Page 1

Manual of Operation and Instruction

Model 5850

Gyratory Compactor

NOTE

Before using the Model 5850 Gyratory Compactor,

carefully read this manual. It is especially important to

understand the Safety Warnings on page 1–2. Keep this

manual in a safe place that is always easily accessible

during the use of the Model 5850.

Troxler Electronic Laboratories, Inc.

3008 E. Cornwallis Road P.O. Box 12057

Research Triangle Park, NC 27709 U.S.A.

Phone: 1.877.TROXLER

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

Page 2

Troxler products are protected by U.S. and foreign patents.

Copyright 2009 – 2011

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

Bindoff is a registered trademark of Chemical Solutions, Inc.

Magnalube-G is a registered trademark of Magnalube, Inc.

Superpave is a trademark of the Strategic Highway Research

Program.

PN 116901

April 2012

Edition 2.1

ii

Page 3

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 E. Cornwallis Road • P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

NORTH CAROLINA SERVICE

CENTER

3008 E. Cornwallis Road

Research Triangle Park, NC 27709

Phone: +1.919.549.8661

Fax: +1.919.549.0761

TroxTechSupport@troxlerlabs.com

FLORIDA BRANCH OFFICE &

SERVICE CENTER

2376 Forsyth Road

Orlando, FL 32807

Phone: +1.407.681.4221

Fax: +1.407.681.3188

TroxTechSupport@troxlerlabs.com

MIDWESTERN BRANCH

OFFICE & SERVICE CENTER

1430 Brook Drive

Downers Grove, IL 60515

Phone: +1.630.261.9304

Fax: +1.630.261.9341

TroxTechSupport@troxlerlabs.com

WESTERN BRANCH OFFICE &

SERVICE CENTER

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Phone: +1.916.631.0234

Fax: +1.916.631.0541

TroxTechSupport@troxlerlabs.com

SOUTHWESTERN BRANCH

OFFICE & SERVICE CENTER

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Phone: +1.817.275.0571

Fax: +1.817.275.8562

TroxTechSupport@troxlerlabs.com

TROXLER EUROPE &

SERVICE CENTER

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr.

Munich, Germany

Phone: ++ 49.8141.71063

Fax: ++49.8141.80731

troxler@t-online.de

TROXLER ELECTRONIC TECHNOLOGIES (ZHANGJIAGANG)

1F, Building G, No. 1 Guotai North Road

ZJG, China, 215600

Phone: 0086.512.56793702 Fax: 0086.512.56793701

kjin@troxlerlabs.cn

To locate an independent, Troxler-authorized service

partner near you, call 1.877.TROXLER (1.877.876.9537).

Model 5850 iii

NOTE

Page 4

ABOUT THIS MANUAL

The Model 5850 Manual of Operation and Instruction provides

detailed information about the compactor. The manual includes

product safety information, as well as instructions for the proper

installation and use of the compactor.

This manual is organized as follows:

Chapter 1, Introduction to the Model 5850 – Provides

information on the safe use of the compactor; a brief overview

of the compactor and its features; a list of parts and accessories;

and instructions for unpacking and inspection.

Chapter 2, Setup and Operation – Describes the compactor

keypad, and provides instructions for setting up, starting, and

operating the compactor.

Chapter 3, Setup Menu – Provides a detailed description of the

options available from the compactor’s Setup menu.

Chapter 4, Calibration and Verification – Includes instructions

for calibrating the compactor and verifying its calibration.

Chapter 5, Special Functions – Describes the functions available

from the compactor’s Special menu.

Appendix A, Troubleshooting and Service – Provides

maintenance and service information, as well as instructions on

basic troubleshooting.

Appendix B, Menu Map – Shows a map of the compactor’s Setup

menu.

Appendix C, Specifications – Contains the environmental,

performance, electrical, and mechanical specifications of the

compactor.

iv

Page 5

HOW TO USE THIS MANUAL

Congratulations on the purchase of the Model 5850 Gyratory

Compactor.

The Model 5850 Manual of Operation and Instruction contains

information on safely using this unit. Also included in this manual

are safety warnings, basic parameter setup, system troubleshooting,

and general maintenance.

Do not attempt to operate the Model 5850 before reading this

manual and the safety warnings posted on the unit. Troxler stresses

that the user is solely responsible for ensuring the safe use of the

Model 5850. The manufacturer, its subsidiary, representatives, and

distributors cannot assume responsibility for any mishaps, damage,

or personal injury that may occur from failure to observe the safety

warnings in this manual and posted on the unit.

Model 5850 v

Page 6

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, symbols and special formatting are used to

reveal the purpose of the text as follows:

WARNING

Warnings indicate conditions or procedures that, if

not followed correctly, may cause personal injury.

CAUTION

Cautions indicate conditions or procedures that, if not

followed correctly, may cause equipment damage.

NOTE

Notes indicate important information that must be read

to ensure proper operation.

KEY Angle brackets and a different typestyle indicate a

key or character (number or letter) to press on the

compactor keypad. For example, “Press START”

means to press the key labeled START.

DISPLAY A different typestyle is used in text to indicate

information or messages displayed on the

compactor.

DISPLAY- Typestyle and

shading used to

simulate the control

panel display

Numbers indicate a procedure with multiple steps.

11..

Diamonds indicate a list of things needed (such as

equipment) or things to know.

Triangles indicate that more than one option is

available. Carefully select the option that applies.

vi

Page 7

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION TO THE MODEL 5850

Safety Warnings ............................................................................ 1–2

Cautions and Warnings ................................................................. 1–3

Introduction ................................................................................... 1–4

Parts and Accessories.................................................................... 1–8

Inspection ...................................................................................... 1–9

Unpacking ................................................................................... 1–10

Site Selection .............................................................................. 1–11

Assembly .................................................................................... 1–12

CHAPTER 2. SETUP AND OPERATION

Control Panel ................................................................................ 2–2

Turning the System On ................................................................. 2–4

Compacting a Specimen ............................................................... 2–7

Cleaning and Lubricating.............................................................. 2–8

Preparing a Specimen ................................................................. 2–10

Compacting the Specimen .......................................................... 2–12

Shear Options & Performance Tests ........................................... 2–13

CHAPTER 3. SETUP MENU

Setup Menu ................................................................................... 3–2

View Settings ................................................................................ 3–3

Change Settings ............................................................................ 3–4

Home Position ............................................................................ 3–13

Calibration .................................................................................. 3–13

Special......................................................................................... 3–13

CHAPTER 4. CALIBRATION

Angle Verification ........................................................................ 4–3

Calibration .................................................................................... 4–5

Model 5850 vii

Page 8

CHAPTER 5. SPECIAL FUNCTIONS

Special Menu ................................................................................. 5–2

Clock/Calendar .............................................................................. 5–3

Erase Records ................................................................................ 5–6

Reset Software ............................................................................... 5–7

APPENDIX A. TROUBLESHOOTIGN AND SERVICE

Troubleshooting.............................................................................A-2

General Maintenance Schedule .....................................................A-4

Replacing the Batteries ..................................................................A-7

Replacement Parts .........................................................................A-8

Returning Parts for Service ...........................................................A-9

APPENDIX B. MENU MAP

Menu Map Description .................................................................. B-2

APPENDIX C. SPECIFICATIONS

Environmental Conditions ............................................................. C-2

Electrical Specifications ................................................................ C-3

Mechanical Specifications ............................................................. C-4

INDEX

WARRANTY

viii

Page 9

LIST OF FIGURES

Figure Title Page

Figure 1–1. Model 5850 Gyratory Compactor ............................. 1–7

Figure 1–2. Hydraulic Reservoir ................................................ 1–12

Figure 1–3. Proper Reservoir Fill Level ..................................... 1–13

Figure 1–4. Place a Funnel in Reservoir Fill Tube ..................... 1–13

Figure 2–1. Model 5850 Control Panel Layout ............................ 2–3

Figure 2–2. Compaction Chamber ................................................ 2–9

Figure 2–3. Loading the Mold .................................................... 2–11

Figure 3–1. Sample Height Versus Gyration Table .................... 3–12

Figure 4–1. Aligning the Internal Angle Device Probes ............... 4–3

Figure 4–2. Puck Centered on Lower Carriage Plate ................... 4–7

Figure 4–3. Routing Load Cell Cables ......................................... 4–8

Figure A–1. Hydraulic Filter Bypass Indicator............................. A-6

Figure B–1. Model 5850 Menu Map ............................................ B-3

Model 5850 ix

Page 10

LIST OF TABLES

Table Title Page

2–1 Control Panel Keys and Button ................................. 2–2

x

Page 11

1. INTRODUCTION

CHAPTER 1

INTRODUCTION TO THE MODEL 5850

The Model 5850 is Troxler’s newest Superpave™ Gyratory

Compactor and the most advanced, easiest to use gyratory

compactor on the market today. This chapter introduces the Model

5850 and provides information on operating the compactor safely.

This chapter also includes a list of parts and accessories, and

instructions for unpacking and inspecting the system.

CONTENTS

Safety Warnings ............................................................................ 1–2

Cautions and Warnings ................................................................. 1–3

Introduction ................................................................................... 1–4

Safe Operation ........................................................................ 1–4

Ease of Operation ................................................................... 1–5

Performance Tests and Shear Options .................................. 2–13

Care and Maintenance ............................................................ 1–6

Parts and Accessories.................................................................... 1–7

Inspection ...................................................................................... 1–9

Unpacking ................................................................................... 1–10

Site Selection .............................................................................. 1–11

Assembly .................................................................................... 1–12

Model 5850 1–1

Page 12

SAFETY WARNINGS

The Troxler Model 5850 is a safe, durable gyratory compactor.

