Page 1

Manual of Operation and Instruction

Model 3191

True Mold Angle

Device

for the

Model 4141 Gyratory Compactor

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Road • P.O. Box 12057

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER

Outside the U.S.A.: +1.919.549.866 1

Fax: +1.919.549.0761

www.troxlerlabs.com

Page 2

Troxler products are protected by U.S. and foreign patents

Copyright © 2002 – 2005

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

PN 109903

February 2005

Edition 2.0

ii

Page 3

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

Research Triangle Park, NC 27709

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2000 East Randol Mill Road

Suite 611

Arlington, TX 76011

Fax: 817.275.8562

P.O. Box 12057

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Canadian Branch Office

7125 Pacific Circle, Unit 13

Mississauga, Ontario L5T-2A5

Canada

Fax: 905.564.7092

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr. Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

Model 3191 True Mold Angle Device iii

Page 4

NOTES

iv

Page 5

INTRODUCTION

Troxler’s Model 4141 Gyratory Compactor provides safe, reliable

gyratory compaction of asphalt specimens at a compaction pressure

of 600 kPa and 1.25° angle of gyration. The Model 3191 True Mold

Angle Device (TMA) provides a real-time display of compaction

angles, enabling the compactor operator to accurately and

independently verify the true angle of the mold while the compactor

is in operation.

To complement the TMA’s real-time data display, a True Mold

Angle software package is provided with the unit. This software can

be used to upload and store angle measurement data on a computer.

The TMA attaches to the frame of the Model 4141, and measures

the mold angle externally.

The TMA is a passive measuring device that does not interfere with

the normal operation of the gyratory compacto r. The TMA does not

affect the mold angle being measured, or the relationship between

the surface of the sample and the active ram head or ram foot.

Because the TMA is external to the mold, it does not limit the

amount of sample that can be placed in the mold during the test.

This enables the TMA to perform dynamic measurements during the

preparation of actual specimens. There is no need to extrapolate or

project possible angles for full-sized samples from one-quarter or

half-sized samples with the TMA.

During compaction, residue from the asphalt sample may bind to the

mold wall creating an uneven surface. These irregularities will

adversely affect the angle measurement of an internal measuring

device if its measurement probes contact the inner walls of the

mold. The TMA, however, measures the angle using the external

surface of the mold.

Model 3191 True Mold Angle Device 1

Page 6

TWO-POINT MEASUREMENT METHOD

The TMA measures mold angle using a simple and traditional twopoint measuring method. Troxler has used this concept to measure

mold angle since the company started manufacturing the original

Model 4140 Gyratory Compactor.

The two-point measurement uses a simple trigonometric function to

calculate gyratory compactor mold angle. Because the TMA is

secured to the frame of the compactor, the angle measu red is net of

frame deflection and therefore is the true mold angle. The result is

that the TMA gives precise and accurate true mold angle

measurements in a passive and independent manner.

The TMA method reasonably assumes that the mold wall is rigid

and non-deformable under normal compaction loads. The mold wall

is parallel to the centerline of the mold so that the measured angle is

concurrent with the cylindrical axis of the mold and specimen

during compaction.

Most importantly, the TMA is capable of isolating gyratory mold

angle from other compaction variables. End plate or platen

deflections and translations do not affect the measured angle.

Mixture surface deflections and temperature variations do not skew

the results. Therefore, compliance with AASHTO T312 §4.1 and

§9.5 is easily ascertained and, if necessary, corrections to gyratory

mold angles can be made reliably.

2

Page 7

UNPACKING AND INSPECTION

Upon receipt of the TMA from the factory, perform a complete

inspection and inventory. If the shipping carton and/or any other

part or accessory appears damaged, notify the carrier and your

Troxler Representative immediately.

NOTE

To ensure the safe return of the TMA to Troxler for

repair or maintenance, please keep the original shipping

box and all packing materials.

Check the shipping carton for the following:

♦ Model 3191 TMA (PN 109861)

♦ Molded transport case (PN 900977)

♦ Cable assembly, power and door interlock (PN 109700)

♦ Serial cable (PN 106514)

♦ Manual of Operation and Instruction (PN 109903)

♦ CD-ROM, True Mold Angle software (PN 110080)

Inspect the outside surfaces of the TMA for damage.

