Page 1

Installation Procedures for the InstroTek Universal Base

Fig.2

Board (UBB)

June 24 2013

The UBB is designed as an easy replacement for Troxler models 3411, 3430, 3440

baseboards as well as the InstroTek 3500. Certain tools are required to install and setup

the UBB for it to function correctly. The InstroTek warranty on this product requires that

only authorized, trained service personnel familiar with these types of products conduct

the installation and setup. Once the UBB is installed, the gauge should be re-calibrated or

verified according to ASTM D2922.

Model 3401 and 3411 Baseboard Installation are covered in Section A

Model 3430 and 3440 Baseboard Installation are covered in Section B

InstroTek Model 3500 Baseboard Installation are covered in Section C

Electronic Adjustment and Setup Procedure are covered in Section D

Tools Required:

• Soldering iron and solder

• De-soldering iron or solder remover (3411 only)

• Phillips screwdriver

• 5/16” nut driver

• Small jewelers screwdriver or Potentiometer adjusting screwdriver

• Oscilloscope

• Digital multi-meter (DMM)

• High voltage probe

SECTION A – Installing the UBB in a 3401 or 3411 Gauge:

Use the following parts from the existing 3411/3401

gauge along with your new UBB to complete this

task

1- GM tube holders and screws(2)

2- GM tubes with nylon spring supports and

springs (2 each)

3- He3 tube (1)

4- metal base plate (1)

5- Copper grounding spring (2)

6- Curved He3 tube support and screw (1each)

7- Screws and washers that attach circuit board

to metal plate.

8- Screws and washers that attach baseboard

assembly to gauge

1

Fig. 1

Page 2

Fig. 5

Disassembling the existing baseboard:

1. Turn off the gauge and place the gauge on a

standard block. Remove the top shell,

disconnect the batteries, discharge the high

voltage and remove the existing baseboard

and metal plate assembly.

2. Remove the He3 tube from the assembly by

removing the curved support bracket and

then pulling the tube downward away from

the baseboard.

3. Use a 5/16 nut driver to remove the screws

securing the GM tube holders. The GM

tube holders are slotted and are held by the

metal plate. One end of the GM tube holder

will still be connected to the baseboard by

soldered resistors. Slide off the other one

and remove the tubes. Figs 1, 2 and 3.

4. Do not discard the copper grounding

springs, as they are needed with the new

UBB assembly.

5. The nylon spring supports and small coil

springs are located in the resistor connected

end of the GM tubes and may drop out if the

tube is turned downward during removal.

Save these.

6. Separate the metal base plate from the

baseboard by removing the screws on the

top of the baseboard.

7. Slide the metal base plate off the remaining

GM tube holder.

8. From the top of the board, use a de-

soldering tool to disconnect the resistors

from the baseboard. This will allow you to

remove the remaining GM tube holder from

the old baseboard.

9. You are now ready to assemble your new

UBB board.

Assembling the new UBB baseboard:

1. Remove the metal cover from the UBB by

removing the screws.

