Page 1

PROTECT YOUR

INVESTMENT!

Completed and signed start-up forms

MUST be submitted and approved

by Tripp Lite to activate your warranty.

SmartOnline™ 3-Phase UPS Systems

Input/Output: 220/380V, 230/400V or 240/415V AC, 3O, 4-wire + ground

Owner’s Manual

Models: SU20KX, SU40KX, SU60KX, SU80KX

Not suitable for mobile applications.

1

2

3

4

5

6

7

8

9

10

11

12

1111 W. 35th Street, Chicago, IL 60609 USA

www.tripplite.com/support

Copyright © 2010 Tripp Lite. All trademarks are the sole property of their respective owners.

1

13

14

Page 2

Table of Contents

1

1 Introduction 3

2 Important Safety Instructions 4

2

3 Control Panel Features 6

4 Front and Rear Panel Features 7

5 Cabinet Installation 9

3

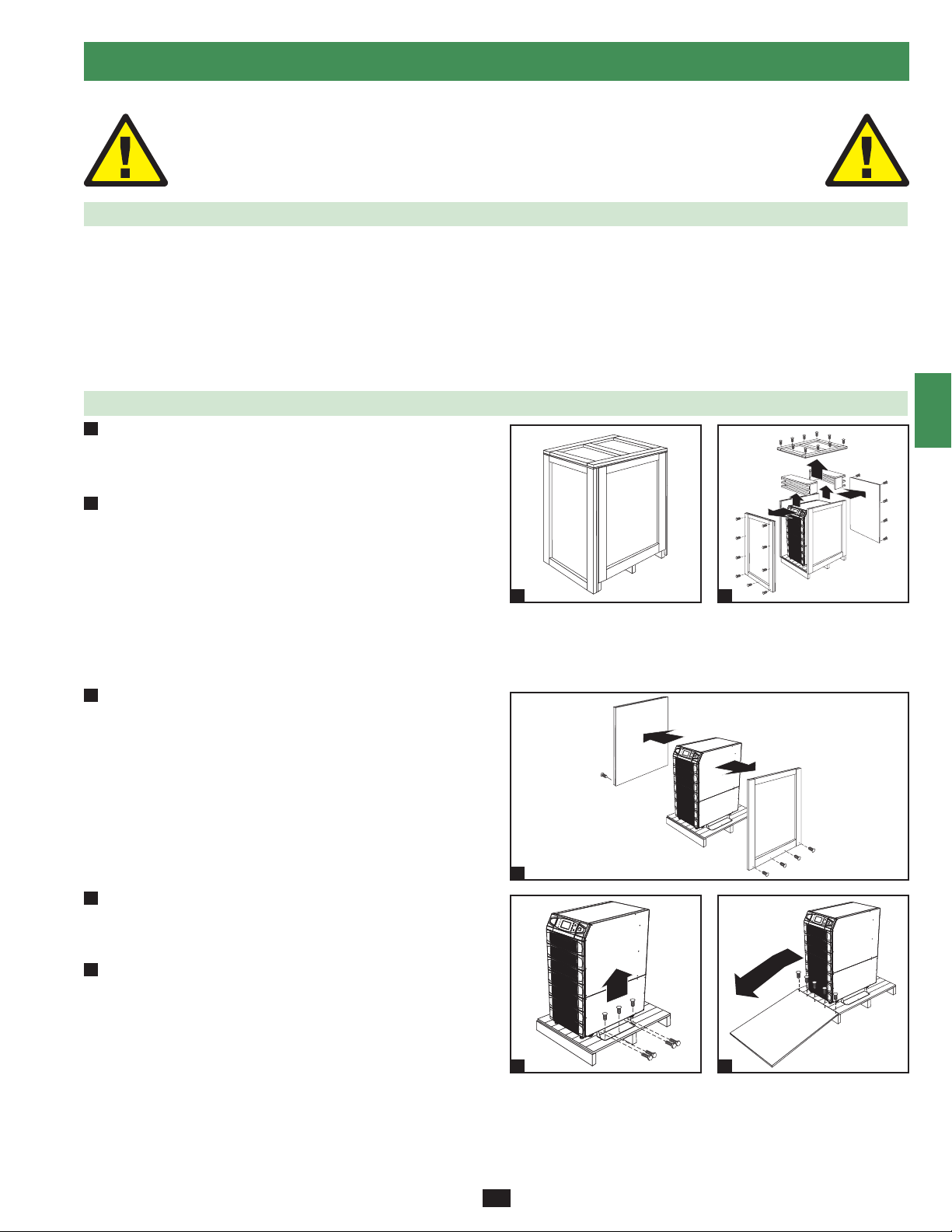

5-1 Preparation 9

5-2 Unpacking 9

5-3 Placement 10

6 Internal Battery Connection 11

4

(Models SU20KX and SU40KX Only)

6-1 Internal Battery Wiring Diagrams 11

6-2 Internal Battery Connection Procedure 13

7 Wiring 16

5

7-1 Wiring Warnings 16

7-2 Wiring Preparation 16

7-3 UPS System Terminal Block Diagram 17

7-4 External Battery Cabinet Wiring Diagrams 17

6

7-5 Electrical and Cable Data 18

7-6 External Battery Cabinet Wiring 19

7-7 AC Input/Output Wiring (Single UPS) 20

7-8 AC Input/Output Wiring (Parallel UPS – Single Input) 21

7

7-9 AC Input/Output Wiring (Parallel UPS – Dual Inputs) 21

8 Operating Modes 22

8-1 Online (Normal) Mode (Single UPS) 22

8

8-2 Battery Backup Mode (Single UPS) 22

8-3 Auto Bypass Mode (Single UPS) 22

8-4 Manual Bypass Mode (Single UPS) 22

8-5 Online Mode (Parallel UPS) 23

9

8-6 Battery Backup Mode (Parallel UPS) 23

8-7 Auto Bypass Mode (Parallel UPS) 23

8-8 Manual Bypass Mode (Parallel UPS) 24

8-9 Hot Standby Mode (Parallel UPS) 24

10

9 Start-Up, Shutdown and Bypass 25

9-1 Control Panel and Breaker Diagrams 25

9-2 Preliminary Checklist (Single UPS) 25

9-3 Normal Start-Up Procedure (Single UPS) 25

11

9-4 Battery Start-Up Procedure (Single UPS) 26

9-5 Manual Bypass Procedure (Single UPS) 27

9-6 Shutdown Procedure (Single UPS) 27

9-7 Preliminary Checklist (Parallel UPS) 28

12

9-8 Start-Up Procedure (Parallel UPS) 29

9-9 Shutdown Procedure (Parallel UPS) 30

9-10 Manual Bypass Procedure (Parallel UPS) 31

9-11 Switching from Manual Bypass to Normal (Parallel UPS) 32

13

10 Display and Configuration 33

10-1 Control Panel Diagram 33

10-2 Display Hierarchy 33

10-3 Default Display 34

10-3-1 Status Display 34

10-4 Main Menu 37

10-5 UPS Setup 39

10-5-1 Bypass Setup 40

10-5-2 Output Setup 41

10-5-3 Battery Setup 43

10-5-4 Charger Setup 46

10-5-5 Parallel Setup 47

10-5-6 Control & Test Setup 48

10-5-7 Local Setup 50

10-6 Maintenance 53

11 Communications 55

11-1 Communications Interfaces 55

11-2 SNMPWEBCARD Slot 55

11-3 Input Dry Contact Interface 55

11-4 Remote Emergency Power Off (EPO) Circuit Diagram 56

11-5 Auxiliary Dry Contact Input Circuit Diagram 56

11-6 External Battery Cabinet Temperature Inputs 56

11-7 External Battery Status Input 56

11-8 Output Dry Contact Interface Detail 57

11-9 Output Dry Contact Circuit Diagram 58

11-10 RS-232 Serial Port Circuit Diagram 58

11-11 Parallel Configuration Port 58

12 Specifications 59

12-1 UPS System Technical Specifications 59

12-2 UPS System Floor Loading Table 59

12-3 Battery Pack Floor Loading Table 59

13 Storage and Service 60

14 Warranty 60

14

2

Page 3

1 – Introduction

Tripp Lite’s SmartOnline 3-Phase UPS Systems (Models SU20KX, SU40KX, SU60KX and SU80KX) are ideal for backing up and protecting data

centers, telecommunications (VoIP), networks, industrial facilities, security/emergency systems and more.

1

Advanced Features:

True on-line double conversion with superior IGBT inverter technology•

Low input current THD allows 1:1 generator sizing for maximum efficiency and cost savings•

Internal N+1 power module redundancy (SU40KX, SU60KX and SU80KX)•

Built-in parallel or hot standby redundancy (1+1) capability for increased capacity or fault-tolerance•

Up to 80kVA capacity in a compact footprint; up to 160kVA in parallel configuration•

High input power factor and high efficiency with low thermal loss and low noise•

Simplified, easy-to-repair, long-life, high-availability system design•

Redundant auxiliary power and control circuits•

Dual input design with separated rectifier and bypass input•

All models support external battery cabinets for extended battery backup runtime•

High-resolution LCD status screen simplifies operation and delivers detailed operational information, including system block diagrams•

2

3

4

5

6

7

8

9

10

11

12

13

14

3

Page 4

2 – Important Safety Instructions

1

SAVE THESE INSTRUCTIONS

All sections of this manual contains instructions and warnings that should be followed during the installation and operation of the UPS

2

systems described in this manual. Read all instructions thoroughly before attempting to move, install or operate the UPS systems described in

this manual. Failure to comply may invalidate the warranty and cause property damage and/or personal injury.

Location Warnings

3

Install the UPS system in a controlled indoor environment, away from moisture, temperature extremes, flammable liquids and gasses, conductive •

contaminants, dust and direct sunlight.

Install the UPS system in a • level, structurally sound location.

4

The UPS system is extremely heavy; be extremely careful when moving or lifting the unit.•

Operate the UPS system at indoor temperatures between 32° F and 104° F (0° C and 40° C) only. For best results, maintain indoor temperatures •

between 62° F and 84° F (17° C and 29° C).

Leave adequate space around all sides of the UPS system for proper ventilation. Do not block, cover or insert objects into the external ventilation •

5

openings of the cabinet.

Do not place any object on the unit, especially containers of liquid.•

Do not mount the unit with its front or rear panel facing down (at any angle). Mounting in this manner will seriously inhibit the unit’s internal •

cooling, eventually causing product damage not covered under warranty.

6

Do not install the UPS system near magnetic storage media, as this may result in data corruption. Keep all recorded magnetic media a minimum •

of 60 cm (24 inches) away from the UPS system.

Do not attempt to stack the UPS system. Attempting to stack the UPS system may cause permanent damage and create a potential for serious •

personal injury.

7

The casters are designed for minor position adjustments within the final installation area only. The casters are not designed for moving the UPS •

system over longer distances.

The casters are not designed to provide long-term support for the UPS system after final installation. Use the levelers to provide long-term •

support.

8

When moving the UPS system, push from the front or rear, not from the sides.•

Do not attempt to unpack or move the UPS system without assistance.•

Connection Warnings

9

The power supply for the UPS system must be 3-phase rated in accordance with the equipment nameplate. It also must be suitably •

grounded and wired according to all applicable national and local electrical wiring standards, codes and regulations.

The UPS system contains hazardous high voltages that have the potential to cause personal injury or death from electric shock.•

10

11

12

The UPS system has its own energy source (battery – internal and/or external). The output terminals may be live even when the UPS system is •

not connected to an AC supply.

If the UPS system receives power from a motor-powered AC generator, the generator must provide clean, filtered, computer-grade output.•

Use of this equipment in life support applications where failure of this equipment can reasonably be expected to cause the failure of the life •

support equipment or to significantly affect its safety or effectiveness is not recommended. Do not use this equipment in the presence of a

flammable anesthetic mixture with air, oxygen or nitrous oxide.

The UPS system is designed to power modern computer loads and associated peripheral devices. Do not use the UPS system to power pure •

inductive or capacitive loads.

Input and output wiring should be performed by trained, qualified electricians only.•

Due to high leakage current, a proper earth ground connection is essential before connecting the AC supply.•

Isolate the UPS system before working on the circuit. An easily accessible disconnect device should be incorporated in the fixed wiring. The •

disconnect device must disconnect all line conductors simultaneously when opened.

13

14

4

Page 5

2 – Important Safety Instructions

Battery Warnings

The UPS system does not require routine maintenance. There are no user-serviceable parts inside. Only qualified service personnel should open •

the access panels for any reason.

Batteries present a risk of electrical shock and burns from high short-circuit current. Battery connection or replacement should be performed •

only by qualified service personnel, observing proper precautions. Turn off the UPS system before connecting or disconnecting internal

batteries. Use tools with insulated handles. Do not open the batteries. Do not short or bridge the battery terminals with any object.

Replace batteries with equivalent batteries available from Tripp Lite. Do not operate the UPS system without batteries.•

The batteries are recyclable. Refer to local codes for disposal requirements.•

Do not dispose of the batteries in a fire, mutilate the batteries or open the battery coverings.•

Battery fuses should be replaced by qualified service personnel only. Blown fuses must be replaced with the same number and type of fuses. •

Potentially lethal voltages exist within the UPS system as long as the battery supply is connected. Service and repair should be performed •

by trained personnel only, while the UPS system is turned off or placed into bypass mode. Disconnect internal batteries (if present) before

performing any service work by switching off the internal battery circuit breaker and removing the battery fuse(s). Disconnect external batteries

(if present) by switching off the external battery cabinet breaker and disconnecting the external battery cabling from the UPS system.

