Page 1

Quality Refrigeration

OWNER’S MANUAL

Instructions for the installation, operation

and maintenance of Traulsen:

TU Series Full-Size Undercounter Refrigerators

TU044HT, TU072HT & TU100HT

TU Series Full-Size Undercounter Freezers

TU044LT & TU072LT

This Traulsen unit is built to our highest quality standards. We build our refrigerators and freezers this way as a matter of

pride. This philosophy has made Traulsen the leader in commercial refrigeration since 1938. We thank you for your choice

and condence in Traulsen equipment and we know you will receive many years of utility from this equipment.

All Traulsen units are placed on a permanent record le with the service department. In the event of any future questions you may have, please refer to the model and serial number found on the name tag axed to the unit. Should

you need service, call us on our toll free number, 800-825-8220 between 7:30 am - 4:30 pm CST, Monday thru Friday.

You may also log onto www.traulsen.com for further information. It is our pleasure to help and assist you in every

possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

FORM NUMBER TR35745 REV. 1/08 P/N 375-60297-00

Page 2

TABLE OF CONTENTS

I. THE SERIAL TAG Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION

a-Location Page 2

b-Packaging Page 2

c-Adjusting the Casters Page 2

d-Cord & Plug Page 2

e-Power Supply Page 2

IV. OPERATION

a-Refrigerators Page 3

b-Freezers Page 3

V. CARE & MAINTENANCE

a-Cleaning The Condenser/Filter Page 3

b-Replacing The Gaskets Page 4

c-Cleaning The Cabinet Surface Page 4

VI. DRAWERS

a-Removing The Door And Installing Drawers Page 4

VII. MICROPROCESSOR CONTROL

a-Control Features Page 5

b-Alarm Explanations Page 6

c-Control Panel Diagram Page 7

d-Notes To The User Page 7

e-Enter The Service Access Page 8

f-Service Parameters Page 9

g-Adjusting Thermostat Set Point High Page 9

h-Adjusting Thermostat Set Point Low Page 10

i-Changing The Temperature Scale Page 10

j-Setting The 24-Hour Clock Page 11

k-Setting The Date Page 12

l-Setting Daylight Savings Time Page 12

m-Starting A Manual Defrost Page 13

n-Setting Defrost Lockouts Page 14

o-Adjusting The Drawer Perimeter Heaters Page 15

p-Adjusting The Room Temperature Oset Page 15

q-Setting The Audible Alarm Style Page 16

r-Viewing Sensor Temperatures Page 16

VIII. WIRING DIAGRAM Page 17

IX. TROUBLE SHOOTING GUIDE Page 18

X. SERVICE ASSISTANCE

a-Service Information Page 19

b-Spare Parts Information Page 19

c-Warranty Registration Page 19

XI. WARRANTIES Page 20

XII. SERVICE PARTS LIST Page 21

FORT WORTH, TX.

SERIAL MODEL

VOLTS Hz PH

TOTAL CURRENT AMPS

MINIMUM CIRCUIT AMPS

MAXIMUM OVERCURRENT PROTECTION AMPS

LIGHTS WATTS

HEATERS AMPS

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

370-60294-00 REV (A)

I. THE SERIAL TAG

The serial tag is a permanently axed label on which

is recorded vital electrical and refrigeration data about

your Traulsen product, as well as the model and serial

number. This tag is located in the right interior compartment on all standard full-size undercounter models.

READING THE SERIAL TAG

• Serial = The permanent ID# of your Traulsen unit

• Model = The model # of your Traulsen unit

• Volts = Voltage

• Hz = Cycle

• PH = Phase

• Total Current = Maximum amp draw

• Minimum Circuit = Minimum circuit ampacity

• Lights = Light wattage

• Heaters = Heater amperage (Hot Food units only)

• Refrigerant = Refrigerant type used

• Design Pressure = High & low side operating

pressures and refrigerant charge

• Agency Labels = Designates agency listings

-1-

Page 3

II. RECEIPT INSPECTION

III. INSTALLATION (continued)

All Traulsen products are factory tested for performance

and are free from defects when shipped. The utmost care

has been taken in crating this product to protect against

damage in transit.

You should carefully inspect your unit for damage during

delivery. If damage is detected, you should save all the

crating materials and make note on the carrier’s Bill Of Lading describing the damage. A freight claim should be led

immediately. If damage is subsequently noted during or

immediately after installation, contact our customer care

team to le a freight claim. There is a fteen (15) day limit

to le freight damage with the carrier. Under no condition

may a damaged unit be returned to Traulsen without rst

obtaining written permission (return authorization). You

may contact Hobart/Traulsen customer care at 800-333-

7447 to request a return or le a claim.

III. INSTALLATION

III. a - LOCATION:

Select a proper location for your unit, away from extreme

heat or cold. Allow enough clearance between the unit

and the side wall in order to make use of the door stay

open feature at 1200 (self-closing feature operates up to

900). The door(s) must be able to open a minimum of 900

in order to make use of the maximum clear door width.

III. b - PACKAGING:

Your Traulsen unit is shipped from the factory bolted to a

sturdy wooden pallet in stretch wrapped material.

Most exterior stainless steel surfaces have a protective

vinyl covering to prevent scratching during manufacturing, shipping and installation. After the unit is installed in

place of application peel, remove and discard the covering

from all surfaces.

To remove the wooden pallet, rst if at all possible, we

suggest that the cabinet remain bolted to the pallet during all transportation to the point of nal installation. The

bolts can then be removed with a 1/2” socket wrench.

Avoid laying the unit on its front, side or back for removal

of the pallet.

NOTE: Traulsen does not recommend laying the unit

on its front, side or back. If you must, please allow the

unit to remain in an upright position for 24 hours before

plugging it in so that the compressor oils and refrigerant

may settle.

