Page 1

Instruction Manual

MODEL 3216

ROOF MOISTURE

GAUGE

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Rd. · P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER

Outside the USA: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

Page 2

Troxler Gauges are protected by U.S.

and foreign patents

Copyright © 1981 - 2006

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or

transmitted in any form or by any means, electronic

or mechanical, including photocopying, recording,

or information storage and retrieval systems, for

any purpose without the express written permission

of Troxler Electronic Laboratories, Inc.

PN 103367

October 2006

Edition 4.1

Page 3

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

P.O. Box 12057

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Phone: 1.877.TROXLER (1.877.876.9537)

Technical Support

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Fax: 817.275.8562

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Canadian Branch Office

7125 Pacific Circle, Unit 13

Mississauga, Ontario L5T-2A5

Canada

Fax: 905.564.7092

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr.

Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

Page 4

NOTES

Page 5

TABLE OF CONTENTS

I. INTRODUCTION AND SPECIFICATIONS

II. OPERATING INSTRUCTIONS

III. FIELD MEASUREMENTS

IV. SENSITIVITY DATA ................. 4-1

V. PERIODIC MAINTENANCE

VI. SERVICE

I-A. Introduction . . . . . . . . . . . . . . . 1-1

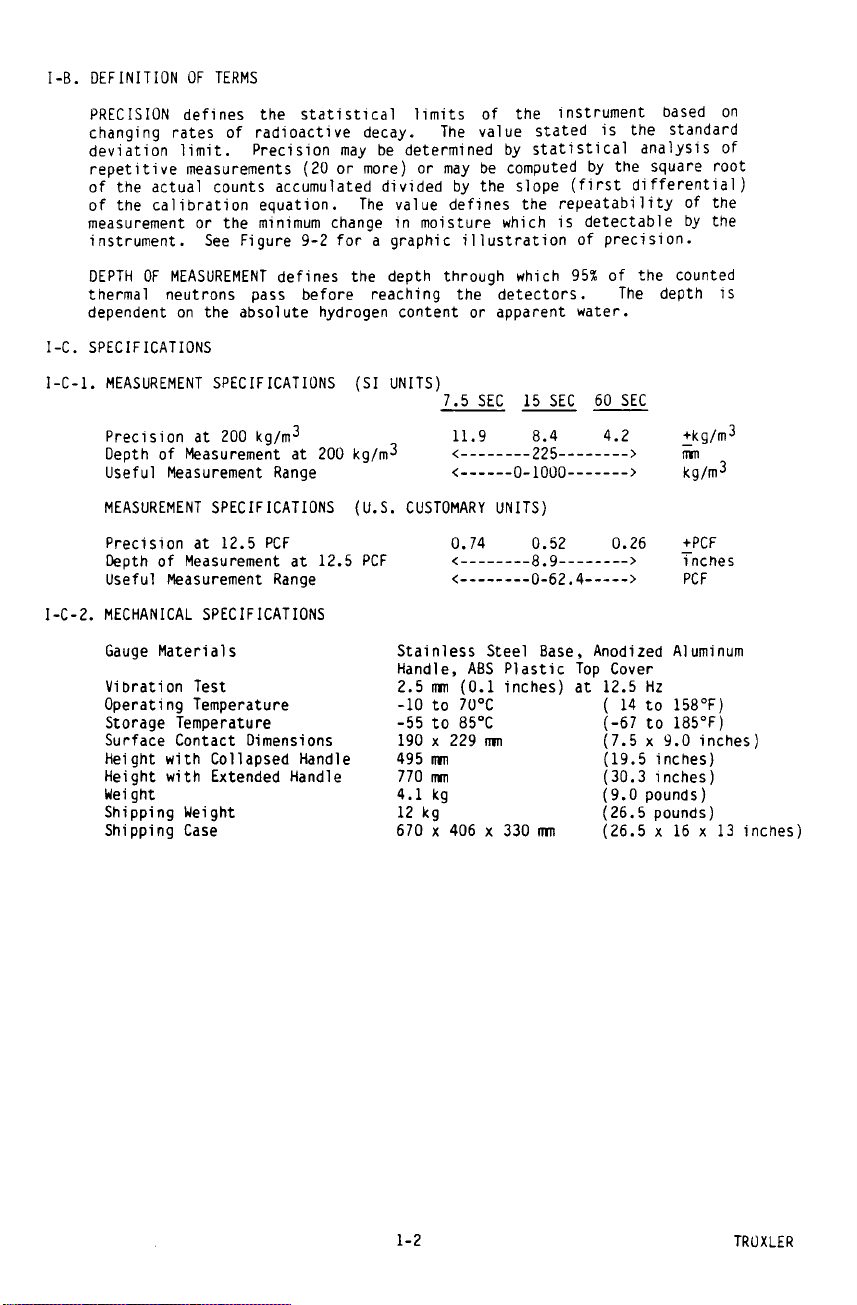

I-B. Definition of Terms . . . . . . . . . . . 1-2

I-C. Specifications . . . . . . . . . . . . . . 1-2

II-A. Getting Acquainted . . . . . . . . . . . . 2-1

II-B. Control Functions and Operations . . . . . 2-1

II-C. Test Functions . . . . . . . . . . . . . . 2-2

III-A. Data Collection . . . . . . . . . . . . . 3-1

III-B. Manual Analysis of Data . . . . . . . . . 3-4

III-C. Computer Aided Analysis of Data . . . . . 3-11

III-D. Vertical Wall Measurements . . . . . . . . 3-12

V-A. Battery Charging . . . . . . . . . . . . . 5-1

V-B. Cleaning ................. 5-1

V-C. Internal Condensation . . . . . . . . . . 5-1

V-D. Gauge Disassembly . . . . . . . . . . . . 5-2

V-E. Leak Test Procedure . . . . . . . . . . . 5-2

VI-A. Equipment Required . . . . . . . . . . . . 6-1

VI-B. Gauge Electronics . . . . . . . . . . . . 6-2

VI-C. Statistical Stability . . . . . . . . . . 6-5

VI-D. Troubleshooting Hints . . . . . . . . . . 6-7

VI-E. Service Centers . . . . . . . . . . . . . 6-8

VII. PARTS LIST

VIII. THEORY OF MEASUREMENT

IX. FACTORY CALIBRATION

X. RADIATION THEORY AND SAFETY

VII-A. Replacement Parts . . . . . . . . . . . . 7-1

VII-B. Accessories . . . . . . . . . . . . . . . 7-1

