Page 1

Manual of Operation and Instruction

Model 3430 Plus & 3440 Plus

Surface Moisture-Density Gauge

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Rd. • P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER

Outside the USA: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

Page 2

Troxler gauges are protected by U.S. and foreign patents

Copyright © 2007

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

Fantastic is a trademark of Dow Consumer Products, Inc.

Federal Express is a registered trademark of the Federal Express

Corporation.

409 is a trademark of the Clorox Company.

Magnalube-G is a registered trademark of Carleton-Stuart

Corporation.

Microsoft, Excel, HyperTerminal, Windows, and Word are

registered trademarks of Microsoft Corporation.

WD-40 is a registered trademark of the WD-40 Company.

PN 110890

February 2007

Edition 1.0

ii

Page 3

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Fax: 817.275.8562

To locate an independent, Troxler-authorized service

center near you, call 1.877.TROXLER (1.877.876.9537).

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr. Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

NOTE

Model 3430 Plus & 3440 Plus iii

Page 4

HOW TO USE THIS MANUAL

Congratulations on the purchase of a Troxler Model 3430 Plus or

3440 Plus Surface Moisture-Density Gauge. Troxler continues the

proven technology of its 3400 Series surface moisture-density

gauges with the Troxler Model 3430 Plus and 3440 Plus.

The Model 3430 Plus & 3440 Plus Manual of Operation and

Instruction contains information on safely using this gauge. Also

included in this manual are safety warnings, gauge setup,

troubleshooting, and general maintenance.

NOTE

Before operating the gauge, read this manual carefully.

If you do not completely understand the sections that

cover radiation safety, contact your company radiation

safety officer (RSO) or the nearest Troxler

representative.

iv

Page 5

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, symbols and special formatting are used to

reveal the purpose of the text as follows:

WARNING

Indicates conditions or procedures that, if not

followed correctly, may cause personal injury.

CAUTION

Indicates conditions or procedures that, if not followed

correctly, may cause equipment damage.

NOTE

Indicates important information that must be read to

ensure proper operation.

〈KEY〉 Angle brackets and a different typestyle indicate a

key or character (number or letter) to press on the

gauge keypad. For example, “Press 〈START〉”

means to press the key labeled START.

DISPLAY A different typestyle is used in text to indicate

information or messages displayed on the gauge.

DISPLAY - Typestyle

and shading used to

simulate the gauge

display

♦ Diamonds indicate a list of things needed (such as

equipment) or things to know.

Check marks indicate the performance of an action.

With lists of check marks, follow the instructions in

the order of the check marks.

Triangles indicate that more than one option is

available. Carefully select the option that applies.

Model 3430 Plus & 3440 Plus v

Page 6

NOTES

vi

Page 7

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION

Introduction................................................................................... 1–2

Gauge Parts and Accessories........................................................1–5

Unpacking and Inspection ............................................................ 1–7

CHAPTER 2. THEORY OF OPERATION

Density..........................................................................................2–2

Moisture........................................................................................ 2–3

Calibration .................................................................................... 2–5

CHAPTER 3. GETTING STARTED

Gauge Illustration ......................................................................... 3–2

Control Panel................................................................................ 3–3

Source Rod Positions.................................................................... 3–5

Daily Inspection............................................................................ 3–6

Turning the Gauge On .................................................................. 3–7

Setup............................................................................................. 3–9

CHAPTER 4. USING THE GAUGE

Taking a Standard Count .............................................................. 4–2

Preparing a Test Site..................................................................... 4–7

Taking Measurements................................................................. 4–10

Recall.......................................................................................... 4–17

CHAPTER 5. SETUP MENU

Setup Menu................................................................................... 5–3

Count Time................................................................................... 5–4

Set Units........................................................................................ 5–4

Depth Mode.................................................................................. 5–4

Stat Test........................................................................................ 5–5

Drift Test....................................................................................... 5–7

Nomograph................................................................................. 5–10

Precision ..................................................................................... 5–15

Options........................................................................................ 5–17

Battery Status.............................................................................. 5–18

Percent Air Voids (Soil Mode)................................................... 5–19

Model 3430 Plus & 3440 Plus vii

Page 8

TABLE OF CONTENTS (Continued)

CHAPTER 6. TARGET MENU

Target Menu..................................................................................6–2

Target Values ................................................................................ 6–3

CHAPTER 7. CALIBRATION OFFSETS

Offset Menu...................................................................................7–2

Density Offset................................................................................ 7–3

Moisture Offset..............................................................................7–4

Trench Offset.................................................................................7–8

CHAPTER 8. PROJECT DATA

Project Menu .................................................................................8–2

Select.............................................................................................8–3

View ..............................................................................................8–4

Create a Project ............................................................................. 8–5

Erase Projects................................................................................8–6

Output Project................................................................................8–7

Set Output Destination ................................................................8–10

Deactivate....................................................................................8–11

Auto-Store................................................................................... 8–12

Manual Store ...............................................................................8–14

CHAPTER 9. EXTENDED MENU

Extended Menu..............................................................................9–2

Clock/Calendar..............................................................................9–3

User ID..........................................................................................9–3

Customer Name.............................................................................9–3

Language....................................................................................... 9–4

Source Decay.................................................................................9–5

Erase Standard Counts...................................................................9–6

Low Battery Warning....................................................................9–7

Software Reset...............................................................................9–8

Test Menu......................................................................................9–9

APPENDIX A. RADIATION THEORY AND SAFETY

Radiation Theory..........................................................................A–2

Radiation Safety...........................................................................A–5

Regulatory Requirements...........................................................A–14

Gauge Use Precautions...............................................................A–17

Radiation Profile.........................................................................A–18

viii

Page 9

TABLE OF CONTENTS (Continued)

APPENDIX B. TRANSPORTATION AND SHIPPING

U.S. Shipping Requirements.........................................................B–2

Canadian Shipping Requirements.................................................B–4

APPENDIX C. TROUBLESHOOTING AND SERVICE

Troubleshooting............................................................................C–2

Display Contrast ...........................................................................C–9

Batteries......................................................................................C–10

Mechanical Maintenance............................................................C–15

Replacement Parts ......................................................................C–18

Returning the Gauge for Service ................................................C–30

APPENDIX D. STANDARD COUNT LOG

APPENDIX E. UNIT CONVERSION

Measurement Units.......................................................................E–2

Radiological Units ........................................................................E–2

APPENDIX F. GAUGE SPECIFICATIONS

Measurement Specifications......................................................... F–2

Radiological Specifications .......................................................... F–4

Electrical Specifications ...............................................................F–5

Mechanical Specifications............................................................F–7

APPENDIX G. SPECIAL EUROPEAN CONSIDERATIONS

Declaration of Conformity........................................................... G–2

Safety Warnings........................................................................... G–3

APPENDIX H. PRINTING (UPLOADING) PROJECT DATA

Windows Hyperterminal.............................................................. H–2

Viewing Project Data................................................................... H–5

APPENDIX I. GLOBAL POSITIONING SYSTEM (GPS)

GPS Accuracy................................................................................I–2

INDEX

WARRANTY

Model 3430 Plus & 3440 Plus ix

Page 10

LIST OF FIGURES

Figure

1–1 Gauge Parts and Accessories.....................................1–5

2–1 Effect of Moisture on Depth of Measurement...........2–4

3–1 Gauge Illustration ......................................................3–2

3–2 Control Panel .............................................................3–3

