Page 1

Manual of Operation and Instruction

Model 3451

Enhanced

RoadReader™ Plus

Surface Moisture-Density Gauge

NOTE

The Model 3451 Enhanced RoadReader Plus is equipped with a

global positioning system (GPS) receiver. If the gauge is moved

a long distance between uses, the GPS system must be allowed

to initialize. In some instances, initialization may take as long as

30 to 45 minutes from the time the gauge is powered on with the

GPS enabled. Note also that the gauge must be positioned such

that the GPS receiver can receive signals from the GPS

satellites (see page 1–5 for more information). If the GPS does

not initialize within 45 minutes, contact your Troxler

representative.

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Rd. P.O. Box 12057

Research Triangle Park, NC 27709 U.S.A.

Phone: 1.877.TROXLER

Outside the USA: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

Page 2

Troxler gauges are protected by U.S. and foreign patents

Copyright 2004 – 2009

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

Bluetooth is a registered trademark of the Bluetooth Special Interest

Group (SIG).

Federal Express is a registered trademark of the Federal Express

Corporation.

Intermec is a registered trademark of Intermec Technologies Corp.

Magnalube-G is a registered trademark of Carleton-Stuart

Corporation.

Microsoft, Windows, Windows XP, Excel, and ActiveSync are

registered trademarks of Microsoft Corporation.

Pentium is a registered trademark of Intel Corporation.

RoadReader is a trademark of Troxler Electronic Laboratories, Inc.

WD-40 is a registered trademark of the WD-40 Company.

PN 110399

July 2009

Edition 3.1

ii

Page 3

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Texas Service Center

2016 East Randol Mill Road

Arlington, TX 76011

Fax: 817.275.8562

Illinois Service Center

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Northern California Service Center

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr. Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

To locate an independent, Troxler-authorized service

partner near you, call 1.877.TROXLER

(1.877.876.9537).

Suite 406

NOTE

Model 3451 iii

Page 4

HOW TO USE THIS MANUAL

Congratulations on the purchase of the Troxler Model 3451

Enhanced RoadReader Plus. Troxler continues the proven

technology of its 3400 Series surface moisture-density gauges with

the Troxler Model 3451 Enhanced RoadReader Plus.

The Model 3451 Manual of Operation and Instruction contains

information on safely using this gauge. Also included in this manual

are safety warnings, gauge setup, troubleshooting, and general

maintenance.

iv

Page 5

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, symbols and special formatting are used to

reveal the purpose of the text as follows:

WARNING

Indicates conditions or procedures that, if not followed

correctly, may cause personal injury.

CAUTION

Indicates conditions or procedures that, if not followed

correctly, may cause equipment damage.

NOTE

Indicates important information that must be read to

ensure proper operation.

Button Angle brackets and a different typestyle indicate a

button or character (number or letter) to press on

the handheld personal digital assistant (PDA) or on

the keyboard of a personal computer (PC) when

using the Data Manager software provided with the

gauge. For example, “Press Start” means to press

the button labeled Start.

Display A different typestyle is used in text to indicate

information or messages displayed on the PDA or

computer.

Diamonds indicate a list of things needed (such as

equipment) or things to know.

Check marks indicate the performance of an action.

With lists of check marks, follow the instructions in

the order of the check marks.

Triangles indicate that more than one option is

available. Carefully select the option that applies.

Model 3451 v

Page 6

NOTES

vi

Page 7

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION TO THE MODEL 3451

Introduction................................................................................... 1–2

Global Positioning System Accuracy ........................................... 1–5

Gauge Parts and Accessories........................................................1–8

Unpacking and Inspection .......................................................... 1–11

CHAPTER 2. THEORY OF OPERATION

Density..........................................................................................2–2

Moisture........................................................................................ 2–3

Thin Layer .................................................................................... 2–5

Calibration .................................................................................... 2–6

CHAPTER 3. GETTING STARTED

Model 3451 Illustration ................................................................ 3–3

Source Rod Positions.................................................................... 3–5

Before Using the Gauge and PDA................................................ 3–6

Turning the Gauge and PDA On................................................... 3–8

Troxler Menu.............................................................................. 3–10

RoadReader Plus Main Menu..................................................... 3–16

Project Files................................................................................ 3–19

Status........................................................................................... 3–24

CHAPTER 4. USING THE GAUGE

Taking a Standard Count .............................................................. 4–2

Preparing a Test Site..................................................................... 4–7

Taking Measurements................................................................. 4–10

CHAPTER 5. SETUP AND TARGET MENUS

Gauge Setup Menu ....................................................................... 5–2

Target.......................................................................................... 5–14

Model 3451 vii

Page 8

TABLE OF CONTENTS (Continued)

CHAPTER 6. ADJUSTING MEASUREMENTS

Calibration Offset..........................................................................6–2

Special Calibration......................................................................6–14

CHAPTER 7. USING DATA MANAGER

Introduction...................................................................................7–3

System Requirements....................................................................7–4

Starting the Data Manager Program..............................................7–5

Manage Project Data .....................................................................7–6

View Project Configuration.........................................................7–11

Recover Projects..........................................................................7–19

APPENDIX A. RADIATION THEORY AND SAFETY

Radiation Theory..........................................................................A–2

Radiation Safety...........................................................................A–5

Regulatory Requirements...........................................................A–14

Gauge Use Precautions...............................................................A–17

3451 Radiation Profile................................................................A–18

APPENDIX B. 3451 SPECIFICATIONS

Measurement Specifications.........................................................B–2

Radiological Specifications..........................................................B–5

Electrical Specifications............................................................... B–6

Mechanical Specifications............................................................ B–7

APPENDIX C. TROUBLESHOOTING AND SERVICE

Diagnostics Menu ......................................................................... C–2

Troubleshooting............................................................................C–9

Batteries...................................................................................... C–24

Replacing Fuse...........................................................................C–26

Mechanical Maintenance............................................................ C–27

Replacement Parts...................................................................... C–29

Returning the Gauge for Service................................................ C–32

viii

Page 9

TABLE OF CONTENTS (Continued)

APPENDIX D. TRANSPORTATION AND SHIPPING

U.S. Shipping Requirements........................................................ D–2

Canadian Shipping Requirements................................................ D–5

APPENDIX E. STANDARD COUNT LOG

APPENDIX F. UNIT CONVERSION

Measurement Units.......................................................................F–2

Radiological Units ........................................................................ F–2

APPENDIX G. SPECIAL EUROPEAN CONSIDERATIONS

Declaration of Conformity........................................................... G–2

Safety Warnings........................................................................... G–3

INDEX

WARRANTY

Model 3451 ix

Page 10

LIST OF FIGURES

Figure

1–1 Model 3451 Parts and Accessories............................1–9

2–1 Effect of Moisture on Depth of Measurement...........2–4

3–1 Model 3451 Illustration .............................................3–3

3–2 Back Panel Details.....................................................3–4

3–3 Source Rod Positions.................................................3–5

3–4 Troxler Menu...........................................................3–10

3–5 Notes Screen............................................................3–10

3–6 Calculator.................................................................3–11

3–7 Intermec Launcher Display......................................3–12

3–8 Windows Desktop....................................................3–12

3–9 Return to Troxler Menu...........................................3–13

3–10 Battery Status Display .............................................3–17

3–11 RoadReader Plus Software Main Menu...................3–18

3–12 Project Menu............................................................3–20

