

Disconnecting an Attachment

Fully stop the power base engine before attempting to perform

any maintenance steps or uncoupling of the attachment.

WARNING! Always turn off the FLEX™ Power Base

engine and remove the key prior to attempting to

uncouple of the power base from the attachment.

1. Fully stop the power base, and wait for all moving parts to

come to a complete stop.

2. Release the Attachment Control Lever.

WARNING! Always be sure to release the

Attachment Control Lever before attempting to

couple or uncouple the power base from an

attachment. Failure to do so can result in damage to

your equipment.

3. With both hands on the handle grips, move the Latch’n

Lock™ kickstand into the unlock (Down) position, see

Figure 5-9.

Figure 5-9

4. Lift up on the handles, pivoting the power base forward

and move the power base backwards, away from the

attachment.

5. Park the power base utilizing the deployed Latch’n Lock™

kickstand, which should still be in the downward position.

18 Section 5— operation

Cold Weather

(Below 32 F.)

Warm Weather

(Above 32 F. )

Maintenance

Maintenance Schedule

6

Clean Engine Cooling Fins

Check Engine Oil Level

Change Engine Oil

Check Air Cleaner

Service Air Cleaner

Check Spark Plug

Replace Spark Plug

Clean Engine Shroud

Clean around Muer

Replace Fuel Filter (If equipped)

First 5 Hours

Each Use or

Every 5 Hrs.

Every Season

or 25 Hours

P

P

P P

P

P

P

P

Every Season

or 50 Hours

Every Season

or 100 Hours

P

P

P

Service Dates

Periodic inspection and adjustment of the engine is essential if

high level performance is to be maintained. Regular maintenance

will also ensure a long service life. The required service intervals

and the kind of maintenance to be performed are described

in the table above. Follow the hourly or calendar intervals,

whichever occur first. More frequent service is required when

operating in adverse conditions.

WARNING! Shut off the engine before performing

any maintenance. To prevent accidental start-up,

disconnect the spark plug boot.

NOTE: If engine must be tipped to transport equipment or to

inspect, keep the spark plug side of the engine up. Transporting

or tipping the engine spark plug side down may cause smoking,

hard starting, spark plug fouling, or oil saturation of air cleaner.