Troxler cannot anticipate every example of improper or

unauthorized use of this unit that may lead to malfunction or

accident. Thus, if a particular use is not specifically mentioned in

this manual as authorized, then consult Troxler about the alternate

use. Otherwise, it is assumed that the use is unauthorized and

improper.

To ensure minimal operator risk, Troxler recommends the following

safety precautions:

Wear safety glasses when preparing an asphalt specimen.

Always wear heat-resistant gloves when handling any hot

substance.

When moving the mold, grasp it firmly on either side under the

top flange.

Remove all objects, except the mold and asphalt specimen, from

the compaction chamber before pressing the START key.

Do not operate the compactor with the chamber door or any

panels removed.

Do not wear loose clothing or jewelry when operating the

compactor.

Keep hands away from the gyratory compactor when the unit is

in motion.

With the service panels removed, the gyratory compactor poses

an electrical hazard. Unplug the gyratory compactor before

removing the panels.

1–2

Page 13

1. INTRODUCTION

CAUTIONS AND WARNINGS

Identification of Interconnects:

Lower Left Side of Compactor

Connection for 100 – 240 VAC, 50/60 Hz power to the

compactor

Upper Left Side of Compactor

9-pin RS-232C serial interface for connecting the

compactor to a computer or serial device

USB port for connecting the compactor to a USB

printer or memory device

Model 5850 1–3

Page 14

INTRODUCTION

The Troxler Model 5850 Superpave Gyratory Compactor

provides compaction of asphalt specimens at a given pressure,

angle, and number of gyrations. The Model 5850 meets or exceeds

all Federal Highway Administration (FHWA) Superpave

specifications.

The Model 5850 Gyratory Compactor provides safe, reliable

gyratory compaction of asphalt specimens using a compaction

pressure and gyration angle selected by the operator. The method of

specimen compaction is crucial to creating asphalt specimens that

behave similar to asphalt used in construction and in obtaining

meaningful test results.

Building upon the successes of Troxler’s Model 4140 and 4141

Gyratory Compactors, the Model 5850 has been completely

redesigned with improved electronics, a robust compaction system,

and software-adjustable angle of gyration. The durable Model 5850

will consistently stand up to the rigors of any asphalt lab.

SAFE OPERATION

For operator safety, all moving parts are covered and cannot be

physically accessed during compaction. An interlock switch

prevents the gyratory compactor from operating with the

compaction chamber door open. The red EMERGENCY safety

switch located at the bottom of the control panel stops all moving

parts.

WARNING

Do not operate the Model 5850 Gyratory Compactor

with the chamber door or any panels removed.

1–4

Page 15

1. INTRODUCTION

EASE OF OPERATION

The Model 5850 is calibrated and ready to use upon arrival. The

unit will compact asphalt samples to a specific height or a specific

number of gyrations, as selected by the operator. The angle of

gyration is recorded with every gyration, assuring angle stability.

As selected by the operator, the Model 5850 provides a compaction

pressure of 200 to 1000 kPa and an angle of gyration between 0.00

and 1.50 degrees. Angle and pressure adjustments can be performed

quickly and easily using the keypad.

For ease of operation, the Model 5850 provides a fully automatic

method of compaction. The Model 5850 compacts an asphalt

specimen at the touch of a single key.

NOTE

Do not attempt to operate the Model 5850 before

reading this manual and the safety warnings posted on

the unit. Troxler stresses that the operator is solely

responsible for ensuring the safe use of the Model 5850.

The manufacturer, its subsidiaries, distributors, or

representatives cannot assume responsibility for any

mishaps, damage, or personal injury which may occur

from failure to observe the safety warnings in this

manual and posted on the unit.

The Model 5850 can be equipped with 150-mm, 100-mm, or 4-inch

diameter molds, and can compact specimens with heights of up to

185 mm.

The Model 5850 features USB and serial ports for transferring data

to USB or serial devices. The operator may choose to automatically

send the compaction data to a computer, printer, or USB device

upon completion of a compaction cycle.

NOTE

A list of USB memory devices and printers that are

compatible with the Model 5850 Gyratory Compactor is

available on the 5850 product page of the Troxler

website (www.troxlerlabs.com).

Model 5850 1–5

Page 16

The Model 5850 also provides storage for and allows manual

printing of the last 20 compacted specimens. All output is in SI units

as described in American Society of Testing and Materials (ASTM)

SI10, Standard for Use of the International System of Units (SI):

The Modern Metric System.

CARE AND MAINTENANCE

The Model 5850 requires little maintenance. To reduce the effects

of gyration on moving parts, the gyratory compactor requires

regular cleaning and lubrication. For a schedule of machine

maintenance, refer to Appendix A.

1–6

Page 17

1. INTRODUCTION

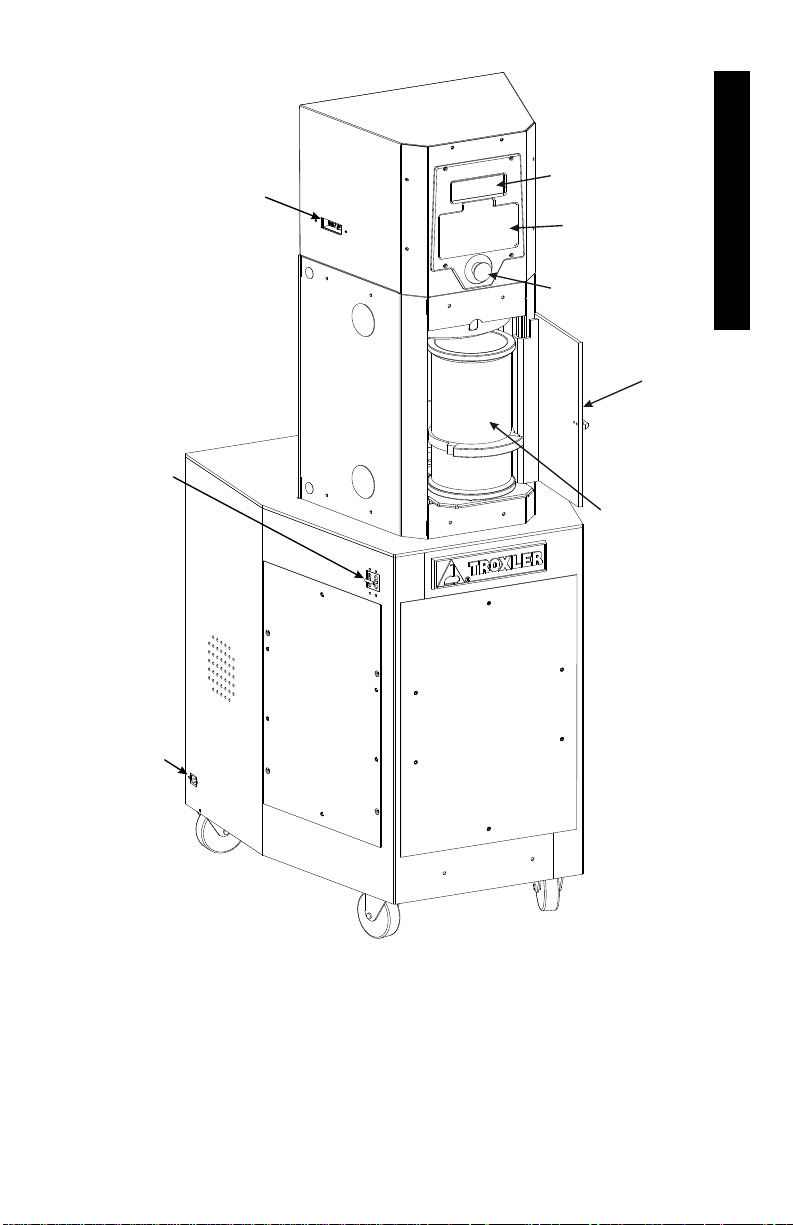

CHAMBER

DOOR

(IN OPEN

POSITION)

KEYPAD

DISPLAY

EMERGENCY

STOP SWITCH

SERIAL & USB

PORTS

AC POWER

INLET

POWER

SWITCH

MOLD

Figure 1–1. Model 5850 Gyratory Compactor

Model 5850 1–7

Page 18

PARTS AND ACCESSORIES

The Model 5850 includes the electrical and mechanical parts

required to continuously compact hot-mix asphalt. Use Figure 1–1

to locate and identify the following parts:

The power switch is located on the left side of the compactor.

The emergency stop switch stops all machine movement.

The keypad and display provide the interface.

The mold with the lower puck inserted receives the asphalt for

making specimens. Troxler offers molds with inside diameters

of 150 mm, 100 mm, and 4 inches. (Part numbers 116066 and

116069)

The USB and serial ports enable the operator to print or

download data to a USB or serial device.

The USB cable (not shown) connects the compactor to the

printer or other USB device. (Part number 110697)

The serial cable (not shown) connects the compactor to a serial

device, such as a computer. (Part number 106514)

The gravity extruder (not shown) is used to remove a

compacted specimen from the mold. (Part number 110665)

The height standard assembly (not shown) is used to calibrate

the specimen height. (Part number 106989)

The Model 5850 Manual of Operation and Instruction (not

shown) provides the operating instructions for the compactor.

