Page 1

Traulsen & Co., Inc.

Quality Refrigeration

OWNER’S MANUAL

Instructions for the installation

and maintenance of most Traulsen models as well as

instructions to operate the following special models:

Pizza Proofer Model

RPP232L-FHS

This Traulsen unit is built to our highest quality standards. We build our refrigerators, freezers and heated

cabinets this way as a matter of pride. This philosophy has made Traulsen the leader in commercial refrigeration since 1938. We thank you for your choice and confidence in Traulsen equipment and we know you

will receive many years of utility from this equipment.

All Traulsen units are placed on a permanent record file with the service department. In the event of any

future questions you may have, please refer to the model and serial number found on the name tag affixed

to the unit. Should you need service, however, call us on our toll free number, 800-825-8220 between 7:30

am and 4:30 pm CST, Monday thru Friday. It is our pleasure to help and assist you in every possible way.

INSTALLER

COMPLETE THE FOLLOWING INFORMATION PRIOR TO UNIT INSTALLATION

INITIAL START DATE: SERIAL NO.

MODEL TYPE:

COMPANY/INDIVIDUAL NAME:

INSTALLER:

FORM NUMBER TR35848 REV. 8/03 P/N 375-60212-00

Page 2

TABLE OF CONTENTS

I. THE SERIAL TAG Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION

a-Location Page 2

b-Packaging Page 2

c-Roll-In Model Installation Page 2

d-Wiring Diagram Page 2

e-Power Supply Page e

f-Clearance Page 3

IV. CARE & MAINTENANCE

a-Cleaning The Exterior Page 3

b-Cleaning The Interior Page 3

c-Hinge Replacement Page 3

d-Replacing The Gaskets Page 3

V. OTHER

a-Service Information Page 3

b-Spare Parts Page 4

c-Warranty Registration Page 4

d-Interior Arrangements Page 4

VI. PIZZA PROOFER OPERATION

a-Controls Page 4

b-ON/OFF Switch Page 4

c-Proofing Page 4

VII. TROUBLE SHOOTING GUIDE Page 5

VIII. WIRING DIAGRAM Page 6

IX. WARRANTY INFORMATION Page 7

FORT WORTH, TX.

SERIAL MODEL

VOLTS Hz PH

TOTAL CURRENT AMPS

MINIMUM CIRCUIT AMPS

MAXIMUM OVERCURRENT PROTECTION AMPS

LIGHTS WATTS

HEATERS AMPS

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

REFRIGERANT TYPE OZ

DESIGN PRESSURE HIGH LOW

370-60294-00 REV (A)

-1-

I. THE SERIAL TAG

The serial tag is a permanently affixed sticker on

which is recorded vital electrical and refrigeration data

about your Traulsen product, as well as the model

and serial number. This tag is located in the upper

right interior compartment on all reach-in/pass-thru

and roll-in/roll-thru refrigerator, freezer and dual-temp

models. For hot food and proofer models, this tag is

located on the top of the unit behind the louvers to

protect it from the heat.

READING THE SERIAL TAG

• Serial = The permanent ID# of your Traulsen

• Model = The model # of your Traulsen

• Volts = Voltage

• Hz = Cycle

• PH = Phase

• Total Current = Maximum amp draw

• Minimum Circuit = Minimum circuit ampacity

• Lights = Light wattage

• Heaters = Heater amperage (Hot Food units only)

• Refrigerant = Refrigerant type used

• Design Pressure = High & low side operating

pressures and refrigerant charge

• Agency Labels = Designates agency listings

Page 3

II. RECEIPT INSPECTION

III. INSTALLATION (continued)

All Traulsen products are factory tested for performance and are free from defects when shipped. The

utmost care has been taken in crating this product to

protect against damage in transit. All interior fittings

have been carefully secured and the legs or casters

are boxed and strapped inside to prevent damage.

Door keys will be attached to the handle with a nylon

strip. The handle is protected by an easily removable

nylon netting.

You should carefully inspect your Traulsen unit for

damage during delivery. If damage is detected, you

should save all the crating materials and make note

on the carrier’s Bill Of Lading describing this. A freight

claim should be filed immediately. If damage is subsequently noted during or immediately after installation, contact the respective carrier and file a freight

claim. Under no condition may a damaged unit be returned to Traulsen & Co. without first obtaining written permission (return authorization).