WARNING! If the engine has been running, the

muffler will be very hot. Be careful not to touch the

Oil Recommendations

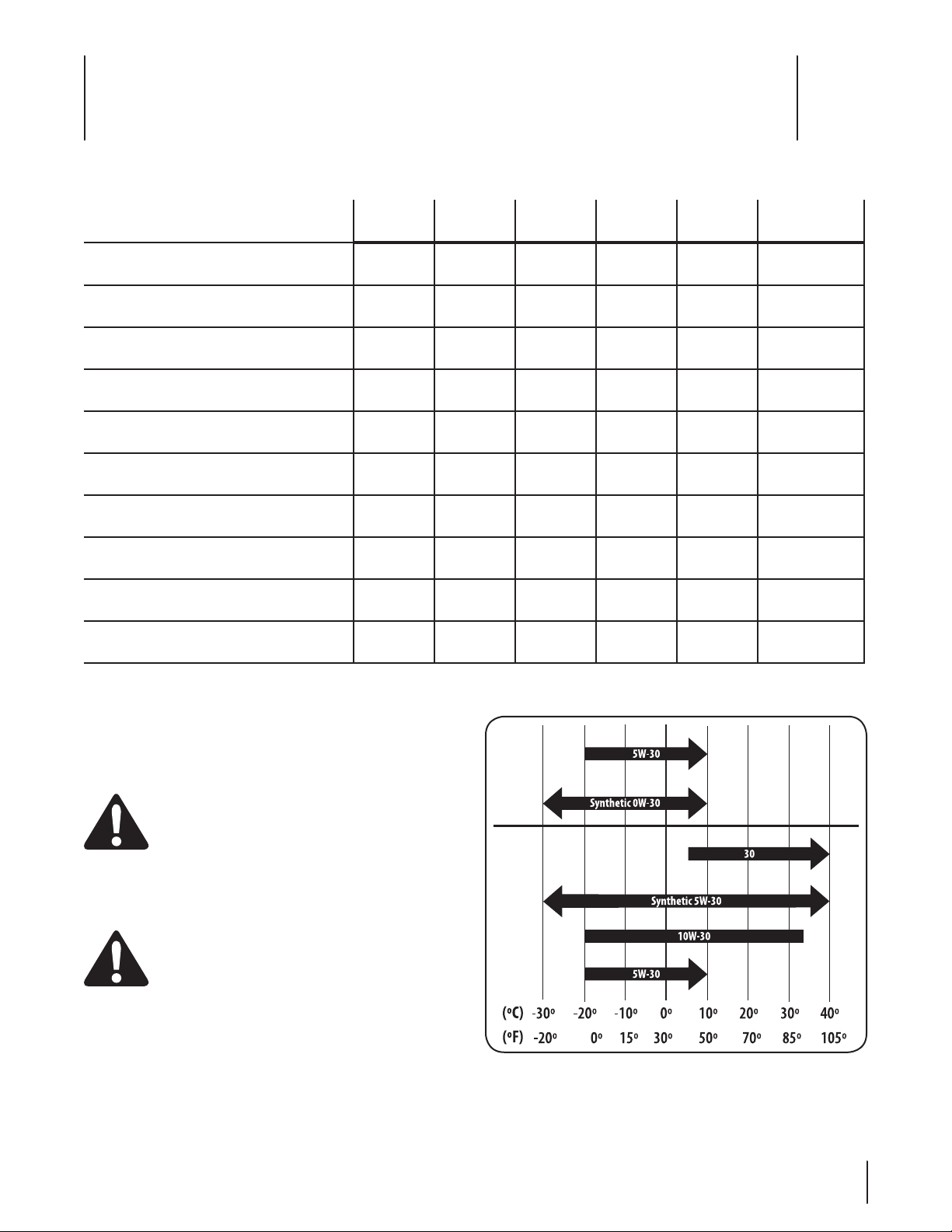

Refer to the viscosity chart (Figure 6-1) for oil recommendations.

Do not over-fill. Use a 4-stroke, or an equivalent high detergent,

premium quality motor oil certified to meet or exceed

U.S. automobile manufacturer’s requirements for service

classification of a minimum level SF or SG (higher letter ratings

are acceptable such as SJ, SL and SM grades). Motor oil will

display this designation on the container.

muffler.

NOTE: Do not use non-detergent oil or 2-stroke engine oil. It

could shorten the engine’s service life.

