WARRANTY

REGISTRATION

Register online today for a

chance to win a FREE Tripp Lite

product www.tripplite.com/warranty

Owner’s Manual

18U SmartRack™ Enclosure

Model: SR18UB

Table of Contents

1. Important Safety Instructions 2

2. Overview 2

3. Feature Identification 3

4. Enclosure Installation 4

4.1 Preparation 4

4.2 Unpacking 4

4.3 Installing Casters and Levelers 4

4.4 Placement 4

4.5 Leveling the Enclosure 5

4.6 Ground Connection 5

5. Enclosure Configuration 6

5.1 Door Locks 6

5.2 Reversing the Doors 6

5.3 Mounting Rails 6

5.4 Adjusting Mounting Rail Depth 6

6. Equipment Installation 7

6.1 Installing or Removing Cage Nuts 7

7. Specifications 7

8. Storage and Service 8

9. Warranty & Warranty Registration 8

Español 9

Français 17

1111 W. 35th Street, Chicago, IL 60609 USA • www.tripplite.com/support

Copyright © 2012 Tripp Lite. All trademarks are the sole property of their respective owners.

1. Important Safety Instructions

SAVE THESE INSTRUCTIONS

This Manual contains instructions and warnings that must be followed during the installation and operation of the product described in this manual. Failure to

comply may invalidate the warranty and cause property damage or personal injury.

• Keep the enclosure in a controlled indoor environment, away from moisture, temperature extremes, flammable liquids and gasses, conductive

contaminants, dust and direct sunlight.

• Leave adequate space at the front and rear of the enclosure for proper ventilation. Do not block, cover or insert objects into the external ventilation

openings of the enclosure.

• The enclosure is extremely heavy. Use caution when handling the enclosure. Do not attempt to unpack, move or install it unassisted. Use a

mechanical device such as a forklift or pallet jack to move the enclosure in the shipping container.

• Do not place any object on the enclosure, especially containers of liquid, and do not attempt to stack the enclosures.

• Inspect the shipping container and the enclosure for shipping damage. Do not use the enclosure if it is damaged.

• Leave the enclosure in the shipping container until it has been moved as close to the final installation location as possible.

• Install the enclosure in a structurally sound area capable of handling the load, or on a level floor that is able to bear the weight of the enclosure, all

equipment that will be installed in the enclosure and any other enclosures and/or equipment that will be installed nearby.

• Use caution when cutting packing materials. The enclosure could be scratched, causing damage not covered by the warranty.

• Save all packing materials for later use. Repacking and shipping the enclosure without the original packing materials may cause product damage

that will void the warranty.

• Do not reship the enclosure with additional equipment unless the enclosure was shipped with a special shock pallet (“SP1” models only). The

combined weight of the enclosure and installed equipment must not exceed the load capacity of the pallet. Tripp Lite is not responsible for any

damage that occurs during reshipment.

• The casters are designed for minor position adjustments within the final installation area only. The casters are not designed for moving the

enclosure over longer distances.

• When rolling the enclosure on its casters, always push it from behind; never pull it toward you.

• A rolling enclosure can cause personal injury and property damage if not properly supervised. If rolling the enclosure down a ramp is required, use

extreme caution. Do not attempt to use ramps that have a slope steeper than 1:12.

• Use of this equipment in life support applications where failure of this equipment can reasonably be expected to cause the failure of the life support

equipment or to significantly affect its safety or effectiveness is not recommended. Do not use this equipment in the presence of a flammable

anesthetic mixture with air, oxygen or nitrous oxide.

2. Overview

SmartRack Enclosures accommodate all standard 19-inch rackmount equipment, regardless of vendor, and ship fully assembled for quick and easy

deployment.

