Page 1

LL200 Laser Level

User Guide

www.trimble.com

•

– 2 –

– 5 –

– 9 –

– 3 – – 4 –

– 6 –

– 10 –

– 7 –

– 11 –

– 8 –

– 12 –

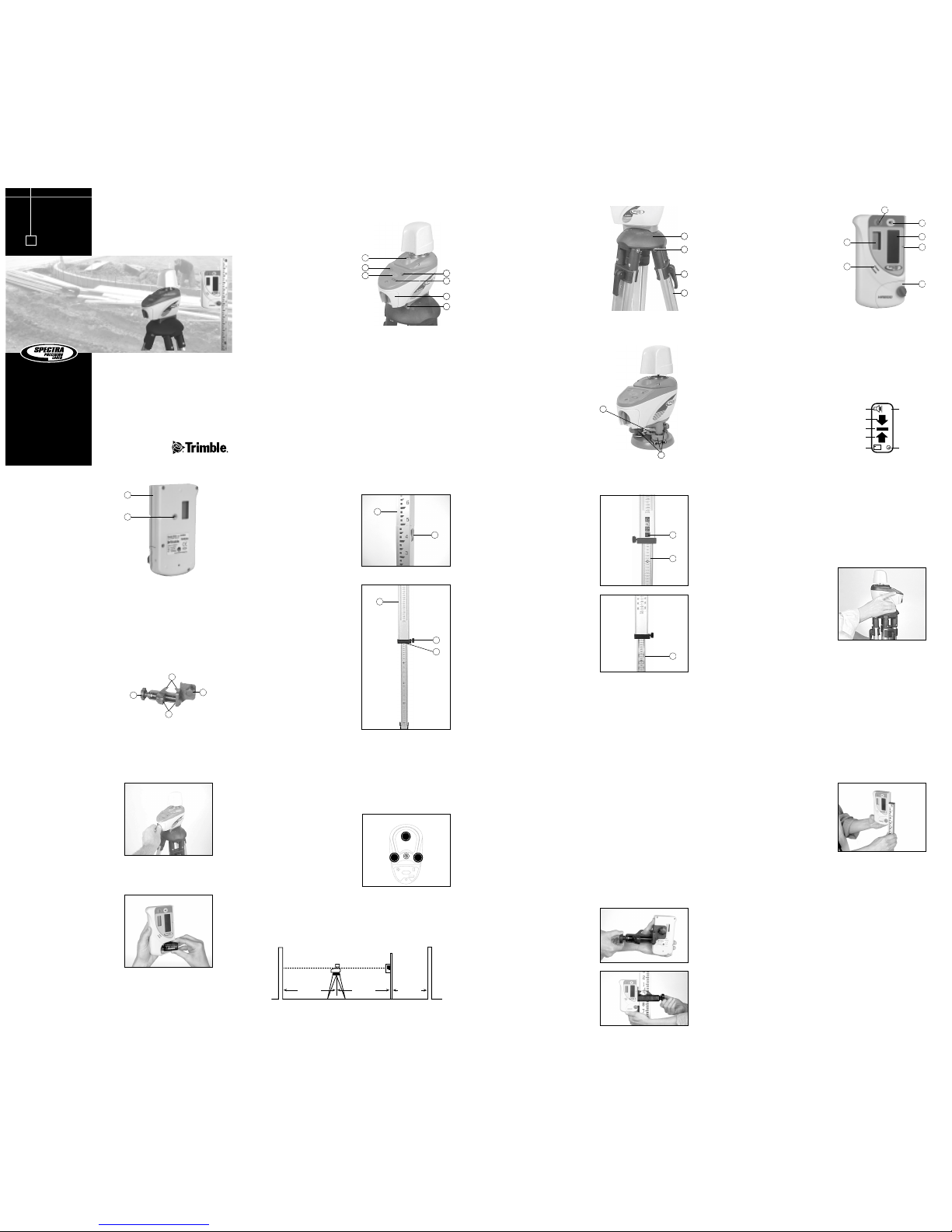

Features and Functions

Model LL200

08. Leveling Dome –

provides a surface for the

laser’s leveling base to

move around on so the

laser can be leveled.