III. INSTALLATION

III. a -

LOCATION:

Select a proper location for your Traulsen unit, away

from extreme heat or cold. Allow enough clearance

between the unit and the side wall in order to make

use of the door stay open feature at 120° (self-closing

feature operates up to 90°). The door(s) must be able

to open a minimum of 90° in order to make use of the

maximum clear door width available.

III. b - PACKAGING:

All Traulsen units are shipped from the factory bolted

to a sturdy wooden pallet and packaged in a durable

cardboard container. The carton is attached to the

wooden skid with the use of large staples. These

should first be removed to avoid scratching the unit

when lifting off the crate.

Most exterior stainless steel surfaces have a protective vinyl covering to prevent scratching during manufacturing, shipping and installation. After the unit is

installed in place of service, remove and discard the

covering from all surfaces.

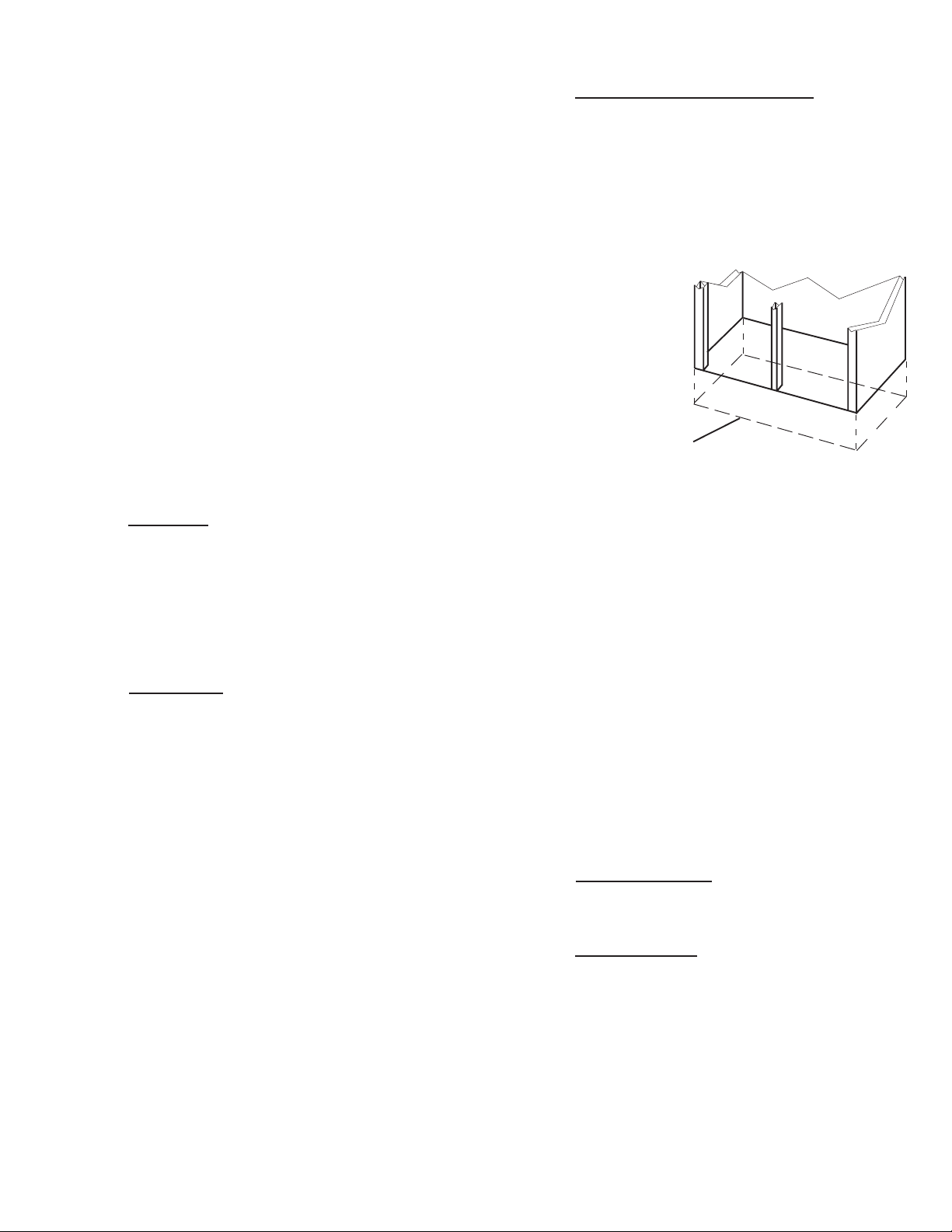

III. c - ROLL-IN MODEL INSTALLATION:

Roll-In cabinets set on the floor require the floor area

to be flat and level. In addition, after the cabinet is set

in place, sealant should be used around the perimeter

of the base to comply with National Sanitation Foundation requirements (see figure 1). After sealing the

unit, the enclosed ramp should then be installed.

SEALING BASE OF ROLL-IN MODELS

A SEALANT MUST BE USED

AROUND THE PERIMETER OF THE

BASE OF CABINET AS SHOWN TO

FULLY COMPLY WITH SANITARY REQUIREMENTS.

A RECOMMENDED SEALANT IS

DOW CORNING SILASTIC RTV #732

Fig. 1

A stainless steel threshold ramp(s) is included to facilitate rolling in racks. It is shipped wrapped in brown

paper and secured to the rack guides inside the cabinet. To secure it in place, remove the two thumb

screws in the breaker strip near the bottom door opening. Next, loosen the thumb screws located along the

floor at the threshold. Place the ramp(s) on top of the

loosened thumb screws and secure tabs on each end

to breaker strips with thumb screws previously removed. After installing the ramp(s), it too should be

sealed to the floor.

Bumper strips are secured to the back of Roll-In models with thumb screws. Loosen these and make them

finger-tight to conform with the requirements of the

National Sanitation Foundation (NSF).

III. d -

WIRING DIAGRAM:

Refer to the wiring diagram on page 6 for any service

work performed on the unit.

To remove the wooden pallet, first if at all possible, we

suggest that the cabinet remain bolted to the pallet