2

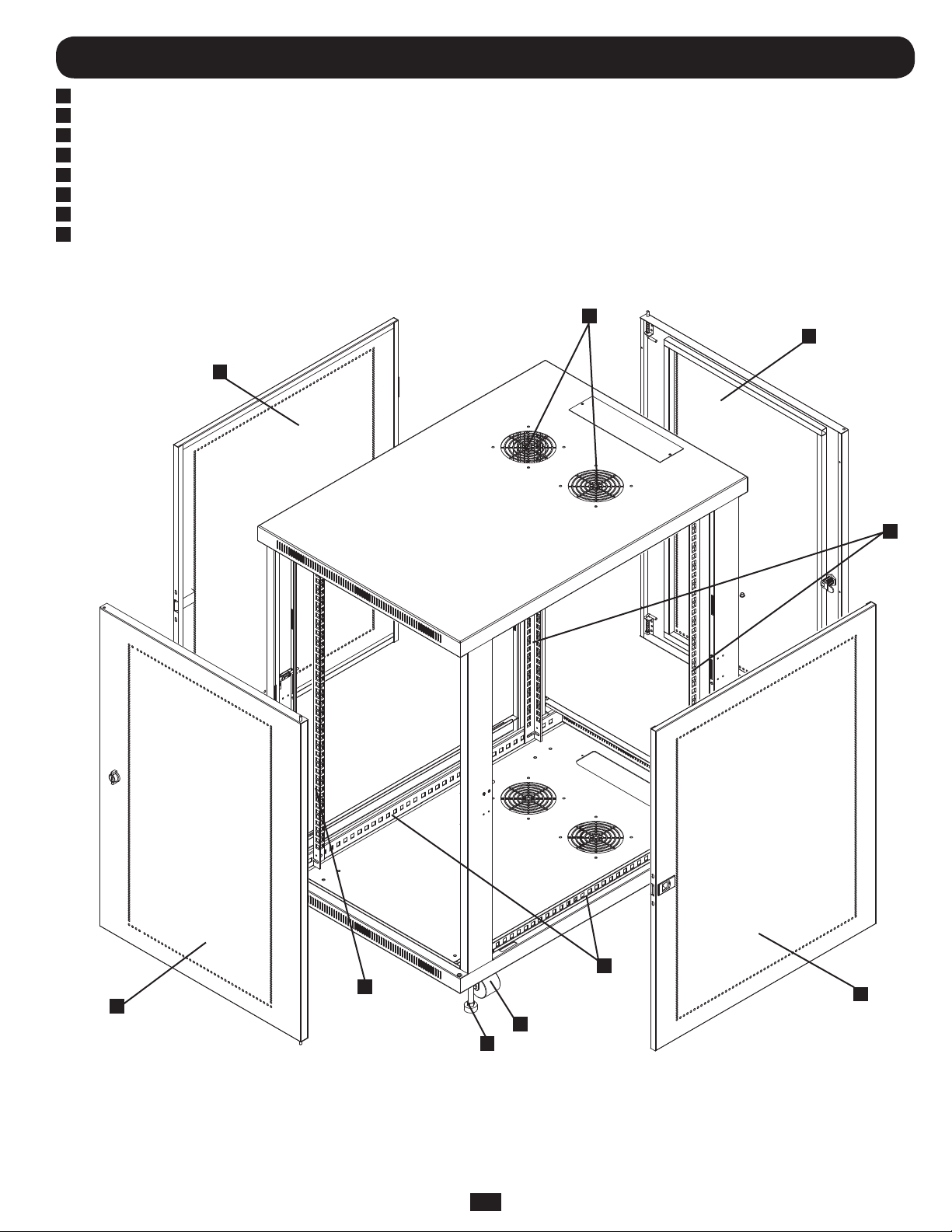

3. Feature Identification

1

Locking/Reversible Front Door

2

Locking/Reversible Back Door

3

Horizontal Rails

4

Vertical Mounting Rails

5

Vents

6

Locking/Removable Side Panels

7

Casters

8

Leveling Feet

6

5

2

4

3

4

1

7

8

6

3

4. Enclosure Installation

Caution! Read All Instructions and Warnings Before Installation!

Warning: Rack enclosures can be extremely heavy. Do not attempt to unpack, move or install the enclosure without assistance. Use

extreme caution when handling the enclosure and be sure to follow all handling and installation instructions. Do not attempt to install

equipment without first stabilizing the enclosure.

4.1 Preparation

The enclosure must be installed in a structually sound area that is able to bear the weight of the enclosure, all the equipment that will be installed in the

enclosure and any other enclosures and/or equipment that will be installed nearby. Before unpacking the enclosure, you should transport the shipping

container closer to the final installation location to minimize the distance you will need to move the unit after the protective packaging has been

removed. If you plan to store the enclosure for an extended period before installation, follow the instructions in the Storage and Service section.

You need several tools:

• Level

• 10 mm Open-End or Combination Wrench (2)

4.2 Unpacking

Use at least two people to unpack the enclosure.

• 14 mm Open-End or Combination Wrench

• Phillips-Head Screwdriver

1

Move shipping pallet to a firm, level surface.