09. 8-mm Cap Screws –

attach the tripod’s

leveling dome to the

tripod’s legs.

10. Leg Clamps – lock/

unlock so the height of

the laser can be adjusted.

HR200 Receiver

1. Power Button – turns the

receiver on/off.

2. Audio Button – turns the

audio on/off.

3. Photocell– detects the

laser beam when it strikes

the receiver. If the photocell

does not detect the laser

beam for eight minutes,

the receiver shuts off

automatically.

4. Marking Notches (front and back) – align with the

on-grade portion of the photocell and are used to mark

elevation readings. The marking notches are 2 inches

(50 mm) from the top of the receiver.

5. Battery Housing – holds one 9-V alkaline batter y. The

battery-housing door is used to attach the receiver to the

grade rod.

6. Audio Port – is the opening the sound comes out of.

7. Front and Back Liquid

Crystal Displays (LCDs) –

show the power, audio,

grade, and battery status.

The LCDs also show when

the laser has been bumped

out of level.

HR200 Receiver (cont.)

8. Groove – is the channel that

the grade-rod tongue fits

into so the receiver can be

attached to the grade rod.

9. Clamp-Screw Opening –

is the threaded brass insert

that allows an optional

1271-1 general-purpose

clamp to be attached to

the receiver.

1271-1 General-Purpose Clamp

The 1271-1 general-purpose clamp allows the receiver to be

attached to a survey rod or wooden 2 x 2 when the 8-ft grade

rod isn’t long enough for applications such as excavating

basements.

1. Receiver Screw – fits into the clamp-screw opening on

the back of the receiver so the receiver can be attached to

a general-purpose clamp.

Grade Rods 0205-2510, 0205-2520, and 0205-2540

1. Tongue – fits into the

receiver groove so the

receiver can be slid

up/down the grade rod.

2. Release Buttons (3) –

snap/unsnap so the grade

rod can be assembled/

disassembled.

Grade Rod 0205-2530

1. Tongue – fits into the

receiver groove so the

receiver can be slid

up/down the grade rod.

2. Extension-Clamp Knob –

turns clockwise/

counterclockwise to

hold/release the upper

rod section.

3. Reading Edge – marks the

elevation where all grade

rod readings are taken.

4. Release Buttons (2) –

snap/unsnap so the grade

rod can be extended/

retracted.

5. Back-Side Scale –

measures between 0.55 and

1.36 meters (1 foot

10 inches and 4 feet

5 inches).

Laser

1. Turn the battery-housing

knob counterclockwise to

release the battery-housing

door.

2. Insert the battery as shown

noting the plus (+) and

minus (–) diagram inside

the housing.

3. Put the battery-housing door in place and turn the batteryhousing knob clockwise.

Receiver

1. Turn the battery-housing

knob counterclockwise to

release the battery-housing

door.

2. Insert the battery as shown

noting the plus (+) and

minus (–) diagram inside

the housing.

3. Put the battery-housing

door in place and turn the

battery-housing knob

clockwise.

Setting Up and Leveling the Laser

1. Set up the laser in the middle of your work area (or

wherever is best for your application needs). Make sure

the setup is stable.

3. Level the laser using the bull’s eye as a reference.

CAUTION: When leveling the LL200, be sure not to rotate

the laser more than 360°. Doing so can cause the extension

spring that holds the laser to the leveling base to break. If

rotating the laser becomes difficult, turn the laser 180° in

the opposite direction.

Note: When the laser is level, the bubble is centered in the

bull’s-eye and the green level LED lights. The LED stays lit

for the first five minutes the laser is level then flashes once

every five seconds.