Figure 6-1

19

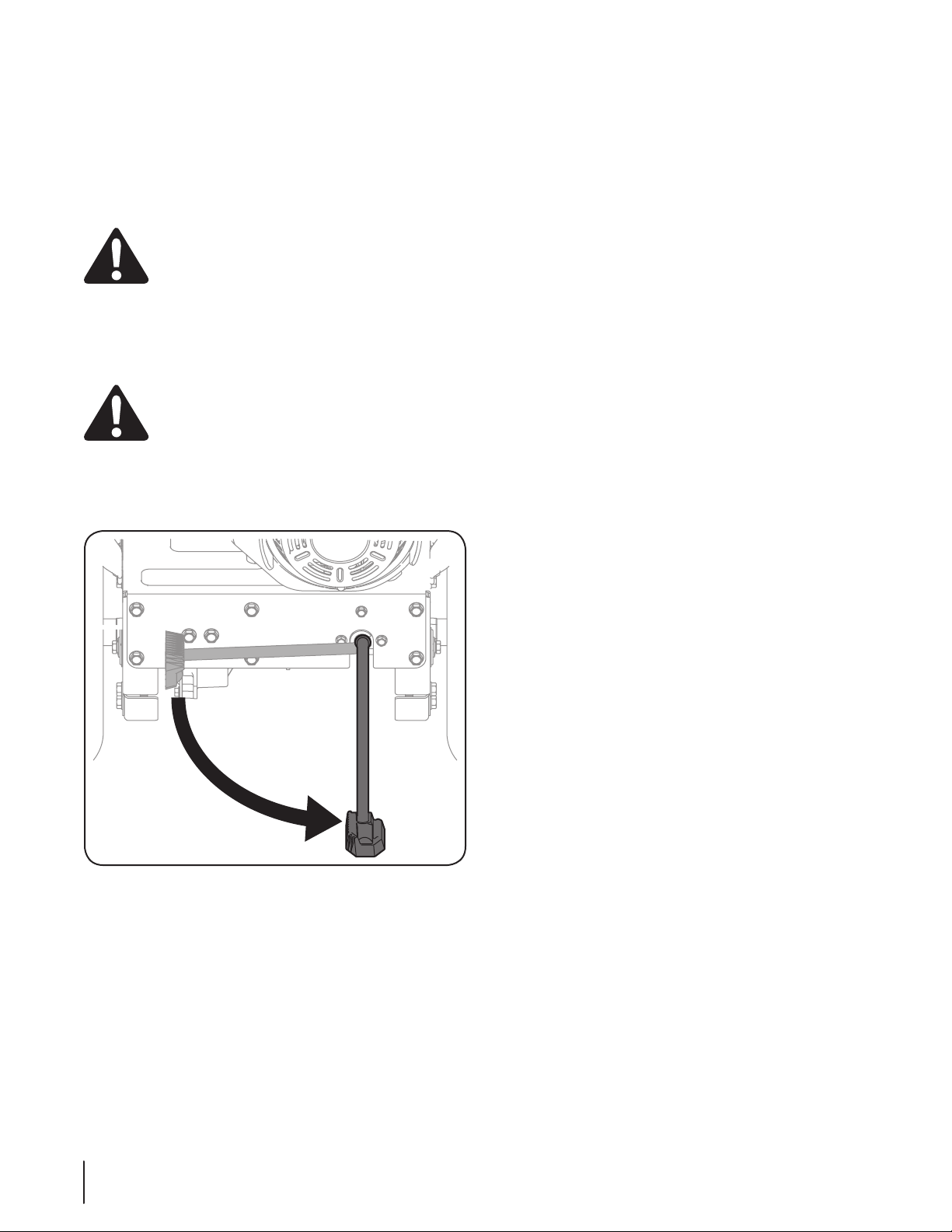

Changing Oil

To avoid engine damage, it is important to:

• Check oil level before each use and every 5 operating hours

when the engine is warm.

• Change the oil after the first 5 operating hours and every

50 operating hours thereafter. Engine should still be warm

but NOT hot from recent use.

Oil Fill Cap and Dipstick

WARNING! Before tipping engine or equipment to

drain oil, drain fuel from tank by running engine

until fuel tank is empty.

1. Carefully disconnect the spark plug wire and keep it away

from the spark plug. Refer to Figure 6-2 for spark plug

location.

• Keep the disconnected spark plug wire securely

away from the metal parts where arcing could

occur.

