Page 1

Manual of Operation and Instruction

Model 2701-B

PaveTracker™ Plus

Troxler Electronic Laboratories, Inc.

3008 Cornwallis Rd. • P.O. Box 12057

Research Triangle Park, NC 27709 U.S.A.

Phone: 1.877.TROXLER

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

www.troxlerlabs.com

Page 2

Troxler gauges are protected by U.S. and foreign patents.

The Model 2701-B PaveTracker™ Plus is protected

by U.S. Patents 6,400,161 and 6,677,763.

Copyright © 2004 – 2007

Troxler Electronic Laboratories, Inc.

All Rights Reserved

No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including

photocopying, recording, or information storage and retrieval

systems, for any purpose without the express written permission of

Troxler Electronic Laboratories, Inc.

409 is a trademark of the Clorox Company.

Excel, HyperTerminal, Microsoft and Windows are registered

trademarks of Microsoft Corporation.

Fantastic is a trademark of Dow Consumer Products, Inc.

Goo Gone is a registered trademark of Magic American Products

Inc.

PaveTracker is a trademark of Troxler Electronic Laboratories, Inc.

PN 113045

December 2007

Edition 5.0

ii

Page 3

TROXLER SERVICE CENTERS

Troxler Corporate Headquarters

3008 Cornwallis Road

P.O. Box 12057

Research Triangle Park, NC 27709 U.S.A.

Phone: 1.877.TROXLER (1.877.876.9537)

Outside the U.S.A.: +1.919.549.8661

Fax: +1.919.549.0761

Web: www.troxlerlabs.com

Technical Support

Phone: 1.877.TROXLER (1.877.876.9537)

E-mail: TroxTechSupport@troxlerlabs.com

Midwestern Branch Office

1430 Brook Drive

Downers Grove, IL 60515

Fax: 630.261.9341

Western Regional Branch Office

11300 Sanders Drive, Suite 7

Rancho Cordova, CA 95742

Fax: 916.631.0541

Southwestern Branch Office

2016 East Randol Mill Road

Suite 406

Arlington, TX 76011

Fax: 817.275.8562

To locate an independent, Troxler-authorized service

center near you, call 1.877.TROXLER (1.877.876.9537).

Florida Service Center

2376 Forsyth Road

Orlando, FL 32807

Fax: 407.681.3188

Troxler European Subsidiary

Troxler Electronics GmbH

Gilchinger Strasse 33

D.82239 Alling nr. Munich, Germany

Phone: ++49.8141.71063

Fax: ++49.8141.80731

E-mail: troxler@t-online.de

NOTE

Model 2701-B iii

Page 4

HOW TO USE THIS MANUAL

Congratulations on the purchase of the Troxler Model 2701-B

PaveTracker™ Plus. Troxler, the leader in density gauge

technology, now offers the PaveTracker Plus, an electromagnetic

sensing device that quickly gives an indication of the density of

asphalt pavement.

The Model 2701-B Manual of Operation and Instruction contains

information on safely using this gauge. Also included in this manual

are safety warnings, gauge setup, troubleshooting, and general

maintenance.

iv

Page 5

CONVENTIONS USED IN THIS MANUAL

Throughout this manual, symbols and special formatting are used to

reveal the purpose of the text as follows:

WARNING

Indicates conditions or procedures that, if not followed

correctly, may cause personal injury.

CAUTION

Indicates conditions or procedures that, if not followed

correctly, may cause equipment damage.

NOTE

Indicates important information that must be read to

ensure proper operation.

〈KEY〉 Angle brackets and a different typestyle indicate a

key or character (number or letter) to press on the

gauge keypad. For example, “Press 〈STORE〉”

means to press the key labeled STORE.

DISPLAY A different typestyle is used in text to indicate

information or messages displayed on the gauge.

DISPLAY - Typestyle

and shading used to

simulate PaveTracker

display

♦ Diamonds indicate a list of things needed (such as

equipment) or things to know.

Check marks indicate the performance of an action.

With lists of check marks, follow the instructions in

the order of the check marks.

f Triangles indicate that more than one option is

available. Carefully select the option that applies.

Model 2701-B v

Page 6

EU DECLARATION OF CONFORMITY

Application of Council EMC Directive 89/336/EEC.

NOTE

The Low Voltage Directive 73/23/EEC does not apply to

the Model 2701-B PaveTracker Plus gauge because

there are no voltages greater than 75 V dc that are

accessible by the operator.

Standards to which Conformity is Declared:

EN 55011:1998+A1:1999+A2:2002 – Industrial, Scientific, and

Medical (ISM) Radio Frequency Equipment

EN 61326:1997+A1:1998+A2:2001+A3:2002 – Electrical

Equipment for Measurement, Control, and Laboratory Use

Manufacturer: Troxler Electronic Laboratories, Inc.

P.O. Box 12057, 3008 Cornwallis Road

Research Triangle Park, North Carolina

27709 U.S.A.

Apparatus: Model 2701-B PaveTracker Plus

Year of Declaration: 2006

vi

Page 7

FCC REGULATIONS

Troxler’s Model 2701-B PaveTracker™ Plus has been tested and

found to comply with the limits for Industrial, Scientific, and

Medical Devices pursuant to Part 18 of Federal Communications

Commission (FCC) Rules. These limits are designed to provide

reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy

and, if not used in accordance with this instruction manual, may

cause harmful interference to radio communications. Operation of

the equipment in a residential area may cause harmful interference.

It is advised that operation in residential areas be as brief as

practicable to minimize the potential for interference.

Model 2701-B vii

Page 8

NOTES

viii

Page 9

TABLE OF CONTENTS

CHAPTER 1. INTRODUCTION TO THE MODEL 2701-B

Introduction................................................................................... 1–2

Features......................................................................................... 1–4

Gauge Parts and Accessories........................................................1–6

Unpacking and Inspection ............................................................ 1–7

CHAPTER 2. GETTING STARTED

Keypad.......................................................................................... 2–2

Turning the PaveTracker Plus On................................................. 2–4

Status............................................................................................. 2–6

Setup Menu................................................................................... 2–7

Target.......................................................................................... 2–14

Mode........................................................................................... 2–16

CHAPTER 3. ADJUSTING MEASUREMENTS

Introduction................................................................................... 3–2

Offset ............................................................................................ 3–3

Mix Calibration............................................................................. 3–6

CHAPTER 4. USING THE GAUGE

Taking a Reference Reading ......................................................... 4–2

Preparing a Test Site..................................................................... 4–4

Taking Measurements................................................................... 4–5

Recall.......................................................................................... 4–12

CHAPTER 5. PROJECT DATA

Handling Project Data................................................................... 5–2

Storing Data.................................................................................. 5–8

Model 2701-B ix

Page 10

TABLE OF CONTENTS (Continued)

APPENDIX A. TROUBLESHOOTING AND SERVICE

Troubleshooting............................................................................A–2

Internal Gauge Temperature.........................................................A–3

Batteries........................................................................................A–4

Cleaning the Base and Top Shell .................................................A–6

Replacing the Protective Cover....................................................A–7

Replacement Parts........................................................................A–8

Returning the Gauge for Service..................................................A–9

Troxler Service Centers..............................................................A–10

APPENDIX B. MENU MAP

Menu Map Description.................................................................B–2

APPENDIX C. MODEL 2701-B SPECIFICATIONS

Measurement Specifications.........................................................C–2

Electrical Specifications...............................................................C–3

Mechanical Specifications............................................................ C–4