VIII-A. Neutron Radiation and Matter . . . . . . . 8-1

VIII-B. Moisture Geometry . . . . . . . . . . . . 8-3

IX-A. Moisture Calibration . . . . . . . . . . . 9-1

IX-B. Moisture Performance Parameters . . . . . 9-2

X-A. Radiation Theory . . . . . . . . . . . . . 10-1

X-A-1. Atomic Structure . . . . . . . . . . . . . 10-1

X-A-2. Radiation Theory . . . . . . . . . . . . . 10-2

X-A-3. Radiation Terminology . . . . . . . . . . 10-2

X-B-1. Radiation Statistics . . . . . . . . . . . 10-2

X-B. Radiation Safety . . . . . . . . . . . . . 10-3

X-B-1. Types of Radiation . . . . . . . . . . . . 10-3

X-B-2. Limiting Exposure . . . . . . . . . . . . 10-4

X-B-4. Monitoring Radiation . . . . . . . . . . . 10-5

i

Page 6

Table of Contents (cont'd)

X-B-4. 3216 Radiation Profile . . . . . . . . . . 10-6

X-B-5. Source Encapsulation . . . . . . . . . . . 10-7

X-B-6. Emergency Procedures . . . . . . . . . . . 10-7

XI. TRANSPORTATION AND SHIPPING

APPENDIX A

XI-A. Requirements . . . . . . . . . . . . . . . 11-1

XI-A-1. Certificate of Competent Authority . . . . 11-1

XI-A-2. Results of Type A Package Testing . . . . 11-2

XI-A-3. Emergency Response Sheet . . . . . . . . . 11-2

XI-A-4. Emergency Response Telephone Number . . . 11-2

XI-A-5. Labeling Requirements . . . . . . . . . . 11-2

XI-A-6. "Bill of Lading" Requirements . . . . . . 11-2

XI-A-7. Locking or Sealing of Package . . . . . . 11-3

XI-A-8. Inspection of Package Prior to Shipment . 11-3

XI-A-9. Accident Notification Requirements . . . . 11-3

XI-A-10 Hazmat Training . . . . . . . . . . . . . 11-3

XI-B. Shipping Forms . . . . . . . . . . . . . . 11-3

BASIC Listing for Standard Deviation . . . . . . . AI

Sample Output from Standard Deviation Program . . . AII

ii

Page 7

LIST OF ILLUSTRATIONS

Figure Description Page

3-1 Gridded Roof Plan 3-3

3-2 Roof Measurement Data 3-3

3-3 Histogram of Sample Data 3-4

3-4 Normal Distribution With

Confidence Limits

3-5 Normal Distribution Overlaying

Histogram

3-6 Standard Deviation for Grouped

Data

3-7 Percent Moisture Correlation Graph

Data

3-8 Graphic Interpretation of Roof

Survey

3-9 Computer Aided Plot 3-11

5-1 Leak Test Analysis Form 5-3

6-1 Interior Layout 6-3

6-2 Block Diagram of Gauge Electronics 6-4

6-3 Statistical Test Data 6-5

8-1 Neutron Interaction Data 8-3

8-2 Effect of Neutron Source-Detector

Distance

8-3 Effect of Moisture on Depth of

Measurement

9-1 3216 Calibration Data 9-4

9-2 Graphic Interpretation of Moisture

Calibration

10-1 Diagram of an Atom 10-1

10-2 Variation of Radioactive Emission 10-3

10-3 Effect of Distance on Exposure 10-4

10-4 3216 Radiation Profile 10-6

11-1 Sample Intra-company "Bill of

Lading"

11-2 Sample Common Carrier "Bill of

Lading"

11-3 Sample Shipper's Declaration of

Dangerous Goods

11-4 Sample Federal Express Form 11-7

3-5

3-6

3-7

3-8

3-9

8-4

8-5

9-6

11-4

11-5

11-6

iii

Page 8

This page intentionally blank

iv

Page 9

Page 10

Page 11

I-C-3. CALIBRATION SPECIFICATIONS

Number of Standards 2

Accuracy of Standards ±4.0%

I-C-4. RADIOLOGICAL SPECIFICATIONS

Neutron Source 1.48 ± 10% GBq

Source Form Stainless steel,

Source Classification ANSI-C54444

per ANSI N542-1977

Shielding Lead and Polyethylene

Maximum Surface Dose Rates See Radiation Profile on

Shipping Case DOT 7A, Type A, Yellow II

Special Form Approval Am-241, SPECIAL FORM

Gauge Classification per ANSI-54-685-685-R2

ANSI N538-1979

I-C-5. ELECTRICAL SPECIFICATIONS

Time Accuracy and Stability ± 0.005% ± 0.0002%/°C

Power Supply Stability ± 0.01%/°C

Battery Capacity 14 W-hr

(40 ± 10% mCi)

70,000 n/sec yield,

TEL A-102451

encapsulated

page 10-6

Label, 0.1 TI

Certificate GB:SFC 7

Charge Source 115/230 V, 50-60 Hz

Battery Recharge Time

AC Charger 14 hr

DC Charger 3 hr

LCD 4 digits

Largest Number Displayable 9999

Count Registers 1

Power Consumption 0.08 W

Power Consumption after 0.001 W

Automatic Battery Cutoff

Battery packs are fully protected against overcharge and

overdischarge. Low Battery alarm is indicated on the display

several hours prior to automatic cutoff.

TROXLER 1-3

or 12-15 VDC

Page 12

Page 13

Page 14

Page 15

Page 16

III-A-2. LAYOUT GRID ON ROOF

The grid pattern (at the selected size) must be laid out

on the roof. Paint, strings, marked ropes, or other

methods can be used to define the grid intersections on

the roof.

One popular method is to use two marked ropes, placed

parallel on opposite sides of the roof. A third marked

rope is stretched between the two parallel ropes. With

spray paint can spot the roof at each marking on the

rope. The "marking stick" listed in the Accessories

Parts List (Section VII-B) is especially useful for this

purpose.

III-A-3. DRAWING OF ROOF PLAN

Make a scaled drawing of the roof's top view. Note on

this drawing all roof structures (drains, heating and

air conditioning units, ventilation shafts, etc.). If

there are no roof structures or other details that

indicate building orientation, then note the north

orientation on the drawing.

Any roof structures the user wishes included on a plot

must also by shown on the roof plan.

III-A-4. COLLECT MEASUREMENT DATA

Set the POWER/TIME switch to the desired accumulation

time period. Use the gauge to make a measurement count

at each grid intersection. Record this count at the

correct position.

III-A-5. CUT CORE SAMPLES

Nuclear gauges register relative hydrogen levels. If

absolute moisture levels are needed, one must correlate

count rates and actual moisture levels. Correlation is

normally done via core samples.

The core samples should be chosen to include the widest

range of count rates possible. The roof plan count rate

data will be useful in choosing where to cut core

samples. If a limited number of core samples are to be

cut, then they should be made at sites (determined from

the count data) that indicate a transition from dry to

wet.

3-2 TROXLER

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

VI-E. TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

P.O. Box 12057

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Phone: 1.877.TROXLER (1.877.876.9537)

Technical Support

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Fax: 817.275.8562

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Canadian Branch Office

7125 Pacific Circle, Unit 13

Mississauga, Ontario L5T-2A5

Canada

Fax: 905.564.7092

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr.

Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

6-8 TROXLER

Page 41

VII. PARTS LIST

VII-A. REPLACEMENT PARTS

103021 Liquid Crystal Display

103286 Moisture Preamplifier Module (2 req'd)

103300 Baseboard PCB Ass'y (without modules)

103321 Power Controller Module

103325 Scaler PCB Ass'y

103355 Battery Pack (2 req'd)

103356 Flat Cable Ass'y

103374 Ratemeter

104094.0001 Moisture Tube Assembly (2 req'd)

104639 High Voltage Module, 900 V

108709 High Voltage Module, 1000 V

VII-B. ACCESSORIES

021140 Radiation Sign Kit

102868 Leak Test Kit, Model 3880

102873 1oz Solution Detergent

102876.0005 Leak Test Replacement Packets (4 units)

102957 12 V DC Charger Cable

103367 Instruction Manual

104508 AC Battery Charger, 13.5 V, 140 mA (Dom. Sales)

104509 AC Battery Charger, 13.5 V, 140 mA (Int. Sales)

104621 3216 Case/Foam Ass'y

109661 Troxler Survey Meter

A "marking stick" is useful for spot marking the grid

intersection points on the roof. This or similar holders for

spray paint cans should be available from local surveyors and

construction equipment dealers.