Do not connect or disconnect batteries when the UPS system is operating from the battery supply or when the unit is not in bypass mode.•

Do not remove the plastic sleeves covering internal batteries.•

Internal and external batteries must be replaced by equivalent batteries available from Tripp Lite.•

Before connecting an external battery cabinet to the UPS system, read the external battery cabinet’s documentation. Use only external battery •

cabinets that have been approved by Tripp Lite.

If the UPS system remains off for an extended period of time, it should be turned on periodically to allow the batteries to recharge. The UPS •

system should be turned on and the batteries should be recharged at least one uninterrupted 24-hour period every 3 months. Failure to recharge

the batteries periodically may cause irreversible battery damage.

Wiring Warnings

See • Section 7-1 for wiring warnings

1

2

3

4

5

6

7

8

9

10

11

12

13

14

5

Page 6

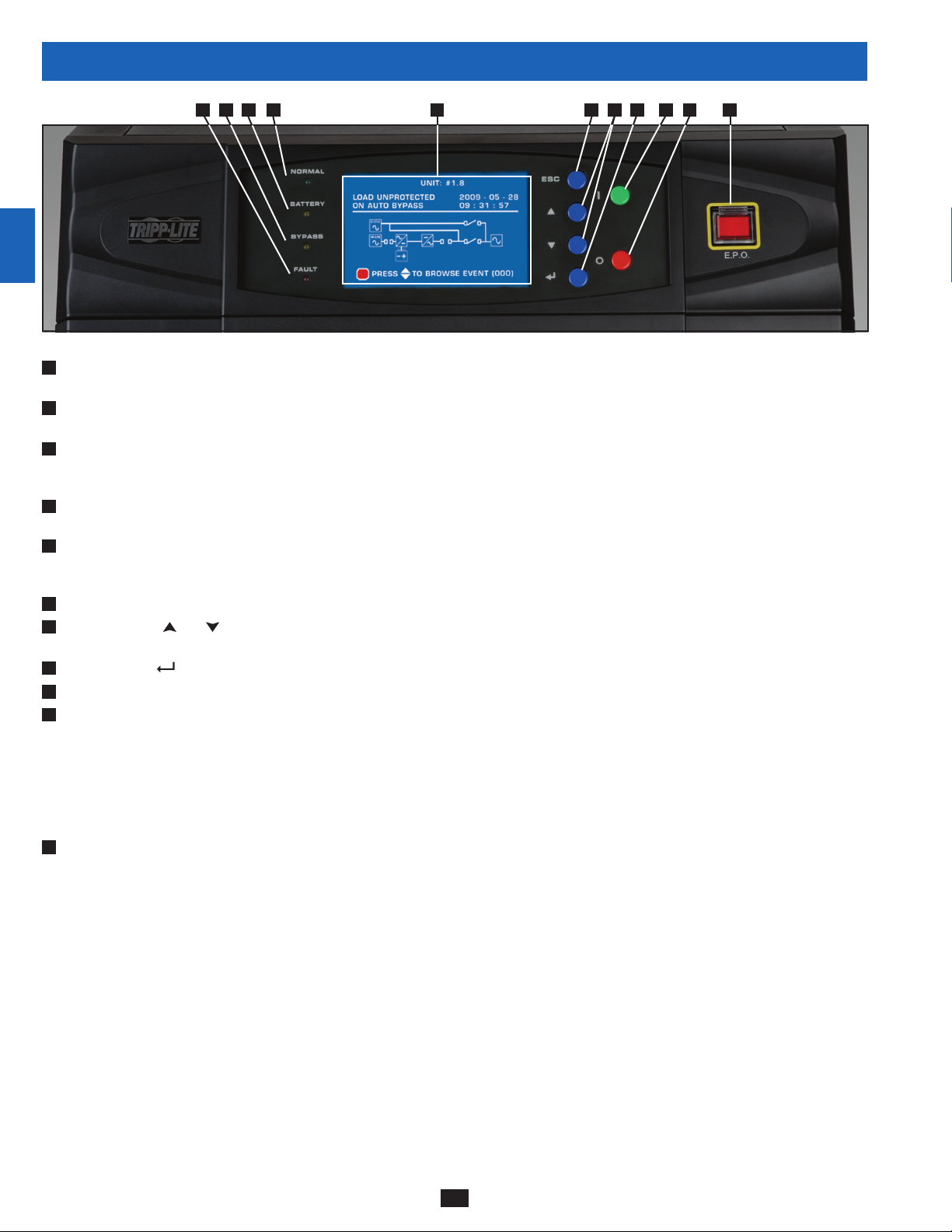

3 – Control Panel Features

1

2

3

4

“NORMAL” LED:• This green light illuminates to indicate that the UPS system is in online (normal) mode. The primary AC input supply is

A

present and within standard operating parameters.

“BATTERY” LED:• This amber light illuminates when the UPS system is in battery backup mode, discharging the batteries to provide power

B

5

6

7

8

9

10

11

12

13

to connected equipment. An audible alarm will also sound.

“BYPASS” LED:• This amber light illuminates when the UPS system is in bypass mode (auto bypass or manual bypass). Battery backup

C

power will not be available to connected equipment while the UPS system is in bypass mode, but connected equipment loads will be

supported by the bypass (reserve) power source.

“FAULT” LED:• This red light illuminates when any UPS system or input power fault occurs. Available diagnostic information will be

D

displayed on the LCD screen.

LCD Status Screen:• This illuminated LCD status screen displays text and graphics to indicate a wide range of UPS system operating

E

conditions and diagnostic data. Note: The LCD backlight will turn off after 10 minutes of inactivity. Turn on the backlight by momentarily

pressing the ON button or one of the scroll buttons.

“ESC” (Escape) Button:• Press this button to return to the previous page or menu.

F

G

Scroll Buttons (• and ): Press these buttons to move the cursor up or down and navigate the control panel menus and screens. These

buttons are also used for data entry in several screens.

Enter Button (• ): Press this button to select a menu item or confirm a setting change.

H

ON Button:• Press and hold this button for 3 seconds to turn the UPS system’s inverter ON.

I

J

OFF Button:• Press and hold this button for 3 seconds to turn the UPS system’s inverter OFF. If the UPS system is in online (normal) mode, it

will switch to auto bypass mode.

Note: Switching the inverter OFF does not stop the converter stage of the UPS and therefore, the connected battery is still charging as

required.

Note: After switching the inverter OFF, if the battery circuit breaker or AC main input circuit breaker are opened and remain open for an

extended period of time, the batteries should be recharged periodically. At a minimum, the batteries should be charged for an uninterrupted

24-hour period every 3 months to maintain their longest usable life. Failure to recharge the batteries may cause irreversible battery damage.

“EPO” (Emergency Power Off) Button:• Press this button to turn the UPS system’s output OFF and also disable bypass output.

K

If the UPS system is in battery backup mode when the EPO button is activated:

Main output and bypass output are turned off, the alarm sounds, fans shut down after approximately one minute, and control circuitry •

remains active.

Releasing the EPO button (by pressing it again) turns off the UPS system completely, including the alarm and control circuit. Press the •

ON button for 3 seconds to restart the UPS system.

If the UPS system is in online (normal) mode when the EPO button is activated:

Main output and bypass output are turned off, the alarm sounds, fans and control circuitry remain active.•

Releasing the EPO button (by pressing it again) turns off the alarm and places the UPS system in auto bypass mode. Press the ON button •

for 3 seconds to return the UPS system to online (normal) mode.

See Section 10 – Display and Configuration for detailed information about the control panel’s menus and displays.

A E F G H I J KBCD

14

6

Page 7

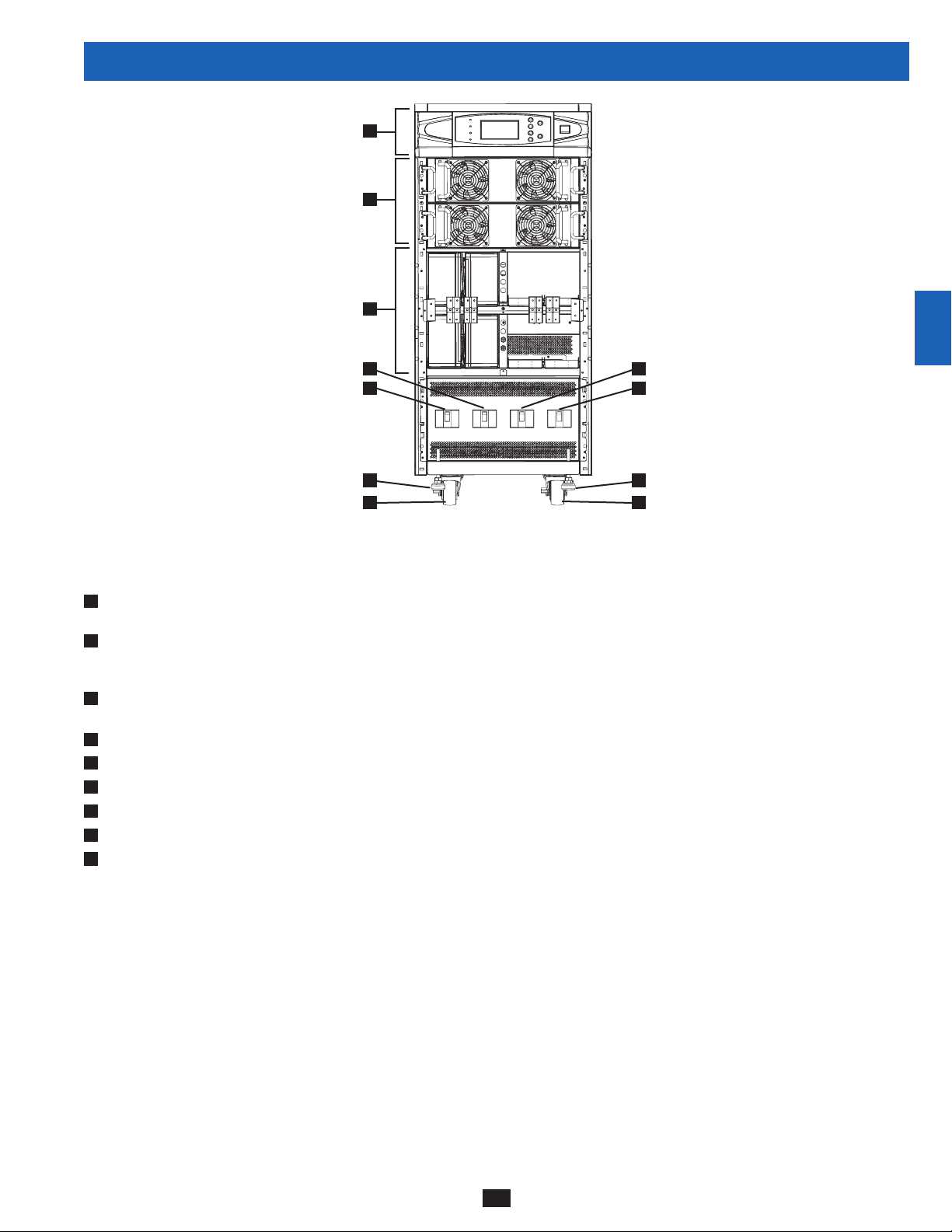

4 – Front and Rear Panel Features

A

B

C

E F

D

1

2

3

4

G

5

H H

I I

SU40KX shown (front)

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

Control Panel:• The control panel allows the operator to monitor and control the UPS system. See Section 3 – Control Panel Features for

A

more information.

B

Internal Power Modules:• 20kVA internal power modules can be replaced in the field without powering down connected equipment loads.

The number of internal power modules varies by model. The internal power modules are capable of N+1 redundancy in SU40KX, SU60KX

and SU80KX models.

C

Internal Battery Pack Compartment (SU20KX and SU40KX only;):• Internal batteries must be connected by a qualified electrician. See

Section 6 – Internal Battery Connection for more information.

D

Output Circuit Breaker Switch (Q4):• Controls AC output power.

E

Manual Bypass Circuit Breaker Switch (Q3):• Controls AC input power to the UPS system during manual bypass operation.

F

Bypass Input Circuit Breaker Switch (Q2):• Controls AC input power to the UPS system during auto bypass operation.

G

Main Input Circuit Breaker Switch (Q1):• Controls AC input power to the UPS system during online (normal) operation.

Levelers:• The levelers provide long-term support for the UPS system.

H

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

I

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

Use the levelers to provide long-term support.