2

Save all packing materials for later use unless you are certain they will not be required. Packing materials are recyclable.

3

With one person on each side, carefully lift the enclosure off of the pallet and place on a firm, level surface.

4

Examine the enclosure for any damage or loose parts. Confirm all parts are present. If anything is missing or damaged, contact Tripp Lite for

assistance. Do not attempt to use the enclosure if it has been damaged.

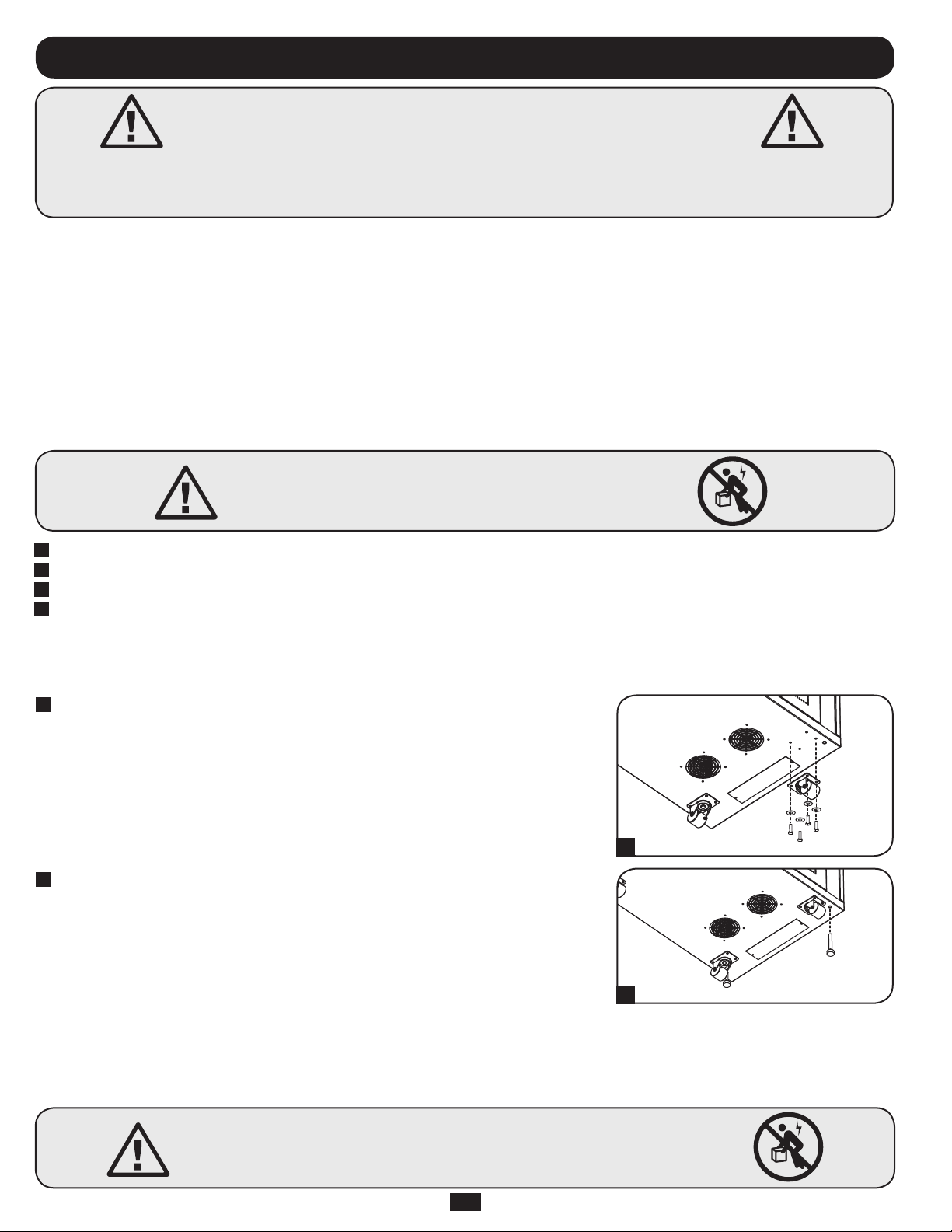

4.3 Installing Casters and Levelers

1

Installing Casters

Tripp Lite’s accessory SRCASTER kit is included with your rack enclosure. This kit consists of 4

casters with required locknuts, washers and bolts for installation. Using two 10 mm open-end or

combination wrenches, install the casters to the base of the unit using the pre-drilled holes near

each

corner of the enclosure.

