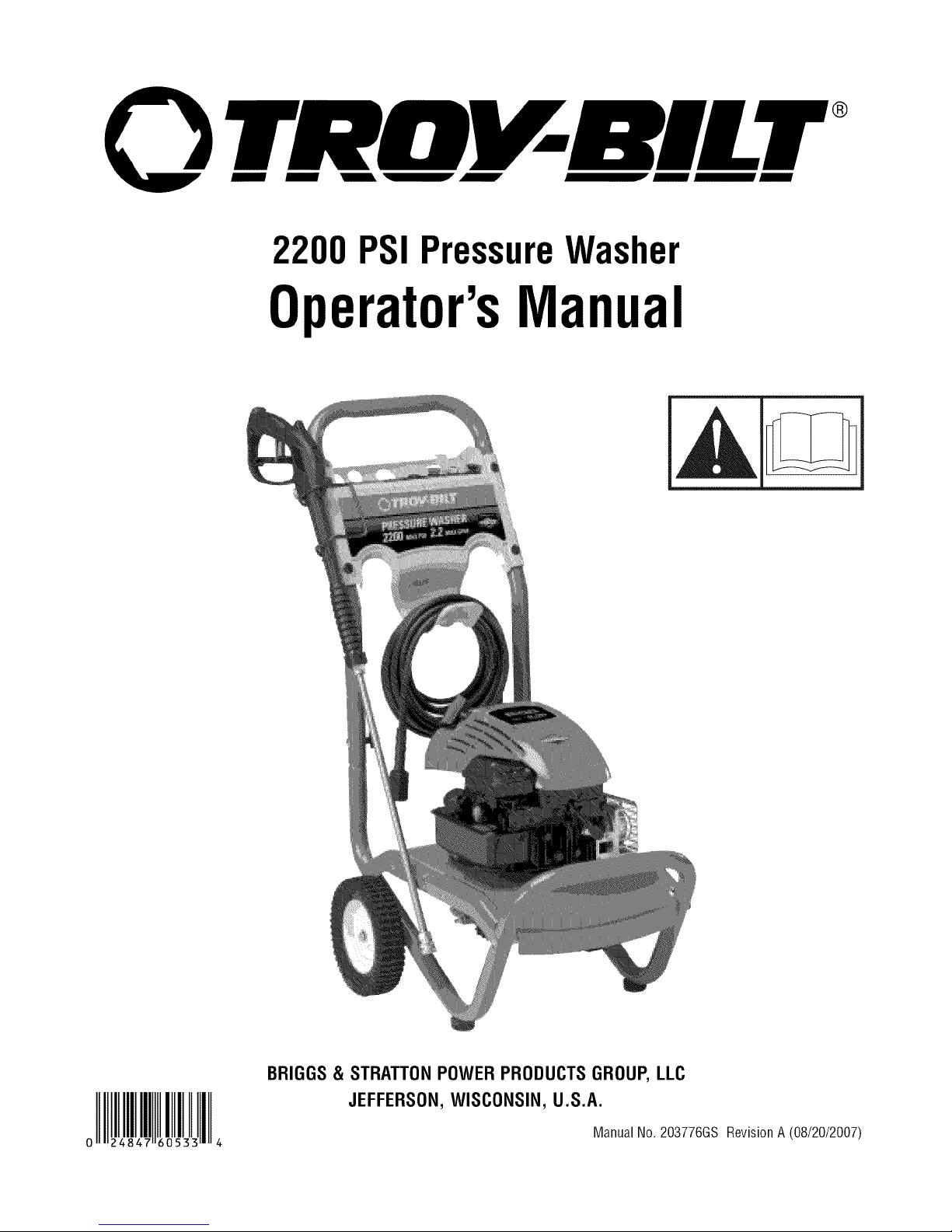

Troy-Bilt 20292 Operator's Manual

i'_rm

2200 PSI PressureWasher

Operator'sManual

,®

BRIGGS & STRATTONPOWER PRODUCTSGROUP, LLC

JEFFERSON, WISCONSIN, U.S.A.

Manual No. 203776GS Revision A (08/20/2007)

Thankyou for purchasing this quality-built Troy-Bilt pressurewasher.We are pleasedthat you've placedyour confidencein

the Troy-Bilt brand.When operatedand maintainedaccording to the instructions in this manual, your Troy-Bilt pressure

washer will provide many yearsof dependableservice.

Thismanualcontainssafety information to makeyou awareof the hazardsand risks associatedwith pressure washersand

how to avoid them. BecauseTroy-Bilt does not necessarilyknow all the applications this pressurewasher could beused for, it

is important that you readand understandthese instructions thoroughly beforeattempting to start or operate this equipment.

Save these instructions for future reference.

Thispressure washer requiresfinal assemblybeforeuse. Referto the Assemb/ysection of this manualfor instructions on

final assembly procedures.Follow the instructions completely.

Where to Find Us

You never have to look far to find Briggs & Stratton support and service for your pressure washer. Consultyour Yellow Pages.

Thereare over 30,000 Briggs & Stratton authorizedservice dealersworldwide who provide qualityservice. You canalso

contact Troy-Bilt Customer Serviceby phone at (888) 611-6708, or on the Internet at www.troybilt.com.

PressureWasher

Model Number

Revision

Serial Number

Engine

III

Model Number

TypeNumber

CodeNumber

DatePurchased

IIIIIIIII

Troy-Bilt® is a registeredtrademark of MTD Products Inc and is used under

license to Briggs & Stratton Power Products.

Briggs & Stratton PowerProducts Group, LLC

900 North Parkway

Jefferson, WI 53549

III

Copyright © 2007 Briggs & Stratton Power Products Group,

LLC. All rights reserved. No part of this material may be

reproduced or transmitted in any form by any meanswithout

the expresswritten permission of Briggs & Stratton Power

Products Group,LLC.