6

7

8

9

10

11

12

13

14

7

Page 8

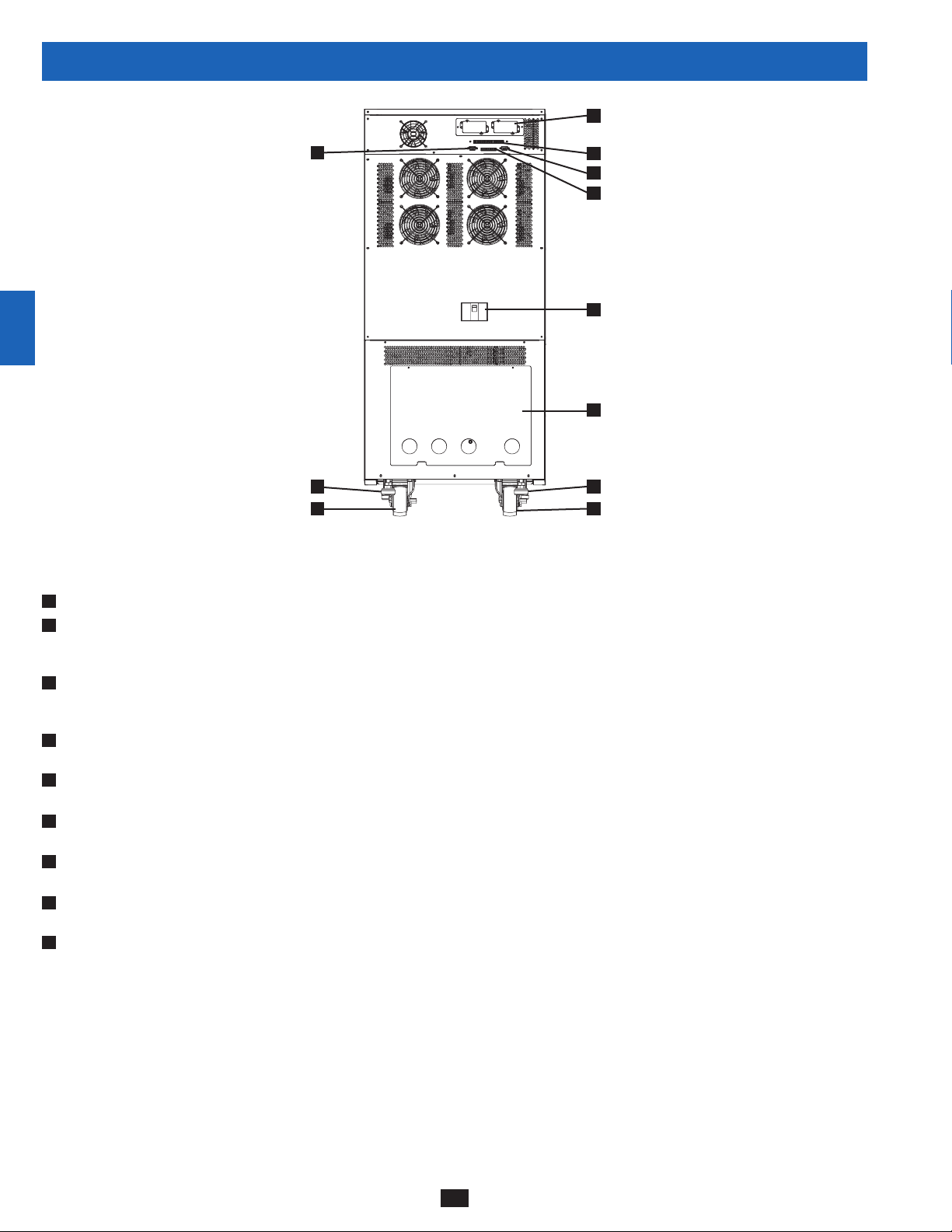

4 – Front and Rear Panel Features (continued)

1

J

2

L

3

4

5

6

7

Note: Individual models may vary from diagrams. Unit shown with front bezels removed.

H

Levelers:• The levelers provide long-term support for the UPS system.

I

Casters:• The casters are designed for small position adjustments within the final installation location only; they are not designed for moving

the UPS system over longer distances. The casters are not designed to provide long-term support for the UPS system after final installation.

8

9

10

11

12

Use the levelers to provide long-term support.

J

Accessory Slot:• Remove the cover panel to install a Tripp Lite SNMPWEBCARD accessory. The SNMPWEBCARD accessory provides an

Ethernet interface for the UPS system and enables remote monitoring and control via SNMP, Web browser or telnet. Visit www.tripplite.com

for more information about the SNMPWEBCARD accessory.

K

RS-232 Serial Communications Port:• This DB9 port connects the UPS system to compatible workstations or servers, enabling automatic

shutdown during extended blackouts and monitoring of operating and power conditions.

L

Parallel Configuration Port:• This DB9 port connects the UPS system to another UPS system of identical type and capacity for use in a

parallel redundancy (1+1) configuration. See Section 7 – Wiring and Section 8 – Operating Modes for more information.

M

Input Dry Contact Interface:• This interface receives dry contact signals that allow the UPS system to receive commands and monitor

external battery conditions. See Section 11 - Communications for more information.

N

Output Dry Contact Interface:• This interface allows the UPS system to send information via dry contact communications. See Section 11 –

Communications for more information.

O

Internal Battery Circuit Breaker Switch (SU20KX and SU40KX only):• Controls the input/output power of the UPS system’s internal

batteries.

P

Terminal Block Cover:• Remove the terminal block cover to access the UPS system’s input, bypass input, external battery cabinet, output and

grounding connection terminals. Wiring conduits pass through the circular knockouts in the terminal block cover. See Section 7 – Wiring for

more information, including a detailed diagram of the terminal block.

H

I I

SU40KX shown (rear)

M

K

N

O

P

H

13

14

8

Page 9

5 – Cabinet Installation

1

Read Section 2 – Important Safety Instructions Before Installation

5-1 Preparation

The UPS system must be installed in a structurally sound area with a level floor that is able to bear the weight of the UPS system, any external

battery cabinet and other equipment that will be installed nearby. The installation site should also have a dedicated AC circuit available that is

compatible with the UPS system’s input requirements. (See Section 12 – Specifications for details on input requirements and floor loading

requirements.) Before unpacking the unit, you should transport the shipping container closer to the final installation site to minimize the distance

you will need to move the unit after the protective shipping container has been removed. If you plan to store the UPS system for an extended

period before installation, follow the instructions in Section 13 – Storage and Service. (Unpacking and storage instructions are also printed on the

“Unpacking and Storage Instructions” sheet secured to the shipping container.) Warning: Do not attempt to unpack or move the UPS system

without assistance.

5-2 Unpacking

1

Inspect the shipping container(s) for visible damage. If you •

determine that the unit has been damaged during shipping, contact

Tripp Lite for assistance. Do not attempt to use the UPS system if

it has been damaged or mishandled.

2

Confirm that the shipping container is upright and use a •

screwdriver to remove its top panel, front panel and back panel.

Also remove the plastic wrap and interior cushioning material.

Confirm that the model name and rating at the rear of the cabinet

match the unit you ordered. Examine the cabinet for any damaged

or loosened parts. Confirm that the shipping container includes the

accessories that ship with the unit. The UPS system should include

an RS-232 serial cable, a parallel redundancy cable, a remote EPO

wiring connector, a dry contact input connector (4 contacts), a dry

contact output connector (12 contacts) and a software CD-ROM. If

anything is missing or damaged, contact Tripp Lite for assistance.

Confirm that the unit is stable, then remove the side panels from •

3

the shipping container.

1

2

2

3

4

5

6

7

8

Remove the bolts from the shipping brackets securing the unit •

4

to the pallet, then remove the shipping brackets from the UPS

system. Warning: Be extremely careful, as the unit could shift

unexpectedly.

5

Use several of the screws you removed in step 2 to attach the top •

panel of the shipping container to the front edge of the shipping

pallet. The smooth surface of the panel should face upward so

that it can be used as a ramp for rolling the unit off the shipping

pallet. Do not attempt to use the top panel as a ramp if it is cracked

or otherwise structurally damaged. Make sure the casters at the

bottom of the unit are unlocked. Using extreme caution, slowly roll

the unit down the ramp with the aid of several assistants.

9

10

3

11

12

4

5

13

14

9

Page 10

50 cm (19.7”)

50 cm (19.7”)

100 cm (39.4”)

5 – Cabinet Installation (continued)

1

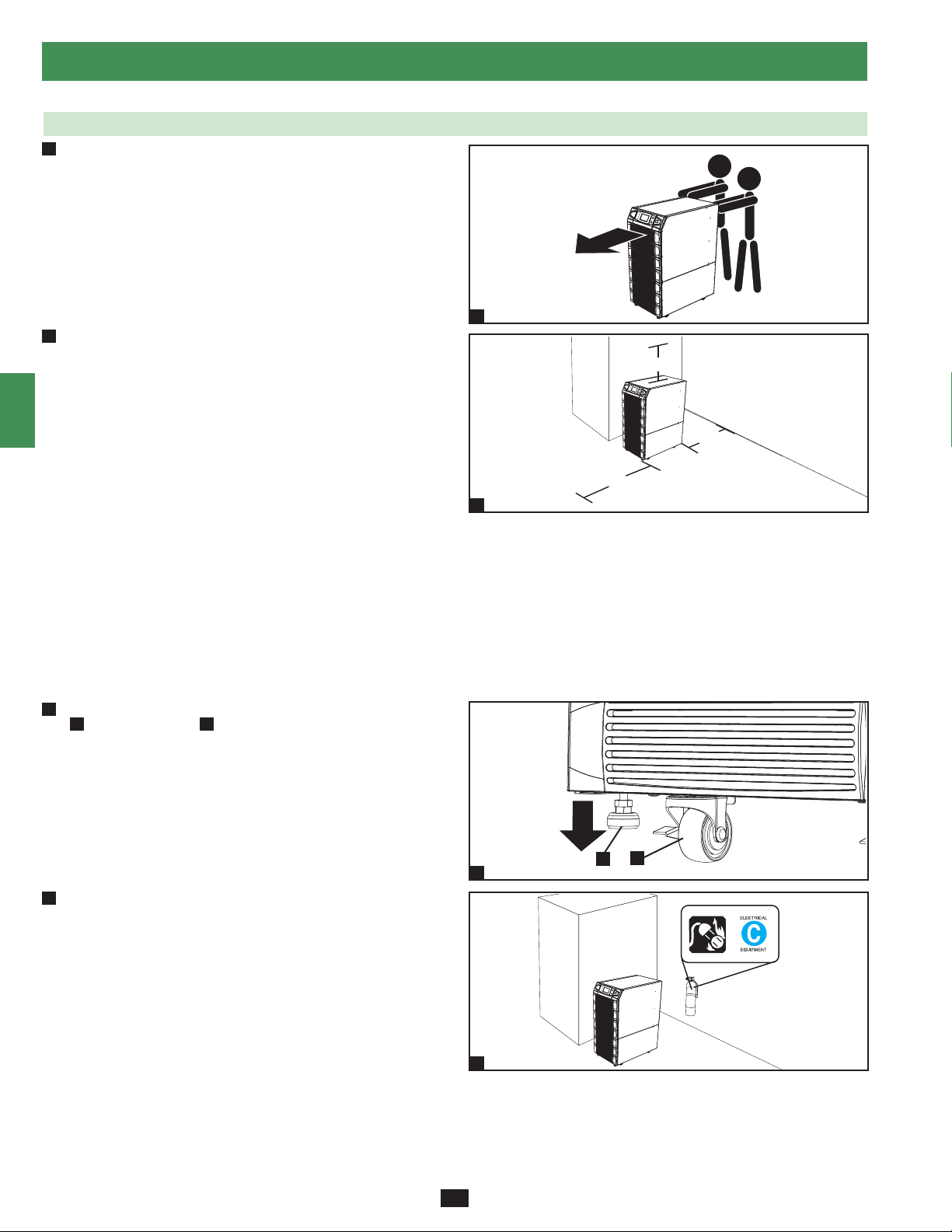

5-3 Placement

Use the casters to move the UPS system for a short distance over •

1

2

3

4

5

6

7

8

9

a level, smooth, stable surface. Do not attempt to use the casters

to move the UPS system over longer distances. The UPS system

should be moved close to its final installation location inside

its shipping container before it is unpacked from the shipping

container. Use a mechanical device of sufficient capacity to move

the shipping container. Warning: The UPS system could tip if it

is moved over an unstable surface. Be extremely careful when

moving the UPS system. Push the UPS system from the front or

rear, not from the sides.

2

Position the UPS system in a structurally sound area with a •

level floor that is able to bear the weight of the UPS system,

any external battery cabinets and other equipment that will be

installed nearby. The installation site should also have a dedicated

AC circuit available that is compatible with the UPS system’s

input requirements. (See the Section 12 – Specifications for

more information about input requirements and floor loading

requirements.) The UPS system must be installed in a clean,

secure environment with a relative humidity less than 90% (noncondensing). Operate the UPS system at indoor temperatures

between 17° C and 29° C (62° F and 84° F). Prevent damage to

cabling by using suitable protective conduits. In order to maintain

proper airflow and service access, you must maintain the following

clearances:

At least 100 cm (39.4”) clearance in front of the UPS system.•

At least 50 cm (19.7”) clearance behind the UPS system.•

At least 50 cm• (19.7”) clearance above the UPS system.

Warning: The cooling fans circulate air from front to back. Do not

use any air conditioning or fan that blows air directly toward the

rear of the UPS system.

After moving the UPS system to its final location, lock the casters •

3

A

and use the levelers B to stabilize the cabinet. Ensure that all

four levelers make firm contact with the floor.

1

2

10

11

12

13

14

For emergency use, install a fire extinguisher rated for energized •

4

electrical equipment fires (Class C rating or exact equivalent, with

a non-conductive extinguishing agent) near the UPS system.