The printer (not shown) allows the operator to print data. (Part

number 116220)

The specimen papers (not shown) prevent the asphalt specimen

from sticking to the puck and ram head. (Part number 106953)

The optional Pressure Verification Kit (not shown) allows the

operator to verify the pressure calibration. The pressure is

initially calibrated at the factory. (Part number 108706)

1–8

Page 19

1. INTRODUCTION

INSPECTION

Upon receiving the Model 5850 Gyratory Compactor from the

factory, perform a complete inspection and inventory as described

below.

Check to see that the following are included:

Model 5850 Gyratory Compactor

Mold

Power cord

Height standard assembly

Specimen papers (500 per package)

Printer

USB cable

Serial cable

Manual of Operation and Instruction

Gravity extruder

Inspect each part for damage that may have occurred during

shipment. If any parts or accessories appear damaged, notify the

carrier and your Troxler representative immediately.

Model 5850 1–9

Page 20

UNPACKING

WARNING

The Model 5850 Gyratory Compactor weighs

approximately 227 kg (500 lb). To prevent personal

injury or equipment damage, exercise care while

unpacking and lifting the unit.

NOTE

Troxler recommends that all packaging material be

saved. It may be reused to pack the compactor for

shipping.

To remove the shipping carton from the top of the unit, cut each

11..

side of the carton approximately 2 inches above the pallet. Lift

the carton up and off the unit.

Remove the metal strap and bolts that secure the compactor

22..

to the pallet.

Remove the two brackets that secure the front casters in

33..

place. The compactor is now free to roll on the pallet.

WARNING

To prevent personal injury or equipment damage,

do not tip the compactor while lifting it from the

pallet.

Using a forklift, lift the compactor from the pallet.

44..

CAUTION

When using a forklift, lift the compactor from the side to

prevent equipment damage.

1–10

Page 21

1. INTRODUCTION

SITE SELECTION

After unpacking and inspecting the compactor as described in the

previous sections, select a suitable site for installation. Apply the

following criteria in selecting the installation site:

Place the compactor on a flat, level location.

Locate the compactor no more than 1.2 m (4 ft) from the

required electrical power source (see Appendix C). Ensure that

the distance does not place stress on the power cord. The power

source must be wired by a qualified electrician.

The power switch is located on the left side panel, as shown in

Figure 1–1. Ensure that the placement of the compactor

provides easy access to the power switch.

Model 5850 1–11

Page 22

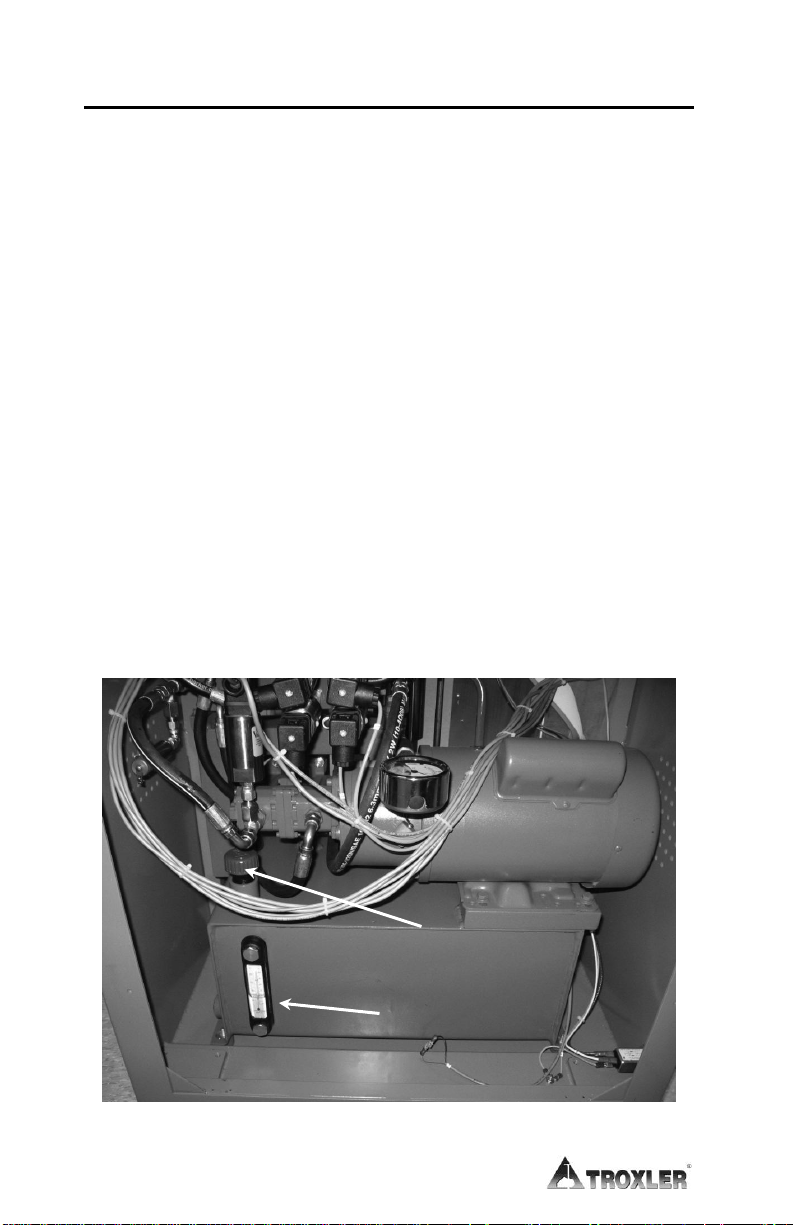

RESERVOIR

FILL CAP

FILL LEVEL

SIGHT GLASS

ASSEMBLY

The hydraulic reservoir is filled with a premium quality, light

11..

grade (ISO VG 32, SAE 10) hydraulic oil prior to shipping.

Before using the compactor, check the oil level as follows:

Remove the rear service panel from the compactor.

aa..

Locate the fill level sight glass as shown in Figure 1–2.

bb..

NOTE

Use only a light grade (ISO VG 32, SAE 10, Troxler part

number 018203) hydraulic oil to fill the hydraulic

reservoir.

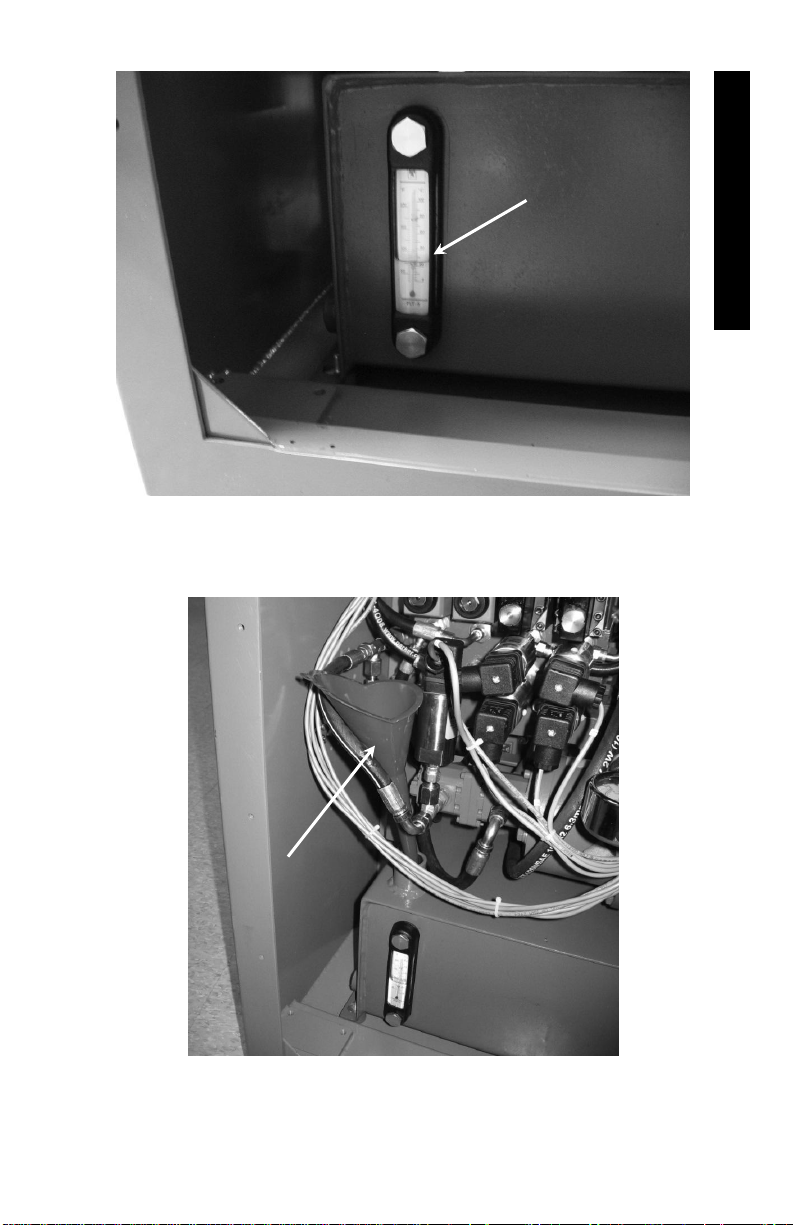

Ensure that the oil level is at the 30-degree mark on the sight

22..

glass, as shown in Figure 1–3. If oil is needed:

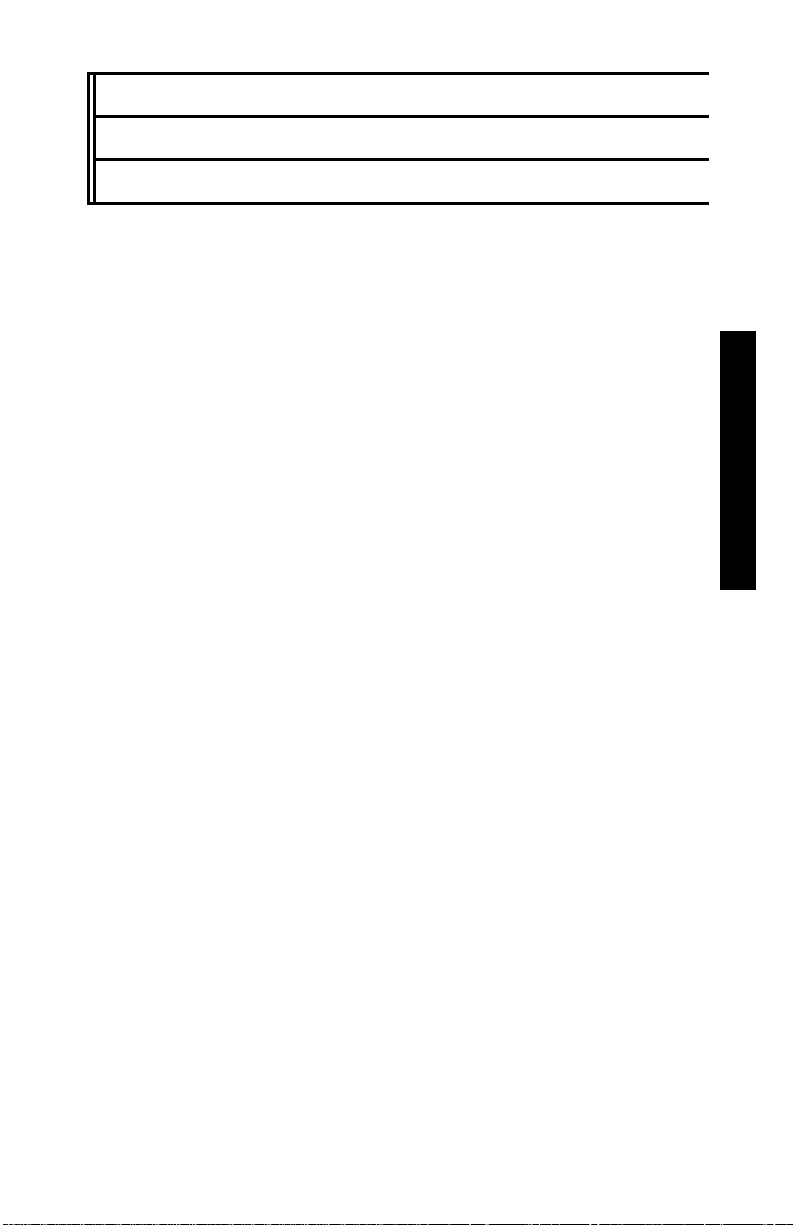

Remove the reservoir fill cap (see Figure 1–2) and place a

aa..

funnel into the fill tube as shown in Figure 1–4.

Add oil until the level is at the 30-degree mark.

bb..

Remove the funnel and replace the reservoir fill cap.

cc..

Re-install the rear service panel.

dd..

1–12

Figure 1–2. Hydraulic Reservoir

Page 23

1. INTRODUCTION

ENSURE

FLUID LEVEL

IS AT 30-DEGREE

MARK

FUNNEL

Figure 1–3. Proper Reservoir Fill Level

Figure 1–4. Place a Funnel in Reservoir Fill Tube

Model 5850 1–13

Page 24

Following the site selection guidelines in the previous section,

33..

set the compactor in place.

Lock the casters so that the unit remains in place.

44..

Plug the ac power cord into the ac power inlet on the

55..

compactor’s lower left panel (see Figure 1–1 on page 1–7).

Connect the ac power cord to the required ac power source

66..

(refer to Appendix C).

NOTE

On 240 VAC units, a connector must be installed on the

ac power cord. The connector must meet local safety and

electrical code requirements. Refer to the Electrical

Specifications section on page C–3 for the current and

voltage ratings for the compactor.

If using the compactor with a USB printer or memory device,

77..

connect the device to the USB port located on the upper left side

of the compactor (see Figure 1–1 on page 1–7).

NOTE

A list of USB memory devices and printers that are

compatible with the Model 5850 Gyratory Compactor is

available on the 5850 product page of the Troxler

website (www.troxlerlabs.com).

If using the compactor with a computer, use a serial cable to

88..

connect the computer to the serial port located on the upper left

side of the compactor (see Figure 1–1 on page 1–7).

1–14

Page 25

2. SETUP & OPERATION

CHAPTER 2

SETUP AND OPERATION

This chapter describes how to get started using the Model 5850

Gyratory Compactor. This information includes a brief description

of the control panel and instructions for turning the compactor on,

setting it up, and compacting an asphalt specimen.

CONTENTS

Control Panel ................................................................................ 2–2

Turning the System On ................................................................. 2–4

First Time Setup ..................................................................... 2–4

Compacting a Specimen ............................................................... 2–7

Cleaning and Lubricating.............................................................. 2–8

Preparing a Specimen ................................................................. 2–10

Compacting the Specimen .......................................................... 2–12

Model 5850 2–1

Page 26

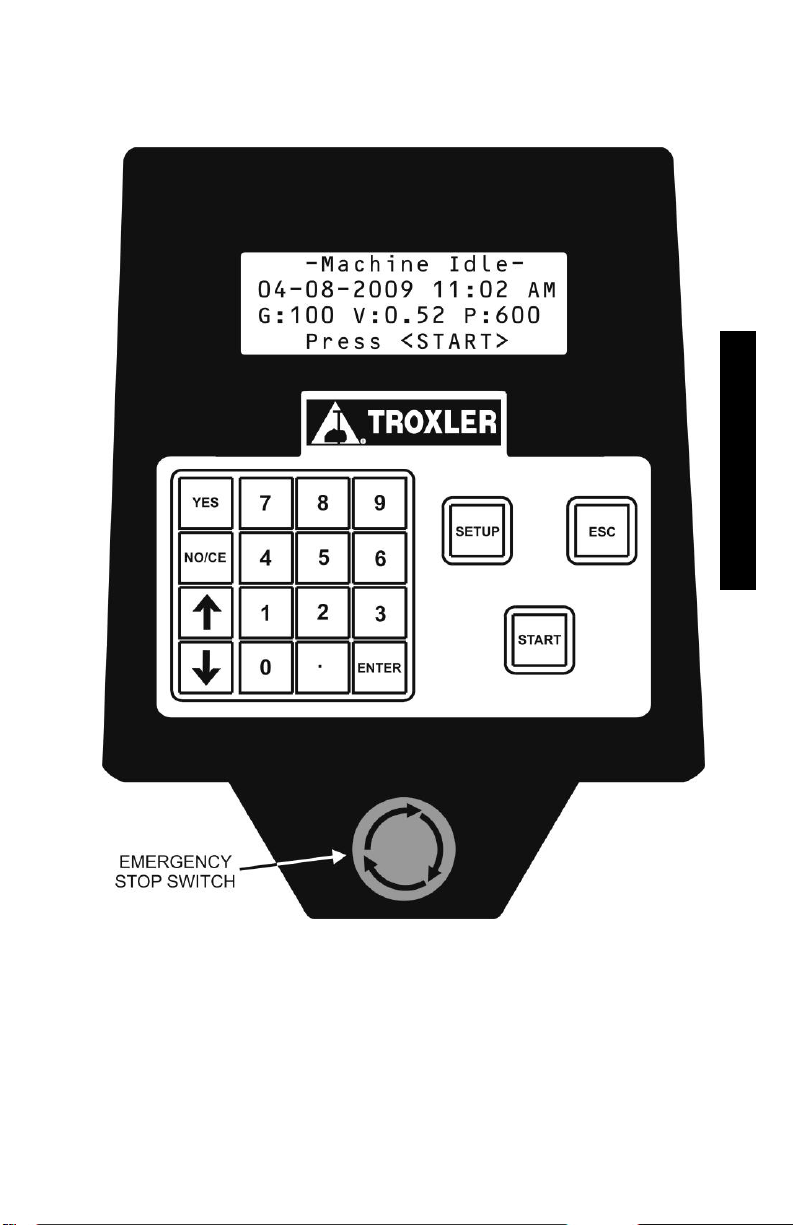

KEY

FUNCTION

EMERGENCY

Stops all machine movement. To release

the button, rotate it clockwise.

START

Begins automatic compaction of asphalt

specimen.

SETUP

Accesses the Setup functions. These

include setting or viewing the run options,

setting the data output options, calibrating

the compactor, verifying the calibration,

and clearing project data.

ESC

Returns to the next higher-level menu

without updating or storing data. In

response to Yes/No questions, it has the

same effect as pressing NO/CE. During

gyration, it aborts the compaction cycle.

YES

Responds Yes to Yes/No questions.

NO/CE

Responds No to Yes/No questions. Also

clears an incorrect entry and allows for reentry.

Scrolls through menu options or views

screens.

0...9

Enters numeric values.

.

Enters a decimal point.

ENTER

Enters data or views screens.

CONTROL PANEL

Figure 2–1 shows the layout of the Model 5850 Gyratory

Compactor control panel. Table 2–1 lists the functions for each key

and button on the panel.

Table 2–1. Control Panel Keys and Button

2–2

Page 27

2. SETUP & OPERATION

Figure 2–1. Model 5850 Control Panel Layout

Model 5850 2–3

Page 28

TURNING THE SYSTEM ON

NOTE

Control panel screens in this manual are intended as

examples only. Values on your displays may differ

slightly from those shown.