Attaching the Receiver to the Grade Rod

With the 1271-1 General-Purpose Clamp

Without the 1271-1 General-Purpose Clamp

Safety Information

Included in this manual are CAUTIONS and Notes. Each of

these words represents a level of danger or concern.

A CAUTION indicates a hazard or unsafe practice that could

result in minor injury or property damage.

A Note indicates important information unrelated to safety.

How to Use the Model LL200

1. Power Button – turns the

laser on/off.

2. Out-of-Level LED (red) –

flashes when the laser is out

of level. If the laser is out of

level for 15 minutes, it

shuts off automatically.

3. Bull’s-Eye Level – provides

an easy reference for

leveling the laser.

4. Low-Battery LED (red) –

flashes when the battery

power is low. The laser operates for a minimum of two

hours after the LED starts flashing.

5. Level LED (green) – lights when the laser is on and level.

6. Battery Housing – holds one 1.5 V D-cell alkaline battery.

7. Leveling Base – moves around on the tripod’s leveling

dome so the laser can be leveled.

9

10

11

2

1

3

4

5

ON

+

Audio

Above Grade

On Grade

Below Grade

Low Battery

Power

Out of Level

Liquid Crystal Display (LCD)

7

6

8

9

2. Jaws– open/close so the

general-purpose clamp can

be attached to the grade

rod.

3. Jaws Screw – controls the

opening/closing of the jaws.

3

1

4

2

4. Alignment Marks – align with the receiver’s on-grade

marking notches.

1

2

1

2

3

6

4

5

6. Front-Side Scale –

measures between 1.30

and 2.11 meters (4 feet

3 inches and 6 feet

11 inches). The upper

section of both sides has an

80-cm (24-in.) scale. This

scale has 40 cm (12 in.)

that are positive and 40 cm

(12 in.) that are negative

and shows the amount

of cut/fill.

CAUTION: Be sure to handle

the laser by the body rather

than the top (sunshade). The

sunshade protects the glass

window that the beam comes

out of. The window can break

if handled improperly.

Installing the Batteries

Note: The laser and receiver have reverse polarity protection.

If you put the batteries in wrong, no damage occurs to the laser

and receiver but they do not work. Allow them one minute to

recover after the batteries have been installed correctly.

Y

X

X

Note: The maximum

operating diameter is

430 ft (130 m) in the

Y axis and 1000 ft

(300 m) in the X axis.

The minimum operating

distance to a wall is

20 ft (6 m).

20 ft (6 m)

minimum

20 ft (6 m)

minimum

5 ft (1.5 m)

minimum

1. Attach the clamp to the

receiver.

1. Turn the battery-housing

knob counterclockwise to

loosen the battery-housing

door.

2. Slide the receiver onto the

grade rod.

3. Turn the battery-housing

knob clockwise to hold the

receiver securely in place.

Using the Receiver

11. Legs – support the laser and allow the height of the laser

to be adjusted.

Model LL200-4

The Model LL200 and Model

LL200-4 are the same except

for the leveling base.

1. Leveling Screws – turn

clockwise/counterclockwise

so the laser can be leveled.

2. Threaded Brass Insert –

allow the laser to be

attached to a standard

5

/8-11 construction tripod.

1

2

8

2. Attach the clamp to the

grade rod.

4

5

6

7

1

2

3

Note: For best system performance, do not set up the laser

within 20 ft (6 m) of a wall. Also do not use the receiver

within 20 ft (6 m) of the laser or within 5 ft (1.5 m) of a

wall. At these close ranges, the receiver’s electronics may give

incorrect beam elevation information due to the laser beam

reflecting off of the walls.

2. Press the power button to turn on the laser. All LEDs flash

once to show that they are working.

1. Attach the receiver to the grade rod.

2. Press the power button to turn on the receiver. The ON

symbol appears in the LCD.

3. If you’re using the audio function, press the audio button to

turn it on. The audio symbol appears in the LCD.