INDEX

WARRANTY

x

Page 11

LIST OF FIGURES

Figure

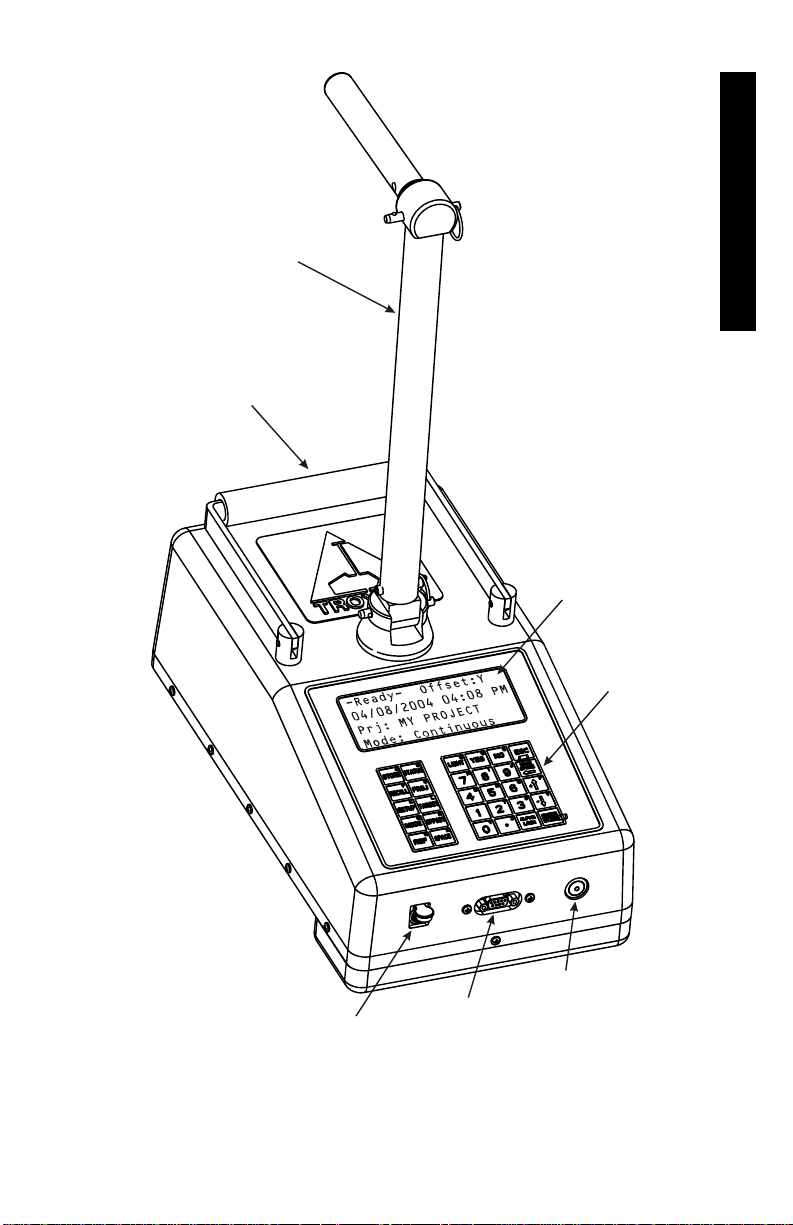

1–1 Model 2701-B PaveTracker Plus .............................. 1–3

2–1 Model 2701-B Keypad.............................................. 2–2

B–1 Model 2701-B Menu Map.........................................B–3

Title Page

LIST OF TABLES

Table

Title Page

2–1 Model 2701-B Keypad Functions.............................2–3

Model 2701-B xi

Page 12

NOTES

xii

Page 13

CHAPTER 1

INTRODUCTION TO THE MODEL 2701-B

This chapter provides a brief overview of the Troxler Model 2701-B

PaveTracker™ Plus, and includes a list of the gauge parts and

accessories, and instructions for unpacking and inspecting the

gauge.

CONTENTS

Introduction................................................................................... 1–2

Features......................................................................................... 1–4

Gauge Parts and Accessories........................................................ 1–6

Unpacking and Inspection ............................................................ 1–7

1. INTRODUCTION

Model 2701-B 1–1

Page 14

INTRODUCTION

Troxler, the leader in density gauge technology, now offers the

Model 2701-B PaveTracker Plus (see Figure 1–1), an

electromagnetic sensing device that quickly gives an indication of

the density of asphalt pavement. The advanced technology in the

patented PaveTracker Plus allows rapid and reliable measurements.

The PaveTracker Plus can be used on existing asphalt pavements or

on freshly placed mats. The unit is ideal for performing quick

quality control measurements to check for segregation, areas of low

density, and overall pavement uniformity.

The PaveTracker Plus is a precision device that is designed to

provide many years of trouble-free service. As any precision device,

the PaveTracker Plus requires reasonable care and maintenance to

ensure its accuracy and reliability. The user should:

♦ Keep the unit clean and free of all road debris.

♦ Return the unit to Troxler for yearly re-calibration and

inspection.

♦ Ensure that the unit remains sealed at all times. There are no

field-serviceable components inside the unit. Opening the case

will affect the integrity of the unit and therefore will void the

warranty.

1–2

Page 15

D

1. INTRODUCTION

HANDLE

CARRYING

HANDLE

DISPLAY

KEYPA

POWER

SWITCH

BATTERY

CHARGER

INPUT

SERIAL

PORT

Figure 1–1. Model 2701-B PaveTracker Plus

Model 2701-B 1–3

Page 16

FEATURES

The PaveTracker Plus (see Figure 1–1) incorporates a number of

features that provide unmatched efficiency, usability, and flexibility.

The PaveTracker Plus takes density measurements using

electromagnetic sensing technology, eliminating the need for

government licenses or special training. Measurements are

completed within 2 seconds, saving time and money.

The unit’s memory can store approximately 1000 readings for later

viewing, printing, or downloading.

Both the 30-button keypad and 4 x 20 liquid crystal display (LCD)

screen are backlit, making them easy to see, day or night.

The gauge includes a replaceable, protective, adhesive-backed

bottom cover disc on its bottom surface. The protective cover

provides thermal protection for the gauge’s internal components and

protects the bottom surface of the gauge against wear.

The carrying case for the Model 2701-B includes a built-in

reference standard, which provides a density measurement standard

for taking reference readings.

The PaveTracker Plus’s advanced software provides three test

modes (continuous, averaging, and segregation) for greater

flexibility and multiple applications. The software also provides

automatic calculations (average density, percent maximum density,

percent air voids, and so on) for greater ease of use.

The gauge allows the operator to specify the layer thickness; the

value entered is stored with other measurement data.

Gauge measurements can be adjusted using a density offset or mix

calibration (which includes slope and intercept values) to increase

accuracy on specific materials.

Both an ac charger and a dc adapter are included with the

PaveTracker Plus, enabling the unit to be recharged from an ac

outlet or a 12 V dc system.

1–4

Page 17

The gauge features two audible indicators, an internally mounted

beeper, as well as a louder, external one mounted on its underside.

The internal beeper emits a short tone in response to a valid

keystroke on the keypad. It sounds a longer tone when the operator

presses an invalid key or if the gauge displays an error message. The

external beeper performs the same functions, and can be enabled or

disabled as desired by the operator.

A serial communications port is mounted on the front of the gauge.

The serial port is used to output data to a serial device, such as a

computer or printer.

The gauge features two handles. The right-angle handle is used to

move and position the gauge while taking measurements. A second

carrying handle is provided for ease of transporting and positioning

the gauge. An optional telescoping handle (PN 113017) is also

available.

1. INTRODUCTION

Model 2701-B 1–5

Page 18

GAUGE PARTS AND ACCESSORIES

1. The gauge is the portable electromagnetic sensing device

containing all electronic modules and a rechargeable battery

pack.

2. The carrying case for the Model 2701-B includes a built-in

reference standard, which provides a density measurement

standard for taking reference readings.

3. The ac charger and dc adapter are used to charge the gauge

batteries. The ac charger accepts 100 – 240 V ac, 47 – 63 Hz

and supplies 12 V dc at 1.8 A. The dc adapter allows recharging

from a 12 V dc system, such as a vehicle cigarette lighter.

4. The manual (not shown) details how to operate and maintain

the gauge.

5. A printer (optional, not shown) connects to the gauge for

printing data.

1–6

Page 19

UNPACKING AND INSPECTION

NOTE

To ensure the safe return of the PaveTracker Plus to

Troxler for repair or maintenance, please keep the

original shipping boxes and all packing materials.

Upon receipt of the gauge from the factory:

1. Perform a complete inspection and inventory. If the shipping

case and/or any other part or accessory appears damaged, notify

the carrier and your Troxler representative immediately.

2. Check the shipping case for the following:

♦ Model 2701-B PaveTracker Plus

♦ Carrying Case (PN 113034)

♦ Handle (PN 113210)

♦ AC Charger (PN 110403)

1. INTRODUCTION

♦ DC Adapter (PN 104156)

♦ 2701-B Cover Kit (PN 113107), containing replacement

bottom covers and cleaning wipes

♦ Manual of Operation and Instruction (PN 113045)

3. Lift the gauge from the carrying case and inspect the outside

surface for damage.

Model 2701-B 1–7

Page 20

NOTES

1–8

Page 21

CHAPTER 2

GETTING STARTED

This chapter provides details on getting started with the Model

2701-B PaveTracker Plus. It describes the gauge keypad, and

provides instructions for turning the gauge on, and setting up the

gauge.

