Page 1

Trimble S, VX, SPS & RTS

F

Total Station

Service Manual

February 2010 P/N 57150002, Revision 5.0

Page 2

F

Trimble S, VX, SPS & RTS Service ManualII P/N 57150002, Revision 5.0

Page 3

F

Table of Contents

Table of Contents

1 General Information and safety . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Statement of Disclamation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Basic Assumptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Electrostatic Discharge (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Service procedure recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-27

Measuring through glass window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-28

2 General Product Information . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Trimble S3 - Product description & Service Information . . . . . . . . . . . . . . . . . . . . 2-2

Trimble S6 - Product description & Service information . . . . . . . . . . . . . . . . . . . . 2-3

Trimble S8 - Product description & Service information . . . . . . . . . . . . . . . . . . . . 2-4

Trimble VX - Product description & Service information . . . . . . . . . . . . . . . . . . . 2-6

Trimble RTS - Product description & Service information . . . . . . . . . . . . . . . . . . . 2-7

Trimble SPS - Product description & Service information . . . . . . . . . . . . . . . . . . . 2-8

Models and serial numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Instrument Model Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

Model definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

3 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Removable handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Battery / radio side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Radio unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Servo side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-14

IPC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

TCU attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

TCU attachment with USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

Face2 panel & optical plummet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

Servo drive system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

Angle Measuring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-36

Base unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-43

PSM board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Tilt sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-48

Software / Instrument application firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

Telescope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-62

Distance unit - DR300+ / DR PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

Distance unit - High Precision / DR Standard / DR . . . . . . . . . . . . . . . . . . . . . . .3-73

Tracklight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-79

Tracker system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-81

Servo focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-87

Video camera (Trimble S8 / VX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-90

P/N 57150002, Version 5.0 III Trimble S, VX, SPS & RTS Service Manual

Page 4

F

Auto focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-95

Tracker Long Range - TLR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-96

High Power Laser Pointer - HPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-102

Service interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-104

Board definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-105

Table of Contents

4 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Save Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Clear Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Basic Function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Distance and Angles Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-10

Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Angle and servo unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Distance unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-21

Tracker unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-22

5 Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Distance and Tracker unit covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Side covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Battery/Radio side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Servo side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

IPC board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-17

TCU attachment with USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-20

Face 1 Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-23

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-24

Face 2 panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-38

Face 2 Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-42

Vertical servo motor & angle unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-44

Regreasing of centre unit axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-50

Base unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-54

Horizontal servo motor & angle unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-59

PSM board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-65

Tilt sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-67

Reticle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-69

Distance unit - DR300+ / DR PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-72

Reticle Illumination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-83

Laser pointer - DR300+ / DR PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-87

Distance unit - High Precision / DR Standard . . . . . . . . . . . . . . . . . . . . . . . . . . 5-91

Distance unit - DR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-107

Tracker unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-110

Tracklight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-113

Servo focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-116

S8 / VX - Camera module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-121

Tracker Long Range - TLR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-127

High Power Laser Pointer - HPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-130

Autolock upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-135

Robotic upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-139

FineLock upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-142

Scanning upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-145

Trimble S, VX, SPS & RTS Service ManualIV P/N 57150002, Version 5.0

Page 5

F

What to do after replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-148

Table of Contents

6 Adjustment and verification . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Battery/radio side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Servo side cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

IPC board - instrument data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

TCU attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-13

TCU Attachment with USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-14

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

Face 2 panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-20

Optical plummet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-22

Pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Servo unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-25

Angle unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-28

Base unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-30

Firmware upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-31

Collimator alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-32

Reticle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Laser pointer - DR300+ / DR PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-51

Distance unit - DR300+ / DR PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-59

Distance unit - High Precision / DR Standard / DR . . . . . . . . . . . . . . . . . . . . . . .6-88

Tracker unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-126

Tracklight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-149

Servo focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-152

Camera module - S8 / VX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-157

Trimble eProtect™ - PIN / PUK code security . . . . . . . . . . . . . . . . . . . . . . . . 6-178

Auto focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-180

Tracker Long Range - TLR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-182

High Power Laser Pointer - HPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-190

Remote control power test - Trimble S8 . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-199

Service interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-200

Software configuration key installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-201

Service check list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-203

7 Service Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

PASS structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Connect to the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

PASS Release 163 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

8 Replacement Parts & Tooling . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Horizontal Turning Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Horizontal Turning Unit - High Angle Accuracy . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Alidade Right . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Servo Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

Battery Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Radio Side Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Alidade Left incl. TCU Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-12

TCU Attachment with USB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-14

Handle - Trimble S6/S8/VX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-16

Handle - Trimble SPS/RTS Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-17

P/N 57150002, Version 5.0 V Trimble S, VX, SPS & RTS Service Manual

Page 6

F

Centre Unit - DR300+/DR PLUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

Centre Unit - High Precision / DR Standard / DR . . . . . . . . . . . . . . . . . . . . . . .8-20

Centre Unit - Tracker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-22

Centre Unit - Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-24

Centre Unit - Camera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-26

Centre Unit - Tracker Long Range / High Power Laser Pointer . . . . . . . . . . . . . . . .8-27

Trimble S3 Total Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-29

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-30

Baselines & Prism type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-46

Table of Contents

Trimble S, VX, SPS & RTS Service ManualVI P/N 57150002, Version 5.0

Page 7

F

Manual Change Log

Manual version

Version Date Changes

1.0 February

2005

First release

1.1 February

2005

1.2 April 2005 Minor updates

1.4 July 2005 Minor updates

1.5 December

2005

2.0 March 2006

Minor updates

Changes

• Autolock upgrade, see page 5-135

• Robotic upgrade, see page 5-139

• Tracker collimation instructions, see page 6-147

• Information about configuration key, see page 3-54

• New face 2 panel incl. new constant settings, see page 3-28

• Optical adjustments on GDM collimator, see page 6-66

• Pictures on spare parts, see page 8-30

• Radio configuration, see page 6-2

• Centring instruction for SRC board incl. magnets and angle disc, see page

5-44 and see page 5-59

• Save and initialization instructions of IPC board constants (instrument

data), see page 6-6

• Vertical oscillation compensation, see page 6-25

Changes

• Trimble S6 High Precision, see page 3-73

• 1” Angle accuracy, see page 3-39

• Instruction how to mount conductive sealing gaskets in the side covers,

see page 5-6

• New sequence how to mount and tighten the distance and tracker unit

cover, see page 5-3

• Trouble shooting information added, see page 4-1

• Minor updates

P/N 57150002, Revision 5.0 VII Trimble S, VX, SPS & RTS Service Manual

Page 8

F

Version Date Changes

2.2 June 2007

3.0 April 2008

4.0 April 2009

Changes

• Regreasing of vertical axes, see page 5-50

• Firmware compatibility, see page 3-54

• Part numbers for RoHS compliant parts added, see page 8-1

• Troubleshooting updated, See page 4-1

• Baselines added, see page 8-46

• Tracker transmitter divergence adjustment added, see page 6-139

• Vertical oscillation compensation updated, see page 6-25

• Firmware upgrade updated, see page 6-31

Changes

• Trimble VX service information added

• Trimble SPS service information added

• Trimble S8 service information added

• Check list after service/repair for each model implemented, see page 6-

203

• Event log analysis implemented, see page 4-3

• Clear event log instruction implemented, see page 4-4

• Troubleshooting flow chart added, see page 4-13

• Service interval function implemented, see page 3-104

• Check/adjustment of reference fibre for DR300+ added, see page 6-72

• Saving and initializing 1” Horizontal Turning Unit constants added, see

page 6-6

• Instruction how to replace reference greywedge added, see page 5-81

• Vertical oscillation compensation software updated, see page 6-25

• Radio short range test from Service Bulletin JE-1007-0046 added, see

page 6-4

• Trunnion axis correction instruction added, see page 6-48

• Removal of Cover objective instruction added, see page 5-135

Changes

• Trimble S8 service information for Long range FineLock & High Power

Laser pointer added

• New Trimble SPS model SPS630added

• Trimble RTS service information added

• Instrument model matrix implemented, see page 2-14

• Prism requirements for EDM offset determination added, see page 8-46

• PASS release 1.6.3 information, see page 7-5

• New function in PASS, Basic Function Test, see page 4-4

• New function in PASS, read out PIN code from instrument (S8 VX &

SPS), see page 6-178

• Software configuration key installation information implemented, see

page 6-201

• Name of Pliobond changed to Glue MS 1855, see page 8-30

Trimble S, VX, SPS & RTS Service ManualVIII P/N 57150002, Revision 5.0

Page 9

F

Version Date Changes

5.0 February

2010

6.0 June 2011

Changes

• Trimble S3 Total Station Servo/Autolock/Robotic service information

added

• DR PLUS EDM service information added

• DR EDM service information added

• TCU Attachment with USB added, see page 6-14

• HTU column added to model matrix, see page 2-14

• Information about measuring through glass added, see page 1-28

• New PASS function, TCXO Frequency calibration instructions, see page

6-80 and see page 6-119

• New PASS function, Logging software instructions, see page 4-10

• Updated Service interval function in PASS, new function to also read out

service interval inform ation from the instrument, see page 6-200

• Updated PASS function, software to install configuration numbers to the

instrument, see page 6-201

• Renamed service part 59010019 Horizontal Turning Unit 1” to

Horizontal Turning Unit High Angle Accuracy, see page 3-39

Changes

• Trimble S3 Total Station Servo/Autolock models with face 2 panel added

• Trimble RTS633 DR PLUS model added

• Trimble SPS620, 720 DR and SPS630, 730, 930 DR PLUS models added

• Trimble S8 High Precision with camera, model added.

P/N 57150002, Revision 5.0 - IX Trimble S, VX, SPS & RTS Service Manual

Page 10

F

Trimble S, VX, SPS & RTS Service Manual - X P/N 57150002, Revision 5.0

Page 11

Chapter 1

F

General Information and safety

1 General Information and safety

Statement of Disclamation

Preface

Basic Assumptions

General Safety

Electrostatic Discharge (ESD)

Laser Safety

Service procedure recommendations

Measuring through glass window

P/N 57150002, Revision 5.0 1 - 1 Trimble S, VX, SPS & RTS Service Manual

Page 12

Chapter 1

F

Statement of Disclamation

Trimble Inc. reserves the right to alter the specification of this product and/or the contents of this

manual without advanced notification.

This manual contains PROPRIETARY information from Trimble Inc. This manual may not be

duplicated, disclosed, copied, or re-transmitted in any form without prior written permission from

Trimble Inc.

©2002 - 2010 Trimble Inc., All Rights Reserved.

General Information and safety

Trimble S, VX, SPS & RTS Service Manual1 - 2 P/N 57150002, Revision 5.0

Page 13

Chapter 1

F

General Information and safety

Preface

This Service manual was prepared as a reference guide for the service personnel of authorized

Trimble service centres to enable them to correctly carry out the task of rendering service and

maintenance on Trimble instruments.

In order to insure that customers are satisfied with Trimble products, proper service and maintenance

must be provided. The service personnel must fully understand the contents of the manual and at the

same time, it is recommended to keep the manual in a place where reference can readily be made.

The information, photographs, drawings and specifications entered in this manual were the best

available at the time of printing. All alterations to this manual will be notified by the issuance of

service information, service bulletins, supplementary pages, exchange pages or revised volumes. It is

therefore recommended that the manual be kept up to date by carefully maintaining a follow-up of

these materials.

This service manual is designed to provide the necessary information for the service, maintenance,

and repair of this product. The manual is divided into the following sections:

1. General Information and Safety: Contains general information about the use of this manual,

contacting Trimble, safety precautions, ESD information, laser safety, etc.

2. General Product Information: Describes basic product description, specifications, warranty,

related documentation, etc.

3. Theory of Operation: Describes the functional operation, mechanical design, electrical

hardware/software operation, optical operation*, and hydraulic operation* of the unit. (* as

required)

4. Troubleshooting: Provides a logical means of determining the source of a malfunction of the

unit.

5. Maintenance and Repair: Describes the steps necessary to operate, test, disassemble, and repair

the unit. Also includes software download information.

6. Assembly Drawings: Reference drawings and exploded views for obtaining assembly and part

information.

7. Adjustments and Verification: Provides the procedures necessary to adjust, calibrate, and

verify the product meets published specifications.

8. Service Software: Documents the hardware and software requirements needed and the

procedures to use service software to repair, upgrade, or reset operation of the product.

9. Replacement Parts: Lists the available service replacement parts and parts ordering

information.

