BarrierGate

®

For Manual Operation

Product Description

Instructional Manual

Revision A May 2013Part No. 619183B

®

BarrierGate

For Manual Operation

Product Description

Instructional Manual

2525 Stemmons Freeway

Dallas, Texas 75207

Important:

assembly, maintenance, and repair of the BarrierGate

instructions are for standard assembly specified by the appropriate highway

authority only. In the event the specified system assembly, maintenance, or

repair would require a deviation from standard assembly parameters, contact the

appropriate highway authority engineer. This system has been accepted for use

by the Federal Highway Administration for use on the national highway system

under strict criteria utilized by that agency. Energy Absorption Systems

representatives are available for consultation if required.

This Manual must be available to the worker overseeing and/or assembling the product

at all times. For additional copies, contact Energy Absorption Systems at (888) 323-6374

or download from websites below.

The instructions contained in this Manual supersede all previous information and Manuals. All

information, illustrations, and specifications in this Manual are based on the latest BarrierGate

system information available to Energy Absorption Systems at the time of printing. We reserve

the right to make changes at any time. Please contact Energy Absorption Systems to confirm

that you are referring to the most current instructions.

These instructions are to be used only in conjunction with the

®

system. These

®

Part No. 619183B

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 1 All rights in copyright reserved

Table of Contents

Customer Service Contacts .............................................................................................. 3

Important Introductory Notes ............................................................................................ 3

Recommended Safety Rules for Assembly ...................................................................... 4

Safety Symbols ................................................................................................................. 5

Warnings and Cautions ..................................................................................................... 5

Limitations and Warnings .................................................................................................. 6

Operation .......................................................................................................................... 7

Maintenance ..................................................................................................................... 8

Drive-By Inspection ........................................................................................................... 8

Walk-Up Inspection ........................................................................................................... 8

Troubleshooting and Repair ............................................................................................ 10

BarrierGate

BarrierGate

Concrete Pad, BarrierGate

Anchor Assembly, BarrierGate

Wall Assembly Pulley, BarrierGate

Wall Assembly Capstan, BarrierGate

Track Assembly, BarrierGate

Gate Assembly, Hook Section, BarrierGate

Gate Assembly, Pin Section, BarrierGate

Debris Skirt Assembly Pin or Hook Section, BarrierGate

®

Repair Guidelines ...................................................................................... 11

®

1.5 Manual Operation ................................................................................ 13

®

1.5 ...................................................................................... 16

®

1.5 ................................................................................ 17

®

1.5 ......................................................................... 19

®

®

1.5 .................................................................................. 23

1.5 ...................................................................... 21

®

1.5 ............................................................ 24

®

1.5 ............................................................... 26

®

1.5 ........................................ 28

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 2 All rights in copyright reserved

Customer Service Contacts

Energy Absorption Systems (a Trinity Highway Products company) is committed to the highest

level of customer service. Feedback regarding the BarrierGate

®

system, its assembly

procedures, supporting documentation, and performance is always welcome. Additional

information can be obtained from the contact information below:

Energy Absorption Systems:

Telephone: (888) 323-6374 (USA Only)

(214) 589-8140 (USA or International)

E-mail: customerservice@energyabsorption.com

Internet: Energy Absorption Systems

Trinity Highway Products, LLC

http://www.energyabsorption.com

http://www.highwayguardrail.com

Important Introductory Notes

Proper assembly, deployment, and future maintenance of the BarrierGate® are critical to

achieve performance of the system under appropriate federal and state criteria. These

instructions should be read in their entirety and understood before assembly of the system.

Take the time to review this Manual thoroughly before performing all necessary work. Do not

attempt to assemble any BarrierGate

highway authority and instructional Manual from the manufacturer. If you need additional

information, or have questions about the BarrierGate

authority that has planned and specified this assembly and, if needed, contact Energy

Absorption Systems Customer Service Department. These instructions are to be used only in

conjunction with the assembly of the BarrierGate

as specified by the applicable highway authority. In the event your system assembly requires or

involves deviation from standard parameters, or during the assembly process a question arises

regarding a particular assembly step, please contact the appropriate highway authority that

specified this system at this location before proceeding. Energy Absorption Systems is available

for consultation with that agency. These instructions are intended for an individual who is

qualified to both read and accurately interpret them as written. They are intended for the

individual who is experienced and skilled in the assembly of highway products which are

specified and selected by the highway authority.

®

without the proper plans and specifications from the

®

system, please contact the highway

®

system and are for standard assemblies only

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 3 All rights in copyright reserved

Important: Read safety instructions thoroughly and follow the assembly

directions and suggested safe practices before assembling, maintaining, or

repairing the BarrierGate

serious injury or death to the worker and/or bystanders. It further compromises

the acceptance of this system by the FHWA. Please have these instructions

available for reference by anyone involved in the assembly of the system.

Warning: Ensure that all of the BarrierGate

Important statements within the BarrierGate

Failure to follow this warning could result in serious injury or death in the event of

a collision.

®

system. Failure to follow this warning can result in

®

system Warnings, Cautions, and

®

Manual are completely followed.

Recommended Safety Rules for Assembly

* Important Safety Instructions *

This Manual must be kept in a location where it is readily available to persons who assemble,

maintain, or repair the BarrierGate

®

system. Additional copies of this Manual are available from

Energy Absorption Systems by calling (888) 323-6374. Please contact Energy Absorption

Systems if you have any questions concerning the information in this Manual or about the

BarrierGate

®

system. This Manual may also be downloaded directly from the websites indicated

below.

Always use appropriate safety precautions when operating power equipment, mixing chemicals,

and when moving heavy equipment or the BarrierGate® components. Gloves, safety goggles,

safety toe shoes, and back protection shall be used.

Safety measures incorporating traffic control devices specified by the highway authority must be

used to provide safety for personnel while at the assembly, maintenance, or repair site. Please

follow the traffic control plan set forth by the appropriate highway authority.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 4 All rights in copyright reserved

Safety Symbols

This section describes the safety symbols that appear in this BarrierGate® Manual. Read the

Manual for complete safety, assembly, operating, maintenance, repair, and service information.

Symbol Meaning

Safety Alert Symbol: Indicates Danger, Warning, or Caution. Failure to read

and follow the Danger, Warning, Safety, or Caution indicators could result in

serious injury or death to the workers and/or bystanders.

Warnings and Cautions

Read all instructions before assembling, maintaining, or repairing the BarrierGate® system.

Warning: Do not assemble, maintain, or repair the BarrierGate

you have read this Manual thoroughly and completely understand it. Ensure that

all Warnings, Cautions, and Important Statements within the Manual are

completely followed. Please call Energy Absorption Systems at (888) 323-6374 if

you do not understand these instructions. Failure to follow this warning could

result in serious injury or death in the event of a collision.

Warning: Safety measures incorporating appropriate traffic control devices

specified by the highway authority must be used to protect all personnel while at

the assembly, maintenance, or repair site. Failure to follow this warning could

result in serious injury or death in the event of a collision. The traffic control plan

established by the highway authority must always be observed in assembling or

utilizing this product.

®

system until

Warning: Use only Energy Absorption Systems parts that are specified herein

for the BarrierGate

Do not utilize or otherwise comingle parts from other systems even if systems are

other Energy Absorption Systems or Trinity Highway Products systems. Such

configurations have not been tested nor have they been accepted for use.

Assembly, maintenance, or repairs using unspecified parts or accessories is

strictly prohibited. Failure to follow this warning could result in serious injury or

death in the event of a vehicle impact with an UNACCEPTED system.

®

for assembling, maintaining, or repairing the BarrierGate®.

Warning: Do NOT modify the BarrierGate

this warning could result in serious injury or death in the event of a collision.

Warning: Ensure that the BarrierGate

federal, state, specifying agency, and local specifications. Failure to follow this

warning could result in serious injury or death in the event of a collision.

®

system and delineation used meet all

Warning: Ensure that your assembly meets all appropriate Manual on Uniform

Traffic Control Devices (MUTCD) and local standards. Failure to follow this

warning could result in serious injury or death in the event of a collision.

®

system in any way. Failure to follow

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 5 All rights in copyright reserved

Limitations and Warnings

Energy Absorption Systems, in compliance with the National Cooperative Research Highway

Program 350 (NCHRP Report 350) “Recommended Procedures for the Safety Performance of

Highway Safety Features”, contracts with FHWA approved testing facilities to perform crash

tests, evaluation of tests, and submittal of results to the Federal Highway Administration for

review.

The BarrierGate

NCHRP Report 350 and has been accepted by the FHWA for use on the national highway

system. These tests, specifically set forth by FHWA, evaluate product performance by utilizing

established criteria for impacts outlined by NCHRP Report 350 involving a typical range of

vehicles on our roadways, from lightweight cars (approx. 820kg [1800 lb.]) to full size pickup

trucks (approx. 2000 kg [4400 lb.]) to single-unit van trucks (approx. 8000 kg [17,600lb.]) as

specified by the FHWA. A product can be certified for multiple Test Levels. The BarrierGate

certified to the Test Level(s) as shown below:

Test Level 3: 100 km/h [62 mph]

Test Level 4: 80 km/h [50 mph] @ 15°

These FHWA directed tests are not intended to represent the performance of systems

when impacted by every vehicle type or every impact condition existing on the roadway.

This system is tested only to the criteria of NCHRP 350 as approved by FHWA.

Energy Absorption Systems does not represent nor warrant that the results of these

NCHRP 350 tests show that vehicle impacts with the products in other conditions would

necessarily avoid injury to person(s) or property. Impacts that exceed the specifications of the

system may not result in acceptable crash performance as outlined in NCHRP Report 350,

relative to structural adequacy, occupant risk, and vehicle trajectory. Energy Absorption

Systems expressly disclaims any warrant or liability for injury or damage to persons or property

resulting from any impact, collision, or harmful contact with products, other vehicles, or nearby

hazards or objects by any vehicle, object or person, whether or not the products were

assembled by or under the direction of Energy Absorption Systems or by third parties.

The BarrierGate

accordance with specific state and federal guidelines. Energy Absorption Systems offers a

reflective delineator panel and has reflective tabs for its BarrierGate

the material is only intended to supplement delineation required by the Department of

Transportation’s “Manual on Uniform Traffic Control Devices” (MUTCD). Design tables are

provided in this Manual to aid in selecting the most appropriate product configuration for proper

application to the site. The appropriate highway authority approved engineer should be careful

to properly select, install, and maintain the product. Careful evaluation of the site geometry,

vehicle population type, speed, traffic direction, and visibility are some of the elements that

require evaluation for the proper selection of a safety appurtenance by the appropriate

specifying highway authority.

®

system was tested to meet the impact criteria, requirements, and guidelines of

®

®

system is intended to be assembled, delineated, and maintained in

®

line of products. However,

is

After an impact occurs, the product must be repaired to its original condition as soon as

possible. When a safety product is impacted, it is mandatory that the highway authority inspect

all the components for damage and repair and/or replace components as necessary. If the

system is not repairable, a complete system replacement is required. The determination of

whether or not a system is repairable should only be determined by a trained and experienced

engineer, experienced in highway products, directed by the appropriate highway authority. That

determination rests in the sound discretion of the appropriate highway authority, who specified

the use of this system, only.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 6 All rights in copyright reserved

Operation

1. Unlock the gate (see Figure 1 & 2).

Open the manual jack access cover located at the middle of the gate and remove the handle

attached to it. Remove the safety retaining pin from the rear of the manual jack support. Insert

the handle onto the jack nut and crank the jack all the way to unlock the gate. (Turn clockwise.)

2. Crank the gates open (see Figure 3).

Open the manual drive cover on the capstan drive enclosure, release the catch on the lid, and

lay the lid back. Remove the guard on the manual drive crank. Insert the manual jack handle

onto the low speed (outermost) drive shaft and crank the gates open. The high speed

(innermost) drive shaft can be used when the gate is opened 3 m [10’] or more.

Figure 1

Unlock Gate

Figure 2

Figure 3

Crank Open

3. Reverse order to close and lock gate.

Caution:

to spin. Hold the handle tightly to maintain control. Low speed operation is

recommended at first until operator becomes familiar with gate manual operation.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 7 All rights in copyright reserved

The weight of the gate may cause the Manual Crank Handle to want

Maintenance

Periodic and thorough maintenance is essential for dependable and proper BarrierGate®

operation. Take the time to review the product limitations, assembly cautions, and maintenance

instructions before performing any necessary work.

The time interval between maintenance inspections depends a great deal upon particular site

conditions. It is recommended the BarrierGate

less frequent inspections will be adequate. Maintenance decisions are made by the highway

authority.

®

be inspected once a month until it is determined

Drive-By Inspection

A slow drive-by visual inspection of the BarrierGate® can often spot damage which requires

maintenance. Some special inspection considerations are:

1. Are the sides of the Gate Assemblies and steel enclosures straight and aligned

properly? If the sides are not straight or aligned then there is likely structural damage

from a vehicle impact. A walk-up inspection is required (See Walk-Up Inspection

Section).

2. Are the Bulkhead Assemblies completely closed and locked? If there is any visible gap

between the Bulkheads then the System is not properly closed and latched. A walk-up

inspection is required.

®

3. Is there an accumulation of dirt, debris, ice or snow around the BarrierGate

Guide Rail and Track Sections are critical for proper BarrierGate

debris is present, maintenance and cleaning is required.

4. Are the covers on the manual drive access fully closed? If not, a walk-up inspection

should be made to further investigate.

®

operation. If dirt and

? Clean

Walk-Up Inspection

If the drive-by visual inspection indicates maintenance is required then a walk-up inspection is

necessary. Some of the most common maintenance concerns and their corresponding repair

techniques are:

Pin and Hook Section Gate Assemblies

1. Inspect the Debris Skirt for tears. Replace as necessary.

2. Inspect for and replace any bent and or damaged Side Panels, Top Covers, Transitions,

etc.

3. Lubricate all Bulkhead Assembly grease fittings every 6 months, or 750 cycles,

whichever comes first (See Figure 4).

Figure 4

4. Inspect and repaint any scratched painted surfaces.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 8 All rights in copyright reserved

5. Inspect for any signs of animals nesting in, chewing on or otherwise damaging the

system.

Capstan Drive Assembly

1. Lubricate all Capstan Drive grease fittings (do not allow grease to spill on drive or driven

drums) every 6 months, or 750 cycles, whichever comes first.

2. Inspect and repaint any scratched painted surfaces.

3. Clean out any debris accumulation.

4. Inspect for excessive drum or wire rope wear.

Tension Pulley Assembly

1. Inspect and adjust for excessive Capstan Drive Cable slack.

2. Inspect and repaint any scratched painted surfaces.

3. Clean out any debris accumulation.

Track Assembly

1. Clean out any debris accumulation.

2. Inspect and tighten any loose nuts.

Misaligned Gate Assemblies

The Gate Assemblies must be properly aligned with and riding on the Guide and Track for

proper operation. Open the Bulkhead and Short Transition Covers and inspect to make sure the

Guide Wheels and V-Guide Rollers are riding properly. If not, adjust them until they ride

properly.

Inspect and replace any Skirt, Side, and Top cover panels that may have been damaged from

vehicle impacts.

Unlocked Gate Assemblies

If the Bulkhead Assemblies are not completely closed and locked, open the Top Covers to

inspect for the cause. There may be debris under the system preventing the Gate Assemblies

from completely closing and locking.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 9 All rights in copyright reserved

Troubleshooting and Repair

The BarrierGate® is designed to operate simply and reliably, when impacted within the

applicable NCHRP 350 criteria, even in adverse highway environments. Most operational

problems have been shown to relate to improper assembly or maintenance. Therefore it is

essential to follow the directives and specifications of the highway authority and the information

provided herein. If operational problems are encountered, begin preparing for the necessary

repair by thoroughly reviewing this Manual and all applicable location, layout, orientation, and

construction plans detailed by the highway authority.

It is critical to become familiar with BarrierGate

basic operating instructions before attempting any repairs. Follow the "BarrierGate

Guidelines" to help diagnose the operational problem then carry out the indicated inspection

and repair step. If these suggestions do not restore BarrierGate

Absorption Systems, Customer Service Department at (888) 323-6374.

A traffic control plan appropriate to the complexity of the repair project should be prepared,

approved by the highway authority, and understood by all parties before moving to the site for

BarrierGate

®

repair. Deploy the appropriate work zone safety devices prior to beginning the

repair and keep them present through all phases of the repair.

The internal components of the BarrierGate

lifting and removing gate halves. Access for inspection and repair can be made through one or

more Enclosure covers, Top Covers, Transition Skirts, Half Skirts, and Bulkhead Covers

(reference the Drawing Section of this Manual and Figure 5). The Enclosure covers can be

removed to gain access to the capstan drive system. The Top Covers can be removed to

provide a wide open area for inspection and a way of reaching or climbing down into the

BarrierGate

®

for repairs.

®

construction, assembly, maintenance, and

®

operations, call Energy

®

can be inspected for necessary repairs without

®

Repair

Caution: Before attempting any repairs, the BarrierGate

®

must be blocked from

moving to avoid injuring maintenance personnel.

The Transition and Half Skirts can be removed to gain access at the extreme ends of the gate.

Some gate inspections and repairs may require the gate halves to be lifted and removed. In this

case, follow the reverse of the steps in the Product Description Manual under “Gate Assembly

Positioning”. Take special care to disconnect all necessary mechanical connections before

lifting the gates.

It may not be practical to complete some repairs in the field. Some breakdowns may require

components to be removed and replaced. Please follow the directives of the highway authority

in these instances.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 10 All rights in copyright reserved

Figure 5

BarrierGate® Repair Guidelines

Warning:

prevent the Gate Assemblies from rolling on slopes.

R1: Check for and remove internal obstructions to Gate movement.

Troubleshooting indicates something inside the Gate may be obstructing free opening or closing

movement. Do not operate Gate or damage to components may result. Remove Top Covers

and inspect the inside of the Gate for possible obstructions. Check for and remove excessive

debris from under the Gate. Check to make sure the V-Guide Rollers in the Bulkheads are

properly engaging the inverted angle iron Tracks and that the Transition Rollers are properly

riding on the Guide Rail. If not, reposition the Gate to bring Rollers back on track.

R2: Check and re-tension the Capstan Drive Cable.

Troubleshooting indicates that the Capstan Drive Cable is not adequately tensioned. Do not

operate gate or damage to components may result. Start by removing the appropriate Enclosure

Cover then inspect the Tension Pulley assembly. The extended length of the springs must not

exceed 330 mm (13"). If the springs exceed this length it may be due to a damaged or worn

Capstan Drive Cable or loose wire rope clamps. Inspect for and correct the cause of the loose

cable. Carry out the "Tension the Drive Cable" step in the Product Description Manual to tension

the Drive Cable.

To avoid risk of serious injury proper precautions must be taken to

Figure 6

R3: Check for and repair damaged Capstan Drive.

Troubleshooting indicate the Capstan Drive is damaged. Only the simplest Capstan Drive

repairs are likely to be made in the field. Inspect the Capstan Drive for obvious problems such

as a bound Drive Cable. If no field adjustments can be made, detach the Drive Cable and

remove the Capstan Drive for replacement.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 11 All rights in copyright reserved

R4: Check for and remove obstructions to gate movement.

Troubleshooting indicates something external to the gate is obstructing movement. Inspect for

and remove excessive buildups of debris, snow, ice, etc. along both sides of the Gate, Long and

Short CMB's, and the exposed portions of the Guide Rail. Also inspect and remove any buildups

that may have occurred around the Anchor Plates, Transitions, and Drive Cable system. Check

for even clearance on both sides of Gate at transition.

R5: Check for and repair the locking linkage in the Bulkheads.

Troubleshooting indicates something may be wrong with the Locking Linkage in the Bulkhead.

Inspect the linkage for loose components. Make sure that all clevis pins are in place and

secured by retainer pins. The Hooks must fully engage the pins in the locked position and be

fully disengaged in the unlocked position. Replace damaged or excessively worn parts.

R6: Check for and repair gate structural damage.

Troubleshooting indicates the Gate has structural damage that must be replaced for proper gate

operation. Assess the degree of structural damage. Minor structural damage to a small number

of Side Panels, Panel Splices, Top Covers, etc. can be easily repaired by removing and

replacing the damaged components. Major structural damage requires full replacement.

R7: Consult Energy Absorption Systems.

If the Repair Guidelines did not restore BarrierGate

®

operations, call Energy Absorption

Systems Customer Service Department at (888) 323-6374 for additional suggestions.

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 12 All rights in copyright reserved

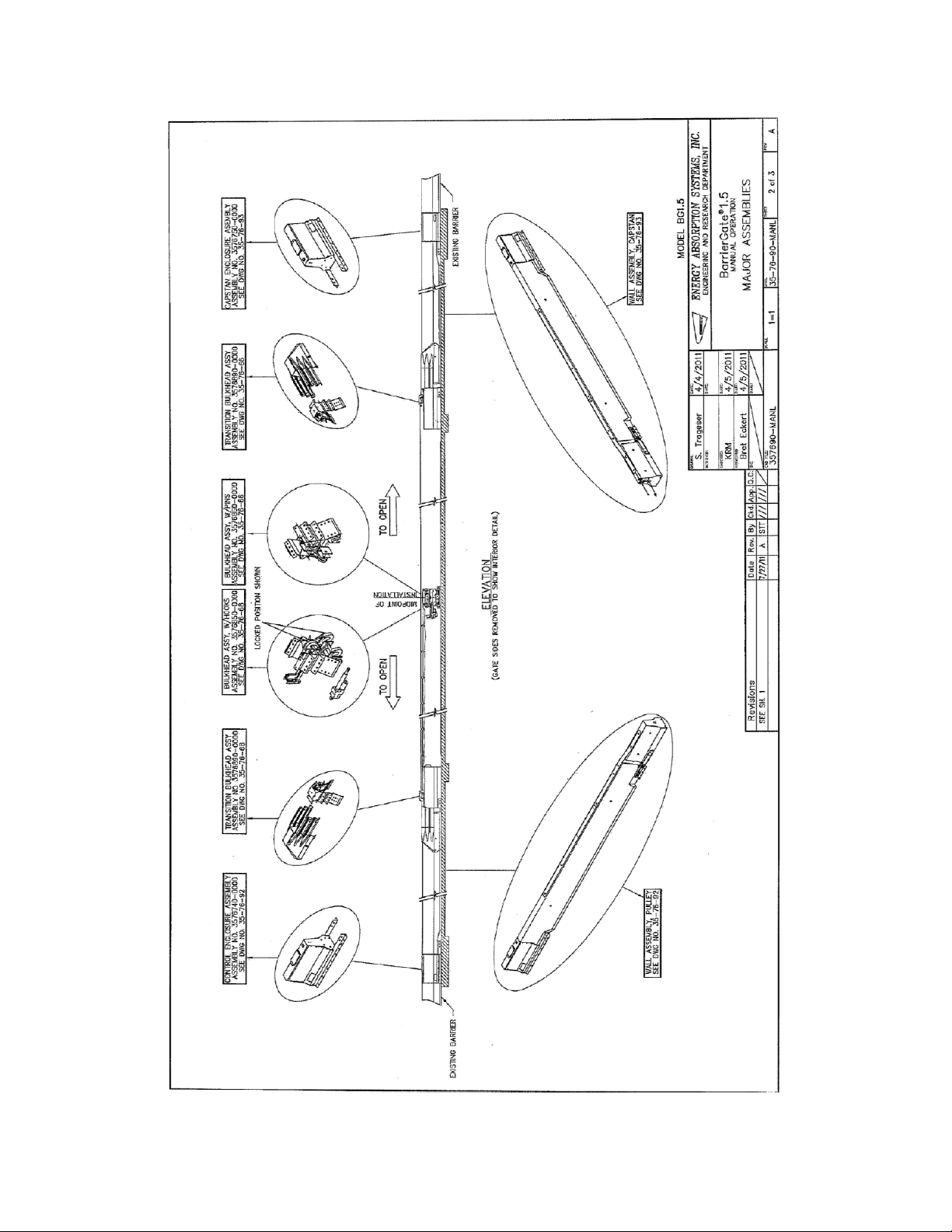

DWG 357690-MANL Sheet 1 of 3

1.5 Manual Operation

®

BarrierGate

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 13 All rights in copyright reserved

DWG 357690-MANL Sheet 2 of 3

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 14 All rights in copyright reserved

DWG 357690-MANL Sheet 3 of 3

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 15 All rights in copyright reserved

1.5

®

Concrete Pad, BarrierGate

DWG 277900-0000

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 16 All rights in copyright reserved

y

1.5

®

, BarrierGate

Anchor Assembl

DWG 3576810-0000 Sheet 1 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 17 All rights in copyright reserved

DWG 3576810-0000 Sheet 2 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 18 All rights in copyright reserved

y

y

1.5

®

, BarrierGate

Pulle

Wall Assembl

DWG 357692 Sheet 1 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 19 All rights in copyright reserved

DWG 357692 Sheet 2 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 20 All rights in copyright reserved

®

1.5

Wall Assembly Capstan, BarrierGate

DWG 357693 Sheet 1 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 21 All rights in copyright reserved

DWG 357693 Sheet 2 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 22 All rights in copyright reserved

®

1.5

Track Assembly, BarrierGate

DWG 3576820-0000

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 23 All rights in copyright reserved

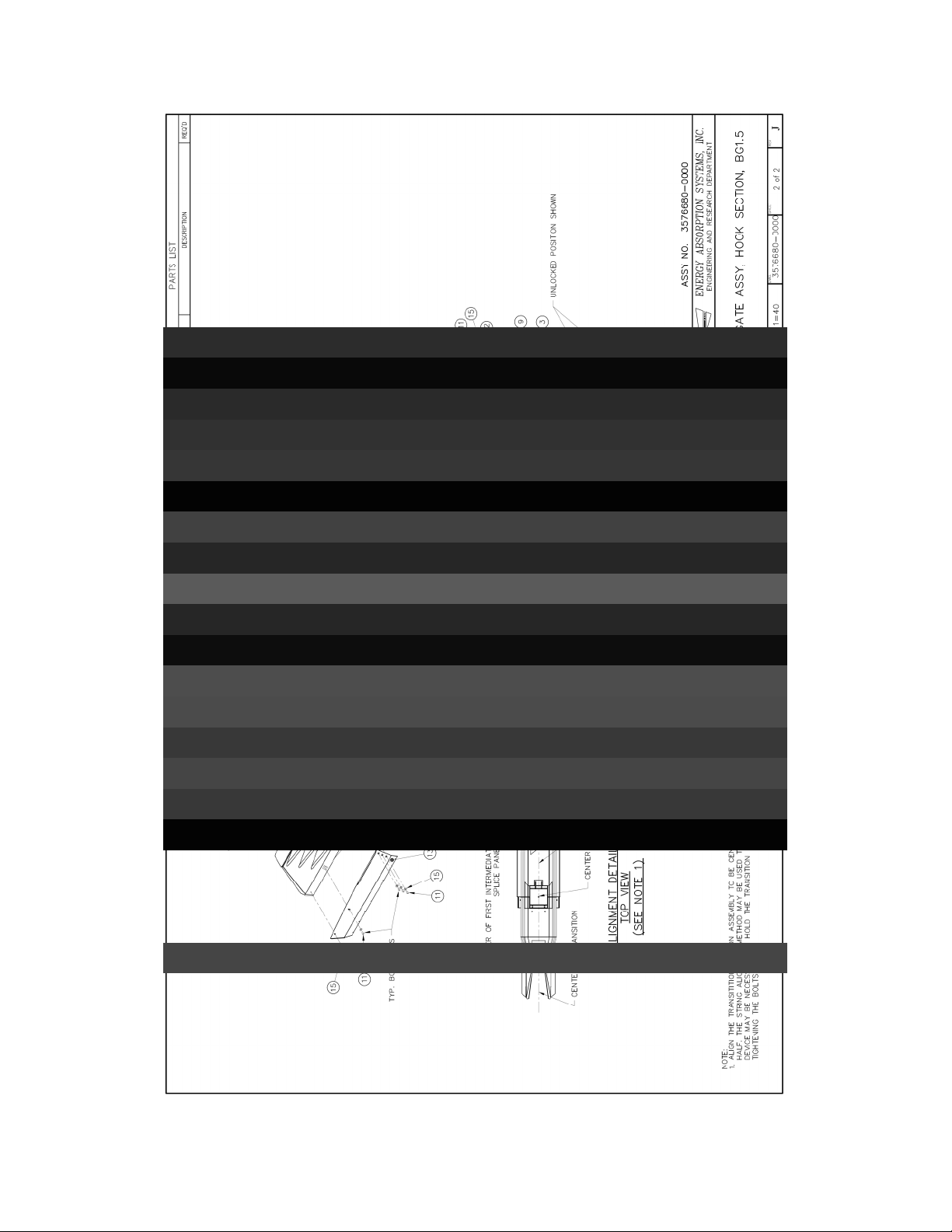

y

1.5

®

, Hook Section, BarrierGate

Gate Assembl

DWG 3576680-0000 Sheet 1 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 24 All rights in copyright reserved

DWG 3576680-0000 Sheet 2 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 25 All rights in copyright reserved

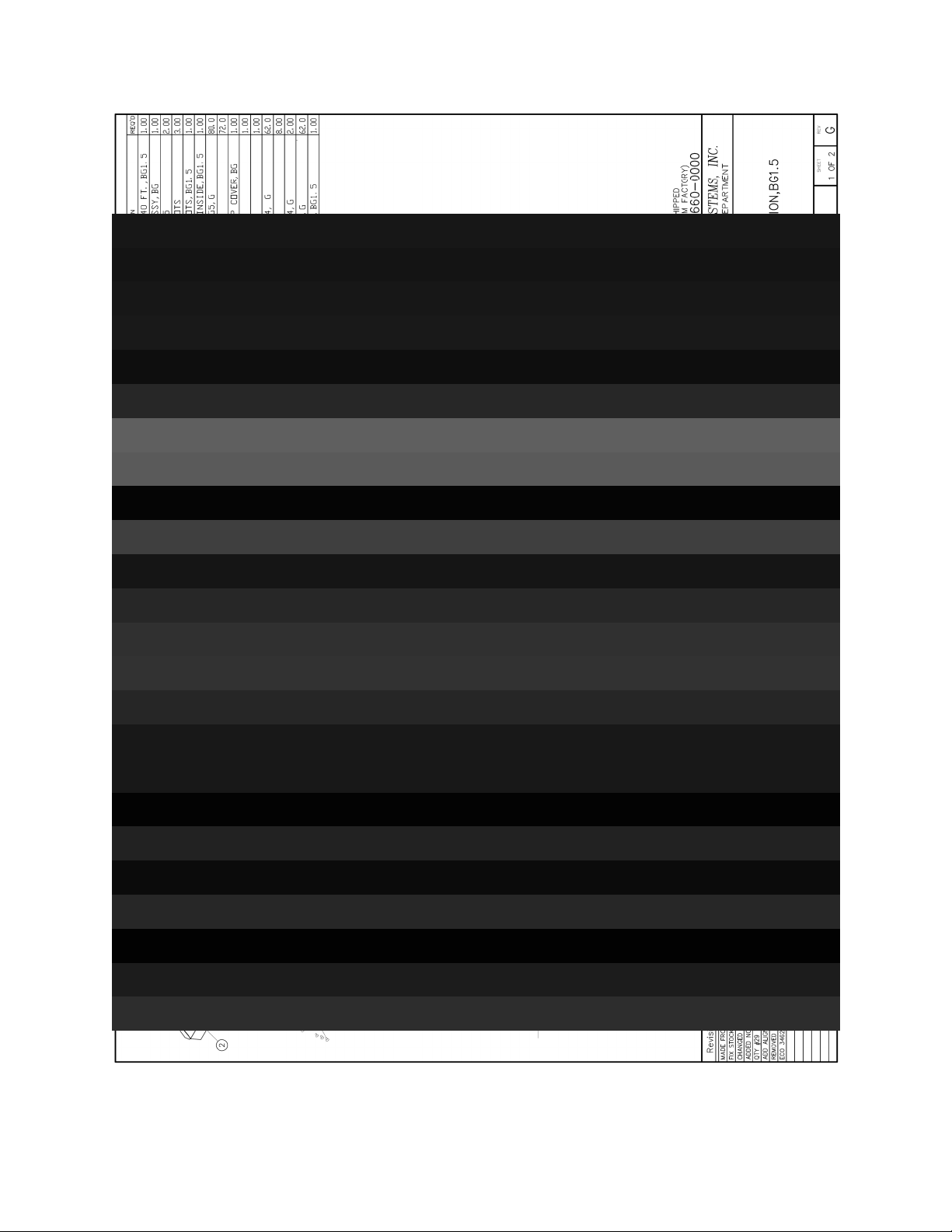

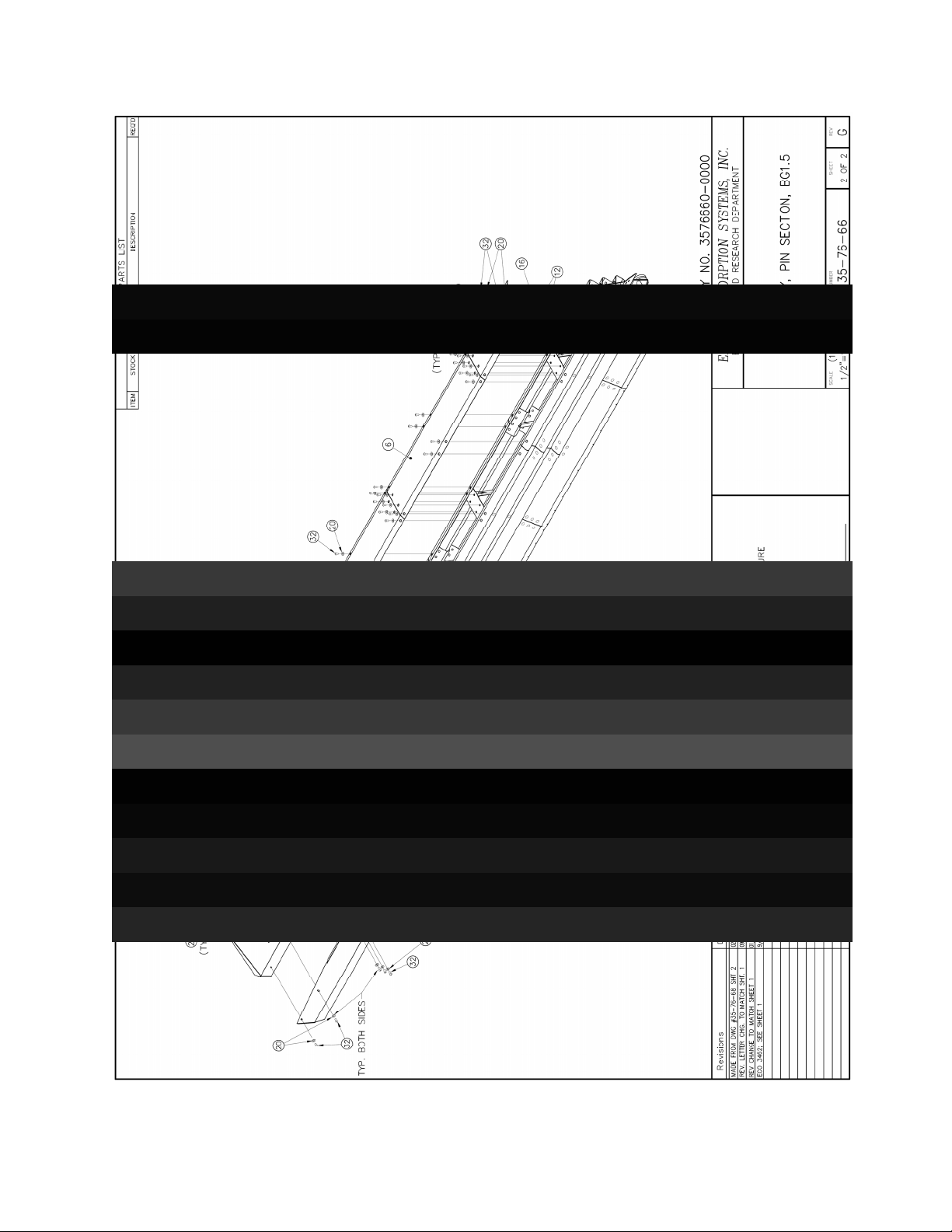

®

1.5

Gate Assembly, Pin Section, BarrierGate

DWG 3576660-0000 Sheet 1 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 26 All rights in copyright reserved

DWG 3576660-0000 Sheet 2 of 2

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 27 All rights in copyright reserved

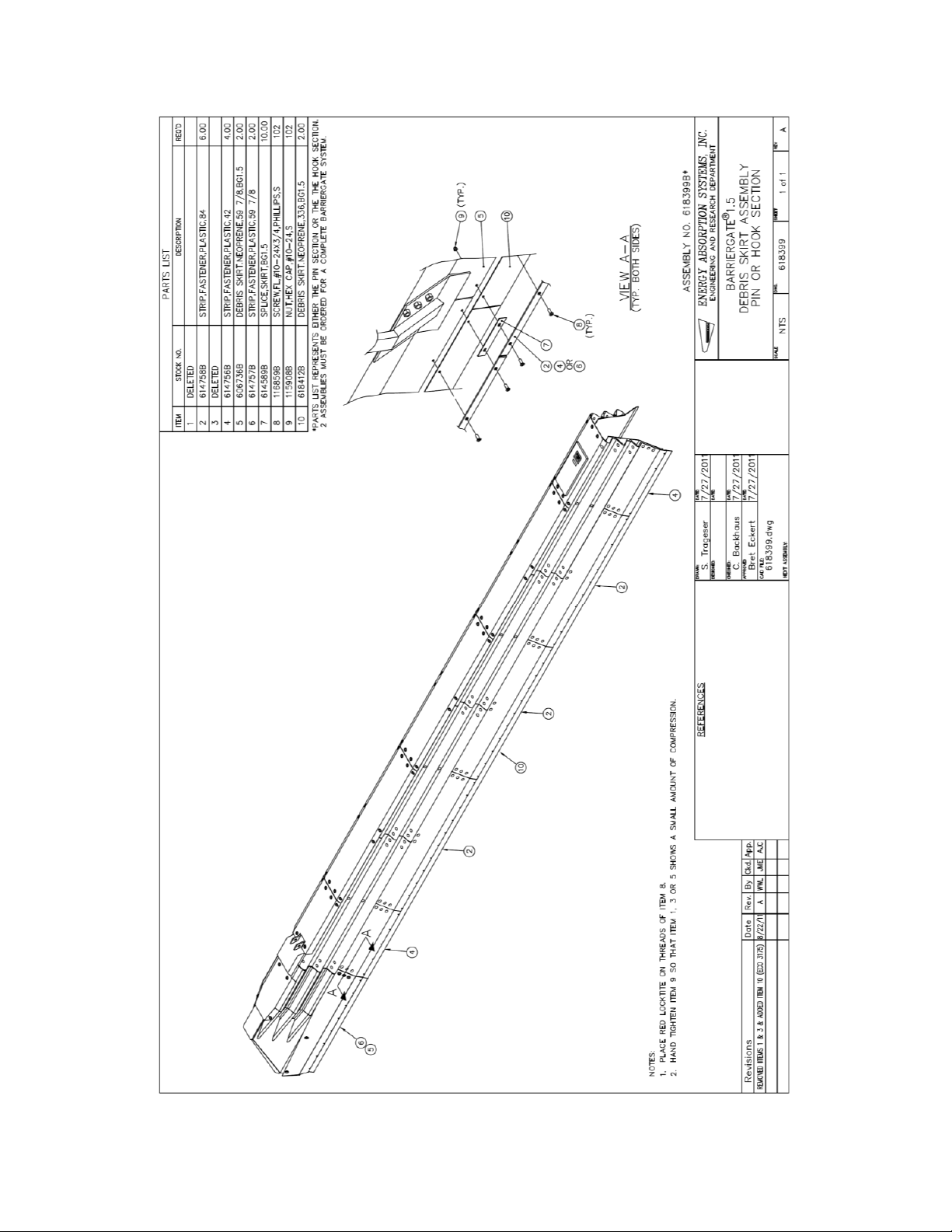

y

1.5

®

Pin or Hook Section, BarrierGate

Debris Skirt Assembl

DWG 618399

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 28 All rights in copyright reserved

Notes:

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 29 All rights in copyright reserved

Notes:

www.energyabsorption.com Revision A May 2013

www.highwayguardrail.com 30 All rights in copyright reserved

2525 Stemmons Freeway

Dallas, Texas 75207

888-323-6374 (USA only)

214-589-8140 (Outside USA)

www .energyabsorption.com

www.highwayguardrail.com

Loading...

Loading...