Page 1

SU-Series 3-Phase UPS Hardware:

Introduction and Troubleshooting

PRELIMINARY

1111 W. 35th Street, Chicago, IL 60609 USA

+1.773.869.1234 • www.tripplite.com

1

Page 2

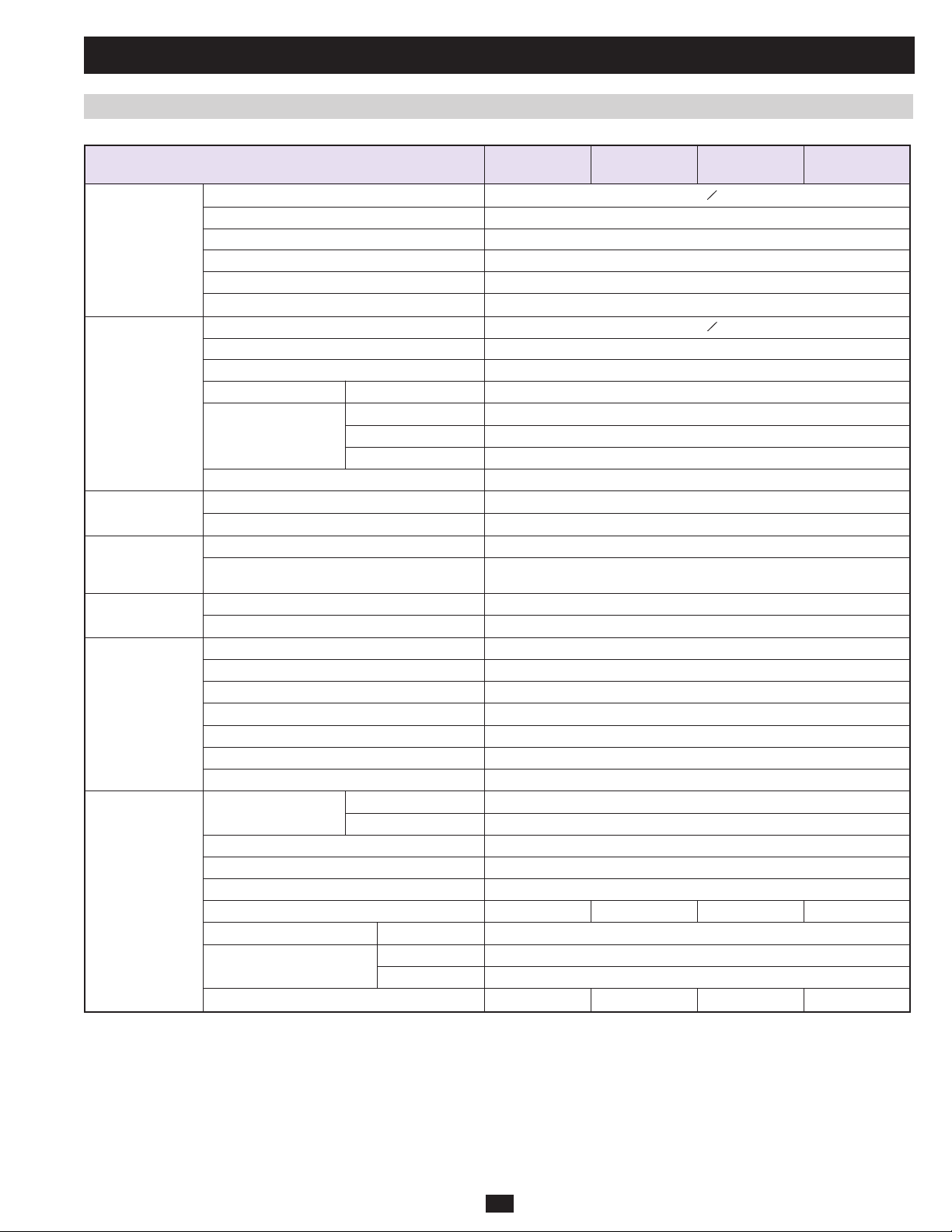

Table of Contents

1 Basic Operation 3

1.1 Technical Specifi cations 3

KX Models 3

K and KTV Models 4

SU80K Model 5

1.2 Features 6

1.2.1 Advanced Features 6

1.2.2 Control Panel Features 6

1.2.3 Front and Rear Panel Features 7

1.3 Operating Principles 13

1.3.1 System Layout 13

1.3.2 Internal Battery Layout 13

1.3.3 Power Module Layout 14

1.4 Opening and Closing the Unit 14

1.5 Operating Modes 15

1.5.1 Online (Normal) Mode (Single UPS) 15

1.5.2 Battery Backup Mode (Single UPS) 15

1.5.3 Auto Bypass Mode (Single UPS) 15

1.5.4 Manual Bypass Mode (Single UPS) 15

1.5.5 Online Mode (Parallel UPS) 16

1.5.6 Battery Backup Mode (Parallel UPS) 16

1.5.7 Auto Bypass Mode (Parallel UPS) 16

1.5.8 Manual Bypass Mode (Parallel UPS) 17

1.5.9 Hot Standby Mode (Parallel UPS) 17

1.6 Start-Up, Shutdown and Bypass 18

1.6.1 Control Panel and Breaker Diagrams 18

1.6.2 Preliminary Checklist (Single UPS) 18

1.6.3 Standard Start-Up Procedure (Single UPS) 18

1.6.4 Battery Start-Up Procedure (Single UPS) 19

1.6.5 Manual Bypass Procedure (Single UPS) 20

1.6.6 Shutdown Procedure (Single UPS) 20

1.6.7 Preliminary Checklist (Parallel UPS) 21

1.6.8 Start-Up Procedure (Parallel UPS) 21

1.6.9 Shutdown Procedure (Parallel UPS) 22

1.6.10 Manual Bypass Procedure (Parallel UPS) 23

1.6.11 Switching from Manual Bypass to Normal Mode

(Parallel UPS) 24

1.7 Printed Circuit Boards (PCB) 25

1.7.1 PCB Location (System) 26

1.7.1.1 KX Models 26

1.7.1.2 K Models 28

1.7.1.3 KTV Models 32

1.7.2 PCB Power Module 33

1.8 Block and Wiring Diagrams 34

1.8.1 KX Models 34

1.8.2 K Models 40

1.8.3 KTV Models 45

2 Theory of Operation 48

2.1 AC Auxiliary Power Circuit 48

2.2 DC Auxiliary Power Circuit 51

2.3 Auxiliary Power Failure Detection 51

2.4 Output Current Detection 52

2.5 Input Voltage Detection 53

2.6 Output Voltage Detection 54

2.7 Battery Voltage Detection 55

2.8 Bypass SCR Short-Circuit Detection 56

2.9 Bypass SCR Driver 57

2.10 Watchdog for System MCU 58

PRELIMINARY

2.11 LCD Panel Control Circuit 59

2.12 Fan Control Circuit 60

2.13 Bypass SCR Temperature Detection 61

2.14 Communication Circuit for RS232 61

2.15 Communication Circuit for Slots 62

2.16 Communication Circuit for Output Dry Contact 63

2.17 Communication Circuit for Input Dry Contact and REPO 64

2.18 External Battery Cabinet Temperature Detection 65

2.19 Detection Circuit for Manual Bypass Switch 66

2.20 Detection Circuit for Output Breaker 66

2.21 Control Circuit for Power Module 67

2.22 Transformer Over Temperature Detection 71

3 Communication 72

3.01 RS232 Port 72

3.02 Emergency Power Off (EPO) 72

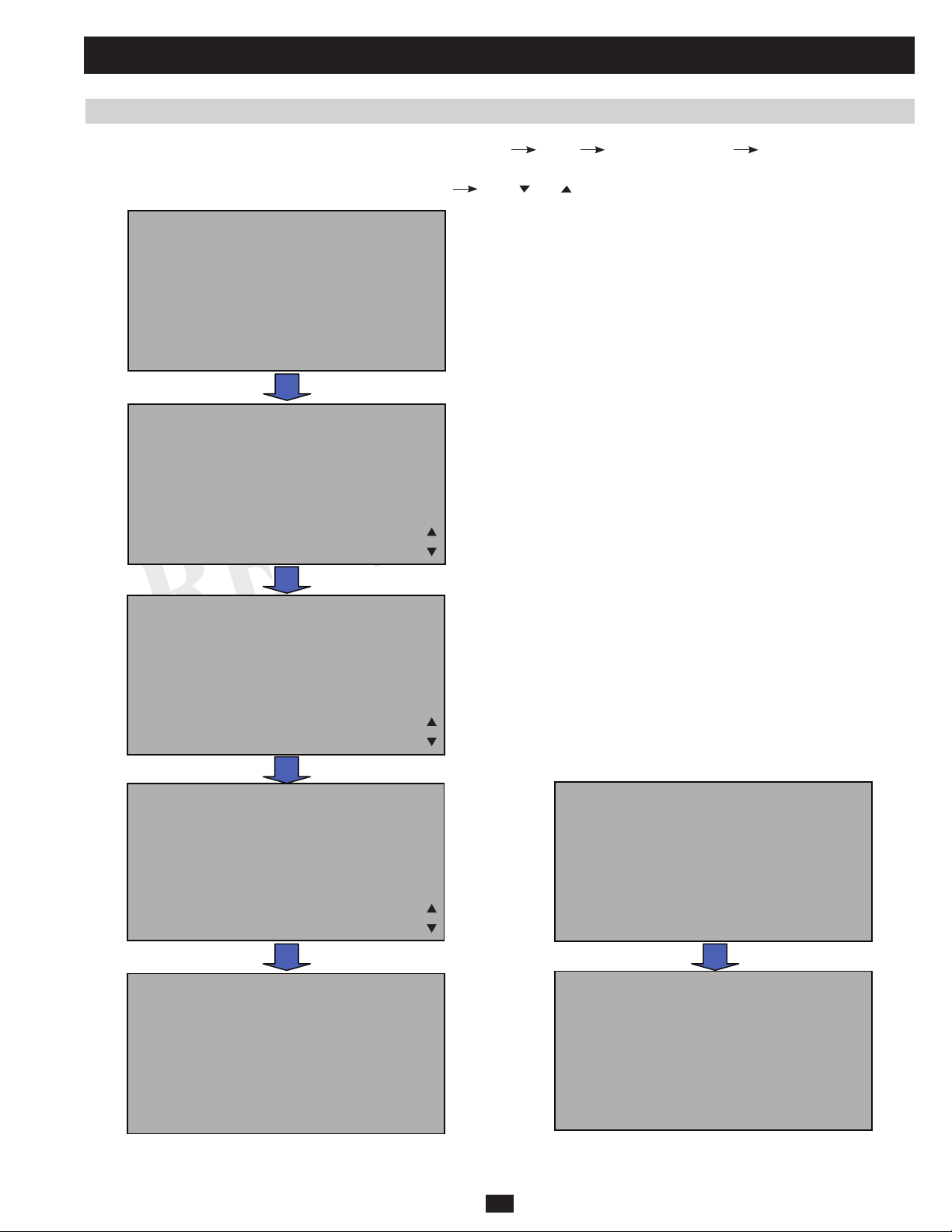

3.1 Setting EEPROM on the NH-M Board 74

3.1.1 Polling and Updating EEPROM 74

3.1.2 Calibrating EEPROM Gain 75

3.2 Setting Output Dry Contact Status 76

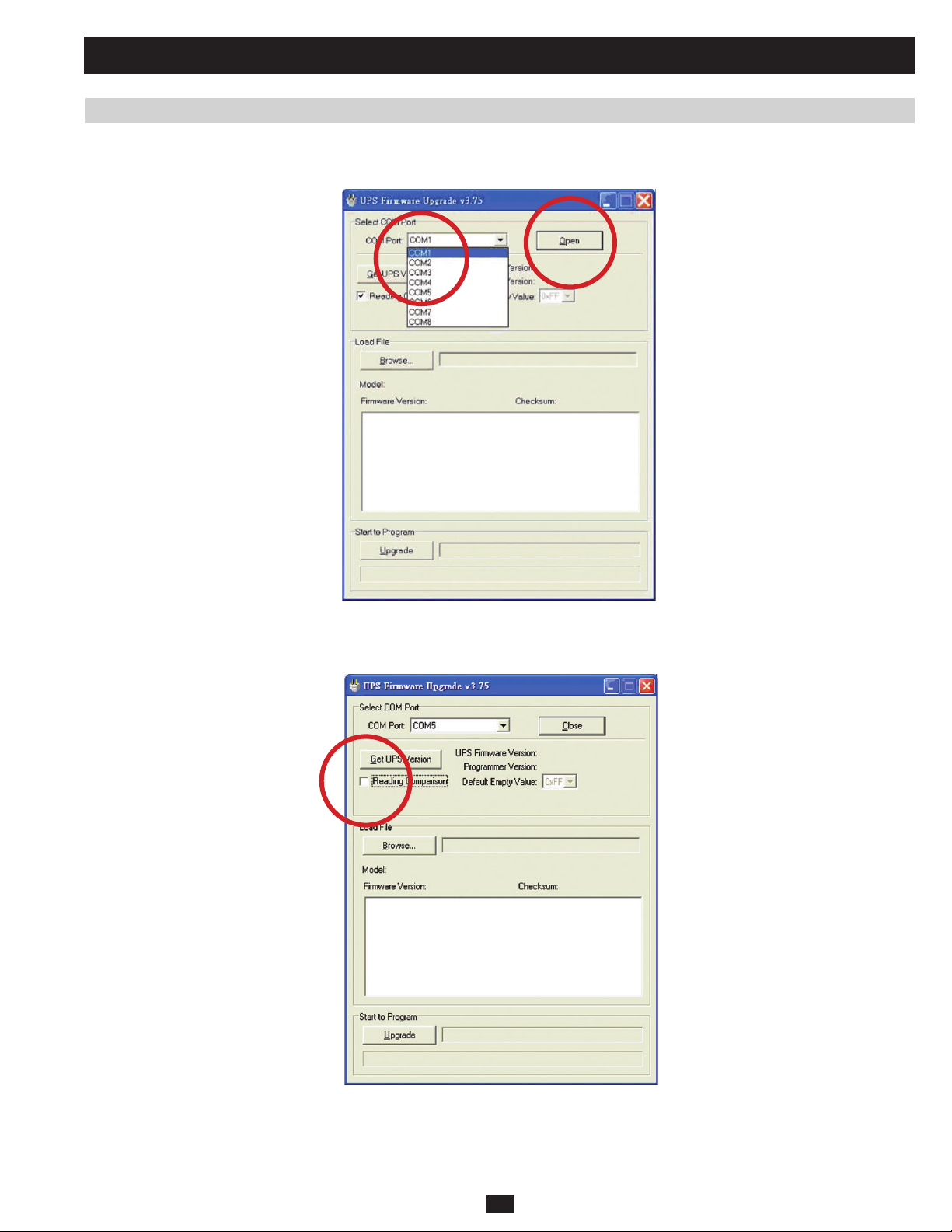

3.3 Upgrading Firmware for the System Board 77

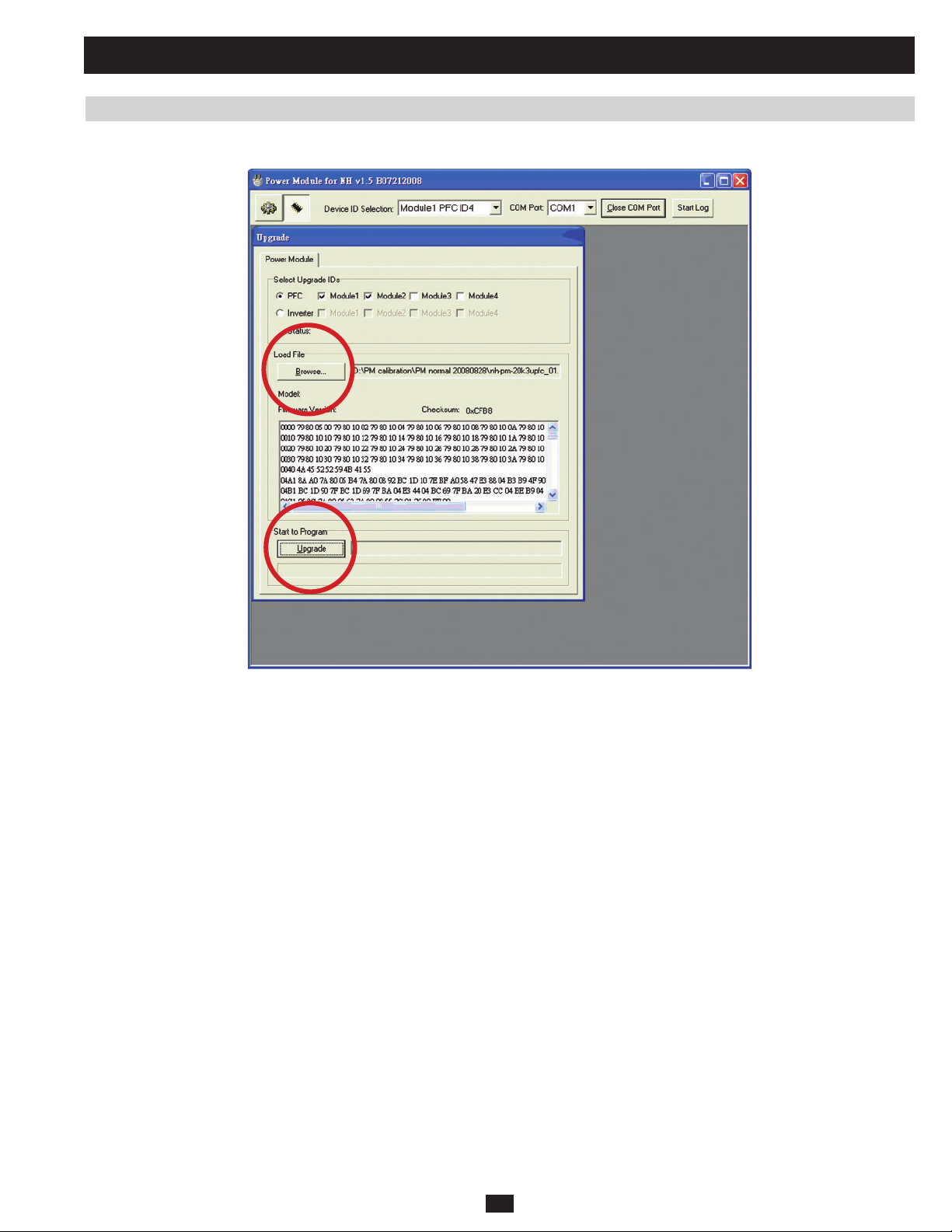

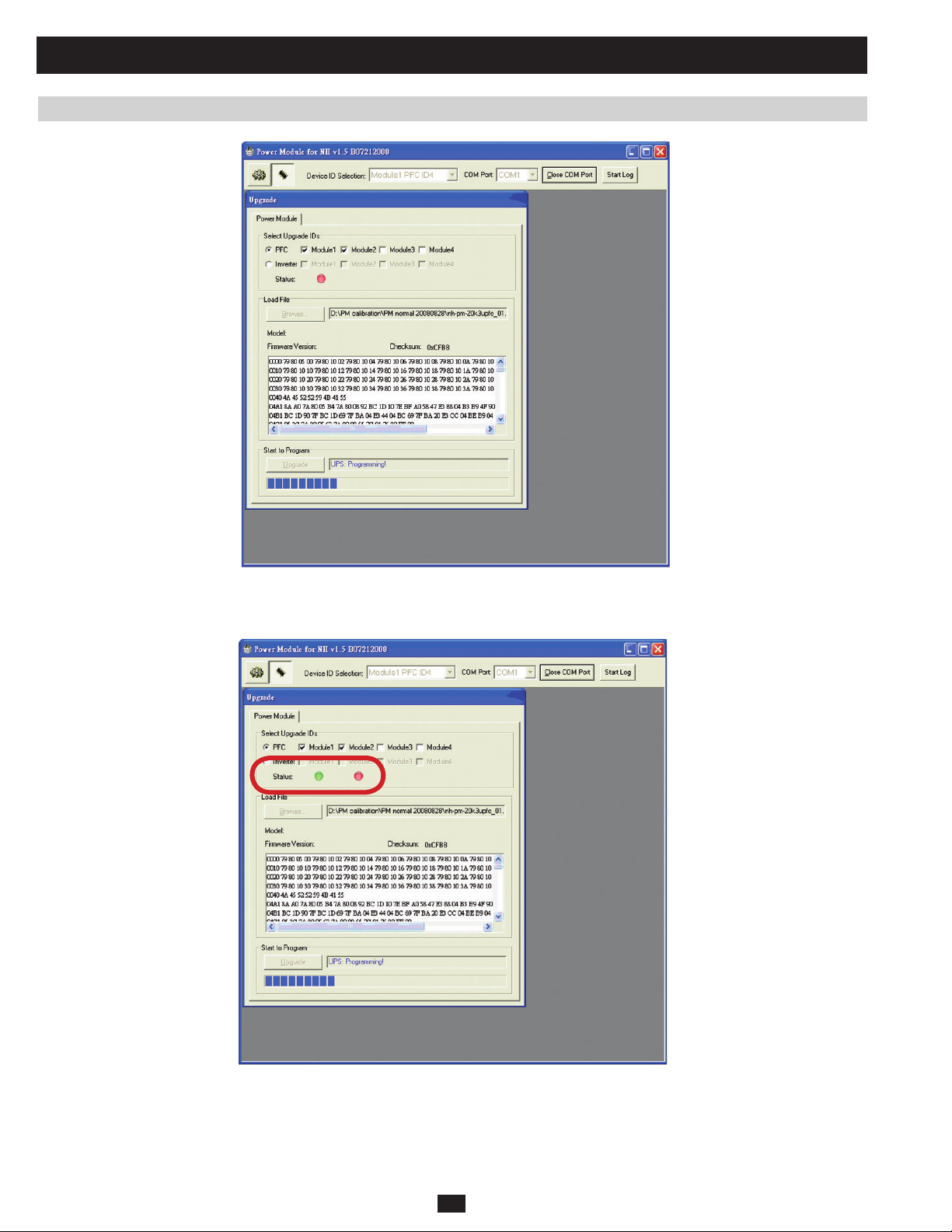

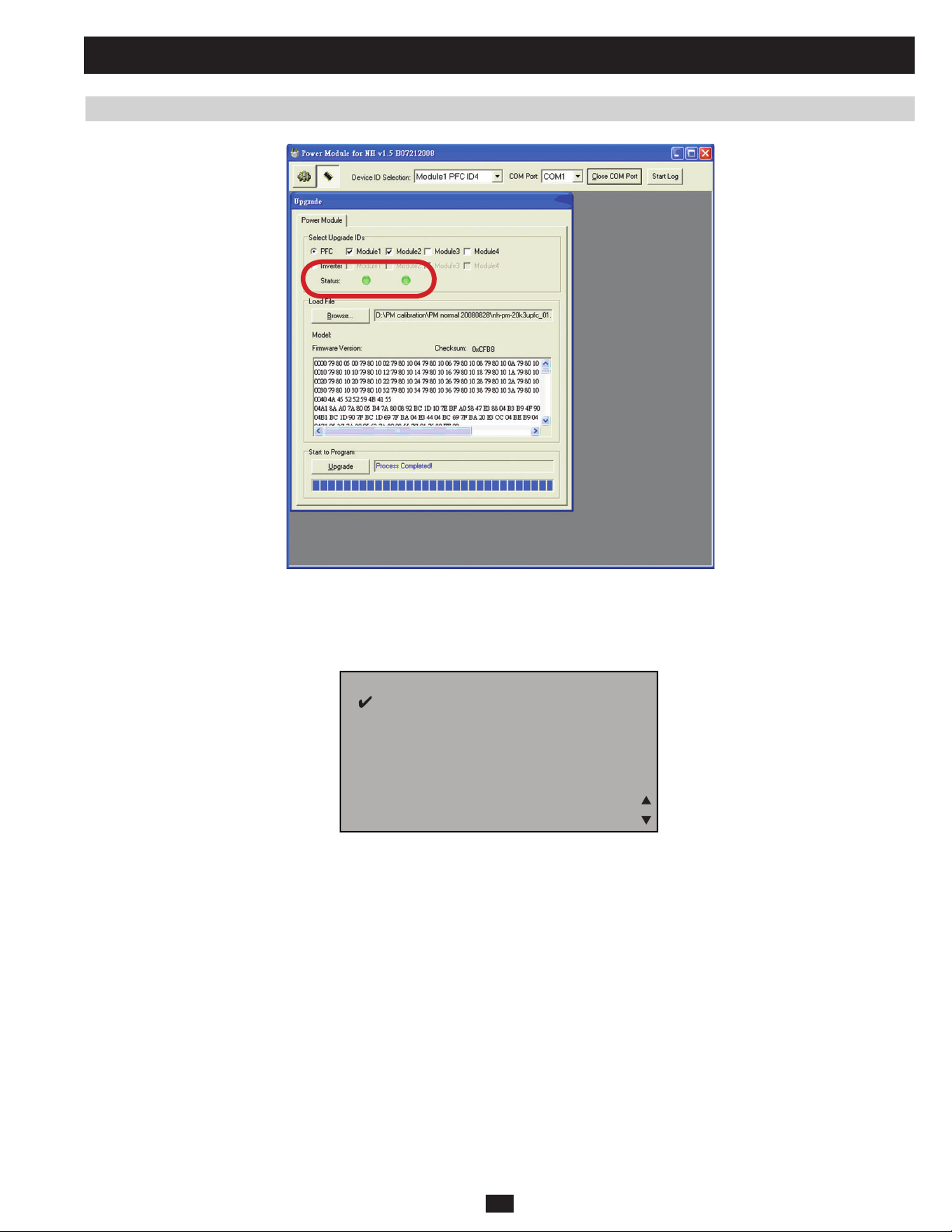

3.4 Upgrading Firmware for the Power Module 82

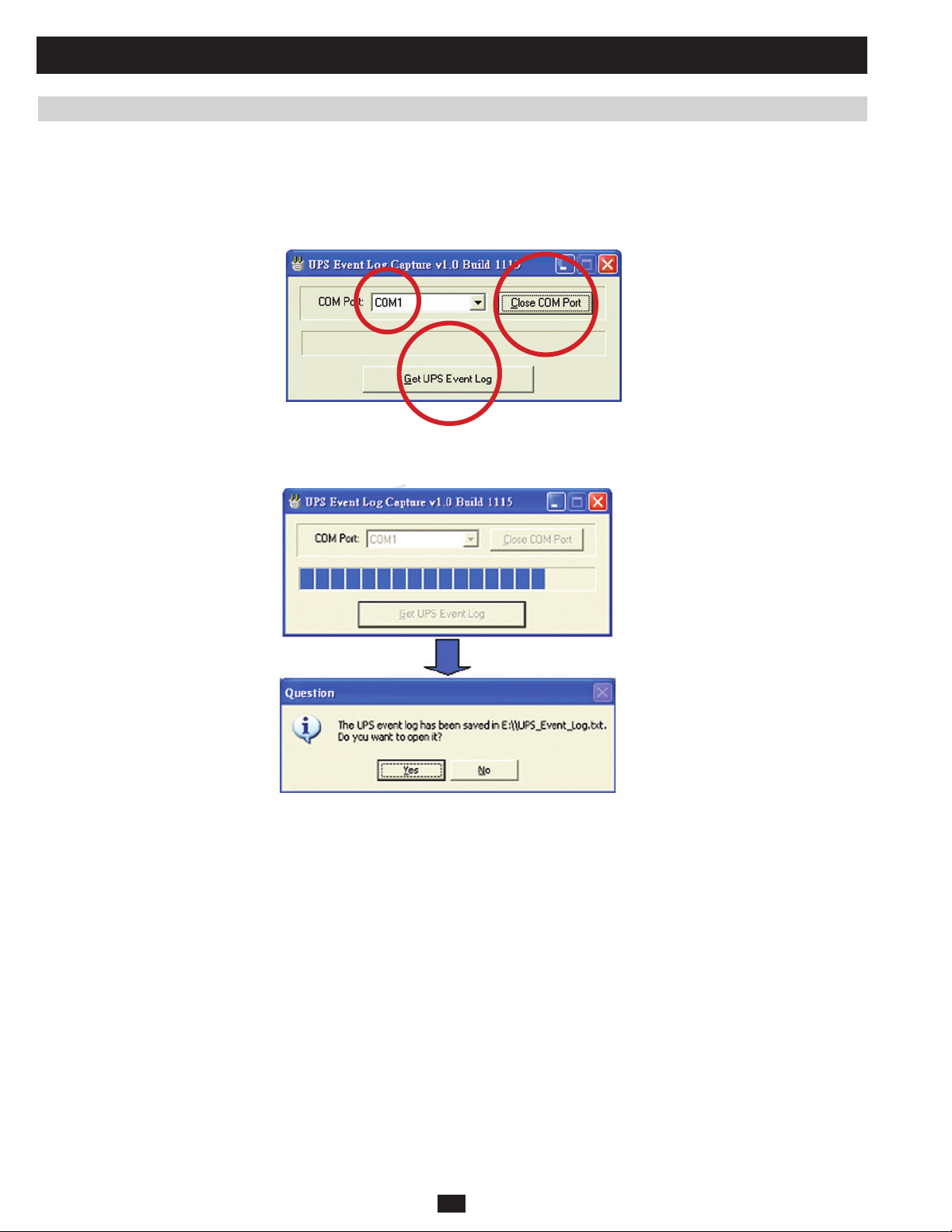

3.5 Downloading the Event Log 90

4 Internal Battery 91

4.1 Installing and Removing Internal Batteries 92

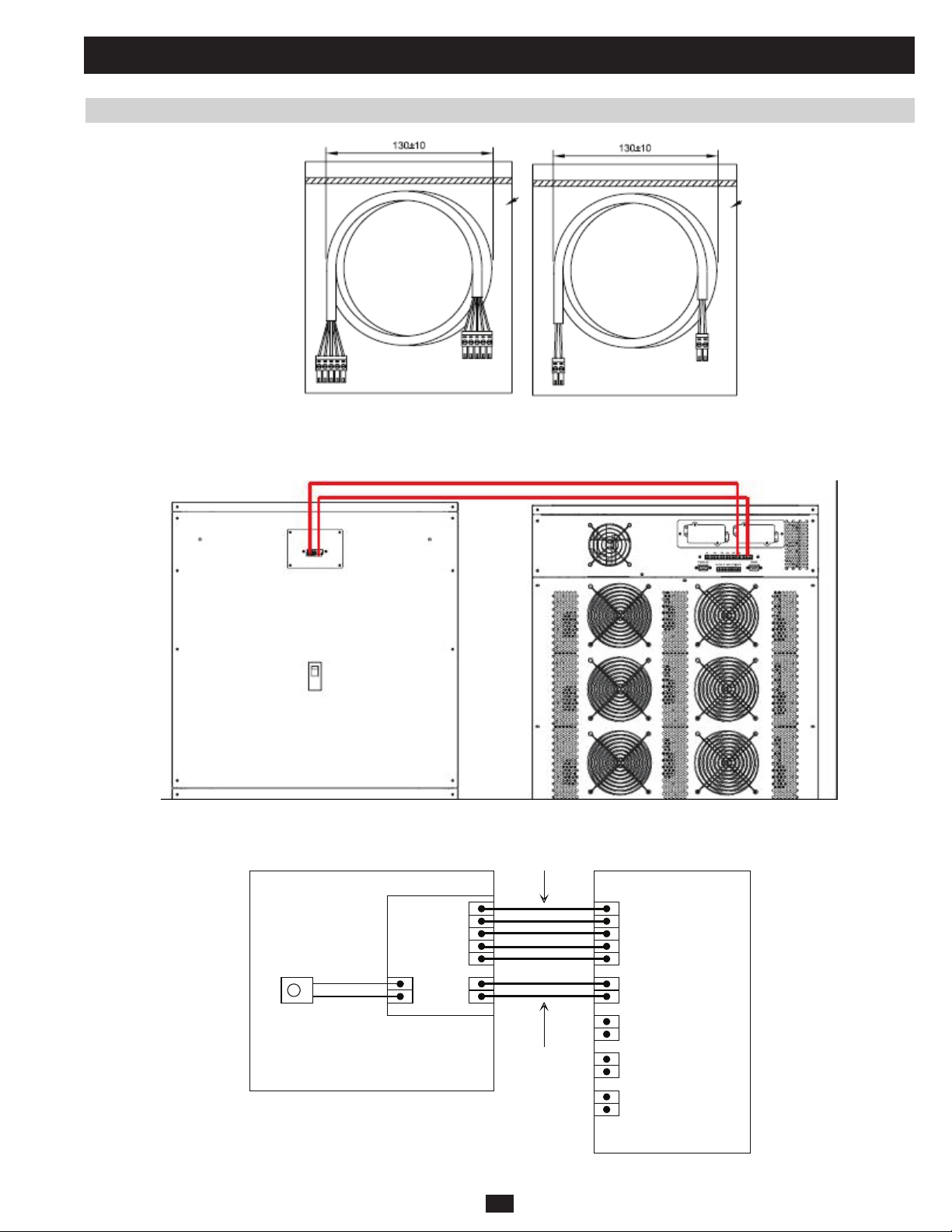

4.2 Battery Cabinet 95

5 Troubleshooting 98

5.1 Alarm Messages 98

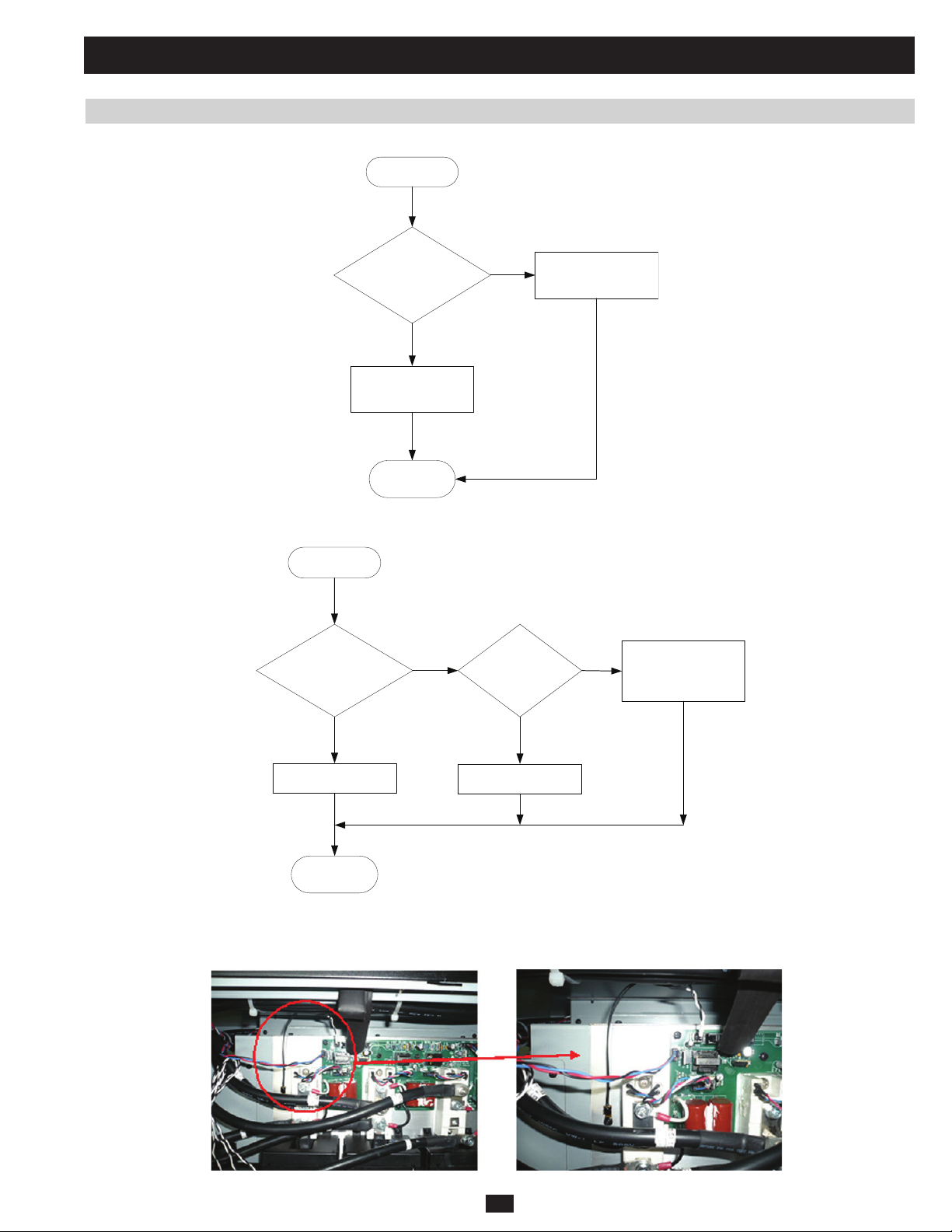

5.2 Troubleshooting Flow Charts 100

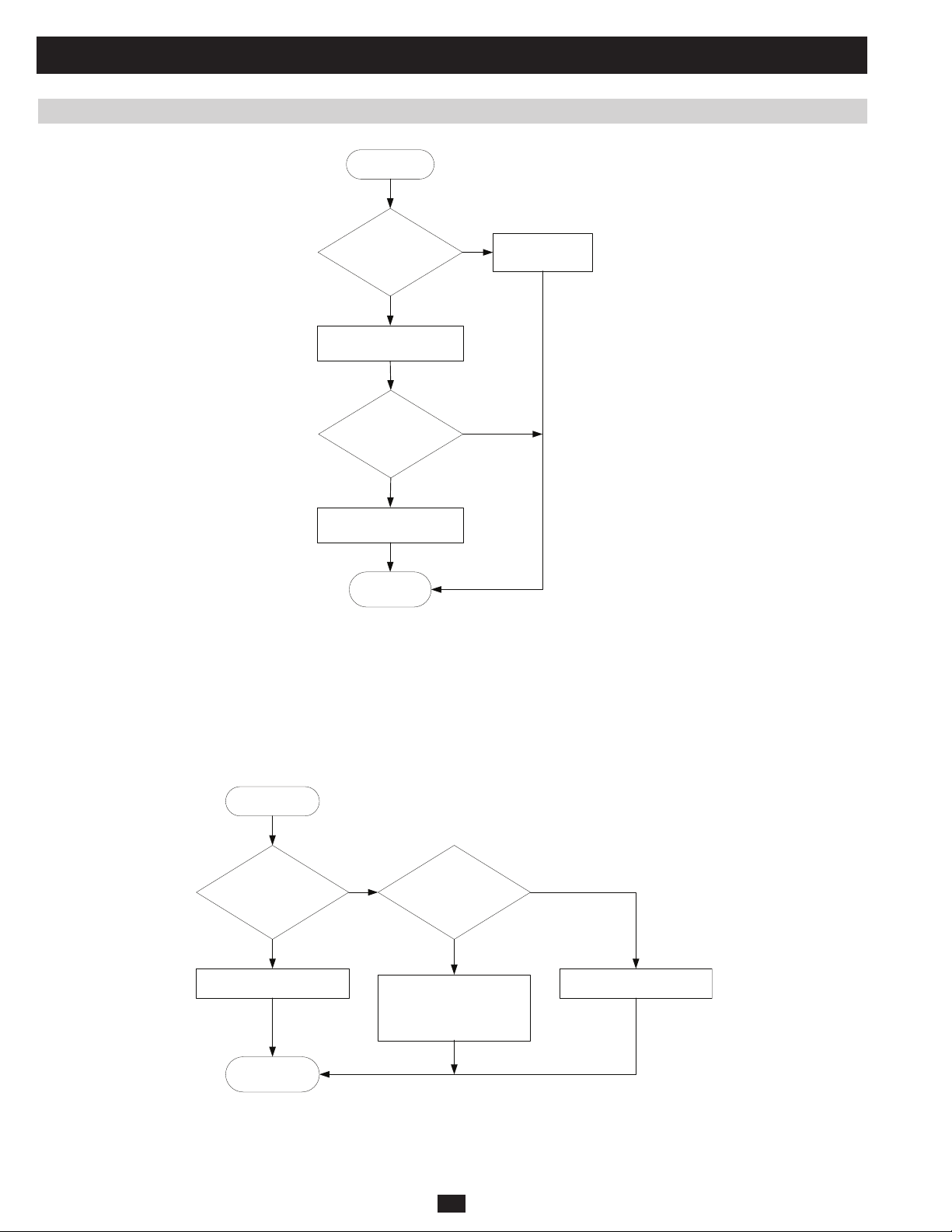

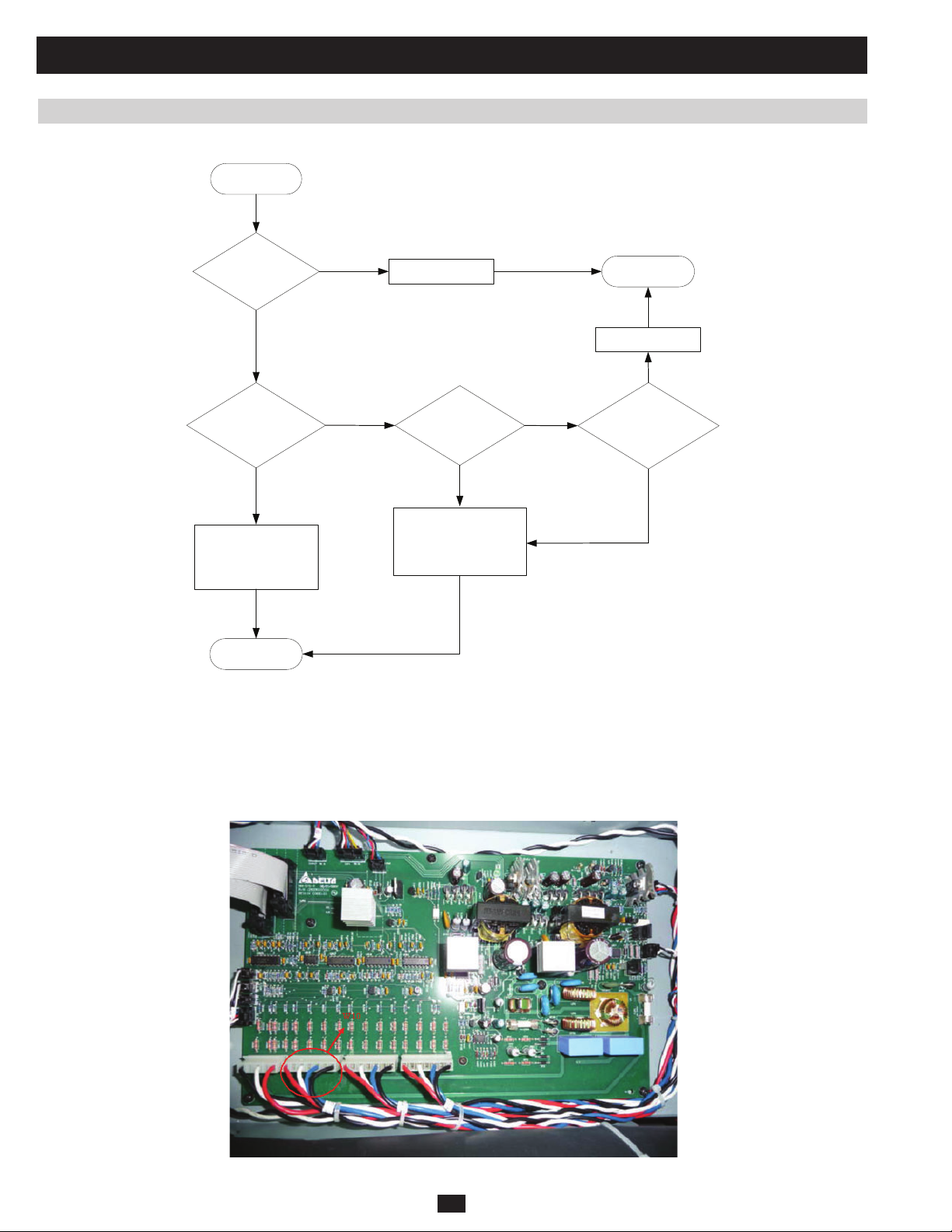

5.2.1 “MAIN VOLT/FREQ NOK” 100