1

2

Installing Levelers

There are 4 levelers included with your rack enclosure, 2 for the front and 2 for the rear. Using a 14

mm open-end wrench, install the levelers at the base of the unit using the threaded holes near

each corner of the enclosure by turning the leveler in counter-clockwise. When the rack enclosure is

moved to its installation location, use a 14mm open-end wrench to level the rack.

2

4.4 Placement

You can use the casters to move the enclosure for a short distance over a level, smooth, stable surface by pushing it from the front or rear (not the

side panels). Do not attempt to roll the enclosure over long distances. The enclosure should be moved close to its installation location inside its

shipping container before it is unpacked. Warning: Use appropriate equipment and follow all applicable safety procedures and regulations.

Warning: Never attempt to lift or install without adequate help.

Do not try lifting the enclosure alone.

4

4. Enclosure Installation

EARTH

GROUND

(

continued

)

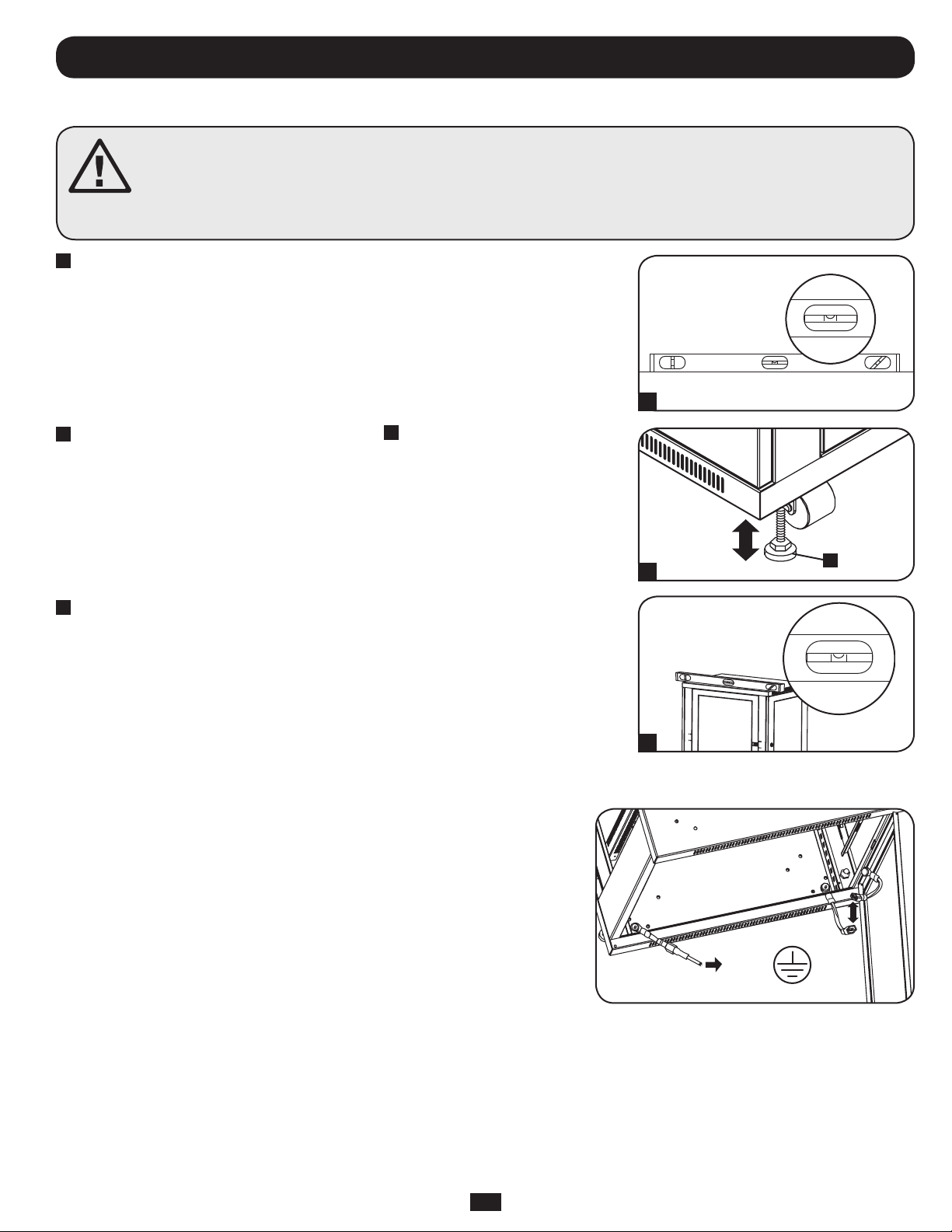

4.5 Leveling

WARNING: Level the enclosure before attempting to install equipment. Install the enclosure in a

structurally sound area with a level floor that is able to bear the weight of the enclosure, all

equipment that will be installed in the enclosure and any other enclosures and/or equipment that

will be installed nearby.