10.Appendix: Provides additional information such as Service Bulletins, updates, notes, software

procedures, etc.

P/N 57150002, Revision 5.0 1 - 3 Trimble S, VX, SPS & RTS Service Manual

Page 14

Chapter 1

F

General Information and safety

Basic Assumptions

1. General: This manual assumes the basic understanding of mechanical design, electronic

theory, general service procedures, and have attended a Trimble, Inc. service training course

regarding this product.

2. Electronic Test Equipment: This manual assumes the proper knowledge and understanding of

the use of basic electronic test equipment such as volt-ohmmeters, oscilloscopes, generators,

power supplies, etc.

3. Computers: This manual assumes the basic knowledge of using a computer with MS-DOS,

Microsoft Windows, or applicable operating system and corresponding software.

Possible Loss of Warranty

The manufacturer's warranty on Trimble instruments can be voided by improper service or repairs

performed by persons other than authorized technicians. Strict compliance with the instructions in

this manual is necessary to prevent loss of coverage under such warranties. See Warranty terms in the

appendices.

Service Information

Assembly drawings depict the relationship between all assemblies that are deemed "serviceable".

Serviceable is defined as those assemblies that are repairable at the service centre level. The

limitation to “serviceable” assemblies is the tooling involved as well as assembly times.

Removal and Replacement

Refer to the parts ordering section of this manual when replacing parts or making any adjustments.

Torque specifications, adhesives, and procedures specified on assembly drawings are essential for

continued successful operation of this product.

Trimble S, VX, SPS & RTS Service Manual1 - 4 P/N 57150002, Revision 5.0

Page 15

Chapter 1

F

General Information and safety

General Safety

This manual contains certain CAUTIONS, which should be carefully read and followed to minimize

risk of personal injury or damage to the instrument. The lack of cautions with respect to specific

service methods does not mean there are no safety risks involved. The following safety rules have to

be observed:

Note – provides information necessary to properly complete a procedure or information, which will

make the procedure easier to understand.

C

C

Caution – indicates a special procedure or special steps that must be taken in the course of

completing the procedure in which the caution is found. These special procedures are necessary

to avoid damage to the assembly on which work is being done.

Warning – indicates a special procedure or special steps that must be taken in the course of

completing the procedure in which the warning is found. These special procedures are

necessary to avoid injury to the person performing the procedure.

P/N 57150002, Revision 5.0 1 - 5 Trimble S, VX, SPS & RTS Service Manual

Page 16

Chapter 1

F

General Information and safety

Electrostatic Discharge (ESD)

The Trimble S6 was constructed in an ESD-protected environment. Most of the semiconductor

devices in the instrument are susceptible to ESD damage.

ESD is generated in many ways.

For example, it can be the result of simple contact, the separation of materials, or the normal motion

of people working with the device. Depending on the magnitude of the charge, device substrates can

be punctured or destroyed by contact with, or by mere proximity to, a static charge. The result can be

immediate destruction, early failure of the device, or degradation of device performance.

To prevent static damage or destruction:

• Take adequate precautions when you handle or service equipment that contains static-sensitive

devices.

• Only attempt to service the circuitry in a static-sensitive device if you are thoroughly familiar

with industry-accepted techniques for handling such devices.

• Always take adequate measures to prevent the buildup of static charge on work surfaces and on

persons handling the Service Manual.

Setting up an ESD workstation

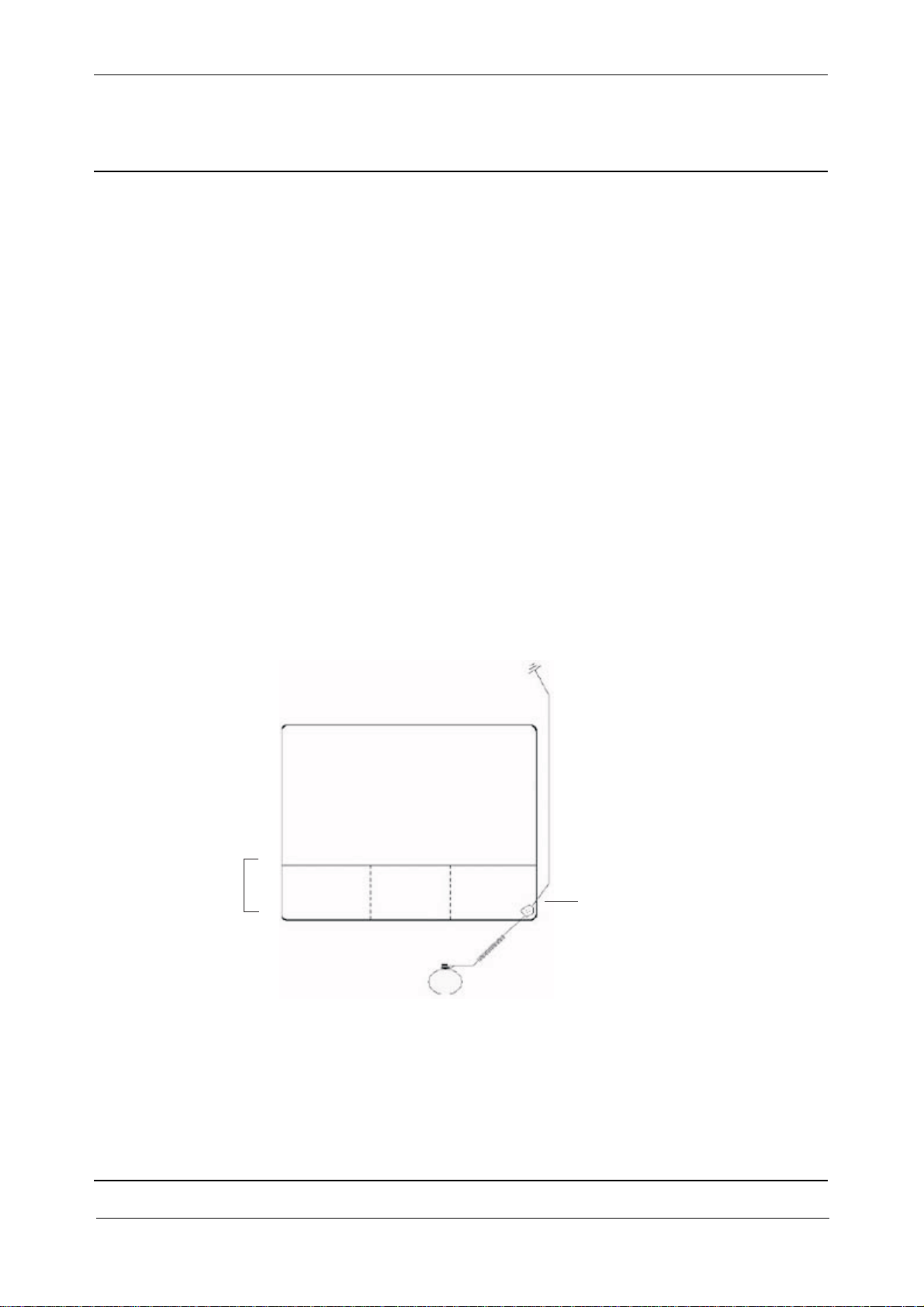

Fig. 1-1 ESD workstation setup

Electrical earth ground

connection

Mat grounding

Dissipative mat

Pockets

Wrist strap

1. Remove the mat grounding cable from the mat pocket.

2. Snap the end of the mat grounding cable onto the common point ground connection on the mat.

3. Connect the other end of the cable to an electrical earth ground, such as a third wire utility

ground, a cold water pipe, or a ground rod.

4. Use the common point ground connection to plug the wrist strap cable into the mat grounding

cable. Make sure the wrist strap includes a 1 Mohm resistor.

Wrist strap cable incl. 1MΩ

cable

Snap-on common point

ground connection

Trimble S, VX, SPS & RTS Service Manual1 - 6 P/N 57150002, Revision 5.0

Page 17

Chapter 1

F

Put on the wrist strap. The wrist strap must fit snugly. To adjust it, unclasp the buckle latch, adjust

the size, and re-clasp the latch.

It is now safe to handle components and printed circuit assemblies on the mat.

Always repackage all ESD-sensitive components before you disconnect the wrist strap.

General Information and safety

P/N 57150002, Revision 5.0 1 - 7 Trimble S, VX, SPS & RTS Service Manual

Page 18

Chapter 1

F

General Information and safety

Laser Safety

Class I, II, and IIIa laser products are defined by the U.S. Bureau of Radiological Health.

C

This equipment has been tested and found to comply with CEI/IEC 60825-1:2007, 21 CFR 1040.10,

and 1040.11 except for deviations to Laser Notice No. 50, dated June 24, 2007.

If the instrument is equipped with a high power laser, this equipment has been tested and found to

comply with IEC 60825-1 2007, 21 CFR 1040.10, and 1040.11 except for deviations to Laser Notice

No. 50, dated June 24, 2007.

Queries

Address any questions you may have about laser safety to:

Warning – Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous LED or laser radiation exposure. As with any bright light

source, such as the sun, electric welding arcs or arc lamps, common sense applies. Avoid direct

eye exposure when the laser is on. For further information regarding safe use of lasers, refer to

the CEI/IEC standard 60825-1:2007.

Trimble Navigation Limited 5475 Kellenburger Road Dayton, OH USA 45424-1099 Attention:

Laser Safety Officer, Quality Assurance Group Phone (937) 233-8921 ext 5824 or (800) 538-7800

Fax (937) 233-9661

Trimble S3 DR / RTS555 DR / RTS655 DR / SPS620 DR / SPS720 DR

The Trimble S3 DR, RTS555 DR , RTS655 DR, SPS620 DR, SPS720 DR Total Stations are CLASS

3R LASER PRODUCT:

Fig. 1-2 Laser warning label

Fig. 1-3 Laser aperture label

Trimble S, VX, SPS & RTS Service Manual1 - 8 P/N 57150002, Revision 5.0

Page 19

Chapter 1

F

The instrument contains visible and invisible laser sources:

• A laser diode for distance measuring in DR mode and laser pointer function operating at 660

nm (visible light), with a beam divergence of 0.4 x 0.4 mrad and an output power of <5 mW,

while the emission is coaxial with the telescope. This mode operates in LASER CLASS 3R.

• The laser diode for distance measuring in prism mode operates at 660 nm (visible light), with

a beam divergence of 0.4 x 0.4 mrad and an output power of <0.017 mW, while the emission is

coaxial with the telescope. This mode operates in LASER CLASS 1.

• An Autolock laser diode operates at 785 nm (infrared, non-visible light), with a beam

divergence of 38.5 mrad and an output power of < 0.35 mW, while the emission is coaxial with

the telescope. This mode operates in LASER CLASS 1.

Laser and LED Information Trimble S3 DR / RTS555 DR / RTS655 DR / SPS620 DR / SPS720 DR