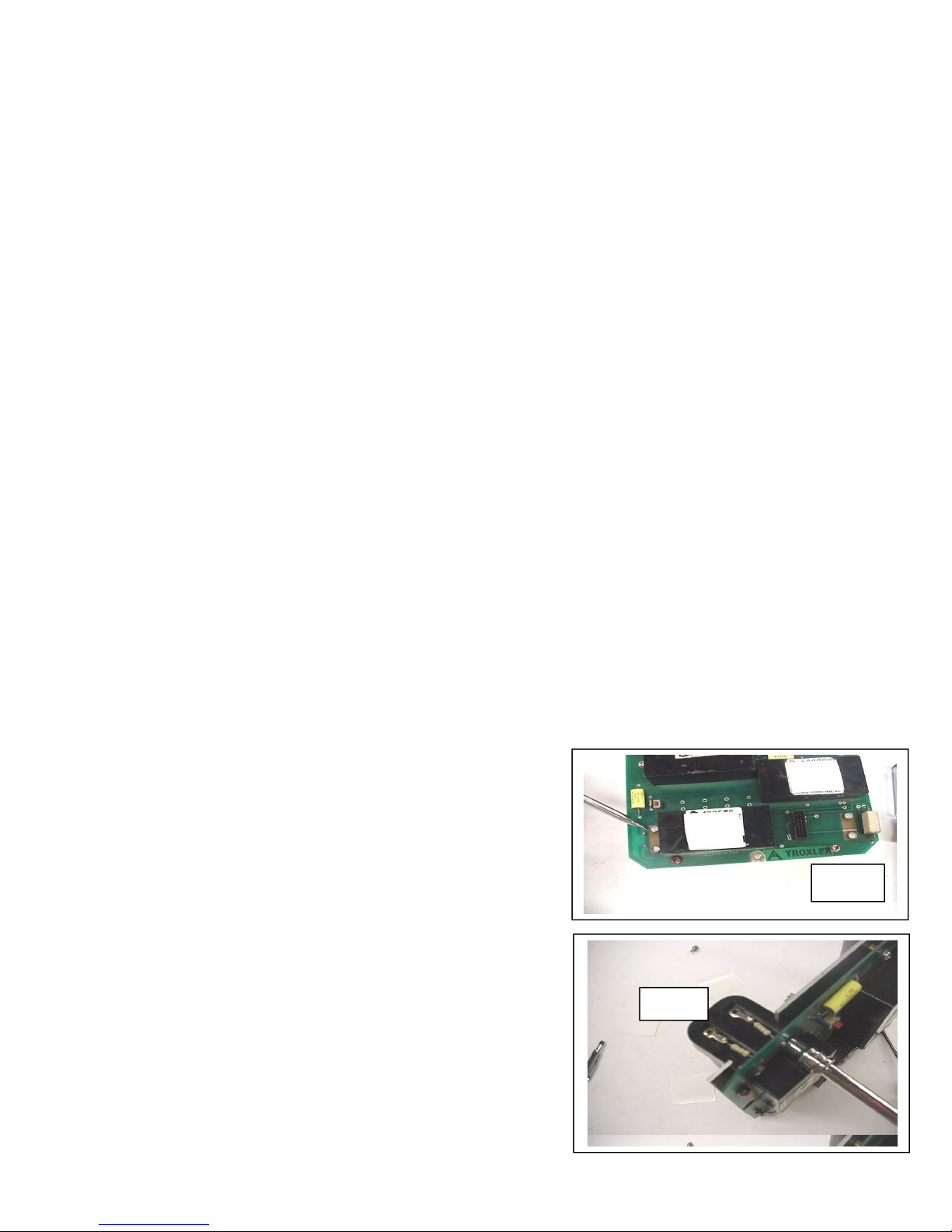

2. Locate the 3 groups of jumpers on the UBB.

Fig 5.

Fig.3

Reuse these parts

Fig.6

2

Page 3

3. The groups of jumpers are marked as

Fig 6b

S4

S6

“3411” “3430” or “3440/ 3500” switches.

4. To configure the UBB for operation as a

3401/3411baseboard, only the group of

jumpers marked as 3411 switches need to

remain shorted by means of the jumpers.

Carefully remove all of the jumpers from

the groups marked as 3430 switches and

3440/3500 switches by cutting them with

wire cutters.

5. Locate the groups of jumpers marked S4 and

S6. Leave the jumpers marked 3411. Cut

the jumpers marked 3500/3430.Fig 6b

6. Place one copper grounding spring between

the bottom side of the UBB and the GM

tube holder with the resistors. Ensure the

resistor leads from the GM tube holder

extend through the solder holes of the UBB.

Secure the GM tube holder with the

mounting screws. Solder the resistor leads

to the UBB at GM1 and GM2 points. Fig.6.

7. Slide the metal base plate into the grooves

on the GM tube holder.

8. Secure the UBB to the metal base plate with

the screws taken out.

9. Place the GM tubes into the secured GM

tube holder making sure the end of the GM

tube with springs and nylon spring supports

are the end inserted into this connector.

10. Install the other copper ground spring and

GM tube holder by sliding it onto the metal

base plate and securing it to the UBB with

the appropriate screws. Fig. 7 and 8.

11. Reinstall the He3 tube and mounting

bracket. Fig.9.

12. Place the complete assembly back into the

gauge and secure it with the appropriate

screws.

13. Connect the batteries and control board

(front panel) to the UBB.

14. The UBB assembly is now complete and

ready for electrical adjustment and setup.

15. Proceed to Section D.

Fig.7

Fig.8

Fig.9

3

Page 4

SECTION B – Installing the UBB in a 3430 or 3440 Gauge:

NOTE: In addition to the UBB, the UBB Base Board Kit, part

#1520103, is required to replace baseboards in Troxler Model 3430 and

3440 gauges.

