Page 1

MODEL RL2000

AUTOMATED TELLER MACHINE

INSTALLATION MANUAL

TDN 07103-00155 Jan 8, 2013

CORPORATE HEADQUARTERS

21405 B St.

Long Beach, MS 39560

Phone: (800) 259-6672

Fax: (228) 868-9445

COPYRIGHT NOTICE

© 2013 Triton. All Rights Reserved. TRITON logo is a

registered trademark of Triton Systems of Delaware, LLC.

Page 2

MODEL RL2000 INSTALLATION MANUAL

INTRODUCTION

The Triton RL2000 is a lobby terminal designed for indoor use only. The following sections provide the

requirements for installing the RL2000 for your particular site location. To assist you in preparing your site,

a check list is provided of various steps that should be carried out

prior to the arrival of the ATM.

WHAT’S IN THIS INSTALLATION GUIDE

This Installation Guide provides information for the physical installation of the RL2000 ATM. It contains

requirements for site preparation, electrical specifications, and cabinet accessibility that comply with all

relevant codes, laws and regulations. The Installation Guide is divided into the following sections:

SITE COMPLIANCE. States the customers responsibilities for ensuring all relevant regulations are adhered

to for installing ATMs.

ATM ENVIRONMENTAL PRECAUTIONS CHECKLIST. Describes the general environmental precautions

considered when installing the ATM. To help ensure proper operation of the ATM, ensure the

environmental criteria listed in this checklist are met.