Model 3191 True Mold Angle Device 3

Page 8

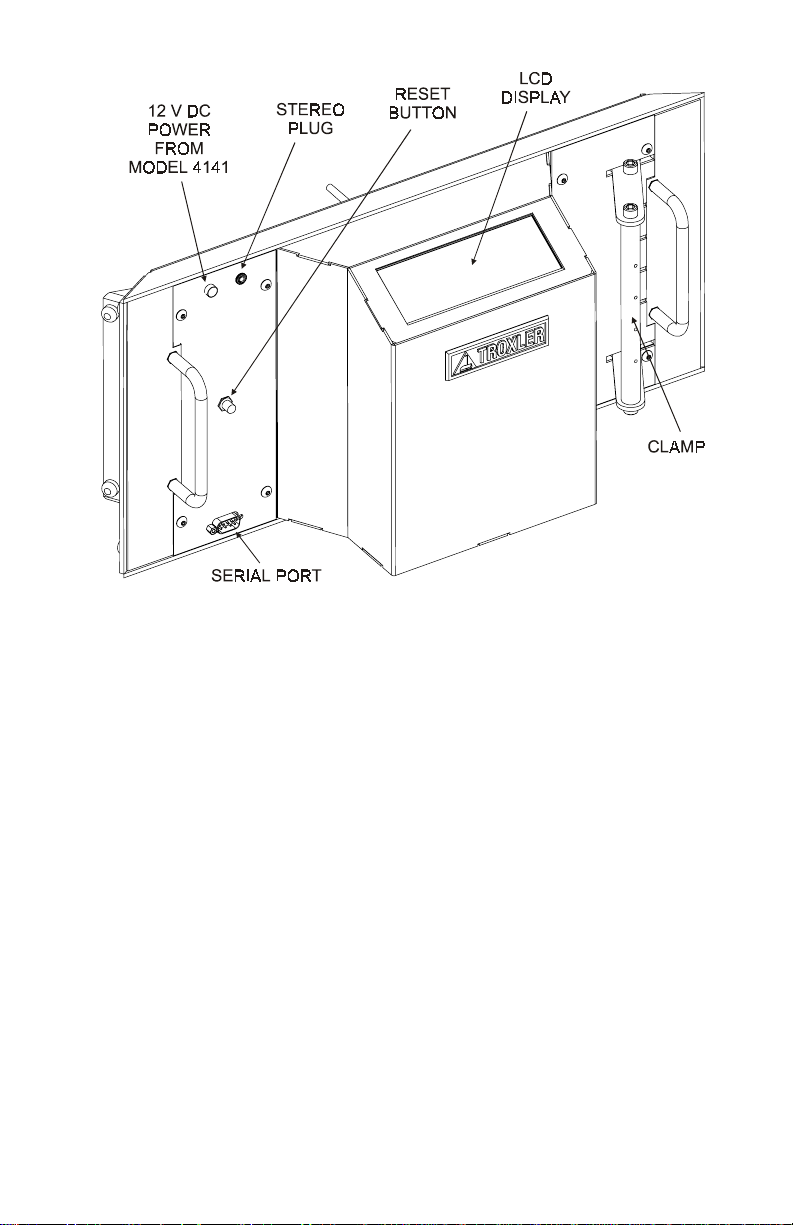

COMPONENTS

Figure 1 shows the TMA and its components. Use the figure to

locate and identify the parts described in the following paragraphs.

During compaction, the TMA’s LCD (liquid crystal display) display

shows the maximum, minimum, and average compaction angles, as

well as the standard deviation of the measurements.

The Reset button clears the TMA memory and restarts the angle

measurements and standard deviation calculations.

A cable assembly (not shown) provided with the TMA connects to

the 12 V dc power and stereo plugs. This assembly is made up of

two cables and is used to connect the TMA to the Model 4141

Gyratory Compactor. The 12 V dc power cable connects the

compactor’s 12 V dc power supply to the TMA. Because the TMA

is powered by the gyratory compactor, a separate power source is

not necessary.

The stereo cable is used to bypass the safety interlock on the

compactor door. For operator safety, the Model 4141 will not

operate unless its door is properly closed, or the TMA device is in

place with the stereo cable connected.

The spring-loaded clamp is used to secur e the TMA in plac e on the

compactor.

The serial cable (not shown) can be connected to the serial port to

upload angle measurements to a PC using the TMA software

provided with the unit.

4

Page 9

Figure 1. Model 3191 True Mold Angle Device

Model 3191 True Mold Angle Device 5

Page 10

SETUP AND OPERATION

This section describes how to use the TMA to monitor the gyration

angle during the compaction of a hot mix asphalt specimen.