The Base Board Kit Includes:

1. Metal base plate assembly (1)

2. GM tube interface circuit board (1)

3. 4-40 screws (4 each)

4. 6-32 x .500 (6 each)

5. 6-32 x .375 (3 each)

6. Interface board header (1)

7. # 4 lock washer (4 each)

8. # 6 lock washer (9 each)

9. metal cover box

Installing the UBB in a 3430 or 3440 gauge:

Use the following parts from the existing 3430/3440

gauge along with your new UBB and Base Board

kit to complete this task.

1. GM tubes (2)

2. GM tube holder and screws(1)

3. He3 tube (1)

4. Curved He3 tube support and screw

5. Screws and washers that attach circuit

board to metal plate.

6.

Screws and washers that attach baseboard

assembly to gauge.

7.

Small angle bracket at GM tube end.

Disassembling the existing baseboard:

1. Turn off the gauge, place the gauge on a

standard block, remove the top shell,

disconnect the batteries, discharge the high

voltage and remove the existing baseboard/

base plate assembly.

2. Remove the He3 tube from the existing

baseboard by removing the metal bracket and

Fig. 10

Fig. 11

4

Fig. 12

Page 5

pulling the tube downward away from the

S4

S6

existing baseboard.

3. Remove the screws securing the plastic GM

tube holder. (Fig 10)

4. Carefully remove the GM tubes by prying

them out of the connectors with a small flat

screwdriver.

