Page 1

ASSEMBLY & OPERATING INSTRUCTIONS

Follow these instructions for correct assembly and operation of this product.

When you’ve finished setting up use some scrap material to work your way through the “Accuracy

Tests” and “Operation” sections, studying the manual before

making the cuts.

If lending or passing on this product to someone else, ensure they also study this manual before

use.

NOTE: “Front of the Saw Table” refers to the end which has the switchbox. The “left-hand & righthand side” are when viewed from the front.

For instructions

on the 184mm saw

supplied with this

product

see page 27.

PTA 001

Page 2

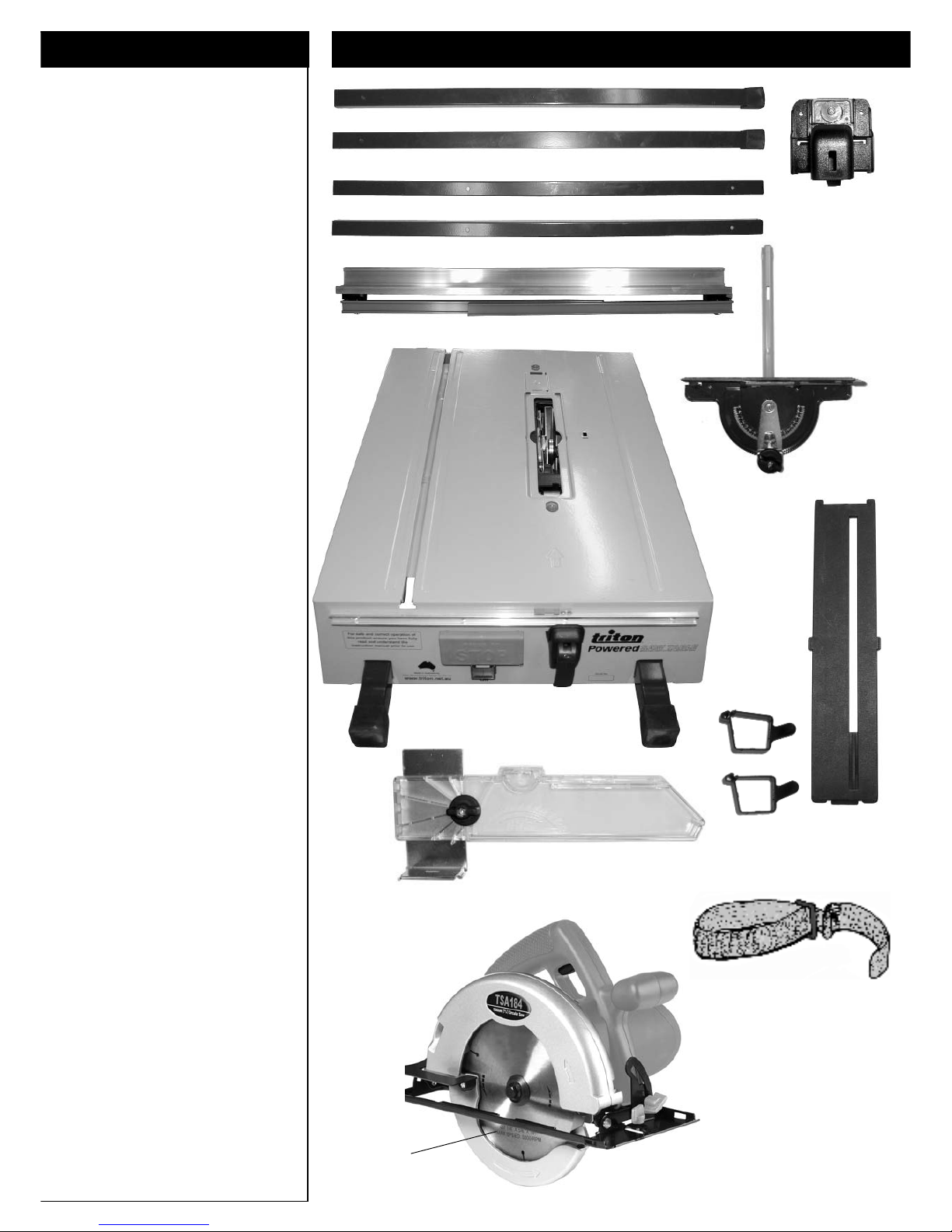

H Overhead Guard

G Overhead Guard Support

A Main Body

F Protractor

(

with Side Pressure

Finger)

E Captive

Push-stick

D Rip Fence

C Front Legs (packed inside Rear Legs)

B Rear Legs (packed in Main Body)

Page 2

L Storage

Hooks

K Trigger

Strap

I 184mm Power Saw

(fitted to Main Body)

PARTS LAYOUT

Safety 3

Set-Up 4

Removing and Fitting the Legs (B & C) 4

Fitting the Saw Slot Insert (J) 4

Fitting the Trigger Strap (K) 5

Removing the Saw 5

Fitting the Saw Blade (N) 5

Fitting the Rip Fence (D) 6

Fitting the Overhead Guard (H & G) 6

Connecting the Power 7

Fitting the Storage Hooks (L) 7

Features & Functions 8

Rip Fence (D) 8

Protractor (F) 9

Captive Push-Stick

and Side Pressure Finger 10

The Overhead Guard (H) 12

Accuracy Tests 13

Trouble-shooting / Fine-Tuning 15

Cuts out of square 15

Workpiece jams 16

Adjusting the protractor pointer 16

Operation 17

Basic Ripping 17

Narrow Ripping 17

Ripping Long Pieces 17

Ripping Larger Sheets 18

Double Ripping 18

Planing an Edge 18

Planing a Face 19

Planing a Wide Sheet 19

Edge Rebating 19

Tongue and Grooving 20

Edge Work on Thin Material 20

Working on End-Grain 20

Taper Ripping 21

Cross-Cutting 22

Multiple Cross-Cutting 22

Multiple Cross-Cutting

against an End Stop 22

Halving Joints & Tenons 23

Mitre Cutting 23

Mitre Cutting Moulding 24

Mitre Cutting to a Length Stop 24

Cutting Sharp Points or Wedges 25

Optional Accessories 25

Bevel Ripping Guide 25

Wheel Kit 25

Router Kit 26

Mini Sliding Extension Table 26

Dust Bag & Collector 26

184mm Saw Instructions 27

Saw Safety 28

Saw Features and Functions 29

Fitting & Removing the Saw Blade 29

Adjusting Cut Depth 29

Bevel Adjustment 30

90˚ Check 29

Power Switch 30

Sighting the Cut Line 31

Saw Operation 31

Hand-Held Operation 31

Ripping 31

Saw Maintenance 32

CONTENTS PG#

J Saw Slot

Insert

N Blade

(packed

separately)

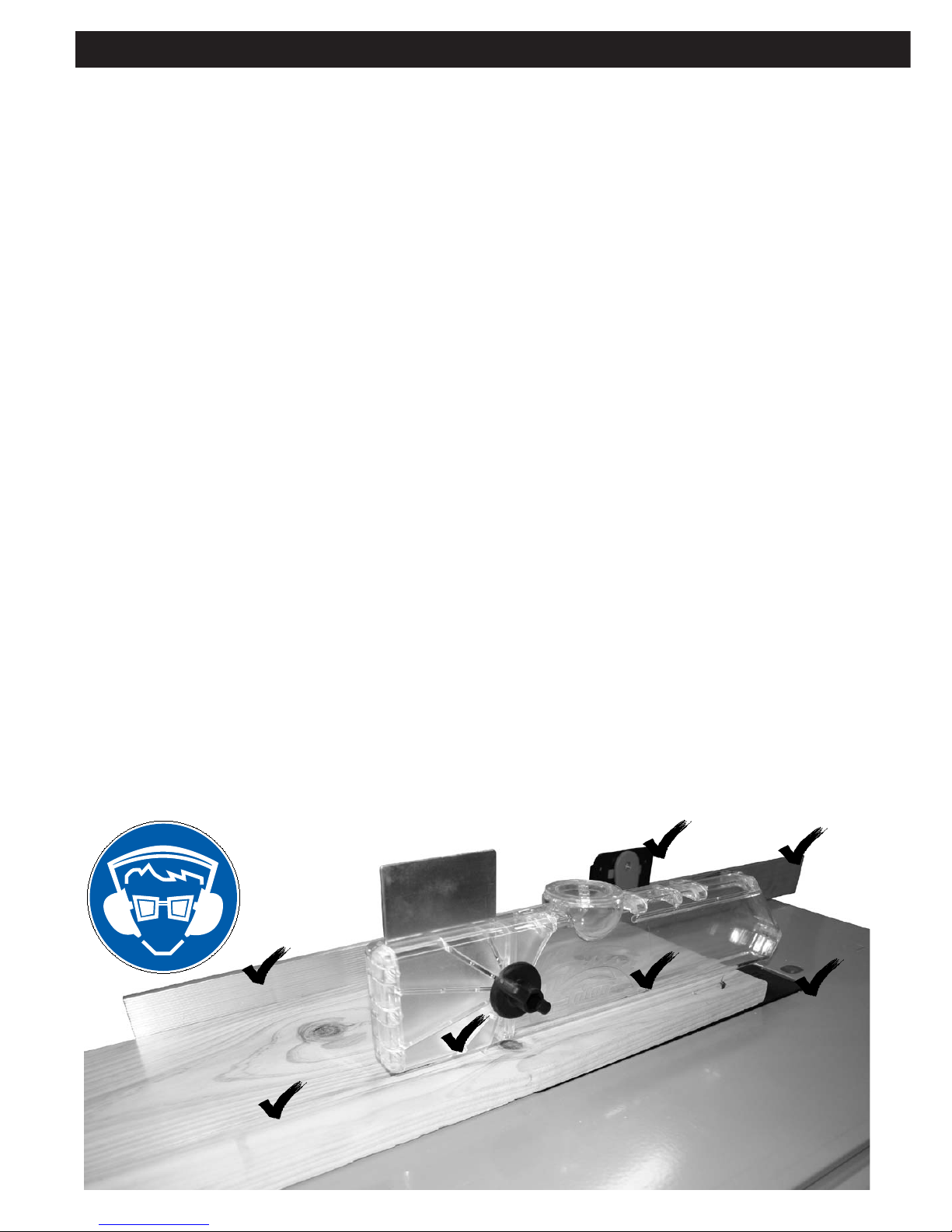

Page 3

1. Never operate the saw hand-held while the

Trigger Strap (K) is fitted. To avoid the potential

for personal injury ensure the trigger strap is

removed before using the saw hand-held.