CONTENTS

Keypad.......................................................................................... 2–2

Turning the PaveTracker Plus On................................................. 2–4

Status............................................................................................. 2–6

Setup Menu................................................................................... 2–7

Set Units................................................................................. 2–8

Date/Time............................................................................... 2–8

Temperature (Optional)........................................................ 2–10

Customer Name.................................................................... 2–11

External Beeper.................................................................... 2–12

User ID................................................................................. 2–12

Mix Calibration.................................................................... 2–13

Layer Thickness ................................................................... 2–13

Target.......................................................................................... 2–14

Enable a Target Value.......................................................... 2–14

Enter a New Target Value.................................................... 2–15

Disable the Target Value...................................................... 2–15

Mode........................................................................................... 2–16

2. GETTING STARTED

Model 2701-B 2–1

Page 22

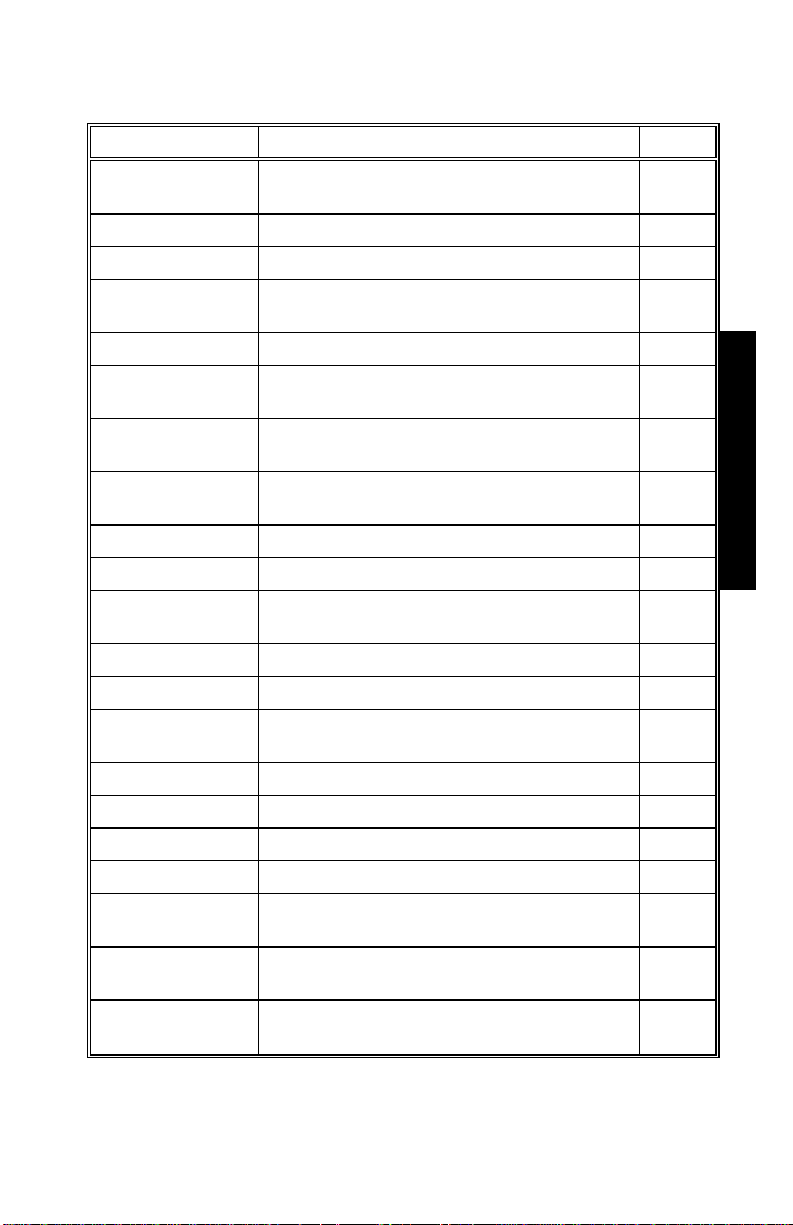

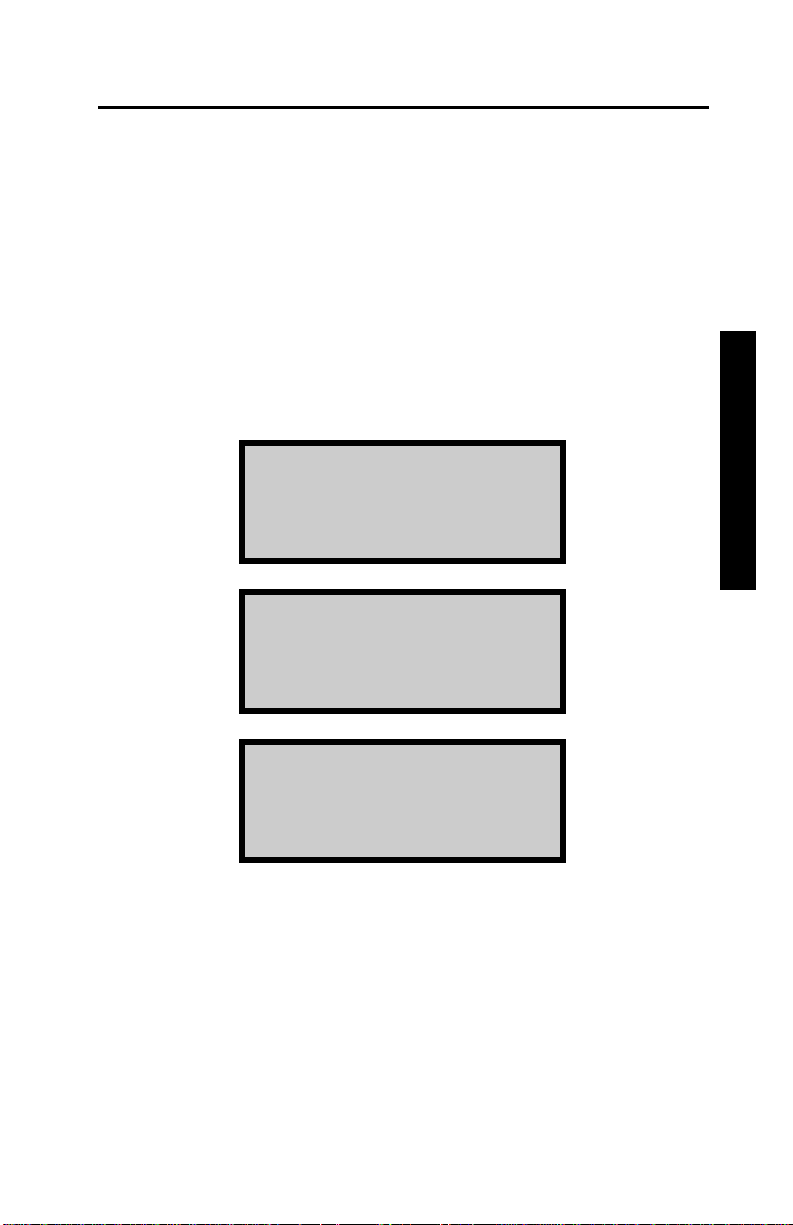

KEYPAD

The Model 2701-B keypad (Figure 2–1) allows the operator to

access the gauge software. Troxler designed the keypad for ease of

use, with large keys and an anti-glare coating. Note that the function

keys are available only when the Ready screen is displayed. Table

2–1 describes the function of each key.

TM

-Ready- Offset:Y

04/08/2004 04:08 PM

Prj: MY PROJECT

Mode: Continuous

R

2–2

STORE

RECALL

SETUP

MODE

REF

STATUS

PROJ

TARGET

OFFSET

SPACE

LIGHT

YES

7

8

5

4

1

2

0

Figure 2–1. Model 2701-B Keypad

NO

9

6

3

ALPHA

LOCK

ESC

BACK

SPACE

+

-

ENTER

START

Page 23

Table 2–1. Model 2701-B Keypad Functions

KEY FUNCTION PAGE

〈STORE〉

〈STATUS〉

〈RECALL〉

〈PROJ〉

〈SETUP〉

〈TARGET〉

〈MODE〉

〈OFFSET〉

〈REF〉

〈SPACE〉

〈LIGHT〉

〈YES〉

〈NO〉

〈ESC〉

〈0〉 .. 〈9〉

〈.〉

〈ALPHA LOCK〉

〈BACK SPACE〉

〈↑〉, 〈↓〉

〈ENTER/START〉

〈A〉 .. 〈Z〉

Store the most recent data in the current

5–8

project file.

Displays gauge status information. 2–6

Display the most recent data. 4–12

Select or create a project file and view,

5–2

output, or erase project data file.

Displays the gauge Setup menu.

Select, enter, or disable a Gmb (Marshall)

2–7

2–14

or Gmm (Voidless density) value.

Select the measurement mode,

2–16

Averaging, Continuous, or Segregation.

Enable, disable, or change a density

3–3

offset.

Take a reference reading. 4–2

Enter a space.

Manually toggle the keypad and LCD

2–5

backlights on and off.

Respond yes to yes/no questions.

Respond no to yes/no questions.

Return the display to the Ready screen

without storing or updating the data.

Enter numbers and access menu options.

Enter a decimal point.

Access the letters.

Moves cursor back one space.

Scroll through menu options or view

screens.

Accept data entry or begin a

measurement.

Enter letters. Access these keys by first

pressing 〈ALPHA LOCK〉.

2. GETTING STARTED

Model 2701-B 2–3

Page 24

TURNING THE PAVETRACKER PLUS ON

To turn on the PaveTracker Plus, press the power switch located on

the front panel next to the serial port (see Figure 1–1).

NOTE

To turn off the PaveTracker Plus, press and hold the

power switch for two seconds.