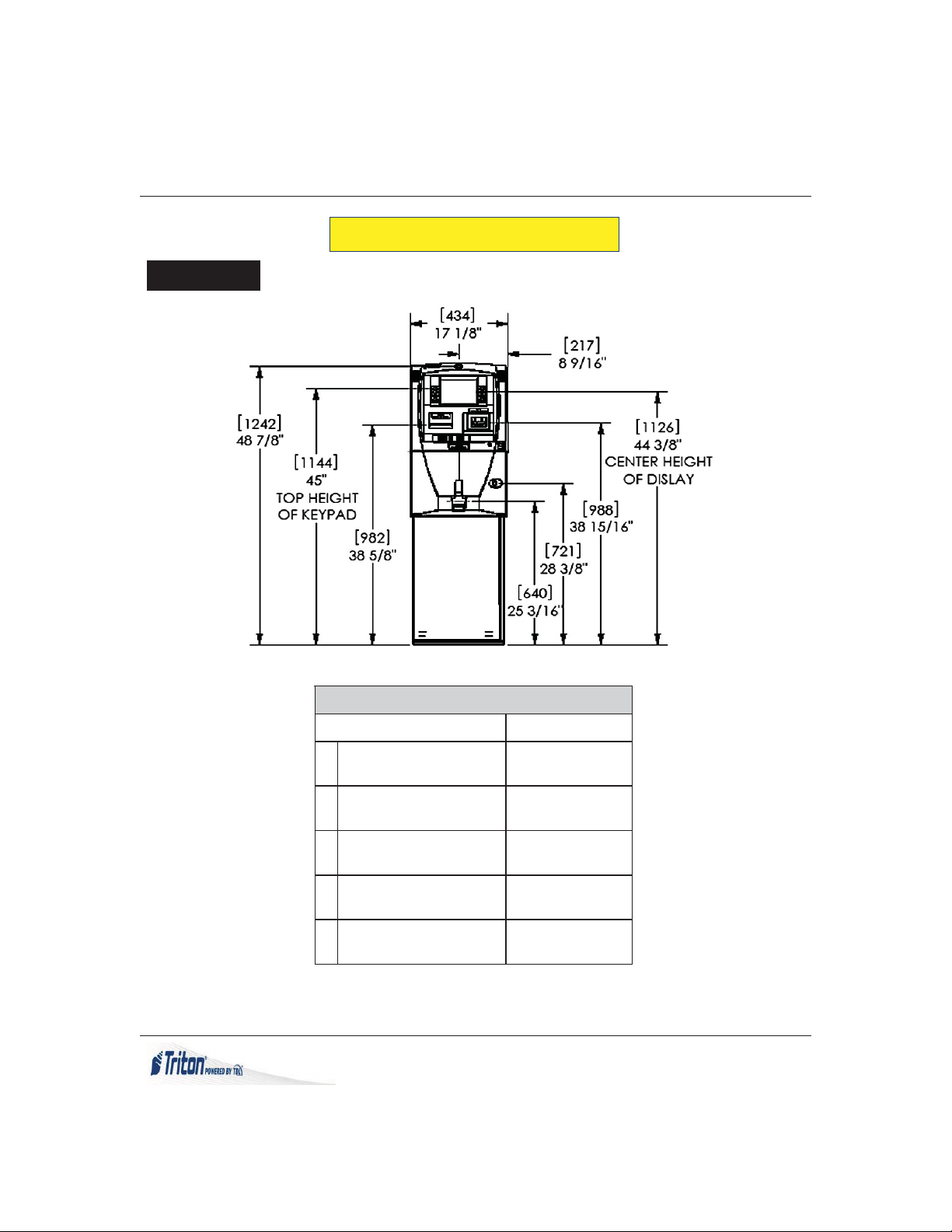

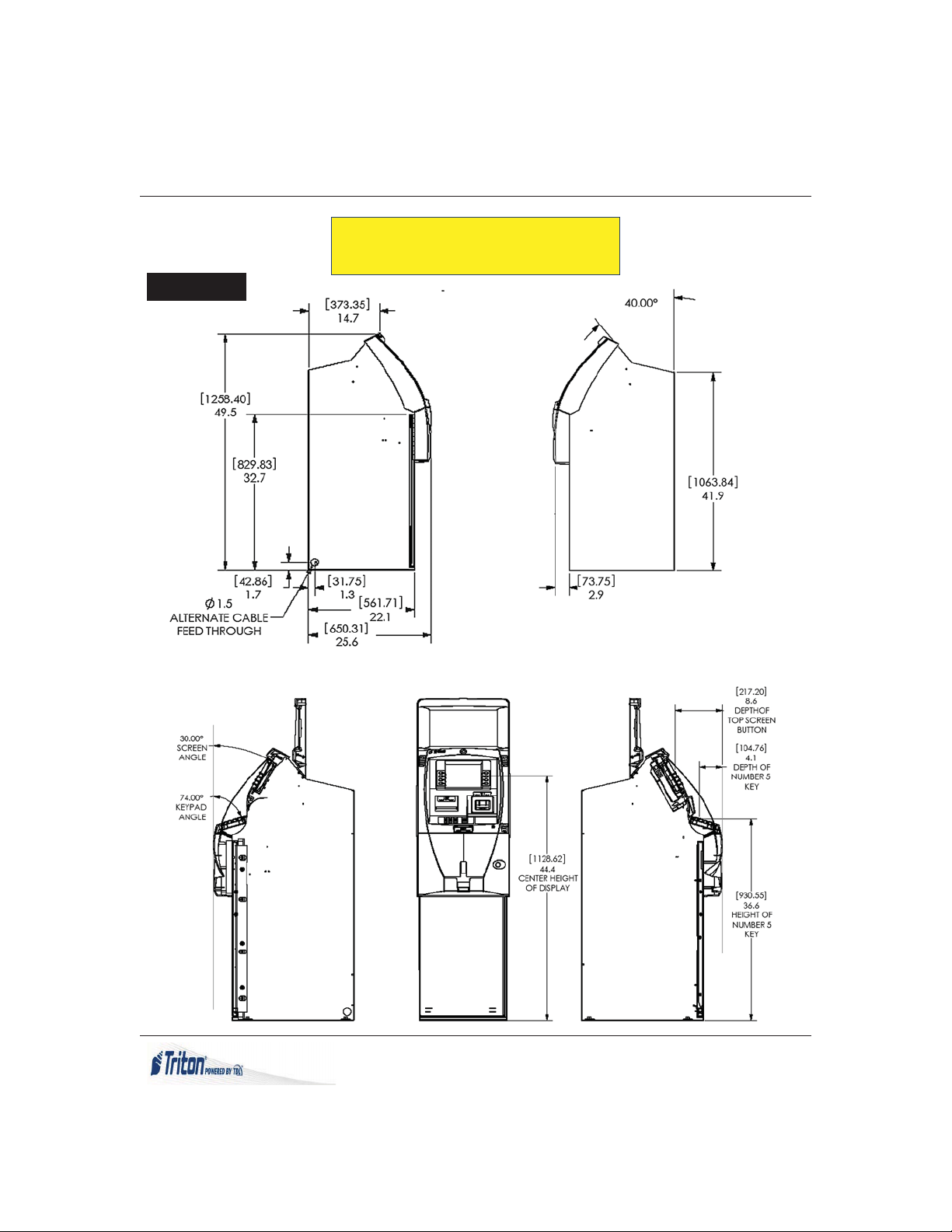

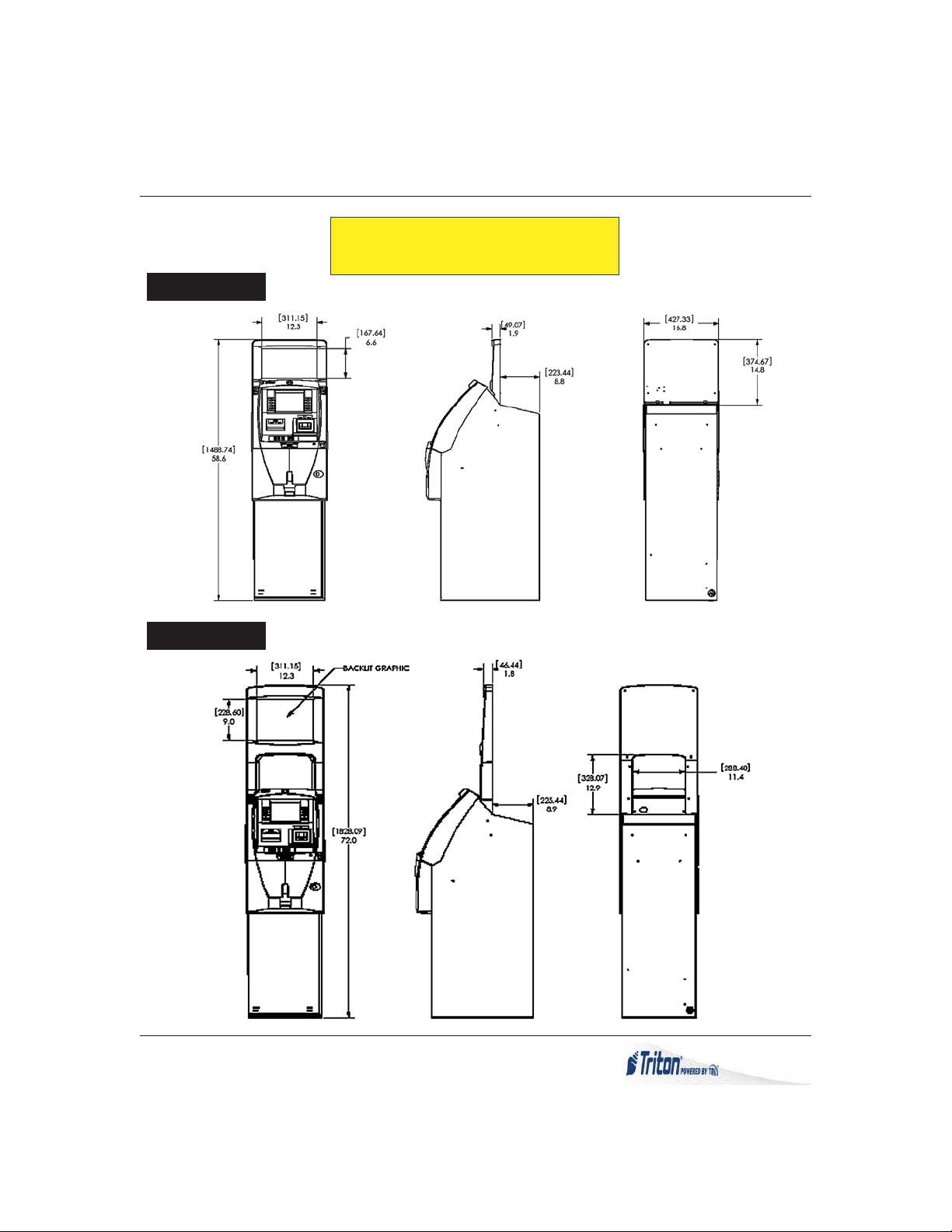

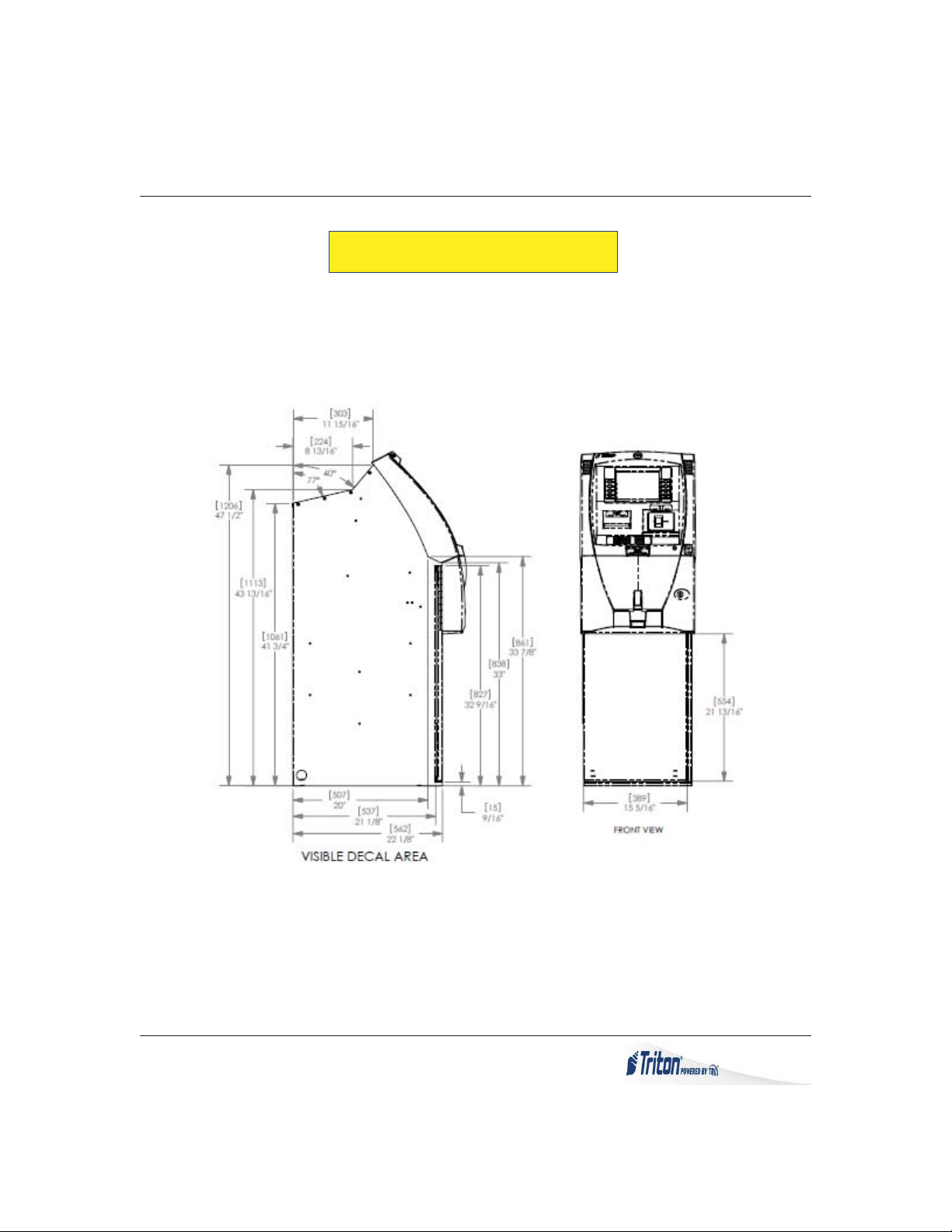

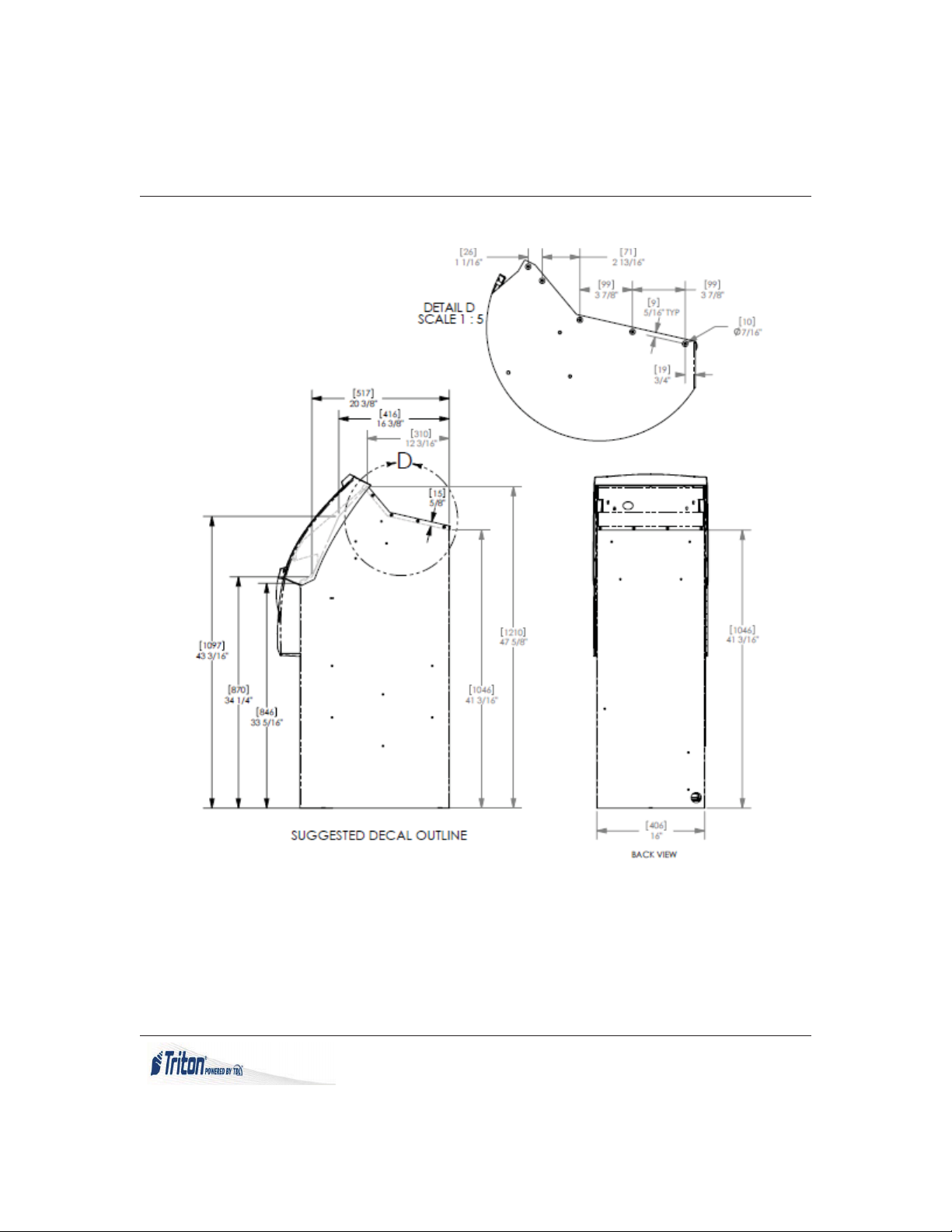

DIMENSIONS. Describes physical dimensions for the cabinet, control panel components, and signage.

¾ Physical dimensions.

¾ Service area dimensions.

¾ Customer access dimensions

INSTALLATION. Describes anchoring the cabinet using standard (steel) or the optional chemical anchors.

Note: Previously, two (2) cabinet designs were offered - shallow and deep. Only one style cabinet

(deep) is now available.

* NOTICE *

The Model RL2000 ATM supports most models of TDM mechanisms, but starting Apr, 08’, Triton will

only ship the TDM-250 in production units. The SDD, Minimech, and NMD-50 dispensers will continue

to be offered. All dispensing mechanisms are shipped installed in the cabinet.

POWER AND COMMUNICATION. Shows cable access area, power requirements, and powering-up the unit.

TCP/IP OR VSAT CONNECTIVITY. Shows unit cable connectivity for communication protocols TCP/IP

and VSAT.

APPENDIX A. Software License Agreement / Compliance/Emissions statements

APPENDIX B. ATM Installation for Accessibility guidelines.

2

Page 3

MODEL RL2000 INSTALLATION MANUAL

CONTENTS

SITE COMPLIANCE ......................................................................................................... 4

E

NVIRONMENTAL PRECAUTIONS ...................................................................................... 5

TEMPERATURE / POWER / RF INTERFERENCE REQUIREMENTS ........................................................................ 6

DIMENSIONS ................................................................................................................. 7

FRONT V IEW / CUSTOMER A CCESS DIMENSIONS ........................................................................................... 8

SERVICE AREA D IMENSIONS ....................................................................................................................... 9

DEEP CABINET (BUSINESS HOURS)

SIDE VIEWS ............................................................................................................................................. 10

MID / HIGH TOPPERS ............................................................................................................................... 11

D

EEP CABINET (VAULT)

SIDE VIEW ......................................................................................................................................... ......12

CABINETS A NCHOR “FOOTPRINTS” ....................................................................................................................... 12

CABINET INSTALLATION ................................................................................................. 13

TOOLS REQUIRED .................................................................................................................................... 14

UNPACKING THE UNIT .............................................................................................................................. 14

MARK / DRILL MOUNTING HOLES ............................................................................................................ 16

INSTALLING STANDARD ANCHORS / BOLT ATM .......................................................................................... 17

I

NSTALL CHEMICAL A NCHORS / BOLT ATM ............................................................................................... 18

ROUTE POWER / COMMUNICATION CABLES .................................................................. 21