2 www.troybilt.com

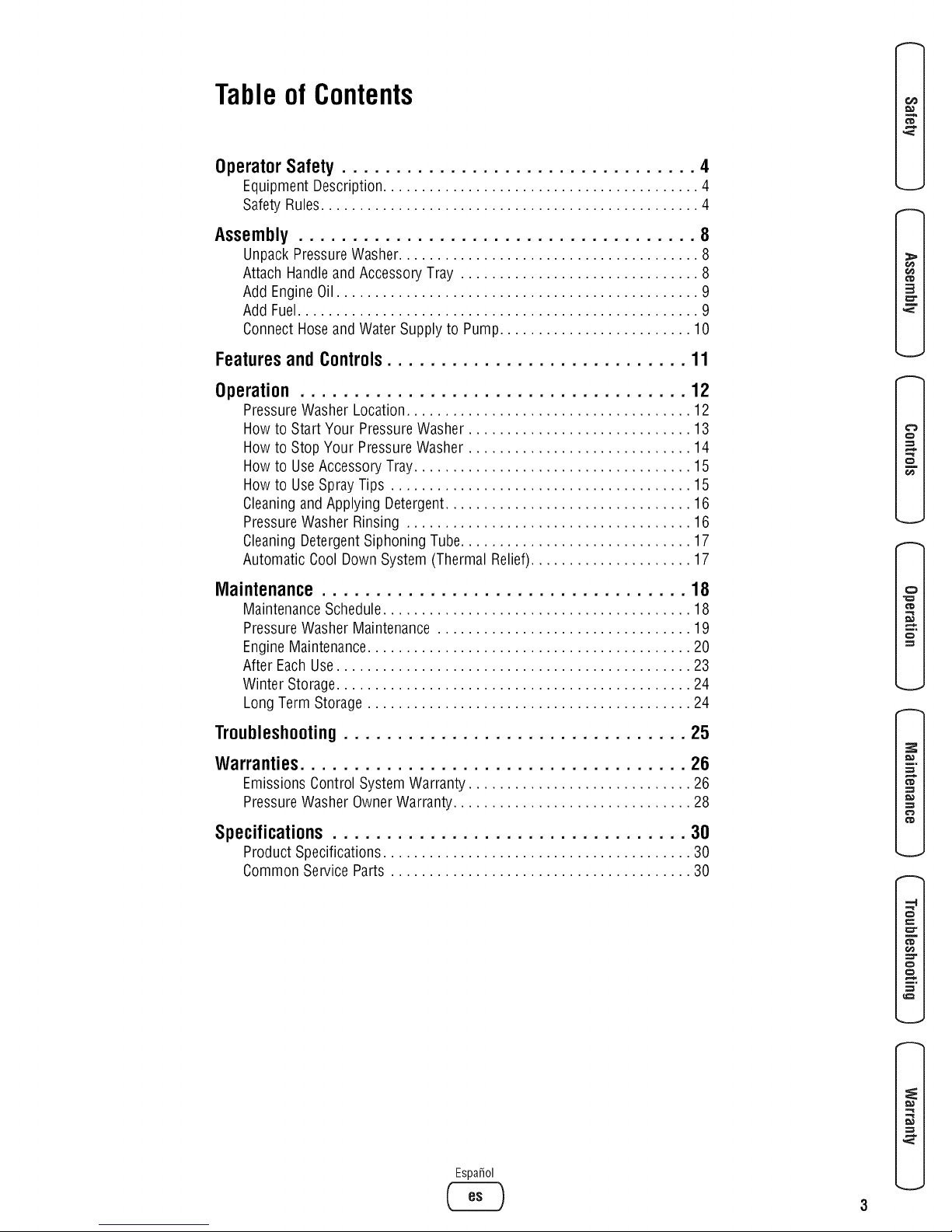

Table of Contents

Operator Safety ................................. 4

Equipment Description......................................... 4

Safety Rules................................................. 4

Assembly ..................................... 8

Unpack PressureWasher....................................... 8

Attach Handleand AccessoryTray ............................... 8

Add Engine Oil............................................... 9

Add Fuel.................................................... 9

Connect HoseandWater Supply to Pump......................... 10

FeaturesandControls............................ 11

Operation .................................... 12

PressureWasher Location..................................... 12

How to Start Your PressureWasher............................. 13

How to Stop Your PressureWasher ............................. 14

How to UseAccessory Tray.................................... 15

How to Use SprayTips ....................................... 15

Cleaningand Applying Detergent................................ 16

PressureWasher Rinsing ..................................... 16

CleaningDetergentSiphoning Tube.............................. 17

Automatic Cool Down System(Thermal Relief)..................... 17

€"D

t.n

t_

3

o

t_

Maintenance .................................. 18

MaintenanceSchedule........................................ 18

PressureWasher Maintenance ................................. 19

Engine Maintenance.......................................... 20

After Each Use.............................................. 23

Winter Storage.............................................. 24

Long Term Storage .......................................... 24

Troubleshooting ................................ 25

Warranties .................................... 26

Emissions Control SystemWarranty ............................. 26

PressureWasher OwnerWarranty............................... 28

Specifications ................................. 30

Product Specifications........................................ 30

Common Service Parts ....................................... 30

"o

€,#

w_

o

€1#

o

6¢

o

o

Espa_ol

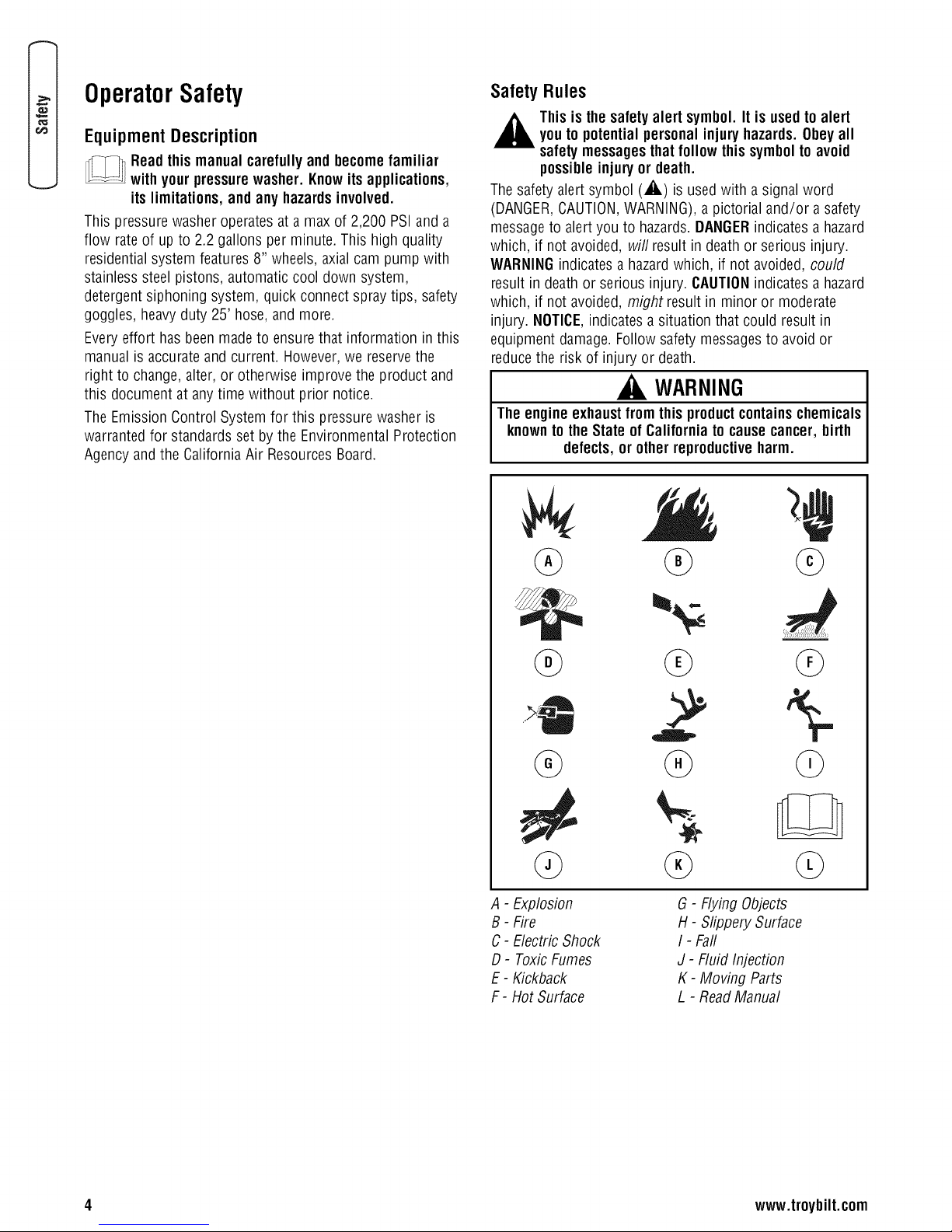

OperatorSafety

SafetyRules

Equipment Description

Readthismanual carefullyand becomefamiliar

withyourpressurewasher. Knowits applications,

its limitations,and any hazardsinvolved.

This pressurewasher operatesat a max of 2,200 PSIanda

flow rateof up to 2.2 gallons per minute. This high quality

residential system features 8" wheels, axial cam pump with

stainless steel pistons,automatic cool down system,

detergent siphoning system, quick connect spray tips, safety

goggles, heavy duty 25' hose, and more.

Everyeffort has been madeto ensurethat information in this

manual is accurateand current. However,we reservethe

right to change,alter, or otherwise improvethe product and

this document at any time without prior notice.

The EmissionControl System for this pressure washeris

warranted for standards set by the Environmental Protection

Agency andthe CaliforniaAir ResourcesBoard.

,_ Thisis thesafetyalert symbol. It is usedto alertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollow thissymboltoavoid

possibleinjury or death.

Thesafety alert symbol (_.) is usedwith a signal word

(DANGER,CAUTION,WARNING),apictorial and/or a safety

messageto alert you to hazards.DANGERindicatesa hazard

which, if not avoided, will result in death or serious injury.

WARNINGindicates a hazardwhich, if not avoided, could

result in deathor serious injury. CAUTIONindicates a hazard

which, if not avoided, might result in minor or moderate

injury. NOTICE,indicates asituation that could result in

equipment damage.Follow safetymessagesto avoid or

reducethe risk of injury or death.

WARNING

The engine exhaustfromthisproductcontainschemicals

knownto the State ofCaliforniato cause cancer, birth

defects, or otherreproductiveharm.

©

4 www.troybilt.com

A - Explosion

B - Fire

C- Electric Shock

D- ToxicFumes

E- Kickback

F - Hot Surface

Ob

G- Flying Objects

H- Slippery Surface

I - Fail

J - FluidInjection

K- Moving Parts

L - ReadManual

WARNING

Running engine gives off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

Some chemicals or detergents may be harmful if

inhaled or ingested, causing severe nausea,

fainting, or poisoning.

• Operatepressurewasher ONLY outdoors.

• Keep exhaustgas from entering a confinedareathrough

windows, doors, ventilation intakes,or other openings.

• DO NOTstart or run engine indoors or in an enclosedarea,even

if windows and doors are open.

• Use arespirator or maskwheneverthere isa chancethat vapors

may beinhaled.

• Readall instructions with mask soyou are certain the mask will

provide the necessaryprotectionagainst inhaling harmful

vapors.

WARNING

Useof pressure washer can createpuddles and

slippery surfaces.

Kickbackfrom spraygun can causeyou to fall.

• Operatepressurewasher from a stablesurface.

• Thecleaning areashould have adequateslopes anddrainage to

reducethe possibility of a fall dueto slippery surfaces.

• Beextremely careful if you must use the pressurewasherfrom

a ladder,scaffolding, or any other similar location.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spraygun kicks back.

WARNING

._ Fuel and its are extremely flammable and

WHENADDINGOR DRAININGFUEL

• Turn pressurewasher OFFand let it cool at least 2 minutes

• Fill or drain fuel tank outdoors.

• DO NOToverfill tank. Allow spacefor fuel expansion.

• Iffuel spills,wait until it evaporatesbefore starting engine.

• Keepfuel awayfrom sparks,open flames, pilot lights, heat, and

• DO NOTlight acigarette or smoke.

WHENSTARTINGEQUIPMENT

• Ensure spark plug, muffler, fuel cap, and air cleanerare in place.

• DO NOTcrank enginewith spark plug removed.

WHENOPERATINGEQUIPMENT

• DO NOTtip engine or equipmentat anglewhich causesfuel to

• DONOTspray flammable liquids.

WHENTRANSPORTINGORREPAIRINGEQUIPMENT

• Transport/repair with fuel tank EMPTYor with fuel shutoff valve

• Disconnect spark plug wire.

WHENSTORINGFUELOR EQUIPMENTWITH FUELIN TANK

• Store awayfrom furnaces, stoves, water heaters,clothes dryers,

explosive.

death.

Fire or explosion can cause severe burns or

before removing fuel cap. Loosen capslowlyto relievepressure

in tank.

other ignition sources.

spill.

OFF.

or other appliancesthat have pilot light or other ignition source

becausethey can ignite fuel vapors.

vapors

WARNING

_¢ Risk of electrocution.

• NEVERspray near power source.

Contact with power source can cause electric

shock or burn.

WARNING

6@

• NEVERpull starter cord without first relievingspray gun

• When starting engine, pull cord slowly until resistanceisfelt and

• After eachstarting attempt, where enginefails to run, always

• Firmly grasp spray gun with both hands when using high

_ Exhaustheat/gases can ignite combustibles,

Starter cord kickback (rapid retraction) can result

_nbodily injury. Kickbackwill pull hand andarm

toward enginefaster than you can letgo.

Brokenbones, fractures, bruises, or sprains

could result.

pressure.

then pull rapidly to avoid kickback.

point spray gun in safe direction and squeezespray guntrigger

to releasehigh pressure. Engagespraygun trigger lock.

pressure spray to avoid injury when spraygun kicks back.

WARNING

Contactwith muffler areacan result in serious

burns.

structures or damagefuel tank causinga fire.

DO NOTtouch hotparts andAVOID hotexhaust gases.

Allow equipment to cool beforetouching.

Keepat least5 feet (1.5 m) of clearanceon all sidesof pressure

washer including overhead.

Codeof FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to havea spark arrester, maintained in

effective working order, complying to USDAForest service

standard 5100-1C or later revision. In the Stateof California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may havesimilar laws.

The high pressure stream of water that this

equipment produces can cut through skin and its

underlying tissues, leading to serious injury and

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

• DONOTallow CHILDRENto operatepressure washer.

• NEVERrepair high pressure hose.Replaceit.

• NEVERrepair leakingconnections with sealantof any kind.

Replaceo-ring or seal.

• NEVERconnect high pressurehose to nozzleextension.

• Keep high pressurehoseconnectedto pumpand spray gun

while system is pressurized.

• ALWAYSpoint spray gun in safedirection and squeezespray

guntrigger, to releasehigh pressure,every time you stop

engine. Engagetrigger lockwhen not inuse.

• NEVERaim spray gun at people, animals,or plants.

• DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machineis running.

• NEVERuse a spray gun which does nothave a trigger lock or

trigger guard inplace andin working order.

• Always becertain spray gun, nozzlesand accessoriesare

correctly attached.

"_ Unintentional sparking can result in fire or

_ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTOYOUR PRESSURE

WASHER

• Disconnect the spark plugwire from the spark plug and place

the wire where it cannot contact spark plug.

WHENTESTINGFORENGINESPARK

• Useapproved spark plug tester.

• DO NOTcheckfor spark with spark plug removed.

WARNING

WARNING

6 www.troybilt.com

WARNING

hands, hair, clothing, or accessories.

Starter and other rotating parts can entangle

• NEVERoperate pressure washerwithout protective housing or

covers.

• DO NOTwear loose clothing, jewelry oranything that may be

caught in thestarter or other rotating parts.

• Tie up long hairand removejewelry.

WARNING

>._ Risk of eye injury.

" Spray can splash back or propel objects.

• Always wearsafety goggleswhen using this equipmentor in

vicinity of where equipment is in use.

• Before starting the pressurewasher, besureyou arewearing

adequatesafety goggles.

• NEVERsubstitute safety glassesfor safety goggles.

NOTICE

High pressure spray may damage fragile items including

glass.

• DO NOTpoint spray gun at glasswhen usingred 0° spray tip.

• NEVERaim spray gun at plants.

NOTICE

Improper treatment of pressure washer can damage it and

shorten its life.

• Ifyou havequestions about intended use,ask dealer or contact

qualified servicecenter.

• NEVERoperate units with brokenor missing parts, or without

protective housing or covers.

• DO NOTby-pass any safety device on this machine.

• DONOTtamper with governedspeed.

• DONOToperate pressurewasher above rated pressure.

• DONOTmodify pressurewasher in any way.

• Before starting pressurewasher in cold weather,check all parts

of the equipment to besure ice hasnot formed there.

• NEVERmove machineby pulling on hoses. Use handleprovided

on unit.

Checkfuel systemfor leaks or signs of deterioration, suchas

chafed or spongy hose, looseor missing clamps, or damaged

tank or cap.Correct all defects before operating pressure

washer.