The power switch is located on the left side panel of the compactor

(see Figure 1–1). After the compactor is turned on, it briefly

displays the model and software version number, then performs a

series of brief self-tests. After self-tests are completed, the

compactor displays the Machine Idle screen shown below:

-Machine Idle04-08-2008 11:02 AM

G:100 AI:1.16 P:600

Press <START>

Where:

G = Operator-selected number of gyrations (this value is

999 if the compactor is set to compact to a target

specimen height)

AI = Operator-selected internal angle of gyration

P = Operator-selected compaction pressure

FIRST TIME SETUP

The Model 5850 is shipped with the current date and time (Eastern

Standard Time) stored in its memory. By default, the date is

displayed in mm/dd/yyyy format and the time in AM/PM format. To

change the date, time, or display format, refer to page 5–3.

The Model 5850 provides a number of operator-definable options

that control its operation. From the Setup menu, the operator can:

Select whether the compactor will run for a specified number of

gyrations (from 1 to 999) or until the specimen has been

compacted to a specified height (50 to 200 mm). Then define

the desired ram pressure (200 to 1000 kPa)

Set the desired gyration angle (0.00 to 1.50 degrees)

2–4

Page 29

2. SETUP & OPERATION

Before using the compactor for the first time, ensure that these

options are set properly. Press SETUP on the keypad to access

the Setup menu:

-Setup-

1- View Settings

2- Change Settings

3- Data Output

Press 1 to access the View Settings selection. The compactor

displays:

Selected run count (number of gyrations)

Selected mode (number of gyrations or specimen height)

Specimen height

Gyration angle

Ram pressure

Mold diameter

Gyrate Delay

Refer to Chapter 3 for instructions on changing any of these

selections.

The Model 5850 also provides numerous options for automatically

outputting or printing data following a compaction cycle. The

compactor can send the data to a computer or serial printer via the

serial (RS-232) port, or to a USB printer or memory device (thumb

drive) via the USB port.

NOTE

A list of compatible USB memory devices and printers is

available on the 5850 product page on Troxler’s website

at www.troxlerlabs.com.

Model 5850 2–5

Page 30

The output data can be formatted either in a height-versus-gyration

table format or in a full table format which includes the height, ram

pressure, gyration angle, and gyration rate for each gyration.

To automatically output gyration versus height data, connect the

compactor to the computer or printer and turn on the Auto Output

option as described on page 3–10.

NOTE

Before outputting data to a printer or computer, ensure

that the Model 5850 is properly connected to the output

device.

2–6

Page 31

2. SETUP & OPERATION

COMPACTING A SPECIMEN

WARNING

To prevent personal injury or equipment damage,

before operating the Model 5850 Gyratory

Compactor, become familiar with the safety

warnings on page 1–2.

The following is a checklist for compacting an asphalt specimen

with the Model 5850 Gyratory Compactor. Each step is discussed in

detail in the following sections.

Set up the gyratory compactor.

11..

Clean the mold tray, ram head, lower carriage, upper carriage

22..

assembly, and upper puck plate.

Lubricate the ram head and upper puck plate with Magnalube-

33..

G.

Prepare the asphalt mixture and place it in the mold.

44..

Place the mold in the compactor chamber, and compact the

55..

specimen.

Remove the mold containing the compacted specimen from the

66..

compactor chamber and extrude the asphalt specimen using the

gravity extruder provided with the compactor. A pneumatic

extruder is also available from Troxler (part number 116089).

Model 5850 2–7

Page 32

CLEANING AND LUBRICATING

CAUTION

Failure to properly clean and lubricate the Model 5850

before each use may result in compaction errors,

premature equipment wear, and other problems.

Before operating the compactor:

Vacuum the mold tray and compaction chamber.

11..

Clean the mold tray, lower carriage plate, and ram head (see

22..

Figure 2–2, View A), as well as the upper carriage assembly and

upper puck plate (View B) with Bindoff or similar cleaner.

Lubricate the ram head and the upper puck plate with

33..

Magnalube-G.

Clean the mold and pucks with Bindoff or similar cleaner.

44..

CAUTION

Do not use a degreasing cleaner or glass cleaner to clean

the clear chamber door. To prevent damage to the door

surface, use a mild detergent only.

Before each use:

If necessary, clean the mold tray, lower carriage plate, and ram

11..

head (see Figure 2–2, View A), as well as the upper carriage

assembly and upper puck plate (View B) with Bindoff or similar

cleaner.

Ensure that the exterior surface of the mold is free of dirt and

22..

asphalt residue.

Lubricate the ram head with Magnalube-G.

33..

Inspect the upper puck plate. If dry, lubricate it with Magnalube.

44..

2–8

Page 33

2. SETUP & OPERATION

LOWER

CARRIAGE

PLATE

RAM HEAD

MOLD TRAY

UPPER PUCK

PLATE

UPPER

CARRIAGE

ASSEMBLY

VIEW A

VIEW B

Figure 2–2. Compaction Chamber

Model 5850 2–9

Page 34

PREPARING A SPECIMEN

Lay the mold on its side and slowly insert the lower puck, with the

small face down, into the mold. For the rest of this chapter, the

mold with the puck inserted will be referred to as the mold.

WARNING

Always wear heat-resistant gloves when handling

any hot substance. When moving the mold, firmly

grasp it on either side under the top flange.

Place the asphalt mixture into an oven. Also place the mold

(containing the lower puck) into the oven. Heat the asphalt mixture

and mold to the compaction temperature of the mixture.

CAUTION

Do not heat the mold above 175 C (350 F). Heating

above this temperature may warp the mold and create

errors in the angle of gyration.

NOTE

Do not place the asphalt mixture into the mold while

heating.

Remove the asphalt mixture from the oven, and place it on a work

surface. Remove the heated mold from the oven and place it next to

the hot-mix asphalt.

Place a specimen paper in the heated mold on top of the lower puck

(see Figure 2–3). Load the hot asphalt mixture into the mold.

NOTE

To maintain the specimen temperature and prevent

segregation of the specimen, the asphalt mixture must

be loaded into the mold in one continuous motion. The

paper thickness will affect compactor results; it is

recommended that you use Troxler specimen papers

(part numbers 106952 or 106953).

2–10

Page 35

2. SETUP & OPERATION

MOLD (WITH

LOWER PUCK

INSTALLED)

ASPHALT

SPECIMEN

PAPERS

MOLD

PULL

UPPER PUCK

Figure 2–3. Loading the Mold

Place another specimen paper on top of the asphalt mix. Place the

upper puck, with its large side down, into the mold. Keep the upper

puck oriented horizontally while inserting it to prevent it from

becoming wedged in the mold.

CAUTION

If the upper or lower puck becomes wedged in the mold,

it must be removed and inserted correctly before

compacting the asphalt specimen.

Wearing heat-resistant gloves and safety glasses, place the hot

mold on the mold tray (see Figure 2–2, View A, on page 2–9).

Slide the mold into the compaction chamber so that it rests against

the two locating pins at the back of the lower carriage plate. Close

the chamber door.

Model 5850 2–11

Page 36

Gyration # =

Number of gyrations completed

Spec. Ht. =

The current specimen height

G =

Operator-selected number of gyrations (this value

is 999 if the compactor is set to compact to a

target specimen height)

AI =

Internal angle of gyration

P =

Operator-selected compaction pressure

COMPACTING THE SPECIMEN

The Model 5850 Gyratory Compactor provides a fully automatic

method of controlling compaction. In Automatic mode, the operator

begins the compaction cycle using a single keystroke. The Model

5850 compacts the specimen based on the number of gyrations or

the target specimen height specified by the operator. In Automatic

mode, the compactor can also automatically print or download

compaction data upon completion of the compaction cycle.

Place the loaded mold into the compaction chamber and close the

chamber door. Press START.

If there is no mold in the chamber, or if the mold is not in the proper

location, the compactor displays an error message.

If the mold is in place, the compactor begins the compaction cycle.

The compactor clamps the mold, raises the ram into position,

induces the angle of gyration, and begins compaction. During the

compaction cycle, the compactor displays a screen similar to the

one shown below:

-Gyrating-

Gyration: #:##

Spec. Ht.: ###.# mm

G:100 AI:1.16 P:600

Where:

2–12

Page 37

2. SETUP & OPERATION

The compactor continues until the desired number of gyrations or

target specimen height, as selected by the operator, is reached. The

compactor then unclamps the mold, removes the angle of gyration,

and lowers the ram to its home position.

If the Post Gyrate Delay function is enabled (see page 3–8), the

compactor will center itself and maintain a minimal pressure for five

minutes before unclamping the mold and lowering the ram.

If the Auto Output function (see page 3–10) is enabled, the

compactor automatically outputs the gyration versus height data.

The compactor then returns to the Machine Idle display shown on

page 2–4.

Open the chamber door and, wearing heat-resistant gloves,

remove the mold from the compaction chamber. Extrude the

specimen from the mold using the extruder provided with the unit.

You can also use the pneumatic extruder, available from your

Troxler representative.

SHEAR OPTIONS & PERFORMANCE TESTS

The Model 5850 can compact samples as tall as 185mm for use with

AMPT (Asphalt Mix Performance Tester). The compactor also

offers a shear option, either before or after purchase. This optional

feature includes transducers that measure the shear forces acting on

the specimen during gyration.

The Model 5850 also utilizes the Gyratory Shear Kit (GSK), which

turns any gyratory compactor into a shear-enabled unit without the

expense of purchasing the shear option. Place the 1.125” tall device

in your 150mm mold, fill with mix, and run the specimen. The GSK

calculates the shear moment at each rotation.