10

A

3

4

B

Page 11

VBoard

W1: RED, W2: BLUE, W3: WHITE, W4: BLACK

12V, 9AH, 10PCS

12V, 9AH, 10PCS

12V, 9AH, 10PCS

12V, 9AH, 10PCS

RED RED

RED RED

BLACK BLACK

BLACK BLACK

RED RED

RED RED

BLACK BLACK

BLACK BLACK

B+

W1

W1

W1

W1

W2

W2

W2

W2

12V, 9AH, 10PCS

12V, 9AH, 10PCS

12V, 9AH, 10PCS

12V, 9AH, 10PCS

W4

W4

W4

W4

W3

W3

W3

W3

B-

N

VBoard

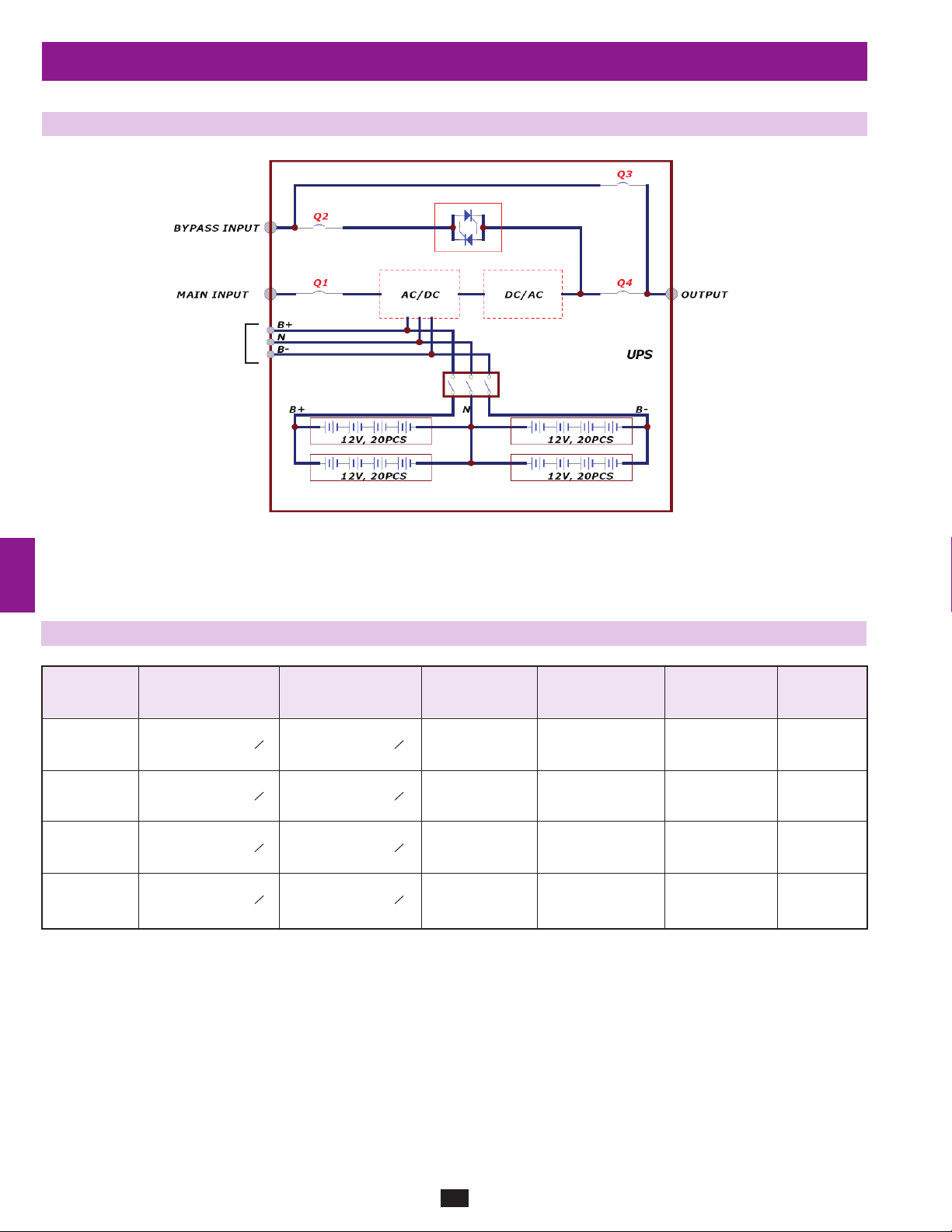

6 – Internal Battery Connection (Models SU20KX and SU40KX Only)

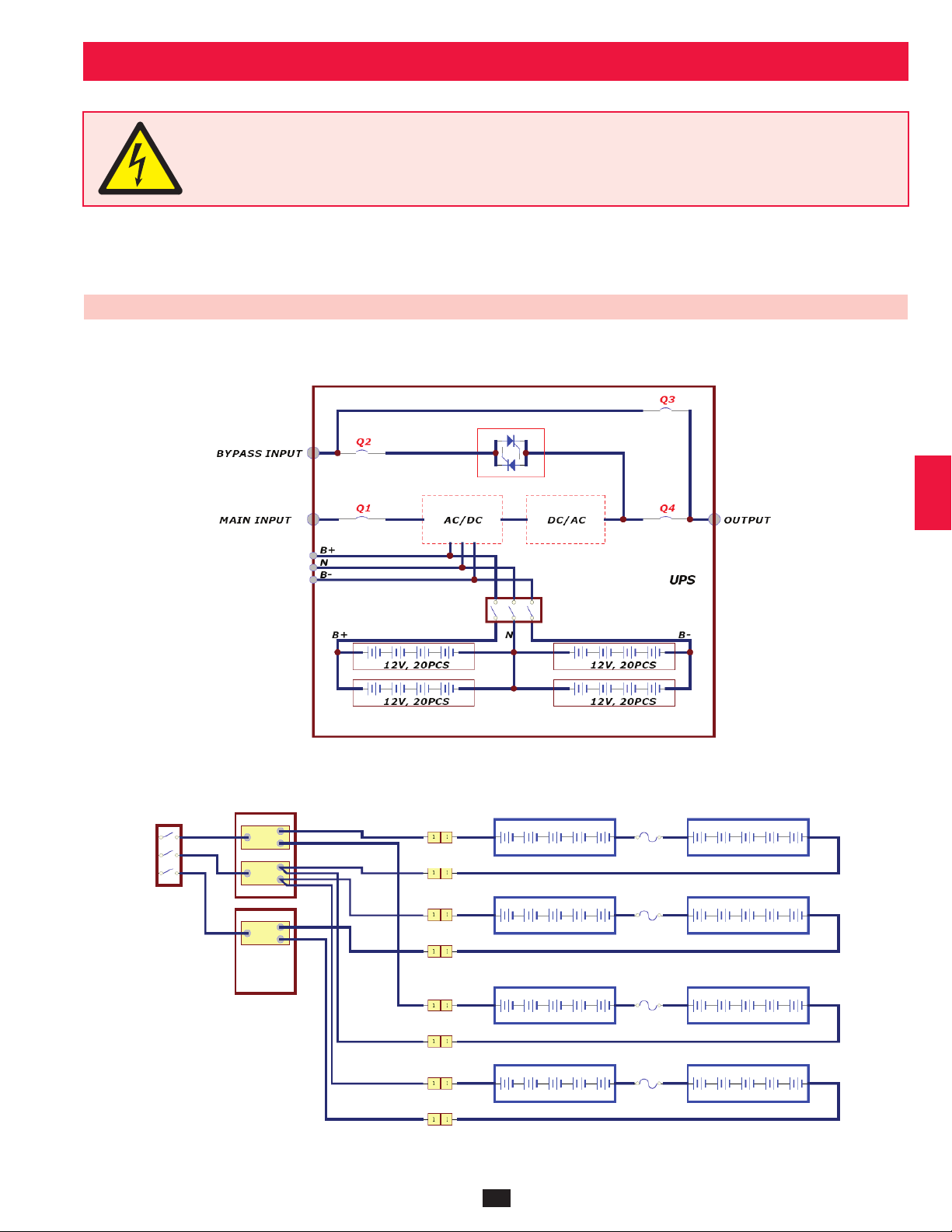

DANGER! LETHAL HIGH VOLTAGE HAZARD!

Potentially lethal high voltage exists within the batteries, even when not connected to a UPS system. Battery connection

should be performed by qualified service personnel only, following all the precautions listed in this manual and adhering to

local electrical codes. Read Section 2 – Important Safety Instructions before proceeding.

1

2

Internal battery connection is for models SU20KX and SU40KX only. Each internal battery pack consists of two strings of batteries: one string

with a black cable and one string with a red cable. The number of internal battery packs varies with model.

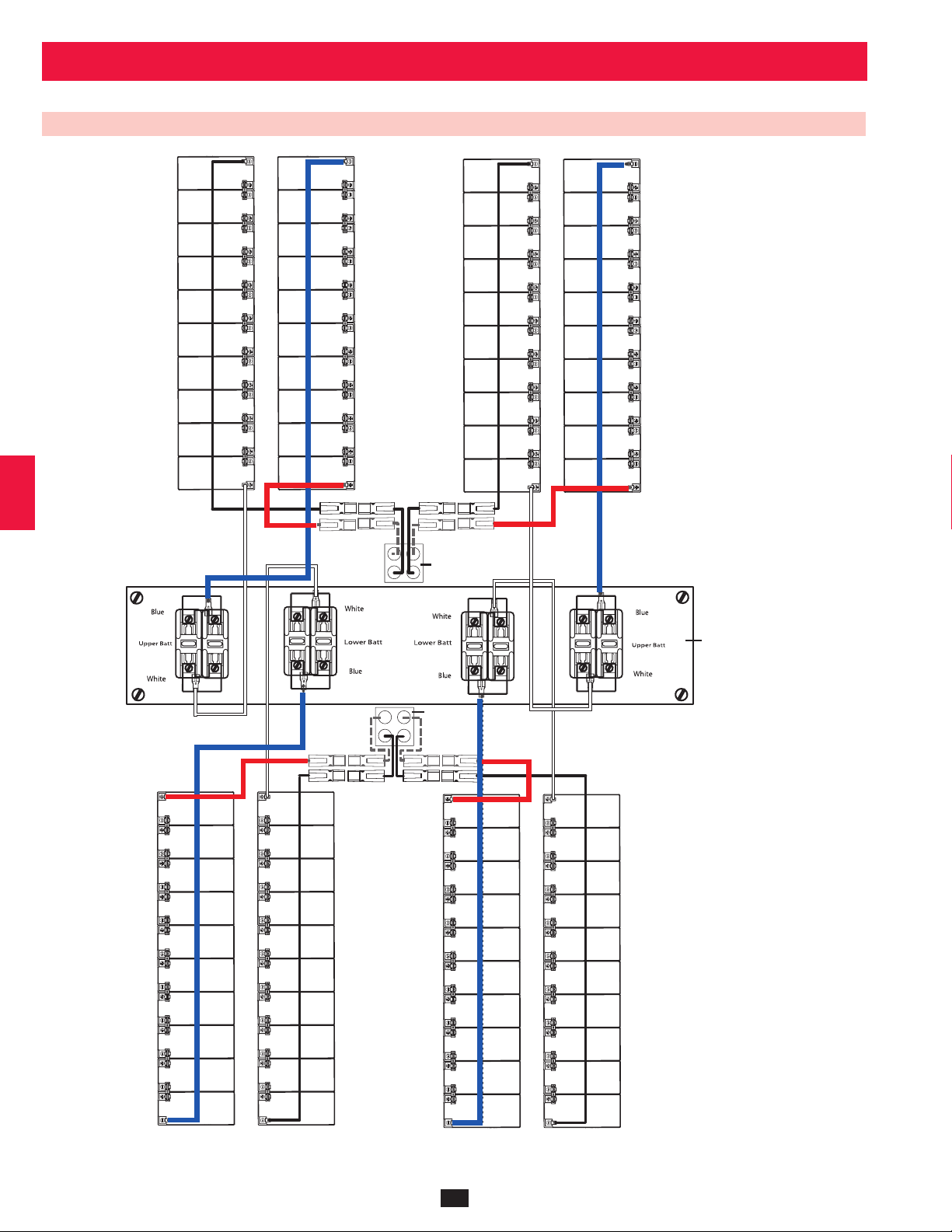

6-1 Internal Battery Wiring Diagrams

Review the internal battery wiring diagrams prior to connecting the internal batteries. The UPS system can accept up to four internal battery packs

(each pack consists of two strings; each string consists of 10 batteries). The number of internal battery packs varies with model.