The Trimble S3 DR, RTS555 DR, RTS 655 DR, SPS620 DR, SPS720 DR Total Stations have been

tested, and complies with the regulations for Class 3R Laser products

Fig. 1-4 Trimble S3 DR Total Station apertures

General Information and safety

P/N 57150002, Revision 5.0 1 - 9 Trimble S, VX, SPS & RTS Service Manual

Page 20

Chapter 1

F

Fig. 1-5 Trimble RTS555 DR / RTS655 DR Total Station apertures

General Information and safety

Distance

measurement

Autolock and

laser pointer

aperture

Tracklight aper ture

Fig. 1-6 Trimble SPS620 DR / SPS720 DR Total Station apertures

Distance

measurement

tracker and

laser pointer

aperture

Tracklight

aperture

Trimble S, VX, SPS & RTS Service Manual1 - 10 P/N 57150002, Revision 5.0

Page 21

Chapter 1

F

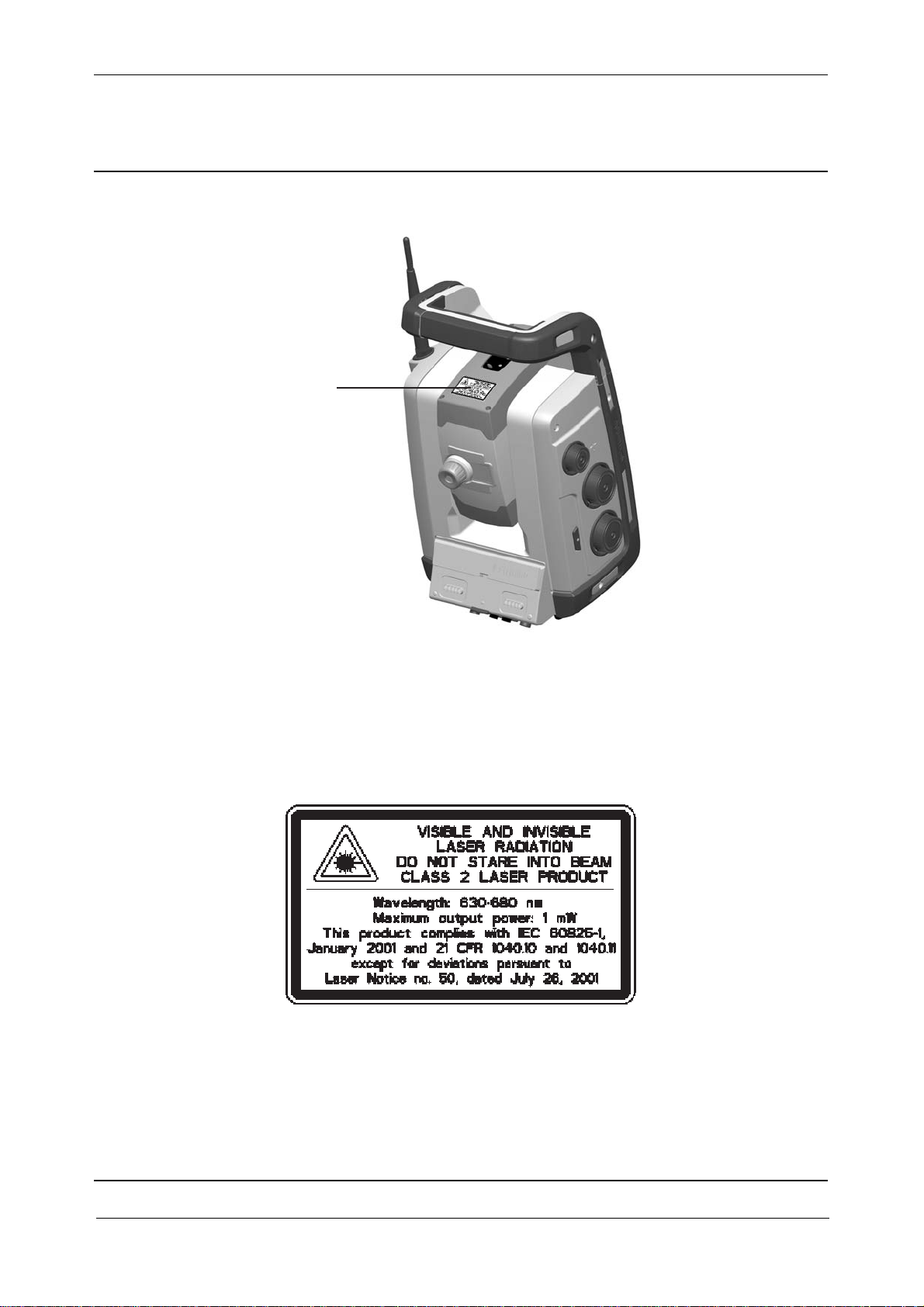

The laser warning label is located on top of the distance measuring unit.

Fig. 1-7 Location of laser warning label on a Trimble S3 DR Total Station

General Information and safety

Fig. 1-8 Location of laser warning label on a Trimble RTS555 DR / RTS655 DR Total Station

aser

arning label

P/N 57150002, Revision 5.0 1 - 11 Trimble S, VX, SPS & RTS Service Manual

Page 22

Chapter 1

F

Fig. 1-9 Location of laser warning label on a Trimble SPS620 DR / SPS720 DR Total Station

Laser

Warning

Label

General Information and safety

Fig. 1-10 Laser warning label Trimble S3 DR / RTS555 DR / RTS655 DR / SPS620 DR / SPS720 DR

Total Station

Trimble S, VX, SPS & RTS Service Manual1 - 12 P/N 57150002, Revision 5.0

Page 23

Chapter 1

F

Fig. 1-11 Location of laser aperture warning label on a Trimble S3 DR Total Station

General Information and safety

Fig. 1-12 Location of laser aperture warning label on a Trimble RTS555 DR / RTS655 DR Total Station

aser aperture

arning label

P/N 57150002, Revision 5.0 1 - 13 Trimble S, VX, SPS & RTS Service Manual

Page 24

Chapter 1

F

Fig. 1-13 Location of laser aperture warning label on a Trimble SPS620 DR / SPS720 DR Total Station

General Information and safety

Laser aperture

warning label

Fig. 1-14 Laser aperture warning label Trimble S3 DR / RTS555 DR / RTS 655 DR / SPS620 DR /

SPS720 DR Total Station

Trimble S6 DR300+ (and Optional Autolock®) / VX / SPS DR300+ / RTS DR300+

The Trimble S6 DR300+ (with Autolock®), VX, SPS DR300+ and RTS DR300+ is a CLASS 2

LASER PRODUCT

Fig. 1-15 Laser pointer warning label

Trimble S, VX, SPS & RTS Service Manual1 - 14 P/N 57150002, Revision 5.0

Page 25

Chapter 1

F

The instrument contains visible and invisible laser sources:

• A laser diode for the distance measuring function operating at 870 nm (infrared, non-visible

light), with a beam divergence of 0.40.8 mrad and an output power of <0.48 mW, laser

CLASS 1.

• A laser diode for laser pointer function operating at 630 - 680 nm (visible light), with a beam

divergence of 0.3 mrad and an output power of < 0.8 mW, while the emission is coaxial with

the telescope. This mode operates in LASER CLASS 2.

• The laser diode for distance measuring in prism and DR mode operates at 870 nm (infrared,

non-visible light), with a beam divergence of 0.40.8 mrad and an output power of <0,48 mW.

This mode operates in LASER CLASS 1.

• As an option, an Autolock laser diode operates at 785 nm (infrared, non-visible light), with a

beam divergence of 38.5 mrad and an out put power of <0.35 mW, while the emission is coaxial

with the telescope. This mode operates in LASER CLASS 1.

When operating in prism mode with Autolock and/or distance measurement the accessible radiation

does not exceed the limits of LASER CLASS 1.

Laser and LED Information Trimble S6 DR300+ / VX / SPS DR300+ / RTS DR300+

General Information and safety

The Trimble S6 DR300+ (with Autolock®), VX, SPS DR300+ and RTS DR300+ has been tested and

complies with the regulations for a Class 1 and Class 2 Laser product.

Fig. 1-16 Trimble S6 DR300+ / VX / SPS DR300+ / RTS 300+

Distance

measurement

Autolock and

Laser pointer

aperture

Tracklight®

aperture

The laser pointer warning label, see Fig. 1-15 on page 1-14 is located on top of the distance unit

cover.

P/N 57150002, Revision 5.0 1 - 15 Trimble S, VX, SPS & RTS Service Manual

Page 26

Chapter 1

F

Fig. 1-17 Location of laser pointer warning label on a Trimble S6 DR300+ / VX / SPS DR300+ / RTS

300+

Laser pointer

warning label

General Information and safety

Trimble S6 DR PLUS / S8 DR PLUS / VX DR PLUS / SPS DR PLUS / RTS DR PLUS

The Trimble S6 DR PLUS / S8 DR PLUS / VX DR PLUS/ SPS DR PLUS / RTS DR PLUS is a

CLASS 2 LASER PRODUCT

Fig. 1-18 Laser pointer warning label

Trimble S, VX, SPS & RTS Service Manual1 - 16 P/N 57150002, Revision 5.0

Page 27

Chapter 1

F

The instrument contains visible and invisible laser sources:

• A laser diode for the distance measuring function operating at 905 nm (infrared, non-visible

light), with a beam divergence of 0.4 x 0.8 mrad and an output power of <1.1 mW, LASER

CLASS 1.

• A laser diode for laser pointer function operating at 630 - 680 nm (visible light), with a beam

divergence of 0.3 mrad and an output power of <0.7 mW, while the emission is coaxial with the

telescope. This mode operates in LASER CLASS 2.

• As an option, an Autolock laser diode operates at 785 nm (infrared, non-visible light), with a

beam divergence of 38.5 mrad and an out put power of <0.35 mW, while the emission is coaxial

with the telescope. This mode operates in LASER CLASS 1.

When operating in prism mode with Autolock and/or distance measurement the accessible radiation

does not exceed the limits of LASER CLASS 1.

Laser and LED Information Trimble S6 DR PLUS / S8 DR PLUS / VX DR PLUS / SPS DR PLUS / RTS DR PLUS

The Trimble S6 DR PLUS / S8 DR PLUS / VX DR PLUS/ SPS DR PLUS/ RTS DR PLUS has been

tested and complies with the regulations for a Class 1 and Class 2 Laser product.

General Information and safety

Fig. 1-19 Trimble S6 DR PLUS

Distance

measurement

Autolock and

Laser pointer

aperture

Tracklight®

aperture

P/N 57150002, Revision 5.0 1 - 17 Trimble S, VX, SPS & RTS Service Manual

Page 28

Chapter 1

F

Fig. 1-20 Trimble S8 DR PLUS / VX DR PLUS

General Information and safety

Distance

measurement

tracker and

laser pointer

aperture

Camera aperture

Fig. 1-21 Trimble SPS DR PLUS / RTS DR PLUS

Distance

measurement

tracker and

laser pointer

aperture

Tracklight

aperture

The laser pointer warning label, see Fig. 1-18 on page 1-16 is located on top of the distance unit

cover.

Trimble S, VX, SPS & RTS Service Manual1 - 18 P/N 57150002, Revision 5.0

Page 29

Chapter 1

F

Fig. 1-22 Location of laser pointer warning label on a Trimble S6 DR PLUS

Laser pointer

warning label

General Information and safety

Fig. 1-23 Location of laser pointer warning label on a Trimble S8 DR PLUS/VX DR PLUS

aser

arning label

P/N 57150002, Revision 5.0 1 - 19 Trimble S, VX, SPS & RTS Service Manual

Page 30

Chapter 1

F

Fig. 1-24 Location of laser warning label on a Trimble SPS DR PLUS / RTS DR PLUS

Laser

Warning

Label

General Information and safety

Trimble S6 High Precision (and Optional Autolock®) / S8 High Precision / SPS DR Standard / RTS DR Standard

The Trimble S Series High Precision / DR Standard (with Autolock®) is a CLASS 2 LASER

PRODUCT:

Fig. 1-25 Laser pointer warning label

Trimble S, VX, SPS & RTS Service Manual1 - 20 P/N 57150002, Revision 5.0

Page 31

Chapter 1

F

The instrument contains visible and invisible laser sources:

• A laser diode for distance measuring in DR- mode and laser pointer function operating at 660

nm (visible light), with a beam divergence of 0.4 x 0.4 mrad and an output power of <1 mW,

while the emission is coaxial with the telescope. This mode operates in LASER CLASS 2.

• The laser diode for distance measuring in prism mode operates at 660 nm (visible light), with

a beam divergence of 0.4 x 0.4 mrad and an output power of <0,017 mW, while the emission is

coaxial with the telescope. This mode operates in LASER CLASS 1.

• As an option, an Autolock laser diode operates at 785 nm (infrared, non-visible light), with a

beam divergence of 38.5 mrad and an output power of < 0.35 mW, while the emission is coaxial

with the telescope. This mode operates in LASER CLASS1.

When operating in prism mode with Autolock and/or distance measurement the accessible radiation

does not exceed the limits of LASER CLASS 1.

Laser and LED Information Trimble S6 High Precision / S8 High Precision / SPS DR Standard / RTS DR Standard

The Trimble S Series High Precision / DR Standard has been tested and complies with the regulations

for a Class 2 Laser product.

General Information and safety

Fig. 1-26 Trimble S6 High Precision / S8 High Precision / SPS DR Standard / RTS DR Standard

Distance

measurement

Autolock and

Laser pointer

aperture

Tracklight®

aperture

The laser pointer warning label, see Figure 1-5 is located on top of the distance unit cover.

P/N 57150002, Revision 5.0 1 - 21 Trimble S, VX, SPS & RTS Service Manual

Page 32

Chapter 1

F

Fig. 1-27 Location of laser pointer warning label on a Trimble S6 High Precision / S8 High Precision

/ SPS DR Standard / RTS DR Standard

Laser pointer

warning label

General Information and safety

Trimble S8 Series High Precision with Long Range FineLock

The Trimble S8 Series High Precision with Long Range FineLock is a CLASS 2 LASER PRODUCT.