ROUTE / CONNECT CABLES ...................................................................................................................... 22

TCP/IP CONNECTIVITY ............................................................................................................................. 24

VSAT C

APPENDIX A - SOFTWARE LICENSE A GREEMENT / COMPLIANCE/EMISSIONS STATEMENTS

ONNECTIVITY ............................................................................................................................... 25

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

3

Page 4

MODEL RL2000 INSTALLATION MANUAL

SITE COMPLIANCE

This document contains the information necessary for the preparation and installation of an RL2000 Triton

ATM. It’s important that the site complies with the requirements specified in this document. In addition,

electrical wiring and mechanical systems must also comply with all relevant laws and regulations.

The site must be prepared by the customer or his agent who is fully conversant with the requirements of

installing ATM equipment. The responsibility for ensuring that the site is prepared in compliance with this

document remains with the customer.

For information and guidance only, a list is provided in general terms of those matters for which the

customer is responsible. The list is not intended to be comprehensive and in no way modifies, alters, or

limits the responsibility of the customer for all aspects of adequate site preparation.

1. Location of the equipment and site preparation.

2. Site wiring (power, communication).

3. Location of other equipment that may cause electrical, electromagnetic or heat induced interference.

4. Make building alterations to meet wiring and other site requirements.

5. Install all communication cables, wall jacks, and associated hardware.

6. Provide and install necessary power distribution boxes, conduits, and grounds.

7. Ensure all applicable codes, regulations, and laws (electrical, building, safety) are adhered to.

8. Ensure the environmental requirements of this unit are met.

9. Install the unit at a height which meets the ADA/DDA/CSA accessibility regulations for the state/

country installed.

TSILKCEHCNOITARAPERPETIS

nalproolfangiseddnaetistceleS

temsnoitidnoclatnemnorivneerusnE

seludehcsrodnevdnarotcartnochsilbatsE

emeriuqerenilnoitacinummockcehC

stn

sdeenyrosseccanoitallatsninalP

a

snoitaretl

stnemeriuqerlacirtcelellatsnI

nilnoitacinummocllatsnI

yrassecenekamdnanalproolfkcehC

sdeennoitacinummocrofetiseraperP

)lanoitpo(gniniartrotareponalP

tsetdnase

elbaliavaeraseirosseccanoitallatsnierusnE

4

Page 5

MODEL RL2000 INSTALLATION MANUAL

ENVIRONMENTAL PRECAUTION CHECKLIST

5

Page 6

MODEL RL2000 INSTALLATION MANUAL

When installing an ATM, some general environmental and power precautions need to be considered. Evaluate the location where the ATM will be

installed. To help ensure proper operation of the ATM, ensure the environmental criteria listed in this checklist are met.

TEMPERATURE / HUMIDITY

1. The ATM will operate over a range of tem-

peratures and humidity. Generally, these parameters must fall within the following

ranges:

Temperature

• 10°C to 40°C

• 50°F to 104°F

Relative Humidity

• 20% to 80%

• (Non-Condensing)

AC POWER REQUIREMENTS

2. Ensure the following AC power requirements

are met:

Current (Max)

• 2.2A @ 115 VRMS at 60 Hz

• 1.1A @ 230 VRMS at 50 Hz

Voltage

• 90 - 136VRMS @ 50/60 Hz

• 198 - 257VRMS @ 50/60 Hz

Power Consumption (Idle)

• 0.6A @ 115 VAC at 60 Hz

• 0.3A @ 230 VAC at 50 Hz

Power Consumption (Max Load)

• 250 Watts @ 120VAC

• 250 Watts @ 240VAC

Surge ~50A @ 230V

* IMPORTANT *

AC power for the terminal should come from a

dedicated source with an isolated ground.