3–13 New Project Setup Wizard, Page 1..........................3–20

3–14 Project File Selector.................................................3–22

3–15 Project Data Display................................................3–22

3–16 Project Erase Prompt ...............................................3–23

3–17 Gauge Tools Menu...................................................3–24

3–18 Gauge Status Menu..................................................3–24

3–19 View Status Display.................................................3–25

3–20 View Constants Display...........................................3–25

3–21 Source Decay Menu.................................................3–27

3–22 GPS Location Display.............................................3–28

4–1 Standard Menu...........................................................4–2

4–2 Standard Count Position ............................................4–3

4–3 Standard Count Results..............................................4–5

4–4 View Standard Screen................................................4–6

4–5 Drill Rod Assembly...................................................4–8

4–6 Marking the Test Area...............................................4–8

4–7 Entering Project Notes.............................................4–12

4–8 Count Results, Soil Mode........................................4–13

4–9 Count Results, Asphalt Mode..................................4–16

4–10 Gauge Positioned Around a Core Site.....................4–18

Title Page

x

Page 11

LIST OF FIGURES (Continued)

Figure

4–11 Gauge Positioned Over Designated Test Site..........4–19

4–12 Individual Count Results, Thin Layer Mode........... 4–20

4–13 Averaged Count Results, Thin Layer Mode............ 4–20

5–1 Change Settings Menu ..............................................5–2

5–2 Gauge Setup Menu....................................................5–2

5–3 View Setup Display................................................... 5–3

5–4 Set Units Menu.......................................................... 5–4

5–5 Mode Change Display...............................................5–6

5–6 Count Time Menu..................................................... 5–7

5–7 Enter Code Menu ...................................................... 5–8

5–8 Enter Customer Name Menu.....................................5–8

5–9 Change User Code Menu .......................................... 5–9

5–10 Depth Indicator Menu............................................. 5–10

5–11 Leak Test Menu.......................................................5–11

5–12 Leak Test Interval Menu......................................... 5–12

5–13 Leak Test Date Menu..............................................5–13

5–14 Target Menus ..........................................................5–15

5–15 Proctor Value Menu................................................ 5–15

5–16 Input Proctor Value Display.................................... 5–16

5–17 Proctor File Selector................................................ 5–17

6–1 Offset Menu .............................................................. 6–3

6–2 Wet Density Offset Select......................................... 6–4

6–3 Input Wet Density Offset .......................................... 6–4

6–4 Moisture Offset Select............................................... 6–5

6–5 Input True Percent Moisture .....................................6–7

6–6 Enter Moisture Offset File Name.............................. 6–7

6–7 Input Moisture Value from Gauge............................ 6–8

6–8 Input True Moisture .................................................. 6–8

6–9 Offset File Selector ................................................... 6–9

6–10 Moisture Offset Erase Prompt.................................6–11

6–11 Trench Offset Select................................................6–12

6–12 New Trench Offset Confirmation ........................... 6–13

6–13 Soil Special Calibration Menu................................ 6–15

6–14 Gauge Positioned Over Designated Test Site..........6–16

6–15 Input True Density ..................................................6–17

Title Page

Model 3451 xi

Page 12

LIST OF FIGURES (Continued)

Figure

6–16 Enter File Name.......................................................6–17

6–17 Special File Selector................................................6–18

6–18 Special Calibration Erase Prompt............................6–18

6–19 Enter Rod Position...................................................6–19

6–20 Taking Measurements Around a Core Site..............6–20

6–21 Thin Lift Special Calibration Menu.........................6–21

6–22 Input Top Layer Thickness......................................6–22

6–23 Input True Density...................................................6–24

6–24 Thin Layer Special Calibration Results...................6–24

6–25 Enter File Name.......................................................6–24

6–26 Thin Lift File Selector..............................................6–25

6–27 Thin Lift Special Calibration Erase Prompt.............6–25

6–28 Input Number of Averages ......................................6–27

7–1 Data Manager Main Menu.........................................7–5

7–2 Manage a Project Menu.............................................7–6

7–3 Connect PDA to PC Prompt ......................................7–8

7–4 View a Project Display..............................................7–8

7–5 Project Data Spreadsheet .........................................7–10

7–6 Print Active Project Menu .......................................7–11

7–7 Gauge Constants Display.........................................7–13

7–8 Project Setup Display...............................................7–14

7–9 Standard Counts Display .........................................7–14

7–10 Project Status Display..............................................7–16

7–11 Source Decay Display..............................................7–16

7–12 Stat Test Display......................................................7–18

7–13 Drift Test Display....................................................7–18

7–14 Recover Project Menu.............................................7–19

7–15 Connect Gauge to PC Prompt..................................7–20

A–1 Diagram of an Atom.................................................A–2

A–2 Effect of Distance on Exposure ................................A–7

A–3 Cleaning the Sliding and Fixed Blocks...................A–12

A–4 Model 3451 Gauge and Transport Case..................A–18

Title Page

xii

Page 13

LIST OF FIGURES (Continued)

Figure

C–1 Diagnostics Menu......................................................C–3

C–2 Stat Test Menu ..........................................................C–3

C–3 View Stat Co unts.......................................................C–4

C–4 Stat Test Results........................................................C–4

C–5 Review Stat Test .......................................................C–4

C–6 Drift Test Menu.........................................................C–6

C–7 View Drift Counts.....................................................C–7

C–8 Drift Test Results ......................................................C–7

C–9 Review Drift Test......................................................C–7

C–10 Replacing NiMH Battery Pack or Fuse...................C–25

D–1 Type A Package Testing Results.............................. D–4

Title Page

Model 3451 xiii

Page 14

LIST OF TABLES

Title Page

Table

1–1 GPS Position Accuracy..............................................1–7

A–1 Radiation Profile for Model 3451 Gauge................A–19

xiv

Page 15

ATTENTION 3451 GAUGE OWNER

This unit contains functions that require an ACCESS CODE.

This code must be entered before these functions may be used.

The ACCESS CODE for this gauge is:

4012

This page should be removed if the access code is not to be

distributed to other parties or users of this gauge.

Model 3451 xv

Page 16

NOTES

xvi

Page 17

CHAPTER 1

INTRODUCTION TO THE MODEL 3451

This chapter provides a brief overview of the Troxler Model 3451

Enhanced RoadReader Plus, as well as an explanation of the

global positioning system (GPS). This chapter also includes a list of

the gauge parts and accessories, and instructions for unpacking and

inspecting the gauge.

CONTENTS

Introduction................................................................................... 1–2

Global Positioning System Accuracy ........................................... 1–5

Gauge Parts and Accessories........................................................ 1–8

Unpacking and Inspection .......................................................... 1–11

1. INTRODUCTION

Model 3451 1–1

Page 18

INTRODUCTION

Troxler’s Model 3451 Enhanced RoadReader Plus combines the

impressive features of the Model 3450 RoadReader Plus with

advanced global positioning system (GPS) and wireless

technologies to provide unparalleled performance, flexibility, ease

of use, and operator safety.

Like the 3450 gauge, the Model 3451 incorporates the proven

capabilities of Troxler’s 3400 (moisture/density) and 4640 (thinlayer density) gauges in a single unit that can perform thin-layer,

backscatter, direct transmission, and moisture measurements. In

addition to the features found in the 3450 gauge:

The Model 3451 is controlled using a handheld personal digital

assistant (PDA), which allows the operator to stand away from

the gauge while operating it via Bluetooth wireless

communications.

An onboard GPS receiver enables the Model 3451 to store

precise GPS coordinates, along with the standard date and time

stamp, for each measurement.

The Data Manager PDA to PC Model 3451 for Windows XP

software included with the gauge enables the operator to collect

project data from the PDA or gauge on a personal computer

(PC), print project configuration information, and recover data

from the gauge in case of an emergency (such as the loss of the

PDA).

With the Model 3451, the operator can quickly and precisely

measure the moisture content and density of construction materials.

The gauge’s features include:

Three measurement modes (soil, asphalt, and thin layer) for

precise compaction control readings in most construction

materials:

Soil Mode: For moisture/density determinations in soil, soil-

stone materials in layers of 4 inches or greater.