during all transportation to the point of final installation. The bolts can then be removed with a 3/4” socket

wrench. Avoid laying the unit on its front, side or

back for removal of the pallet.

NOTE: Traulsen does not recommend laying the unit

down on its front, side or back. However, if you must

please be certain to allow the unit to remain in an upright position afterwards for 24 hours before plugging

it in so that the compressor oils and refrigerant may

settle.

III. e - POWER SUPPLY:

The supply voltage should be checked prior to connection to be certain that proper voltage for the cabinet wiring is available (refer to the serial tag to determine correct unit voltage). Make connections in accordance with local electrical codes. Use qualified

electricians.

Use of a separate, dedicated circuit is required. Size

wiring to handle indicated load and provide necessary

overcurrent protector in circuit (see amperage requirements on the unit’s serial tag).

-2-

Page 4

III. INSTALLATION (continued)

IV. CARE & MAINTENANCE (cont’d)

III. f - CLEARANCE:

In order to assure optimum performance, your

Traulsen unit MUST have an adequate supply of air to

function properly. Therefore, the operating location

must either have a minimum of 12” clearance overhead of the unit or allow for unrestricted air flow at

the back of the unit. Clearance of at least 12” above

is required in order to perform certain maintenance

tasks.

IV. CARE & MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER

SUPPLY BEFORE CLEANING ANY PARTS OF THE

UNIT.

IV. a - CLEANING THE EXTERIOR:

Exterior stainless steel should be cleaned with warm

water, mild soap and a soft cloth. Apply with a dampened cloth and wipe in the direction of the metal grain.

Avoid the use of strong detergents and gritty, abrasive cleaners as they may tend to mar and scratch

the surface. Do NOT use cleansers containing chlorine, this may promote corrosion of the stainless steel.

Care should also be taken to avoid splashing the unit

with water, containing chlorinated cleansers, when

mopping the floor around the unit.

IV. d - REPLACING THE GASKETS:

To remove the gasket to be replaced, grasp it firmly

by one corner and pull it out. Before attempting to

install a new gasket, both the unit and the gasket itself must be at room temperature. Insert the four corners first by using a rubber mallet (or hammer with a

block of wood). After the corners are properly inserted,

work your way towards the center from both ends by

gently hitting with a mallet until the gasket is completely seated in place (see figure 2 for proper gasket

placement).