Dedicated source. The ATM AC power feed will be

a dedicated line, to which no other electrical devices

are connected. The ATM power line will be wired for

a single “duplex”-style outlet and connected directly

to the AC service panel.

Isolated Ground. An equipment grounding conductor that is insulated from the conduit or raceway and

all other grounding points throughout its entire

length. The only points of electrical connection will

be at the duplex outlet and service panel ends of the

line.

DEDICATED TELEPHONE

3. Ensure the following telephone-line requirements are met:

Dedicated line. The telephone line servicing the ATM

will not be a “party” line or any other shared type

connection.

Proximity to Interference Sources. Thetelephone

line must not be in close proximity to “noisy” devices that could induce interference into the ATM

communications channel. See the next section for

additional information on “interference sources.”

RF INTERFERENCE

4. Ensure there are no devices near the terminal

that may cause RF interference, such as:

TVs

Coolers

Security devices

Neon signs

Devices with compressors

6

Page 7

MODEL RL2000 INSTALLATION MANUAL

DIMENSIONS

Dimensions listed comply with US Federal ADA

Guidelines. For USA installations, check for

additional guidance. For non-USA installations,

check regulations relating to the country of

install.

Note:

Dimensions shown in inches and [millimeters]

7

Page 8

Front View

MODEL RL2000 INSTALLATION MANUAL

PHYSICAL DIMENSIONS

1yeKnoitcnuFpoT

2

3redaeRdraC

4retnirPtpieceR

5yarTlliB

erutaeFthgieH

yeK5#

)dapyeKniaM(

8

snoisnemiDsseccAremotsuC

"54

]mm4411[

"63

]mm419[

"6

1/51-83

]mm889[

"8/5-83

)mm289[

"61/3-52

]mm046[

Page 9

MODEL RL2000 INSTALLATION MANUAL

SERVICE A REA DIMENSIONS

2" [51] clearance around

cabinet sides and rear

snoisnemiD

noisnemiD)tluaV(1leveLsruoHssenisuB

A]335["12~]335["12~

B]065["61/

C]065["61/1-22]345["8/3-12

D]863["2/1-41]922["9

E]267["03]117["82

1-82]696["8/3-72

9

]sretemillim[dna)"(sehcnininwohS

Page 10

Side Views

MODEL RL2000 INSTALLATION MANUAL

PHYSICAL DIMENSIONS

(DEEP CABINET - BUSINESS HOURS)

10

Page 11

Mid Topper

MODEL RL2000 INSTALLATION MANUAL

PHYSICAL DIMENSIONS

(DEEP CABINET - BUSINESS HOURS)

High Topper

11

Page 12

Side View

MODEL RL2000 INSTALLATION MANUAL

PHYSICAL DIMENSIONS

(DEEP CABINET - VAULT)

CABINET “FOOTPRINTS”

Anchor “footprint” - Deep cabinet (Business)

F

r

o

n

t

Anchor “footprint” - Deep cabinet (Vault)

F

r

o

n

t

12

Page 13

MODEL RL2000 INSTALLATION MANUAL

DECAL A REA DEEP CABINET

13

Page 14

MODEL RL2000 INSTALLATION MANUAL

14

Page 15

MODEL RL2000 INSTALLATION MANUAL

DECAL A REA VAULT CABINET

15

Page 16

MODEL RL2000 INSTALLATION MANUAL

16

Page 17

MODEL RL2000 INSTALLATION MANUAL

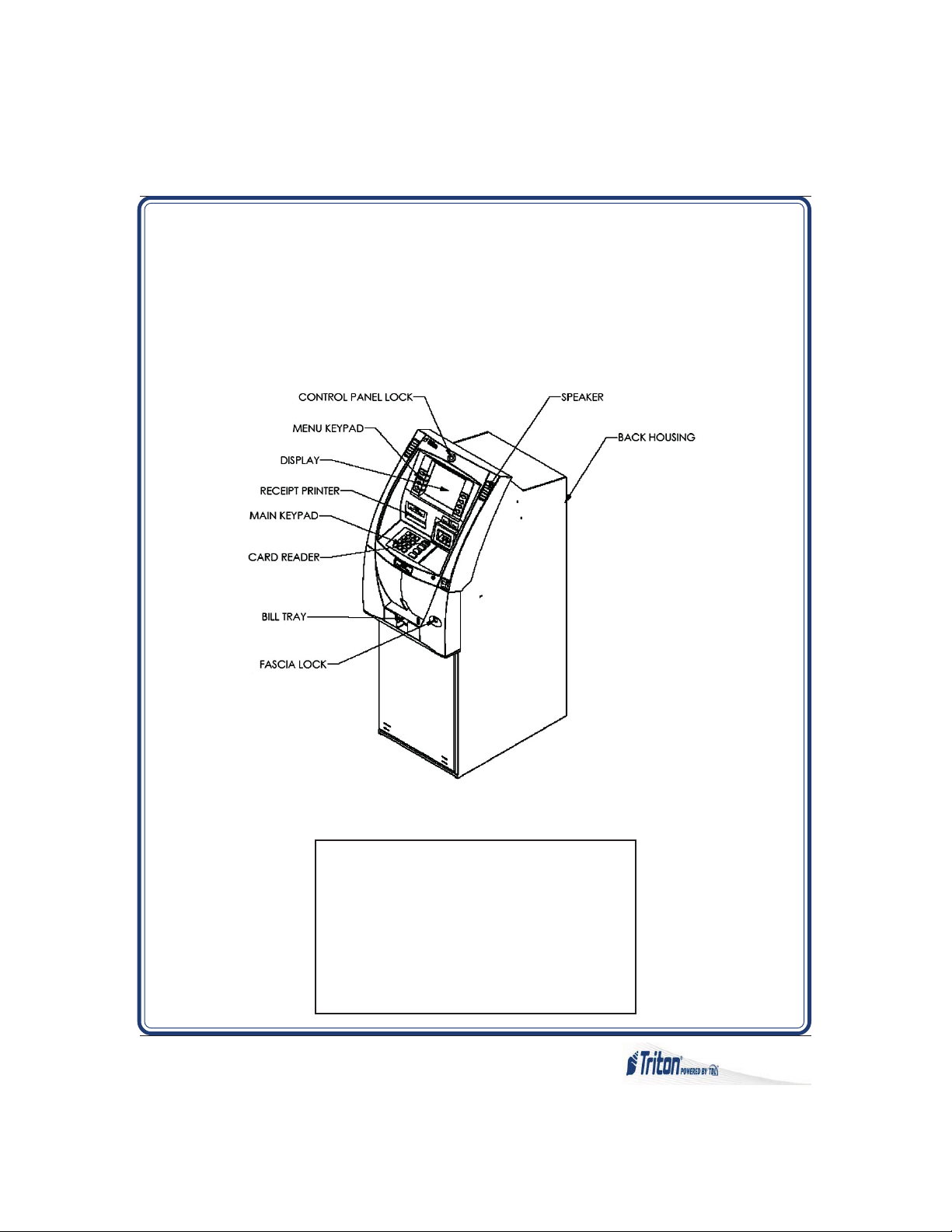

CABINET INSTALLATION

17

Page 18

MODEL RL2000 INSTALLATION MANUAL

CABINET INSTALLATION

The following procedure applies to installing the cabinet assembly using either standard (P/N 06200-00066)

or chemical (06200-00060) anchor kits. The anchor kits are not supplied with the unit.

* IMPORTANT *

Model RL2000 ATM is designed for indoor use only!

deriuqeRslooT

,sdnuoptoof06tsaeltaotelbatsujda,hcnerweuqroT

hcnerwtehctarro,hcnerwtnecsercelbatsujda

amrof)tnelaviuqero(hcnupretneC

remmaHtekcos)mm91("4/3revirdwercstalfegraL

levelelbbuBhcnerwxob/tekcos"61/7s

,)mm21("2/1,)mm6("4/1

noitcetorpgniraeH

"6tsael

tlebtroppuskcaBrenaelcmuucavelbatroPhsurberiW

-edibrac)mm51("61/9dna

ta-stibllirdyrnosamdeppit

gnol

stniopllirdgnikr

elggogytefaS

cirtceleytud-yvaeh"4/3

)remmah/yrator(llird

tiKrohcnAdradnatS

srehsawtalf"2/1

epyt-eveels"4/1-4x"2/1

stlobrohcna

stun"2/1

tiKrohcnAlacimehC

dnastunxeH

srehsaw

seluspacrohcnalacimehC

tniop-lesihcdedaerhT

sdor

UNPACK ATM

1. Carefully inspect the shipping container for any damage and report any damage immediately to the

shipping company. Refer to the warranty information in the User or Service manual (as applicable) for

information about reporting shipping damage.

