Page 1

Operating and

Safety Instructions

Maxi Sliding Extension Table

ETA300

www.tritontools.com

Page 2

2

GB

Thank you for purchasing this Triton product. These instructions contain information necessary

for safe and effective operation of this product.

Please read this manual to make sure you get the full benefit of its unique design.

Keep this manual close to hand and ensure all users of this product have read and fully understand the instructions.

CONTENTS

Symbols 2

Parts list 2

Safety 7

Assembly 6

Operating 7

Angle settings 9

Guarantee 9

SYMBOLS

Conforms to relevant legislation

and safety standards.

PARTS LIST

Table Assembly

1. Long Extrusion (2)

2. Short Extrusion Ass’y (2)

3. Scale (2)

4. Brace (2)

5. Corner Bracket (4)

6. Inner Bearing (smaller) (2)

7. Outer Bearing (larger) (2)

8. Fence Assembly (1)

Fastener Bag 1

9. Brace Bracket (4)

10. Flange Nut M 6 (14)

11. Hex Bolt M6 x 10 (20)

12. Hex Nut M6 (8)

13. Washer M6 (2 0)

14. Screw M6x16 (4)

15. Fence Clamp A ssembly (2)

Always wear ear, eye and respiratory

protection.

Outer Track Assembly

16. Outer Track (1)

17. Leg (2)

18. Foot (2)

19. Leg Plate (4)

20. Leg Clamp Assembly (2)

Fastener Bag 2

21. Hex Bolt M6 x 4 0 (6)

22. Nyloc Nut M6 (6)

23. Screw M4 x 10 (4)

24. Square Nut M4 (4)

25. Height Stop (2)

26. Coach Bolt M6 x 20 (2)

27. Round Knob with Nut (2)

28. Angled Tube Closer (2)

29. Flat Tube Closer (4)

Instruction warning.