Asphalt Mode: For density determinations in asphalt or

hardened concrete layers of 4 inches or greater.

Thin Layer Mode: For density determinations in asphalt layers

of less than 4 inches.

1–2

Page 19

Calibration offsets (wet density, moisture, and trench) and

special calibrations (soil and thin layer) to expand measurement

possibilities, and to enhance gauge readings on materials that

may fall outside the range of factory calibration.

Over 30 functions to facilitate all phases of testing compaction

on construction materials.

To preserve battery life, the gauge shuts down automatically

after five hours of inactivity.

The Model 3451 meets or exceeds all applicable American Society

of Testing and Materials (ASTM) standards (or corresponding

equivalent), including:

ASTM D-2950: Standard Test Method for Density of

Bituminous Concrete in Place by Nuclear Method.

ASTM D-6938: Standard Test Methods for In-Place Density

and Water Content of Soil and Soil-Aggregate by Nuclear

Methods (Shallow Depth)

NOTE

As of November 2006, ASTM D-6938 replaced ASTM

D-2922: Standard Test Methods for Density of Soil and

Soil-Aggregate in Place by Nuclear Methods (Shallow

Depth) and ASTM D-3017: Standard Test Method for

Water Content of Soil and Rock in Place by Nuclear

Methods (Shallow Depth).

Any licensing issues discussed in this manual are for the United

States. To purchase a Model 3451 in Canada, owners must obtain a

radioisotope license from the Canadian Nuclear Safety Commission

(CNSC). The owner should obtain copies of the AECB Regulations

and the Transportation of Dangerous Goods Act and Regulations

(TDG). For other countries, please consult your local regulatory

agency.

1. INTRODUCTION

Model 3451 1–3

Page 20

Owners are encouraged to require study of this manual before

allowing anyone to use the gauge. A potential hazard does exist if

improperly used. Appendices A and D, which cover radiological

safety, should be required reading for all users and potential users.

If these appendices are not completely understood, users should

seek assistance from Troxler, an appointed Troxler

representative, or others designated within the user's

organization.

Additional radiation safety information is available by attending a

Troxler Nuclear Gauge Training Course.

Before operating the Model 3451 gauge, users in European

countries must refer to Appendix G for special considerations,

additional safety warnings, and the Declaration of Conformity.

Since changes are made to local, state, and federal regulations on a

continuing basis, the owner/operator must maintain awareness of

current requirements. The responsibility for compliance ultimately

falls on the owner. An owner in the United States may also wish to

purchase and subscribe to Titles 10 and 49 of the Code of Federal

Regulations (CFR) in addition to applicable local/state regulations.

1–4

Page 21

GLOBAL POSITIONING SYSTEM ACCURACY

As described earlier, the Model 3451 is equipped with a global

positioning system (GPS) receiver that provides accurate

information on the location (latitude and longitude) of the gauge.

This information is stored with each gauge measurement. The GPS

receiver used in the Model 3451 has Wide Area Augmentation

System (WAAS) capabilities, which provides accuracy to within 3 m

(10 ft). However, the accuracy is dependent upon the user’s location

and other factors as described below.

The global positioning system (GPS) is a satellite-based navigation

system that consists of 24 satellites and a network of ground stations

that monitor and control those satellites. The satellites orbit the earth

at an altitude of approximately 11,000 miles, and constantly

transmit signal information back to earth. A GPS receiver uses this

information to determine its location.

To determine its latitude and longitude, a GPS receiver must receive

the signals from at least three satellites.

On average, the receiver used in the Model 3451 gauge is accurate

to with 15 m (approximately 50 ft) when receiving GPS data alone.

However, the WAAS capabilities can increase the accuracy to

within 3 m (10 ft), as shown in Table 1–1.

The accuracy of GPS information can be affected by a number of

atmospheric forces and other conditions. The Wide Area

Augmentation System (WAAS) corrects for these factors by placing

GPS receivers at 25 known, precisely surveyed locations, called

reference stations, across the United States. The reference stations

determined a measured distance to each satellite using the signals

received from the satellites. For each satellite, the stations compare

the measured distance to the actual range (as calculated from its

known position) to determine a differential correction for each

satellite

1. INTRODUCTION

Model 3451 1–5

Page 22

Two master stations, located on either coast, collect data from the

reference stations to create a GPS correction message. This message

is then broadcast through two geostationary satellites that are in a

fixed position over the equator. The GPS receiver applies the

correction factors contained in the correction message to increase

the accuracy of its measurements.

Note that the signals from the WAAS satellites may not be available

to gauge users in locations where trees, mountains, and other large

objects obstruct the view of the horizon. On other occasions, the

GPS receiver may not be able to access the signals from the three

satellites required to determine a position. As noted earlier, the

gauge stores location information with the results of each

measurement. The measurement display also denotes the quality of

the location fix as follows:

If WAAS information is available during a gauge measurement,

the fix quality for that measurement will be denoted as DGPS

fix.

If a GPS location is determined, but the WAAS information is

unavailable, the fix quality will be denoted as GPS fix.

If the GPS receiver cannot determine a location, the latitude and

longitude will be denoted as 0.

NOTE

The Wide Area Augmentation System (WAAS) is

currently functional only in the United States.

NOTE

If the gauge is moved a long distance between uses, the

GPS system must be allowed to initialize. In some

instances, initialization may take as long as 30 to 45

minutes from the time the gauge is powered on with the

GPS enabled. Note also that the gauge must be

positioned such that the GPS receiver can receive signals

from the GPS satellites as described above. If the GPS

does not initialize within 45 minutes, contact your

Troxler representative.

1–6

Page 23

Table 1–1. GPS Position Accuracy

Quality of

GPS Data

1. INTRODUCTION

Accuracy Fix Quality

GPS reading

with WAAS

GPS reading

without WAAS

No GPS reading N/A

Within 3 m

(10 ft)

Within 15 m

(50 ft)

DGPS fix

GPS fix

Latitude and longitude

displayed as 0.

Model 3451 1–7

Page 24

GAUGE PARTS AND ACCESSORIES

Figure 1–1 shows the gauge and its accessories.

1. The Gauge is the portable instrument containing electronic

modules, a cordless serial adapter with Bluetooth wireless

technology, a rechargeable battery pack, detectors, and the

radioactive sources.

2. The Intermec

provides the operator interface with the gauge. Included with

the PDA are a stylus, a rechargeable battery pack, a serial cable,

a dc adapter used to charge the PDA from an automobile

cigarette lighter, a universal ac adapter and ac power cord used

to charge the PDA from an ac outlet, a Quick Start Guide, and a

Pocket PC Companion CD containing Microsoft ActiveSync

software.

3. The Transport Case for the Model 3451 is a Type A package.

Always use a Type A package to ship the Model 3451.

4. The Reference Standard Block provides a measurement

standard for standard counts. It is also used during stability and

drift tests.

5. The Scraper Plate/Drill Rod Guide is used to prepare the test

site and to guide the drill rod when preparing the source rod

hole for direct transmission measurements.

6. The Drill Rod is used to drill holes for direct transmission

measurements. Do not use the gauge source rod to drill holes.

7. The Extraction Tool provides leverage to remove the drill rod

from soil materials.

8. The Model 3451 Manual of Operation and Instruction details

how to use the gauge. Both the manual and the Transportation

Guide discuss radiation safety and gauge shipping concerns.

9. The AC Charger and DC Adapter are used to charge the gauge

batteries. The ac charger accepts 110 (220 and European

optional) V ac, 50/60 Hz and supplies 12 V dc. The dc adapter

allows recharging from an automobile cigarette lighter.

10. The Data Manager PDA to PC Model 3451 for Windows XP

software includes tools for retrieving and managing project data

from the PDA or gauge. This software is provided on CD-ROM

(not shown).