3

4

5

6

7

8

SU40KX shown

10

9

SU40KX shown

11

11

12

13

14

Page 12

UPS System

Battery Back

Connector

UPS System

Battery Back

Connector

Fuse Block Bracket

6 – Internal Battery Connection (continued)

1

6-1 Internal Battery Wiring Diagrams (continued)

2

3

4

5

6

10

11

12

7

8

9

13

14

SU40KX shown

12

Page 13

6 – Internal Battery Connection (continued)

6-2 Internal Battery Connection Procedure

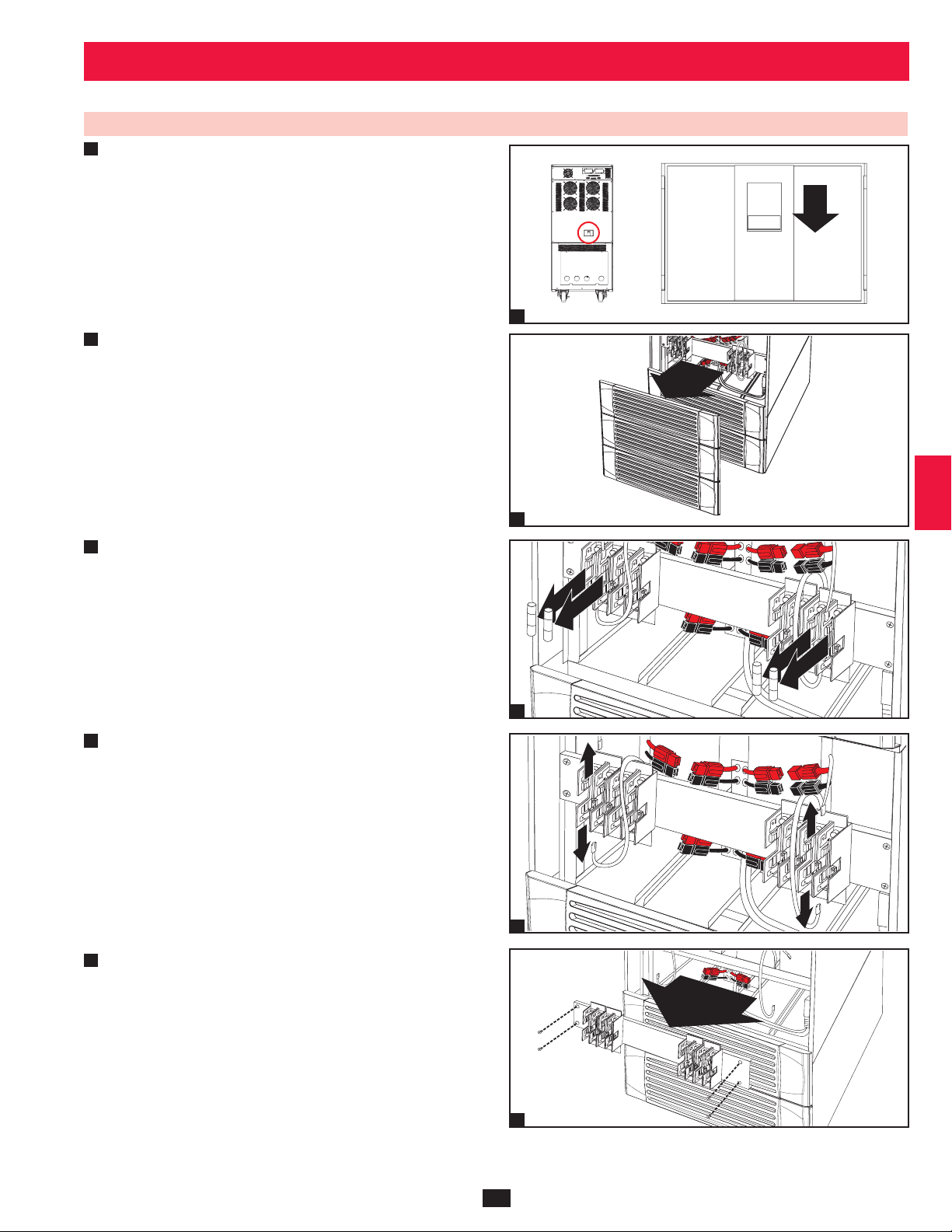

Place the UPS system in bypass (or turn it completely off) and turn •

1

off the internal battery circuit breaker switch, located on the rear of

the UPS system.

1

2

3

Remove the battery access bezels, located on the front of the UPS •

2

system.

3

Remove the battery cartridge fuses from each fuse block.•

Disconnect the blue and white jumper cables attached to each fuse •

4

block. Warning: When disconnecting the jumper cables, pull

them straight away from the fuse block with even force. Do not

wiggle them side-to-side, as this may damage the connector.

1

4

5

6

2

7

8

3

9

5

10

11

4

Remove the fuse block bracket. Note its orientation before •

removal.

12

13

5

14

13

Page 14

6 – Internal Battery Connection (continued)

1

6-2 Internal Battery Connection Procedure (continued)

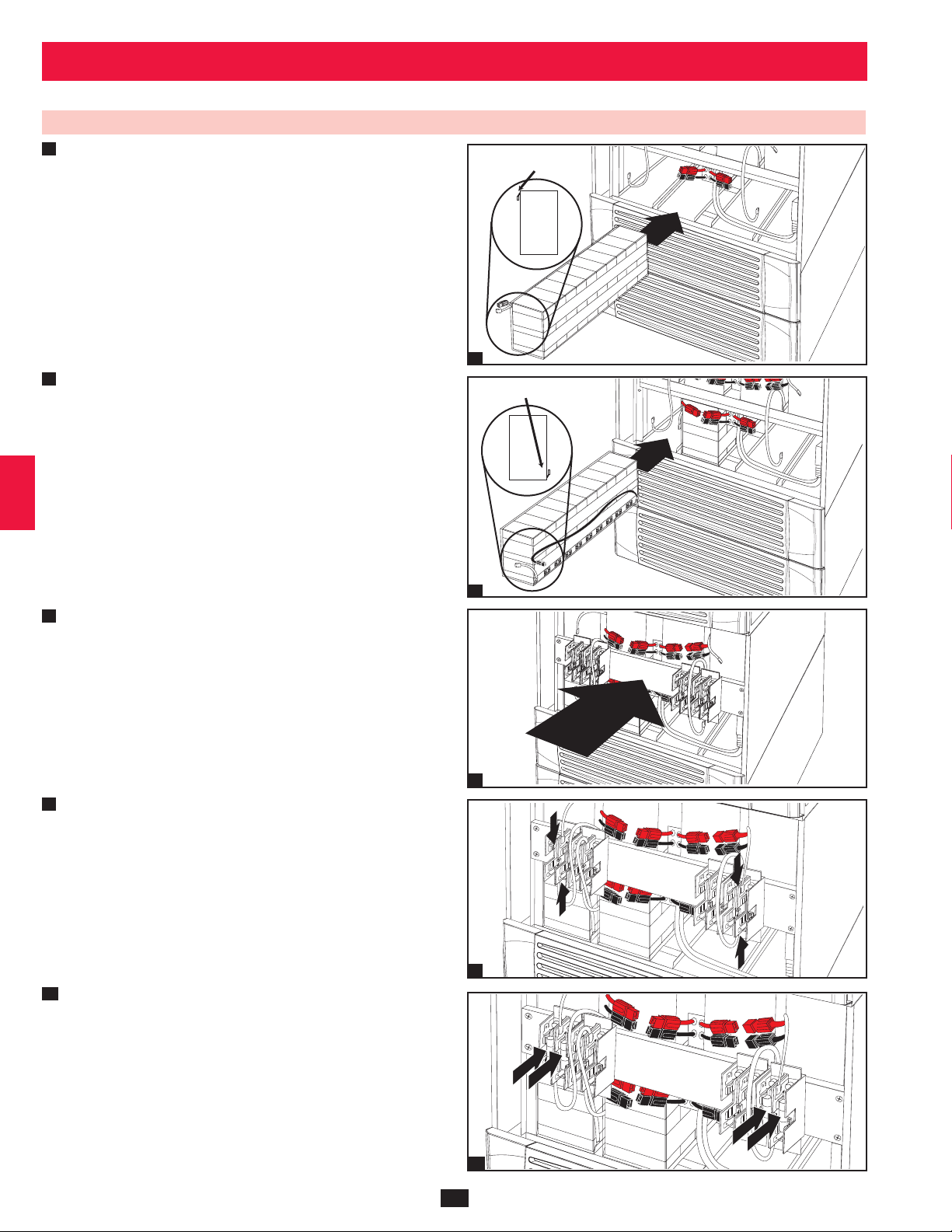

Slide a battery string with a red cable into an empty slot within •

6

2

the battery compartment. Make sure the battery string is oriented

as shown in the diagram. Note: Start with the empty slots at the

bottom of the battery compartment and work toward the empty

slots at the top of the battery compartment.

TERMINALS

3

SIDE VIEW

4

6

7

Slide a battery string with a black cable into an empty slot within •

the battery compartment, next to the battery string that you inserted

5

in step 6. Make sure the battery string is oriented as shown in the

diagram. Repeat steps 6 and 7 as needed until all the battery strings

have been inserted into the empty battery slots. Note: Depending

on the model of the UPS system, some battery compartment slots

may remain empty.

TERMINALS

SIDE VIEW

6

7

7

Reconnect the fuse block bracket. (The letters on the fuse block •

8

bracket should be upright when it is in the correct orientation.)

8

10

11

12

13

14

9

8

Connect the blue and white jumper cables on each internal battery •

9

pack to the corresponding fuse block. The labeling next to the fuse

block identifies the correct fuse block for each cable.

9

10

Insert the battery cartridge fuses into each fuse block. The fuses are •

interchangeable. Make sure the fuses are firmly snapped into place.

Warning: Battery cartridge fuses must be inserted last due to

potential arcing of connectors. Blown fuses must be replaced

by a qualified electrician. Replace only with fuses of the same

type and rating.

10

14

Page 15

240

6 – Internal Battery Connection (continued)

6-2 Internal Battery Connection Procedure (continued)

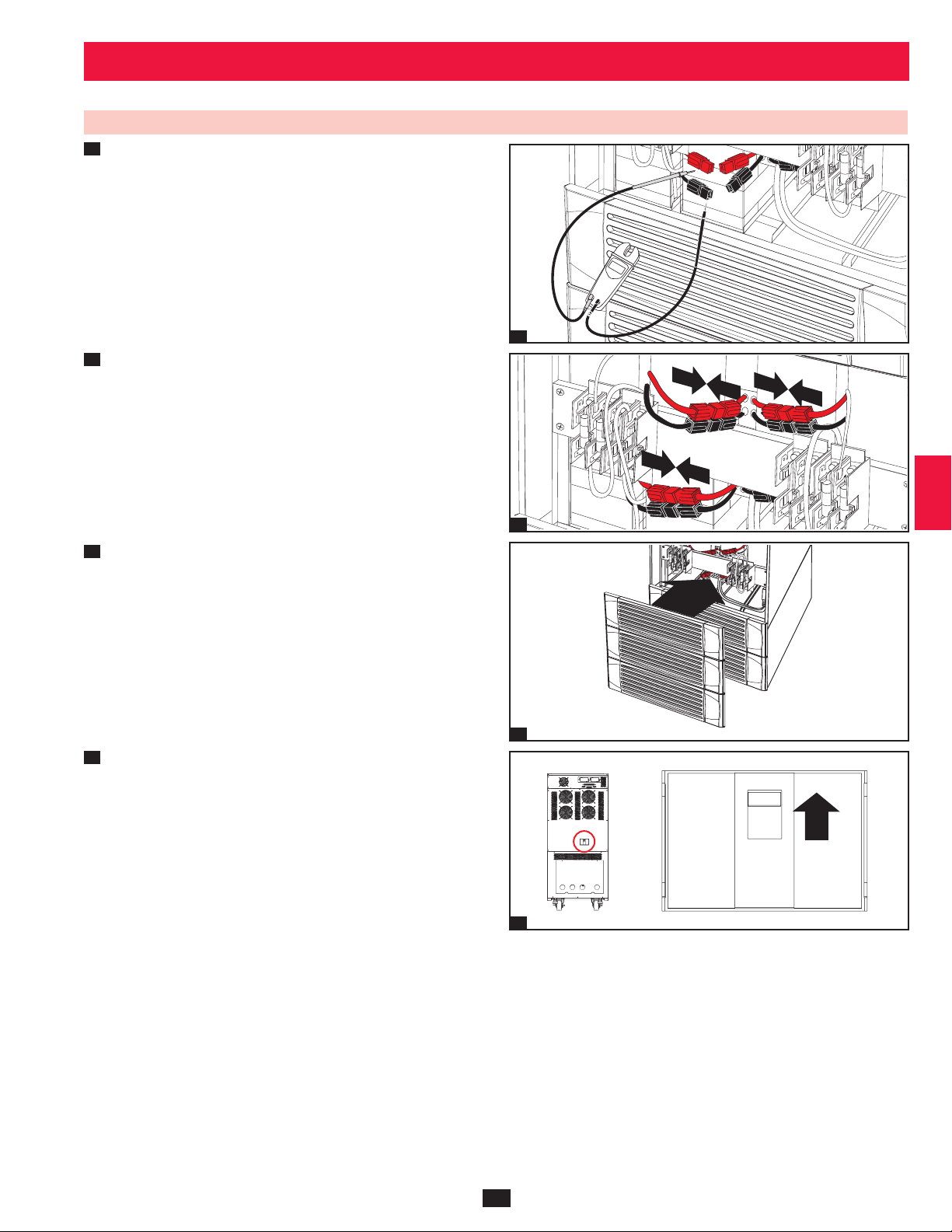

11

Use a voltmeter (user-supplied) to test the voltage of each internal •

battery pack. Observing proper polarity, connect the voltmeter’s

black probe to the battery pack’s black connector; connect the

voltmeter’s red probe to the battery pack’s red connector. Make

sure the voltmeter’s probes touch the metal contacts inside the

battery pack’s connectors. The battery pack’s acceptable DC

voltage range is between 220V and 280V DC (nominal 240V DC).

If several voltmeter tests yield results outside the acceptable DC

voltage range, contact Tripp Lite for assistance in determining the

possible causes of the incorrect voltage reading before proceeding.

1

2

3

Connect the • black cable for each internal battery pack to the

12

nearest black connector located inside the UPS system’s battery

compartment. Connect the red cable for each internal battery

pack to the nearest red connector located inside the UPS system’s

battery compartment. Warning: Observe proper polarity by

connecting negative to negative (black to black) and positive

to positive (red to red). Failure to observe proper polarity will

damage the UPS system and create a serious risk of personal

injury and property damage.

13

Replace the battery access bezels.•

14

Follow the proper procedure to restart the UPS and re-transfer the •

critical load to protected power.