The instrument contains visible and invisible laser sources:

• A laser diode for distance measuring in DR- mode and laser pointer function operating at 660

nm (visible light), with a beam divergence of 0.4 x 0.4 mrad and an output power of <1 mW,

while the emission is coaxial with the telescope. This mode operates in LASER CLASS 2.

• The laser diode for distance measuring in prism mode operates at 660 nm (visible light), with

a beam divergence of 0.4 x 0.4 mrad and an output power of <0,017 mW, while the emission is

coaxial with the telescope. This mode operates in LASER CLASS 1.

• An Autolock laser diode operates at 785 nm (infrared, non-visible light), with a beam

divergence of 38.5 mrad and an output power of < 0.35 mW, while the emission is coaxial with

the telescope. This mode operates in LASER CLASS1.

• A Long Range FineLock laser diode operates at 785 nm (infrared, non-visible light), with a

beam divergence of 2,5 mrad and an output power of <0.35 mW, while the emission is biaxial

and eccentric with the telescope axis. This mode operates in LASER CLASS 1.

The Autolock laser diode and the Long Range FineLock laser diode can not operate at the same time.

When operating in prism mode with Autolock and/or distance measurement the accessible radiation

does not exceed the limits of LASER CLASS 1.

Trimble S, VX, SPS & RTS Service Manual1 - 22 P/N 57150002, Revision 5.0

Page 33

Chapter 1

F

Trimble S8 Series High Precision with High Power Laser Pointer

The Trimble S8 Series High Precision with High Power Laser Pointer is a CLASS 3 LASER

PRODUCT.

Fig. 1-28 High Power Laser pointer warning label

Fig. 1-29 High Power Laser pointer aperture label

General Information and safety

The instrument contains visible and invisible laser sources:

• A laser diode for distance measuring in DR- mode and laser pointer function operating at 660

nm (visible light), with a beam divergence of 0.4 x 0.4 mrad and an output power of <1 mW,

while the emission is coaxial with the telescope. This mode operates in LASER CLASS 2.

• The laser diode for distance measuring in prism mode operates at 660 nm (visible light), with

a beam divergence of 0.4 x 0.4 mrad and an output power of <0,017 mW, while the emission is

coaxial with the telescope. This mode operates in LASER CLASS 1.

• An Autolock laser diode operates at 785 nm (infrared, non-visible light), with a beam

divergence of 38.5 mrad and an output power of < 0.35 mW, while the emission is coaxial with

the telescope. This mode operates in LASER CLASS1.

• A laser pointer function operating at 660 nm (visible light), with a full beam divergence of 0,2

mrad (1/e^2) and an output power of <3,5 mW, while the emission is biaxial and eccentric to

the telescope. This mode operates in LASER CLASS 3R.

The laser for the high power laser pointer and the laser for measuring in DR mode may be run at the

same time. This mode is within LASER CLASS 3R.

P/N 57150002, Revision 5.0 1 - 23 Trimble S, VX, SPS & RTS Service Manual

Page 34

Chapter 1

F

Laser and LED Information Trimble S6 High Precision / S8 / SPS DR Standard / RTS DR Standard

The Trimble S Series High Precision / S8 / SPS DR Standard / RTS DR Standard has been tested and

complies with the regulations for a Class 2 Laser product.

The Trimble S8 High Precision with optional High Power Laser Pointer has been tested and complies

with the regulations for a Class 3R laser product.

Fig. 1-30 Trimble S6 High Precision / S8 / SPS DR Standard / RTS DR Standard

General Information and safety

Distance

measurement

Autolock and

Laser pointer

aperture

Tracklight®

aperture

Trimble S, VX, SPS & RTS Service Manual1 - 24 P/N 57150002, Revision 5.0

Page 35

Chapter 1

F

Fig. 1-31 Location of laser pointer warning label on a Trimble S6 High Precision / S8 / SPS DR

Standard / RTS DR Standard and High Power Laser pointer warning label on a Trimble S8.

Laser pointer

warning label

General Information and safety

Fig. 1-32 Laser pointer warning label

P/N 57150002, Revision 5.0 1 - 25 Trimble S, VX, SPS & RTS Service Manual

Page 36

Chapter 1

F

Fig. 1-33 High Power Laser pointer warning label

Fig. 1-34 Laser pointer warning label with optional High Power Laser Pointer

General Information and safety

Fig. 1-35 High Power Laser pointer aperture label

Trimble S, VX, SPS & RTS Service Manual1 - 26 P/N 57150002, Revision 5.0

Page 37

Chapter 1

F

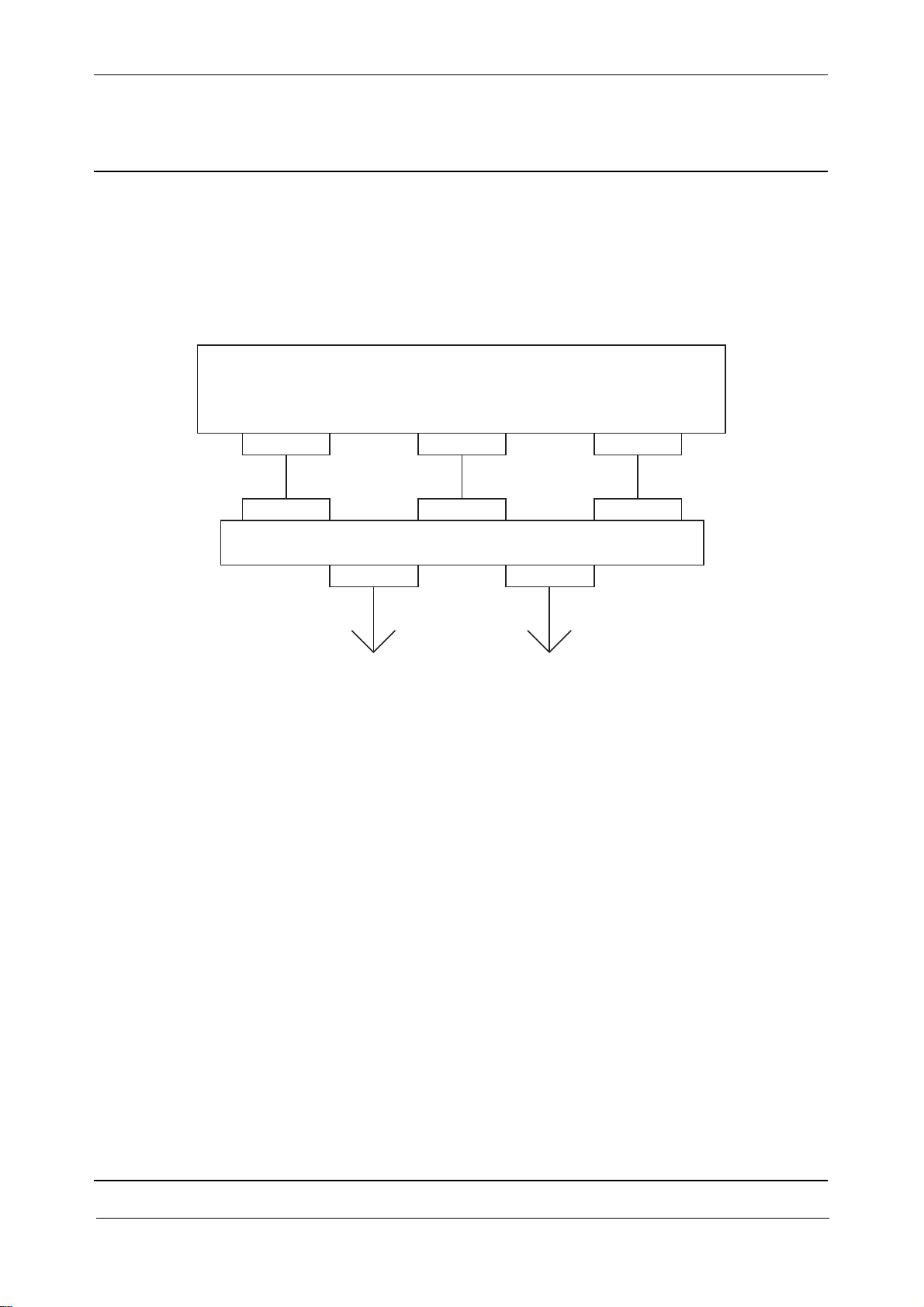

Service procedure recommendations

Updating firmware during service / repair

It is recommended to upgrade the instruments firmware to latest version during service / repair. After

repair if necessary due to customer request (application software compatibility, see “Firmware

Compatibility” on page 3-54.) downgrade the instrument before running Final Test & Report in

PASS.