Fig. 2

Vertical Gasket

Inside Door Panel

○○○

Gasket Assembly

○○○

○○○

NOTE: The gasket may appear too large, but if it is

installed as indicated above it will slip into place.

V. OTHER

V. a - SERVICE INFORMATION:

Before calling for service, please check the following:

Is the power supply ON?

For stubborn odor spills, use baking soda and water

(mixed to a 1 TBSP baking soda to 1 pint water ratio).

IV. b - CLEANING THE INTERIOR:

For cleaning both stainless steel and anodized aluminum interiors, the use of baking soda as described in

section “IV. d” is recommended. Use on breaker strips

as well as door gaskets. All interior fittings are removable without tools to facilitate cleaning.

IV. c - HINGE REPLACEMENT:

Both the door and hinge can be easily removed from

the cabinet. To remove the door, remove the plug at

the bottom of the top hinge. Inside the hinge there is

a small screw which secures the door in place. Remove this with a flat head screwdriver and the door

can then be lifted off the hinge. To remove the door

portion of the hinge from the door, lift off the hinge

cover and then remove the three Phillips head screws

which secure the hinge in place on the door. To remove the cabinet portion of the hinge, remove the

three Phillips head screws which hold it in place. On

solid door units, the top hinge(s) contains a

microswitch for controlling the interior lighting.

Is the fuse OK or circuit breaker on?

Is the power switch “ON”?

If after checking the above items and the unit is still

not operating properly, please contact an authorized

Traulsen service agent. A complete list of authorized

service agents was provided along with your Traulsen

unit. If you cannot locate this, you may also obtain

the name of a service agent from the Tech Service page

of our website: www.traulsen.com.

If service is not satisfactory, please contact our inhouse service department at:

Traulsen & Co., Inc.

4401 Blue Mound Road

Fort Worth, TX 76106

(800) 825-8220

Traulsen & Co., Inc. reserves the right to change specifications or discontinue models without notice.

To reassemble the hinge reverse the previous procedure.

-3-

Page 5

V. OTHER (cont’d)

V. b - SPARE PARTS:

Spare or replacement parts may be obtained through

a parts supplier or one of our authorized service

agents. A complete list of authorized service agents

accompanies this manual and is also posted on our

company’s official website @ www.traulsen.com.

V. c -

WARRANTY REGISTRATION:

For your convenience, the warranties on your new

Traulsen unit may be registered with us by one of two

methods. Completing the enclosed warranty card

(shipped with the unit), or by filling out the on-line

warranty registration form located on the Technical

Service page of our website (www.traulsen.com).

VI. PIZZA PROOFER OPERATION

VI. a - CONTROLS:— Proof Box (see fig. 3)

VI. b -

ON/OFF SWITCH:

Turns the Proofer

Control ON or OFF.

V. d - INTERIOR ARRANGEMENTS:

Traulsen proofer and proofer retarder models are designed to accommodate roll-in bakery racks. See below for size and capacities.

Model RPP232L-FHS can accommodate two (2) standard 18” x 26” pan racks. Maximum rack size with

wheels inboard of frame is 27” wide by 29” deep by

66” high.

Fig. 3

TEMP normally displays the Set-Point temperature. For this unit, the temperature

is pre-set and fixed at 95°F. Contact the factory for adjustment. To display the

actual cabinet temperature, press and hold .

VIEW

TIMER displays the minutes remaining [zero (0) indicates not in use].

To set the Time, press and hold

or

To start the Timer, press

to Decrease.

START

. The Time (minutes) displays and begins

SET

while using to Increase

STOP

flashing as it counts down. When the Timer reaches zero (0), a beeper

SET

sounds for 30 seconds. To stop the beeper, press

. Some units

STOP

may have both a LEFT and RIGHT Timer. They operate independently

and are set and operated as noted above.

VI. c -

PROOFING:

The proofing process promotes yeast fermentation which generates gas and causes the dough to rise.

Proofing takes approximately 90 minutes depending on the product. A temperature setting of 95°F is

typical but will vary slightly depending on the product being proofed.