Note: If you need to remove or replace internal battery packs, modify

steps 6 and 7 by removing and/or replacing the existing internal battery

packs, as required.

11

12

13

4

5

6

7

8

9

10

14

12

13

11

15

14

Page 16

7 – Wiring

1

DANGER! LETHAL HIGH VOLTAGE HAZARD!

2

7-1 Wiring Warnings

3

De-energize all input and output power sources of the UPS system before installing cables or making electrical connections.•

Use flexible cable of sufficient length to permit UPS system servicing. The maximum cable length is 10 m (32.8 ft).•

Use ferrule caps to cover termination cables and prevent frayed ends from shorting on the UPS system terminal block.•

4

Use cabling rated VW-1, FT-1 or better.•

Use cable sleeves and connector clamps.•

The neutral conductor must be the same size as the current conductors.•

Tighten all connections with a torque of at least 3.95 N·m (35 in·lb)•

5

Confirm that all cables are marked correctly according to their purpose, polarity, phase and diameter.•

If the UPS system’s input/output power source is wye-wye, then “Neutral” and “Ground” must not be connected.•

If the input power source has VNG>0, install a grounded wye secondary isolation transformer with a properly bonded neutral to ground before •

6

the UPS system and input power source.

For equipment requiring a neutral connection to an IT power distribution system that requires neutral isolation upon disconnect, the disconnect •

device must be a four-pole device and must disconnect all line conductors and the neutral conductor. If a disconnect device interrupts the neutral

conductor, it must simultaneously interrupt all line conductors.

7

Allow the batteries to charge uninterrupted for 24 hours after the initial wiring connection.•

Observe proper polarity by connecting negative to negative, positive to positive and normal “N” to normal “N”. Failure to observe proper •

polarity will damage the UPS system and create a serious risk of personal injury and property damage.

Observe proper phase by connecting R to R, S to S, T to T and N to N. Source power phase rotation must be verified as RST before powering •

8

the UPS. Failure to observe proper phase will damage the UPS system and create a risk of personal injury and property damage.

All wiring should be performed by a qualified electrician, in accordance with the warnings in this manual and all applicable

electrical and safety codes. Incorrect wiring may damage the UPS system severely and cause serious personal injury and

property damage. Read Section 2 – Important Safety Instructions before proceeding.

7-2 Wiring Preparation

De-energize all input and output (AC and DC) of the UPS system and external battery cabinet (if present).•

9

Mark all cables according to their correct purpose, polarity, phase and diameter.•

Review the diagrams in • Section 7-3 and Section 7-4 to familiarize yourself with the terminal blocks.

Consult the table in • Section 7-5 to find the correct electrical input/output characteristics for the UPS system.

10

Note: If the UPS system’s input/output power source is wye-wye, then “Neutral” and “Ground” must not be connected. If the input power source

has VNG>0, install an isolation transformer before the UPS system and input power source, then connect the UPS system’s “Neutral” and

“Ground” together.

11

12

13

14

16

Page 17

+ –

+

–

7 – Wiring (continued)

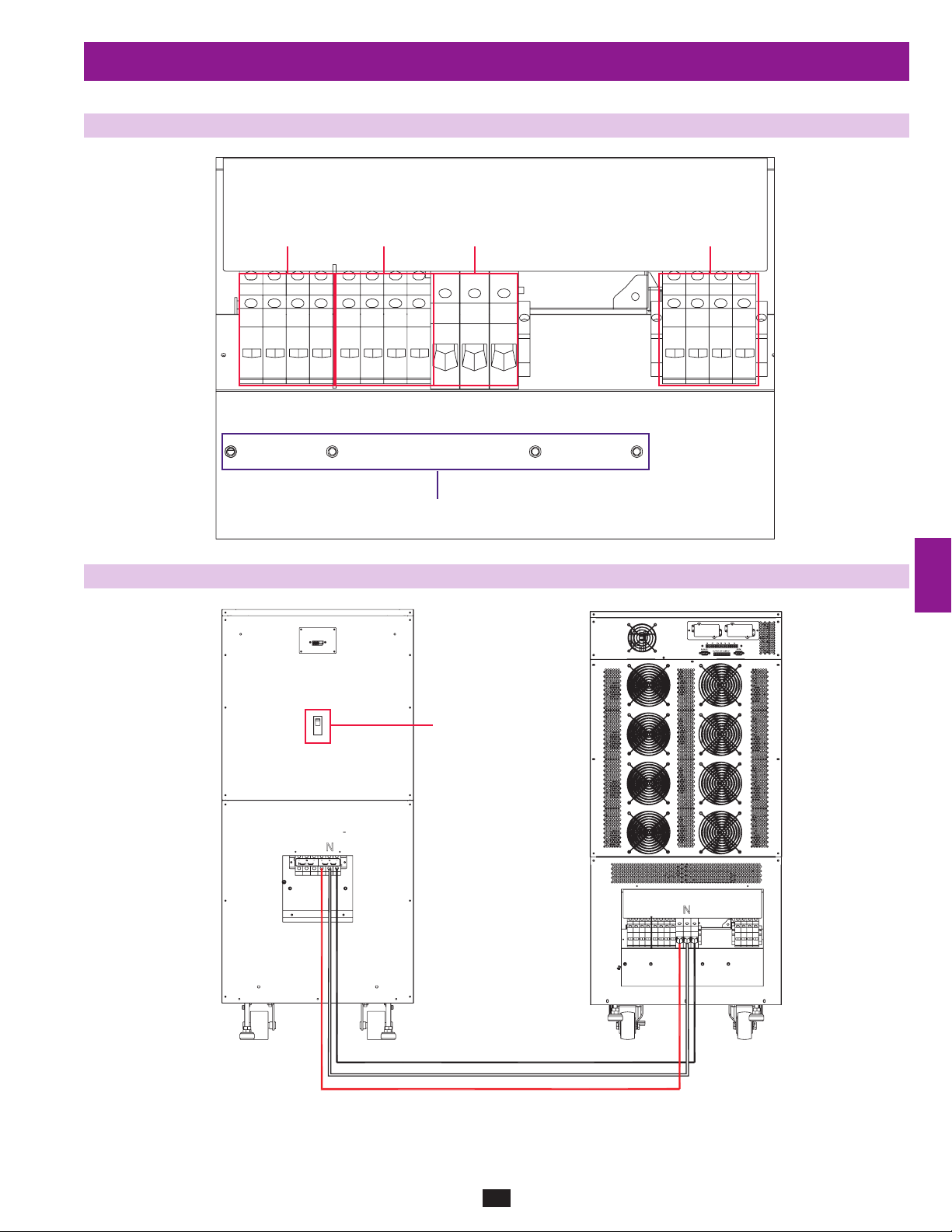

7-3 UPS System Terminal Block Diagram

1

2

Main Input

R

S

R

T

N

S

Grounding Terminals

External Battery

Connection

T

N

7-4 External Battery Cabinet Wiring Diagrams

N+ –

OutputBypass Input

R

S

T

N

3

4

5

6

7

8

External Battery

Cabinet Breaker

Switch

SU80KX and BP480V40C shown for illustration only; consult the battery cabinet’s documentation for exact specifications

9

10

11

12

13

14

17

Page 18

7 – Wiring (continued)

1

7-4 External Battery Cabinet Wiring Diagrams (continued)

2

3

4

TO EXTERNAL

BATTERY CABINET

5

6

External Battery Cabinets

B Cabinet: 26AH, 125A Fuses

C Cabinet: 40AH, 160A Fuses

7

10 Year Cabinet: 55AH, 78AH, 103AH, 140AH; 250A Circuit Breaker

7-5 Electrical and Cable Data

SU40KX shown

8

Input, Bypass Input, Reserve,

and Output Output and Battery Battery Circuit Battery Cable

Model Input Output Breaker Size Cable Size Breaker Fuse Size Size

SU20KX 220/380V, 230/400V 220/380V, 230/400V 125A 50 mm2

9

or 240/415V AC, 3O, or 240/415V AC, 3O, 50A 10 mm2 160A 70 mm2

4-wire + ground 4-wire + ground 250A 70 mm

SU40KX 220/380V, 230/400V 220/380V, 230/400V 125A 50 mm2

or 240/415V AC, 3O, or 240/415V AC, 3O, 75A 25 mm2 160A 70 mm2

4-wire + ground 4-wire + ground 250A 70 mm

10

SU60KX 220/380V, 230/400V 220/380V, 230/400V 125A 50 mm2

or 240/415V AC, 3O, or 240/415V AC, 3O, 125A 50 mm2 160A 70 mm2

4-wire + ground 4-wire + ground 250A 70 mm

SU80KX 220/380V, 230/400V 220/380V, 230/400V 125A 50 mm2

or 240/415V AC, 3O, or 240/415V AC, 3O, 150A 70 mm2 160A 70 mm2

11

4-wire + ground 4-wire + ground 250A 70 mm

2

2

2

2

12

13

14

18

Page 19

+ –

+ –

+

–

7 – Wiring (continued)

7-6 External Battery Cabinet Wiring

Warning: External battery cabinets vary. Read the external battery cabinet’s documentation before attempting to connect it to the UPS

system. Use only external battery cabinets that have been approved by Tripp Lite.

Note: An external battery cabinet is required with models SU60KX and SU80KX. It is optional with models SU20KX and SU40KX. Contact Tripp

Lite for external battery cabinet ordering information.

De-energize all input and output (AC and DC) of the UPS system •

1

and external battery cabinet, and confirm that the external battery

cabinet breaker switch

been wired to an AC power source, see Section 9-6 for shutdown

instructions.)

2

Remove the terminal block covers from the UPS system and •

external battery cabinet.

is off. (If the UPS system has already

A

A

1

1

2

3

4

5

6

3

Connect the positive (+), neutral (N) and negative (-) UPS •

system connection terminals of the external battery cabinet to the

corresponding positive (+), neutral (N) and negative (-) external

battery connection terminals of the UPS system. See Section 7-3

and the external battery cabinet’s documentation for terminal

block diagrams. See Section 7-4 for wiring diagrams. See Section

7-5 for cable size requirements. Cabling should be protected by

flexible conduit and routed through the appropriate knockouts in

the terminal block cover. Warning: Observe proper polarity by

connecting negative to negative and positive to positive. Failure

to observe proper polarity will damage the UPS system and

create a risk of personal injury and property damage.

4

Connect the external battery cabinet’s grounding terminal•

UPS system’s corresponding grounding terminal

(5.189 mm) ground cable. Keep the ground cable connected at all

times after installation.

5

Connect the UPS system’s grounding terminal•

facility’s earth ground

ground cable. Keep the ground cable connected at all times after

installation.

Replace the terminal block cover of the external battery cabinet. If •

6

you do not plan to wire the AC input/output of the UPS system at

this time, replace the terminal block cover of the UPS system.

with a 4 AWG (5.189 mm) minimum

B

with a 4 AWG

B

to your

A

A

to the

2

7

8

9

3

10

A

B

4

11

12

13

B

A

65

19

14

Page 20

+ –

+ –

R S T N R S T N R S T N

7 – Wiring (continued)

1

7-7 AC Input/Output Wiring (Single UPS)

After de-energizing all input and output (AC and DC) of the UPS •

1

2

3

system, remove the terminal block cover from the UPS system.

10

4

If you did not connect the ground cable in • Section 7-6, connect the

2

UPS system’s grounding terminal

B

with a 4 AWG (5.189 mm) ground cable. Keep the ground cable

connected at all times after installation.

to your facility’s earth ground

A

1

5

B

A

6

3

Remove the UPS system’s front bezel to expose the circuit •

breakers. First, confirm that the main input circuit breaker switch

Q1

and the bypass input circuit breaker switch

7

Second, confirm that the manual bypass circuit breaker switch

is off. Third, confirm that the output circuit breaker switch

off.

are both off.

Q2

Q4

Q3

is

2

Q4 Q2 Q1Q3

8

3

4

Confirm the phase of each cable, then connect the cables according •

9

to the UPS system terminal block diagram in Section 7-3. See

Section 7-5 for cable size requirements. Cabling should be

protected by flexible conduit and routed through the appropriate

knockouts in the terminal block cover. Warning: Observe proper

phase rotation by connecting R to R, S to S, T to T and N to N.

Failure to observe proper phase will damage the UPS system

and create a risk of personal injury and property damage.

11

12

13

14

4

5

Replace the UPS system’s terminal block cover.•

5

20

Page 21

7 – Wiring (continued)

7-8 AC Input/Output Wiring (Parallel UPS – Single Input Source)

Parallel UPS Warnings:

The total input cable length must be equal to the total •

output cable length in order to prevent unbalanced load

sharing between two UPS systems under reserve mode

(i.e. Res1 + OP1 = Res2 + OP2; deviation must be <10%).

Parallel configuration only supports 2 UPS systems (1+1 •

redundancy or capacity). Do not attempt to link more than

two UPS systems via parallel configuration.

The UPS systems must have the same rating and capacity •

for parallel UPS installation. Attempting to link

dissimilar UPS systems will damage the UPS systems

and create a serious risk of personal injury and property

damage.

Each UPS must have its Parallel group set to 2 and a •

different “Parallel ID” that indicates the UPS systems are

being run in parallel. (See Section 10-5-5 for more details.)

1

Follow the steps in • Section 7-7, wiring the UPS systems as shown

in the diagram.