For more information about the shear option, or to learn more about

the Gyratory Shear Kit, contact Troxler at 1-877-TROXLER or visit

our website at www.troxlerlabs.com.

Model 5850 2–13

Page 38

NOTES

2–14

Page 39

3. SETUP MENU

CHAPTER 3

SETUP MENU

The compactor’s Setup menu enables the operator to select and

define the operating parameters of the Model 5850 Gyratory

Compactor. This chapter describes the many menu options.

CONTENTS

Setup Menu ................................................................................... 3–2

View Settings ................................................................................ 3–3

Change Settings ............................................................................ 3–4

Operation Mode...................................................................... 3–5

Number of Gyrations .............................................................. 3–5

Specimen Height .................................................................... 3–6

Gyration Angle ....................................................................... 3–6

Pressure .................................................................................. 3–7

Mold Diameter ....................................................................... 3–7

Post Gyrate Delay................................................................... 3–8

Data Output ................................................................................... 3–9

Output Record ...................................................................... 3–10

Auto Output .......................................................................... 3–10

Output Device ...................................................................... 3–11

Output Format ...................................................................... 3–11

Home Position ............................................................................ 3–13

Calibration .................................................................................. 3–13

Special......................................................................................... 3–13

Model 5850 3–1

Page 40

SETUP MENU

The compactor’s Setup menu enables the operator to select and

define the operating parameters of an automatic compaction cycle,

to determine the destination and format for outputting or

downloading compaction data, to calibrate the compactor, and to

perform other special functions.

To access the Setup menu, press SETUP on the keypad. Use the

arrow keys to scroll through the menu options. To select an option,

press the numeric key that corresponds to desired option. The

following sections describe each selection.

-Setup-

1- View Settings

2- Change Settings

3- Data Output

-Setup-

4- Home Position

5- Calibration

6- Special

3–2

Page 41

3. SETUP MENU

VIEW SETTINGS

To view the currently selected run options, select View Settings

from the Setup menu shown on page 3–2. The compactor displays:

Selected run count (number of gyrations)

Selected mode (number of gyrations or specimen height)

Specimen height

Gyration angle

Ram pressure

Mold diameter

Gyrate Delay

Press ESC to return to the Setup menu.

Model 5850 3–3

Page 42

CHANGE SETTINGS

The Change Settings selection from the Setup menu allows

you to:

Select whether the compactor will run for a specified number of

gyrations or until the specimen has been compacted to a

specified height

Specify the number of gyrations (from 1 to 999) the compactor

will run when compacting a specimen

Set the desired specimen height

Set the desired gyration angle (0.00 to 1.50 degrees)

Define the desired ram pressure (200 to 1000 kPa)

Select the mold diameter (150-mm, 100-mm, or 4-inch)

To access these options, press 2 from the Setup menu (see page

3–2). The Change Settings menu displays, as shown below. Use

the arrow keys to scroll through the menu options. To select an

option, press the numeric key that corresponds to desired option.

The following sections describe each selection.

3–4

-Change Settings-

1- Operation Mode

2- # of Gyrations

3- Height

-Change Settings-

4- Angle

5- Pressure

6- Mold Diameter

-Change Settings-

7- Post Gyrate Delay

Page 43

3. SETUP MENU

OPERATION MODE

The Model 5850 provides two modes of gyration. Based on operator

selection, the unit may either compact the specimen for a set number

of gyrations or until the specimen reaches a specified target height.

The default mode of gyration is the number of gyrations.

To select the gyration mode, press 1 from the Change Settings

menu shown on page 3–4. The compactor displays the Operation

Mode menu shown below.

-Operation Mode1- # Gyrations

2- Specimen Height

Press # to Select

Press the numeric key that corresponds to the desired operation

mode. The compactor displays a brief confirmation message, and

then returns to the Change Settings menu.

NUMBER OF GYRATIONS

To enter the number of gyrations for a compaction cycle, press 2

from the Change Settings menu shown on page 3–4. The

compactor displays:

Input Number of

Gyrations

100

Press <ENTER>

Use the number keys to enter the desired number of gyrations (from

1 to 999). Use the NO/CE key to backspace. Press ENTER. The

display returns to the Change Settings menu.

Model 5850 3–5

Page 44

SPECIMEN HEIGHT

The Model 5850 can also compact the asphalt specimen to a

specified target height. The operator can specify a height of 50 to

200 mm. The final specimen height may vary slightly from the

value entered. Differences in specimen height are mix dependent. If

the height is not acceptable, modify the height set on the unit.

To set the desired specimen height, press 3 from the Change

Settings menu shown on page 3–4. The compactor displays:

Input Target

Specimen Height (mm)

115.0

Press <ENTER>

Use the number keys to enter the specimen height (50 to 200 mm).

Use the NO/CE key to backspace. Press ENTER. The display

returns to the Change Settings menu.

GYRATION ANGLE

The Model 5850 can be set to an internal gyration angle of 0.00 to

1.50 degrees. To set the angle, press 4 from the Change

Settings menu shown on page 3–4. The compactor displays:

Input Gyration

Internal Angle

1.16

Press <ENTER>

Use the number keys to enter the desired gyration angle (from 0.00

to 1.50 degrees). Use the NO/CE key to backspace. Press

ENTER. The display returns to the Change Settings menu

shown on page 3–4.

3–6

Page 45

3. SETUP MENU

PRESSURE

NOTE

To ensure proper compactor operation, calibrate the

angle as described in Chapter 4 after changing the ram

pressure.

The Model 5850 ram pressure can be set between 200 and

1000 kPa. To set the ram pressure, press 5 from the Change

Settings menu shown on page 3–4. The compactor displays:

Input Compaction

Pressure (kPa)

600

Press <ENTER>

Use the number keys to enter the desired ram pressure (from 200 to

1000 kPa). Use the NO/CE key to backspace. Press ENTER.

The display returns to the Change Settings menu.

MOLD DIAMETER

CAUTION

Ensure that the mold diameter selected in the compactor

software is correct for the mold size in use before

compacting a specimen. Failure to select the proper

mold diameter in the software can cause erroneous

compaction results or equipment damage.

NOTE

To ensure proper compactor operation, calibrate the

compaction pressure and specimen height as described

in Chapter 4 after changing the mold diameter.

The Model 5850 can produce 150-mm, 100-mm, or 4-inch asphalt

specimens.

Model 5850 3–7

Page 46

To configure the compactor software for the diameter of the mold in

use, press 6 from the Change Settings menu on page 3–4. The

compactor displays:

-Mold Diameter1- 150mm

2- 100mm

3- 4in

Press the numeric key that corresponds to the desired mold

diameter. The compactor displays a brief confirmation message, and

then returns to the Mold Diameter menu shown above. Press ESC

to return to the Change Settings menu shown on page 3–4.

POST GYRATE DELAY

The Model 5850 provides the option for a five-minute delay upon

completing the compaction of a specimen. This delay maintains a

minimum pressure on the sample and allows low gyration

specimens to cool before the ram lowers.

To enable the Post Gyration Delay, press 7 from the Change

Settings menu. The compactor displays:

-Post Gyrate Delay1- Enable

2- Disable

Press 1 to enable the function and press 2 to disable it. The

compactor briefly displays the message Post Gyration Delay

is Enabled (or Disabled), and then returns to Change

Settings menu.

3–8

Page 47

3. SETUP MENU

DATA OUTPUT

The Model 5850 provides numerous options for outputting or

printing data. Compaction data can be printed manually from the

compactor’s memory or automatically upon completion of a

compaction cycle.

The compactor can send the data to a computer or serial printer via

the serial (RS-232) port, or to a USB printer or memory device

(thumb drive) via the USB port.

NOTE

A list of USB memory devices and printers that are

compatible with the Model 5850 Gyratory Compactor is

available on the 5850 product page on the Troxler

website (www.troxlerlabs.com).

The output data can be presented in either a height-versus-gyration

or full table format. These options are described on page 3–11.

NOTE

Before outputting data to a printer or computer, ensure

that the Model 5850 is properly connected to the output

device.

To configure the data output options, press 3 from the Setup

menu (see page 3–2). The compactor displays the Data Output

menu shown below. Use the arrow keys to scroll through the menu

options. To select an option, press the numeric key that corresponds

to desired option. The following sections describe each selection.

-Data Output-

1- Output Record

2- Auto Output

3- Output Device

-Data Output-

4- Output Format

Model 5850 3–9

Page 48

OUTPUT RECORD

The Output Record function allows the operator to manually

download or print compaction data stored in the compactor’s

memory. The compactor stores up to 20 data records that contain

information on the last 20 compaction cycles. Each data record

includes the sample height (in mm), ram pressure, gyration angle,

and gyration rate versus the gyration number for a specimen, as well

as the date and time of compaction. Printed table format data sets

also include a blank for the Sample ID.

To manually download or print a data record, press 3 from the

Data Output menu shown on page 3–9. The compactor searches

the data records and then displays the specimens currently stored in

memory, as shown below:

>04/08/09 04:24P

04/08/09 01:52P

04/08/09 08:45A

04/08/09 08:15A

Using the arrow keys, move the cursor () to the desired data record

and press ENTER. The compactor sends the specimen data in the

desired format to the selected device (see page 3–11), then returns to

the Data Output menu.

AUTO OUTPUT

Upon completion of a compaction cycle, the Model 5850 can

automatically download or print gyration data via the serial or USB

port.

To toggle the Auto Output feature on or off, press 2 from the Data

Output menu shown on page 3–9. The compactor briefly displays

the message Auto Output Is Now ON (or OFF), then returns to

the Data Output menu.