The gauge displays the model number, battery voltage, software

version, and unit serial number as shown below:

-Model 2701BBattery Volts: X.X

V#.## SN: ###

Press <ENTER>

Press the 〈ENTER/START〉 key to continue. The software

performs two tests to ensure that the gauge is working properly. The

gauge first performs a brief self-test, followed by a test of the

display.

Following the test period, the gauge displays the Ready screen:

-Ready- Offset:YES

mm/dd/yyyy hh:mm AM

Prj: PROJECT NAME

Mode: Continuous

The operator can access any gauge function from the Ready screen.

On the first line, the Ready screen displays whether a density offset

(see page 3–3) or mix calibration (see page 3–6) is enabled.

The second line shows the current date and time. The third line

shows the current project (see page 5–2), if any. The last line shows

the measurement mode (see page 2–16).

2–4

Page 25

The PaveTracker Plus features a backlit keypad and display. To

toggle the backlights on and off, press the 〈LIGHT〉 key.

NOTE

The keypad and display backlights increase the power

consumption of the unit. To conserve battery life,

Troxler recommends that the backlights be used only

when necessary.

To conserve power, the PaveTracker Plus provides a sleep mode, as

well as an automatic shutdown. If no key is pressed for five

minutes, the gauge enters sleep mode. In sleep mode, the display

and keypad backlights, and most of the electronics are turned off,

but all data and gauge settings are protected. To exit sleep mode,

press any key. If no key is pressed for 60 minutes, the gauge shuts

down automatically.

NOTE

If the gauge goes into sleep mode while in the continuous

measurement mode (see page 2–16), the display returns

to the Ready screen. In averaging or segregation mode,

the gauge maintains its current state when it enters sleep

mode.

The gauge software monitors the battery voltage. If the voltage falls

below 6.0 V dc, the gauge displays a low battery symbol (

) in the

upper right of the Ready screen. Recharge the batteries as

described on page A–4. After charging, the battery voltage should

be between 6.8 and 7.2 V dc. If the voltage falls below 5.5 V dc, the

gauge powers down automatically after completing any memory

store functions already in progress.

2. GETTING STARTED

Model 2701-B 2–5

Page 26

STATUS

The gauge Status display enables the operator to view gauge status

information, including the battery voltage, internal temperature,

selected measurement units (see page 2–8), and the time and date of

the last reference reading (see page 4–2). To access this information,

press the 〈STATUS〉 key. The gauge displays:

-Status- ¦

Batt. Volts: #.#

Internal Temp: ##°F

Units: English

Last Ref: ¦

hh:mma mm/dd/yy

To scroll through the displays, use the up and down arrow keys.

Return to the Ready screen by pressing the 〈ESC〉 key.

2–6

Page 27

SETUP MENU

After turning the gauge on for the first time, set up the software. The

gauge stores the software setup, so the operator does not need to

enter a new setup each time the gauge is turned on.

The gauge setup includes the measurement units (Metric or

English), date and time, temperature, customer name, external

beeper setup, user ID, mix calibration, and the layer thickness

function.

To access the Setup menu, press the 〈SETUP〉 key. The gauge

displays:

-Setup- ¦

1. Set Units

2. Date/Time

3. Temperature

2. GETTING STARTED

-Setup- ¦

4. Customer Name

5. External Beeper

6. User ID

-Setup- ¦

7. Mix Calibration

8. Layer Thickness

To scroll through the Setup menu, use the arrow keys (screens that

have options the operator can scroll through are indicated with the

up/down arrow symbol in the upper right corner of the screen). To

select a menu option, use the numeric key that corresponds to the

option. To return to the Ready screen, press the 〈ESC〉 key.

The remainder of this section provides details on the setup options.

Model 2701-B 2–7

Page 28

SET UNITS

The gauge can display measurement results in either metric (SI) or

English units. To set the units, press 〈1〉 at the Setup menu shown

on page 2–7. The gauge displays:

-Units-

1. English

2. Metric

Press # to Select

Select the desired measurement units by pressing the corresponding

numeric key. The gauge displays the new units, then returns to the

Setup menu.

DATE/TIME

The Date/Time function allows the operator to change the date and

time, and to select the display format for each. To access the

Date/Time menu, press 〈2〉 at the Setup menu shown on page 2–7.

The gauge displays the Date/Time menu:

-Date/Time- ¦

1. Change Time

2. Change Date

3. Time Format

-Date/Time- ¦

4. Date Format

From this screen, the operator may change the time, date, or

time/date display format. Use the up and down arrows to scroll

between the menu options. To select a menu option, press the

corresponding numeric key. To return to the Setup menu, press the

〈ESC〉 key.

2–8

Page 29

Change Time

To change the time, press 〈1〉 at the Date/Time menu. The gauge

displays:

hh:mm AM

Arrows toggle AM/PM

Input Time and

Press <ENTER>

(Note that in this example, the time is displayed in AM/PM format.

To change the format, see the Time Format section on page 2–10.)

To accept the displayed time, press 〈ENTER/START〉. To change

the time, use the numeric keys to enter the new time, and the arrow

keys to toggle between AM and PM. Press 〈ENTER/START〉. The

gauge sets the time and returns to the Date/Time menu.

Change Date

To change the date, press 〈2〉 at the Date/Time menu. The gauge

displays:

2. GETTING STARTED

04/08/2004

mm/dd/yyyy

Input Date and

Press <ENTER>

(Note that in this example, the time is displayed in mm/dd/yyyy

format. To change the date format, refer to the Date Format section

on page 2–10.) To accept the displayed date, press

〈ENTER/START〉. To change the date, use the numeric keys to

enter the new date. When finished, press 〈ENTER/START〉. The

gauge sets the date and returns to the Date/Time menu.

Model 2701-B 2–9

Page 30

Time Format

The gauge can display the time in either AM/PM or 24-hour format.

To select the desired time format, press 〈3〉 at the Date/Time menu.

The gauge displays:

-Time Format-

1. AM/PM

2. 24-Hour

Use the numeric keys to select the desired time format. The gauge

sets the time format and returns to the Date/Time menu.

Date Format

The gauge can display the date in either mm/dd/yyyy or dd/mm/yyyy

format, where mm = month, dd = day, and yyyy = year. To select the

desired date format, press 〈4〉 at the Date/Time menu. The gauge

displays:

-Date Format-

1. mm/dd/yyyy

2. dd/mm/yyyy

Use the numeric keys to select the desired format. The gauge sets

the date format and returns to the Date/Time menu.

TEMPERATURE (OPTIONAL)

An infrared sensor that measures the temperature of the mat is

available as an option for the gauge. If this option is installed, press

〈3〉 at the Setup menu shown on page 2–7 to display the

temperature reading. Press the 〈ESC〉 key to return to the Setup

menu.

2–10

Page 31

CUSTOMER NAME

The Model 2701-B can store a customer name of up to 12

characters. To enter a customer name, press 〈4〉 at the Setup menu

shown on page 2–7. The gauge displays the current customer name

on the second line.

Customer Name is:

CUSTOMER

Change Name?

<YES> or <NO>

To change the customer name, press 〈YES〉. The gauge displays:

Customer Name: A

Input Name and

Press <ENTER>

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Enter the new name and press the 〈ENTER/START〉 key. The

gauge stores the new customer name, then returns to the Setup

menu.

2. GETTING STARTED

Model 2701-B 2–11

Page 32

EXTERNAL BEEPER

The PaveTracker Plus is equipped with an external beeper mounted

on its underside. The external beeper can be enabled or disabled as

desired. To control the external beeper, press 〈5〉 on the Setup

menu shown on page 2–7. The gauge displays:

-External Beeper-

1. ON

2. OFF

Press # to Select

Press 〈1〉 to enable the external beeper or 〈2〉 to disable it. The gauge

sets the external beeper function to the desired state, displays a brief

confirmation message, and returns to the Setup menu.

USER ID

The PaveTracker Plus stores a three-character user ID with each

measurement. To enter or change the user ID, press 〈6〉 on the

Setup menu shown on page 2–7. The gauge displays:

User ID

XXX

Do You Want To

Change User ID?

To change the user ID, press 〈YES〉. The gauge displays:

Input User ID A

<ALPHA> for Letters

Press <ENTER>

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Enter the new user ID and press 〈ENTER/START〉. The gauge

stores the new user ID and returns to the Setup menu.

2–12

Page 33

MIX CALIBRATION

The Mix Calibration function is used to adjust gauge measurements,

as described on page 3–6.

LAYER THICKNESS

The Layer Thickness function enables the operator to enter the

thickness of the material being measured. When this function is

enabled, the gauge prompts the operator to enter a thickness value

when creating a new project as described on page 5–4. The layer

thickness value is then stored along with other measurement data in

the active project.

To enable or disable the Layer Thickness function, press 〈8〉 on the

Setup menu shown on page 2–7. The gauge displays:

Thickness Option

1. ON

2. OFF

Press # to Select

2. GETTING STARTED

Press 〈1〉 to enable the Layer Thickness function or 〈2〉 to disable it.