5.2.2 “MAIN SEQUENCE NOK” 101

5.2.3 “BYPASS VOLT/FREQ NOK” 102

5.2.4 “BYPASS SEQUENCE NOK” 103

5.2.5 “BYPASS STATIC SWITCH OVER TEMPERATURE” 103

5.2.6 “BYPASS STATIC SWITCH FAULT” 104

5.2.7 “BYPASS STATIC SWITCH OVERLOAD” 104

5.2.8 “UPS INTERNAL COMM ABNORMAL” 105

5.2.9 “BATTERY TEST FAIL” 106

5.2.10 “BATTERY OVER CHARGE” 106

5.2.11 “BATTERY BAD” 107

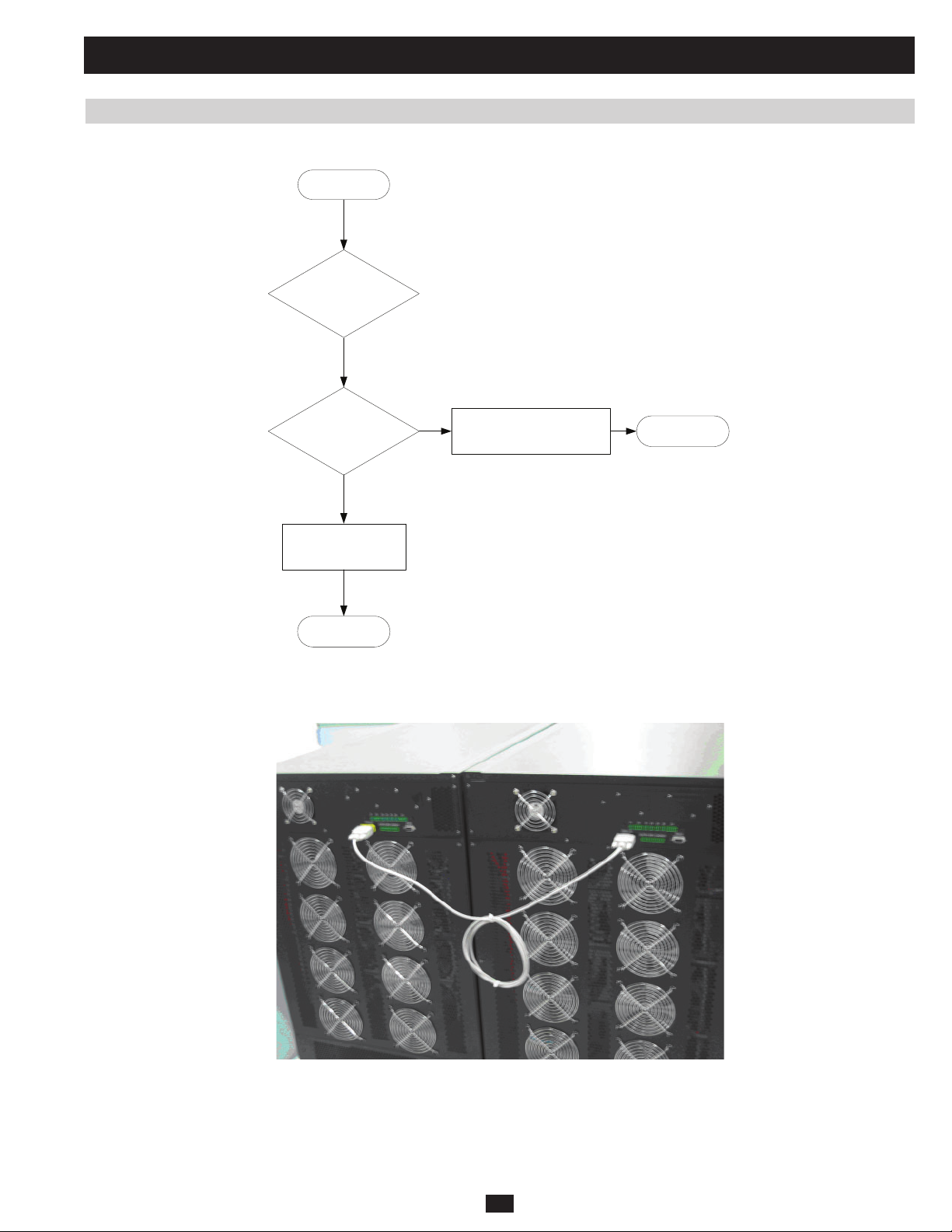

5.2.12 “BYPASS FAN FAILURE” 108

5.2.13 “TRANSFORMER OVERHEAT” 109

5.2.14 “PS OUTPUT VOLT NOK” 110

5.2.15 “PS EXT PARALLEL COMM ABNORMAL” 111

5.2.16 “PARALLEL FAILURE” 112

5.2.17 “REDUNDANCY LOSS” 113

6 Power Module 114

6.1 Failure Power Module Identify 114

6.2 Power Module Replacement 117

7 Preventive Maintenance 121

7.1 Safety Overview 121

7.2 Suggested tools and supplies 121

7.3 UPS Procedure 121

7.4 Internal Battery Procedure 122

Appendix A Service Equipment and Tools 123

Appendix B Torque Table 124

Appendix C PCB and Test Point 128

2

Page 3

1 Basic Operation

1.1 Technical Specifi cations

KX Models:

Model SU20KX SU40KX SU60KX SU80KX

(Capacity) (20kVA/16kW) (40kVA/32kW) (60kVA/48kW) (80kVA/64kW)

Input Input Voltage 220/380V, 230/400V or 240/415V AC, 3O, 4-wire + ground, wye

Voltage Regulation -25% ~ +20%

Harmonic Distortion < 5% (Full Load)

PFC (Full Load) > 0.99

Frequency 50 / 60 Hz

Frequency Tolerance 45 ~ 65 Hz

Output Output Voltage 220/380V, 230/400V or 240/415V AC, 3O, 4-wire + ground, wye

Output Frequency 50 / 60 Hz

Total Harmonic (Linear Load) ≤3%

Voltage Regulation Static ±1%

Dynamic ±7% (10% ~ 90% Linear Load)

Frequency Regulation Interior Oscillator ±0.05 Hz

Synchronized ±5%

Overload ≤125% : 10 minutes; ≤150% : 1 minute

Audible Warning Battery Backup Intermittent

UPS Abnormal Continuous

Display LED UPS Status: Normal • Bypass • Backup • Fault

LCD Input/Output • Bypass • Inverter • Frequency • Loading • Battery Voltage

UPS abnormal messages with intelligent self-diagnosis.

Interface Standard RS-232, Dry Contact

Optional SNMPWEBCARD

Others Parallel Redundancy Yes (1+1 for 2 UPS systems of the same type and capacity only.)

PRELIMINARY

EPO Standard (Local and Remote)

SRAM Event Log 500 Records

Parameter Configuration Yes

Hot Standby Installation Optional

Battery Temperature Compensation Optional

Battery Cold-Start Standard

Overall Efficiency Normal 94%

ECO 97%

Transfer Time 0 ms

Temperature 32° F ~ 104° F (0° C ~ 40° C)

Humidity (non-condensing) 90%

Noise (1 m) 65 dBA 68 dBA 70 dBA 70 dBA

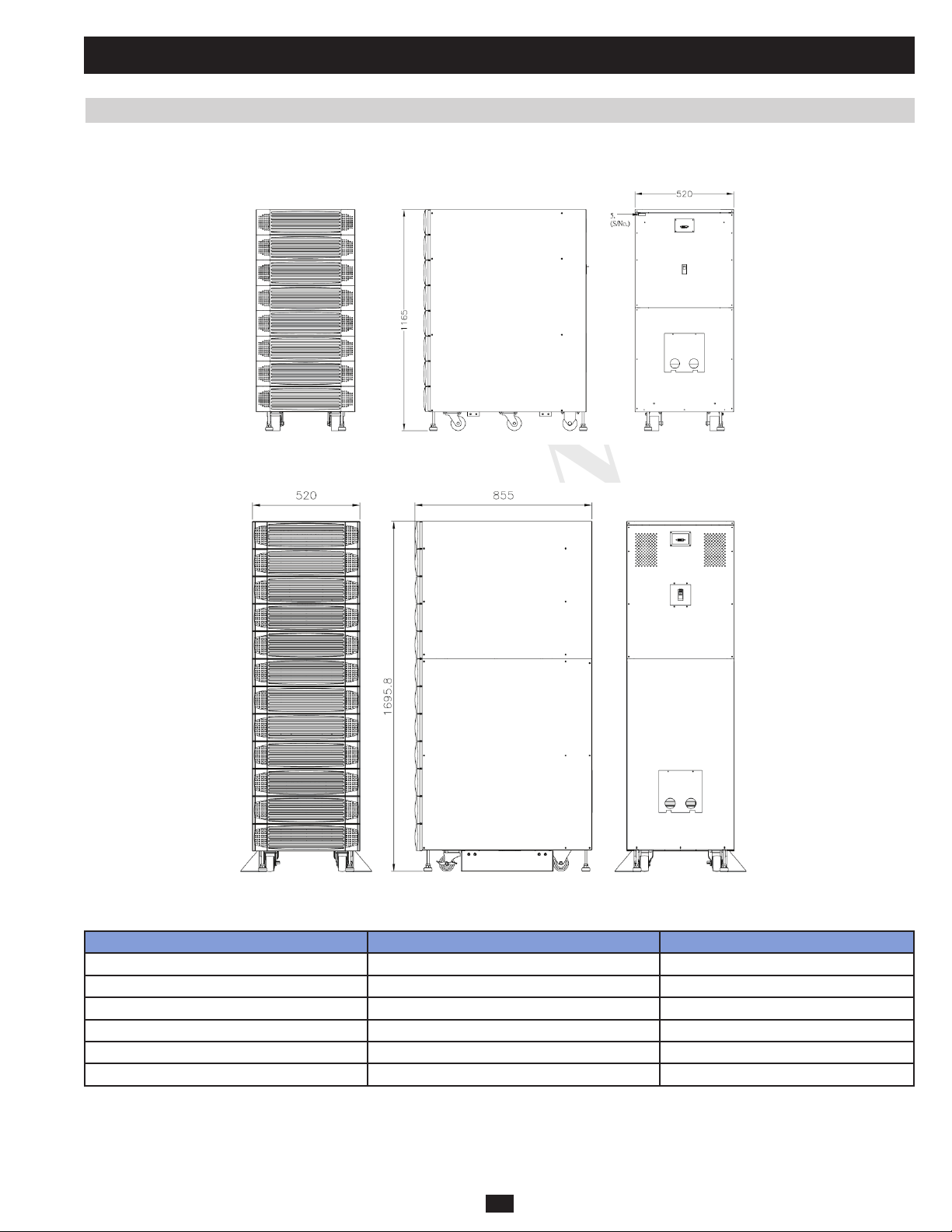

Dimensions (Power Module) Width 520 mm

Depth 850 mm

Height 1165 mm

Weight (Power Module) 267 kg* 412 kg* 210 kg 244 kg

3

Page 4

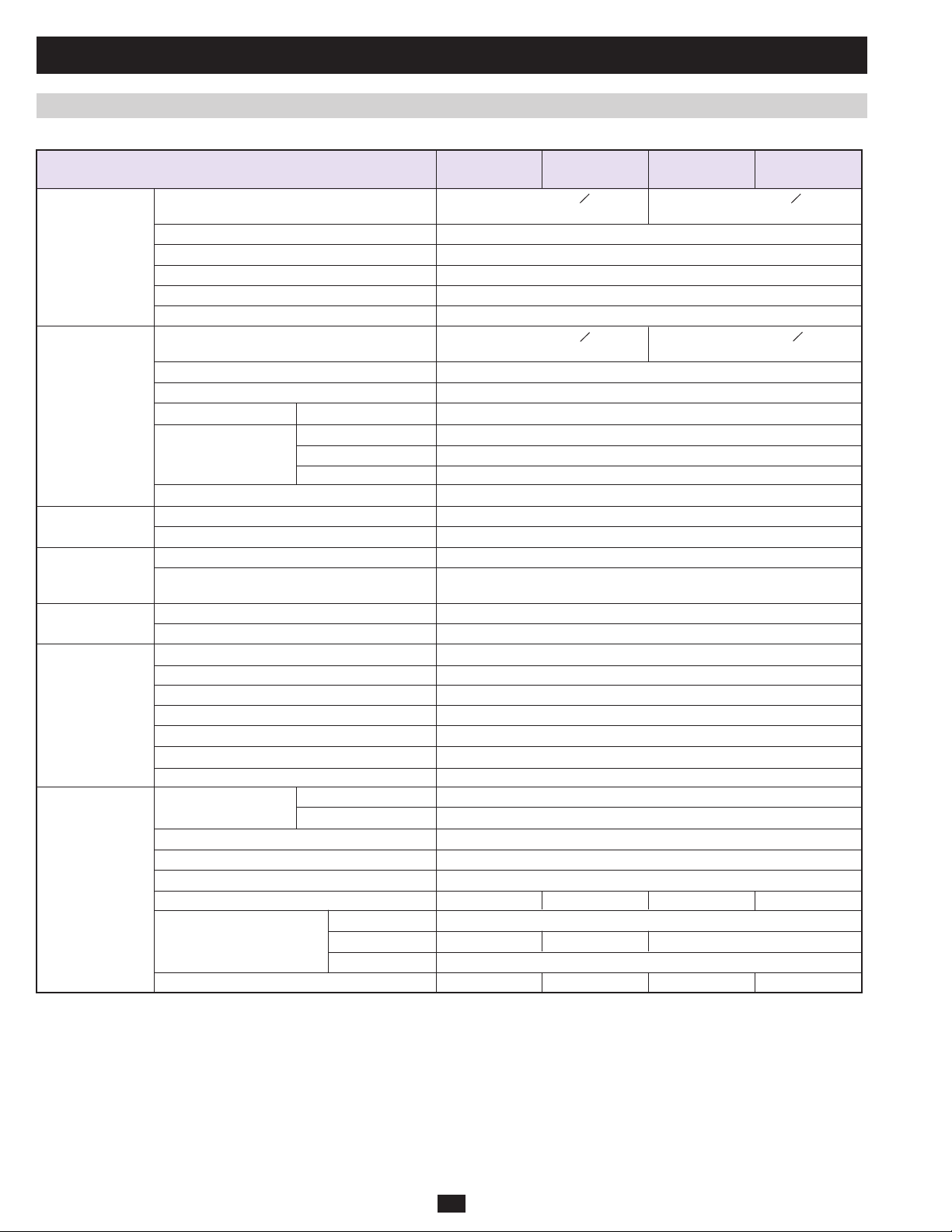

1 Basic Operation (continued)

1.1 Technical Specifi cations (continued)

K and KTV Models:

Model SU40K SU60K SU60KTV SU80KTV

(Capacity) (40kVA/32kW) (60kVA/48kW) (60kVA/48kW) (80kVA/64kW)

Input Input Voltage 120/208V AC, 3O, 277/480V AC, 3O,

4-wire + ground, wye 4-wire + ground, wye

Voltage Regulation -25% ~ +20%

Harmonic Distortion < 5% (Full Load)

PFC (Full Load) > 0.99

Frequency 50 / 60 Hz

Frequency Tolerance 45 ~ 65 Hz

Output Output Voltage 120/208V AC, 3O, 277/480V AC, 3O,

4-wire + ground, wye 4-wire + ground, wye

Output Frequency 50 / 60 Hz

Total Harmonic (Linear Load) ≤3%

Voltage Regulation Static ±1%

Frequency Regulation Dynamic ±7% (10% ~ 90% Linear Load)

Interior Oscillator ±0.05 Hz

Synchronized ±5%

Overload ≤125% : 10 minutes; ≤150% : 1 minute

Audible Warning Battery Backup Intermittent

UPS Abnormal Continuous

Display LED UPS Status: Normal • Bypass • Backup • Fault

LCD Input/Output • Bypass • Inverter • Frequency • Loading • Battery Voltage

UPS abnormal messages with intelligent self-diagnosis.