2. Remove the ATM cabinet from the carton by cutting the straps and removing the top of the box.

3. Remove the packing material from inside of the box.

4. Remove the silver key from the white plastic bag attached to the ATM wrapping.

18

Page 19

MODEL RL2000 INSTALLATION MANUAL

5. Stand the unit up and walk it out of the shipping carton.

6. Remove the wrapping from the ATM.

7. Use the silver key to unlock both the control panel and the

fascia door (which conceals the locking mechanism) on the

front of the cabinet. Open the fascia door.

8. Lift the handle under the bill chute to open the front enclosure

door. If the door is locked, see the sidebar on this page for help

in unlocking the electronic or mechanical lock, if applicable..

9. Remove the packing material from inside the vault enclosure.

10. The accessory box is shipped inside the cabinet enclosure.

Open and inspect the contents. Check the contents against the

enclosed packing list and report any missing parts to Triton.

**WARNING**

DO NOT APPLY POWER TO THIS TERMINAL UNTIL THE INSTALLATION IS

COMPLETE!!

UNLOCKING

COMBINATION LOCKS

Mechanical Lock. There are two

marks on the dial ring. The index

mark at the top of the dial is used

for opening the lock. A revolution

is counted each time the selected

number is aligned with the opening index.

Locks are shipped on a factory setting of ‘50’. To unlock, turn the

dial to the left (counterclockwise)

FOUR (4) turns, stopping on ‘50’.

Then turn the dial to the right

(clockwise) until the bolt is retracted.

Electronic Lock. The combination

of the lock is preset to 1-2-3-4-5-

6. To unlock, enter the preset combination and check for proper operation. After each keypress, the

lock will

has been entered, the lock will beep

twice, and the open period begins.

When a valid combination has

been entered, the operator will have

approximately 3 seconds to open

the lock. To open the lock, turn

the outer ring of the dial clockwise.

After the lock is opened, the vault

door may be opened.

‘beep’. After the final digit

19

Page 20

MODEL RL2000 INSTALLATION MANUAL

Mark/Drill Mounting Holes

Mark the location of the cabinet mounting holes on the concrete

floor. This is accomplished as described below:

1. Move the ATM to the location where it will be installed.

Open the cabinet vault door at least 90° to improve access.

Locate the five (5) anchor-bolt holes in the bottom of the

cabinet (each corner and center). Use a felt-tip pen or other

marker to carefully mark the center of each of these four holes

on the floor; these marks will serve as guides for the anchor

bolt holes that will be drilled in the next step. Move the ATM

aside to provide clear access to the mounting hole marks.

Center punch each mark to help align the drill bit.

2. Use a 1/4" [6 mm] diameter carbide-tipped masonry bit to drill

four pilot holes at the drilling points marked in the previous

step. Drill the pilot holes approximately 1/2" [12 mm] deep into

the floor. These holes will help guide the masonry bit that will

be used to drill the anchor-bolt holes in the next step.

3. Standard anchors: Use a 1/2" [13mm] diameter carbide-tipped

masonry bit to drill four holes at least 2-3/4" [70mm] deep

into the floor. Be sure to take into account the depth of any

floor covering, such as tile or vinyl when gauging the depth

of the anchor holes. Make sure the holes are drilled at least

2- 3/4" into the

concrete floor.

SELECTING THE

INSTALLATION LOCATION

Choosing the right location for your

ATM is very important. Security

concerns suggest a location that is

away from any door or external access point. Ideally, the terminal

should be mounted as close to a

back wall as possible. For marketing reasons, however, it may be desirable to locate the terminal near

the front where your customers can

easily locate it. Wherever you decide to locate the terminal, be sure

to follow the recommended procedures for both mounting the terminal and for removing cash when

the unit will be unattended.

TOOL USE/SAFETY

Observe ALL safety precautions for

operating hand and power tools!

Wear eye and ear protection while

operating the electric drill!

3a. Chemical anchors: Use a 9/16" [15mm] diameter carbide-

tipped masonry bit to drill four holes at least 4-1/2" [115mm]

deep into the floor. Be sure to take into account the depth of

any floor covering, such as tile or vinyl when gauging the

depth of the anchor holes. Make sure the holes are drilled at

least 4- 1/2-inches [115mm] into the

concrete floor.

20

CONCRETE STRENGTH

The floor at the installation location should consist of commercial-grade concrete measuring at

least

2000 psi in compression

strength. The full effectiveness of

the mounting anchors depends

upon meeting this specification!

Check with the contractor/builder

or owner of the installation to

verify that this requirement can

be satisfied.

Page 21

MODEL RL2000 INSTALLATION MANUAL

4. Use a portable vacuum cleaner to remove any dust or debris that may have fallen into the holes during

the drilling process.

Drill anchor holes Blow out dust/debris.

Install Standard Anchors

Bolt ATM to Floor

1. Ensure the leveling feet are flush with the bottom of the cabinet. If necessary, use a screwdriver to

adjust the leveling bolts inside the cabinet (near the four corners) so that the leveling feet are flush with

the bottom of the cabinet.

2 Move the ATM into position for mounting by aligning the base over the four holes drilled in the

previous procedure.

3 Place an anchor bolt through the cabinet base and into one of the mounting holes. Use a ball peen

hammer to tap the bolt completely into the hole.

IMPORTANT: If the anchor bolt “falls” into the hole without needing to be tapped in, the hole is too

large! The mounting-hole pattern will have to be moved and redrilled using smaller holes as

necessary to achieve a snug fit.

Place anchor bolts in mounting holes. Tap anchor bolts into mounting holes.

21

Page 22

MODEL RL2000 INSTALLATION MANUAL

4. Place a flat washer on the anchor bolt followed by a 1/2” (13mm) nut.

5. Repeat Steps 2 and 3 for the remaining anchor bolts.

6. Ensure the cabinet is as level as possible given the floor conditions. Use a bubble level to verify this.

If a bubble-level is not available, the cabinet can be “rocked” gently from front-to-back and side-toside to check the need for leveling.

7. Use a torque wrench and 3/4” [19mm] socket to tighten each nut to a torque setting of

(required to establish the maximum pull-out strength of the anchors). If a torque wrench is not

available, use a ratchet wrench and 3/4” [19mm] socket to tighten the nuts three full turns beyond hand

tight.

8. Once the nuts are tightened as specified in Step 7, install a second nut on each bolt and tighten down

firmly.

60 foot-pounds

Install Chemical Anchors

Bolt ATM to Floor

1. Move the ATM into position for mounting by aligning the base over the four holes drilled in the

previous procedure.

2. Begin by inserting a Chem Stud capsule into one of the mounting holes. Either end of the capsule may

be inserted first.

3. Place a washer and a nut (in that order) onto a chisel point rod. Thread the nut onto the rod, leaving 3

to 4 threads exposed.

4. Thread the rod coupler onto the threaded rod until it is tight against the nut. The threaded rod used

should be free of dirt, grease, oil or other foreign material.

5. Select the drive unit, insert it into a rotary hammer drill and engage the coupling to be used.

Insert Chem Stud capsule in mounting hole.

Prepare chisel point anchor rod.

Add washer and nut.

22

Page 23

MODEL RL2000 INSTALLATION MANUAL

6. Insert the chisel point of the rod into the hole to break the glass capsule. Spin it into the capsule at a

speed of 250 to 500 RPM, until it is fully embedded. IMPORTANT! Turn the rotary hammer drill

OFF IMMEDIATELY when the rod is fully embedded!

7. Pull the driver out of the coupling while holding the rod. Hold the hex nut with a wrench to unthread the

coupler.

8. Repeat steps 1-7 for each of the remaining mounting holes.

9. Allow the adhesive to cure for the specified time (see chart and important

not, which follow) prior to applying any load to the anchors. During the

winter, the hole temperature may be different than the room temperature!

The hole temperature should be measured to determine the curing time

required. DO NOT disturb or load the anchors until they are fully

cured!

*erutarepmeTlairetaMesaB emiTgnitteS

revodnaCº02/Fº86setunim02

Cº02/Fº86otCº01/Fº05setunim03

Cº01/Fº05otCº0/Fº23ruoh1

Fº32sruoh5

Cº0/Fº23otCº5-/

Cº5-/Fº32otCº01-/Fº41sruoh01

to cure.

10. Ensure the ATM is as level as possible given the floor conditions. Use a bubble level to verify this. If

a bubble-level is not available, the cabinet can be “rocked” gently from front-to-back and side-to-side

to check the need for leveling.

11. Use an adjustable wrench or a ratchet wrench with 3/4" [19mm] socket to tighten the nuts down. No

minimum torque setting for the nuts is required. Simply ensure the nuts are tightened down firmly

enough to secure the plinth to the anchors. Tightening the nuts just beyond hand tight should prove

adequate.