This equipment is designed to be usedwith Briggs & Stratton

Power Productsauthorized parts ONLY.If equipment is used

with parts that DO NOTcomply with minimum specifications,

userassumes all risks andliabilities.

€1#

Assembly

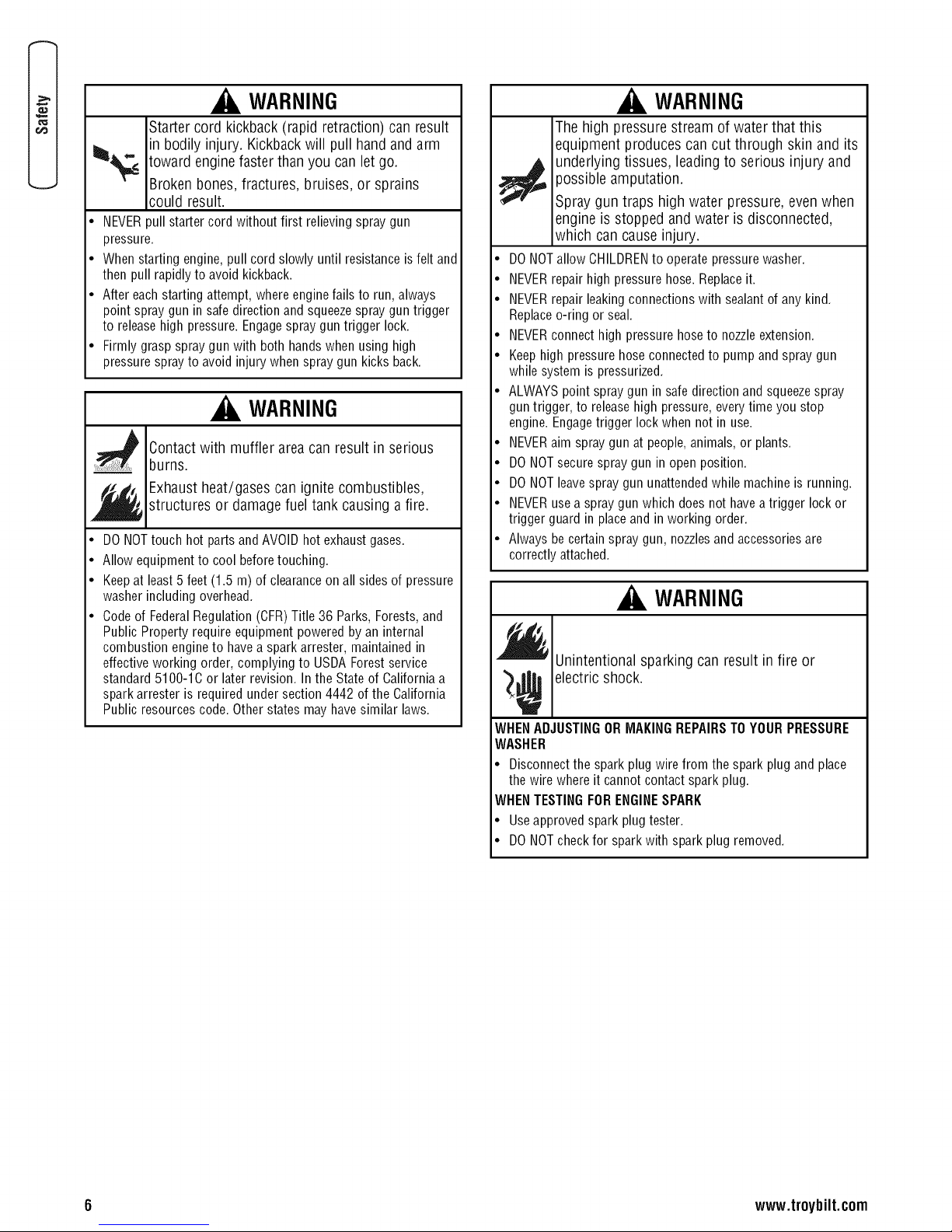

Attach Handle and Accessory Tray

1. Placehandle (A) onto handlesupports (B) connectedto

___i ead entireoperator'smanualbeforeyou attempt

toassemble oroperateyournew pressurewasher.

Your pressure washerrequires some assemblyand is ready

main unit. Makesure holes (C) in handlealign with

holes (C) on handlesupports.

// ,,

for useafter it has beenproperly serviced with the

recommendedoil and fuel.

If you haveanyproblems with the assemblyof your pressure

washer, pleasecall the pressurewasher helplineat

(888} 611-6708. If calling for assistance, pleasehavethe

E

model, revision, and serial number from the datatag

available.

UnpackPressureWasher

1. Removethe parts bag, accessories, and inserts

included with pressurewasher.

2. Opencarton completely by cutting each corner from

top to bottom.

3. Ensureyou haveall included items prior to assembly.

Items in the cartoninclude:

• Main Unit

• Handle

• HighPressure Hose

• Spray Gun

• NozzleExtension with QuickConnectFitting

• PlasticAccessory Tray

• Oil Bottle

• PartsBag(which includes the following):

• SafetyGoggles

• Operator's Manual

• Owner's RegistrationCard

• Bag containing 3 Multi-Colored Spray Tips

• Spray Gun HolderWireform

• HandleFasteningHardwareKit(which includes):

• CarriageBolts (2)

• PlasticKnobs (3)

• TreeClips (4)

To prepare yourpressurewasherfor operation,youwill

need to performthese tasks:

1. Fill out andsend in registration card.

2. Attach handleto main unit.

3. Addoil to engine crankcase.

4. Addfuel to fuel tank.

5. Connecthigh pressurehoseto spray gunand pump.

6. Connectwater supply to pump.

7. Attach nozzleextension to spray gun.

8. Select/attachquick connect spray tip to nozzle

extension.

NOTE:It may be necessaryto move the handlesupports

from sideto side in order to alignthe handle so it will slide

over the handlesupports.

2. Insert carriage bolts (A) through holes from back of

unit andattacha plastic knob (B) from front of unit.

Tighten by hand.

,

Placeaccessorytray (A) over holes (C)on handle

(viewing from front of unit). Pushthe tree clips (B) into

the holes until theysit flat againstthe accessory tray.

,

Insert spray gun holderwireform (A) through hole on

left side of handle(viewing from front of unit). Hold

wireform in place and attach a plastic knob (B) from

inside of unit. Tighten by hand.

t /

/ /

/

/ /

/ , i//i

/ i

8 www.troybilt.com

,/

5. Insert multi-colored spray tips and other supplied

accessoriesin spaces provided in accessorytray. See

"How to UseAccessory Tray".

Add Engine Oil

1. Placepressure washeron a flat, levelsurface.

2. Cleanarea aroundoil fill and removeyellow oil fill

cap/dipstick.

3. Using oil funnel (optional), slowly pour contents of

provided oil bottle into oil fill opening.

NOTICE

Improper treatment of pressurewasher candamage it and

shorten its life.

• DONOTattemptto crankorstarttheenginebeforeit hasbeen

properlyservicedwiththe recommendedoil.Thismayresultin

anenginefailure.

4. Replaceoil fill cap/dipstick and fully tighten.

Add Fuel

Fuel mustmeet theserequirements:

• Clean,fresh, unleadedgasoline.

• A minimum of 87 octane/87 AKI (91 RON).High

altitude use, seeHigh Altitude.

• Gasolinewith up to 10% ethanol (gasohol) or upto

15% MTBE(methyl tertiary butyl ether) is acceptable.

WARNING

._ Fueland its are extremelyflammable and

WHENADDING FUEL

• Turn pressurewasher OFFand let it cool at least 2 minutes

• Fill fuel tank outdoors.

• DO NOToverfill tank. Allow spacefor fuel expansion.

• Iffuel spills,wait until it evaporatesbefore starting engine.

• Keepfuel away from sparks,open flames, pilot lights, heat,and

• DO NOTlight acigarette or smoke.

2.

explosive.

death.

Fireor explosion can causesevere burns or

before removing fuel cap. Loosen capslowly to relieve pressure

in tank.

other ignition sources.

.

Cleanarea around fuel fill cap, removecap.

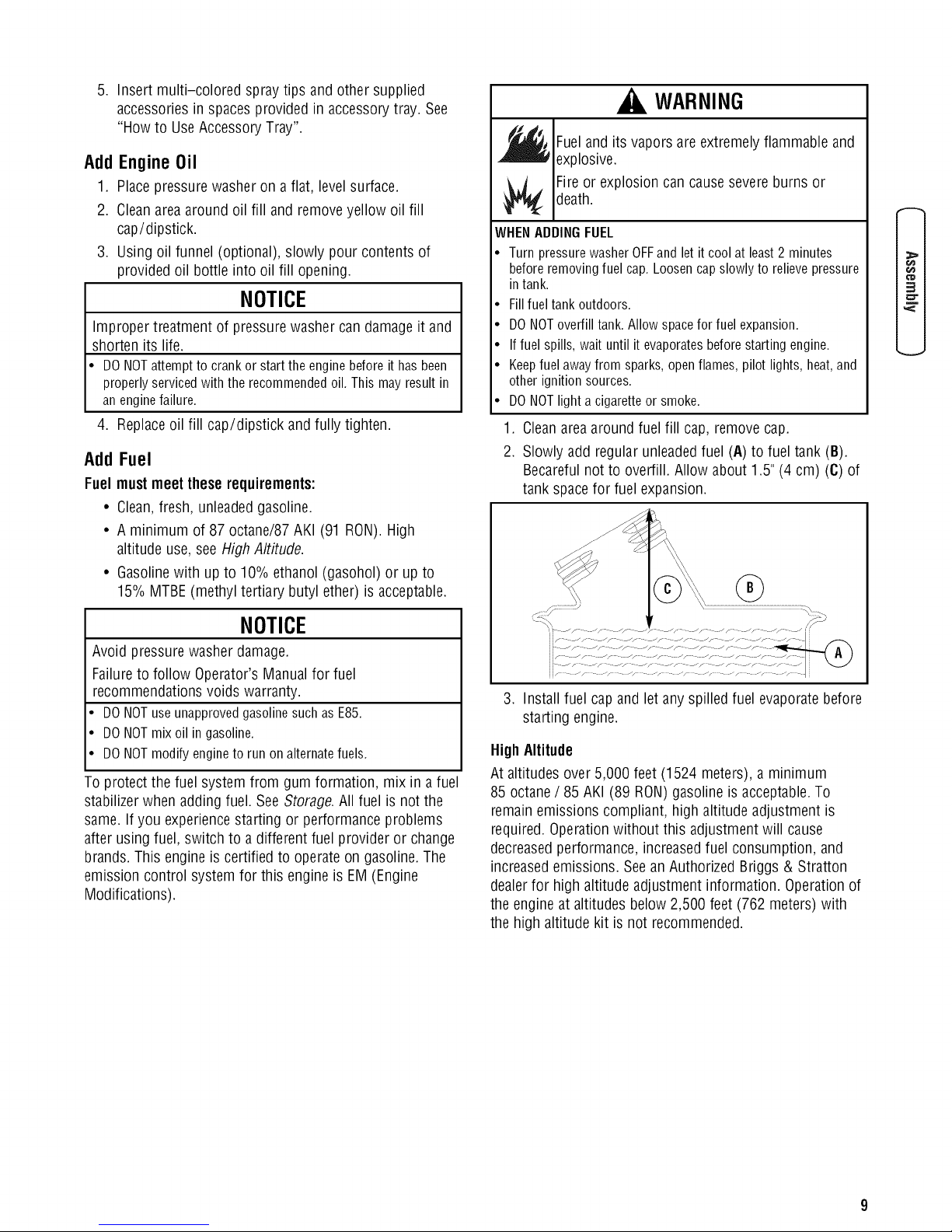

Slowly add regularunleadedfuel (A) to fuel tank (B).

Becareful not to overfill. Allow about 1.5" (4cm) (6) of

tank space for fuel expansion.

vapors

3

NOTICE

Avoid pressure washer damage.

Failureto follow Operator's Manualfor fuel

recommendationsvoids warranty.

• DONOTuseunapprovedgasolinesuchasE85.

• DONOTmixoil in gasoline.

• DONOTmodifyengineto runonalternatefuels.

To protect the fuel system from gum formation, mix in afuel

stabilizerwhen addingfuel. SeeStorage.All fuel is not the

same. If you experiencestarting or performanceproblems

after using fuel, switch to a different fuel provider or change

brands. This engineis certified to operateon gasoline. The

emission control system for this engine is EIVI(Engine

Modifications).

3. Install fuel capand let anyspilled fuel evaporatebefore

starting engine.

HighAltitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/ 85 AKI (89 RON)gasoline is acceptable.To

remainemissions compliant, high altitude adjustment is

required.Operationwithout this adjustment will cause

decreasedperformance, increasedfuel consumption, and

increasedemissions. Seean AuthorizedBriggs & Stratton

dealerfor high altitude adjustment information. Operationof

the engine at altitudes below 2,500 feet (762 meters) with

the high altitude kit is not recommended.

E

ConnectHoseandWaterSupplyto Pump

NOTICE

DONOTrun the pump without the watersupply connected

and turned on.

•" _ e-_p__ _ failuretofollowthis

instructionwillvoidwarranty.

NOTE:Remove and discard the shipping caps from the

pump's high pressureoutlet andwater inlet before attaching

hoses.

1. Uncoil high pressurehoseand attachone end of hose

to baseof spray gun. Tightenby hand.

WARNING

The high pressure stream of water that this

_ quipment produces can cut through skin and its

• NEVERconnect high pressurehose to nozzleextension.

• Keep high pressurehoseconnectedto pumpand spray gun

• Always becertain spray gun, nozzlesand accessoriesare

2. Attach other endof high pressure hoseto high

underlying tissues, leading to serious injury and

)ossible amputation.

while system is pressurized.

correctly attached.

pressure outlet on pump. Tightenby hand.

,

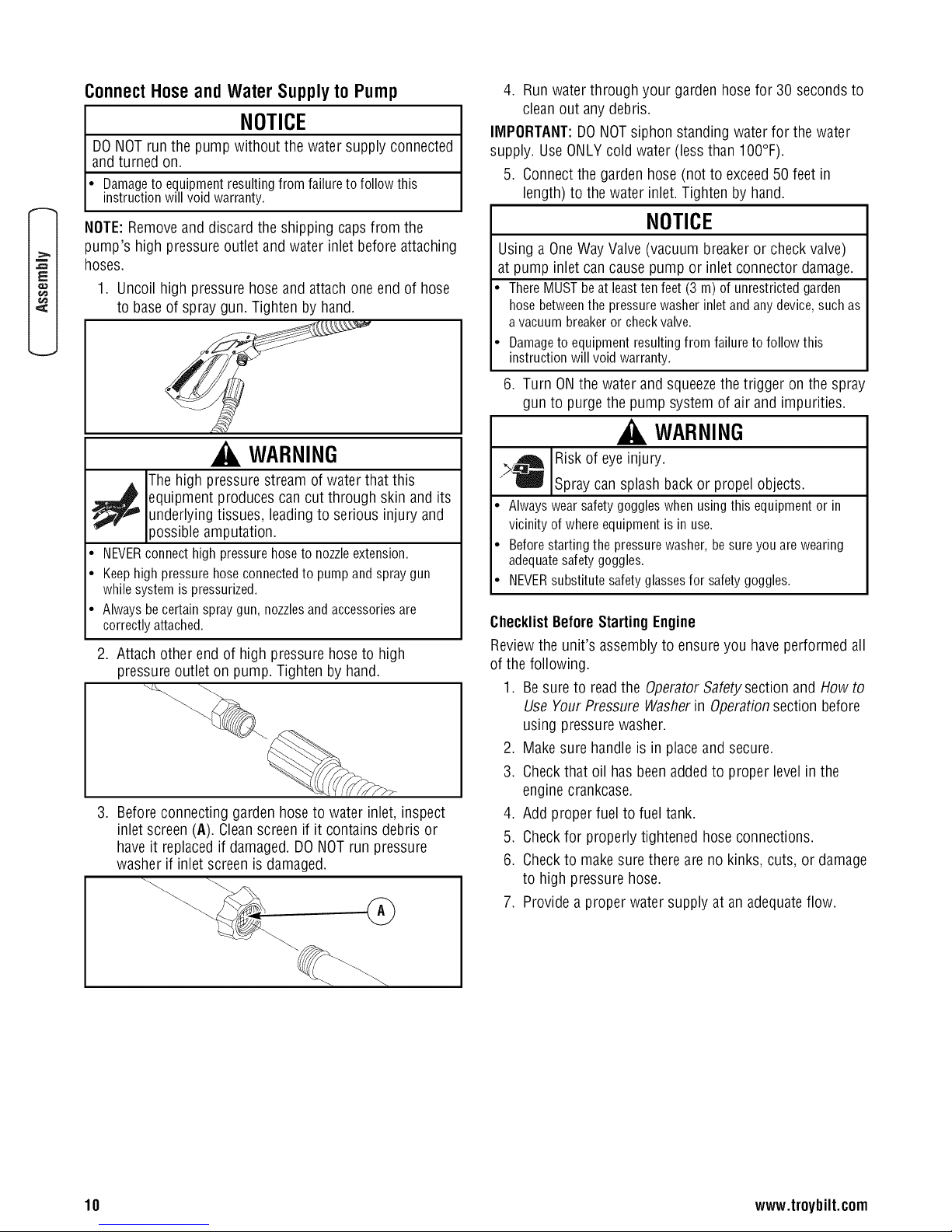

Beforeconnecting garden hose to water inlet, inspect

inlet screen (A). Cleanscreen if it contains debris or

haveit replacedif damaged.DONOTrun pressure

washer if inlet screen is damaged.

4. Run waterthrough your gardenhosefor 30 seconds to

cleanout anydebris.

IMPORTANT:DO NOTsiphon standing water for thewater

supply. UseONLYcold water (less than 100°F).

5. Connectthe garden hose (not to exceed50 feet in

length) to the water inlet. Tighten by hand.

NOTICE

Using a One Way Valve (vacuum breaker or check valve)

at pump inlet can cause pump or inlet connector damage.

• ThereMUST beat leastten feet (3 m) of unrestricted garden

hose betweenthe pressure washer inlet and any device,such as

avacuum breakeror checkvalve.

• Damageto equipment resulting from failure to follow this

instruction will void warranty.

6. Turn ONthe water and squeezethe trigger onthe spray

gun to purge the pump system of air andimpurities.

WARNING

>._ Risk of eye injury.

" Spray can splash back or propel objects.

• Always wearsafety goggleswhen using this equipmentor in

vicinity of where equipment is in use.

• Before starting the pressurewasher, besure you arewearing

adequatesafety goggles.

• NEVERsubstitute safety glassesfor safety goggles.

ChecklistBeforeStarting Engine

Reviewthe unit's assemblyto ensureyou haveperformed all

of the following.

1. Be sure to readthe OperatorSafetysection and Howto

Use Your Pressure Washerin Operationsection before

using pressurewasher.

2. Make sure handle is in placeand secure.

3. Checkthat oil hasbeen addedto proper level in the

engine crankcase.

4. Addproper fuel to fuel tank.

5. Checkfor properly tightened hoseconnections.

6. Checkto make sure there areno kinks, cuts, or damage

to high pressure hose.