Interface Standard RS-232, Dry Contact

Optional SNMPWEBCARD

Others Parallel Redundancy Yes (1+1 for 2 UPS systems of the same type and capacity only.)

EPO Standard (Local and Remote)

SRAM Event Log 500 Records

Parameter Configuration Yes

Hot Standby Installation Optional

Battery Temperature Compensation Optional

Battery Cold-Start Standard

Overall Efficiency Normal 92%

ECO 96%

Transfer Time 0 ms

Temperature 32° F ~ 104° F (0° C ~ 40° C)

Humidity (non-condensing) 90%

Noise (1 m) 65 dBA 68 dBA 70 dBA 70 dBA

Dimensions (Power Module) Width 520 mm

Depth 850 mm 950 mm 850 mm

Height 1696 mm

Weight (Power Module) 682 kg* 534 kg 534 kg 584 kg

* With internal batteries.

PRELIMINARY

4

Page 5

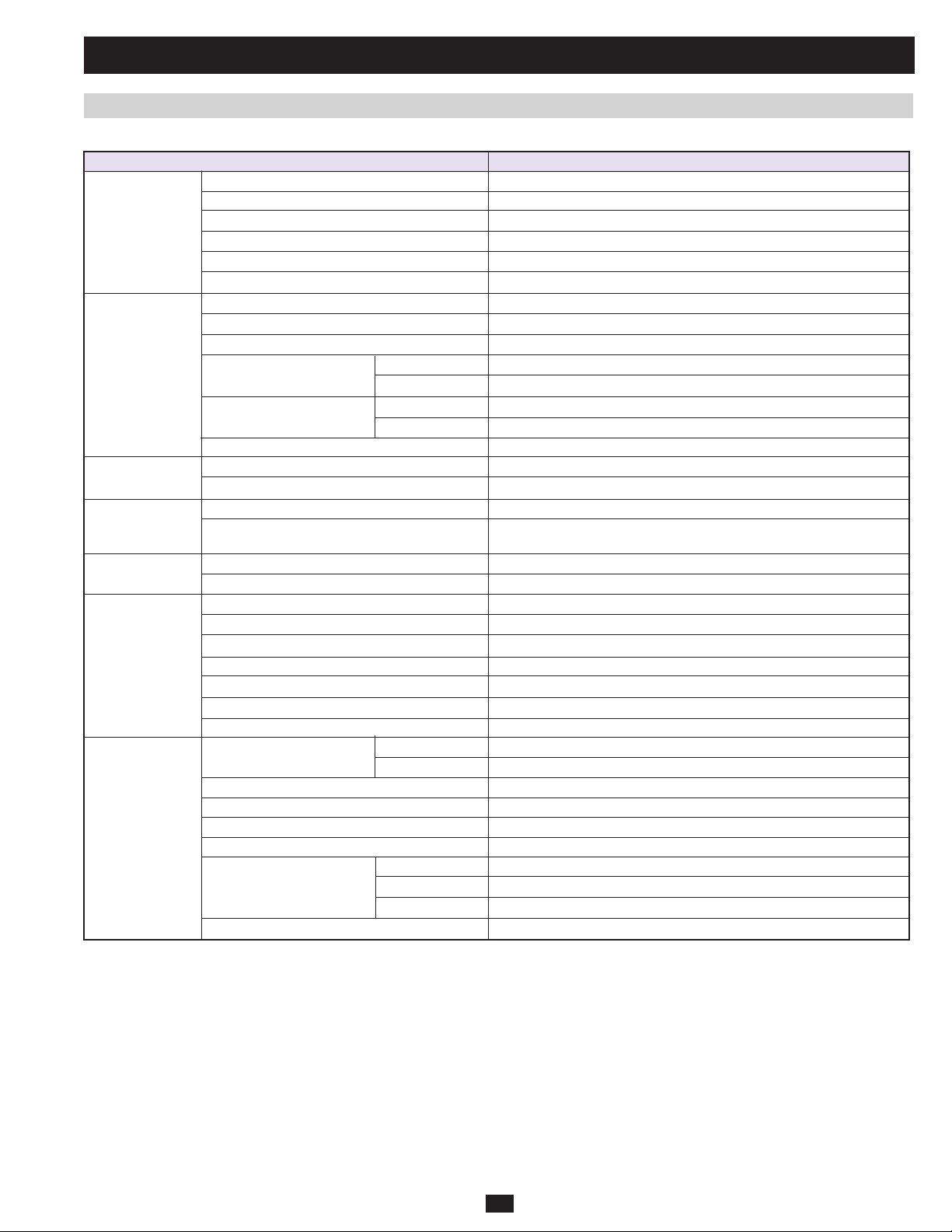

1 Basic Operation (continued)

1.1 Technical Specifi cations (continued)

SU80K Model:

Model (Capacity) SU80K (80kVA/64kW)

Input Input Voltage 120/208V AC, 3Ø, 4-wire + ground, wye

Voltage Regulation -25% ~ +20%

Harmonic Distortion < 5% (Full Load)

PFC (Full Load) > 0.99

Frequency 50 / 60 Hz

Frequency Tolerance 45 ~ 65 Hz

Output Output Voltage 120/208V AC, 3Ø, 4-wire + ground, wye

Output Frequency 50 / 60 Hz

Total Harmonic (Linear Load) ≤3%

Voltage Regulation Static ±1%

Dynamic ±7% (10% ~ 90% Linear Load)

Frequency Regulation Interior Oscillator ±0.05 Hz

Synchronized ±5%

Overload ≤125% : 10 minutes; ≤150% : 1 minute

Audible Warning Battery Backup Intermittent

UPS Abnormal Continuous

Display LED UPS Status: Normal • Bypass • Backup • Fault

LCD Input/Output • Bypass • Inverter • Frequency • Loading • Battery Voltage

UPS abnormal messages with intelligent self-diagnosis.

Interface Standard RS-232, Dry Contact

Optional SNMPWEBCARD

Others Parallel Redundancy Yes (1+1 for 2 UPS systems of the same type and capacity only.)

EPO Standard (Local and Remote)

SRAM Event Log 500 Records

PRELIMINARY

Parameter Configuration Yes

Hot Standby Installation Optional

Battery Temperature Compensation Optional

Battery Cold-Start Standard

Overall Efficiency Normal 92%

ECO 96%

Transfer Time 0 ms

Temperature 32° F ~ 104° F (0° C ~ 40° C)

Humidity (non-condensing) 90%

Noise (1 m) 70 dBA

Dimensions (Power Module) Width 520 mm

Depth 1026 mm

Height 1696 mm

Weight (Power Module) 655 kg

5

Page 6

1 Basic Operation (continued)

1.2 Features

1.2.1 Advanced Features:

• True on-line double conversion with superior IGBT inverter technology

• Low input current THD allows 1:1 generator sizing for maximum effi ciency and cost savings

• Internal N+1 power module redundancy (except for SU20KX model)

• Built-in parallel redundancy (1+1) capability for increased capacity or fault-tolerance

• Up to 80kVA capacity in a compact footprint; up to 160kVA in parallel redundancy (1+1) confi guration

• High input power factor and high effi ciency with low thermal loss and low noise

• Simplifi ed, easy-to-repair, long-life, high-availability system design

• Redundant auxiliary power and control circuits

• Dual input design with separated rectifi er and bypass input (SU20K, SU40K, SU60K, SU80K only)

• All models support external battery cabinets for extended battery backup runtime

• High-resolution LCD status screen simplifi es operation and delivers detailed operational information, including system block diagrams

1.2.2 Control Panel Features

A E F G H I J KBCD

“NORMAL” LED:• This green light illuminates to indicate that the UPS system is in online (normal) mode. The primary AC input supply is

A

present and within standard operating parameters.

“BATTERY” LED:• This amber light illuminates when the UPS system is in battery backup mode, discharging the batteries to provide power

B

C

D

E

F

G

H

I

J

K

If the UPS system is in battery backup mode when the EPO button is activated:

If the UPS system is in online (normal) mode when the EPO button is activated:

PRELIMINARY

to connected equipment. An audible alarm will also sound.

“BYPASS” LED:• This amber light illuminates when the UPS system is in bypass mode (auto bypass or manual bypass). Battery backup

power will not be available to connected equipment while the UPS system is in bypass mode, but connected equipment loads will be

supported by the bypass (reserve) power source.

“FAULT” LED:• This red light illuminates when any UPS system or input power fault occurs. Available diagnostic information will be

displayed on the LCD screen.

LCD Status Screen:• This illuminated LCD status screen displays text and graphics to indicate a wide range of UPS system operating

conditions and diagnostic data. Note: The LCD backlight will turn off after 10 minutes of inactivity. Turn on the backlight by momentarily

pressing the ON button or one of the scroll buttons.

“ESC” (Escape) Button:• Press this button to return to the previous page or menu.

Scroll Buttons (•

buttons are also used for data entry in several screens.

Enter Button (• ): Press this button to select a menu item or confirm a setting change.

ON Button:• Press and hold this button for 3 seconds to turn the UPS system’s inverter ON.

OFF Button:• Press and hold this button for 3 seconds to turn the UPS system’s inverter OFF. If the UPS system is in online (normal) mode,

it will switch to auto bypass mode. Note: If the UPS system remains off for an extended period of time, the batteries should be recharged

periodically. The UPS system should be turned on and the batteries should be recharged at least one uninterrupted 24-hour period every

3 months. Failure to recharge the batteries periodically may cause irreversible battery damage.

“EPO” (Emergency Power Off) Button:• Press this button to turn the UPS system’s output OFF and also disable bypass output.

Main output and bypass output are turned off, the alarm sounds, fans shut down after approximately one minute, and control circuitry •

remains active.

Releasing the EPO button (by pressing it again) turns off the UPS system completely, including the alarm and control circuit. Press the •

ON button for 3 seconds to restart the UPS system.

Main output and bypass output are turned off, the alarm sounds, fans and control circuitry remain active.•

Releasing the EPO button (by pressing it again) turns off the alarm and places the UPS system in auto bypass mode. Press the ON button •

for 3 seconds to return the UPS system to online (normal) mode.

and ): Press these buttons to move the cursor up or down and navigate the control panel menus and screens. These

6

Page 7

1 Basic Operation (continued)

1.2 Features (continued)

1.2.3 Front and Rear Panel Features

A

B

C

E F

D

G

H

I

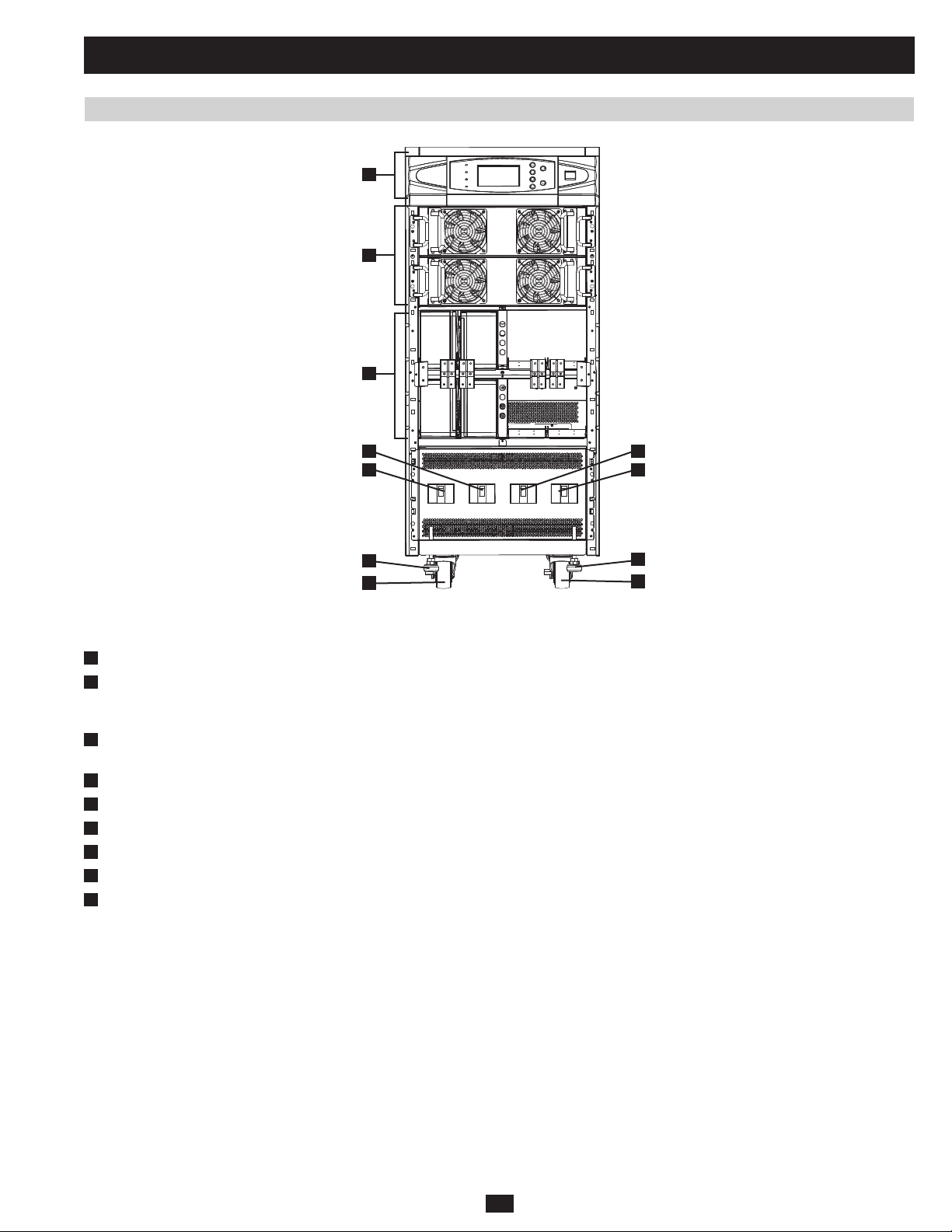

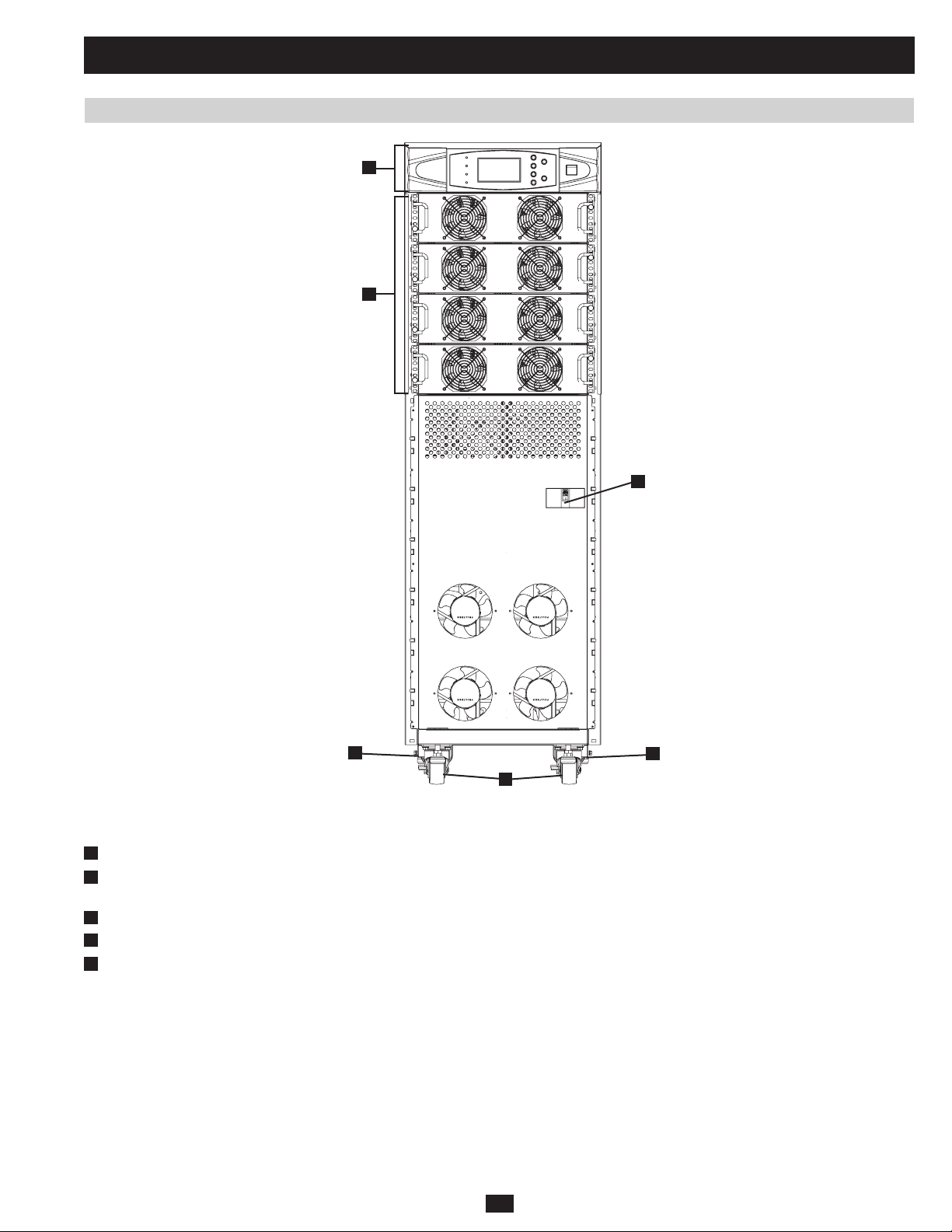

Fig 1.2.3a SU40KX front

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

PRELIMINARY

Control Panel:• The control panel allows the operator to monitor and control the UPS system. (See section 1.2.2 for more information.)

A

Internal Power Modules:• 20kVA internal power modules can be replaced in the field without powering down connected equipment loads. The

B

number of internal power modules varies by model. The internal power modules are capable of N+1 redundancy in SU40KX, SU60KX and

SU80KX models.

Internal Battery Pack Compartment (SU20KX and SU40KX only; shown without batteries):• Internal batteries must be connected by a

C

qualified electrician. (See section 4 for more information.)

Output Circuit Breaker Switch (Q4):• Controls AC output power.

D

Manual Bypass Circuit Breaker Switch (Q3):• Controls AC input power to the UPS system during manual bypass operation.

E

Bypass Input Circuit Breaker Switch (Q2):• Controls AC input power to the UPS system during auto bypass operation.

F

Main Input Circuit Breaker Switch (Q1):• Controls AC input power to the UPS system during online (normal) operation.

G

Levelers:• The levelers provide long-term support for the UPS system.

H

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

I

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

H

I

7

Page 8

1 Basic Operation (continued)

1.2 Features (continued)

J

L

H

I I

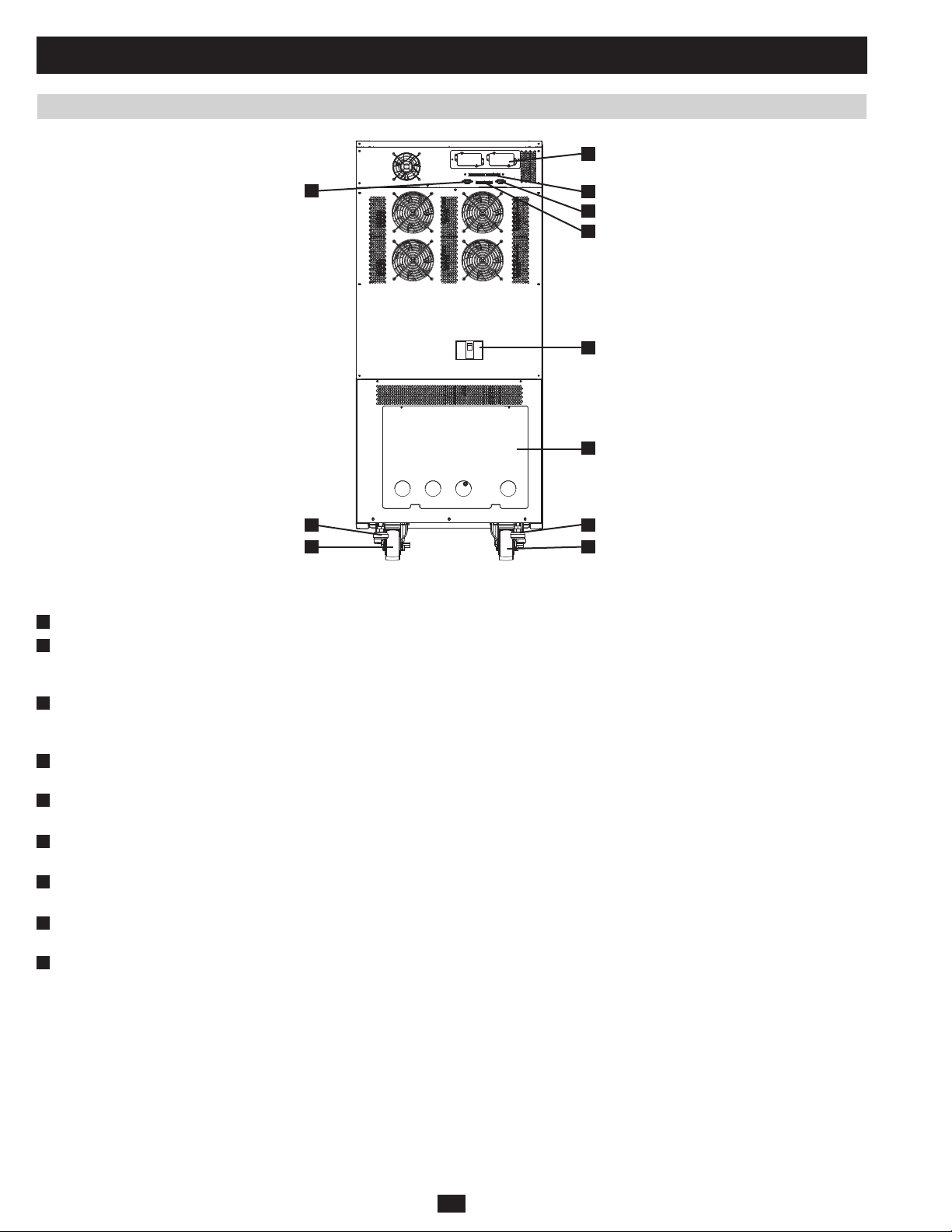

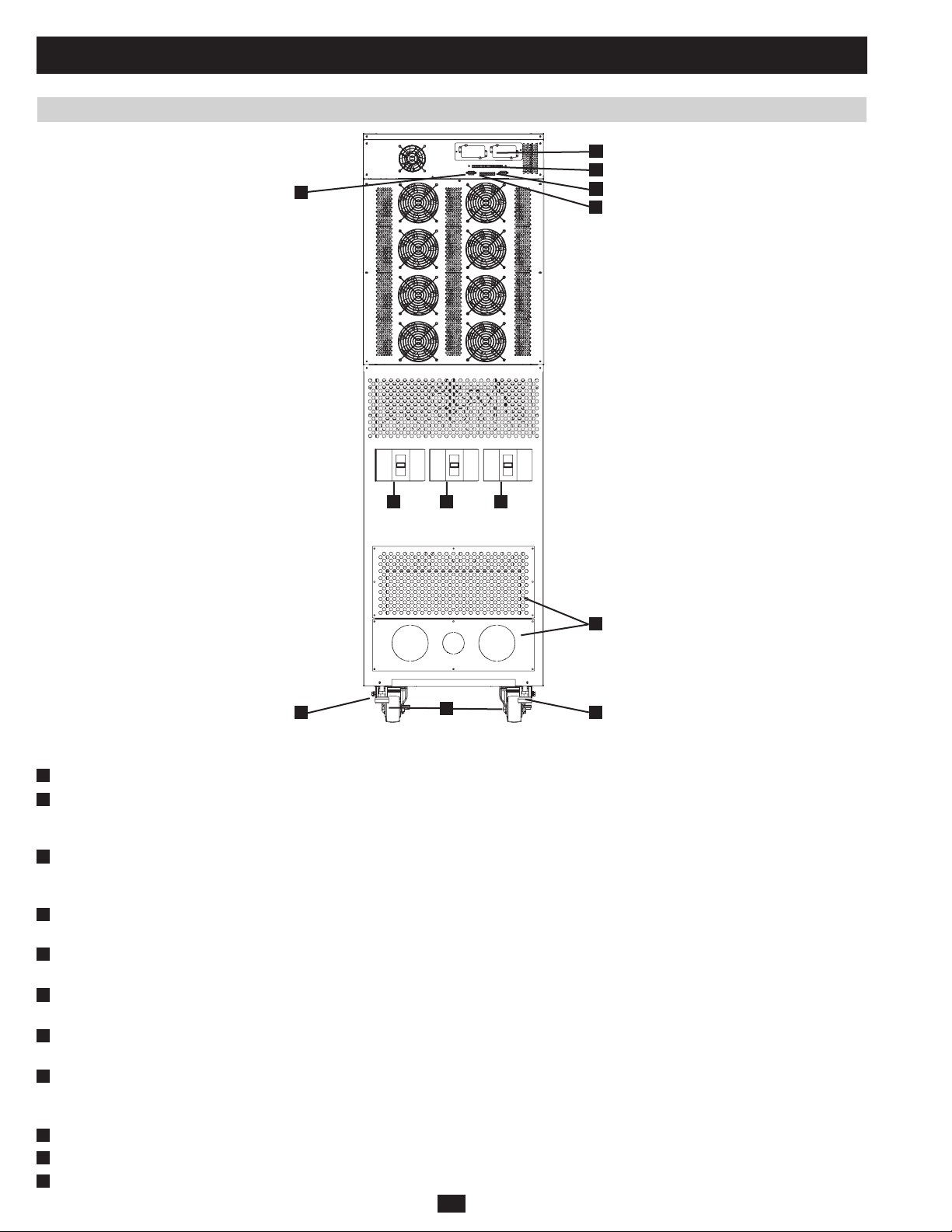

Fig 1.2.3b SU40KX rear

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

Levelers:• The levelers provide long-term support for the UPS system.

H

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

I

J

K

L

M

N

O

P

PRELIMINARY

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

Accessory Slot:• Remove the cover panel to install a Tripp Lite SNMPWEBCARD accessory. The SNMPWEBCARD accessory provides an

Ethernet interface for the UPS system and enables remote monitoring and control via SNMP, Web browser or telnet. Call +1 773 869 1234 for

more information about the SNMPWEBCARD accessory.

RS-232 Serial Communications Port:• This DB9 port connects the UPS system to compatible workstations or servers, enabling automatic

shutdown during extended blackouts and monitoring of operating and power conditions.

Parallel Redundancy Port:• This DB9 port connects the UPS system to another UPS system of identical type and capacity for use in a parallel

redundancy (1+1) configuration. (See sections 1.5 and 1.8 for more information.)

Input Dry Contact Interface:• This interface receives dry contact signals that allow the UPS system to receive commands and monitor

external battery conditions.

Output Dry Contact Interface:• This interface allows the UPS system to send information via dry contact communications. (See section 3.3

for more information.)

Internal Battery Circuit Breaker Switch (SU20KX and SU40KX only):• Controls the input/output power of the UPS system’s internal

batteries.

Terminal Block Cover:• Remove the terminal block cover to access the UPS system’s input, bypass input, external battery cabinet, output and

grounding connection terminals. Wiring conduits pass through the circular knockouts in the terminal block cover. (See section 1.8 for more

information, including a detailed diagram of the terminal block.)

M

K

N

O

P

H

8

Page 9

1 Basic Operation (continued)

1.2 Features (continued)

A

B

C

E

D

F

G

PRELIMINARY

H H

Fig 1.2.3c SU40K front

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

Control Panel:• The control panel allows the operator to monitor and control the UPS system. (See section 1.2.2 for more information.)

A

Internal Power Modules:• 20kVA internal power modules can be replaced in the field without powering down connected equipment loads. The

B

number of internal power modules varies by model. The internal power modules are capable of N+1 redundancy.

Internal Battery Pack Compartment (SU40K only):• Internal batteries must be connected by a qualified electrician. (See section 4 for more

C

information.)

Output Circuit Breaker Switch (Q4):• Controls AC output power.

D

Manual Bypass Circuit Breaker Switch (Q3):• Controls AC input power to the UPS system during manual bypass operation.

E

Bypass Input Circuit Breaker Switch (Q2):• Controls AC input power to the UPS system during auto bypass operation.