3–3 Source Rod Positions.................................................3–5

4–1 Standard Count Position ............................................4–3

4–2 Drill Rod Assembly...................................................4–8

4–3 Marking the Test Area...............................................4–8

8–1 Spreadsheet Column Definitions...............................8–9

A–1 Diagram of an Atom.................................................A–2

A–2 Effect of Distance on Exposure ................................A–7

A–3 Cleaning the Tungsten Sliding Block.....................A–12

A–4 Gauge and Transport Case......................................A–18

C–1 Adjusting the Display Contrast.................................C–9

C–2 NiMH Battery Pack and AA Batteries....................C–11

C–3 Final Assembly, Part Numbers 110795_XXXX

(3430 Plus) and 110800_XXXX (3440 Plus).........C–19

C–4 Base Assembly, Part Number 110015_XXXX.......C–21

C–5 Scaler Assembly, Part Numbers 110791

(3430 Plus) and 110876 (3440 Plus).......................C–23

C–6 Baseboard Assembly, Part Numbers 110790

(3430 Plus) and 110877 (3440 Plus).......................C–26

Title Page

x

Page 11

LIST OF TABLES

Table

Title Page

3–1 Keypad Functions......................................................3–4

A–1 Radiation Profile for Gauge ................................... A–19

C–1 Error Messages..........................................................C–6

C–2 Typical Battery Operating Life ...............................C–11

I–1 GPS Position Accuracy..............................................I–4

Model 3430 Plus & 3440 Plus xi

Page 12

NOTES

xii

Page 13

ATTENTION

MODEL 3430 PLUS OR 3440 PLUS

GAUGE OWNER

This unit contains functions that require an ACCESS CODE.

This code must be entered before these functions may be used.

For more information on using the access code, refer to

Chapter 9.

The ACCESS CODE for this gauge is:

4708

This page should be removed if the access code is not to be

distributed to other parties or users of this gauge.

Model 3430 Plus & 3440 Plus xiii

Page 14

NOTES

xiv

Page 15

CHAPTER 1

INTRODUCTION

This chapter provides a brief overview of the Troxler Model 3430

Plus and 3440 Plus Surface Moisture-Density Gauges, and includes

a list of the gauge parts and accessories, as well as instructions for

unpacking and inspecting the gauge.

CONTENTS

Introduction................................................................................... 1–2

Gauge Parts and Accessories........................................................ 1–5

Unpacking and Inspection ............................................................ 1–7

1. INTRODUCTION

Model 3430 Plus & 3440 Plus 1–1

Page 16

INTRODUCTION

Since 1958, Troxler has been the worldwide leader in precision

quality control and measurement equipment for the highway and

construction industry. Troxler’s Model 3430 and 3440 Surface

Moisture-Density Gauges have become the industry standard for

measuring the moisture content and density of construction

materials. With the Model 3430 Plus and 3440 Plus gauges, Troxler

has added a number of new features to the proven technology of the

company’s earlier products to provide increased performance,

flexibility, ease of use, and operator safety.

Using the Model 3430 Plus and 3440 Plus gauges, the operator can

quickly and precisely measure the moisture content and density of

construction materials. Both gauges feature:

♦ Two measurement modes (Soil and Asphalt) for precise

compaction control readings in most construction materials:

Soil Mode: For moisture/density determinations in soil and soil-

stone materials in layers of 4 inches or greater.

Asphalt Mode: For density determinations in asphalt or

hardened concrete layers of 4 inches or greater.

♦ A Nomograph function for density determinations in asphalt

layers of less than 4 inches.

♦ Calibration offsets (density, moisture, and trench) to expand

measurement possibilities, and to enhance gauge readings on

materials that may fall outside the range of factory calibration.

♦ Over 30 functions to facilitate all phases of testing compaction

on construction materials.

♦ A backlit liquid crystal display (LCD) to help the operator read

the display during night construction.

♦ Easy-to-use keypad and user-friendly menus to reduce training

time to increase productivity.

♦ An internally mounted beeper, which emits a short tone in

response to a valid keystroke on the keypad. The beeper sounds

a longer tone if the operator presses an invalid key, if the gauge

displays an error message, or to signal the conclusion of a

measurement.

1–2

Page 17

♦ A serial port used to connect the gauge to an RS-232 device,

such as a computer or printer.

In addition to the items listed above, the Model 3440 Plus gauge

includes the following features:

♦ A backlit keypad for greater ease of use in low-light conditions.

♦ A remote keypad, including a 〈START〉 and 〈ESC〉 key, at the

top of its source rod housing. The remote keypad reduces the

amount of bending and stooping the operator must do while

operating the gauge.

♦ A USB port, which can be used to output data to a USB printer

or flash drive. A list of compatible USB devices is available at:

www.troxlerlabs.com/PRODUCTS/PRODLIT/otherlit.shtml

.

♦ In addition to its internal beeper, a louder, external beeper is

included on the Model 3440 Plus. The external beeper performs

the same functions as the internal one, and can be enabled or

disabled as desired by the operator.

The Model 3440 Plus can also be equipped with an optional global

positioning system (GPS) receiver. The GPS receiver enables the

gauge to store precise GPS coordinates, along with the standard date

and time stamp, for each measurement. For more information on the

GPS option, refer to Appendix I.

The Model 3430 Plus and 3440 Plus gauges meet or exceed all

applicable American Society of Testing and Materials (ASTM)

standards (or corresponding equivalent), including:

♦ ASTM D-2950: Standard Test Method for Density of

Bituminous Concrete in Place by Nuclear Method.

♦ ASTM D-6938-06: Standard Test Methods for In-Place Density

and Water Content of Soil and Soil-Aggregate by Nuclear

Methods (Shallow Depth)

NOTE

As of November 2006, ASTM D-6938-06 replaces ASTM

D-2922: Standard Test Methods for Density of Soil and

Soil-Aggregate in Place by Nuclear Methods (Shallow

Depth) and ASTM D-3017: Standard Test Method for

Water Content of Soil and Rock in Place by Nuclear

Methods (Shallow Depth).

1. INTRODUCTION

Model 3430 Plus & 3440 Plus 1–3

Page 18

Any licensing issues discussed in this manual are for the United

States. To purchase a Model 3430 Plus or 3440 Plus in Canada,

owners must obtain a radioisotope license from the Canadian

Nuclear Safety Commission (CNSC). The owner should obtain

copies of the CNSC Regulations and the Transportation of

Dangerous Goods Act and Regulations (TDG). For other countries,

please consult your local regulatory agency.

Owners are encouraged to require study of this manual before

allowing anyone to use the gauge. A potential hazard does exist if

improperly used. Appendices A and B, which cover radiological

safety and transportation requirements, should be required reading

for all users and potential users. If these appendices are not

completely understood, users should seek assistance from

Troxler, an appointed Troxler representative, or others

designated within the user's organization.

Additional radiation safety information is available by attending a

Troxler Nuclear Gauge Safety Training Course. For pricing and

availability of these courses, visit the Troxler website at

www.troxlerlabs.com/TRAINING/training.shtml

Troxler representative.

Before operating the gauge, users in European countries must refer

to Appendix G for special considerations, additional safety

warnings, and the Declaration of Conformity.

Since changes are made to local, state, and federal regulations on a

continuing basis, the owner/operator must maintain awareness of

current requirements. The responsibility for compliance ultimately

falls on the owner. An owner in the United States may also wish to

purchase and subscribe to Titles 10 and 49 of the Code of Federal

Regulations (CFR) in addition to applicable local/state regulations.

or contact your

1–4

Page 19

GAUGE PARTS AND ACCESSORIES

1. INTRODUCTION

Figure 1–1. Gauge Parts and Accessories

Model 3430 Plus & 3440 Plus 1–5

Page 20

1. The Gauge is the portable instrument containing all electronic

modules, the rechargeable battery pack, detectors, and the

radioactive sources.

2. The Reference Standard Block provides a measurement

standard for standard counts. It is also used during stability and

drift tests.

3. The Drill Rod is used to drill holes for direct transmission

measurements. Do not use the source rod of the gauge to drill

holes.

4. The Scraper Plate/Drill Rod Guide is used to prepare the test

site and to guide the drill rod when preparing the source rod

hole for direct transmission measurements.