700 Series Color Mobile Computer, or PDA,

1–8

Page 25

1. INTRODUCTION

MODEL 3451 GAUGE

TRANSPORT CASE

PN 110422.3451

REFERENCE STANDARD BLOCK

PN 107830

DRILL ROD

PN 100421

EXTRACTION TOOL

PN 103680.1000

SERIAL CABLE,

PN 110708

(GAUGE TO PC)

SCRAPER PLATE/

DRILL ROD GUIDE

PN 107795

Note: Images not to scale.

Figure 1–1. Model 3451 Parts and Accessories

Model 3451 1–9

Page 26

AC CHARGER

PN 110403

(FOR GAUGE)

INTERMEC 700 SERIES

MOBILE COMPUTER (PDA)

PN 110687

DC (AUTO) ADAPTER

UNIVERSAL AC ADAPTER

PN 104156

(FOR GAUGE)

PN 110691

&

AC POWER CORD

PN 110690

(FOR PDA)

DC (AUTO) ADAPTER

PN 110692

(FOR PDA)

SERIAL CABLE ASSEMBLY

PN 110693

(PDA to PC)

Note: Images not to scale.

Figure 1–1. Model 3451 Parts and Accessories (Continued)

1–10

Page 27

UNPACKING AND INSPECTION

Troxler recommends that the operator wear a dosimeter while

working with the gauge. Upon receipt of the gauge from the factory,

perform a complete inspection and inventory. If the shipping case

and/or any other part or accessory appears damaged, notify the

carrier and your Troxler Representative immediately.

Check the shipping cases for the items listed on page 1–8. In

addition, the shipping cases should contain the Gauge Warranty and

a Source Certificate.

For shipping to another location or back to the factory, save the

boxes and any packing material. For shipping instructions and

regulations, please see Appendix D.

NOTE

Charge the 3451 batteries for 2.5 hours prior to initial

use. Install the PDA battery pack and charge the PDA as

directed in the Quick Start Guide provided with the unit.

NOTE

If the PDA battery pack is completely discharged when

the gauge and accessories are unpacked, charge the PDA

for 4 hours before use. Refer to the Quick Start Guide

provided with the unit for instructions on installing and

charging the battery pack.

Lift the gauge from the transport case and inspect the outside

surface for damage. Check the lock on the source rod handle and

make sure the keys fit. Remove the lock, release the trigger, and

check the source rod operation. It should move up and down with

little effort. Return the gauge to the transport case.

1. INTRODUCTION

Model 3451 1–11

Page 28

NOTES

1–12

Page 29

CHAPTER 2

THEORY OF OPERATION

This chapter provides a brief description of the theory of operation

of the Troxler Model 3451 Enhanced RoadReader Plus. The direct

transmission and backscatter modes of operation are illustrated,

along with an explanation of the cesium-137 source,

americium-241:beryllium source, and detector geometry.

CONTENTS

Density.......................................................................................... 2–2

Moisture........................................................................................ 2–3

Thin Layer .................................................................................... 2–5

Calibration .................................................................................... 2–6

Offsets .................................................................................... 2–6

2. THEORY OF OPERATION

Model 3451 2–1

Page 30

DENSITY

The Troxler Model 3451 Enhanced RoadReader Plus uses two

modes of operation: direct transmission mode (with the source rod

extended into the material to be measured) and backscatter mode

(with the source rod in the backscatter position). Source rod

positions are described in Chapter 3.

Direct transmission mode is used on materials with layers four

inches thick or more. This mode is most commonly used on soils,

but can also be used to measure asphalt and concrete. In the direct

transmission position, the source rod extends through the base of the

gauge into a pre-drilled hole to a desired depth. Photons from the

cesium-137 (Cs-137) source in the source rod pass through the test

material. While passing through the test material, the photons

collide with electrons and lose energy. A high material density

increases the probability of these photon collisions. This decreases

the number of photons that reach the Geiger-Mueller (G-M)

detectors in the base of the gauge. Thus, the number of photons

reaching the detectors is inversely related to the density of the

material: the higher the density of the material, the fewer the

photons that reach the detectors. Using the gauge calibration, the

gauge software converts the G-M detector counts to a density value.

Backscatter mode is used on concrete, asphalt, and soil layers

approximately four inches thick. In the backscatter position, the

source rod is lowered to the first notch below the SAFE (shielded)

position. This places the source and the detectors in the same plane.

Shielding between the source and detectors greatly reduces the

number of photons reaching the detectors in a direct path from the

source. Thus, the photons from the Cs-137 source must travel into

the test material and scatter (or reflect) at least once to reach the

G-M detectors. The detectors in the gauge base count these scattered

photons. For thin layer readings, the gauge uses two sets of G-M

detectors. Refer to the Thin Layer section on page 2–5.

2–2

Page 31

MOISTURE

The Model 3451 uses the principle of neutron thermalization to

monitor the moisture content of a material. The gauge includes an

americium-241:beryllium (Am-241:Be) source that is fixed in the

gauge’s base. Fast neutrons emitted by the Am-241:Be source pass

into the test material. Multiple collisions between the fast neutrons

and a similarly sized mass (such as the nuclei of hydrogen atoms)

cause the neutrons to slow to the point where further collisions with

hydrogen or other materials will not continue to reduce the neutron

energy further. These neutrons are said to have been thermalized.

The 3451 gauge contains a helium-3 detector that is sensitive only

to thermalized, or “slow,” neutrons. As a result, the moisture counts

relate directly to the amount of hydrogen in the material. Using the

gauge calibration, the gauge software converts the helium-3 detector

counts to a moisture content. (Note that the helium-3 detector is in

the same plane as the Am-241:Be source. Therefore, moisture

measurement is similar to a density measurement taken in

backscatter mode, as described earlier in this chapter.)

The depth of measurement is defined in terms of a maximum depth

beneath the surface of the material being measured. Of the neutrons

counted by the gauge, 98 percent will penetrate no deeper than the

depth of measurement. The depth of measurement is a function of

moisture content. The following equations can be used to determine

the approximate depth of measurement.

Depth (inches) = 11 – (0.17

Depth (mm) = 280 - (0.27

The normalized curve set shown in Figure 2–1 illustrates the effects

of moisture content on the depth of measurement.

M), where: M = moisture in pcf

or

M), where: M = moisture in kg/m3

2. THEORY OF OPERATION

Model 3451 2–3

Page 32

Figure 2–1. Effect of Moisture on Depth of Measurement

2–4

Page 33

THIN LAYER

The Model 3451 contains two sets of G-M tubes for photon

detection. The set closest to the source rod is referred to as System 1,

while the set farthest from the source rod is System 2. When the

source rod is in the backscatter position, the source and the detectors

are on approximately the same plane.

Both System 1 and System 2 tube sets will primarily detect photons

that have been scattered by the material as described in the Density

theory of operation (see page 2–2). However, due to its greater

distance from the source, System 2 is more likely to detect scattered

photons from deeper in the material than is System 1. The density

measured by each system, the factory calibration, and mathematical

modeling allow the 3451 gauge to determine the density of the top

layer of material.

2. THEORY OF OPERATION

Model 3451 2–5

Page 34

CALIBRATION

Troxler calibrates the 3451 gauge at the factory. The calibration

standards used represent “average” soil, covering a density range of

1100 to 2700 kg/m

Troxler also calibrates the Model 3451 for thin layer measurements.

The thin layer factory calibration covers a thickness range of 2.5 to

10 cm (1.0 to 4.0 in.).

OFFSETS

The factory calibration provides accurate results for the majority of

materials found in the field. If the gauge is to be used to test

materials not covered by the factory calibration, the readings can be

adjusted using either an offset as described below or a special

calibration as described in Chapter 6.