The gauge sets the function to the desired state, displays a brief

confirmation message, and returns to the Setup menu.

Model 2701-B 2–13

Page 34

TARGET

The Model 2701-B can store up to four Gmb (Marshall) and four

Gmm (Voidless density) target values. A Gmb value is the bulk

density of a material, often determined using the Marshall method.

A Gmm value is the maximum theoretical density for a test material

as obtained in laboratory tests. The gauge uses target values to

determine the percent compaction and/or percent voids (if a Gmm

value is entered) as compared to the measured density of the test

material.

With the Target function, the operator can enter a new target value,

enable a stored target value, or disable a target value. To access the

Target function, press the 〈TARGET〉 key. The gauge displays the

Target menu:

-Target-

1. Gmb(Marshall)

2. Gmm(Voidless)

Press # to Select

To enter, enable, or disable a Gmb (Marshall) or Gmm (Voidless

density) value, press the corresponding numeric key. For example,

to edit the Gmb (Marshall) value, press 〈1〉. The gauge displays the

Gmb(MA) Value: menu shown below. The Gmm(Void) Value:

menu is similar and operates in the same manner.

Gmb(MA) Value:

1. #.# 2. #.#

3. #.# 4. #.#

5. New 6. Disable

The target value menu shows the four stored target values (if any)

and the New and Disable options.

ENABLE A TARGET VALUE

To enable a displayed target value, press the corresponding numeric

key on the target value menu. The gauge enables the target value

and returns to the Ready screen.

2–14

Page 35

ENTER A NEW TARGET VALUE

To enter a new target value, press 〈5〉 at the target value menu. The

gauge displays:

Gmb(Marshall) Value:

0.0 pcf

Press <ENTER>

Use the numeric and decimal keys to enter the target value. Press

the 〈ENTER/START〉 key. The gauge displays:

Gmb(MA) = ##.#

Do You Want to

Save This Value

for Late Use?

To store the value, press the 〈YES〉 key. To use the value now

without storing it for later use, press the 〈NO〉 key.

If the operator presses the 〈YES〉 key to store the target value, the

gauge displays:

2. GETTING STARTED

Select Memory Cell

1. #.# 2. #.#

3. #.# 4. #.#

Press # To Select

The gauge can store the target value in one of four memory cells.

Use the numeric keys to store the target value. Note that this will

replace any target value that was previously stored in the memory

cell. The gauge enables the target value, displays a brief

confirmation message and returns to the Ready screen.

DISABLE THE TARGET VALUE

To disable the current target value, press 〈6〉 at the target value

menu. The gauge disables the target value, displays a brief

confirmation message, and returns to the Ready screen.

Model 2701-B 2–15

Page 36

MODE

The Model 2701-B provides three measurement modes:

♦ In continuous mode, the gauge takes a measurement and

updates the display every second. This mode is used for typical

quality control measurements.

♦ In averaging mode, the operator can take up to 30

measurements at selected locations. The gauge then calculates

the average of the measurements. This mode enables the

operator to determine the average density over a selected area.

The Store function (see page 5–10) records the most recent

results screen when in this mode.

♦ In segregation mode, the operator can take up to 30

measurements at selected locations. The gauge then displays the

high, low, and average density of the readings. This mode

enables the operator to determine the degree of segregation in

the area being measured. The Store function (see page 5–10)

records the most recent results screen when in this mode.

Before taking a measurement, select the appropriate measurement

mode. To select a measurement mode, press the 〈MODE〉 key. The

gauge displays:

-MODE-

1. Continuous

2. Averaging

3. Segregation

Press the numeric key that corresponds to the desired measurement

mode. The gauge enables the selected mode, displays a brief

confirmation message, and returns to the Ready display.

2–16

Page 37

CHAPTER 3

ADJUSTING MEASUREMENTS

This chapter explains how to adjust gauge measurements using

density offsets and mix calibration (slope and intercept) values for a

particular material.

CONTENTS

Introduction................................................................................... 3–2

Offset ............................................................................................ 3–3

Determining the Density Offset ............................................. 3–3

Managing Density Offsets...................................................... 3–4

Mix Calibration............................................................................. 3–6

Enable a Mix Calibration ....................................................... 3–6

New Mix Calibration.............................................................. 3–7

Disable the Mix Calibration................................................. 3–10

3. ADJUSTING MEASUREMENTS

Model 2701-B 3–1

Page 38

INTRODUCTION

As described on page 4–2, Troxler recommends taking a reference

reading each day that the gauge will be used, and periodically while

taking measurements. The reference reading consists of placing the

gauge on the reference standard contained in the gauge carrying

case and pressing the 〈Ref〉 key. The density read by the gauge is

then compared to the known density of the reference standard. The

result of this comparison is used to automatically adjust gauge

measurements.

For increased accuracy, measurements can be adjusted using density

offset and mix calibration values described in the following

sections.

To determine the density offset, take a gauge reading and compare

the measured value to an alternative density value, as measured by

another method (such as using a nuclear gauge or extraction and

analysis of a road core).

For a given material, the slope and intercept values can also be

determined using the Mix Calibration function (see page 3–6).

3–2

Page 39

OFFSET

To improve the accuracy of the PaveTracker Plus for a specific

material of known density, the unit can be calibrated using a density

offset. A density offset is determined by taking in-place

measurements using the PaveTracker Plus, then comparing the

measured density to an alternative density, as determined using a

nuclear gauge reading or road core extraction and analysis.

DETERMINING THE DENSITY OFFSET

To determine the density offset for a given material:

1. Take a reference reading using the PaveTracker Plus as

described on page 4–2.

NOTE

Before using the PaveTracker Plus, inspect the

protective cover of the bottom surface of the gauge’s

sensor. Ensure that the cover is in good condition, and

has no deep scratches or buildup of material. If

necessary, replace the cover as described on page A–7.

2. Measure the in-place density of the material using the

PaveTracker Plus to find the measured density. Mark the test

site so that nuclear gauge readings or core extraction can be

conducted in the same location. If the core has already been

removed, take the measurement as close as possible to the core

location.

NOTE

When taking PaveTracker Plus measurement on a core

site, be sure to take measurements before the core is cut,

as the water used during the core cutting process may

affect PaveTracker Plus measurements.

3. Determine the alternative density of the material using a nuclear

gauge reading or road core extraction and analysis. Be sure to

conduct the gauge measurements or core extraction in the same

location as the PaveTracker Plus reading.

3. ADJUSTING MEASUREMENTS

Model 2701-B 3–3

Page 40

4. Subtract the measured density from the alternative density to

determine the density offset to be entered into the PaveTracker

Plus software. For example, if the density as determined by a

core analysis is 150 pcf, and the density measured by

PaveTracker Plus is 146 pcf, the density offset is +4 pcf.

NOTE

For best results, repeat the above procedure to

determine the density offset at each of several in-place

locations. Then calculate the average density offset.

MANAGING DENSITY OFFSETS

Density offsets are managed using the Density Offset menu. To

access this menu, press 〈OFFSET〉. The gauge displays:

Density Offset

#.## pcf

1-Enable 2-Disable

3-Change Offset

The gauge displays the current density offset on the second line. To

enable the offset, press 〈1〉. To disable the offset, press 〈2〉.

To enter a new density offset, press 〈3〉. The gauge prompts for the

density offset as shown below:

3–4

Density Offset

#.## pcf

Select (+/-)

Page 41

To change the offset, use the arrow keys to select the offset sign

(positive or negative). The gauge displays:

Density Offset

+ #.## pcf

Input and

Press <ENTER>

Enter the density offset as determined from the procedure on page

3–3 and press 〈ENTER/START〉. The gauge enables the new offset

and returns to the Ready screen.

3. ADJUSTING MEASUREMENTS

Model 2701-B 3–5

Page 42

MIX CALIBRATION

As noted earlier, the PaveTracker Plus can be calibrated for a

specific mix using the Mix Calibration function. To use this

function, the operator takes gauge measurements at three to ten

locations across the material. The gauge compares these values to

values obtained by core analysis or another method to determine a

slope and intercept for that particular material. The gauge can store

up to four mix calibrations.

NOTE

In order for the gauge to calculate both a slope and an

intercept for the test material, measurements must be

performed at a minimum of three locations. Also, the

difference between the minimum and maximum reading

must be at least 3 pcf. For best results, Troxler

recommends taking measurements at seven to ten

locations.

To access the Mix Calibration function, press 〈7〉 on the Setup

menu shown on page 2–7. The gauge displays:

1. 2.

3. 4.

5. New 6. Disable

7. View

Selections 1 through 4 show the mix calibrations that have been

stored previously. Use the numeric keys to enable an existing mix

calibration, create a new calibration, disable an active calibration, or

view a calibration.

ENABLE A MIX CALIBRATION

To enable a displayed mix calibration, press the corresponding

numeric key. The gauge enables the mix calibration and returns to

the Setup menu.