F

Main Input Circuit Breaker Switch (Q1):• Controls AC input power to the UPS system during online (normal) operation.

G

Levelers:• The levelers provide long-term support for the UPS system.

H

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

I

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

I

9

Page 10

1 Basic Operation (continued)

1.2 Features (continued)

L

J

M

K

N

O

P

PRELIMINARY

H

Fig 1.2.3d SU40K rear

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

H

Levelers:• The levelers provide long-term support for the UPS system.

I

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

J

Accessory Slot:• Remove the cover panel to install a Tripp Lite SNMPWEBCARD accessory. The SNMPWEBCARD accessory provides an

Ethernet interface for the UPS system and enables remote monitoring and control via SNMP, Web browser or telnet. Call (773) 869-1234 for

more information about the SNMPWEBCARD accessory.

K

RS-232 Serial Communications Port:• This DB9 port connects the UPS system to compatible workstations or servers, enabling automatic

shutdown during extended blackouts and monitoring of operating and power conditions.

L

Parallel Redundancy Port:• This DB9 port connects the UPS system to another UPS system of identical type and capacity for use in a parallel

redundancy (1+1) configuration. (See sections 1.5 and 1.8 for more information.)

M

Input Dry Contact Interface:• This interface receives dry contact signals that allow the UPS system to receive commands and monitor

external battery conditions.

N

Output Dry Contact Interface:• This interface allows the UPS system to send information via dry contact communications. (See section 3.3

for more information.)

O

Internal Battery Circuit Breaker Switch (SU40K only):• Controls the input/output power of the UPS system’s internal batteries.

Terminal Block Cover:• Remove the terminal block cover to access the UPS system’s input, external battery cabinet, output and grounding

P

connection terminals. Wiring conduits pass through the circular knockouts in the terminal block cover. (See section 1.8 for more information,

including a detailed diagram of the terminal block.)

I

H

10

Page 11

1 Basic Operation (continued)

1.2 Features (continued)

A

B

C

PRELIMINARY

D

E

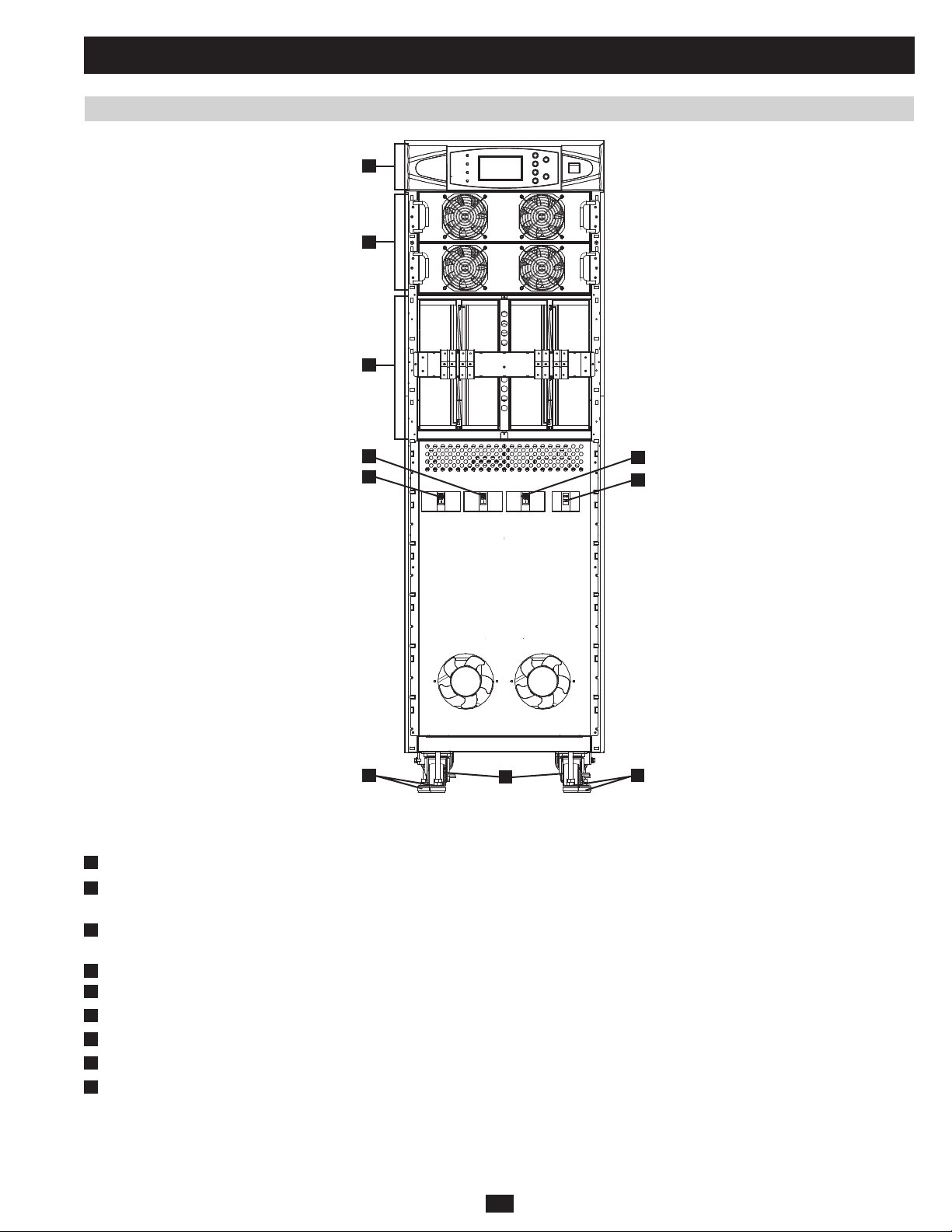

Fig 1.2.3e SU80K front

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

Control Panel:• The control panel allows the operator to monitor and control the UPS system. (See section 1.2.2 for more information.)

A

Internal Power Modules:• 20kVA internal power modules can be replaced in the field without powering down connected equipment loads. The

B

number of internal power modules varies by model. The internal power modules are capable of N+1 redundancy.

Main Input Circuit Breaker Switch (Q1):• Controls AC input power to the UPS system during online (normal) operation.

C

D

Levelers:• The levelers provide long-term support for the UPS system.

E

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

D

11

Page 12

1 Basic Operation (continued)

1.2 Features (continued)

H

F

I

G

J

L

M N

K

PRELIMINARY

D

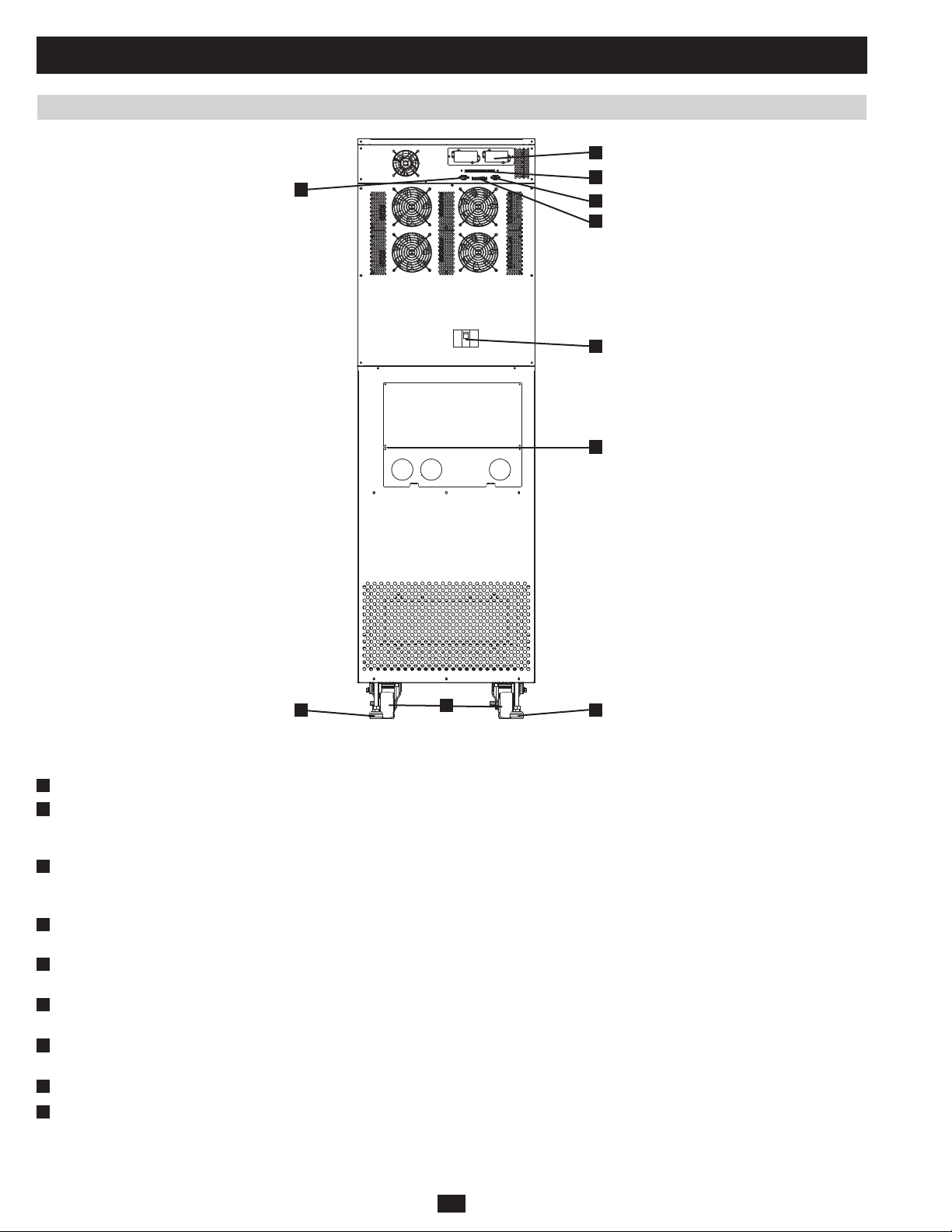

Fig 1.2.3f SU80K rear

Note: Individual models may vary from diagrams. Unit shown with breaker guard removed.

D

Levelers:• The levelers provide long-term support for the UPS system.

E

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

F

Accessory Slot:• Remove the cover panel to install a Tripp Lite SNMPWEBCARD accessory. The SNMPWEBCARD accessory provides an

Ethernet interface for the UPS system and enables remote monitoring and control via SNMP, Web browser or telnet. Call (773) 869-1234 for

more information about the SNMPWEBCARD accessory.

G

RS-232 Serial Communications Port:• This DB9 port connects the UPS system to compatible workstations or servers, enabling automatic

shutdown during extended blackouts and monitoring of operating and power conditions.

H

Parallel Redundancy Port:• This DB9 port connects the UPS system to another UPS system of identical type and capacity for use in a parallel

redundancy (1+1) configuration. (See sections 1.5 and 1.8 for more information.)

I

Input Dry Contact Interface:• This interface receives dry contact signals that allow the UPS system to receive commands and monitor

external battery conditions.

J

Output Dry Contact Interface:• This interface allows the UPS system to send information via dry contact communications. (See section 3.3

for more information.)

K

Terminal Block Cover:• Remove the terminal block cover to access the UPS system’s input, external battery cabinet, output and grounding

connection terminals. Wiring conduits pass through the circular knockouts in the terminal block cover. The UPS system includes alternate

circular knockouts in the bottom panel. (See section 1.8 for more information, including a detailed diagram of the terminal block.)

L

Bypass Input Circuit Breaker Switch (Q2):• Controls AC input power to the UPS system during auto bypass operation.

M

Manual Bypass Circuit Breaker Switch (Q3):• Controls AC input power to the UPS system during manual bypass operation.

N

Output Circuit Breaker Switch (Q4):• Controls AC output power.

E

12

D

Page 13

1 Basic Operation (continued)

1.3 Operating Principles

1.3.1 System Layout

MAIN

BATTERY

Q3

Manual Bypass

Circuit Breaker

Q2

Bypass Input

Circuit Breaker

Q1 LOAD

Main Input

Circuit Breaker

Main

Manual Input

Bypass Input

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

STS

Output

Circuit Breaker

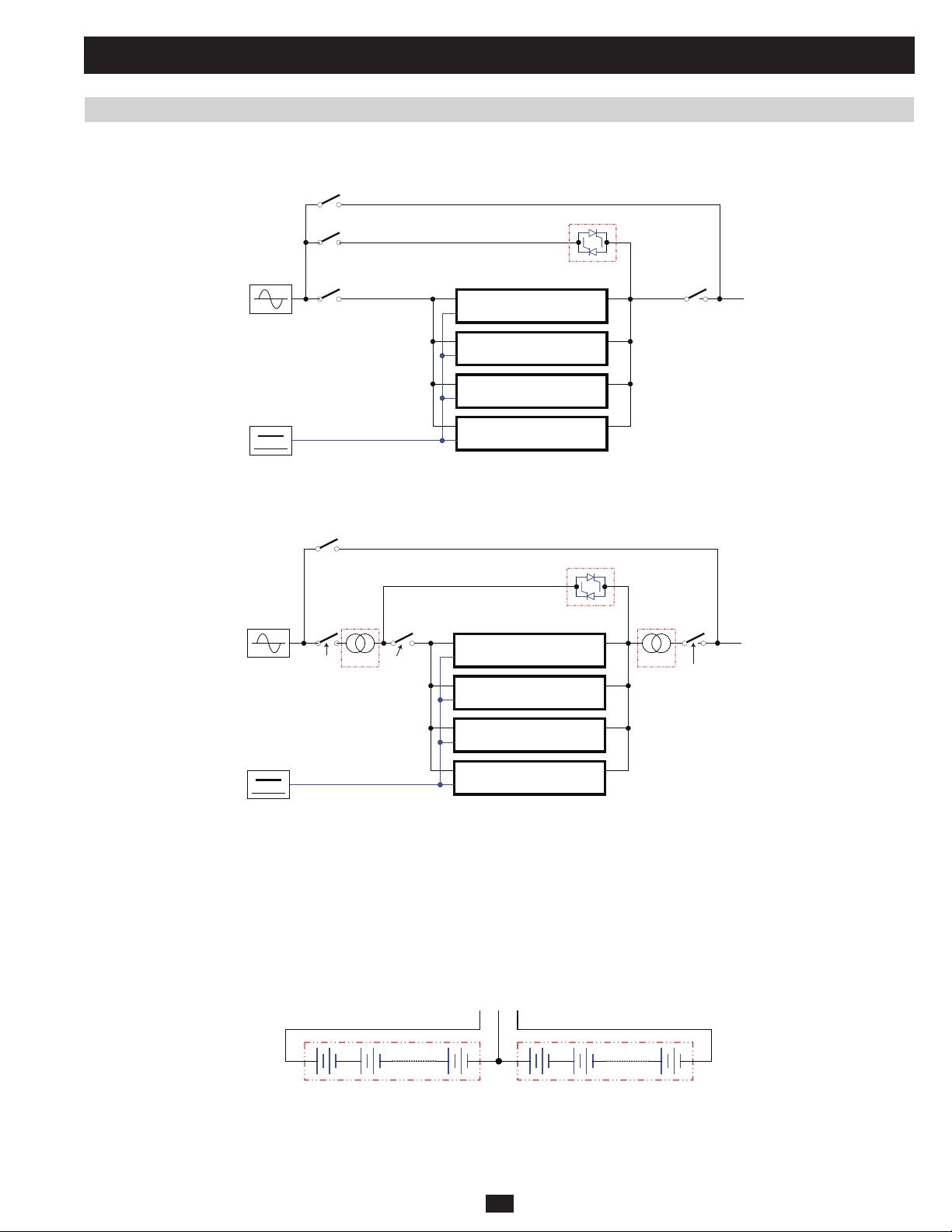

Fig 1.3.1a System Block Diagram for KX models

Q3

Manual Bypass

Circuit Breaker

Manual Input

Bypass Input

Q4

STS

Q4

Output

LOAD

PRELIMINARY

MAIN

BATTERY

Bypass Input

Circuit Breaker

XFMR XFMR

Q2

Q1

Main Input

Circuit Breaker

Fig 1.3.1b System Block Diagram for K and KTV models

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

Circuit Breaker

The SU-Series 3-Phase UPS is confi gured with 3-phase 20kVA power modules that can be paralleled for redundancy or capacity upgrades. Each

KX- (Figure 1.3.1a), K- , and KTV-series (Figure 1.3.1b) UPS includes three key functions:

1) A central bypass static switch, which causes a critical load to automatically bypass any overload or fault conditions that occur.

2) A maintenance bypass switch, which eliminates UPS faults by supplying a critical load.

3) A matched transformer, which increases and decreases the input/output voltage

1.3.2 Internal Battery Layout

B+ N B-

12Vdc, 20pcs 12Vdc, 20pcs

Fig 1.3.2a Battery Strings

An internal battery pack (number of packs vary by model) supplies the UPS system with battery backup power. Each internal battery pack consists

of 40 12Vdc VRLA batteries arranged in two strings: one string of 20 positive batteries (black cable) and one string of 20 negative batteries (red

cable). The two strings are connected by a neutral (N) point (Figure 1.3.2a).

13

Page 14

1 Basic Operation (continued)

1.3 Operating Principles (continued)

1.3.3 Power Module Layout

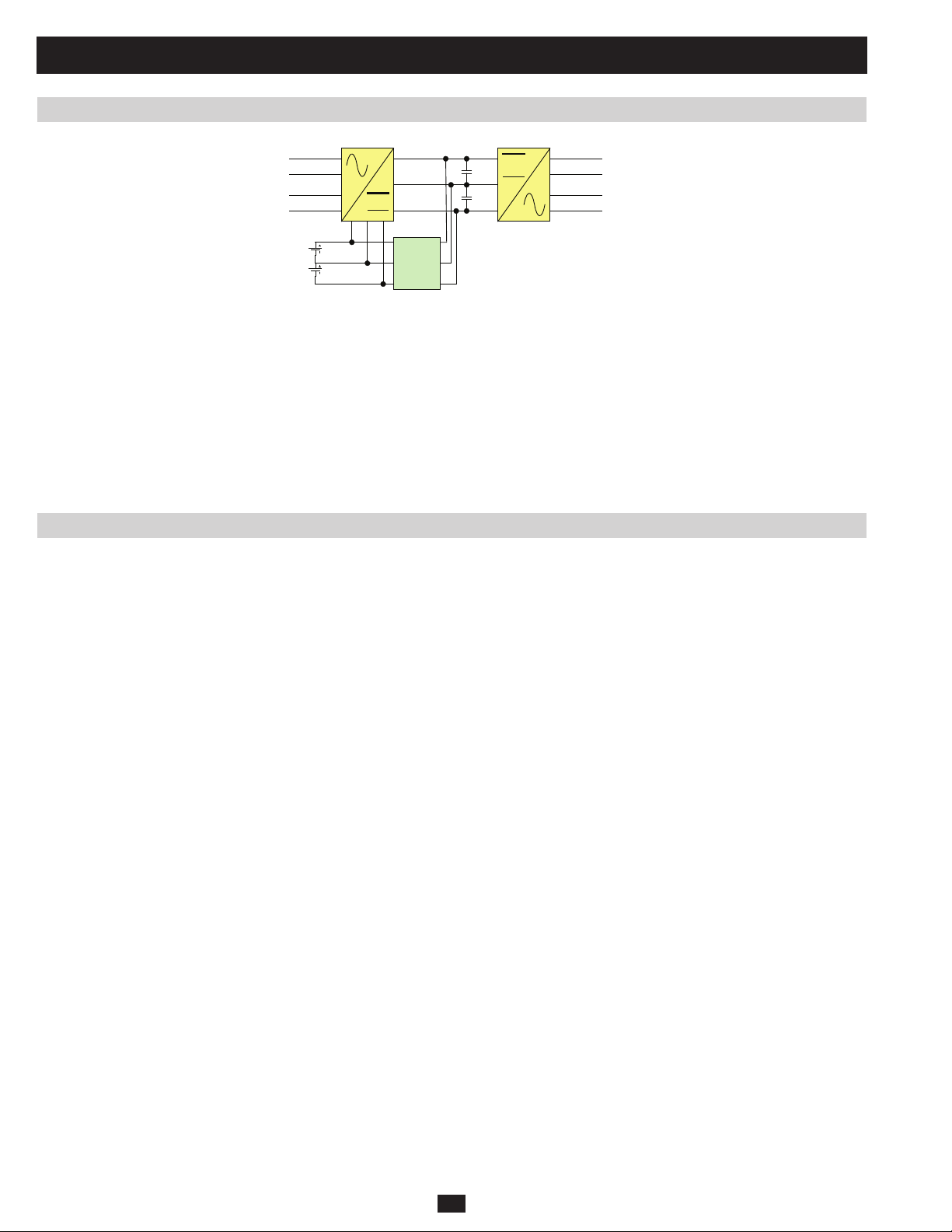

The SU-Series 3-Phase UPS double-conversion power modules consist of three components (Figure 1.3.3a):

1) An AC/DC converter

2) An AC/DC inverter

3) A charger

The power module’s 3-phase, 4-wire input runs A/C current through the AC/DC converter to generate regulative dual DC bus (±370Vdc). During

backup mode, this current is provided by battery power.

The dual DC bus then runs through the AC/DC inverter to generate a pure sine wave of AC power (3-phase, 4-wire). The DC bus also charges the

dual battery strings by running current through the charger. Each power module has a maximum charge current of 5 A.

R

S

INPUT OUTPUT

T

N

BATTERY

Fig 1.3.3a Power Module Block Diagram

Charger

U

V

W

N

1.4 Opening and Closing the Unit

[PENDING]

PRELIMINARY

14

Page 15

1 Basic Operation (continued)

1.5 Operating Modes

This section provides a basic description of the UPS system’s operating modes. For more information about switching between operating modes,

refer to Section 1.6 – Start-Up, Shutdown and Bypass.

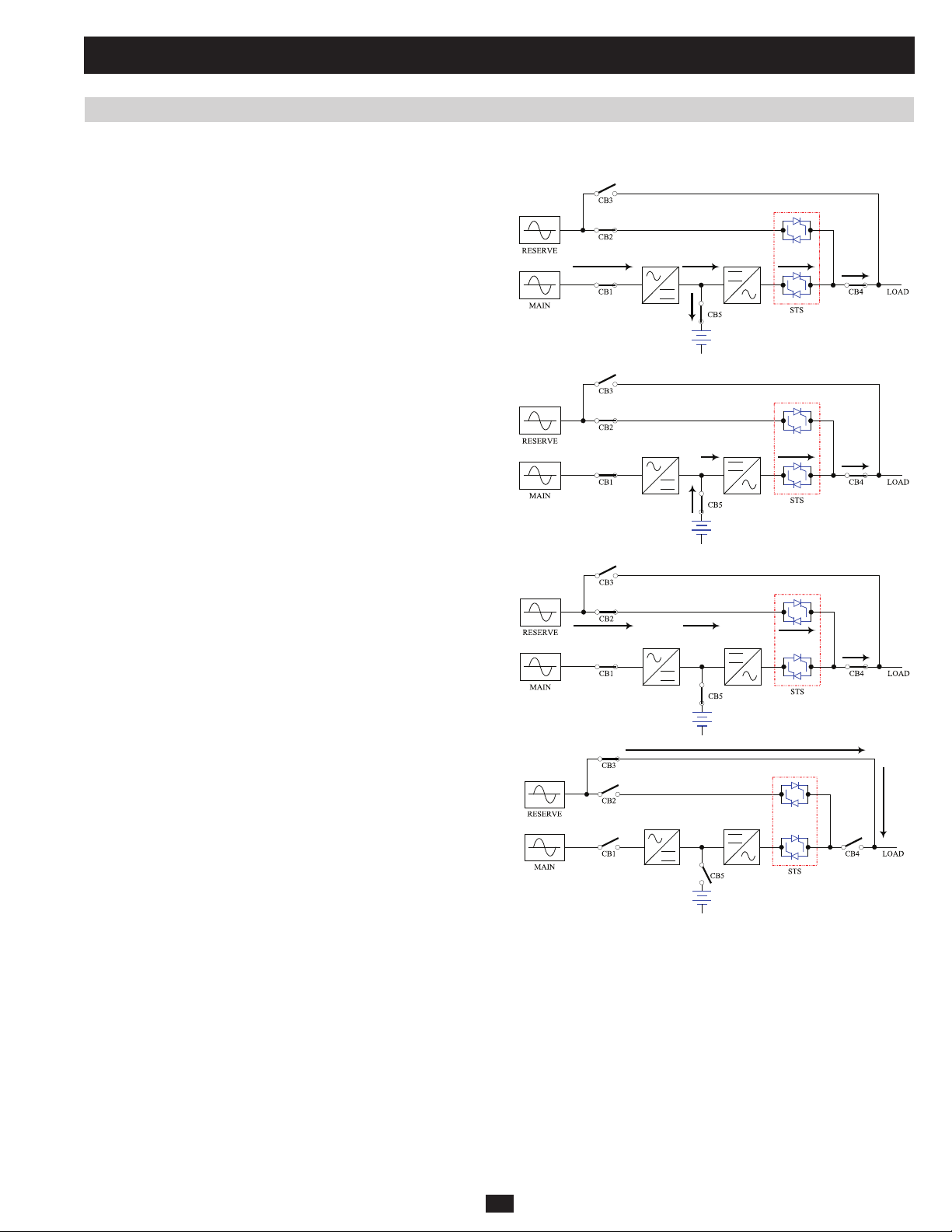

1.5.1 Online (Normal) Mode (Single UPS)

In online (normal) mode, the UPS system’s rectifier converts incoming

AC utility power to DC power that charges the batteries and supplies the

inverter. The inverter transforms the DC power to precision-regulated,

pure sine wave AC power that supports the operation of connected

equipment. This dual conversion technology isolates connected

equipment from all power problems and ensures that connected

equipment receives ideal power at all times.

1.5.2 Battery Backup Mode (Single UPS)

When a blackout or other extreme power event occurs, the UPS system

automatically switches from normal mode to battery backup mode. The

UPS system’s batteries (internal and/or external) provide emergency DC

power to the inverter. The inverter transforms the DC power to precisionregulated, pure sine wave AC power that supports the operation of

connected equipment.

1.5.3 Auto Bypass Mode (Single UPS)

If the inverter malfunctions due to excessive temperature, overload,

output short circuit, abnormal voltage or battery problems, the inverter

will shut down. If the UPS system detects a bypass (reserve) power

source that conforms to normal parameters, then the UPS system

automatically switches to auto bypass mode to continue supplying power

PRELIMINARY

to connected equipment. When all problems are eliminated, the UPS

system switches back to online (normal) mode automatically.

1.5.4 Manual Bypass Mode (Single UPS)

If UPS system maintenance or repair is required, you can bypass

the UPS system and enable bypass (reserve) power manually. After

confirming that bypass (reserve) power is present, switch the UPS

system into manual bypass mode. This allows service technicians to

perform maintenance or repair jobs without interrupting the flow of AC

power to connected equipment. Warning: The UPS system must be

de-energized completely before performing maintenance or repair

by shutting it down completely after switching it to manual bypass

mode.

15

Page 16

1 Basic Operation (continued)

1.5 Operating Modes (continued)

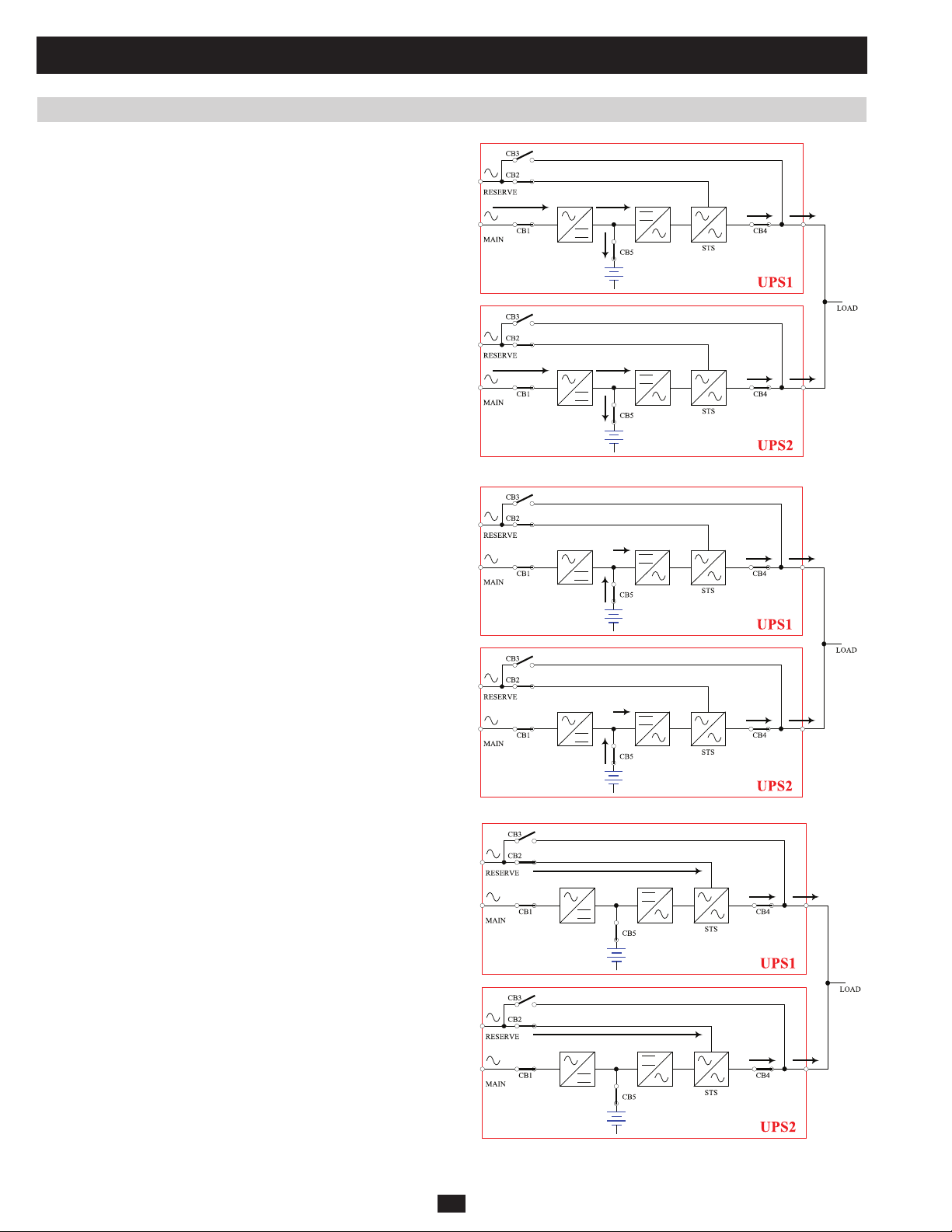

1.5.5 Online Mode (Parallel UPS)

Parallel redundancy (1+1) provides UPS system redundancy or increased

total capacity. Under parallel redundancy, the total load is shared by

two UPS systems. If one of the UPS systems malfunctions, the total

connected equipment load is supported by the remaining UPS system. If

the total load exceeds the capacity of the remaining UPS system, it will

switch to auto bypass mode.