General Information and safety

P/N 57150002, Revision 5.0 1 - 27 Trimble S, VX, SPS & RTS Service Manual

Page 38

Chapter 1

F

General Information and safety

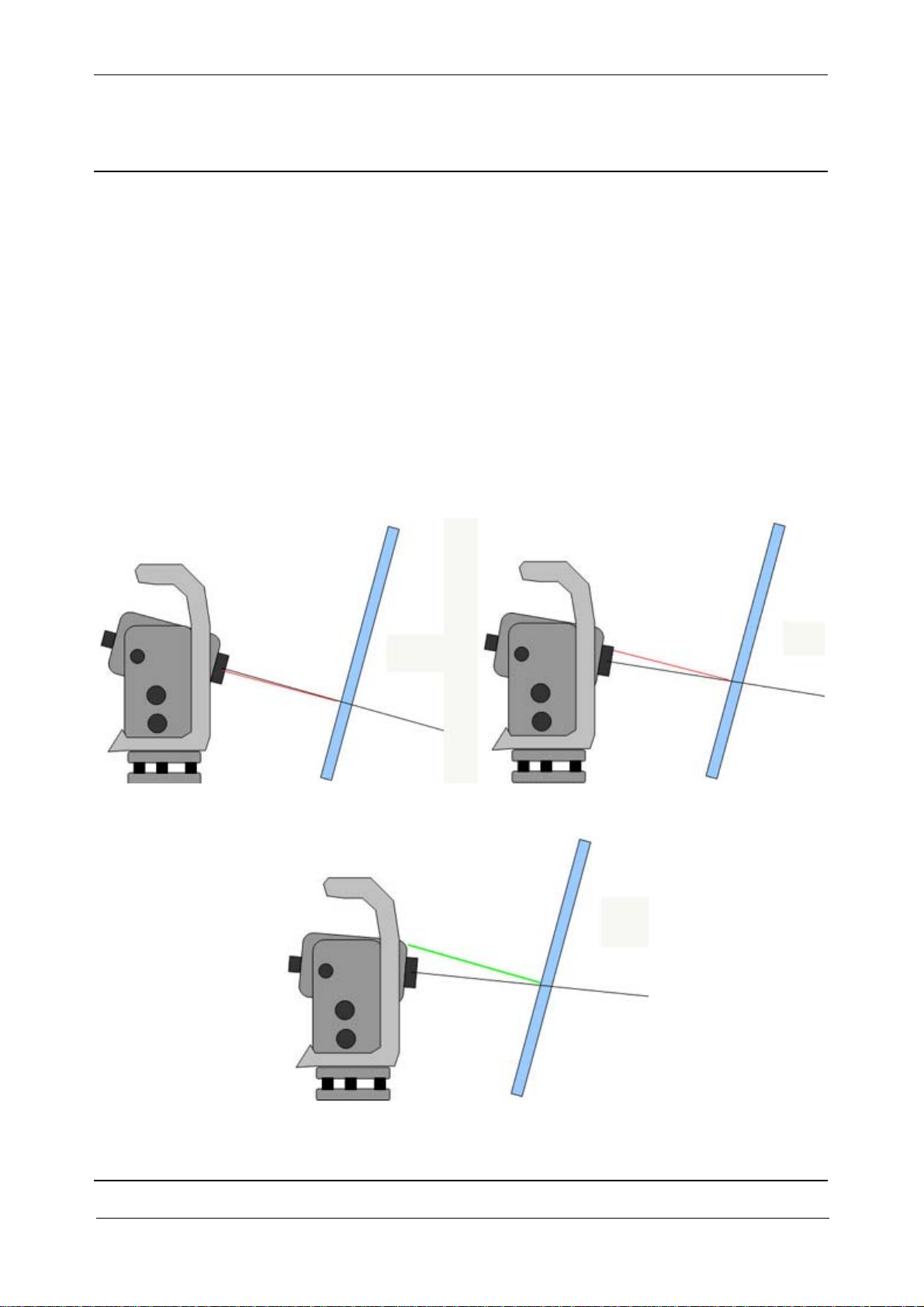

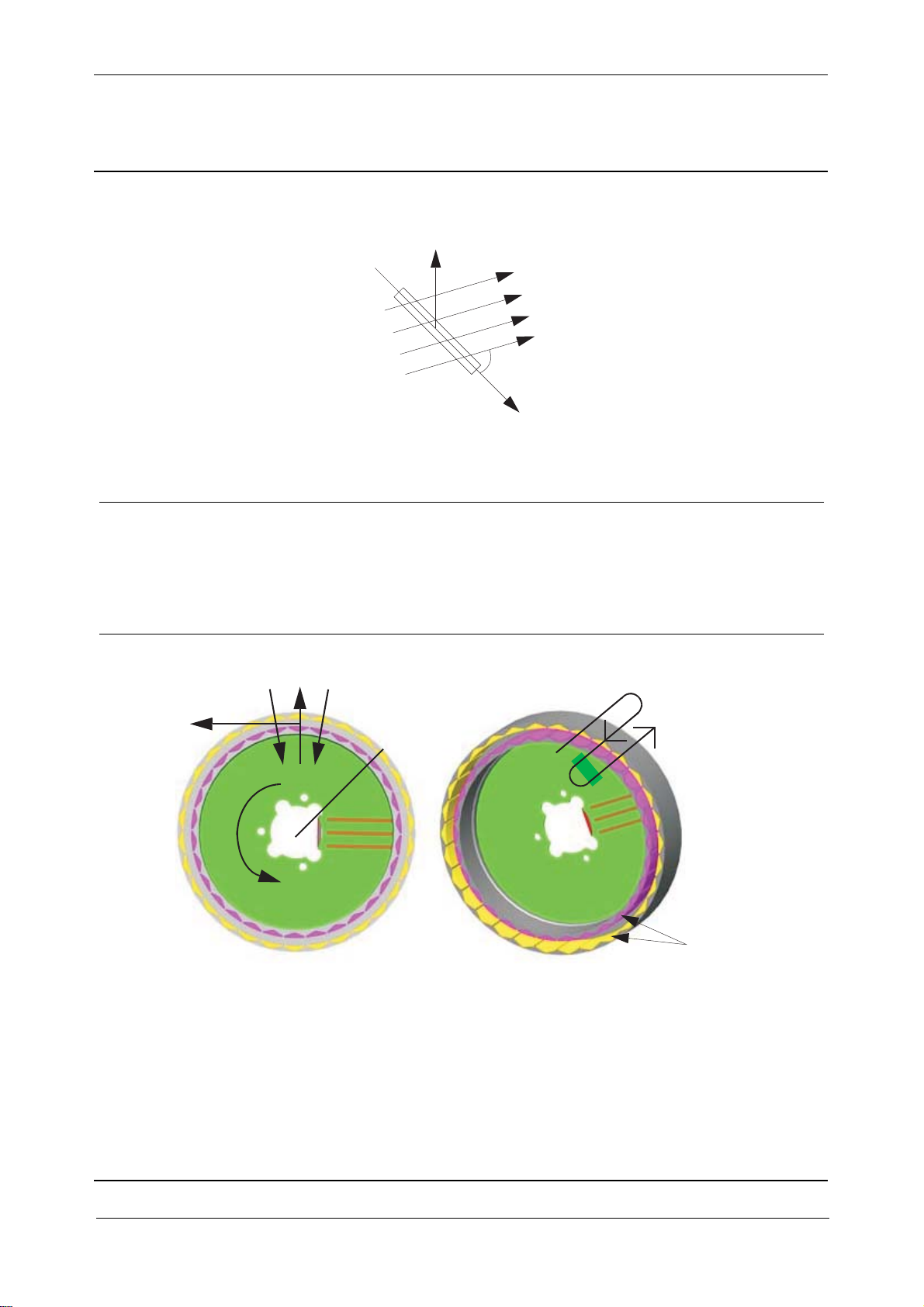

Measuring through glass window

Guidelines when measuring through glass windows

• A modern window glass should be fine. Avoid using tinted glass window.

• The range is reduced by 10-20% when measuring through a window.

• Depending on the window angle to the instrument the window can introduce back reflection

from the EDM to the instrument front lens. See fig below.

• The field of view through the glass window is limited horizontal by +/-60 deg and vertical by

+/-30 deg.

Window reflection from EDM

Use the laser pointer to verify the EDM reflex is outside the optical lens.

Fig. 1-36 Problem with reflection

Fig. 1-37 No problem with reflection

Trimble S, VX, SPS & RTS Service Manual1 - 28 P/N 57150002, Revision 5.0

Page 39

Chapter 2

F

General Product Information

2 General Product Information

Trimble S3 - Product description & Service Information

Trimble S6 - Product description & Service information

Trimble S8 - Product description & Service information

Trimble VX - Product description & Service information

Trimble RTS - Product description & Service information

Trimble SPS - Product description & Service information

Models and serial numbers

Instrument Model Matrix

Product Specifications

Model definition

P/N 57150002, Revision 5.0 2 - 1 Trimble S, VX, SPS & RTS Service Manual

Page 40

Chapter 2

F

General Product Information

Trimble S3 - Product description & Service Information

Product description

Trimble S3 Total Station — A Total Station with MagDrive™ Technology

The Trimble S3 Total Station is available as Servo, Autolock or Robotic. The S3 Total Station Servo

and Autolock has a fixed control panel. The Trimble S3 Total Station Robotic has no panel attachment and is used together with a hand held controller e.g. Trimble TSC2.

The Trimble® S3 Total Station is based on the Trimble® S6 Total Station

Differences to Trimble S6 Total Station

All models:

• DR EDM based on High Precision /DR Standard EDM

• MagDrive™ servo technology, 85 degrees per second (S6 115 degrees per second)

• Not upgradable

• No SurePoint

• No Face 2 display/panel (Face 2 display/panel available for some markets on Servo/Autolock

models)

• No pressure sensor

• Optical plummet in tribrach

• Yellow center unit and side covers

Servo/Autolock models:

• Fixed control panel

Robotic models:

• Radio range of 300m

• 10mW 2.4GHz radio

• No panel attachment

Service information

The Trimble S3 Total Station is adjusted and tested in the same procedure as the Trimble S6 Total

Station except for the differences described herein.

Trimble S, VX, SPS & RTS Service Manual2 - 2 P/N 57150002, Revision 5.0

Page 41

Chapter 2

F

General Product Information

Trimble S6 - Product description & Service information

Product description

Trimble S6 — A Servo, Autolock, or Robotic Total Station with MagDrive™ Technology

The Trimble® S6 DR (direct reflex) Total Station offers advanced MagDrive technology for breathtaking speed. It takes the work out of conventional servo or robotic surveying.

For your unsurpassed efficiency, the Trimble S6 is a 100% cable-free robotic total station and rover.

Numerous new features and the latest technologies will catapult your productivity and profitability

forward. And as an entirely upgradable surveying solution, the Trimble S6 will grow with your business.

Advanced MagDrive Technology

Fast. Silent. Precise. The Trimble S6 Total Station redefines these words with exceptional servo performance. The Trimble S6 is engineered with innovative MagDrive™ servo technology that silently

spins the instrument at just 115 degrees per second. For more detailed information, please download

the MagDrive Technology White Paper.

Trimble MultiTrack Target for Both Active and Passive Tracking

Choose from active or passive tracking with the Trimble MultiTrack™ Target, the only target of its

kind in the surveying industry. Active tracking ensures you always locate and lock on to the correct

target. When you're using the Trimble MultiTrack Target, nearby reflective surfaces, such as road

signs, cars, safety vests, and other prisms, will not disrupt your surveys.

Trimble GPS Search for Even Faster Measurements

If MagDrive and MultiTrack speed still aren't enough, the robotic Trimble S6 instrument goes to the

extreme with Trimble® GPS Search. A new function in Trimble field software, GPS Search employs

GPS to quickly locate a lost prism. In just 3 seconds the Trimble S6 can zip to the correct position

and lock onto the robotic rover. For more details, download the GPS Search white paper.

See Trimble S6 Total Station brochure on www.trimble.com for more information.

See White Paper about Direct reflex EDM technology on www.trimble.com for more technical infor-

mation.

See White Paper about MagDrive servo technology on www.trimble.com for more technical infor-

mation.

P/N 57150002, Revision 5.0 2 - 3 Trimble S, VX, SPS & RTS Service Manual

Page 42

Chapter 2

F

General Product Information

Trimble S8 - Product description & Service information

Product description

The Trimble® S8 Total Station is Trimble's most advanced Autolock and Robotic total station. It's

designed to deliver unsurpassed performance and productivity in land surveying and specialized

engineering applications, such as monitoring and tunnelling.

A Complete System For Engineering Applications

The Trimble S8 Total Station works with Trimble Survey Controller™ field software and Trimble®

4D Control™ processing software to provide a seamless connected, complete solution for engineering jobs.

• Angular accuracy of 0,5” or 1”

• High Precision EDM of 1 mm + 1 ppm or DR Plus EDM of 2 mm + 2 ppm

• Trimble® FineLock™ technology: FineLock technology is a smart tracker sensor with a

narrow field of view that enables the Trimble S8 to detect a target without interference from

surrounding prisms. This is especially useful in engineering applications such as monitoring

and tunnelling where multiple targets with very tight spacing are used.

• Trimble VISION™ on board the Trimble S8 enables users to control the instrument and to see

everything the instrument sees with live video on the controller.

• 10 Hz high-speed synchronized data output makes data collection faster and more accurate,

e.g., during railway monitoring a trolley or ATV, the prism can move more quickly without

compromising accuracy.

• Trimble eProtect™ security uses a 4-digit password to prevent access by unauthorized users.

Optional Features for Specialized Engineering Applications

1. The Long-Range FineLock™ configuration extends 1 cm precision to 2500 meters.

2. For tunnelling, a long-range laser pointer cuts through dusty conditions to provide precision

stakeout for bolts and other assets.

3. Trimble 4D Control™ is a comprehensive software solution designed for engineering

applications. Enabling both real-time and post processor applications, it allows users to

accurately characterize and interrogate data to determine movement over time.

4. The Engineering Option for Trimble Survey Controller expedites data collection for

monitoring applications and leads you through tasks such as marking areas of under and

overcut with the laser pointer.

Difference to Trimble S6

• Trimble FineLock and optional Long-Range FineLock™, see above.

• Optional High Power Laser Pointer (3R laser pointer).

• Tracklight module is replaced by Tracker Long Range or High Power Laser Pointer module.

• 10 Hz high-speed synchronized data output.

• PIN/PUK code security, see “Trimble eProtectTM - PIN/PUK code security” on page 3-59.

• Instrument Remote control, connecting a special cable (53094001) to the instrument makes it

possible to switch the instrument between ON and STANDBY modes via cable/radio

connection.

Trimble S, VX, SPS & RTS Service Manual2 - 4 P/N 57150002, Revision 5.0

Page 43

Chapter 2

F

Service information

The tracker is adjusted and tested in the same procedure as the Trimble S6.

Check Monitoring option is available in face2 display at start up.

General Product Information

P/N 57150002, Revision 5.0 2 - 5 Trimble S, VX, SPS & RTS Service Manual

Page 44

Chapter 2

F

General Product Information

Trimble VX - Product description & Service information

Product description

Trimble VX Spatial Station can be ordered with or without the scanning option (model code 936).

This option can later be installed in the instrument.

Designed to capture shapes, details, and coordinates, the Trimble VX offers an easy entry into Spatial

Imaging. The instrument is optimized for the acquisition of information using integrated video, scanning and positioning technologies. The Trimble VX Spatial Station is the ideal solution for combining

standard resolution 3D scans and digital imaging with survey-precise coordinate measurements and

2D deliverables:

• Intuitive video overlay provides visual cues on screen to speed data collection

• Spinning 115 degrees per second, MagDrive™ servo movement ensures fast, efficient

measuring.

• Trimble VISION technology, enhances data deliverables with images captured at the jobsite.

• Trimble VX measurements can be complemented with GNSS positioning for more flexibility

in the field.

The Trimble® VX™ Spatial Station for Spatial Imaging integrates state-of-the-art optical, 3D scanning, and digital imaging technology to capture the shape, detail and precise coordinates of any job.

The resulting 2D and 3D enhanced deliverables will satisfy colleagues and clients alike.

Difference to Trimble S6

• Tracklight module replaced by video camera module

• PIN/PUK code security, see “Trimble eProtectTM - PIN/PUK code security” on page 3-59.

Service information

Video camera is focused and calibrated in the instrument.

Trimble S, VX, SPS & RTS Service Manual2 - 6 P/N 57150002, Revision 5.0

Page 45

Chapter 2

F

General Product Information

Trimble RTS - Product description & Service information

Trimble RTS is a product line for the Layout segment within Construction division.