3–6

Page 43

NEW MIX CALIBRATION

To determine a new mix calibration or to manually enter the slope

and intercept values, press 〈5〉 on the menu shown on page 3–6. The

gauge displays:

-Entry Method-

1. Data Pairs

2. Slope/Intercept

To determine a new mix calibration based on gauge measurements

and values determined by an alternate method, press 〈1〉 to access

the Data Pairs function. To enter slope and intercept values

manually, press 〈2〉 to access the Slope/Intercept function. These

functions are described in the following sections.

Data Pairs

To determine a new mix calibration based on gauge measurements

and values determined by an alternate method, press 〈1〉 at the

Entry Method menu shown above. The gauge displays:

3. ADJUSTING MEASUREMENTS

Input Reading #: 1

0.0 pcf

Press <ENTER>

Using the numeric and decimal keys, enter the measured density

(the density as measured by the gauge) at the first test location.

Press the 〈ENTER/START〉 key. The gauge displays:

Input Core Value 1:

0.0 pcf

Press <ENTER>

Enter the actual density (the density as determined from an alternate

method) and press the 〈ENTER/START〉 key.

Model 2701-B 3–7

Page 44

The gauge displays:

<STORE> for Next

<ENTER> to Calculate

Press the 〈STORE〉 key to store the values and to enter those for the

next location. When the measured and actual densities for each

location have been entered, press the 〈ENTER/START〉 key to

calculate the mix calibration. The gauge displays:

Slope = #.##

Intercept = ###.#

Do you want to

accept this mix?

To return to the Setup menu without saving the mix calibration,

press the 〈NO〉 key. To save the mix calibration, press the 〈YES〉

key. The gauge requests a mix calibration ID as shown:

Mix Calib. ID

<ALPHA> for Letters

Press <ENTER>

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Enter a unique mix calibration ID and press 〈ENTER/START〉. The

gauge displays:

Select Memory Cell

1. Empty 2. Empty

3. Empty 4. Empty

Press # To Select

3–8

Page 45

The gauge can store the mix calibration in one of four memory cells.

Use the numeric keys to store the mix calibration. Note that this will

replace any mix calibration that was previously stored in that cell.

The gauge enables the mix calibration, displays a brief confirmation

message, and returns to the Setup menu.

Slope/Intercept

The Slope/Intercept function is used to manually enter the slope

and/or intercept for a particular material. These values can be

determined using the Data Pairs function described on page 3–7, or

can be calculated manually.

To access the Slope/Intercept function, press 〈2〉 on the Entry

Method menu shown on page 3–7. The gauge prompts for the

slope and intercept values. Press 〈ENTER/START〉 after each value

is entered. After both values have been entered, the gauge displays:

Slope = #.##

Intercept = ###.#

Do you want to

accept this mix?

To return to the Setup menu without saving the mix calibration,

press the 〈NO〉 key. To save the mix calibration, press the 〈YES〉

key. The gauge requests a mix calibration ID as shown:

Mix Calib. ID

<ALPHA> for Letters

Press <ENTER>

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Model 2701-B 3–9

3. ADJUSTING MEASUREMENTS

Page 46

Enter a unique mix calibration ID and press 〈ENTER/START〉. The

gauge displays:

Select Memory Cell

1. Empty 2. Empty

3. Empty 4. Empty

Press # To Select

The gauge can store the mix calibration in one of four memory cells.

Use the numeric keys to store the mix calibration. Note that this will

replace any mix calibration that was previously stored in that cell.

The gauge enables the mix calibration, displays a brief confirmation

message, and returns to the Setup menu.

DISABLE THE MIX CALIBRATION

To disable the current mix calibration, press 〈6〉 at the mix

calibration menu. The gauge disables the mix calibration, displays a

brief confirmation message, and returns to the Setup menu.

3–10

Page 47

CHAPTER 4

USING THE GAUGE

This chapter explains the basic use of the Model 2701-B

PaveTracker Plus. Basic use includes taking a reference reading,

preparing measurement sites, setting the measurement mode, and

taking measurements.

CONTENTS

Taking a Reference Reading ......................................................... 4–2

Preparing a Test Site..................................................................... 4–4

Taking Measurements................................................................... 4–5

Continuous Mode................................................................... 4–6

Averaging Mode..................................................................... 4–7

Segregation Mode .................................................................. 4–9

Recall.......................................................................................... 4–12

4. USING THE GAUGE

Model 2701-B 4–1

Page 48

TAKING A REFERENCE READING

To ensure the accuracy of gauge measurements, Troxler

recommends that a reference reading be taken each time the gauge

is powered on, and periodically while taking measurements. A

reference reading consists of taking a density measurement on a

material of known density. The gauge then compares the reading to

the known value and uses the result of that comparison to adjust

future gauge readings.

NOTE

A reference standard, built into the gauge carrying case,

is provided for this purpose. Always take reference

readings using the reference standard in the carrying

case provided with the specific unit.

Turn the gauge on as described on page 2–4. At the Ready screen,

press the 〈REF〉 key. The gauge displays:

Place Gauge on

Reference Standard

(Carrying Case)

Press <START>

Place the gauge on the reference standard (in the carrying case).

Ensure that the circular sensor on the bottom of the gauge is

centered between the four locating pins inside the case, and that the

sensor rests flat against the surface.

Press the 〈ENTER/START〉 key to begin the reference reading.

Upon completion, the gauge displays:

Reference Reading

Complete

Press <ENTER>

Press the 〈ENTER/START〉 key to continue. The gauge stores the

result of the reading and returns to the Ready screen. The result is

then used to adjust all gauge readings.

4–2

Page 49

NOTE

If the reference reading is out of range and the gauge

displays an error message, check the following:

♦ Ensure that the circular sensor cover is firmly in

place on the gauge sensor (press firmly around the

perimeter of the cover).

♦ Ensure that the cover and reference standard are

totally clean and free of any asphalt residue,

moisture, or debris. Clean with WD-40 or other

suitable means.

♦ Ensure that the sensor cover is seated flat and flush

on the reference standard, within the four locating

pins, with the gauge in the case.

Repeat the reference reading. If the reference reading

still does not pass, contact Troxler technical support (see

page A–10).

To verify that the gauge is still accurate during use,

perform the following check:

♦ Ensure that the gauge is turned on and in

measurement mode.

♦ Turn off (disable) all operator-installed density

offsets and mix calibrations. See Chapter 3 for

specifics.

♦ Place the gauge on the reference standard and verify

that it reads within ± 0.5 pcf (±8 kg/m

3

) of the actual

density value stamped on the reference standard. If

the reading is outside these limits, take a reference

reading as described in this section to adjust the

4. USING THE GAUGE

gauge.

Note that each reference standard is unique to that

individual gauge. Use care to not intermix different

gauges and cases.

Model 2701-B 4–3

Page 50

PREPARING A TEST SITE

To ensure measurement accuracy, properly prepare the test site

before taking gauge measurements.

Locate a smooth site on the asphalt.

To ensure accurate readings, the gauge sensor must be

completely in contact with the test material. If the gauge rocks,

then find a more suitable test site. If taking a measurement

around a core, the gauge may be moved a few inches away from

the core to level it.

4–4

Page 51

TAKING MEASUREMENTS

The Status feature (see page 2–6) allows the operator to view the

current gauge status. This feature provides a quick overview of the

battery voltage, internal temperature, selected measurement units,

and the date and time of the last reference reading. If necessary,

check the gauge’s current status before taking measurements.

NOTE

To ensure the accuracy of gauge measurements, take a

reference reading each day the gauge is to be used (see

page 4–2) and periodically while taking measurements.

As described on page 2–16, the PaveTracker Plus provides three

measurement modes: continuous, averaging, and segregation.

Before taking a measurement, select the appropriate measurement

mode.

CAUTION

High internal temperatures may damage the gauge’s

electronic components. To reduce the risk of damage,

DO NOT allow the gauge to sit on hot asphalt for

extended periods.

If the internal temperature of the gauge reaches a level

that is considered excessive, the beeper will sound and

the warning message Internal temp. high Allow

gauge to cool will be displayed. The gauge should be

taken to a shady or air-conditioned environment and

allowed to cool before continuing. If measurements are

performed before the gauge is allowed to cool, the

warning symbol ! is displayed.

4. USING THE GAUGE

CAUTION

The gauge includes a replaceable protective cover that

protects the bottom surface of the gauge’s sensor

assembly against wear and provides thermal protection

for the gauge’s internal components. To prevent damage

to the gauge, DO NOT operate the gauge without the

protective cover.

Model 2701-B 4–5

Page 52

NOTE

Before using the gauge, inspect the protective cover of

the bottom surface of the gauge’s sensor. Ensure that

the cover is in good condition, and has no deep scratches

or buildup of material. If necessary, replace the cover as

described on page A–7.

CONTINUOUS MODE

In continuous mode, the gauge takes a measurement and updates the

display every second. This mode is used for typical quality control

measurements.

Extend the telescoping handle (see Figure 1–1) to reduce the

bending required while taking measurements.

