Page 1

OFFSET FUNCTION

The gauge can be adjusted using an offset. The gauge applies

the offset to measurements until the offset is disabled or the

gauge is turned off.

Press 〈OFFSET〉. The gauge displays the Offset menu.

WET DENSITY OFFSET

To select wet density offset from the Offset menu, press 〈1〉. If

the function is disabled, enable it by pressing 〈YES〉. To

change the current factor, press 〈YES〉. To enter a new wet

density offset, select either + (positive) or – (negative) to

display:

-WD Offset-

Press Enter

when completed

Enter the new factor and press 〈ENTER〉.

MOISTURE OFFSET

To select moisture offset from the Offset menu, press 〈2〉. After

selection, enable the function by pressing 〈YES〉.

When prompted Do you want a new M–Offset?, press

〈YES〉. For a gauge-derived offset, value 〈1〉. For a stored

value, press 〈2〉.

For more information on offsets, see the Model 3440

Manual of Operation and Instruction.

TESTING AND MEASUREMENT

Ensure that the gauge is in the correct mode. Press 〈SHIFT〉

and 〈MODE〉.

For Soils mode, press 〈1〉. For Asphalt mode, press 〈2〉.

Ensure that the count time is correct.

Ensure that the depth is set properly. If not, see if the Depth

function is set to Automatic. To check the mode, press 〈SHIFT〉

then 〈DEPTH〉.

When the gauge is in the correct position, press 〈START〉 to

begin the test.

SOIL AND BASE COURSES

After the measurement is complete, the gauge displays:

%PR = xxxx%

DD = xxxx

WD = xxxx

M = xxx% M = xxx

To store the reading, press 〈STORE〉 (see Storage Function).

ASPHALT SURFACE

After the measurement is complete, the gauge displays:

%MA = xxxx

WD = xxxx

M= xxxx %M= xxxx

%VOIDS = xxxx

To store the reading, press 〈STORE〉 (see Storage Function).

STORAGE FUNCTION

When storing a reading, the gauge can also prompt the operator

for information required on U.S. Federal Highway

Administration (FHWA) projects. To select this option, select

Special Rdwy from the Special functions menu. The gauge

displays the current storage status. Press 〈YES〉 to toggle the

function ON or OFF. To accept the displayed status, press

〈NO/CE〉.

Assign a project number before storing readings by pressing

〈SHIFT〉 and 〈PROJECT〉. If the displayed project number is

correct, press 〈NO〉. If the project number is incorrect, press

〈YES〉 and enter a new project number (up to 12 characters).

To store readings, press 〈STORE〉. Follow the gauge prompts

to enter any additional project information.

Model 3440

Surface Moisture-Density Gauge

QUICK

REFERENCE

CARD

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Road

P.O. Box 12057

Research Triangle Park, NC 27709

Tel (919) 549-8661 Fax (919) 549-0761

PN 104337

October 1999

Edition 1.1

Page 2

GAUGE START UP

NOTE

The operator should wear a dosimeter or radiation

badge when working with the 3450 Surface MoistureDensity Gauge.

Press 〈ON〉. The display will come on and the gauge performs a

short self-test routine. Following the self-test, the gauge

displays:

READY mm/dd/yyyy

Depth: XXXX

Time: XXXXXX

Batt volts: XX

While displaying the count time, depth, and remaining battery

life, the screen alternates between displaying the current time

and date.

GAUGE SET UP

TIME FUNCTION

To view the current time for test measurements, press 〈TIME〉.

Make the desired time selection with the numeric keys and

press 〈ENTER〉.

CHANGING THE DATE AND TIME

To access the current date and time settings, press 〈SHIFT〉

then 〈SPECIAL〉. Press 〈1〉, 〈9〉, and 〈ENTER〉. Enter the

access code and press 〈ENTER〉. To select the Time/Date

function, press 〈1〉.

Current Date:

mm/dd/yyyy

Do you want to

change Date?

To change the date and time, press 〈YES〉. Both the date and

time must include leading zeros. For example, September 5,

1999 must be entered as 09051999 and 9:05 must be entered as

0905. Enter the new date and, when prompted, the new time.

CHANGING MARSHALL/PROCTOR/VOIDLESS VALUES

To select or change a Marshall, Proctor, or voidless density

value, press 〈PROCTOR/MARSHALL〉. At the Want to

change? display, press 〈YES〉. At the next display, use the

numeric keys to select the type of value you are using.

Marshall or Proctor Value

If changing either a Marshall or Proctor value, the gauge

prompts for either a Stored value (press 〈1〉) or a New value

(press 〈2〉).

If enabling a stored value, the gauge displays the values. Press

the numeric key that corresponds to the desired value.

For a new value, use the numeric keys number keys to enter the

new value, then press 〈ENTER〉. At the Do you want to

save this value for later use? prompt, press 〈YES〉. As

when enabling a stored value, select the desired value.

Density Value

Enter the voidless density value and press 〈ENTER〉.

THE STANDARD COUNT

To check the gauge operation and allow the gauge to

compensate for natural source decay, take a standard count

daily. Use the reference standard block for this operation.

Place the reference standard block on a dry, flat surface of

asphalt or compacted soil with a density of at least 100 pcf

(1600 kg/m

any building or vertical structure and 10 m (33 ft) from any

other nuclear gauge or radioactive source.

Ensure that the top surface of the reference standard block and

bottom of the gauge are clean of debris. Place the gauge

between the grooves on the reference standard block with the

source rod to the left and the right side of the gauge against the

metal butt plate on the block.

For the first display, press 〈STANDARD〉. For the second

display, press 〈YES〉.

-Standard Count Is gauge on Ref.

block & Source

rod in SAFE pos?