1. Prepare the asphalt specimen as described on page 4–3 of the

Model 4141 Manual of Operation and Instruction.

2. Place the loaded mold into the Model 4141 compaction

chamber.

3. Lift the TMA into place. Hook the fixed (left) end of the TMA

around the left frame rail of the Model 4141.

4. Squeeze the spring-loaded clamp on the right end of the TMA,

and push the TMA against the compactor’s right frame rail.

Release the clamp to secure the TMA in place.

NOTE

Ensure that the TMA does not rest on the compactor

table.

5. Connect the 12 V dc and stereo cables from the TMA (see

Figure 1) to the appropriate connectors on the Model 4141 as

shown in Figure 2.

6. If using the True Mold Angle software to upload angle data to a

computer, connect the serial cable from the TMA to a serial port

on the computer. Refer to page 8 for instructions on installing,

starting, and using the software.

7. Compact the specimen as described on page 4–5 of the Model

4141 Manual of Operation and Instruction. During the

compaction process, the TMA displays the maximum,

minimum, and average measured mold angle, as well as the

standard deviation of the measurements. This information is

updated each gyration.

6

Page 11

NOTE

When processing an asphalt specimen, the average mold

angle should be between 1.23° and 1.27°.

NOTE

If excursion data is to be downloaded from the TMA to

a computer, do not disconnect the 12 V dc and stereo

cables from the compactor.

8. To remove the TMA from the compactor, disconnect the 12 V

dc and stereo cables from the Model 4141. Squeeze the springloaded clamp on the right end of the TMA, and lift the TMA

from the compactor.

STEREO

PLUG

12 V DC

POWER

TO TM A

DEVICE

Figure 2. TMA Connections on the Model 4141

Model 3191 True Mold Angle Device 7

Page 12

TRUE MOLD ANGLE SOFTWARE

During a compaction cycle, the TMA measures the excursions of its

upper and lower probes and uses these values to determine the

gyration angle. Starting with the third gyration of the cycle, the

TMA stores the excursion values and resulting angle for each

gyration.

The True Mold Angle software supplied with the TMA is used to

upload and store the excursion and angle data on a computer. The

data is stored in a comma-delimited format, as shown in Figure 3.

The following sections provide instructions on the installation,

setup, and use of the True Mold Angle software.

3,1.249,.000,6.092,.000

4,1.288,3.480,9.760,.000

5,1.286,3.476,9.748,.000

6,1.286,3.476,9.748,.000

7,1.284,3.480,9.744,.000

8,1.283,3.480,9.736,.000

9,1.284,3.480,9.740,.000

10,1.280,3.480,9.724,.000

11,1.279,3.488,9.728,.000

12,1.279,3.484,9.724,.000

13,1.279,3.484,9.724,.000

14,1.279,3.484,9.724,.000

15,1.278,3.484,9.716,.000

16,1.279,3.484,9.720,.000

17,1.279,3.484,9.724,.000

18,1.279,3.488,9.724,.000

19,1.277,3.488,9.716,.000

20,1.277,3.488,9.716,.000

21,1.278,3.488,9.720,.000

22,1.276,3.492,9.716,.000

23,1.276,3.492,9.716,.000

24,1.275,3.492,9.712,.000

25,1.277,3.492,9.720,.000

•

•

•

Figure 3. Sample Data from TMA

8

Page 13

SOFTWARE INSTALLATION

To install the True Mold Ang le softwar e:

1. Insert the True Mold Angle CD-ROM into the computer’s

CD-ROM drive.

2. From the Windows 95/98 desktop, click on the Start button in

the taskbar.

3. Select R

4. Type d:tmainstall.exe (where d: is the letter designation of

the CD-ROM drive) and then press the 〈Enter〉 key or click on

the OK button. Follow the instructions on the screen.

5. The installation program adds a Troxler group to the Programs

menu, with the program items: TMA and Uninstall TMA. The

installation program also places a shortcut icon for the TMA

application on the Windows desktop.

un. The dialog box shown in Figure 4 is displayed.