5. The Extraction Tool provides leverage to remove the drill rod

from soil materials.

6. The AC Charger and DC Adapter are used to charge the

gauge batteries. The ac charger accepts 90 – 220 V ac, 50/60 Hz

and supplies 12 V dc. The dc adapter allows recharging from an

automobile cigarette lighter.

7. The Transport Case provided with the gauge has been

approved as a Type A package. Always use this transport case

when transporting or shipping the gauge.

8. The Manual details how to use the gauge. Both the manual and

the Transportation Guide discuss radiation safety and gauge

shipping concerns.

9. A Printer (optional, not shown) connects to the gauge for

printing data.

10. A Printer Cable (optional, not shown) is used to connect the

gauge to a serial printer or computer.

1–6

Page 21

UNPACKING AND INSPECTION

Troxler recommends that the operator wear a dosimeter while

working with the gauge. Upon receipt of the gauge from the factory,

perform a complete inspection and inventory. If the shipping case

and/or any other part or accessory appears damaged, notify the

carrier and your Troxler Representative immediately.

For shipping to another location or back to the factory, save the box

and any packing material. For shipping instructions and regulations,

please see Appendix B.

Check the shipping case for the following:

♦ Gauge

♦ Reference Standard Block

♦ Drill Rod

♦ Scraper Plate/Drill Rod Guide

♦ Extraction Tool

♦ AC Charger

♦ DC Adapter (for a vehicle cigarette lighter)

♦ Manual of Operation and Instruction

♦ Gauge Warranty

♦ Source Certificate

♦ Transportation Guide (This guide refers to U.S. standards. All

other countries please refer to local regulations. In the absence

of local regulations, please use this guide as a reference only)

1. INTRODUCTION

WARNING

The source rod should always be in the SAFE

position when the gauge is not in use.

NOTE

Charge the batteries for four hours prior to initial use.

Model 3430 Plus & 3440 Plus 1–7

Page 22

Lift the gauge from the transport case and inspect the outside

surface for damage. Check the lock on the source rod handle and

make sure the keys fit. Remove the lock, release the trigger, and

check the source rod operation. It should move up and down with

little effort. Return the gauge to the transport case.

1–8

Page 23

CHAPTER 2

THEORY OF OPERATION

This chapter provides a brief description of the theory of operation

of the Troxler Model 3430 Plus and 3440 Plus Surface MoistureDensity Gauges. The direct transmission and backscatter modes of

operation are illustrated, along with an explanation of the

cesium-137 source, americium-241:beryllium source, and detector

geometry.

CONTENTS

Density.......................................................................................... 2–2

Moisture........................................................................................ 2–3

Calibration .................................................................................... 2–5

Offsets .................................................................................... 2–5

2. OPERATION THEORY

Model 3430 Plus & 3440 Plus 2–1

Page 24

DENSITY

The Troxler Model 3430 Plus and 3440 Plus Surface MoistureDensity Gauges use two modes of operation: direct transmission

mode (with the source rod extended into the material to be

measured) and backscatter mode (with the source rod in the

backscatter position, just above the surface of the material). Source

rod positions are described in Chapter 3.

WARNING

The source rod should always be in the SAFE

position when the gauge is not in use.

In the direct transmission position, the source rod extends through

the base of the gauge into a pre-drilled hole to a desired depth.

Photons from the cesium-137 (Cs-137) source in the source rod pass

through the test material. While passing through the test material,

the photons collide with electrons and lose energy. A high material

density increases the probability of these photon collisions. This

decreases the number of photons that reach the Geiger-Mueller

(G-M) detectors in the base of the gauge. Thus, the number of

photons reaching the detectors is inversely related to the density of

the material: the higher the density of the material, the fewer the

photons that reach the detectors. Using the gauge calibration, the

gauge software converts the G-M detector counts to a density value.

In the backscatter position, the source rod is lowered to the first

notch below the SAFE (shielded) position. This places the source

and the detectors in the same plane, with the source just above the

surface of the material. Shielding between the source and detectors

greatly reduces the number of photons reaching the detectors in a

direct path from the source. Thus, the photons from the Cs-137

source must travel into the test material and scatter (or reflect) at

least once to reach the G-M detectors. The detectors in the gauge

base count these scattered photons.

2–2

Page 25

MOISTURE

The gauge uses the principle of neutron thermalization to monitor

the moisture content of a material. The gauge includes an

americium-241:beryllium (Am-241:Be) source that is fixed in the

gauge’s base. Fast neutrons emitted by the Am-241:Be source pass

into the test material. Multiple collisions between the fast neutrons

and a similarly sized mass (such as the nuclei of hydrogen atoms)

cause the neutrons to slow to the point where further collisions with

hydrogen or other materials will not continue to reduce the neutron

energy further. These neutrons are said to have been thermalized.

The gauge contains a helium-3 detector that is sensitive only to

thermalized, or “slow,” neutrons. As a result, the moisture counts

relate directly to the amount of hydrogen in the material. Using the

gauge calibration, the gauge software converts the helium-3 detector

counts to a moisture content. (Note that the helium-3 detector is in

the same plane as the Am-241:Be source. Therefore, moisture

measurement is similar to a density measurement taken in

backscatter mode, as described earlier in this chapter.)

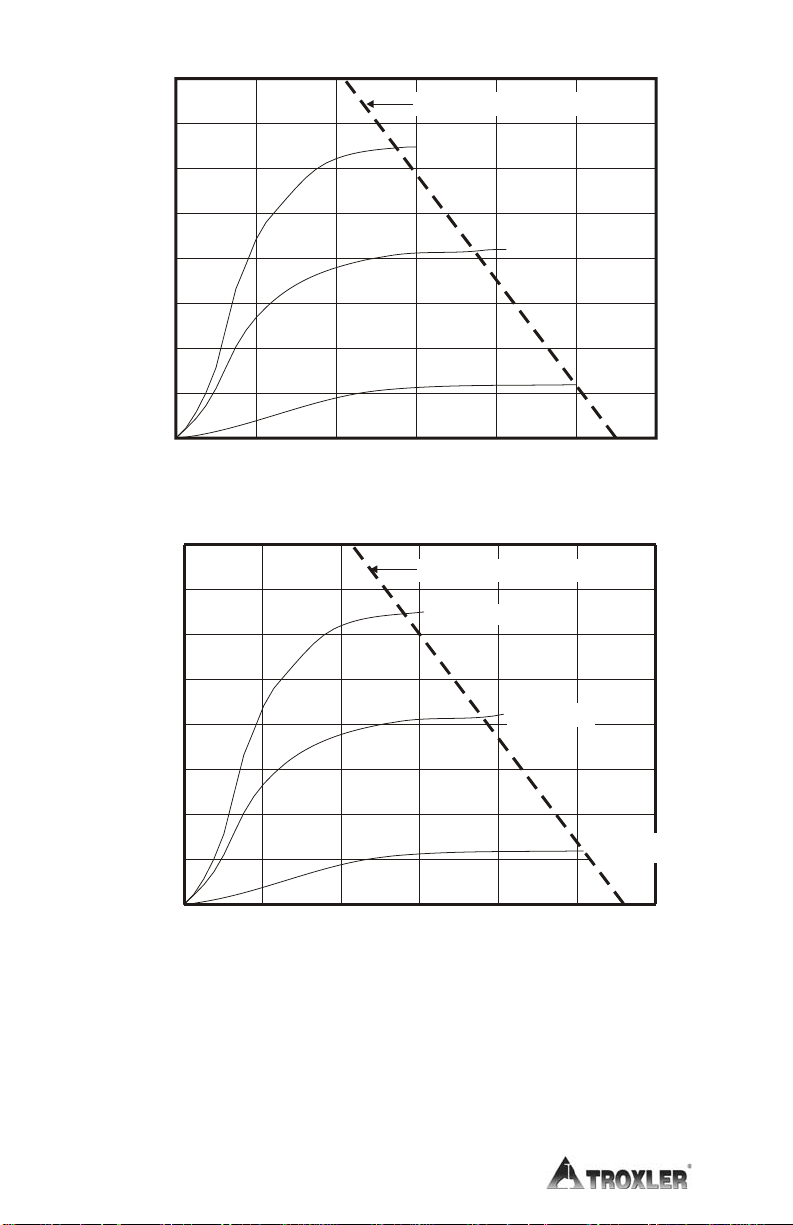

The depth of measurement is defined in terms of a maximum depth

beneath the surface of the material being measured. Of the neutrons

counted by the gauge, 98 percent will penetrate no deeper than the

depth of measurement. The depth of measurement is a function of

moisture content. The following equations can be used to determine

the approximate depth of measurement.