Do not use before viewing and

understanding the full operating

instructions

Inner Track Assembly

30. Inner Track (1)

31. Support Bracket (2)

32. Skid A ssembly (2)

33. Front Panel Bracket (1)

34. Rear P anel Bracket (1)

Fastener Bag 3

10. Flange Nut M6 (2)

13. Washer M6 (4)

22. Nyloc Nut M6 (6)

26. Coach Bolt M6 x 20 (2)

27. Round Knob with nut (2)

35. Coach Bolt M6 x 12 (4)

36. Locking Latch (2)

37. Hex Bolt M6 x 45 (2)

38. Screw M6 x 10 (2)

Contents / Symbols / Parts List

Page 3

3

GB

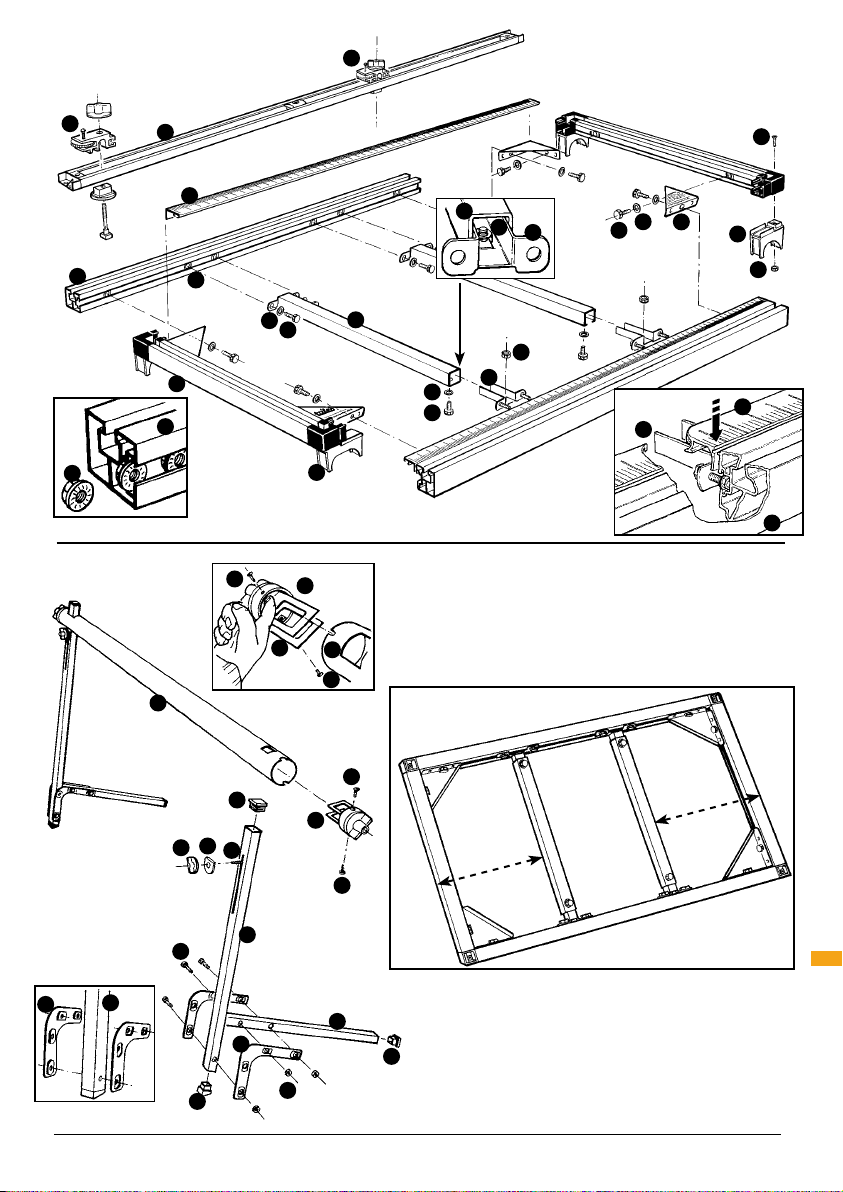

Fig. 1

15

15

10

Inset 1

Fig. 3

8

3

15

1

10

13

11

2

1

4

7

Inset 2

13

11

4

12

9

12

9

13

11

5

9

Inset 3

23

16

24

20

16

23

Fig. 2

14

6

12

3

1

23

29

20

25

27

26

315m m

315m m

23

21

19

17

17

18

19

28

22

29

Underside of table

Parts List

Page 4

4

GB

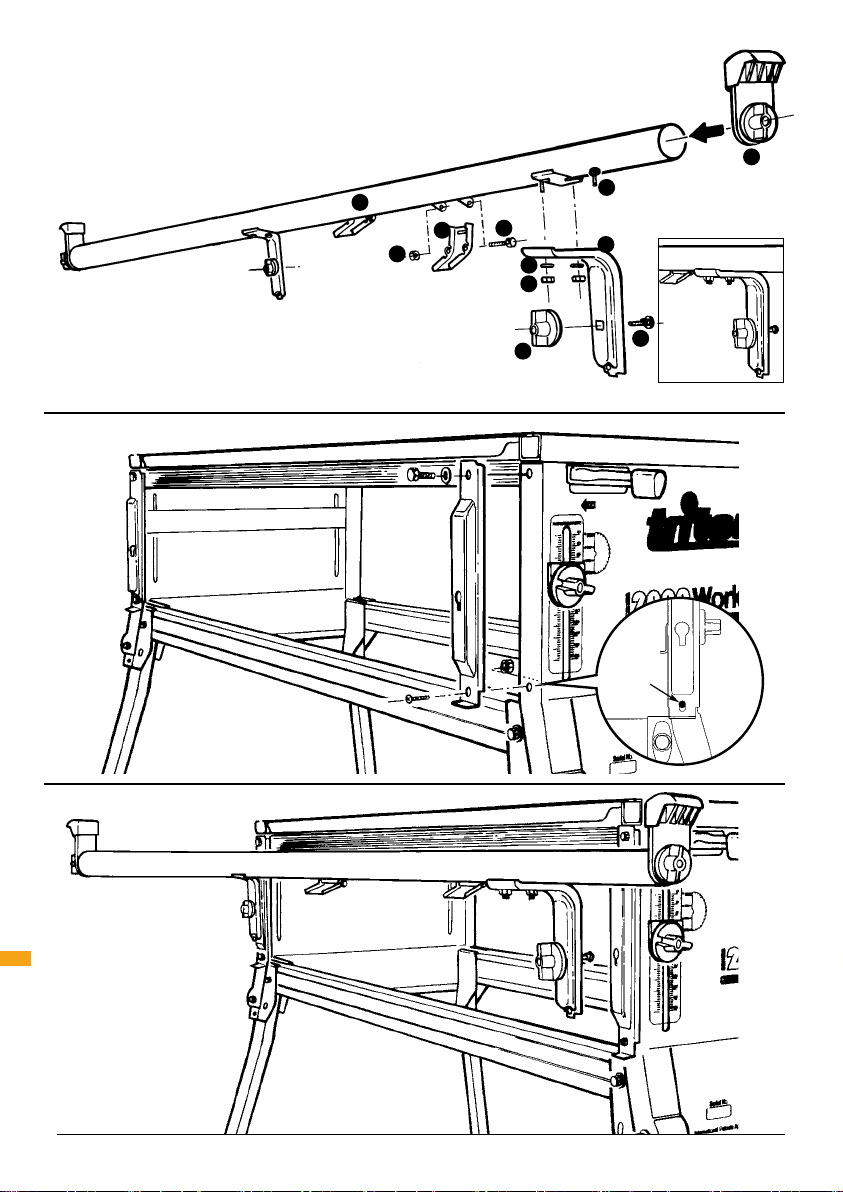

Fig. 4

32

30

36

22

37

13

22

35

31

Fig. 5

Fig. 6

27

26

6.5mm

(1/4”).

Parts List

Page 5

5

GB

SAFETY INSTRUCTIONS

WARNING. Read all instructions. Read all

safety warnings and all instructions. Failure

to follow the warnings and instructions my

result in electric shock, fire and/or serious injury.

Save these instructions

1. WORK AREA SAFETY

a. Keep work area clean and well lit. Cluttered and

dark areas invite accidents.

b. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c. Keep children and bystanders away while

operating a power tool. Distractions can cause

loss of control.

2. ELECTRICAL SAFETY

a. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep the cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e. When operating a power tool outdoors, use an

extension cord suitable for outdoor use, this will

reduce the risk of electric shock.

f. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply, which will reduce the risk of

electric shock.

3. PERSONAL SAFETY

a. Do not use power tools while you are tired

or under the influence of drugs, alcohol or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

b. Always use safety equipment: wearing eye

protection, dust mask, non-slip safety shoes,

hard hat and hearing protection used in