1.5.6 Battery Backup Mode (Parallel UPS)

Similar to on battery backup mode for a single UPS system (Section

1.5.2), except the total connected equipment load is shared by the parallel

(1+1) UPS systems.

PRELIMINARY

1.5.7 Auto Bypass Mode (Parallel UPS)

Similar to auto bypass mode for a single UPS system (Section 1.5.3),

except with parallel (1+1) UPS systems.

16

Page 17

1 Basic Operation (continued)

1.5 Operating Modes (continued)

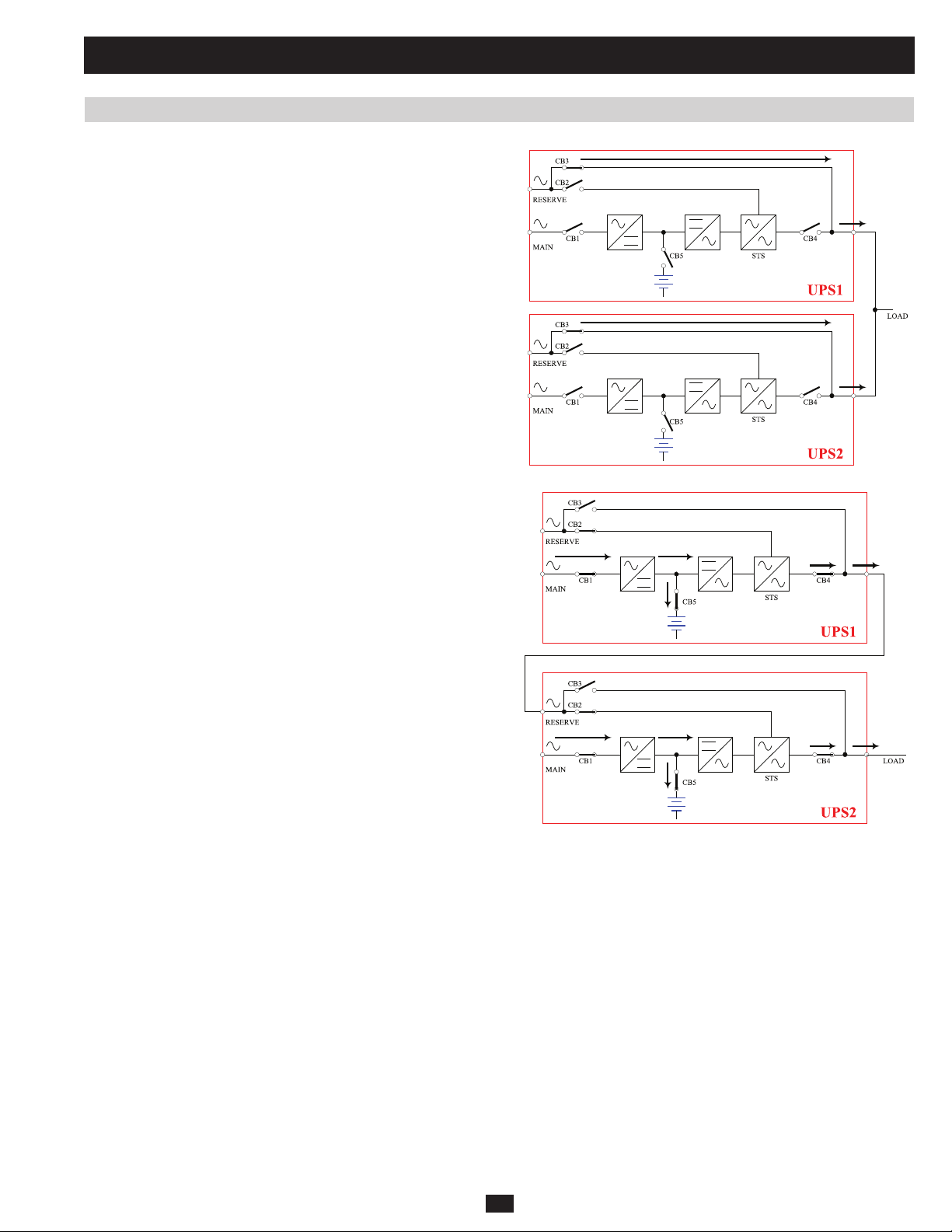

1.5.8 Manual Bypass Mode (Parallel UPS)

Similar to manual bypass mode for a single UPS system (Section 1.5.4),

except with parallel (1+1) UPS systems. Note: Both UPS systems must

be switched into manual bypass mode.

1.5.9 Hot Standby Mode (Parallel UPS)

For added fault-tolerance, the redundant UPS system acts as the bypass

(reserve) power source for the main UPS system.

PRELIMINARY

17

Page 18

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass

Warning: The UPS system’s output voltage is set at 220/380V by default. If you require output voltage of 230/400V or 240/415V, you must

change the UPS system’s output voltage by accessing the output setup menu described in Section 10-9 of the owner’s manual. You must

place the UPS system in bypass mode before changing the output voltage. Do not connect your equipment to the UPS system’s output until

you have set the proper parameters.

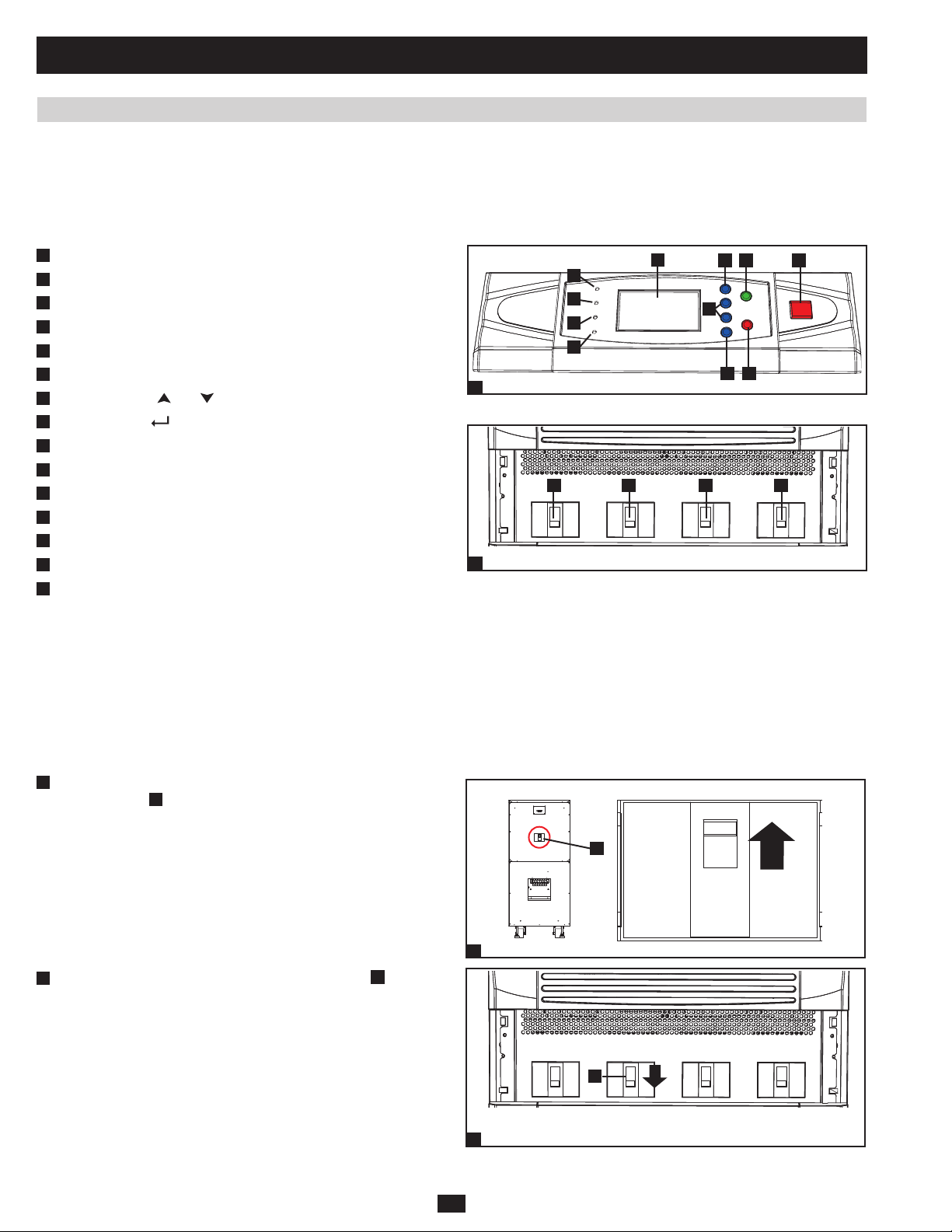

1.6.1 Control Panel and Breaker Diagrams

“NORMAL” LED•

A

“BATTERY” LED•

B

C

“BYPASS” LED•

“FAULT” LED•

D

LCD Status Screen•

E

F

“ESC” (Escape) Button•

Scroll Buttons (•

G

H

Enter Button (• )

I

ON Button•

OFF Button•

J

K

“EPO” (Emergency Power Off) Button•

Output Circuit Breaker Switch•

L

M

Manual Bypass Circuit Breaker Switch•

N

Bypass Input Circuit Breaker Switch•

Main Input Circuit Breaker Switch•

O

and )

A

B

C

D

1

L

Output

2

Circuit Breaker Switches (UPS System Front Panel)

E

Control Panel

M

Manual

Bypass

G

N

Bypass

Input

F

I

J

H

O

Main

Input

K

1.6.2 Preliminary Checklist (Single UPS)

• All circuit breaker switches should be off, including the breaker of the external battery cabinet (if present).

PRELIMINARY

• Confi rm that no voltage potential exists between Neutral and Ground.

• Confi rm that the input power source matches the rating (voltage, frequency and phase) of the UPS system.

Note: After start-up, the UPS system will perform a brief self-test and display the results on the LCD screen. After a successful self-test, the UPS

system will provide AC power to the connected equipment load.

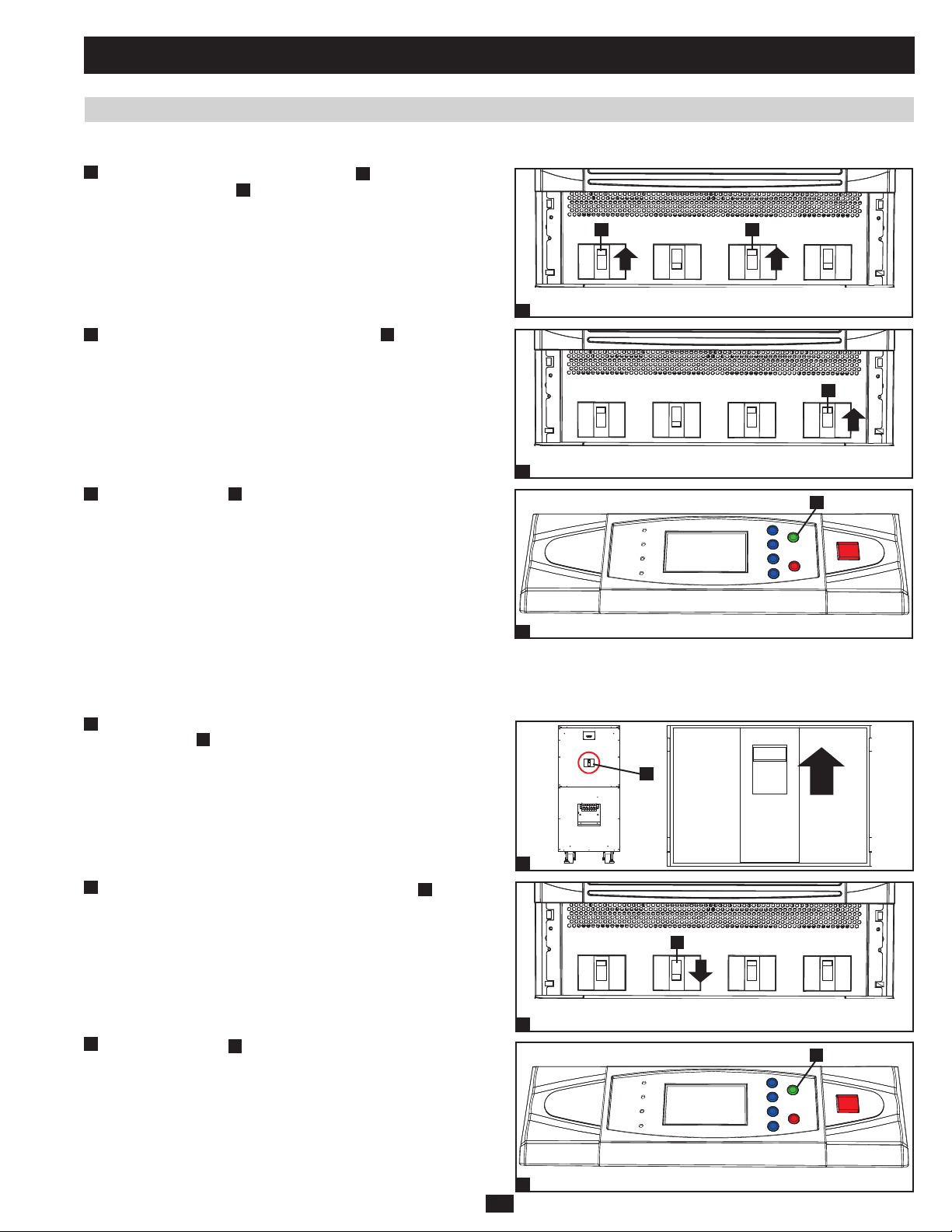

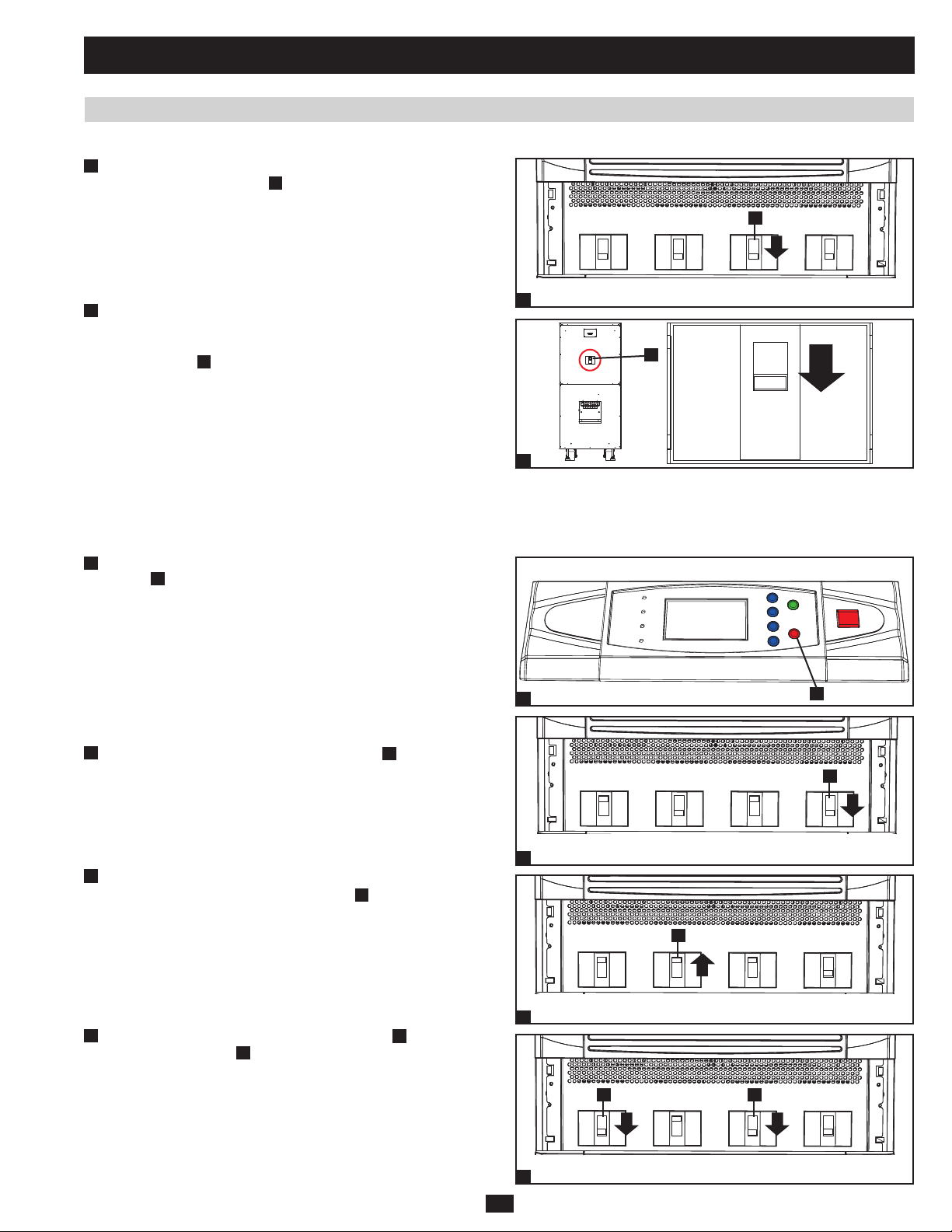

1.6.3 Standard Start-Up Procedure (Single UPS)

1

If there is an external battery cabinet connected, switch on the •

circuit breaker

Confirm that the manual bypass circuit breaker switch •

2

A

of the external battery cabinet.

A

is off.

A

1

18

A

Output

2

Manual

Bypass

Bypass

Input

Main

Input

Page 19

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass (continued)

1.6.3 Standard Start-Up Procedure (Single UPS) (continued)

3

Switch on the output circuit breaker switch •

circuit breaker switch B. After a brief initialization process, the

LCD screen will show “ON AUTO BYPASS”, the “BYPASS”

LED will illuminate and UPS system output will be supplied by the

bypass (reserve) power source.

A

and bypass input

A B

Output Manual

3

Switch on the main input circuit breaker switch •

4

A

. If the AC input

Bypass

Bypass

Input

Main

Input

power source is normal, the UPS system is ready for start-up.

A

5

Press the ON button •

A

for 3 seconds (until you hear a beep), then

release the button. The inverter will activate and synchronize with

Output Manual

4

Bypass

Bypass

Input

A

Main

Input

the bypass source, then automatically switch from auto bypass

(reserve) mode to online (normal) mode. The “BYPASS” LED will

darken and the “NORMAL” LED will illuminate.

5

PRELIMINARY

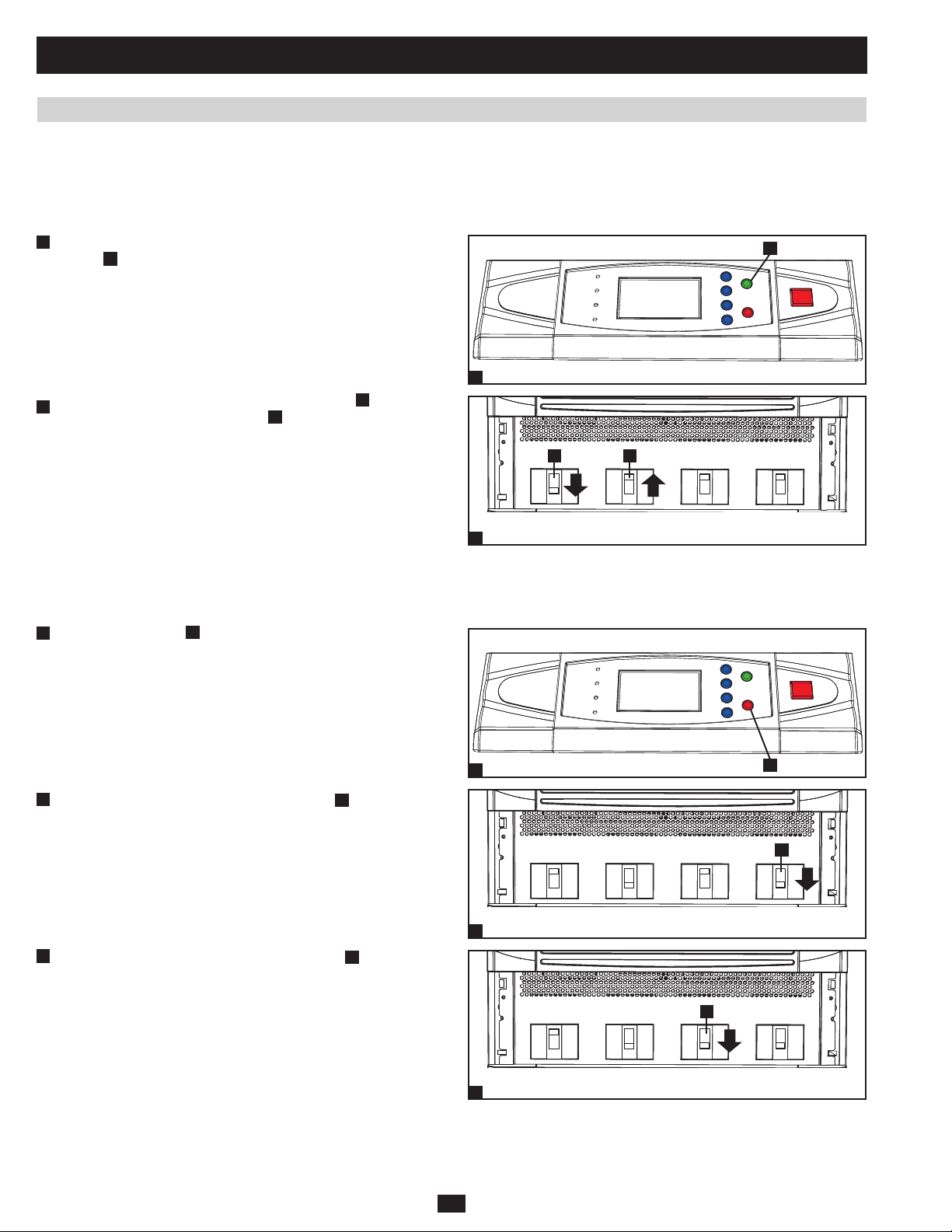

1.6.4 Battery Start-Up Procedure (Single UPS)

Note: The battery must be at least partially charged for this operation to succeed.

If there is an external battery cabinet connected, switch on the •

1

A

circuit breaker

of the external battery cabinet.

2

Confirm that the manual bypass circuit breaker switch •

3

Press the ON button •

A

for 3 seconds (until you hear a beep), then

release the button. The inverter will activate and use stored DC

battery power to supply AC power to connected equipment. The

“BATTERY” LED will illuminate.

A

is off.

19

A

1

A

Output Manual

2

3

Bypass

Bypass

Input

Input

A

Main

Page 20

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass (continued)

1.6.5 Manual Bypass Procedure (Single UPS)

Warning: Placing the UPS system in manual bypass will disable the inverter and power all loads from the manual bypass (reserve) source,

but the UPS system will still be energized. Before performing maintenance or repair on the UPS system, shut down and de-energize the

UPS system completely by following the steps in Section 1.6.6. Although connected equipment loads will be powered by the bypass (reserve)

power source, they will not receive battery backup in the event of a utility power failure.

1

When the UPS system is in online (normal) mode, press the ON •

A

button

for 3 seconds (until you hear a beep), then release the

button. The inverter will automatically switch to bypass mode and

the “BYPASS” LED will illuminate.

Switch on the manual bypass circuit breaker switch •

2

off the output circuit breaker switch

B

.

A

, then switch

1

AB

A

Output Manual

2

Bypass

Bypass

Input

Main

Input

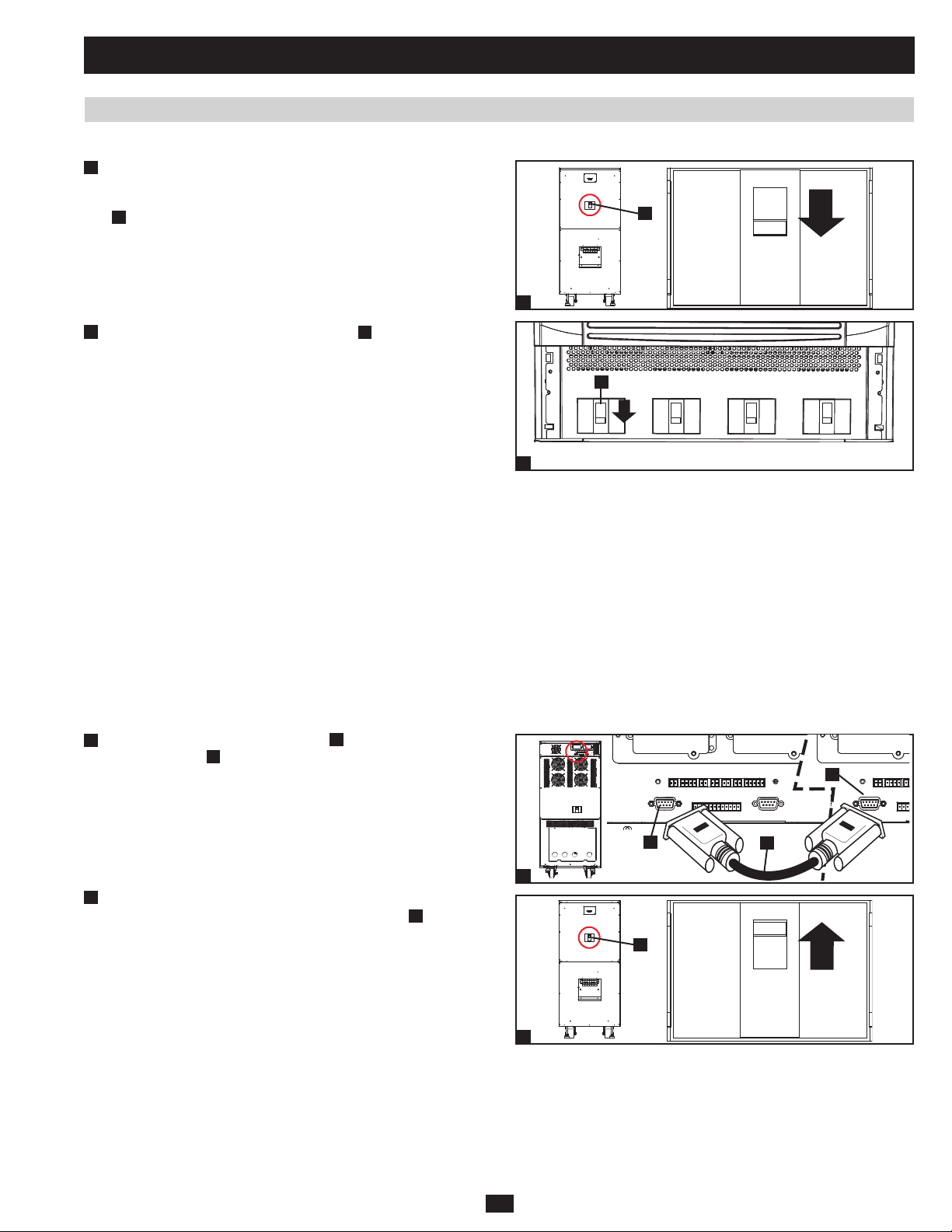

1.6.6 Shutdown Procedure (Single UPS)

Warning: The UPS system shutdown procedure will eliminate the AC power output for all loads. Before shutdown, confirm that all loads

are turned off or place the UPS system in manual bypass mode to keep loads powered by the reserve (bypass) power source.

Press the OFF button •

1

release the button. If the UPS system is in online (normal) mode, it

PRELIMINARY

A

for 3 seconds (until you hear a beep), then

will switch to bypass mode. If the UPS system is in battery backup

mode, the inverter will shut down and AC output power will be

interrupted.

1

2

Switch off the main input circuit breaker switch •

3

Switch off the bypass input circuit breaker switch •

A

.

Output

2

A

.