1

After the enclosure has been moved to the installation location, use a carpenter's level to check

the slope of the floor. If the floor slopes more than 1%, choose an alternate installation site.

2

Use a 14 mm open-end wrench to lower each leveler A until it reaches the floor. (There are 4

levelers, 2 at the front and 2 at the rear.) Make sure each leveler contacts the floor solidly.

Note: Lower a leveler by turning it clockwise; raise a leveler by turning it counter-clockwise.

3

After lowering each leveler, use the carpenter's level to confirm that the enclosure is level in all

directions. Adjust the levelers as required until the enclosure is level.

4.6 Ground Connection

• All parts of the enclosure are grounded to the frame of the enclosure.

• Grounding studs have been provided in all four corners of the enclosure to allow for

grounding in any configuration (including front or back door reversals).

• Grounding holes are also provided on top and bottom corners of both front and back

doors to accommodate any configuration.

• To ground the enclosure simply connect the two quick-disconnect grounding wires, one

to the hole provided on the inside of either the front or back door and the other to the

stud provided in any corner of the enclosure. Connect your facility’s earth ground

connection to the grounding stud not used by door connections, using an 8 AWG

(3.264 mm) wire.

Warning: Attach each enclosure to earth ground separately. Do not use the

enclosure without an earth ground connection.