Perform a wet density offset if the test material is outside the density

range for average soil or if the material composition varies from

average soil/asphalt. Perform a moisture offset if the test material

contains hydrogenous materials other than water or materials that

absorb neutrons. Materials such as cement, gypsum, coal, mica, and

lime are all hydrogenous. Material such as boron and cadmium are

neutron absorbers.

Vertical structures scatter neutrons and gamma photons back to the

gauge. This could result in inaccurate moisture and density readings.

To take readings in a trench or within 0.6 m (2 ft) of a large vertical

structure, perform a trench offset.

If the composition of the test material differs greatly from average

soil and an offset does not provide adequate measurement accuracy,

then the gauge may need to be calibrated specifically for that

material. A special calibration allows the operator to calculate new

calibration constants. For more information on the Special

Calibration feature, see Chapter 6.

3

(70 to 170 pcf).

2–6

Page 35

CHAPTER 3

GETTING STARTED

This chapter provides details on getting started with the Troxler

Model 3451 Enhanced RoadReader Plus. It provides instructions for

turning the gauge and PDA on, and explains how to set up and

manage project files and how to check the gauge status.

CONTENTS

Model 3451 Illustrations............................................................... 3–3

Source Rod Positions.................................................................... 3–5

Before Using the Gauge and PDA................................................ 3–6

Turning the Gauge and PDA On................................................... 3–8

Troxler Menu.............................................................................. 3–10

Notes .................................................................................... 3–10

Calculator............................................................................. 3–11

System.................................................................................. 3–12

PDA ActiveSync Configuration........................................... 3–13

Bluetooth Communication Configuration............................ 3–14

RoadReader Plus Main Menu..................................................... 3–16

Project Files................................................................................ 3–19

New Project.......................................................................... 3–19

View Project......................................................................... 3–21

Erase Project......................................................................... 3–22

Enable Project ...................................................................... 3–23

Disable Project ..................................................................... 3–23

3. GETTING STARTED

Model 3451 3–1

Page 36

CONTENTS (Continued)

Status...........................................................................................3–24

View Status...........................................................................3–25

View Constants.....................................................................3–25

Gauge Temperature...............................................................3–26

Battery Status........................................................................3–26

Source Decay........................................................................3–27

GPS Location........................................................................3–28

3–2

Page 37

MODEL 3451 ILLUSTRATIONS

Figure 3–1 illustrates various components of the Model 3451

Enhanced RoadReader Plus referred to throughout this chapter and

the remainder of the manual. Figure 3–2 is a detailed view of the

gauge back panel.

DEPTH

INDICATOR

TRIGGER

STRIP

INDEX ROD

Figure 3–1. Model 3451 Illustration

SOURCE

ROD

3. GETTING STARTED

BACK PANEL

(SEE DETAILS,

FIGURE 3–2)

Model 3451 3–3

Page 38

POWER

SWITCH

9-PIN SERIAL

PORT W/

BLUETOOTH

ADAPTER

BEEPER

CHARGER

CONNECTOR

Figure 3–2. Back Panel Details

NOTE

To adjust the volume of the gauge beeper, open or close

the beeper’s built-in shutters.

3–4

Page 39

A

SOURCE ROD POSITIONS

As shown in Figure 3–3, the source rod can be placed in the SAFE,

backscatter, or direct transmission positions. When not taking

measurements, keep the source rod in the SAFE position. When

measuring thin layer or other materials through which you cannot

drill a hole, use the backscatter position. In the direct transmission

positions, the source rod extends into a pre-drilled hole.

NOTE

The source rod should always be in the SAFE position

when the gauge is not in use.

NOTE

As shown below, the Model 3451 is available with

maximum source depths of 200 mm (8 in.) and 300 mm

(12 in.). The index rod can be incremented at either

25-mm (1-in.) or 50-mm (2-in.) intervals.

SAFE POSITION

lways use for storage

()

TRIGGER

BACKSCATTER POSITION

3. GETTING STARTED

50 mm (2 in.)

SOURCE

ROD

INDEX

ROD

TRANSMISSION

300 mm (12 in.) or

200 mm (8 in.)

DIRECT

POSITIONS

Figure 3–3. Source Rod Positions

Model 3451 3–5

Page 40

BEFORE USING THE GAUGE AND PDA

Before using the gauge and PDA for the first time:

Review the Quick Start Guide provided with the PDA, and

become familiar with the use and operation of the unit.

Install the PDA battery pack as described in the Quick Start

Guide provided with the unit.

NOTE

If the PDA battery pack is completely discharged,

charge the PDA for 4 hours before use.

NOTE

Because of the advanced features installed in the PDA,

its battery life is approximately 6 hours. Troxler

recommends charging the PDA battery pack when the

unit is not in use. As listed below, additional PDA

battery packs and a battery pack charger kit are

available from Troxler, and are recommended:

Part #

Description

110705 PDA Battery Pack, Lithium Ion, Spare

110709 PDA Battery Pack Charger Kit

Refer to the Quick Start Guide provided with the PDA

for more information on charging and/or changing the

battery pack.

CAUTION

DO NOT change the Regional Settings in the PDA. If

these settings are changed, the RoadReader Plus

software in the PDA will be unable to calculate test

results.

3–6

Page 41

If desired, follow the instructions in the Quick Start Guide

provided with the PDA to install the Microsoft ActiveSync

software included on the Pocket PC Companion CD provided

with the unit. The ActiveSync software enables the user to link

the PDA to the computer when using applications other than the

Troxler Data Manager software.

NOTE

Before installing the Troxler Data Manager PDA to PC

Model 3451 for Windows XP software, ensure that the

computer meets the system requirements listed on page

7–4.

Install the Troxler Data Manager PDA to PC Model 3451 for

Windows XP software as follows. Refer to Chapter 7 for

information on managing project data using the Data Manager

software.

Insert the Data Manager CD-ROM into the computer’s

CD-ROM drive.

From the Windows XP desktop, click on the Start button in

the taskbar.

Select R

un.

In the displayed dialog box, type d:setup (where d: is the

letter designation of the CD-ROM drive) and press the

Enter key or click on the OK button. Follow the

instructions on the screen to complete the installation.

The installation program adds a DataManager group to

rograms menu, with one program item:

the P

DataManager.

Model 3451 3–7

3. GETTING STARTED

Page 42

TURNING THE GAUGE AND PDA ON

NOTE

The gauge should be inspected each day before use to

ensure proper operation of all safety features. Refer to

page A–10 for the daily inspection procedure.

NOTE

Charge the 3451 batteries for 2.5 hours prior to initial

use. Charge the PDA as directed in the documentation

provided with the unit.

NOTE

When controlling the gauge with the PDA, the PDA

should be within 4.6 m (15 ft) of the gauge. The

operating range may be as much as 15.2 m (50 ft)

depending upon various conditions.

CAUTION

DO NOT change the Regional Settings in the PDA. If

these settings are changed, the RoadReader Plus

software in the PDA will be unable to calculate test

results.

To turn on the gauge, press the power switch located on the rear

panel of the gauge (see Figure 3–2). The internal beeper will sound

to signify that the gauge is ready for use.

Press the power switch (labeled I/O) located in the upper left corner

of the PDA keypad. The PDA powers up, then displays the Troxler

menu shown in Figure 3–4.

NOTE

If the PDA has been completely discharged, the first

time it is powered up after recharging, it will go through

a series of reboots, during which it reloads the

RoadReader Plus software and other applications.

Please be patient, as this process may take several

minutes. Do not attempt to use the PDA until it displays

the menu shown in Figure 3–4.