2. Always keep fingers well clear of the blade.

Fit the overhead guard as low as possible, to just

allow the work to pass beneath. Make sure fingers

and thumbs are tucked in, and will not pass near

the blade even if the wood kicks or your hands slip.

3. Never reach over or behind a spinning blade.

Most table saw accidents occur when operators

reach over an unguarded or poorly guarded blade

to remove off-cuts. Always use a stick to flick offcuts away, or preferably, switch off and wait until

the blade has stopped spinning.

4. Always use the safety guard when ripping.

The blade can lift the wood up and fling it towards

you with great force if the guard is not fitted. Do not

stand directly in line with the blade, and keep the

guard lowered so that the two anti-kickback

pressure fingers hold the work down on the table.

5. Always use the captive push-stick and side

pressure finger when ripping narrow pieces.

It is important to keep control of the piece between

the blade and the fence - especially short pieces.

Use the captive push-stick rather than your fingers.

6. Always use the rip fence when ripping.

Never attempt a freehand cut, for example following

a pencil line. The blade can fling the wood towards

you with great force if you twist the work even

slightly during the cut.

7. Always try to have the larger part of the

workpiece between the blade and the fence.

Say for example you want to rip a 90mm wide piece

down to 80mm, removing 10mm. You could set the

fence at 7.5mm (allowing for a 2.5mm saw cut), but

you would be creating an uncontrolled narrow offcut

trapped between the blade and the fence, and it

could be flung out towards you.

It’s easier, safer and more accurate to set the fence

to your desired size (80mm) and keep good control

of it, allowing the offcut to fall harmlessly aside.

8. Always have the saw blade as low as possible.

You’ll get best results if you work with a lowered

saw blade. It is safer, and gives a smoother, less

splintered cut. You can also improve the quality of

your cuts by ripping slightly oversize (say 1 mm

more than you need) then re-setting the fence by 1

mm and making a finishing cut.

9. Always set the fence parallel to the blade, and

lock it securely at both ends.

You must never angle the fence to the blade. Your

wood will jam between the blade and the fence,

and could be flung out towards you.

10. Always prevent narrow off-cuts jamming in

the blade slot. Avoid creating thin off-cuts (say

around 1-2mm thick) on short pieces, as they could

become trapped in the table slot beside the blade

and could jam against the side of the blade.

11. Ensure the saw slot insert (J) is correctly

fitted at all times. If damaged or functioning poorly,

cease operation until replaced.

12. Always wear eye & ear protection.

Serious accidents can occur when operators get

sawdust or chips in their eyes during a cut. Use of

ear muffs, a dust mask and a dust collection system

are also highly recommended, especially when

using tools for prolonged periods.

Page 3

SAFETY

-

Observe the following rules at all times for safe, accurate work.

7.

8.

9.

4.

6.

5.

11.

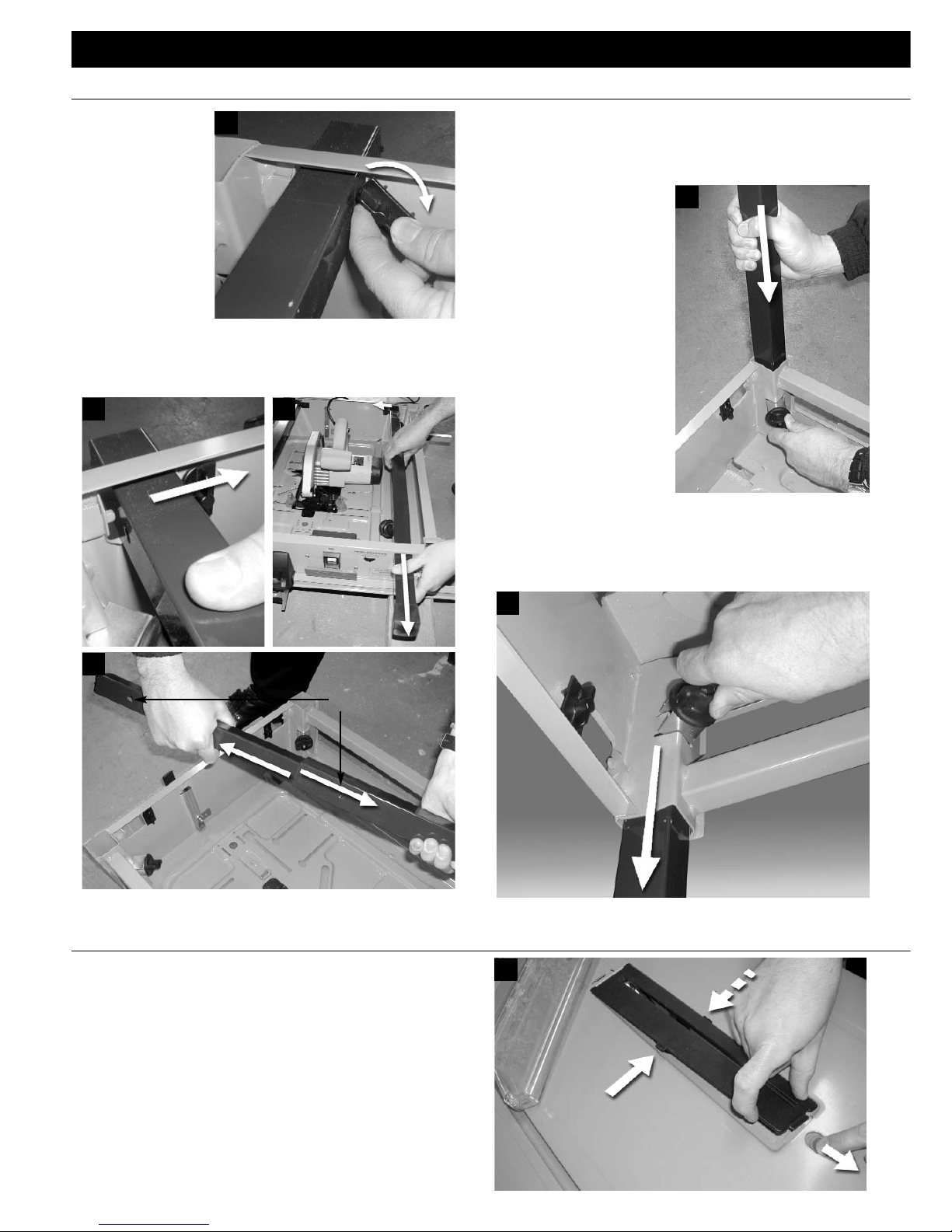

Page 4

Page 4

6

Turn the unit right way up and test that all four feet

are sitting on the ground. Make any necessary

adjustments by extending one of the legs slightly

from its’ sockets to prevent the unit from rocking.

The front legs are stored inside the rear ones. Slide

the front legs out, as shown above. (Note that the

locking holes (shown) must align for leg storage.)

Plug the Rear Legs (B)

(with rubber feet) fully

into the sockets at the

rear of the unit (furthest

end from the switchbox). Plug the Front

Legs (C) (with plastic

foot plugs) in the front

panel sockets.

Lock them by tightening

the round knobs.

Locking

holes

4

5

SET-UP

Removing and Fitting the Le gs

Set up the unit in

a well-lit,

uncluttered

environment,

preferably on a

bench or table.

Release the lock

knobs inside the

rear panel by

rotating them.

1

Move the legs (B & C) sideways to disengage them

from the locking tabs.

Slide them out from their storage position.

2

Fitting the Saw Slot Insert (J)

Release the height lever on the saw and allow the

blade to drop beneath the table surface.

With the red plastic latch at the front of the saw slot

slid backward, insert the tabs at the front of the

saw slot insert (J) into the two cut-outs in the table

depression. Twist it slightly to engage the tabs on

either side of the insert. Push the latch forward to

lock it in position.

Raise the saw all the way up and re-lock the saws

height lever and remove the rubber band holding

back the saw guard.

1

3

Page 5

Never fit the trigger strap when using the saw hand-held.

Before fitting the Trigger Strap (K) always

ensure that the saw is not connected to

the power and that the switchbox is in

the “OFF” position.