Manual

Bypass

Bypass

Input

A

A

Main

Input

20

A

3

Output

Manual

Bypass

Bypass

Input

Main

Input

Page 21

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass (continued)

1.6.6 Shutdown Procedure (Single UPS) (continued)

4

Confirm that the UPS system is off and that all main output circuits •

are off. If the UPS system is connected to an external battery

cabinet, turn off the external battery cabinet circuit breaker switch

A

.

A

4

5

Switch off the output circuit breaker switch •

power source is normal, the UPS system is ready for start-up.

Note: If the UPS system remains off for an extended period of time, it

should be turned on periodically to allow the batteries to recharge. The

UPS system should be turned on and the batteries should be recharged

at least one uninterrupted 24-hour period every 3 months. Failure

to recharge the batteries periodically may cause irreversible battery

damage.

1.6.7 Preliminary Checklist (Parallel UPS)

Warning: Parallel redundancy requires exactly two UPS systems (1+1 redundancy ). Do not attempt to link more than two UPS systems

via parallel redundancy. The UPS systems must have the same rating and capacity for parallel redundancy installation. Attempting to link

dissimilar UPS systems will damage the UPS systems and create a serious risk of personal injury and property damage.

All circuit breaker switches should be off, including the breakers of the external battery cabinets.•

Confirm that no voltage potential exists between Neutral and Ground.•

Confirm that the input power source matches the rating (voltage, frequency and phase) of the UPS systems.•

You must use the control panel to set the parallel ID numbers of the UPS systems to be 1 and 2. See section 10-11 of the owner’s •

manual for information about setting the parallel ID numbers.

PRELIMINARY

Note: After start-up, the UPS systems will perform a brief self-test and display the results on the LCD screen. After a successful self-test, the UPS

systems will provide AC power to the connected equipment load.

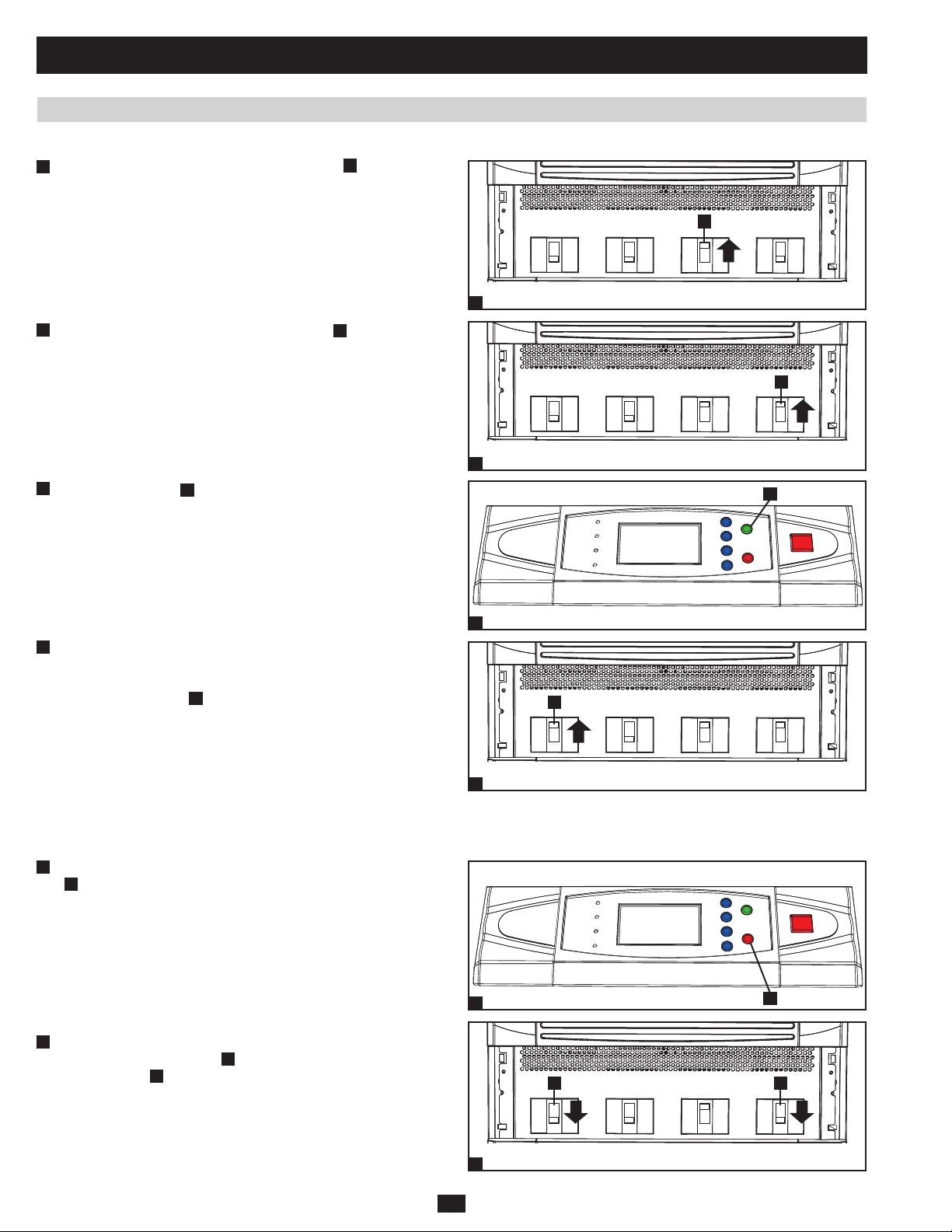

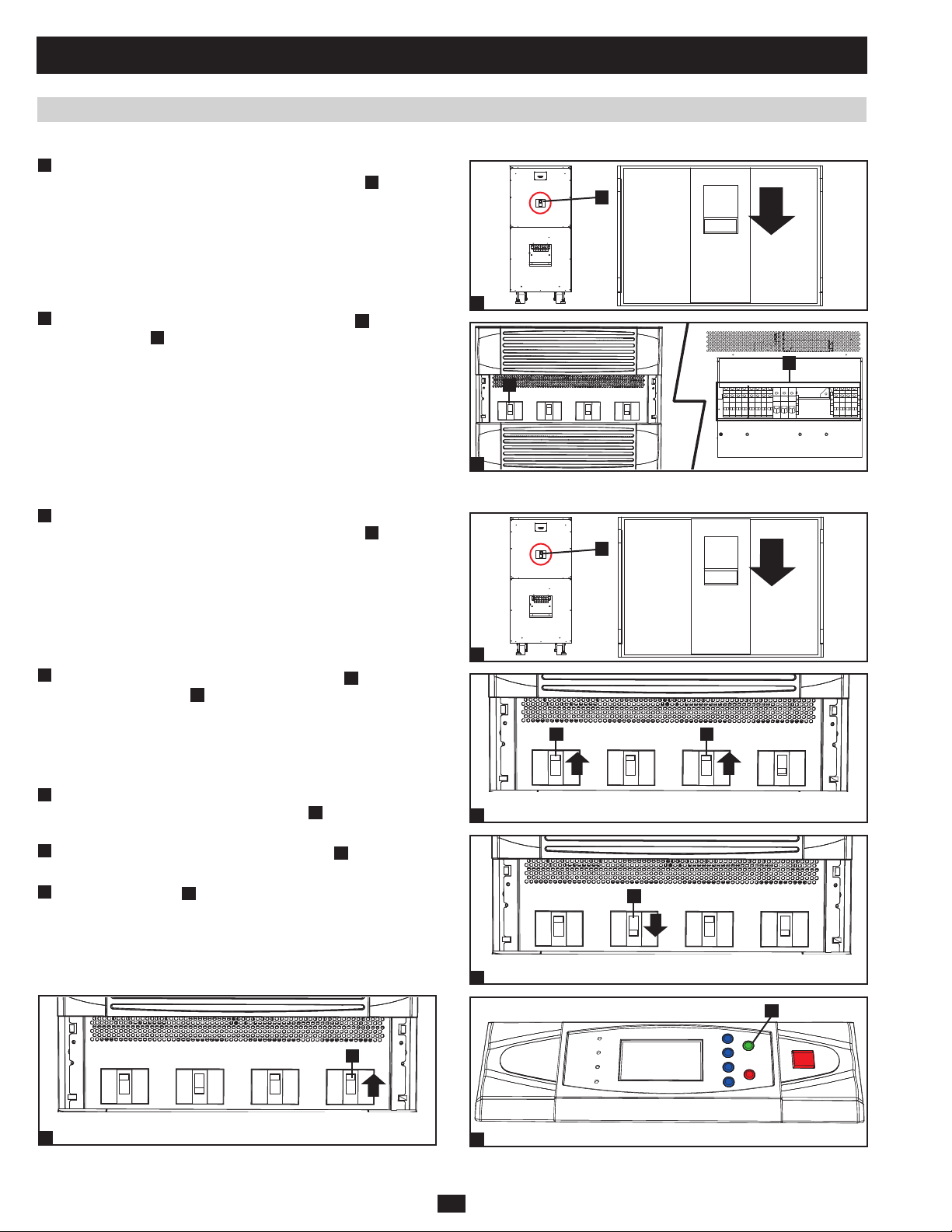

1.6.8 Start-Up Procedure (Parallel UPS)

Connect the parallel redundancy cable •

1

redundancy port B of each UPS system.

A

. If the AC input

A

to the DB9 parallel

A

Output Manual

5

Bypass

Bypass

Input

Main

Input

B

2

If the UPS systems have external battery cabinets connected, switch •

on the external battery cabinet circuit breaker switch

battery pack.

A

of each

21

B

1

A

2

A

Page 22

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass (continued)

1.6.8 Start-Up Procedure (Parallel UPS) (continued)

Switch on the bypass input circuit breaker switch •

3

UPS system. After a brief initialization process, the LCD screen

will show “ON AUTO BYPASS” and the “BYPASS” LED will

illuminate.

A

of each

A

4

Switch on the main input circuit breaker switch •

A

of each UPS

system.

5

Press the ON button •

A

of one of the UPS systems for 3 seconds

(until you hear a beep), then release the button. The inverter will

activate and synchronize with the bypass source. Press the ON

button for the other UPS system for 3 seconds (until you hear a

beep), then release the button. When the inverter of each UPS

system is operating normally, they will automatically switch from

auto bypass (reserve) mode to online (normal) mode at the same

time. The “BYPASS” LED will darken and the “NORMAL” LED

will illuminate.

6

Check the output voltage of each UPS system. The phase deviation •

PRELIMINARY

between each UPS system should be less than 5V. If the phase

deviation is within the acceptable range, switch on the output

circuit breaker switch

A

of each UPS system. Note: For more

information on checking the output voltage of each UPS system,

see section 10-6 of the owner’s manual.

Output Manual

3

Output Manual

4

5

A

Bypass

Bypass

Bypass

Input

Bypass

Input

Main

Input

Main

Input

A

A

Output Manual

6

Bypass

Bypass

Input

Main

Input

1.6.9 Shutdown Procedure (Parallel UPS)

Warning: The UPS system shutdown procedure will eliminate the AC power output for all loads. Before shutdown, confirm that all loads

are turned off or place the UPS systems in manual bypass mode to keep loads powered by the bypass (reserve) power source.

1

For the UPS system you wish to shut down, press the OFF button •

A

for 3 seconds (until you hear a beep), then release the button.

If the other UPS system can support the connected equipment

loads alone, the UPS system that was turned off will shut down its

inverter and its LCD screen will read “LOAD NOT POWERED”.

The other UPS system’s LCD screen will read “ONLINE MODE”.

If the total connected equipment load is too large to be handled

by a single UPS system, both UPS systems will shut down their

inverters and switch to bypass mode, and their LCD screens will

1

A

read “ON AUTO BYPASS.”

2

For the UPS system you wish to shut down, switch off the main •

input circuit breaker switch

B

breaker switch

.

A

, then switch off the output circuit

22

AB

Output Manual

2

Bypass

Bypass

Input

Main

Input

Page 23

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass (continued)

1.6.9 Shutdown Procedure (Parallel UPS) (continued)

3

For the UPS system you wish to shut down, switch off the bypass •

input circuit breaker switch A.

A

Output Manual

4

When the UPS system is completely shut down, the LCD screen •

3

Bypass

Bypass

Input

Main

Input

will be completely off. If the UPS systems have external battery

cabinets connected, switch off the external battery cabinet circuit

breaker switch

A

of each battery pack.

A

Note: If the UPS system remains off for an extended period of time, it

should be turned on periodically to allow the batteries to recharge. The

UPS system should be turned on and the batteries should be recharged

at least one uninterrupted 24-hour period every 3 months. Failure

to recharge the batteries periodically may cause irreversible battery

damage.

4

1.6.10 Manual Bypass Procedure (Parallel UPS)

Warning: When the UPS system is in manual bypass, the inverter shuts down. Connected equipment loads are powered by the bypass

(reserve) power source and will not receive battery backup during a utility power failure.

For the first UPS system you wish to shut down, press the OFF •

1

A

button

for 3 seconds (until you hear a beep), then release

the button. If the other UPS system can support the connected

equipment loads alone, the UPS system that was turned off will

shut down its inverter and its LCD screen will read “LOAD NOT

POWERED”. The other UPS system’s LCD screen will read

PRELIMINARY

“ONLINE MODE”. If the total connected equipment load is too

large to be handled by a single UPS system, both UPS systems

will shut down their inverters and switch to bypass mode, and their

1

A

LCD screens will read “ON AUTO BYPASS”. Repeat step 1 for

the second UPS system you wish to shut down.

2

Switch off the main input circuit breaker switch •

system.

A

of each UPS

A

3

Confirm that both UPS systems are shut down, then switch on the •

manual bypass input circuit breaker switch

A

of each UPS system.

The bypass (reserve) power source will power the loads and the

LCD screen will read “ON MANUAL BYPASS.”

4

Switch off the bypass input circuit breaker switch •

circuit breaker switch

B

of each UPS system. The LCD screen

A

and the output

will turn off completely.

23

Output

2

Output

3

Output

4

Manual

Bypass

A

Manual

Bypass

Manual

Bypass

Bypass

Input

Bypass

Input

AB

Bypass

Input

Main

Input

Main

Input

Main

Input

Page 24

1 Basic Operation (continued)

1.6 Start-Up, Shutdown and Bypass (continued)

1.6.10 Manual Bypass Procedure (Parallel UPS) (continued)

5

If the UPS systems have external battery cabinets connected, switch •

off the external battery cabinet circuit breaker switch

battery pack.

6

In this mode, only the output circuit breaker switch •

terminal block B contain hazardous voltage, allowing qualified

service personnel to perform maintenance or repair. Note:

Qualified service personnel may prefer to de-energize the UPS

systems completely, depending on local codes and the nature of the

maintenance or repair.

1.6.11 Switching from Manual Bypass to Normal Mode (Parallel UPS)

1

If the UPS systems have external battery cabinets connected, switch •

off the external battery cabinet circuit breaker switch

battery pack.

A

of each

A

and the

A

of each

5

6

A

B

A

A

PRELIMINARY

2

Switch on the bypass input circuit breaker switch •

circuit breaker switch B of each UPS system.

3

Confirm that both UPS systems are shut down, then switch off the •

manual bypass input circuit breaker switch

The LCD screen will read “ON AUTO BYPASS.”

4

Switch on the main input circuit breaker switch •

system.

5

Press the ON button •

A

of the first UPS systems for 3 seconds

(until you hear a beep), then release the button. Press the ON button

for the second UPS system for 3 seconds (until you hear a beep),

then release the button. When the inverter of each UPS system is

operating normally, they will switch to online (normal) mode at the

same time.

A

and the output

A

of each UPS system.

A

of each UPS

A

1

AB

Output Manual

2

Output

3

Bypass

A

Manual

Bypass

Bypass

Input

Bypass

Input

Main

Input

Main

Input

A

Output

4

Manual

Bypass

Bypass

Input

Main

Input

5

24

Page 25

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB)

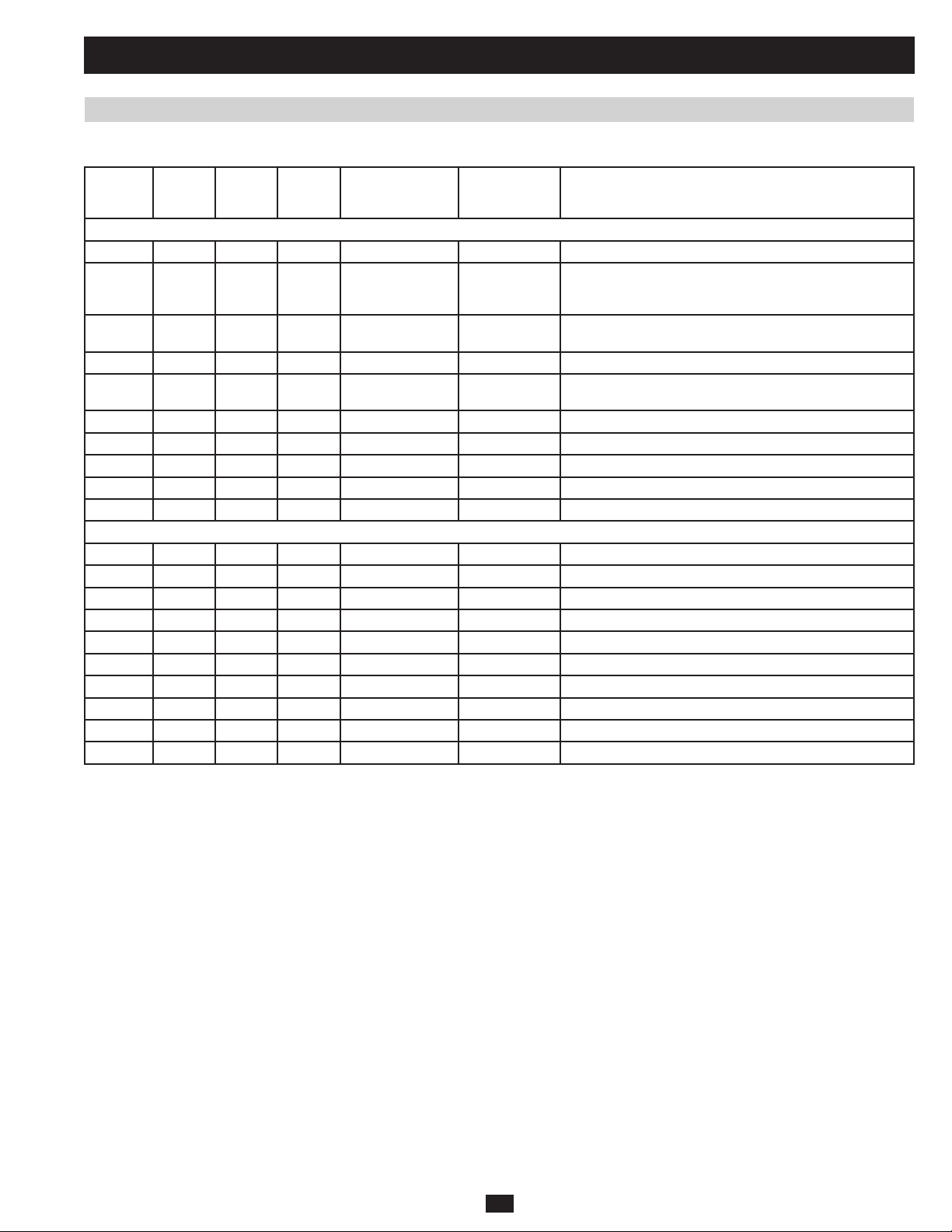

Table 1.7a lists the printed circuit boards present in each UPS system:

SU80KX

SU80K

SU80KTV

V (2pcs) V (2pcs) NH-SYS-F1(BYP) 16-5505001371 Input EMI Filter for Bypass

V (2pcs) V (2pcs) NH-SYS-F1(MAIN) 16-5505001371 Input EMI Filter for Main

PRELIMINARY

SU60KX

SU60K

V V V V NH-SYS-LCD 16-5505001323 Circuit for LCM, Circuit for LED and Function Key

V V V V NH-SYS-R 16-5505001327 Circuit for RS232, Output Dry Contact, Parallel Port,

V V V V NH-SYS-X 16-5505001319 Circuit for REPO, Input Dry Contact and Circuit for sense

V V V V NH-SYS-M 16-5505001321 System MCU and Control Circuit

V V V V NH-SYS-P 16-5505001325 Auxiliary Power for System, Detect Circuit for Voltage and

V V V V NH-SYS-B 16-5505001317 EMI Filter for Battery Input

V V V V NH-SYS-LA 16-5505001322 Input EMI Filter for each Power Module

V V V NH-SYS-LB 16-5505001353 Input EMI Filter for each Power Module

V V NH-SYS-LC 16-5505001354 Input EMI Filter for each Power Module

V NH-SYS-LD 16-5505001355 Input EMI Filter for each Power Module

V V NH-SYS-S 16-5505001326 Driver Circuit for Bypass SCR

V V V V NH-SYS-FC 16-5505001349 Output EMI Filter

V V NH-SYS-F2(MAIN) 16-5505001373 Input EMI Filter for Bypass

V V NH-SYS-F2(BYP) 16-5505001374 Input EMI Filter for Main

V V NH-SYS-F3 16-5505001372 Circuit for Surge suppress

V V V V NH-SYS-FB 16-5505001346 Circuit for Bypass Back-feed Detect

SU40KX

SU40K SU20KX PCB name P/N Description

TOP

Connector to connect with each Power Module, Circuit for

2 Slots

External Battery Cabinet Temperature

Current

BOTTOM

V V NH-SYS-SA 16-5505001370 Driver Circuit for Bypass SCR

V (2pcs) V (2pcs) NH-SYS-FA 16-5505001347 Input EMI Filter

Table 1.7a

25

Page 26

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB) (continued)

1.7.1 PCB Location (System)

1.7.1.1 KX Models

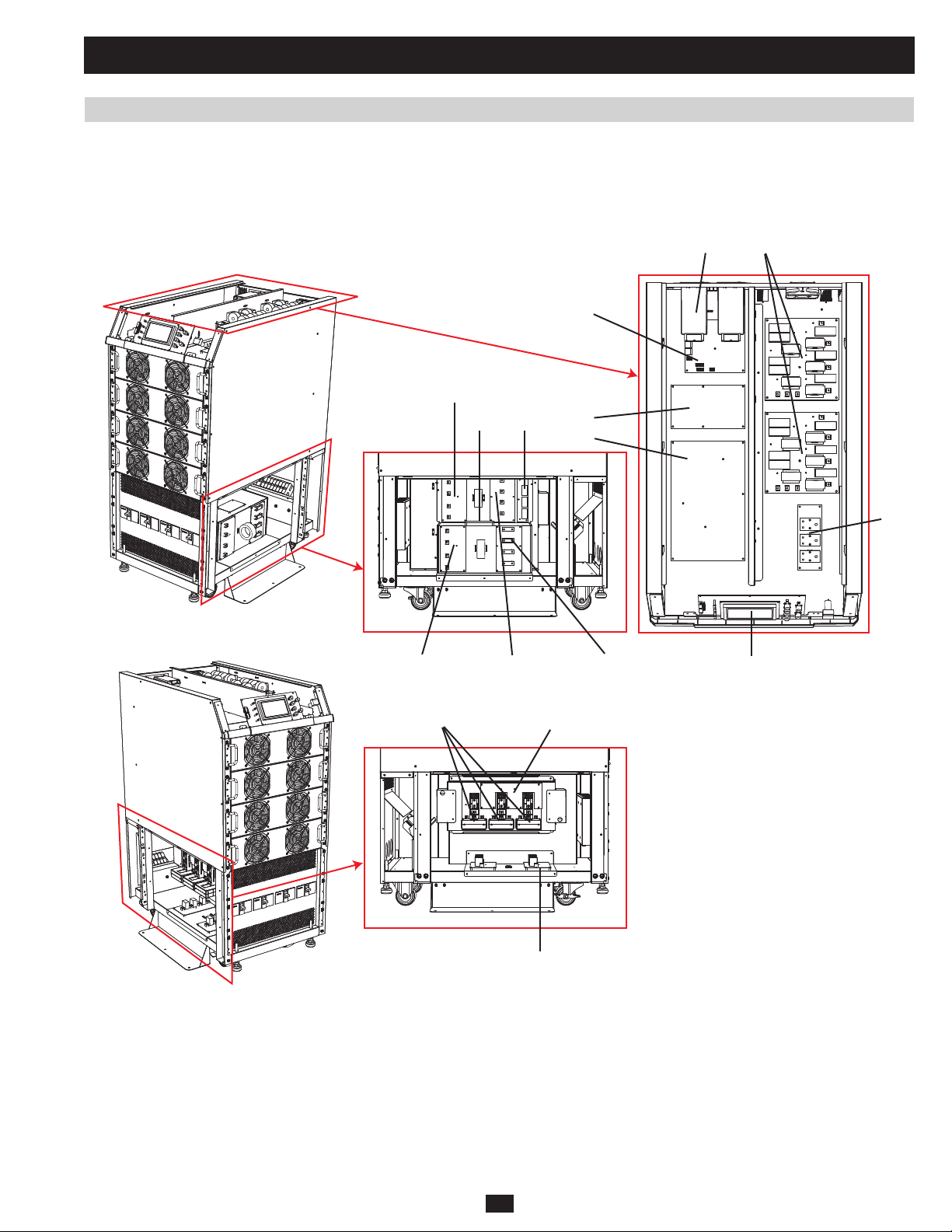

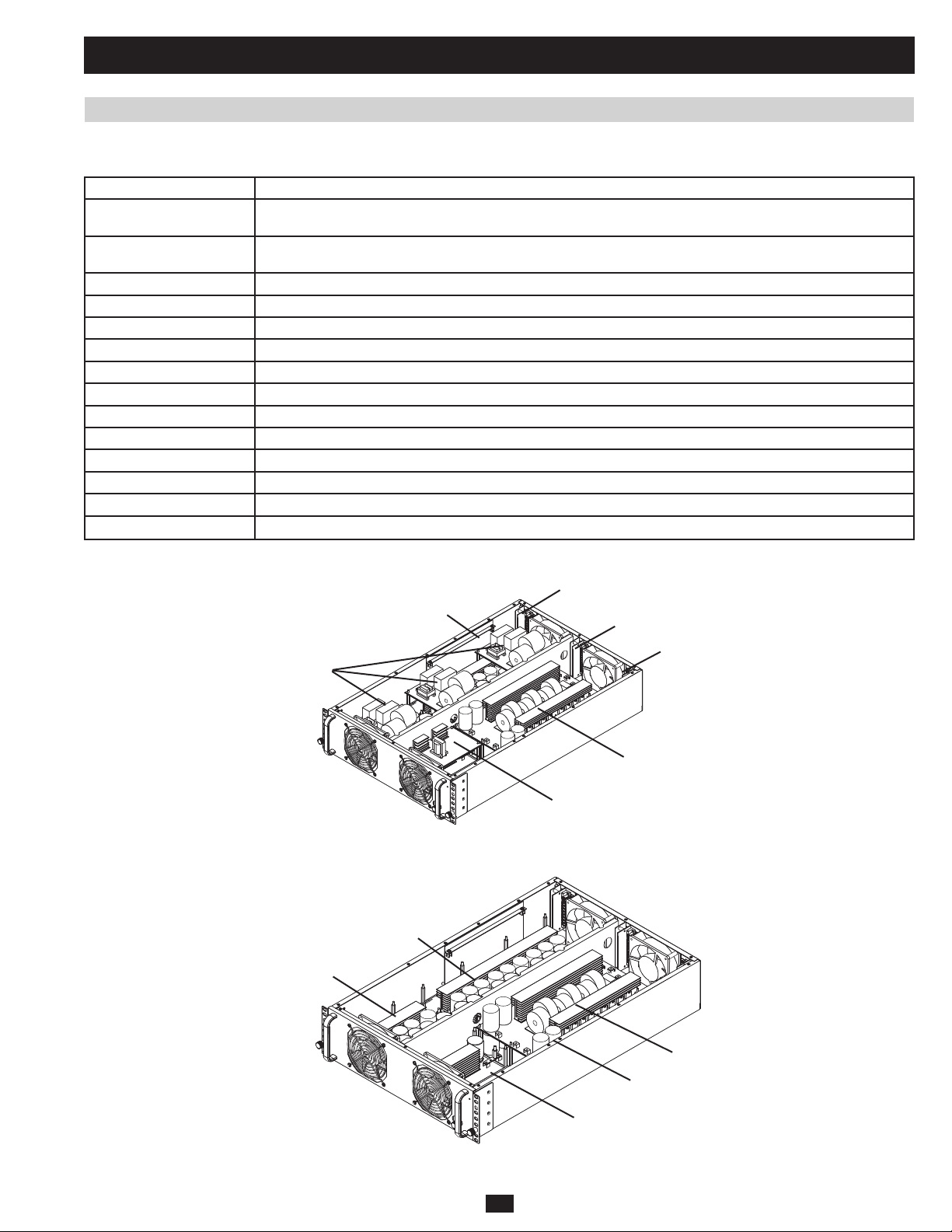

SU20KX and SU40KX:

FA (BYP)

FB

X LA and LB

R

M

P

B

PRELIMINARY

O/P CT FCBYPASS SCR

FA (MAIN)

SA

LCD

26

Page 27

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB) (continued)