2

Connect the included parallel UPS cable•

of each UPS system.

to the parallel port

A

B

1

1

2

3

4

5

B

6

2

7-9 AC Input/Output Wiring (Parallel UPS – Dual Input Sources)

Parallel UPS Warnings:

The total input cable length must be equal to the total •

output cable length in order to prevent unbalanced load

sharing between two UPS systems under reserve mode

(i.e. Res1 + OP1 = Res2 + OP2; deviation must be <10%).

Parallel configuration only supports 2 UPS systems (1+1 •

redundancy or capacity). Do not attempt to link more than

two UPS systems via parallel configuration.

The UPS systems must have the same rating and capacity •

for parallel UPS installation. Attempting to

link dissimilar UPS systems will damage the UPS systems

and create a serious risk of personal injury and property

damage.

Each UPS must have its Parallel group set to 2 and a •

different “Parallel ID” that indicates the UPS systems are

being run in parallel. (See Section 10-5-5 for more details.)

1

Follow the steps in • Section 7-7, wiring the UPS systems as shown

in the diagram.

2

Connect the included parallel UPS cable •

of each UPS system.

A

to the parallel port B

1

B

A

7

8

9

10

11

B

B

A

12

13

21

2

14

Page 22

8 – Operating Modes

1

This section provides a basic description of the UPS system’s operating modes. For more information about switching between operating modes,

refer to Section 9 – Start-Up, Shutdown and Bypass.

2

8-1 Online (Normal) Mode (Single UPS)

In online (normal) mode, the UPS system’s rectifier converts incoming

AC utility power to DC power that charges the batteries and supplies the

inverter. The inverter transforms the DC power to precision-regulated,

3

pure sine wave AC power that supports the operation of connected

equipment. This dual conversion technology isolates connected

equipment from all power problems and ensures that connected

equipment receives ideal power at all times.

4

8-2 Battery Backup Mode (Single UPS)

5

When a blackout or other extreme power event occurs, the UPS system

automatically switches from normal mode to battery backup mode. The

UPS system’s batteries (internal and/or external) provide emergency

DC power to the inverter. The inverter transforms the DC power

to precision-regulated, pure sine wave AC power that supports the

6

operation of connected equipment.

7

8-3 Auto Bypass Mode (Single UPS)

If the inverter malfunctions due to excessive temperature, overload,

output short circuit, abnormal voltage or battery problems, the inverter

8

will shut down. If the UPS system detects a bypass (reserve) power

source that conforms to normal parameters, then the UPS system

automatically switches to auto bypass mode to continue supplying

power to connected equipment. When all problems are eliminated, the

UPS system switches back to online (normal) mode automatically.

9

10

8-4 Manual Bypass Mode (Single UPS)

If UPS system maintenance or repair is required, you can bypass

the UPS system and enable bypass (reserve) power manually. After

confirming that bypass power is present, stop the inverter by pressing

11

the OFF button and answering “YES” to the question “Transfer to

Bypass Mode?” (this transfers the UPS to static bypass), then switch the

UPS system into manual bypass mode. (See Section 9-5 for complete

manual bypass procedure.) This allows service technicians to perform

maintenance or repair jobs without interrupting the flow of AC power

12

to connected equipment. Warning: The UPS system must be deenergized completely before performing maintenance or repair by

shutting it down completely after switching it to manual bypass

mode.

13

14

22

Page 23

8 – Operating Modes (continued)

8-5 Online Mode (Parallel UPS)

Parallel redundancy (1+1) provides UPS system redundancy or

increased total capacity. Under parallel redundancy, the total load is

shared by two UPS systems. If one of the UPS systems malfunctions,

the total connected equipment load is supported by the remaining UPS

system. If the total load exceeds the capacity of the remaining UPS

system, it will switch to auto bypass mode.

1

2

3

4

5

8-6 Battery Backup Mode (Parallel UPS)

Similar to on battery backup mode for a single UPS system (Section

8-2), except the total connected equipment load is shared by the parallel

(1+1) UPS systems.

8-7 Auto Bypass Mode (Parallel UPS)

Similar to auto bypass mode for a single UPS system (Section 8-3),

except with parallel (1+1) UPS systems.

6

7

8

9

10

11

23

12

13

14

Page 24

8 – Operating Modes (continued)

1

8-8 Manual Bypass Mode (Parallel UPS)

Similar to manual bypass mode for a single UPS system (Section 8-4),

except with parallel (1+1) UPS systems. Note: Both UPS systems must

2

be switched into manual bypass mode.

3

4

5

8-9 Hot Standby Mode (Parallel UPS)

6

For added fault-tolerance, the redundant UPS system acts as the bypass

(reserve) power source for the main UPS system.

10

11

12

7

8

9

13

14

24

Page 25

9 – Start-Up, Shutdown and Bypass

Warning: The UPS system’s output voltage is set at 220/380V by default. If you require output voltage of 230/400V or 240/415V, you must

change the UPS system’s output voltage by accessing the output setup menu described in Section 10-5-2. You must place the UPS system in

bypass mode before changing the output voltage. Do not connect your equipment to the UPS system’s output until you have set the proper

parameters.

9-1 Control Panel and Breaker Diagrams

“NORMAL” LED•

A

“BATTERY” LED•

B

“BYPASS” LED•

C

“FAULT” LED•

D

LCD Status Screen•

E

F

“ESC” (Escape) Button•

Scroll Buttons (• and )

G

Enter Button (• )

H

ON Button•

I

OFF Button•

J

K

“EPO” (Emergency Power Off) Button•

Main Input Circuit Breaker Switch•

Q1

Bypass Input Circuit Breaker Switch•

Q2

Manual Bypass Circuit Breaker Switch•

Q3

Output Circuit Breaker Switch•

Q4

A

B

C

D

1

Q4

Output

2

Circuit Breaker Switches (UPS System Front Panel)

E

Control Panel

Q3

Manual

Bypass

G

Q2

Bypass

Input

F

I

J

H

Q1

Main

Input

K

1

2

3

4

5

6

7

9-2 Preliminary Checklist (Single UPS)

All circuit breaker switches should be off, including the breaker of the external battery cabinet (if present).•

Confirm that no voltage potential exists between Neutral and Ground.•

Confirm that the input power source matches the rating (voltage, frequency and phase) of the UPS system.•

Note: After start-up, the UPS system will perform a brief self-test and display the results on the LCD screen. After a successful self-test, the UPS

system will provide AC power to the connected equipment load.

9-3 Standard Start-Up Procedure (Single UPS)

If there is an external battery cabinet connected, switch on the •

1

circuit breaker A of the external battery cabinet. On the SU20KX

or SU40KX, turn on the battery breaker on the back of the UPS.

A

1

2

Confirm that the manual bypass circuit breaker switch •

Q3

is off.

8

9

10

11

12

13

25

Q3

Output

2

Manual

Bypass

Bypass

Input

Main

Input

14

Page 26

9 – Start-Up, Shutdown and Bypass (continued)

1

9-3 Standard Start-Up Procedure (Single UPS) (continued)

3

Switch on the bypass input breaker switch •

2

circuit breaker switch Q4. After a brief initialization process, the

LCD screen will show “ON AUTO BYPASS”, the “BYPASS”

LED will illuminate and UPS system output will be supplied by

the bypass (reserve) power source.

3

4

Switch on the main input circuit breaker switch •

4

input power source is normal, the UPS system is ready for start-up.

5

Press the ON button •

5

6

release the button. The inverter will activate and synchronize with

the bypass source, then automatically switch from auto bypass

(reserve) mode to online (normal) mode. The “BYPASS” LED will

darken and the “NORMAL” LED will illuminate.

A

for 3 seconds (until you hear a beep), then

Q2

and then output

Q1

. If the AC

Q4 Q2

Output Manual

3

Output Manual

4

Bypass

Bypass

Bypass

Input

Bypass

Input

A

Main

Input

Q1

Main

Input

7

9-4 Battery Start-Up Procedure (Single UPS)

8

Note: The battery must be at least partially charged for this operation to succeed.

If there is an external battery cabinet connected, switch on the •

1

circuit breaker A of the external battery cabinet. On the SU20KX

9

or SU40KX, turn on the battery breaker on the back of the UPS.

10

2

Confirm that the manual bypass circuit breaker switch •

Q3

is off.

11

12

A

for 3 seconds (until you hear a beep), then

13

Press the ON button •

3

release the button. The inverter will activate and use stored DC

battery power to supply AC power to connected equipment. The

“BATTERY” LED will illuminate.

5

A

1

Q3

Output Manual

2

Bypass

Bypass

Input

A

Main

Input

14

3

26

Page 27

9 – Start-Up, Shutdown and Bypass (continued)

9-5 Manual Bypass Procedure (Single UPS)

Warning: Placing the UPS system in manual bypass will disable the inverter and power all loads from the manual bypass (reserve) source,

but the UPS system will still be energized. Before performing maintenance or repair on the UPS system, shut down and de-energize the

UPS system completely by following the steps in Section 9-6. Although connected equipment loads will be powered by the bypass (reserve)

power source, they will not receive battery backup in the event of a utility power failure.

If the UPS is in NORMAL mode (green LED ON, LCD displays •

1

“Load Protected – On Line Mode”), then you must stop the

inverter by pressing and holding the red OFF (“O”) button A until

the UPS beeps, then release the button and answer “YES” to the

question “Transfer to Bypass Mode?”. The UPS should transfer to

Bypass.

2

Confirm the UPS is in BYPASS • mode (amber Bypass LED is ON;

LCD displays “Load Unprotected – On Auto Bypass”). Do not

proceed if it is not in BYPASS mode.

3

Turn OFF the MAIN INPUT circuit breaker •

4

Wait until the Power Module fans turn OFF (this may take a •

Q1

.

minute or two), then turn OFF the BATTERY BREAKER. On the

40K unit, the BATTERY BREAKER (for the internal battery) is

on the back of the UPS; on the 60K and 80K units, the BATTERY

BREAKER is on the back of the matching battery cabinet. Note:

Some external battery cabinets may have the BATTERY BREAKER

behind the front door or elsewhere.

5

Turn ON the MANUAL BYPASS circuit breaker •

Q3

. The LCD

will display “Load Unprotected – On Manual Bypass” and you will

hear an audible alarm.

6

Turn OFF the OUTPUT circuit breaker •

Turn OFF the BYPASS INPUT circuit breaker •

7

Q4

.

Q2

. The unit’s LCD

will go blank after a few seconds.

8

The critical load is now supported by unconditioned utility power.•

1

3-7

6 5 7 3

Q3 Q1Q4 Q2

Output Manual

Bypass

Bypass

Input

A

Main

Input

1

2

3

4

5

6

7

8

9-6 Shutdown Procedure (Single UPS)

Warning: The UPS system shutdown procedure will eliminate the AC power output for all loads. Before shutdown, confirm that all loads

are turned off or place the UPS system in manual bypass mode to keep loads powered by the reserve (bypass) power source.

If the UPS is in NORMAL mode (green LED ON, LCD displays •

1

“Load Protected-On Line Mode”), then you must stop the inverter

by pressing and holding the red OFF button A until the UPS beeps,

then release the button. The UPS should transfer to Bypass.

2

Confirm the UPS is in BYPASS (amber Bypass LED is ON; LCD •

displays “Load Unprotected-On Auto Bypass”). Do not proceed if

it is not on BYPASS.

3

Turn OFF the OUTPUT circuit breaker •

Turn OFF the MAIN INPUT circuit breaker •

4

5

Turn OFF the BYPASS UNIT circuit breaker •

6

Wait until the Power Module fans power OFF and the LCD •

goes blank (this may take a minute or two), then turn OFF the

BATTERY BREAKER (on the SU20KX and SU40KX units, the

BATTERY BREAKER is on the back of the UPS; on the SU60KX

and SU80KX units, the BATTERY BREAKER is on the back of

the battery cabinet).

Note: If the UPS system remains off for an extended period of

time, it should be turned on periodically to allow the batteries to

recharge. The UPS system should be turned on and the batteries

should be recharged at least one uninterrupted 24-hour period

every 3 months. Failure to recharge the batteries periodically may

cause irreversible battery damage.

Q4

.

Q1

.

Q2

.

1

3 5 4

Q3 Q1Q4 Q2

Output Manual

2

Bypass

Bypass

Input

A

Main

Input

9

10

11

12

13

14

27

Page 28

9 – Start-Up, Shutdown and Bypass (continued)

1

9-6 Shutdown Procedure (Single UPS) (continued)

To transfer the critical load to NORMAL mode from Manual

2

Bypass:

1. Confirm the UPS is in MANUAL BYPASS (the MANUAL

1

BYPASS circuit breaker Q3 is ON; the OUTPUT Q4, BYPASS

INPUT Q2 and MAIN INPUT Q1 circuit breakers are OFF).

2

2. Turn ON the BATTERY BREAKER (on the SU20KX and

3

SU40KX units, the BATTERY BREAKER is on the back of

the UPS; on the SU60KX and SU80KX units, the BATTERY

BREAKER is on the back of the battery cabinet).

3

3. Turn ON the BYPASS INPUT circuit breaker Q2 (the amber

4

5

6

7

8

9

Bypass LED should come on and the LCD will display “Load

Unprotected-On Manual Bypass).

4. Confirm the amber BYPASS LED is ON. Do not proceed if it is

4

not ON.

5

5. Turn ON the OUTPUT circuit breaker Q4.

6

6. Turn OFF the MANUAL BYPASS circuit breaker Q3. The LCD

will display “Load Unprotected-On Auto Bypass”.

7

7. Turn ON the MAIN INPUT circuit breaker Q1. The Power

Module fans will turn ON.