TROXLER 7-1

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

IX. FACTORY CALIBRATION

IX-A. MOISTURE CALIBRATION

Many attempts have been made to create satisfactorily

stable moisture standard either by using water and soil

mixes or by simulating moisture by mixing hydrogenbearing materials with other materials simulating soils.

Some standards are totally inaccurate, and some are very

unstable unless particular attention is paid to

During the development of moisture measurement gauges,

The count rate data accumulated during the calibration

Where m is the slope of the calibration curve and b is

The value (b/m) is often referred to as the offset value

maintaining water levels and preventing evaporation.

Troxler Electronic Laboratories, Inc. developed a set of

standards made from laminated sheets of plastic and a

non-absorber of thermal neutrons. This process has been

patented (.) During the process of manufacture the ratio

of plastic (or other hydrogen-bearing material) and a

non-absorber can be accurately controlled. To ensure

uniformity, laminations were chosen rather than mixing

of small particles. Such a mixing process tends to

result in segregation due to the differences in the

specific gravity of the materials. The materials used in

the Troxler standards are non-hydroscopic and have zero

voids, so changes in humidity do not affect the

equivalent water content.

process are used to solve the equation:

Count Rate = m x (Moisture Content) + b

the intercept of the calibration curve. Once the values

of m and b are evaluated, the terms of this equation are

usually re-arranged so that the moisture content can be

computed from the count rate. The resulting equation is:

Moisture Content = (1/m) x (Count Rate) – (b/m)

of the calibration equation.

TROXLER 9-1

Page 50

IX-B. MOISTURE PERFORMANCE PARAMETERS

A computer-generated calibration report is supplied with

the 3216 gauge. This 2-page report summarizes the

calibration process and results. While the 3216 is

intended for relative moisture measurements, it must be

calibrated against known moisture standards to verify

the gauge characteristics. An example of a typical Model

3216 calibration report is shown in Figure 9-1.

A summary of the contents of a Model 3216 calibration

report is presented hereunder. The report consists of

six separate parts, contained on two pages:

1. The first four lines of text at the top of the first

and second pages of the report are the header. His

portion of the calibration report contains data that

identify the gauge itself (gauge serial number, model

number, source serial number, gauge type) and the

date when the calibration was done and the report was

printed.

2. The second section of the calibration report is

composed of two sentences that identify the units

that are used with the different quantities listed in

the calibration report and instruct the user on how

to distinguish these units.

3. The section beginning with “Calibration Measurement

Data” lists the data collected during the calibration

of the gauge that are used to compute the slope and

the intercept of the calibration curve itself. These

data include the moisture values of the two

calibration blocks and the counts that were acquired

by the gauge on these blocks.

4. The section beginning with “Calibration Equation”

explains the form and meaning of the calibration

equation. This section also describes how the

calibration equation is re-arranged in order to

compute soil moisture values directly by using the

gauge count.

9-2 TROXLER

Page 51

5. The section beginning with “Precision for various

measurement times” lists the precision values for the

calibration equation. These precision values are

presented in tabular form and are evaluated at three

different moisture levels and three different

counting times. The precision defines the

repeatability of a measurement or the minimum change

in moisture that is detectable by the gauge. The

precision is the uncertainty (expressed as one

standard deviation) in the measured moisture content

based on the uncertainty (expressed as one standard

deviation) of a given gauge count due to the decay

rates of radioactive material. Figure 9-2, a plot of

a calibration curve for a Model 3216 gauge, includes

a graphic illustration of precision.

6. The second page of the calibration report begins with

the header, followed by six paragraphs of summary

information. This summary information is included to

address specific requirements for calibration

reports. The first paragraph of the summary

information defines the ideal conditions of the

measurement material for which ensure the optimal

performance of the gauge. The second paragraph

references the traceability of the moisture value of

the mag/poly block used in the calibration. The third

paragraph ensures the user that the gauge was

operating properly during and after the calibration,

instructs the user that the report is applicable only

to the specific instrument described in the report,

and informs the user of the identity of the

technician who calibrated this instrument and when it

was calibrated. Paragraph 4 gives the address of the

facility where the gauge was calibrated, and

paragraph five is the special considerations and

limitations statement. Finally, paragraph six

requests that the data in the report not be

misrepresented by omitting or altering its contents,

unless such a modification is formally approved by

Troxler Electronic Labs.

TROXLER 9-3

Page 52

IX.B. MOISTURE PERFORMANCE PARAMETERS (cont’d)

Model: 3216A Serial: 00512 Calib. date: Mar 21, 2005

Source: AM-241/Be Serial: 78-976 Print date: Dec 07, 2005

Neutron Surface Moisture Gauge

******

The performance parameters, calibration constants, and moisture values for this

instrument are listed both in SI units (kilograms per cubic meter) and in

US Customary Units (pounds per cubic foot). In each instance where the SI and

US Customary values differ, the SI will be listed first, followed by the

US Customary Units in parentheses.

******

Calibration Measurement Data

Standard Moisture Content Counts/Min.

kg/M3 (pcf)

--------- ---------------- ---------- Magnesium 0 9.0

Mag/Poly 606 (37.8) 108.4

******

Calibration Equation:

For the form of the linear equation y = mx + b, where x is the independent

variable (moisture content), y is the dependent variable (gauge count),

m is the slope of the calibration curve, and b is the intercept of the

calibration curve, the calibration equation for this gauge is:

y = 0.1640x + 9.000, where x in in units of kilograms per cubic meter

or,

y = 2.626473x + 9.000, where x in in units of pounds per cubic feet.

For the form of the linear equation x = my + b, where x is the independent

variable (moisture content), y is the dependent variable (gauge count),

m is the slope of the calibration curve (also known as the Resolution), and

b is the intercept of the calibration curve, the calibration equation for

this gauge is:

x = 6.0987y - 54.888, where x in in units of kilograms per cubic meter

or,

x = 0.380739y - 3.427, where x in in units of pounds per cubic feet.

******

Precision for various measurement times

Moisture <--------- Measurement Time --------->

kg/m3 (pcf) 7.5 Sec. 15 Sec. 60 Sec

--------- ---------- ---------- --------- 0 ( 0.0) 4.6 (0.29) 3.2 (0.20) 1.6 (0.10)

100 ( 6.2) 7.7 (0.48) 5.4 (0.34) 2.7 (0.17)

200 (12.5) 9.9 (0.62) 7.0 (0.44) 3.5 (0.22)

Troxler Model 3216 Calibration Report - Page 1 of 2

3216 Calibration Data (Sheet 1 of 2)

Figure 9-1

9-4 TROXLER

Page 53

IX.B. MOISTURE PERFORMANCE PARAMETERS (cont’d)

Troxler Model 3216 Calibration Report - Page 2 of 2

Model: 3216A Serial: 00512 Calib. date: Mar 21, 2005

Source: AM-241/Be Serial: 78-976 Print date: Dec 07, 2005

Neutron Surface Moisture Gauge

******

The calibration parameters for this instrument are based upon the measured

material having a uniform moisture content equally distributed throughout the

measured depths. The depth of measurement of this instrument will vary from

100 mm (4 inches) to upwards of 250 mm (10 inches) depending upon the moisture

content of the material. These parameters may be significantly altered if the

material thickness is reduced below the depth of measurement.

The above referenced equipment has been calibrated by the manufacturer to

established and documented procedures. Moisture values for the standards used

in the calibration of this equipment are based upon instrument response in

siliceous soil. Test procedures and supporting documentation are available

upon request

This instrument was found to be mechanically sound and electronically stable both

prior to and after its calibration. All data listed in the preceding page of this

report are applicable to this instrument only. This calibration was performed by

JRS on 03-21-2005 at:

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Road

Research Triangle Park, NC 27709

www.troxlerlabs.com

Special considerations and limitation of use for this device and its calibration are

described in the Manual of Operation and Instruction provided with this instrument.

This report shall not be reproduced, except in full, without the written approval of

Troxler Electronic Laboratories, Inc.

3216 Calibration Data (Sheet 2 of 2)

Figure 9-1

TROXLER 9-5

Page 54

IX.B. MOISTURE PERFORMANCE PARAMETERS (cont’d)

Graphic Interpretation of Moisture Calibration

Figure 9-2

9-6 TROXLER

Page 55

X. RADIATION THEORY AND SAFETY

The quantities of radioactive material contained in Troxler

moisture gauges are quite small, and an operator may safely

use a gauge daily without receiving any biological damage

due to radiation. In addition, each radioactive source is

doubly encapsulated to afford greater protection for the

operator. However, all radioactive sources, no matter how

small, should be handled with care.

The purpose of this section is to acquaint the operator with

the types and characteristics of radiation with which he/she

will be working and to describe methods to ensure safe

operation of Troxler gauges.

X-A. RADIATION THEORY

A more detailed discussion of radiological theory can be

found in the Troxler Nuclear Gauge Safety Training

Program manual, provided at the Troxler radiation safety

class.

X-A-1. ATOMIC STRUCTURE

All materials consist of chemical elements that can not

decompose by ordinary chemical methods. Some examples

are:

(H) Hydrogen (C) Carbon (O) Oxygen

(U) Uranium (Cf) Californium (Co) Cobalt

Each element contains an atom with a unique structure.