Figure 4. Installing the True Mold Angle Software

Model 3191 True Mold Angle Device 9

Page 14

STARTING THE TRUE MOLD ANGLE SOFTWARE

To start the True Mold Angle software, double-click on the TMA

icon on the Windows 95/98 desktop or click on the Start button,

select the P

TMA menu item. The software briefly displays a copyright screen

while loading. Upon completion, the software displays the Main

Menu shown in Figure 5.

rograms menu and the Troxler folder, and select the

Figure 5. True Mold Angle Software Main Menu

10

Page 15

UPLOADING DATA

The True Mold Angle software can upload excursion data from the

TMA into the computer either in real-time (during a compaction

cycle) or after a compaction cycle is complete.

NOTE

The TMA stores only the angle data from the most

recent compaction cycle. This data is available for

uploading at any time until a new compaction cycle is

begun or power has been removed from the TMA.

Uploading Data During Compaction

To acquire data from the TMA during a compaction cycle:

1. Click the Start button on the Main Menu. The software

requests a file name as shown in Figure 6.

2. Enter a filename, followed by the extension .txt, but do not press

the 〈Enter〉 key or click on the OK button.

3. Follow the directions on page 6 for operating the TMA while

compacting the specimen. After the compactor has begun

gyrating, press the 〈Enter〉 key or click on the OK button.

4. The command line at the bottom of the Main Menu displays

Initializing…, then Waiting for data… During the

compaction cycle, the software uploads excursion data from the

TMA and writes this data into the filename entered in step 2.

Figure 6. File Name Prompt

Model 3191 True Mold Angle Device 11

Page 16

Uploading Stored Data

NOTE

The TMA stores only the angle data from the most

recent compaction cycle. This data is available for

uploading at any time until a new compaction cycle is

begun or power has been removed from the TMA.

To upload the excursion data stored in the TMA from the most

recent compaction cycle:

1. Click the Upload button. The software requests a file name as

shown in Figure 6.

2. Enter a filename, followed by the extension .txt, and then press

the 〈Enter〉 key or click on the OK button.

3. The command line at the bottom of the Main Menu displays

Initializing…, then Collecting data… Please wait. The

software uploads the angle data from the TMA and writes this

data into the filename entered in step 2 above.