1

2

3

FLOOR

A

5

5. Enclosure Configuration

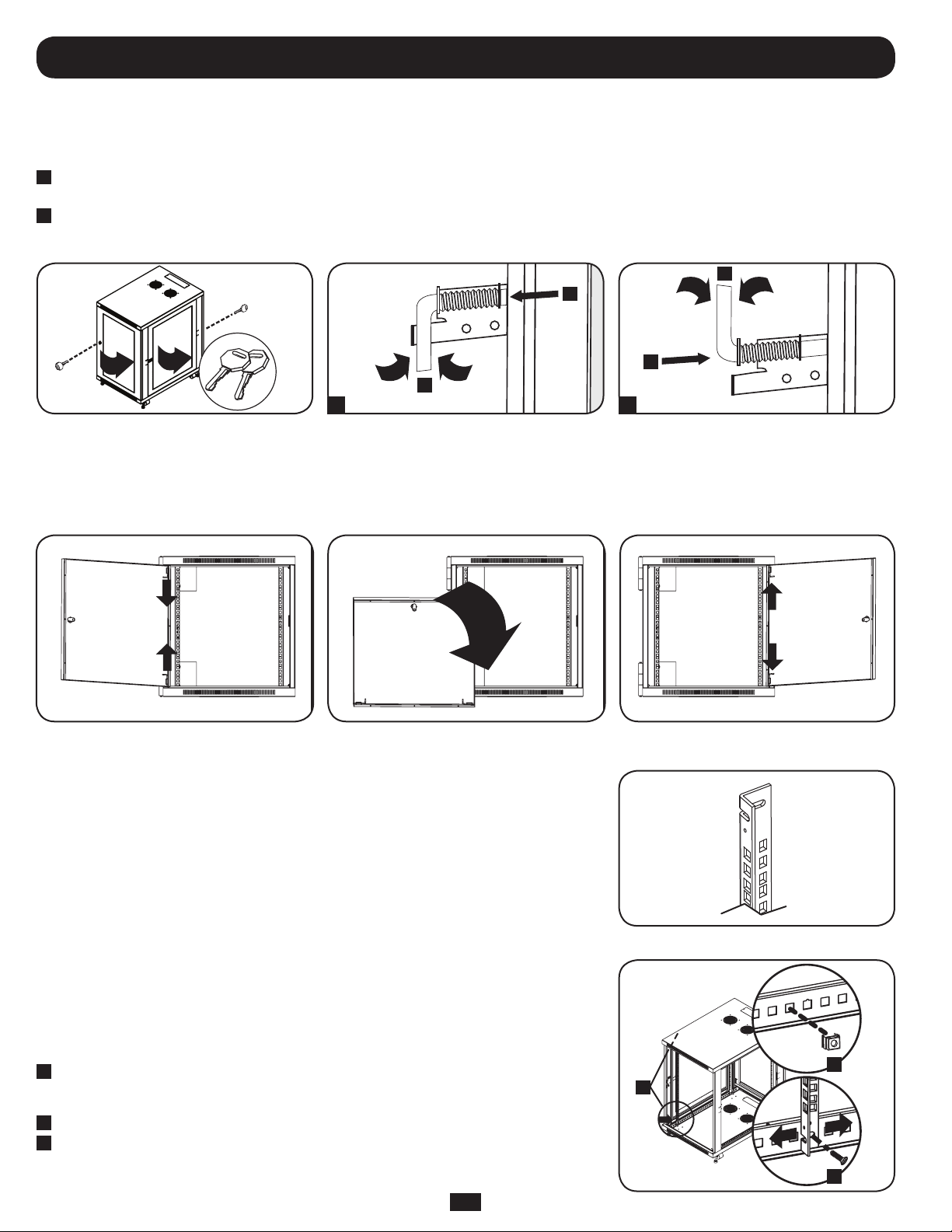

5.1 Door Locks

The front and back doors have locks that are accessible by the included keys.

Each side panel locks using an L-shaped lever on the inside of the enclosure.

1

To unlock and remove the side panels, lift the shorter leg of the “L” up and pull it away from the side panel. Pull the tab on the side panel and

remove it from the enclosure.

2

To re-lock the side panels, secure it in the proper position, lift the shorter leg of the “L” up and push it toward the side panel, back into the hole that it was

in initially. Once it is in place, push the shorter leg of the “L” down to lock it. Note: To lock and unlock the side panels, you will need to have access to the

interior of the enclosure.

A

B

B

A

1 2

5.2 Reversing the Doors

The doors of the enclosure are held in position on the enclosure’s frame with two spring-loaded pins. To reverse the door’s swing direction, simply

release the pins by pulling them up (lower pin) or down (upper pin) and remove them from the mounting holes on the frame of the enclosure.

Flip the door in the opposite direction and replace the pins in the identical mounting holes on the other side of the enclosure’s frame by lining them up

with the mounting holes and engaging them again.

5.3 Mounting Rails

The enclosure comes with mounting rails that have square holes for mounting rack equipment. To

install equipment, use the included cage nuts and other hardware. (See page 7 for installation of

cage nuts.) Warning: Be sure to have the enclosure in its final position on the floor before

mounting any equipment inside. Also be sure to have all the right adjustments on your rails

before mounting equipment. (See below for Adjusting Mounting Rail Depth.)

5.4 Adjusting Mounting Rail Depth

Warning: Do not attempt to adjust rails while equipment is installed in the enclosure.

Do not attempt to use rails without screws installed. (2 per rail.)

The 4 mounting rails are pre-installed to accommodate equipment with a mounting depth of 20.5

inches (521 mm). Do not adjust the mounting rails unless your equipment requires a different

mounting depth. The front and rear sets of rails can be adjusted independently for mounting of

equipment with depths between 3 inches (76 mm) and 32.5 inches (826 mm).

1

Each rail is connected to the enclosure with 2 screws and 2 cage nuts: 1 set in the upper

corner and another in the lower corner. Using a Phillips-head screwdriver, remove the screws

that fasten the rails to the enclosure.

2

Move cage nuts to desired depth and reinstall.

3

Slide the mounting rails to the desired depth and reattach them using the screws you removed

in Step 1.

6

2

1

3

6. Equipment Installation

20

22

21

20

22

21

20

22

21

20

22

21

24

25

26

27

28

29

23

24

25

26

27

28

29

23

24

1 Rack Unit

Warning: Do not install equipment until you have stabilized the enclosure. Install heavier equipment first and install it towards the bottom

of the enclosure. Install equipment starting from the bottom of the enclosure and proceeding toward the top of the enclosure - never the

reverse. If using sliding equipment rails, be careful when extending the rails. Do not extend more than one set of sliding equipment rails

at one time. Avoid extending sliding equipment rails near the top of the enclosure.

Note: The square holes in the middle of each rack unit are numbered and also include a small notch to aid identification. A single rack unit includes the space

occupied by the numbered hole and the holes directly above and below.