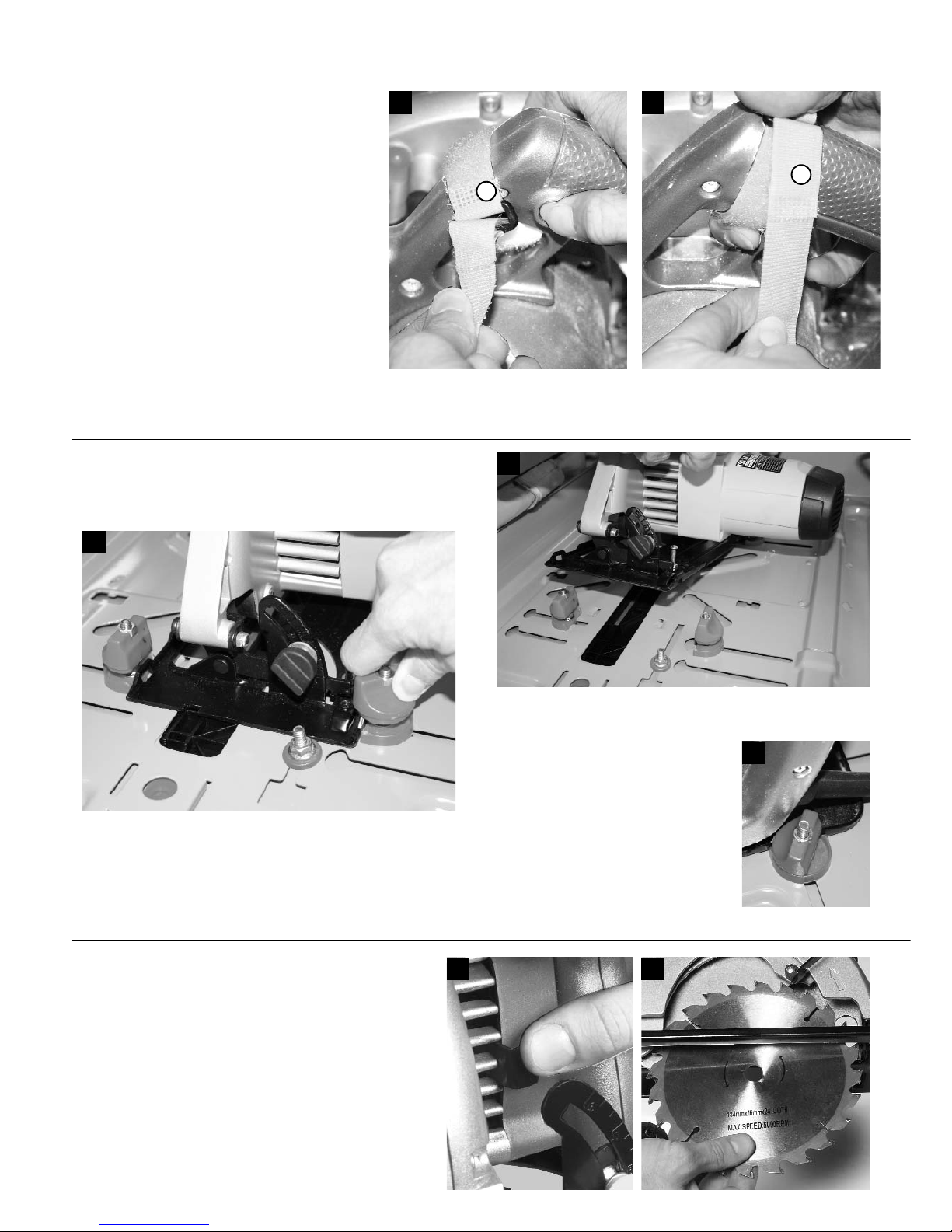

Wrap the trigger strap around the

handgrip of the saw, with the hook & loop

side facing inwards.

Pass the end of the strap through the

buckle, until the security loop has passed

through.

Hold in the “lock-out” button on the saw

handle and engage the trigger while

tightening the strap back onto itself.

Ensure the trigger is locked fully “on”.

Page 5

K

K

Fitting the Trigger Strap (K)

1

2

The clamp knobs have cut-away edges. When all four

cut-aways are facing the saw and correctly lined up,

the saw can be lifted straight out of the clamps.

The clamp bases will ensure the

saw returns to the same position

when re-fitted. Turn the knobs

clockwise about half a turn to

tighten the saw back down.

NOTE: Rotate the clamp knob

beneath the saw handle to allow

full adjustment depth of the saw

while clamped securely down.

2

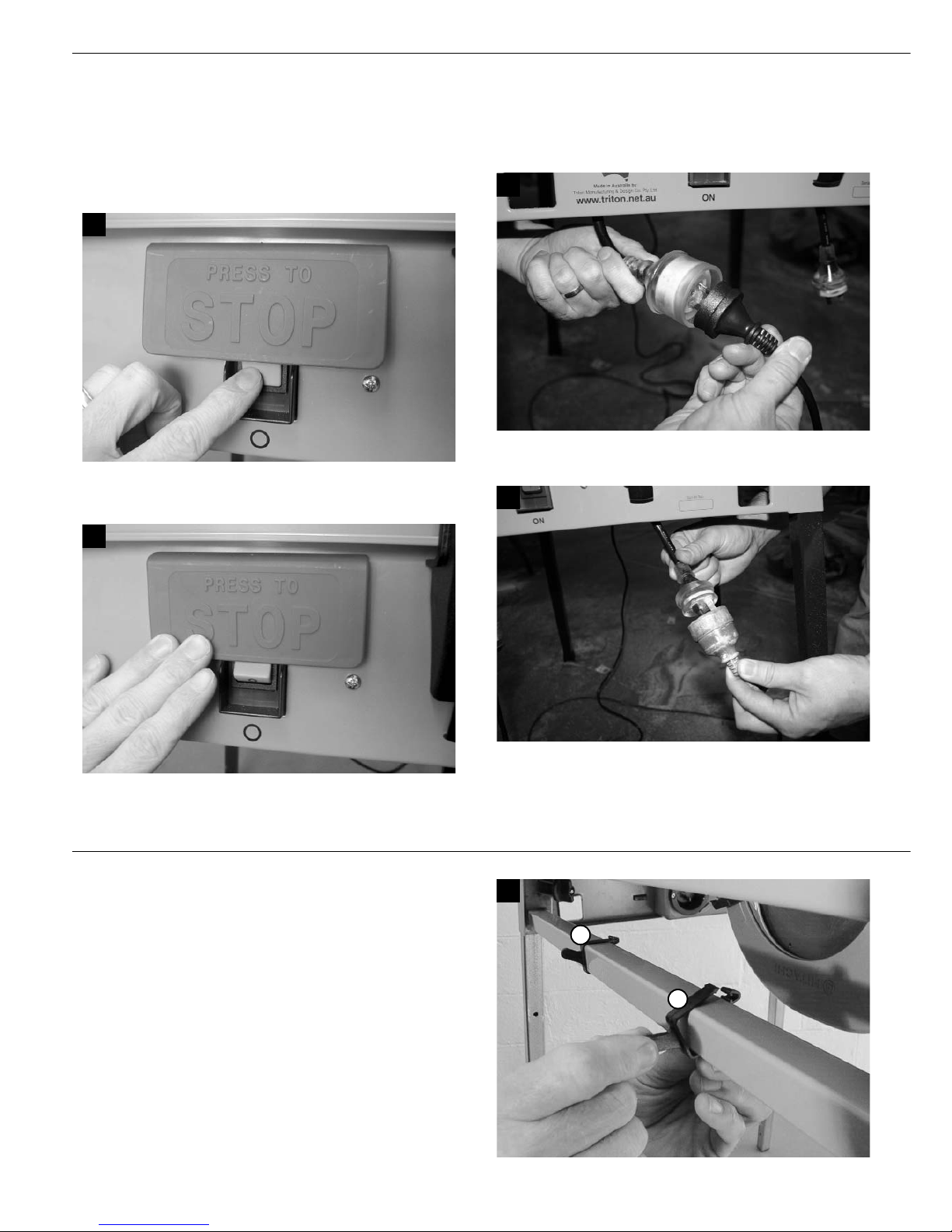

Removing the Saw (I)

Ensure the trigger strap is removed before

using the saw hand-held.

Rest the saw table upside down on packers.

Release the saw height lever and pivot the saw

away from the baseplate so that all four clamp

knobs can be accessed.

1. With the saw removed from the saw table,

hold in the shaft lock button and use the saw

spanner to remove the arbor bolt - turn in the

direction of the blade rotation. The shaft will

turn slightly before locking, allowing the bolt

and outer arbor washer to be removed.

2. Hold the lower blade guard fully back and

carefully slide the blade through the baseplate

and position it onto the inner washer on the

shaft. The graphics should face out and the

arrow on the blade should point in the same

direction as the arrow on the guard.

Fitting the Saw Blade

2

1

1

3

Page 6

3. Refit the outer arbor washer and while

depressing the shaft lock button, tighten the

arbor bolt firmly into position - turn against the

direction of blade rotation. Ensure the blade

seats flush between the inner and outer washers

then tighten firmly with the spanner.

Refit the saw to the saw table and turn the saw

table upright.

Try to wobble the

guard support

(G) to ensure it is

properly locked.

The red latch

should pop up

and be flush with

the table top

when locked.

The saw slot is made from machinable material

which can be replaced if significantly damaged. It

must only be removed when fitting the Router Kit.

Pull back the red locking latch, and press the guard

support (G) into the table depression. If necessary

loosen the round knob on the guard (H) and slide it

to the top of the guard support.

H

G

Fitting the Overhead Guard (H & G)

1

2

Locking latch

Page 6

Spin the blade by hand before connecting the

power to ensure the blade is not touching anything.

Loosen the knob on the overhead guard (H) and

slide it up and down the guard support several

times to enable a freer sliding motion.

The teeth on your blade should be pointing in the

same direction as the etched symbols on the sides

of the guard (H).

H

3

G

To set the fence on the right, slide the arms along

the fence tracks from the right hand side of the unit

(when viewed from the switchbox end). The taller

part of the fence should face the plastic insert in

the tabletop.

3

The fence can be fitted on the right-hand side or

left-hand side of the blade, depending on the cut

you are making or your personal preference.

Unfold the arms

from beneath

the Rip Fence

(D).

Fully raise the

fence lock

levers on the

end panels.

