TROXLER 3216 User Manual

Instruction Manual

MODEL 3216

ROOF MOISTURE

GAUGE

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Rd. · P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER

Outside the USA: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

Troxler Gauges are protected by U.S.

and foreign patents

Copyright © 1981 - 2006

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or

transmitted in any form or by any means, electronic

or mechanical, including photocopying, recording,

or information storage and retrieval systems, for

any purpose without the express written permission

of Troxler Electronic Laboratories, Inc.

PN 103367

October 2006

Edition 4.1

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

P.O. Box 12057

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Phone: 1.877.TROXLER (1.877.876.9537)

Technical Support

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Fax: 817.275.8562

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Canadian Branch Office

7125 Pacific Circle, Unit 13

Mississauga, Ontario L5T-2A5

Canada

Fax: 905.564.7092

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr.

Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

NOTES

TABLE OF CONTENTS

I. INTRODUCTION AND SPECIFICATIONS

II. OPERATING INSTRUCTIONS

III. FIELD MEASUREMENTS

IV. SENSITIVITY DATA ................. 4-1

V. PERIODIC MAINTENANCE

VI. SERVICE

I-A. Introduction . . . . . . . . . . . . . . . 1-1

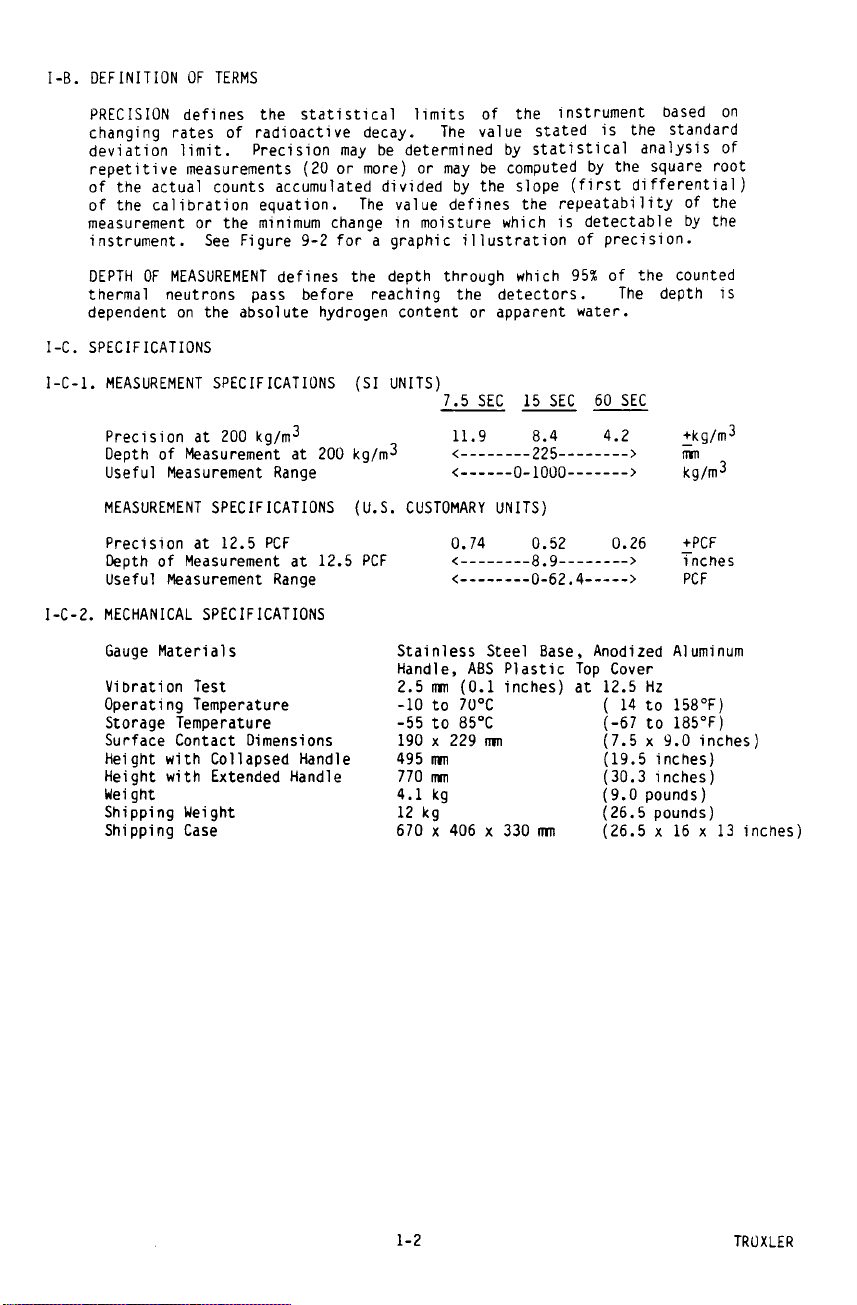

I-B. Definition of Terms . . . . . . . . . . . 1-2

I-C. Specifications . . . . . . . . . . . . . . 1-2

II-A. Getting Acquainted . . . . . . . . . . . . 2-1

II-B. Control Functions and Operations . . . . . 2-1