1.7.1 PCB Location (System) (continued)

1.7.1.1 KX Models (continued)

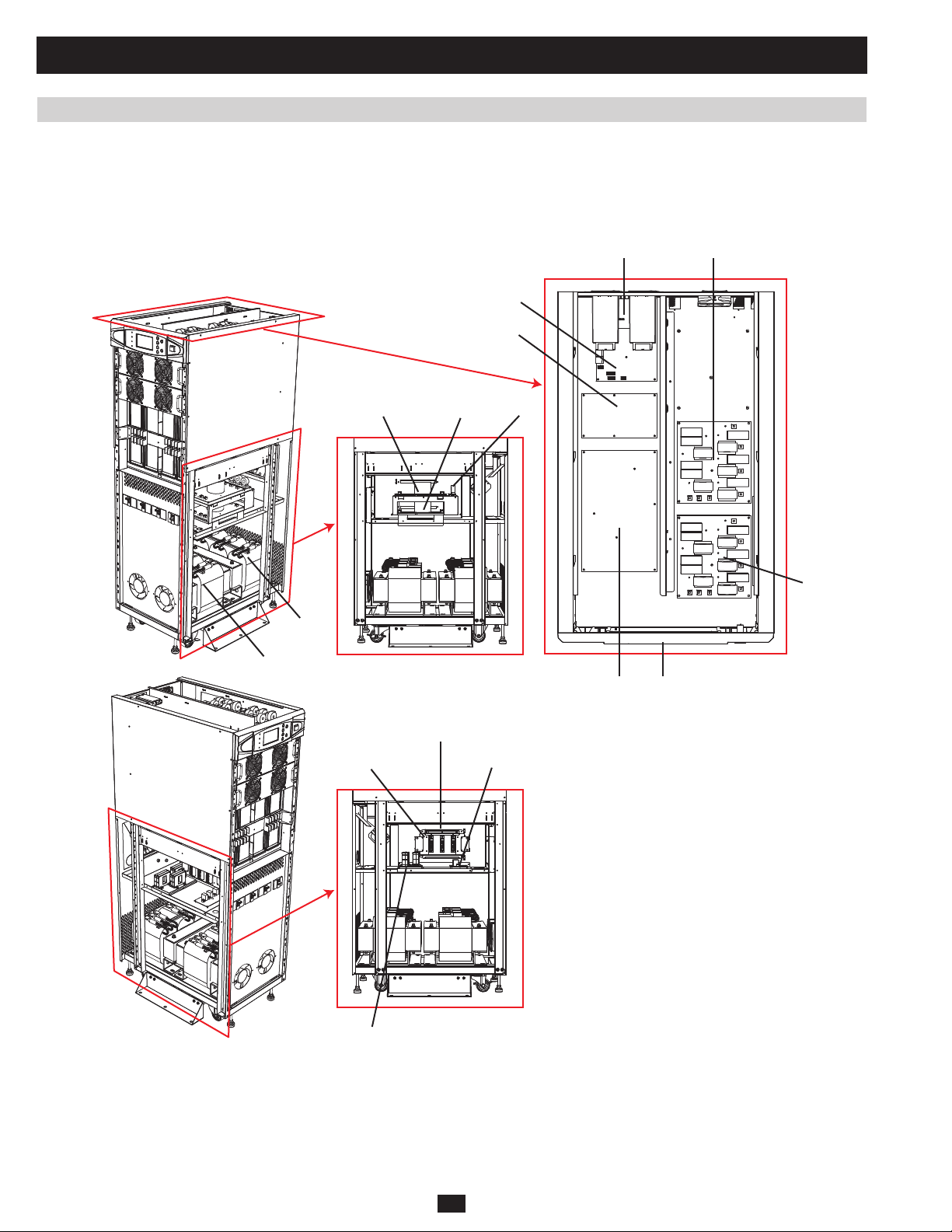

SU60KX and SU80KX:

F1 (BYP)

XBLA, LB, LC, LD

R

F3 FB

M

P

PRELIMINARY

LCDF1 (MAIN) F2 (BYP) F2 (MAIN)

O/P CT S

27

PC

Page 28

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB) (continued)

1.7.1 PCB Location (System) (continued)

1.7.1.2 K Models

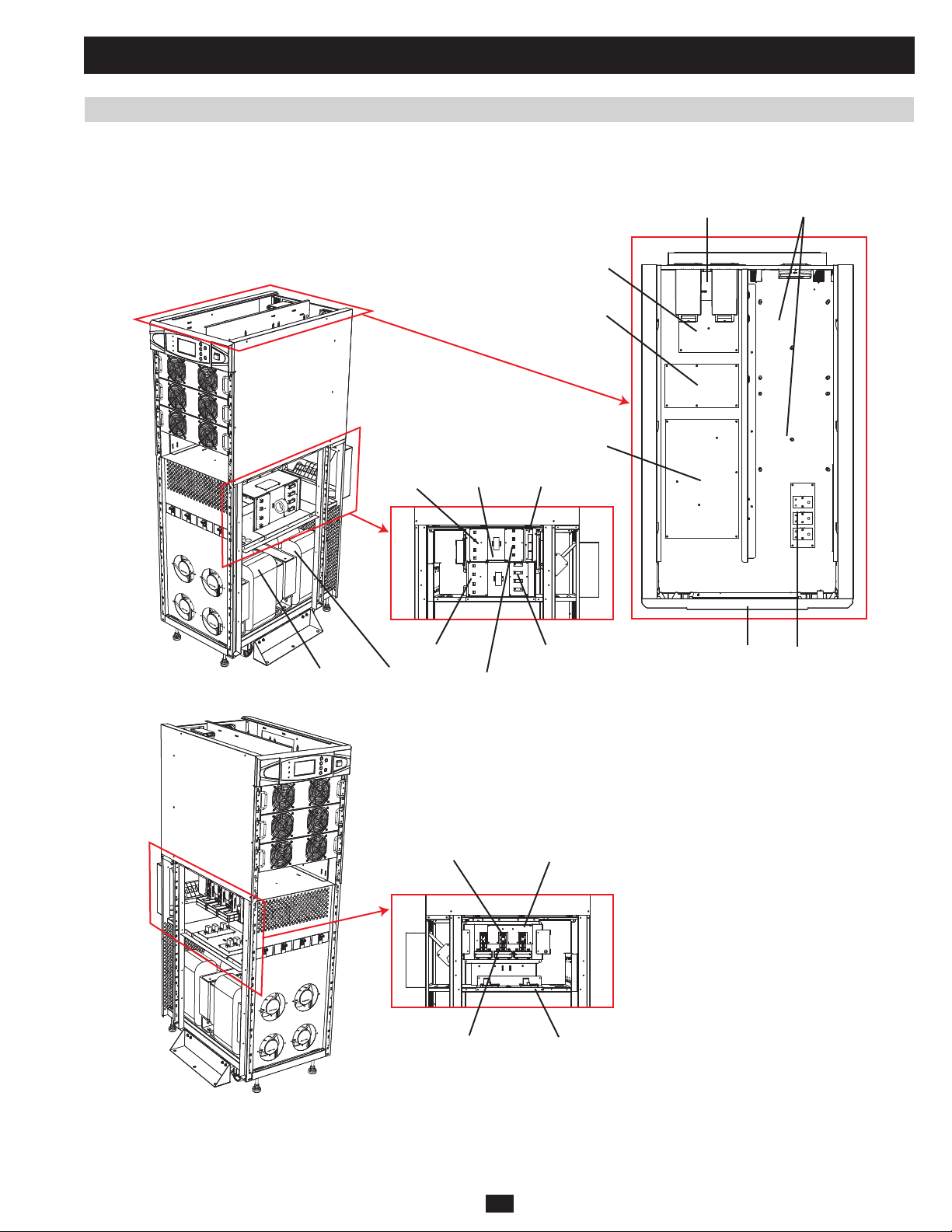

SU40K:

X LA, LB

R

M

FA (BYP) FA (MAIN)

O/P

PRELIMINARY

Transfer

I/P

Transfer

SA

Bypas SCR FC

FB

B

P

LCD

O/P CT

28

Page 29

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB) (continued)

1.7.1 PCB Location (System) (continued)

1.7.1.2 K Models (continued)

SU60K:

X LA, LB, LC

R

M

P

F1 (BYP)

PRELIMINARY

I/P Tx

F1 (MAIN)

O/P Tx

Bypas SCR S

F3

F2 (BYP)

FB

F2 (MAIN)

BLCD

O/P CT FC

29

Page 30

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB) (continued)

1.7.1 PCB Location (System) (continued)

1.7.1.2 K Models (continued)

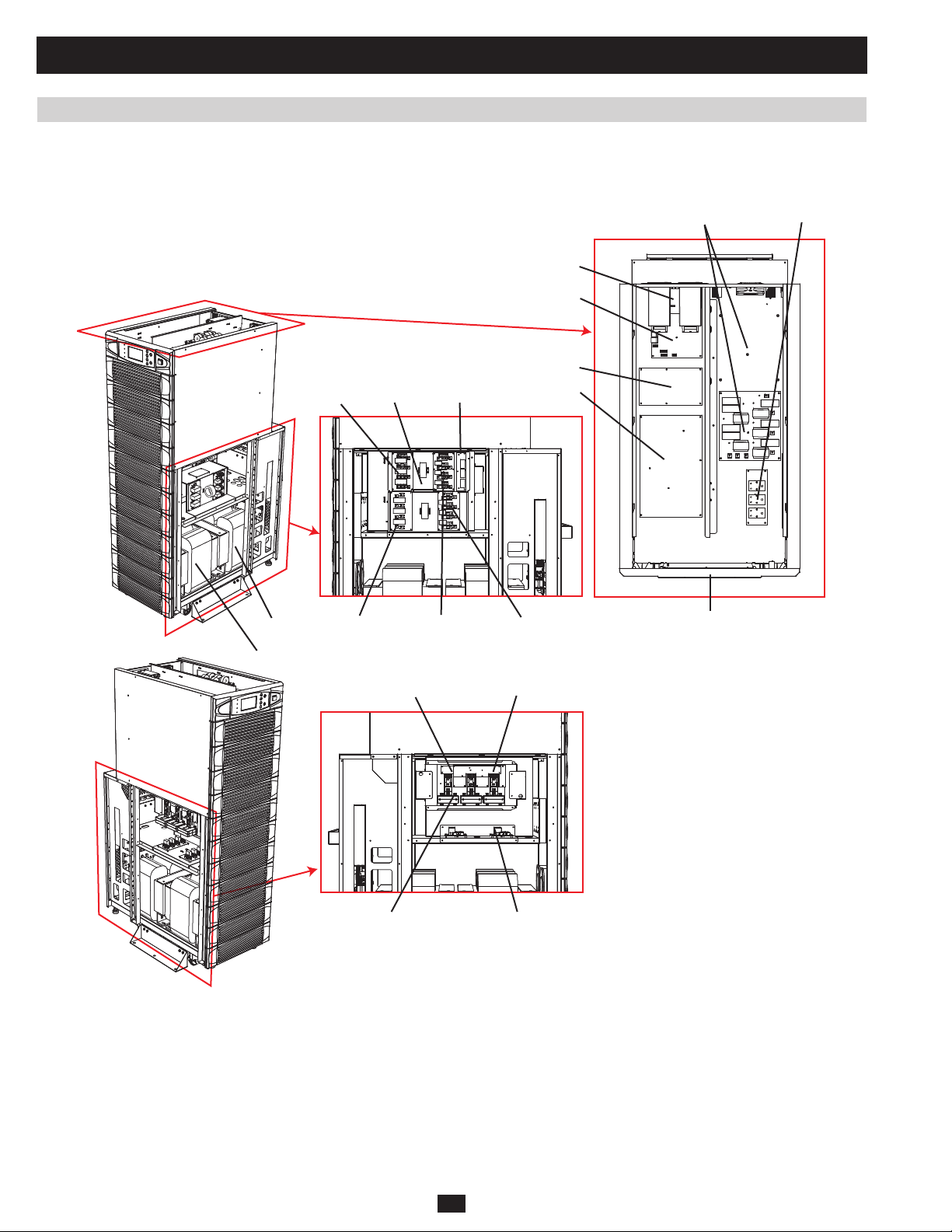

SU80K:

LA, LB, LC, LD

X

R

M

FBF2F1(BYP)

P

B

O/P Tx

PRELIMINARY

I/P Tx

F1(MAIN)

O/P CT FC

F2(BYP) F2(MAIN)

Bypass SCR S

LCD

30

Page 31

1 Basic Operation (continued)

1.7 Printed Circuit Boards (PCB) (continued)

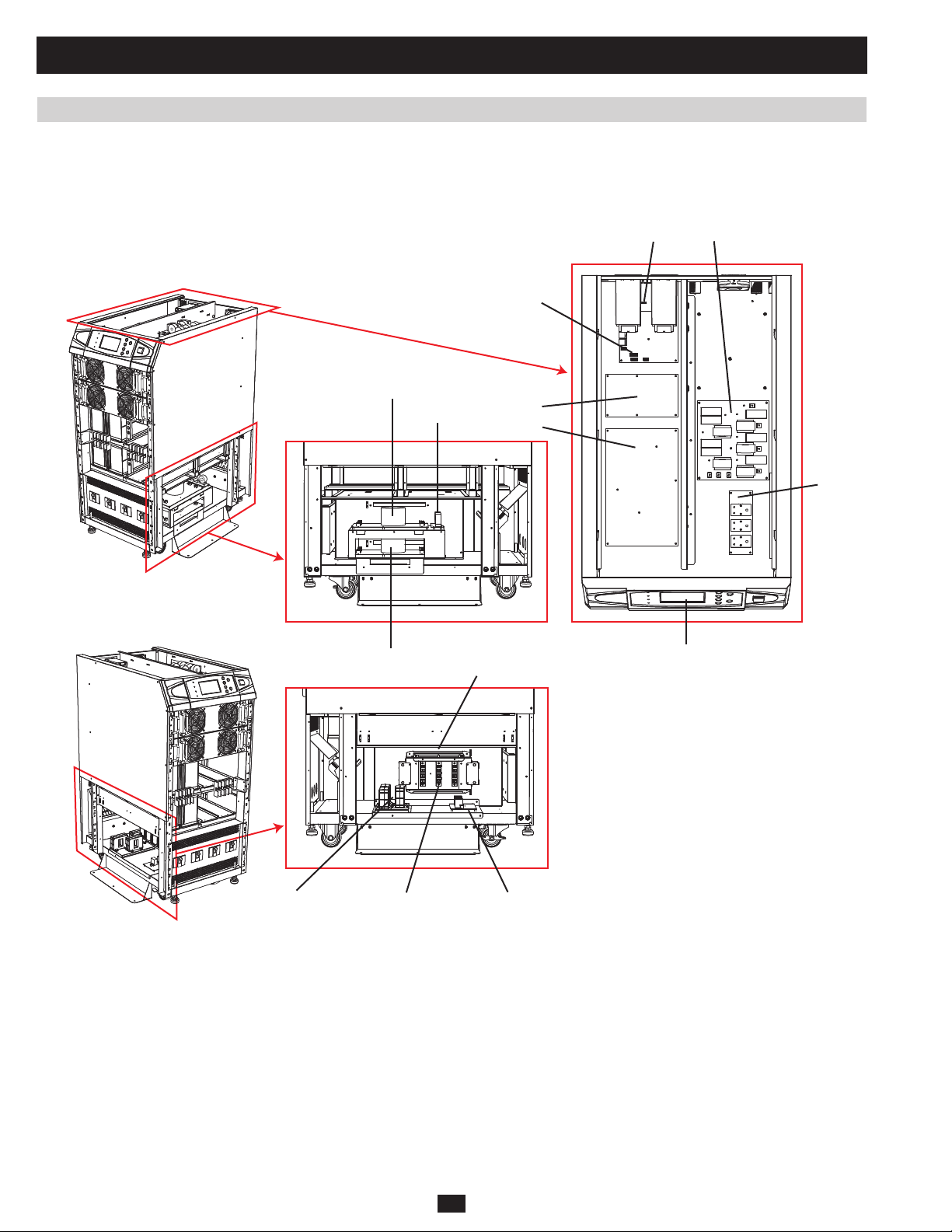

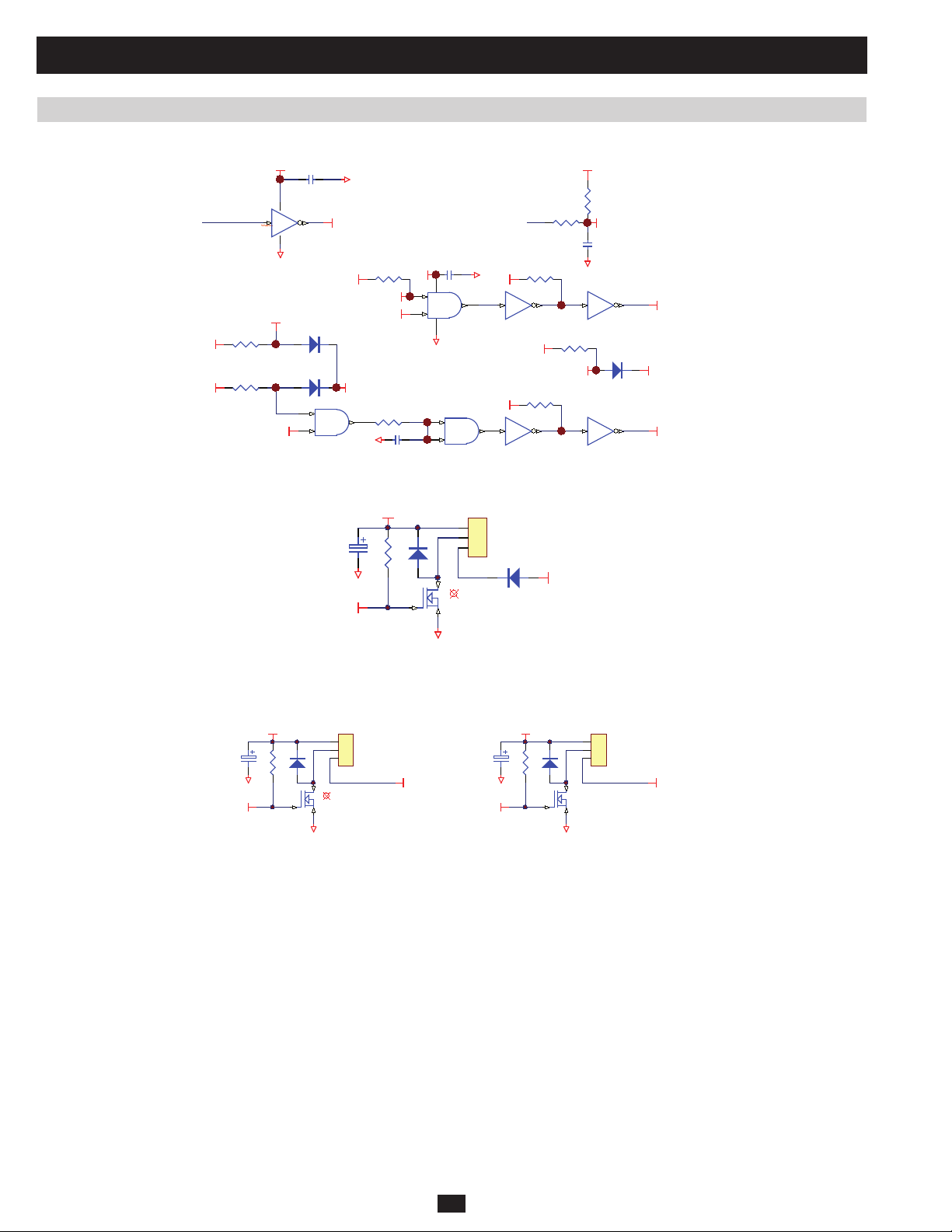

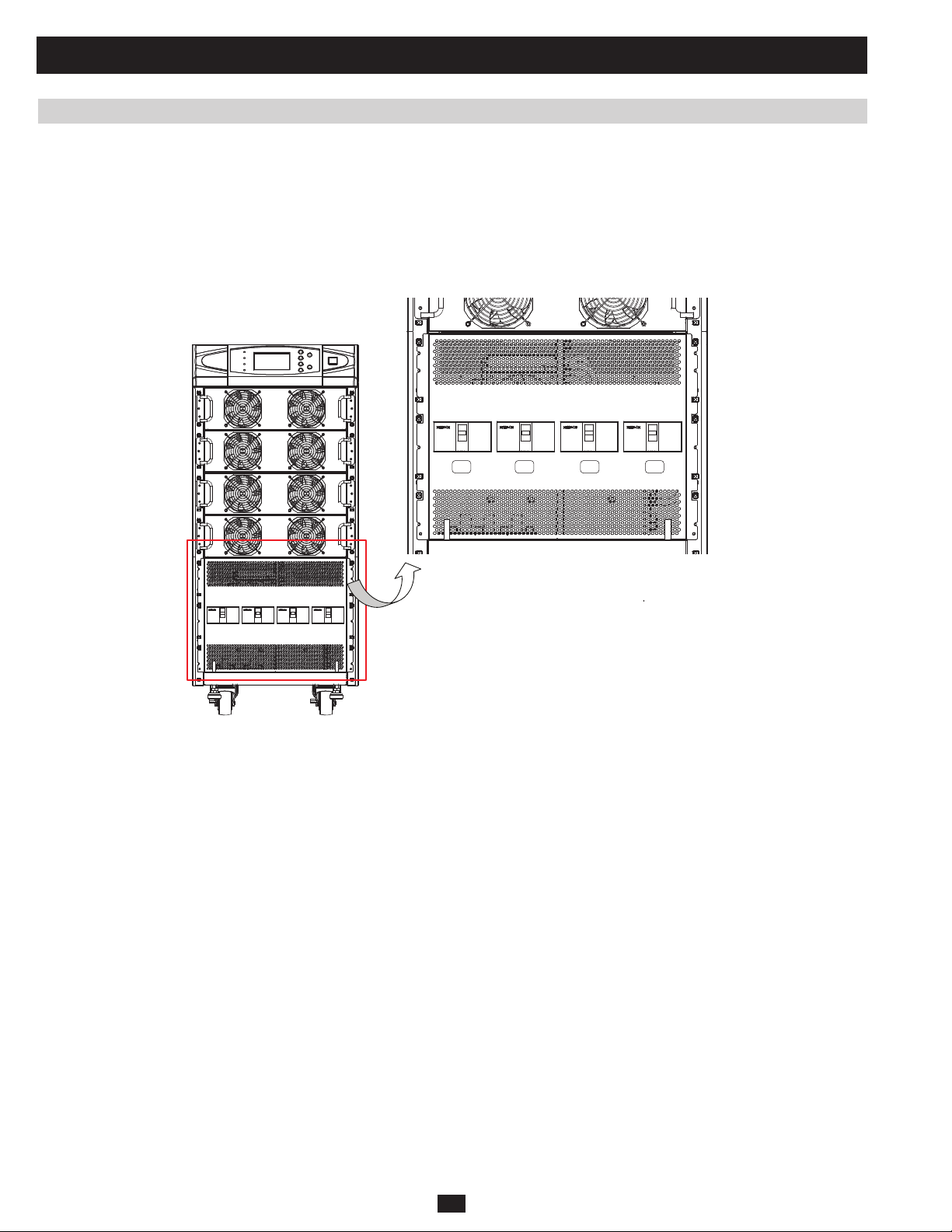

1.7.2 PCB Location (Power Module)

PCB Board Name Description

NH-PM-A Rectifi er of Phase R and S, Inductance and Switching Devices of DC-DC Converter, Bus Capacitors and Battery SCR

NH-PM-K Rectifi er of Phase T and S, Inductance and Switching Devices of DC-DC Converter, Bus Capacitors and Battery SCR

NH-PM-C Charger

NH-PM-P Auxiliary Power

NH-PM-M Control Circuit for PFC and Charger

NH-PM-DSP(PFC) DSP Chip (Assemble on NH-PM-M Board)

NH-PM-B Switching Devices of Inverter (Phase T) and Bus Capacitors

NH-PM-D Switching Devices of Inverter (Phase R and S) and Bus Capacitors

NH-PM-L LC Filter of Inverter, Current Sensor and Static Switch Circuit of Inver ter

NH-PM-N Control Circuit for Inverter

NH-PM-DSP(INV) DSP Chip (Assemble on NH-PM-N Board)

NH-PM-H1 External Connector of Power Module AC Input

NH-PM-H2 External Connector of Power Module Battery Input

NH-PM-H3 External Connector of Power Module AC Output

circuit

circuit

H3

N

H2

PRELIMINARY

L

P

Fig 1.7.2a

D

B

H1

K

Fig 1.7.2b

33

A

M

C

Page 32

1 Basic Operation (continued)

1.8 Block and Wiring Diagrams (continued)

1.8.1 KX Models

Input: 3-phase 4-wire 230/380Vac

Output: 3-phase 4-wire 230/380Vac

The SU20KX (Figure 1.8.1a) has a model rating of 20kVA UPS and contains one power module and 40 internal batteries (which can be increased to

80, if necessary). (See Figure 1.8.1b for wiring.)

Q3

Manual Bypass

Circuit Breaker

Manual Input

Q5

Bypass Input

20kVA/3U POWER MODULE

EMPTY

12V, 9AH, 10PCS

12V, 9AH, 10PCS 12V, 9AH, 10PCS

EMPTY EMPTY

EMPTY EMPTY

12V, 9AH, 10PCS

STS

Q4

Output

Circuit Breaker

MAIN

INPUT

EXTERNAL

BATTERY

Q2

Bypass Input

Circuit Breaker

Main

Q1 LOAD

Main Input

Circuit Breaker

Fig 1.8.1a SU20KX Block Diagram

The SU40KX (Figure 1.8.1c) has a model rating of 40kVA UPS and contains two power modules and 80 internal batteries.

(See Figure 1.8.1d for wiring.)

PRELIMINARY

Q3

Manual Bypass

MAIN

INPUT

EXTERNAL

BATTERY

Circuit Breaker

Q2

Bypass Input

Circuit Breaker

Main

Q1

Main Input

Circuit Breaker

Q5

Manual Input

Bypass Input

STS

20kVA/3U POWER MODULE

20kVA/3U POWER MODULE

12V, 9AH, 10PCS

12V, 9AH, 10PCS 12V, 9AH, 10PCS

12V, 9AH, 10PCS 12V, 9AH, 10PCS

12V, 9AH, 10PCS 12V, 9AH, 10PCS

12V, 9AH, 10PCS

Q4

Output

Circuit Breaker

LOAD

Fig 1.8.1c SU40KX Block Diagram

34

Page 33

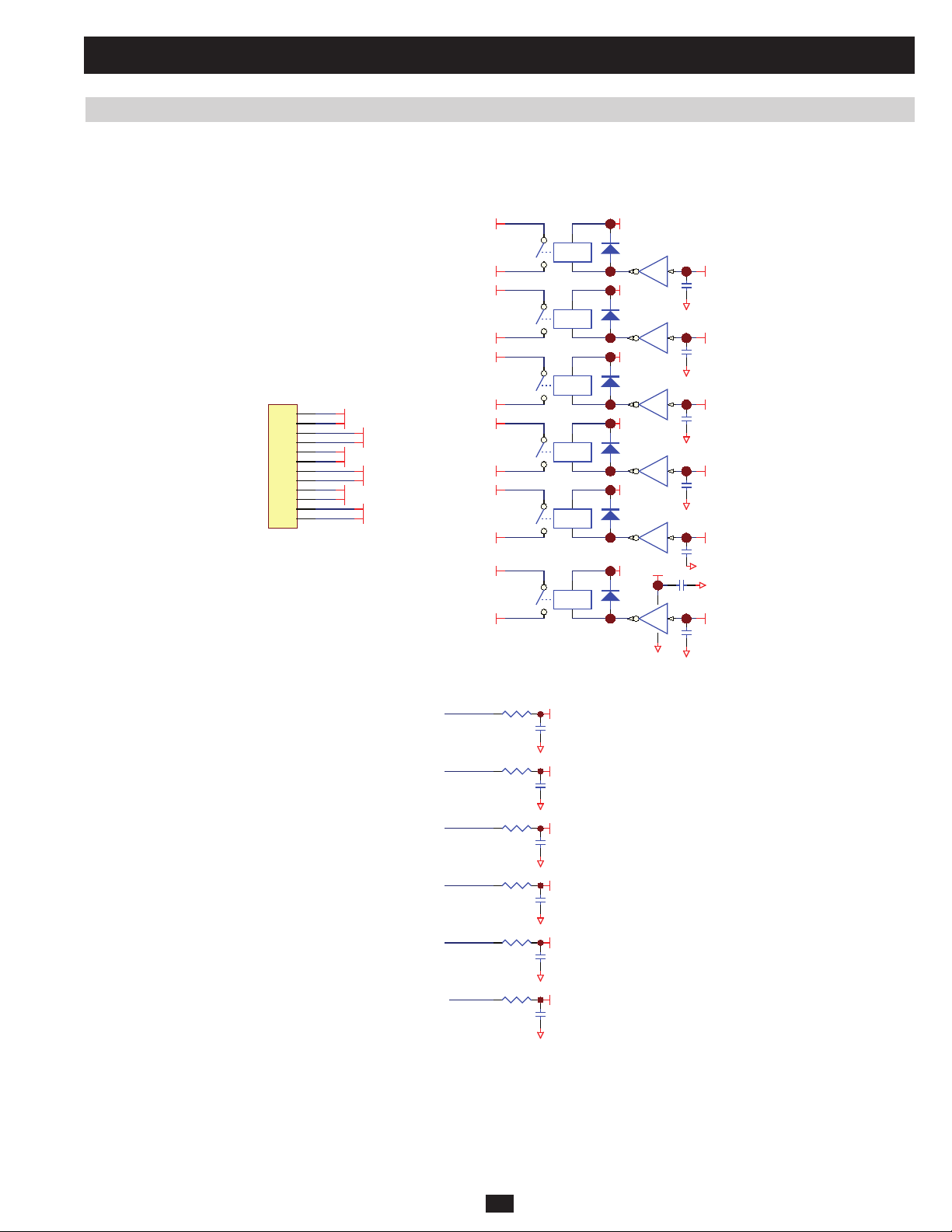

2 Theory of Operation (continued)

2.2 DC Auxiliary Power Circuit (continued)

Located at NH-SYS-M board (System MCU and Control Circuit)

RM42

5VS

K- ON

(a) The input of DC auxiliary power circuit is from positive battery.