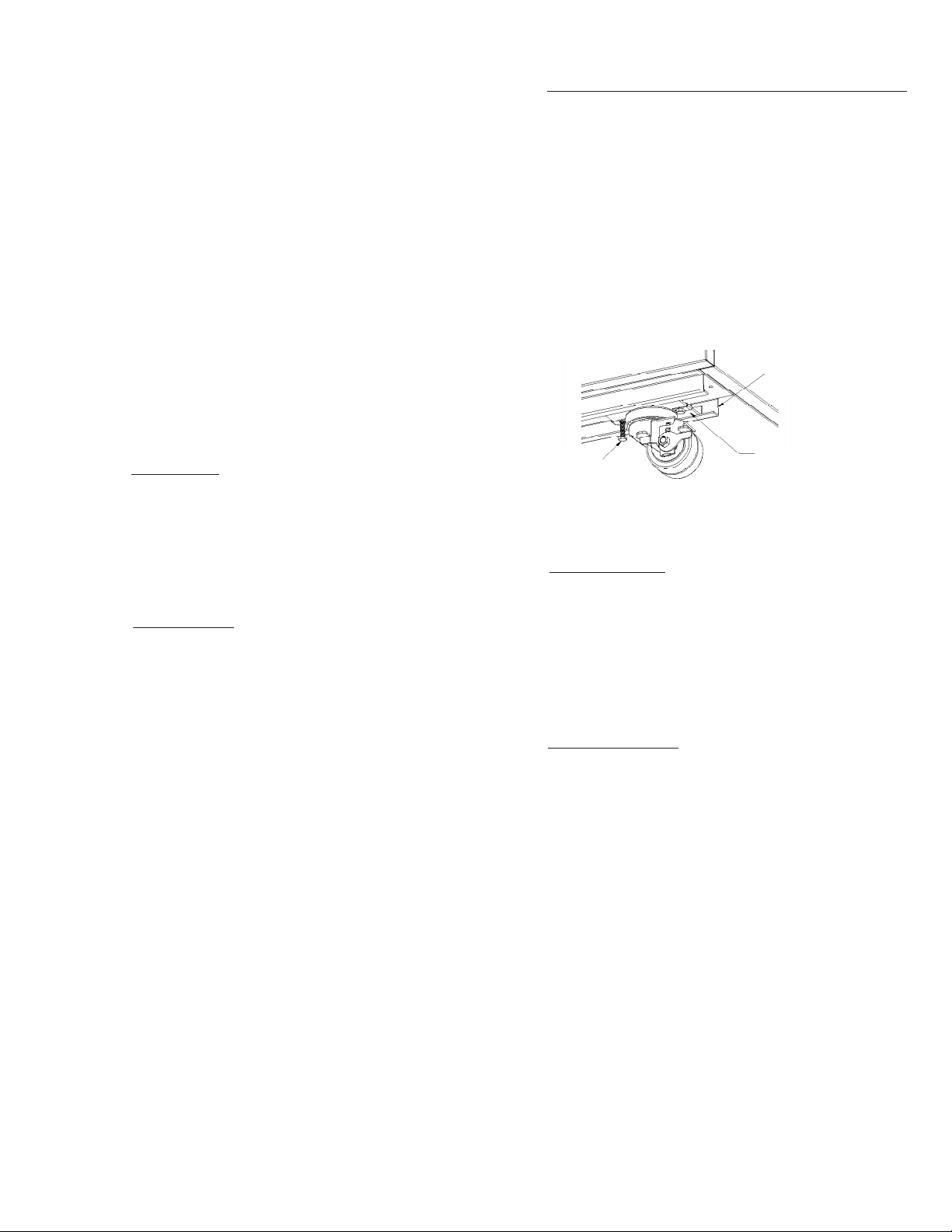

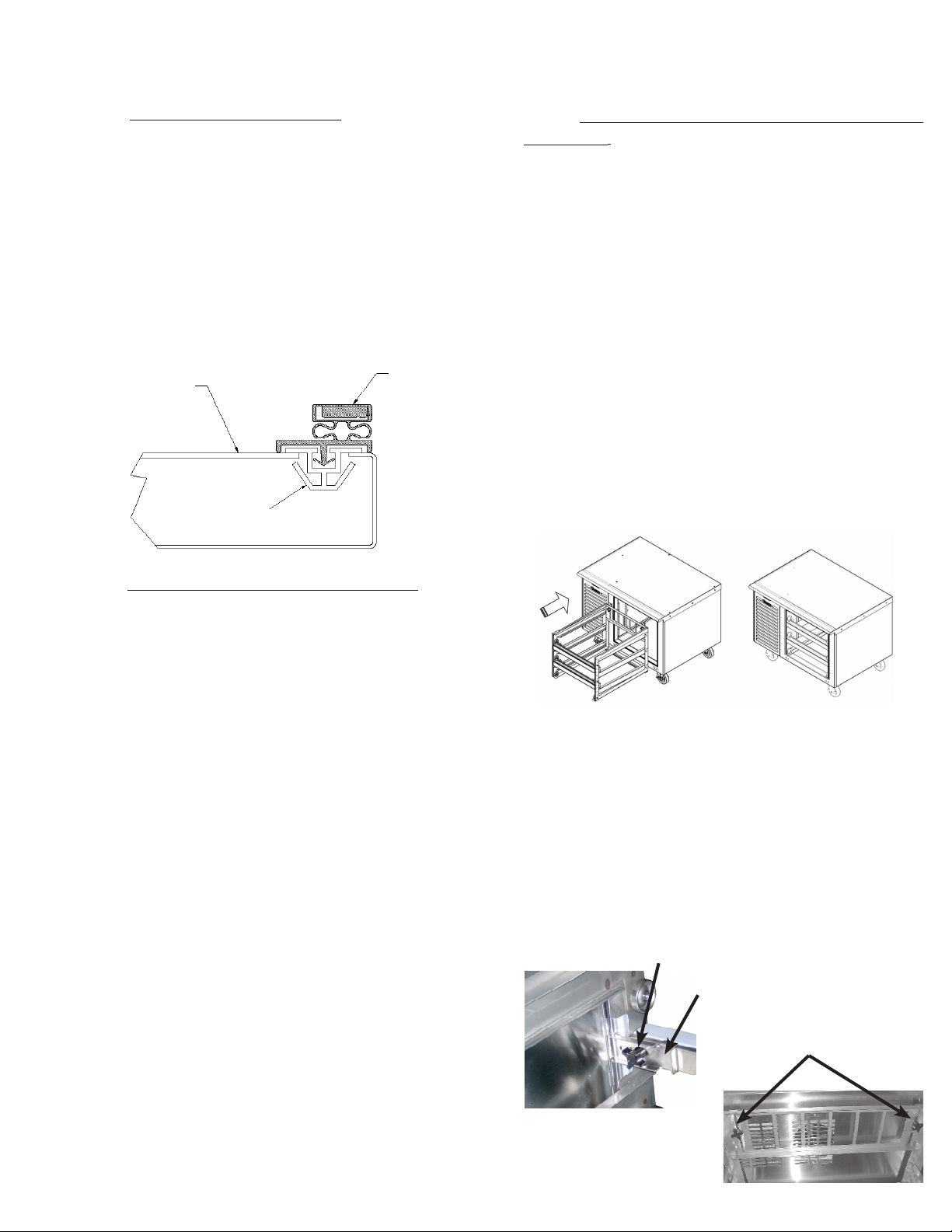

III. c - INSTALLING/ADJUSTING LEGS OR CASTERS:

To install legs or casters, slide leg or caster into the caster

channel from the side of the unit without the refrigeration

system.

To adjust the legs or casters, loosen the two bolts and move

leg or caster to desired location, spacing between leg or caster

not to exceed 48 inches. Leg or caster on each end of the unit

can not exceed 8 inches from the end of the cabinet.

NOTE: Traulsen recommends to position legs or casters under

the mullion when possible.

CASTER CHANNEL

BOLT

CASTER PLATE

III. d - CORD & PLUG:

All self-contained models are shipped standard with a NEMA

5-15P plug and 9 foot cord . Select only a dedicated electrical

outlet for power source.

NOTE: Do not under any circumstances, cut or remove the

round grounding prong from the plug, or use an extension

cord.

III. e - POWER SUPPLY:

The supply voltage should be checked prior to connection to

be certain that proper voltage for the cabinet wiring is available

(refer to the serial tag to determine correct unit voltage, see

page 1). Make connections in accordance with local electrical

codes. Use qualied electricians.

Use of a separate, dedicated circuit is required. Size wiring

to handle indicated load and provide necessary overcurrent

protector in circuit (see amperage requirements on the unit’s

serial tag).

-2-

Page 4

IV. OPERATION

V. CARE & MAINTENANCE

IV. a - REFRIGERATORS:

Both refrigerators and Freezers do not require manual

defrosting. During normal operation, a refrigerator continuously circulates above freezing cabinet air through the

coil. A compressor “OFF” cycle occurs every 2 1/2 Hours

for 20 minutes to melt any frost which may accumulate

on the coil during the compressor “ON” cycle. The control

will read “dEF” and the green water drop will be illuminated. With standard holding refrigerators, high relative

humidity is also maintained to prevent dehydration of

stored product.

INTELA-TRAUL

°F °C

FREEZER

SET

IV. b - FREEZERS:

During normal operation, a freezer continuously circulates below freezing cabinet air through the coil. The

coil requires a periodic defrosting for proper operation.

This is accomplished by an automatic, time activated,

temperature/time terminated, defrost program, utilizing

hot gas from the refrigeration system. The controller is

preset at the factory for six equally spaced defrost cycles

within each 24-hour period.

IV. b - FREEZERS (continued):

During freezer defrost operation, heat is conned to the

coil enclosure to prevent any signicant rise in temperature within the food zone. The fan delay control function

upon termination of a defrost cycle is two-fold. First, to

prevent blowing warm air into the food storage area.