7. Provide aproper watersupply at anadequateflow.

10 www.troybilt.com

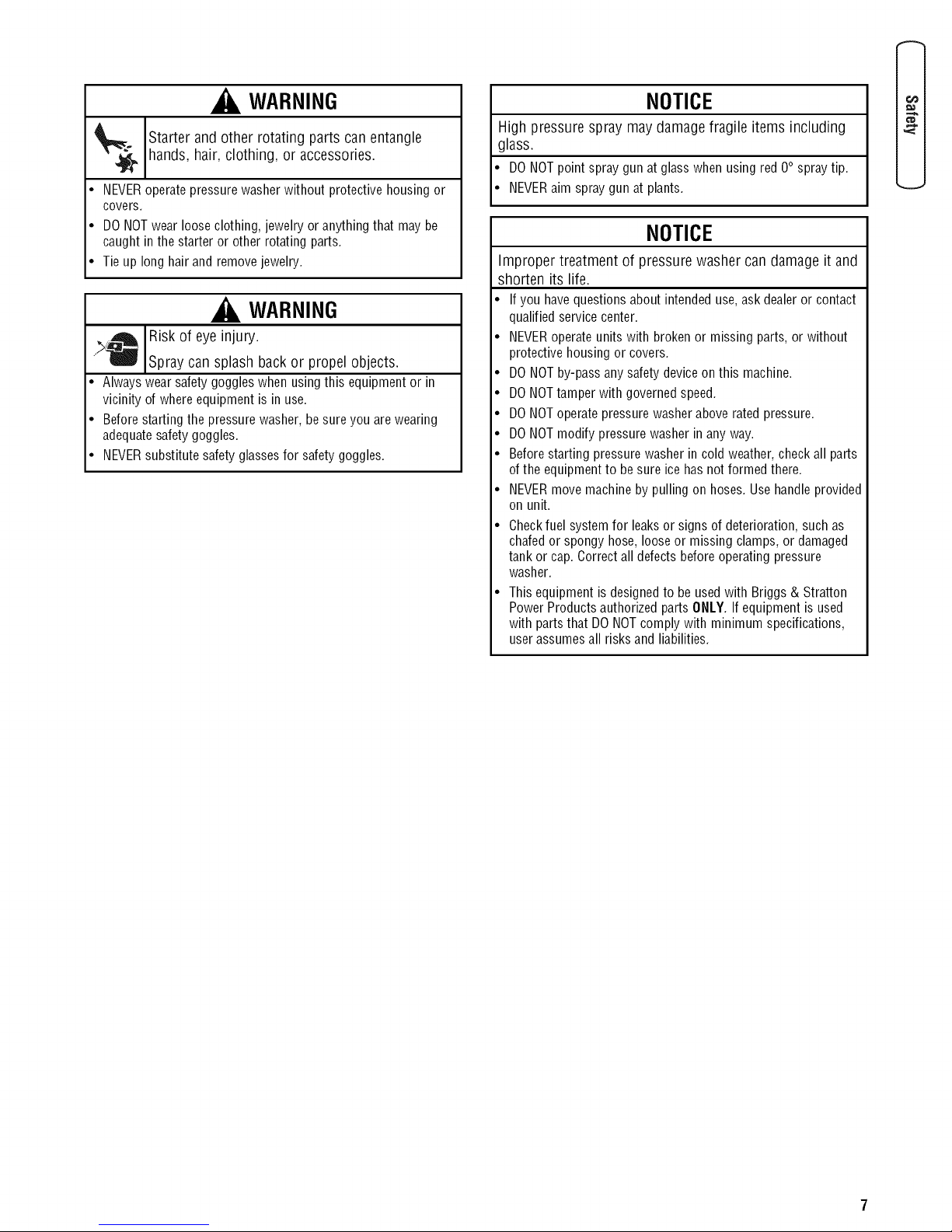

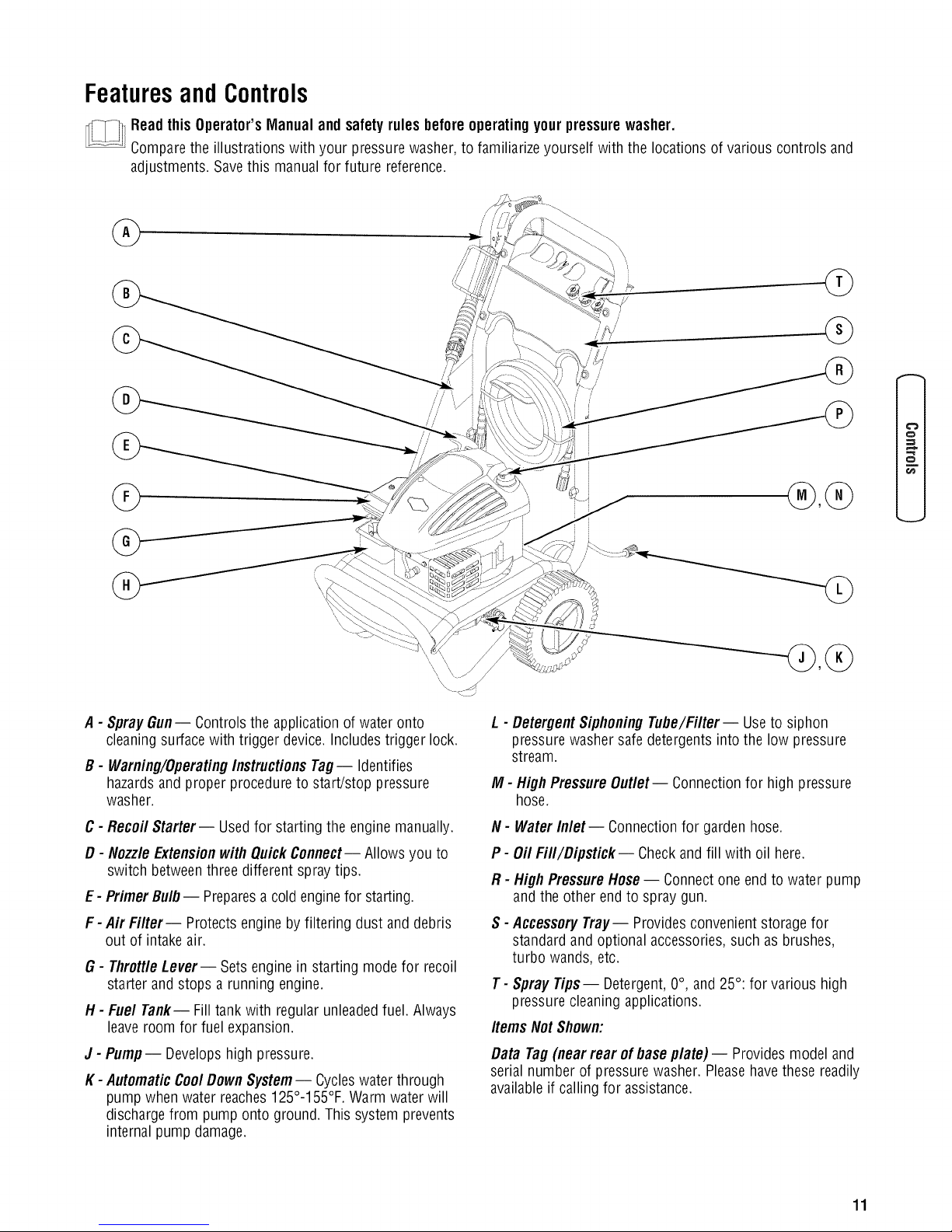

FeaturesandControls

_i eadthis Operator'sManual and safetyrulesbeforeoperatingyourpressurewasher.

Comparethe illustrations with your pressure washer,to familiarizeyourself with the locations of various controls and

adjustments. Save this manual for future reference.

////

O

;=1

A - SprayGun-- Controls the application of wateronto

cleaningsurfacewith trigger device. Includes trigger lock.

B - Warm'rig/OperatingInstructionsTag- Identifies

hazardsand proper procedureto start/stop pressure

washer.

C - Recoil Starter-- Usedfor starting the engine manually.

D - Nozzle ExtensionwithQuickConnect-- Allows you to

switch betweenthree different spraytips.

E- Primer Bulb -- Preparesacold enginefor starting.

F-Air Filter-- Protects engine by filtering dust and debris

out of intakeair.

G - Throttle Lever-- Setsengine instarting mode for recoil

starter and stops a running engine.

H - Fuel Tank-- Fill tankwith regular unleadedfuel. Always

leaveroom for fuel expansion.

J - Pump-- Developshigh pressure.

K - AutomaticCoolDown System-- Cycleswater through

pump when water reaches125°-155°F. Warm water will

dischargefrom pump onto ground. This system prevents

internal pump damage.

L - DetergentSiphoningTube/Filter-- Useto siphon

pressure washer safe detergents into the low pressure

stream.

M - HighPressure Outlet-- Connectionfor high pressure

hose.

N - WaterInlet-- Connection for garden hose.

P - Oil Fill/Dipstick-- Checkand fill with oil here.

R - High PressureHose-- Connectone end to water pump

and the other end to spray gun.

S - AccessoryTray-- Providesconvenientstorage for

standard and optional accessories,such as brushes,

turbo wands, etc.

T- Spray Tips-- Detergent,0°, and 25°: for various high

pressure cleaning applications.

Items Not Shown:

Data Tag(near rear ofbaseplate) -- Provides model and

serial number of pressurewasher. Pleasehave thesereadily

availableif calling for assistance.

11

Operation

If you haveanyproblems operating your pressure washer,

pleasecallthe pressure washer helpline at (888) 611-6788.

PressureWasherLocation

Clearancesand Air Movement

WARNING

_ Exhaustheat/gases can ignite combustibles,

• Keepat least5 ft. (1.5m) clearanceonall sidesof pressure

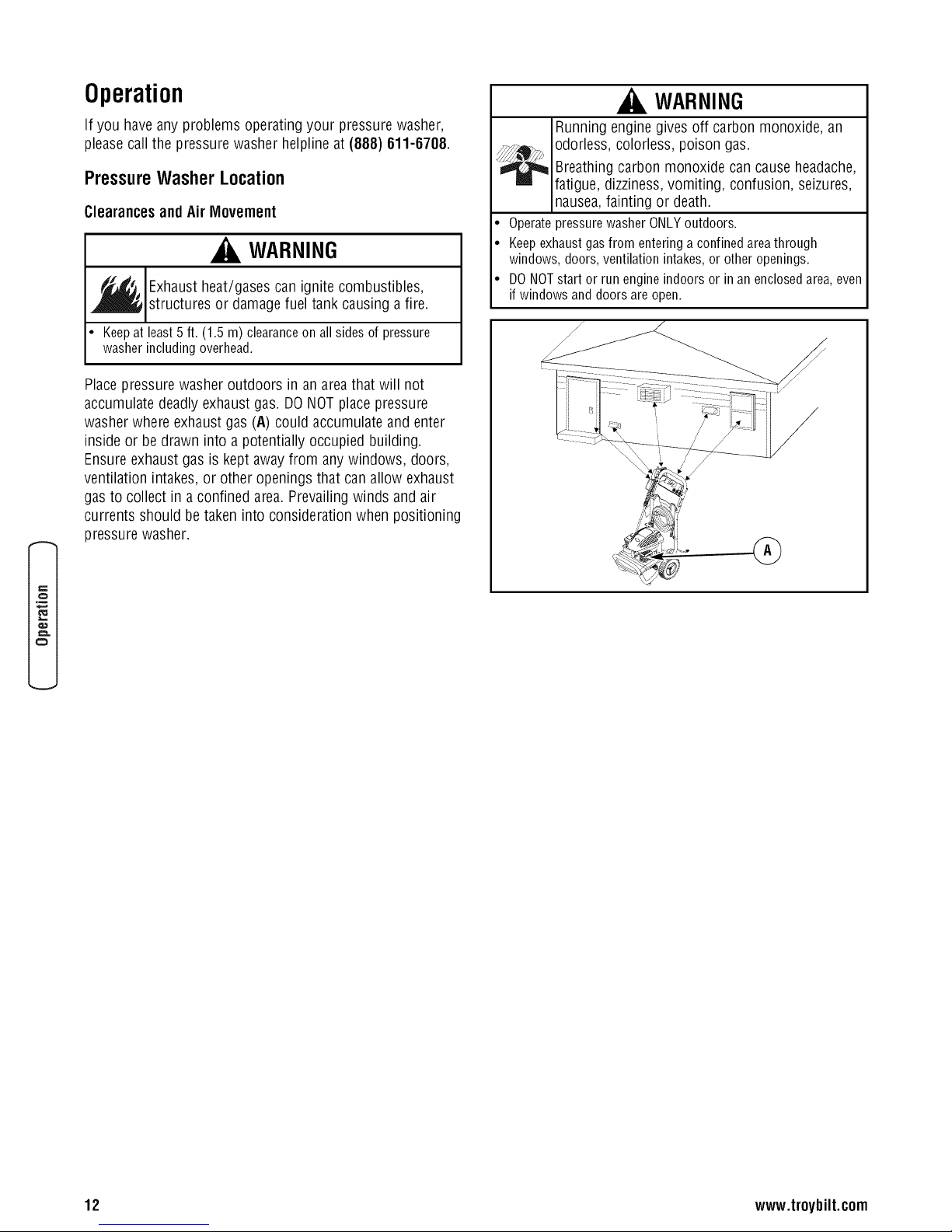

Placepressure washeroutdoors in anarea that will not

accumulate deadly exhaustgas. DONOTplacepressure

washer where exhaust gas (A) could accumulateand enter

inside or be drawn into a potentially occupiedbuilding.

Ensureexhaustgas is kept awayfrom anywindows, doors,

ventilation intakes, or other openingsthat can allow exhaust

gasto collect in aconfined area. Prevailingwinds andair

currents should betaken into consideration when positioning

pressure washer.

structures or damagefuel tank causinga fire.

washerincludingoverhead.

WARNING

Running enginegives off carbon monoxide, an

odorless, colorless, poison gas.

Breathingcarbon monoxide can cause headache,

fatigue, dizziness,vomiting, confusion, seizures,

nausea,fainting or death.

• OperatepressurewasherONLYoutdoors.

• Keepexhaustgasfromenteringa confinedareathrough

windows,doors,ventilationintakes,orotheropenings.

• DONOTstartor runengineindoorsor inanenclosedarea,even

if windowsanddoorsareopen.

12 www.troybilt.com

How to Start Your Pressure Washer

To start your pressurewasher for the first time, follow these

instructions step-by-step. This starting information also

applies if you havelet the pressure washersit idlefor at least

a day.

1. Placepressure washernear anoutside watersource

capableof supplying water at aflow rate greater than

3.2 gallons per minute andno less than 20 PSI at

pressure washer end of garden hose. DONOTsiphon

supply water.

2. Checkthat high pressurehoseis tightly connectedto

spray gun and pump. SeeAssembly section.

3. Makesure unit is in a level position.

4. Connectgarden hoseto water inlet on pressurewasher

pump.

NOTICE

DONOTrun the pump without the watersupply connected

and turned on.

: failuretofollowthis

instructionwillvoidwarranty.

