Trinity SRT Series, SRT-350, HBA Series Assembly Manual

ENERGY ABSORPTION SYSTEMS

SRT-350

Guardrail End

Treatment

Assembly Manual

Part No. 620295B Revised March 2010

®

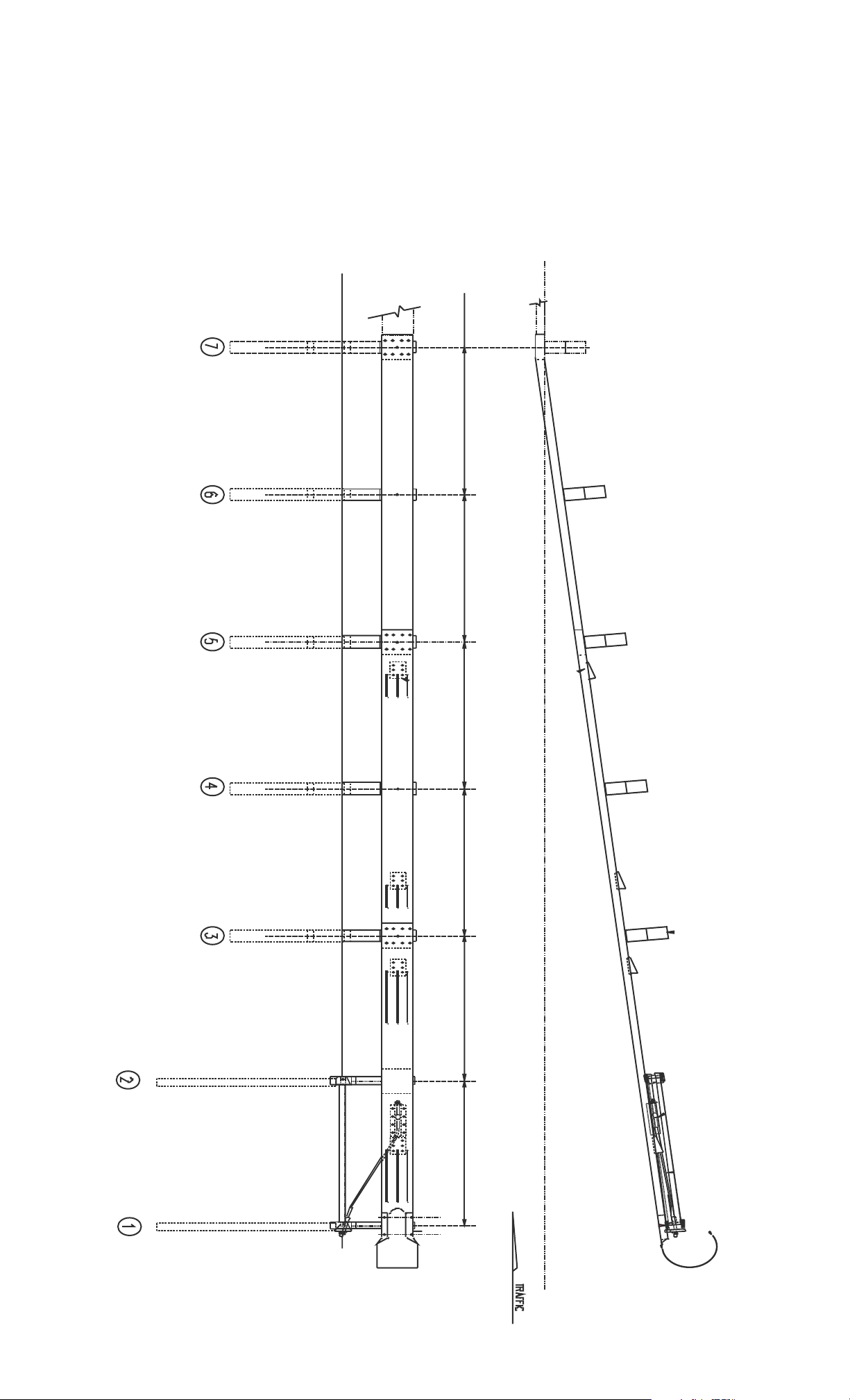

6 POST

2

SRTTM/ HBA

TM

6-POST SYSTEM

FOR SPECIFIC DETAILS, REFER TO THE

STATE STANDARD DRAWING

"3-'6

"3-'6

"3-'6

"3-'6

"3-'6

"3-'6

SRT

TM

/ HBA

TM

6-POST SYSTEM

BILL OF MATERIAL ENGLISH (METRIC)

(FOR QUANTITIES, SEE STATES OPTION(S))