Second, to prevent any condensation on the defrost coil

from being blown into the food storage area.

The microprocessor control is set from the factory to terminated defrost at 20 minutes in the event of sensor failure.

This setting should never be tampered with, without rst

consulting Traulsen’s Technical Service department.

V. a - CLEANING THE CONDENSER/FILTER:

The most important thing you can do to insure a long,

reliable service life for your Traulsen is to regularly clean

the condenser coil and or lter if provided.

The microprocessor control will notify you through a

“CLN-FIL” message when the condensing temperature of

the refrigerator reaches 140 degrees F or greater. If the

condensing temperature reaches 160 degrees F the compressor will automatically turn o . When the temperature

drops below 140 degrees F the compressor will restart

and when the temperature drops below 120 degrees F

the alarm will reset.

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY

BEFORE CLEANING ANY PARTS OF THE UNIT.

At the start of a freezer defrost cycle, the compressor,

condenser fan and evaporator fan shut o. The hot gas

relay will be energized, this will energize the hot gas

solenoid valve thru the normally open contacts and the

condenser fan circuit will be de-energized thru the (normally closed contacts), and the compressor will restart.

When the evaporator coil sensor reaches 400 F the coil is

fully defrosted or if the maximum time of defrost duration (20 minutes) is reached (which ever comes rst) then

the defrost hot gas relay is de-energized. The condenser

fan restarts and the hot gas solenoid valve closes, The

compressor system returns to the cooling mode. Total

refrigeration system operation is then resumed (green

snowake icon goes out) and the display will show def

for an additional 10 minutes then return to reading the

inside cabinet temperature. The evaporator fan(s) are

delayed from starting at the termination of the defrost

cycle and will automatically resume by time or temp delay

(5 minutes or 300 F coil sensor temperature, whichever

comes rst ).

To clean the condenser/lter, rst disconnect electrical

power to the cabinet and remove the front louver assembly. To do so, place hands under the louver panel and

pull out and up to get louver panel o bracket of the unit.

See diagram below.

Proceed to vacuum or brush any dirt, lint or dust from

the nned condenser coil/lter, the compressor and other

cooling system parts. If signicant dirt is clogging the condenser ns or lter, use compressed air to blow this clear.

To replace the louver assembly reverse the process.

-3-

Page 5

V. CARE & MAINTENANCE-(continued) VI. DRAWERS

V. b - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it rmly by one

corner and pull it out. Before attempting to install a new

gasket, both the unit and the gasket itself must be at room

temperature. Insert the four corners rst by using a rubber

mallet (or hammer with a block of wood). After the corners

are properly inserted, work your way towards the center from

both ends by gently hitting with a mallet until the gasket

is completely seated in place (see gure below for proper

gasket placement).

NOTE: The gasket may appear too large, but if it is installed

as indicated above it will slip into place.