appropriate conditions will reduce personal

injuries.

c. Avoid accidental starting. Ensure the switch is

in the ‘Off’ position before plugging in. Carrying

power tools with your finger on the switch or

connecting to power with the switch on the ‘On’

position invites accidents.

d. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e. Do not over-reach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

f. Wear suitable clothing and footwear. Do not

wear loose clothing, neckties, jewellery, or other

items which may become caught. Wear non-slip

footwear or where appropriate, footwear with

protective toe caps. Long hair should be covered

or tied back.

g. If devices are provided for the collection of

dust particles, ensure these are connected and

properly used. Use of these devices can reduce

dust related hazards.

4. POWER TOOL USE AND CARE

a. Do not force the power tool. Using the correct

power tool for your application will be safer and

produce better results at the rate for which it

was designed.

b. Do not use the power tool if the ‘On/Off’ switch

is not working correctly. Power tools that cannot

be controlled by the switch are dangerous and

must be repaired prior to use.

c. Disconnect the plug from the power source

before making any adjustments, changing

accessories or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d. Power tools are dangerous in the hands of

untrained users. Store power tools out of reach

of children, and do not allow persons who are

unfamiliar with the product or these instructions

to operate the power tool.

e. Maintain power tools. Check for misalignment,

binding or breakage of moving parts, and any

other condition that may affect the operation of

Safety Instructions

Page 6

6

GB

the power tool. If damaged, have the power tool

repaired before use. Accidents are caused by

poorly maintained power tools.

f. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g. Use the power tool, accessories and tool bits in

accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed. Failure to use

the tool for its intended purposes could result

in a hazardous situation and may invalidate the

warranty.