3–10

Page 49

3. SETUP MENU

OUTPUT DEVICE

The compactor can send the data to a computer or serial printer via

the serial (RS-232) port, or to a USB printer or memory device

(thumb drive) via the USB port. To select the destination for the

output data, press 3 from the Data Output menu shown on page

3–9. The compactor displays:

-Output Destination1- Serial Port

2- USB Printer

3- Thumb Drive

Press the numeric key that corresponds to the desired output

destination. The compactor displays a brief confirmation message

and returns to the Output Destination menu. Press ESC to

return to the Data Output menu.

The GyroImport software is used to convert the data on the USB

memory device to a Microsoft Excel workbook. The software may

be downloaded from the 5850 product page on the Troxler website

(www.troxlerlabs.com) or it can be requested from Customer

Service at 1-877-TROXLER.

OUTPUT FORMAT

The Model 5850 outputs data in a height-versus-gyration format,

similar to the one shown in Figure 3–1, and shows the specimen

height, or thickness, for each gyration during a compaction cycle. A

full table output includes specimen height, gyration angle, ram

pressure, and shear stress (if enabled) for each gyration.

To print the output data, press 4 from the Data Output menu

(shown on page 3–9). The compactor displays:

Model 5850 3–11

-Output Format1- Table

2- Formatted

3- GyroPave

Page 50

Press 1 to select the Table format. The compactor displays a

brief confirmation message, and then returns to the Data

Output menu.

Figure 3–1. Sample Height Versus Gyration Table

Press 2 to select the formatted data. The data is output in

Comma Separated Variable (.csv) format. The compactor

displays a confirmation message, and then returns to the

Data Output menu.

Press 3 to select GyroPave software compatible data format.

The data is similar to the Table format, but only height

measurements are output. The compactor displays a

confirmation message and then returns to the Data Output

menu.

NOTE

If Thumb Drive is the selected output device, the result

will be the following files: Ax.hdr (header file); Ax.txt

(formatted data format); AxGP.txt (GyroPave data

format); AxTABLE.txt (table data format). (Where “x”

represents the file index number of the data stored in

the compactor’s memory.)

3–12

Page 51

3. SETUP MENU

HOME POSITION

The Model 5850 contains hydraulic actuators that control specimen

compaction. One actuator applies ram pressure; another actuator

clamps the mold; and two actuators inside the compaction chamber

set and control the gyration angle.

The Home Position function returns all the hydraulic actuators to

their home position. To access this function, press 4 from the

Setup menu (see page 3–2). The compactor drives the four

actuators to their home position, while displaying Moving

Gyratory to Home Position. When the actuators are in their

home position, the compactor returns to the Setup menu.

CALIBRATION

Chapter 4 describes the calibration functions available from the

compactor’s Calibration menu. To access this menu, press 5

from the Setup menu (see page 3–2).

SPECIAL

Chapter 5 describes the functions available from the compactor’s

Special menu. To access this menu, press 6 from the Setup

menu (see page 3–2).

Model 5850 3–13

Page 52

NOTES

3–14

Page 53

4. CALIBRATION

CHAPTER 4

CALIBRATION

The Model 5850 allows for simple calibration of the specimen

height and compaction pressure, and for offsetting the angle of

gyration. This chapter provides a recommended schedule for

calibration and verification of these parameters, as well as

instructions for performing these procedures.

CONTENTS

Calibration Schedule ..................................................................... 4–2

Pressure Calibration ............................................................... 4–2

Specimen Height Calibration ................................................. 4–2

Angle Verification and Offset ................................................ 4–2

Angle Verification ........................................................................ 4–3

Calibration .................................................................................... 4–5

Pressure .................................................................................. 4–6

Specimen Height .................................................................. 4–10

Angle Offset ......................................................................... 4–12

Print Calibration ................................................................... 4–13

Model 5850 4–1

Page 54

CALIBRATION SCHEDULE

The Troxler Model 5850 Gyratory Compactor is calibrated at the

factory, and requires no initial calibration upon receipt.

Troxler recommends the following calibration schedule for the

Model 5850. If calibrating the compaction pressure and specimen

height, calibrate the pressure first and then calibrate the height.

NOTE

To ensure proper compactor operation, calibrate the

compaction pressure and specimen height after

changing the ram pressure (see page 3–7).

PRESSURE CALIBRATION

See page 4–6 for details on pressure calibration.

Calibrate the compaction pressure every 3 months.

SPECIMEN HEIGHT CALIBRATION

See page 4–10 for details on specimen height calibration.

Calibrate the specimen height daily.

Calibrate the specimen height after calibrating the compaction

pressure.

ANGLE VERIFICATION AND OFFSET

See page 4–3 for details on angle verification.

Verify the angle as described on page 4–3 after every 800 samples

or once per year, whichever comes first. If the angle is more than

±0.03° from the target, use the Angle Offset function as described on

page 4–12.

4–2

Page 55

4. CALIBRATION

ANGLE VERIFICATION

The operator-selected internal angle of gyration is displayed on the

Machine Idle screen as well as during gyration. This angle can be

easily verified using an internal angle device, such as the Dynamic

Angle Verification (DAV) device available from Troxler (part

number 108706).

To verify the internal angle, follow the instructions in Chapter 3 to:

Set the operation mode to number of gyrations.

11..

Set the number of gyrations to 20.

22..

Set the compaction pressure to 600 kPa.

33..

Set the gyration angle to 1.16.

44..

NOTE

To ensure the accuracy of internal angle measurements,

the probes of the internal angle device must be aligned

with the edge of the mold pull as shown below.

Figure 4–1. Aligning the Internal Angle Device Probes

Model 5850 4–3

Page 56

Follow the instructions provided with the internal angle device

55..

to measure the bottom angle. Ensure that the probes of the

internal angle device are aligned along Position 1 with the edge

of the mold pull as shown in Figure 4–1.

Remove the mold from the chamber and record the measured

66..

angle from the internal angle device (if you use a device with

recording capabilities).

Repeat the two previous steps to obtain a second bottom angle

77..

measurement where the device is aligned along Position 2.

Follow the instructions provided with the internal angle device

88..

to measure the top angle. Ensure that the probes of the internal

angle device are aligned along Position 1 with the edge of the

mold pull as shown in Figure 4–1.

Remove the mold from the chamber and record the measured

99..

angle from the internal angle device.

Repeat the two previous steps to obtain a second top angle

1100..

measurement where the device is aligned along Position 2.

Calculate the average of the bottom angle and top angle

1111..

measurements (four measurements total).

Compare the average to the entered angle of 1.16. If the

1122..

difference is more than ±0.03°, refer to the Angle Offset section

on page 4–12.

4–4

Page 57

4. CALIBRATION

CALIBRATION

WARNING

To prevent personal injury or equipment damage,

before operating the Model 5850 Gyratory

Compactor, become familiar with the safety

warnings on page 1–2.

The Model 5850 allows for simple calibration of the compaction

pressure and specimen height, and for offsetting the gyration angle.

To access the Calibration menu, press 5 from the Setup menu

shown on page 3–2. The compactor displays:

-Calibration-

1- Pressure

2- Height

3- Angle Offset

-Calibration-

4- Print Calibration

Use the arrow keys to scroll through the menu options. To select an

option, press the numeric key that corresponds to desired option.

The following sections describe each selection.

Model 5850 4–5

Page 58

PRESSURE

NOTE

For optimum performance—if operating the compactor

at a ram pressure other than 600 kPa—calibrate the

specimen height and gyration angle after changing the

ram pressure (see page 3–7).

The Pressure Verification Kit includes all the equipment needed to

calibrate and/or verify the compaction pressure, including a

calibration load cell.

Before calibrating or verifying the pressure, clean the compactor

and connect the load cell as described below:

To remove any grease or asphalt, clean the mold tray, ram head,

11..

lower carriage plate, upper carriage assembly, and upper puck

plate (see Figure 2–2 on page 2–9) with Bindoff or similar

cleaner.

Connect the load cell as follows:

22..

Using the supplied serial cable, connect the load cell to the

aa..

control unit’s serial port.

Connect the dc charger to the load cell, and plug the charger

bb..

into an electrical outlet.

To begin pressure calibration, press 1 at the Calibration menu

shown on page 4–5. The compactor displays:

Connect Load cell to

ser. Port. Set it in

chamber (ON A PUCK!)

Press <ENTER>

CAUTION

Ensure that the load cell is placed on a puck as

described below. Failure to do so will cause damage to

the load cell.

4–6

Page 59

4. CALIBRATION

PUCK

LOWER

CARRIAGE PLATE

LOAD

CELL

Place the lower puck, larger edge down, in the center of the

11..

lower carriage plate as shown in Figure 4–2.

Place the calibration load cell in the center of the puck as shown

22..

below.

Place the upper puck, larger edge down, centered on top of the

33..

load cell.

Route the load cell cables through the notch in the upper center

44..

of the chamber opening as shown in Figure 4–3. Close the

chamber door.

Model 5850 4–7

Figure 4–2. Puck Centered on Lower Carriage Plate

Page 60

ROUTE CABLES

THROUGH

NOTCH

LOAD

CELL

Figure 4–3. Routing Load Cell Cables

4–8

Page 61

4. CALIBRATION

CAUTION

Use caution when opening and closing the chamber door

to prevent catching or pinching the load cell cables.

Press ENTER. The compactor measures the unloaded

55..

pressure on the load cell. During this measurement, the control

unit displays:

Pressure Cal/Verify

Testing Calibration

Load Cell

Please Wait

NOTE

If the load cell is not properly connected, the control

unit briefly displays the following error message. Check

the load cell connection. Press ENTER to continue.