GASKET ASSEMBLY

SIDE DOOR PANEL

VERTICAL GASKET

RETAINER

Fig. 5

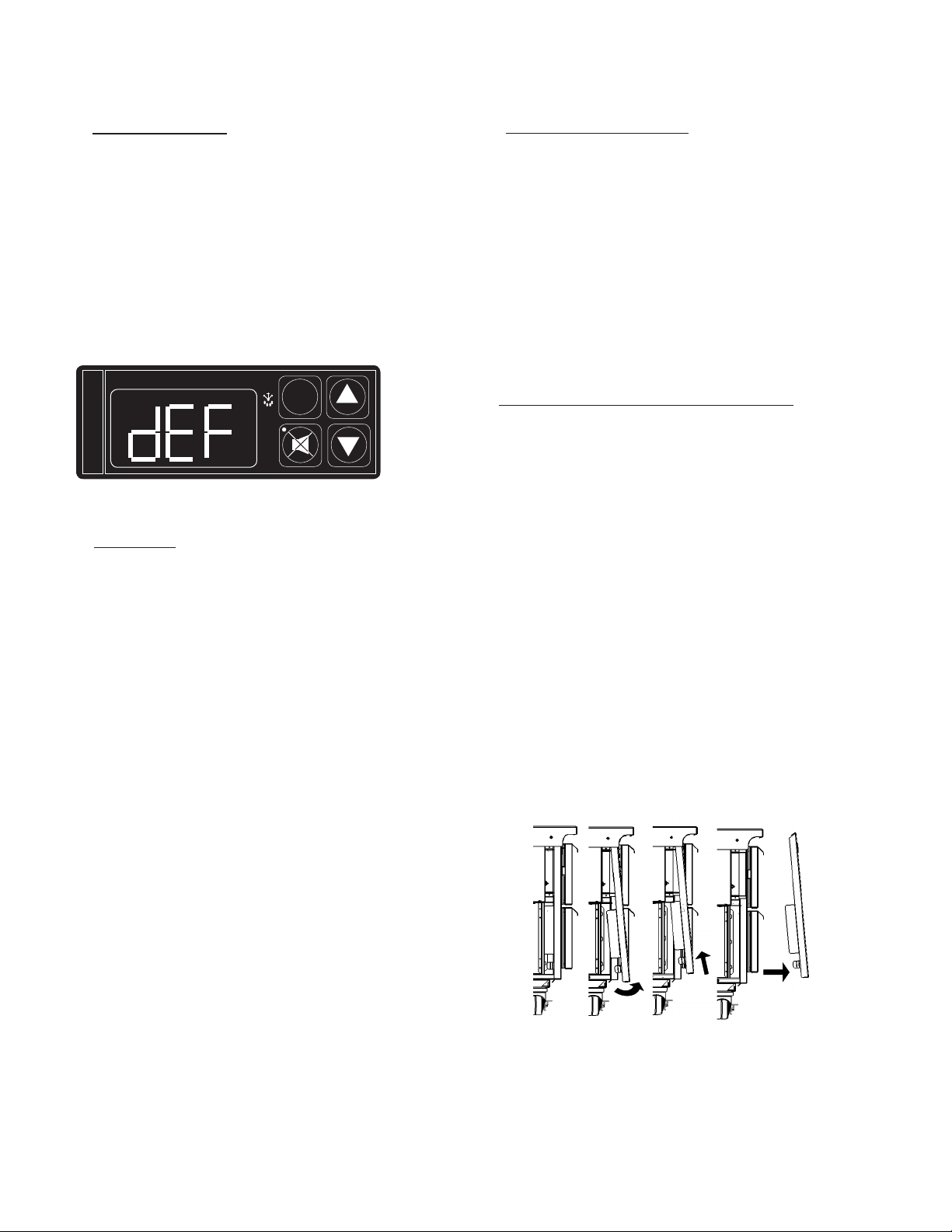

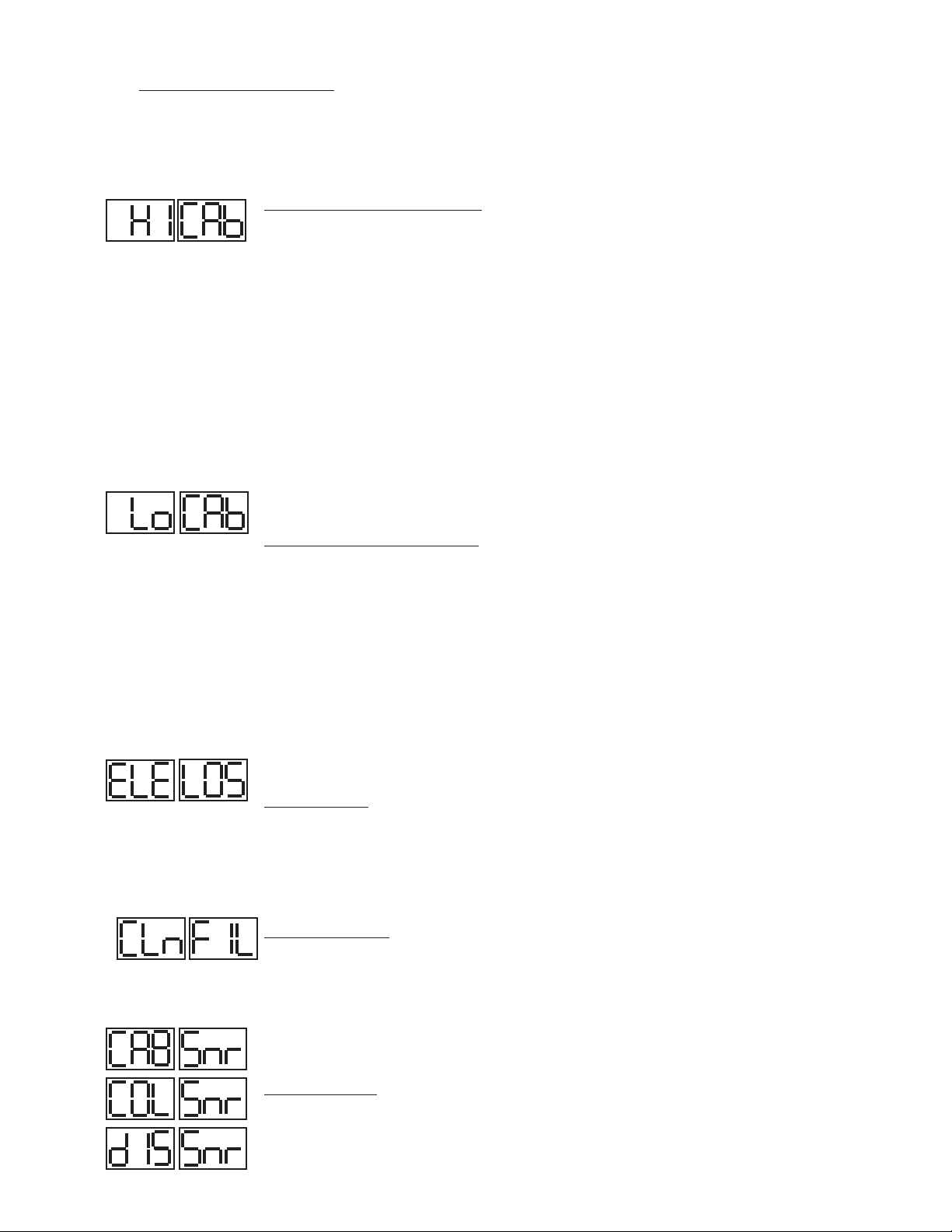

VI. a - REMOVING THE DOOR AND INSTALLING

DRAWERS:

Doors are supplied standard on all TU Series Full-Size Undercounter models. However, we have engineered our

models with a drop-in feature that allows you to easily

convert door(s) into two 6” deep drawers or three 4” deep

drawers.

The door(s) on all models can easily be converted to drawers in the eld. To begin the process, open the door to

its maximum position. Support the non-hinged end of

the door so minimum movement occurs. When the bolts

from the lower hinge plate are removed, remove the lower

hinge plate and then the door from the top hinge bracket

plate and then the door from the top hinge bracket. The

hinge plate pin and plastic bushing will remain in the top

hinge plate.

NOTE: The lower hinge plate is under spring tension.

Once the door(s) have been removed, Insert drawer frame

as shown below.

V. c - CLEANING THE CABINET SURFACES:

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY

BEFORE CLEANING ANY PARTS OF THE UNIT.

Exterior stainless steel should be cleaned with warm water,

mild soap and a soft cloth. Apply with a dampened cloth and

wipe in the direction of the metal grain.

Avoid the use of strong detergents and gritty, abrasive cleaners as they may tend to mar and scratch the surface. Do NOT

use cleansers containing chlorine, such as bleach, this may

promote corrosion of the stainless steel.

Care should also be taken to avoid splashing the unit with

water, containing chlorinated cleansers, when mopping the

oor around the unit.

For stubborn odor or spills, use baking soda and water (mixed

to a 1 tbsp baking soda to 1 pint water ratio).

A stainless steel polish is recommended for shining of unit.

Once the drawer frame has been inserted, the drawer frame

module can be installed by tighting the black front and back

clamping knobs (2 of each) located on the cross rail locks

and liner locks. Slide the front cross rail locks towards the

center of the drawer frame module and allow the liner locks

to drop down from the top of the liner. Insert the door frame

module push towards the back of the unit. The entire frame

assembly is now installed and ready for use.

NOTE: Repeat process for multiple drawer(s) inserts.

Front Clamping

Knobs

Front Cross

Rail Locks

-4-

Back Clamping

Knobs

Page 6

VII. MICROPROCESSOR CONTROL

Your new refrigerator or freezer cabinet is equipped with a state-of-the-art microprocessor control, which precisely

regulates operation and provides alarms when problems occur. It is supplied from the factory completely ready for

use and requires no adjustments, but without the audible alarms activated. See pages 6 thru 16 for more information.

INTELA-TRAUL

°F °C

FREEZER

VII. a - CONTROL FEATURES:

1- Internal Time Clock

• Eliminates external defrost time clock.

• Defrost cycle can be quickly adjusted to suit individual location and use.

• Must be set at power-up. (See page 11, “Setting the 24-Hour Clock”)

• Will automatically update for Daylight Savings Time.

2- Water Resistant Housing - The face of the control is water resistant to provide for protection during cleaning.

3- Parameter/Service Levels

• See “Customer / Service Parameters” on Page 9.

SET

MICROPROCESSOR CONTROL

4- Defrost Lockouts - See “Setting Defrost Lockouts” on page 14.

Customers can set up to 4 dierent defrost lockout periods. The lockout prevents the unit from going into a defrost

cycle during peak kitchen use. Note: The 24-hour clock must be set for this feature to operate correctly.

5- Communication Ability - A NAFEM Data Protocol (NDP) compliant RS-485 serial communications port is available to

interface with data collection software (by others). All microprocessor control equipped models are capable of com-

municating within a NAFEM Data Protocol network if provided with an optional Gateway Hub (available from Traulsen).

The actual communications software is available from a number of third party software vendors.

6- Anti-Condensate Door Perimeter Heater Control

The “No-Sweat” feature is an energy savings system that allows the customer to adjust the percent of time for the door/

drawer heater to be “On” as needed for the prevailing ambient conditions (from 0 - 100% of the time each day). It is

used to prevent condensation from forming around the perimeter of the drawers. The factory default setting is 100%.

Adjust this set point down to a point just before condensation forms to save energy.

7- Alarms (See the following pages for explanations)

• High Cabinet Air Temperature

• Low Cabinet Air Temperature

• Loss Of Power

• Sensor Failure

• Clean Condenser

8- Display Features

• 3-Digit LED Display

• Defrost in Progress Icon

• Fahrenheit or Celsius Temperature Scale In Use

-5-

Page 7

VII. MICROPROCESSOR CONTROL (continued)

VII. b - ALARM EXPLANATIONS:

*NOTE: Explanation of alarms assume the audible alarm style is set at a 3-second burst or a continuous audible

alarm. References to the audible alarm do not apply if the audible alarm style is set to OFF (Refer to page 16 for

setting the audible alarm style).

High Cabinet Air Temperature: The audible alarm will sound and the display will read HI

CAb when the temperature inside the cabinet rises above a pre-programmed limit. The limit

is determined by the type of unit being operated (i.e.: refrigerator/freezer). To turn o the

audible alarm, press the alarm cancel button. The visual alarm text will continue to display

until the cabinet air temperature falls below the limit. If the temperature does not fall below

the limit within 5 minutes, the audible alarm* will sound again and an additional Call Service

message will display.

POSSIBLE CAUSES:

• Doors open for extended periods of time.

• Large amounts of hot product placed inside the cabinet.