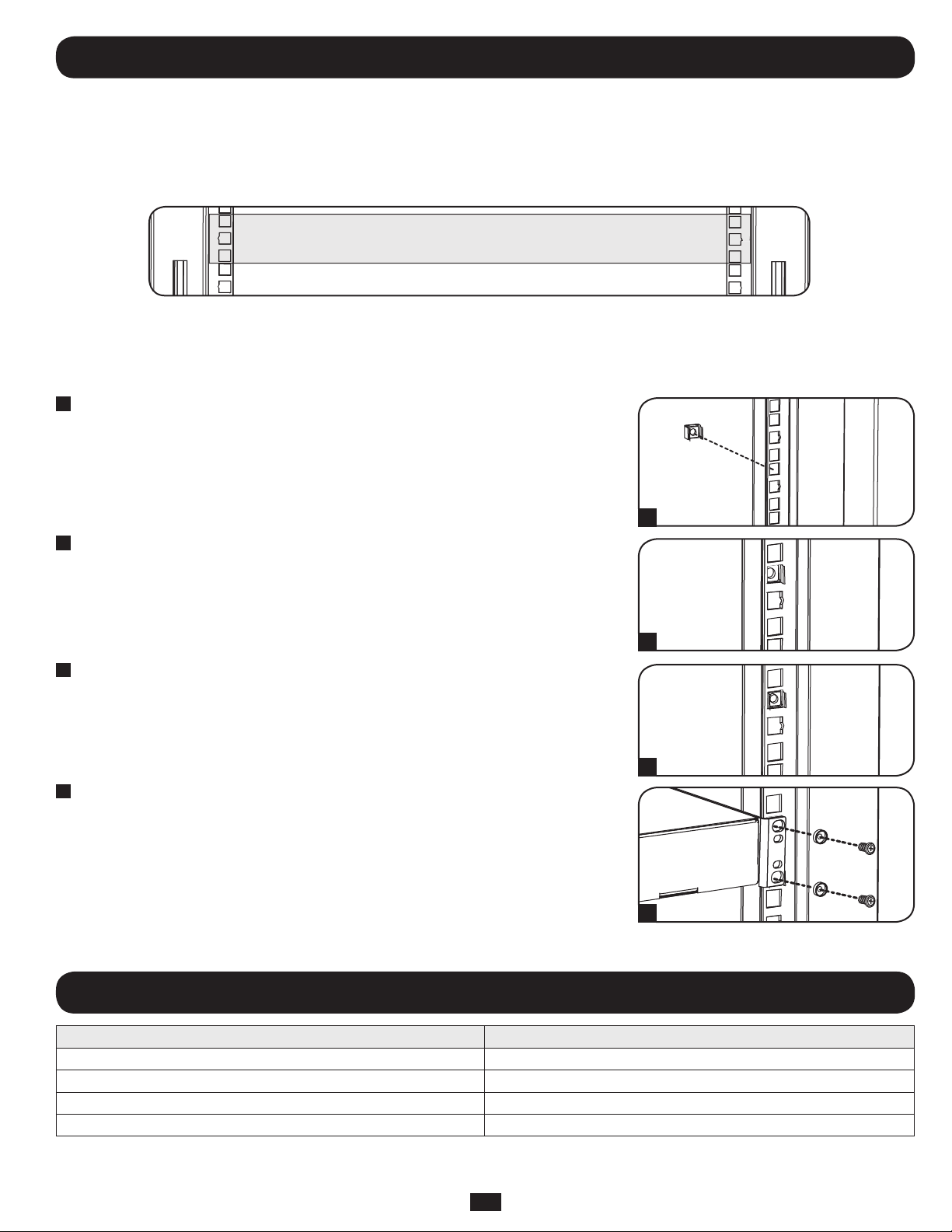

6.1 Installing or Removing Cage Nuts

WARNING: The flanges of the cage nuts should engage the sides of the square opening in the rail, not the top and bottom. Follow the

instructions in your equipment documentation to ensure proper installation of your equipment.

1

Locate the numbered square openings in the mounting rails where you plan to install your

equipment. You will install cage nuts (included) into the square openings in order to provide an

attachment point for the mounting screws (included). Note: Consult your equipment

documentation to determine how many cage nuts will be required and where they will need to

be installed.

2

From the inside of the mounting rail, insert one of the flanges of the cage nut through the

square opening. Press it against the side of the square opening. Each flange should engage one

side of the square opening, not the top or bottom.