Note: The receiver beeps quickly when the receiver is above

the laser beam, slowly when below it, and continuously

when centered in the laser beam or on grade. If, however,

the laser gets bumped out of level while it is being used, the

receiver beeps once every second.

Page 2

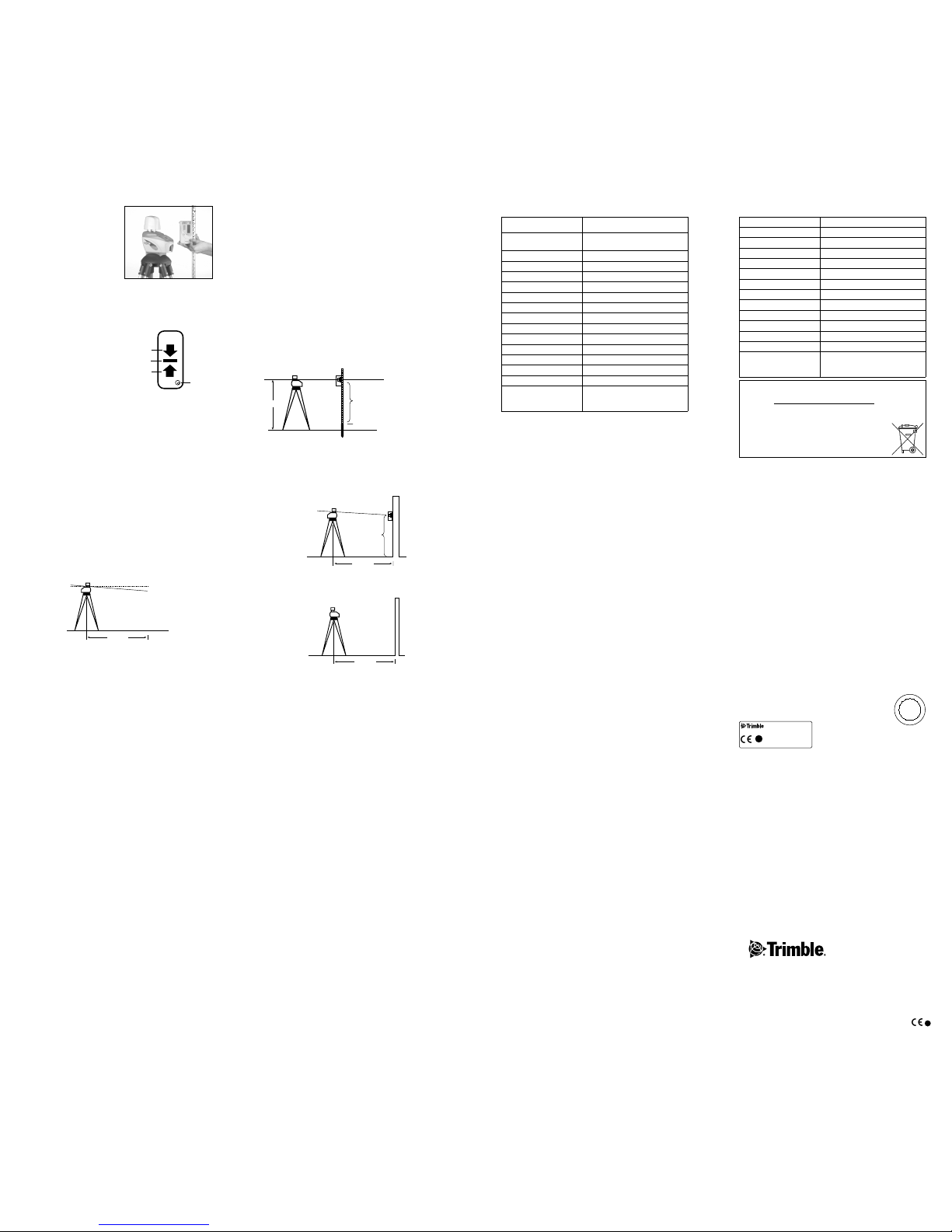

Declaration of Conformity

Application of 89/336/EEC

Council Directive(s):