• Condenser coil dirty.

• Cooling Compressor Failure. Call Service.

• Refrigeration Problems.

Low Cabinet Air Temperature: The audible alarm will sound and the display will read Lo

Cab when the temperature inside the cabinet falls below a pre-programmed limit. The limit

is determined by the type of unit being operated (i.e.: refrigerator/ freezer). To turn o the

audible alarm, press the alarm cancel button. The visual alarm text will continue to display

until the cabinet air temperature rises above the limit. If the temperature does not rise above

the limit within 5 minutes, the audible alarm will sound again and an additional Call Service

message will display.

POSSIBLE CAUSES:

• No product in unit.

• Failed sensors.

• Stuck Evaporator Relay.

Loss Of Power: The audible alarm will sound and the display will read ELE LOS, when the

unit regains power after an outage. To turn o the audible alarm and/or clear the visual text,

press the alarm cancel button.

Condenser Clean: The audible alarm will sound and the display will read “Clean Filter” when

discharge temperatures exceeds 140 degrees. As the load on the condenser decreases, the

alarm will turn o by itself. As the temperature on the condenser continue to rise, the audible

alarm will return until the problem has been eliminated.

NOTE: If discharge temperature rises above 1600F the compressor & condenser fan motor

will be switched o until the discharge temp falls below 1400F

Sensor Failures:

The audible alarm will sound and the display will read CAB SEN, COL SEN or DIS SEN when

that particular sensor has failed to operate. To turn o the audible alarm, press the alarm

cancel function of the sensor, the audible alarm will sound again in either 5 minutes or 24

hours. Note: Test sensor in ice water.

-6-

Page 8

VII. MICROPROCESSOR CONTROL (continued)

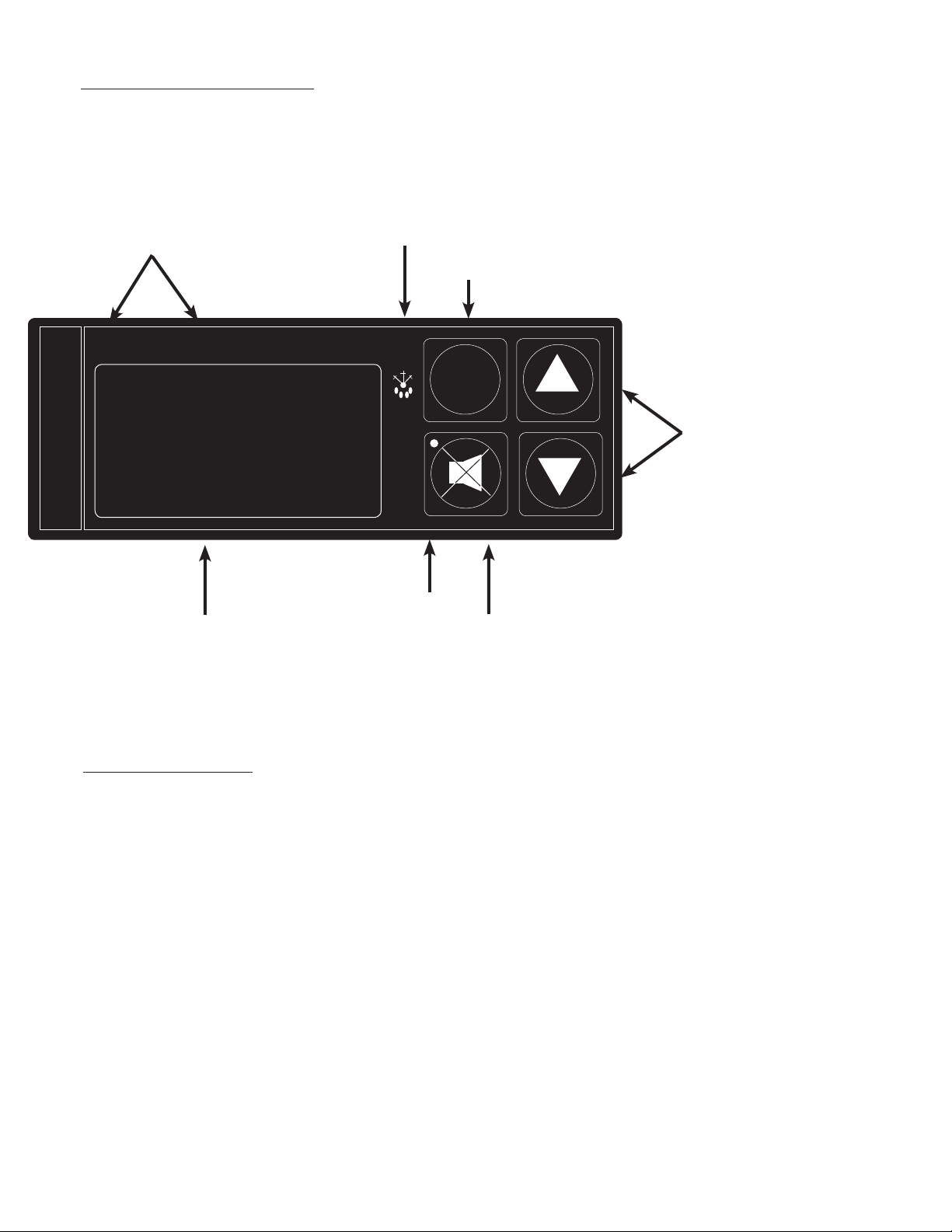

VII. c - CONTROL PANEL DIAGRAM:

0

F LED & 0C LED

°F °C

FREEZER

INTELA-TRAUL

LED DISPLAY

DEFROST SYBMBOL

SET BUTTON

SET

RED ALARM

LIGHT

UP BUTTON

&

DOWN BUTTON

ALARM CANCEL BUTTON

VII. d - NOTES TO THE USER:

You only have 20-30 seconds between button pushes. If you take longer than 30 seconds, the controller will revert back

to displaying the cabinet temperature. If you enter the wrong security code, the controller will revert back to displaying

the cabinet temperature. You can exit the parameters at any time by pressing the alarm cancel button or by waiting 20-30

seconds.

-7-

Page 9

VII. MICROPROCESSOR CONTROL (continued)

VII. e - ENTER THE SERVICE ACCESS:

Use the security code 0, A, 1 and the following instructions:

Press the set button . The display will read Service Access.

Press the set button .

The display will show three zeros with the left zero ashing

Press the set button .

The display will show three zeros with the center zero ashing

Press the down arrow key to sequence through F, E, d, C, b, A, 9, 8, 7,…etc.

When you reach A press set .

The display will show zero, A, zero with the right zero ashing .

Press the up arrow key to sequence through 1, 2, 3, 4, 5, 6, 7, 8, 9, A, b,…etc.

SET

SET

SET

SET

When you reach 1 press set .

The display will read Thermostat Set Point High. Press to view and again to exit.

You are now in the SERVICE PARAMETERS.

SET

SET SET

-8-

Page 10

VII. MICROPROCESSOR CONTROL (continued)

VII. f - SERVICE PARAMETERS:

Listed below are the available parameters in the order they appear, using the down arrow key on the controller. You can

use either the up or down arrow keys to scroll through the options.

Thermostat Set Point High Defrost Lockout 3

Thermostat Set Point Low Defrost Lockout 4

Temperature Scale Dew Point Compensation Factor

Time (24-hour clock) Room Temperature Oset

Date (month-day-year) Audible Alarm Style

Daylight Savings Cabinet Air Sensor Temp

Start Manual Defrost Evaporator Coil Sensor Temp

Defrost Lockout 1 Discharge Line Sensor Temp

Defrost Lockout 2

VII. g - ADJUSTING THERMOSTAT SET POINT HIGH:

This parameter sets the high point of the desired cabinet temperature range. Typically, freezers will range from -3° F to 0°

F (-19° C to –18° C) and refrigerators will range from 36° F to 40° F (2° C to 4° C) for this parameter setting. This parameter

is preset at the factory and does not have to be adjusted unless the customer chooses to do so. Note: Set Point Low and

Set Point High cannot be set to the same temperature. There must be at least 1-2 degree dierence between the two settings.