12

Page 17

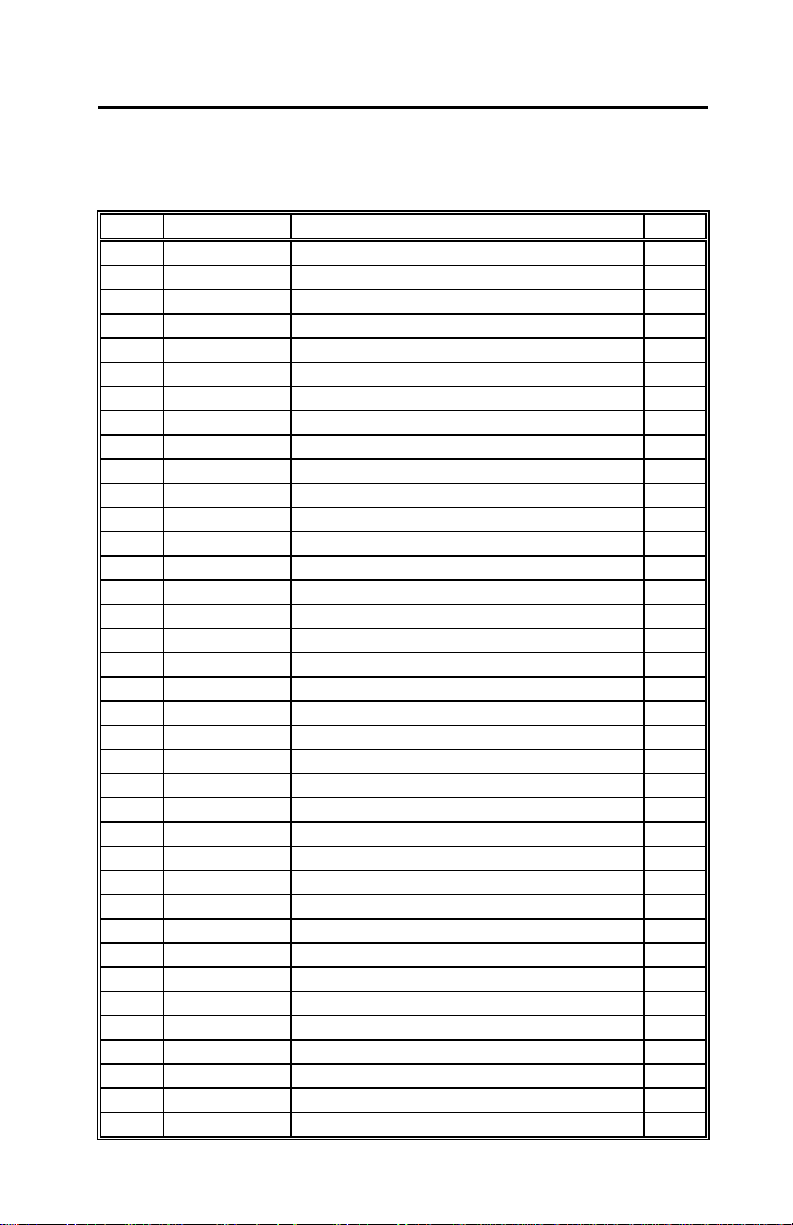

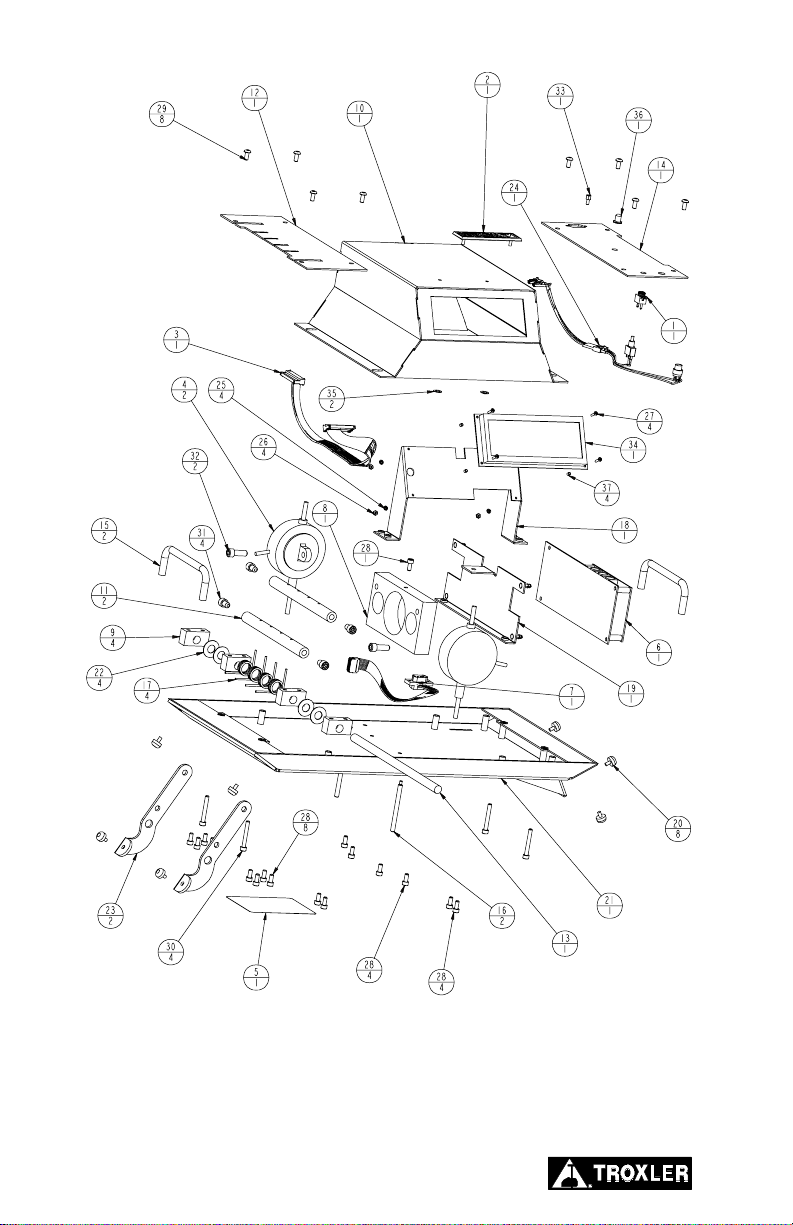

REPLACEMENT PARTS

Match the reference number (Ref #) shown below with the correct

part in Figure 7 on the following page.

ITEM BIN NO. DESCRIPTION QTY.