Fitting the Rip Fence (D)

1

2

2

Page 7

Page 7

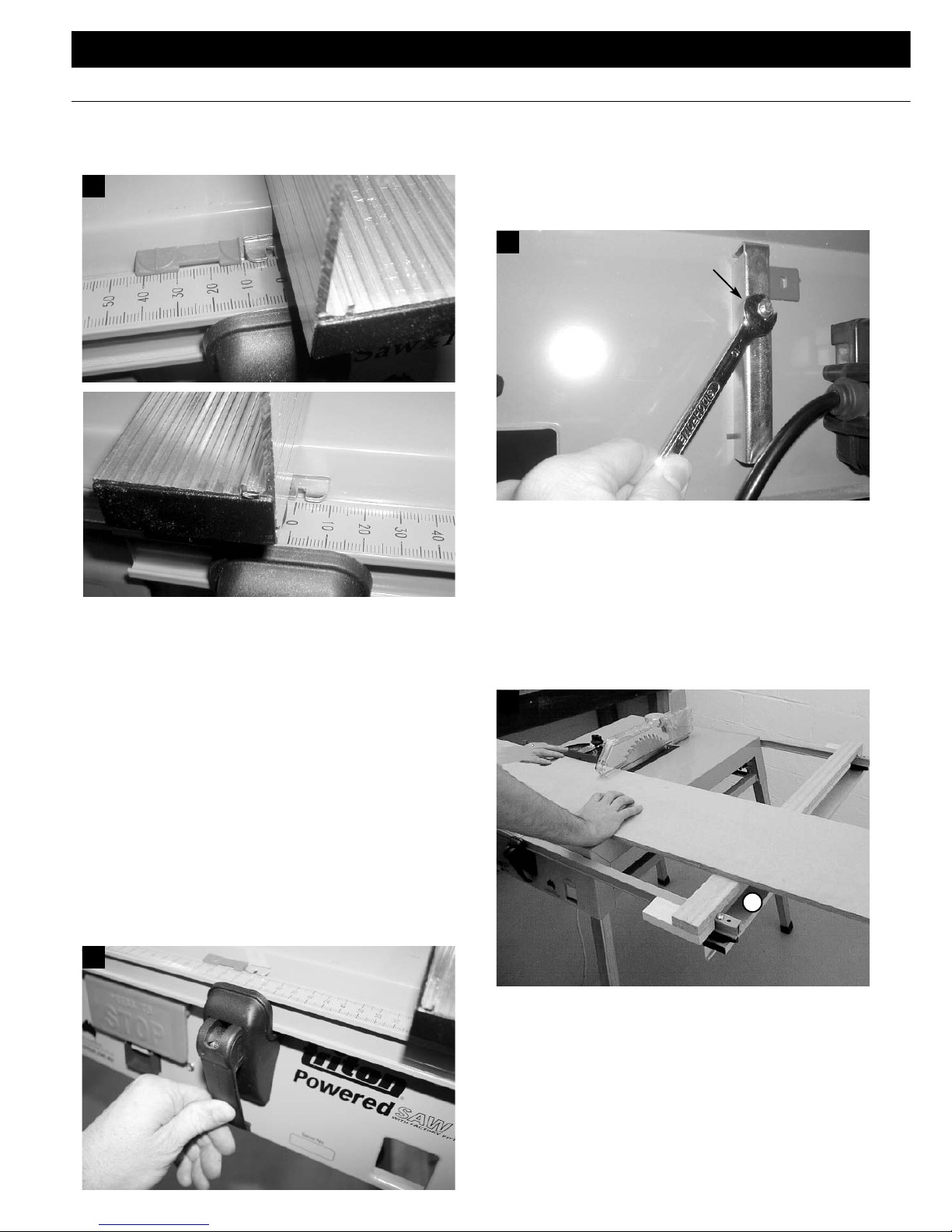

Tap the stop plate with your hand or thigh to switch

“OFF”.

Make sure the switch is “OFF”, plug the saw into

the female lead extending from the switchbox.

Remove the tie from the saw power cord and

unravel it to remove any folds.

Bring power to the switchbox via a good quality

extension cord (minimum 10 Amp).

Before switching on the power, make sure that

nothing is touching the saw blade, or is likely to

vibrate into it and that your hands are well clear of

the blade.

The Storage Hooks (L) enable temporary storage

of table accessories when not in use.

Fit them onto the left or right hand base tube by

opening them and clipping around the tube. The

tab should be facing out and pointing upwards, as

shown.

1

L

L

Connecting the Power

Fitting the Storage Hooks (L)

Before connecting the power, practice switching on

and off.

Do not raise the Stop Plate.

Press the power switch with your finger to switch

the power “ON”.

1

2

4

3

Page 8

Page 8

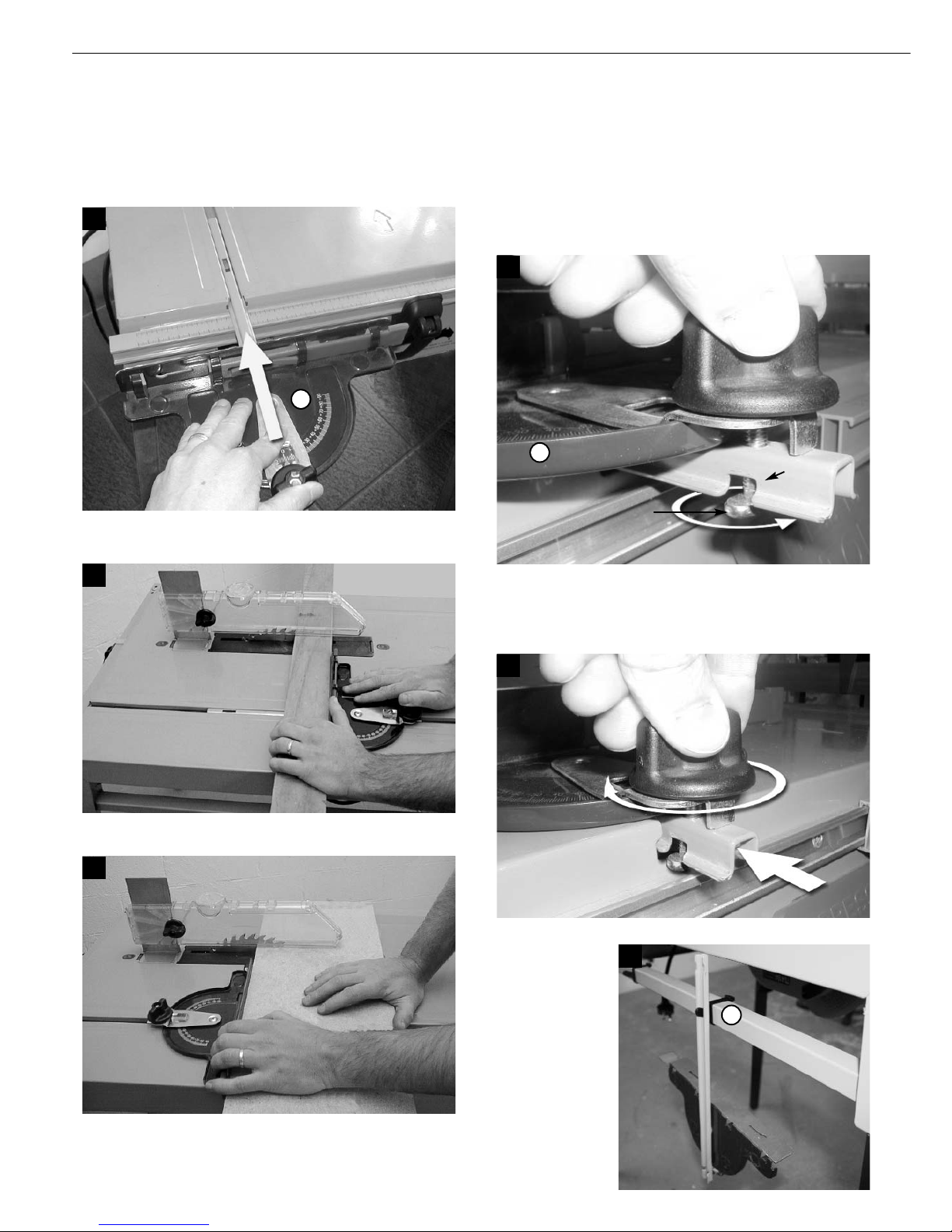

The rip fence can be fitted to the left or right hand

side of the unit depending on which is most

comfortable, or to suit certain cuts or jigs.

Calibration Settings

The metal pointer is used for sawing applications. It

has a 2.5mm wide notch which represents the kerf

(width of cut) of the blade. Align your scale reading

with the side of the notch closest to the fence.

Always sight down directly from above the notch to

avoid sighting errors.

The red scale indicators are only used when the

optional Router Kit is fitted.

Outboard Support

By removing the fence (D) and replacing it upside

down, it can be used to provide effective outboard

support when crosscutting larger workpieces

against the protractor.

Locking Lever

The fence is locked by depressing the front and

rear fence lock levers until they tighten firmly.

Secure a batten over the fence arms to create a

surface level with the table. (The batten should be

approximately 25mm thick, as shown, or rebated to

25mm thick.)

You can vary the tension of the fence locking levers

if locking is too firm or too loose.

Adjust the Nyloc nut on the inside of each end

panel until you are satisfied with the tension of the

locking lever.

D

FEATURES & FUNCTIONS

The Rip Fence (D)

4

FENCE SET ON

THE RIGHT

FENCE SET ON

THE LEFT

1

Adjust Nyloc

nut tension

3

Fence Storage

The fence (D) can be stored upside down in its’

tracks, as shown above, when not in use.

2

Page 9

Page 9

With the sandpaper face forward (away from you)

guide the protractor strip into the slot at the front

panel (switchbox end), and slide the protractor fully

along the slot to check that it slides freely.

HINT: If necessary apply a spray lubricant into the

slot for a smoother sliding action.

1

F

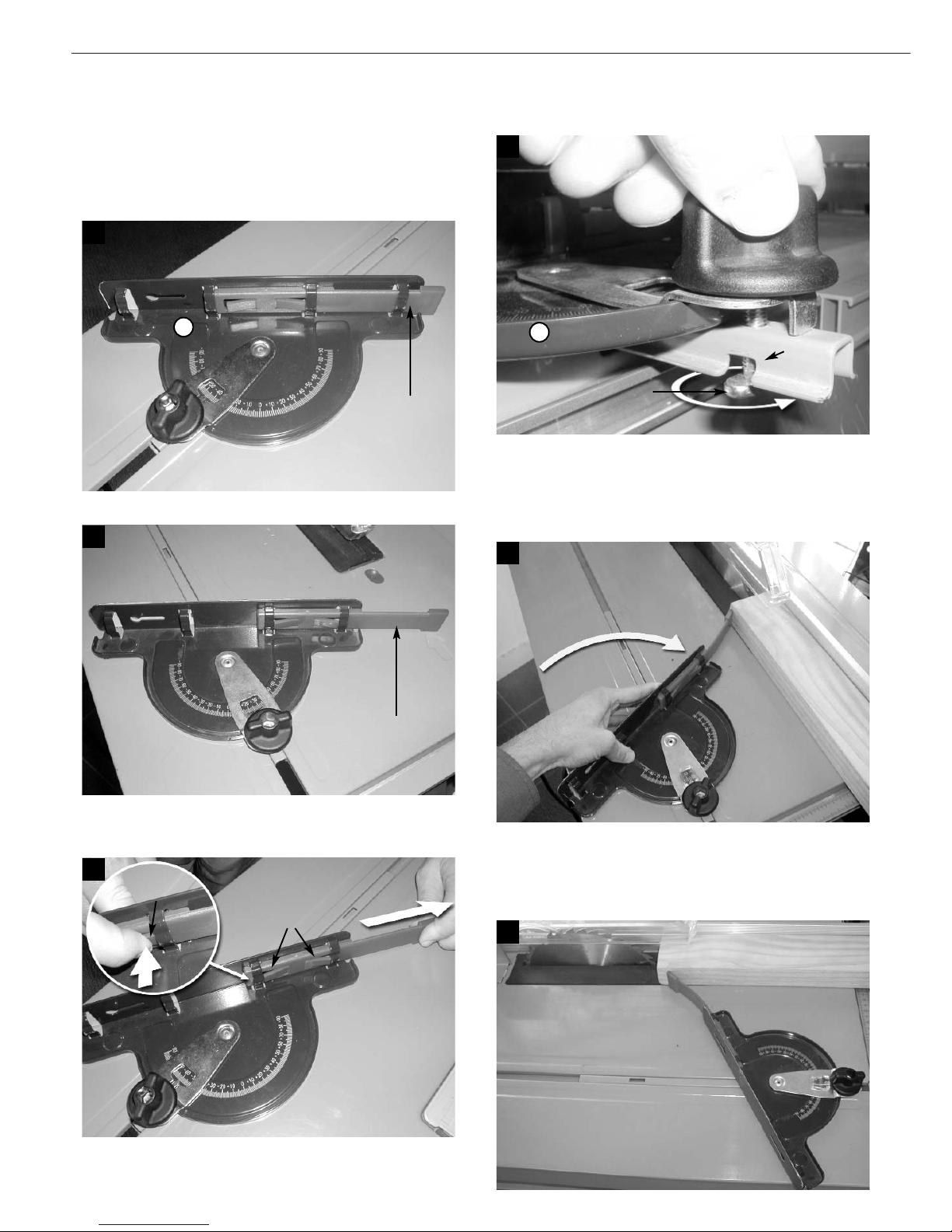

The Protr actor (F)

The Protractor (F) can be used in a trailing mode

(protractor behind the workpiece)...

...or a leading mode (protractor in front of the

workpiece).

It allows a 250mm crosscut capacity in the trailing

mode and approximately 450mm in the leading

mode. If the material is narrow enough, the trailing

mode is preferred.

2

3

Locking the Protractor (F) from Sliding

The protractor (F) can be locked against sliding in

its’ slot, when using the Side Pressure Finger detailed below.

Slide it partly out of the table slot, loosen the round

knob by about 8 turns and rotate the T-bolt 90

degrees, so it protrudes through the windows in the

strip.

Do up the knob about 6 turns, then slide the

protractor back along the slot to the desired

position and tighten the knob. Check that the

protractor is firmly locked in the slot.

4

5

F

Window

Storage

When not in

use, the

protractor can

be hung from

one of the

storage hooks

(L) .

6

L

T-bolt

Page 10

Page 10

The Captive Push-Stick and Side Pressure Finger

Side Pressure Finger

The side pressure finger is on the inside face of the

protractor (F), and when extended presses your

wood against the fence, with the fence on the right

hand side of the blade.

The finger can be locked fully retracted...

Prepare the protractor for locking (T-bolt across the

slot as in “The Protractor”) and fully extend the side

pressure finger.

Place the wood in position against the fence and

adjust the protractor angle until the finger presses

the wood against the fence. The finger should flex

a little, but avoid applying excessive pressure.

Adjust the position of the protractor in the slot until

the finger is about 25mm in front of the blade. Then

tighten the protractor knob, locking both the

protractor and the angle setting.

...or fully extended.

The finger is released by pressing the tabs, and

sliding sideways.

1

F

2

3

Tab

Tabs

5

6

4

F

Window

T-bolt

Side pressure

finger

retracted

Side pressure

finger

extended

Page 11

Page 11

2

4

5

“stop”

H

E

Captive Push-stick (E)

The Captive Push-stick (E) slides along the tracks

on the back face of the rip fence (D). The swingarm rests against the front face of the fence, and

should pivot freely.

1

E

D

The lock direction of the swing-arm can be

reversed, depending on which side of the blade the

rip fence is used. To change the direction, press

the rocker switch firmly and the other red “stop” will

appear through the face.

Use the “stop” which allows the swing arm to pivot

towards the blade, not away from it.

Position the push-stick (E) with the swing arm

either raised up, or resting on top of the workpiece

in front of the overhead guard (H).

As the end of the workpiece passes the captive

push-stick, the swing-arm will drop behind it,

allowing you to push the work through with your

fingers clear of the blade.

Storage

When not in use the captive push-stick (E) can be

hung from the storage hook (L) .

6

E

L

3

“stop”

E

Swing-arm

Rocker

switch

Page 12

Page 12

1

3

D

H

Hold

down fingers

The overhead guard (H) has hold-down fingers to

prevent kick-back of the workpiece. Always ensure

the guard is lowered until the fingers flex a little,

and lightly press the workpiece down on the table.

The bolt and knob on the overhead guard can be

reversed, if necessary, to allow the rip fence (D) to

be adjusted closer to the blade when using the

fence on the left-hand side of the blade.

The Overhead Guard (H)

H

2

D

H

FENCE SET ON

THE RIGHT

FENCE SET ON

THE LEFT

Page 13

Hold the base of the square against the edge

which was against the protractor face. If necessary

adjust the protractor angle slightly then reset the

protractor scale pointer as described in Troubleshooting (page 16).

Page 13

ACCURACY TESTS

Checking your Square

Crosscutting with the Protractor

First check to see if your square is accurate. Many

are not, especially handyman quality adjustable

squares.

Use a board with an absolutely straight edge.

Press the handle (base) of the square firmly

against it, and use a sharp pencil or a utility knife to

trace the edge of the blade on the board.

Then flip the square over, press it against the

straight edge again, and move the blade to the line.

Any error in your square is seen as doubled, and is

more clearly visible.

2

Set up as described in “Features and Functions”,

then lower the safety guard (H) to just admit the

piece of wood. Check that the protractor (F) is set

at exactly “0”. Switch on the power. Hold the wood

firmly against the main face of the protractor, and

push down lightly with your other hand, as you feed

the wood smoothly into the blade.

1

H

F

G

Push the protractor until the workpiece is past the

back of the blade, then switch off the power by

bumping the STOP plate with your thigh.

If the leading edge of the wood fouled the

overhead guard support (G), or if the back of the

blade re-cut or burnished the cut end, your saw is

mounted slightly crookedly. Check the saw

alignment, as described in the next section, then

repeat the test.

Then hold the square against the face which was

on the table and adjust the angle of the saw blade

to the table. If necessary refer to Trouble-shooting

on page 15.

1

2

3

Page 14

Page 14

1

3

H

H

D

Take a straight piece of wood at least 70mm wide

and say 35mm thick. Place it flat on the table and

lower the overhead guard to just above the

workpiece.

Lock the rip fence exactly parallel to the blade with

a fence setting that will give you an off-cut of say

5mm [eg. 70mm wide wood less 3mm for the sawcut, less 5mm for the off-cut = 62mm].

If the leading edge of the wood fouled the

overhead guard support (G), or if the back of the

blade re-cut or burnished the cut edge, check the

saw alignment and overhead guard support as

outlined in “Troubleshooting”, then repeat the test.

Hold the base of your square against the face that

was on the table and check the cut.

Set up the captive push-stick (E) and side pressure

finger as described earlier. Switch on the power,

and feed the wood smoothly. Keep pushing it preferably without pausing - until it is fully past the

blade.

Keep fingers well away from the blade.

Ripping Test

E

2

E

Page 15

Page 15

With the fence set on (or near) “0” turn the unit

upside down and place it on packers or on a

bench, to prevent the fence and blade from

touching the ground.

Once satisfied with the alignment re-tighten the

nuts and turn the clamp knobs until they hold down

the baseplate of the saw.

Turn the unit right way up again and check that the

teeth at the front and rear of the blade lightly touch

the fence when set at “0”.

3

Loosen all 4 clamps knobs 2 full turns.

One at a time, release the nut with a 10mm

spanner, and slide each clamp toward or away

from the fence, as necessary until the blade skims

the fence when set at “0”.

4

5

TROUBLE-SHOOTING / FINE-TUNING

Cuts out of square

First check that the blade is square to the table and

make any necessary adjustments using the saws

bevel adjuster.

1

Lock the fence at “0” and check that the teeth at

the front and rear of the blade lightly touch the

fence. If there is any misalignment, or the blade

prevents you from locking the fence at “0”, proceed

with the steps below.

2

Page 16

Page 16

Loosen the knob on the overhead guard about one

turn, and remove it for the moment. Check that the

overhead guard support (G) is square to the table.

If not, lower the saw blade below the table then

bend the guard support square using a straight

piece of material.

G

3

Workpiece jams between the fence (D) and guard support (G)

If tightening the jacking screw, first loosen the pivot

screw. If loosening the jacking screw, then tighten

the pivot screw later.

When adjusting the screws ensure the fence arms

pivot firmly but freely, without wobbling.

Use an accurate square to check that the vertical

face of the rip fence is exactly square to the table

at both ends.

If necessary use a Philips-head screwdriver to

adjust the jacking and pivot screws until the fence

face is square.

Jacking

screw

pivot

screw

1

2

1

After performing several mitre cuts (as outlined in

“Mitre Cutting” on page 24) and you have

established the protractor position for a true 45˚,

adjust the degree pointer on the protractor by

prising it sideways with a screwdriver until it points

exactly to “0”.

Adjusting the protractor pointer

Page 17

Page 17

1

D

E

1

1

OPERATION

Basic Ripping

The rip fence (D) must be set parallel to the blade,

firmly locked at both ends, and the safety guard (H)

must be correctly lowered.

It’s always best to have the wider section between

the blade and the fence, as shown, so you can

keep good control over it with your hand(s) or with

the captive push-stick (E).

Avoid trapping narrow off-cuts between the blade

and the fence, and do not stand directly in line with

the blade in case an offcut shoots out towards you.

If the wood binds slightly between the overhead

guard support and the fence (D), you can increase

the rear fence setting slightly - around 1mm.

Narrow Ripping

If you want to rip a board into a number of identical

narrow strips, or if you want to set the fence closer

than 17mm to the blade, the safety guard will

prevent access for the fence and the captive pushstick.

Make up a notched pusher say 75mm wide, and

use it as shown with the side pressure finger. It will

enable the guard to be correctly lowered, while

creating access for the push-stick.

Ripping Long Pieces

When ripping long pieces which will overhang the

rear of the table by more than half their length,

either have a friend help you, or rig up a “tail-out”

support. The Triton Multi-Stand, shown, is perfectly

suited to this application.

Try to keep the workpiece moving, even slowly,

during a long rip. Pauses can cause slight steps in

the cut. Afinishing cut, removing another 1mm,

should help if you need a completely smooth edge.

H

Page 18

Page 18

1

Ripping Larger Sheets

Lock the rip fence firmly with the same reading at

both ends and adjust the overhead guard as low as

possible.

Push the workpiece against the fence and feed it

gently into the blade, keeping one hand on either

side of the work. Switch off with your thigh when

you finish the cut.

1

For ripping up to 450mm off very large sheets, use

one or two Triton Multi-Stands with a suitable

length of wood clamped in the head(s), to support

the offcut.

For ripping widths up to 1000mm, consider the

optional Mini Sliding Extension Table (see page

26). Alternatively, use the saw hand-held. Remove

the saw, disengage the trigger strap (K), and

check the operation of the saw guard. Clamp a

guide to the workpiece, which should be securely

supported off the floor on battens or packers.

Never

do a free hand cut, following a pencil line.

It’s dangerous.

2

Double Ripping

You can double your maximum depth of cut by

turning the wood over, end for end, and making a

second cut. If the blade is exactly square to the table,

and if both edges of the wood are dressed square, the

two cuts should line up.

You won’t be able to use the safety guard for the first

cut, so be especially careful, and keep fingers well

clear of the blade area, even if your hands slip or the

wood kicks. Re-fit the guard for the second cut.

Use the captive push-stick and side pressure finger.

Make both cuts of similar depth: slightly over half the

depth of the workpiece.

This cut puts a lot of load on your saw and blade.

Never force a dull blade to cut. Slow down your

feed rate, and replace or sharpen the blade.

Planing an Edge

A tungsten carbide tipped blade or a planer blade

can give an excellent finish on poorly dressed,

weather-stained or painted material. It can also

remove any slight step left after double ripping.

Place the workpiece between the stationary blade

and the unlocked fence so it is lightly touching

them both. Fine-tune the fence position until the

scale readings at both end panels are the same.

Remove the workpiece and move the fence 1 or

2mm closer to the blade. Lock it off securely. Or,

simply measure the workpiece - say 90mm wide and set the fence at 88 or 89mm.

Hold the workpiece against the fence and smoothly

push it past the blade, as shown. Use the captive

push-stick and side pressure finger to control the

workpiece, especially when planing narrow pieces.

Keep the blade as low as possible and try not to

pause during the cut.

1

For planing a bowed workpiece, attach a straight

piece of scrap to the piece so it slightly overhangs

one edge for the full length. (Use strong doublesided tape, hot melt glue or brads.) Run the

straight piece along the fence. After dressing one

edge straight, remove the piece of scrap and run

the just-dressed edge against the fence.

Page 19

Page 19

1

Planing a Face

If planing a face wider than your maximum depth of

cut, set up as described above, and make two

planing cuts, turning the workpiece over (end-for-end)

after the first cut. Use the side pressure finger and

captive push-stick to control the workpiece.

You won’t be able to use the safety guard for the first

cut, so be especially careful, and keep fingers well

clear of the blade area, even if your hands slip or the

wood kicks. Re-fit the guard for the second cut.

Try to make both cuts of similar depth. i.e. plane a

90mm wide face with two cuts of around 46mm deep.

Planing a Wide Sheet

Workpieces more than 450mm wide cannot be

passed between the blade and the fence. To

remove a small amount from large workpieces, do

not set the fence in close to the blade. Make up two

wooden sub-fences to attach to the rip fence in front

of and behind the blade, as shown.

The front sub-fence must be narrower than the rear

one, by not more than one blade width. Drill suitable

sized holes in the face of your fence and attach the

sub-fences using screws or countersunk bolts, or

use strong double-sided tape. (2” carpet-laying tape

is ideal.)

Lock the rip fence so the rear sub-fence is exactly

flush with the left hand edge of the blade, as

shown. It acts as a “catcher” for the workpiece once

it comes past the overhead guard support (G).

For regular planing using such a jig, make up

several front sub-fences of different widths. Or just

make up one - say 1mm narrower than the rear

sub-fence - and make 3 passes to remove 3mm

from a wide sheet.

1

G

Wooden

sub-fences

Edge Rebating

By lowering the saw blade and adjusting the fence,

you can make a wide variety of rebates.

To set the blade height,

mark the desired depth

of cut on a piece of

wood. Lay the piece

alongside the blade,

leaving both hands free

to adjust the saw blade

height.

You can’t use the overhead guard on edge rebates,

so be very careful with hand positions and ensure

that your fingers will be clear of the blade even if

they slip, or if the wood kicks.

Most rebates create a narrow off-cut. You should

avoid trapping the off-cut between the blade and

the fence. If you can’t avoid this, make sure you

are not standing directly behind the blade because

the off-cut could come spearing out towards you at

high speed, especially if it’s a short workpiece.

1

When rebating

wood which is

rectangular in

profile always

make the first

cut with the

wood standing

on edge ...

... and the second

cut with the wood

lying flat.

Otherwise, if the

workpiece is a bit

narrow, it could

balance unsafely

on a narrow edge

after the second

cut.

2

3

Beware of trapped offcut

Page 20

Page 20

Tongue and Grooving

Study the previous section on Edge Rebating, and

then make two identical rebates from opposite

faces of the workpiece. This will leave you with a

central tongue.

Always make the first two cuts into the narrower

edge of the workpiece ...

To make a matching, central groove, move the

fence outwards by one blade thickness, and make

two cuts from opposite faces. Then reset the fence

if necessary to machine out the waste between

your two cuts.

You cannot use the overhead guard, so be very

careful with your hand positions.

Test tongue & grooving settings on short off-cuts of

the wood you’ll be using.

... and the two final cuts with the workpiece lying

down flat.

If you do the cuts in reverse order, your workpiece

will be left standing unsafely on the narrow tongue

after the fourth cut.

1

2

Beware of trapped offcut

Edge Work on Thin Material

If you want to rebate or groove very thin boards,

you will have to take some precautions, because

the workpiece could be unstable while standing on

it’s narrow edge.

Attach a suitable height sub-fence to the rip fence

to give extra vertical support to the workpiece. (See

“Planing a Wide Sheet” for attachment methods.).

If the width of the saw slot in the table also causes

a support problem, you may want to use a piece of

ply or hardboard with a thin slot in it for the blade,

securely taped to the table as a mask, as shown.

You cannot use the overhead guard so be very

careful with your hand positions.

1

1

Working on End-Grain

Attach a straight, wide board onto the rip fence for

extra vertical support. Use screws or bolts. Make

sure the working face is square to the table and

use packers between it and the fence to adjust if

necessary.

Make a captive “pusher” as shown, to slide along

the top of the board. Use it to support the

workpiece, and to hold it square to the table as you

push it past the blade. You may wish to clamp the

workpiece to the pusher.

Page 21

Page 21

If making splined right-angled joints ... or splined butt joints...

... cut all pieces from opposite faces,

without changing the fence setting. This

will ensure the grooves line up.When

working with narrow wood, make sure

the workpiece cannot jam in the blade

slot (during or after the cut. You may

have to use a mask taped to the table

(as described in “Edge Work on Thin

Material”), or clamp the work to the

pusher.

2 3

Taper Ripping

To rip tapers, the workpiece must be angled to the

blade by a guide that travels parallel to the blade.

Never angle the rip fence to the blade for taper

ripping. Taper cuts cannot be made in this way and

are extremely dangerous if attempted.

There are three recommended methods. For tapers

up to approximately 750mm long, you can use the

protractor.

Hold the workpiece tightly against the sandpaper

face and down on the table, as shown. Keep

fingers well clear of the blade. Make sure the

overhead guard is fitted and correctly lowered.

It is best to rehearse these cuts with the blade

dropped below the table level, in order to check

your hand positions throughout the cut.

The width of material you can handle is limited and

you may have to insert a packer between the

workpiece and the protractor face to achieve a

desired cutting line. The packer should either be

attached to the workpiece, (using double sided

tape, hot melt glue, or mechanical fasteners), or be

attached to the protractor face. Attaching to the

protractor face is best - especially when cutting

multiple pieces at the same angle. Glue a strip of

sandpaper to the working edge for extra grip.

1

2

Scrap, attached to

workpiece, slides

against fence

If you regularly cut tapers of different angles, make

up an adjustable jig to angle the workpieces to the

blade. Two pieces can be hinged at the front and

then locked open at any desired taper angle. An

angled block holds the workpiece down, and

pushes it as the jig slides along the parallel fence.

On long taper cuts, the protractor slider strip may

protrude beyond the rear of the table. For adequate

guidance ensure at least half of the strip is always

engaged in the slot.

Another method, which is also suitable for longer

tapers, is to tack or tape a straight piece of scrap

onto the workpiece at the desired angle, and slide

the edge of the scrap against the fence, as shown.

3

The jig must be slid

along the fence, set

parallel to the blade.

Page 22

Page 22

1

Pieces not

trapped against

fence

Spacer

Cross-Cutting

When crosscutting, make sure the workpiece is of

a manageable length, and that both the workpiece

and the offcut you’ll create are well supported

during and after the cut.

With larger pieces, use a Triton Multi-Stand, and/or

reverse the fence and use a packer to support the

workpiece or the off-cut. (See Features &

Functions).

Set the protractor at “0” and make sure the

overhead guard is correctly lowered.

Hold the wood firmly against the sandpaper face of

the protractor and down on the table while moving

it smoothly past the blade.

Never set the fence as a stop The offcut trapped

between the blade and the fence is uncontrolled,

and will be flung out towards you, possibly causing

injury and damage.

2

WRONG

Do not use the fence as a stop unless

a spacer block is fitted. See “Multiple

Crosscutting” below.

1

Multiple Cross-Cutting

If you want to use the fence to crosscut a number

of short pieces to the same length, you must attach

a spacer at least 19mm thick to the front of the

fence using screws, tape, hot-melt glue or a Gclamp.

Set the fence to the desired length of the pieces,

plus the thickness of the spacer.

By using the spacer as a length stop, you don’t

have to individually measure, mark, and line up

each piece.

By ending the spacer before the front of the blade,

the cut-off pieces are not trapped between the

blade and the fence.

Multiple Cross-Cutting against an End Stop

Attach a straight sub-fence to the face of the

protractor, and clamp or screw a stop block to it.

Each piece pushed up against the block will be cut

to exactly the same length.

You can end the sub-fence at the side of the blade,

or you can extend it right across the table (provided

you make it out of a wider piece that you can

partly cut into without greatly weakening it.)

You can make the sub-fence up to around 900mm

long (longer if you have a Multi-Stand or reversed

fence for outboard support), and attach a tape

1

Page 23

Page 23

measure or a ruler to it, with “0” on the ruler being

flush with the edge of the blade. Use the ruler to

cut pieces accurately to length, or to set a stop

block.

When attaching a sub-fence to the protractor, it’s

best to use screws with suitable sized heads

through the keyholes in the protractor face. This

will enable easy fitting and removal, by just

loosening the screws and sliding the sub-fence

sideways.

2

Sub-fence

with stop

block fitted

Halving Joints & Tenons

Using the fence as a length stop is permitted when

cutting halving joints (rebates) and tenons,

because there is no offcut to be trapped between

the blade and the fence.

For rebates less than 450mm from the end, butt the

wood against the fence, and use the protractor as

shown to slide the wood. Make the outside

(defining) cuts using the fence and scales, then

make a series of cuts, moving away from the fence

by one blade-width after each cut.

Only move the wood sideways when fully clear

of the blade.

When tenoning, if you machine opposite faces, as

shown, without changing the blade height setting,

the tenons will all be perfectly central on the ends

of the pieces.

If using a router to make the mortices, select the

cutter first (say

1

/2” diameter) and make your tenons

1

/2” thick. The mortices will be easier - just a single

setup for your router.

1

2

Mitre Cutting

With the protractor in the trailing position (for best

support of the workpiece) lock it at 45˚.

Make sure the protractor slides freely along the

slot. Hold the wood firmly against the face during

the cut - it will tend to “creep” sideways during a

mitre cut.

To test that you are set at exactly

45˚, cut about

250mm off the end of a straight piece of scrap. Fit

the pieces together and check with a square that

they form a perfect 90˚ right-angle.

If making any slight protractor adjustment, re-cut

both pieces, and check again.

1

Page 24

Page 24

Once you have established a true protractor

adjustment, refer to “Trouble-shooting” (page 15) to

adjust the protractor pointer position.

If the wood is flat on both faces, cut the reverse

mitre at the other end by turning the piece end-forend, and lying it on it’s other face for the second

cut.

3

Mitre Cutting Moulding

Mouldings should always be cut with the flat base

resting against the table, and the taller edge

against the protractor. It gives better support, and

less splintering on the moulded visible faces,

because they were facing upwards where the cut is

always cleanest.

If you can’t turn the workpiece over, (e.g. picture

framing or beading) cut the mitres with the

protractor set to +45˚ for the first cut...

... and at -45˚, for the second cut.

When cutting flexible materials - such as thin

beading or moulding - the protractor face is too far

from the blade for adequate support, when the

protractor is set at negative angles. Attach a subfence to the protractor face, or insert a stiffer piece

of parallel scrap between the protractor and the

moulding, for back-up.

1

2

Mitre Cutting to a Length Stop

First crosscut your pieces to length, a small amount

longer than you’ll need. With the protractor carefully

set, at say +45˚, mitre cut one end of each piece.

For perfect length accuracy without measuring,

marking and sighting up each cut, fit a sub-fence to

the protractor, and clamp a mitred stop block to it for

the second cut, as shown.

Set the protractor to the reverse angle, -45˚, and cut

the other ends. All cuts are made with the moulded

face upwards (better support and less visible

splintering) and all pieces will be identical in length.

Grip the workpieces firmly because there is a

tendency for them to “creep” during the cut. Or glue

a sandpaper strip to the face of the sub-fence for

extra grip, if not using a stop block.

Mitred corner against mitred stop block.

1

Page 25

Page 25

Cutting Sharp Points or Wedges

Sharp stakes, pegs or wedges can be safely cut using

the protractor - set at say 15˚ - and making two or four

cuts, turning the wood over after each cut.

You should use a sub-fence, because the protractor

face may not give sufficient support, especially when

cutting sharp points on stakes. Also your fingers might

have to pass too close to the blade for safety, without

a sub-fence.

Glue sandpaper to the sub-fence for extra grip, or

attach a rear stop block to the sub-fence and butt each

workpiece up against it. Provided your workpieces are

all the same length, it ensures the points will be central

-without measuring, marking or sighting up - and

makes it easier and safer to hold the workpieces.

If the workpieces are too long to fit a stop block, use

sandpaper or clamps. Sight up cuts by using a line

squared around each workpiece - say 100mm in from

the end - reference it to a pencil mark on the sub-fence.

45 x 19mm material on edge is ideal for a sub-fence.

Rebate the end closest to the blade to allow the

overhead guard to adjust to 10mm above the table.

Adjust the overhead guard so the workpiece just

passes under it. Keep the blade as low as possible.

Bevel Ripping Guide (BRA100)

The optional Triton Bevel Ripping Guide enables

accurate bevels and chamfers from 15˚ through 90˚,

and makes use of the protractor for perfect compound

mitres.

Lower the saw blade to below table level and

rehearse this cut, without power, to confirm your

hand positions.

Be careful of the small wedge-shaped off-cuts.

They can vibrate into the blade and become re-cut,

or flung out, or can wedge in the table slot beside

the blade. Keep a stick handy to move them away

from the blade after each cut.

If one becomes wedged in the slot, stop cutting,

switch off the power with your thigh, and wait until

the blade stops completely before withdrawing the

workpiece and removing the jammed off-cut.

1

Line-up reference mark

sub-fence and workpiece

Sand-paper faced

sub-fence

1

OPTIONAL ACCESSORIES

Wheel Kit (AWA100)

Add a pair of wheels for even greater portability.

1 2

Page 26

Page 26

Router Kit (RKA 001)

Mini Sliding Extension Table (ETA100)

Dust Bag (DCA100) and Dust Collector (DCA300)

1

1

Fits quickly to the unit for a substantial increase in

capacity. 1000mm ripping capacity and 600mm

crosscut capacity. Sliding and fixed table operations.

Fully adjustable fence arrangement for added

versatility.

Folds to a convenient size for storage.

Fits to the unit for a for a cleaner, healthier work

environment.

Collects almost 100% of the saw dust created,

when vacuum cleaner is attached.

1

The Router Kit enables you to fit a 1/2” or 1/4” router

to the Powered Saw Table for accurate and safe

moulding, planing, rebating and trenching cuts.

The kit comprises of a fully adjustable fence with

pressure fingers and a 3 piece guard (which can be

mounted directly to the table when the fence is not

used). Aquick-fit mounting plate and table insert are

also supplied.

If the Router Kit is not stocked by your local retailer

they can order it in on request. Alternatively, it can be

ordered directly from Triton by phoning 1300 655 686.

Page 27

OPERATING & SAFETY INSTRUCTIONS

SPECIFICATIONS

Motor Size: 1600W

Blade Diameter: 184mm (71/4”)

Arbour: 16mm

No load speed: 4800rpm

Cut depth: 90˚ - 63mm

(hand-held) 45˚ - 45m

Cut depth: 90˚ - 55mm

(saw table mounted)

TSA 184

184mm (7

1

/4”)

Circular Saw

IMPORTANT: Before operating, carefully read and understand all instructions

contained in this manual .

Save these instructions for future reference. If lending or passing on this product to

someone else, ensure that they also study these instructions carefully before use.

Due to our company policy of continuous product improvement, specifications may change without notice.

Page 28

Page 28

1. Keep children and pets away. Do not allow

children, by-standers or animals to come near

the work area or to touch the saw or power lead.

2. Eye, ear and respiratory protection should

always be used with power tools.

3. Dress appropriately (eg. no loose fitting clothes,

neckties or jewellery, long hair should be tied

back, legs covered & footwear worn. Shirt

sleeves should be buttoned, or rolled up).