Follow the instructions to enter the customer access code on page 8. When the control

display reads Thermostat Set Point High. Press the set button .

Use the arrow keys to adjust the temperature to your desired setting.

When the display shows the temperature you want press the set button .

The display will then read Thermostat Set Point High.

SET

SET

You can use the up or down arrow keys to scroll to the next parameter .

)

)

or press the alarm cancel button to exit .

)

-9-

Page 11

VII. MICROPROCESSOR CONTROL (continued)

VII. h - ADJUSTING THERMOSTAT SET POINT LOW:

This parameter sets the low point of the desired cabinet temperature range. Typically, freezers will range from –6° F to -4° F

(-21° C to –20° C) and refrigerators will range from 32° F to 34° F ( 0° C to 1° C) for this parameter setting. This parameter is

preset at the factory and does not have to be adjusted unless the customer chooses to do so. Note: Set Point Low and Set

Point High cannot be set to the same temperature. There will be at least 1-2 degree dierence between the two settings.

Follow the instructions to enter the service access code on page 8. When the control

displays Thermostat Set High, press the down arrow key until the control

display reads Thermostat Set Point Low. Press the set button .

Use the arrow keys to adjust the temperature to your desired setting.

When the display shows the temperature you want press the set button .

The display will then read Thermostat Set Point Low.

You can use the up or down arrow keys to scroll to the next parameter .

)

)

or press the alarm cancel button to exit .

)

SET

SET

VII. i - CHANGING THE TEMPERATURE SCALE:

The temperature scale determines if the temperature displayed will be in degrees

Fahrenheit or degrees Celsius.

Follow the instructions to enter the customer access code on page 8. When the control

displays Thermostat Set High, press the down arrow key until the control

display reads Temperature Scale. Press the set button .

The display will start with the current setting either for degrees Fahrenheit

or for degrees Celsius. Use the arrow keys to toggle between the options.

When the display shows the scale you want press the set button .

The display will then read Temperature Scale.

You can use the up or down arrow keys to scroll to the next parameter

or press the alarm cancel button to exit .

)

)

)

-10-

SET

SET

Page 12

VII. MICROPROCESSOR CONTROL (continued)

VII. j - SETTING THE 24-HOUR CLOCK:

The internal time clock must be set in order for the data storage memory to correctly log events and to allow any defrost

lockout to occur at the correct time of day. If the clock is not set, the control assumes the time is 12 am at the time power

is supplied to the unit. The hours on a 24-hour time clock read the following way:

H01 = 1:00 a.m. H07 = 7:00 a.m. H13 = 1:00 p.m. H19 = 7:00 p.m.

H02 = 2:00 a.m. H08 = 8:00 a.m. H14 = 2:00 p.m. H20 = 8:00 p.m.

H03 = 3:00 a.m. H09 = 9:00 a.m. H15 = 3:00 p.m. H21 = 9:00 p.m.

H04 = 4:00 a.m. H10 = 10:00 a.m. H16 = 4:00 p.m. H22 = 10:00 p.m.

H05 = 5:00 a.m. H11 = 11:00 a.m. H17 = 5:00 p.m. H23 = 11:00 p.m

H06 = 6:00 a.m. H12 = 12:00 p.m. H18 = 6:00 p.m. H24 = 12:00 a.m.

Follow the instructions to enter the customer access code on page 8. When the control

displays Thermostat Set High, press the down arrow key until the control

display reads Clock. Press the set button .

The display will show Hours. The right two numbers will be ashing.

Use the arrow keys to set the hour.

When the correct hour is displayed, press the set button .

The display will show Minutes. The right two numbers will be ashing.

Use the arrow keys to set the minutes .

When the correct minutes are displayed, press the set button .

The display will then read Clock.

You can use the up or down arrow keys to scroll to the next parameter

SET

SET

SET

or press the alarm cancel button to exit .

)

)

)

-11-

Page 13

VII. MICROPROCESSOR CONTROL (continued)

VII. k - SETTING THE DATE:

The date must be set in order for the data storage memory to correctly log events. Follow the instructions to enter the

service access code on page 8. When the control displays Thermostat Set Point High, press the down arrow

key until the control display reads Date. Press the set button . The display will show

(year). The right two numbers will be ashing. Press the arrow keys to set the year. When the

correct year is displayed, press the set button . The display will show (month). The right two num-

bers will be ashing. Use the arrow keys to set the month. When the correct month is displayed, press

the set button . The display will show (day). The right two numbers will be ashing. Press the arrow

keys to set the day. When the correct day is displayed, press the set button . The display will then

read Date. You can use the up or down arrow keys to scroll to the next parameter, press the

alarm cancel button to exit .

SET

)

)

)

SET

SET

SET

VII. l - SETTING DAYLIGHT SAVINGS TIME:

This parameter is preset at the factory to automatically adjust the 24-hour clock for Daylight Savings Time. Follow the in-

structions to enter the customer access code on page 8. When the control displays Thermostat Set Point High,

press the down arrow key until the display reads Daylight Savings Time. Press the set button

SET

. The display will show Daylight Savings Time (Yes, automatically adjust for Daylight Savings Time).

For “YES” press the set button ,for “NO” press the up or down arrow key . The display will read

Daylight Savings Time (no). Press the set button . The display will read Daylight Savings

Time. You can press the up or down arrow keys to scroll to the next parameter or press the alarm cancel

button to exit .

)

)

)

SET

SET

-12-

Page 14

VII. MICROPROCESSOR CONTROL (continued)

VII. m - STARTING A MANUAL DEFROST CYCLE:

This parameter allows a service technician to start a defrost cycle at any time. This parameter will override any lock-

out settings. Follow the instructions to enter the customer access code on page 8. When the control displays

Thermostat Set High, press the down arrow key until the control display reads Start

Manual Defrost.

Press the set button

The display will show

Press either arrow key

The display will show

Press the set button

SET

SET

DEFROST ICON

The defrost icon will be lit, and the display will

read when the unit is in defrost.

NOTE: Traulsen refrigerator units also have an o-cycle defrost, at which time the control will read This

defrost is temperature terminated and can last from 3 - 20 minutes (dEF will be displayed for 20-37 minutes time).

-13-

Page 15

VII. MICROPROCESSOR CONTROL (continued)

VII. n - SETTING THE DEFROST LOCKOUTS:

The defrost lockout parameters allow the customer to prevent the unit from going into a defrost cycle for two hours during

a set time frame. Customers can set up to four defrost lockout parameters. They are all programmed the same way. The

parameters will be set for the time the lockout is to start. The controller automatically calculates 2 hours from that setting.

The options are similar to the 24-hour clock settings and are in 30-minute increments. Each of the lockout parameters covers 6 hours of the 24-hour clock. Note: The 24-hour clock must be set for this feature to operate at the correct time of day.

See “Setting the 24-Hour Clock” on page 11.

Sample:

OFF OFF OFF OFF

020 = 2:00 a.m. 080 = 8:00 a.m. 140 = 2:00 p.m. 200 = 8:00 p.m.

023 = 2:30 a.m. 083 = 8:30 a.m. 143 = 2:30 p.m. 203 = 8:30 p.m.

030 = 3:00 a.m. 090 = 9:00 a.m. 150 = 3:00 p.m. 210 = 9:00 p.m.

033 = 3:30 a.m. 093 = 9:30 a.m. 153 = 3:30 p.m. 213 = 9:30 p.m.

040 = 4:00 a.m. 100 = 10:00 a.m. 160 = 4:00 p.m. 220 = 10:00 p.m.