II-C. Test Functions . . . . . . . . . . . . . . 2-2

III-A. Data Collection . . . . . . . . . . . . . 3-1

III-B. Manual Analysis of Data . . . . . . . . . 3-4

III-C. Computer Aided Analysis of Data . . . . . 3-11

III-D. Vertical Wall Measurements . . . . . . . . 3-12

V-A. Battery Charging . . . . . . . . . . . . . 5-1

V-B. Cleaning ................. 5-1

V-C. Internal Condensation . . . . . . . . . . 5-1

V-D. Gauge Disassembly . . . . . . . . . . . . 5-2

V-E. Leak Test Procedure . . . . . . . . . . . 5-2

VI-A. Equipment Required . . . . . . . . . . . . 6-1

VI-B. Gauge Electronics . . . . . . . . . . . . 6-2

VI-C. Statistical Stability . . . . . . . . . . 6-5

VI-D. Troubleshooting Hints . . . . . . . . . . 6-7

VI-E. Service Centers . . . . . . . . . . . . . 6-8

VII. PARTS LIST

VIII. THEORY OF MEASUREMENT

IX. FACTORY CALIBRATION

X. RADIATION THEORY AND SAFETY

VII-A. Replacement Parts . . . . . . . . . . . . 7-1

VII-B. Accessories . . . . . . . . . . . . . . . 7-1

VIII-A. Neutron Radiation and Matter . . . . . . . 8-1

VIII-B. Moisture Geometry . . . . . . . . . . . . 8-3

IX-A. Moisture Calibration . . . . . . . . . . . 9-1

IX-B. Moisture Performance Parameters . . . . . 9-2

X-A. Radiation Theory . . . . . . . . . . . . . 10-1

X-A-1. Atomic Structure . . . . . . . . . . . . . 10-1

X-A-2. Radiation Theory . . . . . . . . . . . . . 10-2

X-A-3. Radiation Terminology . . . . . . . . . . 10-2

X-B-1. Radiation Statistics . . . . . . . . . . . 10-2

X-B. Radiation Safety . . . . . . . . . . . . . 10-3

X-B-1. Types of Radiation . . . . . . . . . . . . 10-3

X-B-2. Limiting Exposure . . . . . . . . . . . . 10-4

X-B-4. Monitoring Radiation . . . . . . . . . . . 10-5

i

Table of Contents (cont'd)