3

Compress the cage nut at the sides slightly to allow the remaining flange to fit through the

square opening. When the cage nut is properly installed, both flanges will protrude through the

square opening and will be visible on the outer surface of the mounting rail. Repeat steps 1-3

until all required cage nuts are installed.

4

After installing the required cage nuts, use the included mounting screws and cup washers to

secure your equipment to the rack rail. Place the cup washers between the screws and the

equipment mounting brackets.

Note: Your equipment may also include mounting hardware. Read the mounting instructions that came

with your equipment before installing your equipment.

To Remove Cage Nuts, Reverse Steps 1-3

Note: You may wish to use a cage nut tool (user-supplied) to aid cage nut installation and removal.

1

2

3

4

7. Specifications

Model SR18UB

Dimensions (H x W x D) 35.6 x 23.63 x 33.5” (905 x 600 x 850 mm)

Unit Weight 105 lb (48 kg)

Load Capacity 500 lb (226 kg) Stationary or Rolling

Mounting Depth (Adjustable) 3” to 32.5” (76 to 826 mm)

7

6. Operation

(

continued

)

8. Storage and Service

Storage

The enclosure should be stored in a controlled indoor environment, away from moisture, temperature extremes, flammable liquids and gasses,

conductive contaminants, dust and direct sunlight. Store the enclosure in its original shipping container if possible.

Service

Your Tripp Lite product is covered by the warranty described in this manual. A variety of Extended Warranty and On-Site Service Programs are also

available from Tripp Lite. For more information on service, visit www.tripplite.com/support. Before returning your product for service, follow these steps:

1. Review the installation and operation procedures in this manual to insure that the service problem does not originate from a misreading of the

instructions.

2. If the problem continues, do not contact or return the product to the dealer. Instead, visit www.tripplite.com/support.

3. If the problem requires service, visit www.tripplite.com/support and click the Product Returns link. From here you can request a Returned Material

Authorization (RMA) number, which is required for service. This simple on-line form will ask for your unit’s model and serial numbers, along with

other general purchaser information. The RMA number, along with shipping instructions will be emailed to you. Any damages (direct, indirect, special

or consequential) to the product incurred during shipment to Tripp Lite or an authorized Tripp Lite service center is not covered under warranty.

Products shipped to Tripp Lite or an authorized Tripp Lite service center must have transportation charges prepaid. Mark the RMA number on the

outside of the package. If the product is within its warranty period, enclose a copy of your sales receipt. Return the product for service using an

insured carrier to the address given to you when you request the RMA.

9. Warranty and Warranty Registration

5-Year Limited Warranty

Seller warrants this product, if used in accordance with all applicable instructions, to be free from original defects in material and workmanship for a

period of 5 years from the date of initial purchase. If the product should prove defective in material or workmanship within that period, Seller will repair

or replace the product, at its sole discretion.

THIS WARRANTY DOES NOT APPLY TO NORMAL WEAR OR TO DAMAGE RESULTING FROM ACCIDENT, MISUSE, ABUSE OR NEGLECT. SELLER MAKES

NO EXPRESS WARRANTIES OTHER THAN THE WARRANTY EXPRESSLY SET FORTH HEREIN. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW,

ALL IMPLIED WARRANTIES, INCLUDING ALL WARRANTIES OF MERCHANTABILITY OR FITNESS, ARE LIMITED IN DURATION TO THE WARRANTY PERIOD

SET FORTH ABOVE; AND THIS WARRANTY EXPRESSLY EXCLUDES ALL INCIDENTAL AND CONSEQUENTIAL DAMAGES. (Some states do not allow

limitations on how long an implied warranty lasts, and some states do not allow the exclusion or limitation of incidental or consequential damages, so

the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may have other rights which vary from

jurisdiction to jurisdiction).

WARNING: The individual user should take care to determine prior to use whether this device is suitable, adequate or safe for the use intended. Since

individual applications are subject to great variation, the manufacturer makes no representation or warranty as to the suitability or fitness of these

devices for any specific application.

Warranty Registration

Visit www.tripplite.com/warranty today to register the warranty for your new Tripp Lite product.You’ll be automatically entered into a drawing for a

chance to win a FREE Tripp Lite product!*

* No purchase necessary. Void where prohibited. Some restrictions apply. See website for details.

Tripp Lite has a policy of continuous improvement. Specifications are subject to change without notice.

1111 W. 35th Street, Chicago, IL 60609 USA • www.tripplite.com/support

8

Loading...

Loading...