Manufacturer’s Name: Trimble Navigation Limited

Manufacturer’s Address: 5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

European Representative Trimble GmbH

Address: Am Prime Parc 11

65479 Raunheim, Germany

Model Number(s): LL200/HR200

Conformance to EC Directive 89/336/EEC using

Directive(s): EN55022 and EN50082-1

Equipment Type/ ITE/residential, commercial

Environment: & light industrial

Product Standards: Product meets the limit B and

methods of EN55022

Product meets the levels

and methods of IEC 801-2,

8 kV air, 4 kV contact

IEC 801-3, 3 V/m 26 to 1000

MHz 80%, @ 1 kHz

Warranty

Trimble warrants the laser system (laser, receiver, tripod, and

grade rod) to be free of defects in material and workmanship

for a period of one year. The Warranty is in effect twelve

months from the date the system is delivered by Trimble or its

authorized dealer to the purchaser, or is put into service by a

dealer as a demonstrator or rental component. If the laser fails

due to damage to the beam reflecting compensator or laser

source, those components will be repaired or replaced at no

charge during the original warranty period.*

Special precautions have been taken to ensure the calibration

of the laser; however, calibration is not covered by this

warranty. Verifying the laser’s calibration is the responsibility

of the customer.

Trimble or its authorized service center will repair or replace,

at its option, any defective part for which notice has been given

during the warranty period. If required, travel and per diem

expenses to and from the place where repairs are made will be

charged to the customer at the prevailing rates.

Customers should send the product to Trimble or the nearest

authorized service center for warranty repairs, freight prepaid.

In countries with Trimble subsidiary service centers, the

repaired product will be returned to the customer, freight

prepaid.

– 13 – – 14 – – 15 – – 16 –

–

17 – – 18 –

– 19 – – 20 –

– 21 – – 22 – – 23 –

✔

N324

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

+1-937-245-5600 Phone

www.trimble.com

© 2002-2005, Trimble Navigation Limited. All rights reserved.

Reorder PN 0205-0080 Rev. C (07/05)

Receiver (cont.)

4. Position the receiver so

that its photocell faces

the laser. For best results,

the photocell should be as

perpendicular to the laser

as possible.

Determining the Height of Instrument (HI)

The height of instrument (HI) is the elevation of the laser’s

beam. The HI is determined by adding the grade-rod reading

to a benchmark or known elevation.

1. Set up and level the laser.

2. Attach the receiver to a grade rod and turn on the receiver.

3. Place the grade rod on a job-site benchmark (BM) or known

elevation.

4. Slide the receiver up/down the grade rod until the LCD

shows an on-grade reading.

5. Add the grade-rod reading to the benchmark to determine

the height of instrument.

Example: Benchmark elevation = 100.23 ft (30.55 m)

On-grade rod reading = + 4.34 ft (1.32 m)

Height of instrument = 104.57 ft (31.87 m)

6. Use this HI as a reference for all other elevations.

Specifications

Laser

Accuracy ±15 arc seconds

or ±3/32 in./100 ft (±2.2 mm/30 m)

Operating Diameter 430 ft (130 m)—Y axis

1000 ft (330 m)—X axis

Minimum Operating Range 20 ft (6 m)

Self-Leveling Range ±30 minutes

Level Bubble Sensitivity 45 arc minutes/0.1 inch movement

Out-of-Level Indication Flashing LED

Power Source One 1.5 V D-cell alkaline battery

Battery Life 100 hours @ 70 °F (23 °C)

Low Battery Operation 2 hours minimum

Automatic Shutoff 15 minutes if the laser is not level

Tripod Mount

5

/8-11

Water Resistant Yes

Operating Temperature –10 °F to 120 °F (–23 °C to 50 °C)

Storage Temperature –40 °F to 140 °F (–40 °C to 60 °C)