3–8

Page 43

NOTE

If the gauge is moved a long distance between uses, the

GPS system must be allowed to initialize. In some

instances, initialization may take as long as 30 to 45

minutes from the time the gauge is powered on with the

GPS enabled. Note also that the gauge must be

positioned such that the GPS receiver can receive signals

from the GPS satellites (see page 1–5 for more

information). If the GPS does not initialize within 45

minutes, contact your Troxler representative.

Model 3451 3–9

3. GETTING STARTED

Page 44

TROXLER MENU

Figure 3–4 shows the Troxler menu that is displayed when the

PDA is powered up. From this menu, the user can start the

RoadReader Plus software, launch the Windows Notes or

Calculator function, or display the Windows desktop. A description

of the RoadReader Plus software begins on page 3–16.

NOTES

To launch the Notes function, press the Notes button. The PDA

displays a Notes screen similar to that shown in Figure 3–5. This

function allows the user to capture information as written or typed

notes, or as audio recordings. For more information on using the

Notes function, press the Notes button in the upper left corner of

the screen and select Help from the dropdown menu.

NOTE

The Notes function described here is not related to the

project notes that can be stored with measurement data

(see Figure 4–7 on page 4–12).

Figure 3–4. Troxler Menu

3–10

Figure 3–5. Notes Screen

Page 45

CALCULATOR

To launch the Calculator function, press the Calculator button.

The PDA displays the Calculator shown in Figure 3–6. For more

information on using the Calculator, press the Calculator button

in the upper left corner and select Help from the dropdown menu.

Figure 3–6. Calculator

Model 3451 3–11

3. GETTING STARTED

Page 46

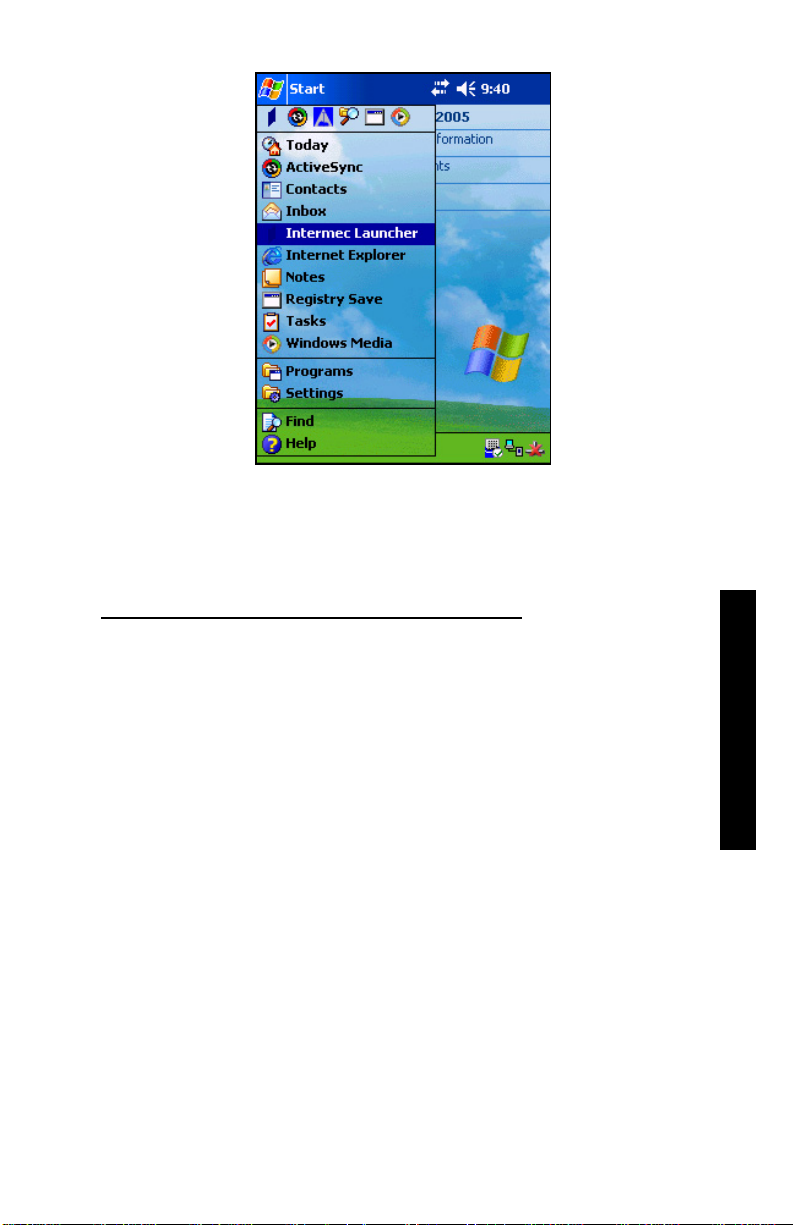

SYSTEM

To display the Windows desktop, press the Options button in the

lower right of the Troxler menu. The PDA displays the Intermec

Launcher screen shown in Figure 3–7. This screen shows the

status of the PDA battery pack. To return to the Troxler menu, press

the Back button.

To continue to the Windows desktop, press System. When

prompted for a password, leave the password field blank and press

OK. The PDA displays the Windows desktop, as shown in Figure

3–8.

To return to the Troxler menu, press the Start button in the upper

left and select Intermec Launcher from the dropdown menu, as

shown in Figure 3–9.

Figure 3–7. Intermec

Launcher Display

3–12

Figure 3–8. Windows Desktop

Page 47

Figure 3–9. Return to Troxler Menu

PDA ACTIVESYNC CONFIGURATION

The Microsoft ActiveSync software provided on the Pocket PC

Companion CD allows the user create a partnership between the

PDA and a desktop computer using the serial cable provided with

the PDA. ActiveSync must be properly configured in order to use

the Data Manager software included with the gauge.

If the PDA becomes completely discharged, verify the ActiveSync

configuration after the unit is recharged.

To check the PDA’s ActiveSync settings:

Follow the directions on page 3–12 to display the Windows

desktop.

Press the Start button in the upper left corner of the desktop

and select ActiveSync from the dropdown menu.

3. GETTING STARTED

Model 3451 3–13

Page 48

Press the Tools button in the lower left corner of the

ActiveSync display and select Options… from the menu.

The ActiveSync PC Synchronization screen is displayed.

Press the Options… button. The ActiveSync PC

Synchronization Options screen is displayed.

Ensure that the Enable PC sync using this connection

checkbox is checked, and that 115200 Default is selected from

the dropdown menu. Also ensure that the Maintain

connection radio button is selected.

Press the ok button to return to the ActiveSync PC

Synchronization screen.

Press the ok button to the ActiveSync display.

Press the X button to return to the Windows desktop.

Follow the directions on page 3–12 to return to the Troxler

menu.

BLUETOOTH COMMUNICATION CONFIGURATION

The PDA is configured at the factory to enable Bluetooth

communications with the gauge. If communications between the

PDA and gauge cannot be established, check the Bluetooth

configuration as follows:

Follow the directions on page 3–12 to display the Windows

desktop.

Press the Start button in the upper left corner of the desktop

and select Settings from the dropdown menu.

Select the Connections tab at the bottom of the Settings

display.

Press the Bluetooth icon. A Bluetooth Settings window is

displayed with the Mode tab selected.

3–14

Page 49

Ensure that the On radio button is selected.

Select the File Transfer tab at the bottom of the display.

Ensure that the Enable radio button is selected.

Select the Wireless Printing tab at the bottom of the display.

Ensure that a gauge (3451-XXXX) is displayed in the lower

Connected box. If not:

Ensure that the gauge is turned on as described on page 3–8.

Press the Device Discovery button on the PDA. The PDA

will attempt to establish communications with (or discover)

the gauge. Upon discovery, the gauge will be listed in the

upper Devices box.