The atom consists of smaller particles such as protons,

neutrons and electrons. The protons and neutrons are

grouped together in the nucleus (Figure 10-1). The

electrons orbit the nucleus. An atom is normally

electrically neutral because the positive protons cancel

out the negative electrons.

Diagram of an Atom

Figure 10-1

Protons carry a positive charge and are described as

having a mass of one. Neutrons have a neutral charge and

also have a mass of one. Electrons carry a negative

charge and essentially have no mass.

MASS

(ATOMIC WEIGHT SCALE) CHARGE

Protons 1.0073 +1

Neutrons 1.0087 0

Electrons 0.0006 -1

TROXLER 10-1

Page 56

Since protons and neutrons are clustered together in the

nucleus, the mass of an atom is concentrated in the

nucleus. The atom in Figure 10-1 has two protons and two

neutrons; therefore, it is a helium atom. The atomic

weight of an atom is the sum of the protons and neutrons.

X-A-1. RADIATION THEORY

Radioactivity is the spontaneous breakdown of unstable

nuclei (radioisotopes) with the resulting emission of

radiation. The basic unit of radiation used in the U.S.

is the curie (Ci). The Curie is defined as 3.7 x 10

disintegrations of nuclei per second. In the "special

form," encapsulated sealed source used in the 3216, the

unit of measure is the millicurie (1/1,000 of a curie).

The SI unit of radiation is the Becquerel (Bq). The

Becquerel equals to one disintegration per second.

Therefore, one curie equals 3.7 x 10 Becquerels.

The strength of radioactive material is measured by its

activity, or rate of decay. This activity decreases with

time. The length of time it takes a given amount of

radioactive material to decay to half of its original

strength is referred to as the "half-life." The halflife of the 3216's source is approximately 432 years.

X-A-3. RADIATION TERMINOLOGY

10

10

The curie, defined as the quantity of radioactive

material giving 3.7 x 10 disintegrations per second, is

equal to the number of disintegrations/second of one gram

of radium-226. Note that the source used in the 3216 is

small, with quantities expressed in millicurie (mCi).

The rad or "radiation absorbed dose," is the unit of

absorbed dose equal to 0.01 Joules/kg in any medium. To

account for the effect of various types of radiation on

biological tissue, the "roentgen equivalent man" (rem) or

more appropriate for Troxler users - the millirem - is

used when measuring radiation dose. The unit rem is

derived from scaling the radiation absorbed dose (rad) by

a quality factor (QF). One rem is equal to the exposure

of one rad of gamma radiation. For example, the average

energy of an americium-241:beryllium neutron source is

4.5 MeV. The quality factor (QF) for this source is

approximately 10. The absorbed dose of 1 rad of neutron

radiation gives a dose equivalent of (absorbed dose x QF)

10 rem.

X-A-4. RADIATION STATISTICS

Radioactive emission is a random process. The number of

emissions in a given time period is not constant but

varies statistically about an average value. The

variation about the true mean value is a Poisson

distribution (Figure 10-2). In this distribution, the

standard deviation (F) about the mean (n) is defined as:

10

F = % n

10-2 TROXLER

Page 57

When the mean is greater than 100, the Poisson

distribution can be closely approximated by the normal

distribution (Figure 10-2). The normal distribution

predicts the probability that any given count rate will

fall within a selected region about the mean.

Normal Distribution

Figure 10-2

Variation of Radioactive Emission

Using the mean of a larger number of counts to

approximate the true mean, the distribution shows that

68.3% of the time the count rate obtained will be within

±1 standard deviation of the mean. The figure above shows

the probabilities for three different standard deviations

of the mean. A statistical stability test may be

performed to compare the experimental standard deviation

to the theoretical standard deviation (see AII).

X-B. RADIATION SAFETY

This section provides a brief discussion of general

radiation safety. The exposure profile for the Model

3216 gauge is also included, along with a discussion of

the source encapsulation.

X-B-1. TYPES OF RADIATION

The radioactive source in the Model 3216 produces three

types of radiation:

Alpha Particles

Gamma Rays (Photons)

Neutrons

The alpha particles are stopped by the source capsule.

Only the gamma and neutron radiation can contribute to

any occupational radiation exposure.

TROXLER 10-3

Page 58

Gamma radiation is electromagnetic radiation, as are

x-rays, radio waves, and visible light. Visible light

and gamma rays have no mass, a zero electrical charge and

travel at the speed of light. Gamma rays are energetic

and penetrating. Dense materials (i.e., lead, cadmium,

etc.) provide the best shielding against gamma radiation.

Neutron radiation allows measurement of the hydrogen

(moisture) content in a material because the neutrons are

slowed by collisions with materials containing hydrogen

atoms (i.e. water, polyethylene, etc.). Neutrons have a

neutral charge and are very penetrating.