5. SERVICE

a. Have your power tool serviced by a qualified

repair technician, using only identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

ASSEMBLY

ASSEMBLING THE TABLE & RIP FENCE

STEP 1

Using the fasteners from Fastener Bag 1, insert 6

Flange Nuts (10) into each Long Extrusion (1) as

shown in Inset 1, (Fig. 1).

Lay out the two long extrusions and the two short

extrusions as shown in (Fig. 1), making sure that all

of the flange nuts are facing inwards.

Plug the corner blocks of the Short Extrusions (2)

into the ends of the long extrusions and tap fully

home with a mallet (or similar).

STEP 2

Turn the table over (face down, as in Fig. 2) on a

flat surface and loosely attach the Corner Brackets

(5), using the Hex Bolts (11) and Washers (13) into

the flange nuts. (Slide the flange nuts into position

using a screwdriver).

Ensure that the two printed corner brackets are

bolted with their correct edges on the same long

extrusion (Fig. 1).

Loosely fit the Brace Brackets (9) to the Braces (4)

using Hex Bolts (11), Washers (13) and Hex Nuts

(12). See Inset 2 (Fig 1).

Position the braces about 315mm in from each side

of the frame (Fig. 2) and loosely attach the braces

NOTE: The tool must be used only for its prescribed

purpose. Any use other than those mentioned in

this manual will be considered a case of misuse.

The user and not the manufacturer shall be liable

for any damage or injury resulting from such

cases of misuse. To use this tool properly observe

the safety regulations, assembly instructions

and operating instructions, which can be found

in this manual. All persons who use and service

the machine must be informed about its potential

hazards and be acquainted with this Manual.

Children and frail people must not use this tool.

Children should be supervised at all times if they

are in the area in which the tool is being used. It

is also imperative that you observe the accident

prevention regulations in force in your area. The

same applies for general rules of occupational

health and safety. The manufacturer shall not be

liable for any changes made to the tool nor for any

damage resulting from such changes. Even when

the tool is used as prescribed it is not possible to

eliminate all residual risk factors.

with hex bolts and washers into the remaining

flange nuts. Do not tighten any of the fasteners yet.

There should be two flange nuts left over. These

can be used later for fitting jigs etc (Fig. 9).

STEP 3

Turn the table face upwards and insert the Scales

(3) between the long extrusions and the brace and

corner brackets. Position them with the 380mm

ends hard up against the short extrusion on the

'map of Australia' side of the table. Push the scales

down until they 'click' into position, flush with the

top face of the long extrusions, as shown in Inset 3

on (Fig. 1).

Turn the table over (face down). Make sure the

corner brackets are pushed fully home into the

corners, and the plastic corner blocks are still fully

inserted into the ends of the extrusions.

Tighten the 8 bolts holding the corner brackets. Do

not over-tighten. (Tighten each pair of bolts a little

at a time, to ensure you don’t distort the frame).

Next tighten the 8 bolts holding the brace brackets

to the long extrusions, and finally tighten the 4

bolts through the braces.

Safety Instructions / Assembly

Page 7

7

GB

STEP 4

Plug the two smaller Inner Bearings (6) into the

corner blocks below the 380mm scale readings and

tighten using the Countersunk Screws (14) and Hex

Nuts (12). The two longer Outer Bearings (7) are

fitted to the corner blocks near the 1220mm scale

readings (Fig. 1).

STEP 5

Take apart the Fence Clamp Assemblies (15) and

reassemble them through the slot in the Fence

Assembly (8) (Fig. 1).

Turn the table face up once again. With the clamp

assemblies loosened, lower the square feet on the

clamp bolts into two of the table corner blocks.

Slide the fence along the extrusions to position it

wherever you like, and tighten the round knob to

lock it in place.

ASSEMBLING THE OUTER TRACK

STEP 6

Insert the Coach Bolts (26) through the slots in the

Legs (17), and fit the Height Stops (25) and Round

Knobs with Nuts (27) onto them, as shown in (Fig.

3). Attach the Feet (18) to the legs using the Leg

Plates (19), Hex Bolts (21) and Nyloc Nuts (22).

Note: the raised bumps on the leg plates must face

inwards, touching the legs (see lower Inset Fig. 3).

The feet should face away from the leg slots (Fig. 3).

Tighten the bolt which passes through each leg

until the feet pivot smoothly. The foot is designed to

swing around on this bolt for easy storage.

Loosen the large round knobs and align the cutouts in the clamps with the square cut-outs in the

track. Insert the legs through the track cut-outs and

tighten the large round knobs to clamp. Now tighten

the Phillips screws (23). Slide the height stops up

the leg slots until they touch the outer track and

tighten into position. They help set the correct

height for future set ups, and serve as protection

against track slippage under heavy load.

FITTING THE INNER TRACK

STEP 9

Loosely bolt the Support Brackets (31) to the

brackets on the Inner Track (30) using the short

Coach Bolts (35), Washers (13) and Nyloc Nuts (22),

(Fig. 4). Do not tighten yet. Note the orientation of

the brackets in regard to the long overhang of the

inner track (Fig.4).

Loosely fasten the longer Coach Bolts (26) and

Round Knobs with Nuts (27) onto the support

brackets (Fig. 4).

Unscrew the large round knob (one turn only) on

each Skid Assembly (32) and insert them into the

ends of the inner track. With the skids pointing up,

firmly tighten the knobs.

STEP 10

Fasten the two Locking Latches (36) onto the latch

brackets using the Hex Bolts (37) and Nyloc Nuts

(22). Ensure the rectangular windows in the latches

are oriented (Fig. 4). Tighten the bolts until the

latches pivot firmly.

STEP 7

Tap the Angled Tube Closers (28) into the bottom of

the legs ensuring they are correctly oriented. Tap

the Flat Tube Closers (29) into the remaining tube

ends.

STEP 8

Loosely fit the Phillips Screws (23) and Square Nuts

(24) through the holes in each Clamp Assembly

(20) as shown in the top inset (Fig. 3). Tap the

assemblies onto the ends of the Outer Track (16)

locating the screws in the notches.

STEP 11

Fit the Front Panel Brackets (33) and (34) to the

left-hand side of the Workcentre (when viewed

from the front panel, which has the switchbox). The

brackets are left or right handed. The long edge

flanges should wrap around the faces of the end

panels (Fig. 5).

At the top of each bracket, use the bolt, washer

and nut which hold the left-hand bearing channel

in position. At the bottom of each bracket, fit the

Phillips Screw (38) and Flange Nut (10), do not

tighten yet.

Note: if you have a MK3 Workcentre or an early

Series 2000 Workcentre (pre- serial no. 305000) it

Safety Instructions / Assembly

Page 8

8

GB

will be necessary to drill the lower holes through

the end panel flanges. If drilling, make sure you

position the holes as shown in the inset in (Fig. 5),

to give you the full range of height adjustment in

the bracket. Centre punch the hole positions and

1

⁄4" or 6.5mm holes.

drill

Fit the inner track to the Workcentre by locating the

coach bolt heads through the keyholes in the end

panel brackets (Fig. 6). Tighten the round knobs

and then temporarily tighten the four Nyloc Nuts

(12) holding the inner track to the brackets.

ALIGNING THE TRACKS

STEP 12

On Series 2000 Workcentres, push the legs of the

Workcentre diagonally outwards to ensure that it is

fully stable on the folding stand.

Position the outer track parallel to the inner track

approximately 700mm away from it. Place the table

onto the tracks with the inner (smaller) bearings

on the inner track. Always fit the table in this

orientation. Slide the table to each end of its travel

and adjust the position of the outer track. The

lengthened outer bearings make this a non-critical

adjustment.

Adjust the Phillips

screws until the heads

enter the rectangular

windows and the table

cannot be lifted.

(It will be necessary to

unlock the latches and

lift the table clear to

make these adjustments).

Fig. 7

STEP 15 - Fine-tuning the Inner Track

The last step is to fine-tune the inner track position

in the horizontal plane, to ensure that the extension

table scales are accurate.

Series 2000 Workcentres: With the extension

table fitted and locked, and the rip fence removed,

insert the standard Workcentre rip fence and set it

to 500mm using the end panel calibration marks.

Loosen the four nyloc nuts on the inner track

support brackets and adjust the inner track

sideways until both front and rear scales read

exactly 500mm, when sighting down the front face

of the Workcentre rip fence. Tighten the four nuts

and remove the Workcentre rip fence.

STEP 13 - Adjusting Inner Track Height

Next you have to fine-tune the height of the inner

track. Fit the extension table fence to the sliding

table so that it extends across the Workcentre table

(Fig. 12). Loosen the front bearing channel bolt

and adjust the height of the front panel bracket

until the bottom of the fence is around 0.5 - 1mm

above the Workcentre table. Slide the table to the

rear of the workcentre and adjust the height of the

rear bracket. Tighten the bolts and Phillips screws

holding the brackets to the end panels.

STEP 14 - Adjusting Outer Track Height

Next, adjust the height of the outer track until the

fence is level, and parallel to the Workcentre table.

Check the table throughout its travel for diagonal

rocking on the tracks, and fine tune the height of

the outer track if necessary. Adjust the height stops

on the outer track legs to lock-in the correct height.

With the sliding table positioned midway along the

tracks, engage the front and rear locking latches

(Fig. 7).

Assembly

MK3 Workcentres: Extend the extension table

fence across the Workcentre until the tip is level

with the left-hand edge of the saw slot. Check for

parallel by sliding the extension table so that the

fence tip runs the length of the saw slot. Loosen

the four nyloc nuts on the inner track support

brackets and adjust the position of the track until

the fence tip aligns perfectly with the saw slot at

both ends of the table travel.

To ensure the correct scale reading, position the

extension table with the front scale level with

the front of the saw blade and measure from the

blade teeth to check the scale reading. Adjust the

position of the inner track if necessary until the

scales are accurate, ensuring the track is moved by

exactly the same amount at each end.

Finally, double check the parallel alignment and

scale accuracy by repeating the above steps, or by

making a test cut.

Your Sliding Extension Table is now fully assembled

and ready for use.

Page 9

9

GB

Using the Hold-Down Clamps

When cutting large or awkward pieces in any of

the Sliding Table modes, you should secure your

workpiece using the hold-down clamps.

Swing the fence

Fig. 8

clamps around until

the hold-down feet

0verhang the

workpiece. With the

fence locked, lower

the feet until they

press firmly on the

workpiece by

spinning the thumb wheels clockwise (Fig. 8).

Attaching Fixtures to the Fence

Two additional flange nuts have been provided in

Fastener Bag 1 for attaching fixtures or sub-fences

to the rip fence. Rotate the fence clamps so the rear

is level with the front face of the rip fence. Insert

the flange nuts into the slots (Fig. 9) and attach your

fixture using M6 bolts (not supplied).

Fig. 9

clamps around so they don’t overhang the

workpiece.

Ensure that the overhead guard is lowered onto the

workpiece. Press the sheet against the fence at all

times. When ripping large sheets the plastic skids

at the ends of the inner track will provide additional

support. For very large workpieces the Triton Multistands, (Fig.11) are better suited, otherwise have

someone assist you.

Fig. 11

When ripping thin workpieces you may need to fit

an edge support (Inset - Fig. 11) against the rip

fence, to prevent the corner of the workpiece from

dipping into the table openings.

MK3 Workcentres: to rip in the 260mm - 380mm

range, clamp a 1200mm long x 200mm wide packer

to the extension table fence, using the hold-down

clamps. When setting the desired width, remember

to add 200mm.

OPERATING - Table Locked

Lock the table using the front and rear locking

latches and fit the rip fence (Fig. 10). Set your

width by

sighting the

scales down

the front

face of the

fence.

Ensure the

fence is

always set

parallel to

the blade.

Turn the

hold-down

Fig. 10

OPERATING - Table Sliding

• Always slide the extension table the full length of

the tracks before making your cut. Check that the

rip fence clears the saw blade, and does not hit or

ride up on the Workcentre table. Check that the

sliding table does not rock on its tracks. Adjust

the outer track height if necessary.

• Use the hold-down clamps whenever possible.

Crosscutting

Position the rip fence (Fig. 12). When tightening the

clamps, ensure that the fence is pulled fully toward

the outer edge of the table, for absolute squareness.