Product description

Trimble RTS555 DR Standard Total Station - WLAN

The Trimble RTS555 DR Standard utilizes 802.11 Wireless Local Area Network (WLAN) technology to create a wireless link between the controller and robotic total station to increase layout convenience and productivity in the field. The wireless solution reduces the number of components

needed, such as the external radio, battery and cable when used with the wireless Trimble LM80 Layout Manager, minimizing the weight and complexity of the system while providing a more ergonomic

and convenient layout solution.

The RTS555 DR Standard includes a WLAN radio in the instrument instead of a 2.4 Radio in the

instrument. This instrument can communicate to a Nomad controller also including a WLAN radio

running application software LM80.

Trimble RTS633 DR 300+ Total Station

Replaces Trimble SPS710 DR300+ Total Station.

Trimble RTS655 DR Standard Total Station

Replaces Trimble SPS610 DR Standard Total Station.

Difference to Trimble S6

• Different style with rugged side covers (same as SPS).

• RTS555 includes a WLAN radio

Service information

WLAN radio is configured in the face 2 panel and not in PASS.

P/N 57150002, Revision 5.0 2 - 7 Trimble S, VX, SPS & RTS Service Manual

Page 46

Chapter 2

F

General Product Information

Trimble SPS - Product description & Service information

Trimble SPS is a product line for the Heavy & Highway segment within Construction division.

Product description

Trimble SPSx20 Robotic Total Station

The SPS620 and SPS720 Robotic Total Stations offer a cost-effective solution for construction site

measurement and stakeout operations in Servo, Autolock, or Robotic mode. Both models provide a

robotic operating range of 500 meters, making them ideal for smaller site operations and work on

structures such as bridges or culverts.

The SPS620 and SPS720 use the Trimble DR short-range reflectorless EDM technology for singleshot measurements and operate with TSC2® or Trimble Tablet running the SCS900 Site Controller

Software. The SPS620 provides 5 arc second accuracy in the vertical and horizontal angles. The

SPS720 provides 3 arc second accuracy in the horizontal angle and 2 arc second accuracy in the vertical, and is well suited to more accurate site positioning work.

Trimble SPSx30 Universal Total Stations

Trimble SPS630, SPS730, and SPS930 Universal Total Stations can be ordered with or without the

machine control option (model codes 721/722/723) and OEM option. These options can later be

installed in the instrument.

Trimble SPS630 Universal Total Stations

Trimble SPS630 5” instrument satisfies all site measurement, stakeout, reflectorless measurement,

and grade control needs from a single instrument. Target customers are contractors performing their

own stakeout and site measurement tasks, who may also be somewhat price sensitive.

Applications

• Smaller operations where most of the work is performed close to the instrument

• In partnership with the GCS900-UTS-based system for excavators this system is typically used

on small sites where the machine operates close to the instrument

• Mining and quarry operations, where an instrument is needed for scanning quarry walls or

stockpiles of material

Trimble SPS730 and SPS930 Universal Total Stations

The SPS730 and SPS930 have been designed to operate as a universal total station. The instruments

have a machine control mode that optimizes the angle and distance measurement system through a

synchronization process that also reduces latency (age) of the data. In addition the instruments when

in machine control mode will output data at a higher rate than conventional total stations (20Hz). The

instrument radio system is designed to reduce jitter significantly, the instrument tracking and search

functions are optimized for dynamic tracking applications, and the instrument also features trajectory

prediction helping reacquire lock after the prism is obscured.

When operated in Site Positioning modes (SCS900 Standing, Walking and Vehicle modes) the instrument will also utilize the high update rates and synchronized data, however the radio master is at the

Trimble S, VX, SPS & RTS Service Manual2 - 8 P/N 57150002, Revision 5.0

Page 47

Chapter 2

F

instrument allowing for a one to one operation with the robotic rod controller. When operated in

Machine Control mode, the radio master shifts to the machine control box, so that it can control up

to five instruments on the same radio channel and network. In this mode the radio system is also optimized to eliminate jitter, which provides enhanced positioning control for the machine system

hydraulics.

When used for any machine control application, the instrument should be setup first with the SCS900

software, a station establishment carried out and then perform the shut down process and place the

instrument in Machine Control mode. This process involves placing the station establishment information in the instrument memory, so that it can be transferred to the calling machine control application.

The instrument capability to track moving vehicles and machines is referred to as Advanced Tracking

Sensor (ATS).

ATS capability delivers the following performance benefits for dynamic positioning applications

• Low, fixed and well defined latency of data output from the instrument and over the radio

• Synchronized angle and distance measurements

• 20Hz data update rates

General Product Information

• 16 Channel Target ID - 1-8 for Site Positioning mode and 9-16 for Machine Control mode.

• Optimized search routines designed for tracking a machine with trajectory prediction.

• Radio scanning capability, instrument can be programmed to sequentially scan a series of radio

channel and network ID combinations, allowing it to serve a number of machines, all on

different channels at a single location on demand.

• Radio network capability allowing up to 5 instruments to be operated from a single machine on

the same channel and network ID

Difference to Trimble S6

• Different style with rugged side covers, (same as RTS).

• Second configuration number to activate Site Positioning / Advanced Tracking Sensor (ATS)

function.

Service information

Check Machine Control option / OEM option are available in face2 display at start up.

Trimble SPS620 and SPS720 uses M firmware

Trimble SPS630, SPS730 and SPS930 uses C firmware

P/N 57150002, Revision 5.0 2 - 9 Trimble S, VX, SPS & RTS Service Manual

Page 48

Chapter 2

F

General Product Information

Models and serial numbers

Trimble S3 DR

Trimble model Model code Serial number

Trimble S3 2” DR / 2mm+2ppm (Servo) 910 91010001

Trimble S3 5” DR / 2mm+2ppm (Servo) 911 91110001

Trimble S3 2” DR / 2mm+2ppm (Autolock) 912 91210001

Trimble S3 5” DR / 2mm+2ppm (Autolock) 913 91310001

Trimble S3 2” DR / 2mm+2ppm (Robotic) 914 91410001

Trimble S3 5” DR / 2mm+2ppm (Robotic) 915 91510001

Trimble S3 2” DR / 2mm+2ppm (Servo) with Face2 display* 916 91610001

Trimble S3 2” DR / 2mm+2ppm (Autolock) with Face2 display* 917 91710001

* Models only available on some markets

Trimble S6 DR300+

Trimble model Model code Serial number

Trimble S6 2” DR300+ / 3mm+2ppm 926 92610001

Trimble S6 3” DR300+ / 3mm+2ppm 927 92710001

Trimble S6 5” DR300+ / 3mm+2ppm 928 92810001

Trimble S6 DR PLUS

Trimble model Model code Serial number

Trimble S6 2” DR PLUS/ 2mm+2ppm 930 93010001

Trimble S6 3” DR PLUS/ 2mm+2ppm 931 93110001

Trimble S6 5” DR PLUS/ 2mm+2ppm 932 93210001

Trimble S6 High Precision EDM with DR

Trimble model Model code Serial number

Trimble S6 1” High Precision / 1mm+1ppm 921 92110001

Trimble S8 High Precision

Trimble model Model code Serial number

Trimble S8 DR STD/1mm+1ppm/0,5" 988 98810001

Trimble S8 High Precision

- With FineLock option as standard

Trimble model Model code Serial number

Trimble S8 1" High Precision / 1mm+1ppm 980 98010001

Trimble S, VX, SPS & RTS Service Manual2 - 10 P/N 57150002, Revision 5.0

Page 49

Chapter 2

F

Trimble S8 High Precision

- Without FineLock option as standard

- Optional Long Range FineLock

- Optional High Power Laser Pointer

Trimble model Model code Serial number

Trimble S8 1” High Precision / 1mm+1ppm 981 98110001

Trimble S8 High Precision Railway

Trimble model Model code Serial number

Trimble S8 1” High Precision / 1mm+1ppm 982 98210001

Trimble S8 0.5” High Precision / 1mm+1ppm 983 98310001

Trimble S8 DR PLUS

Trimble model Model code Serial number

Trimble S8 2” DR PLUS/ 2mm+2ppm 990 99010001

Trimble S8 High Precision with camera

General Product Information

Trimble model Model code Serial number

Trimble S8 1” High Precision / 1mm+1ppm 989 98910001

Trimble S8 0.5” High Precision / 1mm+1ppm 991 99110001

Trimble S8 DR PLUS

- With FineLock option as standard

Trimble model Model code Serial number

Trimble S8 1" DR PLUS/ 2mm+2ppm 992 99210001

Trimble VX - With Scanning as standard option

Trimble model Model code Serial number

Trimble VX 1” DR 300+ / 3mm+2ppm 935 93510001

Trimble VX - Without Scanning as standard option

Trimble model Model code Serial number

Trimble VX 1” DR 300+ / 3mm+2ppm 936 93610001

Trimble VX

Trimble model Model code Serial number

Trimble VX 1” DR PLUS/ 2mm+2ppm 937 93710001

Trimble RTS Total Station - Building Construction

Model Model code Serial number

Trimble RTS555 5"/5" DR Standard / 2mm+2ppm 730 73010001

P/N 57150002, Revision 5.0 2 - 11 Trimble S, VX, SPS & RTS Service Manual

Page 50

Chapter 2

F

Model Model code Serial number

Trimble RTS633 3"/2" DR 300+ / 3mm+2ppm 731 73110001

Trimble RTS655 5"/5" DR Standard / 2mm+2ppm 732 73210001

Trimble RTS633 3"/2" DR PLUS / 2mm+2ppm 733 73310001

Trimble RTS555 5"/5" DR / 2mm+2ppm 734 73410001

Trimble RTS655 5"/5" DR / 2mm+2ppm 735 73510001

Trimble SPS Total Station - Building Construction / Heavy & Highway

Model Model code Serial number

Trimble SPS700 5"/2" DR 300+ / 3mm+2ppm 712 71210001

Trimble SPS610 5"/5" DR Standard / 2mm+2ppm 713 / 717 71320001

Trimble SPS710 3"/2" DR 300+ / 3mm+2ppm 718 71810001

Trimble SPS620 5"/5" DR / 2mm+2ppm 727 72710001

Trimble SPS720 3"/2" DR / 2mm+2ppm 728 72810001

Trimble SPS Total Station - Heavy & Highway

- With Machine Control option as standard

General Product Information

Model Model code Serial number

Trimble SPS730 3"/2" DR 300+ / 3mm+2ppm 714 71420001

Trimble SPS930 1"/1" DR 300+ / 3mm+2ppm 715 71520001

Trimble SPS Total Station - Heavy & Highway

- Without Machine Control option as standard

Model Model code Serial number

Trimble SPS630 5"/5" DR 300+ / 3mm+2ppm 721 72110001

Trimble SPS730 3"/2" DR 300+ / 3mm+2ppm 722 72210001

Trimble SPS930 1"/1" DR 300+ / 3mm+2ppm 723 72310001

Trimble SPS630 5"/5" DR PLUS / 2mm+2ppm 724 72410001

Trimble SPS730 3"/2" DR PLUS / 2mm+2ppm 725 72510001

Trimble SPS930 1"/1" DR PLUS / 2mm+2ppm 726 72610001

Trimble S3 model information

Trimble S3 is available as Servo, Autolock or Robotic. the instruments are not upgradable.

Trimble S6 model information

Trimble S6 is available in Servo, Autolock or Robotic configurations.

Trimble S, VX, SPS & RTS Service Manual2 - 12 P/N 57150002, Revision 5.0

Page 51

Chapter 2

F

General Product Information

Trimble S8 model information

Trimble S8 is available in Servo, Autolock or Robotic configurations.

Trimble VX model information

Trimble VX is only available in Robotic configuration.

Trimble RTS model information

Trimble RTS555 DR / DR Standard - WLAN available in Robotic configuration.

Trimble RTS655 DR / DR Standard - 2.4 Radio available in Robotic configuration.

Trimble RTS633 DR 300+ / DR PLUS available in Robotic configuration.

Trimble SPS model information

Trimble SPS610 DR Standard available in Autolock or Robotic configurations

Trimble SPS620 DR available in Robotic configuration.

Trimble SPS720 DR available in Robotic configuration.

Trimble SPS710 DR 300+ available in Robotic configuration.

Trimble SPS730 DR 300+ available in Autolock or Robotic configurations.

Trimble SPS930 DR 300+ available in Autolock or Robotic configurations.

Trimble SPS630 DR PLUS available in Autolock or Robotic configurations.