1 002492 STEREO JACK SOCKET 1

2 104663 SMALL TROXLER LOGO PLATE 1

3 107692 CABLE, LCD 1

4 108555 LOGIC PROBE, TMA, 319X 2

5 108835 LABEL, TRUE MOLD ANGLE 1

6 109550 ELECT. BOARD ASSY, TMA: 3191,1,2 1

7 109697 ANGLE SERIAL CABLE ASSY 1

8 109798 LOGIC PROBE BRACKET, TMA: 319X 1

9 109802 CLAMP PIVOT MOUNT, TMA: 3191 4

10 109804 COVER ASSEMBLY, TMA: 3191,1 1

11 109805 CROSSBAR, TMA: 3191,2 2

12 109807 RIGHT SIDE COVER, TMA: 3191 1

13 109809 PIVOT BAR, TMA: 3191,2 1

14 109822 LEFT SIDE COVER, TMA: 3191 1

15 109824 ALUMINUM HANDLE, TMA: 3191,1,2 2

16 109833 DIAL INDICATOR EXT, 3/16 x 2-1/4 2

17 109834 COIL SPRING, RHW, TMA: 3191,2 4

18 109852 DISPLAY BRACKET, TMA: 3191,1 1

19 109853 ELECTRONICS BRACKET, TMA: 3191,1 1

20 109854 RUBBER BUMPER, TMA: 3191,2 8

21 109855 BACKPLATE ASSEMBLY, TMA, 3191 1

22 109858 DELRIN WASHER, TMA: 3191, 2 4

23 109859 CLAMP ARM, TMA: 3191 2

24 109911 CABLE ASSY POWER, RESET 1

25 000001-0200 LOCKWASHER #2 INT TOOTH SS 4

26 000061-1000 #2 HEX NUT SS 4

27 000106-1401 SCREW, 2-56 x .375 PHIL HD, SS 4

28 000406-4801 SCREW, 8-32 x .375 SHCS, SS 17

29 000406-4901 SCREW, 8-32 x .375 BHCS, SS 8

30 000420-4801 SCREW 8-32 X 1-1/4 SHCS SS 4

31 000806-4801 SCREW, 1/4-20 x .375 SHCS, SS 4

32 000812-4801 SCREW, 1/4-20 x .750 SHCS, SS 2

33 100-0003 HARDWARE KIT 1

34 108192-3191 LCD DISPLAY ASSY, TMA: 3191,1,2 1

35 27-5050 PUSH NUT FLAT-ROUND 3/8 OD 2

36 7607-1000 PUSH BUTTON BOOT 1

37 910-0434 #2 ROUND SPACER, 125", PLASTIC 4

Model 3191 True Mold Angle Device 13

Page 18

Figure 7. TMA Assembly Drawing

14

Page 19

RETURNING PARTS FOR SERVICE

Items returned for service must be accompanied by an RGA

(Returned Goods Authorization) number, and a description of the

instrument and its problem. This information is used by Troxler

shipping and service personnel to expedite the repair work.

To obtain an RGA number, please call or fax Troxler headquarters

at Research Triangle Park, or one of the branch offices with your

request (see list on page iii).

Please have the following information available when requesting an

RGA number:

• Unit (or part) model and serial number.

• Part number/serial number (if applicable).

• Is the unit (part) still under warranty?

• Problem or difficulty you are having with the unit.

• Shipment method to Troxler and for return shipment.

• Shipping and billing address (not P.O. Box) – street address and

zip.

• Phone number/contact (for questions from Troxler).

• Will estimate be required prior to performing any work on the

part?

• Payment method: credit card, account number, or purchase

order number. All government agencies (city, county, state,

and federal) must

To prevent order duplication, if an order has been

placed by telephone, please write “Confirming Order”

on any follow-up written requests.

Model 3191 True Mold Angle Device 15

send purchase order numbers.

NOTE

Page 20

SPECIFICATIONS

ENVIRONMENTAL CONDITIONS

Ambient Storage –55 to 85 °C

Temperature (–67 to 185 °F)

Ambient Operating 10 to 50 °C

Temperature (50 to 122 °F)

Altitude Rating 2000 meters maximum

Humidity 92% maximum

ELECTRICAL SPECIFICATIONS

Power Requirements 12 V dc (supplied by the Model

4141 Gyratory Compactor)

Serial Port: 9-pin male D-subminiature

connector

MECHANICAL SPECIFICATIONS

Size, Unit with 61L × 25W × 43H cm

Transport Case 24L × 10W × 17H in

Weight 3.6 kg (8lb)

Shipping Weight, 6.4 kg (14 lb)

Unit with Packaging

16

Loading...

Loading...