To take a measurement in continuous mode, select the mode as

described on page 2–16. Place the gauge on the test site and press

〈ENTER/START〉.

The gauge displays the measurement results, updated every second,

as shown:

##.#% Gmb(MA)

##.#% Gmm(Voidless)

D: ###.#

##.#% Voids <ESC>

NOTE

If the Temperature option (see page 2–10) is installed, the

mat temperature is also shown in the upper right corner

of the display.

Press 〈ESC〉 to return to the Ready screen.

For more information on storing measured data, see the Storing

Data section on page 5–8.

4–6

Page 53

NOTE

If the gauge goes into sleep mode while in the continuous

measurement mode (see page 2–16), the display returns

to the Ready screen. To exit sleep mode and continue

taking measurements, press the 〈ENTER/START〉 key.

AVERAGING MODE

In averaging mode, the operator can take up to 30 measurements at

selected locations. The gauge then calculates the average of the

measurements. This mode enables the operator to determine the

average density over a larger area.

Extend the telescoping handle (see Figure 1–1) to reduce the

bending required while taking measurements.

To take a measurement in averaging mode, select the mode as

described on page 2–16.

4. USING THE GAUGE

Model 2701-B 4–7

Page 54

Press the 〈ENTER/START〉 key. The gauge displays:

Averaging Mode

Reading #: 1

Press <START>

<STORE>/<ESC> to End

Place the gauge on the first test site and press 〈ENTER/START〉.

The gauge takes a measurement, then displays the results:

##.#% Gmb(MA)

##.#% Gmm(Voidless)

Avg of 1: ###.#

#.#% Voids <ENTER>

NOTE

If the Temperature option (see page 2–10) is installed, the

mat temperature is also shown in the upper right corner

of the display.

Press 〈ENTER/START〉 to continue. Repeat the steps above to take

a measurement at up to 30 test locations. When all locations are

complete, press the 〈STORE〉 or 〈ESC〉 key to continue.

If the 〈ESC〉 key is pressed, the gauge displays:

End of Measurement

Do You Want To

Store ?

<YES> or <NO>

Press 〈NO〉 to return to the Ready screen without storing the results

or 〈YES〉 to continue as described below.

4–8

Page 55

If the 〈STORE〉 key is pressed at the end of the measurements (or if

the operator presses 〈ESC〉 then 〈YES〉), the gauge displays:

Do You Want To

Add Notes?

<YES> or <NO>

When storing test results, the gauge can also store project notes,

such as location information, with the measurement data. To include

project notes, press 〈YES〉. The gauge displays:

Input Location

Press <ENTER>

Enter any desired information (up to eight characters) and press

〈ENTER/START〉. The gauge stores the last displayed results and

notes under the active project and returns to the Ready screen. For

more information on storing measured data, see the Storing Data

section on page 5–8.

NOTE

The gauge stores only the data shown in the last display.

It does not store the results of each individual reading.

SEGREGATION MODE

In segregation mode, the operator can take up to 30 measurements

at selected locations. The gauge then displays the high, low, and

average density of the readings. This mode enables the operator to

determine if there is a large degree of segregation in the area being

measured.

Extend the telescoping handle (see Figure 1–1) to reduce the

bending required while taking measurements.

4. USING THE GAUGE

Model 2701-B 4–9

Page 56

To take a measurement in segregation mode, select the mode as

described on page 2–16.

Press the 〈ENTER/START〉 key. The gauge displays:

Segregation Mode

Reading #: 1

Press <START>

<STORE>/<ESC> to End

Place the gauge on the first test site and press 〈ENTER/START〉.

The gauge takes a measurement, then displays the results:

Avg D: ##.#

Hi D: ##.#

Low D: ##.#

Den: ##.# <ENTER>

NOTE

If the Temperature option (see page 2–10) is installed, the

mat temperature is also shown in the upper right corner

of the display.

Press 〈ENTER/START〉 to continue. Repeat the previous steps to

take a measurement at up to 30 test locations. When all locations are

complete, press the 〈STORE〉 or 〈ESC〉 key to continue.

If the 〈ESC〉 key is pressed, the gauge displays:

End of Measurement

Do You Want To

Store ?

<YES> or <NO>

Press 〈NO〉 to return to the Ready screen without storing the results

or 〈YES〉 to continue as described below.

4–10

Page 57

If the 〈STORE〉 key is pressed at the end of the measurements (or if

the operator presses 〈ESC〉 then 〈YES〉), the gauge displays:

Do You Want To

Add Notes?

<YES> or <NO>

When storing test results, the gauge can also store project notes,

such as location information, with the measurement data. To include

project notes, press 〈YES〉. The gauge displays:

Input Location

Press <ENTER>

Enter any desired information (up to eight characters) and press

〈ENTER/START〉. The gauge stores the last displayed results and

notes under the active project and returns to the Ready screen. For

more information on storing measured data, see the Storing Data

section on page 5–8.

NOTE

The gauge stores only the data shown in the last display.

It does not store the results of each individual reading.

4. USING THE GAUGE

Model 2701-B 4–11

Page 58

RECALL

To view the results of the most recent measurement, press the

〈RECALL〉 key from the Ready screen. The gauge displays the

results of the most recent measurement. To return to the Ready

screen, press the 〈ENTER/START〉 key.

4–12

Page 59

CHAPTER 5

PROJECT DATA

The Model 2701-B PaveTracker Plus allows unique project names

to be entered into the gauge memory. Subsequent measurements can

then be stored under these project names. This chapter describes

how to handle project data.

CONTENTS

Handling Project Data................................................................... 5–2

Select...................................................................................... 5–2

View....................................................................................... 5–3

Create a Project ...................................................................... 5–4

Erase Projects......................................................................... 5–5

Output Project Data................................................................ 5–5

Storing Data.................................................................................. 5–8

Continuous Mode................................................................... 5–9

Averaging or Segregation Mode .......................................... 5–10

5. PROJECT DATA

Model 2701-B 5–1

Page 60

HANDLING PROJECT DATA

The Model 2701-B can store approximately 1000 readings. The

Project and Store functions allow handling of measurement data.

Measurement results are stored in files (memory locations) called

projects, which are named by the operator. The Project function

allows the operator to create a new project, view project data, select

a project (make an existing project active so that additional data

may be added to it), output the data stored in the project, or erase

projects. The Store function allows the operator to store

measurement results and other test-identifying information in a

selected project. Refer to page 5–8 for information on the Store

function.

To access the Project function, press the 〈PROJ〉 key. The gauge

displays the Project menu:

-Project- ¦

1. Select

2. View

3. Create

-Project- ¦

4. Erase

5. Output

Use the arrow keys to scroll through the menu options. Use the

numeric keys to select a menu option. Press 〈ESC〉 to return to the

Ready screen.

SELECT

To select an existing project, press 〈1〉 at the Project menu shown

above. If no projects have been created, the gauge displays the

message No Projects are stored.

5–2

Page 61

If a project has been created, the gauge displays:

Project XXX ¦

Arrows for Scroll

<ENTER> to Select

Use the arrow keys to scroll through the names of the existing

projects. Press 〈ENTER/START〉 when the desired project is

displayed. The gauge sets the selected project as active, briefly

displays a confirmation message, and returns to the Project menu.

VIEW

The Model 2701-B offers two methods of viewing data. The

operator can either view the last measurement results using the

Recall function described on page 4–12, or any measurement

results, including project notes, stored in a project file using the

View function available from the Project menu.

To view data stored in a project file, press 〈2〉 at the Project menu.

The gauge displays:

5. PROJECT DATA

Prj: XXX ¦

mm/dd/yy hh:mmp

Rec: # UID: XXX

<ENTER> to select

Use the arrow keys to scroll through the project names. Press

〈ENTER/START〉, when the gauge displays the desired project

name. If any measurement data has been stored in the selected

project file, the gauge displays the data for the first measurement.

Five screens of information are displayed for each measurement.

Use the up and down arrows to scroll through the project data.

Press the 〈ESC〉 key to return to the project selection screen shown

above.

Model 2701-B 5–3

Page 62

CREATE A PROJECT

To create a new project, press 〈3〉 at the Project menu shown on

page 5–2. The gauge displays:

Project Name

<ALPHA> for Letters

<ENTER> to Exit

Press the 〈ALPHA LOCK〉 key to enable the alphabetic keys on the

gauge. When the alphabetic keys are enabled, the symbol A appears

in the upper right of the display, as shown above.

Enter the project name (up to twelve characters) and press the

〈ENTER/START〉 key.

If the Layer Thickness function (see page 2–13) is enabled, the

gauge prompts for the layer thickness:

Input Layer

Thickness

51 mm

Press <ENTER>

Enter a layer thickness from 25 to 102 mm (2.0 to 4.0 in.) and press

the 〈ENTER/START〉 key.

The gauge displays:

Make Project

XXX

Active?

<YES> or <NO>

To enable the new project, press the 〈YES〉 key. The gauge enables

the new project, displays a brief confirmation message, and returns

to the Project menu.