Highlight the 3451-XXXX listing in the Devices box and

press the Connect button. The 3451-XXXX listing should

move to the Connected box.

Highlight 3451-XXXX listing in the Connected box and press

the Properties button.

In the Choose COM Port box, ensure that the Com 6 radio

button is selected.

Ensure that the Enable Wireless Printing box is checked.

Press the ok button to return to the Bluetooth Settings

display.

Press the ok but

ton to return to the Settings display.

Press X to return to the Windows desktop.

Follow the directions on page 3–12 to return to the Troxler

menu.

3. GETTING STARTED

Model 3451 3–15

Page 50

ROADREADER PLUS MAIN MENU

NOTE

To ensure proper communications between the PDA and

gauge, always power the gauge on before starting the

RoadReader Plus software.

To start the RoadReader Plus software, press the Troxler 3451

button on the Troxler menu (see Figure 3–4 on page 3–10). The

software displays a splash screen that includes the software version

and gauge serial number. The software then establishes Bluetooth

wireless communications between the PDA and gauge.

When communications have been established, the software checks

the leak test interval and the date of the last leak test stored in the

PDA memory (see page 5–11). If the leak test interval has been

exceeded, the software displays Warning! Leak test is due. If

this warning appears, perform a leak test (see page A–13 and update

the leak test date (see page 5–13). Press the ok button to continue.

The software then checks the date of the last gauge calibration. If

the gauge is due for calibration, the software displays Warning!

Calibration is due. If this warning appears, Troxler recommends

returning the gauge and PDA to the nearest service center (refer to

page C–Error! Bookmark not defined.) for calibration. Press the

ok button to continue.

The software then communicates with the gauge to check the status

of the gauge battery. If the PDA cannot establish communications

with the gauge, the PDA displays Error! Checking Battery

Voltage. If this error message is displayed:

Check that the gauge is powered on.

Ensure that the gauge was powered on before the RoadReader

Plus software was started.

Ensure that the PDA is within 4.6 m (15 ft) of the gauge.

Verify the PDA’s Bluetooth communications configuration as

described on page 3–14.

Verify the PDA’s ActiveSync configuration as described on

page 3–13.

3–16

Page 51

Once the PDA establishes communications with the gauge, the

software displays the status of the gauge’s nickel-metal hydride

(NiMH) batteries, as shown in Figure 3–10. This display includes

the charger status (ON or OFF), the actual battery voltage, and the

battery status (OK or LOW). Press the Done button to continue.

NOTE

If the battery voltage falls below 5.5 V, the gauge shuts

off. Recharge the NiMH batteries as described on page

C–24.

The gauge then enters a five-minute warmup period, which allows

the baseboard electronics to warm up, and the gauge to acquire GPS

data.

NOTE

If the operator presses Abort to bypass the gauge

warmup, Troxler does not guarantee the accuracy of the

GPS location data.

NOTE

To preserve battery life, the gauge shuts down

automatically after five hours of inactivity.

3. GETTING STARTED

Figure 3–10. Battery Status Display

Model 3451 3–17

Page 52

When all of the checks performed at power on are complete, the

RoadReader Plus software displays the main menu shown in Figure

3–11). From this menu, the operator can take a reading or standard

count, change the gauge settings, or access a set of gauge tools.

The main menu also displays the measurement mode (Soil, Asphalt,

or Thin Layer), count time (15 seconds, 1 minute, or 4 minutes), and

the selected project name (if any).

Before taking measurements, read this manual carefully. If you do

not completely understand the sections that cover radiation safety,

contact your company radiation safety officer (RSO) or the nearest

Troxler representative.

NOTE

Pressing the Exit button on the main menu shuts down

the RoadReader Plus software and commands the gauge

to power off.

Figure 3–11. RoadReader Plus Software Main Menu

3–18

Page 53

PROJECT FILES

The Model 3451 stores measurement results in files called projects,

which are named by the operator. The Project function allows the

operator to create a new project, view project data, erase projects,

enable a project (make an existing project active so that additional

data may be added to it), or disable the active project.

NOTE

The gauge will not take a reading unless a project has

been created and is active.

To access the Project function, press Project Access on the

main menu (see Figure 3–11). The PDA displays the Project

Menu shown in Figure 3–12.

When checked, the Disable Storage to Gauge check box

prevents the PDA from storage measurement data to the gauge for

storage following a reading. The Disable Project Notes check

box disables the Would you like to add project notes? prompt

that otherwise is displayed following a measurement.

The following sections describe the other functions available from

the Project Menu.

NOTE

The Project function cannot be used to enter target

values, offsets, or special calibrations. For information

on entering target values, see page 5–14. For

information on using offsets and special calibrations,

refer to Chapter 6.

NEW PROJECT

To create a new project, press the New button on the Project

Menu shown in Figure 3–12. The PDA displays the first page of the

setup Wizard for a new project, as shown in Figure 3–13.

3. GETTING STARTED

Model 3451 3–19

Page 54

Figure 3–12. Project Menu

The Wizard is a series of screens that provides step-by-step

instructions for setting up a new project. Using the wizard, the

operator is prompted to:

Select the measurement mode (Soil, Asphalt, or Thin Layer).

For more information, refer to page 5–5.

Select the desired measurement units. For more information on

measurement units, refer to page 5–4.

Set the count time. For more information, see page 5–6.

For thin layer mode, enter the thickness of the top layer.

Enable any previously entered target values. For more

information on target values, see page 5–14.

The Wizard displays the operator selections for review. To change

a setting, press the Back button to return to the page for that

function or press the Cancel button to start over. When all

settings are correct, press the Next button to continue.

Figure 3–13. New Project

Setup Wizard, Page 1

3–20

Page 55

The Wizard displays an information screen, then requests a project

name. Enter a descriptive name for the project using the PDA’s

Block Recognizer, Keyboard, Letter Recognizer, or Transcriber

functions. For more information on these functions, refer to the

documentation provided with the PDA.

Press the Ok button when finished. The PDA displays the

confirmation message Gauge configuration has been set

according to your specifications. Press ok to continue.

VIEW PROJECT

The Model 3451 allows the operator to view measurement data

stored in any of the defined project files. To view project data, press

the View button on the Project Menu (see Figure 3–12). The

PDA displays the Project File Selector screen shown in Figure 3–14.

To select a project, press the project file name twice. The PDA

displays the measurement data stored in the project, as shown in

Figure 3–15. The data is stored sequentially, with the earliest

measurement listed first. To scroll through the data, press the scroll

bar using the stylus. If the selected project contains no measurement

data, the display will be blank. Press the Done button to return to

the Project Menu.

NOTE

The View Project function is intended to view

measurement data. To view setup information for the

active project, use the View Status function described on

page 3–25 and the View Setup function described on

page 5–3.

3. GETTING STARTED

Model 3451 3–21

Page 56

Figure 3–14. Project

File Selector

Figure 3–15. Project

Data Display

ERASE PROJECT

The Erase function enables the operator to delete a project file and

any data stored in it. To erase a project file, press the Erase

button on the Project Menu (see Figure 3–12). The PDA displays

the Project File Selector, as shown in Figure 3–14.

To select a project file, press the project file name twice. The PDA

displays the prompt shown in Figure 3–16.

Press OK to erase the project file. The PDA displays Project

file XXX has been erased. Press ok to continue.

If the erased project was not previous active, the PDA

returns to the Project Menu.

If the erased project was previously active, the PDA

displays Project XXX disabled! Press ok to return to

the Project Menu.

Press Cancel to exit without erasing the project file. The

PDA displays The project file named XXX will not be

erased! Press ok to return to the Project Menu.

3–22

Page 57

Figure 3–16. Project Erase Prompt

ENABLE PROJECT

To enable a project file, press the Enable button on the Project

Menu (see Figure 3–12). The PDA displays the Project File

Selector, as shown in Figure 3–14.