12. Once the ATM is square (level), install a second nut on each bolt and tighten down firmly.

Allow seated anchor

23

Page 24

MODEL RL2000 INSTALLATION MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

24

Page 25

MODEL RL2000 INSTALLATION MANUAL

3. Secure/plug the unused access hole with the grommet or plug provided.

ROUTE POWER AND COMMUNICATION

25

Page 26

MODEL RL2000 INSTALLATION MANUAL

Route AC Power and

Communication Cable

NOTE: Before you start, unlock and open the control panel. Verify that the power switch on the unit’s

power supply is in the OFF (0) position. Close the control panel.

NOTE

The Power Cord interface cable is located inside the vault area (Dispenser location) of the cabinet.

To gain access and connect the power cord included in the accessory box, you may have to

remove the dispenser.

1. Obtain the AC power cord that is located in the accessory box. From the exterior of cabinet, feed the

small end of cable through a cable access hole (lower part of cabinet).

Main cable

access hole

2. Connect and route the power cord in the unit as shown in figure at right.

26

Page 27

MODEL RL2000 INSTALLATION MANUAL

Power Outlet Accessibility

Whether you are installing a new AC socket outlet or plan to use an existing

outlet to supply power to the ATM, make sure the following requirements are

met:

1. The outlet is located near the equipment.

2. AC power for the terminal should come from a dedicated source with an

isolated ground. The ATM is designed to work on an IT (Isolated-Terra)

type power system having a phase-to-phase voltage not exceeding 240

volts.

3. The outlet is easily accessible and will not be blocked once the equipment is installed.

POWER SUPPLY CORD -

SPECIFICATIONS

For European applications, the power

supply cord must conform to the following specifications:

1. Two-conductor with Physical

Earth (PE) ground.

2. IEC 320 molded connector on

one end and molded plug on the

other end.

3. Certified for country of

installation.

4. Rated minimum H05VV-F with

minimum 0.75 mm2 (except where

specific countries require 1.0

mm2) conductors.

5. Maximum length: 3 meters.

27

Page 28

MODEL RL2000 INSTALLATION MANUAL

TCP/IP (ETHERNET)

The Ethernet option makes your RL2000 ATM LAN (Local Area Network) or WAN (Wide Area Network)

capable. The ATM functions that are normally performed via the dial-up telephone system, such as

customer transactions and remote monitoring, can now be performed using existing in-house communications network. ATM transaction processing and hardware monitoring functions are performed across a

shared network medium. Ethernet is popular because it strikes a good balance between speed, cost and

ease of installation. These benefits, combined with wide acceptance in the computer marketplace and the

ability to support virtually all popular network protocols, make the Ethernet option an ideal networking

solution for your RL2000 ATM.

TCP/IP CABLE (CAT-5) CONNECTIVITY

1. If the unit is ON, enter MANAGEMENT FUNCTIONS > SYSTEM PARAMETERS > SHUT DOWN THE TERMINAL.

When prompted on the screen, open the control panel hood and turn the power switch on the power

supply to the OFF (0) position.

2. Refer to the section on

cabinet base cable access hole. Secure cable inside vault area and continue up to the control panel

access holes.

3. Connect the RJ-45 end of CAT-5 cable to the TCP/IP connector located on the X2 MAIN BOARD

assembly as shown in figure below.

4. Secure cable into existing cable harness runs. Refer to the Configuration manual for programming

Ethernet options.

“Power and Communication”. Route the 10Base-T (CAT-5) cable through the

RJ-45 (CAT-5)

TCP/IP P

USB PORTS

ORT

28

Page 29

MODEL RL2000 INSTALLATION MANUAL

VSAT (SATELLITE)

VSAT stands for “Very Small Aperture Terminal” and refers to receive/transmit terminals installed at dispersed

sites connecting to a central hub via satellite using small diameter antenna dishes (0.6 to 3.8 meter).

VSAT technology represents a cost effective solution for users seeking an independent communications

network connecting a large number of geographically dispersed sites. VSAT networks offer value-added

satellite-based services capable of supporting the Internet, data, LAN, voice/fax communications, and can

provide powerful, dependable private and public network communications solutions.

INSTALLING THE VSAT CABLES (OPTIONAL KIT)

1. If the unit is ON, enter Management Functions>System Parameters>Shut Down the Terminal. When

prompted, open the control panel hood and turn the power switch on the power supply to the OFF (0)

position.

2. Refer to the section on

base cable access hole. Secure cable inside vault area and continue up to the control panel access

holes.

3. Connect the RJ-45 connector end of the Comms cable to the A

assembly.

4. Connect other end of Comm cable (RJ-45 connector) to the Sub-D adapter. Refer to the Configuration

manual for programming VSAT options.

“Power and Communication”. Route the Comms cable through the cabinet

UXILLARY PORT on the Docking board

Sub-D adapter.

29

Page 30

MODEL RL2000 INSTALLATION MANUAL

THIS PAGE INTENTIONALLY LEFT BLANK

30

Page 31

APPENDIX A

SOFTWARE LICENSE A GREEMENT

COMPLIANCE / EMISSION STATEMENTS

Page 32

APPENDIX A - SOFTWARE LICENSE A GREEMENT / COMPLIANCE/EMISSION STATEMENTS

AUTOMATED TELLER MACHINE (“ATM”) SOFTWARE

END-USER A GREEMENT

IMPORTANT: PLEASE READ CAREFULLY:

BY INSTALLING OR OTHERWISE USING THE ATM, YOU (AS THE OWNER OR LESSEE OF THE ATM).

AGREE TO BE BOUND BY THE FOLLOWING TERMS AND CONDITIONS, INCLUDING, WITHOUT

LIMITATION, THE WARRANTY DISCLAIMERS, LIMITATIONS OF LIABILITY AND TERMINATION

PROVISION WHICH APPLY TO YOUR USE OF THE ATM SOFTWARE CONTAINED IN THIS ATM AND

IS HEREBY LICENSED BY TRITON SYSTEMS OF DELAWARE, INC. (“Triton”) TO YOU PURSUANT TO

THIS AGREEMENT.

IF YOU DO NOT AGREE TO OR ARE NOT WILLING TO BE BOUND BY THE TERMS AND CONDITIONS

OF THIS AGREEMENT, DO NOT INSTALL OR OTHERWISE USE THIS ATM AND PROMPTLY CONTACT YOUR VENDOR. INSTALLING OR OTHERWISE USING THE ATM INDICATES THAT YOU ACCEPT THESE TERMS.

This ATM is manufactured by, and utilizes proprietary software owned by Triton Systems of Delaware, Inc.

and/or its suppliers. All right, title and interest in and to all component software installed or embedded in

the ATM (“ATM Software”) including all associated intellectual property rights, are and will remain the

property of Triton and/or its suppliers.

LICENSE: Triton grants you a limited, nonexclusive license to use the ATM Software but only in connection with the operation of this ATM subject to the terms and restrictions set forth in this License Agreement.

You are not permitted to use the ATM Software in any manner not expressly authorized by this License. You

acknowledge and agree that ownership of the ATM Software and all subsequent copies thereof regardless

of the form or media are held by Triton or its suppliers.

The software is licensed for use on this specific Triton ATM product and may not be used on any other

product. Otherwise, the supporting documentation, if any, may be copied only as essential for backup or

archive purposes in support of your use of the ATM. You must reproduce and include all copyright notices

and any other proprietary rights notices appearing on any copies that you make.

ASSIGNMENT: NO REVERSE ENGINEERING: You may transfer the ATM Software to another party but

only in connection with a transfer of all your right, title and interest in and to this ATM and if such party

accepts the terms and conditions of this License Agreement. If you transfer the ATM, you must at the same

time transfer the supporting documentation, if any, to the same party or destroy any such materials not

transferred. Modification, reverse engineering, reverse compiling, or disassembly of the ATM and/or the

ATM Software is expressly prohibited.