X-B-2. LIMITING EXPOSURE

Under normal conditions a full time operator of the 3216

will receive less than 150 millirem per year.

Taking advantage of all available means to limit

radiation exposure is always recommended. The three

methods of limiting exposure are:

These methods are a part of an "ALARA" (As Low As

Reasonably Achievable) program.

TIME

TIME

DISTANCE

SHIELDING

The simplest way to reduce exposure is to keep the time

spent around a radioactive source to a minimum. If time

is cut in half, so is the exposure, with all other

factors remaining constant.

DISTANCE

Distance is another effective means to reduce radiation

exposure. A formula known as the "inverse square law"

relates the radiation exposure rate to distance (Figure

10-3). Doubling the distance from a radiation source

reduces the exposure to one-fourth its original value.

If the distance is tripled, the exposure is reduced by a

factor of nine, etc.

Effect of Distance on Exposure

Figure 10-3

10-4 TROXLER

Page 59

SHIELDING

Shielding is any material used to reduce the radiation

reaching the user from a radioactive source. While some

types of radiation such as alpha particles may be stopped

by a single sheet of paper, other particles such as gamma

rays and neutrons require much more shielding. Dense

materials, such as lead, shield gamma rays. Materials

containing large amounts of hydrogen, such as

polyethylene, shield neutrons. The Model 3216 has

shielding built into the system which reduces the

exposure.

X-B-3. MONITORING RADIATION

Government agencies set occupational exposure limits.

The current limit in the United States and many other

countries is 5,000 millirem per year. Under average

conditions a full time employee working with the 3216

will receive less than 150 millirem per year.

Anyone working with or near radioactive materials is

subject to the limits of occupational exposure and must

complete a radiation safety training course to be

designated an authorized user. As an authorized user, an

individual so designated must work in a "controlled"

environment to the extent that their exposure to

radiation must be monitored. Several means of personnel

monitoring or dosimetry exist; the most common methods

are film badges and TLD badges.

TROXLER 10-5

Page 60

X-B-4. 3216 RADIATION PROFILE

RADIATION PROFILE FOR 3216/3218 GAUGE

LOCATION

FRONT 0.20 3.0 3.2 * 0.8 0.8 * 0.3 0.3 * * *

BACK * 0.4 0.4 * 0.2 0.2 * 0.1 0.1 * * *

SIDES 0.15 1.4 1.55 * 0.5 0.5 * 0.3 0.3 * * *

TOP * 1.5 1.5 * 0.6 0.6 * 0.3 0.3 * * *

BOTTOM 1.00 4.5 5.5 * 2.5 2.5 * 0.5 0.5 * 0.1 0.1

HANDLE * 0.3 0.3 * 0.15 0.15 * * * * * *

LOCATION

LEFT 0.4 1.3 1.7 * 0.4 0.4 * 0.1 0.1

BACK * 0.2 0.2 * * * * * *

RIGHT * 0.2 0.2 * * * * * *

FRONT * 0.7 0.7 * 0.2 0.2 * * *

BOTTOM * 0.4 0.4 * 0.2 0.2 * * *

TOP * 0.3 0.3 * * * * * *

SURFACE 10 cm 30 cm 1 m

Gamma Neutron Total Gamma Neutron Total Gamma Neutron Total Gamma Neutron Total

RADIATION PROFILE FOR 3216 GAUG E IN PLASTIC CASE

SURFACE 10 cm 30 cm 1 m

Gamma Neutron Total Gamma Neutron Total Gamma Neutron Total Gamma Neutron Total

1. Dose rates measured by the State of North Carolina Department of Environment, Health and Natural

Resources, Division of Radiation Protection.

2. Gamma Measurements in case made using Ludlum 14C Survey Meter, Calibrated March 1990.

3. Neutron Measurements in case made with Nuclear Research Corp. Model NP-2 Survey Meter, Calibrated

March 1990.

4. Gamma Measurements of gauge alone made with a Victoreen Model 2035 Survey Meter.

5 Neutron Measurements of gauge alone made with a Nuclear Research Corporation Model NP-2 Survey Meter

(detector physical location is 11.5 mm inside thermalizing housing).

6. Dose rates for 40 mCi Am-241:Be source.

7. * indicates a reading of less than 0.1 millirem/hour.

NOTE: RADIATION DOSE RATES IN MILLIREMS PER HOUR

Figure 10-4

10-6 TROXLER

Page 61

X-B-5. SOURCE ENCAPSULATION

The source in the Model 3216 meets regulatory

requirements of U.S. and international authorities as

"SPECIAL FORM," or encapsulated, sealed source material.

The "sealed" source used is encapsulated to prevent

leakage of the radioactive material and meet radiation

safety requirements.

Proper use of this instrument (following the instructions

in this manual) and the shielding design of the

instrument will keep the exposure levels at a minimum

under normal conditions. It is, however, required that

personnel dosimetry be used when using the 3216.