4. Guard against electric shock. Prevent body

contact with earthed or grounded surfaces (e.g.

puddles, pipes, radiators, cookers and

refrigerators). Consider using a E.L.C.B. (Earth

Leakage Circuit Breaker) for added electrical

safety.

5. Ensure you always operate on stable ground

with clear access to your work.

6. Never work in confined and/or low-lit areas.

7. Use a good quality extension lead, where

required. Aheavy duty type, fully unwound,

should be used when working outdoors. Check

power leads regularly for damage. Faulty leads

should be replaced or repaired.

8. Do not subject the saw to excessive

dampness or humidity, or to an environment

where explosive or corrosive gases could be

present.

1. Ensure the trigger strap is removed before

using the saw hand-held. Locking the trigger

“on” when using hand-held can be hazardous.

2. Disconnect the saw from power and ensure

the blade has stop completely before making

adjustments. (ie. fitting or removing the saw

blade, fitting the trigger strap, mounting the saw

in the table or other maintenance work).

3. Ensure the blade retaining nut and depth &

angle adjusters are firmly tightened prior to

each use.

4. Do not remove or obstruct functioning of the

lower blade guard. Regularly check that it is in

good working order.

5. Avoid accidental starting of the saw. Keep

fingers clear of the saw trigger until required.

6. Always have your workpiece securely

clamped. Do not attempt to hold the workpiece

in your hand while cutting. Keep both hands on

the saw handles.

7. Keep hands away from cutting area and

blade. Use both hands and hold the saw firmly to

prevent loss of control. Do not place your hand

behind the saw blade as kickback could cause

the saw to jump backwards over your hand.

8. Do not over-reach or stand behind the cut

line. Adopt a stance where your limbs will be

safe even if the saw kicks back.

9. Do not force the saw. Adjust your feed rate to

allow the tool to run at its’ intended speed

without labouring.

10. Do not apply lateral pressure on the blade or

in any other way attempt to slow down or forcibly

stop the blade from spinning.

11. Avoid removing off-cuts while the blade is

still spinning.

12. Avoid blade and/or arbor damage by ensuring

the saw guard has fully closed before setting the

saw down.

13. Do not use blades which are deformed or

damaged. Check the blade prior to each use.

14. Only use 184mm (7

1

/4”) blades, with a kerf

between 2.2 & 3.5mm, designed for circular saws

with a no-load speed rating of at least 4500rpm.

Never fit high speed steel blades or abrasive

discs (except Triton Sanding Discs).

15. Any damage should be repaired and carefully

inspected before use.

16. Perform required saw maintenance and

adjustments according to the instructions.

Keep handles and switches dry, clean and free

from oil and grease.

17. Ensure the saw is disconnected from power

before leaving it unattended.

18. Store the saw in a dry location, out of the

reach of children.

SAW SAFETY

-

Carefully read the following warnings prior to operating the saw.

Saw Safety

General Safety

Page 29

Page 29

1. Hold in the shaft lock button and use the saw

spanner supplied to remove the arbor bolt - turn

in the direction of the blade rotation. The shaft

will turn slightly before locking, allowing the bolt,

outer arbor washer and saw blade (if already

fitted) to be removed. If removing the blade,

carefully slide it out through the baseplate.

2. Hold the lower blade guard fully back and

carefully slide the blade through the baseplate

and position it onto the inner washer on the

shaft. The graphics should face out and the

arrow on the blade should point in the same

direction as the arrow on the guard.

3. Refit the outer arbor washer and while

depressing the shaft lock button, tighten the

arbor bolt firmly into position - turn against the

direction of blade rotation. Ensure the blade

seats flush between the inner and outer washers

then tighten firmly with the spanner.

SAW FEATURES AND FUNCTIONS

Ensure the tool is disconnected from

power.

Loosen the depth adjustment lever and

pivot the saw body away from the

baseplate until the approximate depth is

achieved. Push down on the lever to

lock, but do not over-tighten.

For best cutting results the blade should

extend no more than one tooth depth

beyond the thickness of the material

being cut.

The height lever can be repositioned if

the mechanism is a bit firm or loose

with the lever raised.

To re-position the lever, prise off the

e-clip securing the lever with a blade

screwdriver. Remove the lever from the

hex nut and relocate it clockwise (if too

firm) or anti-clockwise (if too loose) one

position then refit.

Replace the e-clip and re-check the

locking position of the lever.

WARNING! Disconnect the plug from the power source and remove the trigger strap (K) before

assembling, making any adjustments or changing accessories. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Fitting & Removing the Saw Blade

Adjusting Cut Depth

2

1 2

3

1 2

Height

lever

E-clip

1

Page 30

Page 30

IMPORTANT: Never use the trigger strap to lock

the trigger “ON” when using the saw hand-held. It

can remain fitted around the hand-grip of the saw,

allowing it to be slid into place when mounted to

the saw table.

Power Switch

1

With the lock-out button pressed in the trigger will

be free to pull “ON”. Releasing the trigger will switch

the tool “OFF”.

Do not engage the blade with your workpiece until

it is spinning at full speed - likewise avoid switching

off the tool until the cut is complete.

Ensure that both hands are firmly on the hand grips

of the tool before switching on.

2

Ensure the tool is disconnected from power.

Set the saw to maximum cut depth. Set the bevel

adjuster to 0˚ on the quadrant.

Use a square to check that the blade is 90 degrees

to the saw baseplate, and make any necessary

bevel adjustments

1

90˚ Check

Lock-out

button

IMPORTANT: Do not attempt to bevel the saw

when mounted in the saw table.

Ensure the tool is disconnected from power.

Bevel angles can be set anywhere within the range

-0˚ to 50˚. Loosen the bevel adjuster at the front of

the saw then angle the saw body to the desired

degree setting, as marked on the quadrant.

Re-tighten the bevel adjuster.

Bevel Adjustment

1

Page 31

Page 31

Rest the front of the baseplate on the workpiece

with your pencil mark aligned with the correct side

of the sighting notch. Ensure the blade is not

touching the workpiece.

Hold the saw firmly with both hands, and press the

trigger while holding in the lock-out button. When

the saw motor reaches full rotational speed, guide

the saw smoothly along the cut line.

SAW OPERATION

Hand-Held Operation

1

Make sure the workpiece cannot move during the cut

- use clamps wherever possible. Never perform any

cuts on a workpiece held in the hand.

Large panels and long pieces must be well

supported close to both sides of the cut to avoid

pinching and kickback. Ensure the saw is positioned

with the wider part of the baseplate resting on the

larger piece, or on the piece with the best support.

Maintain a consistent feed rate - too fast may put

excessive strain on the motor, while too slow may

burnish your workpiece. Avoid any sudden

movements of the saw.

When cutting veneered board or wood less than

20mm thick, set the blade to protrude 5-10mm

through the work. This will reduce splintering.

When cutting thicker wood, set the blade to

maximum depth to reduce kickback.

Wherever possible, avoid free-hand cutting. It is

much safer and more accurate to cut with the saw

mounted in the saw table or guided by a clamped

on batten. Only consider using the saw free-hand

if, for some reason, it is not possible to perform the

cut on the saw table. If cutting free-hand, always

mark a straight cutting line and keep the saw from

wandering away from it.

2

Prevent kickback by ensuring that you move the

saw in a straight line. Ensure that your blade is in

good order and that the cut does not close in on

the blade. (Use a small wedge or 3mm spacer in

the cut to prevent it closing if you’re cutting difficult

material). Release the trigger if the saw gives any

sign of stalling but do not remove the saw until the

blade stops spinning.

Avoid cutting any nails, screws etc. by inspecting

your workpieces and removing any fasteners prior

to cutting.

If any unusual noise or odour occurs during

operation stop the saw immediately and contact

Triton.

The sighting indicators in front of the

saw blade provide guidance when

cutting along a pencil line.

For 90˚ cuts use the right hand

indicator and the left hand indicator

for 45˚ cuts.

The accuracy of the sighting

indicators can be adjusted using a

philips-head screwdriver.

Sighting the Cut Line

1 2

90˚ cut indicator

45˚ cut indicator

Page 32

Triton Manufacturing & Design Co. AUSTRALIA

Ph: (03) 9584 6977 Fax: (03) 9584 5510

triton.com.au

Due to our company policy of continuous product improvement, specifications may change without prior notice.

SAW MAINTENANCE -

Disconnect the saw from power before any maintenance

•

Regularly check that the saw arbor and arbor

washers are clean, and free of built-up gum

deposits or caked-on saw dust. Check that the

faces of the arbor washers are smooth and free

from burrs. Check that the blade retaining bolt is

correctly tightened.

•

Check the operation of the spring-loaded guard. It

must close quickly and without scraping

anywhere. Remove the blade and clean

accumulated saw dust or wood slivers from the

guard area using warm soapy water.

•

The saw ventilation slots should be kept clean

and clear of any foreign matter. Use a lightly

dampened cloth to wipe the saw clean - do not

use solvents.

•

Regularly check the saw blade for flatness. Use

of the saw with a buckled blade places excessive

load on the motor and gearbox assembly, and

may affect your warranty rights.

•

Triton Manufacturing & Design Co. will not be

responsible for any damage or injury caused by

unauthorised repair of the saw or by mishandling

of the tool.

•

Regularly check that the blade is free from a build

up of gum resins or saw dust. If necessary clean

with a solvent such as WD40, RP7 or mineral

turpentine.

•

The tungsten carbide teeth should be checked

regularly for sharpness and tooth breakages, and

repaired or replaced as required.

Saw Blade

1

•

The carbon brushes are a consumable item

which should be inspected periodically and

replaced when worn.

•

With the saw disconnected from power,

unscrew the brush caps located near the end of

the motor. Remove the brushes by pulling

carefully on the protruding springs.

If either of the brushes is worn to less than 6mm

long, they must both be replaced.

Brushes

1

Loading...

Loading...