A-2

Page 33

APPENDIX A - SOFTWARE LICENSE A GREEMENT / COMPLIANCE/EMISSION STATEMENTS

DISCLAIMER OF WARRANTIES AND LIMITATION OF DAMAGES

TO THE EXTENT PERMITTED BY LAW, THIS ATM SOFTWARE, INCLUDING ALL INCORPORATED

THIRD PARTY SOFTWARE, AND DERIVATIVES IS PROVIDED, “AS IS”. TRITON MAKES NO REPRESENTATIONS WITH RESPECT TO, AND DOES NOT WARRANT THE PERFORMANCE OR RESULTS

YOU OR YOUR CUSTOMERS MAY OBTAIN BY USING THE ATM. TRITON SPECIFICALLY DISCLAIMS

ANY AND ALL WARRANTIES, EXPRESS, IMPLIED OR STATUTORY, INCLUDING WITHOUT LIMITATION, WARRANTIES OF QUALITY, PERFORMANCE, NONINFRINGEMENT, AND MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

TRITON MAKES NO REPRESENTATIONS OR WARRANTIES AND ASSUMES NO OBLIGATIONS TO

YOU OR YOUR CUSTOMERS WITH RESPECT TO ANY TRANSACTION OR SERVICES ACCESSED

AND/OR UTILIZED IN CONSUMER-INITIATED TRANSACTIONS MADE FROM THIS ATM. IN NO

EVENT WILL TRITON, ITS AFFILIATES, DIRECTORS, OFFICERS, EMPLOYEES, AGENTS OR SUPPLIERS BE LIABLE TO YOU UNDER ANY THEORY OF TORT, CONTRACT, STRICT LIABILITY OR OTHER

LEGAL OR EQUITABLE THEORY FOR ANY PUNITIVE, CONSEQUENTIAL, INCIDENTAL, SPECIAL OR

SIMILAR DAMAGES, INCLUDING ANY LOSS PROFITS OR LOST SAVINGS, EVEN IF A TRITON AGENT

OR REPRESENTATIVE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES, OR FOR ANY

CLAIM BY ANY THIRD PARTY.

YOUR SOLE REMEDY AGAINST TRITON FOR DEFECTIVE PERFORMANCE OF THE ATM SOFTWARE

WILL BE LIMITED EXCLUSIVELY TO REPAIR OR REPLACEMENT OF THE ATM AND/OR THE ATM

SOFTWARE, AT TRITON’S SOLE DISCRETION.

Any warranty pertaining to the ATM, its mechanical components exclusive of the ATM software, shall be

governed and controlled by any warranty given to you by Triton in a separate document accompanying

this ATM.

The foregoing limitation of liability and exclusion of certain damages will apply regardless of the success or

effectiveness of other remedies.

GOVERNING LAW: This License Agreement shall be governed by the laws of the State of Mississippi and

by the laws of the United States, excluding their conflicts of laws principles.

SEVERABILITY: In the event any provision of this License Agreement is found to be invalid, illegal or

unenforceable, the validity, legality and enforceability of any of the remaining provisions shall not in any

way be affected or impaired.

ENTIRE AGREEMENT: This License Agreement and the accompanying Limited Warranty set forth the

entire agreement between you and Triton, supersedes all prior agreements, whether written or oral, with

respect to the ATM Software, and may be amended only in writing signed by both parties.

A-3

Page 34

APPENDIX A - SOFTWARE LICENSE A GREEMENT / COMPLIANCE/EMISSION STATEMENTS

COMPLIANCE / EMISSION STATEMENTS

DISCLAIMER

The manufacturer of the Automated Teller Machine (ATM) product(s) described herein makes no

representations or warranties, either expressed or implied, by or with respect to anything in this manual, and

shall not be liable for any implied warranties of fitness for a particular purpose or for any indirect, special, or

consequential damages. Information in this document is subject to change without notice and does not

represent a commitment on the part of the manufacturer.

EMISSIONS (EMI)

** CAUTION **

(US Requirements)

This device complies with Part 15 of the FCC rules.

Changes or modifications not expressly approved

by Triton Systems could void the regulatory

compliance approval and the warranty. Use of this

product in a manner other than those described in

this manual may result in personal injury!

Operation is subject to the following two (2)

conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received,

including interference that may cause undesired

operation.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to

Part 15 of FCC rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his

own expense. Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

CANADIAN REQUIREMENTS

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set

in the Radio Interference Regulations of the Canadian Department of Communications. This Class A digital

apparatus complies with Canadian ICES-003.

Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux

appareils numeriques de la Class A prescrites dans le Reglement sur le brouillage radioelectrique edicte par

le ministere des Communications du Canada. Cet appareil numerique de la classe A est conforme a la norme

NMB-003 Canada.

UK / AUSTRALIA / SOUTH A FRICA REQUIREMENTS

Warning:

This is a Class A product. In a domestic environment, this product may cause radio interference in which

case the user may be required to take adequate measures.

A-4

Page 35

APPENDIX B

ATM INSTALLATION FOR A CCESSIBILITY

Page 36

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

A Guide to the New ADA-ABA Accessibility Guidelines

On July 23, 2004, the U.S. Access Board, an independent Federal agency, issued updated accessibility

guidelines for new or altered facilities covered by Americans with Disabilities Act and the Architectural

Barriers Act. These guidelines address a wide range of facilities in the private and public sectors. Presented here is an overview of the new guidelines that also highlights significant changes.The following

guidelines (305 and 308) pertain to floor/ground space and reach ranges.

When will the new guidelines take effect?

The Board’s guidelines are not mandatory on the public, but instead serve as the baseline for enforceable

standards (which are) maintained by other Federal agencies. In this respect, they are similar to a model

building code in that they are not required to be followed except as adopted by an enforcing authority.

Under the ADA, the Department of Justice (and in the case of transit facilities, the Department of Transportation) are responsible for enforceable standards based on the Board’s guidelines. These agencies will

update their ADA standards based on the new guidelines. In doing so, they will indicate when the new

standards are to be followed. Several other agencies (the General Services Administration, Department of

Defense, Department of Housing and Urban Development, and the U.S. Postal Service) hold a similar

responsibility for standards used to enforce the ABA.

Existing Facilities

The ADA and ABA guidelines cover new construction and planned alterations and generally do not apply

to existing facilities except where altered. Facilities built or altered according to earlier versions of the ADA

or ABA standards will not necessarily have to meet the updated version except where they are subsequently altered or renovated. The Department of Justice, which regulates requirements for existing facilities under the ADA, intends to address coverage of facilities built or altered according to the original ADA

standards in its rulemaking to update the standards. It will also address facilities retrofitted under ADA

provisions for existing facilities, such as the requirement for barrier removal in places of public accommodation. With respect to ABA facilities, the Board has clarified in the guidelines that facilities built to earlier

ABA standards are subject to the new requirements only in relation to planned alterations.

305. Clear Floor or Ground Space

305.1 General. Clear floor or ground space shall comply with

305.

305.2 Floor or Ground Surfaces. Floor or ground surfaces of a

clear floor or ground space shall comply with 302. Changes in level

are not permitted.

EXCEPTION: Slopes not steeper than 1:48 shall be permitted.

305.3 Size. The clear floor or ground space shall be 30 inches

(760 mm) minimum by 48 inches (1220 mm) minimum.

B-2

Figure 305.3 Clear Floor or

Ground Space

Page 37

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

305.4 Knee and Toe Clearance. Unless otherwise specified, clear floor or ground space shall be permit-

ted to include knee and toe clearance complying with 306.

305.5 Position. Unless otherwise specified, clear floor or ground space shall be positioned for either

forward or parallel approach to an element.

Figure 305.5 Position of Clear Floor or Ground Space

305.6 Approach. One full unobstructed side of the clear floor or ground space shall adjoin an accessible

route or adjoin another clear floor or ground space.

305.7 Maneuvering Clearance. Where a clear floor or ground space is located in an alcove or otherwise

confined on all or part of three sides, additional maneuvering clearance shall be provided in accordance with

305.7.1 and 305.7.2.

305.7.1 Forward Approach. Alcoves shall be 36 inches (915 mm) wide minimum where the depth exceeds

24 inches (610 mm).

305.7.2 Parallel Approach. Alcoves shall be 60 inches (1525 mm) wide minimum where the depth exceeds

15 inches (380 mm).

Figure 305.7.1 Maneuvering Clearance in an

Alcove, Forward Approach

Figure 305.7.2 Maneuvering Clearance in an

Alcove, Parallel Approach

B-3

Page 38

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

308. Reach Ranges

308.1 General. Reach ranges shall comply with 308.

308.2 Forward Reach.

308.2.1 Unobstructed. Where a forward reach is unobstructed, the high forward reach shall be 48 inches

(1220 mm) maximum and the low forward reach shall be 15 inches (380 mm) minimum above the finish floor

or ground.

Figure 308.2.1 Unobstructed Forward Reach

308.2.2 Obstructed High Reach. Where a high forward reach is over an obstruction, the clear floor space

shall extend beneath the element for a distance not less than the required reach depth over the obstruction.

The high forward reach shall be 48 inches (1220 mm) maximum where the reach depth is 20 inches (510 mm)

maximum. Where the reach depth exceeds 20 inches (510 mm), the high forward reach shall be 44 inches

(1120 mm) maximum and the reach depth shall be 25 inches (635 mm) maximum.