Laser Type/Classification 780 nm IR/Class 1

Regulatory Conformance CDRH: Class 1

EC Directive 89/336/EEC using

EN55022 and EN50082-1

Receiver

Accuracy <±1/16 in. (±1.5 mm)

Elevation Readout Front and back LCDs

Out-of-Level Indication Audio and visual

Audio Control On/Off

Capture Height 2 in. (50 mm)

Marking Notches 2 in. (50 mm) below top of receiver

Power Source One 9-V alkaline battery

Battery Life 45 hours

Low Battery Operation 1 hour

Automatic Shutoff 8 minutes

Water Resistant Yes

Operating Temperature –10 °F to 120 °F (–23 °C to 50 °C)

Storage Temperature –40 °F to 140 °F (–40 °C to 60 °C)

Regulatory Conformance RFI (Radio Frequency Interference

Protection) per 89/336/EEC using

EN55022 and EN50082-1

CAUTION: When checking all four axes for a calibration

error, be sure not to rotate the laser more than 360°. Doing

so can cause the extension spring that holds the laser to the

leveling base to break. If rotating the laser becomes difficult,

turn the laser 180° in the opposite direction.

1. Set up and level the laser 100 ft (30 m) from a wall.

Checking Calibration

As with any precision instrument, the calibration needs

checking on a regular basis (such as at the beginning of a job,

or if the laser has been handled roughly). If the laser is being

used at temperatures below freezing, be sure to check

calibration under those conditions.

The laser is calibrated if the laser plane is within ±3/32 inch

(±2.2 mm) of true level at 100 ft (30 m). If the laser has a

calibration error, go to the “Request for Service” section of

this manual to get more information.

2. Use the receiver to take an elevation reading for the +Y axis.

Request for Service

To locate your local dealer or authorized Trimble Service

Center outside the U.S.A for service, accessories, or spare parts,

contact one of our offices listed below.

North America

Trimble Construction Division

5475 Kellenburger Road

Dayton, Ohio 45424-1099

U.S.A.

(800) 538-7800 (Toll Free)

+1-937-245-5600 Phone

+1-937-233-9004 Fax

Europe

Trimble GmbH

Am Prime Parc 11

65479 Raunheim

GERMANY

+49-6142-2100-0 Phone

+49-6142-2100-550 Fax

Latin America

Trimble Navigation Limited

6505 Blue Lagoon Drive

Suite 120

Miami, FL 33126

U.S.A.

+1-305-263-9033 Phone

+1-305-263-8975 Fax

Africa & Middle East

Trimble Export Middle-East

P.O. Box 17760

Jebel Ali Free Zone, Dubai

UAE

+971-4-881-3005 Phone

+971-4-881-3007 Fax

Asia-Pacific

Trimble Navigation

Australia PTY Limited

Level 1/120 Wickham Street

Fortitude Valley, QLD 4006

AUSTRALIA

+61-7-3216-0044 Phone

+61-7-3216-0088 Fax

China

Trimble Beijing

Room 2805-07, Tengda Plaza,

No. 168 Xiwai Street

Haidian District

Beijing, China 100044

+86 10 8857 7575 Phone

+86 10 8857 7161 Fax

www.trimble.com.cn

EMC Declaration of Conformity

This laser has been tested and found to comply with the limits

for a Class B digital device for radio noise for digital apparatus

set out in the Radio Interference Regulations of the Canadian

Department of Communication, and is pursuant to part 15 of

the Federal Communication Commission (FCC) rules. These

limits are designed to provide reasonable protection against

harmful interference in a residential installation. This laser

generates radio frequency. If it’s not used in accordance with

the instructions, it may cause harmful interference to radio or

television reception. Such interference can be determined by

turning the laser off and on. You are encouraged to try

eliminating the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the laser and the receiver.

For more information, consult your dealer or an experience

radio/television technician.

CAUTION: Changes or modifications to the laser that are not

expressly approved by Trimble Construction Instruments

Division could void authority to use the equipment.

Any evidence of negligence or abnormal use, including a

broken lighthouse, or any attempt to repair the product by

other than factory-authorized personnel using Trimble certified

or recommended parts, automatically voids the warranty.

The foregoing states the entire liability of Trimble regarding

the purchase and use of its equipment. Trimble will not be held

responsible for any consequential loss or damage of any kind.

This warranty is in lieu of all other warranties, except as set

forth above, including any implied warranty merchantability

of fitness for a particular purpose, are hereby disclaimed. This

warranty is in lieu of all other warranties, expressed or implied.

}

±3/32 inch

(±2.2 mm)

100 ft (30 m)

True Level

Calibration Error

100 ft (30 m)

+ Y

Y

1

100 ft (30 m)

-Y

3. Rotate the laser 180° (–Y axis toward the wall) and re-level

the laser.

HI

Rod Reading

4.34 ft (1.32 m)

Benchmark

100.23 ft (30.55 m)

HI = Rod Reading + Benchmark

HI = 4.34 ft + 100.23 ft = 104.57 ft (1.32 m + 30.55 m = 31.87 m)

Height of Instrument (HI)

4. Use the receiver to take an elevation reading for the –Y axis.

5. Calculate the difference between the two elevation readings.

If they differ more than 3/16 in. (4.4 mm), the laser needs

calibrating. Return the laser to an authorized Trimble service

center for servicing.

6. To check the X axis, repeat steps 1–5 using the X axis

instead of the Y axis.

Above Grade

On Grade

Below Grade

Out of Level

ON

Laser Safety

The United States Government Center of Devices for

Radiological Health (CDRH) has classified this laser as a Class

1 laser product. The classification is the safest one available in

that it uses laser energy similar to that used in a compact disc

player. A Class 1 certification means that NO risk of injury

exists when this laser product is used in accordance with the

instructions in this manual.

CAUTION: If you’re using an optical instrument within

10 ft (30 m) of the laser, do not point it toward the laser.

No OSHA or ANSI requirements with regard to signs,

warning labels, or operator’s licensing are needed because of

the laser’s low operating power. Question about laser safety

should be address to:

Trimble Navigation Limited

5475 Kellenburger Road

Dayton, OH 45424-1099 U.S.A.

Attention: Quality Assurance Group, Laser Safety Officer

Phone: (937) 245-5824

(800) 538-7800

FAX: (937) 233-9661

Labels required for this product:

The DANGER label is under the sunshade and

is visible only when the product is serviced by an

authorized repair technician.

D

A

N

G

E

R

I

N

V

I

S

I

B

L

E

L

A

S

E

R

R

A

D

I

A

T

I

O

N

A

V

O

I

D

D

I

R

E

C

T

E

X

P

O

S

U

R

E

Complies with CFR 1040 as applicable.

U.S. PATENTS: 4,679,937

4,767,208

4,674,870

5,257,279

4,732,471

4,111,564

Model:

✔

N324

S/N MFG:

5. Turn the battery-housing

knob counterclockwise

slightly to loosen the battery-housing door. (If you are using

the general-purpose clamp, turn the jaws screw to loosen the

jaws.) Slide the receiver up/down the grade rod until the

LCD shows an on-grade reading.

Note: The LCD shows

a down arrow when the

receiver is above the laser

beam, an up arrow when

below it, and a horizontal

line when centered in the

laser beam or on grade.

If, however, the laser gets

bumped out of level while it is being used, the LCD shows

an out-of-level level bubble (the same symbol as appears on

the laser).

6. Turn the battery-housing knob (jaws screw) clockwise to

hold the receiver securely in place.

Note: The receiver can also be used without the grade rod.

Notice to Our European Union Customers

For product recycling instructions and more information,

please go to: www.trimble.com/environment/summary.html

Recycling in Europe

To recycle Trimble WEEE, call: +31 497 53 2430, and ask for the “WEEE

associate,” or

mail a request for recycling instructions to:

Trimble Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

Loading...

Loading...