For gauging lengths up to 1220mm, you can align

the end of the workpiece with the required scale

reading. For longer workpieces, touch the fence tip

Assembly

Page 10

10

GB

against the saw blade teeth and use this to align a

cutting mark on the workpiece.

Note: if you wish to prevent the gradual cutting

away of the fence tips (which were designed for this

purpose) attach a small wooden fence tip using the

screw holes provided.

Panel Saw

This position gives a maximum width capacity of

around 1220mm, depending on saw size. Position

the fence (Fig. 13). Ensure it is pushed fully toward

the outer edge of the table before tightening the

clamps, for absolute squareness.

Mitre Cutting

Mitres can be cut with

the fence set at a

trailing angle (Fig. 14)

or leading angle

(Fig. 15) and with the

workpiece in front

(Fig. 14) or behind the

fence (Fig. 15).

Assembly

Fig. 12

Fig. 13

Fig. 14

You can use the

Workcentre protractor

to set the required

mitre angle. Place it in

the protractor slot

(Fig. 15).

Align the extension

table fence to the

protractor in the

position which best suits your workpiece, then

remove the protractor.

Taper Ripping

For slight tapers on large workpieces (ie. doors), set

the extension table fence to Panel Saw mode and

insert a packer against it (Fig. 16).

Fig. 16

Tapers can also be cut by angling the rip fence

(Fig. 17). The required angle can be achieved by

using the Workcentre protractor as outlined in Mitre

Cutting (Fig. 14). A parallel sided packer will be

required to offset the distance between the fence

and the protractor in establishing the correct taper

angle.

If the fence hold-

down clamps do not

adequately secure

your work when

taper ripping, use

additional means of

clamping the work to

the sliding table.

USE WITH A ROUTER TABLE

Edge planing and trenching can be performed in all

modes of operation with a Triton Router Table.

Fig. 15

Fig. 17

Page 11

11

GB

Edge Planing

For edge planing pieces up to 1220mm wide, any

length, use the Fixed Table position (Fig. 18).

Fig. 18

Set the extension table fence to the required

width by measuring the distance from the router

cutter to the fence, or by performing a test cut.

On early model Router and Jigsaw Tables set the

rear section of the router table fence flush with

the router cutter and set the front sub-fence to

the maximum depth of cut.

If using the Router Table model RTA300, remove

the fence and fit the guard to the tabletop.

Fig. 19

For planing long edges use the sliding table mode

with the extension table fence positioned as

shown in (Fig. 19). Use the extension table fence

to align the workpiece, and set the router fence, if

fitted, clear of the work.

Trenching

Trenching is possible in all modes of operation. In

the Table Sliding mode clamp a wooden batten to

extension table fence and extend it past the cutter

(Fig. 20). Run the batten through the cutter to

create a sighting notch and to prevent tear-out in

your workpiece.

Fig. 20

For long trenches in the Table Sliding mode fit

the extension table fence in the leading position

(furthest away from you) (Fig. 19).

Longer trenches can be performed in the Table

Locked mode (Fig. 18). Always use extreme care if

using the Router Table without the guard.

For large, awkward objects (eg. heavy staircase

stringers) it may be necessary to use the router

hand-held against a guide clamped to the

workpiece.

Always guide your work along the extension table

fence, not the router fence.

Assembly

Page 12

GUARANTEE

To register your guarantee visit our web site at

www.tritontools.com* and enter your details.

Your details will be included on our mailing list

(unless indicated otherwise) for information on future

releases. Details provided will not be made available to

any third party.

PURCHASE RECORD

Date of Purchase: ___ / ___ / ____

Model: ETA300

Retain your receipt as proof of purchase

Triton Precision Power Tools guarantees to

the purchaser of this product that if any part

proves to be defective due to faulty materials

or workmanship within 12 MONTHS from the

date of original purchase, Triton will repair, or

at its discretion replace, the faulty part free of

charge.

This guarantee does not apply to commercial

use nor does it extend to normal wear and

tear or damage as a result of accident, abuse

or misuse.

* Register online within 30 days.

Terms & conditions apply.

This does not affect your statutory rights

Hand-Held Operation

GB

12

Warranty

Loading...

Loading...