5. Turn ONwater, point spray gun in a safe direction and

squeezetrigger to purge pump system of air and

impurities.

6. Attach nozzleextension to spray gun. Tighten by hand.

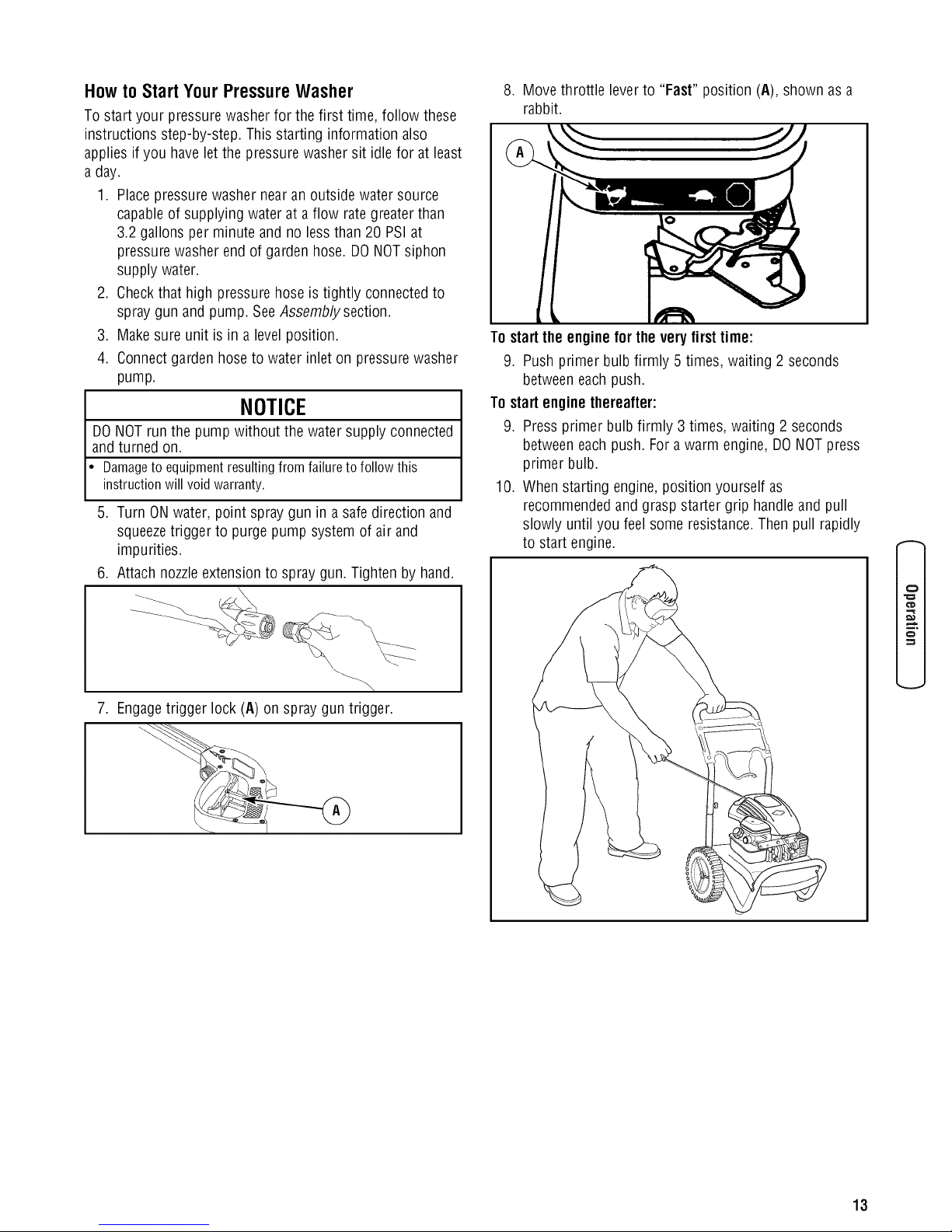

8. Move throttle lever to "Fast" position (A), shown as a

rabbit.

To startthe engine forthe veryfirst time:

9. Push primer bulbfirmly 5 times, waiting 2 seconds

between each push.

To start enginethereafter:

9. Press primer bulb firmly 3 times, waiting 2 seconds

between each push. Fora warm engine, DONOTpress

primer bulb.

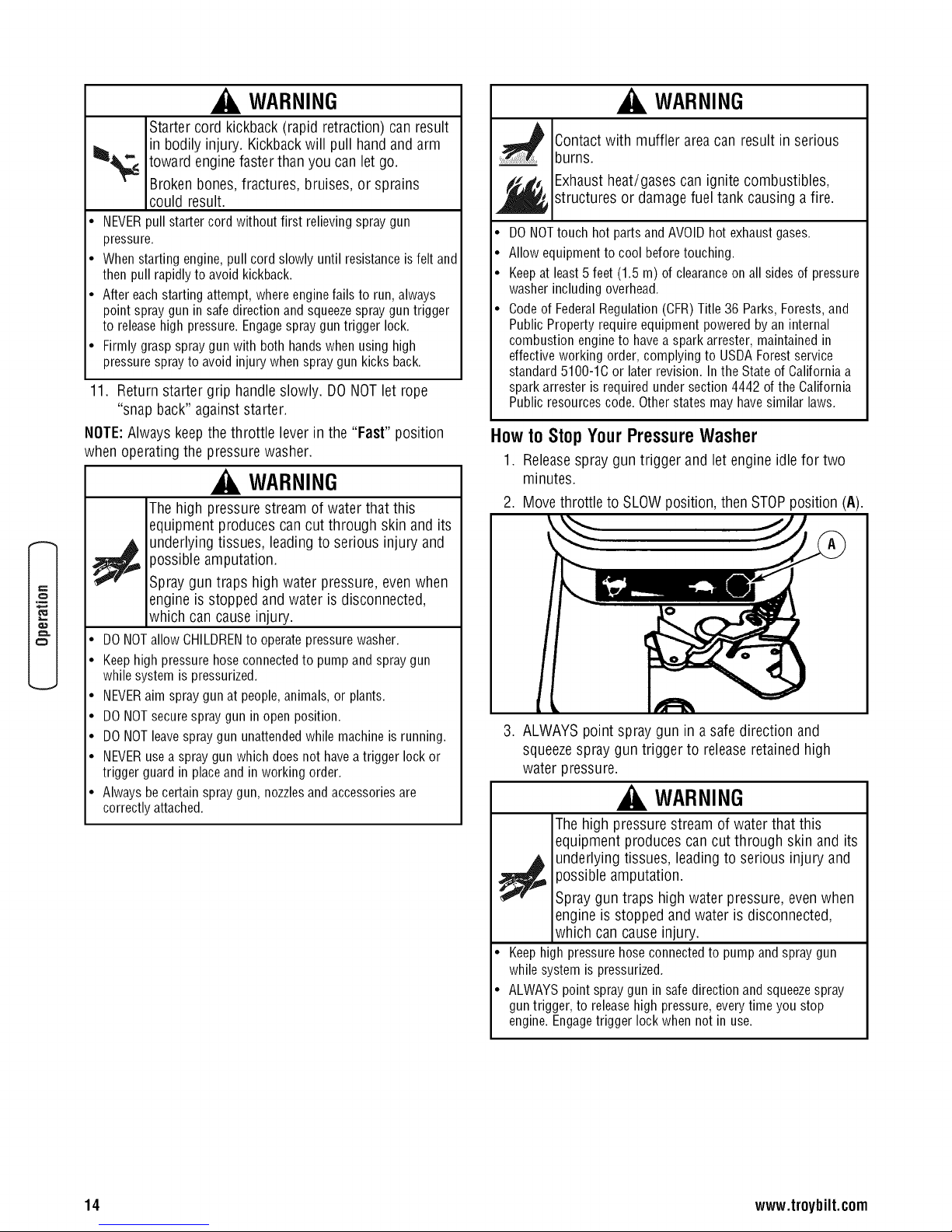

10. Whenstarting engine, position yourself as

recommendedand grasp starter grip handleand pull

slowly until you feel some resistance.Then pull rapidly

to start engine.

,

Engagetrigger lock (A) on spray gun trigger.

o

13

WARNING

Starter cord kickback (rapid retraction) can result

_nbodily injury. Kickback will pull hand and arm

toward engine faster than you can let go.

Broken bones, fractures, bruises, or sprains

could result.

• NEVERpull starter cord without first relievingspray gun

pressure.

• When starting engine, pull cord slowly until resistanceisfelt and

then pull rapidly to avoid kickback.

• After eachstarting attempt, where enginefails to run, always

point spray gun in safe direction and squeezespray guntrigger

to releasehigh pressure. Engagespraygun trigger lock.

• Firmly grasp spray gun with both hands when using high

pressure spray to avoid injury when spraygun kicks back.

11. Return starter grip handleslowly. DO NOTlet rope

"snap back" againststarter.

NOTE:Always keepthe throttle leverin the "Fast" position

when operating the pressurewasher.

WARNING

The high pressure stream of water that this

equipment produces can cut through skin and its

WARNING

Contactwith muffler areacan result inserious

burns.

._ Exhaustheat/gases can ignite combustibles,

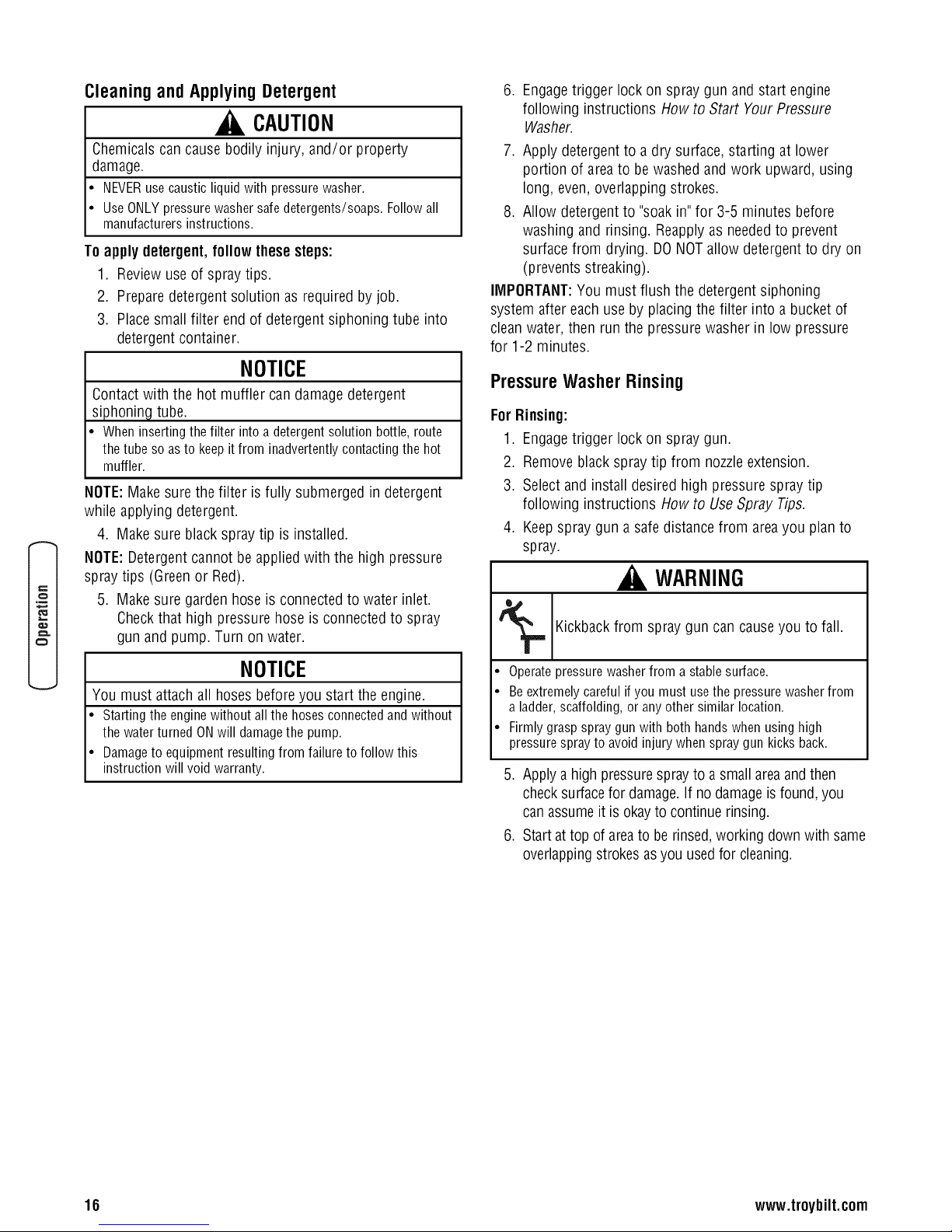

Howto StopYourPressureWasher

1. Release spray gun trigger and let engine idle for two

2. Move throttle to SLOW position, then STOP position (A).

structures or damagefuel tank causing a fire.