X-B-4. 3216 Radiation Profile . . . . . . . . . . 10-6

X-B-5. Source Encapsulation . . . . . . . . . . . 10-7

X-B-6. Emergency Procedures . . . . . . . . . . . 10-7

XI. TRANSPORTATION AND SHIPPING

APPENDIX A

XI-A. Requirements . . . . . . . . . . . . . . . 11-1

XI-A-1. Certificate of Competent Authority . . . . 11-1

XI-A-2. Results of Type A Package Testing . . . . 11-2

XI-A-3. Emergency Response Sheet . . . . . . . . . 11-2

XI-A-4. Emergency Response Telephone Number . . . 11-2

XI-A-5. Labeling Requirements . . . . . . . . . . 11-2

XI-A-6. "Bill of Lading" Requirements . . . . . . 11-2

XI-A-7. Locking or Sealing of Package . . . . . . 11-3

XI-A-8. Inspection of Package Prior to Shipment . 11-3

XI-A-9. Accident Notification Requirements . . . . 11-3

XI-A-10 Hazmat Training . . . . . . . . . . . . . 11-3

XI-B. Shipping Forms . . . . . . . . . . . . . . 11-3

BASIC Listing for Standard Deviation . . . . . . . AI

Sample Output from Standard Deviation Program . . . AII

ii

LIST OF ILLUSTRATIONS

Figure Description Page

3-1 Gridded Roof Plan 3-3

3-2 Roof Measurement Data 3-3

3-3 Histogram of Sample Data 3-4

3-4 Normal Distribution With

Confidence Limits

3-5 Normal Distribution Overlaying

Histogram

3-6 Standard Deviation for Grouped

Data

3-7 Percent Moisture Correlation Graph

Data

3-8 Graphic Interpretation of Roof

Survey

3-9 Computer Aided Plot 3-11

5-1 Leak Test Analysis Form 5-3

6-1 Interior Layout 6-3

6-2 Block Diagram of Gauge Electronics 6-4

6-3 Statistical Test Data 6-5

8-1 Neutron Interaction Data 8-3

8-2 Effect of Neutron Source-Detector

Distance

8-3 Effect of Moisture on Depth of

Measurement

9-1 3216 Calibration Data 9-4

9-2 Graphic Interpretation of Moisture

Calibration

10-1 Diagram of an Atom 10-1

10-2 Variation of Radioactive Emission 10-3

10-3 Effect of Distance on Exposure 10-4

10-4 3216 Radiation Profile 10-6

11-1 Sample Intra-company "Bill of

Lading"

11-2 Sample Common Carrier "Bill of

Lading"

11-3 Sample Shipper's Declaration of

Dangerous Goods

11-4 Sample Federal Express Form 11-7

3-5

3-6

3-7

3-8

3-9

8-4

8-5

9-6

11-4

11-5

11-6

iii

This page intentionally blank

iv

I-C-3. CALIBRATION SPECIFICATIONS

Number of Standards 2

Accuracy of Standards ±4.0%

I-C-4. RADIOLOGICAL SPECIFICATIONS

Neutron Source 1.48 ± 10% GBq

Source Form Stainless steel,

Source Classification ANSI-C54444

per ANSI N542-1977

Shielding Lead and Polyethylene

Maximum Surface Dose Rates See Radiation Profile on

Shipping Case DOT 7A, Type A, Yellow II

Special Form Approval Am-241, SPECIAL FORM

Gauge Classification per ANSI-54-685-685-R2

ANSI N538-1979

I-C-5. ELECTRICAL SPECIFICATIONS

Time Accuracy and Stability ± 0.005% ± 0.0002%/°C

Power Supply Stability ± 0.01%/°C

Battery Capacity 14 W-hr

(40 ± 10% mCi)

70,000 n/sec yield,

TEL A-102451

encapsulated

page 10-6

Label, 0.1 TI

Certificate GB:SFC 7

Charge Source 115/230 V, 50-60 Hz

Battery Recharge Time

AC Charger 14 hr

DC Charger 3 hr

LCD 4 digits

Largest Number Displayable 9999

Count Registers 1

Power Consumption 0.08 W

Power Consumption after 0.001 W

Automatic Battery Cutoff

Battery packs are fully protected against overcharge and

overdischarge. Low Battery alarm is indicated on the display

several hours prior to automatic cutoff.

TROXLER 1-3

or 12-15 VDC

III-A-2. LAYOUT GRID ON ROOF

The grid pattern (at the selected size) must be laid out

on the roof. Paint, strings, marked ropes, or other

methods can be used to define the grid intersections on

the roof.

One popular method is to use two marked ropes, placed

parallel on opposite sides of the roof. A third marked

rope is stretched between the two parallel ropes. With

spray paint can spot the roof at each marking on the

rope. The "marking stick" listed in the Accessories

Parts List (Section VII-B) is especially useful for this

purpose.

III-A-3. DRAWING OF ROOF PLAN

Make a scaled drawing of the roof's top view. Note on

this drawing all roof structures (drains, heating and

air conditioning units, ventilation shafts, etc.). If

there are no roof structures or other details that

indicate building orientation, then note the north

orientation on the drawing.

Any roof structures the user wishes included on a plot

must also by shown on the roof plan.

III-A-4. COLLECT MEASUREMENT DATA

Set the POWER/TIME switch to the desired accumulation

time period. Use the gauge to make a measurement count

at each grid intersection. Record this count at the

correct position.

III-A-5. CUT CORE SAMPLES

Nuclear gauges register relative hydrogen levels. If

absolute moisture levels are needed, one must correlate

count rates and actual moisture levels. Correlation is

normally done via core samples.

The core samples should be chosen to include the widest

range of count rates possible. The roof plan count rate

data will be useful in choosing where to cut core

samples. If a limited number of core samples are to be

cut, then they should be made at sites (determined from

the count data) that indicate a transition from dry to

wet.

3-2 TROXLER

Loading...

Loading...