Depth (inches) = 11 – (0.17

Depth (mm) = 280 – (0.27

The normalized curve set shown in Figure 2–1 illustrates the effects

of moisture content on the depth of measurement.

×

M), where: M = moisture in pcf

or

×

M), where: M = moisture in kg/m3

2. OPERATION THEORY

Model 3430 Plus & 3440 Plus 2–3

Page 26

40

Depth = 11 - (0.17 X M)

35

30

25

E

32.3 pcf

S

20.8 pcf

3

336 kg/m

5.95 pcf

12

3

96 kg/m

Gauge Measured Moisture Content (pcf)

3

20

15

10

5

0

0

)

640

560

480

400

320

240

160

80

Gauge Measured Moisture Content (kg/m

0

0 50 100 150 200 250 300

24

6810

Depth (in)

Depth = 280 - (0.27 X M)

521 kg/m

Depth (mm)

The dotted lines indicate the maximum depth of gauge

measurement at a given soil moisture content.

Figure 2–1. Effect of Moisture on Depth of Measurement

3

2–4

Page 27

CALIBRATION

Troxler calibrates the gauge at the factory and recommends that it

always be calibrated by an authorized Troxler service center. For a

list of Troxler and authorized Troxler service centers, refer to page

iii of this manual or visit the Troxler website at

www.troxlerlabs.com/SERVICES/services.shtml

The operating range of the gauge is from 1100 to 2700 kg/m

(approximately 70 to 170 pcf).

OFFSETS

The factory calibration provides accurate results for the majority of

materials encountered in construction. If the gauge is to be used to

test materials not covered by the factory calibration, the readings

can be adjusted using an offset.

Perform a density offset if the test material is outside the density

range for average soil or if the material composition varies from

average soil/asphalt. Perform a moisture offset if the test material

contains hydrogenous materials (other than water) or materials that

absorb neutrons. Materials such as cement, gypsum, coal, mica, and

lime all contain chemically bound hydrogen that will cause the

gauge to display a moisture content that is higher than actual.

Material such as boron and cadmium are neutron absorbers and will

cause the gauge to display a moisture count that is lower than actual.

Vertical structures scatter neutrons and gamma photons back to the

gauge. This could result in inaccurate moisture and density readings.

To take readings in a trench or within 0.6 m (2 ft) of a large vertical

structure, perform a trench offset.

.

3

2. OPERATION THEORY

Model 3430 Plus & 3440 Plus 2–5

Page 28

NOTES

2–6

Page 29

CHAPTER 3

GETTING STARTED

This chapter provides details on getting started with the Model 3430

Plus and 3440 Plus Surface Moisture-Density Gauges. It describes

the gauge keypad, and provides instructions for conducting daily

gauge inspections, turning the gauge on, and setting up the gauge.

CONTENTS

Gauge Illustration ......................................................................... 3–2

Control Panel................................................................................ 3–3

Source Rod Positions.................................................................... 3–5

Daily Inspection............................................................................ 3–6

Turning the Gauge On .................................................................. 3–7

Setup............................................................................................. 3–9

Setup Menu ............................................................................ 3–9

Extended Menu .................................................................... 3–11

Measurement Mode.............................................................. 3–15

Project Function ................................................................... 3–16

Display Backlight................................................................. 3–16

3. GETTING STARTED

Model 3430 Plus & 3440 Plus 3–1

Page 30

GAUGE ILLUSTRATION

Figure 3–1 illustrates various components of the gauge referred to

throughout this chapter and the remainder of the manual.

3–2

Figure 3–1. Gauge Illustration

Page 31

CONTROL PANEL

The gauge control panel (see Figure 3–2) contains the power switch,

display, USB port (only on the Model 3440 Plus), battery charging

indicator, charger connector, RS-232 port, and keypad.

The keypad allows the operator to access the gauge software.

Troxler designed the keypad for ease of use, with large keys and an

anti-glare coating. Pressing a function key activates the function

only when the Ready screen is displayed. Table 3–1 describes the

function of each key.

POWER SWITCH

-Ready04-08-2007 10:39 AM

Prj: TROXLER

Press <START>

3. GETTING STARTED

USB PORT*

BATTERY

CHARGING

INDICATOR

CHARGER

CONNECTOR

RS-232 PORT

* The USB port is included only on the Model 3440 Plus.

Figure 3–2. Control Panel

Model 3430 Plus & 3440 Plus 3–3

Page 32

Table 3–1. Keypad Functions

KEY FUNCTION PAGE

〈STORE〉

〈RECALL〉

〈PROJ〉

〈STATUS〉

〈SETUP〉

〈OFFSET〉

Store the most recent data in the

current project file.

Display the most recent data. 4–17

Select or create a project file and view,

output, or erase project data file.

Displays gauge status information. 3–9

Displays the gauge Setup menu.

Enable, disable, or change a density,

moisture, or trench offset.

Select, enter, or disable a Gmb

〈TARGET〉

(Marshall), Proctor, or Gmm (Voidless

density) value.

〈MODE〉

〈STD〉

〈SPACE〉

〈LIGHT〉

〈YES〉

〈NO〉

〈ESC〉

〈0〉 .. 〈9〉

〈.〉

〈ALPHA LOCK〉

〈BACK SPACE〉

〈↑〉, 〈↓〉

〈ENTER/START〉

〈A〉 .. 〈Z〉

Select the measurement mode,

Asphalt or Soil.

Take a standard count. 4–2

Enter a space.

Manually toggle the LCD and keypad

backlights on and off.

Respond yes to yes/no questions.

Respond no to yes/no questions.

Return the display to the Ready screen

without storing or updating the data.

Enter numbers and access menu

options.

Enter a decimal point.

Access the letters.

Moves cursor back one space.

Scroll through menu options or view

screens.

Accept data entry or begin a

measurement.

Enter letters. Access these keys by

first pressing 〈ALP HA LOCK〉.

4–13, 4–16,

8–14

8–2

5–3

7–2

6–2

3–15

3–16

3–4

Page 33

SOURCE ROD POSITIONS

As shown in Figure 3–3, the source rod can be placed in the SAFE,

backscatter, or direct transmission positions. When not taking

measurements, keep the source rod in the SAFE position. When

measuring thin layer or other materials through which you cannot

drill a hole, use the backscatter position. In the direct transmission

positions, the source rod extends into a pre-drilled hole.

WARNING

The source rod should always be in the SAFE

position when the gauge is not in use.

BS

2"

50mm

3"

75mm

4"

100mm

5"

125mm

6"

150mm

7"

175mm

8"

200mm

9"

225mm

10"

250mm

11"

275mm

12"

300mm

Figure 3–3. Source Rod Positions

(Maximum Depth of 300 mm in Increments of 50 mm)

Model 3430 Plus & 3440 Plus 3–5

3. GETTING STARTED

Page 34

DAILY INSPECTION

The gauge should be inspected daily before use to ensure proper

operation of all safety features. Refer to page A–10 for the daily

inspection procedure.