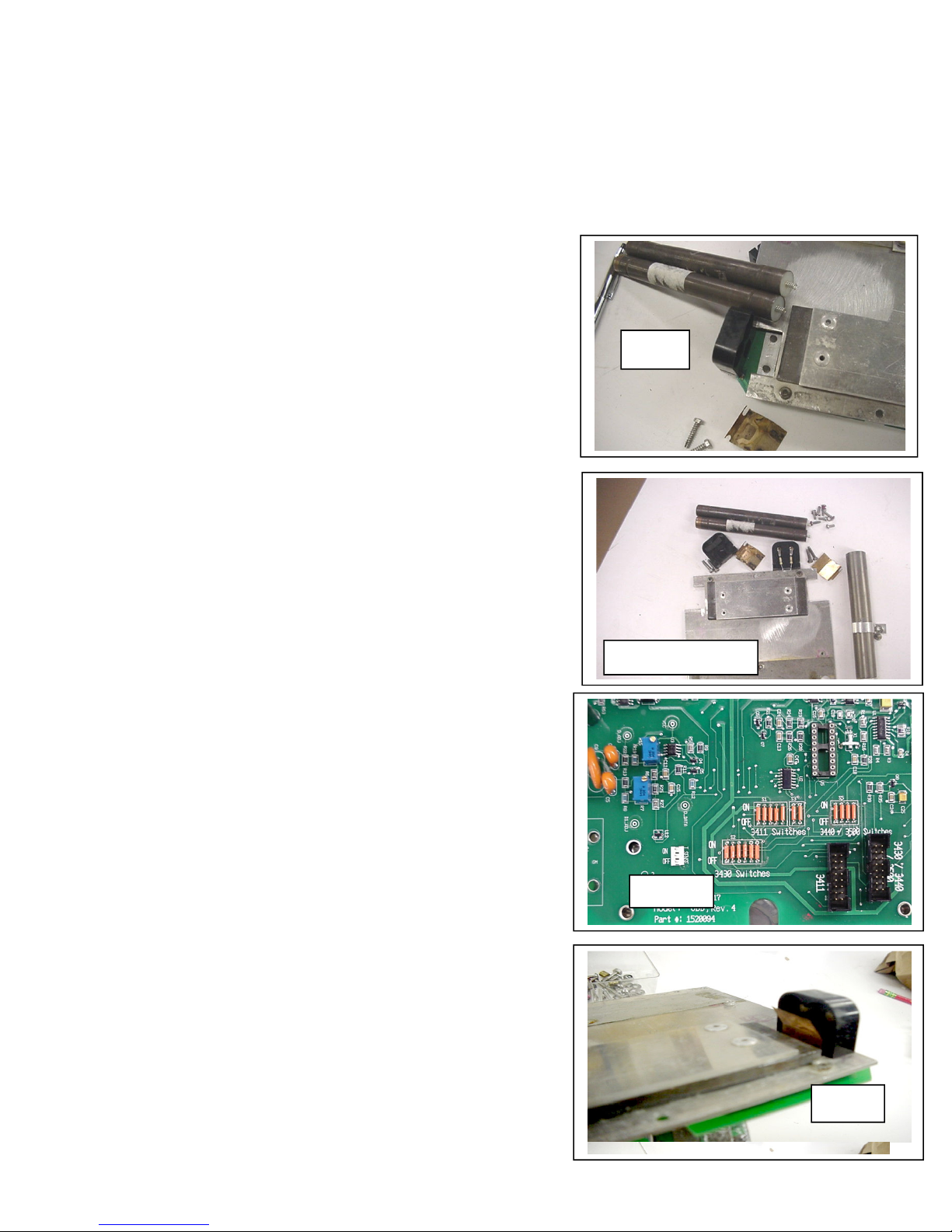

Assembling the new UBB baseboard:

1. Remove the metal cover from the UBB by

removing the 3 screws and washers. Fig. 11.

2. Locate the 3 groups of jumpers on the UBB.

See Fig. 5.

3. The groups of jumpers are marked as “3411”

“3430” or “3440/ 3500” switches. To

configure the UBB for operation baseboard

of your choice, only the group of jumpers

for your selection of baseboard need to

remain shorted by means of the jumpers.

Carefully remove all jumpers of the

remaining 2 groups by cutting them with

wire cutters.

4. Locate the groups of jumpers marked S4 and

S6. Leave the jumpers marked 3500/3430.

Cut the jumpers marked 3411. Fig 12b

5. Looking down on the UBB with the jumpers

at the bottom section of the board, locate the

3 holes on the left side. Solder the GM

assembly header on the underside the board

at this location. The header should sit flush

on the board. Fig. 12.

6. Attach the small angle bracket to the new

metal base plate. Fig 13a &13b.

7. Secure the UBB to the base plate with the

appropriate screws. Use the provided flat

washers under the lock washers. Fig 14.

8. Carefully press the GM tubes into the

contacts on the GM tube interface board.

9. Slide the GM tubes into the GM tube holder

mounted on the metal base plate and attach

the GM tube interface board to the baseboard

mounted header. Fig. 15.

10. Secure the GM tube interface board with the

provided 4-40 screws and washers. Fig. 16.

12b

Fig. 13a

Fig. 13b

Fig. 14

5

Page 6

11. Reinstall the He3 tube and mounting bracket.

12. Place the complete UBB assembly back into

the gauge and secure it.

13. Connect the batteries and scaler to the UBB.

14. For 3440 gauges connect the depth strip to

the header on the upper edge of the UBB.

Fig. 16.

15. The UBB assembly is now complete and

ready for setting up.

SECTION C – Installing the UBB in

an InstroTek 3500 Gauge:

All existing hardware from the presently installed

3500 baseboard is utilized for the replacement

baseboard.

Disassembling the existing baseboard:

1. Turn off the gauge, place the gauge on a standard

block, remove the top shell, disconnect the

batteries, and remove the 3 screws securing the

metal cover from the top of the existing

baseboard. Discharge the high voltage by shorting

the pins on the upper left side of the baseboard.

2. Remove the 6 screws securing the existing

Base board to the base plate.

3. Using both hands, gently pull the baseboard

directly upward removing it from the base plate.

Assembling the new UBB baseboard:

1. Align the HE3 tube with the connector on the

new UBB and firmly press the UBB downward.

Verify the HE3 tube makes a secure connection to

the UBB connector.

2. Gently raise the lower left side of the UBB and

visually align the GM pins on the UBB with

the GM header assembly connected to the

baseplate.

3. Press down on the UBB seating the GM pins into

the GM tube header.

4. Secure the UBB to the baseplate with the 6

baseboard securement screws.

Fig. 15

Fig. 16

6

Page 7

5. Before installing the metal UBB cover verify the

setup procedure in Section D.