PC

3G 12/12"/ BACKUP (2.67/0.305) GUARDRAIL

9G 12/12.5'/6'3"/S (2.67/3.81/1.905/S) GUARDRAIL

30G 12/12.5'/6'3"/S (2.67/3.81/1.905/S) SRT-1 ANC GUARDRAIL

39G 12/12.5'/6'3"/S (2.67/3.81/1.905/S) SR T-2 GUARDRAIL

700A CABLE ANCHOR BRACKET

907G 12 (2.67)/BUFFER/ROLLED (TERMINAL)

3000G CABLE ASSEMBLY 3/4" x 6'6" (19 x 1981)

3300G 5/8" (16) WASHER

3340G 5/8" (16) HGR NUT

3360G 5/8" DIA. x 1 1/4" (16 DIA x 35) HGR SPLICE BOLT

3380G 5/8" DIA. x 1 1/2" (16 DIA. x 38) HEX HEAD BOLT

3400G 5/8" DIA x 2" (16 DIA. x 50) POST BOLT

3580G 5/8" DIA x 18" (16 DIA x 460) HGR POST BOLT

3701G 3/4" (19) WASHER

3704G 3/4" (19) HEX NUT

3718G 3/4" DIA X 3 "(19 DIA. x 75) HIGH STRENGTH HEX HEAD

3900G 1" (25) WASHER

3910G 1" (25) HEX NUT

4063B WOOD POST 6" x 8" x 6'0" (150 x 200 X 1830)

4075B WOOD BLOCK 6" x 8" x 14" (150 x 200 x 360) DR

4254G 3/8" (10) WASHER

4258G 3/8" (10) LOCKWASHER

4261G 3/8" x 1 1/2" (10 DIA. x 38) HEX HEAD BOLT (GR 5)

4699G 3/4" (19) LOCKWASHER

6321G 3/8" DIA. X 2 " (10 DIA x 50) HEX HEAD BOLT (GR 5)

6405G 3/8" (10) HEX NUT

9960G SLOT GUARD

9961G 3/8" x

33876A HBA POST 1 TOP (W6 x 8.5)

33877A HBA POST 2 TOP (W6 x 8.5)

33878A HBA POST 1 & 2 BOT (TS 6 x 4)

33879G ANGLE STRUT 2" X 2" X 3/8" (50 x 50 x 10)

33880G 1" x 6" x 8" (25 x 150 x 200) BEARING PLATE

33881G CABLE WEB PL 4" x 1/4" x 5 3/4" (100 x 6 x 146)

QTY DESCRIPTION

1

1

1

1

1

1

1

14

58

44

8

2

4

10

4

4

BOLT

1

1

4

4

5

4

1

4

4

5

4

1

1

1

2

2

1

1

3" x 4" (10 x 75 x 100) PLATE WASHER

DELINEATION OPTIONS

6665B 1 STRIPED (YELLOW/BLACK) REFLECTOR 16" x 16"

(400 x 400)

3

4

INSTALLING THE

SRT

TM

/ HBATM6-POST SYSTEM

MATERIALS

As packaged, the SRTTM/HBATMPost System includes all materials needed

for the installation.

Note that concrete footings or foundations are not required.

TOOLS REQUIRED

Tools required are those ordinarily used to install standard highway

guardrail (HGR). They include 9/16", 15/16", 1-1/4" and 1-1/2" sockets

and wrenches and such other equipment as augers and post pounders

commonly used in driving posts.

SITE PREPARATION

Site grading is usually necessary for the proper placement of the HBA

TM

posts and the Controlled Release Terminal (CRT) posts. It is suggested

that this grading be completed before the start of the installation of the

SRT

TM

/HBATM.

INSTALLATION

Be sure adequate time is allowed for "same day" complete installation.

If special field conditions are encountered when installing t he

SRT

TM

/HBATMPost System, contact Trinity Engineering @ 1-800-644-7976

to review the conditions.

POST LAYOUT

The SRTTM/HBATMPost System is a 37'6" (11.43 m) that utilizes a straight

flare. Start at the end (post location 7) of the guardrail run and measure

along the flared system a distance of 37'6" (11.43 m). At this point,

measure an offset of 4'0" (1.21 m) perpendicular to the road. This

establishes the face location of post no. 1. A straight line between post

no. 1 and face of the blockout of post no. 7 establishes the location of

either the face of the post or the face of the blockout for each of the

posts. All posts are spaced at 6'3" (1905 mm) on center.

Trinity Highway Products drawings for the SRT should be used with

these instructions. The states standard drawings for this system need

to be reviewed for details that will be specific to that state.

The SRT™/HBA™ Post System has a straight flare; the earlier versions of

the SRT-350™ used a parabolic (curved) flare. At posts one and two,

HBA™ posts are used in place of the soil tubes and wood posts. The

same equipment and expertise is required for both systems. Anyone with

experience installing the SRT-350™ should have no difficulty installing the

SRT™/HBA™ Post System.

Loading...

Loading...