-4-

Page 6

VII. TROUBLE SHOOTING GUIDE

FIND YOUR PROBLEM HERE REMEDY

1. Unit fails to start. a. Check power supply.

2. Condensing unit operates for a. Are doors closing properly?

prolonged periods or continuously. b. Dirty condenser or filter. Clean properly.

c. Evaporator coil iced. Needs to defrost.

d. Shortage of refrigerant, call service.

3. Food compartment is too warm. a. Check door(s) and gasket(s) for proper seal

b. Perhaps a large quantity of warm food has

recently been added or the door was kept

open for a long period of time, in both

cases, allow adequate time for the cabinet

to recover its normal operating temperature.

4. Food compartment is too cold. a. Perhaps a large quantity of very cold or frozen

food has recently been added. Allow adequate

time for the cabinet to recover its normal operating

temperature.

5. Condensation on the exterior surface. a. Check door alignment and gaskets for proper seal.

b. Condensation on the exterior surface of the

unit is perfectly normal during periods of

high humidity.

6. Compressor hums but does not start. a. Call for service.

-5-

Page 7

VIII. WIRING DIAGRAM

-6-

Page 8

IX. WARRANTY INFORMATION

STANDARD DOMESTIC WARRANTY

TRAULSEN & CO., INC. warrants new equipment to the original purchaser, when installed within the United States against

defective material and workmanship for one (1) year from the date of original installation. Under this warranty, TRAULSEN

& CO., INC. will repair or replace, at its option, including service and labor, all parts found to be defective and subject to

this warranty. The compressor part is warranted for an additional four (4) years. During this period TRAULSEN & CO.,

INC. will supply replacement compressor(s) if deemed defective, however, all installation, recharging and repair costs

will remain the responsibility of the owner.

This warranty does not apply to damage resulting from fire, water, burglary, accident, abuse, misuse, transit, acts of

God, terrorism, attempted repairs, improper installation by unauthorized persons, and will not apply to food loss.

THERE ARE NO ORAL, STATUTORY OR IMPLIED WARRANTIES APPLICABLE TO TRAULSEN, INCLUDING BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. TRAULSEN SHALL HAVE NO OBLIGATION OR LIABILITY FOR

CONSEQUENTIAL OR SPECIAL DAMAGES, GROWING OUT OF OR WITH RESPECT TO THE EQUIPMENT OR ITS SALE,

OPERATION OR USE, AND TRAULSEN NEITHER ASSUMES NOR AUTHORIZES ANYONE ELSE TO ASSUME FOR IT ANY

OBLIGATION OR LIABILITY IN CONNECTION WITH THE EQUIPMENT OR ITS SALE, OPERATION OR USE OTHER THAN

AS STATED HEREIN.

INTERNATIONAL COMMERCIAL WARRANTY

(for Canadian warranties see domestic US warranty)

TRAULSEN & CO., INC. warrants to the original purchaser the Refrigeration Equipment manufactured and sold by it to be free

from defects in material and workmanship under normal use and service for a period of one (1) year from date of shipment. Under

this warranty, TRAULSEN & CO., INC. will reimburse the purchaser for the replacement of any part of said equipment (excluding

dryers & refrigerant gas) which then proves to be defective. This warranty does not apply to damage resulting from fire,

water, burglary, accident, abuse, misuse, transit, acts of God, terrorism, attempted repairs, improper installation by

unauthorized persons, and will not apply to food loss.

TRAULSEN’S standard warranty does not apply to Export Sales. Rather, for a period of one (1) year from date of original

installation not to exceed Fifteen (15) months from date of shipment from factory, TRAULSEN:

will replace, F.O.B. factory, any defective parts normally subject to warranty.

will not cover the cost of packing, freight or labor such costs being the sole responsibility of the dealer.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EITHER EXPRESSED OR IMPLIED AND CONSTITUTES

TRAULSEN’S FULL OBLIGATION AND LIABILITY. WARRANTIES NOT AVAILABLE ON REMOTE MODELS.

HOURS OF OPERATION:

Monday thru Friday 7:30 am - 4:30 pm CST

Traulsen & Co., Inc.

4401 Blue Mound Road Fort Worth, TX 76106

Phone: (800) 825-8220 Fax-Svce: (817) 740-6757

Website: www.traulsen.com

Quality Refrigeration

-7-

Loading...

Loading...