Figure 308.2.2 Obstructed High Forward Reach

B-4

Page 39

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

308.3 Side Reach.

308.3.1 Unobstructed. Where a clear floor or ground space allows a parallel approach to an element and

the side reach is unobstructed, the high sidereach shall be 48 inches (1220 mm) maximum and the low side

reach shall be 15 inches (380 mm) minimum above the finish floor or ground.

EXCEPTIONS:

1. An obstruction shall be permitted between the clear

floor or ground space and the element where the depth

of the obstruction is 10 inches (255 mm) maximum.

2. Operable parts of fuel dispensers shall be permitted to be 54 inches (1370 mm) maximum measured from

the surface of the vehicular way where fuel dispensers are installed on existing curbs.

Figure 308.3.1 Unobstructed Side Reach

308.3.2 Obstructed High Reach. Where a clear floor or ground space allows a parallel approach to an

element and the high side reach is over an obstruction, the height of the obstruction shall be 34 inches (865

mm) maximum and the depth of the obstruction shall be 24 inches (610 mm) maximum. The high side reach

shall be 48 inches (1220 mm) maximum for a reach depth of 10 inches (255 mm) maximum. Where the reach

depth exceeds 10 inches (255 mm), the high side reach shall be 46 inches (1170 mm) maximum for a reach

depth of 24 inches (610 mm) maximum.

EXCEPTIONS:

1. The top of washing machines and clothes dryers shall be permitted to be 36 inches (915 mm) maximum

above the finish floor.

2. Operable parts of fuel dispensers shall be permitted to be 54 inches (1370 mm) maximum measured from

the surface of the vehicular way where fuel dispensers are installed on existing curbs.

Figure 308.3.2 Obstructed High Side Reach

B-5

Page 40

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

ATM INSTALLATION FOR A CCESSIBILITY

1. This document supersedes all other information provided by Triton for ATM installation for accessibility.

2. Information provided in this manual is based on federal guidelines (ADA Accessibility Guidelines for

Buildings and Facilities – ADAAG) as amended through January 1998. You should verify it has not

been amended. States may also have accessibility codes. These codes may be more restrictive than the

federal guidelines. Please verify this with the state where the ATM is to be installed prior to installation.

For state contact information, you may call the ADA information line at 1-800-514-0301.

3. For countries other than the US, please use the guidelines for accessibility for that country.

4. A complete copy of the ADAAG referred to here can be found at http://www.access-board.gov. Included in this document is the section of the ADAAG specifically for ATMs. For additional information

on floor surfaces and other ADAAG requirements, please see the complete specification.

4.34 Automated Teller Machines.

4.34.1 General. Each automated teller machine machine required to be accessible by 4.1.3 (Accessible

Buildings: New Construction) shall be on an accessible route and shall comply with 4.34 (Automated

Teller Machines).

4.34.2 Clear Floor Space. The automated teller machine shall be located so that clear floor space comply-

ing with 4.2.4 (Clear Floor or Ground Space for Wheelchairs) is provided to allow a person using a

wheelchair to make a forward approach, a parallel approach, or both to the machine.

4.34.3 Reach Ranges.

(1) Forward Approach Only. If only a forward approach is possible, operable parts of all controls shall be

placed within the forward reach range specified in 4.2.5 (Forward Reach).

(2) Parallel Approach Only. If only a parallel approach is possible, operable parts of controls shall be

placed as follows:

(a) Reach Depth Not More Than 10 inches (255 mm). Where the reach depth to the operable parts of all

controls as measured from the vertical plane perpendicular to the edge of the unobstructed clear floor space at

the farthest protrusion of the automated teller machine or surround is not more than 10 inches (255 mm), the

maximum height above the finished floor or grade shall be 54 inches (1370 mm).

(b) Reach Depth More Than 10 inches (255 mm). Where the reach depth to the operable parts of any control

as measured from the vertical plane perpendicular to the edge of the unobstructed clear floor space at the farthest

protrusion of the automated teller machine or surround is more than 10 inches (255 mm), the maximum height

above the finished floor or grade shall be as follows:

B-6

Page 41

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

SNOITACIFICEPSYTILIBISSECCA

HTPEDHCAERTHGIEHMUMIXAM

sehcnI sretemilliM sehcnI sretemilliM

01552450731

110822/1350631

21503355431

310332/1255331

415532/1150131

51083155921

615042/1055821

71034050721

815542/1945521

9158

020152/1840321

125352/1745021

22065745911

325852/1640811

42016640711

4945421

(3) Forward and Parallel Approach. If both a forward and parallel approach are possible, operable parts

of controls shall be placed within at least one of the reach ranges in paragraphs (1) or (2) of this section.

(4) Bins. Where bins are provided for envelopes, waste paper, or other purposes, at least one of each

type provided shall comply with the applicable reach ranges in paragraph (1), (2), or (3) of this section.

EXCEPTION: Where a function can be performed in a substantially equivalent manner by using an

alternate control, only one of the controls needed to perform that function is required to comply with this

section. If the controls are identified by tactile markings, such markings shall be provided on both controls.

4.34.4 Controls. Controls for user activation shall comply with 4.27.4 (Operation).

4.34.5 Equipment for Persons with Vision Impairments. Instructions and all information for use shall

be made accessible to and independently usable by persons with vision impairments.

(20) Where automated teller machines (ATMs) are provided, each ATM shall comply with the requirements of 4.34 (Automated Teller Machines) except where two or more are provided at a location, then only

one must comply.

EXCEPTION: Drive-up-only automated teller machines are not required to comply with 4.27 (Controls

and Operating Mechanisms) and 4.34.3 (Reach Ranges).

B-7

Page 42

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

4.2.4 Clear Floor or Ground Space for Wheelchairs.

4.2.4.1 Size and Approach. The minimum clear floor or ground space required to accommodate a single,

stationary wheelchair and occupant is 30 inches by 48 inches (760 mm by 1220 mm) (see Fig.4a). The

minimum clear floor or ground space for wheelchairs may be positioned for forward or parallel approach to

an object (see Fig. 4b and 4c). Clear floor or ground space for wheelchairs may be part of the knee space

required under some objects.

Figure 4a. Clear floor space.

Figure 4b. Forward approach.

4.2.4.2 Relationship of Maneuvering Clearance to Wheelchair Spaces. One full unobstructed side of

the clear floor or ground space for a wheelchair shall adjoin or overlap an accessible route or adjoin another

wheelchair clear floor space. If a clear floor space is located in an alcove or otherwise confined on all or part

of three sides, additional maneuvering clearances shall be provided as shown in Fig. 4(d) and 4(e).

Figure 4c. Parallel approach.

Figures 4d. Clear Floor Space in Alcoves. Figures 4e. Clear Floor Space in Alcove.

For a front approach, where the depth of the alcove

is equal to or less than 24 inches (610 mm), the required

clear floor space is 30 inches by 48 inches (760 mm

by 1220 mm).

For a front approach, if the depth of the alcove is

greater than 24 inches (610 mm), then in addition to

the 30-inch (760 mm) width, a maneuvering clearance

of 6 inches (150 mm) in width is required.

B-8

Page 43

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

Figures 4d. Clear Floor Space in Alcoves.

For a side approach, where the depth of the alcove is

equal to or less than 15 inches (380 mm), the required

clear floor space is 30 inches by 48 inches (760 mm

by 1220 mm).

4.2.4.3 Surfaces for Wheelchair Spaces. Clear floor or ground spaces for wheelchairs shall comply with

4.5 (Ground and Floor Surfaces).

4.2.5 Forward Reach. If the clear floor space only allows forward approach to an object, the maximum

high forward reach allowed shall be 48 inches (1220 mm) (see Fig. 5(a)). The minimum low forward reach is

15 inches (380 mm). If the high forward reach is over an obstruction, reach and clearances shall be as shown

in Fig. 5(b).

Figures 4e. Clear Floor Space in Alcove.

For a side approach, where the depth of the alcove is

greater than 15 inches (380 mm), then in addition to

the 48-inch (1220 mm) length, an additional

maneuvering clearance of 12 inches (350 mm) is

required.

Figure 5a. Forward reach, unobstructed.

B-9

Page 44

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

Figure 5b. Forward reach, obstructed.

4.2.6 Side Reach. If the clear floor space allows parallel approach by a person in a wheelchair, the

maximum high side reach allowed shall be 54 inches (1370 mm) and the low side reach shall be no less than

9 inches (230 mm) above the floor (Fig. 6(a) and 6(b)). If the side reach is over an obstruction, the reach and

clearances shall be as shown in Fig 6(c).

Figure 6a. Parallel approach - side reach.

Figure 6c. Side reach, obstructed.

Figure 6b. Parallel approach - high/low side reach.

B-10

Page 45

APPENDIX B - ATM INSTALLATION FOR A CCESSIBILITY

THIS PAGE INTENTIONALLY LEFT BLANK

B-12

Loading...

Loading...