043 = 4:30 a.m. 103 = 10:30 a.m. 163 = 4:30 p.m. 223 = 10:30 p.m.

050 = 5:00 a.m. 110 = 11:00 a.m. 170 = 5:00 p.m. 230 = 11:00 p.m.

053 = 5:30 a.m. 113 = 11:30 a.m. 173 = 5:30 p.m. 233 = 11:30 p.m.

060 = 6:00 a.m. 120 = 12:00 p.m. 180 = 6:00 p.m. 240* = 12:00 a.m.

063 = 6:30 a.m. 123 = 12:30 p.m. 183 = 6:30 p.m. 243* = 12:30 a.m.

070 = 7:00 a.m. 130 = 1:00 p.m. 190 = 7:00 p.m. 010 = 1:00 a.m.

073 = 7:30 a.m. 133 = 1:30 p.m. 193 = 7:30 p.m. 013 = 1:30 a.m.

080 = 8:00 a.m. 140 = 2:00 p.m. 200 = 8:00 p.m. 020 = 2:00 a.m.

* Denotes not available.

A lockout can not be programmed to start at 12:00 am or 12:30 am due to conicts with other internal programs. The defrost lockouts can not be programmed to run back-to-back. For example, if dL1 is set to 080, then a defrost cycle would

be locked out from 8:00 am to 10:00 am. Because of the dL1 setting the dL2 parameter would not let the user choose a

lockout start time before 10:30 am. All lockouts are preset at the factory to OFF.

Follow the instructions to enter the customer access code on page 9. When the control

displays Thermostat Set High, press the down arrow key until the control the

control display reads or . Press the set button .

The display will show O. Press the arrow keys to set the start time.

When the correct time is displayed, press the set button .

The display will then read or .

You can press the up or down arrow keys to scroll to the next parameter

SET

SET

or press the alarm cancel button to exit .

)

)

)

-14-

Page 16

VII. MICROPROCESSOR CONTROL (continued)

VII. o - ADJUSTING THE DRAWER PERIMETER HEATERS:

This parameter allows the customer to turn ON and OFF the anti-condensate door/drawer perimeter heaters. This parameter is set to the highest setting (100) at the factory so that the door/drawer heaters stay on continuously. If you choose to

have the door/drawer heaters cycle on and o, lower this parameter to approximately 30. If condensation forms around

the door/drawers, increase the parameter until condensation stops. The exact setting will vary depending on ambient

conditions.

Follow the instructions to enter the customer access code on page 8. When the control displays

Thermostat Set High, press the down arrow key until the control display reads

SET

DewPoint Compensation Factor. Press the set button . Press the arrow keys to adjust the factor to

SET

your desired setting. When the display shows the factor you want press the set button . The display will then

read DewPoint Compensation Factor. You can use the up or down arrow keys to scroll to the

)

)

)

next parameter or press the alarm cancel button to exit .

VII. p - ADJUSTING THE ROOM TEMPERATURE OFFSET:

The room temperature oset parameter allows a service technician or end user the ability to have the display show a temperature that is within three degrees of the actual temperature being read by the cabinet air sensor. This allows for continuity

of reading between dierent temperature reading devices. (i.e.: thermistor vs. thermocouple vs. handheld thermometer)

This parameter is preset at the factory to “-2.50F”.

Follow the instructions to enter the customer access code on page 8. When the control displays

Thermostat Set High, press the down arrow key until the control display reads

Room Temperature Oset. Press the set button . Use the arrow keys to adjust the oset to your

desired setting. When the display shows the oset you want press the set button . The display will then read

Room Temperature Oset. You can use the up or down arrow keys to scroll to the next param-

eter or press the alarm cancel button to

)

exit .

)

)

SET

SET

-15-

Page 17

VII. MICROPROCESSOR CONTROL (continued)

VII. q - SETTING THE AUDIBLE ALARM STYLE:

These parameters will allow the customer to turn on/o the audible alarm feature on the INTELA-TRAUL® control. The

audible alarm is preset from the factory to OFF. The customer can choose between an audible alarm that sounds for 3

seconds then automatically turns o, or a continuous audible alarm that must be manually acknowledged. Regardless of

this feature’s setting, visual alarm text will display when conditions warrant.

To adjust this setting, follow the instructions to enter the customer access code on page 8. When the control displays

Thermostat Set Point High, press the up arrow key until the display reads Audible Alarm

Style. Press the set button . The display will read OFF. Use the arrow keys to scroll be-

tween for the 3-Second Audible Alarm Burst or for Continuous Audible Alarm. When the display

shows your choice of style, press the set button . The display will then read thermostat Set Point High.

Use the arrow keys to scroll to the next parameter or press the Alarm Cancel Button to exit.

SET

SET

)

)

)

VII. r - VIEWING SENSOR TEMPERATURES:

These parameters allow a service technician or customer to view the temperature of all sensors within the unit. The

temperatures cannot be adjusted.

Follow the instructions to enter the customer access code on page 8. When the control displays Thermostat Set Point

High , press the up arrow key unit the display reads Cabinet Air Sensor Evaporator Coil Sen-

sor or Disharge Line Sensor or press the SET button . The display will read the temperature

of the designated sensor.

Press the UP or DOWN arrow keys to scroll through the parameters or press the ALARM CANCEL button

)

)

)

to exit.

-16-

SET

Page 18

VIII. WIRING DIAGRAM

Note: Refer to the wiring diagram below (applies to refrigerators and freezers units) for any service work performed

by a qualied technician.

-17-

Page 19

IX. TROUBLE SHOOTING GUIDE

PROBLEM POSSIBLE SOLUTION

1. Condensing unit fails to start. a. Check if cord & plug has been disconnected.

b. Clean Condenser

2. Condensing unit operates for prolonged

periods or continuously.

3. Food Compartment is too warm.

(NOTE: Compressor may be cycling ON/OFF

frequently)

4. Food Compartment is too cold. a. Check if a large quantity of very cold or frozen food has recently

5. Condensation on exterior surface. a. Check door(s) alignment and gaskets for proper seal.

a. Are doors closed properly?

b. Dirty condenser or lter. Clean properly.

c. Evaporator coils iced. Needs to defrost. See instructions for setting a manual defrost cycle p. 13.

a. Check door(s) and gasket(s) for proper seal.

b. Check if a large quantity of warm food was recently added or the

door was kept open for a long period of time.

c. Microprocessor Control setting is too high. Readjust per instructions on p. 9 and 10.

d. Clean Condenser

been added. Allow adequate time for the cabinet to recover its

normal operating temperature.

b. Adjust the microprocessor control to warmer setting. Readjust

per instruction on p. 9 and 10.

b. Condensation on the exterior surface of the unit is perfectly normal during periods of high humidity.

c. Check perimeter heat setting and increase setting if <100 (see

section VII).

6. Compressor hums & does not start. a. Call for service.

-18-

Page 20

X. SERVICE ASSISTANCE

X. a - SERVICE INFORMATION:

Before calling for service, please check the following:

Is the electrical cord plugged in?

Is the fuse OK or circuit breaker on?

Clean condenser coil

Is the power switch on?

Reset microprocessor control values to factory defaults.

If after checking the above items and the unit is still not operating properly, please contact an authorized Traulsen service

agent. A complete list of authorized service agents was provided along with your Traulsen unit. If you cannot locate this,

you may also obtain the name of a service agent from the Tech Service page of our website: www.traulsen.com. If service

is not satisfactory, please contact our in-house service department at:

Traulsen & Co., Inc.

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

Traulsen & Co., Inc. reserves the right to change specications or discontinue models without notice.

X. b - SPARE PARTS INFORMATION:

To purchase replacement parts or to speak to service support for Traulsen and most Hobart Refrigeration units please contact

our Ft. Worth facility by phone at 800-825-8220 or fax to 817-740-6748 (parts) or 817-740-6757 (service).