5–4

Page 63

ERASE PROJECTS

To erase either a selected project file or all project files, press 〈4〉 at

the Project menu shown on page 5–2. The gauge displays:

Erase:

1. One Project

2. All Projects

Press # to Select

To erase a single project, press 〈1〉. If more than one project has

been created, the gauge displays:

Prj: XXX ¦

Arrows for Scroll

<ENTER> to Select

Use the arrow keys to scroll through the project names displayed on

the first line. When the gauge displays the desired project, press

〈ENTER/START〉. At the Are you sure? prompt, press the

〈YES〉 key. The gauge erases the project and returns to the Project

menu.

To erase all projects, press 〈2〉

Sure? prompt, press the 〈YES〉 key. The gauge erases all the

projects and returns to the Project menu.

at the Erase menu. At the Are You

OUTPUT PROJECT DATA

The Output function within the Project menu allows the operator

to print (or upload) project data stored in the gauge to a printer or

computer.

To output project data, connect a serial cable to the 9-pin serial port

on the front of the gauge. Ensure that the serial cable meets the

pinout shown on page C–3. An optional serial cable, PN

106514.0002, is available from Troxler. Connect the serial cable to

the printer (or computer) serial port.

5. PROJECT DATA

Model 2701-B 5–5

Page 64

NOTE

To upload data to a computer, use the HyperTerminal®

application available from the Windows® Accessories

menu. This application can be used to transfer data

from the gauge to the computer.

At the Project menu shown on page 5–2, press 〈5〉. The gauge

displays the Output menu:

Output:

1. One Project

2. All Projects

Press # to Select

From this menu, the gauge can print (or upload) either a single

project or all projects.

To output a single project, press 〈1〉. The gauge displays:

Prj: XXX ¦

Arrows for Scroll

<ENTER> to Select

Use the arrow keys to scroll through the project names displayed on

the first line. When the gauge displays the desired project, press

〈ENTER/START〉.

To output the data from all projects, press 〈2〉.

For either selection, the gauge displays:

Output:

1. 32 Column Report

2. Spreadsheet

Press # to Select

5–6

Page 65

The 32 Column Report option is formatted for a standard printer

width. This format is recommended when outputting the data to a

printer. The Spreadsheet option is sent in a comma-delimited

format, which can then be imported easily into a spreadsheet

program, such as Microsoft Excel®. The information output using

the Spreadsheet option is shown on page 5–8.

The gauge prints (or uploads) the project and returns to the Project

menu shown on page 5–2. Press the 〈ESC〉 key to return to the

Ready screen.

5. PROJECT DATA

Model 2701-B 5–7

Page 66

STORING DATA

The Model 2701-B can store approximately 1000 readings. As

described in the previous section, the gauge stores readings under

the project name that has been enabled. For more information on

selecting a project, see page 5–2.

Project data can be output as described on page 5–5. When using the

Spreadsheet option, the gauge outputs the following information for

each reading:

♦ Project name

♦ Layer Thickness – This value is displayed only if the Layer

Thickness function is enabled.

♦ Record number

♦ Measurement time

♦ Measurement date

♦ Measurement mode

♦ Gmb (Marshall) – This value is 0.0 if the Gmb (Marshall) target

is 0.0.

♦ Gmm (Voidless) – This value is 0.0 if the Gmm (Voidless)

target is 0.0.

♦ Density measurement

♦ Low density – This value is 0.0 if not in segregation mode.

♦ High density – This value is 0.0 if not in segregation mode.

♦ Air voids – This value is 0.0 if Gmm (Voidless) target is 0.0.

♦ Slope

♦ Offset

♦ Gmb (Marshall) target

♦ Gmm (Voidless) target

♦ Mat temperature – This value is 0 if the Temperature option

(see page 2–10) is not installed.

♦ Station ID

♦ User ID

♦ Location (right or left) of centerline – This value is blank if not

in continuous mode.

♦ Distance from centerline – This value is 0.0 if not in continuous

mode.

5–8

Page 67

Note that the station number, distance from centerline, and location

with respect to centerline fields are available only for continuous

mode measurements.

CONTINUOUS MODE

When taking measurements in continuous mode, the operator can

store the data in the selected project by pressing the 〈STORE〉 key

at any time when the gauge is displaying measurement data, or after

returning to the Ready screen. The gauge displays:

Do You Want To

Add Notes?

<YES> or <NO>

f Press 〈NO〉 to store only the measurement results under the

active project and return to the previous screen.

f Press 〈YES〉 to store the station number, distance from

centerline, and location with respect to centerline project notes

along with the measurement. The gauge displays:

5. PROJECT DATA

Input Station #

Press <ENTER>

Enter the station number (up to eight characters) and press

〈ENTER/START〉. The gauge displays:

Station Distance

From Center Line?

#.# ft

Press <ENTER>

Model 2701-B 5–9

Page 68

Enter the distance from the centerline and press

〈ENTER/START〉. The gauge displays:

Left or Right

of Center Line?

1. Left

2. Right

Press 〈1〉 if the station was to the left of the centerline or 〈2〉 if

the station was to the right.

The gauge stores the measurement data and notes under the

selected project and returns to the previous screen.

AVERAGING OR SEGREGATION MODE

After taking a measurement in averaging or segregation mode, the

operator can store the data in the selected project by pressing the

〈STORE〉 key when the gauge displays the test results or after

returning to the Ready screen. The gauge displays:

Do You Want To

Add Notes?

<YES> or <NO>

f Press 〈NO〉 to store only the measurement results under the

active project and return to the previous screen.

f Press 〈YES〉 to include project notes along with the

measurements results. The gauge displays:

Input Location

Press <ENTER>

Enter any desired information (up to eight characters) and press

〈ENTER/START〉. The gauge stores the test results and notes

under the active project and returns to the previous screen.

5–10

Page 69

A

APPENDIX A

TROUBLESHOOTING AND SERVICE

This appendix provides details for troubleshooting and servicing the

Model 2701-B PaveTracker Plus. For further details, call the nearest

Troxler Service Center or representative.

CONTENTS

Troubleshooting........................................................................... A–2

Internal Gauge Temperature........................................................ A–3

Batteries....................................................................................... A–4

Charging................................................................................ A–4

Replacing the Batteries.......................................................... A–5

Cleaning the Base and Top Shell................................................. A–6

Replacing the Protective Cover ................................................... A–7

Replacement Parts ....................................................................... A–8

Accessories............................................................................ A–8

Options.................................................................................. A–8

Returning the Gauge for Service ................................................. A–9

Troxler Service Centers............................................................. A–10

. TROUBLESHOOTING

Model 2701-B Appendix A–1

Page 70

TROUBLESHOOTING

GAUGE WILL NOT COMMUNICATE WITH PRINTER OR

COMPUTER

Check that the correct cable is being used.

Ensure that the printer/computer baud rate is 9,600 bps.

Ensure that all other parameters match:

♦ Data bits = 8

♦ Stop bits = 2

♦ Parity = none

♦ Protocol = DSR/DTR

GAUGE TURNS OFF AFTER IT IS TURNED ON

To conserve power, the gauge provides an automatic shutdown

if no key is pressed for 60 minutes. To turn the gauge on, press

the power switch.

If the rechargeable NiMH battery pack is below 5.5 V dc, the

gauge shuts down. Recharge or replace the batteries (see page

A–4).

SHORT BATTERY LIFE AFTER RECHARGING

NiMH batteries may be charged up to 500 or more full

charge/discharge cycles, and typically have a 4-year life. The

batteries may be reaching the end of their life cycle, and should

be replaced.

Charger/adapter may not be supplying full charge – check the ac

outlet and the dc output (12 V dc) using a voltmeter on the

proper setting.

Check that you are using the correct charger.

The ac charger may be defective. To check, use the dc adapter

to charge the batteries.

Appendix A–2

Page 71

A

INTERNAL GAUGE TEMPERATURE

High internal temperatures may damage the gauge’s electronic

components. To reduce the risk of damage, DO NOT allow the

gauge to sit on hot asphalt for extended periods.

If the internal temperature of the gauge reaches a level that is

considered excessive, the beeper will sound and the following

warning message is displayed:

Internal temp. high

Allow gauge to cool

Press Enter to

resume

The gauge should be taken to a shaded or air-conditioned

environment and allowed to cool before continuing. If

measurements are performed before the gauge is allowed to cool,

the warning symbol ! is displayed.

. TROUBLESHOOTING

Model 2701-B Appendix A–3

Page 72

BATTERIES

The PaveTracker Plus is equipped with one set of rechargeable

nickel-metal hydride (NiMH) batteries (pack of five C batteries).

The gauge software monitors the NiMH battery voltage. When the

batteries are fully charged, the battery voltage should be between

6.8 and 7.2 V dc. If the voltage falls below 6.0 V dc, the gauge

displays a low battery symbol (

screen. Recharge the batteries as described below.

If the voltage falls below 5.5 V dc, the gauge powers down