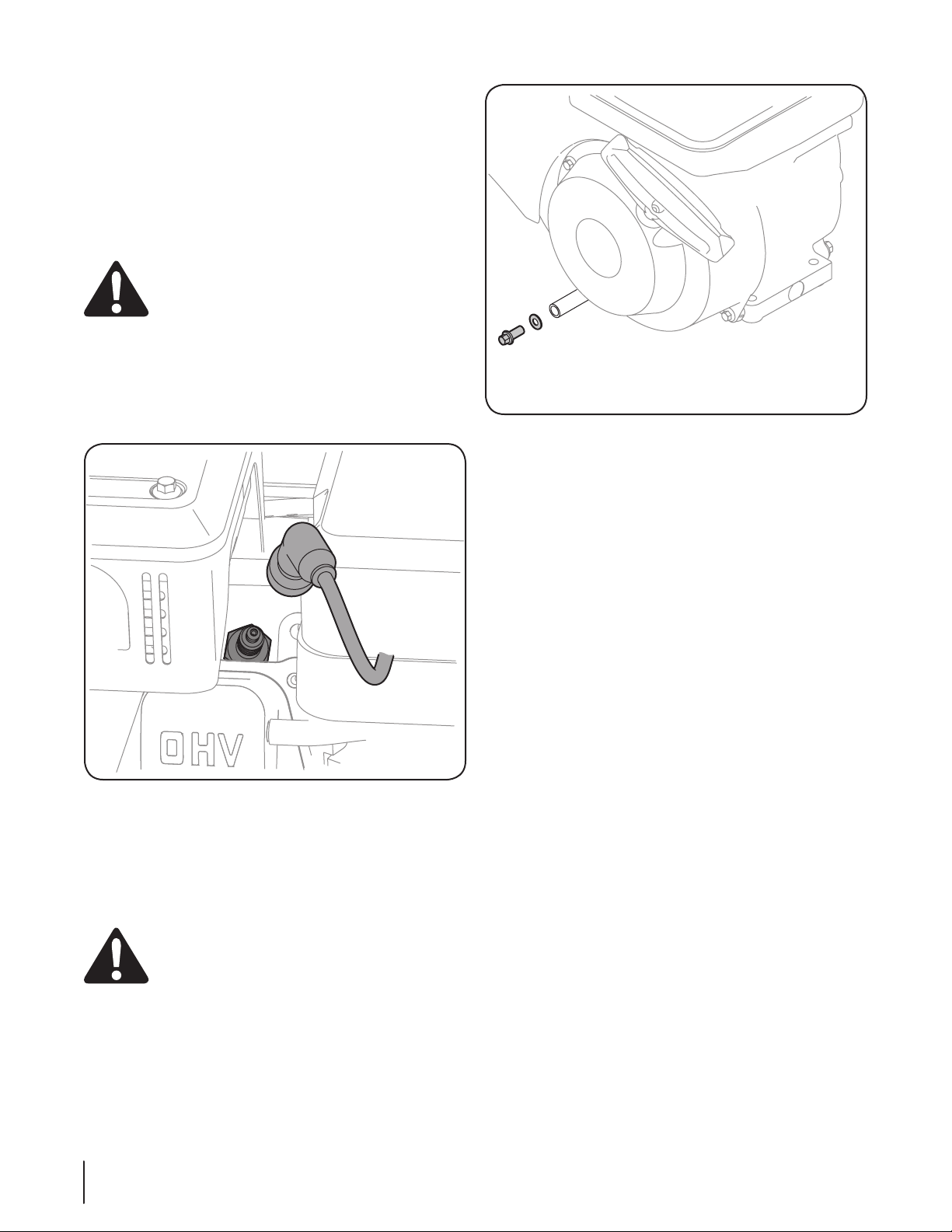

Figure 6-2

2. Be sure that the fuel fill cap is on and securely tightened.

3. Clean area around the oil drain plug.

4. Place an approved recyclable oil container under the oil

drain plug.

5. Remove the oil drain plug. See Figure 6-3.

WARNING! Used motor oil may cause skin cancer

if repeatedly left in contact with the skin for

prolonged periods. Although this is unlikely unless

you handle used oil on a daily basis, it is still

advisable to thoroughly wash your hands with soap

and water as soon as possible after handling used

oil.

Figure 6-3

6. Drain the oil into an approved recyclable oil container.

NOTE: Please dispose of used motor oil in a manner that is

compatible with the environment. We suggest you take it in a

sealed container to your local service station for reclamation.

Do not throw it in the trash or pour it on the ground.

7. Install the oil drain plug and tighten securely.

8. Remove the oil fill cap dipstick.

9. Fill with the recommended Oil. See Figure 6-1.

NOTE: DO NOT overfill. Doing so may result in oil carry-over

to the equipment and cause malfunction or damage.

NOTE: DO NOT allow oil level to fall below and “L” mark on

dipstick. Doing so may result in equipment malfunction or

damage.

10. Wipe away any spilled oil.

11. Check the oil level by installing the Oil Fill Cap/Dipstick.

• The Oil Fill Cap/Dipstick requires a quarter-turn

to tighten. Be sure to tighten down the cap to

check the oil level.

NOTE: See the Set-Up section earlier in this manual for

detailed instructions on checking the oil.

12. Remove the oil filler cap/dipstick. If the level is low, slowly

add oil until oil level registers between the high (H) and low

(L) mark on the dipstick. See Figure 3-6 in the Assembly &

Set-Up section for reference.

13. Repeat Steps 11 & 12 to be sure that the correct oil level has

been achieved.

14. Once the proper oil level has been confirmed, install the Oil

Fill Cap/Dipstick. Tighten securely

15. Carefully reconnect the spark plug wire to the spark plug.

NOTE: It is advisable to recheck the oil level after you have

operated the engine for a short while, and the normal engine

operating temperature has been achieved.

20 Section 6— Maintenance

Loading...

Loading...