To source parts locally follow instructions below for nearest location:

1. Log onto www.traulsen.com

2. Select Service Directory (top of screen)

3. Select Locate Parts (left side of screen)

4. Click on State desired

To source service support locally follow instructions below for nearest authorized service agent:

1. Log onto www.traulsen.com

2. Select Service Directory (top of screen)

4. Click on State desired

Note: When calling for spare parts or service support, please make sure you have model and serial number of unit

available.

X. c - WARRANTY REGISTRATION:

The warranties for your new Traulsen unit may be registered with us by contacting our Ft. Worth facility by phone at 800825-8220 or you may register on line:

1. Log onto www.traulsen.com

2. Select Service Directory (top of screen)

3. Select Warranty Registration Form (left side of screen)

4. Fill out information requested

5. Select Submit to complete unit warranty registration

-19-

Page 21

XI. WARRANTIES

STANDARD DOMESTIC WARRANTY

TRAULSEN & CO., INC. warrants new equipment to the original purchaser, when installed within the United States against

defective material and workmanship for one (1) year from the date of original installation. Under this warranty, TRAULSEN

& CO., INC. will repair or replace, at its option, including service and labor, all parts found to be defective and subject to this

warranty. The compressor part is warranted for an additional four (4) years. During this period TRAULSEN & CO., INC. will

supply replacement compressor (s) if deemed defective, however, all installation, recharging and repair costs will remain the

responsibility of the owner. However, all installation and repair costs will remain the responsibility of the owner.

This warranty does not apply to damage resulting from re, water, burglary, accident, abuse, misuse, transit, acts of God, terrorism, attempted repairs, improper installation by unauthorized persons, and will not apply to food loss.

For Traulsen units purchased with a remote feature, standard warranty will apply only to those components contained within

the unit to the point of connection of the refrigeration lines leading to the remote compressor.

THERE ARE NO ORAL, STATUTORY OR IMPLIED WARRANTIES APPLICABLE TO TRAULSEN, INCLUDING BUT NOT LIMITED TO,

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE HEREOF. TRAULSEN SHALL HAVE NO OBLIGATION OR LIABILITY FOR CONSEQUENTIAL OR SPECIAL

DAMAGES, GROWING OUT OF OR WITH RESPECT TO THE EQUIPMENT OR ITS SALE, OPERATION OR USE, AND TRAULSEN NEITHER ASSUMES NOR AUTHORIZES ANYONE ELSE TO ASSUME FOR IT ANY OBLIGATION OR LIABILITY IN CONNECTION WITH

THE EQUIPMENT OR ITS SALE, OPERATION OR USE OTHER THAN AS STATED HEREIN.

MICROPROCESSOR CONTROL WARRANTY

TRAULSEN, warrants to the original purchaser of the microprocessor control when installed as part of the Refrigeration/Hot

Food Equipment manufactured and sold by TRAULSEN, to be free of defects in material and workmanship under normal

service and use for a period of two (2) years from the date of installation. Under this warranty statement, TRAULSEN will repair

or exchange at TRAULSEN’S discretion, F.O.B. factory, any part of said control, which proves to be defective. Inspection by

the TRAULSEN Service Department of parts claimed defective shall be nal in determining warranty status. The warranty is

to include repair or exchange of any defective In-Warranty control or part (s) of said control for:

Part (s) –Any TRAULSEN microprocessor control supplied part (s) found to be defective.

Labor –The labor charges from a TRAULSEN Certied Service Agent to eect the repair or exchange of the defective part(s).

“Defective Part Return” – All claimed defective part(s) must be returned to TRAULSEN for defect validation within

30 days from the date of the repair. Failure to return all claimed defective part(s) to TRAULSEN will invalidate the warranty

claim, this warranty statement, and forfeit payment for those repairs eected.

This warranty does not apply to damage resulting from re, water, burglary, accident, abuse, misuse, transit, acts of God,

terrorism, attempted repairs, improper installation by unauthorized persons, and will not apply to food loss,

and will not apply if said equipment is located outside The United States.

INTERNATIONAL COMMERCIAL WARRANTY

TRAULSEN & CO., INC. warrants to the original purchaser the Refrigeration Equipment manufactured and sold by it to be free from defects in material and

workmanship under normal use and service for a period of one (1) year from date of shipment. Under this warranty, TRAULSEN & CO., INC. will reimburse the

purchaser for the replacement of any part of said equipment (excluding dryers & refrigerant gas) which then proves to be defective. This warranty does not

apply to damage resulting from re, water, burglary, accident, abuse, misuse, transit, acts of God, terrorism, attempted repairs, improper installation by

unauthorized persons, and will not apply to food loss.

TRAULSEN’S standard warranty does not apply to Export Sales. Rather, for a period of one (1) year from date of original installation not to exceed Fifteen (15)

months from date of shipment from factory, TRAULSEN:

will replace, F.O.B. factory, any defective parts normally subject to warranty.

will not cover the cost of packing, freight or labor such costs being the sole responsibility of the dealer/end user.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED AND CONSTITUTES

TRAULSEN’S FULL OBLIGATION AND LIABILITY. WARRANTIES NOT AVAILABLE ON REMOTE MODELS.

(for Canadian warranties see domestic US warranty)

-20-

Page 22

XII. SERVICE PARTS LIST

NOTE: Part numbers listed are for standard products as currently manufactured.

For products manufactured as other than standard, please contact the factory.

ITEM DESCRIPTION PART NUMBER

CASTER ALL MODELS

6” ADJUSTABLE CASTER NO LOCK SER-60538-00

6” ADJUSTABLE CASTER WITH LOCK SER-60538-01

LEG ALL MODELS

6” LEG SER-60542-00

DOOR ALL MODELS

DOOR ASSEMBLY, HINGED LEFT 200-60593-00

DOOR ASSEMBLY, HINGED RIGHT 200-60593-01

DOOR GASKET 341-60197-00

DRAWER 2 DRAWER 6” DEEP PAN

DRAWER ASSEMBLY 550-10108-00

DRAWER FACE ASSEMBLY 550-10114-00

DRAWER FRAME ASSEMBLY 550-10104-00

DRAWER FRAME INSERT SER-60539-00

DRAWER GASKET 341-60176-07

DRAWER ROLLER 344-60155-00

DRAWER 3 DRAWER 4” DEEP PAN

DRAWER ASSEMBLY 550-10098-00

DRAWER FACE ASSEMBLY 550-10099-00

DRAWER FRAME ASEMBLY 550-10104-00

DRAWER FRAME INSERT SER-60541-00

DRAWER GASKET 341-60176-06

DRAWER ROLLER 344-60155-00

SHELF MODEL TU044

SHELF, CHROME, 1 SECTION 340-60230-01

SHELF MODEL TU072 & TU100

SHELF, CHROME 2 & 3 SECTION, LH 340-60231-02

SHELF, CHROME 2 & 3 SECTION, RH 340-60231-03

SHELF MODEL TU100 (CENTER SHELF)

SHELF, CHROME, 3 SECTION, CENTER 340-60232-01

LOUVER ALL MODELS

LOUVER PANEL 500-70081-00

MICROPROCESSOR ALL MODELS

MICROPROCESSOR CONTROL HEAD 337-60403-00

MICROPROCESSOR CABINET TEMPERATURE SENSOR 337-60405-01

MICROPROCESSOR COIL TEMPERATURE SENSOR 337-60406-01

MICROPROCESSOR LIQUID LINE TEMPERATURE SENSOR 337-60407-01

MICROPROCESSOR RELAY MODULE 337-60317-00

-21-

Page 23

NOTES:

Page 24

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Traulsen

4401 Blue Moud Road Fort Worth, TX 76106

Phone (800) 825-8220 Fax (817) 740-6757

Website: www.traulsen.com

Quality Refrigeration

© 2008 Traulsen - All Rights Reserved

Loading...

Loading...