Trimble SPS730 DR PLUS available in Autolock or Robotic configurations.

Trimble SPS930 DR PLUS available in Autolock or Robotic configurations.

P/N 57150002, Revision 5.0 2 - 13 Trimble S, VX, SPS & RTS Service Manual

Page 52

Chapter 2

F

General Product Information

Instrument Model Matrix

The table below is a summary of existing Trimble S3/S6/S8/ VX / SPS and RTS released instruments.

Model matrix

Model Model

code

S3 DR 910 2” No 2010 Active -

S3 DR 911 5” No 2010 Active -

S3 DR 912 2” No 2010 Active -

S3 DR 913 5” No 2010 Active -

S3 DR 914 2” No 2009 Active -

S3 DR 915 5” No 2009 Active -

S3 DR 916 2” No 2010 Active -

S3 DR 917 2” No 2010 Active -

S6 DR300+ 926 2” No 2005 Obsolete since 2010 S6 DR

Angle

Accuracy

HTU

unit

Introduced Status Replaced by

model

PLUS

S6 DR300+ 927 3” No 2005 Obsolete since 2010 S6 DR

PLUS

S6 DR300+ 928 5” No 2005 Obsolete since 2010 S6 DR

PLUS

S6 HP 921 1” Yes 2006 Obsolete since 2008 S8

S6 DR PLUS 930 2” No 2010 Active -

S6 DR PLUS 931 3” No 2010 Active -

S6 DR PLUS 932 5” No 2010 Active -

S8 HP 988 0,5” Yes 2010 Active -

S8 HP 980 1” Yes 2007 Obsolete since 2008 S8 (981)

S8 HP 981 1” Yes 2008 Active -

S8 HP 982 1” Yes 2010 Active -

S8 HP 983 0,5” Yes 2010 Active -

S8 HP 989 1” Yes 2010 Active -

S8 DR PLUS 990 2” No 2010 Active -

S8 HP 991 0.5” Yes 2010 Active -

S8 DR PLUS 992 1” Yes 2011 Active -

VX 935 1” Yes 2007 Obsolete since 2008 VX (936)

VX 936 1” Yes 2008 Obsolete since 2010 VX DR

PLUS

Trimble S, VX, SPS & RTS Service Manual2 - 14 P/N 57150002, Revision 5.0

Page 53

Chapter 2

F

Model Model

code

VX DR

PLUS

SPS700 712 5"/2" No 2006 Obsolete since 2007 -

SPS610 713/

SPS710 718 3"/2" No 2007 Obsolete since 2009 SPS730 /

RTS555 730 5"/5" No 2009 Obsolete since 2010 RTS555 DR

RTS633 731 3"/2" No 2009 Obsolete since 2010 RTS633 DR

RTS633 733 3"/2" No 2010 Active -

RTS655 732 5"/5" No 2009 Obsolete since 2010 RTS655 DR

RTS555 DR 734 5"/5" No 2010 Active -

RTS655 DR 735 5"/5" No 2010 Active -

937 1” Yes 2010 Active -

717

Angle

Accuracy

5"/5" No 2007 Obsolete since 2009 SPS630 /

HTU

unit

General Product Information

Introduced Status Replaced by

model

RTS655

RTS633

PLUS

SPS730 714 3"/2" No 2007 Obsolete since 2009 SPS730

(722)

SPS930 715 1"/1" Yes 2007 Obsolete since 2009 SPS930

(723)

SPS630 721 5"/5" No 2009 Obsolete since 2010 SPS630

(724)

SPS730 722 3"/2" No 2009 Obsolete since 2010 SPS730

(725)

SPS930 723 1"/1" Yes 2009 Obsolete since 2010 SPS930

(726)

SPS630 724 5"/5" No 2010 Active -

SPS730 725 3"/2" No 2010 Active -

SPS930 726 1"/1" Yes 2010 Active -

SPS620 727 5"/5" No 2010 Active -

SPS720 728 3"/2" No 2010 Active -

P/N 57150002, Revision 5.0 2 - 15 Trimble S, VX, SPS & RTS Service Manual

Page 54

Chapter 2

F

Product Specifications

See Datasheet for each model on www.trimble.com for information.

General Product Information

Trimble S, VX, SPS & RTS Service Manual2 - 16 P/N 57150002, Revision 5.0

Page 55

Chapter 2

F

General Product Information

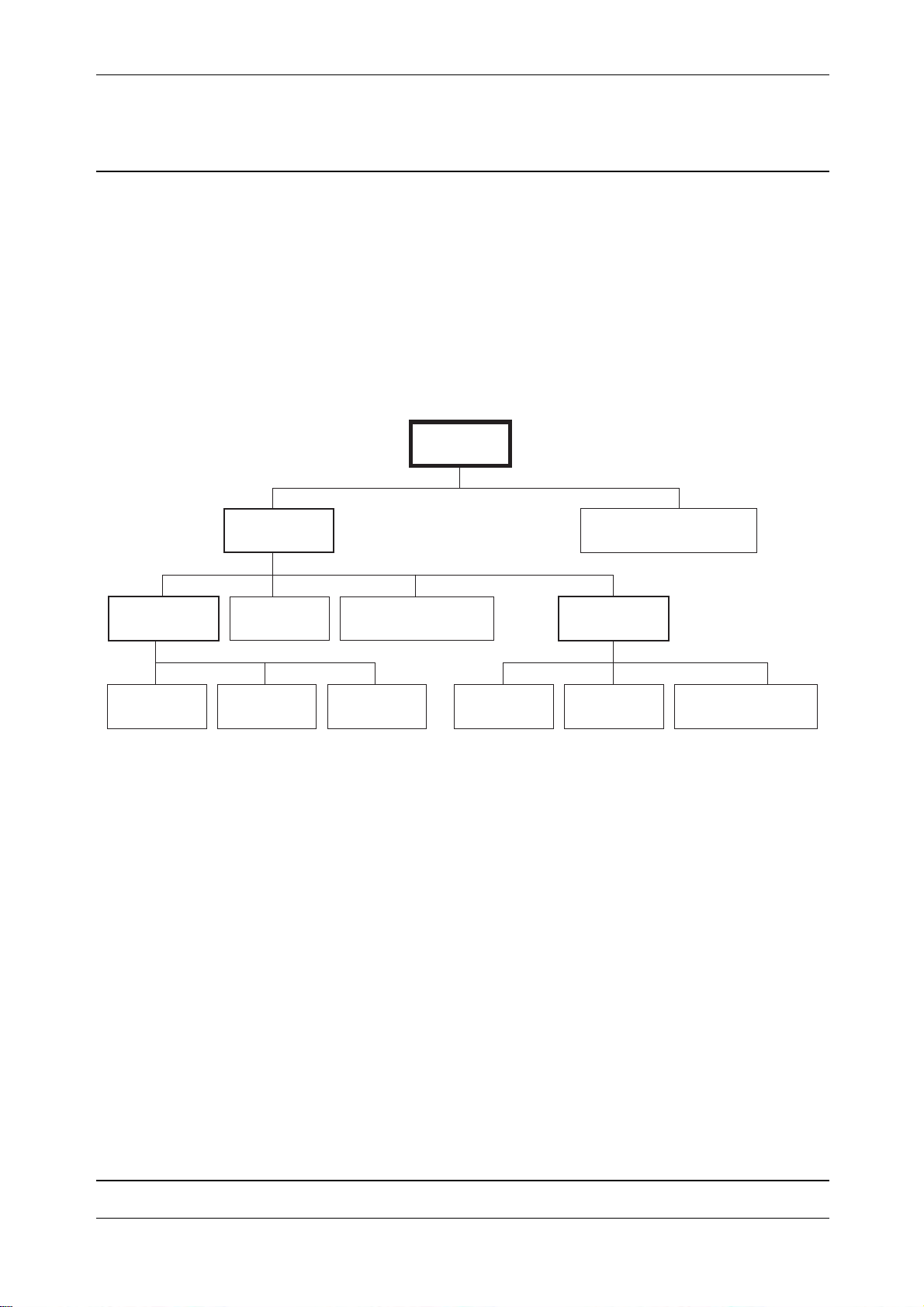

Model definition

The Trimble S3/ S6/S8/VX/SPS/RTS instruments has different functions and specifications but from

a service point the instrument has many common service operations.

The alidade is the base for all instruments, same as for Trimble S3/S6/S8/VX/SPS and RTS.

The centre unit can differs between models.

Centre unit- Distance unit

The Trimble S6 High Precision / Trimble S8 / Trimble RTS 555 DR Standard / Trimble RTS 655 DR

Standard and Trimble SPS610 DR Standard distance units has different specifications but uses the

same hardware and same service operations.

P/N 57150002, Revision 5.0 2 - 17 Trimble S, VX, SPS & RTS Service Manual

Page 56

Chapter 2

F

General Product Information

Trimble S, VX, SPS & RTS Service Manual2 - 18 P/N 57150002, Revision 5.0

Page 57

Chapter 3

F

3 Theory of Operation

Instrument

Removable handle

Battery / radio side cover

Radio unit

Servo side cover

IPC board

TCU attachment

TCU attachment with USB

Control Panel

Face2 panel & optical plummet

Pressure sensor

Servo drive system

Theory of Operation

Angle Measuring System

Base unit

PSM board

Tilt sensor

Software / Instrument application firmware

Telescope

Distance unit - DR300+ / DR PLUS

Distance unit - High Precision / DR Standard / DR

Tracker system

Tracklight

Servo focus

Video camera (Trimble S8 / VX)