X-B-6. EMERGENCY PROCEDURES

If the nuclear gauge is lost or stolen, then immediately

notify the Radiation Safety Officer (RSO).

The gauge owner should complete the emergency contact information on

the lines furnished below.

The company RSO is ___________________________________.

Call the RSO at _______________________________________.

The regulatory agency is ________________________________.

Call the agency at _____________________________________.

If a gauge is damaged, then follow the steps below:

T Locate the gauge and/or source.

T Do not touch or move the gauge.

T Immediately cordon off an area around the nuclear

gauge and/or source. A radius of fifteen feet (5 m)

will be sufficient. Do not leave the area unattended.

T Keep all unauthorized personnel from the nuclear

gauge.

T If a vehicle is involved, it must be stopped until the

extent of contamination, if any, can be established.

T The gauge user should perform a visual inspection of

the nuclear gauge to determine if the source housing

and/or shielding has been damaged.

T Use a survey meter to measure the dose rate at a

distance of three feet (1 m) from the gauge.

TROXLER 10-7

Page 62

T Contact the company RSO (name and number given at the

beginning of this section). Provide the RSO with the

following:

Ë the date, time, and location of the accident,

Ë the gauge model and serial number,

Ë the nature of the accident,

Ë the location and condition of the gauge and/or

source,

Ë the dose rate at three feet (1 m) from the gauge.

T If you are unable to reach the RSO, then call your

regulatory agency (name and number given at the

beginning of this section).

T Follow the instructions of the RSO. The RSO should

report the incident to the regulatory agency. The RSO

may also be required to notify the USDOT of accidents

during transport.

T Before shipping a damaged gauge to Troxler, obtain a

RGA (returned goods authorization) number from the

Troxler RSO.

10-8 TROXLER

Page 63

XI. TRANSPORTATION AND SHIPPING

Devices containing radioactive materials must be transported

in accordance with the rules of the U.S. Department of

Transportation (DOT) and the International Atomic Energy

Agency (IAEA). The IAEA recommendations have been codified

in the International Air Transport Association (IATA)

Dangerous Goods Regulations. International customers should

consult their local government or licensing authority for

applicable regulations.

XI-A. U.S. SHIPPING REQUIREMENTS

The U.S. DOT hazmat regulations (49 CFR, Parts 100-185)

apply any time a nuclear device is transported by motor

vehicle on a public highway or by other means of

transport (rail, air, ship).

The major requirements for transporting a nuclear gauge

in the United States are listed below. For more detailed

information about these requirements, please refer to the

Troxler Transportation Guide.

Ë A copy of the current IAEA Certificate of Competent

Authority for each source in the gauge (Special Form

Certificate) must be kept on file. Current versions

can be downloaded from the Troxler website,

www.troxlerlabs.com.

Ë A copy of the results of the Type A package testing

must be kept on file.

Ë Hazmat employee training records must be kept on

file.

Ë An Emergency Response Information document must be

in the vehicle and immediately accessible to the

driver.

Ë A properly completed bill of lading must be in the

vehicle and immediately accessible to the driver.

The shipping papers must include a 24-hr emergency

response phone number.

Ë If shipping by air, a Shipper’s Declaration for

Dangerous Goods must accompany the air waybill.

Ë The package must be properly marked and labeled in

accordance with hazmat regulations.

Ë The package must have a tamper-evident seal.

Ë The package must be inspected prior to each

shipment.

Ë The package must be securely blocked and braced in

the vehicle to prevent shifting during transport.

TROXLER 11-1

Page 64

XI-A-1. ACCIDENT NOTIFICATION REQUIREMENTS

In the event of a reportable incident involving

radioactive material, notify the licensing agency as soon

as practical. The operator is also required to notify, at

the earliest practical moment, the U.S. DOT at

1-800-424-8802 of an accident that occurs during the

course of transportation (including loading, unloading,

and temporary storage) in which fire, breakage, spillage,

or suspected contamination occurs involving shipment of

radioactive materials.

XI-A-2. HAZMAT TRAINING

The U.S. DOT regulations require every hazmat employer to

train, test, certify, and maintain records for each

hazmat employee. Hazmat training applies to anyone who

transports or prepares for transport radioactive

materials. Refresher training is required every three

years.

XI-B. CANADIAN SHIPPING REQUIREMENTS

The Transportation of Dangerous Goods Act and Regulations

(TDG) and Transport Packaging of Radioactive Materials

Regulations (TPRM) apply any time a nuclear device used

in commerce is transported by any means in Canada.

For training and accident notification requirements,

consult the Transportation Of Dangerous Goods

Regulations. For further information on transporting a

nuclear device, contact the transportation section of The

Canadian Nuclear Safety Commission (CNSC).

11-2 TROXLER

Page 65

APPENDIX

Page 66

Page 67

Page 68

Loading...

Loading...