3–6

Page 35

TURNING THE GAUGE ON

To turn on the gauge, press the power switch. Upon power-up, the

gauge briefly displays the model number, software version, and

serial number as shown below.

-Model 3440 Plus-

Vx.xx SN: xxx

The software then performs a brief self-test, followed by a display

test to ensure that the gauge is working properly. Following the two

tests, the gauge enters a 300-second warmup period.

NOTE

To bypass the warmup period, press 〈ESC〉.

Following the warmup period, the gauge displays the Ready

screen:

3. GETTING STARTED

-READY- g

04-08-2007 12:21 PM

Prj: TROXLER

Press <START>

NOTE

The symbol g in the upper right of the display indicates

that the GPS option (see page 5–17) is installed, the

option is enabled, and the gauge is receiving GPS

satellite signals. This option is available only on the

Model 3440 Plus.

The operator can access any gauge function from the Ready screen.

The Ready screen displays the current date and time, as well as the

current project (see Chapter 8), if any.

Model 3430 Plus & 3440 Plus 3–7

Page 36

NOTE

If the gauge display is difficult to read in bright light,

adjust the contrast as described in the Display Contrast

section on page C–9.

After 5 hours of no activity, the gauge automatically performs a

total power shutdown.

NOTE

If the charge calibration (see page C–11) is BAD, the

gauge will not perform an automatic shutdown.

3–8

Page 37

SETUP

After turning the gauge on for the first time, set up the software

parameters described in the following sections. Several of these

parameters accessed from the gauge’s Setup and Extended

menus. Other parameters are accessed via dedicated function keys.

The gauge stores the software setup, so the operator does not need

to enter a new setup each time the gauge is turned on. The setup

may be changed at any time, however.

The gauge offers a Status function that enables the operator to view

selected information concerning the current gauge status and setup.

To access the Status function, press the 〈STATUS〉 key. The gauge

displays two screens of information, including the measurement

units, count time, measurement mode, battery status, Gmb

(Marshall) value, Proctor value, Gmm (Voidless density) value, and

measurement depth. Use the arrow keys to scroll between the two

screens.

SETUP MENU

The gauge provides three different count times to be used in taking

measurements. The gauge can also display measurement results in

either U.S. units (pcf) or metric (SI) units (kg/m

Model 3440 Plus gauge offers two depth modes: automatic and

manual. These settings are accessed from the gauge’s Setup menu.

To display this menu, press the 〈SETUP〉 key. For information on

all of the functions available from the Setup menu, see Chapter 5.

Count Time

The count time defines how long the gauge reads (15 seconds, 1

minute, or 4 minutes). Longer count times produce better

measurement precision. Troxler recommends a count time of

1 minute for most sample measurements.

3

or g/cm3). The

3. GETTING STARTED

Model 3430 Plus & 3440 Plus 3–9

Page 38

To change the count time, press 〈1〉 at the Setup menu. The gauge

displays:

Time: 1 m

1. 15 sec

2. 1 min

3. 4 min

The gauge displays the current count time on the first line and

options on subsequent lines. To select the desired count time, press

the corresponding number key. The gauge sets the new count time,

then returns to the Setup menu.

Set Units

The gauge can display measurement results in either U.S. units (pcf)

or metric (SI) units (kg/m

the Setup menu. The gauge displays:

3

or g/cm3). To select the units, press 〈2〉 at

-Units-

1. pcf

2. kg/m3

3. g/cm3

Select the new units using the corresponding number key. The

gauge displays the new units, then returns to the Setup menu.

Depth Mode

The Model 3440 Plus gauge offers two depth modes: Automatic and

Manual. In the Automatic mode, the gauge software determines the

source rod depth automatically. In the Manual mode, the operator

must enter the source rod depth at a gauge prompt whenever taking

a measurement.

NOTE

The Automatic depth mode is not available on the Model

3430 Plus gauge.

3–10

Page 39

The Depth Mode function allows the operator to set the depth mode.

To access this function, press 〈2〉 at the Setup menu shown on page

5–3. The gauge displays:

Mode: Manual

1. Manual

2. Auto

Press # to Select

Select the desired depth mode using the corresponding number key.

After the depth mode is selected, the gauge sets the mode and

returns to the Setup menu.

EXTENDED MENU

The gauge is shipped with the current date and time (Eastern

Standard Time) stored in its memory. In addition, the gauge can

store a user ID and customer name. These settings are accessed

from the Extended menu. This menu includes functions that are

intended for use by authorized personnel only, and requires the use

of the access code shown on page xiii.

To access the Extended menu, press 〈.〉 〈9〉 at the Setup menu.

The gauge requests an access code:

3. GETTING STARTED

Input Access Code

_

Press <ENTER>

Enter the access code shown on page xiii and press the

〈ENTER/START〉 key. The gauge displays the Extended menu.

After setting the date and time, user ID, and/or customer name as

described in the following sections, press 〈ESC〉 to return to the

Setup menu.

For information on all of the functions available from the

Extended menu, refer to Chapter 9.

Model 3430 Plus & 3440 Plus 3–11

Page 40

Clock/Calendar

The Clock/Calendar function allows the operator to change the date

and time, and to select the display format for each. To access the

Clock/Calendar menu, press 〈1〉 at the Extended menu. The

gauge displays the Clock/Calendar menu:

-Clock/Calendar-

1. Change Time

2. Change Date

3. Time Format

-Clock/Calendar-

4. Date Format

Use the up and down arrows to scroll between the menu options. To

select a menu option, press the corresponding numeric key. To

return to the Extended menu, press the 〈ESC〉 key.

CHANGE TIME. To change the time, press 〈1〉 at the

Clock/Calendar menu. The gauge displays:

hh:mm AM

Arrows toggle AM/PM

Input Time and

Press <ENTER>

(Note that in this example, the time is displayed in AM/PM format.

To change the format, see the Time Format section on the following

page.) To accept the displayed time, press 〈ENTER/START〉. To

change the time, use the numeric keys to enter the new time, and the

arrow keys to toggle between AM and PM. Press

〈ENTER/START〉. The gauge sets the time and returns to the

Clock/Calendar menu.

3–12

Page 41

CHANGE DATE. To change the date, press 〈2〉 at the

Clock/Calendar menu. The gauge displays:

04/08/2006

mm/dd/yyyy

Input Date and

Press <ENTER>

(Note that in this example, the time is displayed in mm/dd/yyyy

format. To change the date format, refer to the Date Format section

below.) To accept the displayed date, press 〈ENTER/START〉. To

change the date, use the numeric keys to enter the new date. When

finished, press 〈ENTER/START〉. The gauge sets the date and

returns to the Clock/Calendar menu.

TIME FORMAT. The gauge can display the time in either AM/PM

or 24-hour format. To select the desired time format, press 〈3〉 at the

Clock/Calendar menu. The gauge displays:

-Time Format-

1. AM/PM

2. 24-Hour

Use the numeric keys to select the desired time format. The gauge

sets the time format and returns to the Clock/Calendar menu.

DATE FORMAT. The gauge can display the date in either

mm/dd/yyyy or dd/mm/yyyy format, where mm = month, dd = day,

and yyyy = year. To select the desired date format, press 〈4〉 at the

Clock/Calendar menu. The gauge displays:

-Date Format-

1. mm/dd/yyyy

2. dd/mm/yyyy

Use the numeric keys to select the desired format. The gauge sets

the date format and returns to the Clock/Calendar menu.

Model 3430 Plus & 3440 Plus 3–13

3. GETTING STARTED

Page 42

User ID

The gauge can store a three-character alphanumeric user ID with

each measurement. To enter or change the user ID, press 〈2〉 at the

Extended menu. The gauge displays:

User ID is:

XXX

Change ID?

<YES> or <NO>

To change the user ID, press 〈YES〉. The gauge displays:

User ID: A

Input ID and

Press <ENTER>

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Enter the new user ID and press 〈ENTER/START〉. The gauge

stores the new user ID and returns to the Extended menu.

Customer Name

The gauge can store a customer name of up to 12 alphanumeric

characters. To enter a customer name, press 〈3〉 at the Extended

menu. The gauge displays the current customer name on the second

line.

3–14

Customer Name is:

CUSTOMER

Change Name?

<YES> or <NO>

Page 43

To change the customer name, press 〈YES〉. The gauge displays:

Customer Name: A

Input Name and

Press <ENTER>

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Enter the new name and press the 〈ENTER/START〉 key. The

gauge stores the new customer name, then returns to the Extended

menu.

Press 〈ESC〉 twice to return to the Ready screen.

MEASUREMENT MODE

The gauge provides two measurement modes (Soil and Asphalt) for

precise readings on base asphalt, concrete, soil, soil-stone aggregate,

and similar materials. The gauge can also be used to determine the

density of thin-layer overlays using the Nomograph function

described on page 5–10.

Before taking a measurement, select the appropriate measurement

mode.

To select the measurement mode, press the 〈MODE〉 key. The gauge

displays:

3. GETTING STARTED

Mode: Asphalt

1. Asphalt

2. Soil

Press # to Select

NOTE

The 〈MODE〉 key is active only when the Ready screen

is displayed.

Model 3430 Plus & 3440 Plus 3–15

Page 44

The current mode (Asphalt, Soil, or Nomograph) is displayed on the

top line of the display. Use the Soil mode when measuring soil or a

soil-stone aggregate. Use Asphalt mode when measuring concrete or

asphalt layers of 4 inches or greater. Use the number keys to select

either Asphalt or Soil mode, or refer to page 5–10 for instructions on

enabling the Nomograph function for taking thin-layer

measurements. The gauge enables the selected measurement mode

and returns to the Ready display.

PROJECT FUNCTION

The gauge allows unique project names to be entered into the gauge

memory. Subsequent measurements can then be stored under these

project names. To access the Project function, press the 〈PROJ〉

key.

NOTE

The 〈PROJ〉 key is active only when the Ready screen is

displayed.

Chapter 8 provides detailed instructions on the Project function.

DISPLAY BACKLIGHT

Both the Model 3430 Plus and 3440 Plus gauges provide a backlight

for the liquid crystal display (LCD). The backlight can help the

operator read the display at night. The Model 3440 Plus also

features a backlit keypad; this feature is not available on the Model

3430 Plus gauge. To activate the backlight, press the 〈LIGHT〉 key.

NOTE

Using the display backlight reduces the battery life. To

conserve battery life, turn the backlight off when it is

not needed. Also note that the backlight turns off

automatically after 3 minutes to conserve power.

3–16

Page 45

NOTE

The gauge also features a hardware adjustment for the

display contrast. If the gauge display is difficult to read

in bright light, adjust the contrast as described in the

Display Contrast section on page C–9.

Model 3430 Plus & 3440 Plus 3–17

3. GETTING STARTED

Page 46

NOTES

3–18

Page 47

CHAPTER 4

USING THE GAUGE

This chapter explains the basic use of the Troxler Model 3430 Plus

and 3440 Plus Surface Moisture-Density Gauges. Basic use includes

taking the daily standard count, preparing measurement sites, setting

the measurement mode, and taking measurements.

CONTENTS

Taking a Standard Count .............................................................. 4–2

New Standard Count .............................................................. 4–3

View Standard Counts............................................................ 4–6

Preparing a Test Site..................................................................... 4–7

Soil Site.................................................................................. 4–7

Asphalt Site............................................................................ 4–9

Taking Measurements................................................................. 4–10

Soil Mode............................................................................. 4–11

Asphalt Mode....................................................................... 4–14

Recall.......................................................................................... 4–17

4. USING THE GAUGE

Model 3430 Plus & 3440 Plus 4–1

Page 48

TAKING A STANDARD COUNT

To adjust readings for source decay (see Appendix A) and natural

background radiation, take a daily standard count. A four-minute

daily standard count helps ensure the highest measurement

accuracy.

Locate the reference standard block shipped with the gauge.

NOTE

Always take standard counts using the reference

standard block provided with the gauge.

Before taking a standard count, ensure that the gauge base and

reference standard block are dry and free of debris.

Choose a standard count site that meets the following criteria:

♦ A smooth surface such that the reference standard block does

not rock

♦ At least 3 meters (10 ft) from any large vertical surface

♦ At least 10 meters (33 ft) from any other radioactive source

♦ On asphalt, concrete, or compacted soil at least 10 centimeters

(4 in.) thick

Turn the gauge on. At the Ready display, press the 〈STD〉 key. The

gauge displays the last standard counts for density (DS) and

moisture (MS).

Standard Count

DS= ####

MS= ####

Take New Count?

NOTE

The 〈STD〉 key is active only when the Ready screen is

displayed.

To take a new standard count, press 〈YES〉 and follow the

instructions in the New Standard Count section that follows.

To view the last four standard counts, press 〈NO〉 and follow the

instructions in the View Standard Counts section on page 4–6.

4–2

Page 49

NEW STANDARD COUNT

When taking a new standard count, the gauge displays:

Place Gauge on

Std. Block & Source

Rod in SAFE Pos.

Press <ENTER>

Place the reference standard block on the standard count site. As

shown in Figure 4–1, place the gauge on the reference standard

block, with the right side (keypad side) of the gauge against the

metal butt plate.

NOTE

Ensure that the source rod is in the standard (SAFE)

position and is securely seated by firmly tapping down

on the handle of the source rod.

Figure 4–1. Standard Count Position

Model 3430 Plus & 3440 Plus 4–3

4. USING THE GAUGE

Page 50

Begin the standard count by pressing the 〈ENTER/START〉 key.

The gauge displays:

Taking

Standard Count

### s

Remaining

After taking the standard count, the gauge displays the results:

DS= #### ##.#% P

MS= #### ##.#% P

Do You Want to

Use the New Std.?

Troxler recommends that the operator keep a daily log of the

moisture and density standard counts (see Appendix D). To verify

gauge stability, compare the daily standard count to a reliable

reference as follows:

♦ During the first four days of operation of a new or recalibrated

gauge, compare the daily standard count to the factorycalibrated values (which are shown on the calibration report sent

with the gauge).

♦ After the first four days of operation (or after taking four

standard counts), compare the daily standard count to the

average of the last four counts. Acceptable standard count limits

are:

±1.0% for DS (density standard) and

±2.0% for MS (moisture standard).

If the standard count passes, record the standard counts, then

press the 〈YES〉 key. The gauge returns to the Ready screen.

NOTE

The factory standard count values should be used as a

reference if the daily standard counts are ever in

question. Be sure to refer to the most recent calibration

report for the gauge in question.

4–4

Page 51

If the standard count fails and it has been more than a month

since the last standard count, then accept the standard count by

pressing the 〈YES〉 key. At the Do You Want To Erase Last

Four Standard Counts? prompt, press the 〈YES〉 key. The

gauge displays:

Depth Calibration

Set Rod To BS.

And Press ENTER

Follow the displayed instructions, and take four additional

standard counts. The last of these counts will be compared to

the previous four, and the standard counts should pass. If not,

repeat the procedure. If it still fails, perform a stat test (see page

5–5) and a drift test (see page 5–7), then contact your Troxler

representative.

If the standard count fails and it has been less than a month

since the last standard count, but the count was performed

correctly and the failure is less than 5%, press the 〈YES〉 key. If

the failure is more than 5%, press the 〈NO〉 key. Ensure that the

gauge is properly positioned on the reference standard block

(Figure 4–1). Verify that the standard count site meets the

criteria listed on page 4–2. Take another standard count and

accept it if it fails by less than 5%. If the standard count fails

four times, perform a stat test (see page 5–5) and a drift test (see

page 5–7), then contact your Troxler representative.

After the standard count passes, the operator can take measurements

with the gauge. When not taking readings, always keep the source

rod in the SAFE position. For added user safety, the source rod

automatically retracts to the SAFE position when the gauge is lifted

using the handle.

4. USING THE GAUGE

Model 3430 Plus & 3440 Plus 4–5

Page 52

VIEW STANDARD COUNTS

To view the last four standard counts, press 〈NO〉 at the display

shown at the bottom of page 4–2. The gauge displays:

Standard Count

Want to View

Last Four Counts?

<YES> or <NO>

Press 〈YES〉 to view the last four standard counts. The gauge

displays the last four density standard counts. Press 〈YES〉 to

view the last four moisture standard counts. Press

〈ENTER/START〉 to return to the Ready screen.

Press 〈NO〉 to return to the Ready screen.

4–6

Page 53

PREPARING A TEST SITE

To ensure measurement accuracy, properly prepare the test site

before taking gauge measurements. This section describes how to

prepare test sites properly for soil and asphalt measurements.

SOIL SITE

Locate a smooth site on the soil that is free from any large

holes, cracks, or debris.

If necessary, smooth the surface by moving the scraper plate in

a back and forth motion.

Fill any voids or depressions with fine sand or soil particles.

Strike off any excess fill.

Place the scraper plate back on the surface and press down

slightly to level the surface.

WARNING

Under no circumstances should the source rod of the

gauge be used to drill holes.

For direct transmission measurements:

Put the drill rod through the extraction tool and then through

one of the guides on the scraper plate (Figure 4–2).

Wear safety glasses and a radiation dosimeter.

Place the drill rod assembly on the test site.

Step on the scraper plate.

Hammer the drill rod at least 50 mm (2 in.) deeper than the

desired test depth. The drill rod increments include the

additional depth.

Before removing the drill rod, mark the outline of the scraper

plate as shown in Figure 4–3 to ensure the gauge is placed over

the same area as the scraper plate.

Model 3430 Plus & 3440 Plus 4–7

4. USING THE GAUGE

Page 54

Figure 4–2. Drill Rod Assembly

Remove the drill rod by pulling straight up and twisting the

extraction tool. Do not loosen the drill rod by tapping from side

to side with a hammer. Also, do not rock the extraction tool

from side to side. This will distort the hole or cause loose

material to fall into the hole.

Carefully pick up the scraper plate.

EDGE

PLATE CENTER

MARKSMARK FOR SCRAPER

4–8

SCRAPER

PLATE

METHOD 1

SCRAPER

MARK FOR DRILL

ROD CENTER

PLATE

METHOD 2

Figure 4–3. Marking the Test Area

Page 55

ASPHALT SITE

This also applies to hardened concrete sites and soil.

NOTE

These directions also apply to taking a backscatter

measurement on soil.

Locate a smooth site on the asphalt.

Fill the voids on open mixes with sand or cement. The gauge

base must rest on the asphalt, not the fill material!

Ensure that the gauge does not rock. To ensure accurate

readings, the gauge base must be completely in contact with the

test material. If the gauge rocks, then find a more suitable test

site. If taking a measurement around a core, the gauge may be

moved a few inches away from the core to level it.

Model 3430 Plus & 3440 Plus 4–9

4. USING THE GAUGE

Page 56

TAKING MEASUREMENTS

WARNING

When not taking readings, always keep the source

rod in the SAFE (shielded) position. For added user

safety, the source rod automatically retracts to the

SAFE position when the gauge is lifted by the

handle.

If you do not hear a click when the gauge is raised to the SAFE

position, look at the bottom of the gauge to verify that the tungsten

sliding block is completely closed. If the gauge base opening is not

completely closed by the sliding block, the block may require

cleaning. Refer to page A–11 for cleaning instructions.

WARNING

Do not store or transport the gauge unless the

sliding block is completely closed. Increased

radiation levels may cause excessive personnel

radiation exposure and may violate transportation

regulations.

The Status function (see page 3–9) allows the operator to view

selected information concerning the current gauge status and setup.

To access the Status function, press the 〈STATUS〉 key. Check the

gauge’s current status before taking measurements.

Remember to take a standard count at least once each day the gauge

is to be used (see page 4–2). Note that some states may require that

a standard count be taken more frequently than once per day.

The gauge can store measurement results in files (memory

locations) called projects. For information on creating and

activating project files, refer to Chapter 8. Upon completion of a

measurement, the results can be stored either automatically by

enabling the Auto-Store function (see page 8–12) or manually by

using the Store function (see page 8–14).

4–10

Page 57

SOIL MODE

To measure the moisture and density of soil, soil-stone aggregate,

and similar materials, follow the steps below:

Select the Soil mode (see page 3–15).

If desired, enter, change, or enable the Proctor value as

described in Chapter 6.

Prepare the test site as described on page 4–7.

Place the gauge on the test area.

Insert the source rod into the hole made by the drill rod. Use

care when inserting the source rod. Try not to disturb the soil

around the hole.

Lower the source rod to the measurement depth. Release the

trigger. Gently push the handle down to lock the source rod into

position. You should hear a click when the source rod locks into

position.

Gently slide the gauge to the right (towards the keypad) so the

source rod makes contact with the wall of the hole.

Press the 〈ENTER/START〉 key.

In the Manual depth mode (see page 5–4), the gauge

prompts for the source rod depth. Enter the source rod depth

using the number keys. For example, with the source rod in

the backscatter position, press 〈0〉. Then press

〈ENTER/START〉.

In the Automatic depth mode (available only on the Model

3440 Plus), the gauge software determines the source rod

depth automatically.

Note that the Proctor value is based on soil particles 3/8

inches or less in diameter (or those passing a #4 sieve). If an

unusual reading is obtained and oversize particles are

suspected, rotate the gauge 90°. Use the same drill hole to

take a second reading.

Model 3430 Plus & 3440 Plus 4–11

4. USING THE GAUGE

Page 58

The gauge displays the time remaining while taking a

measurement.

After the count time, the gauge displays the measurement

results:

%PR= ###.#

DD= ##.#

WD= ###.#

M= ##.# %M= ##.#

Lat: +hh mm ss.ss

Lng: -hh mm ss.ss

where: %PR = percent Proctor %M = percent moisture

DD = dry density Lat = latitude

WD = wet density Lng = longitude

M = moisture

NOTE

The latitude and longitude display, showing the location

of the measurement, is available only on Model 3440

Plus gauges equipped with the GPS option and is shown

only when this option is enabled.

The latitude and longitude values denote the quality of

the location fix. If WAAS information is available

during a gauge measurement, the latitude and longitude

will be displayed to the nearest hundredth (1/100) of a

second. If a GPS location is determined, but the WAAS

information is unavailable, the latitude and longitude

will be displayed to the nearest tenth (1/10) of a second.

If the GPS receiver cannot determine a location, the

latitude and longitude will be denoted as 0. For more

information on GPS accuracy, see Appendix I.

4–12

Page 59

If a project is active (see Chapter 8) and the Auto-Store

function (see page 8–12) is enabled, press 〈ESC〉 or

〈ENTER/START〉 to continue. For each measurement, the

gauge can store a location description of up to 12

characters, as well as a note of up to 15 characters. Follow

the prompts to enter location information and/or a note.

If a project is active but the Auto-Store function is not

enabled:

Press 〈STORE〉

to enter location information and/or notes. For more

information on storing results manually, see page 8–14.

Press 〈ESC〉 to return to the Ready screen without

storing the results. Note that, until another measurement

has been taken, the results can be recalled as described

on page 4–17 and stored later.