(b) MCU detects the “on” key (on LCD board) status through KEY-ON(21)

(c) When AC auxiliary power circuit is activated and battery is present, AUXON (64) is high and DC auxiliary power circuit will be on.

(d) If AUXOFF (44) is high during backup mode, DC auxiliary power will be off.

G1

RM43

CM24

KEY_ON

(21)

AUXON

(64)

AUXOFF

(44)

RM22

AUX- ON

RM26

AUX- OFF

2.3 Auxiliary Power Failure Detection

Located at NH-SYS-P board (Auxiliary Power for System, Detect Circuit for Voltage and Current)

DP11

QP8

AUX-FAI L

+12VB

RP 18

+12VS

ZDP5

RP 20

RP 19

G1

PRELIMINARY

+12VP

Located at NH-SYS-M board (System MCU and Control Circuit)

RP 21

+12VS

RP 23

ZDP6

RP 22

DP12

QP10

QP9

G1

RP 24

G1

RM34

G1

RM35

CM23

AUXFAIL

(71)

5VS

AUX- FAI L

+12VP is from AC auxiliary power and +12VB is from DC auxiliary power. During AC mode, +12VP and +12VB should both be live. If one or

both of them fails, MCU can detect auxiliary power failure through AUXFAIL (71) (low active).

51

Page 34

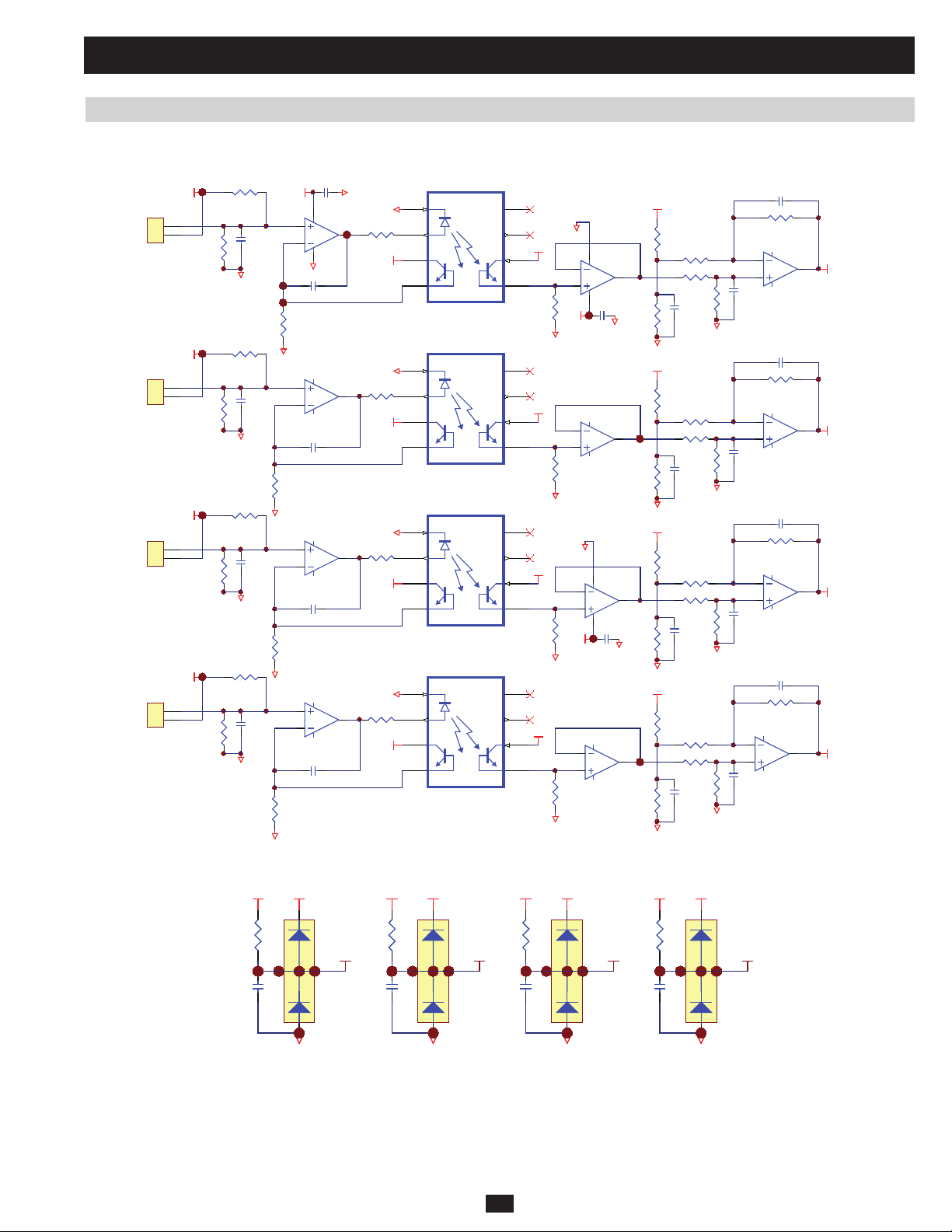

2 Theory of Operation (continued)

2.4 Output Current Detection

Located at NH-SYS-P board (Auxiliary Power for System, Detect Circuit for Voltage and Current)

CP 25

RP119

RP120

RP124

RP130

RP135

RP140

RP146

RP147

RP155

RP158

(W18)

(W19)

(W20)

CNP 1 1

1

2

CNP 1 2

1

2

CNP 1 3

1

2

OPCT_R+

OPCT_R-

OPCT_S+

OPCT_S-

OPCT_T+

OPCT_T-

OPCT_R-

RP 12 1 RP122

RP 12 5

OPCT_R+

OPCT_S-

RP 13 7 RP138

RP 14 1

OPCT_S+

OPCT_T-

RP 15 0 RP151

RP 15 6

OPCT_T+

PRELIMINARY

CP 89

CP 92

CP 94

G1

G1

G1

-12VS

RP126

RP142

RP157

2

3

411

CP 91

RP136

9

10

CP 93

RP148

13

12

CP 26

UP19 A

CP 90

UP19 C

UP19 D

G1

1

IoutR

G1+12VS

8

IoutS

14

IoutT

Located at NH-SYS-M board (System MCU and Control Circuit)

5VS

RM25

IoutR IoutS I outT

RM33

DM3

3

Iout_R Iout_TIout_S

(101)

CM22

12

G1

RM44

RM47

5VS

G1

3

CM25

12

DM7

(103)

RM61

5VS

RM58

DM13

3

(90)

CM30

12

G1

(a) Connectors CNP11, CNP12 and CNP13 connect to 3 Output CT individually.

(b) MCU detects 3-phase output currents through Iout_R (101), Iout_S (103) and Iout_T (90). The output current could be bypass current or in-

verter current, depending on the operation mode.

52

Page 35

2 Theory of Operation (continued)

2.5 Input Voltage Detection

Located at NH-SYS-P board (Auxiliary Power for System, Detect Circuit for Voltage and Current)

CP8 3

RP1 6 0

UP20B

6

5

9

10

13

12

UP20C

UP20D

CP8 7

RP1 7 6

CP8 8

RP1 8 4

7

VinR

8

VinS

14

VinT

CNP 7

CNP 8

CP7 8

RP159

RP1 6 5RP 1 6 4

RP162RP 161

BYP / R

IP/R

IP/S

IP/T

IP/N

BYP / S

BYP / T

BYP / R

BYP / N

BYP / N

BYP / S

BYP / T

1

2

3

4

5

6

7

1

2

3

4

5

6

7

RP163

RP168RP 167 RP169

RP178RP 177

RP186RP 185

RP173

RP179

RP187

CP9 5

G1

UP18B

6

5

9

10

13

12

UP18C

UP18D

7

CP8 1

RP175

8

CP8 2

RP183

14

Vby pR

Vby pS

Vby pT

IP/R

IP/N

IP/S

IP/T

RP1 6 6

RP1 7 1RP 1 7 0 RP1 72

RP1 8 1RP 1 8 0

RP1 8 2

RP1 8 9RP 1 8 8

RP1 9 0

RP1 7 4

CP8 6

G1

Located at NH-SYS-M board (System MCU and Control Circuit)

5VS

Vby pR

5VS

DM1

RM27

RM23

RM30

5VS

DM2

RM28

VinR

BYP Z O_ R INPZO_R

(12)

QM1

PRELIMINARY

RM36

RM40

DM5

3

Vbyp_R

(89)

RM38

G1

CM20

RM37

RM41

DM6

Vin _R

3

Vin_R

(92)

5VS

RM24

RM31

(14)

QM2

CM21

RM39

G1

Vby pS

RM50

RM54

12

G1

5VS

DM9

3

12

Vbyp_S

(91)

G1

RM63

Vby pT

RM67

5VS

DM16

3

(93)

12

G1

Vbyp_T

VinS

RM53

RM51

12

G1

5VS

DM11

3

12

Vin_S

(94)

G1

(a) MCU detects RMS value of bypass 3-phase voltage via Vbyp_R (89), Vbyp_S (91) and Vbyp_T (93).

(b) MCU detects RMS value of main input 3-phase voltage via Vin_R (92), Vin_S (94) and Vin_T (96).

(c) MCU detects the bypass frequency and zero crossing via BYPZO_R (12) at falling edge.

(d) MCU detects the main input frequency and zero crossing via INPZO_R (14) at falling edge.

VinT

RM64

RM68

5VS

DM17

3

12

Vin_T

(96)

G1

53

Page 36

2 Theory of Operation (continued)

2.6 Output Voltage Detection

Located at NH-SYS-P board (Auxiliary Power for System, Detect Circuit for Voltage and Current)

CP 7 3

RP 1 23

OP/ R

OP/ N

OP/ R

CNP 9

1

2

3

OP/ S

4

5

OP/ T

6

7

OP/ N

Located at NH-SYS-M board (System MCU and Control Circuit)

PRELIMINARY

5VS

OP/ S

OP/ T

RP128RP127

RP132RP131 RP 1 3 3

RP144RP143

RP153RP152

RP 1 29

RP 1 45

RP 1 54

5VS

RP 1 34

UP17 B

6

5

CP 7 2

G1

9

10

13

12

CP 7 6

RP 1 39

UP17 C

CP 7 7

RP 1 49

UP17 D

7

VoutR

8

VoutS

14

VoutT

5VS

VoutR

RM29

RM32

DM4

3

12

Vout_ R Vout_TVout_S

(95)

G1

VoutS

RM45

RM46

DM8

3

(97)

12

G1

VoutT

(a) MCU detects RMS value of 3-phase output voltage via Vout_R (95), Vout_S (97) and Vout_T (99).

RM59

RM60

DM14

3

(99)

12

G1

54

Page 37

2 Theory of Operation (continued)

2.7 Battery Voltage Detection

Located at NH-SYS-P board (Auxiliary Power for System, Detect Circuit for Voltage and Current)

CP 5 7

RP 9 0

G1

UP 10 A

CP 8 0

G1

RP 1 06

UP 10 B

CP 7 9

1

7

Vbatt+

Vbatt-

BAT +

BAT -

RP 9 5RP 94

RP100RP 9 9 RP 1 0 1

RP109RP108

RP115RP114 RP 1 16

RP 9 6

RP 1 10

RP118

RP102

G1

G1

CP 5 8

CP 6 0

-12VS

2

3

84

+12VS

CP 5 9

6

5

PRELIMINARY

Located at NH-SYS-M board (System MCU and Control Circuit)

Vba tt+

RM49

CM28RM5 5

5VS

DM1 0

3

Vba tt_+

(98)

RM70

Vba tt-

RM62

CM32

5VS

DM1 5

3

Vba tt_-

(100)

12

G1

(a) MCU detects battery voltage via Vbatt_+ (98) and Vbatt_- (100).

12

G1

55

Page 38

2 Theory of Operation (continued)

2.8 Bypass SCR Short-Circuit Detection

Located at NH-SYS-FB board (Circuit for Bypass Back-Feed Detect)

CFB18

SCCT_ S+

CFB19

SCCT_ T+

CFB20

RFB1

RFB2

RFB7

RFB3

RFB4

RFB8

RFB5

RFB6

RFB9

BKFD_ R

BKFD_ S

BKFD_ T

CTFB1

SCCT_R+

CTFB2

CTFB3

R

CFA22

S

CFA18

CNFB13

1

2

3

4

T

CFA12

N

DFB1

DFB2

DFB3

BKFD_ R

QFB1

BKFD_ S

QFB2

BKFD_ T

QFB3

Located at NH-SYS-P board (Auxiliary Power for System, Detect Circuit for Voltage and Current)

+12VS

RP3 4 RP 3 3

PRELIMINARY

BKFD_ R

+12VS

RP8 8

BKFD_ S

+12VS

RP104

BKFD_ T

CP6 2

RP8 7

CP6 7

RP103

CP7 0

-12VS

RP8 6

-12VS

+12VS

RP9 8

-12VS

+12VS

RP117

CP6 3

G1

UP18A

2

3

411

CP6 4

UP20A

2

3

411

CP8 5

UP17A

2

3

411

CP7 5

DP13

DP15

DP46

RP3 8

RP9 3

RP112

RP3 5

RP3 7

CP6 5

G1

RP8 9

RP9 2

CP6 8

G1

RP1 0 5

RP1 1 1

CP7 1

1

G1+12VS

CP8 4

G1

1

G1

CP7 4

G1

1

G1

SCRST_R

QP13

SCRST_S

QP15

SCRST_T

QP17

G1

Located at NH-SYS-M board (System MCU and Control Circuit)

RM48

5VS

SCRST_R

RM52

STSho r t _R STSho r t _ S ST Sh or t _ T

(5)

CM26

G1

RM56

5VS

SCRST_S

RM57

(129)

CM29

G1

RM65

5VS

SCRST_T

RM66

(128)

CM33

G1

(a) During backup mode, bypass 3 SCRs should be off and zero current should be running through CTFB1, CTFB2 and CTFB3. If current is

running through CTFB1, CTFB2 or CTFB3, then STShort_R (5), STShort_S (129) or STShort_T (128) will be low. The UPS will turn off its

inverter to prevent back-feed voltage.

56

Page 39

2 Theory of Operation (continued)

2.9 Bypass SCR Driver

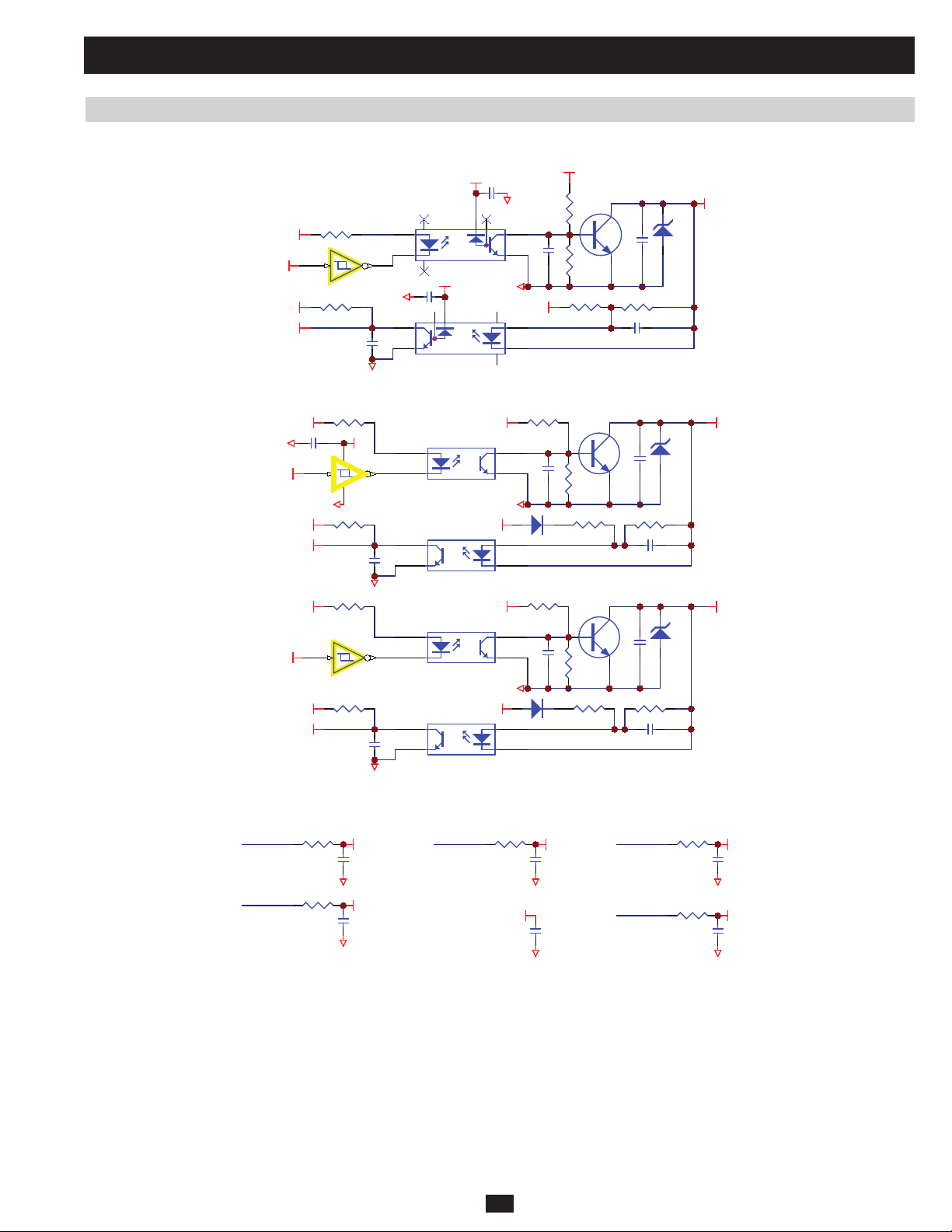

Located at NH-SYS-S or NH-SYS-SA board (Driver Circuit for Bypass SCR)

CSA1

+12VS

BYP ST S1

RSA1

+12VS+12VS

RSA3

RSA6

QSA4QSA7

RSA2

G1

G1

+12VS

RSA4

RSA8

QSA5

G1

+12VS

RSA5

RSA10

QSA6

G1

RSA7

RSA9

RSA11

G1

QSA1

G

G1

QSA2

G

G1

QSA3

G

G1

CSA5

D

RSA12

S

CSA2

+12VS

G1

CSA7

D

RSA13

S

CSA3

+12VS

G1

CSA9

D

RSA14

S

Located at NH-SYS-M board (System MCU and Control Circuit)

(1)

5VS

BYP STS

DM19

RM78

RM82

CM50

BYP STS2

Q

DIS

CM53

G1

RM75

5VS

RM91

3

7

6

RM103

TOBYP-J

DM28 DM2 9

#TOBYP_O

DM21

DM22

RM83

QM4

RM93

RM92

RM96

G1

RM102

TOBYP_O

(47)

QM6

#TOBYP_I

RM141

TOBYP_I

(131)

BYPASS Static Transfer Switch Control CKT.

8

UM6C

5VS

RM99

9

CM54

G1 5VS

CM122

5VS

14

1

+

3

UM6A

-

2

7

G1

BYP STS2

RM101

TOBYP-J

PRELIMINARY

(70)

CENT RAL _ OK

UM9

4

2

CM52

DM27

G1

8

R

VCC

TRIG

GND

CVol t5THR

1

G1

CSA4

CSA6

CSA8

10

G1

DSA1

DSA4

DSA7

#TOBYP_O

CM92

G1

CM97

G1

5

6

RM98

TSA 1

2

3

4

2803402000

TSA 2

2

3

4

2803402000

TSA 3

2

3

4

2803402000

#TOBYP_I

UM6B

DM26

12

UM6D

13

DSA2

6

7

9

10

6

7

9

10

6

7

9

10

4

RSA15

CSA10

DSA3

RSA16

CSA11

DSA5

RSA17

CSA12

DSA6

RSA18

CSA13

DSA8

RSA19

CSA14

DSA9

RSA20

CSA15

DM25

DM30

DM31

11

DM39

RM97

RM90

QM8

FAN_ON

RM94

RM2

CM51

CNSA1

6

5

4

3

2

1

CNSA2

6

5

4

3

2

1

CNSA3

6

5

4

3

2

1

+12VS

G1

RM100

G1

G2

K2

K1

G1

G2

K2

K1

G1

G2

K2

K1

G1

RM95

BYP STS1

QM7

Located at NH-SYS-R board (Circuit for RS232, Output Dry Contact, Parallel Port, Connector to connect with each Power Module, Circuit for 2 Slots)

G1

#TOBYP_O

#TOBYP_I

5VS

5VS

CR8

RR1

5VS

14

1 2

7

G1

RR8

CR10

UR4A

G1

UR3

1

2

+12VSF

UR6

4

3

RR2

QR1

VS TOBYP

CR4

4

3

RR6

G4

DR16

RR9

ZR1

CR7

RR10

1

2

CR9

57

Page 40

2 Theory of Operation (continued)

K

2.9 Bypass SCR Driver (continued)

(a) The bypass SCR driver signal “BYPSTS1” is controlled by MCU or “TOBYP_J” according to the signal “CENTRAL_OK.”

(b) “CENTRAL_OK” is the output of MCU watchdog. If MCU is operating normally, “CENTRAL_OK” will be high and the bypass SCR driver

signal will be controlled by “BYPSTS” (1) (high active). If MCU is not operating normally, “CENTRAL_OK” will be low and the bypass SCR

driver signal will be controlled by “TOBYP_J” (high active).

(c) UM9 is a 45 kHz self-oscillator that can provide pulse signal for driver bypass SCR.

(d) The “TOBYP_J” signal is limited by “#TOBYP_I.”

2.10 Watchdog for System MCU

Located at NH-SYS-M board (System MCU and Control Circuit)

5VS

LEDM1

G1

RM72

Q

DIS

THR

UM3

TLC555C

CM46

RM89

LED(GRN)

RM1

3

7

6

RM88

CENT RA L_ O

(70)

5VS

5VS

CM36

QM5

G1

4

2

5

CM45

R

TRIG

CVo l t

8

VCC

GND

1

RM71

1

2

CNM2

2.5X2P

CM39

RM81

RM86

QM3

DM24

G1

SYS_RD Y

(4)

PRELIMINARY

(a) SYS_RDY (4) will send out a pulse to reset CM46. CM46 will then be recharged by 5V through RM88. “CENTRAL_OK” will maintain a high

level. If SYS_RDY (4) does not send out a pulse during a specifi c period (for example, during an MCU crash), then “CENTRAL_OK” will be

low.

(b) Test JUMP (CNM2): If CNM2 is shorted, then “CENTRAL_OK” will be low. If CNM2 is opened, “CENTRAL_OK” will stay high during

normal operation.

58

Page 41

2 Theory of Operation (continued)

2.11 LCD Panel Control Circuit

Located at NH-SYS-M board (System MCU and Control Circuit)

TO LCD

CNM5

RM127

RM135

RM143

RM149

RM154

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

KEY_ESC

(8)

KEY_DOWN

(9)

KEY_OFF

(22)

KEY_UP

(10)

KEY_ENT

(7)

G1

(2)

(70)

U-Lc mCA

(62)

(73)

(74)

(75)

(76)

(77)

(78)

VLED

G1

U-Lc mBL

G1

U-LED0

U-LED1

U-LED2

U-LED3

U-LED4

U-LED5

CENT RAL _ OK

+12VS

5VS

RM15 5

G1

LcdD1

LcdD3

LcdD5

LcdD7

UM5

8

COM

GND

7B77C

6B66C

5B55C

4B44C

3B33C

2B22C

1B11C

RM134

RM137

QM9

RM13 9

G1

RM144

RM14 8

NO+

CM104

G1

+12VS G1

4 11

CM11 3

2

1

3

G1

UM7A

LM324AD

CM112

(33)

(35)

(37)

(39)

9

10

11

12

13

14

15

16

LED0

LED1

LED2

LED3

LED4

LED5

BYP _ OK

BKLI T

(50)

(49)

(63)

RM13 8

G1

CM12 1

EPO

(85)

1

CONT RAST

VLED

LED0 LED1

LED2 LED3

LED4 LED5

OFF ENT

ESC UP

DOWN BKLI T

NO+ G1

CONTRAST Lc dDATA

LcdD0

(32)

LcdD2

(34)

LcdD4

(36)

LcdD6

(38)

LcdWR LcdCS

G1

CM75CM74CM73CM72 CM79CM78CM77CM76

RM126

ESC

KEY_ESC

CM85

G1

RM133

DOWN

KEY_DOWN

CM91

G1

RM140

OFF

KEY_OFF

CM96

G1

RM147

RM152

KEY_UP

CM103

G1

KEY_ENT

UP

PRELIMINARY

ENT

CM110

G1

St and- A l one

NORMAL LED

LED0

BYPA SS LED

LED1

FAULT LED

LED2

BATTERY L ED

LED3

NC

LED4

NC

LED5

G1

G1

G1

RM11 6

ZDM1

RM12 1

ZDM2

RM132

ZDM3

LcdDATA

LcdCS

LcdWR

HSM1

1

U-Lc dDATA

CM67

U-Lc dCS

CM80

U-Lc dWR

CM90

HS

+12VS

RM158

UM10

1

Vin

+5V

CM11 8 CM119

GND

2

G1

3

CM120

VLED

(a) MCU detects the status of EPO button (on LCD display panel) via “EPO” (85) (low active). When the EPO button is activated, UPS will shut

down the output and turn off the inverter. When the EPO button is released, UPS will stay in bypass mode.

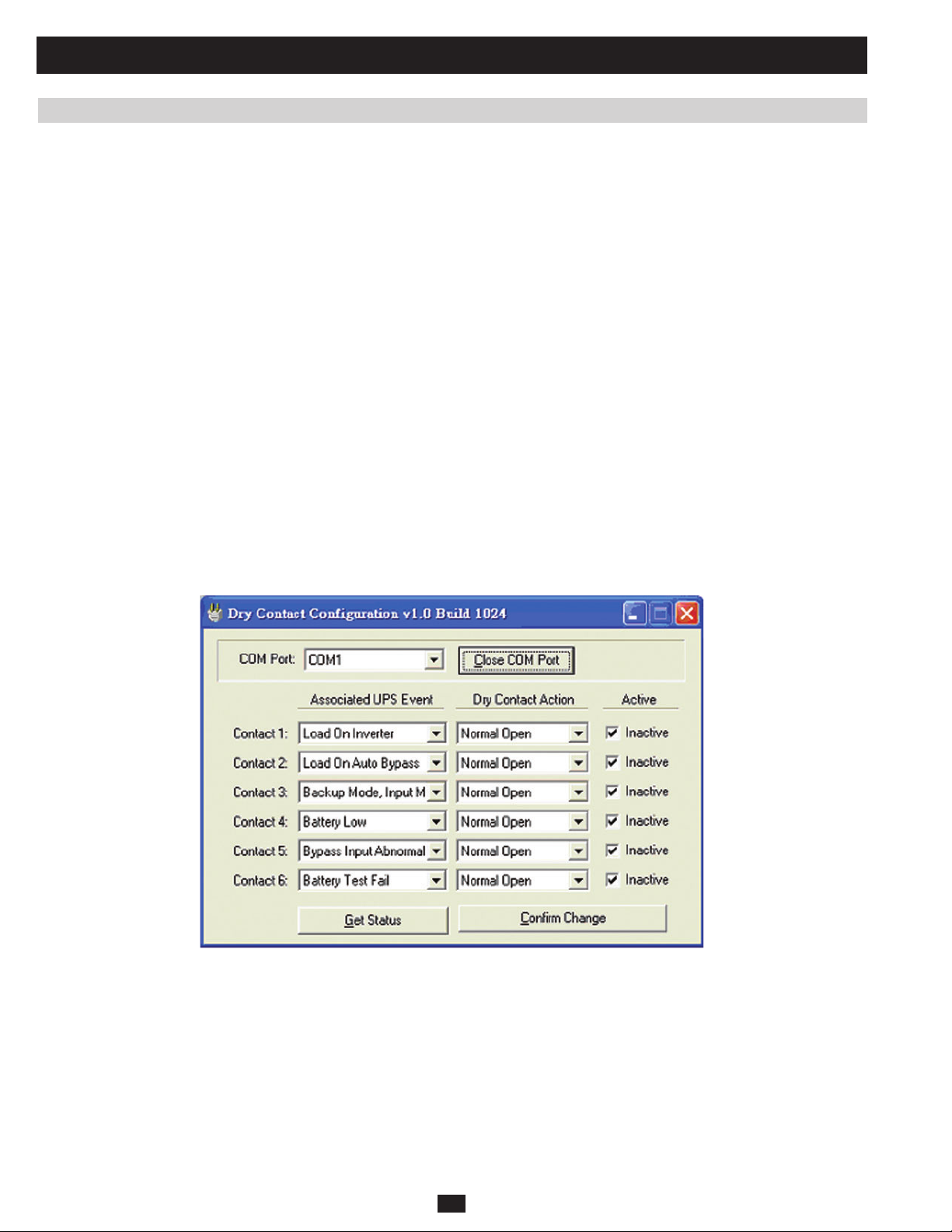

(b) MCU can control the LCD backlight via “U-lcmBL” (62).