To select a project file, press the project file name twice. The PDA

displays The project XXX has been enabled. Press ok to

return to the Project Menu.

DISABLE PROJECT

To disable the currently active project file, press the Disable

button on the Project Menu (see Figure 3–12). The PDA displays

Do you wish to disable the currently active project, XXX?

Press Yes to disable the project. The PDA displays Project

XXX disabled! Press ok to return to the Project Menu.

Press No to return to the Project Menu without disabling the

project.

3. GETTING STARTED

Model 3451 3–23

Page 58

STATUS

The RoadReader Plus software enables the operator to view

information concerning the current gauge status, calibration

constants, temperature, battery status, and source decay. To access

these functions, press the Gauge Tools button on the main menu

(see Figure 3–11). The software displays the Gauge Tools menu

shown in Figure 3–17.

Press the Gauge Status button on the Gauge Tools menu to

access the Gauge Status Menu (see Figure 3–18).

NOTE

The PDA queries the gauge during the Gauge

Temperature and Battery Status functions. Therefore,

these functions can also be used to verify that the PDA

and gauge can communicate properly.

Figure 3–17. Gauge

Tools Menu

3–24

Figure 3–18. Gauge

Status Menu

Page 59

VIEW STATUS

The gauge status information includes the software version;

measurement units; count time; measurement mode; Marshall,

Proctor, and voidless density values; measurement mode status;

percent air voids status; specific gravity; and offset status and

values. To view this information, press the View Status button

on the Gauge Status Menu. The PDA displays a View Status

screen similar to the one shown in Figure 3–19. To scroll through

the various gauge values, press the scroll bar using the stylus. Press

the Done button to return to the Gauge Status Menu.

VIEW CONSTANTS

The constants include the calibration constants, as well as the date

of the most recent calibration. To view this information, press the

View Constants button on the Gauge Status Menu. The

PDA displays the View Constants screen shown in Figure 3–20.

To scroll through the calibration constant values, press the scroll bar

using the stylus. Press the Done button to return to the Gauge

Status Menu.

3. GETTING STARTED

Figure 3–19. View

Status Display

Figure 3–20. View

Constants Display

Model 3451 3–25

Page 60

GAUGE TEMPERATURE

To view the gauge temperature, press the Gauge Temperature

button on the Gauge Status Menu (see Figure 3–18). The PDA

displays the gauge temperature both in degrees Fahrenheit and in

degrees Celsius. Press the Done button to return to the Gauge

Status Menu.

BATTERY STATUS

To view the current status of the gauge’s NiMH batteries, press the

Battery Status button on the Gauge Status Menu (see Figure

3–18). The software displays the status of the batteries, as shown in

Figure 3–10 on page 3–17. This display includes the charger status

(ON or OFF), the actual battery voltage, and the battery status (OK

or LOW). Press the Done button to return to the Gauge Status

Menu.

NOTE

If the battery voltage falls below 5.5 V, the gauge shuts

off. Recharge the NiMH batteries as described on page

C–24.

3–26

Page 61

SOURCE DECAY

The strength of radioactive material is measured by its activity, or

rate of decay. This activity decreases with time. The length of time

it takes a given amount of radioactive material to decay to half of its

original strength is referred to as the half-life. The half-life of the

Am-241:Be source is 432 years. The half-life of the Cs-137 source

is 30 years.

The Source Decay Menu (see Figure 3–21) allows the operator

to view how the decrease in the radiation intensity of the source

affects standard counts. It displays the actual standard count, the

predicted standard count, and the difference between the two counts.

The gauge calculates the predicted standard count by adjusting the

calibration standard count for source decay.

To access the Source Decay Menu, press the Source Decay

button on the Gauge Status Menu (see Figure 3–18). Press the

Done button to return to the Gauge Status Menu.

3. GETTING STARTED

Figure 3–21. Source Decay Menu

Model 3451 3–27

Page 62

GPS LOCATION

To view the gauge’s current GPS location, press the GPS

Location button on the Gauge Status Menu (see Figure 3–18).

The PDA queries the gauge to take a GPS reading, and displays the

message Collecting GPS Data. Upon completion, the PDA

displays the gauge’s GPS location as shown in Figure 3–22. Press

OK to return to the Gauge Status Menu.

Figure 3–22. GPS Location Display

3–28

Page 63

CHAPTER 4

USING THE GAUGE

This chapter explains the basic use of the Troxler Model 3451

Enhanced RoadReader Plus. Basic use includes taking the daily

standard count, preparing measurement sites, setting the

measurement mode, and taking measurements.

CONTENTS

Taking a Standard Count .............................................................. 4–2

Take a New Standard Count................................................... 4–3

View Standard Counts............................................................ 4–6

Preparing a Test Site..................................................................... 4–7

Direct Transmission Mode..................................................... 4–7

Backscatter Mode................................................................... 4–9

Taking Measurements................................................................. 4–10

Soil Mode............................................................................. 4–11

Asphalt Mode....................................................................... 4–15

Thin Layer Mode.................................................................. 4–18

Model 3451 4–1

4. USING THE GAUGE

Page 64

TAKING A STANDARD COUNT

To adjust readings for source decay (see Appendix A) and natural

background radiation, take a daily standard count. A four-minute

daily standard count helps ensure the highest measurement

accuracy.

Locate the reference standard block shipped with the gauge. Always

take standard counts using the reference standard block.

Choose a standard count site. The standard count site should be:

Dry and flat

At least 3 meters (10 ft) from any large vertical surface

At least 10 meters (33 ft) from any other radioactive source

On asphalt, concrete, or compacted soil at least 10 centimeters

(4 in.) thick

Turn the gauge and PDA on as described on page 3–8. At the

RoadReader Plus main menu (see Figure 3–11 on page 3–18), press

the Standard Count button. The PDA displays the Standard

Menu (see Figure 4–1), which shows the last standard counts for

moisture (MS) and density (DS1 and DS2).

4–2

Figure 4–1. Standard Menu

Page 65

L

TAKE A NEW STANDARD COUNT

To take a new standard count, press the Take New Count

button. The PDA displays the prompt Place the gauge on the

standard block with the source rod in the STD position

and click OK.

Place the reference standard block on the standard count site. As

shown in Figure 4–2, place the gauge on the reference standard

block, with the right side (Troxler logo side) of the gauge against

the metal butt plate. Ensure that the source rod is in the standard

(SAFE) position and is firmly seated.

4. USING THE GAUGE

META

BUTT

REFERENCE STANDARD BLOCK

PLATE

Figure 4–2. Standard Count Position

Model 3451 4–3

Page 66

Press the OK button to begin the standard count. After taking the

standard count, the gauge software displays the results, as shown in

Figure 4–3.

Troxler recommends that the operator keep a daily log of the

standard counts (see Appendix E). To verify gauge stability,

compare the daily standard count to a reliable reference as follows:

During the first four days of operation of a new or recalibrated

gauge, compare the daily standard count to the factorycalibrated values.

After the first four days of operation (or after taking four

standard counts), compare the daily standard count to the

average of the last four counts. Acceptable standard count limits

are:

1% each day for DS1 (density standard),

1.3% each day for DS2 (density standard), and

2% each day for MS (moisture standard).

If the standard count passes, record the standard counts, then

press the Yes button. The PDA displays the prompt Do you

wish to erase the last four standard counts? Press

No. The PDA displays Standard counts have been

stored. Press the ok button to return to the Standard

Menu.

If the standard count fails by less than 10% and it has been more

than a month since the last standard count, then accept the

standard count by pressing the Yes button. At the Do you

wish to erase the last four standard counts? prompt,

press the Yes button. The PDA displays Standard counts

have been stored. Previous four standard counts were

erased from memory.