Lift the gauge from the test site by the source rod handle. This

returns the source rod to the SAFE position. When not taking

readings, always keep the source rod in the SAFE position.

to store the results. Follow the prompts

4. USING THE GAUGE

Model 3430 Plus & 3440 Plus 4–13

Page 60

ASPHALT MODE

To measure the density of asphalt (and hardened concrete of 4

inches or more) follow the steps below:

Select the Asphalt mode (see page 3–15).

If desired, enter or enable the Marshall value and/or voidless

density value as described in Chapter 6.

Prepare the test site as described on page 4–9.

Place the gauge on the test area.

Lower the source rod to the backscatter position (just below the

SAFE position). Release the trigger. Gently push the handle

down to lock the source rod into position. You should hear a

click when the source rod locks into position.

Press the 〈START〉 key.

In the Manual depth mode (see page 5–4), the gauge

prompts for the source rod depth. Enter the source rod depth

using the number keys. For example, with the source rod in

the backscatter position, press 〈0〉. Then, press

〈ENTER/START〉.

In the Automatic depth mode (available only on the Model

3440 Plus), the gauge software determines the source rod

depth automatically.

The gauge displays the time remaining while taking a

measurement.

4–14

Page 61

After the count time, the gauge displays the measurement

results:

%Gmb= ###.#

WD= ###.#

M= ##.# %M= ##.#

%Voids= ###.#

Lat: +hh mm ss.ss

Lng: -hh mm ss.ss

where:

%Gmb = percent of laboratory bulk density

WD = wet density

M = moisture value

%M = percent moisture

−×=

1100%Voids

WD

Voidless

⎛

⎜

⎝

(displayed only when enabled)

⎞

⎟

⎠

Lat = latitude

Lng = longitude

NOTE

The latitude and longitude display, showing the location

of the measurement, is available only on Model 3440

Plus gauges equipped with the GPS option and is shown

only when this option is enabled.

The latitude and longitude values denote the quality of

the location fix. If WAAS information is available

during a gauge measurement, the latitude and longitude

will be displayed to the nearest hundredth (1/100) of a

second. If a GPS location is determined, but the WAAS

information is unavailable, the latitude and longitude

will be displayed to the nearest tenth (1/10) of a second.

If the GPS receiver cannot determine a location, the

latitude and longitude will be denoted as 0. For more

information on GPS accuracy, see Appendix I.

Model 3430 Plus & 3440 Plus 4–15

4. USING THE GAUGE

Page 62

If a project is active (see Chapter 8) and the Auto-Store

function (see page 8–12) is enabled, press 〈ESC〉 or

〈ENTER/START〉 to continue. For each measurement, the

gauge can store a location description of up to 12

characters, as well as a note of up to 15 characters. For an

Asphalt mode measurement, the gauge can also store

location with respect to the centerline (left, right, or

neither), and the distance from the centerline. Follow the

prompts to enter location information and/or a note.

If a project is active but the Auto-Store function is not

enabled:

Press 〈STORE〉

to enter location information and/or notes. For more

information on storing results manually, see page 8–14.

Press 〈ESC〉 to return to the Ready screen without

storing the results. Note that, until another measurement

has been taken, the results can be recalled as described

on page 4–17.

Lift the gauge from the test site using the source rod handle.

This returns the source rod to the SAFE position. When not

taking readings, always keep the source rod in the SAFE

position.

to store the results. Follow the prompts

4–16

Page 63

RECALL

To view the results of the most recent measurement, press the

〈RECALL〉 key from the Ready screen. To return to the Ready

screen, press the 〈ENTER/START〉 key.

NOTE

The 〈RECALL〉 key is active only when the Ready

screen is displayed.

NOTE

The Recall function can also be used to view the gauge

counts from the most recent measurement.

Model 3430 Plus & 3440 Plus 4–17

4. USING THE GAUGE

Page 64

NOTES

4–18

Page 65

CHAPTER 5

SETUP MENU

The gauge software includes a Setup menu that allows the operator

to manually set or change operating parameters of the gauge. This

chapter describes these parameters.

CONTENTS

Setup Menu................................................................................... 5–3

Count Time................................................................................... 5–4

Set Units........................................................................................ 5–4

Depth Mode.................................................................................. 5–4

Stat Test........................................................................................ 5–5

Taking a Stat Test................................................................... 5–5

Reviewing the Stat Test.......................................................... 5–6

Printing the Stat Test.............................................................. 5–6

Drift Test....................................................................................... 5–7

Taking a Drift Test................................................................. 5–8

Reviewing the Drift Test........................................................ 5–9

Printing the Drift Test ............................................................ 5–9

Nomograph................................................................................. 5–10

Enable Nomograph............................................................... 5–11

Disable Nomograph.............................................................. 5–11

Change/View Nomograph Data ........................................... 5–11

Taking Nomograph Measurements...................................... 5–14

5. SETUP MENU

Model 3450 5–1

Page 66

CONTENTS (Continued)

Precision......................................................................................5–15

Options........................................................................................5–17

External Beeper.....................................................................5–17

GPS Option...........................................................................5–17

Battery Status ..............................................................................5–18

Percent Air Voids (Soil Mode)....................................................5–19

5–2

Page 67

SETUP MENU

The gauge software groups most of the setup features into one

menu. To access the Setup menu, press the 〈SETUP〉 key. The

gauge displays:

-Setup-

1. Count Time

2. Set Units

3. Depth Mode

-Setup-

4. Stat Test

5. Drift Test

6. Nomograph

-Setup-

7. Precision

8. Options

9. Battery Status

5. SETUP MENU

-Setup-

.0-% Voids (soil)

NOTE

The 〈SETUP〉 key is active only when the Ready screen

is displayed.

Use the arrows keys to scroll through the menu screens. To select a

menu option, use the number key that corresponds to that option.

The remainder of this section provides details on the functions

available from the Setup menu.

Model 3450 5–3

Page 68

COUNT TIME

The gauge provides three different count times for taking

measurements. The Count Time function is described on page 3–9.

SET UNITS

The gauge can display measurement results in either U.S. units (pcf)

or metric (SI) units (kg/m

described on page 3–10.

3

or g/cm3). The Set Units function is

DEPTH MODE

The Model 3440 Plus gauge offers two depth modes: Automatic and

Manual. The Depth Mode function allows the operator to set the

depth mode, as described on page 3–10.

5–4

Page 69

STAT TEST

Erratic readings, or readings that seem to fluctuate, may indicate a

problem with the gauge. If the readings are suspect, perform a stat

test, or statistical stability test, to validate the normal operation of

the gauge.

A stat test consists of twenty 1-minute counts. From the twenty

counts, the gauge calculates the standard deviation. This standard

deviation is compared to a theoretical standard deviation value.

Ideally, this ratio should be 0.25, with acceptable limits from 0.17 to

0.33. The gauge is considered unstable if the ratio is outside these

limits and the stat test will fail. If the stat test fails, ensure that the

gauge setup and testing was conducted correctly, and take an

additional test. If the second test fails, contact the nearest Troxler

service center for assistance. For a list of Troxler and authorized

Troxler service centers, refer to page iii of this manual or visit the

Troxler website at www.troxlerlabs.com/SERVICES/services.shtml

To access the Stat Test function, press 〈4〉 at the Setup menu. The

gauge displays the Stat Test menu:

5. SETUP MENU

.

1. Take STAT Test

2. Review STAT Test

3. Print STAT Test

<ESC> to Exit

To select a menu option, press the corresponding numeric key or

press 〈ESC〉 to return to the Setup menu.

TAKING A STAT TEST

Choose an area free of other nuclear gauges or radioactive sources.

Place the gauge on the reference standard block as shown in Figure

4–1 on page 4–3.

To take a new stat test, press 〈1〉 at the Stat Test menu shown

above. The gauge prompts the operator to place the gauge on the

reference standard block with the source rod in the SAFE (shielded)

position. Ensure that the gauge is properly positioned and press the

〈ENTER/START〉 key.