DO NOTtouch hotparts andAVOID hotexhaust gases.

Allow equipment to cool beforetouching.

Keepat least5 feet (1.5 m) of clearanceon all sidesof pressure

washer including overhead.

Code of FederalRegulation (CFR)Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engineto have a spark arrester, maintained in

effective working order, complying to USDAForest service

standard 5100-1C or later revision. Inthe State of California a

spark arrester is required under section 4442 of the California

Public resources code. Otherstates may havesimilar laws.

minutes.

_ nderlying tissues, leading to serious injury and

o

• DONOTallow CHILDRENto operatepressure washer.

• Keep high pressurehoseconnectedto pumpand spray gun

while system is pressurized.

• NEVERaim spray gun at people,animals, or plants.

• DO NOTsecure spray gun in open position.

• DO NOTleavespray gun unattendedwhile machineis running.

• NEVERuse a spray gun which doesnot haveatrigger lock or

trigger guardin place andin working order.

• Always becertain spray gun, nozzlesand accessoriesare

correctly attached.

)ossible amputation.

Spray gun traps high water pressure, even when

engine is stopped and water is disconnected,

which can cause injury.

3. ALWAYSpoint spray gun in a safedirection and

squeezespray gun trigger to release retained high

water pressure.

WARNING

Thehigh pressure stream of water that this

equipment produces cancut through skin and its

_ nderlying tissues, leading to serious injury and

)ossible amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which can causeinjury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

• ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennotinuse.

14 www.troybilt.com

IMPORTANT:Spray gun traps high water pressure,even

when engine is stopped and water is disconnected.

4. Engagetrigger lock on spray gunwhen not in use.

Howto UseAccessoryTray

The unit is equippedwith an accessorytray with placesto

store your spray gun, nozzleextension and quick connect

spray tips. Thereis also a hook atthe front of the accessory

tray to hold your high pressurehose.

NOTE:The extra hole in the tray is for storing a utility brush.

Theextra clip in the tray is for storing a turbo nozzle.The

brush and turbo nozzleare NOTincluded with your pressure

washer.You can buy these items asoptional accessories.

1. Placenozzleextensionthrough hole on accessorytray,

as shown.

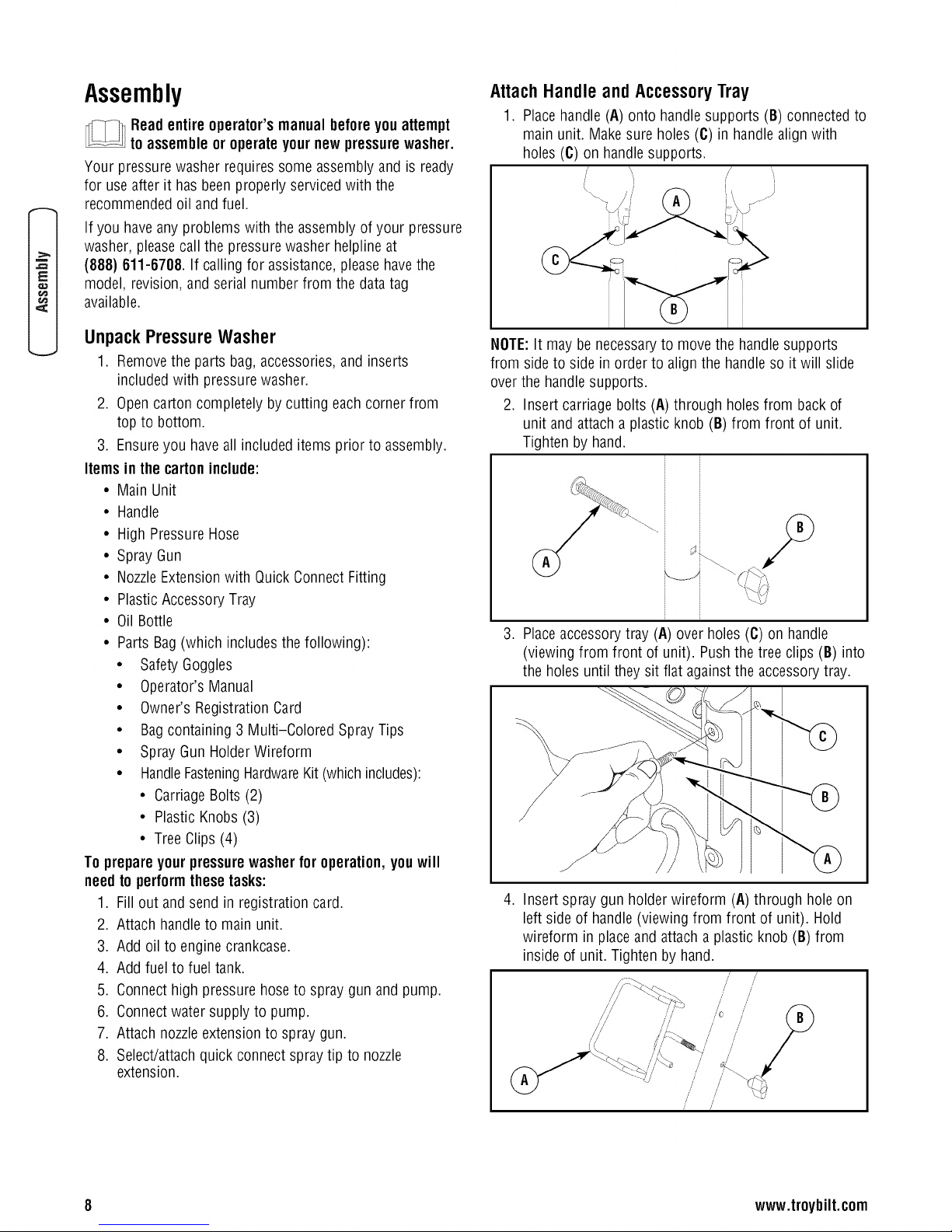

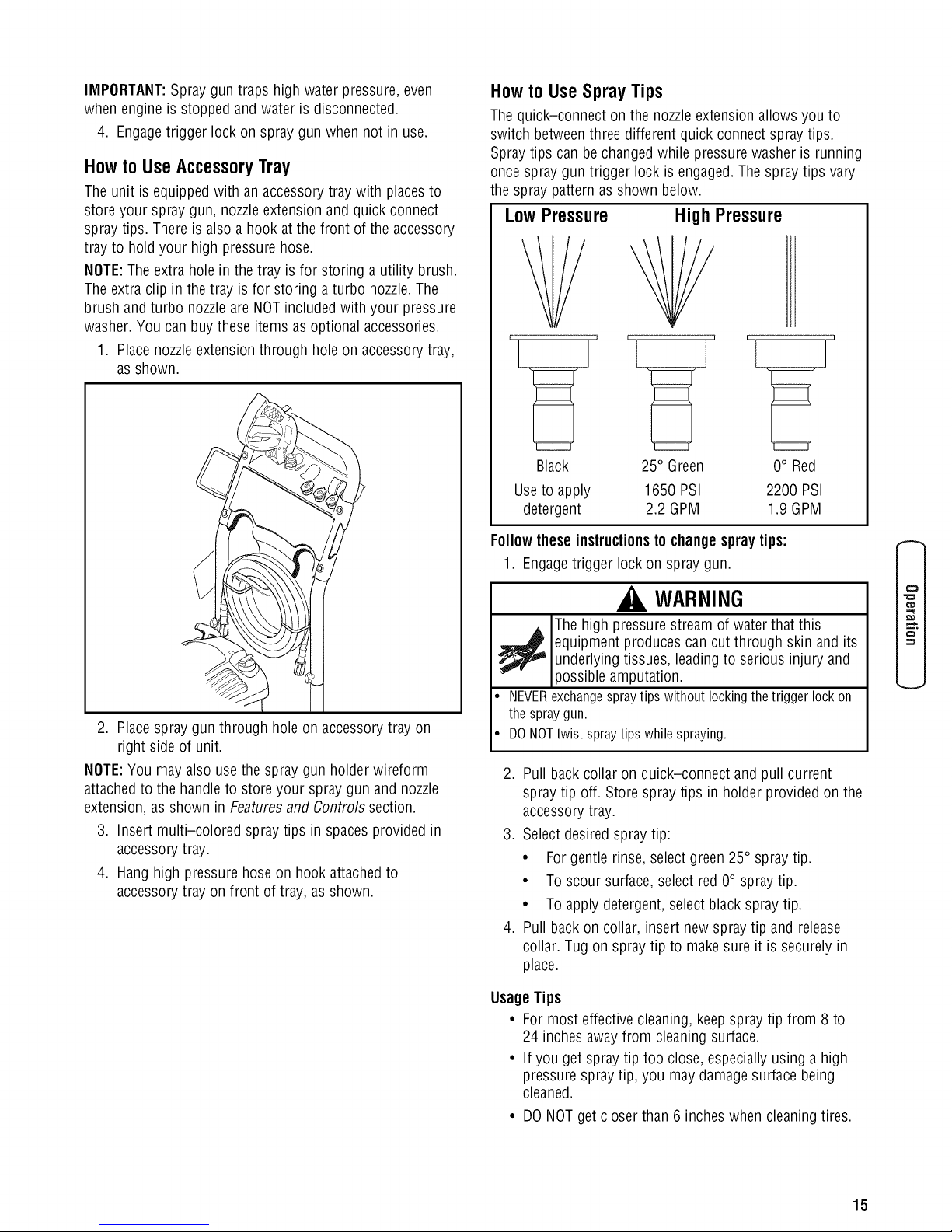

How to Use Spray Tips

Thequick-connect on the nozzleextensionallows you to

switch betweenthree different quick connect spray tips.

Spraytips can bechanged while pressure washer is running

once spray gun trigger lock is engaged.The spray tips vary

the spray pattern asshown below.

Low Pressure High Pressure

i i

2. Placespray gun through hole on accessorytray on

right side of unit.

NOTE:You may alsouse the spray gun holder wireform

attachedto the handleto storeyour spray gun and nozzle

extension, as shown in Featuresand Controls section.