8

8. Press and hold the green ON button until the UPS beeps, then

release the button. The UPS will perform a self-test diagnostic and

the LCD will display “Self Diagnosis”. After the UPS self-test is

completed, the UPS will transfer to NORMAL mode (green LED

ON and LCD displays “Load Protected-On Line Mode”).

9

9. Confirm there are no active alarms present (“!” on the display and

audible beeping). If an alarm is present, press the UP or DOWN

arrows to display the active alarm. Correct the action as required.

10

10. Scroll through the Measure Menu and confirm all input and output

power readings are within the recommended specifications.

11

11. If any problems are noted, contact your technical support personnel

for further assistance.

12. The critical load is now supported by conditioned battery back-up

12

power.

Q4 Q3 Q2 Q1

Output Manual

1

Q2

3

Q3

6

Bypass

Bypass

Input

5

7

Q4

Q1

Main

Input

9-7 Preliminary Checklist (Parallel UPS)

10

Warning: Parallel configuration requires exactly two UPS systems (1+1 redundancy or capacity). Do not attempt to link more than two

UPS systems via parallel configuration. The UPS systems must have the same rating and capacity for parallel UPS installation. Attempting

to link dissimilar UPS systems will damage the UPS systems and create a serious risk of personal injury and property damage.

All circuit breaker switches should be off, including the breakers of the external battery cabinets.•

11

12

Note: After start-up, the UPS systems will perform a brief self-test and display the results on the LCD screen. After a successful self-test, the UPS

systems will provide AC power to the connected equipment load.

Confirm that no voltage potential exists between Neutral and Ground.•

Confirm that the input power source matches the rating (voltage, frequency and phase) of the UPS systems.•

Each UPS must have a different “Parallel ID”that indicates the UPS systems are being run in parallel. See • Section 10-5-5 for more

details.

13

14

28

Page 29

9 – Start-Up, Shutdown and Bypass (continued)

9-8 Start-Up Procedure (Parallel UPS)

Connect the parallel configuration cable •

1

configuration port B of each UPS system. Note: Before starting up

the Parallel UPS system, ensure that the “Parallel ID” is different

for each UPS and parallel group is set. (See Section 10-5-5 for

more details.

A

to the DB9 parallel

1

2

B

2

If the UPS systems have external battery cabinets connected, •

switch on the external battery cabinet circuit breaker switch A

of each battery pack. On the SU20KX or SU40KX, turn ON the

battery breaker on the back of the UPS.

9-8 Start-Up Procedure (Parallel UPS) (continued)

Switch on the bypass input circuit breaker switch •

3

UPS system. After a brief initialization process, the LCD screen

will show “ON AUTO BYPASS” and the “BYPASS” LED will

illuminate.

4

Switch on the main input circuit breaker switch •

system.

Q2

of each

Q1

of each UPS

B

1

A

3

4

A

5

2

6

Q2

Output Manual

3

Bypass

Bypass

Input

Main

Input

7

8

5

Press the ON button •

A

of one of the UPS systems for 3 seconds

(until you hear a beep), then release the button. The inverter will

activate and synchronize with the bypass source. Press the ON

button for the other UPS system for 3 seconds (until you hear a

beep), then release the button. When the inverter of each UPS

system is operating normally, they will automatically switch from

auto bypass (reserve) mode to online (normal) mode at the same

time. The “BYPASS” LED will darken and the “NORMAL” LED

will illuminate.

6

Check the output voltage of each UPS system. The phase deviation •

between each UPS system should be less than 5V. If the phase

deviation is within the acceptable range, switch on the output

circuit breaker switch Q4 of each UPS system. Note: For more

information on checking the output voltage of each UPS system,

see Section 10-4.

Q1

9

Output Manual

4

Bypass

Bypass

Input

Main

Input

10

A

11

5

12

Q4

13

Output Manual

6

Bypass

Bypass

Input

Main

Input

14

29

Page 30

9 – Start-Up, Shutdown and Bypass (continued)

1

9-9 Shutdown Procedure (Parallel UPS)

Warning: The UPS system shutdown procedure will eliminate the AC power output for all loads. Before shutdown, confirm that all loads

2

are turned off or place the UPS systems in manual bypass mode to keep loads powered by the bypass (reserve) power source.

1

For the UPS system you wish to shut down, press the OFF button •

A

for 3 seconds (until you hear a beep), then release the button.

If the other UPS system can support the connected equipment

3

4

5

loads alone, the UPS system that was turned off will shut down its

inverter and its LCD screen will read “LOAD NOT POWERED”.

The other UPS system’s LCD screen will read “ONLINE MODE”.

If the total connected equipment load is too large to be handled

by a single UPS system, both UPS systems will shut down their

inverters and switch to bypass mode, and their LCD screens will

read “ON AUTO BYPASS”.

2

For the UPS system you wish to shut down, switch off the main •

input circuit breaker switch Q1, then switch off the output circuit

breaker switch Q4.

1

A

Q1Q4

6

For the UPS system you wish to shut down, switch off the bypass •

3

input circuit breaker switch Q2.

7

8

4

When the UPS system is completely shut down, the LCD screen •

will be completely off. If the UPS systems have external battery

cabinets connected, switch off the external battery cabinet circuit

breaker switch A of each battery pack. On the SU20KX or

9

10

SU40KX, turn OFF the battery breaker on the back of the UPS.

Note: If the UPS system remains off for an extended period of time, it

should be turned on periodically to allow the batteries to recharge. The

UPS system should be turned on and the batteries should be recharged

at least one uninterrupted 24-hour period every 3 months. Failure

to recharge the batteries periodically may cause irreversible battery

damage.

11

Output Manual

2

Output Manual

3

4

Bypass

Bypass

A

Bypass

Input

Q2

Bypass

Input

Main

Input

Main

Input

12

13

14

30

Page 31

9 – Start-Up, Shutdown and Bypass (continued)

9-10 Manual Bypass Procedure (Parallel UPS)

Warning: When the UPS system is in manual bypass, the inverter shuts down. Connected equipment loads are powered by the bypass

(reserve) power source and will not receive battery backup during a utility power failure.

For the first UPS system you wish to shut down, press the OFF •

1

button A for 3 seconds (until you hear a beep), then release

the button. If the other UPS system can support the connected

equipment loads alone, the UPS system that was turned off will

shut down its inverter and its LCD screen will read “LOAD NOT

POWERED”. The other UPS system’s LCD screen will read

“ONLINE MODE”. If the total connected equipment load is too

large to be handled by a single UPS system, both UPS systems

will shut down their inverters and switch to bypass mode, and their

LCD screens will read “ON AUTO BYPASS”. Repeat step 1 for

the second UPS system you wish to shut down.

2

Switch off the main input circuit breaker switch •

Q1

of each UPS

system.

1

A

Q1

1

2

3

4

5

3

Confirm that both UPS systems are shut down, then switch on •

the manual bypass input circuit breaker switch Q3 of each UPS

system. The bypass (reserve) power source will power the loads

and the LCD screen will read “ON MANUAL BYPASS”.

Switch off the bypass input circuit breaker switch •

4

Q2

and the

output circuit breaker switch Q4 of each UPS system. The LCD

screen will turn off completely.

5

If the UPS systems have external battery cabinets connected, •

switch off the external battery cabinet circuit breaker switch A

of each battery pack. On the SU20KX or SU40KX, turn OFF the

battery breaker on the back of the UPS.

Output

2

Manual

Bypass

Q3

Bypass

Input

Main

Input

6

7

Output

3

Manual

Bypass

Bypass

Input

Main

Input

8

Q2Q4

9

Output

4

Manual

Bypass

Bypass

Input

Main

Input

10

A

11

6

In this mode, only the manual bypass path (including the manual •

bypass circuit breaker Q3), the load terminals of the output

circuit breaker switch Q4 and the terminal block B contain

hazardous voltage, allowing qualified service personnel to perform

maintenance or repair. Note: Qualified service personnel may

prefer to de-energize the UPS systems completely, depending on

local codes and the nature of the maintenance or repair.

5

12

B

Q4 Q3

13

6

14

31

Page 32

9 – Start-Up, Shutdown and Bypass (continued)

1

9-11 Switching from Manual Bypass to Normal Mode (Parallel UPS)

If the UPS systems have external battery cabinets connected, •

1

2

3

4

5

6

7

switch off the external battery cabinet circuit breaker switch A

of each battery pack. On the SU20KX or SU40KX, turn OFF the

battery breaker on the back of the UPS.

2

Switch on the bypass input circuit breaker switch •

Q2

and the

output circuit breaker switch Q4 of each UPS system.

3

Confirm that both UPS systems are shut down, then switch off •

the manual bypass input circuit breaker switch Q3 of each UPS

system. The LCD screen will read “ON AUTO BYPASS”.

4

Switch on the main input circuit breaker switch •

Q1

of each UPS

system.

5

Press the ON button •

A

of the first UPS systems for 3 seconds

(until you hear a beep), then release the button. Press the ON

button for the second UPS system for 3 seconds (until you hear

a beep), then release the button. When the inverter of each UPS

system is operating normally, they will switch to online (normal)

mode at the same time.

1

2

3

A

Output Manual

Output

Bypass

Q3

Manual

Bypass

Q2Q4

Bypass

Input

Bypass

Input

Main

Input

Main

Input

10

11

12

13

8

A

Q1

9

Output

Manual

Bypass

Bypass

Input

Main

Input

54

14

32

Page 33

10 – Display and Configuration

10-1 Control Panel Diagram

“NORMAL” (Green) LED: Illuminated when the UPS input •

A

power is normal.

B

“BATTERY” (Amber) LED: Illuminated when the UPS is in •

C

Battery Backup mode.

D

“BYPASS” (Amber) LED: Illuminated when the UPS is in •

E

Manual Bypass mode.

F

“FAULT” (Red) LED: Illuminated when any fault occurs.•

G

LCD Status Display: Multi-language display.•

H

“ESC” (Escape) Button: Escape/Page Up.•

I

Scroll Buttons (• and ): Scroll cursor Up or Down.

J

Enter Button (• ): Confirm settings.

K

ON Button: Press and hold for 3 seconds to start up the UPS •

(turns Inverter ON).

L

OFF Button: Press and hold for 3 seconds to power OFF the •

UPS (turns Inverter OFF).

M

“EPO” (Emergency Power Off) Button: Pressing the EPO •

button will completely remove power from the UPS output.

1

2

E

A

B

C

D

Control Panel

F

I

G

K

3

J

H

4

5

6

10-2 Display Hierarchy

The Tripp Lite E3 Series UPS features a user-friendly LCD screen to show messages and display UPS Status screens.

7

8

9

10

11

33

12

13

14

Page 34

10 – Display and Configuration (continued)

1

10-3 Default Display

After the UPS system starts up and completes the self-test, the •

1

2

3

4

5

6

LCD status screen will show the default display. The default

display includes a status message and diagram that shows the

operational status of the UPS system.

When any event occurs, you will see the sign “!” flashes. You can press “ ” to see the details. For example:

1

7

8

9

10

10-3-1 Status Display

The UPS system output is off and the connected equipment loads •

1

11

12

are not powered. This condition may be due to automatic UPS

shutdown or manually switching off the output circuit breaker

switch.

Possible causes:

The UPS automatically shuts down by itself.•

Manually switch off the output circuit breaker.•

Press “ ” again to go to the next message. If there is no further message, the screen will return to the default screen.

13

14

1

34

Page 35

10 – Display and Configuration (continued)

10-3-1 Status Display (continued)

The loads are supplied by bypass source due to initial startup of •

2

the UPS.

3

The UPS is starting up by battery power.•

1

2

3

4

5

2

6

4

The UPS system is in auto bypass mode. Connected equipment •

loads will lose power if the bypass power source fails.

7

8

3

9

10

11

12

35

4

13

14

Page 36

10 – Display and Configuration (continued)

1

10-3-1 Status Display (continued)

5

The UPS system is operating in online (normal) mode. Connected •

2

3

4

5

6

equipment loads will receive battery backup power if the mains

(utility or generator) power source fails.

6

The UPS is in battery backup mode. The loads are supplied by •

battery power.

5

10

11

12

7

8

9

7

The UPS is performing the “battery test”.•

6

13

14

7

36

Page 37

10 – Display and Configuration (continued)

10-3-1 Status Display (continued)

The UPS system is operating in economy mode, and connected •

8

equipment loads are being powered by the bypass source.

The UPS system is in manual bypass mode in order to allow •

9

qualified service personnel to perform maintenance or repair on

the UPS system. Connected equipment loads will lose power if

the bypass power source fails.

1

2

3

4

5

8

6

10-4 Main Menu

From the default display, press the enter button ( ) to access the main

menu. Press the scroll down button ( ) or the scroll up button

( ) to move the cursor. Press the enter button ( ) to select one of the

available menu options.

7

8

9

9

10

11

12

37

13

14

Page 38

10 – Display and Configuration (continued)

1

10-4 Main Menu (continued)

UPS System “Measure Menu

2

1. Press the enter button ( ) to select “MEASURE” from the main menu.

2. Use the scroll buttons ( or ) to scroll through the available data screens. Press the “ESC” button to return to the previous menu.

3

4

5

6

10

11

12

7

8

9

13

14

38

Page 39

10 – Display and Configuration (continued)

10-5 UPS Setup

Before changing the setting of each SETUP, you have to login first.

Accessing the UPS system setup menu requires a password. From •

1

the login screen, press the enter button ( ) to select whether to

log in as an administrator or user.

ADMINISTRATOR: