Page 1

Troubleshooting Guide

Ag

GPS® EZ-Boom® 2010 System

Version 2.00

Revision A

August 2009

F

Page 2

Contact Information

Trimble Agriculture Division

10355 Westmoor Dr

Suite #100

Westminster, CO 80021

USA

800-865-7438 (US toll free)

+1-913-495-2700 Phone

+1-913-495-2750 Fax

trimble_support@trimble.com

www.EZ-Boom.com

Legal Notices

Copyright and Trademarks

© 2006-2009, Trim ble N avi gati on L imit ed. All rights reserved. Trimble, AgGPS,

EZ-Boom, EZ-Guide, and EZ-Steer are trademarks of Trimble Navigation

Limited, registered in the United States and in other countries. Autopilot,

EZ-Toolbox, FieldManager, and FmX are trademarks of Trimble Navigation

Limited.

All other trademarks are the property of their respective owners.

Release Notice

This is the August 2009 release (Revision A) of the EZ-Boom 2010 Automated

Application Control System Troubleshooting Guide. It applies to version 2.00 of

the EZ-Boom 2010 automated application control system.

LIMITED WARRANTY TERMS AND CONDITIONS

Product Limited Warranty

Subject to the following terms and conditions, Trimble Navigation Limited

(“Trimble”) warrants that for a period of one (1) year from date of purchase

this Trimble product (the “Product”) will substantially conform to Trimble's

publicly available specifications for the Product and that the hardware and

any storage media components of the Product will be substantially free from

defects in materials and workmanship.

Product Software

Produ ct software, w hether buil t into hardware circuitry as firmware, provided

as a standalone computer software product, embedded in flash memory, or

stored on magnetic or other media, is licensed solely for use with or as an

integral part of the Product and is not sold. If accompanied by a separate end

user license agreement (“EULA”), use of any such software will be subject to

the terms of such end user license agreement (including any differing limited

warranty terms, exclusions, and limitations), which shall control over the

terms and conditions set forth in this limited warranty.

Software Fixes

During the limited warranty period you will be entitled to receive such Fixes

to the Product software that Trimble releases and makes commercially

available and for which it does not charge separately, subject to the

procedures for delivery to purchasers of Trimble products generally. If you

have purchased the Product from an authorized Trimble dealer rather than

from Trimble directly, Trimble may, at its option, forward the software Fix to

the Trimble dealer for final distribution to you. Minor Updates, Major

Upgrades, new products, or substantially new software releases, as identified

by Trimble, are expressly excluded from this update process and limited

warranty. Receipt of software Fixes or other enhancements shall not serve to

extend the limited warranty period.

For purposes of this warranty the following definitions shall apply: (1)

“Fix(es)” means an error correction or other update created to fix a previous

software version that does not substantially conform to its Trimble

specifications; (2) “Minor Update” occurs when enhancements are made to

current features in a software program; and (3) “Major Upgrade” occurs when

significant new features are added to software, or when a new product

containing new features replaces the further development of a current

product line. Trimble reserves the right to determine, in its sole discretion,

what constitutes a Fix, Minor Update, or Major Upgrade.

Warranty Remedies

If the Trimble Product fails during the warranty period for reasons covered by

this limited warranty and you notify Trimble of such failure during the

warranty period, Trimble will repair OR replace the nonconforming Product

with new, equ ivalen t to new, or reco ndition ed par ts or Pr oduct, OR refu nd the

Product purchase price paid by you, at Trimble’s option, upon your return of

the Product in accordance with Trimble's product return procedures then in

effect.

How to Obtain Warranty Service

To obtain warranty service for the Product, please contact your local Trimble

authorized dealer. Alternatively, you may contact Trimble to request warranty

service at +1-408-481-6940 (24 hours a day) or e-mail your request to

trimble_support@trimble.com. Please be prepared to provide:

– your name, address, and telephone numbers

– proof of purchase

– a copy of this Trimble warranty

– a description of the nonconforming Product including the model

number

– an explanation of the problem

The customer service representative may need additional information from

you depending on the nature of the problem.

Warranty Exclusions and Disclaimer

This Product limited warranty shall only apply in the event and to the extent

that (a) the Product is properly and correctly installed, configured, interfaced,

maintained, stored, and operated in accordance with Trimble's applicable

operator's manual and specifications, and; (b) the Product is not modified or

misused. This Product limited warranty shall not apply to, and Trimble shall

not be responsible for, defects or perfor mance problems resultin g from (i) the

combination or utilization of the Product with hardware or software

products, information, data, systems, interfaces, or devices not made,

supplied, or specified by Trimble; (ii) the operation of the Product under any

specification other than, or in addition to, Trimble's standard specifications

for its products; (iii) the unauthorized installation, modification, or use of the

Product; (iv) damage caused by: accident, lightning or other electrical

discharge, fresh or salt water immersion or spray (outside of Product

specifications); or exposure to environmental conditions for which the

Product is not intended; (v) normal wear and tear on consumable parts (e.g.,

batteries); or (vi) cosmetic damage. Trimble does not warrant or guarantee

the results obtained through the use of the Product, or that software

components will operate error free.

NOTICE REGARDING PRODUCTS EQUIPPED WITH TECHNOLOGY

CAPABLE OF TRACKING SATELLITE SI GNALS FROM SATELLITE BASED

AUGMENTATION SYSTEM S (SBAS) (WAAS/EGNOS, AND MSAS),

OMNISTAR, GPS, MODERNIZED GPS OR GLONASS SATELLITES, OR

FROM IALA BEACON SOURCES: TRIMBLE IS NOT RESPONSIB LE FOR

THE OPERATION OR FAILURE OF OPERATION OF ANY SATELLITE

BASED POSITIONING SYSTEM OR THE AVAI LABILITY OF ANY

SATELLITE BASED POSITIONING SIGNALS.

THE FOREGOING LIMITED WARRANTY TERMS STATE TRIMBL E’S ENTIRE

LIABILITY, AND YOUR EXCLUSIVE REMEDIES, REL ATING TO THE TRIMBLE

PRODUCT. EXCEPT AS OTHERWISE EXPRESSLY PROVIDED HEREIN, THE

PRODUCT, AND ACCOMPANYING DOCUMENTATION AND MATERIALS

ARE PROVIDED “AS-IS” AND WITHOUT EXPRESS OR IMPLIED WARRANTY

OF ANY KIND, BY EITHER TRIMBLE OR ANYONE WHO HAS BEEN

INVOLVED IN ITS CREATION, PRODUCTION, INSTALLATION, OR

DISTRIBUTION , INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, TITLE, AND NONINFRINGEMENT. THE ST ATED EXPRESS

WARRANTIES ARE IN LIEU OF ALL OBLIGATIONS OR LIABILITIES ON THE

PART OF TRIMBLE ARISING OUT OF, OR IN CONNECTION WITH, ANY

PRODUCT. BECAUSE SOME STATES AND JURISDICTIONS DO NOT ALLOW

LIMITATIONS ON DURATION OR THE EXCLUSION OF AN IMPLIED

WARRANTY, THE ABOVE LIMITATION MAY NOT APPLY OR FULLY APPLY

TO YOU.

Limitation of Liability

TRIMBLE'S ENTIRE LIABILITY UNDER ANY PROVISION HEREIN SHALL BE

LIMITED TO THE AMOUNT PAID BY YOU FOR THE PRODUCT. TO THE

MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW, IN NO EVENT

SHALL TRIMBLE OR ITS SUPPLIERS BE LIABLE FOR ANY INDIRECT,

SPECIAL , INCIDENTAL, OR CONSEQUENTIAL DAMAGE WHATSOEVER

UNDER ANY CIRCUMSTANCE OR LEGAL THEORY RELATI NG IN ANYWAY

TO THE PRODUCTS, SOFTWARE AND ACCOMPANYING DOCUMENTATION

AND MATERIALS, (INCLUDING, WITHOUT LIMITATION, DAMAGES FOR

LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS OF DATA, OR

ANY OTHER PECUNIARY LOSS), REGARDL ESS OF WHETHER TRIMBLE HAS

BEEN ADVISED OF THE POSSIBILITY OF ANY SUCH LOSS AND REGARDLESS

OF THE COURSE OF DEALING WHICH DEVELOPS OR HAS DEVELOPED

BETWEEN YOU AND TRIMBLE. BECAUSE SOME STATES AND

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF

LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

PLEASE NOTE: THE ABOVE TRIMBLE LIMITED WARRANTY PROVISIONS

WILL NOT APPLY TO PRODUCTS PURCHASED IN THOSE

JURISDICTIONS (E.G., MEMBER STATES OF THE EUROPEAN ECONOMIC

AREA) IN WHICH PRODUCT WARRANTIES ARE THE RESPONSI BILITY

OF THE LOCAL TRIMBLE AUTHORIZED DEALER FROM WHOM THE

PRODUCTS ARE ACQUIRED. IN SUCH A CASE, PLEASE CONTACT YOUR

LOCAL TRIMBLE AUTHORIZED DEALER FOR APPLICABLE WARRANTY

INFORMATION.

Official Language

THE OFFICIAL LANGUAGE OF THESE TERMS AND CONDITIONS IS

ENGLISH. IN THE EVENT OF A CONFLICT BETWEEN ENGLISH AND OTHER

LANGUAGE VERSIONS, THE ENGLISH LANGUAGE SHALL CONTROL.

Registration

To receive information regarding updates and new products, please contact

your local dealer or visit the Trimble website at www.trimble.com/register.

Upon registration you may select the newsletter, upgrade, or new product

information you desire.

Class A Warning

This is a Class A product. In a domestic environment the product may cause

radio interference in which case the user may be required to take adequate

measures.

Notice to Our European Union Customers

For product recycling instructions and more information, please go to:

www.trimble.com/ev.shtml

Recycling in Europe: To recycle Trimble WEEE, Call

+31 497 53 2430, and ask for the "WEEE Associate"

Or

Mail a request for recycling instructions to:

Tri mbl e Europe BV

c/o Menlo Worldwide Logistics

Meerheide 45

5521 DZ Eersel, NL

2 EZ-Boom 2010 System Troubleshooting Guide

Page 3

Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Configuring vehicles with solenoid boom valves for use with the EZ-Boom 2010 System. . . . . 8

Calculating the maximum total current draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Reducing the maximum total current draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 EZ-Boom 2010 System Error Messages. . . . . . . . . . . . . . . . . . . . . . 9

LED errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Viewing error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EZ-Guide Plus lightbar guidance system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

EZ-Guide 500 lightbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

AgGPS FieldManager display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

FmX integrated display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Clearing the error log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

The EZ-Boom icon does not appear on the lightbar . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CAN communication issue when using cable P/N 62063 . . . . . . . . . . . . . . . . . . . . . . . . 17

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EZ-Boom system error message 4500: “Setup Invalid” . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

EZ-Boom system error message 4600: “Rate Not Responding”. . . . . . . . . . . . . . . . . . . . . 20

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

EZ-Boom system error message xx01: “Boom Over Current”. . . . . . . . . . . . . . . . . . . . . . 22

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EZ-Boom system error message xx02: “Boom Driver Failure” . . . . . . . . . . . . . . . . . . . . . 23

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EZ-Boom system error message 5101: “Flow Valve Over Current” . . . . . . . . . . . . . . . . . . 24

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

EZ-Boom system error message 5102: “Flow Valve Driver Failure” . . . . . . . . . . . . . . . . . . 25

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EZ-Boom 2010 System Troubleshooting Guide 3

Page 4

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EZ-Boom system error message 5103: “Flow Valve Open”. . . . . . . . . . . . . . . . . . . . . . . . 26

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

EZ-Boom system error message 5201: “Main Pressure Below Min” . . . . . . . . . . . . . . . . . . 27

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

EZ-Boom system error message 5202: “Main Pressure Above Max” . . . . . . . . . . . . . . . . . 29

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

EZ-Boom system error message 6B00: “Minimum Flow” . . . . . . . . . . . . . . . . . . . . . . . . 31

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Operating the Rate Increment/Decrement switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Spray booms do not turn on in a corner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

The system shuts off when GPS signal is lost. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

System behavior following loss of GPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Boom sections do not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rate not responding and Min Flow reached . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Not reading any Applied Rate "With supported flow meter" . . . . . . . . . . . . . . . . . . . . . . 40

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Incorrect tank volume message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Pressure stays at Set limit on Pressure sensor Cal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Boom section 1 on an SPX sprayer does not turn on . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 EZ-Boom 2010 System Troubleshooting Guide

Page 5

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

“Rate not responding” message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rate fluctuates around the Target Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Flow Control Valve Error Driver Failure (-1 mA) Fault . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control Valve in headland fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sections not mapping when EZ-Boom controller is controlling sections only . . . . . . . . . . . 48

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Boom sections do not turn off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Cause . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Possible failure modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

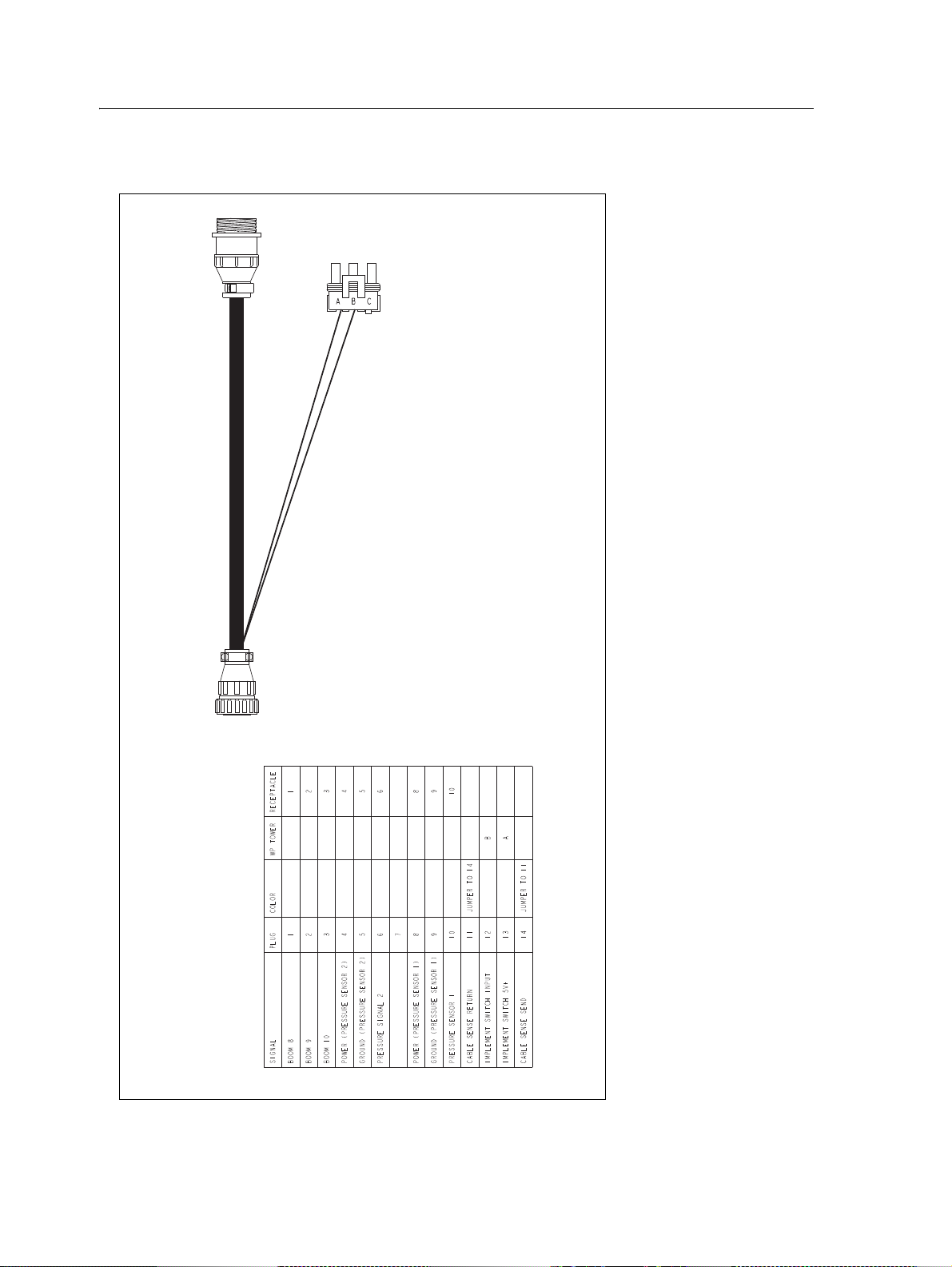

2 EZ-Boom 2010 System Harness Schematics . . . . . . . . . . . . . . . . . . 51

EZ-Boom 2010 system cable pinout information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

EZ-Guide-to-EZ-Steer harness: P/N 52763 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

EZ-Steer-to-EZ-Boom harness: P/N 58377 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Terminator connector: P/N 58378 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Raven 4x0 series “Y” cable: P/N 58560 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

CAN terminator: P/N 59783 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

AgGPS FieldManager display harness (Rev B): P/N 59872. . . . . . . . . . . . . . . . . . . . . . . . 58

FieldManager-to-EZ-Boom-extension-cable: P/N 59873 . . . . . . . . . . . . . . . . . . . . . . . . 59

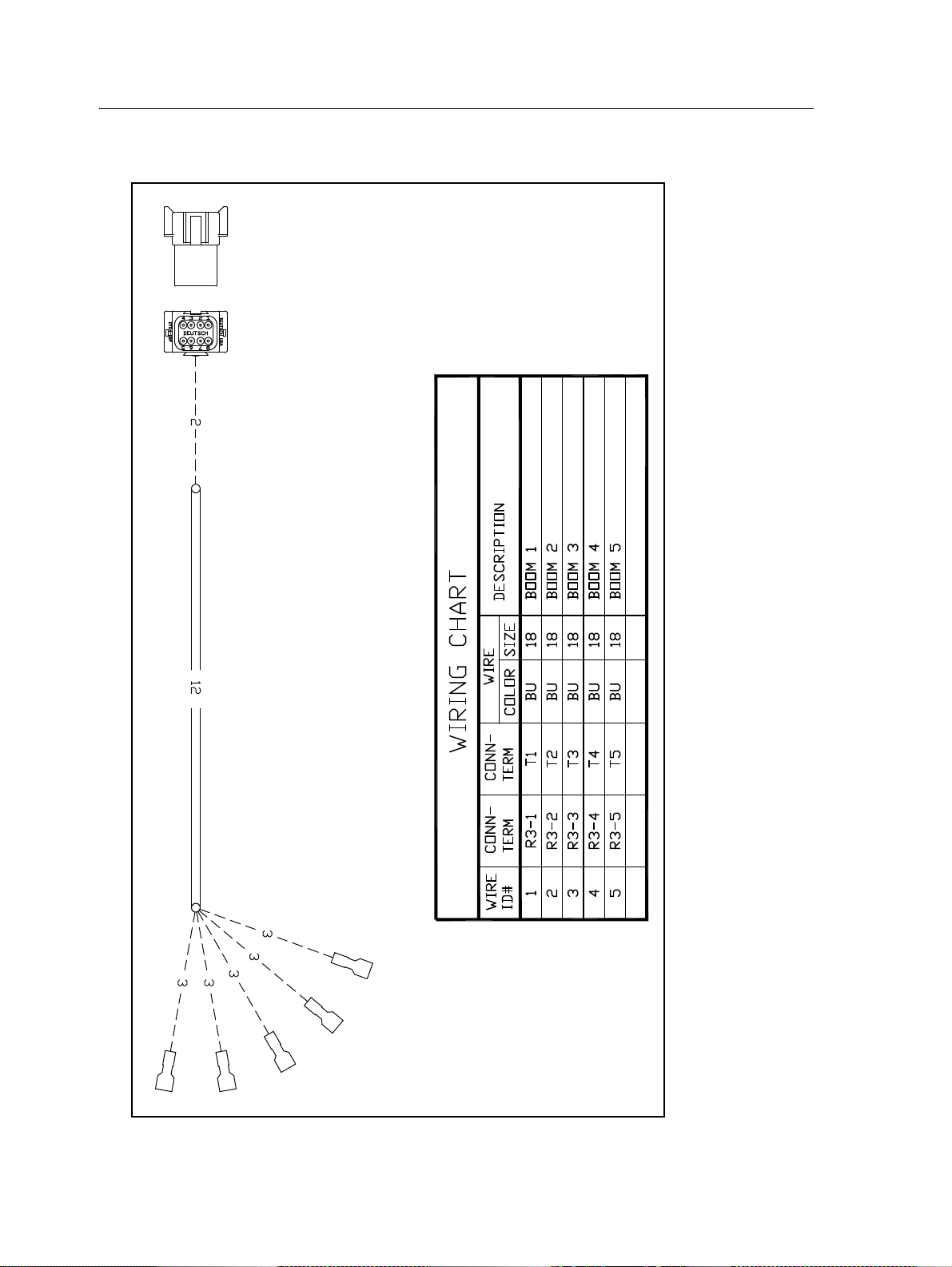

Raven 4x00 series “Y ” cable: P/N 59942 (see next page) . . . . . . . . . . . . . . . . . . . . . . . . . 60

EZ-Boom-to-Raven-4x00 adaptor harness: P/N 59943 . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Implement switch harness: P/N 60477. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Implement tee harness: P/N 60567 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Implement switch extension harness (10 ft): P/N 60478. . . . . . . . . . . . . . . . . . . . . . . . . 65

Implement switch extension harness (25 ft): P/N 60479. . . . . . . . . . . . . . . . . . . . . . . . . 66

Raven to EZ-Boom harness: P/N 58560 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Foot pedal assembly: P/N 60490. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

EZ-Boom cable John Deere 4710, 4720, 4920: P/N 61593 . . . . . . . . . . . . . . . . . . . . . . . . 69

EZ-Boom 2010 System Troubleshooting Guide 5

Page 6

EZ-Boom cable John Deere 4710, 4720, 4920: P/N 61593 (Pinouts) . . . . . . . . . . . . . . 70

Spracoupe to EZ-Boom harness: P/N 61991-00 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Flowmeter: P/N 62136 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

EZ-Boom to Flexicoil adapter: P/N 64396 (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

EZ-Boom to Flexicoil adapter: P/N 64396 (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Spracoupe to EZ-Boom adapter: P/N 64670 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Spracoupe to EZ-Boom cable: P/N 64671 (1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Spracoupe to EZ-Boom cable: P/N 64671 (2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

FmX to CAN w/port replicator : P/N 67087 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

3 EZ-Boom 2010 System Technical Specifications . . . . . . . . . . . . . . . 79

Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

6 EZ-Boom 2010 System Troubleshooting Guide

Page 7

Safety Information

In this chapter:

Configuring vehicles with

solenoid boom valves for use with

the EZ-Boom 2010 System

Always follow the instructions that

accompany a Caution. The information it

provides is intended to minimize the risk of

personal injury and/or damage to property.

CAUTION – This alert warns of a

C

Note – An absence of specific alerts does not

mean that there are no safety risks involved.

hazard or unsafe practice which,

if not avoided, can cause injury or

damage.

EZ-Boom 2010 System Troubleshooting Guide 7

Page 8

Safety Information

Configuring vehicles with solenoid boom valves for use with the EZ-Boom 2010 System

For vehicles equipped with three-wire motorized boom valves, the EZ-Boom® 2010

system controller is rated to drive all ten (10) boom sections.

For vehicles with solenoid boom valves, you may need to modify the vehicle, or the

vehicle configuration, to ensure that the total current draw does not exceed 16 Amps.

C

CAUTION – Before using solenoid boom valves, calculate the maximum total current

draw. Do not allow the total to exceed 16 Amps. A higher current draw can cause the

EZ-Boom controller to overheat and malfunction. To keep below the 16 Amp limit, modify

your vehicle setup or configuration.

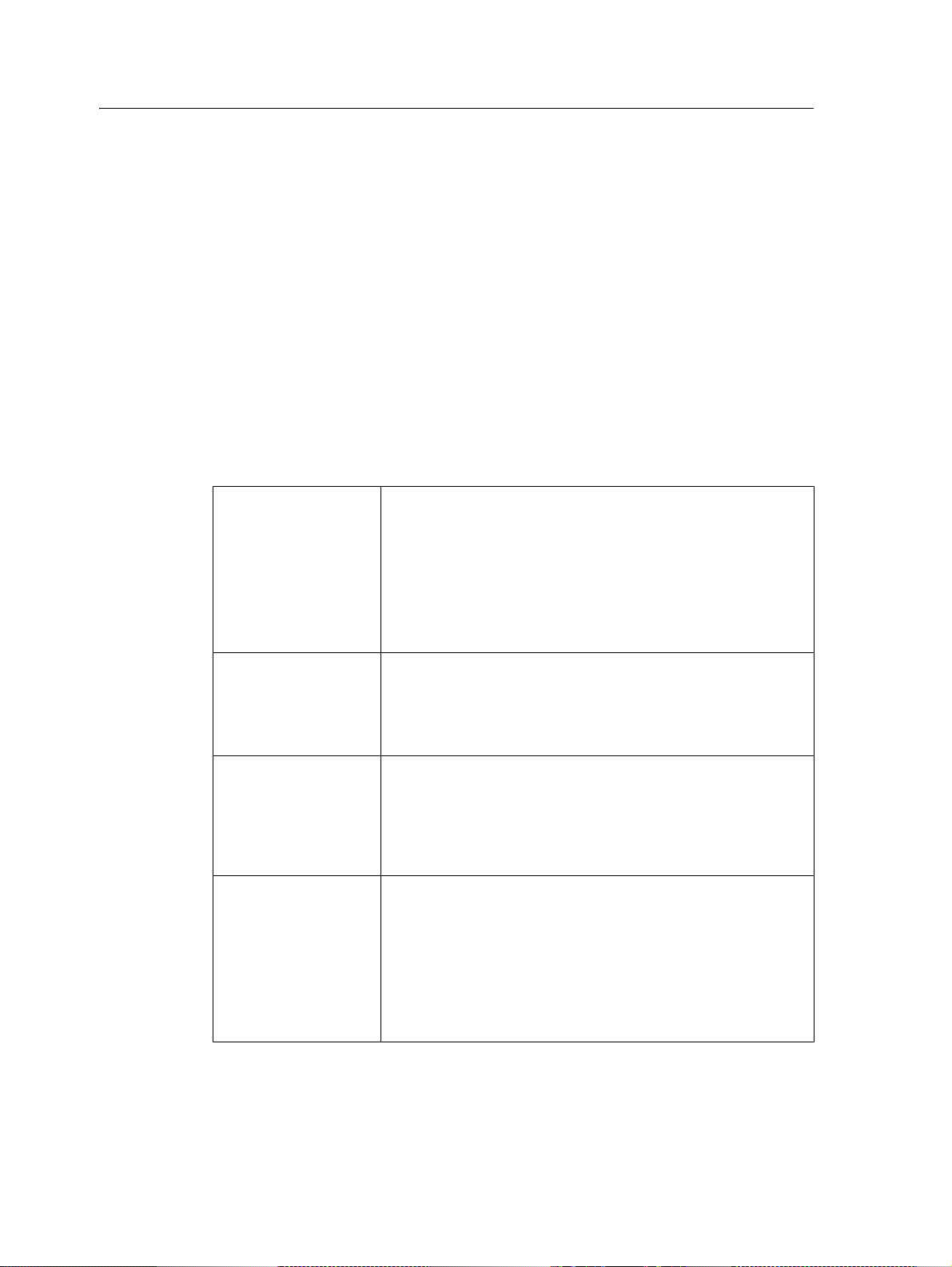

Calculating the maximum total current draw

1. Find the maximum current draw for one of the solenoid boom valves. If there is

no rating in the manufacturer’s documentation, contact the vendor.

2. Multiply the maximum current draw for one valve by the total number of

solenoid boom valves on the vehicle. For example, if one valve has a maximum

current draw of 3 Amps:

This many boom

valves...

5 5 x 3 Amp = 15 Amp

9 9 x 3 Amp = 27 Amp

Would result in a total maximum current

draw of...

Reducing the maximum total current draw

If the total current draw is greater than 16 Amps, do one of the following:

• Use fewer boom valves on the vehicle.

• Add external relays to each of the solenoid valves to reduce the current draw

from the EZ-Boom system.

• Replace solenoid valves with three-wire motorized boom valves.

8 EZ-Boom 2010 System Troubleshooting Guide

Page 9

EZ-Boom 2010 System Error

CHAPTER

1

Messages

In this chapter:

LED errors

Viewing error messages

Clearing the error log

EZ-Boom system error messages

1

This chapter describes the controller LED

states and system error messages from the

EZ-Boom 2010 automated application control

system. It then explains how to correct the

errors.

EZ-Boom 2010 System Troubleshooting Guide 9

Page 10

1 EZ-Boom 2010 System Error Messages

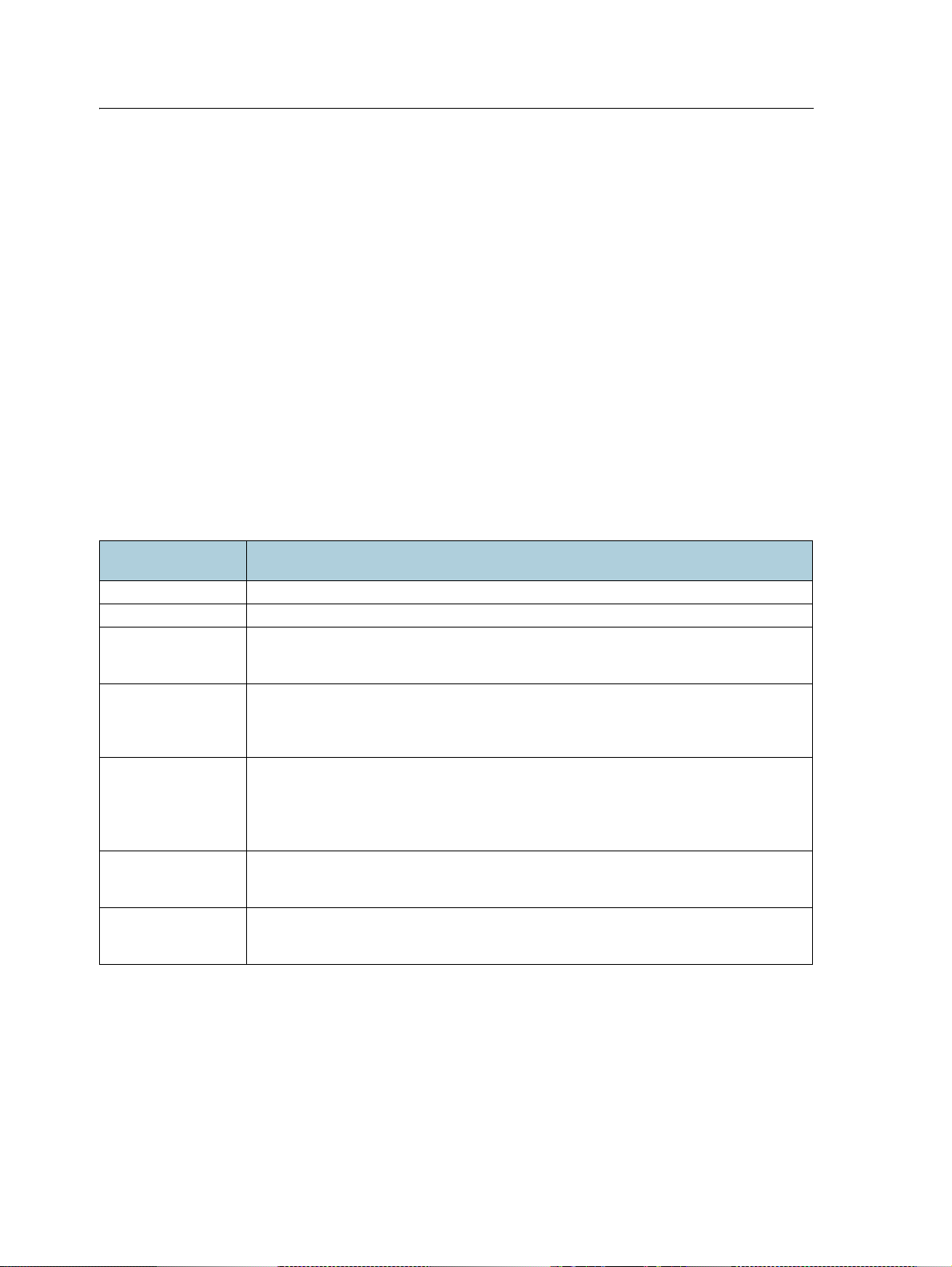

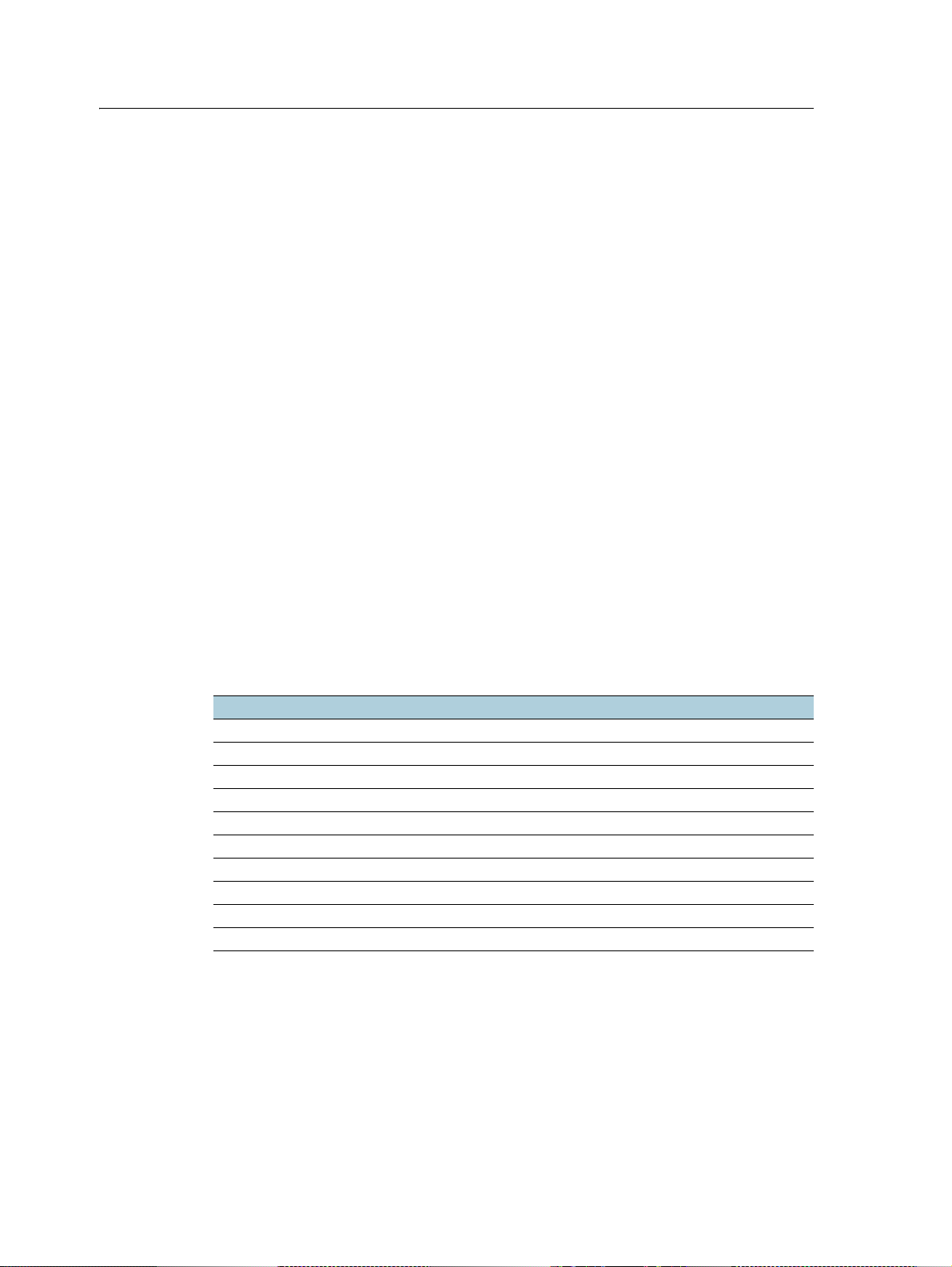

Status LED

LED errors

The status LED on the EZ-Boom 2010 controller indicates the current operating state.

It does this by displaying different colors and flash patterns:

LED state Description

Off No power

Steady green Normal operation

Flashing 1 Hz yellow CAN bus errors detected (error active/passive state)

Steady yellow CAN bus off

Steady red Hardware or initialization failure

Flashing 1 Hz red Firmware download in process

Flashing fast red Firmware download error

10 EZ-Boom 2010 System Troubleshooting Guide

Page 11

Viewing error messages

EZ-Guide Plus lightbar guidance system

EZ-Boom 2010 System Error Messages 1

To view error messages on the EZ-Boom 2010 system when it is connected to an

EZ-Guide

®

Plus lightbar guidance system:

1. From the lightbar navigation screen, select 7.

2. Select EZ-Boom / Fault History.

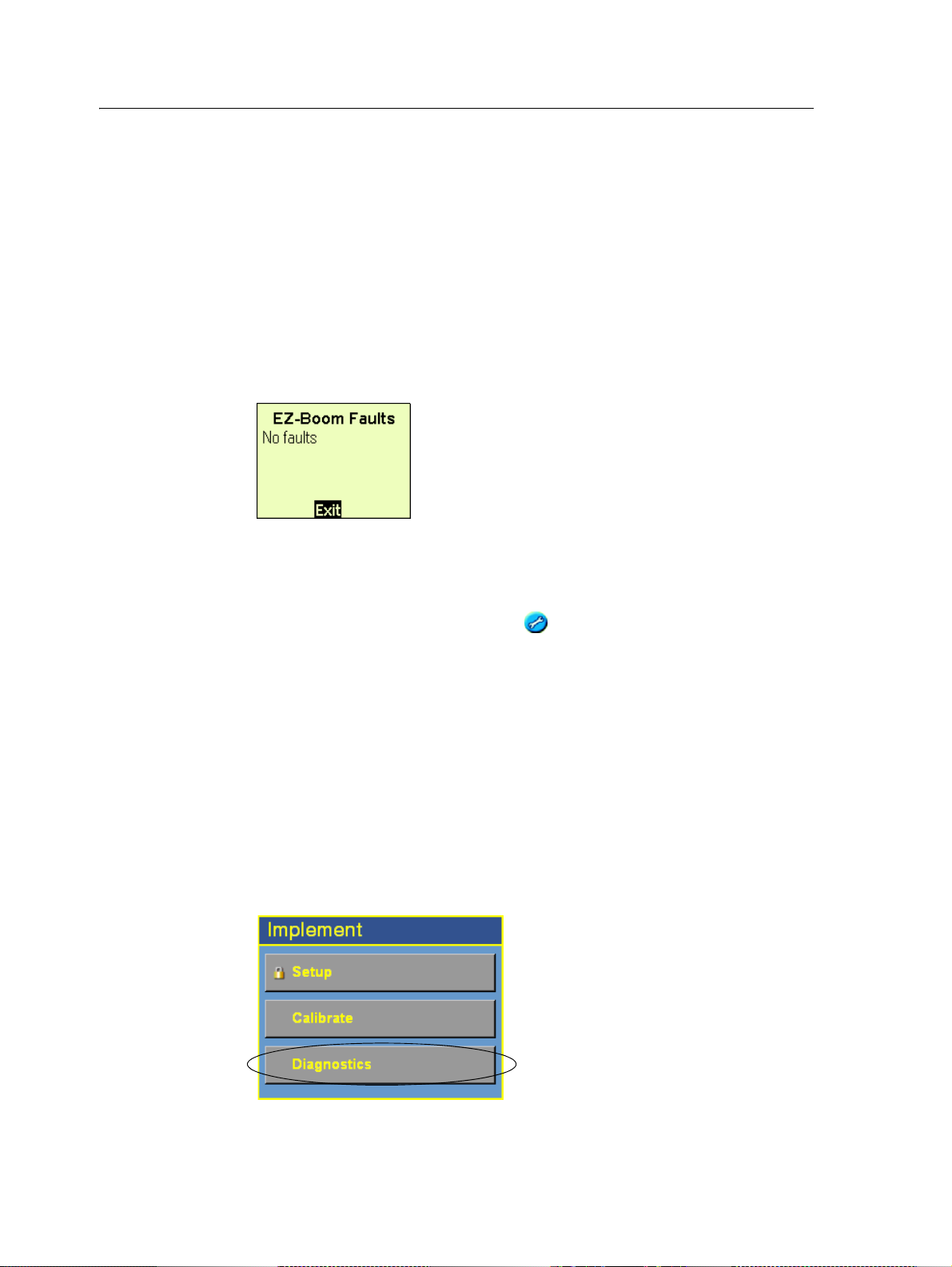

The EZ-Boom Faults screen appears. The previous four error messages that the

EZ-Boom 2010 system has encountered appear on the screen.

EZ-Guide 500 lightbar

To view error messages on the EZ-Boom 2010 system when it is connected to an

EZ-Guide 500 lightbar guidance system:

1. From the lightbar home screen, select .

2. Select Fault History.

3. Select EZ-Boom Fault History.

The EZ-Boom Faults screen appears.

AgGPS FieldManager display

To view error messages on the EZ-Boom 2010 system when it is connected to an

®

AgGPS

FieldManager™ display:

1. From the FieldManager display home screen, press the Configuration button.

The Configuration screen appears.

2. Highlight the EZ-Boom plugin and then tap Diagnostics.

EZ-Boom 2010 System Troubleshooting Guide 11

Page 12

1 EZ-Boom 2010 System Error Messages

The EZ-Boom Diagnostics screen appears. This is the same as shown below for

the FMX integrated display.

3. Tap the View Error Log button. The EZ-Boom Error History screen appears. It

displays the EZ-Boom system errors.

Note – Because this is a list of errors that have occurred, errors on the list are not

necessarily still occurring.

A error message also pops up on the main navigation screen of the display when the

error is encountered.

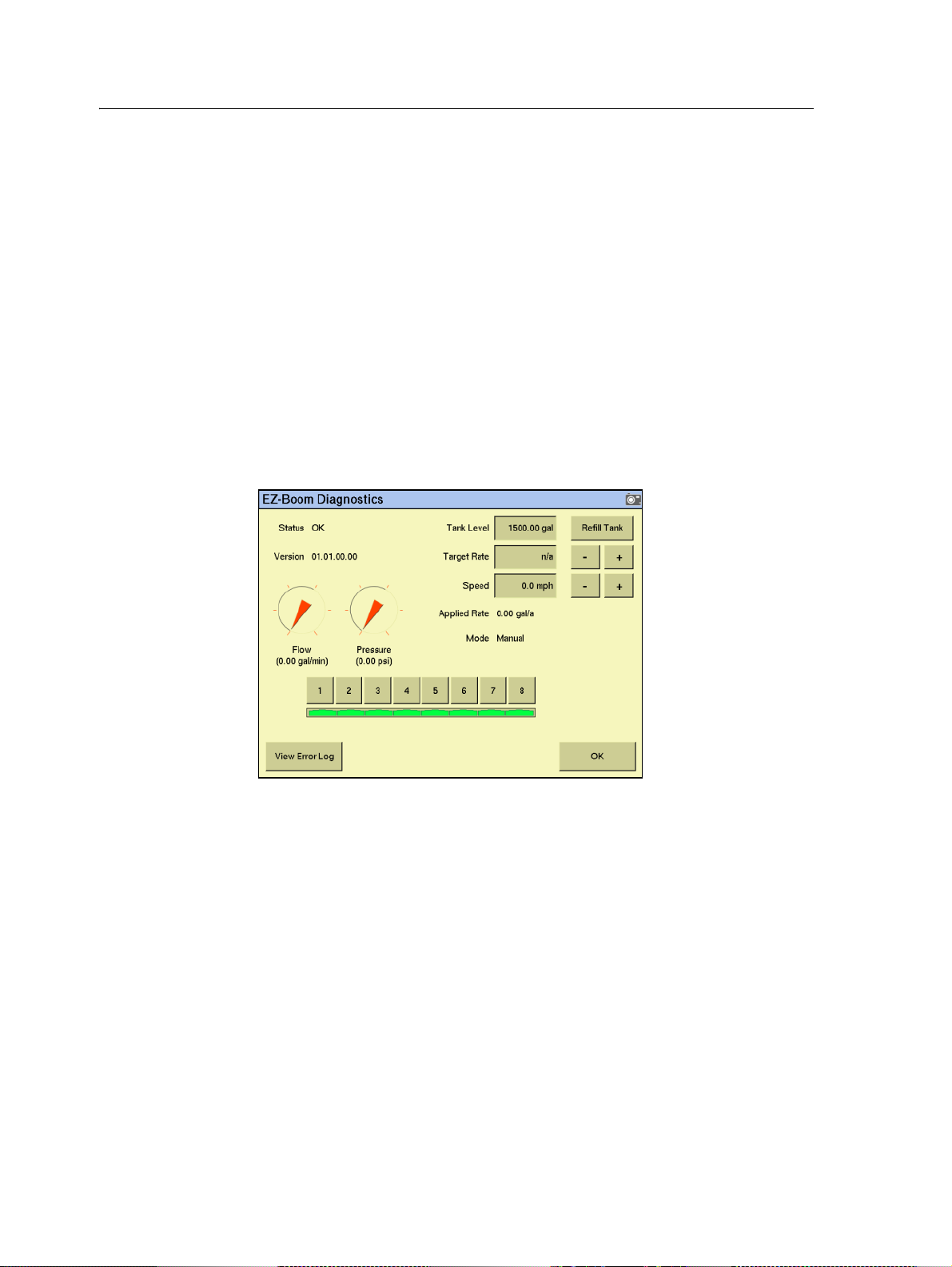

FmX integrated display

To view error messages on the EZ-Boom 2010 system when it is connected to an

™

AgGPS FmX

integrated display:

1. From the Configuration screen, select the EZ-Boom plugin and then tap

Diagnostics:

The EZ-Boom Diagnostics screen includes information on:

–current flow

– current pressure

–boom valve state

– EZ-Boom controller version number

It also shows the status of the EZ-Boom controller to ensure that it is working as

expected.

2. To check that the system is responding as expected, set the Targ et Rate and

Speed fields to a fixed known value.

3. To view previous errors, tap View Error Log.

12 EZ-Boom 2010 System Troubleshooting Guide

Page 13

Clearing the error log

These steps apply to all systems unless otherwise specified.

Step 1: Clear the error message

a. Write down the error message.

b. Check the details.

c. Press .

Step 2: Do one or both of the following, as directed:

• Check the current to the EZ-Boom controller. Details are given with each error

message.

• Check the flow control valve setup parameters.

EZ-Boom 2010 System Error Messages 1

FmX integrated

display

EZ-guide 500

lightbar

EZ-Guide Plus

lightbar

FieldManager

display

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Highlight the EZ-Boom plugin and then tap the Setup

button.

c. Make sure that the EZ-Boom system settings are correct.

d. Highlight the Implement plugin and then tap the Setup

button.

e. Make sure that the Implement system settings are correct.

a. From the main navigation screen, select 7. The Configuration

menu appears.

b. Select Application Control. The Application Control screen

appears.

c. Make sure that the Application system settings are correct.

a. From the main navigation screen, select 7. The setup menu

appears.

b. Select EZ-Boom/Control Valve. The Ctrl. Valve Setup screen

appears.

c. Check through the flow control valve settings, to ensure that

they are correct.

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Highlight the EZ-Boom plugin and then tap the Setup

button.

c. Make sure that the EZ-Boom system settings are correct.

d. Highlight the Implement plugin and then tap the Setup

button.

e. Make sure that the Implement system settings are correct.

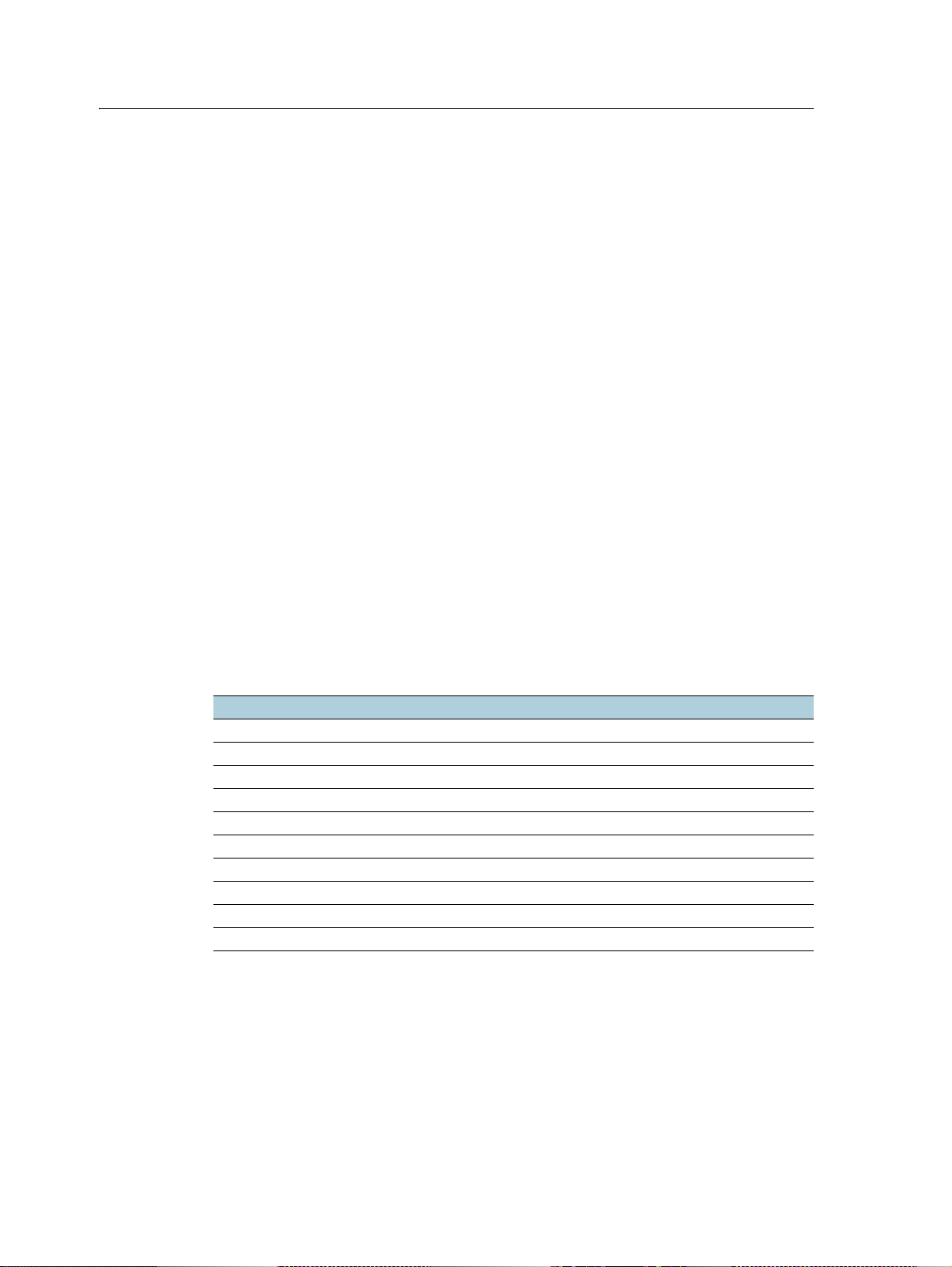

Step 3: Check that pin 3 and pin 1 share a grounding point

Check that pin 3 on the CAN connector and pin 1 on the 16-pin main connector

are both connected to the same electrical ground point:

EZ-Boom 2010 System Troubleshooting Guide 13

Page 14

1 EZ-Boom 2010 System Error Messages

a. Attach a multitester to pin 3 on the CAN connector harness and pin 1 on

the 16-pin main connector harness.

b. Measure the resistance. The resistance should be < 0.3 ohms.

14 EZ-Boom 2010 System Troubleshooting Guide

Page 15

EZ-Boom 2010 System Error Messages 1

The EZ-Boom icon does not appear on the lightbar

Cause

There are several factors that can cause this issue. To resolve it, see the following

sections:

• CAN bus communication error

• Wrong firmware version

• Wrong configuration

Solution

CAN bus communication error

When the EZ-Boom 2010 system and the EZ-Guide Plus lightbar are communicating

correctly, the EZ Boom status light is solid green. If the light is anything else, check the

wiring and all of the connectors between the EZ-Boom 2010 system and the lightbar.

Status light

condition

Off No power to the EZ-Boom 2010 system.

Steady green Normal operation

Steady yellow The CAN bus is off. There is no communication between the EZ-Boom 2010 system and

Flashing yellow

(once per second)

Steady red There is a hardware or initialization failure. The EZ-Boom 2010 system has started up

Flashing red

(once per second)

Flashing red

(faster than once

per second)

Description

the lightbar. Check power on the lightbar, and check the cabling between the lightbar

and the EZ-Boom 2010 system.

CAN bus error. There is a communication error between the EZ-Boom 2010 system and

the lightbar. Turn off the EZ-Boom controller and the lightbar and then turn them on

again. Verify that the EZ-Boom controller and the lightbar have the latest firmware

version installed.

incorrectly and may have a hardware problem. Turn off the EZ-Boom 2010 system and

the lightbar and then turn them on again. Verify that the EZ-Boom controller and the

lightbar have the latest firmware version installed.

If this does not resolve the issue, try another EZ-Boom controller.

Firmware download is in progress. Firmware or software is being downloaded to the

EZ-Boom controller. This is a normal operation and may take several minutes to

complete.

Firmware download error: An error has occurred while downloading firmware to the

EZ-Boom controller. Restart the firmware download.

Wrong firmware version

Check which version of firmware is installed on the EZ-Guide Plus lightbar:

1. From the main guidance screen, select Configuration.

2. Select About.

EZ-Boom 2010 System Troubleshooting Guide 15

Page 16

1 EZ-Boom 2010 System Error Messages

3. The Ver field shows the current firmware version. Do one of the following:

–If the firmware is not version 4.00 or later, download the latest firmware

and the EZ-Toolbox

™

software onto your computer from

www.EZ-Guide.com.

–If the firmware is the latest version, restore the lightbar defaults.

To re store d e f a u lt s:

1. From the main screen, select the Configuration icon and then press .

2. Select Defaults.

3. Select Restore Defaults.

If this does not resolve the issue, use the EZ-Toolbox software to reinstall the firmware

on the lightbar:

1. Turn off the lightbar.

2. Start the EZ-Toolbox software on your computer.

3. Select the EZ-Guide+ tab.

4. If the current firmware version does not appear in the Select firmware file field,

select the drop down menu arrow to view all available firmware versions. If the

current firmware is not in this list, click

you saved the downloaded file, highlight the folder and then click

Browse, navigate to the folder where

OK.

5. Click Proceed in the top right corner of the EZ-Toolbox screen and then follow

the instructions in the Status messages field.

Wrong configuration

Set the Path Display for the EZ-Boom 2010 system:

1. From the main guidance screen, press Configuration.

2. Select Lightbar / Display Config.

3. Set the Path Display field to EZ-Boom and then press .

If this does not resolve the issue, restore the lightbar default settings. See above.

If restoring the defaults does not resolve the issue, use the EZ-Toolbox software to

reinstall the firmware on the lightbar. See above.

16 EZ-Boom 2010 System Troubleshooting Guide

Page 17

EZ-Boom 2010 System Error Messages 1

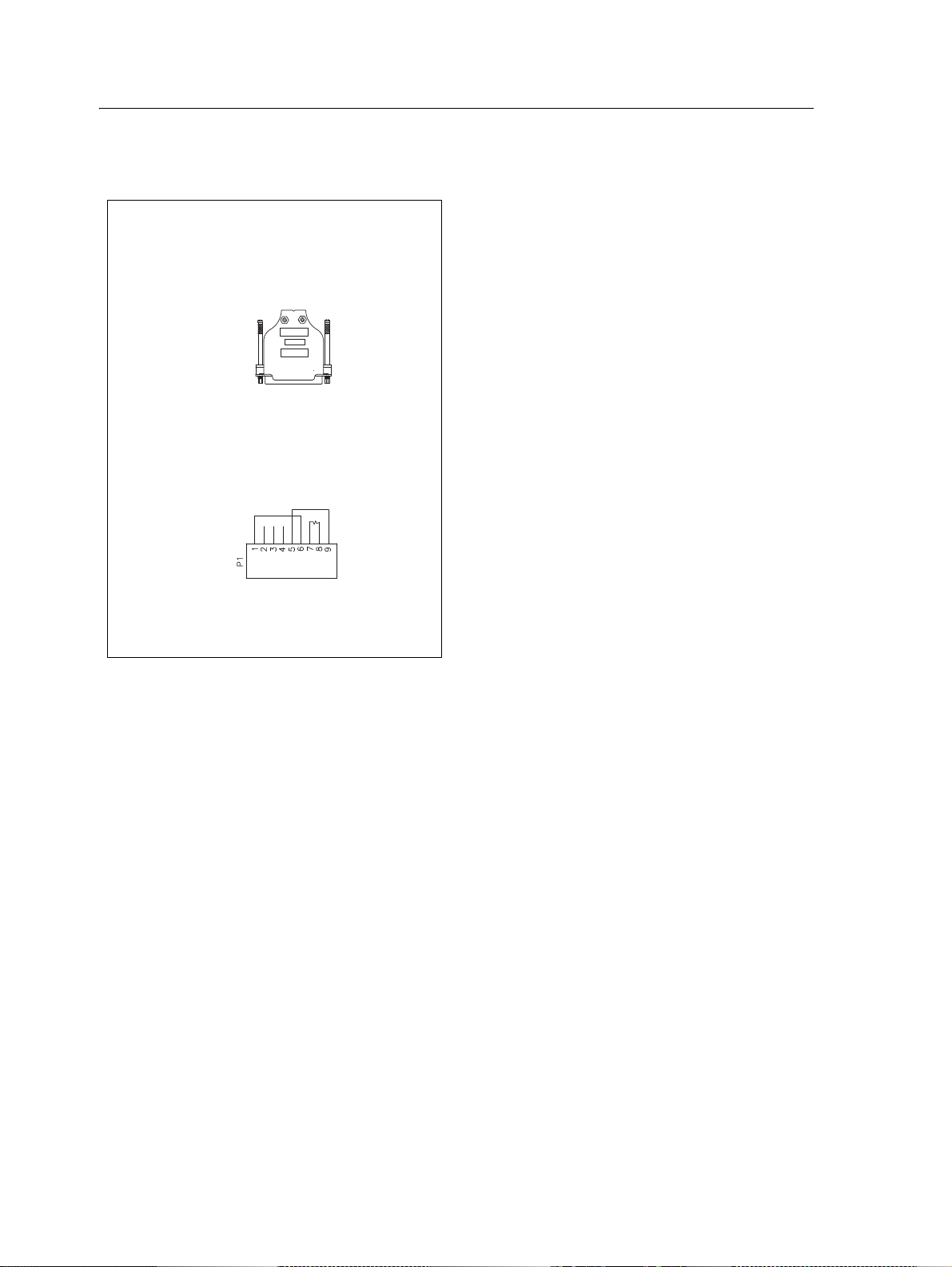

CAN communication issue when using cable P/N 62063

Cause

When you use cable P/N 62063 to connect an EZ-Boom system to an EZ-Guide 500

lightbar with an Autopilot

™

system, there is no CAN communication with the EZBoom system. This is because the CAN HI and CAN LO on cable P/N 62603 have been

swapped or there is not a CAN terminator connected to the EZ-Boom cable.

To identify whether there is CAN communication, check the color of the LED on the

EZ-Boom controller. If the LED lights up orange, there is no CAN communication: If

the LED lights up green, CAN communication has been established.

Solution

Replace cable P/N 62063 with the new cable configuration shown below.

Item Description P/N

11 S5 connector

12 CAN terminator 59783

14 S3 connector

15 P1 connector

16 EZ-Boom cable 61437

17 P3 connector

18 EZ-Boom controller

19 Autopilot to EZ-Guide 500 cable 62063

20 AgGPS Autopilot controller 66100-xx / 66200-xxtr>

21 EZ-Guide 500 lightbar 50449

EZ-Boom 2010 System Troubleshooting Guide 17

Page 18

1 EZ-Boom 2010 System Error Messages

Item Description P/N

22 GPS antenna cable

23 GPS antenna 57200-00

18 EZ-Boom 2010 System Troubleshooting Guide

Page 19

EZ-Boom 2010 System Error Messages 1

EZ-Boom system error message 4500: “Setup Invalid”

Cause

A critical EZ-Boom system error has occurred. This message appears at start-up and

every time the setup process is ended, if the configuration is invalid.

Possible failure modes

• One or more of the setup parameters are invalid.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message (page 13)

STEP 2: Check all setup parameters

FmX integrated

display

EZ-guide 500

lightbar

EZ-Guide Plus

lightbar

FieldManager

display

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Highlight the EZ-Boom plugin and then tap Setup.

c. Make sure that the EZ-Boom system settings are correct.

d. Highlight the Implement plugin and then tap Setup.

e. Make sure that the Implement system settings are correct.

a. From the main navigation screen, select "wrench icon". The

configuration menu appears.

b. Select Application Control. The Application Control screen

appears.

c. Make sure that the Application system settings are correct.

a. From the main navigation screen, select 7. The Setup menu

appears.

b. Select EZ-Boom. The EZ-Boom screen appears.

c. Make sure that the EZ-Boom system settings are correct.

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Highlight the EZ-Boom plugin and then tap Setup.

c. Make sure that the EZ-Boom system settings are correct.

d. Highlight the Implement plugin and then tap Setup.

e. Make sure that the Implement system settings are correct.

EZ-Boom 2010 System Troubleshooting Guide 19

Page 20

1 EZ-Boom 2010 System Error Messages

EZ-Boom system error message 4600: “Rate Not Responding”

Cause

A critical EZ-Boom system error has occurred. The difference between the actual flow

and the target flow has been greater than 30% for at least 6 seconds. This message

appears when the error first occurs and every second of continuous error after that

until it is corrected.

Possible failure modes

• The flow meter calibration number is incorrect.

• The target rate is outside the operating range of the spray nozzles.

• The target rate is outside the operating range of the solution pump.

• The target rate cannot be maintained because the sprayer speed is too low or

too high.

• The flow control valve setup is incorrect.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

B

B

STEP 1: Clear the error message (page 13)

STEP 2: Check the following setup parameters

a. Do a catch test to confirm that the flowmeter calibration number is

correct.

b. Check that the flow control valve setup is correct.

Tip – If your sprayer has a bypass servo, check that there is no crossover cable

connected to the flow control valve. On Raven systems, this cable is required

to allow the Raven flow controller to correctly adjust the valve. On an

EZ-Boom system, this cable is not required. If a crossover cable is not fitted but

the EZ-Boom system cannot properly control a bypass flow control valve, try

changing the control valve setup to Inline Servo.

c. Check that the target rate is within the operating parameters of the spray

nozzles at your spraying speed.

Tip – Refer to your spray nozzle selection chart for information relating to

flow and speed.

If necessary, do one of the following:

– change the spray nozzles

– adjust your target rate and/or speed to match the target rate to the

sprayer nozzles

20 EZ-Boom 2010 System Troubleshooting Guide

Page 21

EZ-Boom 2010 System Error Messages 1

d. Check that the solution pump is able to deliver the correct flow for your

specified target rate. If necessary, change the spray nozzles or adjust your

target rate and/or speed to bring the required flow to within the

capabilities of the solution pump.

Step 3: Check the strainers

Check that the strainers on the sprayer are not blocked.

EZ-Boom 2010 System Troubleshooting Guide 21

Page 22

1 EZ-Boom 2010 System Error Messages

EZ-Boom system error message xx01: “Boom Over Current”

Cause

A critical EZ-Boom system error has occurred. The boom is turned on and the current

feedback is greater than 5.3

every 10 seconds of continuous error after that until it is corrected.

Possible failure modes

• There is a faulty boom valve.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

Step 1: Clear the error message(page 13)

Step 2: Check the current to the EZ-Boom controller

a. With a multitester, check the current to the specified test pin of the 16-pin

connector on the EZ-Boom controller while the associated boom section is

turned on. For example, when diagnosing Error Message 4701, supply

power to pin 16, and Ground to pin 1 and then hook a multi-meter into the

circuit on pin 6.

A. This message appears when the error first occurs and

b. If the current is greater than 5.3 A, check the vehicle wiring and the boom

valve.

Error number Boom section Test p i n

4701 1 6

4801 2 2

4901 3 5

4A01 4 7

4B01 5 8

4C01 6 9

4D01 7 15

4E01 8 1

4F01 9 2

5001 10 3

Step 3: Check that pin 3 and pin 1 share a grounding point (page 13)

22 EZ-Boom 2010 System Troubleshooting Guide

Page 23

EZ-Boom 2010 System Error Messages 1

EZ-Boom system error message xx02: “Boom Driver Failure”

Cause

A critical EZ-Boom system error has occurred. The boom is turned off and the current

feedback is greater than approximately 2.0

first occurs and every 10 seconds of continuous error after that until it is corrected.

Possible failure modes

• There is a faulty boom valve or wiring harness.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the current to the EZ-Boom controller

a. With a multitester, check the current to the specified test pin of the 16-pin

connector on the EZ-Boom controller while the associated boom section is

turned on. For example, when diagnosing Error Message 4702, supply

power to pin 16, and Ground to pin 1 and then hook a multi-meter into the

circuit on pin 6.

A. This message appears when the error

b. If the current is greater than 2.0 A, check the vehicle wiring and the boom

valve.

Error number Boom section Test p i n

4702 1 6

4802 2 2

4902 3 5

4A02 4 7

4B02 5 8

4C02 6 9

4D02 7 15

4E02 8 1

4F02 9 2

5002 10 3

STEP 3: Check that pin 3 and pin 1 share a grounding point (page 13)

EZ-Boom 2010 System Troubleshooting Guide 23

Page 24

1 EZ-Boom 2010 System Error Messages

EZ-Boom system error message 5101: “Flow Valve Over Current”

Cause

A critical EZ-Boom system error has occurred. When the valve is being adjusted, the

current feedback is greater than approximately 4.0

error first occurs and every 10 seconds of continuous error after that until it is

corrected.

Possible failure modes

• There is a faulty control valve or wiring harness.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the flow control valve setup parameters (page 13)

A. This message appears when the

STEP 3: Check the current to the EZ-Boom controller

a. With a multitester, check the current to pins 3 and 4 of the 16-pin

connector on the EZ-Boom controller while the valve is being adjusted.

If checking at the EZ-Boom controller, supply power to pin 16 and Ground

to pin 1.

b. If the current is greater than approximately 4.0 A, check the vehicle wiring

and the control valve.

24 EZ-Boom 2010 System Troubleshooting Guide

Page 25

EZ-Boom 2010 System Error Messages 1

EZ-Boom system error message 5102: “Flow Valve Driver Failure”

Cause

A critical EZ-Boom system error has occurred. The valve is not being adjusted and the

current feedback is greater than approximately 2.0

error first occurs and every 10 seconds of continuous error after that until it is

corrected.

Possible failure modes

• There is a faulty flow control valve or wiring harness.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the flow control valve setup parameters (page 13)

A. This message appears when the

STEP 3: Check the current to the EZ-Boom controller

a. With a multitester, check the current to pins 3 and 4 of the 16-pin

connector on the EZ-Boom controller while the valve is not being adjusted.

b. If the current is greater than approximately 2.0 A, check the vehicle wiring

and the flow control valve.

EZ-Boom 2010 System Troubleshooting Guide 25

Page 26

1 EZ-Boom 2010 System Error Messages

EZ-Boom system error message 5103: “Flow Valve Open”

Cause

A critical EZ-Boom system error has occurred. There are two possible causes of this

error code:

• The driver part has a digital status feedback. The error is triggered when the

status indicates an error opening or closing.

• A count is kept for the digital status feedback of the driver part. When normal

operation occurs, the count decreases by 1. When an error occurs, the count

increases by 1. If the error count reaches 50, the device enters an error state and

the valve is no longer adjusted.

This message appears when the error first occurs and every 10 seconds of continuous

error after that until it is corrected.

Possible failure modes

• There is a faulty flow control valve or wiring harness.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the flow control valve setup parameters (page 13)

STEP 3: Turn the controller off and on again

If the error count has reached 50 and the device has entered a error state:

a. Turn the controller off.

b. Wait for 5 seconds.

c. Turn the controller on again. This will reset the error count to 0.

26 EZ-Boom 2010 System Troubleshooting Guide

Page 27

EZ-Boom 2010 System Error Messages 1

EZ-Boom system error message 5201: “Main Pressure Below Min”

Cause

A critical EZ-Boom system error has occurred. There are two possible causes of this

error message:

• The pressure is lower than -70 kPa.

• A pressure indication of < 0 psi occurred for a period of at least three seconds.

This message appears when the error first occurs and every 10 seconds of continuous

error after that until it is corrected.

Note – This error will only occur if the pressure sensor is enabled in the EZ-Boom system

setup.

Possible failure modes

• There is a faulty pressure sensor or wiring harness.

• The pressure sensor is not calibrated correctly.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the pressure setup parameters

FmX integrated

display

EZ-guide 500

lightbar

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Select the EZ-Boom plugin and then tap Calibrate.

c. Select Pressure Calibration and then tap Start.

d. Check that the pressure sensor is enabled and that the valve

settings are correct.

e. If necessary, re-calibrate the sensor.

a. On the display select the wrench icon. The Configuration

screen appears.

b. Select Application Control, select Pressure Calibration and

then select Calibrate Pressure Sensor.

c. Set Pressure Sensor State to On.

d. Ensure that the Slope value is correct and that the Set point

matches the charged system pressure gauge.

EZ-Boom 2010 System Troubleshooting Guide 27

Page 28

1 EZ-Boom 2010 System Error Messages

EZ-Guide Plus

lightbar

FieldManager

display

a. From the main navigation screen, select 7. The setup menu

appears.

b. Select EZ-Boom/Pressure Cal. The Pressure Cal screen appears.

c. Ensure that the sensor is enabled and the settings are correct.

d. If necessary, re-calibrate the sensor.

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Select the EZ-Boom plugin and then tap Calibrate.

c. Select Pressure Calibration and then tap Start.

d. Check that the pressure sensor is enabled and that the valve

settings are correct.

e. If necessary, re-calibrate the sensor.

Step 3: Check the wiring harness and the pressure sensor output

a. Check that the sensor is receiving 12 VDC from the EZ-Boom controller.

b. Check that the sensor is outputting 1 V–5 V.

28 EZ-Boom 2010 System Troubleshooting Guide

Page 29

EZ-Boom 2010 System Error Messages 1

EZ-Boom system error message 5202: “Main Pressure Above Max”

Cause

A critical EZ-Boom system error has occurred. There are two possible causes of this

error message:

• The pressure is lower than -70 kPa.

• The input voltage is greater than approximately 4.95 V for 3 seconds

continuously.

This message appears when the error first occurs and every 10 seconds of continuous

error after that until it is corrected.

Note – This fault will only appear if the pressure sensor is enabled in the EZ-Boom system

setup.

Possible failure modes

• There is a faulty pressure sensor or wiring harness.

• The pressure sensor is not calibrated correctly.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the pressure setup parameters

FmX integrated

display

EZ-guide 500

lightbar

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Select the EZ-Boom plugin and then tap Calibrate.

c. Select Pressure Calibration and then tap Start.

d. Check that the pressure sensor is enabled and that the valve

settings are correct.

e. If necessary, re-calibrate the sensor.

a. On the display select the wrench icon. The Configuration

screen appears.

b. Select Application Control, select Pressure Calibration and

then select Calibrate Pressure Sensor.

c. Set Pressure Sensor State to On.

d. Ensure that the Slope value is correct and that the Set point

matches the charged system pressure gauge.

EZ-Boom 2010 System Troubleshooting Guide 29

Page 30

1 EZ-Boom 2010 System Error Messages

EZ-Guide Plus

lightbar

FieldManager

display

a. From the main navigation screen, select 7. The setup menu

appears.

b. Select EZ-Boom/Pressure Cal. The Pressure Cal screen appears.

c. Ensure that the sensor is enabled and the settings are correct.

d. If necessary, re-calibrate the sensor.

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Select the EZ-Boom plugin and then tap Calibrate.

c. Select Pressure Calibration and then tap Start.

d. Check that the pressure sensor is enabled and that the valve

settings are correct.

e. If necessary, re-calibrate the sensor.

Step 3: Check the wiring harness and the pressure sensor output

a. Check that the sensor is receiving 12 VDC from the EZ-Boom controller.

b. Check that the sensor is outputting 1 V–5 V.

30 EZ-Boom 2010 System Troubleshooting Guide

Page 31

EZ-Boom 2010 System Error Messages 1

EZ-Boom system error message 6B00: “Minimum Flow”

Cause

A critical EZ-Boom system error has occurred. This error message appears when the

actual flow is less than the Minimum Flow setting (scaled for the current swath) and

the target flow is less than the actual flow:

This message appears when the error first occurs and every second of continuous error

after that until it is corrected.

Possible failure modes

• There is a faulty flow meter or wiring harness.

• The sprayer is traveling so slowly that the target rate cannot be maintained

unless the flow drops below the Minimum Flow setting.

• The Minimum Flow setting is too high.

Note – If this is only an occasional problem, use the display to clear the controller error

and continue to operate.

Solution

STEP 1: Clear the error message(page 13)

STEP 2: Check the Minimum Flow setting

FmX integrated

display

EZ-guide 500

lightbar

EZ-Guide Plus

lightbar

FieldManager

display

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Select the EZ-Boom plugin and then tap Calibrate.

c. Select Flow Calibration and then tap Start.

d. Make sure that the value in the Min Flow field is appropriate

(not too high).

a. On the display select the wrench icon. The Configuration

screen appears.

b. Select Application Control and then select Application Setup.

c. Make sure that the value in the Min Flow field is appropriate

(not too high).

a. From the main navigation screen, select 7. The setup menu

appears.

b. Select EZ-Boom/Application. The Application Setup screen

appears.

c. Ensure that the Min Flow setting is appropriate (not too

high).

a. On the display, press the Configuration button. The

Configuration screen appears.

b. Select the EZ-Boom plugin and then tap Calibrate.

c. Select Flow Calibration and then tap Start.

d. Make sure that the value in the Min Flow field is appropriate

(not too high).

EZ-Boom 2010 System Troubleshooting Guide 31

Page 32

1 EZ-Boom 2010 System Error Messages

Step 3: Check the liquid flow

FmX integrated

display

EZ-guide 500

lightbar

EZ-Guide Plus

lightbar

FieldManager

display

a. Check the output from the flow meter when liquid is flowing

through the sprayer. To do this, perform a flow calibration:

b. On the display, press the Configuration button. The

Configuration screen appears.

c. Select the EZ-Boom plugin and then tap Calibrate. The

Implement Calibration screen appears.

d. Select Flow Calibration. The EZ-Boom Flow Calibration screen

appears.

e. Tap the Recalibrate button to run the flow calibration

sequence.

f. Follow the onscreen instructions or refer to the AgGPS

FieldManager Display User Guide version 2.00.

a. On the display, select the wrench icon. The Configuration

screen appears.

b. Select Application Control and then select the Flow

Calibration wizard.

c. Select Calibrate Now to begin calibration.

Check the output from the flow meter when liquid is flowing

through the sprayer. To do this, perform a flow calibration:

a. From the main navigation screen, select 7. The setup menu

appears.

b. Select EZ-Boom/Flow Calibration. The Flow Calibration screen

appears.

c. Press until you have selected Calibrate.

d. Press to run the flow calibration sequence.

a. Check the output from the flow meter when liquid is flowing

through the sprayer. To do this, perform a flow calibration:

b. On the display, press the Configuration button. The

Configuration screen appears.

c. Select the EZ-Boom plugin and then tap Calibrate. The

Implement Calibration screen appears.

d. Select Flow Calibration. The EZ-Boom Flow Calibration screen

appears.

e. Tap the Recalibrate button to run the flow calibration

sequence.

f. Follow the onscreen instructions or refer to the AgGPS

FieldManager Display User Guide version 2.00.

Step 4: Check the wiring harness and flow meter output

Check that the flow meter is being supplied the correct voltage from the

EZ-Boom controller.

32 EZ-Boom 2010 System Troubleshooting Guide

Page 33

EZ-Boom 2010 System Error Messages 1

Operating the Rate Increment/Decrement switch

Description

Setting the amount by which the current application rate (Rate 1 or Rate 2) increases

and decreases each time you press the Rate Adjustment (increase/decrease) switch.

Summary

If you use the pre-selected target rates (Rate 1 or Rate 2), toggle the switch every time

that you want to increase or decrease the rate. When the system is in manual mode,

you can hold the switch in the upward position-the application will continue to

increase automatically. Release the switch when you reach the required rate.

Solution

The Increment/Decrement switch depends on the setting of the Rate switch: Rate 1,

Rate 2, or Manual mode.

Note – The way that the switch works depends on the display you are using.

EZ-Guide Plus lightbar: Rate 1 or Rate 2

Set the Step value in the Application Setup screen.

• To increase the flow by that step value, press the

Increment/Decrement switch up.

• To decrease the flow by that step value, press the

switch down.

If you hold the switch up or down, the flow increases or decreases by only one step. To

increase or decrease by another step, you must release the switch and then press it

again.

EZ-Guide 500 system: Rate 1 or Rate 2

Set the Rate Increment value in

the Application Setup screen.

• To increase the flow by

that step value, press the

Increment/Decrement

switch up.

• To decrease the flow by

that step value, press the

switch down.

If you hold the switch up or down, the flow increases or decreases by only one step. To

increase or decrease by another step, you must release the switch and then press it

again.

EZ-Boom 2010 System Troubleshooting Guide 33

Page 34

1 EZ-Boom 2010 System Error Messages

FieldManager display: Rate 1 or Rate 2

Set the Rate Increment value in

the EZ-Boom Setup screen.

• To increase or decrease

the flow by the rate increment value, enter the required value into the

appropriate field.

If you hold the switch up or down, the flow increases or decreases by only one step. To

increase or decrease by another step, you must release the switch and then press it

again.

Manual mode

The Increment/Decrement switch adjusts the rate control valve while you hold the

switch up or down.

• When you hold the switch in the Increment position (up), the rate control valve

opens until it is fully open or until you release the switch.

• When you hold the switch in the Decrement position (down), the rate control

valve closes until it is fully closed or until you release the switch.

34 EZ-Boom 2010 System Troubleshooting Guide

Page 35

Spray booms do not turn on in a corner

Cause

The sprayer has no ground speed.

Solution

Use the manual-rate-from-stationary mode to spray the corners of fields. This ensures

maximum spray coverage of your field, while minimizing repeat coverage.

1. Drive around the corner while spraying. An area of land is missed.

2. Once you pass the corner and straighten up, stop the vehicle.

EZ-Boom 2010 System Error Messages 1

3. Use the master switch to turn off the EZ-Boom controller.

4. Reverse the vehicle until the spray boom is at the field boundary ( for example,

the fence).

5. Adjust the EZ-Boom controller switches:

a. Set the rate switch to manual mode (M).

b. Turn on the master switch.

Because the vehicle is starting from a stationary position, automated boom

switching is disabled.

Note – Once the boom sections are open, you may need to adjust the flow rate with the rate

adjustment Inc/Dec switch.

EZ-Boom 2010 System Troubleshooting Guide 35

Page 36

1 EZ-Boom 2010 System Error Messages

6. Begin driving. As soon as the vehicle begins moving, set the rate switch back to

one of the automated spray modes (Rate 1 or Rate 2). This re-enables automated

boom switching. Any boom sections that are re-covering an area that was

previously sprayed will turn off.

7. Continue driving the field as before.

36 EZ-Boom 2010 System Troubleshooting Guide

Page 37

EZ-Boom 2010 System Error Messages 1

The system shuts off when GPS signal is lost

Cause

The system no longer has a vehicle speed input, which the EZ-Boom controller needs

to calculate the GPS position and the spray rate.

Solution

To continue spraying if the GPS signal is lost, switch to manual rate control mode (the

M position), which does not require vehicle speed input. However, the EZ-Boom

controller cannot then calculate an automatic spray rate or adjust the spray rate if the

vehicle speed increases or decreases.

For more information, see System behavior following loss of GPS below.

Note – When in manual mode, use the vehicle speedometer and system pressure gauges to

maintain the correct spray volume.

Rate control and the loss of GPS

To determine a spray rate, you need the following information:

• Sprayer speed (mph)

• Sprayer boom width (inches)

• Flow of spray (Gallons per minute)

Boom control and the loss of GPS

Position information is lost when GPS is lost. Without position information, the

EZ-Boom 2010 system cannot determine the location of the spray boom and so cannot

detect previously-sprayed areas in order to control individual boom sections.

If the system is in the Auto Rate 1 or Auto Rate 2 mode, the loss of GPS turns off all the

boom sections. Switch the rate control to manual mode to turn on the boom sections

and continue to spray.

While the EZ-Boom 2010 system is without a valid GPS position, mapping or coverage

logging is disabled.

System behavior following loss of GPS

System Behavior

EZ-Guide Plus The system uses "dead reckoning" for five seconds; the speed and heading are

assumed to remain the same. After five seconds, if the rate control is in Rate 1 or

Rate 2, the EZ-Guide Plus lightbar turns off the boom sections.

EZ-Guide 500 The display immediately turns off all boom sections.

FieldManager The display immediately turns off all boom sections.

FmX The display immediately turns off all boom sections.

EZ-Boom 2010 System Troubleshooting Guide 37

Page 38

1 EZ-Boom 2010 System Error Messages

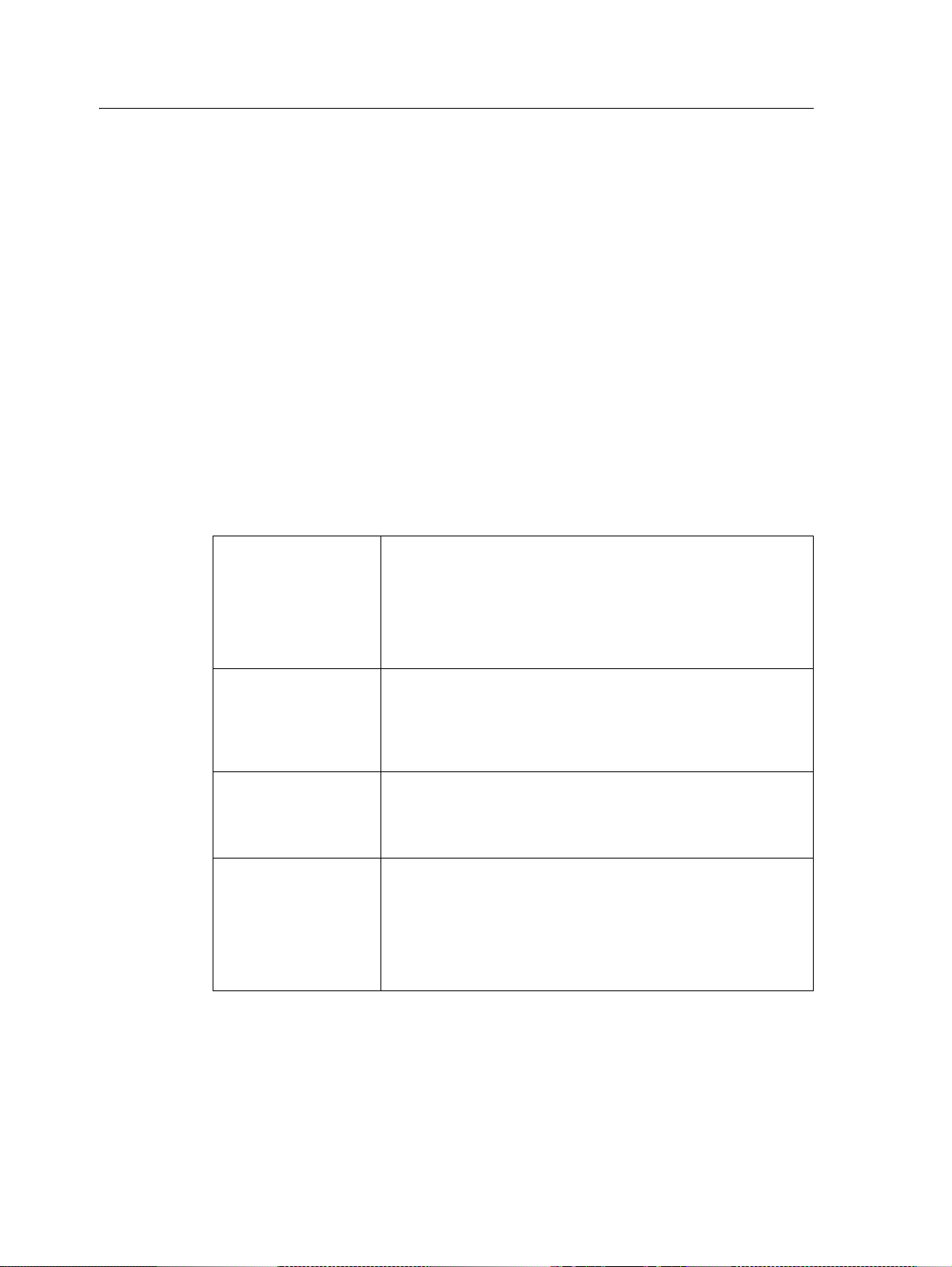

Boom sections do not turn on

Cause

Boom sections do not receive a signal voltage to open.

Solution

Check the state of the boom section on the display.

LED color The section is...

Red Off.

Green On.

Sending power to the boom valves.

Yel low

or

Grey

Looking for a non-covered area.

No power is supplied to the boom valves.

or

Looking for flow.

Sending power to the boom valves.

Waiting to see flow.

Check the system setting:

1. Turn off the Rate Control.

2. Set the Off When Stopped option to Yes.

3. Move the EZ-Boom rate switch to Rate 1 or Rate 2 and then to Manual.

The system should turn boom section LEDs to green and send power to turn on

the boom valves.

4. Do one of the following:

–If the section LEDs do not turn green, check if there is a cable plugged into

the 14-pin connector. If there is, unplug this connector and see if all

sections then turn green.

–If the section LEDs do turn green, look for a missing implement plug or

implement switch.

38 EZ-Boom 2010 System Troubleshooting Guide

Page 39

EZ-Boom 2010 System Error Messages 1

Rate not responding and Min Flow reached

Cause

The system is a the minimum flow setting and cannot adjust the rate any lower.

Solution

Set Min Flow to the lowest possible rate for the control valve and flow meter.

EZ-Boom 2010 System Troubleshooting Guide 39

Page 40

1 EZ-Boom 2010 System Error Messages

Not reading any Applied Rate "With supported flow meter"

Cause

No signal from the flow meter.

Solution

1. Check the flow meter power, signal, and ground wiring:

– Depending on the flow meter, the power wire may have 5 V or 12 V.

– The signal wire should have 5 V.

– The ground wire should show good continuity to ground “under 1 ohm".

2. Check for good continuity on the signal wire from the flow meter back to pin 13

on the harness going to the 16-pin connector on the EZ-Boom controller.

3. If the wires are satisfactory, check for a Hz reading on the EZ-Boom pin 13. You

will need to back-probe the wire to do this test.

– If there is a Hz reading, reinstall the EZ-Boom and display firmware. If that

does not resolve the issue, try a different EZ-Boom controller.

– If there is no Hz reading, try a different flow meter.

40 EZ-Boom 2010 System Troubleshooting Guide

Page 41

Incorrect tank volume message

Cause

Amount that is applied does not match tank volume.

Possible failure modes

• The system reports that there are X number of gallons left, but the tank is empty.

• The system reports that the tank is empty but there are still X number of gallons

left.

Solution

1. Perform a catch test to make sure that the system is outputting the correct

amount for the sprayer tips.

2. If the system is incorrect by a small amount, increase the Cal number slightly to

output more or decrease the Cal number slightly to output less.

Note – The tank volume markings may not be exact; change the Cal number by only a

small amount because it affects how much is being sprayed.

EZ-Boom 2010 System Error Messages 1

EZ-Boom 2010 System Troubleshooting Guide 41

Page 42

1 EZ-Boom 2010 System Error Messages

Pressure stays at Set limit on Pressure sensor Cal.

Cause

No change in voltage from the pressure sensor.

Solution

Do one or more of the following:

• Make sure that the pressure changes at the pressure sensor.

• Make sure that the correct sensor (Aux or Main) is calibrated.

• Make sure the slope value is set correctly: 27 mV/PSI for Trimble implements.

• Check for power, ground, and signal voltage at the pressure sensor. Power goes

into the pressure sensor and then the signal voltage out should change when PSI

changes. Back-probe the signal wire and then vary the pressure to make sure

that the signal voltage changes.

• If the signal voltage does not vary with pressure change, replace the pressure

sensor.

• If the signal voltage does vary with pressure change, check continuity from the

signal wire out at the pressure sensor to the 14-pin connector on the EZ-Boom

controller. Main pressure sensor is pin 10; Aux pressure sensor is pin 6.

• If continuity is satisfactory, reinstall the EZ-Boom and display firmware. If that

does not resolve the issue, try a different EZ-Boom controller.

42 EZ-Boom 2010 System Troubleshooting Guide

Page 43

EZ-Boom 2010 System Error Messages 1

Boom section 1 on an SPX sprayer does not turn on

Cause

There may be a diode molded in the connector on the sprayer.

Solution

Check continuity on pin 6 of the 16-pin connector going into to the back of the

EZ-Boom controller to the boom section 1 signal wire.

If there is a diode in the system, you see continuity with the leads one way and when

you reverse them, you see an open.

In this case, use a Y-harness to jump pin 6 on the Y-harness to pin 6 on the sprayer

harness.

If you see an open with the leads both ways, look for broken wiring from the EZ-Boom

controller out to the number 1 boom valve.

EZ-Boom 2010 System Troubleshooting Guide 43

Page 44

1 EZ-Boom 2010 System Error Messages

“Rate not responding” message

Cause

Applied rate is unable to reach the Target Rate.

Possible failure modes

Message appears when speeding up or slowing down.

Solution

1. Check the following:

–The tips in use

–Tip spacing

– Required target rate

– Require running speed

2. Check the sprayer tip chart to make sure that the tips can run that speed.

3. Do one of the following:

– If the tips cannot run at that speed, change the tips.

– If the tips can output the required rate at that speed but the message still

appears, perform a catch test to double-check the flow calibration number.

44 EZ-Boom 2010 System Troubleshooting Guide

Page 45

Rate fluctuates around the Target Rate.

Cause

The control valve is either responding too quickly and overshooting the target rate, or

moving too slowly and drifting away from the target rate.

Possible failure modes

Incorrect settings for Response 1, Response 2, or Threshold.

Solution

Do one of the following:

• If the EZ-Boom system is not controlling rate, check and adjust as necessary the

other rate controller settings.

• If the EZ-Boom system is controlling rate, check and adjust as necessary the

Response 1, Response 2, and Threshold values.

– Response 1 shows the response speed for the control valve once the Target

rate goes beyond the threshold value.

EZ-Boom 2010 System Error Messages 1

– Response 2 shows the response speed for the control valve when within the

threshold.

– Threshold shows the distance allowed from the Target rate before

switching from Response 2 to Response 1.

For a faster control valve response speed, set a higher number.

For a slower response speed, set a lower number.

Note – Trimble does not average the application rate so there will be more fluctuations.

EZ-Boom 2010 System Troubleshooting Guide 45

Page 46

1 EZ-Boom 2010 System Error Messages

Flow Control Valve Error Driver Failure (-1 mA) Fault

Cause

Probably a poor electrical system ground.

Solution

Do one or more of the following:

• Check the EZ-Boom ground wiring. Jump a separate ground wire into pin 1 of

the 16-pin connector on the back of the EZ-Boom controller.

• Check that the continuity of the cabling from the EZ-Boom controller to the

control valve is less than 1

• Repeat the tests on another EZ-Boom controller and/or control valve.

ohm.

46 EZ-Boom 2010 System Troubleshooting Guide

Page 47

Control Valve in headland fault

Cause

The control valve shuts completely when Close on zero flow is set to Yes, or the master

switch is turned off.

Possible failure modes

The Control Valve closes when you enter a headland and then takes a long time to

build pressure when you leave the headland.

Solution

Do one or more of the following:

• Make sure that Close on Zero Flow is set to No.

• Make sure that the master switch stays turned on and is not turned off when

you enter a headland.

• If there is section overlap when you go into or come out of the headland, the

flow rate may be too low for the control valve. Enter a minimum flow value to

keep the valve open.

EZ-Boom 2010 System Error Messages 1

EZ-Boom 2010 System Troubleshooting Guide 47

Page 48

1 EZ-Boom 2010 System Error Messages

Sections not mapping when EZ-Boom controller is controlling sections only

Cause

Rate control is set to On and is looking for a flow meter signal to start mapping, but

there is no flow meter signal available when doing section control.

Possible failure modes

Section LEDs turn from red to yellow/grey on the display but do not map.

Solution

Turn off the Rate Control.

48 EZ-Boom 2010 System Troubleshooting Guide

Page 49

Boom sections do not turn off

Cause

If either the Master switch or the Aux-Master switch is turned on, the sections stay on.