Pressure Cal/Verify

Communication Error

Check Load Cell

Press <ENTER>

After measuring the unloaded pressure on the load cell, the

66..

compactor raises the ram until the load cell contacts the upper

puck plate. The compactor then applies pressure and displays:

Pressure Cal/Verify

Applying Pressure

During calibration and verification, the compactor raises the

compaction ram and performs a series of pressure measurements at

high and low pressure. Upon completion, the compactor verifies the

pressure calibration, and then displays the compaction pressure as

measured internally by the compactor (System) and as measured by

the load cell (Load Cell):

Model 5850 4–9

Page 62

-Pressure Readings System: ###

Load Cell: ###

Press <ENTER>

If the System pressure differs from the Load Cell pressure by

77..

more than 10 kPa, or if the System pressure is not within 600

18 kPa, check all cable connections and the position of the

load cell and puck. Repeat the calibration. If repeated attempts

to calibrate the pressure fail, contact your Troxler

representative.

Press ENTER. The compactor stores new calibration

88..

constants based on the System and Load Cell values. It then

lowers the ram and returns to the Calibration menu shown on

page 4–5.

Open the chamber door and remove the calibration load cell and

99..

pucks. Unplug the dc charger from the electrical outlet, and

disconnect the load cell from the dc charger and control unit.

Return all parts to the Performance Verification Kit case.

SPECIMEN HEIGHT

If calibrating the height and pressure, calibrate the pressure first.

Then calibrate the specimen height.

NOTE

For optimum performance—if operating the compactor

at a ram pressure other than 600 kPa—calibrate the

specimen height and gyration angle after changing the

ram pressure.

NOTE

Before calibrating the specimen height, clean the ram

head, lower carriage plate, upper carriage assembly,

and upper puck plate with de-greaser. Failure to do so

may cause the height calibration to be inaccurate.

4–10

Page 63

4. CALIBRATION

A height standard assembly is supplied with each compactor. This

standard, along with two pucks and two specimen papers, is used to

calibrate the specimen height.

To begin height calibration, press 2 at the Calibration menu

11..

shown on page 4–5. The compactor displays:

Put Height Std,

Pucks and Papers

Into the Chamber

Press <ENTER>

Place a clean puck, with the large side down, in the center of the

22..

carriage plate. Place two specimen papers and the height

standard assembly in the center of the puck. Place a second

clean puck on the top of the height standard assembly.

Close the chamber door and press ENTER. The compactor

33..

displays:

Height Calibration

Enter Std Height

###.##

Press <ENTER>

The height of the height standard assembly is stamped on its side.

Enter the height to the nearest hundredth and press ENTER. The

compactor finds its home position and then raises the ram until the

upper puck reaches the upper puck plate.

The compactor then applies pressure and waits for the pressure to

stabilize. When the pressure has stabilized, the compactor takes a

series of measurements and then verifies the height calibration.

When the calibration is complete, the compactor displays the

Measured height and the Standard height, as shown below. The

displayed height should be within 0.10 mm of the value stamped

on the height standard assembly. If not, repeat the height calibration.

Model 5850 4–11

Page 64

Height Calibration

Measured:###.##mm

Standard:###.##mm

Press <ENTER>

Press ENTER. The compactor stores the new calibration

44..

constants based on the Measured and Standard values. It then

displays the message Calibration Finished and lowers the

ram to its home position. When the ram reaches the home

position, the compactor returns to the Calibration menu shown

on page 4–5. Open the chamber door and remove the height

standard assembly, pucks, and specimen papers.

ANGLE OFFSET

The Model 5850 can be set to a gyration angle of 0.00 to 1.50

degrees. As noted earlier, Troxler recommends verifying the angle

after every 800 samples or once per year using an internal angle

device, such as the Dynamic Angle Verification (DAV) device

available from Troxler. Refer to page 4–3 for instructions on

verifying the angle.

Use the internal angle device during verification to take two bottom

angle measurements and two top angle measurements. Determine

the average of these four measurements. If the average angle is more

than ±0.03° from the target, the Angle Offset function can be used to

compensate for the difference by comparing control system

feedback parameters to the average measured internal angle.

To use the Angle Offset function, press 3 at the Calibration menu

shown on page 4–5. The compactor displays:

-Angle Offset-

0.00 Degrees

1- Change

2- Enable

4–12

Page 65

4. CALIBRATION

Press 1 to enter the average of the four internal angle

measurements. The compactor displays:

Input Measured

Internal Angle

#.###

Press <ENTER>

Enter the measured angle and press ENTER. The compactor

displays the following (where #.## is the value just entered):

-Angle Offset #.## Degrees

1- Change

2- Enable

To enable the Angle Offset function using this value, press 2.

PRINT CALIBRATION

The Print Calibration function can be used to manually download

or print calibration data from the compactor. To use this function,

press 4 at the Calibration menu shown on page 4–5. The

compactor sends the calibration data to the selected output device

(see page 3–11), then returns to the Calibration menu.

Model 5850 4–13

Page 66

NOTES

4–14

Page 67

5. SPECIAL FUNCTIONS

CHAPTER 5

SPECIAL FUNCTIONS

The Model 5850 Gyratory Compactor firmware includes a number

of functions that typically are not used on a day-to-day basis. These

functions are accessed from the Special menu, which is a submenu

of the Setup menu.

CONTENTS

Special Menu ................................................................................ 5–2

Clock/Calendar ............................................................................. 5–3

Change Time .......................................................................... 5–3

Change Date ........................................................................... 5–4

Time Format ........................................................................... 5–5

Date Format ............................................................................ 5–5

Erase Records ............................................................................... 5–6

Reset Software .............................................................................. 5–7

Model 5850 5–1

Page 68

SPECIAL MENU

The Special menu provides access to a number of functions that

typically are not used on a day-to-day basis. These functions enable

the operator to set the date and time, to clear all project (specimen)

data, and to reset the software.

To access these functions, press 6 from the Setup menu. The

compactor displays the Special menu shown below.

-Special-

1- Clock/Calendar

2- Erase Records

3- Reset Software

Use the arrow keys to scroll through the menu options. To select an

option, press the numeric key that corresponds to the desired option.

The following sections describe each selection.

5–2

Page 69

5. SPECIAL FUNCTIONS

CLOCK/CALENDAR

The compactor stores the gyration data for the last 20 specimens,

using the date and times to identify each specimen. The time and

date of compaction are downloaded with the data.

To set the current time and date, press 1 from the Special menu

shown on page 5–2. The compactor displays the Clock/Calendar

menu shown below. Use the arrow keys to scroll through the menu

options. To select an option, press the numeric key that corresponds

to desired option. The following sections describe each selection.

-Clock/Calendar-

1- Change Time

2- Change Date

3- Time Format

-Clock/Calendar-

4- Date Format

CHANGE TIME

To set the time, press 1 from the Clock/Calendar menu shown

above. The compactor displays:

08:45 AM

Arrows toggle AM/PM

Input Time and

Press <ENTER>

Note that in this example, the time is displayed in AM/PM format.

To change the format, see the Time Format section on page 5–5.

Model 5850 5–3

Page 70

The top line of the display shows the current clock setting. To

accept this setting, press ENTER. The compactor returns to the

Clock/Calendar menu. To change the clock setting, enter the

current time using the numeric keys and press ENTER. The

compactor returns to the Clock/Calendar menu.

NOTE

The hour and minutes must be entered as two-digit

numerals, with leading zeroes as required. For example,

to set the time to 7:06, press 0 7 0 6, and then

press ENTER.

CHANGE DATE

To set the date, press 2 from the Clock/Calendar menu shown

on page 5–3. The compactor displays:

04/08/2009

mm/dd/yyyy

Input Date and

Press <ENTER>

Note that in this example, the date is displayed in mm/dd/yyyy

format. To change the format, see the Date Format section on page

5–5.

The top line of the display shows the current date setting. To accept

this date and return to the Clock/Calendar menu, press ENTER.

To change the date, enter the current date using the numeric keys

and press ENTER. The compactor returns to the

Clock/Calendar menu.

NOTE

The month and day must be entered as two-digit

numerals, with leading zeroes as required. The year

must be entered as a four-digit numeral. For example, to

set the date to April 8, 2009, press 0 4 0 8 2 0

0 9, then press ENTER.

5–4

Page 71

5. SPECIAL FUNCTIONS

TIME FORMAT

The compactor can display the time in either AM/PM or 24-hour

format. To set the desired format, press 3 from the

Clock/Calendar menu shown on page 5–3. The compactor

displays:

-Time Format1- AM/PM

2- 24-Hour

Press the numeric key that corresponds to the desired time format.

The compactor returns to the Clock/Calendar menu.

DATE FORMAT

The compactor can display the date in either mm/dd/yyyy or

dd/mm/yyyy format, where mm = month, dd = day, and yyyy = year.

To set the desired format, press 4 from the Clock/Calendar

menu shown on page 5–3. The compactor displays:

-Date Format1- mm/dd/yyyy

2- dd/mm/yyyy

Press the numeric key that corresponds to the desired date format.

The compactor returns to the Clock/Calendar menu.

Model 5850 5–5

Page 72

ERASE RECORDS

The Erase Records function erases all data records stored in the

compactor’s memory. To erase data records, press 2 from the

Special menu shown on page 5–2. The compactor displays:

Permanently Erase

all Data Records?

<YES> or <NO>

To erase all data records, press YES. The compactor restores