To begin the count, press 〈YES〉. Upon completion of the

count, the gauge will “beep.” Write the count in the standard

count log and accept the count by pressing 〈YES〉. When in the

Ready mode, the gauge is ready to take test measurements.

3

). The location should be at least 2 m (6 ft) from

-Standard Count DS=xxxx

MS=xxxx

Take new count?

SITE PREPARATION

Surface preparations are critical to gauge performance and test

result accuracy. The following procedures will help ensure

accurate test results.

SOIL AND BASE COURSES

CAUTION

Safety glasses must be worn during this procedure.

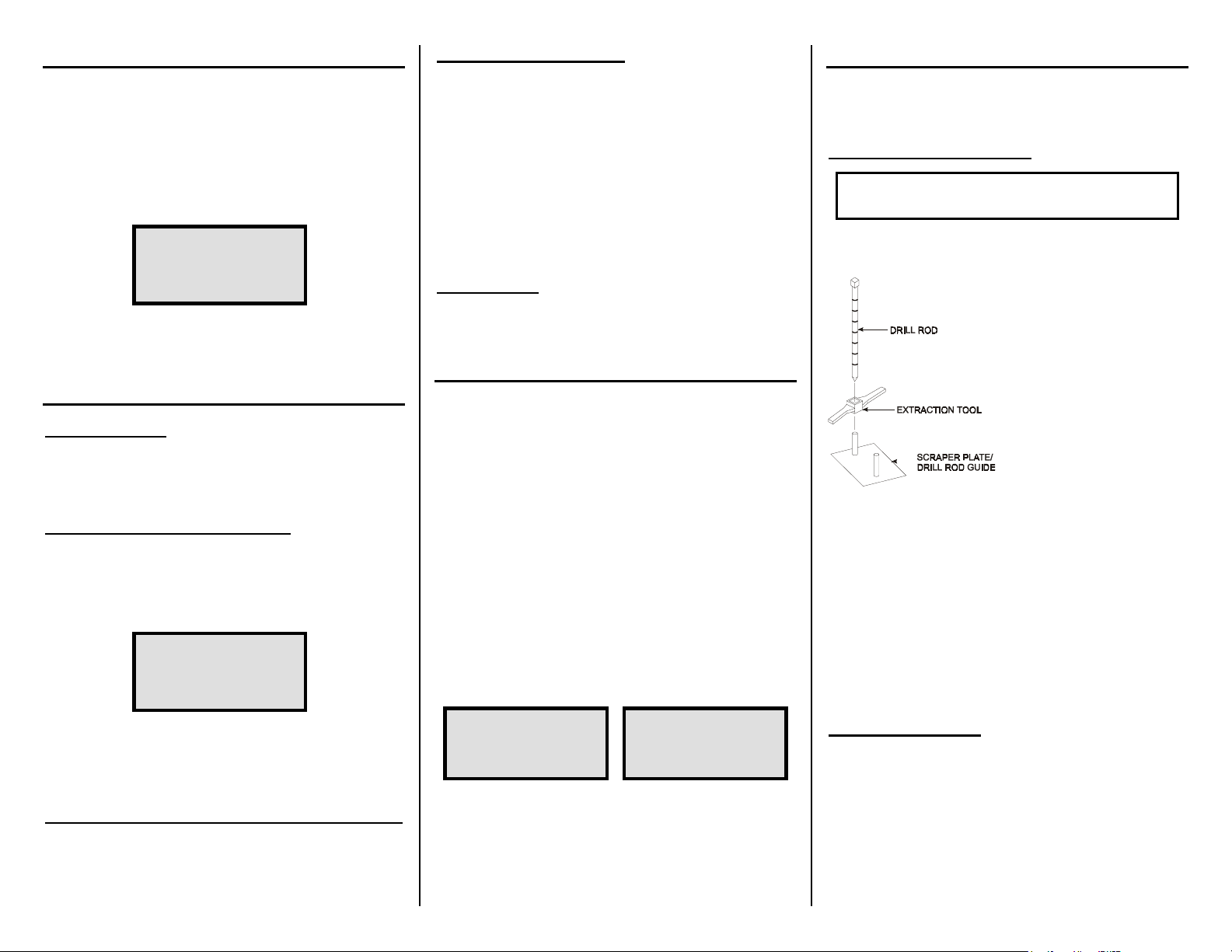

Place the scraper plate on the test surface. Smooth the area by

sliding the plate back and forth. Lift the plate from the surface

and fill any voids or

depressions. Replace the plate

and press down slightly to

further level the surface.

Put the drill rod through the

extraction tool then through

one of the guides on the

scraper plate (see figure).

Wearing safety glasses, step

on the scraper plate and

hammer the drill rod at least

50 millimeters (2 in) deeper

than the desired test depth.

The drill rod increment

markings include the additional depth. Mark the test area.

Remove the drill rod by pulling straight up on the drill rod

extraction tool. Do not loosen the drill rod by moving it from

side-to-side.

To ensure no debris falls into the hole, remove the scraper plate

by lifting it straight up.

Place the gauge on the smoothed surface and ensure the source

rod is over the drilled hole. Lower the source rod to the correct

depth and release the trigger. Gently slide the gauge to the

right, so the source rod touches the side of the hole.

ASPHALT SURFACE

Locate a smooth, level site on the asphalt. Fill the voids on

open mixes with sand or cement. The gauge base must rest on

the asphalt, not the fill material! Ensure that the gauge does

not "rock." It must remain level and steady. If the gauge rocks,

then find a more suitable test site.

Place the source rod in the backscatter position (lower the

source rod one notch) and release the trigger. Ensure that the

source rod is in the proper index rod notch and not resting

on the asphalt.

Loading...

Loading...