3. Insert multi-colored spray tips in spaces provided in

accessorytray.

4. Hang high pressure hoseon hook attachedto

accessorytray on front of tray, as shown.

Black

25° Green 0° Red

Useto apply 1650 PSI 2200 PSI

detergent 2.2 GPM 1.9 GPM

Followtheseinstructionsto changespraytips:

1. Engagetrigger lock on spray gun.

WARNING

The high pressure stream of waterthat this

_ quipment produces can cut through skin and its

• NEVERexchangespraytipswithoutlockingthe triggerlockon

• DONOTtwistspraytipswhilespraying.

2. Pull back collar on quick-connect and pull current

3. Select desired spraytip:

4. Pull back on collar, insert newspray tip and release

underlying tissues, leadingto serious injury and

possible amputation.

thespraygun.

spray tip off. Store spray tips in holder provided on the

accessorytray.

• Forgentle rinse,select green 25° spraytip.

• To scour surface, select red0° spray tip.

• To apply detergent,select black spray tip.

collar. Tug on spray tip to make sure it is securely in

place.

o

UsageTips

• For most effective cleaning,keep spraytip from 8 to

24 inches awayfrom cleaning surface.

• If you get spray tip too close, especially using a high

pressure spray tip, you may damagesurface being

cleaned.

• DONOTget closer than 6 inches when cleaning tires.

15

CleaningandApplyingDetergent

CAUTION

Chemicalscan cause bodily injury, and/or property

damage.

• NEVERusecausticliquidwith pressurewasher.

• UseONLYpressurewashersafedetergents/soaps.Followall

manufacturersinstructions.

To applydetergent,follow thesesteps:

1. Reviewuse of spray tips.

2. Preparedetergent solution as required by job.

3. Placesmall filter end of detergent siphoning tube into

detergent container.

6. Engagetrigger lock on spray gun and start engine

following instructions How to Start YourPressure

Washer.

7. Apply detergentto a dry surface,starting at lower

portion of areato be washedand work upward, using

long, even,overlapping strokes.

8. Allow detergentto "soak in"for 3-5 minutes before

washing and rinsing. Reapplyas neededto prevent

surfacefrom drying. DO NOTallow detergentto dry on

(prevents streaking).

IMPORTANT:You must flush the detergent siphoning

system after each use by placingthe filter into a bucket of

cleanwater, then runthe pressure washer in low pressure

for 1-2 minutes.

NOTICE

Contact with the hot muffler can damage detergent

siphoning tube.

• Wheninsertingthefilter intoadetergentsolutionbottle,route

thetubesoasto keepitfrom inadvertentlycontactingthehot

muffler.

NOTE:Make surethe filter is fully submerged in detergent

while applying detergent.

4. Makesure black spraytip is installed.

NOTE:Detergent cannot be appliedwith the high pressure

spray tips (Greenor Red).

5. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hoseis connectedto spray

C_

gun and pump. Turn on water.

PressureWasherRinsing

ForRinsing:

1. Engagetrigger lock on spray gun.

2. Removeblack spraytip from nozzleextension.

3. Select and install desired high pressurespray tip

following instructions How to UseSpray Tips.

4. Keepspray gun a safedistance from areayou planto

spray.

WARNING

_r= Kickback spray gun can cause you to

from fall.

NOTICE

You must attach all hosesbeforeyou start the engine.

• Startingtheenginewithoutall thehosesconnectedandwithout

thewaterturnedONwill damagethe pump.

• Damageto equipmentresultingfromfailuretofollowthis

instructionwillvoidwarranty.

• Operatepressure washerfrom a stable surface.

• Beextremely careful if you must use the pressurewasher from

a ladder,scaffolding, or anyother similar location.

• Firmly grasp spray gun with both hands when usinghigh

pressure spray to avoid injury when spraygun kicks back.

5. Applya highpressuresprayto asmall areaandthen

checksurfacefor damage.If no damageis found,you

canassumeit is okayto continue rinsing.

6. Start at top of areato be rinsed,working down with same

overlappingstrokes asyou usedfor cleaning.

16 www.troybilt.com

CleaningDetergentSiphoningTube

If you usedthe detergent siphoning tube, you must flush it

with clean water before stopping the engine.

1. Placedetergent siphoning tube/filter in a bucket full of

cleanwater.

2. Engagetrigger lock on spray gun.

3. Removehigh pressurespray tip from nozzleextension.

4. Selectand install black detergentspray tip following

instructions How to Use Spray Tips.

5. Flushfor 1-2 minutes.

6. Shut off engine following instructions How to Stop

Pressure Washerand turn off watersupply.

WARNING

Thehigh pressure stream of water that this

equipment produces cancut through skin and its

7. ALWAYSpoint spray gun in a safedirection and

squeezespray gun trigger to release retained high

water pressure.

IMPORTANT:Spraygun traps high water pressure, even

when engine is stopped andwater is disconnected.

AutomaticCoolDownSystem (ThermalRelief)

If you run the engineon your pressure washer for

3-5 minutes without pressing the trigger on the spray gun,

circulating water in the pump can reachtemperatures above

125°F.The system engagesto cool the pump by discharging

the warm water ontothe ground.

_ nderlying tissues, leadingto serious injury and

)ossible amputation.

Spraygun traps highwater pressure, evenwhen

engine is stopped and water is disconnected,

which can cause injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemis pressurized.

• ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennot inuse.

('D

0

.,..e

17

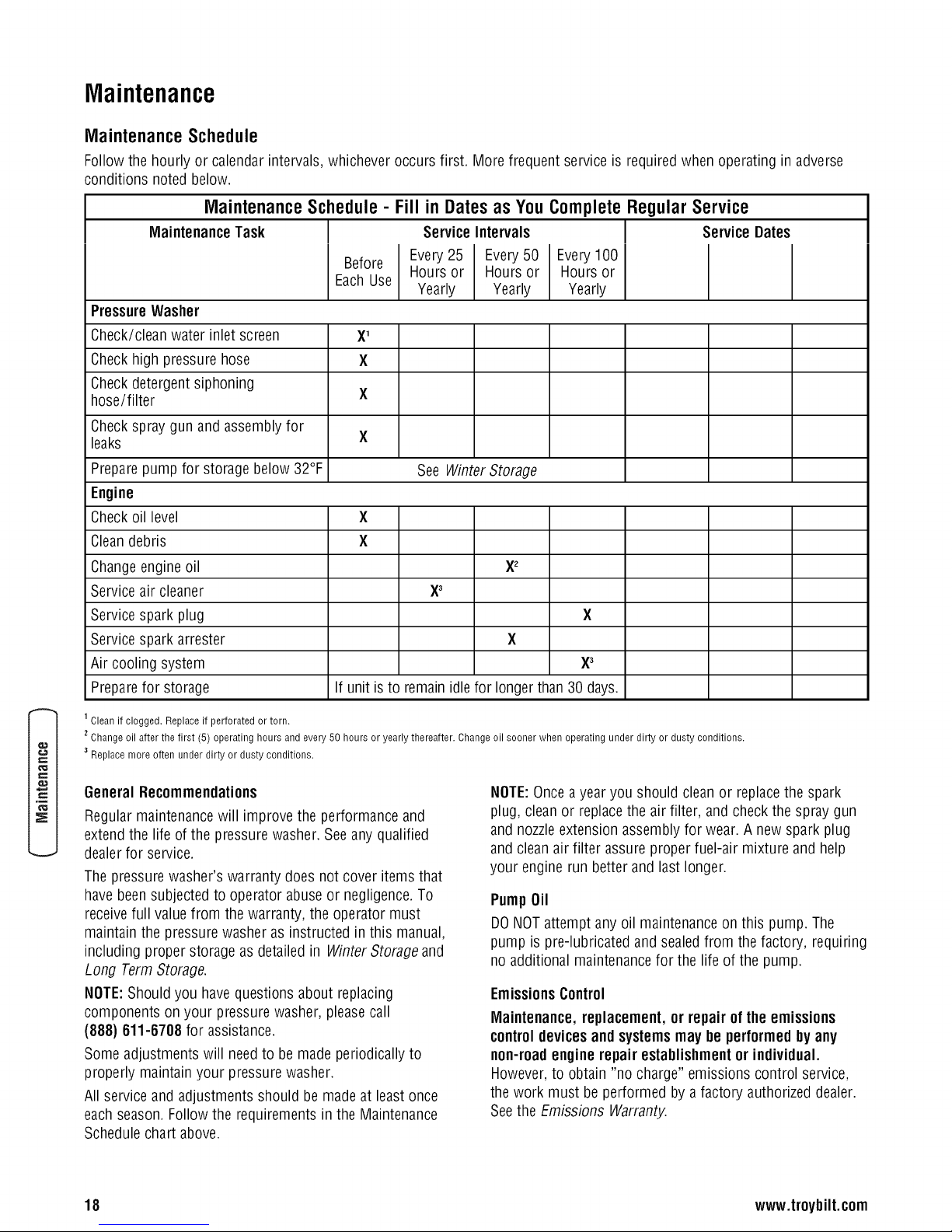

Maintenance

MaintenanceSchedule

Follow the hourly or calendarintervals, whichever occurs first. More frequent service is required when operating inadverse

conditions noted below.

MaintenanceSchedule- Fill in DatesasYouCompleteRegularService

MaintenanceTask ServiceIntervals Service Dates

Before Hours or Hours or Hours or

EachUse Yearly Yearly Yearly

Pressure Washer

Check/clean water inlet screen X'

Checkhigh pressure hose X

Checkdetergent siphoning

hose/filter X

Checkspray gun and assembly for

leaks X

Preparepump for storage below 32°F See WinterStorage

Engine

Checkoil level X

Cleandebris X

Every25 Every50 Every100

Changeengine oil X2

Service air cleaner X3

Service spark plug X

Service spark arrester X

Air cooling system X3

Preparefor storage If unit is to remainidle for longer than 30 days.

1Clean if clogged. Replace if perforated ortorn.

2Change oil after the first (5) operating hours and every 50 hours or yearly thereafter. Change oil sooner when operating under dirty or dusty conditions.

3Replace more often under dirty or dusty conditions.

€

GeneralRecommendations

Regular maintenancewill improve the performance and

extend the life of the pressure washer.See anyqualified

dealerfor service.

The pressurewasher's warranty does not cover items that

havebeen subjectedto operator abuseor negligence.To

receivefull valuefrom the warranty, the operator must

maintain the pressure washeras instructed inthis manual,

including proper storage as detailedin Winter Storageand

Long TermStorage.

NOTE:Should you havequestions about replacing

components on your pressurewasher, pleasecall

(888) 611-6708 for assistance.

Someadjustments will needto be made periodically to

properly maintainyour pressure washer.

All service and adjustments should bemadeat least once

eachseason.Follow the requirements in the Maintenance

NOTE:Once ayear you should cleanor replacethe spark

plug, clean or replacethe air filter, and checkthe spray gun

and nozzleextension assembly for wear. A new spark plug

and clean air filter assure properfuel-air mixture andhelp

your enginerun betterand last longer.

PumpOil

DONOTattempt any oil maintenanceon this pump. The

pump is pre-lubricated and sealedfrom the factory, requiring

no additional maintenancefor the life of the pump.

EmissionsControl

Maintenance, replacement, orrepair of theemissions

controldevicesand systemsmay beperformedby any

non-roadengine repair establishmentor individual.

However,to obtain "no charge" emissions control service,

the work must be performed by a factory authorizeddealer.

Seethe Emissions Warranty.

Schedulechart above.

18 www.troybilt.com

Loading...

Loading...