SECTION D -

and Setup Procedures

Electronic Adjustment

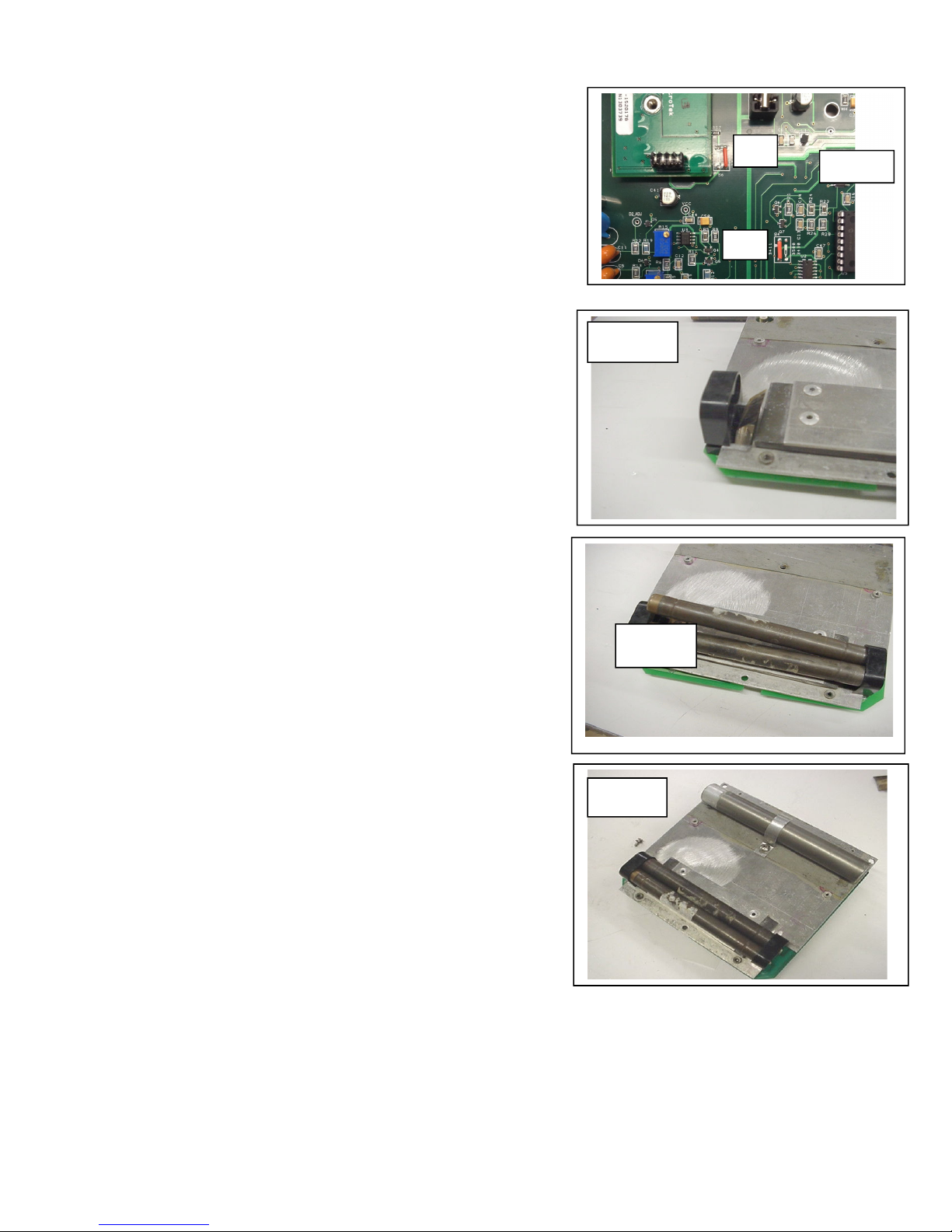

1. Place the gauge on the standard block. Turn

on the gauge.

Setting up the moisture signal:

2. Set the oscilloscope to 200 mV scale, ac coupled and very small

µsec(s) time base.

3. Locate the test point “M-ADJ” on the UBB. This is located at the

upper right of the UBB below the battery connections.

4. Place the scope probe in the test point and connect the ground lead

of the probe to the gauge aluminum base.

5. Using the scope and small screwdriver, adjust potentiometer R33

until you have a moisture signal at this test point with peak

amplitude of 600 mV.

Setting up the Density signal:

6. Locate the test point “D2-ADJ” and “D1-ADJ” on the UBB.

These are located on the lower side of the UBB left of the jumpers.

7. Place the scope probe in one test point and connect the ground lead

of the probe to the aluminum gauge base.

8. Using the scope and small screwdriver, adjust potentiometer R15

(for “D2-ADJ”) and R7 (for “D1-ADJ”) until you have a density

signal for each of these test points with a peak amplitude of 600

mV.

Reassemble the gauge:

9. Turn off the gauge and discharge the high voltage circuit by

shorting the “HV-Discharge” pins on the upper left corner of the

UBB with an insulated metal object such as a screwdriver.

10. Place and secure the metal cover on the UBB.

11. Reassemble the gauge.

12. The gauge will need to re-calibrated or

verified for accurate results according to

ASTM D2922.

7

Loading...

Loading...