Auto focus

Tracker Long Range - TLR

High Power Laser Pointer - HPL

Service interval

Board definitions

P/N 57150002, Revision 5.0 3 - 1 Trimble S, VX, SPS & RTS Service Manual

Page 58

Chapter 3

F

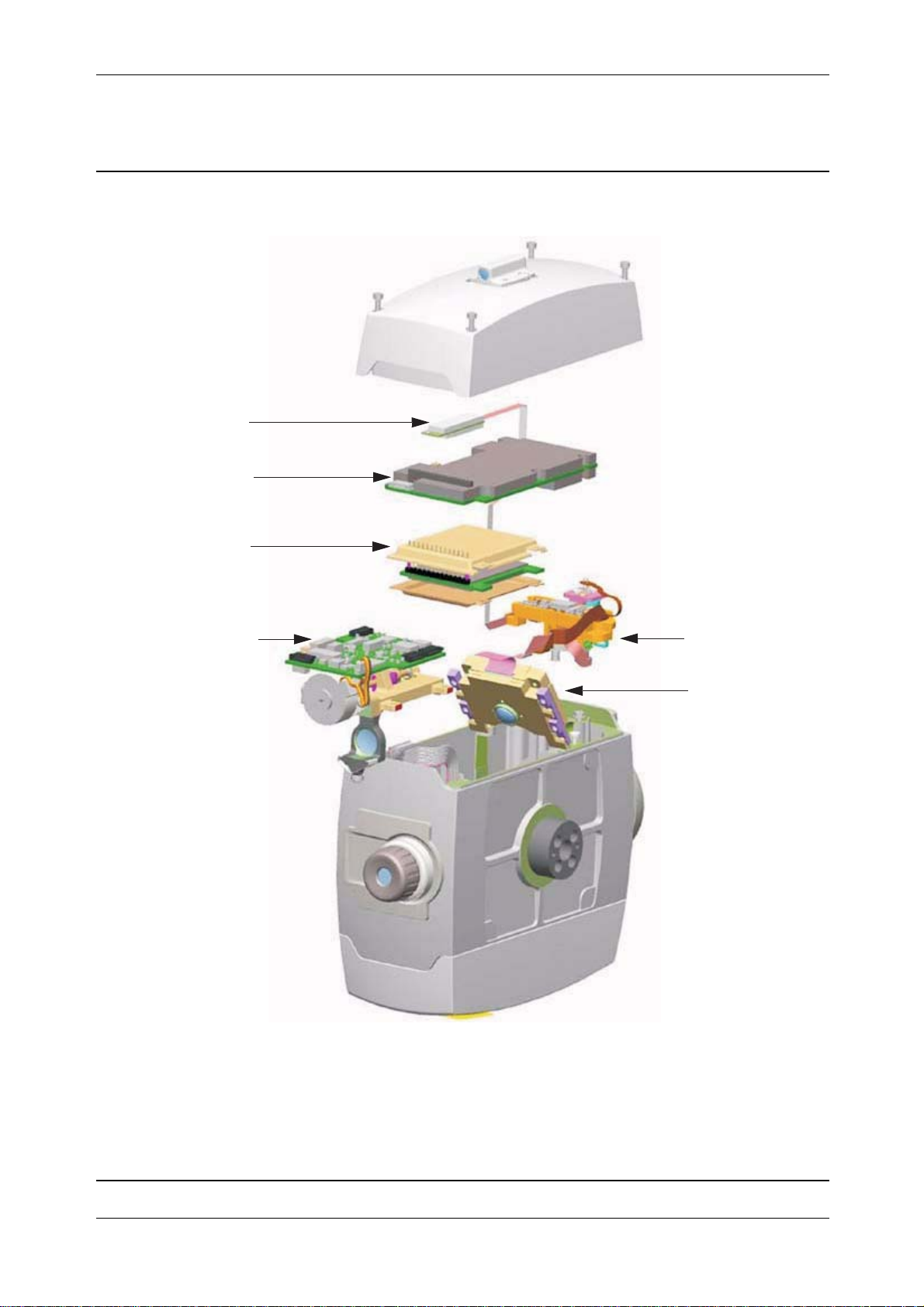

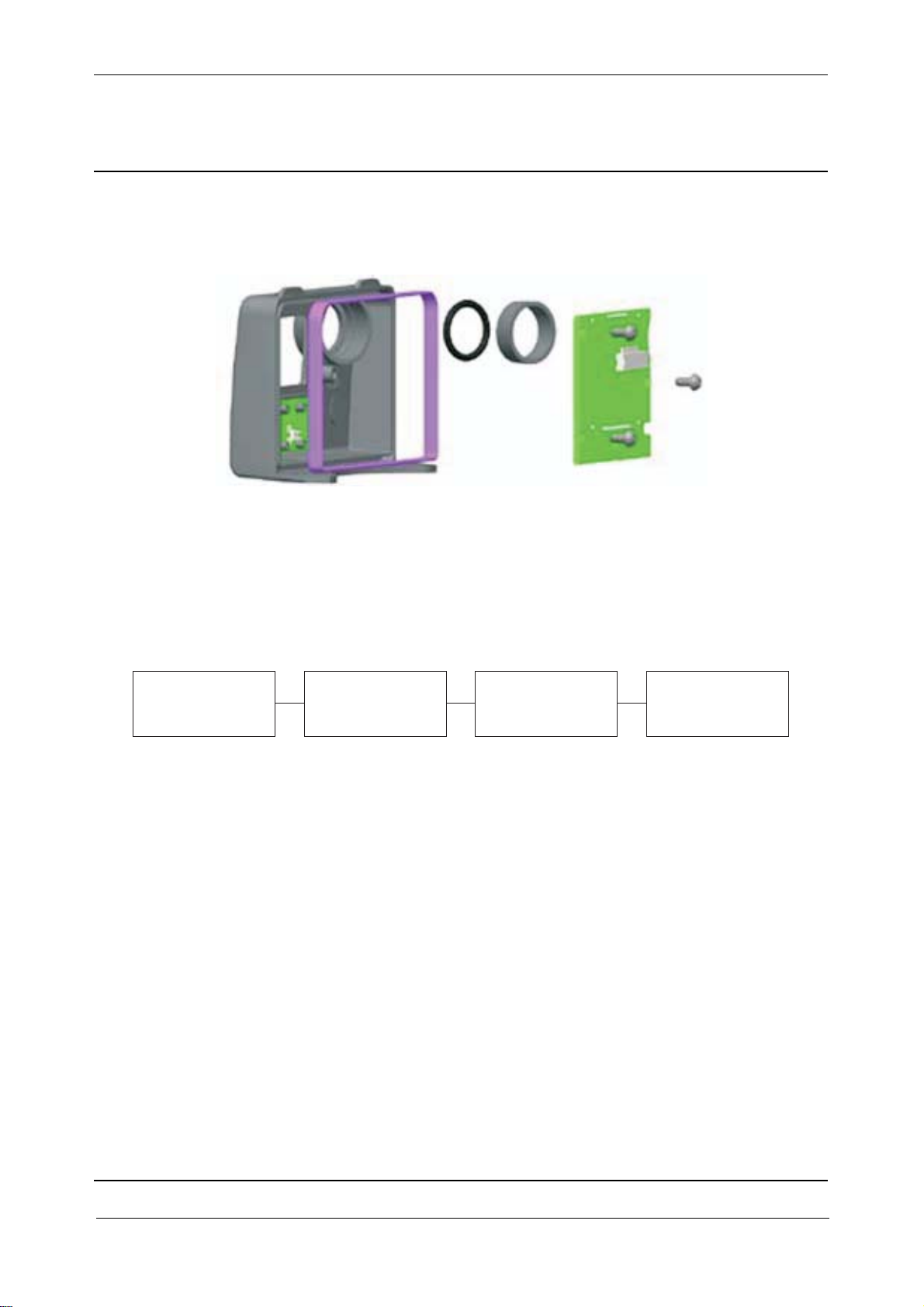

Instrument

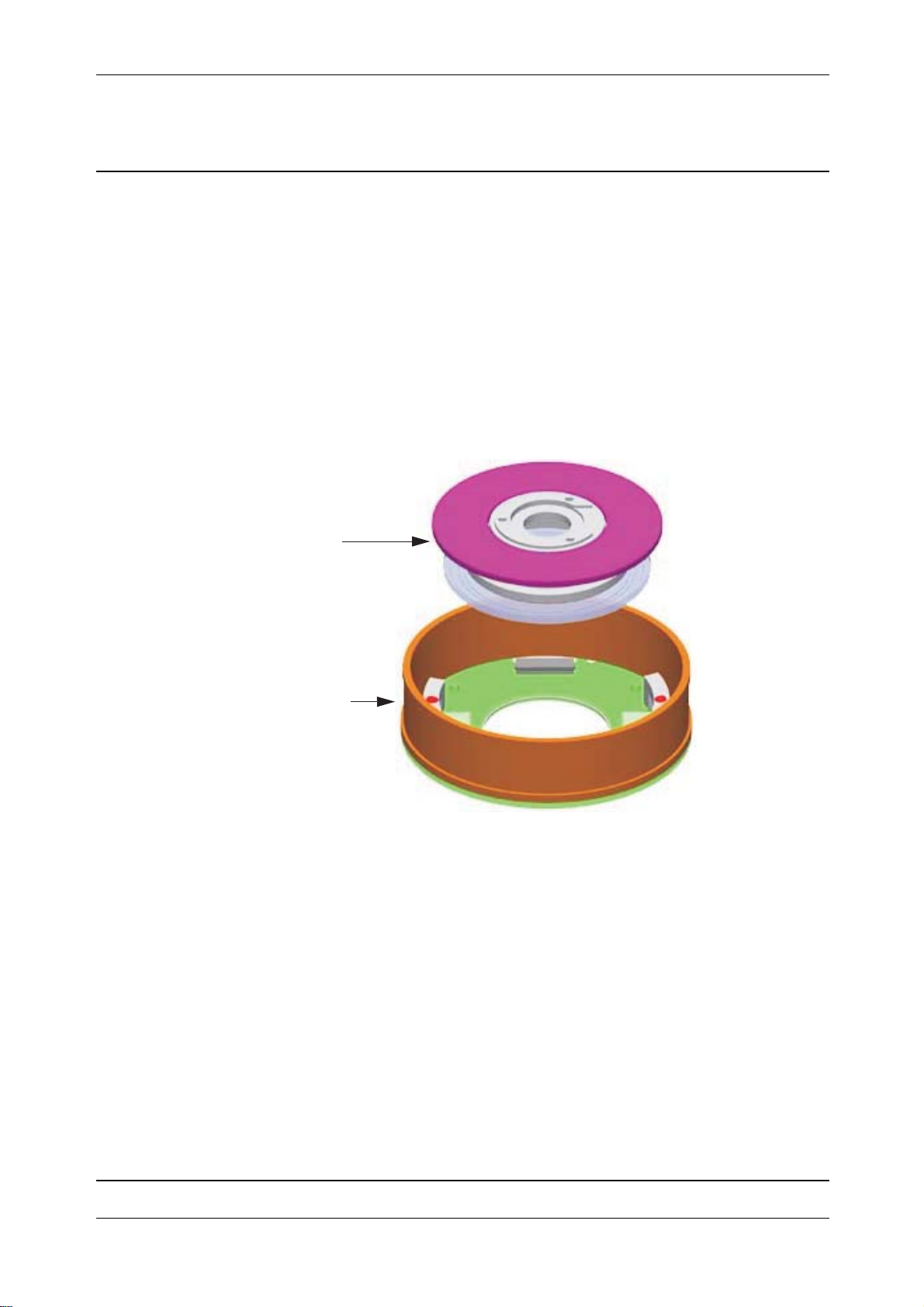

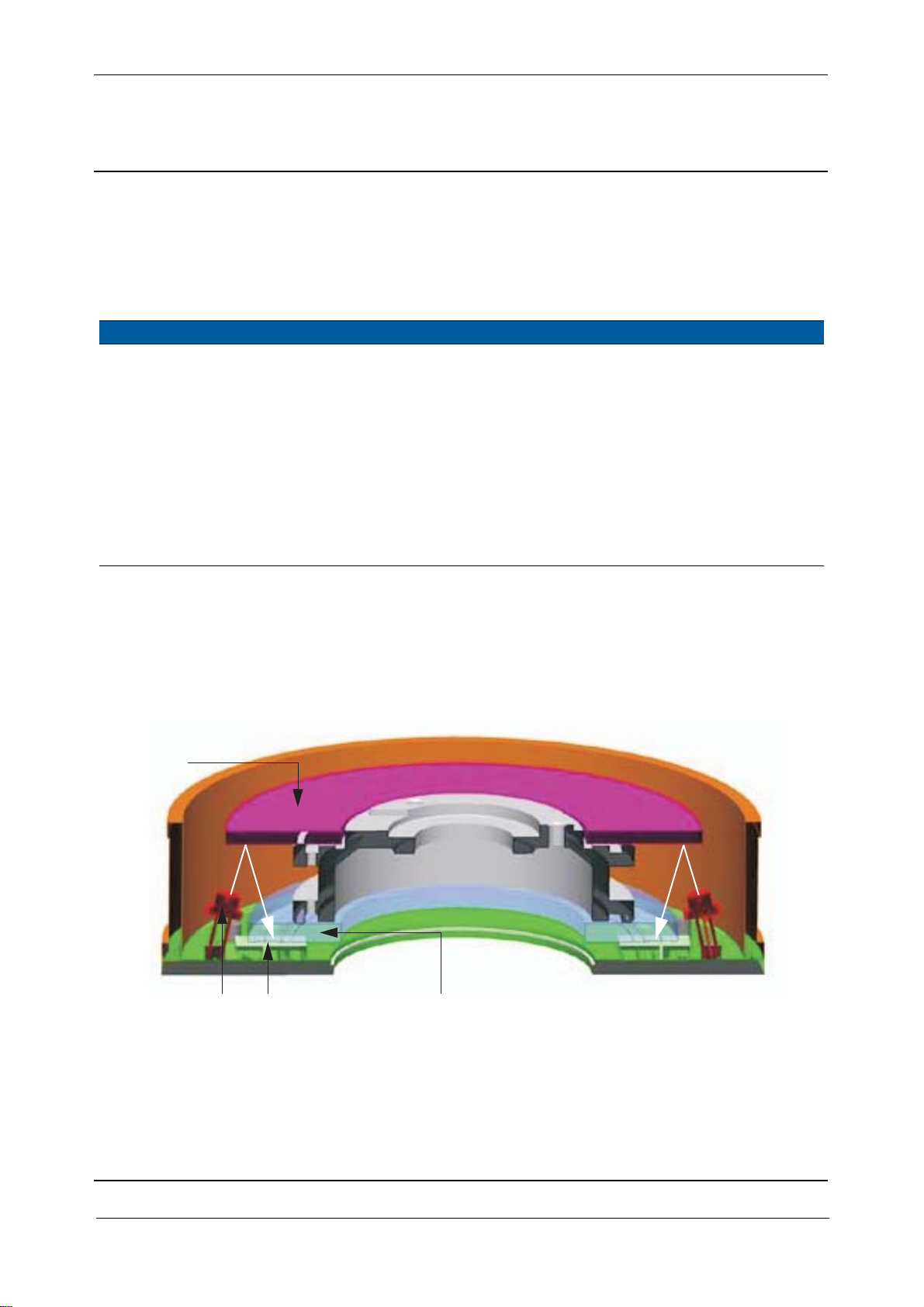

Fig. 3-1 Base instrument parts

Battery &

Radio side